Page 1

Hardware Reference, Installation, and Troubleshooting Manual D2-3411-8

LiquiFlo AC Power Modules

Version 6.4

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Chapter 1

Chapter 2

C

ONTENTS

Introduction

1.1 Related Publications ........................................................................................ 1-1

1.2 Getting Assistance from Reliance Electric....................................................... 1-1

About the Drive

2.1 Identifying the Drive by Model Number ........................................................... 2-1

2.2 Enclosure Ratings ........................................................................................... 2-2

2.3 B-Frame LiquiFlo Drive Component Locations................................................ 2-2

2.4 C-Frame LiquiFlo Drive Component Locations ............................................... 2-4

2.5 D-Frame LiquiFlo Drive Component Locations ............................................... 2-6

2.6 Regulator Board Description ........................................................................... 2-8

2.6.1 Jumper Locations and Settings ........................................................... 2-10

2.6.1.1 Setting the Analog Input Speed Reference Jumper (J4) ...... 2-10

2.6.1.2 Setting the Analog Output Jumper (J17)............................... 2-11

2.6.2 Wiring the Regulator Board Terminal Strip.......................................... 2-12

2.6.3 RS-232 Communication Port............................................................... 2-13

2.6.4 RMI Board Connector ......................................................................... 2-13

2.6.5 Operator Interface Module Connector................................................. 2-14

2.6.6 Keypad/Display ................................................................................... 2-14

2.7 RMI Board Description .................................................................................. 2-15

2.7.1 Digital Inputs ....................................................................................... 2-15

2.7.2 Digital Outputs..................................................................................... 2-15

2.7.3 Relay Outputs ..................................................................................... 2-15

2.7.4 Analog Input ........................................................................................ 2-15

2.7.5 Analog Outputs ................................................................................... 2-15

2.7.6 Frequency Input .................................................................................. 2-15

2.7.7 Wiring the RMI Board Terminal Strip................................................... 2-16

2.8 Optional Equipment ....................................................................................... 2-17

Contents

Chapter 3

Planning the Installation

3.1 General Requirements for the Installation Site ................................................ 3-1

3.1.1 Making Sure Environmental Conditions are Met ................................... 3-1

3.1.2 Determining Total Area Required Based on Drive Dimensions ............ 3-2

3.1.3 Verifying the Site Provides for Recommended Air Flow Clearances .... 3-6

3.1.4 Verifying Power Module Input Ratings Match Supplied Power ............. 3-6

3.2 Wiring Requirements for the Drive .................................................................. 3-6

3.2.1 Meeting Terminal Strip Input and Output Specifications ....................... 3-6

3.2.2 Determining Wire Size Requirements ................................................... 3-6

3.2.2.1 Conduit Entry Opening Sizes .................................................. 3-6

3.2.2.2 Recommended Power Wire Sizes .......................................... 3-6

3.2.2.3 Recommended Control and Signal Wire Sizes ....................... 3-7

3.2.2.4 Recommended Motor Lead Lengths....................................... 3-8

3.2.2.5 Recommended Serial Communication Cable Lengths ........... 3-8

3.2.3 Selecting Input Line Branch Circuit Fuses ............................................ 3-8

3.2.4 Meeting Encoder Specifications (FVC Regulation Only)....................... 3-9

3.2.4.1 Encoder Wiring Guidelines ..................................................... 3-9

3.2.5 Verifying Power Module Output Current Rating Is

Greater Than Motor Full Load Amps..................................................... 3-9

I

Page 4

Chapter 4

Chapter 5

Chapter 6

Mounting the Drive, Grounding, and Finding Wire Routing Locations

4.1 Lifting and Mounting the Drive .........................................................................4-1

4.1.1 Verifying the Drive’s Watts Loss Rating.................................................4-2

4.2 Determining Input, Motor Output, Ground, and Control Wire

Routing for the Drive ........................................................................................4-2

4.3 Installing the DC Bus Reactor Fan (C-Frame Drives Only)..............................4-6

4.4 Grounding the Drive .........................................................................................4-7

4.5 Connecting Coolant Lines ................................................................................4-7

4.5.1 B-Frame Coolant Connections ..............................................................4-7

4.5.2 C-Frame Coolant Connections ..............................................................4-7

4.5.3 D-Frame Coolant Connections ..............................................................4-8

Installing Input Power Wiring

5.1 Installing Transformers and Reactors (Optional) .............................................5-1

5.2 Installing Fuses for Branch Circuit Protection ..................................................5-1

5.3 Installing a Required External/Separate Input Disconnect...............................5-4

5.4 Installing Power Wiring from the AC Input Line to the

Drive’s Power Terminals ..................................................................................5-4

Installing Output Power Wiring

6.1 Installing Output Contactors (Optional) ............................................................6-1

6.2 Installing Mechanical Motor Overload Protection (Optional) ............................6-1

6.3 Installing Output Wiring from the Drive Output Terminals to the Motor............6-2

Chapter 7

Chapter 8

Chapter 9

Appendix A

Appendix B

Wiring the Regulator Board and RMI Board Terminal Strips

7.1 Stopping the Drive............................................................................................7-7

7.2 Wiring the Encoder Feedback Device

(FVC Regulation Only)8

7.3 Wiring the Signal and Control I/O...................................................................7-10

7.4 Wiring the RMI Board Terminal Strip .............................................................7-19

Completing the Installation

8.1 Checking the Installation ..................................................................................8-1

8.2 Powering Up After Installation Is Complete......................................................8-2

Troubleshooting the Drive

9.1 Test Equipment Needed To Troubleshoot .......................................................9-1

9.2 Drive Alarms and Faults...................................................................................9-1

9.3 Verifying That DC Bus Capacitors Are Discharged..........................................9-1

9.4 Checking the Power Modules with Input Power Off .........................................9-5

9.5 Replacement Parts...........................................................................................9-7

Technical Specifications........................................................................................... A-1

Cooling System Specifications................................................................................. B-1

Appendix C

B-Frame LiquiFlo Drive Wiring Diagrams................................................................. C-1

II

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 5

Appendix D

Appendix E

C-Frame LiquiFlo Drive Wiring Diagrams .................................................................D-1

D-Frame LiquiFlo Drive Wiring Diagrams .................................................................E-1

Contents

III

Page 6

IV

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 7

List of Figures

Figure 2.1 – Identifying the Drive Model Number ..................................................... 2-1

Figure 2.2 – B-Frame LiquiFlo Drive Component Locations..................................... 2-3

Figure 2.3 – C-Frame LiquiFlo Drive Component Locations .................................... 2-5

Figure 2.4 – D-Frame LiquiFlo Drive Component Locations .................................... 2-7

Figure 2.5 – LiquiFlo Regulator Board Component Locations.................................. 2-9

Figure 2.6 – Jumper J4 Settings for Analog Input Speed Reference ..................... 2-11

Figure 2.7 – Jumper J17 Settings for Analog Outputs............................................ 2-12

Figure 2.8 – Typical Regulator Board Terminal Strip Connections......................... 2-13

Figure 2.9 – Keypad/Display................................................................................... 2-14

Figure 2.10 – Terminal Connections on the RMI Board ......................................... 2-16

Figure 3.1 – B-Frame Drive Dimensions .................................................................. 3-3

Figure 3.2 – C-Frame Drive Dimensions .................................................................. 3-4

Figure 3.3 – D-Frame Drive Dimensions .................................................................. 3-5

Figure 4.1 – Wire Routing Locations for B-Frame LiquiFlo Drives ........................... 4-3

Figure 4.2 – Wire Routing Locations for C-Frame LiquiFlo Drives ........................... 4-4

Figure 4.3 – Wire Routing Locations for D-Frame LiquiFlo Drives ........................... 4-5

Figure 4.4 – DC Bus Reactor Cooling Fan Mounting Location ................................. 4-6

Figure 4.5 – Coolant Connector Locations for B-Frame LiquiFlo Drives .................. 4-8

Figure 4.6 – Coolant Connector Locations for C-Frame LiquiFlo Drives .................. 4-9

Figure 4.7 – Coolant Connector Locations for D-Frame LiquiFlo Drives .................. 4-9

Figure 5.1 – Typical AC Input/Output Electrical Connections

(6-Pulse Rectifier, All Frames)................................................................ 5-2

Figure 5.2 – Typical AC Input/Output Electrical Connections

(12-Pulse Rectifier, B- and C-Frames Only) ........................................... 5-3

Figure 7.1 – Two-Wire Start/Stop Sample Control Wiring ........................................ 7-5

Figure 7.2 – Three-Wire Start/Stop Sample Control Wiring...................................... 7-6

Figure 7.3 – Encoder Wiring Connections ................................................................ 7-9

Figure 7.4 – Terminal Connections on the RMI Board ........................................... 7-19

Figure 9.1 – DC Bus Voltage Terminals (B-Frame Drives)....................................... 9-2

Figure 9.2 – DC Bus Voltage Terminals (C-Frame Drives) ...................................... 9-3

Figure 9.3 – DC Bus Voltage Terminals (D-Frame Drives) ...................................... 9-4

Contents

V

Page 8

VI

LiquiFlo 2.0 AC Drive User Manual

Page 9

List of Tables

Table 2.1 – Power and Enclosure Ratings ............................................................... 2-2

Table 2.2 – Available Kits and Options................................................................... 2-17

Table 3.1 – Environmental Conditions...................................................................... 3-2

Table 3.2 – Drive Dimensions and Weights.............................................................. 3-2

Table 3.3 – Recommended Power Wire Sizes for B-Frame Drives.......................... 3-7

Table 3.4 – Recommended Power Wire Sizes for C-Frame Drives ......................... 3-7

Table 3.5 – Recommended Power Wire Sizes for D-Frame Drives ......................... 3-7

Table 3.6 – Recommended Terminal Strip Wire Sizes............................................. 3-8

Table 3.7 – AC Input Line Fuse and Circuit Breaker Selection Values .................... 3-9

Table 5.1 – Terminal Tightening Torques................................................................. 5-4

Table 7.1 – RS-232 Connections (Terminals 1-3) .................................................... 5-1

Table 7.2 – Encoder Connections (Terminals 4-9) ................................................... 7-1

Table 7.3 – Analog Output Connections (Terminals 10 and 11)............................... 7-2

Table 7.4 – Analog Speed/Torque Reference Connections (Terminals 12-15)........ 7-2

Table 7.5 – Digital Input Connections (Terminals 16-25) ......................................... 7-3

Table 7.6 – Reserved Connections (Terminals 26 and 27) ...................................... 7-3

Table 7.7 – Status Relay Connections (Terminals 28-31) ........................................ 7-4

Table 7.8 – Wiring Signal and Control I/O to the Regulator Board Terminal Strip.. 7-10

Table 7.9 – Wiring Signal and Control I/O to the RMI Board Terminal Strip........... 7-20

Table 9.1 – Resistance Checks ................................................................................ 9-6

Table 9.2 – B-Frame LiquiFlo Drive Replacement Parts .......................................... 9-7

Table 9.3 – C-Frame LiquiFlo Drive Replacement Parts .......................................... 9-8

Table 9.4 – D-Frame LiquiFlo Drive Replacement Parts .......................................... 9-9

Contents

VII

Page 10

VIII

LiquiFlo 2.0 AC Drive User Manual

Page 11

This instruction manual describes the LiquiFlo™ drive’s Power Module and regulator

hardware. It does not cover the LiquiFlo software. For software information, refer to the

LiquiFlo AC General Purpose (V/Hz) and Vector Duty Drive Software Start-Up and

Reference Manual (D2-3410).

This manual is intended for qualified electrical and plumbing personnel.

LiquiFlo drives will typically be referenced by frame size. If additional clarity is

required, drive model numbers wil also be included.

1.1 Related Publications

Refer to the following related publications as necessary for more information:

• D2-3410 - LiquiFlo AC General Purpose (V/Hz) and Vector Duty Drive Software

Start-Up and Reference Manual

• D2-3305 - Motor Encoder Cable Kit

C

HAPTER

Introduction

1

• D2-3348 - Control and Configuration Software (CS3000)

• D2-3341 - Remote Meter Interface Board

• D2-3342 - Operator Interface Module

• D2-3449 - LiquiFlo AC Drive Panel Mount Kit

1.2 Getting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, contact your local Reliance Electric sales office. For technical assistance, call

1-864-284-5444.

Introduction

1-1

Page 12

1-2

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 13

C

HAPTER

About the Drive

This chapter describes how to identify the drive using the model number matrix and

shows the major drive components.

The LiquiFlo AC drive is a PWM (pulse-width-modulated) liquid-cooled drive that

provides vector and general purpose regulation for a wide range of applications.

Using vector regulation, the drive can provide high dynamic response, maintain full

rated motor torque to zero speed, and precisely control motor speed in both

directions. The drive can provide this functionality either with encoder feedback (flux

vector control or FVC) or without (sensorless vector control or SVC).

Using general purpose (volts/hertz or V/Hz) regulation, the drive is suited for a broad

range of applications requiring adjustable speed control of motors.

2.1 Identifying the Drive by Model Number

Each LiquiFlo AC drive can be identified by its model number. See figure 2.1. This

number appears on the shipping label and on the drive’s nameplate. The drive’s model

number includes the Power Module and the regulator version. Drive power ratings are

provided in table 2.1.

2

Continuous Ampere Rating (x10)

41 = 414 amps

50 = 500 amps

64 = 643 amps

120 = 1200 amps

LW= water-cooled

LR = refrigerant-cooled

Voltage

2 = 200 to 230 VAC

3 = 270 to 310 VAC

4 = 380 to 480 VAC

Enclosure

0 = Open Chassis

1 = NEMA 1

2 = NEMA 12 Only

4 = NEMA 4x (Indoor Only) or NEMA 12

Regulator V e rsio n

60 = Version 6.x Firmware

Figure 2.1 – Identifying the Drive Model Number

NNN AA N N NN

About the Drive

2-1

Page 14

Table 2.1 – Power and Enclosure Ratings

Frame Size and

Model

Number

41L4060

41LR4060

50LW4060

50LR4060

64LW4060

64LR4060

120L4060 D-Frame

* With V/Hz regulation, 110% continuous output current capability. With vector regulation, 150% output current capability for 5 sec.

**Note that LiquiFlo drives are rated for use with water at specified temperatures and pressures as the coolant. Some coolant fluids may

allow an increased output rating while others may require the output to be derated. The LiquiFlo drive is also capable of running at 4 kHz

or 8 kHz. Contact Reliance Electric for ratings.

Selected

Regulation*

B-Frame

V/Hz or Vector

C-Frame

V/Hz or Vector

C-Frame

V/Hz or Vector

V/Hz or Vector

Enclosure

Rating

Open-Chassis

Style

Open-Chassis

Style

Open-Chassis

Style

Open-Chassis

Style

Input

Power

(KVA)

344 414 414 4600 / 1100

398 500 500 5500 / 1500

512 643 643 7000 / 2000

956 1200 1200 11700/4000

Input

Current

(Amps)

Output Current

at 2 kHz**

(Amps)

Full Load

Power Loss Watts

Fluid / Air

2.2 Enclosure Ratings

LiquiFlo drives have the following enclosure rating:

• Open-Chassis Style: Intended to be installed in an enclosure.

LiquiFlo drives must be placed in an enclosure.

2.3 B-Frame LiquiFlo Drive Component Locations

The B-Frame LiquiFlo drives have the following main components. The numbered

items listed below provided correspond to the numbers used in figure 2.2.

Replacement parts are listed in chapter 9.

1. Bus Bars (3) (AC Output)

2. Bus Bars (6) (AC Input)

3. IGBT Modules

4. Output Laminate

5. Capacitors

6. RMI Board

7. Casting

8. Membrane Switch Keypad

9. Coolant Lines - (a) Inlet, (b) Outlet

10. Regulator Board

11. Power Module Control (PCB)

12. Current Feedback Devices (3)

2-2

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 15

1

2

3

12

9b

4

11

5

10

9a

About the Drive

8

7

6

Figure 2.2 – B-Frame LiquiFlo Drive Component Locations

2-3

Page 16

2.4 C-Frame LiquiFlo Drive Component Locations

The C-Frame LiquiFlo drives have the following main components. The numbered

items listed below provided correspond to the numbers used in figure 2.3.

Replacement parts are listed in chapter 9.

1. Bus Bars (AC Input)

2. SCR Bridge (AC to DC Converter)

3. Power Module Adapter Printed Circuit Board (PCB)

4. Power Interface Harness

5. Bus Bars (AC Output)

6. LEM InterfaceHarness

7. DC Bus Control PCB

8. Gate Driver PCB -Low Side

9. DC Bus Laminate Assembly

10. Output Current Feedback Devices

11. IGBT Modules

12. Chillplate (Heatsink)

13. Capacitors

14. Drive Baseplate

15. Reactor (Not Shown)

16. Discharge Resistors (Not Shown)

17. Control Panel Assembly

18. Bus Control - PMA Harness

19. Bus Control - Gate Drive Harness

20. Gate Driver PCB- High Side (Not Shown)

21. Membrane Switch Keyboard/Bracket

22. Regulator PCB

23. Option Board (Optional)

24. Coolant Lines - (Not Shown)

2-4

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 17

16

1

2

3

17

4

5

10

12

11

6

7

8

9

18

19

20

21

22

23

13

About the Drive

14

15

Figure 2.3 – C-Frame LiquiFlo Drive Component Locations

24

2-5

Page 18

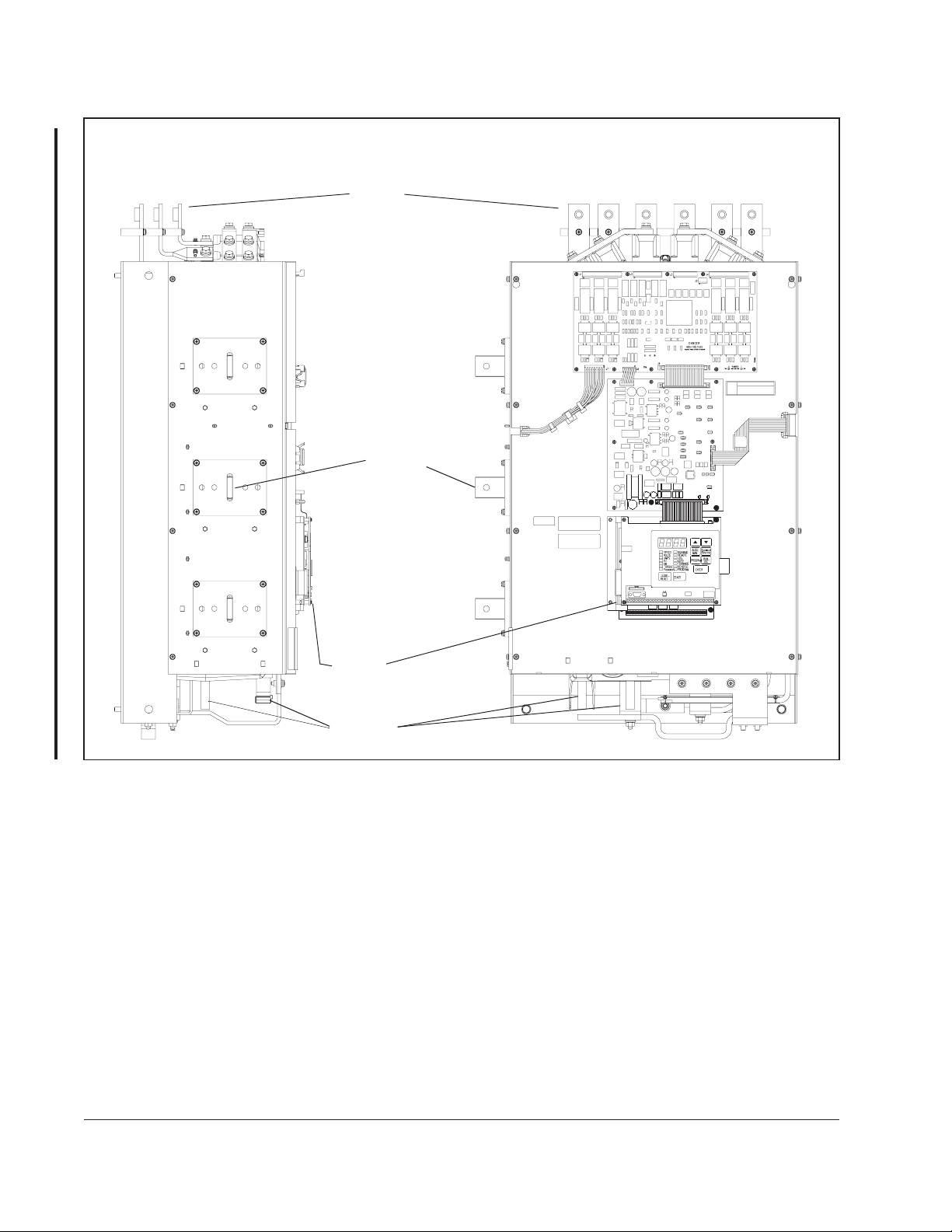

2.5 D-Frame LiquiFlo Drive Component Locations

The D-Frame LiquiFlo drives have the following main components. The numbered

items listed below provided correspond to the numbers used in figure 2.4.

Replacement parts are listed in chapter 9.

1. Chillplate Harness

2. Bus Bars (AC Input)

3. Bus Bars (AC Output)

4. Power Module Control PCB

5. Membrane Switch Keypad

6. Regulator PCB

7. RMI Option PCB

8. Current Feedback Devices

9. Gate Driver PCB

10. Coolant Connection (Outlet)

11. IGBT Module

12. Capacitors

13. Coolant Connection (Inlet)

14. Output Laminate

2-6

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 19

1

2

3

4

14

5

6

7

8

9

Figure 2.4 – D-Frame LiquiFlo Drive Component Locations

1310 11 12

About the Drive

2-7

Page 20

2.6 Regulator Board Description

LiquiFlo drive regulation is performed by a microprocessor on the Regulator board.

See figure 2.5. Drive operation is adjusted by the parameters entered through the

keypad. The Regulator board accepts power circuit feedback signals and an external

speed reference signal, as well as data from an encoder that is attached to the motor

when set up for FVC regulation. The Regulator board provides:

• PWM gating signals to the IGBT power devices

Based on the output of the control loop, the regulator sends PWM gating signals to

isolated drivers on the Gate Driver board. These drivers switch the Insulated Gate

Bi-polar Transistors (IGBTs), producing a waveform that corresponds to the voltage

and frequency outputs of the inner V/Hz, FVC, or SVC regulators. The IGBTs can be

switched at either a 2, 4, or 8 kHz carrier frequency.

• Form A and B contacts for drive status indicators

The Form A and B contacts are under control of the user via programmable

parameters. A Form A or B transition can indicate drive status. The contacts are

rated for 5 amps resistive load at 250 VAC/30 VDC and are made available through

the terminal strip.

• Display data for a four-character display and fourteen indicator LEDs

For a description of the keypad/display refer to section 2.6.6. For operational

instructions, see the LiquiFlo Software Reference manual (D2-3410).

• An analog output

The analog output is a scaled voltage (0-10 VDC) or current (4-20 mA) signal

proportional to either motor speed (RPM), motor torque, or current (%TORQUE).

The current signal selection (via jumper J17) requires a power supply for operation.

The power can be sourced from the encoder terminals (4 and 9) or from an external

15 V power supply. See table 7.1, terminals 10 and 11, for more information. The

analog output signal is available through the terminal strip.

2-8

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 21

J3

J16

60-Pin Ribbon Cable

USER DISPLAY

J9

J7

J17

J4

34-Pin Ribbon Cable

J8

USER I/O TERMINAL STRIP

J3 - Option Board Connector

J4 - Analog Input Jumper

J7 - OIM (Optional) Connector

J9 - Keypad/Display Connector

J16 - Power Module Feedback Cable

J17 - Analog Output Jumper

J8 - RS-232C Port

Figure 2.5 – LiquiFlo Regulator Board Component Locations

About the Drive

2-9

Page 22

2.6.1 Jumper Locations and Settings

Jumpers J4 and J17 on the Regulator board are factory-set for voltage in and voltage

out signals. Refer to figure 2.5 for their locations on the Regulator board. If you need

to change the jumpers’ settings, use the following procedures.

ATTENTION:Do not alter the setting of any jumper not described in this

instruction manual. Failure to observe this precaution could result in

!

2.6.1.1 Setting the Analog Input Speed Reference Jumper (J4)

Jumper J4 is the analog speed/torque (U.000) reference jumper. This jumper selects

either +/- 10 VDC or 0-20 mA input. Parameters P.009, P.010, and P.011 are used in

conjunction with the jumper.

Note that if the position of jumper J4 is changed after the parameters are

programmed, the software will not recognize that the input reference or polarity has

been changed. Be sure to verify that parameters P.009, P.010, and P.011 are correct

before starting the drive. Refer to the LiquiFlo Software Start-Up and Reference

manual for more information.

Use the following procedure to set jumper J4:

damage to, or destruction of, the equipment.

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

!

Step 1. Turn off input power to the drive and wait five minutes.

Step 2. Open the door of the enclosure.

Step 3. Verify that the DC bus voltage is zero by following the procedure in section

Step 4. Locate jumper J4 on the Regulator board. Refer to figure 2.5.

Step 5. Locate pin 1 on jumper J4. Move the jumper to the desired setting as shown

Step 6. Close the door of the enclosure.

Step 7. Reapply input power.

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

9.3.

in figure 2.6.

2-10

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 23

Step 8. Verify that Terminal Strip Analog Input Offset (P.009), Terminal Strip Analog

Input Gain (P.010), and Terminal Strip Analog Input Configure (P.011) are

correctly set. Note that the jumper settings must match the software settings;

otherwise, the reference value may differ from what is expected. Refer to the

LiquiFlo Software Start-Up and Reference manual for more information.

Voltage Input Option Current Input Option

Pins 2-3 Pins 1-2

+10 VDC

J4 J4

(default)

Figure 2.6 – Jumper J4 Settings for Analog Input Speed Reference

2.6.1.2 Setting the Analog Output Jumper (J17)

Jumper J17 is the analog output jumper. This jumper selects either a 0-10 VDC or

4-20 mA scaled signal output that is programmable to be proportional to either speed

or torque using parameter P.012. Refer to the LiquiFlo Software Reference manual for

more information about this parameter.

The jumper only selects a 0-10 VDC source voltage or 4-20 mA sink current to

represent speed or torque. Note that the 4-20 mA current selection requires a power

supply for operation as shown in table 7.8, terminals 10 and 11.

Use the following procedure to set jumper J17:

0-20 mA

About the Drive

ATTENTION:DC bus capacitors retain hazardous voltages after input

power has been disconnected. After disconnecting input power, wait five

!

Step 1. Turn off input power to the drive and wait five minutes.

Step 2. Open the door of the enclosure.

Step 3. Verify that the DC bus voltage is zero by following the procedure in section

Step 4. Locate jumper J17 on the Regulator board. Refer to figure 2.5.

Step 5. Locate pin 1 on jumper J17. Move the jumper to the desired setting as shown

Step 6. Close the door of the enclosure.

(5) minutes for the DC bus capacitors to discharge and then check the

voltage with a voltmeter to ensure the DC bus capacitors are discharged

before touching any internal components. Failure to observe this

precaution could result in severe bodily injury or loss of life.

9.3.

in figure 2.7.

2-11

Page 24

Step 7. Reapply input power.

Step 8. Verify that parameter P.012 is set correctly for either speed or current.

Voltage Output Option

Pins 2-3

+10 VDC

J17 J17

(default)

Figure 2.7 – Jumper J17 Settings for Analog Outputs

Current Output Option

Pins 1-2

4-20 mA

2.6.2 Wiring the Regulator Board Terminal Strip

The terminal strip on the Regulator board provides terminals for connecting customer

I/O devices. See figures 2.5 and 2.8. The following terminals are provided:

• Terminals 1-3: RS-232 connections

• Terminals 4-9: encoder connections

• Terminals 10-11: analog output connections

• Terminals 12-15: analog speed/torque reference connections

• Terminals 16-25: 24 VDC digital input connections

• Terminal 26: no connection

• Terminal 27: 24 VDC common

• Terminals 28-31: status relay connections

See chapter 7 for a complete description of, and how to wire, all of the signals

available through the Regulator board terminal strip.

2-12

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 25

RS-232 Tx

12 435197698

RS-232

Connections Connections

Phase A Not

Encoder

Phase B

Figure 2.8 – Typical Regulator Board Terminal Strip Connections

Phase A

+15 VDC

RS-232 Regulator Common

RS-232 Rx

2.6.3 RS-232 Communication Port

The Regulator board contains a 9-pin D-shell RS-232 communication port (J8). This

port provides RS-232 communication between the LiquiFlo drive and a personal

computer running the Control and Configuration (CS3000) software. See

Refer to instruction manual D2-3348 for more information about the CS3000 software.

2.6.4 RMI Board Connector

The flat-ribbon cable connector (J3) on the left side of the Regulator board is a parallel

bus connection port that is used on LiquiFlo drives for the Remote Meter Interface

(RMI) board.

Isolated Reference Voltage

VDC Speed Reference

Ma Speed Reference

Isolated Reference Gnd

+24 VDC

Digital Input 8 (Remote/Local)

Analog Meter Output

Regulator Common

Phase B Not

Regulator Common

10 1211 1413 15 171618 22

Analog

Output

Analog Speed

Reference

Digital Input 7 (Ramp1/Ramp2)

Configurable

(Isolated 24 VDC)

Digital Input 6 (Forward/Reverse)

Function Loss

Run / Jog

20

21

Digital Inputs

Stop

Reset

Factory

Installed

Jumper

Start

2423 25

+24 VDC Common

No Connection

+24 VDC Common

Status Relays

N.O. Relay Contact

N.C. Relay Common

N.C. Relay Contact

31

292726 28 30

figure 2.5.

N.O. Relay Common

About the Drive

The RMI board provides an extended set of terminal strip inputs and outputs for the

LiquiFlo drive. When the drive control source is the terminal strip (P.000 = rE), the RMI

board can be used to provide additional speed reference selections. The RMI board

also provides an outer PI regulator that is used to adjust trim. An optional adjustable

torque (vector) or current (V/Hz) limit is available using the RMI board's analog or

frequency input. See section 2.7 for a more detailed description of the RMI board.

Refer to section 7.4 for a detailed description of the RMI terminal strip signals, and

how to wire the RMI board.

The J3 connector can also be used to provide a means of attaching optional boards

such as the DeviceNet

™

Option board, the AutoMax™ Network Option board, or

similar boards to the LiquiFlo drive. Note that you must first remove the RMI board

before a communication board can be added to the LiquiFlo drive.

2-13

Page 26

Refer to the appropriate board instruction manual for more information. Refer to

section 2.8 of this manual for more information on optional drive kits.

2.6.5 Operator Interface Module Connector

Flat-ribbon connector J7 provides a means of attaching the optional Operator

Interface Module (OIM). The OIM is available for use as a remote keypad for the

LiquiFlo drive. Refer to the OIM instruction manual (D2-3342) for more information.

2.6.6 Keypad/Display

The front panel keypad/display is used to program and operate the LiquiFlo drive. See

figure 2.9. The four-character display is used to indicate drive parameters, parameter

values, and fault codes. The fourteen single LEDs indicate drive status and mode, as

well as identifying drive outputs whose values are displayed on the four-character

display.

Refer to the LiquiFlo Software Start-Up and Reference manual for more information.

Drive Status LEDs

Monitor Mode LEDs

Password LED

Display

Stop/Reset

Key

Keypad

Start Key

2-14

Figure 2.9 – Keypad/Display

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 27

2.7 RMI Board Description

The following signals are available at the RMI board terminal strip. Refer to figure 2.10

for terminal identification. For a detailed description of the RMI board signals, refer to

section 7.4.

2.7.1 Digital Inputs

Four 24 volt DC digital inputs provide additional speed reference options. The inputs

are active high. A 24 VDC supply is provided by the RMI board for use with the digital

inputs. The supply is short circuit- and overvoltage-protected.

2.7.2 Digital Outputs

Four 24 volt digital outputs are turned on and off as a result of data comparisons in the

drive. All digital outputs are source-driven (active high with common ground) and short

circuit-protected. Each output has an adjustable time delay that can be programmed

as an on-delay or an off-delay. An option to select an external 24 volt supply for

increased current capability at the outputs is jumper-selectable.

2.7.3 Relay Outputs

Three relay outputs can be turned on and off as a result of data comparisons in the

drive. Each output has an adjustable time delay that can be programmed as an

on-delay or an off-delay. All contacts are rated at 2

A, 24 VDC or 250 VA, 120 VAC.

2.7.4 Analog Input

The analog input is based on a 10-bit analog-to-digital (A/D) converter and is

jumper-selected between 0 to 10 volts or 0 to 20 mA. Separate connection terminals

are provided for voltage input and current input. The inputs are overvoltage-protected.

Offset and gain are computed by software.

2.7.5 Analog Outputs

Three analog output channels can be configured. The outputs are short circuit

protected. The output value is modulated over four 1 msec scans to provide 10-bit

data resolution.

2.7.6 Frequency Input

The frequency input operates from 0 to 200 kHz, 15 VDC. The input is single-ended

and uses the same common as the analog input.

About the Drive

2-15

Page 28

2.7.7 Wiring the RMI Board Terminal Strip

ATTENTION:You are responsible for conforming with all applicable local,

national, and inter national codes. Failure to obser ve this precaution could

!

Refer to figure 2.10 for the signal and control I/O terminal connections on the RMI

board. terminal strip connections and related parameters. Refer to section 7.4 for

descriptions of, and how to wire, all RMI board terminal strip connections.

result in damage to, or destruction of, the equipment.

Digital Input 1

Digital Input 2

Digital Input 3

Digital Input 4

+24 V (for digital inputs only)

External +24 V Input for Digital Outputs

Digital Output 1

Digital Output 2

Digital Output 3

Digital Output 4

Digital Output Common

Relay 1 Common

Relay 1 Normally Open

Relay 2 Normally Closed

Relay 2 Common

Relay 2 Normally Open

Not Used

Relay 3 Normally Closed

Relay 3 Common

Relay 3 Normally Open

Not Used

Analog Input: 0 to 10 V

Analog Input: 0 (4) to 20 mA

Analog I/O Common

Analog Output 1: 0 to 10 V

Analog Output 2: +/-10 V

Analog Output 3: 0 to 10 V/0 to 20 mA

Analog I/O Common

41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69

Figure 2.10 – Terminal Connections on the RMI Board

Frequency Input (Ground = Analog I/O Common)

2-16

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 29

2.8 Optional Equipment

Table 2.2 lists standard available LiquiFlo kits and options.

Table 2.2 – Available Kits and Options

Description Model Number

Instruction

Manual

2TC3025

2TC3075

Motor Encoder Cable

DeviceNet Network Option Board 2DV3000 MAN0096-03

ControlNet Network Option Board 2CN3000 D2-3390

InterBus-S Network Option Board 2NB3000 49’1333

AutoMax Network Option Board with

762mm (30”) of Cable

Johnson Metasys N2 Option Board 2MT3000 HE-HGV3MT

Landis and Staefa P1 Option Board

Modbus Option Board 2MB3000 MAN0183-02

PROFIBUS Option Board 2PB3000 49’1355

AutoMax RS-232 Adapter Cable 2CA3001 D2-3348

2TC4025

2TC4075

2TC4100

2TC4300

2AX3000 D2-3308

2LS3000 Horner Electric

D2-3305

Application 2710

Manual

About the Drive

Operator Interface Module (OIM) 2RK3000 D2-3342

CS3000 Control and Configuration

Software

CS3000 RS-232 Computer Cable 2CA3000 D2-3348

115 VAC Interface Option Board 2LB3000 D2-3376

2CS3000 D2-3348

2-17

Page 30

2-18

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 31

C

HAPTER

Planning the Installation

This chapter provides how to plan a LiquiFlo drive installation.

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

!

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:When the level-sense start feature is enabled (P.054 =

ON), the user must ensure that automatic start up of the driven equipment

will not cause injury to operating personnel or damage to the driven

equipment. In addition, the user is responsible for providing suitable

audible or visual alarms or other devices to indicate that this function is

enabled and the drive may start at any moment. Refer to the

LiquiFlo Software Start-Up and Reference manual for additional

information. Failure to observe this precaution could result in severe

bodily injury or loss of life.

ATTENTION:Use of power correction capacitors on the output of the

drive can result in erratic operation of the motor, nuisance tripping, and/or

permanent damage to the drive. Remove power correction capacitors

before proceeding. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

ATTENTION:The user is responsible for conforming with all applicable

local, national, and international codes. Failure to obser ve this precaution

could result in damage to, or destruction of, the equipment.

3

3.1 General Requirements for the Installation Site

3.1.1 Making Sure Environmental Conditions are Met

Planning the Installation

It is important to properly plan before installing a LiquiFlo drive to ensure that the

drive’s environment and operating conditions are satisfactory. Read the following

recommendations before continuing with drive installation.

Before deciding on an installation site, consider the following guidelines:

• Verify that open-chassis style drives can be kept clean and dry. LiquiFlo drives must

be placed in an enclosure.

• The area chosen should allow the space required for proper air flow as defined in

section 3.1.3.

• Be sure that open-chassis style drives are installed away from oil, coolants, or other

airborne contaminants.

3-1

Page 32

• Do not install the drive above 1000 meters (3300 feet) without derating output

power. For every 91.4 meters (300 feet) above 1000 meters (3300 feet), derate the

output current 1%.

• Verify that the drive location will meet the environmental conditions specified in table

3.1.

Table 3.1 – Environmental Conditions

Condition Specification

LiquiFlo

Drive M/N

41L4060

41LR4060

50LW4060

50LR4060

64LW4060

64LR4060

Operating Temperature (inside a NEMA cabinet)

0°C to +55°C

1

(32° to 131°F)

Storage Temperature (Ambient) -40°C to 65°C (−40° to 149°F)

Humidity 5% to 95% (non-condensing)

1

With typical heat rise inside a cabinet, 40°C ambient outside usually results in 55°C inside.

3.1.2 Determining Total Area Required Based on Drive Dimensions

Drive dimensions and weights are listed in table 3.2. Overall drive dimensions are

illustrated in figures 3.1, 3.2, and 3.3 as an aid in calculating the total area required by

the LiquiFlo drives.

Table 3.2 – Drive Dimensions and Weights

Frame Dim. A Dim. B Dim. C Dim. D Dim. E Dim. F Dim. G Weight

B 475 mm

18.69”

C 583 mm

22.96”

C 583 mm

22.96”

800 mm

31.52”

971 mm

38.23”

971 mm

38.23”

357 mm

14.06”

347 mm

13.66”

347 mm

13.66”

397 mm

15.63”

464 mm

18.25”

464 mm

18.25”

711mm

28.00”

787 mm

31.00”

787 mm

31.00”

39 mm

1.53”

28 mm

1.09”

28 mm

1.09”

20 mm

0.79”

25 mm

1.00”

25 mm

1.00”

125 kg

275 lb

168 kg

370 lb

170 kg

375 lb

120L4060 D 1010 mm

3-2

39.75”

1245 mm

49.00”

360 mm

14.16”

838 mm

33.00”

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

1200 mm

47.25”

29 mm

1.12”

25 mm

1.00”

386 kg

850 lb

Page 33

.563" Thru

4 Places

B

E

F (Typ. 4 Pl.)

G (Typ. 4 Pl.)

D

A

C

Right Side ViewFront View

Figure 3.1 – B-Frame Drive Dimensions

Planning the Installation

3-3

Page 34

.563" Thru

4 Places

B

E

F (Typ. 4 Pl.)

D

G (Typ. 4 Pl.)

A

Front View (Control Panel Assembly and Bus Laminate Removed) Right Side View

Figure 3.2 – C-Frame Drive Dimensions

3-4

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

C

Page 35

C

A

13.93

F

16.5016.50

D

0.56

6 Pl.

B

E

Left Side View

Planning the Installation

G

Figure 3.3 – D-Frame Drive Dimensions

Front View

3-5

Page 36

3.1.3 Verifying the Site Provides for Recommended Air Flow Clearances

Be sure there is adequate clearance for air circulation around the user-supplied

enclosure. A 6-inch minimum clearance is required wherever vents are located in the

cabinet.

3.1.4 Verifying Power Module Input Ratings Match Supplied Power

It is important to verify that plant power will meet the input power requirements of the

LiquiFlo drive’s Power Module circuitry. Refer to table 2.1 for input power rating

specifications. Be sure input power to the drive corresponds to the drive nameplate

voltage and frequency.

3.2 Wiring Requirements for the Drive

Certain drive requirements should be checked before continuing with the drive

installation. Wire sizes, branch circuit protection, encoder feedback (for FVC

regulation), and E-stop wiring (see chapter 7) are all areas that need to be evaluated.

3.2.1 Meeting Terminal Strip Input and Output Specifications

The terminal strip on the Regulator board provides terminals for 24 VDC power for the

eight remote control inputs. Refer to tables A.3 and A.4 for control input and output

specifications.

3.2.2 Determining Wire Size Requirements

Wire size should be determined based on the size of conduit openings, and applicable

local, national, and international codes (e.g., NEC/CEC regulations).

ATTENTION:The user is responsible for conforming with all applicable

local, national, and international codes. Failure to obser ve this precaution

!

3.2.2.1 Conduit Entry Opening Sizes

It is important to determine the size of the conduit openings in the cabinet that the

drive is mounted in so that the wire planned for a specific entry point will fit through the

opening.

3.2.2.2 Recommended Power Wire Sizes

Input power wiring should be copper and should be sized according to applicable

codes to handle the drive’s continuous-rated input current. Output wiring should be

copper and should be sized according to applicable codes to handle the drive’s

continuous-rated output current. See tables 3.3, 3.4, and 3.5 for recommended power

wire sizes. See figures 5.1 and 5.2 for input and output wiring connections.

could result in damage to, or destruction of, the equipment.

3-6

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 37

Table 3.3 – Recommended Power Wire Sizes for B-Frame Drives

Type of Power Wiring

AC Input Power (R/L1, S/L2, T/L3)

Drive M/N 41L4060, 41LR4060

with kit M/N 41L4060PM

Output Power (U/T1, V/T2, W/T3)

Delta-Wye Transformer (S1 to S6)

1

accepts two (2) 300 MCM to 6 AWG

Lug

conductors

Ground (PE)

1

Lugs not provided with standard drive. They are available as part of kit M/N 41L4060PM.

Table 3.4 – Recommended Power Wire Sizes for C-Frame Drives

Drive M/N 50LW4060, 50LR4060,

64LW4060, 64LR4060

Type of Power Wiring

with kit M/N 64L4060PM

AC Input Power (R/L1, S/L2, T/L3)

Output Power (U/T1, V/T2, W/T3)

Delta-Wye Transformer (S1 to S6)

1

accepts two (2) 350 MCM to 4 AWG

Lug

conductors

Ground (PE)

1

Lugs not provided with standard drive. They are available as part of kit M/N 64L4060PM.

Table 3.5 – Recommended Power Wire Sizes for D-Frame Drives

3.2.2.3 Recommended Control and Signal Wire Sizes

Planning the Installation

Drive M/N 120L4060

Type of Power Wiring

with kit M/N 120L4060PM

AC Input Power (R/L1, S/L2, T/L3)

Output Power (U/T1, V/T2, W/T3)

Delta-Wye Transformer (S1 to S6)

1

accepts two (2) 800 MCM to

Lug

300 MCM conductors

Ground (PE)

1

Lugs not provided with standard drive. They are available as part of kit M/N 120L4060PM.

The recommended wire sizes to connect I/O signals to the terminal strip on the

Regulator board and RMI board are shown in table 3.6. Recommended terminal

tightening torque is 0.5 Newton-meters (4.5 in-lbs). Operator controls can be up to 303

meters (1000 feet) from the LiquiFlo drive.

3-7

Page 38

Table 3.6 – Recommended Terminal Strip Wire Sizes

Ter minals Wi re Size

1 to 31 (Regulator)

41 to 69 (RMI)

3.2.2.4 Recommended Motor Lead Lengths

Motor lead lengths can total up to 76 meters (250 feet).

3.2.2.5 Recommended Serial Communication Cable Lengths

Connector J8 on the Regulator boards is an RS-232 serial communication port. This

connector allows the LiquiFlo drive to communicate with external devices such as a

personal computer using RS-232 protocol. See table A.5.

Two RS-232 cables are available from Reliance Electric:

20 to 14 AWG, 2 to 0.5 (mm

• A 3 meter (10 feet) D-shell 9-pin to 9-pin cable (M/N 2CA3000)

• A 0.3 meter (1 foot) D-shell 9-pin to 25-pin adaptor cable (M/N 2CA3001).

User-constructed cables can be up to 15 meters (50 feet) in length.

Note that for communication between a LiquiFlo drive and a personal computer, the

Control and Configuration Software must also be used. Refer to instruction manual

D2-3348 for more information about the CS3000 software.

2

)

The Regulator boards have one set of RS-232 transmit/receive lines. These lines can

be accessed by only one

on the terminal strip, or an Operator Interface Module (OIM).

device at a time: connector J8, the RS-232 terminals (1-3)

3.2.3 Selecting Input Line Branch Circuit Fuses

ATTENTION:Most codes require that upstream branch circuit protection

be provided to protect input power wiring. Install the fuses recommended

!

Input line branch circuit protection fuses must be used to protect the input power lines.

See figures 5.1 and 5.2. Recommended fuse values are shown in table 3.7. The input

fuse ratings listed in table 3.7 are applicable for one drive per branch circuit. No other

load may be applied to that fused circuit.

in table 3.6. Do not exceed the fuse ratings. Failure to observe this

precaution could result in damage to, or destruction of, the equipment.

3-8

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 39

Table 3.7 – AC Input Line Fuse and Circuit Breaker Selection Values

Model Number

41L4060

Input Voltage

(+/-10%) Fuse Rating

380-480 VAC

600 A

1

Motor Circuit Protector

or Circuit Breaker

600 A

41LR4060

50LW4060

380-480 VAC

750 A

2

800 A

50LR4060

64LW4060

380-480 VAC

1000 A

2

1000 A

64LR4060

120L4060 380-480 VAC

1

Recommended fuse type: UL Class J, 600 V, time-delay, or equivalent.

2

Recommended fuse type: UL Class L, 600 V, time-delay, or equivalent.

1600 A

2

1500 A

3.2.4 Meeting Encoder Specifications (FVC Regulation Only)

LiquiFlo drives set up for FVC regulation require an encoder for closed-loop operation.

Refer to table A.6 for specifications. Drives set up for V/Hz or SVC regulation do not

require an encoder for feedback because they operate in the open loop mode.

3.2.4.1 Encoder Wiring Guidelines

Encoder connections are considered signal level wiring and, therefore, must be run

separate from control and power wiring. Reliance Electric recommends 18 AWG

unshielded twisted pair wires with 2-3 twists per inch for applications to a maximum

distance of 303 meters (1000 feet). The recommended Reliance Electric part number

is 417900-207CG, 18 AWG, 6 conductor (3 twisted pairs).

3.2.5 Verifying Power Module Output Current Rating Is Greater Than

Motor Full Load Amps

Verify that the LiquiFlo output current rating is equal to or greater than the motor’s full

load current (amps). Table 2.1 lists the output current values.

Planning the Installation

3-9

Page 40

3-10

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 41

Mounting the Drive, Grounding, and

Finding Wire Routing Locations

This chapter shows how to mount the drive and properly ground it. Also shown are the

entry areas where wiring is to be routed in and out of the drive.

4.1 Lifting and Mounting the Drive

Use the following procedure to lift the LiquiFlo drive and mount it in the required

enclosure:

Step 1. For M/N 50LW4060, 50LR4060, 64LW4060, and 64LR4060, install two

eyebolts into the drive to serve as lifting points. Two 3/4” nuts are welded to

the drive’s baseplate. Screw two eyebolts (2” eye I.D., 6” long shank) into the

nuts.

For M/N 41L4060 or 41LR4060, install two clevis clamps into the drive to

serve as lifting points. Two 9/16” through holes are machined into the casting

protrusions.

For M/N 120L4060, install two clevis pins into the drive to serve as lifting

points. Two 1.00" through holes are provided in the sheet metal chassis.

C

HAPTER

4

Step 2. For M/N 41L4060, 41LR4060, M/N 50LW4060, 50LR4060, 64LW4060, and

64LR4060, connect 18” (nominal) of chain between the eyebolts or attached

clevis clamps and secure them with a clevis clamp.

For M/N 120L4060, connect 50" (nominal) of chain between the eyebolts or

attached clevis clamps and secure them with a clevis clamp.

Step 3. Using an overhead or portable hoist (minimum 1/2 ton rated capacity), attach

a free-fall chain to the chain secured to the drive. Take up any vertical slack in

the chain.

Step 4. Using the hoist, lift the drive from the horizontal shipping pallet.

Step 5. Position the drive in the enclosure.

Step 6. For M/N 41L4060, 41LR4060, M/N 50LW4060, 50LR4060, 64LW4060, and

64LR4060, attach the drive to the vertical surface selected using the four (4)

mounting holes provided.

For M/N 120L4060, attach the drive to the vertical surface using the six (6)

mounting holes provided.

Mounting the Drive, Grounding, and Finding Wire Routing Locations

4-1

Page 42

In order to maintain a flat mounting surface and to ensure that bolt tightness

is maintained, use flat washers and split-ring lock washers under the bolt

heads. Refer to table 3.2 and figures 3.1 to 3.3 for drive mounting

dimensions. Use the following user-supplied mounting bolts and washers on

C-frame drives: 1/2”-13, UN/UNC-2A, Grade 2.

Step 7. For M/N 50LW4060, 50LR4060, 64LW4060, and 64LR4060, remove the

eyebolts and the chain between them.

For M/N 41L4060, 41LR4060, and 120L4060, remove the clevis clamps and

chain between them.

4.1.1 Verifying the Drive’s Watts Loss Rating

When mounting the drive inside of an enclosure, you should determine the watts loss

rating of the drive from table 2.1. This table lists the typical full load power loss watts

value at 2 kHz (rated carrier frequency). Ensure that the enclosure is adequately

ventilated with 0

° to 40°C ambient air based on the drive’s watts loss rating.

4.2 Determining Input, Motor Output, Ground, and

Control Wire Routing for the Drive

All wiring should be installed in conformance with the applicable local, national, and

international codes (e.g., NEC/CEC). Signal wiring, control wiring, and power wiring

must be routed in separate conduits to prevent interference with drive operation. Use

grommets, when hubs are not provided, to guard against wire chafing. Figures 4.1,

4.2, and 4.3 show the wire routing, grounding terminal, and power terminal strips of

the B-frame, C-frame, and D-frame LiquiFlo drives.

ATTENTION:Do not route signal and control wiring with power wiring in

the same conduit. This can cause interference with drive operation.

!

Do not route more than three sets of motor leads through a single conduit. This will

minimize cross-talk that could reduce the effectiveness of noise reduction methods. If

more than three drive/motor connections per conduit are required, shielded cable

must be used. If possible, each conduit should contain only one set of motor leads.

!

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

ATTENTION: Unused wires in conduit must be grounded at both ends

to avoid a possible shock hazard caused by induced voltages. Also, if a

drive sharing a conduit is being serviced or installed, all drives using this

conduit should be disabled to eliminate the possible shock hazard from

cross-coupled motor leads. Failure to observe these precautions could

result in bodily injury.

4-2

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 43

Drive Input

Wiring

(6 Places)

Drive Output

Wiring

(3 Places)

Front View

Coolant Connections

User Connection

Wiring

User

Connections

Figure 4.1 – Wire Routing Locations for B-Frame LiquiFlo Drives

Top View

Bottom View

Mounting the Drive, Grounding, and Finding Wire Routing Locations

4-3

Page 44

Drive

Input

Wiring

Drive

Output

Wiring

To Motor

(3 Places)

User

Connections

Coolant

Connections

Figure 4.2 – Wire Routing Locations for C-Frame LiquiFlo Drives

4-4

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 45

L1

L4

Drive

Input

6 Places

U

L2

L5

L3

L6

Left Side View

W

Drive

V

Output

To Motor

User Control

Front View

Connections

User Control

Wire Openings

Figure 4.3 – Wire Routing Locations for D-Frame LiquiFlo Drives

Mounting the Drive, Grounding, and Finding Wire Routing Locations

Bottom View

4-5

Page 46

4.3 Installing the DC Bus Reactor Fan (C-Frame Drives

Only)

A fan must be installed in the LiquiFlo drive enclosure to keep the DC bus reactor at

the proper operating temperature. The fan should be a Comair Rotron M/N PT2B3

rated at 0.26 amps, 31 watts, 235 CFM (115 VAC, 60 Hz), or equivalent.

Use the following procedure to install the DC bus reactor fan:

Step 1. Open the door of the enclosure.

Step 2. Mount the fan beneath the drive in the enclosure as shown in figure 4.4 such

that the air flow is directed up through the drive.

Step 3. Connect the fan to a 115 VAC, 60 Hz power source inside of the enclosure.

Step 4. Close the door of the enclosure.

4-6

FAN

Coolant

Connections

Enclosure

Floor

Figure 4.4 – DC Bus Reactor Cooling Fan Mounting Location

Airflow

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

FAN

0.0”

Clearance

Allowable

4.0" Max.

1.0" Min.

Page 47

4.4 Grounding the Drive

ATTENTION:The user is responsible for conforming with all applicable

local, national, and international codes. Failure to obser ve this precaution

!

Use the following steps to ground the drive:

Step 1. Open the door of the enclosure.

Step 2. Run a suitable equipment grounding conductor unbroken from the drive to

Step 3. Connect a suitable grounding conductor to the motor frame and the remote

Step 4. Close the door of the enclosure.

could result in damage to, or destruction of, the equipment.

the motor’s ground terminal and then to earth ground. (For B and C-frame

drives, use one of the bolts that pass through the drive baseplate and are

used to fasten the drive to the wall or cabinet. For D-frame drives, use the

ground stud provided.) See figures 4.1, 4.2, 4.3, 5.1, and 5.2. Tighten these

grounding connections to the proper torque as shown in table 5.1.

control station (if used). Run each conductor unbroken to earth ground.

When adding more than one grounding conductor wire to a single chassis

ground, twist the conductors together. Tighten these grounding connections

to the proper torque as shown in table 5.1.

4.5 Connecting Coolant Lines

LiquiFlo drives are rated for use with clean, potable water as the coolant. Coolant must

be properly filtered to ensure it is free from contamination. Some coolant fluids may

allow an increased output rating while others may require a derating. For LiquiFlo

drive M/N 41LR4060, contact Reliance Electric for additional information.

4.5.1 B-Frame Coolant Connections

B-frame LiquiFlo drives have inlet and outlet coolant connections as shown in figure

4.5. The inlet and outlet connectors are 3/4” nominal, 7/8” O.D. copper sweat fittings.

Use the appropriate sweat fittings attached to hoses or copper tube for the coolant

supply and return lines. Supply and return lines should be sized for 9 gpm/120 psi

service with a maximum operating temperature of 40°C (104°F). Actual operating flow

rate through the drive is 8 gpm at 10 psi. It is recommended that a flow switch be

installed after the coolant outlet to shut off the drive if coolant flow drops below 4 gpm.

It is also recommended that the water pump not be powered unless the drive is also

powered. Failure to do this may result in condensation accumulating on the casting

and/or circuit boards, which could damage the drive.

4.5.2 C-Frame Coolant Connections

C-frame LiquiFlo drives have inlet and outlet coolant connections as shown in figure

4.6. The inlet and outlet connectors are size 10, SAE 37° flare female fittings. Use the

appropriate male fittings attached to hoses or for the coolant supply and return lines.

These fittings should be torqued to 80 Nm (60 ft-lb). Supply and return lines should be

sized for 5 gpm/120 psi service with a maximum operating temperature of 40°C

(104°F). Actual operating flow rate through the drive is 5 gpm at 30 psi. It is

recommended that a flow switch be installed after the coolant outlet to shut off the

drive if coolant flow drops below 4 gpm. It is also recommended that the water pump

Mounting the Drive, Grounding, and Finding Wire Routing Locations

4-7

Page 48

not be powered unless the drive is also powered. Failure to do this may result in

condensation accumulating on the casting and/or circuit boards, which could damage

the drive.

4.5.3 D-Frame Coolant Connections

D-frame LiquiFlo drives have inlet and outlet coolant connections as shown in figure

4.7. The inlet and outlet connections are tapped holes suitable for two bolt-hole

flanges. The internal threads of the tapped holes are 5/16-18 UNC-2B. The depth of

thread is 3/4". The center-to-center hole dimension is 1.625". Use the appropriate

sweat fittings to connect the two bolt-hole flanges to hoses or copper tube. For

adequate sealing, a compressed fiber gasket is required between each flange and the

drive. For bolted joint strength, use a 5/16" split ring lockwasher between each 5/16-18

bolt and flange and a nonpermanent thread locking compound on each bolt. The

flange screws should be torqued to 13.6 Nm (10 ft-lb). Supply and return lines should

be sized for 9 gpm/50 psi service with a maximum operating temperature of 40°C

(104°F). A pressure regulator or pressure relief device to control the drive inlet

pressure below 50 psi is recommended. Actual operating flow rate through the drive is

8 gpm at 10 psi. It is recommended that a flow switch be installed after the coolant

outlet to shut off the drive if the coolant flow drops below 4 gpm. It is also

recommended that the water pump not be powered unless the drive is also powered.

A corrosion inhibitor is required. An approved source is Chemtool Inc., part number

CT787-C. The recommended concentration of the inhibitor is 2% by volume.

Tube assemblies for water cooling

are provided with kit M/N 41L4060PM,

or can be user-supplied.

Figure 4.5 – Coolant Connector Locations for B-Frame LiquiFlo Drives

Coolant Outlet

Connection

Coolant Inlet

Connection

Right Side View

4-8

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 49

Coolant Outlet

Connection

Coolant Inlet

Connection

Hose assemblies

are provided with

the drive. Hose

assemblies of

longer length are

provided with kit

M/N 64L4060PM,

or can be usersupplied.

Figure 4.6 – Coolant Connector Locations for C-Frame LiquiFlo Drives

Tube assemblies,

gaskets, and hardware

are provided with kit

M/N 120L4060PM, or

can be user-supplied.

Coolant Outlet

Connection

Coolant Inlet

Connection

Front View

Figure 4.7 – Coolant Connector Locations for D-Frame LiquiFlo Drives

Mounting the Drive, Grounding, and Finding Wire Routing Locations

4-9

Page 50

4-10

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 51

C

HAPTER

Installing Input Power Wiring

This chapter describes incoming line components and how to install them.

5.1 Installing Transformers and Reactors (Optional)

The LiquiFlo AC drive may be used on distribution systems with 85,000 amps or less

symmetrical fault current capacity. Line reactors are not needed for safe operation of

the drive but may be required to reduce line harmonics.

Input isolation transformers might be needed to help eliminate the following:

• Damaging line voltage transients from reaching the drive.

• Line noise from the drive back to the incoming power source.

• Damaging currents that could develop if a point inside the drive becomes grounded.

Observe the following guidelines when installing an isolation transformer:

5

• A power disconnecting device must be installed between the power line and the

primary of the transformer.

• If the power disconnecting device is a circuit breaker, the circuit breaker trip rating

must be coordinated with the in-rush current (10 to 12 times full load current) of the

transformer.

5.2 Installing Fuses for Branch Circuit Protection

Install the required, user-supplied branch circuit protection fuses according to the

applicable local, national, and international codes (e.g., NEC/CEC). The fuses must

be installed in the line before the drive input terminals. See figures 5.1 and 5.2. Fuse

value selections are provided in table 3.7.

ATTENTION:Most codes require that upstream branch protection be

provided to protect input power wiring. Failure to observe this precaution

!

could result in severe bodily injury or loss of life.

Installing Input Power Wiring

5-1

Page 52

Manual

Disconnect

User-Supplied

Interconnecting bus bar provided with

M/N 41L4060PM, 64L4060PM, or

or can be user-supplied.120L4060PM kit,

3-Phase AC Input Voltage 380/480 V

L2

L1

Fuse

L1 L2 L3 L6 L5 L4

L3

GND

GND

(PE)

LiquiFlo

Power

Module

UW

V

User-Supplied

M

Figure 5.1 – Typical AC Input/Output Electrical Connections (6-Pulse Rectifier, All Frames)

GND

5-2

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 53

User-Supplied

Manual

Disconnect

Fuse

Transformer

3-Phase AC Input Voltage 380/480 V

181 182 183

L1 L2 L3 L6 L5 L4

GND

LiquiFlo

Power

Module

GND

(PE)

User-Supplied

Figure 5.2 – Typical AC Input/Output Electrical Connections (12-Pulse Rectifier, B- and C-Frames Only)

Installing Input Power Wiring

UW

V

M

GND

5-3

Page 54

5.3 Installing a Required External/Separate Input

Disconnect

An input disconnect must be installed in the line before the drive input terminals in

accordance with local, national, and international codes (e.g., NEC/CEC). The

disconnect should be sized according to the in-rush current as well as any additional

loads the disconnect might supply. The trip rating for the inrush current (10-12 times

full load current) should be coordinated with that of the input isolation transformer, if

used. Refer to section 5.1 for additional information.

5.4 Installing Power Wiring from the AC Input Line to the

Drive’s Power Terminals

Use the following steps to connect AC input power to the drive:

Step 1. Wire the AC input power leads by routing them as shown in figure 4.1. Tables

3.3. 3.4, and 3.5 contains the recommended power wiring sizes.

ATTENTION:Do not route signal and control wiring with power wiring in

the same conduit. This can cause interference with drive operation.

!

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

Step 2. Connect the three-phase AC input power leads (three-wire 380-480 VAC) to

the appropriate terminals.

On 6-pulse rectifier drives, connect the AC input power leads to the L1, L2,

and L3 terminals. See figure 5.1.

On 12-pulse rectifier drives, connect the AC input power leads to the L1, L2,

L3, L4, L5, and L6 terminals. See figure 5.2.

Step 3. Tighten the AC input power terminals to the proper torque as shown in table

5.1.

Table 5.1 – Terminal Tightening Torques

Maximum Tightening Torque

Drive Type Terminals Hardware Type

L1 to L6 1/4-20, Gr. 5 13 Newton-meters (10 ft-lb)

B-Frame

C-Frame

D-Frame L1 to L6 1/2-13; Gr. 5 100 Newton-meters (75 ft-lb)

U, V, W 5/16-18, Gr. 5 24 Newton-meters (18 ft-lb)

GND, PE 5/16 Hex 31 Newton-meters (23 ft-lb)

L1 to L6 1/2-13; Gr. 5 100 Newton-meters (75 ft-lb)

U, V, W 3/8-16, Gr. 5 42 Newton-meters (31 ft-lb)

GND, PE 5/16 Hex 31 Newton-meters (23 ft-lb)

U, V, W 1/2-13; Gr. 5 100 Newton-meters (75 ft-lb)

GND, PE 1/2 Hex 58 Newton-meters (42 ft-lb)

(+10%)

5-4

LiquiFlo AC Power Modules, Hardware Reference Version 6.4

Page 55

C

HAPTER

Installing Output Power Wiring

This chapter provides instructions on wiring output contactors, motor overload

protection, and output wiring to the motor.

6.1 Installing Output Contactors (Optional)

Output contactors provide a positive means of disconnecting the motor from the drive.

If the application requires the use of output contactors, contact Reliance Electric for

assistance.

6.2 Installing Mechanical Motor Overload Protection

(Optional)

To provide the motor with overload protection, local, national, and international codes

(e.g., NEC/CEC) may require one of the following:

• a motor thermostat be installed internal to the motor

6

• a mechanical thermal motor overload relay, sized to protect the motor, be installed

between the motor and the drive’s output terminals.

The Motor Overload Enable parameter (P.040) can be used in place of thermal motor

overload relays in single motor applications. Note, however, that temperature

measuring devices integral to the motor are the best way to thermally protect AC

motors under all conditions. Parameter P.040 must be enabled to provide overload

protection. Refer to the LiquiFlo Software Start-Up and Reference manual for more

information.

In multiple motor applications (V/Hz regulation only), each motor must have its own

user-supplied overload and branch circuit protection.

Installing Output Power Wiring

6-1

Page 56

6.3 Installing Output Wiring from the Drive Output

Terminals to the Motor

Important: The total motor lead length must not exceed 76 meters (250 feet).

Use the following steps to connect the AC output power wiring from the drive to the

motor:

Step 1. Wire the three-phase AC output power motor leads by routing them as shown

in figures 4.1, 4.2, or 4.3. Tables 3.3, 3.4, and 3.5 contain the recommended

power wiring sizes.

Do not route more than three sets of motor leads through a single conduit.

This will minimize cross-talk that could reduce the effectiveness of noise

reduction methods. If more than three drive/motor connections per conduit

are required, shielded cable must be used. If possible, each conduit should

contain only one set of motor leads.

ATTENTION:Do not route signal and control wiring with power wiring in

the same conduit. This can cause interference with drive operation.

!

Failure to observe these precautions could result in damage to, or

destruction of, the equipment

ATTENTION:Unused wires in conduit must be grounded at both ends

to avoid a possible shock hazard caused by induced voltages. Also, if a

drive sharing a conduit is being serviced or installed, all drives using this

conduit should be disabled to eliminate the possible shock hazard from

cross-coupled motor leads. Failure to observe these precautions could

result in bodily injury.

Step 2. Connect the three-phase AC power motor leads to the appropriate output

terminals. Figures 4.1, 4.2, and 4.3 show the locations of the output power

terminals.