Page 1

Trane

Liqui-Flo Adden du m

Instruction Manual

D2-3415

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation

are property of their respective companies.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:The user must provide an external, hardwired emergency stop circuit outside of

the drive circuitry . This circuit must disable the system in case of improper operation. Uncontrolled

machine operation may result if this procedure is not followed. Failure to observe this precaution

could result in bodily injury.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

Flexibar is a trademark of Erico.

Trane and CenTraVac are trademarks of American Standard, Inc.

Liqui-Flo and Reliance are trademarks of Rockwell Automation.

©1998 Rockwell International Corporation

Page 3

C

ONTENTS

Chapter 1 Introduction

1.1 Intended Audience........................................................................................... 1-1

1.2 Other Required Manuals .................................................................................1-1

Chapter 2 About the Drive and Cabinet

2.1 Identifying the Trane Model Number ...............................................................2-1

2.2 Enclosure Rating ............................................................................................. 2-2

2.3 Identifying Trane Cabinet Components...........................................................2-2

2.4 Trane Options..................................................................................................2-6

Chapter 3 Cabinet Mounting, Wire Routing, and Liquid-Cooling Connections

3.1 Planning the Cabinet Installation.....................................................................3-1

3.2 Mounting the Cabinet ......................................................................................3-1

3.3 Cabinet Wire Routing ......................................................................................3-4

3.4 Grounding the Cabinet ....................................................................................3-4

3.5 Liquid-Cooling Connections............................................................................. 3-6

Chapter 4 Connecting Cabinet Power Wiring

4.1 Cabinet Input Disconnect ................................................................................4-1

4.2 Installing Input Power Wiring (6-Pulse Rectifier Cabinet)................................4-1

4.3 Installing Input Power Wiring (12-Pulse Rectifier Cabinet)..............................4-3

4.4 Installing Output Power Wiring ........................................................................ 4-5

4.5 Regulator Board Wiring ................................................................................... 4-5

Chapter 5 Cabinet Servicing

5.1 Removing the Liqui-Flo Drive from the Cabinet...............................................5-1

5.1.1 Removing the Drive from a 6-Pulse Rectifier Cabinet...........................5-1

5.1.2 Removing the Drive from a 12-Pulse Rectifier Cabinet.........................5-3

5.2 Replacement Parts.................................................. ...... ...... ....... ...... ....... ...... .. 5-6

Appendix A Trane Liqui-Flo Wiring Diagrams..............................................................................A-1

Index ........................................................................................................................... Index-1

Contents

I

Page 4

II

Trane Liqui-Flo Addendum

Page 5

List of Figures

Figure 2.1 – Identifying the Trane Model Number ....................................................2-1

Figure 2.2 – Trane Cabinet Component Locations (6-Pulse Rectifier)..................... 2-3

Figure 2.3 – Trane Cabinet Component Locations (12-Pulse Rectifier)................... 2-5

Figure 3.1 – Cabinet Dimensions .............................................................................3-2

Figure 3.2 – Cabinet Mounting Holes....................................................................... 3-3

Figure 3.3 – Cabinet Wire Routing Locations (6-Pulse Rectifier).............................3-5

Figure 3.4 – Cabinet Wire Routing Locations (12-Pulse Rectifier) ...........................3-6

Figure 3.5 – Liquid Cooling Bulkhead Fittings .......................................................... 3-7

Figure 3.6 – Liquid-Cooling Connections..................................................................3-8

Figure 4.1 – Trane Cabinet Electrical Connections (6-Pulse Rectifier) ....................4-2

Figure 4.2 – Trane Cabinet Electrical Connections (12-Pulse Rectifier) ..................4-4

Contents

III

Page 6

IV

Trane Liqui-Flo Addendum

Page 7

List of Tables

Table 2.1 – Power and Enclosure Ratings ...............................................................2-2

Table 3.1 – Cabinet Dimensions...............................................................................3-1

Table 3.2 – Cabinet Mounting Hole Dimensions ......................................................3-1

Table 5.1 – Hardware Tightening Torques...............................................................5-3

Table 5.2 – C-Frame Liqui-Flo Drive Replacement Parts......................................... 5-6

Contents

V

Page 8

VI

Trane Liqui-Flo Addendum

Page 9

This addendum covers the features and specifications that are unique to the

AC Liqui-Flo drives being produced for the Trane Company. Only product

information that differs from that presented in the standard Liqui-Flo instruction

manuals is covered here. This addendum must be used with the Liqui-Flo software

and hardware instruction manuals listed below.

1.1 Intended Audience

This addendum is intended for the following qualified electrical personnel: Trane

manufacturing, Trane service, and Rockwell Automation Global Technical Service

personnel who are familiar with the custom liquid-cooling features described.

1.2 Other Re qui red Manuals

This addendum must be used with the following publications:

•

D2-3410 Liqui-Flo AC Drive Software Startup and Reference Manual

C

HAPTER

Introduction

1

•

D2-3411 Liqui-Flo AC Power Modules Hardware Reference, Installation,

and Troubleshooting

•

D2-3341 Remote Meter Interface (RMI) Board

Introduction

1-1

Page 10

1-2

Trane Liqui-Flo Addendum

Page 11

C

About the Drive and Cabinet

This chapter describes how to identify the Trane cabinet and the Liqui-Flo drive using

the Trane model number matrix. Liqui-Flo drive power ratings are listed as well as

available Trane options. Cabinet component drawings are also provided. Note that in

this manual references to the “cabinet” refer to both the 6-pulse and 12-pulse rectifier

cabinets, unless otherwise indicated.

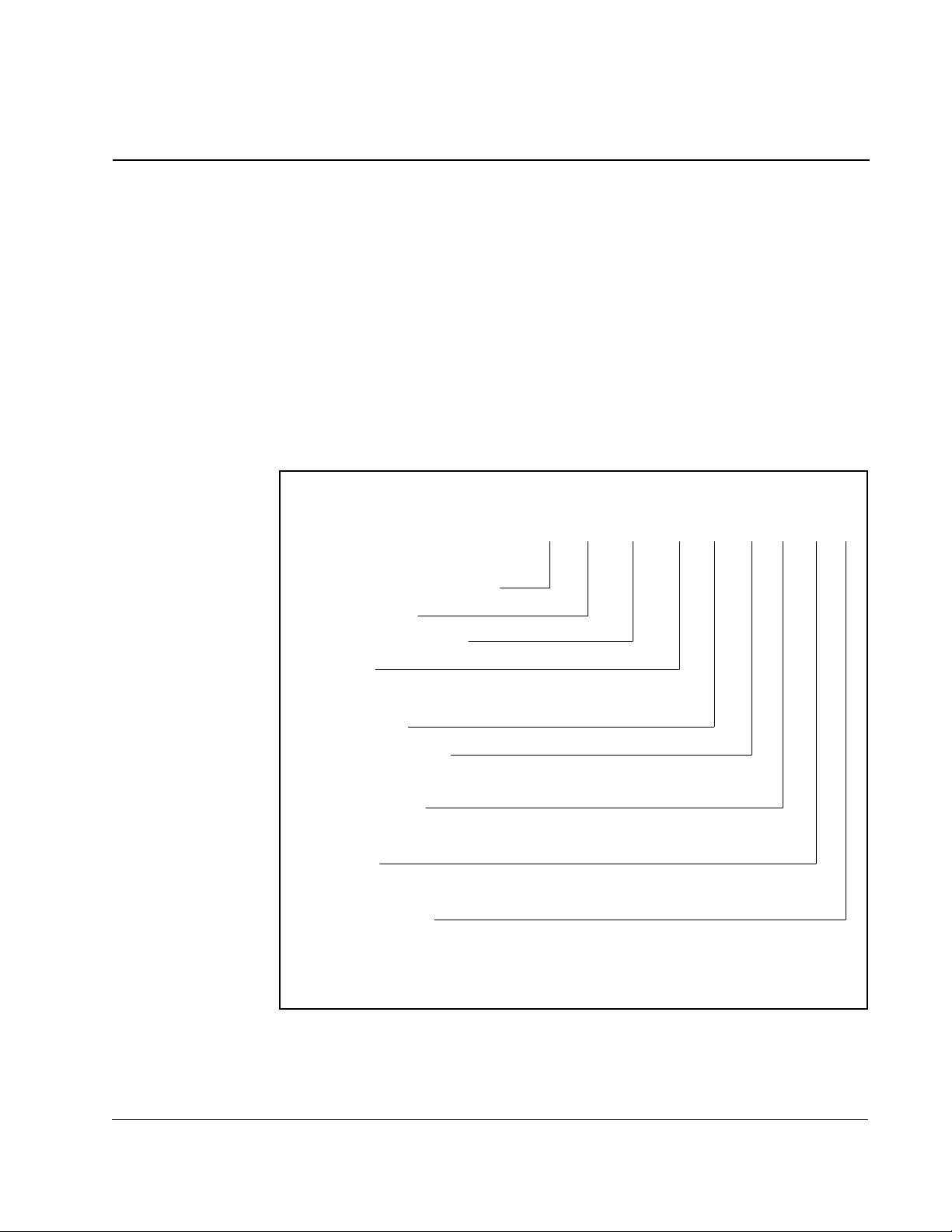

2.1 Identif ying the Tran e Model Number

Each Trane cabinet can be identified by its model number. See figure 2.1. A typical

cabinet model number is shown in table 2.1 as are the Liqui-Flo drive power ratings.

HAPTER

2

Adaptive Frequency Drive

Liquid-Cooled

Running Load Amps

Voltage

F = 460 V, 60 Hz, 3-Phase

G = 480 V, 60 Hz, 3-Phase

First Design

Mounting Location

A = Unit Mounted

B = Remote Mounted

Agency Listing

1 = UL/CUL Listed

2 = California Code (includes UL)

Rectifier

0 = 6-Pulse Rectifier

A = 12-Pulse Rectifier

Special Options

0 = None

S = Special

AFD B NA0NNNN

NNNN

About the Drive and Cabinet

Figure 2.1 – Identifying the Trane Model Number

2-1

Page 12

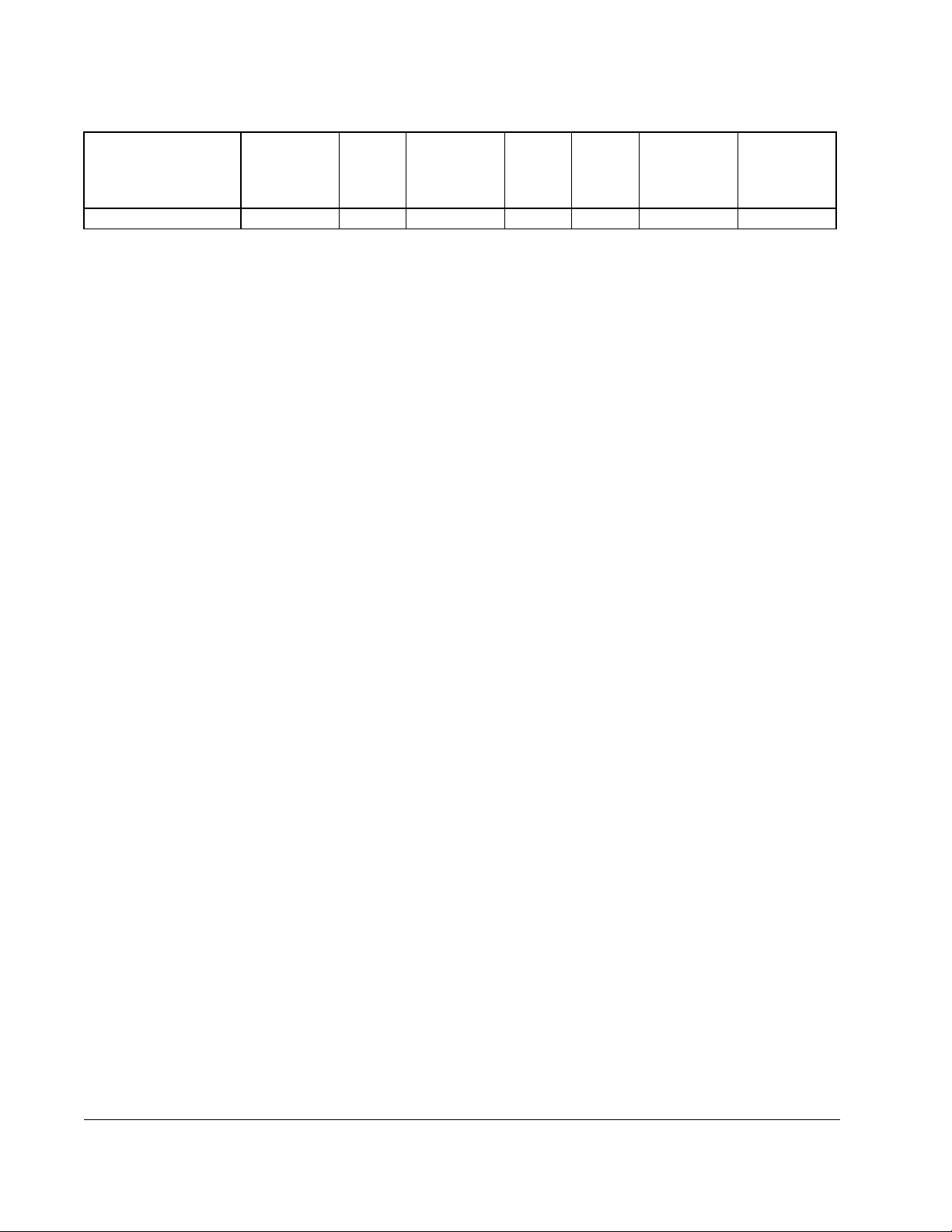

Table 2.1 – Power and Enclosure Ratings

Output

Trane Cabinet M/N

Reliance

Liqui-Flo

Drive M/N

Frame

Size

Cabinet

Enclosure

Rating

Input

Power

(KVA)

Input

Current

(Amps)

Current

at 2 kHz

(Amps)

Full Load

Power

Loss Watts

AFDB0643GA0A10 64L4060 C NEMA 1 555 667 643 9500

2.2 Enclosure Rating

The Trane cabinet has a NEMA 1 enclosure rating:

•

NEMA 1: Vented. Intended for general-purpose indoor applications.

NEMA 1 enclosures are to be located in a clean and dry environment that is away

from oil, coolant, or other airborne contaminants.

2.3 Identifying Trane Cabinet Components

The 6-pulse rectifier Trane cabinets have the following main components. The

identification numbers provided correspond to the numbers used in figure 2.2.

t

Cabine

1.

Control Panel Assembly

2.

C-Frame Liqui-Flo Drive

3.

Liqui-Flo Power Module Adapter Board

4.

electronics and power structure

Liqui-Flo Bus Control Board

5.

Liqui-Flo Regulator Board

6.

Super Remote Meter Interface (RMI) Board

7.

under the Regulator board)

Coolant Lines -

8.

Motor Connection Studs (6) P/O CTV

9.

AC Input Bus Bars

10.

Current Transformers (3)

11.

current

1200 A Circuit Breaker

12.

4 KVA Transformer

13.

(3) Type RK-5 Fuses

14.

(2 fuses: 15 amp)

(2) Type K5Fuses

15.

module’s 115 VAC line (1 fuse: 30 amp)

Terminal Block

16.

Potential Transformers (3)

17.

480 VAC input voltage

Trane Starter Module

18.

Relay 2K1

19.

Relay 2K2

20.

Relay 2K3

21.

50 VA Transformer 460VAC / 115VAC/ 24 VAC

22.

Module

- Provides cooling for the DC bus reactor

Fan

23.

Removab le Plate

24.

Surge Suppressor

25.

(a) Outlet, (b) Inlet

(6-Pulse Rectifier)

- Steps down the 480 VAC input voltage to 115 VAC

- Protect the primary of the 4 KVA transformer - (1 fuse: 2 amp)

- Protect the coolant pump’s reactor (1 fuse: 10 amp) and the Starter

- Provides termination points for cabinet I/O wiring

- Interfaces the Liqui-Flo drive to the Trane UCP2 Control Panel

- Circulating coolant pump motor interposing relay

- Oil pump interposing relay

- Run/stop function interposing relay

- Provides chain hoist access

- Controls the drive’s power supplies and SCRs

- Controls overall drive operation

- Used by the Trane UCP2 Control Panel to monitor output

- Used by the Trane UCP2 Control Panel to measure the

- Provides the interface between the drive’s

- Provides additional analog I/O (located

- Supplies power to the Trane Starter

2-2

Trane Liqui-Flo Addendum

Page 13

24

1

25

9

T1

T2

T3

10

11

12

13

14

15

16

15A

15A

2A

30A 10A

T4

T5T6

2

3

4

5

6

7

8a

17

About the Drive and Cabinet

18

19

20 21

23

Front View

Figure 2.2 – Trane Cabinet Component Locations (6-Pulse Rectifier)

8b

22

2-3

Page 14

The 12-pulse rectifier Trane cabinets have the following main components. The

identification numbers provided correspond to the numbers used in figure 2.3.

Cabinet

1.

AC Input to Drive

2.

Control Panel Assembly

3.

C-Frame Liqui-Flo Drive

4.

Liqui-Flo Power Module Adapter Board

5.

electronics and power structure

Liqui-Flo Bus Control Board

6.

Liqui-Flo Regulator Board

7.

Super Remote Meter Interface (RMI) Board

8.

under the Regulator board)

Coolant Lines -

9.

Motor Connection Studs (6) P/O CTV

10.

AC Output from Load Side of Circuit Breaker

11.

AC Input Connections

12.

Current Transformers (3)

13.

current

1200 A Circuit Breaker

14.

4 KVA Transformer

15.

(3) Type RK-5 Fuses

16.

(2 fuses: 15 amp)

(2) Type K5 Fuses

17.

module’s 115 VAC line (1 fuse: 30 amp)

Terminal Block

18.

Potential Transformers (3)

19.

480 VAC input voltage

Trane Starter Module

20.

Relay 2K1

21.

Relay 2K2

22.

Relay 2K3

23.

50 VA Transformer 460 VAC/ 115 VAC / 24 VAC

24.

Module

Fan

25.

Removab le Plate

26.

Surge Suppressor

27.

- Circulating coolant pump motor interposing relay

- Oil pump interposing relay

- Run/stop function interposing relay

- Provides cooling for the DC bus reactor

(from Secondary of Delta-Wye Transformer)

- Provides the interface between the drive’s

- Controls the drive’s power supplies and SCRs

- Controls overall drive operation

- Provides additional analog I/O (located

(a) Outlet, (b) Inlet

(located behind item 12)

(to Line Side of Circuit Breaker)

- Used by the Trane UCP2 Control Panel to monitor output

- Steps down the 480 VAC input voltage to 115 VAC

- Protect the primary of the 4 KVA transformer - (1 fuse: 2 amp)

- Protect the coolant pump’s reactor (1 fuse: 10 amp) and the Starter

- Provides termination points for cabinet I/O wiring

- Used by the Trane UCP2 Control Panel to measure the

- Interfaces the Liqui-Flo drive to the Trane UCP2 Control Panel

- Supplies power to the Trane Starter

- Provides chain hoist access

2-4

Trane Liqui-Flo Addendum

Page 15

10

11

12

13

T6

T1

T2 T3

T4 T5

26

1

27

2

3

4

5

14

15

16

17

18

19

30A 10A

20

15A

15A

2A

22

Front View

6

7

8

9a

9b

2321

25

24

About the Drive and Cabinet

Figure 2.3 – Trane Cabinet Component Locations (12-Pulse Rectifier)

2-5

Page 16

2.4 Trane Options

There is one available Trane option, the 12-pulse rectifier cabinet, which is described

in this addendum. Note that all Trane Liqui-Flo drives have a factory-installed Remote

Meter Interface (RMI) board and meet California code regulations.

2-6

Trane Liqui-Flo Addendum

Page 17

Cabinet Mounting, Wire Routing,

and Liquid-Cooling Connections

This chapter provides cabinet dimension information that must be considered when

installing a Trane cabinet. It describes how to mount the Trane cabinet and shows

where the wire entry areas and liquid-cooling connection points are located.

3.1 Planning the Cabinet Installation

Cabinet dimensions and weights are listed in table 3.1. Overall cabinet dimensions are

illustrated in figure 3.1. Cabinet mounting holes are shown in figure 3.2.

Table 3.1 – Cabinet Dimensions

Dim. A Dim. B Dim. C Dim. D Dim. E Dim. F Weight

C

HAPTER

3

965 mm

38.0"

Be sure there is adequate clearance for air ventilation around the cabinet. Allow a

minimum clearance of 1 foot per side. Allow 4 feet of clearance for the door to open.

1524 mm

60.0"

379 mm

15.1"

3.2 Mounting the Cabinet

Attach the cabinet to the CenTraVac chiller using the 8 mounting holes provided. In

order to maintain a flat mounting surface and to ensure that screw tightness is

maintained, use a washer and lock washer under the screw heads. Refer to figure 3.1

and table 3.1 for cabinet mounting dimensions. Use 3/8” (upper) and 1/2” (lower)

mounting screws and washers to attach the cabinet to the chiller. See figure 3.2 and

table 3.2 for mounting hole locations and dimensions.

Table 3.2 – Cabinet Mounting Hole Dimensions

Dim. A Dim. B Dim. C Dim. D Dim. E Dim. F Dim. G

1268.4mm

49.94"

85.7mm

3.38"

114.3mm

4.5"

1608 mm

63.3"

314.3mm

12.38"

60 mm

2.4"

127.0mm

5.0"

23 mm

0.91"

254.0mm

10.0"

440 kg

970 lbs

660.4mm

26.0"

Cabinet Mounting, Wire Routing, and Liquid-Cooling Connections

3-1

Page 18

CA

E

D

F

Figure 3.1 – Cabinet Dimensions

B

3-2

Trane Liqui-Flo Addendum

Page 19

D

A

3/8" Screws, 4 Pl. (Inside Cabinet)

E

F

(3 Pl.)

1/2" Screws, 4 Pl.

C

Figure 3.2 – Cabinet Mounting Holes

Cabinet Mounting, Wire Routing, and Liquid-Cooling Connections

GB

3-3

Page 20

3.3 Cabin et Wire Routing

All wiring should be installed in conformance with the applicable local, national, and

internation al co des (for example, NEC/CEC). Figures 3.3 and 3.4 show the wire

routing, grounding terminal, and power terminal strips of the cabinet. Control wiring

enters the cabinet through the three holes on the left side and terminates at the

control panel’s terminal block. Tighten the control wire connections from 7.1 to 8.9

in-lb.

3.4 Grounding the Cabinet

ATTENTION:

local, national, and international codes. Failure to observe this precaution

!

Use the following steps to ground the cabinet:

Step 1. Open the cabinet’s door. The grounding stud is located on the left side of the

Step 2. Run a suitable grounding conductor unbroken from the cabinet’s ground stud

Step 3. Connect a suitable grounding conductor to the motor frame and the

could result in damage to, or destruction of, the equipment.

cabinet.

to the motor’s ground terminal and then to earth ground. See figures 3.3 and

3.4. The cabinet’s ground stud connection point has two 5/16" socket-head

screws. Tighten the ground connections to 23 ft lbs (+

delta-wye transformer (if used). Run each conductor unbroken to earth

ground.

The user is responsible for conforming with all applicable

10%).

3-4

Trane Liqui-Flo Addendum

Page 21

3-Phase AC

Voltage Enters

Cabinet Here

Top View

3-Phase

AC Volts

Input to

Line Side

of Circuit

Breaker

Ground Stud

Connections

(Left Side Wall)

127.0 mm (5.0")

Recommended, 3 Pl.

T1

T6

T2

T4

T3

T5

3-Phase

AC Volts

Output to

Motor

28.58 mm

(1.125")

22.23 mm

(0.875")

Coolant

Bulkhead

Fittings

2 Pl.

15A

Signal Control

Wiring Enters

15A

2A

30A 10A

Cabinet Here

Signal

Control

Wiring

Front ViewSide View

Figure 3.3 – Cabinet Wire Routing Locations (6-Pulse Rectifier)

Cabinet Mounting, Wire Routing, and Liquid-Cooling Connections

3-5

Page 22

Top View

111.1 mm (4.38")

Recommended, 8 Pl.

28.58 mm

(1.125")

22.23 mm

(0.875")

Coolant

Bulkhead

Fittings

2 Pl.

Side View

3-Phase AC

Volt Output

from Load Side

of Circuit Breaker

to Primary of

Delta-Wye

Transformer

Ground Stud

Connections

(Left Side Wall)

3-Phase AC

Volt Input to

Line Side

of Circuit

Breaker

Signal Control

Wiring Enters

Cabinet Here

Signal

Control

Wiring

15A

15A

2A

30A 10A

T1

T2

T6

T4

Front View

127.0 mm (5.0")

Recommended, 3 Pl.

T3

T5

3-Phase AC Volt

Input to C-Frame

Liqui-Flo Drive

from Secondary of

Delta-Wye Transformer

(6 Places)

3-Phase

AC Volts

Output to

Motor

3-6

Figure 3.4 – Cabinet Wire Routing Locations (12-Pulse Rectifier)

3.5 Liquid-Cooling Connections

External coolant lines connect to the cabinet through two bulkhead fittings. The

bulkhead fittings are located on the rear panel of the cabinet as shown in figure 3.5.

Use the following steps to connect the coolant lines to the cabinet:

Step 1. Be sure the threads of the bulkhead fittings and the CenTraVac chiller’s

tubing connectors are free of dirt, burrs, and excessive nicks.

Step 2. Apply liquid sealer to the pipe thread end of the chiller’s tubing connectors.

Screw the connectors into the cabinet’s bulkhead fittings until they are

finger-tight. See figure 3.6.

Trane Liqui-Flo Addendum

Page 23

Step 3. Use a wrench to further tighten the connectors 1.5 to 2.5 turns. Do not hold

the bulkhead fitting with a pipe wrench when tightening the connectors as the

fitting may be damaged. Note that the bulkhead fitting has a built-in

anti-rotation feature and will not turn as the connector is screwed in.

ATTENTION: The cabinet’s bulkhead fittings may be damaged if they are

held with a pipewrench. Do not hold the bulkhead fitting with a pipe

!

wrench when tightening the connectors. The bulkhead fitting has a built-in

anti-rotation feature and will not turn as the connector is screwed in.

Failure to observe this precaution could result in damage to, or

destruction of, the equipment

Step 4. Visually inspect the connections for leaks.

Rear View

Figure 3.5 – Liquid Cooling Bulkhead Fittings

Cabinet Mounting, Wire Routing, and Liquid-Cooling Connections

Coolant Input

Fitting

Coolant Output

Fitting

3-7

Page 24

Drive

Side

SAE 37× Swivel Nut, Thread Size 7/8-14

Hex Nut

Lock Washer

Flat Washer

Double-D Anti-Rotation Feature Between

the Bulkhead Fitting and Main Panel Assembly

Main Panel Assembly

Bulkhead Fitting @ Rear of Cabinet

1-11 1/2 NPTF - Dryseal American Standard Taper

Pipe Thread (SAE J476)

Chiller

Side

Tubing Connection from Trane-Supplied

Heat Exchanger / Pump Assembly

Figure 3.6 – Liquid-Cooling Connections

3-8

Trane Liqui-Flo Addendum

Page 25

Connecting Cabinet Power Wiring

This chapter describes how to connect input and output power to the cabinet.

4.1 Cabin et Input Disconnect

C

HAPTER

4

ATTENTION:

local, national, and international codes. Failure to observe this precaution

!

An input disconnect circuit breaker is factory-installed in the cabinet. Verify that the

available fault current is less than the interrupting rating on the circuit breaker

nameplate, which is 65,000 amps at 480 VAC.

could result in damage to, or destruction of, the equipment.

The user is responsible for conforming with all applicable

4.2 Installing Input Power Wiring (6-Pulse Rectifier

Cabinet)

ATTENTION:

local, national, and international codes. Failure to observe this precaution

!

Use the following steps to connect AC input power to the cabinet:

Step 1. Remove the top panel of the cabinet.

Important:

could result in damage to, or destruction of, the equipment.

Care must be taken to prevent debris from falling into the cabinet while

performing this installation.

The user is responsible for conforming with all applicable

Step 2. Drill the wire routing holes in the panel. Note that the wire routing hole

Step 3. Install the appropriate conduit hubs.

Step 4. Reinstall the cabinet’s top panel.

Step 5. Connect the three-phase 480 VAC input power leads to circuit breaker

Connecting Cabinet Power Wiring

patterns shown in figure 3.3 are recommendations only. These wire routing

holes are the only entry points for input power wiring into the cabinet.

terminals L1, L2, and L3. See figure 4.1 and Appendix A. Tighten these

connections to 23 ft-lb (+

power leads.

10%). Use only copper conductors for the input

4-1

Page 26

AC Input

3-Phase 380/480 V

L1 L2 L3

RST

Liqui-Flo

AC Drive

On-Site Connections

Will Accept Four 3/0

To 400 MCM/Phase

(Copper Conductors Only)

Circuit

Breaker

On-Site Ground

Connection

Will Accept Two

4/0 to 350 MCM

(Copper Conductors Only)

UW

V

Flexibar

8x40x1

T3T1 T2

T5T6 T4

Motor

Figure 4.1 – Trane Cabinet Electrical Connections (6-Pulse Rectifier)

Inside

Cabinet

Trane-Supplied

Connections

4-2

Trane Liqui-Flo Addendum

Page 27

4.3 Installing Input Power Wiring (12-Pulse Rectifier

Cabinet)

ATTENTION:

local, national, and international codes. Failure to observe this precaution

!

Use the following steps to connect AC input power to the cabinet:

Step 1. Remove the top panel of the cabinet.

Important:

Step 2. Drill the wire routing holes in the panel. Note that the wire routing hole

Step 3. Install the appropriate conduit hubs.

Step 4. Reinstall the cabinet’s top panel.

Step 5. Connect the three-phase 480 VAC input power leads to circuit breaker

Step 6. Twelve-pulse cabinets require a delta-wye transformer be installed external

could result in damage to, or destruction of, the equipment.

Care must be taken to prevent debris from falling into the cabinet while

performing this installation.

patterns shown in figure 3.4 are recommendations only. These wire routing

holes are the only entry points for input power wiring into the cabinet.

terminals L1, L2, and L3. See figure 4.2 and Appendix A. Tighten these

connections to 23 ft-lb (+

power leads.

to the cabinet. Install the Trane-specified transformer by following the

installation instructions supplied with it.

The user is responsible for conforming with all applicable

10%). Use only copper conductors for the input

Step 7. Connect the load side of the circuit breaker to the R, S, and T teminals on the

delta-wye transformer. Tighten these connections to 23 ft-lb (+

Step 8. Connect the load side of the delta-wye transformer to the S1 through S6

terminals on the Liqui-Flo drive. Tighten these connections to 23 ft-lb

10%).

(+

10%).

Connecting Cabinet Power Wiring

4-3

Page 28

AC Input

3-Phase 380/480 V

Circuit

Breaker

L1 L3L2

R

S2S1

ST

S4S3 S5 S6

On-Site Connections

Will Accept Four 3/0

To 400 MCM/Phase

(Copper Conductors Only)

Inside

Cabinet

On-Site Connections

Will Accept Four 3/0

To 400 MCM/Phase

(Copper Conductors Only)

Transformer

On-Site Connections

Will Accept Two 6 AWG

To 250 MCM/Phase

(Copper Conductors Only)

On-Site Ground

Connection

Will Accept Two

4/0 To 350 MCM

(Copper Conductors Only)

4-4

U

Liqui-Flo

AC Drive

WV

Flexibar

Inside

Cabinet

8x40x1

T1

T2

T3

Trane-Supplied

Connections

T6

T4

Figure 4.2 – Trane Cabinet Electrical Connections (12-Pulse Rectifier)

T5

Motor

Trane Liqui-Flo Addendum

Page 29

4.4 Installing Output Power Wiring

ATTENTION:

local, national, and international codes. Failure to observe this precaution

!

Use the following steps to connect the cabinet’s output power wiring from the Liqui-Flo

drive to the chiller motor:

Step 1. Connect the Trane-supplied Flexibar (8x40x1) conductors to the Liqui-Flo

Step 2. Tighten these connections to Trane specifications.

Step 3. Connect the Flexibar conductors to the T1, T2, and T3 motor connection

Step 4. Tighten these connections to Trane specifications.

could result in damage to, or destruction of, the equipment.

drive’s U, V, W output terminals using the Trane-supplied hardware. See

figures 3.3, 3.4, 4.1, and 4.2.

studs using the Trane-supplied hardware. See figures 3.3, 3.4, 4.1, and 4.2.

The user is responsible for conforming with all applicable

4.5 Regulat or Board Wiring

The cabinet’s start/stop wiring on the Regulator board’s terminal strip is factory-wired

as shown in Appendix A.

Connecting Cabinet Power Wiring

4-5

Page 30

4-6

Trane Liqui-Flo Addendum

Page 31

C

HAPTER

Cabinet Servicing

This chapter describes how to remove the Liqui-Flo drive from the cabinet and

provides a list of replacement parts.

5.1 Removing the Liqui-Flo Drive from the Cabinet

Follow the procedure in section 5.1.1 if you are removing a Liqui-Flo drive from a

6-pulse rectifier cabinet. Follow the procedure in section 5.1.2 if you are removing a

Liqui-Flo drive from a 12-pulse rectifier cabinet.

5.1.1 Removing the Drive from a 6-Pulse Rectifier Cabinet

Use the following procedure to remove a Liqui-Flo drive from a 6-pulse rectifier

cabinet:

5

ATTENTION:

power has been disconnected. After disconnecting input power, wait five

!

Step 1. Turn off and lock out AC input power to the cabinet.

Step 2. Place the circuit breaker in the Off position. Wait five minutes.

Step 3. Verify that there is no voltage at the drive’s input power terminals.

Step 4. Check the DC bus potential with a voltmeter to ensure that the DC bus

Step 5. Drain the drive’s coolant and disconnect the coolant lines.

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

capacitors are discharged.

a. Use a ball valv e at the inlet connection to drain the coolant while running

the pump for 1 to 2 minutes.

b. Connect one end of a drain hose to the accumulator on the closed loop

coolant system. Connect the other end of the hose to a drain.

c. Connect a shop air line to the closed loop coolant system at the quick

disconnect fitting. Pressurize the line to 60-90 psi for 1 to 2 minutes to

flush all of the cool ant out of the drive.

d. Remove the basket from the Y-strainer and check for any contaminants.

DC bus capacitors retain hazardous voltages after input

Cabinet Servicing

e. F rom inside the cabinet, disconnect the coolant lines from the panel using

a 1-1/16” wrench on the swivel nut connected to the bulkhead fitting. A

crow’s-foot wrench is recommended. Verify that no residual coolant

remains in the drive.

5-1

Page 32

Step 6. Disconnect the Flexibar conductors at the drive’s U, V, and W output

terminals.

a. Remove the two 3/8”-16-UNC-2B nuts from the clamp holding the

Flexibar to the AC output busbar at output terminals U, V, and W.

b. Remove the load plate and the clamps.

c. Save this hardware for reassembly.

Step 7. Remove the rigid buswork that connects the load side of the circuit breaker to

the drive.

a. Remove the 1/12”-13 bolts and washers from each of the drive’s AC input

terminals (L1 through L6).

b. Remove the two 3/8”-16 bolts, washers, and nuts from each of the six

circuit breaker input busbar connections.

c. Save this hardware for reassembly.

Step 8. Disconnect the 12-position terminal connection located on the lower left side

of the drive. Cut the wire tie on the wire mounting base leading to the panel.

Step 9. Disconnect the leads from each of the three current transformers (CTs).

Wrap the CT leads around the AC output busbar to keep them from being

damaged. Cut the wire ties on the wire mounting bases.

Step 10. Disconnect the AC busbar support from the AC input busbar.

a. Remove the six M5 pan head screws that connect the AC input busbar

(L1 through L6) to the busbar support.

b. Save this hardware for reassembly.

Step 11. Remove the removable plate and wire entry panels. See figure 2.2.

a. Remove the four 1/4” screws and washers from the upper-right corner of

the cabinet that hold the removable plate in place. Remove the removable

plate which will expose a 2” gap in the lip of the cabinet.

b. Remove the eight 1/4” screws that hold the wire entry panel to the top of

the cabinet.

c. Save the panels and hardware for reassembly.

Step 12. Install two eyebolts into the drive to serve as lifting points.

a. Two 3/4” nuts are welded to the drive’s baseplate. Screw the eyebolts

(recommended: 2” eye I.D., 6” long shank) into the nuts.

b. Connect 18” (nominal) of chain between the eyes, securing them with a

clevis clamp.

Step 13. Using an overhead or portable hoist (minimum 1/2 ton rated capacity), bring

a free-fall chain into the cabinet through the access panel and the wire entry

panel.

Step 14. Attach the free-fall chain to the chain secured to the eye bolts. Take up any

vertical slack in the chain.

5-2

Step 15. Remove the four 1/2” nuts and washers that secure the baseplate of the drive

to the cabinet. Save this hardware for reassembly.

Trane Liqui-Flo Addendum

Page 33

Step 16. Using the hoist, lift the drive slightly to take the load off of the cabinet’s panel

studs. Pull the drive off of the studs and up through the wire entry and access

panels until it is clear of the cabinet enclosure. Note that drive’s center of

gravity is forward of the hoist, which will result in the top of the drive tilting

forward during removal.

Step 17. Move the drive to a horizontal pallet for servicing or shipment. The eyebolts

and the chain between them do not need to be removed.

Step 18. Reinstall the drive by following steps 17 to 1 in reverse order.

a. During reinstallation, tighten the hardware to the torque values (+

shown in table 5.1

b. Visually inspect the insulation of the wiring and buswork to ensure that it

was not damaged.

c. Refill the drive with coolant.

Step 19. Test the drive for proper operation by following the start-up procedures in

instruction manual D2-3410.

Table 5.1 – Hardware Tightening Torques

Maximum Recommended

Hardware

1/4” - 20 UNC Screws 75 in-lb

1/2” - 13 UNC- 2B Nut 45 ft-lb

3/8” - 16 UNC - 2B Nut 19 ft-lb

I/O Terminal Block Screws 4.5 in-lb

Tightening Torque

5.1.2 Removing the Drive from a 12-Pulse Rectifier Cabinet

Use the following procedure to remove a Liqui-Flo drive from a 12-pulse rectifier

cabinet:

10%)

Cabinet Servicing

ATTENTION:

power has been disconnected. After disconnecting input power, wait five

!

Step 1. Turn off and lock out AC input power to the cabinet.

Step 2. Place the circuit breaker in the Off position. Wait five minutes.

Step 3. Verify that there is no voltage at the drive’s input power terminals.

Step 4. Check the DC bus potential with a voltmeter to ensure that the DC bus

Step 5. Drain the drive’s coolant and disconnect the coolant lines.

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

capacitors are discharged.

a. Use a ball valv e at the inlet connection to drain the coolant while running

the pump for 1 to 2 minutes.

DC bus capacitors retain hazardous voltages after input

5-3

Page 34

b. Connect one end of a drain hose to the accumulator on the closed loop

coolant system. Connect the other end of the hose to a drain.

c. Connect a shop air line to the closed loop coolant system at the quick

disconnect fitting. Pressurize the line to 60-90 psi for 1 to 2 minutes to

flush all of the cool ant out of the drive.

d. Remove the basket from the Y-strainer and check for any contaminants.

e. F rom inside the cabinet, disconnect the coolant lines from the panel using

a 1-1/16” wrench on the swivel nut connected to the bulkhead fitting. A

crow’s-foot wrench is recommended. Verify that no residual coolant

remains in the drive.

Step 6. Disconnect the Flexibar conductors at the drive’s U, V, and W output

terminals.

a. Remove the two 3/8”-16-UNC-2B bolts and washers from the clamp

holding the Flexibar to the AC output busbar at output terminals U, V,

and W.

b. Remove the load plate and the clamps.

c. Save this hardware for reassembly.

Step 7. Disconnect the AC input wiring at the drive’s AC input terminals (L1 through

L6) and at the circuit breaker’s line and load terminals.

a. Loosen all of the pressure lugs.

b. Bend the individual wires vertically within the cabinet.

Step 8. Disconnect the 12-position terminal connection located on the lower left side

of the drive. Cut the wire tie on the wire mounting base leading to the panel.

Step 9. Disconnect the leads from each of the three current transformers (CTs).

Wrap the CT leads around the AC output busbar to keep them from being

damaged. Cut the wire ties on the wire mounting bases.

Step 10. Remove the removable plate. See figure 2.3.

a. Remove the four 1/4” screws and washers from the upper-right corner of

the cabinet that hold the removable plate in place. Remove the removable

plate which will expose a 2” gap in the lip of the cabinet.

b. Save the panel and hardware for reassembly.

Step 11. Place the lifting support bar in the cabinet’s stainless steel C-channel

brackets. The support bar’s pipe supports should face you.

a. Screw two 3/4” screws through the pipe support into the 3/4” nuts which

are welded to the drive’ s baseplate.

b. Hand tighten the screws.

Step 12. Remove the four 1/2” nuts and washers that secure the drive’s baseplate to

the cabinet. Save the hardware for reassembly.

Step 13. Tighten the two 3/4” screws to remove the load on the baseplate. Slide the

support bar along the C-channel brackets until it reaches the cabinet’s front

seal lip.

5-4

Trane Liqui-Flo Addendum

Page 35

Step 14. Using an overhead or portable hoist (minimum 1/2 ton rated capacity), attach

a free-fall chain to the 1.5” hole in the support bar. Take up any vertical slack

in the chain.

Step 15. Vertically lift the support bar and the drive 3” to 4”.

a. Rotate the support bar to the right side, towards you, and slip the support

bar/drive assembly out of the cabinet.

Step 16. Move the drive to a horizontal pallet for servicing or shipment. The support

bar and screws do not need to be removed.

Step 17. Reinstall the drive by following steps 16 to 1 in reverse order.

a. During reinstallation, tighten the hardware to the torque values

(+

10%) shown in table 5.1.

b. Visually inspect the insulation of the wiring and buswork to ensure that it

was not damaged.

c. Refill the drive with coolant.

Step 18. Test the drive for proper operation by following the start-up procedures in

instruction manual D2-3410.

Cabinet Servicing

5-5

Page 36

5.2 Replacement Parts

Table 5.2 lists the replacement parts that are available from Reliance Electric.

Table 5.2 – C-Frame Liqui-Flo Drive Replacement Parts

Quantity

Description Part Number

Power Module Adapter (PMA) Printed Circuit

179067 1

M/N 64L4060

Board (PCB)

DC Bus Control PCB 179069 1

Gate Driver PCB 179065 2

Membrane Switch Keypad/Bracket 410483-15B 1

Regulator PCB 179116 1

Current Feedback Devices 25503-011-01 3

SCR Module 22501-025-04 6

Bus/Gate Driver Interface Harness 179055 1

Gate Driver Jumper Harness 179056 1

Bus/PMA Interface Harness 179057 1

Power Interface Harness 179058 1

SCR (S1, S2, S3) Gate Interface Harness 179059 1

SCR (S4, S5, S6) Gate Interface Harness 179060 1

5-6

LEM Interface Harness 179061 1

Laminate PMA Interface Harness 179062 1

Chill Plate Interface Harness 179063 1

Remote Meter Interface (RMI) PCB 2SI3000 1

Internal Fan Assembly * 1

*Comair - Rotron M/N PT2B3 or equivalent.

Trane Liqui-Flo Addendum

Page 37

I

NDEX

A

Air ventilation, 3-1

Audience, intended, 1-1

B

Board

Bus Control, 2-2 to 2-5

Power Module Adapter (PMA), 2-2 to 2-5

Regulator, 2-2 to 2-5

Remote Meter Interface, 2-2 to 2-5

C

Cabinet

dimensions, 3-1 to 3-2

electrical connections, 4-2, 4-4

grounding, 3-4 to 3-6

mounting, 3-1 to 3-3

weight, 3-1

wire routing, 3-4 to 3-6

Component locations, 2-2 to 2-5

F

Fan, 2-2 to 2-5, 5-6

Fuses, 2-2 to 2-5

G

Grounding, 3-4

H

I

Input current rating, 2-2

Input disconnect, 4-1

Input power rating, 2-2

Installation

input power wiri ng, 4-1 to 4-4

output power wiring, 4-5

planning, 3-1

D

Dimensions, 3-1 to 3-3

Disconnect, input, 4-1

Drive removal, 5-1 to 5-5

E

Enclosures, NEMA, 2-2, 3-1

Index

J

K

L

Liquid-cooling

bulkhead fittings, 3-5 to 3-7

connections, 3-6 to 3-8

Index-1

Page 38

M

Model numbers

Trane, 2-1

Reliance, 2-2

Mounting dimensions, 3-1 to 3-2

T

U

N

NEMA enclosure, 2-2

O

Options, Trane, 2-6

Output current rating, 2-2

P

Planning, cabinet installation, 3-1

Power wiring, 4-1 to 4-5

input, 4-1 to 4-4

output, 4-5

sizes, 4-2, 4-4

Publications, related, 1-1

Q

V

W

Watts loss rating, 2-2

Weight, cabinet, 3-1

Wire

routing, 3-4 to 3-6

sizes, 4-2, 4-4

Wiring diagrams, A-1 to A-2

X

Y

R

Ratings

input, 2-2

output, 2-2

power loss, 2-2

Regulator board, 2-2 to 2-3, 4-5

Replacement parts, 5-6

S

Index-2

Z

Trane Liqui-Flo Addendum

Page 39

Page 40

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Publication D2-3415-July 1998 Copyright © 1998 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...