Page 1

User Manual

LDC-Series Iron Core Linear Servo Motors

Catalog Numbers

LDC-C030xxx-xHT11, LDC-C050xxx-xHT11, LDC-C075xxx-xHT11,LDC-C100xxx-xHT11,

LDC-C150xxx-xHT11

LDC-C030xxx-xHT20, LDC-C050xxx-xHT20, LDC-C075xxx-xHT20, LDC-C100xxx-xHT20,

LDC-C150xxx-xHT20

LDC-M030xxx, LDC-M050xxx, LDC-M075xxx, LDC-M100xxx, LDC-M150xxx,

LDC-030-xxx-CP, LDC-050-xxx-CP, LDC-050-xxx-CP, LDC-075-xxx-CP, LDC-100-xxx-CP,

LDC-150-xxx-CP

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, CompactLogix, ControlLogix, Kinetix, LD C-Series, Logix5000, Rockwell Automation, Rockwell Software, TechConnect, Ultra3000, and Ultra5000 are trademark s of Rockwell Automation, Inc

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information.

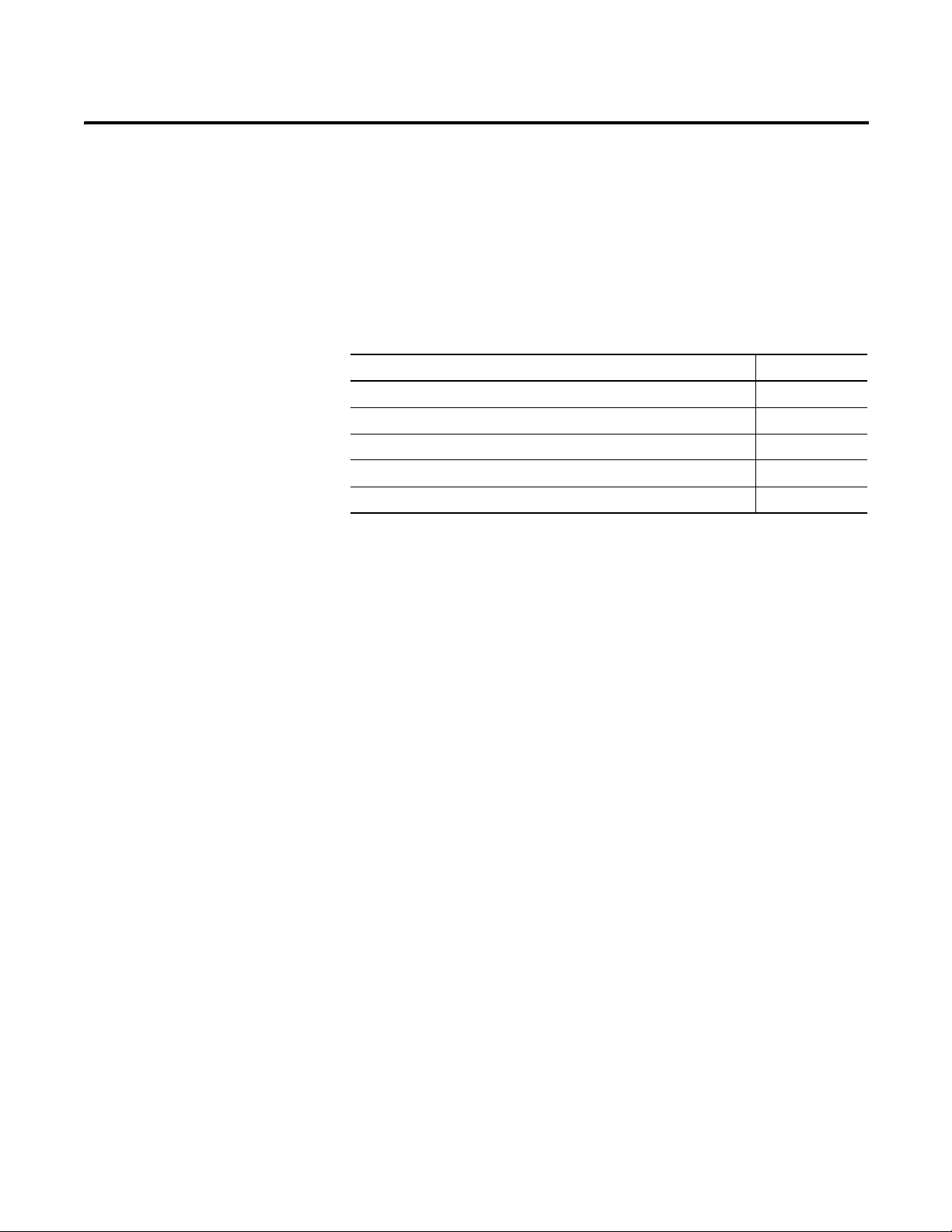

New and Updated Information

This table contains the changes made to this revision.

Topic Page

Updated SIN and COS signal names 81

Updated SIN and COS signal names 85

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 5

Table of Contents

Preface

Safety Considerations

Start

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

High Energy Magnets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unpacking and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Air Freight Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vertical or Incline Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operational Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Linear Motor Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Design Consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Motor Air Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Bumpers, Shock Absorbers, or End Stops . . . . . . . . . . . . . . . . . . . . . . . 21

Linear Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Carriage/Heat Sink. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Motor Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install the LDC-Series Linear

Motor

LDC-Series Linear Motor

Connector Data

Chapter 3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing Linear Motor Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mount a Single Coil with Multiple Magnet Tracks . . . . . . . . . . . . . . 24

Mount a Single Coil with a Single Magnet Track . . . . . . . . . . . . . . . . 29

Chapter 4

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Linear Motor Coil Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

PTC Thermistor Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Hall Effect Module Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Feedback Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

PTC Thermistor Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Encoder Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 5

Page 6

Table of Contents

Chapter 5

Wire the LDC-Series Linear

Motor

Configure and Start Up the

LDC-Series Linear Motor

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connect the Linear Motor Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Signal and Wire Definitions for Flying Lead Components . . . . . . . . . . . 40

Linear Motor Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Hall Effect Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Making Your Own Extension Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mounting and Wiring Two Identical Coils in Tandem . . . . . . . . . . . . . . 42

Cables Exit to the Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cables Exit in the Center. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cables Exit on Opposite Ends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Motor Direction Defined. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Required Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Update the Linear Motor Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Set Up the Connection to a Kinetix 6000, Kinetix 6500/6200, or

Kinetix 2000 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Set Up the Connection to an Ultra3000 Drive . . . . . . . . . . . . . . . . . . . . . . 53

Verify Motor Encoder Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Verify Motor Encoder Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Verify Linear Motor Wiring and Function. . . . . . . . . . . . . . . . . . . . . . . . . . 56

Additional Adjustments for Cooling Plate Option . . . . . . . . . . . . . . . . . . 60

Appendix A

Specifications and Dimensions

6 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Common Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Weight Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Carriage Weight and Heat Sink Area Requirements . . . . . . . . . . . . . 69

Cooling Plate Flow Rate Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 70

Product Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Motor Coil Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Magnet Track Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Cooling Plate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Page 7

Appendix B

Table of Contents

Interconnect Diagrams

Sin/Cos Linear Encoder and

Kinetix 6000 Drives

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Appendix C

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Kinetix 6000 Drive Feedback Connection. . . . . . . . . . . . . . . . . . . . . . . . . . 89

Encoder Counting Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Set Up the Axis Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

93

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 9

Preface

About This Publication

Who Should Use This Manual

Additional Resources

This manual provides detailed installation instructions for mounting, wiring, and

maintaining your LDC-Series iron core linear servo motors.

This manual is intended for engineers or technicians directly involved in the

installation, wiring, and maintenance of LDC-Seriesiron core linear motors.

If you do not have a basic understanding of linear motors, contact your local

Rockwell Automation sales representative for information on available training

courses before using this product.

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

Kinetix 2000 Multi-axis Servo Drive User

Manual, publication 2093-UM001

Kinetix 6000 Multi-axis Servo Drive User

Manual, publication 2094-UM001

Ultra3000 Digital Servo Drives Installation

Manual, publication 2098-IN003

Ultra3000 Digital Servo Drives Integration

Manual, publication 2098-IN005

How to install, set up, and troubleshoot a

Kinetix 2000 drive

How to install, set up, and troubleshoot a

Kinetix 6000 drive

How to install, set up, and troubleshoot an

Ultra3000 drive

Ultra3000 Digital Servo Drives User

Manual, publication 2098-UM001

Motion Analyzer CD, download at

.http://www.ab.com/e-tools

Motion Modules in Logix5000 Control

Systems User Manual,

publication LOGIX-UM002

System Design for Control of Electrical

Noise Reference Manual,

publication GMC-RM001

Kinetix Motion Control Selection Guide,

publication GMC-SG001

Safety Guidelines for the Application,

Installation, and Maintenance of Solid State

Controls, publication SGI-IN001

Allen-Bradley Industrial Automation

Glossary, publication AG-7.1

Instruction on configuring Ultra3000 and

Ultra5000 drives, creating and configuring

project, source, and header files, and

creating and running programs

Drive and motor sizing with application

analysis software

Information on configuring and

troubleshooting your ControlLogix and

CompactLogix SERCOS interface modules,

and using the home to torque-level

sequence

Information, examples, and techniques

designed to minimize system failures

caused by electrical noise

Information about Kinetix products

Characteristics, application, installation,

and maintenance of solid state controls

A glossary of industrial automation terms

and abbreviations

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 9

Page 10

Preface

Resource Description

Rockwell Automation Product Certification

Website, publication available at

http://www.ab.com

National Electrical Code. Published by the

National Fire Protection Association of

Boston, MA.

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

For declarations of conformity (DoC)

currently available from Rockwell

Automation

An article on wire sizes and types for

grounding electrical equipment

Provides general guidelines for installing a

Rockwell Automation industrial system

You can view or download publications at http://www.rockwellautomation.com/

literature/. To order paper copies of technical documentation, contact your local

Rockwell Automation distributor or sales representative.

10 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 11

Safety Considerations

DANGER

MAGNETIC FIELDS

LOCATED IN THIS AREA.

Can be harmfull to

pacemakers and other

sensitive equipment.

Chapter

1

Introduction

Labels

Table 1 - Safety Labels

Title Location Label Details

Magnetic Field

Danger

This chapter describes the safety issues encountered while using a linear motor

and the precautions you can take to minimize risk. Potential hazards discussed

here are identified by labels affixed to the device.

Topic Page

Labels 11

High Energy Magnets 13

Vertical or Incline Installation 14

Operational Guidelines 15

Here you will find the safety and identification labels affixed to your linear motor

components. To prevent injury and damage to the linear motor, review the safety

label and its details and location before using the linear motor

A The Magnetic Fields label identifies non-ionizing radiation

found in the magnet tracks. Magnet tracks are constructed

with strong magnets. Strong magnets can disrupt the

functionality of automatic implantable cardioverter

defibrillators (AICD); people with a pacemaker should not

work near the magnet tracks. Maintenance personnel

working near the magnet tracks should avoid the use of

metallic tools and secure items, such as a badge clip and

other personal effects, that could be attracted by the strong

magnets. Strong magnets can erase magnetic media. Never

let credit cards or electronic media contact or come near the

magnet tracks.

.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 11

Page 12

Chapter 1 Safety Considerations

D

C

B

A

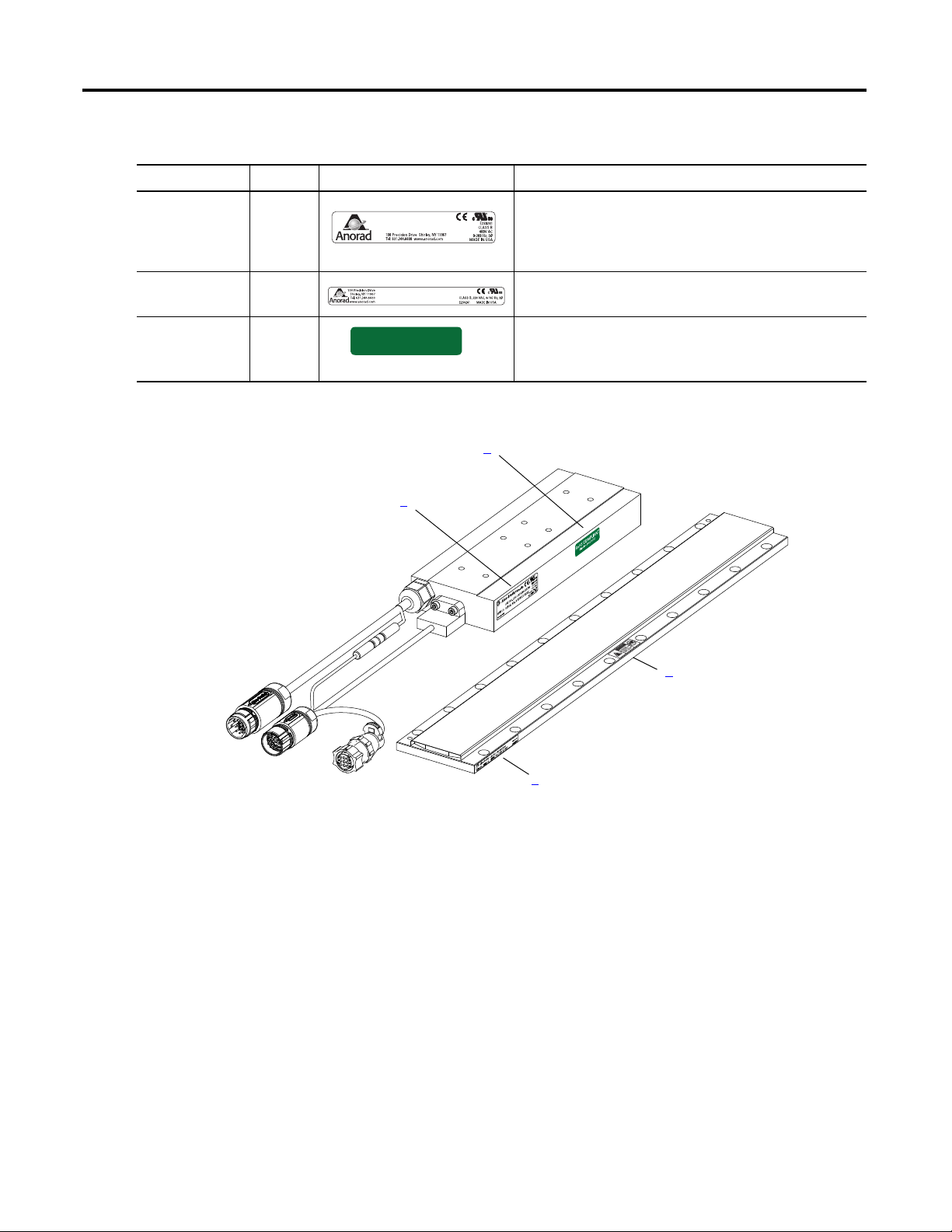

Table 2 - Identification Labels

Title Location Label Details

Coil Nameplate B This nameplate shows the coil catalog number, serial

number, operating voltage, and frequency.

Magnet Track

Nameplate

RoHS Compliant D LDC-Series linear motor components are RoHS compliant.

C This nameplate shows the magnet track catalog number,

serial number, operating voltage, and frequency.

RoHS COMPLIANT

Directive 2002/95/EC

Label Locations for LDC-Series Linear Motor

12 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 13

Safety Considerations Chapter 1

High Energy Magnets

Linear motor magnets contain high energy magnets that attract ferrous metals

from a considerable distance. Precautions must be taken while unpacking,

handling, and shipping by air.

Unpacking and Handling

Unpack magnet tracks one at a time. Repack magnet tracks after inspection and

before they are stocked or staged for installation. Leave protective wrapping,

cardboard, and flux containment plates in place until the magnet track is

installed. Clear the inspection and repacking area of any ferrous metals that will

be attracted to or attract the magnetic assembly. If magnet tracks must be

unpacked at the same time, maintain a distance of 1.5 m (5 ft) between

assemblies.

Air Freight Restrictions

When air freighting linear motors special preparations and precautions must be

taken. The following information outlines the basic requirements at the

publication date of this document. However, regulations are subject to change

and additional area or carrier restrictions may be imposed. Always check with

your carrier or logistics specialist regarding current local, regional, and national

transportation requirements when shipping this product.

Linear motor magnet tracks contain magnetized material, as classified by

International Air Transport Association (IATA) Dangerous Goods Regulations.

An IATA trained individual must be involved when shipping this product via

domestic or international air freight. Packing Instruction 902 provides

information regarding the preparation of this product for air transportation.

Follow these regulations for general marking and labeling requirements, the

application of specific Magnetized Material Handling Labels, and instructions for

preparing the Shipper's Declaration for Dangerous Goods.

At a minimum, refer to the following IATA Dangerous Goods Regulations:

• Subsection 1.5: Training

• Subsection 3.9.2.2: Classification as Magnetized Material

• Subsection 4.2: Identification as UN 2807, Magnetized Material, Class 9,

Packing Instruction 902

• Subsection 7.1.5: Marking

• Subsection 7.2: Labeling

• Subsection 7.4.1: Magnetized Material Label

• Section 8: Shipper's Declaration for Dangerous Goods

When shipped via ground in the United States, these products are not considered

a U.S. D.O.T. Hazardous Material and standard shipping procedures apply.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 13

Page 14

Chapter 1 Safety Considerations

Vertical or Incline Installation

A linear motor driven system mounted vertically or on an incline will not

maintain position when the power is removed. Under the influence of gravity, the

motion platform and its payload will fall to the low end of travel. Design

engineers should allow for this by designing in controlled power-down circuits or

mechanical controls to prevent the linear motor driven system and its payload

from being damaged when the power fails.

ATTENTION: Linear motors are capable of high accelerations, sudden

and fast motion. Rockwell Automation is not responsible for misuse, or

improper implementation of this equipment.

ATTENTION: Linear motor driven systems must have end of travel

bumpers. They must be designed to take a large impact from uncontrolled

motion. The payload must be secured to the system such that it will not

sheer off in the event of an impact in excess of the bumper ratings.

ATTENTION: The Hall effect module contains an electrostatic discharge

(ESD) sensitive device. You are required to follow static-control

precautions when you install, test, service, or repair this assembly. If you

do not follow ESD control precautions, components can be damaged. If

you are not familiar with static control precautions, refer to Guarding

Against Electrostatic Damage, publication 8000-4.5.2

applicable ESD awareness handbook.

, or any other

BURN HAZARD: When the linear motors are running at their maximum

rating, the temperature of attached heat sinks can reach 100 ºC (212 ºF).

SHOCK HAZARD: An assembled linear motor will generate power if the

coil or magnet track is moved. Unterminated power cables present an

electrical shock hazard. Never handle flying leads or touch power pins

while moving the motor.

14 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 15

Safety Considerations Chapter 1

IMPORTANT

Operational Guidelines

Please read and follow the guidelines shown here to safely operate the linear

motor created from these linear motor components.

ATTENTION: Observe maximum safe speed. Linear motors are capable

of very high forces, accelerations, and speeds. The maximum obtainable

acceleration and speed is based on the drive output (bus voltage and

current settings). The allowable maximum speed is application specific

and partly based on the linear motion mechanics supplied by others.

ATTENTION: Moving parts can cause injury. Before operating the linear

motor, make sure all components are secure and magnet mounting

hardware is below the magnet surface. Remove all unused parts from the

motor travel assembly to prevent them from jamming in the motor air gap

and damaging the coil or flying off and causing bodily injury.

You are responsible for making sure the servo control system safely

controls the linear motor with regards to maximum safe force,

acceleration, and speed, including runaway conditions.

A runaway condition can be caused by incorrect motor, hall effect, and

position feedback wiring resulting in violent uncontrolled motion.

ATTENTION: Keep away from the line of motor travel at all times.

Always have bumpers in place and securely fastened before applying

power to your linear motor.

ATTENTION: High voltage can kill. Do not operate with exposed wires.

Do not go near electrically live parts.

ATTENTION: Large Position Error Tolerances, such as those calculated by

the Auto Tune function in RSLogix 5000 programming software, or when

configuring a new axis with RSLogix 5000 software, can lead to

undetected and repetitive high energy impacts against axis end stops if

proper precautions are not in place. These tolerances can also lead to

undetected and repetitive high energy impacts against unexpected

obstructions. Such impacts can lead to equipment damage and/or serious

injury.

To identify the safety concerns that you have with default Position Error

Tolerance or after an Auto-Tune Function go to the Rockwell Automation

Knowlegebase. Click Find Technical Support Answers and search for

Answer Id 55937.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 15

Page 16

Chapter 1 Safety Considerations

Notes:

16 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 17

Start

Chapter

2

Introduction

Use this chapter to become familiar with the linear motor components, their

maintenance needs, and their configuration.

Topic Page

Catalog Number Explanation 18

Linear Motor Components 19

Design Consideration 20

Maintenance 22

Motor Storage 22

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 17

Page 18

Chapter 2 Start

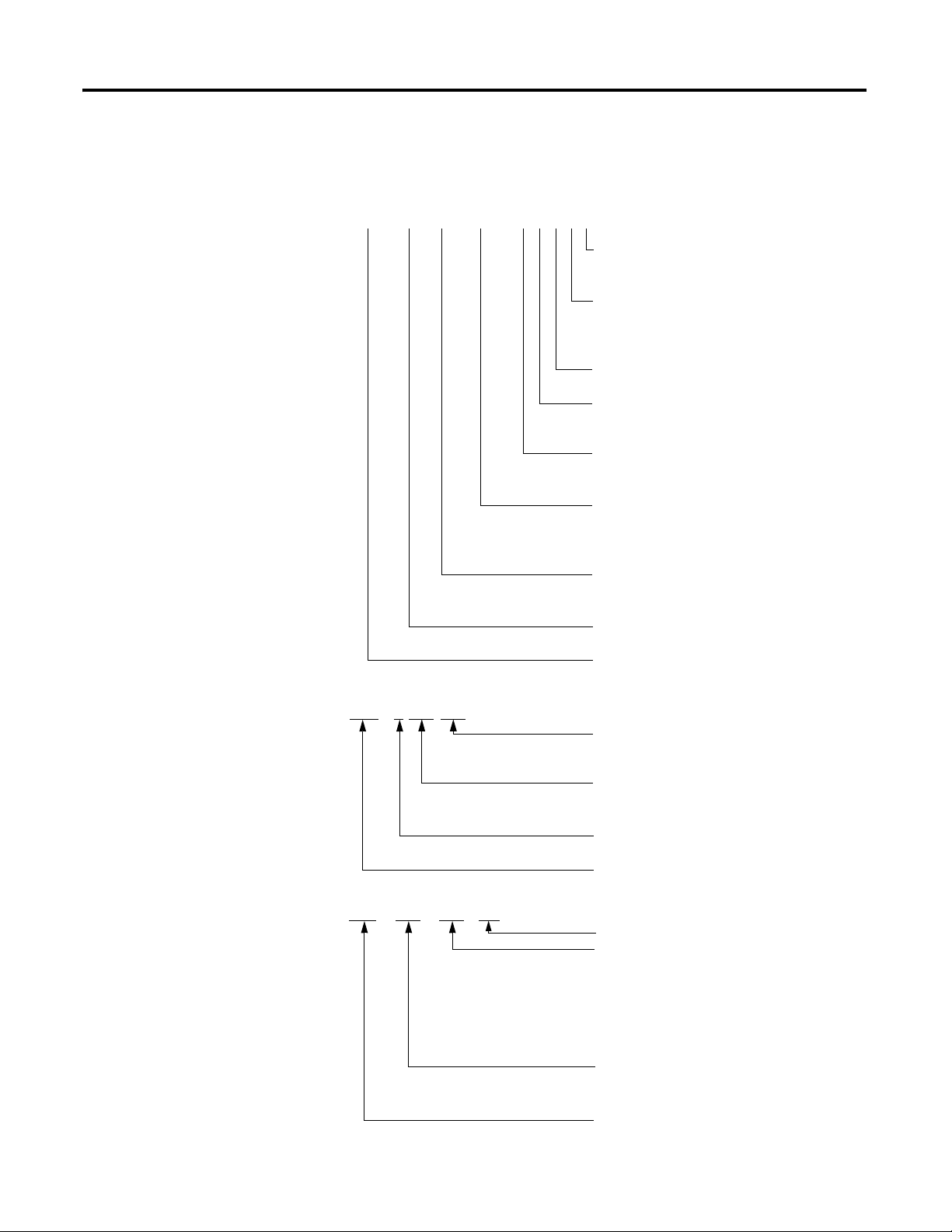

Cable Termination

0 = Flying Leads

1 = Circular DIN-Type Connector

Cable Length

0 = 300 mm

1 = 600 mm

2 = 1000 mm

Thermal Protection

T = PTC Thermal Sensor and Switch

Feedback

N = No Feedback

H = Hall Effect (Trapezoidal)

Winding Code

D = D Winding

E = E Winding

Coil Length

100 = 100 mm (4.15 in.) 400 = 400 mm (16.60 in.)

200 = 200 mm (8.30 in.) 600 = 600 mm (23.62 in.)

300 = 300 mm (12.45 in.)

Frame Size

030 075 150

050 100

Coil Designation

C = Standard Coil

Bulletin Number

LDC

LDC - x xxx xxx - x x x x x

LDC - x xxx xxx

Magnet Track Length

100 = 100 mm (4.15 in.)

500 = 500 mm (19.7 in.)

Frame Size

030 075 150

050 100 200

Magnet Plate Designation

M = Magnet Plate

Bulletin Number

LDC

Cooling Plate

Coil Length

100 = 134.0 mm (5.28 in.)

200 = 234.0 mm (9.21 in.)

300 = 334.0 mm (13.15 in.)

400 = 434.0 mm (17.09 in.)

600 = 634.0 mm (25.31 in.)

800 = 834.0 mm (32.84 in.)

Frame Size

030 075 150

050 100 200

Bulletin Number

LDC

LDC - xxx - xxx - CP

Catalog Number Explanation

An iron core linear motor is comprised of a coil and one or more magnet tracks.

The following keys show the catalog definition for the LDC-Series linear motors.

18 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 19

Start Chapter 2

1

2

3

5

6

7

LDC-M050500

Magnet Track Shown

LDC-C075120-xHT11

Motor Coil Shown

4

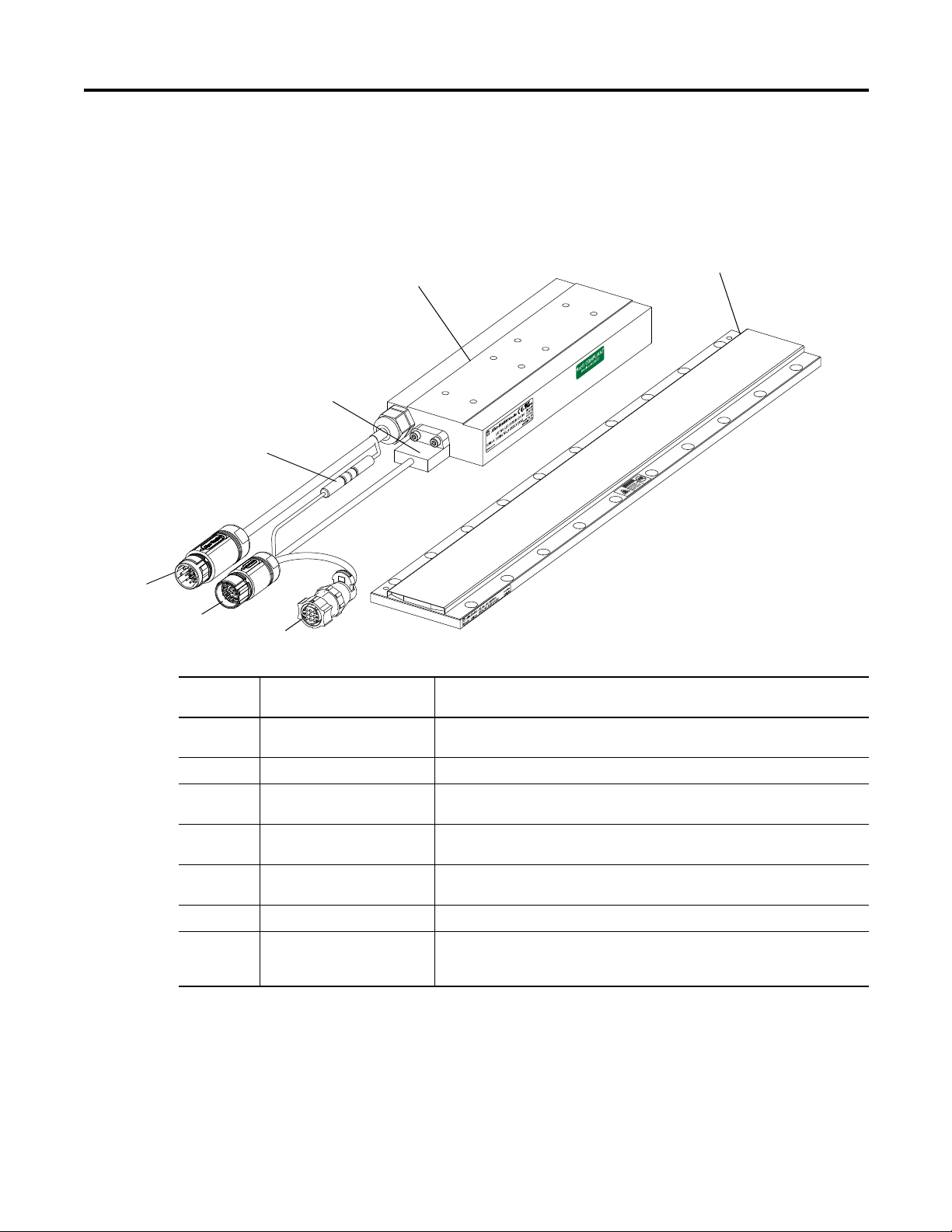

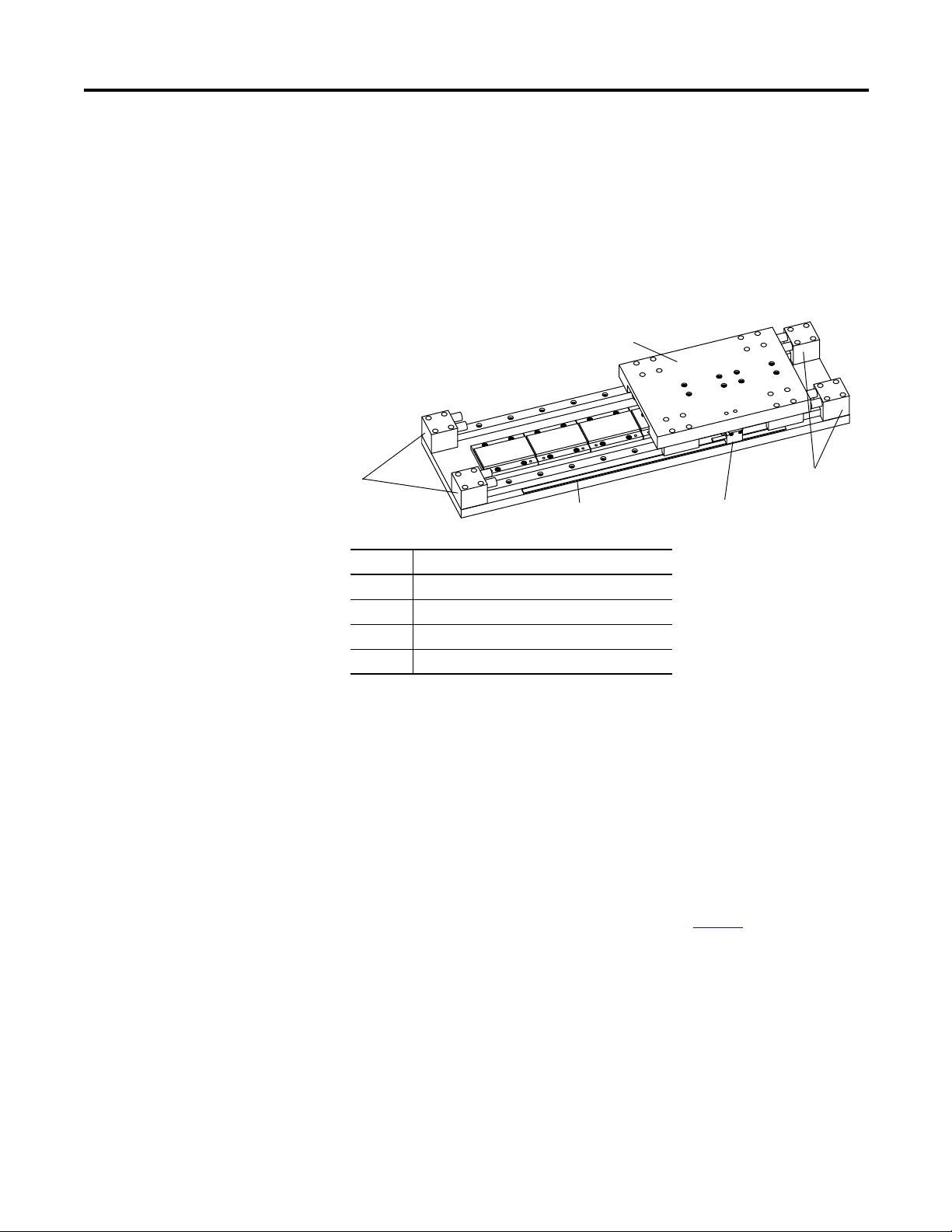

Linear Motor Components

Use the diagrams and descriptions to identify the unique components of the

linear motor.

Figure 1 - Components of Iron Core Motor Coil and Magnet Track

Component

Number

1 Iron core motor coil

2 Magnet track High powered static magnets create the flux field the powered coil interacts with.

3 Encoder connector

4 Feedback connector

5 Power connector

6 Thermal protection connector Connects the thermal protection signal to the feedback connector.

7 Hall effect module

Component Description

Copper coils are contained in an epoxy form. When powered, the coil interacts with

the flux field of the magnet track.

Connect your encoder here by using the connector kit, catalog number LDC-ENCCNCT.

Connect to your drive feedback by using either catalog number 2090-CFBM7DFCDAFxx (for moving coil) or 2090-XXNFMF-Sxx (for moving magnet).

Connect to your drive power by using either catalog number 2090-CPWM7DFxxAFxx (for moving coil) or 2090-XXNPMF-xxSxx (for moving magnet).

This module provides input signals for commutation startup. Replacement catalog

numbers for the Hall effect module are LDC-HALL-C for the LDC-xxxxxxx-xHT1 and

LDC-HALL-F for the LDC-xxxxxxx-xHT20.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 19

Page 20

Chapter 2 Start

Overall dimension with cooling plate.

Overall dimension

without cooling plate.

1

2

3

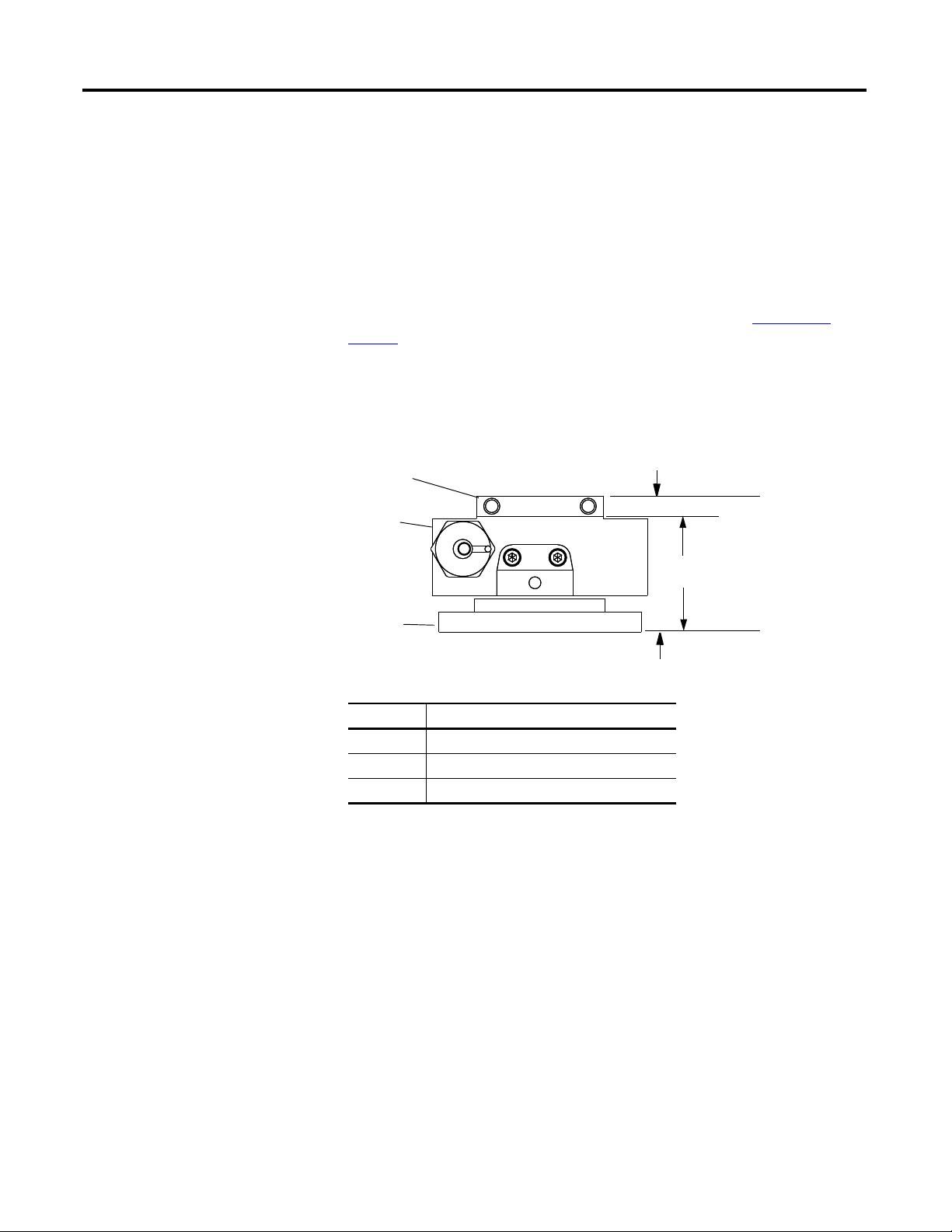

Design Consideration

The information provided here is critical to using linear motor components.

Design your system to comply with the following points to run safely and

successfully.

Motor Air Gap

Maintaining the air gap is critical to proper installation and operation of the

linear motor components. Use the coil, and magnet drawing in Appendix A

page 61

to calculate the installation envelope dimension. Size the carriage,

bearings, and base plate to withstand the force of attraction between the coil and

magnet track. By maintaining the installation envelope dimension in your design,

the vertical air gap requirement will be met. The following diagram shows the

critical dimensions.

on

Item Description

1 Magnet track

2Coil

3 Optional cooling plate assembly

20 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 21

Start Chapter 2

1

1

3

4

2

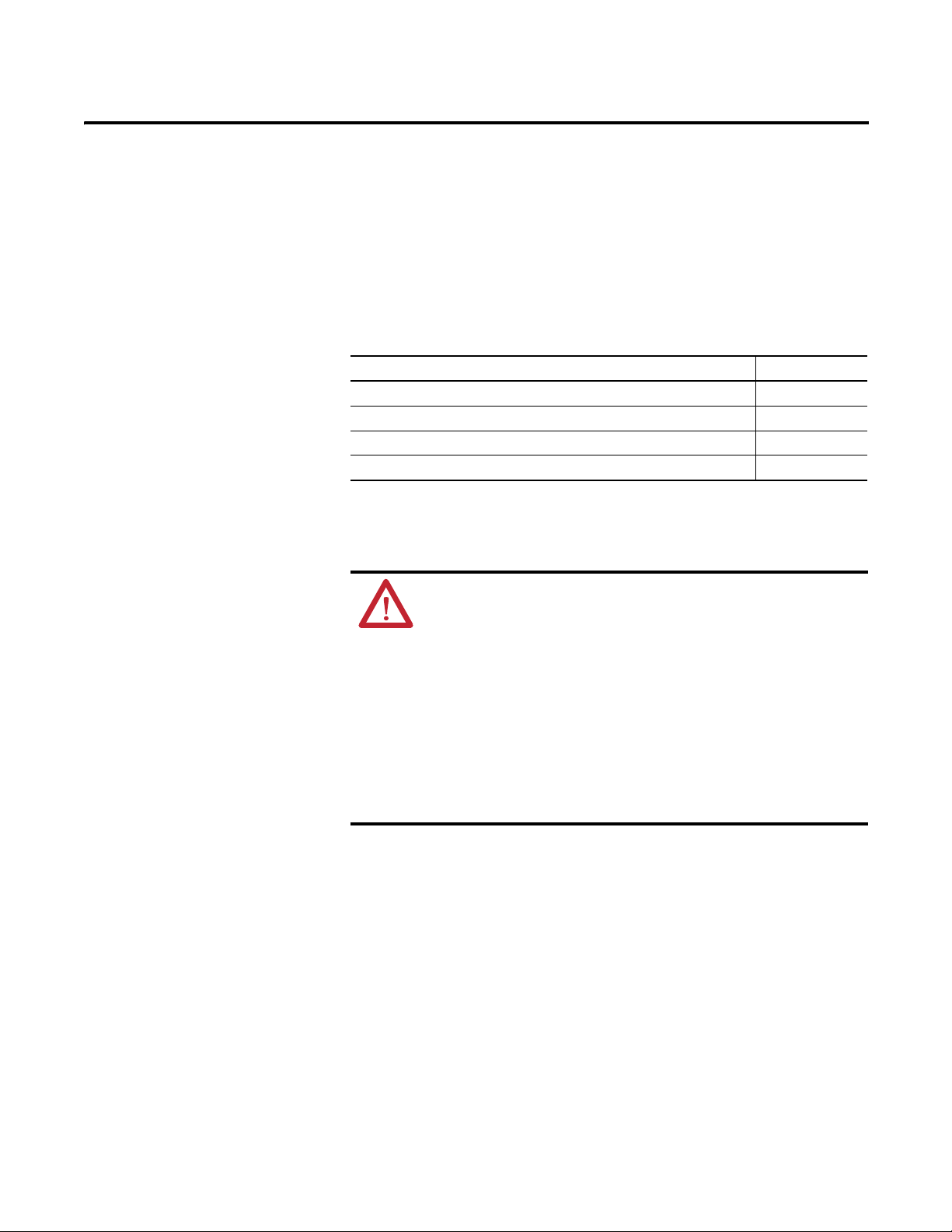

Bumpers, Shock Absorbers, or End Stops

Include in your design a mechanical stop at each end of travel. Design the stops so

they can prevent the moving mass from leaving its travel limits. Take into

consideration the maximum speed and inertia of your moving mass when

designing your mechanical stops. The following diagram shows a minimal system

with mechanical stops.

Figure 2 - Mechanical Stops

Item Description

1 Mechanical stops

2 Carriage/heat sink

3 Encoder readhead

4 Encoder strip

Linear Encoder

Your linear motor components need to be integrated with a linear encoder

purchased from a third party.

Carriage/Heat Sink

The linear motor coil requires a heat sink to maintain performance. The heat sink

requires a minimal mass and surface area as shown on page 69

the carriage in a moving coil system or be designed into the base in a moving

magnet system.

. It can also serve as

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 21

Page 22

Chapter 2 Start

Maintenance

Motor Storage

Linear motors require no maintenance when operated in relatively clean

environments. For operation in harsh and dirty environments, we recommend

cleaning every 6 months.

Clean the metallic debris and other contaminants from the air gap. Use a strip of

masking tape to remove the metal debris. Apply a strip of tape on the magnet

track and then remove it. Keeping the magnet track clean will prevent witness

marks. Witness marks are caused by metal debris being dragged across the surface

of the stainless steel by the magnet field of the moving coil. Witness marks have

no effect on the performance of the motor.

The motor storage area should be clean, dry, vibration free, and have a relatively

constant temperature. If a motor is stored on equipment, it should be protected

from the weather. All motor surfaces subject to corrosion should be protected by

applying a corrosion resistant coating.

22 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 23

Chapter

Install the LDC-Series Linear Motor

3

Introduction

Unpacking and Inspection

In this section you will unpack, inspect, and install your linear motor components

by creating your own linear motor.

Topic Page

Unpacking and Inspection 23

Installing Linear Motor Components 24

Mount a Single Coil with Multiple Magnet Tracks 24

Mount a Single Coil with a Single Magnet Track 29

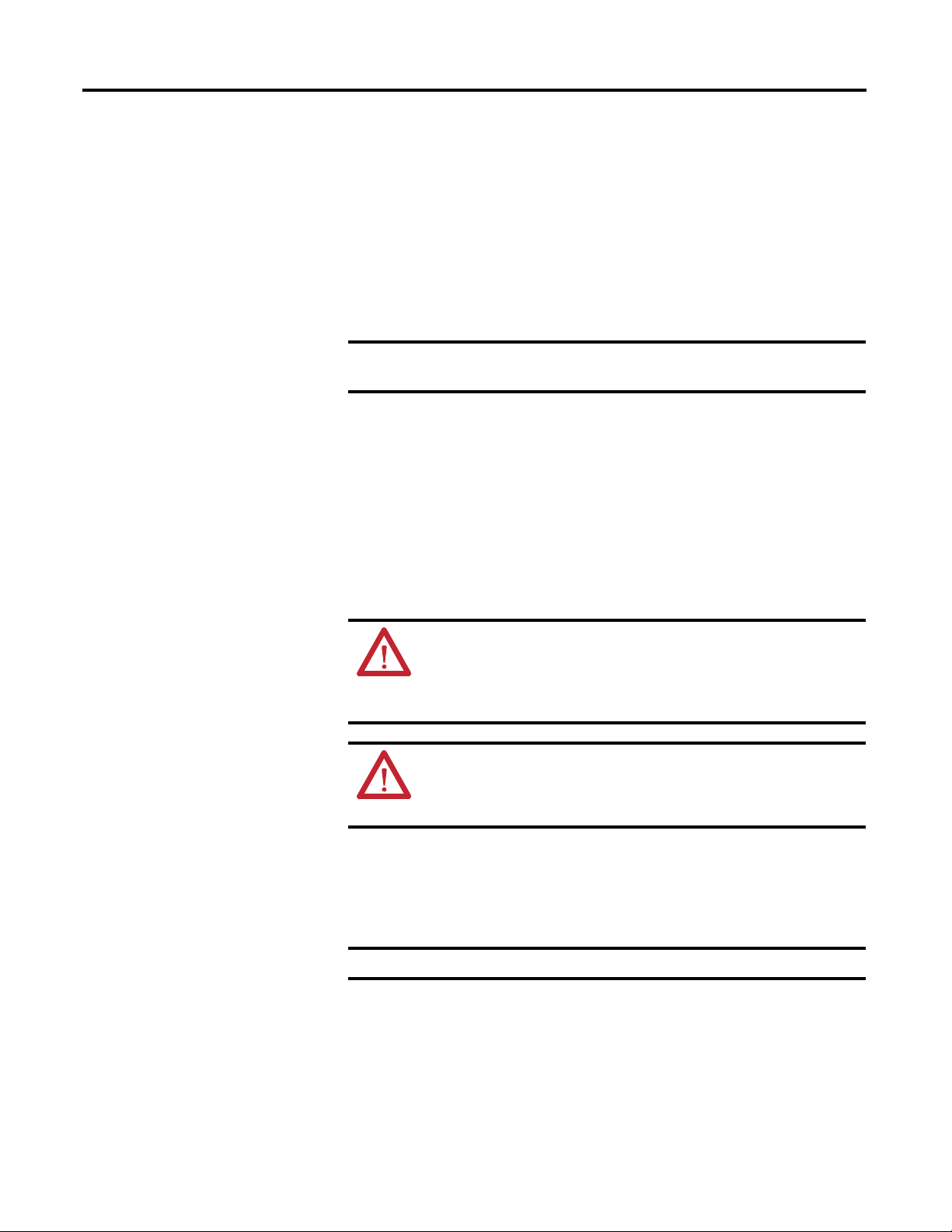

Read the following guidelines to handle magnet tracks carefully.

ATTENTION: Linear motors contain powerful permanent magnets

which require extreme caution during handling. When handing

multiple magnet tracks do not allow the tracks to come in contact

with each other. Do not disassemble the magnet tracks. The forces

between tracks are very powerful and can cause bodily injury.

Persons with pacemakers or Automatic Implantable Cardiac

Defibrillator (AICD) should maintain a minimum distance of 0.33 m

(1 ft) from magnet assemblies. Additionally, unless absolutely

unavoidable, a minimum distance of 1.5 m (5 ft) must be

maintained between magnet assemblies and other magnetic/

ferrous composite materials. Use only non-metallic

instrumentation when verifying assembly dimension prior to

installation.

Inspect motor components and verify they are damage free. Any damage or

suspected damage should be immediately documented. Claims for damage due to

shipment are usually made against the transportation company. Contact

Rockwell Automation for further advice:

• Compare the purchase order with the packing slip.

• Check the quantity of magnet tracks received matches your job

requirements.

• Identify the options that came with your linear motor.

• Inspect the assemblies and confirm the presence of specified options.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 23

Page 24

Chapter 3 Install the LDC-Series Linear Motor

IMPORTANT

TIP

IMPORTANT

Installing Linear Motor Components

Use one of the following procedures to install the magnet track or tracks and the

motor coil.

Required Tools

• Aluminum straight edge

• Non-magnetic M4 or M5 hex wrench

• Magnet channel alignment tool

The alignment tool is shipped attached to the cables next to the

Hall effect module. Remove before operating the linear motor.

Use non-magnetic tools and hardware made of beryllium

copper, 300 series stainless steel. If these tools are not

available, proceed carefully as the magnet track attracts

magnetic and ferrous items.

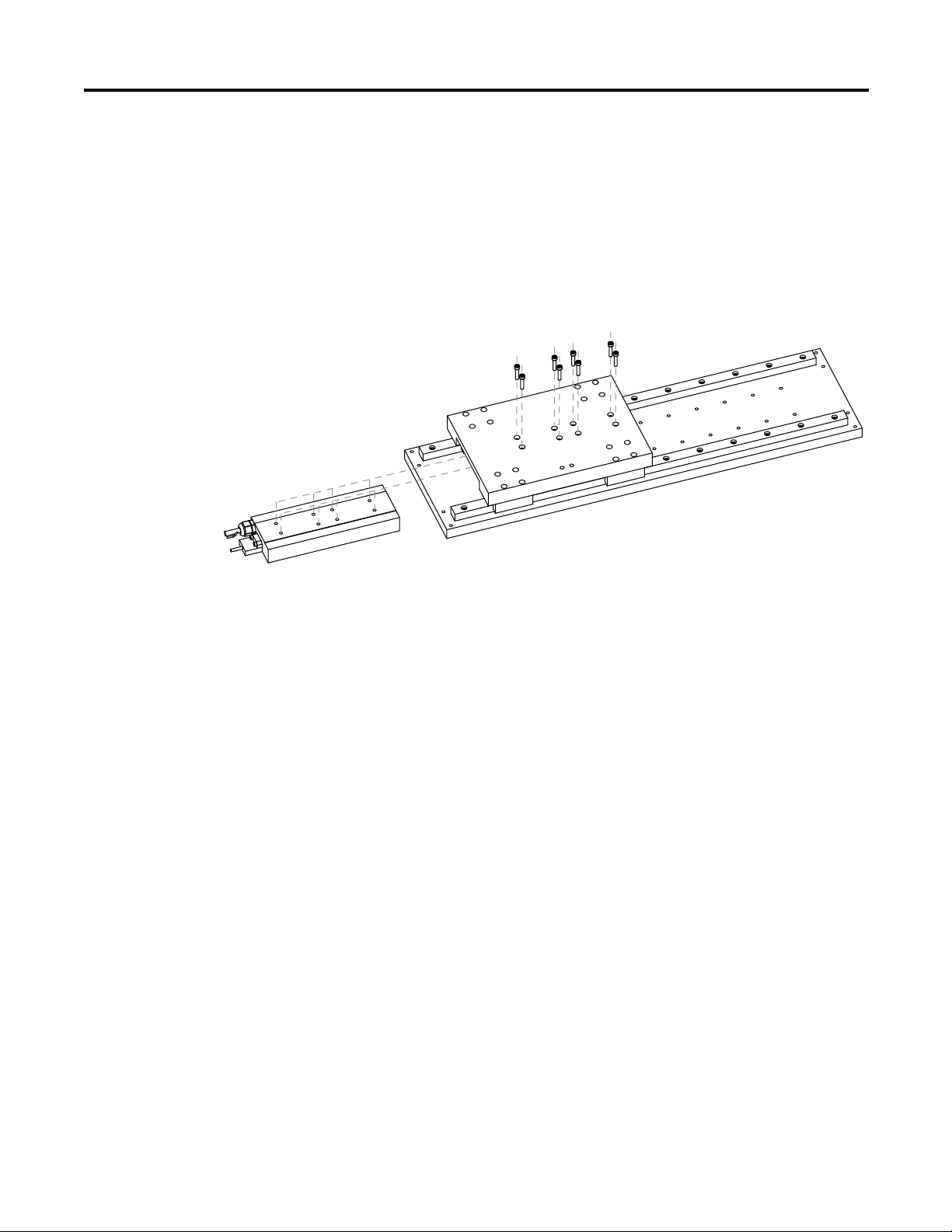

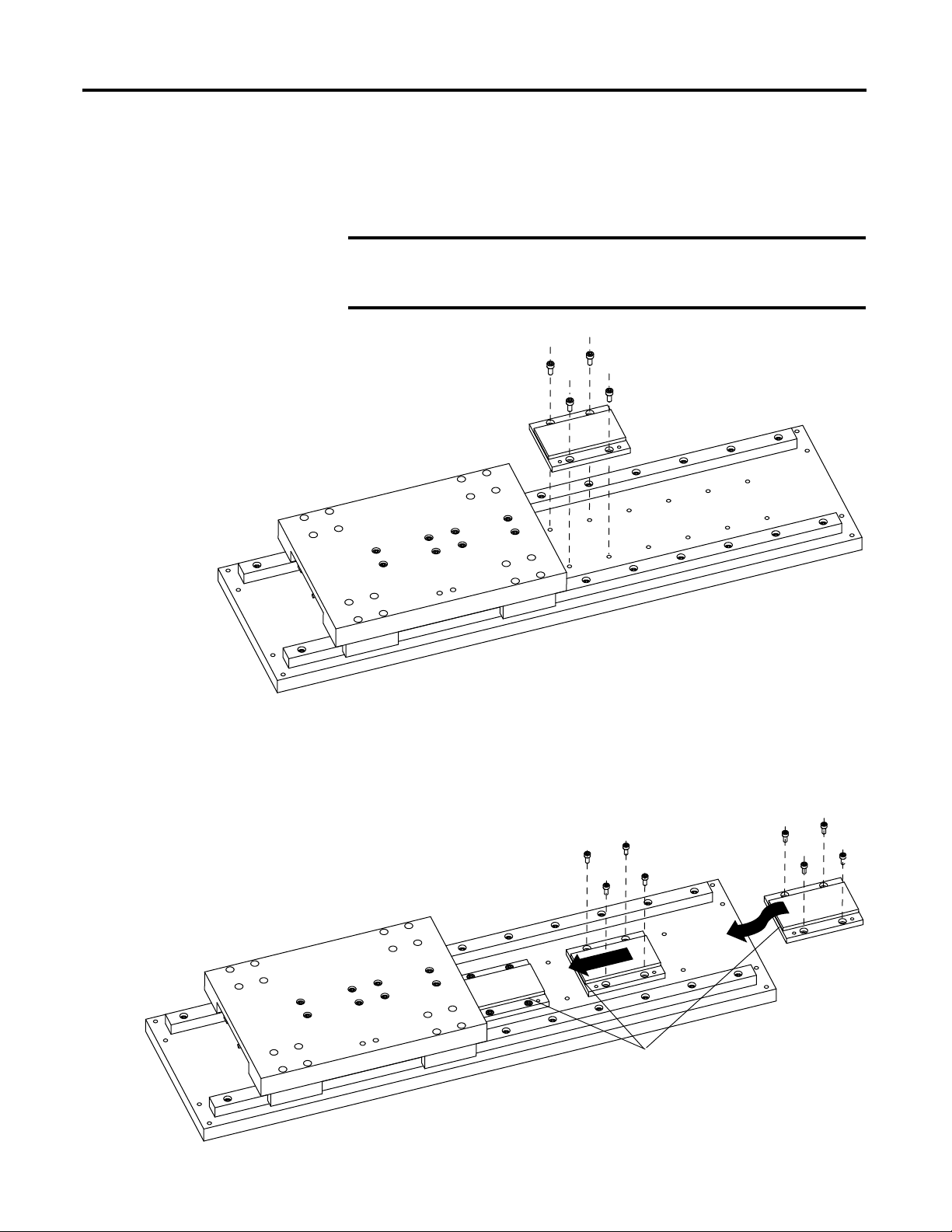

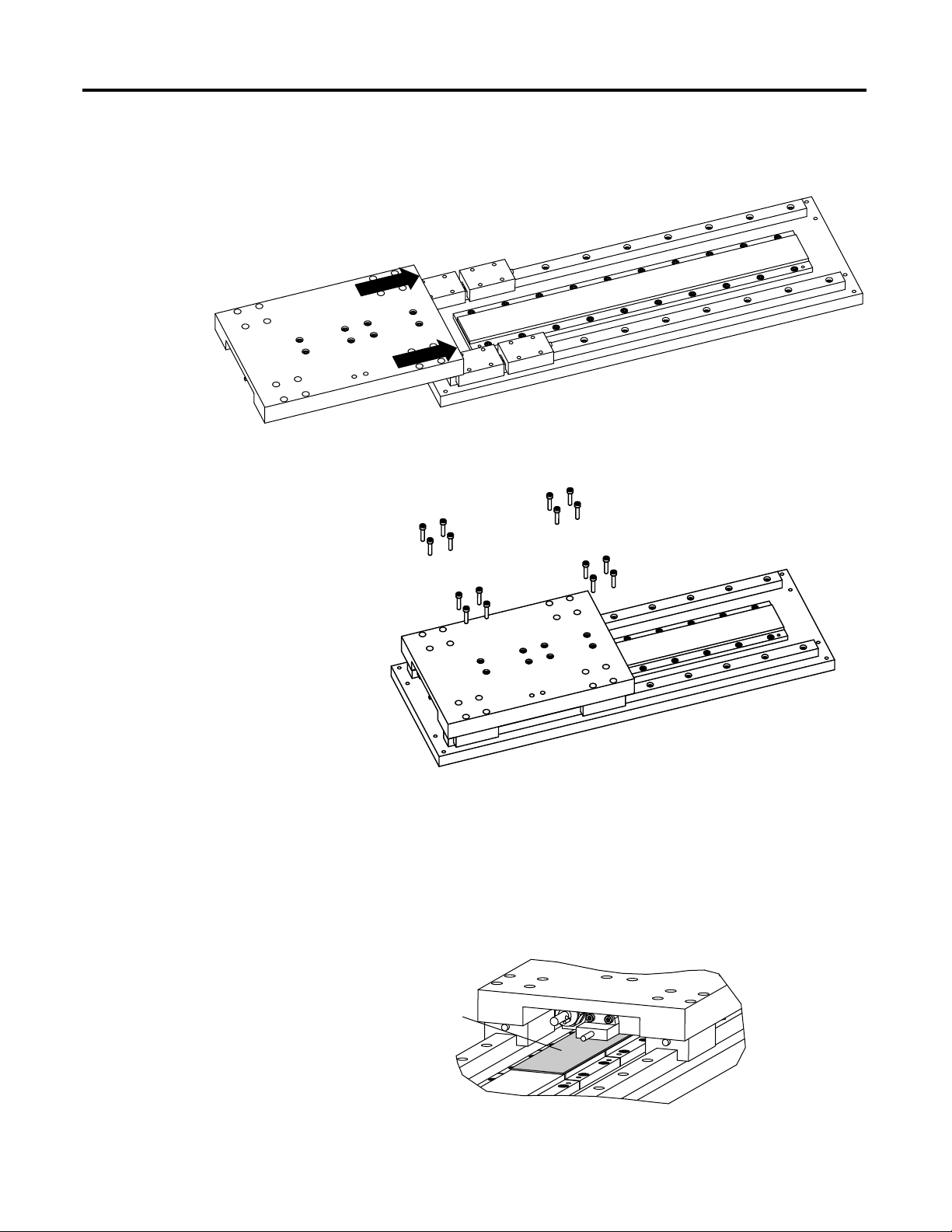

Mount a Single Coil with Multiple Magnet Tracks

Follow these steps to install a single coil with multiple magnet tracks.

ATTENTION: To avoid damage due to the magnetic attraction

between the magnet tracks, maintain a minimum distance of 1.5 m

(5 ft) between the magnet tracks that are being installed and the

magnet tracks awaiting installation. Keep the protective cardboard

and the metal plate in place until the installation is complete.

ATTENTION: Never attempt to place the coil assembly directly on

the magnet plates. Strong magnetic attraction will cause

uncontrolled movement causing a pinch hazard and possible

damage to the components.

1. Clear the magnet track mounting surface of foreign material.

If necessary stone the mounting surface, acetone or methanol may be

applied as cleaning agent.

Do not use abrasives to clean the surface.

2. Verify the flatness of the surface to which the magnet track is to be

mounted.

Total Indicator Reading (TIR) is 0.127 mm (.005 in.) per

300 mm (12.0 in.). TIR or runout correlates to the overall flatness

requirement of the surface.

24 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 25

Install the LDC-Series Linear Motor Chapter 3

3. Verify the dimension of the opening for the magnet track, coil, and cooling

plate if used.

4. Remove all burrs and clean the motor coil mounting surface.

5. Position the carriage toward the end of travel where you want the cable to

exit.

6. Install the motor under the carriage, using M5 x 0.8 bolts that extend

through the slide by at least 12 mm (0.5 in.), but no more then

20 mm (0.7 in.).

7. Tighten the screws but do not torque.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 25

Page 26

Chapter 3 Install the LDC-Series Linear Motor

IMPORTANT

3

2

Alignment Holes

8. On the opposite end of the base, install the first magnet track using

M5 x 0.8 x 16 mm Socket Head Captive Screw (SHCS).

Do not tighten screws.

Use non-magnetic tools and hardware such as beryllium copper,

300 series stainless steel. If not available proceed with care

since ferrous items will be attracted to the magnet tracks.

9. Install additional magnet tracks.

Place each magnet track on the base and slide towards the previously install

magnet track. For correct magnetic polarity the alignment holes should all

be on the same side.

26 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 27

Install the LDC-Series Linear Motor Chapter 3

Shim

4

5

6

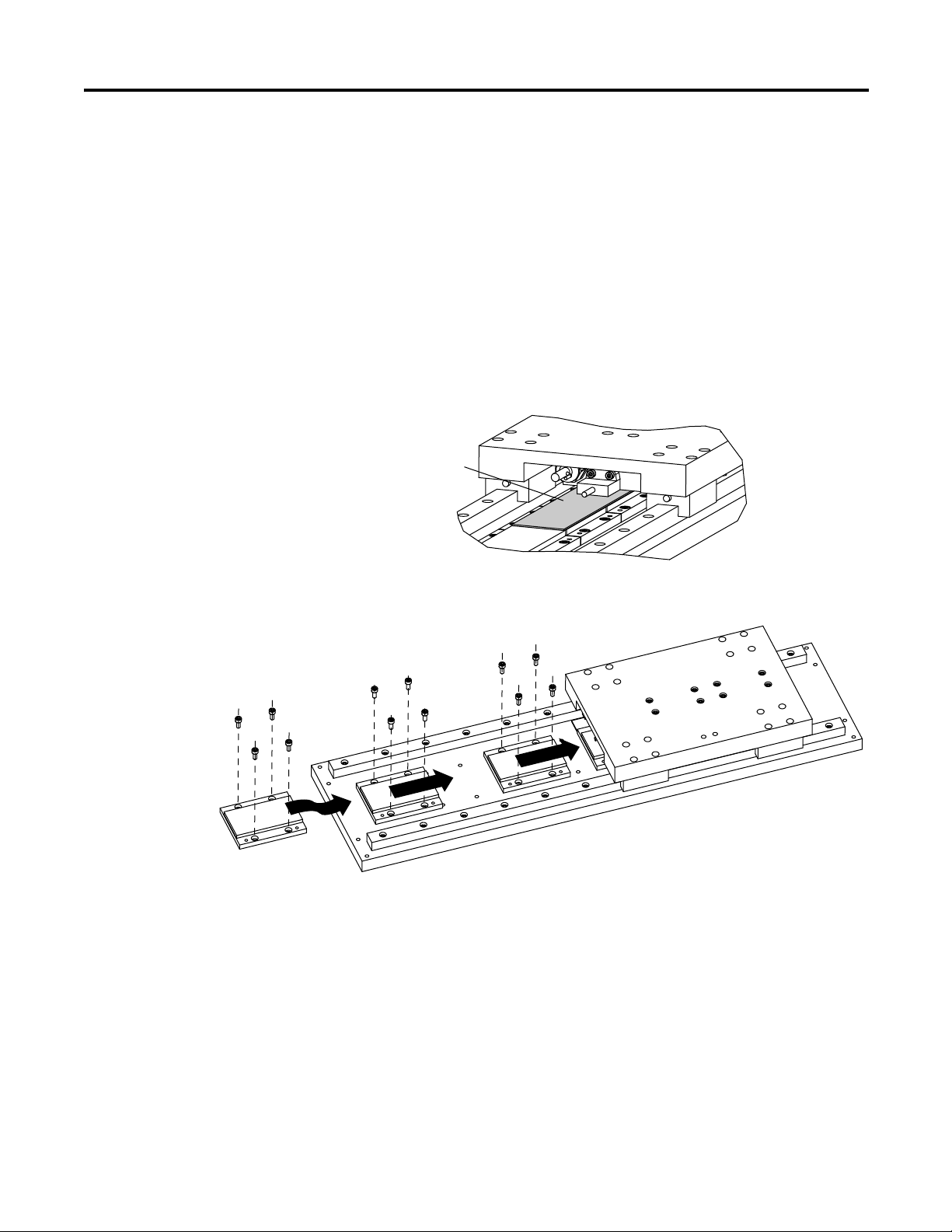

10. Move the carriage with motor coil installed over the installed magnet

tracks.

There may be some resistance while moving onto the tracks, this is normal.

11. Measure the gap between the motor coil and magnet track using plastic

shim stock.

The gap should be 0.79 mm (0.031 in.) to 1.70 mm (0.067 in.).

If gap is too large, add a brass or a stainless steel shim between the motor

coil and carriage. If the gap is too small, machine the slide or place shims

under the bearing pucks.

12. Install the remaining magnet tracks in the order shown.

13. Slightly loosen the mounting screws on the exposed magnet tracks.

Do not loosen the magnet tracks that are covered by the motor coil.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 27

Page 28

Chapter 3 Install the LDC-Series Linear Motor

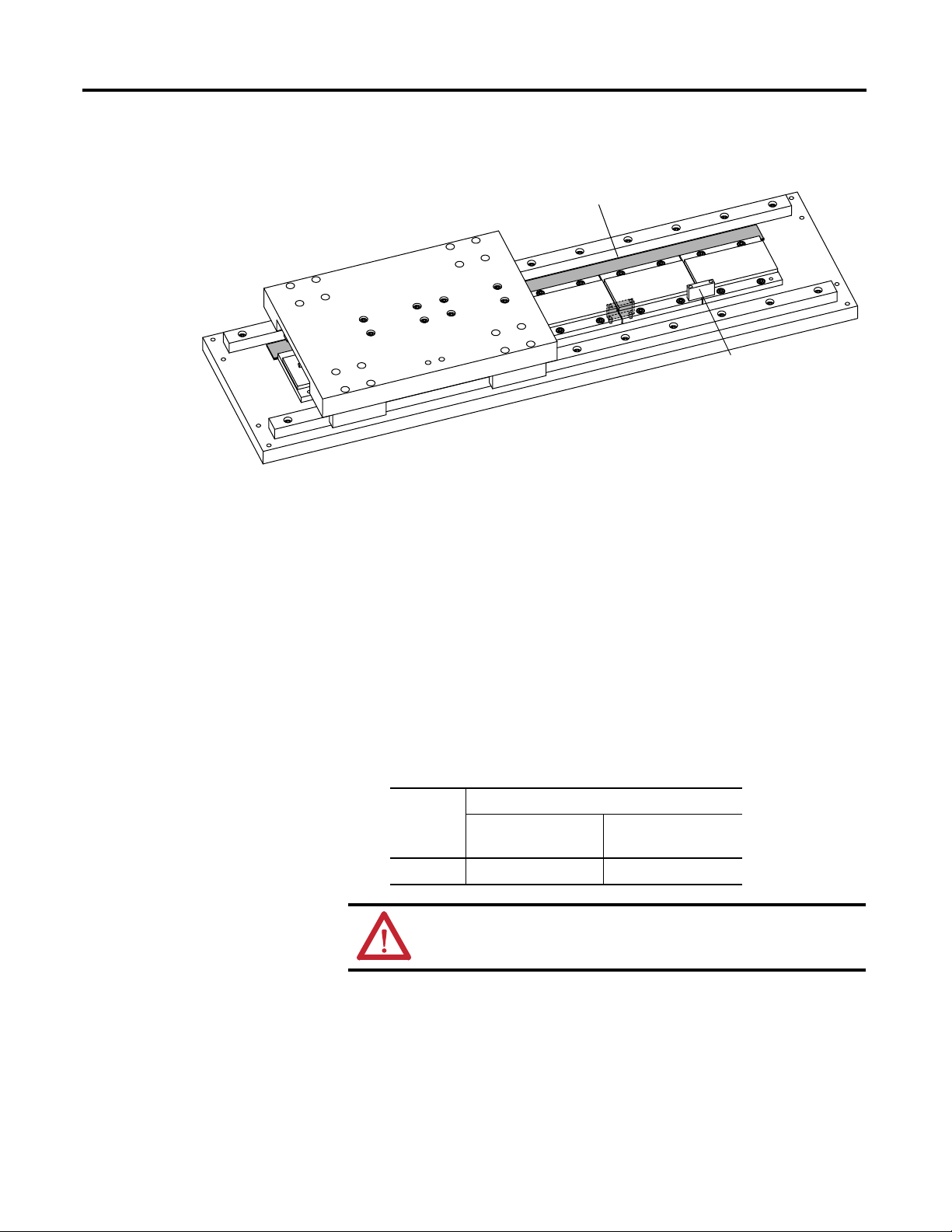

Aluminum Straight Edge

Alignment Tool

TIP

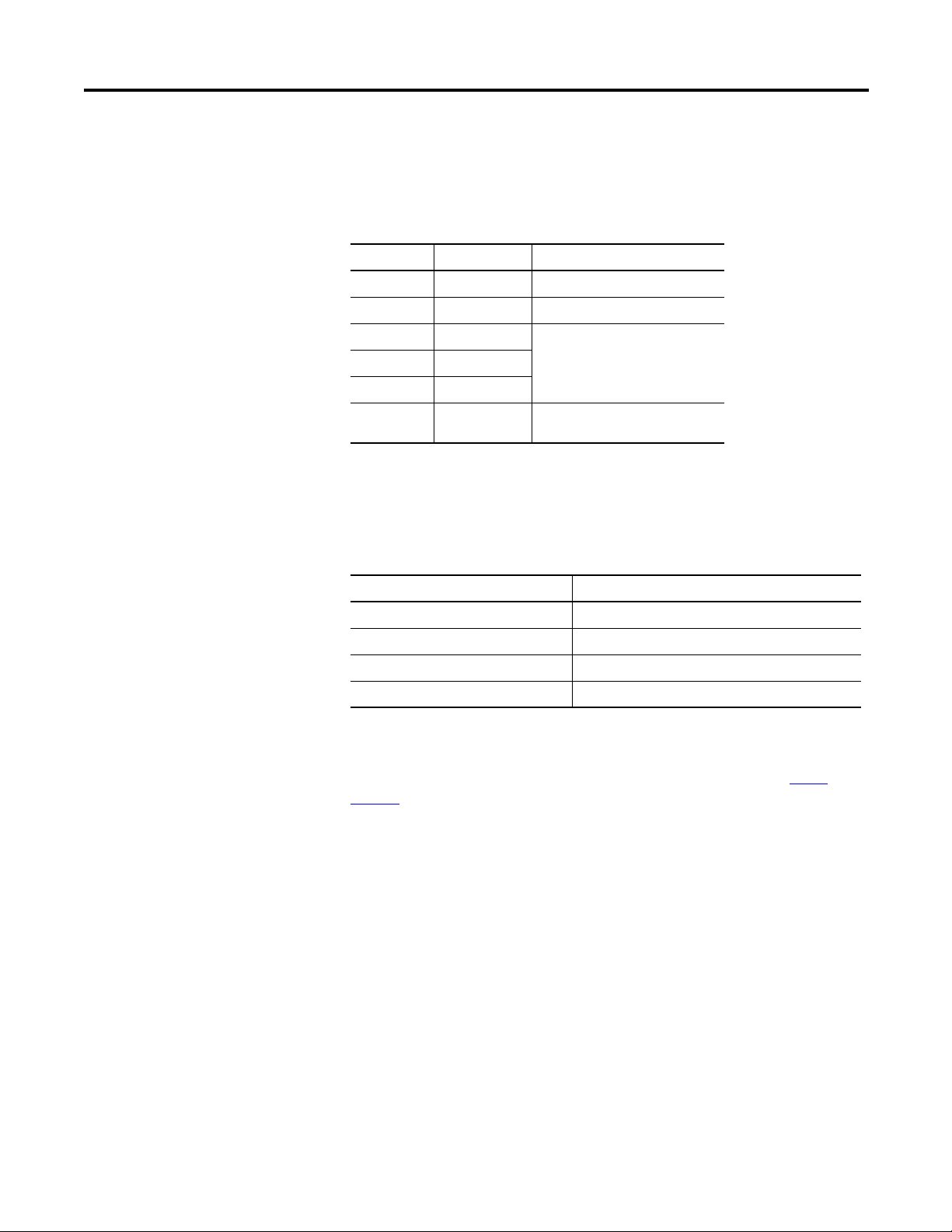

14. Align the magnet tracks with an aluminum straight edge, and the supplied

alignment tool.

15. Place the alignment tool in the holes on each of the magnet tracks.

16. Align the edges of the magnet tracks with the aluminum straight edge and

tighten the bolts.

17. Position the carriage over the complete sections and continue aligning the

remainder of the magnet tracks.

If space limitation prevents the use of an aluminum

straight edge. Place a 0.5 mm (0.020 in.) plastic shim

between the magnet tracks, tighten the bolts, and then

remove the shim.

18. Torque all screws to the values listed in the table, securing assemblies in

place by using all mounting holes.

SHCS Torque

SHCS

M5 9.5 (7.0) 6.36 (4.7)

Black Oxide Steel

N•m (lb•ft)

ATTENTION: Remove the alignment tool and make certain all

magnet-track mounting hardware is flush or below the magnet

surface to prevent damage to the coil.

Stainless Steel

N•m (lb•ft)

28 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 29

Install the LDC-Series Linear Motor Chapter 3

Mount a Single Coil with a Single Magnet Track

Follow these steps to install a single coil with single magnet track.

1. Install the magnet track by using M5 x 0.8 x 16 mm SHCS.

2. Remove any burrs and clean the motor-coil mounting surface.

3. Install the motor coil under the carriage, by using M5 x 0.8 screws that

extend through the carriage by at least 12 mm (0.5 in.), but no more than

20 mm (0.7 in.).

4. Tighten screws but do not torque them.

5. Slide the carriage assembly onto the bearing pucks.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 29

Page 30

Chapter 3 Install the LDC-Series Linear Motor

Shim

There will be resistance from magnetic forces while moving onto the

bearing pucks; this is normal.

6. Attach the carriage assembly to the bearing pucks.

7. Measure the gap between the motor and magnet by using plastic shim

stock.

The gap should be 0.79…1.70 mm (0.031…0.067 in.). If the gap is too

large, add a brass or stainless steel shim between the motor and carriage. If

the gap is too small, machine the carriage or place shims under the bearing

pucks.

30 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 31

Install the LDC-Series Linear Motor Chapter 3

8. Torque all screws to the values listed in the table, securing assemblies in

place by using all mounting holes.

SHCS Torque

SHCS

M5 9.5 (7.0) 6.36 (4.7)

Black Oxide Steel

N•m (lb•ft)

Stainless Steel

N•m (lb•ft)

ATTENTION: Remove the alignment tool and make certain all the

magnet-track mounting hardware is flush or below the magnet

surface to prevent damage to the coil.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 31

Page 32

Chapter 3 Install the LDC-Series Linear Motor

Notes:

32 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 33

Chapter

4

LDC-Series Linear Motor Connector Data

Introduction

This chapter provides power, thermistor, and Hall effect cable-connector

information for the linear motor coil and Hall effect module.

Topic Page

Linear Motor Coil Connectors 34

Hall Effect Module Connectors 35

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 33

Page 34

Chapter 4 LDC-Series Linear Motor Connector Data

Mating Connector Kit Allen-Bradley 2090-KPBM4-12AA

Intercontec P/N BKUA090NN00420220000

A

CB

D

E

H

L

F

G

1

4

3

Linear Motor Coil Connectors

There are two connectors on the linear motor coil, catalog number

LDC-xxxxxxxx-xxT11; the power connector and the Positive Temperature

Coefficient (PTC) thermistor.

Power Connector

The following tables identifies the power signals for the DIN-style circular

connector.

PinColor Signal

A Red U (A) Phase

B White V (B) Phase

C Black W (C) Phase

D Green/Yellow Ground

Case Shield

Cable Shield

and GND

ATTENTION: Properly ground the coil as described in this manual

and the drive manual.

PTC Thermistor Connector

The following tables identifies the power signals for the PTC connector.

Pin Description Signal

1 PTC thermistor + TS+

3 PTC thermistor - TS4– Reserved

Mates with PTC thermistor

connector on Hall effect

module.

34 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 35

LDC-Series Linear Motor Connector Data Chapter 4

Intercontec P/N AKUA015NN00400220000

Mating Connector Kit Allen-Bradley 2090-KFBM4-CAAA

Hall Effect Module Connectors

Pin Description Signal

1 A quad B TTL (1V p-p), + A differential AM+ (SIN+)

2 A quad B TTL (1V p-p), - A differential AM- (SIN-)

3 A quad B TTL (1V p-p), + B differential BM+ (COS+)

4 A quad B TTL (1V p-p), - B differential BM- (COS+)

5 TTL + index mark differential IM+

6 TTL - index mark differential IM7

Reserved –

8

9 Encoder and Hall sensor power +5V DC

10 Common Common

11 Reserved –

The following tables show the pinouts of the LDC-Series linear motors with the

Hall effect module, catalog number LDC-xxxxxxx- xHTxx.

Feedback Connector

These are the feedback connector pinouts .

11

1

12

13

16

10

2

9

3

17

1415

4

8

6

7

5

12 Common Common

13 PTC thermistor sensor + TS+

14 PTC thermistor sensor - TS15 TTL - trapezoidal Hall commutation S1

16 TTL - trapezoidal Hall commutation S2

17 TTL - trapezoidal Hall commutation S3

Case Shield –

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 35

Page 36

Chapter 4 LDC-Series Linear Motor Connector Data

4

31

4

1

3

6

9

7

Mating connector available as

part of encoder connector kit,

catalog number LDC-ENC-CNCT.

PTC Thermistor Connector

These are the thermal protection connector pinouts .

Encoder Connector

These are the encoder connector pinouts.

Pin Description Signal

1 PTC thermistor sensor + TS+

4Reserved –

3 PTC thermistor sensor - TS-

Mates with PTC thermistor

connector on linear motor coil.

Pin Description Signal

1 A quad B TTL, + A differential AM+

2 A quad B TTL, + B differential BM+

3 TTL + index mark differential IM+

4 A quad B TTL, - A differential AM5 A quad B TTL, - B differential BM6 TTL - index mark differential IM7 5V DC return Common

8 Encoder and Hall sensor power +5V DC

9 Shield drain –

36 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 37

Wire the LDC-Series Linear Motor

Chapter

5

Introduction

Connect the Linear Motor Coil

This section shows you how to wire your LDC-Series linear motor.

Topic Page

Connect the Linear Motor Coil 37

Signal and Wire Definitions for Flying Lead Components 40

Making Your Own Extension Cables 41

Mounting and Wiring Two Identical Coils in Tandem 42

Use the following procedure to connect your linear motor, catalog number

LDC-xxxxxxx-xHT11.

1. Wire your encoder to the connector by using the Encoder Connector Kit,

catalog number LDC-ENC-CNCT, and the connector data on page 35

ATTENTION: Be sure that cables are installed and restrained to

prevent uneven tension or flexing at the cable connectors. Use the

Bulk Head Connector Kit, catalog number LDC-BULK-HD, for

mounting these connectors.

Excessive and uneven lateral force at the cable connectors may

result in the connector’s environmental seal opening and closing

as the cable flexes.

Failure to observe these safety precautions could result in damage

to the motor and its components.

.

2. Connect your encoder to the encoder connector on the Hall effect

module.

3. Attach the motor feedback and power cables.

ATTENTION: Do not connect or disconnect the motor feedback

cable or the power cable while power is applied. It may result in

unexpected motion or cause damage to the components.

a. If using a quick-connect connector, remove the o-ring before making

the connection.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 37

Page 38

Chapter 5 Wire the LDC-Series Linear Motor

3

1

2

4

6

5

To User Supplied Encoder

To Drive

b. If using thread type connectors, leave the o-ring in place.

ATTENTION: Remove the o-ring when using a quick-connect

connector. The o-ring will block the locking mechanism, rendering

it ineffective.

A threaded connector will fit on the male connector with or without

the o-ring. If the o-ring is not used on a threaded connector, the

connection will eventually vibrate loose.

c. Align flats on each connector.

Do not apply excessive force when mating the cable and motor

connectors. If the connectors do not go together with light hand force,

realign and try again For the quick-connect connector, push the

connector on and apply a quarter turn.

Item Description

1 Power connector

2 Feedback connector

3 Encoder connector

4 Connect your encoder using Encoder Connector Kit, catalog

5 Feedback Extension Cable, catalog number 2090-CFB7DF-CDAFxx or 2090-

6 Power Extension Cable, catalog number 2090-CPWM7DF-xxAFxx or 2090-

38 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

number LDC-ENC-CNCT

XXNFMF-Sxx

XXNPMF-xxSxx

Page 39

Wire the LDC-Series Linear Motor Chapter 5

ATTENTION: Be sure that cables are installed and restrained to

prevent uneven tension or flexing at the cable connectors.

Excessive and uneven lateral force at the cable connectors may

result in the connector’s environmental seal opening and closing

as the cable flexes. Failure to observe these safety precautions

could result in damage to the motor or encoder.

d. For the threaded connector, hand-tighten the knurled collar with five to

six turns to fully seat the connector.

ATTENTION: Keyed connectors must be properly aligned and

hand-tightened the recommended number of turns.

Improper alignment is indicated by the need for excessive force,

such as the use of tools, to fully seat connectors.

Connectors must be fully tightened for connector seals to be

effective.

Failure to observe these safety precautions could result in damage

to the motor, cables, and connector components.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 39

Page 40

Chapter 5 Wire the LDC-Series Linear Motor

Signal and Wire Definitions for Flying Lead Components

For linear motors, catalog numbers LDC-xxxxxxx-xxT20, wire them by using the

wiring diagram on page 79

gauge information see page 71

Linear Motor Coil

These are the wire colors and signals for the linear motor-coil power and thermal

protection cables, catalog numbers LDC-xxxxxxx-xxT20.

Table 3 - Power Signals

. Wire colors and signal types are shown here; for wire

.

Color Signal Comments

Red Motor Phase U (A) • Observe maximum applied voltage specification.

White Motor Phase V (B)

Black Motor Phase W (C)

Green Motor Ground • Terminate per drive manual instructions.

Shield Cable Shield

ATTENTION: Disconnect the input power supply before installing or

servicing the motor. Motor lead connections can short and cause damage

or injury if not well secured and insulated. Insulate the connections, equal

to or better than the insulation on the supply conductors. Properly ground

the motor per the selected drive manual.

• Consult the drive manual or supplier for specific

wiring instructions to the drive. Wiring is phase/

commutation sensitive.

• Shield is not connected to the motor frame.

These are the PTC thermistor sensor wire colors and signals for the linear motor

coil power and thermal protection cables, catalog number LDC-xxxxxxx-xxT20.

Table 4 - PTC Thermistor Sensor Signals

Color Description Signal

Black PTC thermistor sensor + TS+

Black PTC thermistor sensor - TS-

40 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 41

Wire the LDC-Series Linear Motor Chapter 5

Hall Effect Module

This table shows the signal and wire colors for the Hall effect module with flying

leads, catalog number LDC-HALL-F.

Color Signal Signal Spec

Red +V 5…24V DC Hall supply, 20 mA.

Black VRTN Hall effect signal common.

White S1

Making Your Own Extension Cables

Blue S2

Orange S3

Silver braid Cable shield

–

Terminate at drive end per drive

manual instructions.

Flying lead coil and Hall effect modules require circular DIN-style connectors to

interface with Allen-Bradley extension cables. The following connectors kits are

available for terminating flying lead coils and Hall effect modules.

Connector Kit Cat. No. Application

2090-KFBM7-CAAA Feedback flex extension cable

2090-KPBM4-12AA Power flex extension cable

2090-KFBE7-CAAA Feedback non-flex extension cable

2090-KPBE7-12AA Power non-flex extension cable

The cable length from the coil to drive should be limited to 10 m (32.8 ft). If

longer cables are necessary, a 1321-3Rx-x series line reactor is required. Refer to

the 1321 Power Conditioning Products Technical Data, publication 1321-

TD001, to choose a line reactor for applications requiring cable longer than 10 m

(32.8 ft).

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 41

Page 42

Chapter 5 Wire the LDC-Series Linear Motor

Coil #1

Coil #2

Coil #1 is the master.

Hall Effect

Module

L

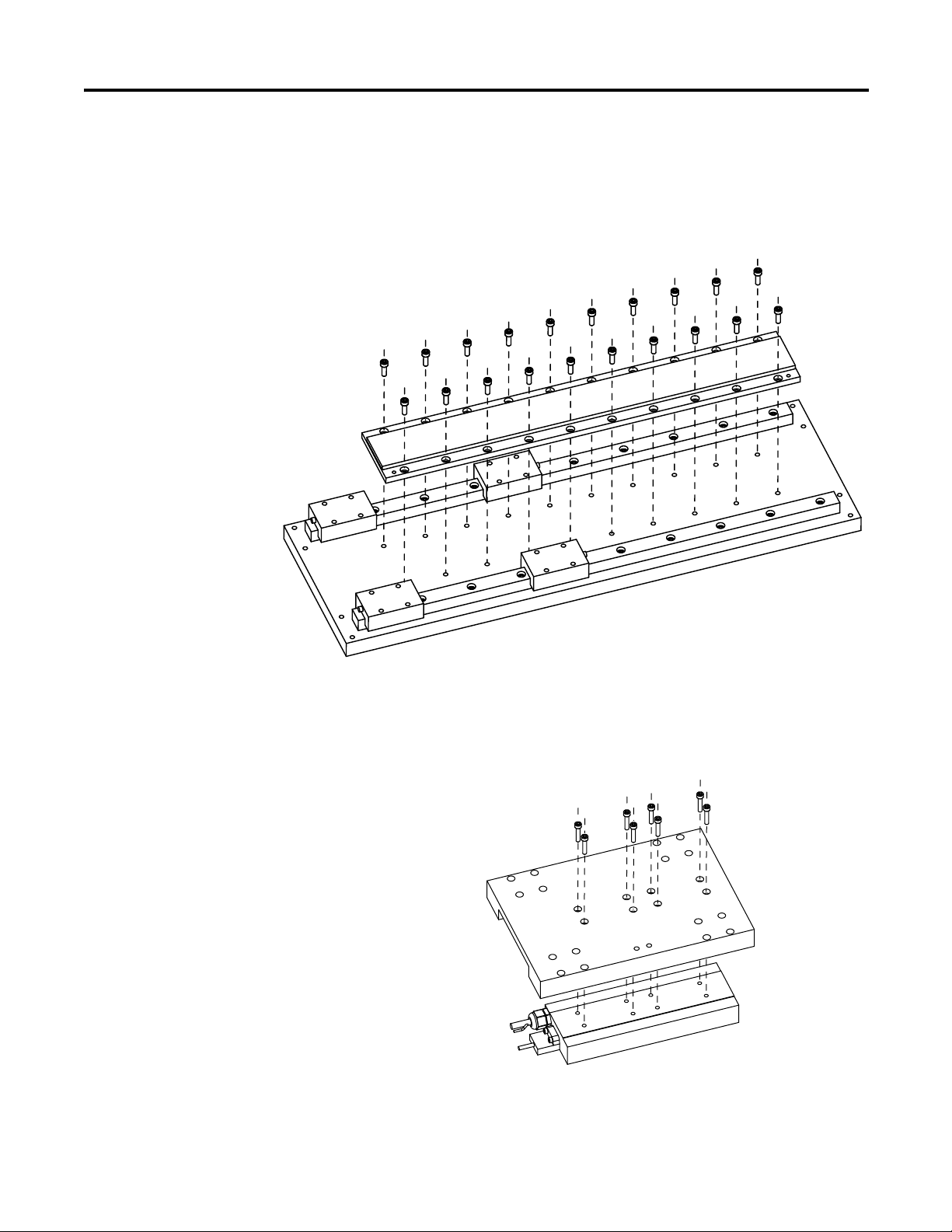

Mounting and Wiring Two Identical Coils in Tandem

This type of installation requires a custom motor-database file, which is available

upon request. Contact Application Engineering at 631.344.6600 to request this

file.

These tables and figures show the wiring and spacing for two identical coils

mechanically top mounted to the same plate and driven by one amplifier. There

are three configurations shown here for mounting motors in tandem: power and

encoder cables exiting on the right, the center, and on opposite ends.

Coils must have identical part numbers. Using mismatched coils

will cause a hazardous condition resulting in damage to the

equipment and a possible fire.

Cables Exit to the Right

If mounting coils in tandem, such that the power cables exit both the coils on

right side, as shown, use the following table to find the mounting distance and the

phase wiring.

Figure 3 - Mounting Two Coils with Cables Exit to the Right

Table 5 - Phase Wiring for Right-exit Power Cables

L

mm (in.)

133.33 (5.249) Red Red U

(1) Master has Hall effect module.

(2) Slave has no Hall effect module.

42 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Coil # 1

(1)

Master

White White V

Black Black W

Coil # 2

(2)

Slave

Amplifier

Phase

Page 43

Wire the LDC-Series Linear Motor Chapter 5

Coil #1

Coil #2

Coil #1 is the master.

Hall Effect

Module

L

Cables Exit in the Center

If mounting coils in tandem, such that the power cables exit in the center as

shown, use the following table to find the mounting distance and the phase

wiring.

Figure 4 - Mounting Two Coils with Cables Exit in the Center

Table 6 - Phase Wiring for Center-exit Power Cables

L

mm (in.)

133.33 (5.249) Red Black U

(1) Master has Hall effect module.

(2) Slave has no Hall effect module.

Coil # 1

(1)

Master

White White V

Black Red W

Coil # 2

Slave

(2)

Amplifier

Phase

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 43

Page 44

Chapter 5 Wire the LDC-Series Linear Motor

Coil #1

Coil #2

Coil #1 is the master.

Hall Effect

Module

L

Cables Exit on Opposite Ends

If mounting coils in tandem such that the power cables exit opposite to each other

as shown, use the following table to find the mounting distance and the phase

wiring.

Figure 5 - Mounting Two Coils with Cables Exit on Opposite Ends

Table 7 - Phase Wiring for Opposite End-exit Power Cables

L

mm (in.)

100.00 (3.94)

133.33 (5.249)

(1) Master has Hall effect module.

(2) Slave has no Hall effect module.

Coil # 1

(1)

Master

Red Red U

White Black V

Black White W

Red Black U

White White V

Black Red W

Coil # 2

Slave

(2)

Amplifier

Phase

44 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 45

Chapter

IMPORTANT

6

Configure and Start Up the LDC-Series Linear Motor

Introduction

Before You Begin

This section covers the set up and connection verification of a linear motor with

either Kinetix 6000, Kinetix 6500/6200, Kinetix 2000, or Ultra3000 drives.

Topic Pages

Before You Begin 45

What You Need 46

Required Files 46

Follow These Steps 47

Update the Linear Motor Database 47

Set Up the Connection to a Kinetix 6000, Kinetix 6500/6200, or Kinetix 2000 Drive 48

Set Up the Connection to an Ultra3000 Drive 53

Verify Motor Encoder Direction 55

Verify Motor Encoder Resolution 56

Verify Linear Motor Wiring and Function 56

This chapter assumes you have wired your linear motor and Allen-Bradley drive

as shown in wiring diagrams in Appendix A

starting on page 61.

It is important that the brushless linear motor coil, Hall sensor, and the

linear encoder be wired correctly for proper drive commutation and servo

operation to get positive motion when commutated.

Please read and understand Motor Direction Defined

.

Motor Direction Defined

Positive motion is dependent on encoder orientation, encoder wiring, and coil or

magnet track motion.

Most linear encoders are attached to the motor coil with the encoder cable facing

the same direction as the motor coil cable.

Wire the linear encoder such that the position feedback is positive (phase A+

leads phase B+) when the motor is moving in the positive direction.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 45

Page 46

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

Coil Motion

Stationary Magnet

Stationary Coil

Magnet Motion

When the motor power and Hall sensor wiring is connected as shown in the

wiring diagrams in Appendix A

motor coil moving toward its power cable. This diagram shows positive motion

for both a moving coil and a moving magnet track.

Figure 6 - Motor Direction

, the positive direction of motion is defined as the

What You Need

You need a computer with RSLogix 5000 software installed and current files to

support your motor.

Required Files

Firmware revisions and software versions required to support the linear motors

include the following:

• RSLogix 5000 software, version 16.00 or later

• Kinetix 2000 or Kinetix 6000 multi-axis drives

– Firmware revision 1.96 or later

– For RSLogix 5000 software, version 16.xx

use Motion Database file, version 4_17_0 or later

– For RSLogix 5000 software, version 17.xx or later

use Motion Database file, version 5_8_0 or later

46 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 47

Configure and Start Up the LDC-Series Linear Motor Chapter 6

Update the Linear Motor Database

Verify Motor Encoder

Resolution

Set Up the Connection to a

Kinetix 6000, Kinetix 6500/

6200, or Kinetix 2000 Drive

Verify Motor Encoder

Direction

Verify Linear Motor

Wiring and Function

Set Up the Connection to an

Ultra3000 Drive

Drive Model?

Ultra3000 Drive

Kinetix 6000 Drive,

Kinetix 6200/6500 Drive,

or Kinetix 2000 Drive

page 56

page 56

page 55

page 53page 48

page 47

• Ultra3000 drives

–Firmware revision 1.52 or later

–Motor Database, motor_03_18_09.mdb or later

– Motion Analyzer software, version 4.7 or later

Follow These Steps

Download these files from http://www.rockwellautomation.com/support

.

Contact Rockwell Automation Technical Support at 440.646.5800 for assistance.

The following flow chart illustrates the required steps.

Update the Linear Motor

Database

Install the current Motion Database, as required, before commissioning your

linear motor. See the Required Files

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 47

on page 46.

Page 48

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

Set Up the Connection to a Kinetix 6000, Kinetix 6500/ 6200, or Kinetix 2000 Drive

This procedure configures the Kinetix 6000, Kinetix 6500/ 6200, or

Kinetix 2000 drive for your linear motor and encoder combination.

For help in setting up your linear motor with RSLogix 5000 software, refer to

Additional Resources

on page 9. This procedure assumes you are familiar with

RSLogix 5000 software.

1. Click the Driver/Motor tab.

2. Click Change Catalog and select the appropriate motor catalog number

from the following list.

Your catalog number will have a letter append to the end to indicate what

drive you are using to power it: A = 230V drive and B = 460V drive.

Cat. No. Cat. No.

LDC-C030100-DHTxxA LDC-C030100-DHTxxB

LDC-C030200-DHTxxA LDC-C030200-DHTxxB

LDC-C030200-EHTxxA LDC-C030200-EHTxxB

LDC-C050100-DHTxxA LDC-C050100-DHTxxB

LDC-C050200-DHTxxA LDC-C050200-DHTxxB

LDC-C050200-EHTxxA LDC-C050200-EHTxxB

LDC-C050300-DHTxxA LDC-C050300-DHTxxB

LDC-C050300-EHTxxA LDC-C050300-EHTxxB

LDC-C075200-DHTxxA LDC-C075200-DHTxxB

LDC-C075200-EHTxxA LDC-C075200-EHTxxB

LDC-C075300-DHTxxA LDC-C075300-DHTxxB

LDC-C075300-EHTxxA LDC-C075300-EHTxxB

LDC-C075400-DHTxxA LDC-C075400-DHTxxB

LDC-C075400-EHTxxA LDC-C075400-EHTxxB

LDC-C100300-DHTxxA LDC-C100300-DHTxxB

LDC-C100300-EHTxxA LDC-C100300-EHTxxB

LDC-C100400-DHTxxA LDC-C100400-DHTxxB

LDC-C100400-EHTxxA LDC-C100400-EHTxxB

LDC-C100600-DHTxxA LDC-C100600-DHTxxB

LDC-C100600-EHTxxA LDC-C100600-EHTxxB

LDC-C150400-DHTxxA LDC-C150400-DHTxxB

LDC-C150400-EHTxxA LDC-C150400-EHTxxB

LDC-C150600-DHTxxA LDC-C150600-DHTxxB

LDC-C150600-EHTxxA LDC-C150600-EHTxxB

LDC-C030100-DHTxxA LDC-C030100-DHTxxB

LDC-C030200-DHTxxA LDC-C030200-DHTxxB

48 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 49

Configure and Start Up the LDC-Series Linear Motor Chapter 6

Using the screen image as a reference, configure the parameters as shown in

the Setting column.

Parameter Setting Comment

Loop Configuration Position Servo –

200 5 µm encoder

500 2 µm encoder

1000 1 µm encoder

Drive Resolution

Drive Counts per Motor Millimeter –

Real Time Axis Information

Attribute 1 Position Feedback –

2000 0.5 µm encoder

10,000 0.1 µm encoder

51200 20 µm pitch Sin/Cos encoder

25600 40 µm pitch Sin/Cos encoder

3. Click OK.

4. Click the Motor Feedback tab.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 49

Page 50

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

5. Using the screen image as a reference, configure the parameters as shown in

the Setting column.

Parameter Setting Comment

Feedback Type TTL or Sin/Cos For RSLogix 5000 software,

TTL with Hall or Sin/Cos with Hall For RSLogix 5000 software,

Cycles 50 5 µm encoder

125 2 µm encoder

250 1 µm encoder

500 0.5 µm encoder

2500 0.1 µm encoder

50 20 µm Sin/Cos encoder

25 40 µm Sin/Cos encoder

per Millimeters –

Interpolation Factor 4 TTL

1024 Sin/Cos

version 16

version 17

Figure 7 - RSLogix 5000 Software, Version 15.00 and 16.00, TTL Encoder

Figure 8 - RSLogix 5000 Software, Version 15.00 and 16.00, Sin/Cos Encoder

50 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 51

Configure and Start Up the LDC-Series Linear Motor Chapter 6

EXAMPLE

Figure 9 - RSLogix 5000 Software, Version 17.00 and Later, TTL Encoder

Figure 10 - RSLogix 5000 Software, Version 17.00 and Later, Sin/Cos Encoder

6. Click OK to sets the values.

7. Click the Units tab.

8. Using the screen image as a reference, configure the parameters as shown in

the Setting column.

Parameter Setting

Position Units mm

Average Velocity Timebase 0.25 s

You can change position units to inches, or other units, on this tab.

This is an example for a 5 µm resolution encoder:

200 drive cnts/mm x 25.4 mm/in.

Conversion Constant = 5080 drive cnts/in.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 51

Page 52

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

9. Click OK to set the values.

10. Click the Conversion tab.

11. Using the screen image as a reference, configure the parameters as shown in

the Setting column.

Parameter Setting Comment

Positioning Mode Linear –

Conversion Constant 200 5 µm encoder

500 2 µm encoder

12. Click OK.

1000 1 µm encoder

2000 0.5 µm encoder

10,0000 0.1 µm encoder

51200 20 µm pitch Sin/Cos encoder

25600 40 µm pitch Sin/Cos encoder

52 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 53

Configure and Start Up the LDC-Series Linear Motor Chapter 6

Set Up the Connection to an Ultra3000 Drive

This procedure configures the Ultra3000 drive for your linear motor and encoder

combination.

For help using Ultraware software as it applies to setting up your linear motor,

refer to Additional Resources

with Ultraware software.

on page 9. This procedure assumes you are familiar

1. Open your Motor Configurator Utility.

2. Select the linear motor catalog number.

3. From the Edit menu, choose Duplicate.

4. Rename the Model.

5. Click Encoder Type and select either Incremental or Sin/Cos.

6. Click Lines Per Meter and enter the value.

The following tables list typical values for lines per meter.

Incremental Sin/Cos

Resolution Value Encoder Scale Pitch Value

10 µm 25,000 100 µm 10,000

5 µm 50,000 40 µm 25,000

2 µm 125,000 20 µm 50,000

1 µm 250,000

0.5 µm 500,000

0.1 µm 2,500,000

Figure 11 - Incremental Encoder

Figure 12 - Sin/Cos Encoder

7. Click Close.

8. Open your Ultraware software.

9. Configure your Ultra3000 drive.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 53

Page 54

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

10. From the Workspace dialog box, select Motor.

11. Click Motor Model.

12. Choose the model you created from the pull-down menu.

If using an incremental encoder, you are finished. For Sin/Cos encoders,

continue with steps 12 and 13.

13. From the Workspace dialog box, select Encoders.

14. Click Motor Encoder Interpolation.

15. Select a value from the pull-down menu.

This table shows the encoder resolutions that could be achieved when

using a 20 μm Sin/Cos encoder and different interpolation values.

Value Encoder Resolution

X4 5 µm

X8 2.5 µm

X16 1.25 µm

X32 0.625 µm

X64 0.3125 µm

X128 0.15625 µm

X256 0.078125 µm

X512 0.0390 µm

X1024 0.01953125 µm

54 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 55

Configure and Start Up the LDC-Series Linear Motor Chapter 6

Verify Motor Encoder Direction

In this section, you use the monitor tags to evaluate the encoder installation.

1. Disable the drive.

2. Note the ActualPostion tag value.

3. Move the axis in the positive direction.

See page 45

for definition for positive direction.

4. Verify that the ActualPostion tag value increases as the axis moves.

If the positive direction of travel does not match what has been defined by

the motor power and Hall Sensing wiring, then change the direction by

rewiring the encoder by using the following table.

Move To

Encoder Phase Drive CN2, Pin Encoder Phase Drive CN2, Pin

A+ 1 B+ 3

A- 2 B- 4

B+ 3 A+ 1

B- 4 A- 2

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 55

Page 56

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

IMPORTANT

Verify Motor Encoder Resolution

Verify Linear Motor Wiring and Function

This test compares the physically measured distance to the distance calculated by

the software. It also verifies the encoder setting in the RSLogix 5000 software.

1. Measure and mark a fixed distance of travel on the axis.

2. Record the ActualPosition tag value with carriage at the starting position.

3. Move the carriage to the end position.

4. Record the ActualPosition tag value.

5. Calculate the distance moved by using the record values.

6. Compare the actual distance and the calculated distance.

If the values do not match, verify the resolution of the installed encoder

and the values used in the Motor Feedback, Conversion, and Units tabs.

In RSLogix 5000 software, click the Homing and Hookup tabs to check that the

motor power, Hall sensing, and the encoder signal wiring is correct.

The following components must be wired correctly for your drive and

linear motor to operate properly:

• Hall effect module

• Coil power wires

• Thermistor or thermal switch

• Encoder

Follow these steps to verify your motor wiring and function.

1. Click the Hookup tab.

2. Configure the parameters.

The following table shows the suggested settings.

Parameter Suggested Setting

Test Increment 60.00 mm

Drive Polarity Positive

56 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 57

Configure and Start Up the LDC-Series Linear Motor Chapter 6

IMPORTANT

IMPORTANT

3. Click OK.

4. Click Test Marker.

Refer to your encoder user documentation for the location and frequency

of markers.

5. Position the coil so that it can move 60 mm (2.36 in.) in the forward or

reverse direction.

6. Click Test Feedback.

Move the axis by hand at least 60 mm (2.36 in.) when prompted.

When using Allen-Bradley servo drives, match the counting direction of

your position feedback encoder to the direction the motor moves when a

positive current is applied.

7. Click Test Command & Feedback.

Follow the on-screen instructions.

Be sure all the tests on the Hookup tab have passed before

proceeding.

When using a Kinetix 6000 or a Kinetix 2000 drive, the Test

Command Feedback test may pass even though the Hall effect

module is not wired correctly.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 57

Page 58

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

8. Click the Tune tab.

9. Configure the parameters in the Tune tab as suggested in the Initial Setting

column, leaving all other tune options off for your first pass.

If necessary, reduce the Velocity Loop Proportional Gain to maintain

stability.

WARNING: Large Position Error Tolerances, such as those

calculated by the Auto Tune function in the RSLogix 5000

programming software, or when configuring a new axis with the

RSLogix 5000 software, can lead to undetected and repetitive

high-energy impacts against axis end stops if proper precautions

are not in place. These tolerances can also lead to undetected and

repetitive high-energy impacts against unexpected obstructions.

Such impacts can lead to equipment damage and/or serious injury.

To identify the safety concerns that you have with default Position

Error Tolerance or after an Auto Tune Function, go to the Rockwell

Automation Knowlegebase. Click Find Technical Support Answers

and search for Answer ID 55937.

Parameter Initial Setting Units Note

Travel Limit 100 mm Suggested

Speed 250 mm/sec –

Torque/Force 50 % Rated –

Direction Forward Bi-directional – –

Damping Factor 0.8 – (default)

58 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 59

Configure and Start Up the LDC-Series Linear Motor Chapter 6

10. Click the Homing tab.

11. From the Sequence pull-down menu, choose Switch-Marker, or Torque

Level-Marker when a repeatable power-up position is desired.

Typical linear TTL and Sin/Cos encoders will home repeatability to

within one count of resolution when their index mark is used.

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 59

Page 60

Chapter 6 Configure and Start Up the LDC-Series Linear Motor

IMPORTANT

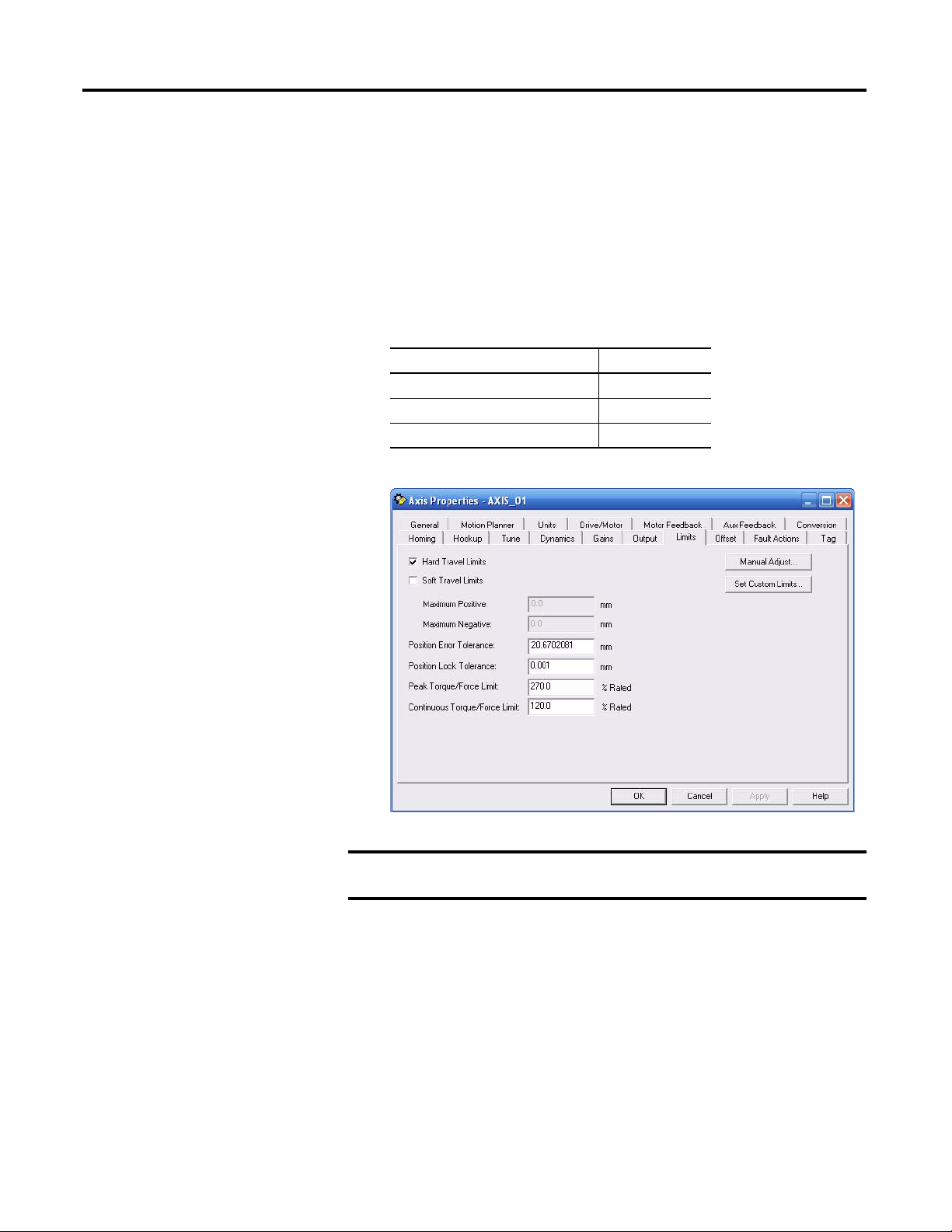

Additional Adjustments for Cooling Plate Option

If your linear servo motor has the cooling plate option installed, catalog number

LDC-xxxxxx-CP, follow these steps to adjust Continuous Torque/Force Limit.

1. Click the Limits tab.

2. Set the Continuous Torque/Force Limit to reflect the motor cooling

configuration.

For linear motors, this field data entry is limited to integer values from

0…150%.

Cooling Option Used Value

No cooling plate 0…100%

Cooling plate with forced air 0…120%

Cooling plate with forced water 0…150%

Increasing or decreasing the motor continuous current rating does not

change the drives’ continuous current limiting.

60 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 61

Specifications and Dimensions

Appendix

A

Introduction

This appendix provides product specifications and mounting dimensions for

your LDC-Series iron core linear servo motor components

Topic Page

Performance Specifications 62

General Specifications 68

Product Dimensions 71

Rockwell Automation Publication LDC-UM001B-EN-P - March 2011 61

Page 62

Appendix A Specifications and Dimensions

Performance Specifications

These tables provide performance specifications for the LDC-Series iron core

linear servo motors.

Common Performance Specifications

These performance specifications apply to all LDC-Series iron core linear servo

motors.

Attribute Value

Motor type 3 phase, wye winding, synchronous permanent magnet

Operating speed, max 10 m/s (32.8 ft/s)

Operating voltage, (not for direct connection to AC line) 460V AC rms

Dielectric rating of motor power connections (U,V,W), to ground for 1.0 s

Cogging torque < 5% of the continuous force

Applied bus voltage, max

Electrical cycle length 50 mm (1.9685 in.)

Coil temperature, max 130 °C (266 °F)

Insulation class 130 °C (266 °F) Class B

Thermal time constant, Ref, winding to ambient 45 min

Paint color Black

(2)

(1)

stator, non-ventilated linear motor

2500V AC rms 50/60 Hz

650V DC

(1) Tested during manufacturing process. Do not re-apply test voltage. Contact Application Engineering (631.344.6600) for advice on testing coils post production.

(2) Maximum cable length is 10 m (32.8 ft). Consult Application Engineering (631.344.6600) for applications requiring longer cables.

62 Rockwell Automation Publication LDC-UM001B-EN-P - March 2011

Page 63

Specifications and Dimensions Appendix A

Performance Specifications

Motor performance specifications are with sinusoidal commutation. Cooling

options include NC (no cooling), AC (air cooling), and WC (water cooling).

Table 8 - LDC-Series Iron Core Linear Motors (30 mm frame size)

Attribute Units Symbol LDC-C030100-DxTxx LDC-C030200-DxTxx LDC-C030200-ExTxx

NC AC WC NC AC WC NC AC WC

(4)

(5) (6) (7)

(4) (6)

(5) (7)

(1) (2) (3)

(5) (6) (7)

(1) (2) (3) (6)

(8)

(5) (7)

N

(lbf)

N

(lbf)

N/A

pk

(lbf/Apk)

Vp/m/s

(Vp/in/s)

A

pk

(A

rms

A

pk

(A

rms

Ohms R

F

c

F

p

th

K

f

K

e

I

p

)

I

c

)

20

74

(17)93(21)

188

(42)

111

(25)

148

(33)

375

(84)

185

(42)

222

(50)

148

(33)

2.24 1.43 1.00 1.12 0.72 0.50 1.12 0.72 0.50

18.2

(4.1)

21.5

(0.55)

12.1

(8.6)

4.1

(2.88)

5.1

(3.6)

6.1

(4.3)

18.2