Page 1

Technical Data

Original Instructions

IEC Busbar Mounting System Specifications

Bulletins 141A, 141C

Top ic Pa ge

Product Overview 2

141C Crossboard® Mounting System 3

Catalog Number Explanation 3

Product Selection 4

Accessories 6

Specifications 7

Approximate Dimensions 9

141A Classic Mounting System 17

Catalog Number Explanation 17

Product Selection 19

Specifications 32

Approximate Dimensions 38

Additional Resources 55

Page 2

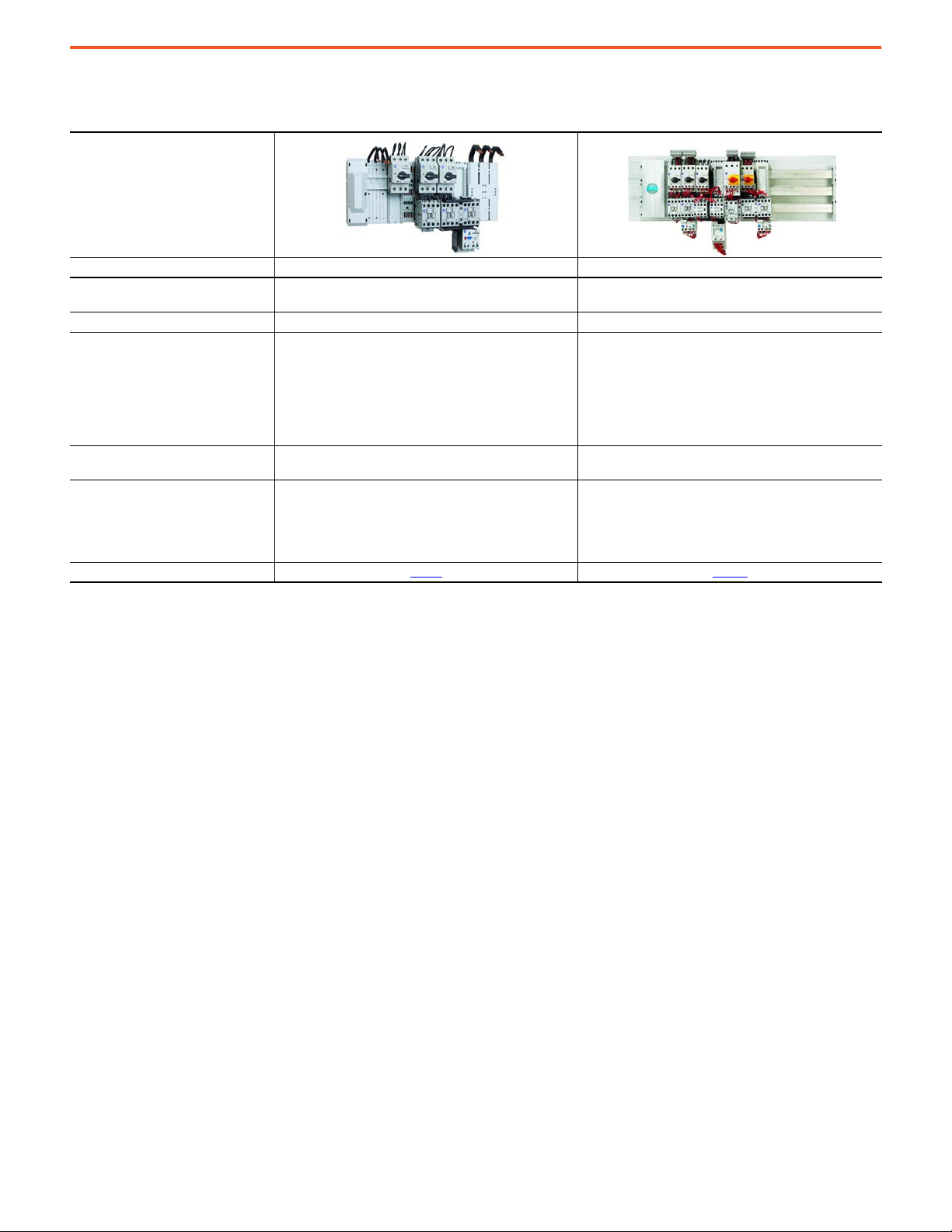

Product Overview

Product Overview

Bulletin No. 141C Crossboard® Mounting System 141A MCS Mounting System

Current Rating, Max.

Degree of Protection (Ingress Rating) IP20 IP20B (finger safe)

•IEC/EN 61439-1:2011

•UL 508

Standards Compliance

Certifications

Features

Product Selection page 3

(1) Most components comply with UL 508; there some exceptions. Consult your local Rockwell Automation sales office or Allen-Bradley distributor.

• CSA C22.2, No 14

•EN 60947-1 + A1:2007

•EN 60947-1 + A2:2011

• EN 60947-3 + A1:2008

• EN 60947-3 + A2:2012

• Reduced power wiring

• Efficient design with decreased panel space

• Adapters to support a wide range of devices

• Plug-and-play design

UL: 100 A

IEC: 125 A

CE

cULus Listed

•IEC/EN 61439-1

(1)

•UL 508

• CSA C22.2, No 14

• Reduced power wiring

• Efficient design with decreased panel space

• Factory-assembled starters

• Adapters to support a wide range of devices

• Plug-and-play design

UL: 1400 A

IEC: 1175 A

CE

cULus Recognized

page 17

2 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 3

141C Crossboard® Mounting System

Catalog Number Explanation

Examples that are given in this section are not intended to be used for product selection. Not all combinations produce a valid catalog

number.

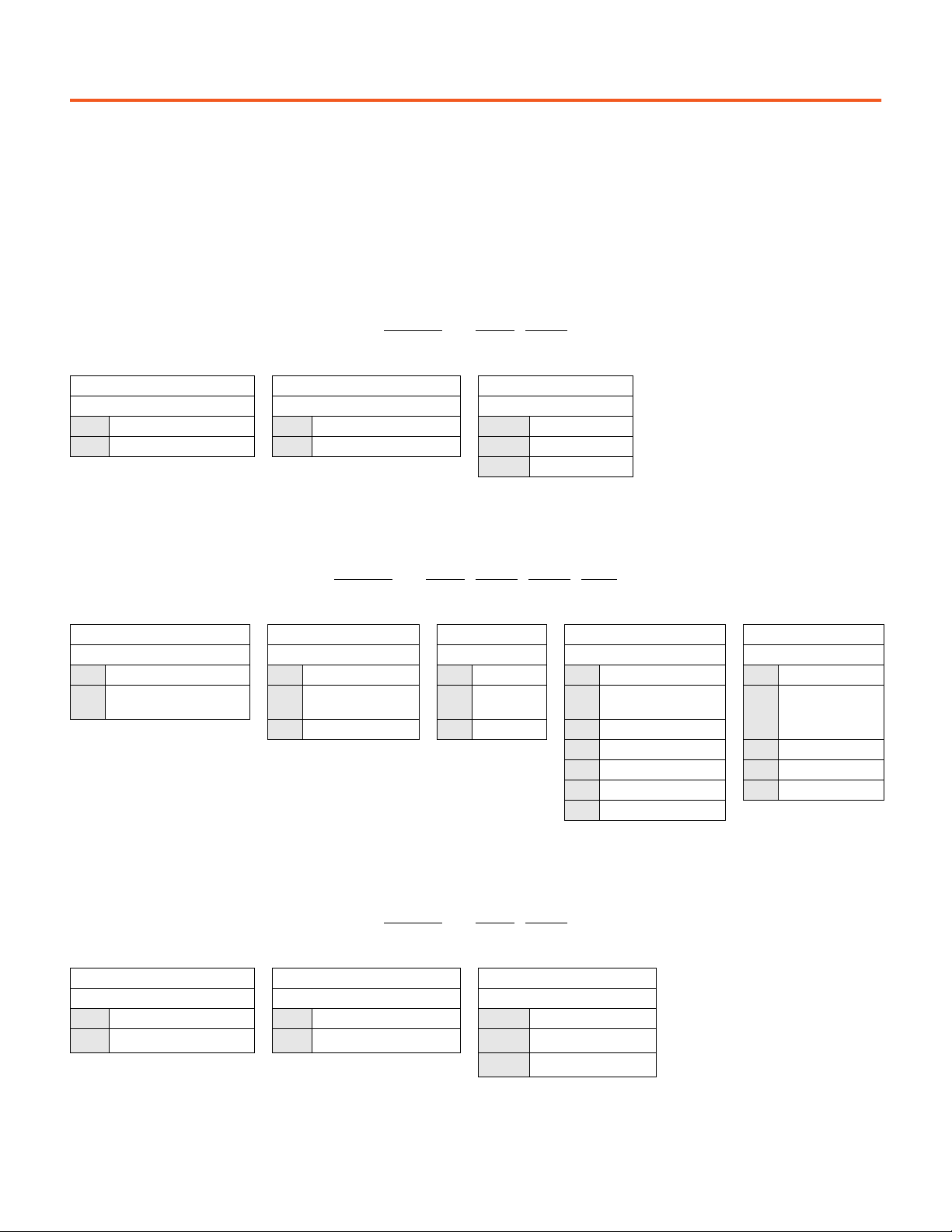

Busbar Bases

141C – B 225

abc

abc

Bulletin Number Type Length

Code Description Code Description Code Description

141C Crossboard Mounting System B Busbar system base, 3-pole 225 225 mm (8.86 in.)

405 405 mm (15.94 in.)

Busbar Adapters

141C – 18 S 16 L1

abcde

abcde

Bulletin Number No. of Poles/Width Mounting Rail Current Rating Terminal Connection

Code Description Code Description Code Description Code Description Code Description

141C Crossboard Mounting System 18 1 pole, 18 mm (0.71 in.) S Fixed Blank

45 3 poles, 45 mm (1.77 in.) R Adjustable 16 16 A

0 A (no electrical

connection)

25 25 A L1 L1

32 32 A L2 L2

45 45 A L3 L3

63 63 A

Blank

No electrical

connection

Connection Modules

141C – VN 16

abc

abc

Bulletin Number Type Wire Size

Code Description Code Description Code Description

141C Crossboard Mounting System VN Connection module, 3-pole 16

50

16 mm2, #14…6 AWG

50 mm2, #10…1 AWG

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 3

Page 4

141C Crossboard® Mounting System Product Selection

Busbar Adapters for Bulletin 140G Molded Case Circuit Breakers, 140MG Motor Protection Circuit Breakers, and 140MG Motor Circuit Protectors

141C – G G U

abcd

abcd

Bulletin Number Type Frame Size Terminals

Code Description Code Description Code Description Code Description

141C Crossboard Mounting System

Busbar adapters for Bulletin 140G and

G

MG devices

G G-Frame U Universal Connection

H H-Frame

Product Selection

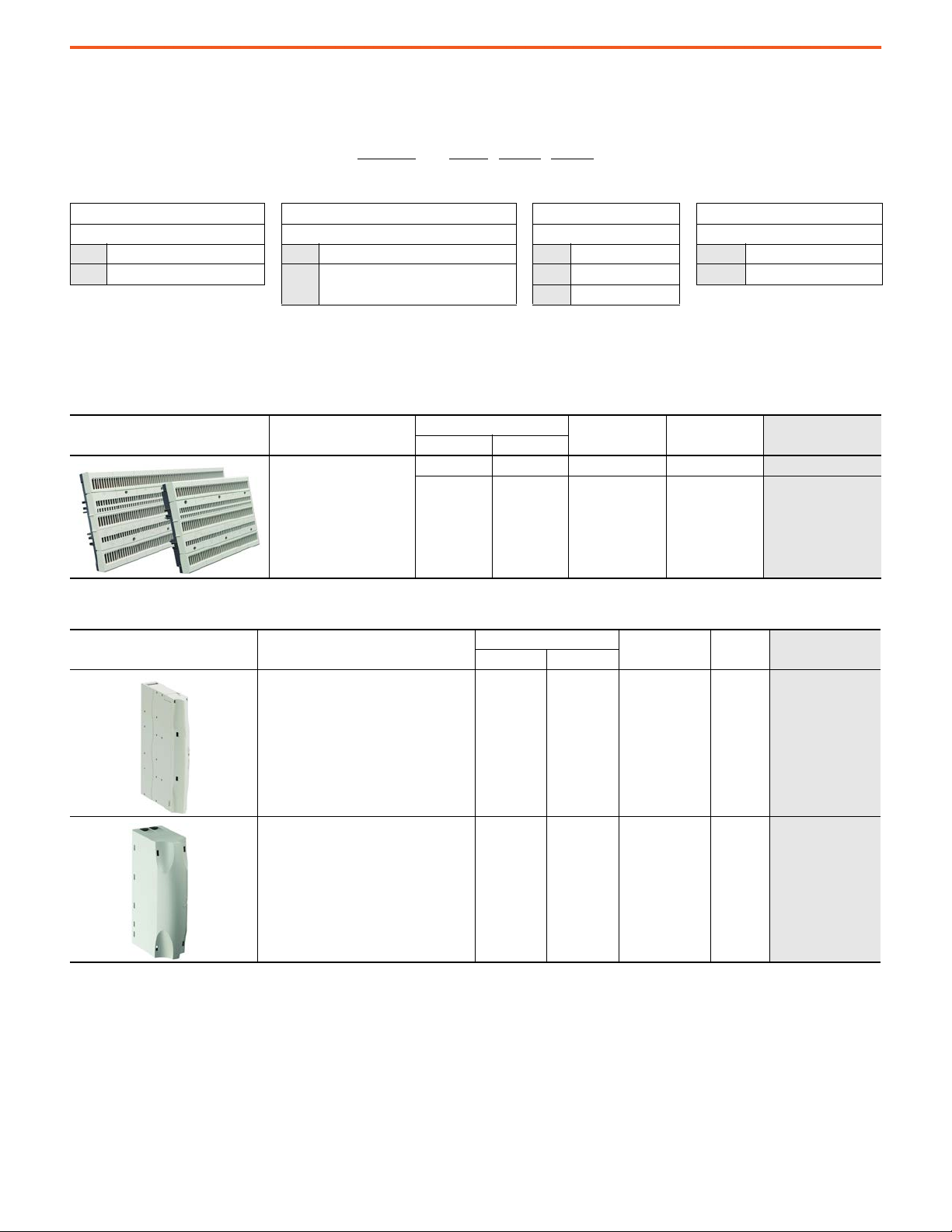

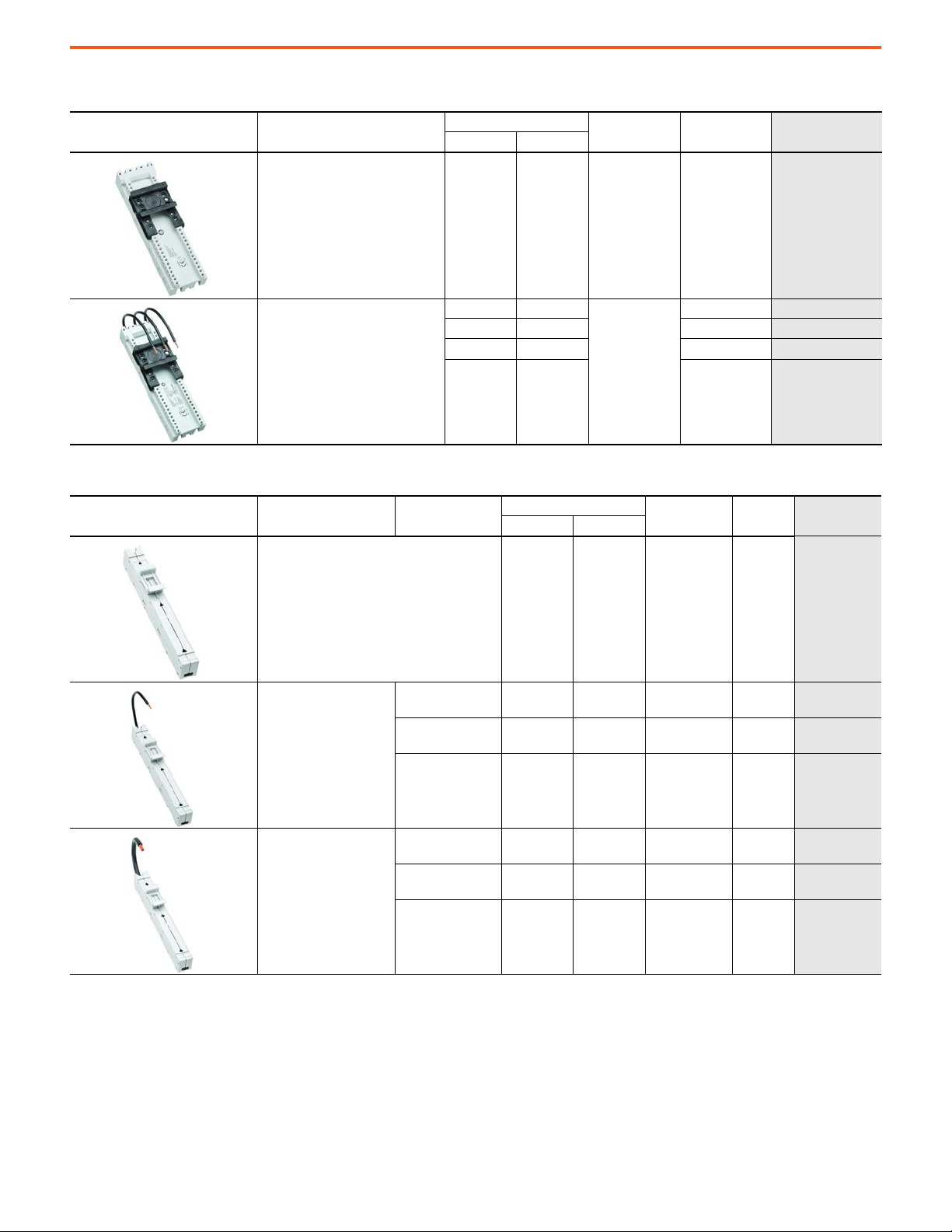

Busbar System Bases

Connection Modules

Description

Busbar system base

•3 poles

Description

Connection module

•3-pole

• Spring terminals

•16 mm2, #14…6 AWG wire size

Connection module

•3-pole

• Box terminals

2

•50 mm

, #10…1 AWG wire size

Rated Thermal Current [A]

IEC UL

125 100 225 (8.86) 1

125 100 405 (15.94) 1

Rated Thermal Current [A]

IEC UL

63 48 22.5 (0.89) 1 141C-VN16

125 100 45 (1.77) 1 141C-VN50

Width [mm (in.)] Pkg. Qty. Cat. No.

Width [mm (in.)] Pkg. Qty. Cat. No.

141C-B225

141C-B405

4 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 5

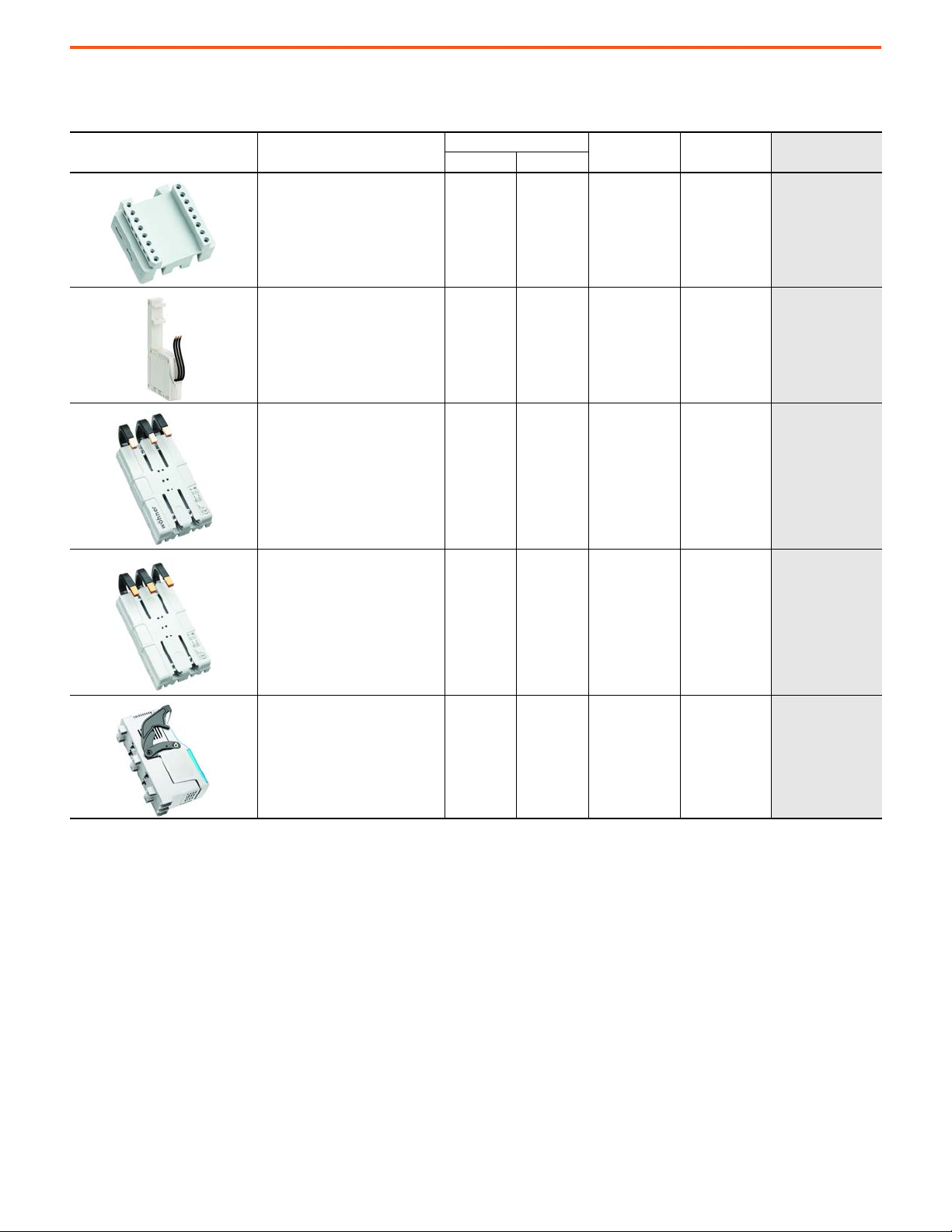

Adapters, 3 Poles

141C Crossboard® Mounting System Product Selection

Adapters, 1 Pole

Description

3-Pole Adapter

• without electrical connection

• 1 adjustable mounting rail

3-Pole Adapter

• 1 adjustable mounting rail

Description Connection

Rated Thermal Current [A]

IEC UL

— — 45 (1.77) 1

16 12

25 25 1 141C-45R25

32 30 1

45 45 1 141C-45R45

Rated Thermal Current [A]

IEC UL

Width [mm (in.)] Pkg. Qty. Cat. No.

1 141C-45R16

45 (1.77)

Width

[mm (in.)]

Pkg. Qty. Cat. No.

141C-45R

141C-45R32

1-Pole Adapter

• without electrical connection

• 1 adjustable mounting rail

1-Pole Adapter

•#14 AWG wires

• 1 fixed mounting rail

• White indicator shows

which pole is active

1-Pole Adapter

•#8 AWG wires

• 1 fixed mounting rail

• White indicator shows

which pole is active

•L1

•Top busbar

•L2

•Middle busbar

•L3

• Bottom busbar

•L1

•Top busbar

•L2

•Middle busbar

•L3

• Bottom busbar

——18 (0.71)6

16 16 18 (0.71) 6

16 16 18 (0.71) 6 141C-18S16L2

16 16 18 (0.71) 6

63 63 18 (0.71) 6 141C-18S63L1

63 63 18 (0.71) 6

63 63 18 (0.71) 6 141C-18S63L3

141C-18S

141C-18S16L1

141C-18S16L3

141C-18S63L2

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 5

Page 6

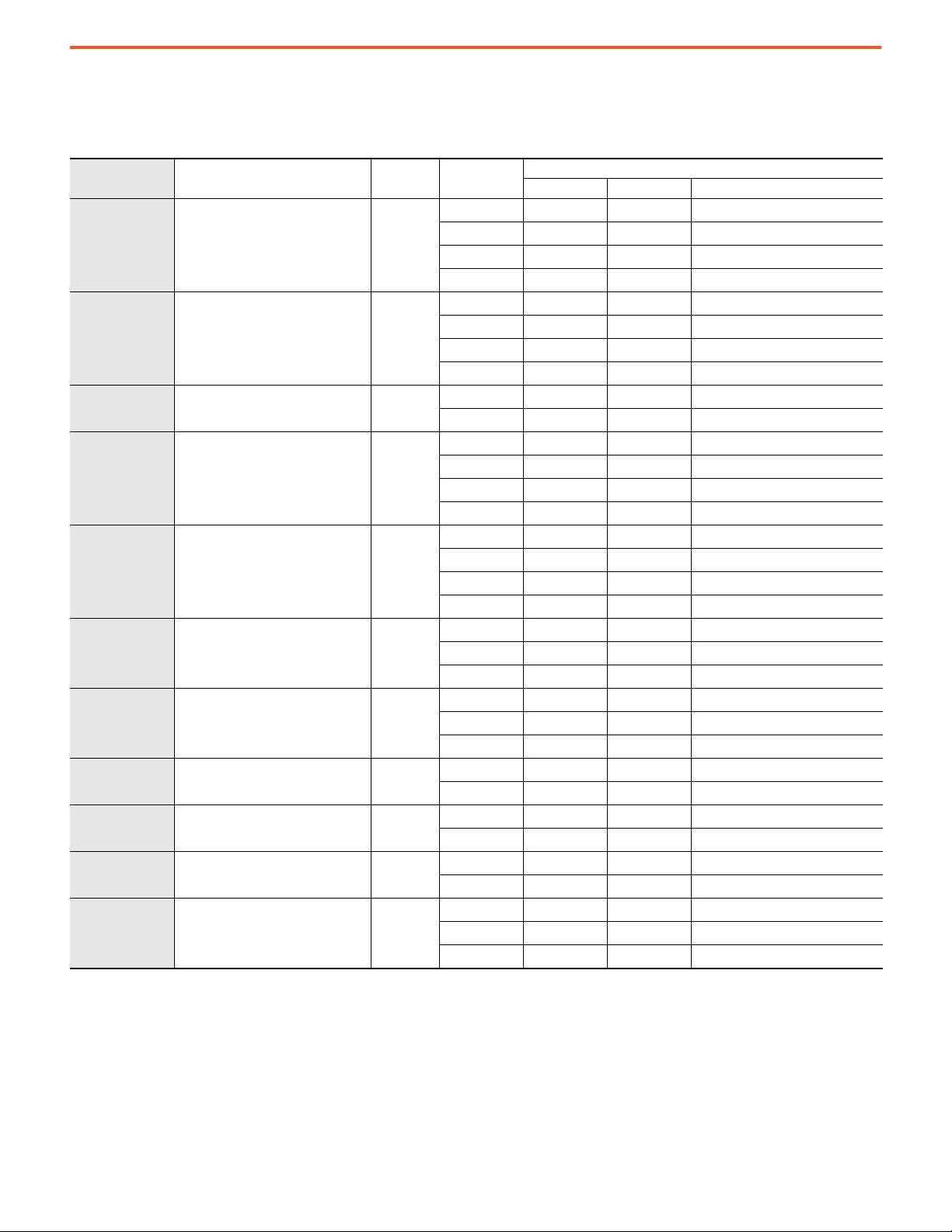

141C Crossboard® Mounting System Accessories

Accessories

Description

Adapter Extension Module

• For 45 mm adapters

Fuse Holder

• For 10 x 38 and Class CC fuses

•3-pole

• 1 fixed mounting rail

Breaker Adapter

• For 140G-G Molded Case Circuit

Breaker (MCCB)

• Universal Terminals for Top or

Bottom Mount

Rated Thermal Current [A]

IEC UL

— — 45 (1.77) 8

16 12.5 22.5 (0.89) 1

160 100 90 (3.54) 1

Width [mm (in.)] Pkg. Qty. Cat. No.

141C-X40

141C-23S16F

141C-GGU

Breaker Adapter

•For 140G-H MCCB

• Universal Terminals for Top or

Bottom Mount

Fused Switch Disconnector 125 49.5 (1.95) 1

160 100 90 (3.54) 1

141C-GHU

141C-NFD125

6 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 7

Specifications

Table 1 - Short-circuit Current Rating (SCCR)

141C Crossboard® Mounting System Specifications

Cat. No. Description Rating SCCR [kA]

10 kA 600V — None (3-cycle)

141C-B225 Busbar base, 225 mm (8.86 in.) 600V/100 A

141C-B405 Busbar base, 405 mm (15.94 in.) 600V/100 A

141C-VN16 Connection module, 22.5 mm (0.89 in.) 600V/48 A

141C-VN50 Connection module, 45 mm (1.77 in.) 600V/100 A

141C-18S16L1

141C-18S16L2

141C-18S16L3

141C-18S63L1

141C-18S63L2

141C-18S63L3

141C-45R16 Busbar adapter, 3-pole, 45 mm (1.77 in.) 600V/12 A

141C-45R25 Busbar adapter, 3-pole, 45 mm (1.77 in.) 600V/25 A

141C-45R32 Busbar adapter, 3-pole, 45 mm (1.77 in.) 600V/30 A

141C-45R45 Busbar adapter, 3-pole, 45 mm (1.77 in.) 600V/45 A

141C-GGU

141C-GHU

Busbar adapter, 1-pole, 18 mm (0.71 in.) 600V/16 A

Busbar adapter, 1-pole, 18 mm (0.71 in.) 600V/63 A

Busbar adapter, 3-pole, 90 mm (3.54 in.) 600V/125 A

100 kA 480V 125 A Circuit breaker (DIVQ)

65 kA 600V 125 A Circuit breaker (DIVQ)

100 kA 600V 175 A Fuse (Class J)

10 kA 600V — None (3-cycle)

100 kA 480V 125 A Circuit breaker (DIVQ)

65 kA 600V 125 A Circuit breaker (DIVQ)

100 kA 600V 175 A Fuse (Class J)

6 kA 600V — None (3-cycle)

50 kA 600V 50 A Fuse (Class J)

10 kA 600V — None (3-cycle)

100 kA 480V 125 A Circuit breaker (DIVQ)

65 kA 600V 125 A Circuit breaker (DIVQ)

100 kA 600V 175 A Fuse (Class J)

6 kA 600V — None (3-cycle)

50 kA 600V 20 A Fuse (Class CC)

14 kA 480/277V 20 A Circuit breaker (DIVQ)

65 kA 480/277V 16 A NKJH type E

6 kA 600V — None (3-cycle)

10 kA 480/277V 30 A Circuit breaker (DIVQ)

65 kA 480/277V 65 A NKJH type E

5 kA 600V — None (3-cycle)

50 kA 600V 20 A Fuse (Class CC)

65 kA 480V 12 A NKJH type E

5 kA 600V — None (3-cycle)

65 kA 480V 32 A NKJH type E

5 kA 600V — None (3-cycle)

65 kA 480V 32 A NKJH type E

6 kA 600V — None (3-cycle)

65 kA 480V 55 A NKJH type E

10 kA 600V — None (3-cycle)

100 kA 480V 125 A Circuit breaker (DIVQ)

42 kA 600V 125 A Circuit breaker (DIVQ)

Protection

Vol tag e Cu rren t Typ e

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 7

Page 8

141C Crossboard® Mounting System Specifications

General Data

Table 2 - Main Circuits

Attribute Value

Rated insulation

voltage U

i

Rated impulse withstand voltage U

Rated frequency [Hz] 50…60

Pollution degree 2

Protection class

Standards Compliance

Certifications CE, cULus Listed

IEC, EN [V] 690

UL, CSA [V] 600

imp

Adapters and busbars IP00

Adapters and busbars mounted on

plate, connected conductors, and

usage of busbar covers

[kV] 6

•IEC/EN 61439-1:2011

•UL 508

• CSA C22.2, No 14

• EN 60947-1 + A1:2007

• EN 60947-1 + A2:2011

•EN 60947-3 + A1:2008

•EN 60947-3 + A2:2012

IP20

Table 3 - Adapter Data

3-Pole Adapters 1-Pole Adapters

141C-45R16 141C-45R25 141C-45R32 141C-45R45 141C-18S16… 141C-18S63…

Rated current at 60 °C I

Flexible with ferrule

Insulation rating of conductors 105 °C (221 °F) 105 °C (221 °F)

(1) The admissible load of a complete system depends on the system topography and the application parameters. Factors of influence are ambient temperature, air

circulation, busbar load, distribution of busbar load, mix of adapters and switchgear components.

(1)

th

[A] 16 25 32 45 16 63

2

[mm

[AWG] 14 12 10 8 14 8

2.5 4 6 10 2.5 10

]

Table 4 - Weights

Cat. No. Weight [g] Cat. No. Weight [g]

141C-VN16 182 141C-18S 44

141C-VN20 272 141C-45R 89

141C-B225 765 141C-45R16 109

141C-B405 1326 141C-45R25 117

141C-18S16L1 51 141C-45R32 124

141C-18S16L2 51 141C-GGU 519

141C-18S16L3 51 141C-GHU 519

141C-18S63L1 72 141C-45R45 150

141C-18S63L2 72 141C-X40 18

141C-18S63L3 72 141C-NFD125 422

141C-23S16F 92

8 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 9

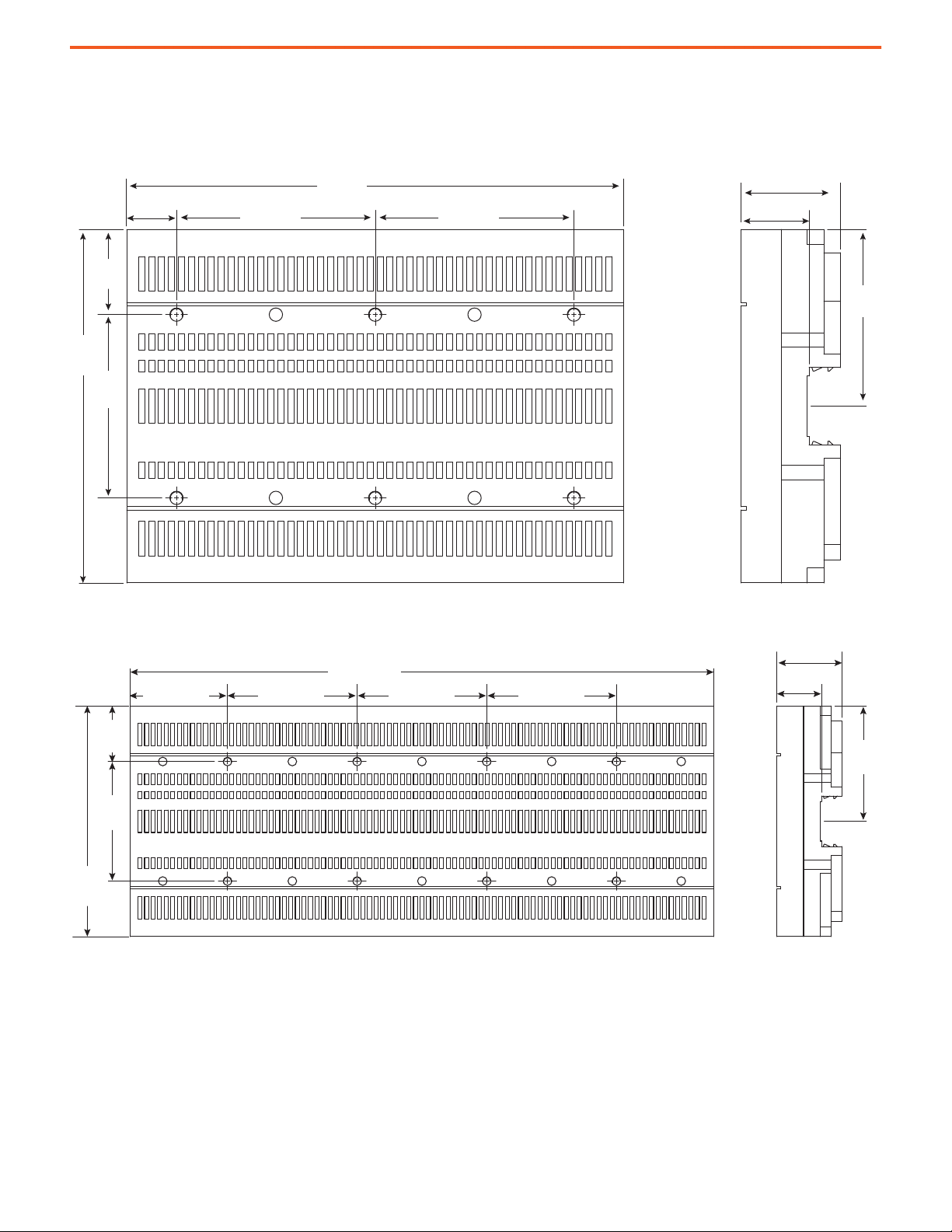

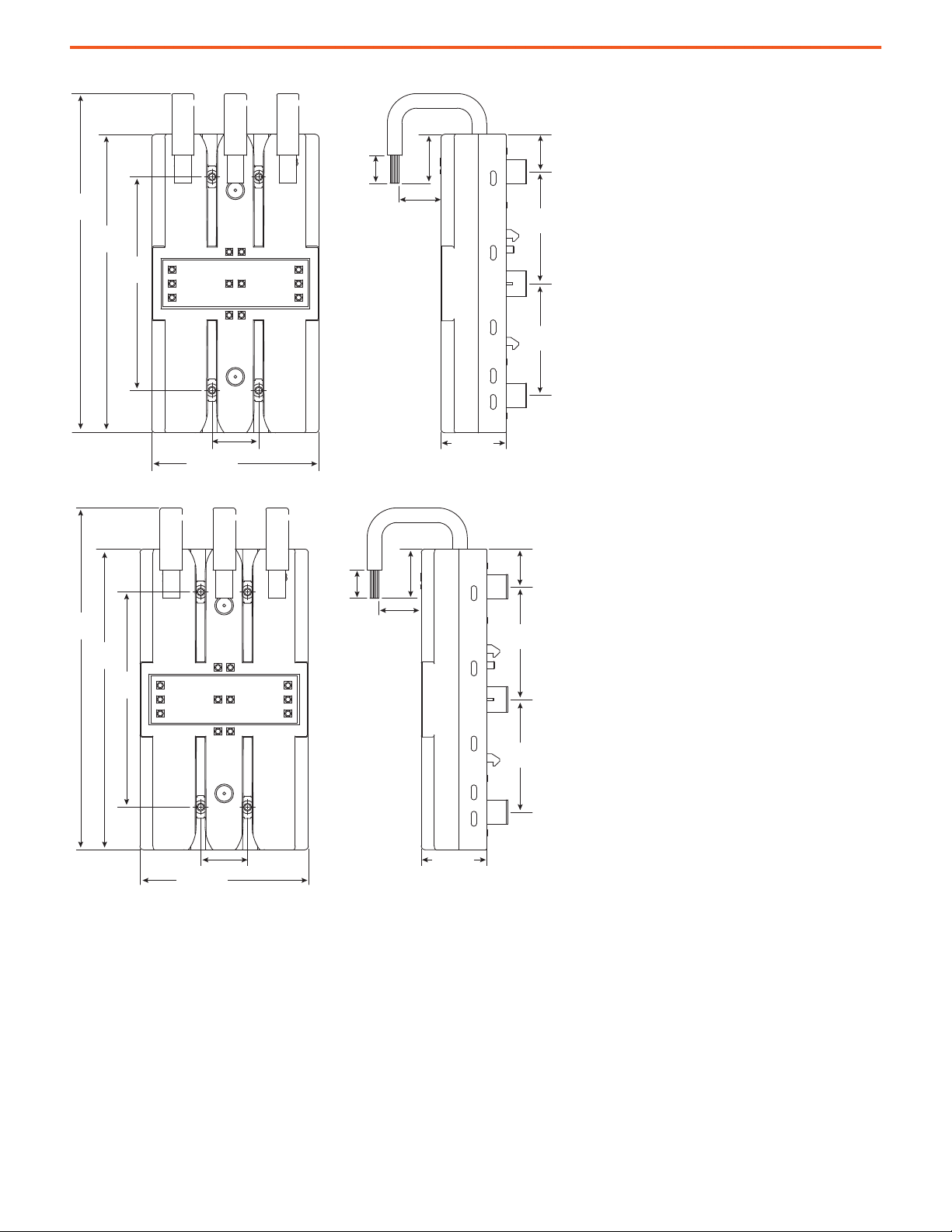

141C Crossboard® Mounting System Approximate Dimensions

160.0

(6.3)

83

(3.27)

90.0 (3.54)

45.1 (1.78)

80

(3.15)

30.9 (1.22)

38.5

(1.52)

22.5

(0.89)

225 (8.86)

90.0 (3.54)

160.0

(6.3)

83

(3.27)

38.5

(1.52)

67.5 (2.66) 90.0 (3.54)

405 (15.94)

90.0 (3.54) 90.0 (3.54)

45.1

(1.78)

80

(3.15)

30.9

(1.22)

Approximate Dimensions

Dimensions are in millimeters (inches.) and are not intended to be used for manufacturing purposes.

Figure 1 - Cat. No. 141C-B225 Busbar System Base

Figure 2 - Cat. No. 141C-B405 Busbar System Base

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 9

Page 10

141C Crossboard® Mounting System Approximate Dimensions

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

160.0

(6.3)

99.0 (3.9)

22.1

(0.87)

110.0 (4.33)

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

160.0

(6.3)

81.5 (3.21)

45.0 (1.77)

92.5 (3.64)

Figure 3 - Cat. No. 141C-VN16 Connection Module with Spring Terminals

Figure 4 - Cat. No. 141C-VN50 Connection Module with Box Terminals

10 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 11

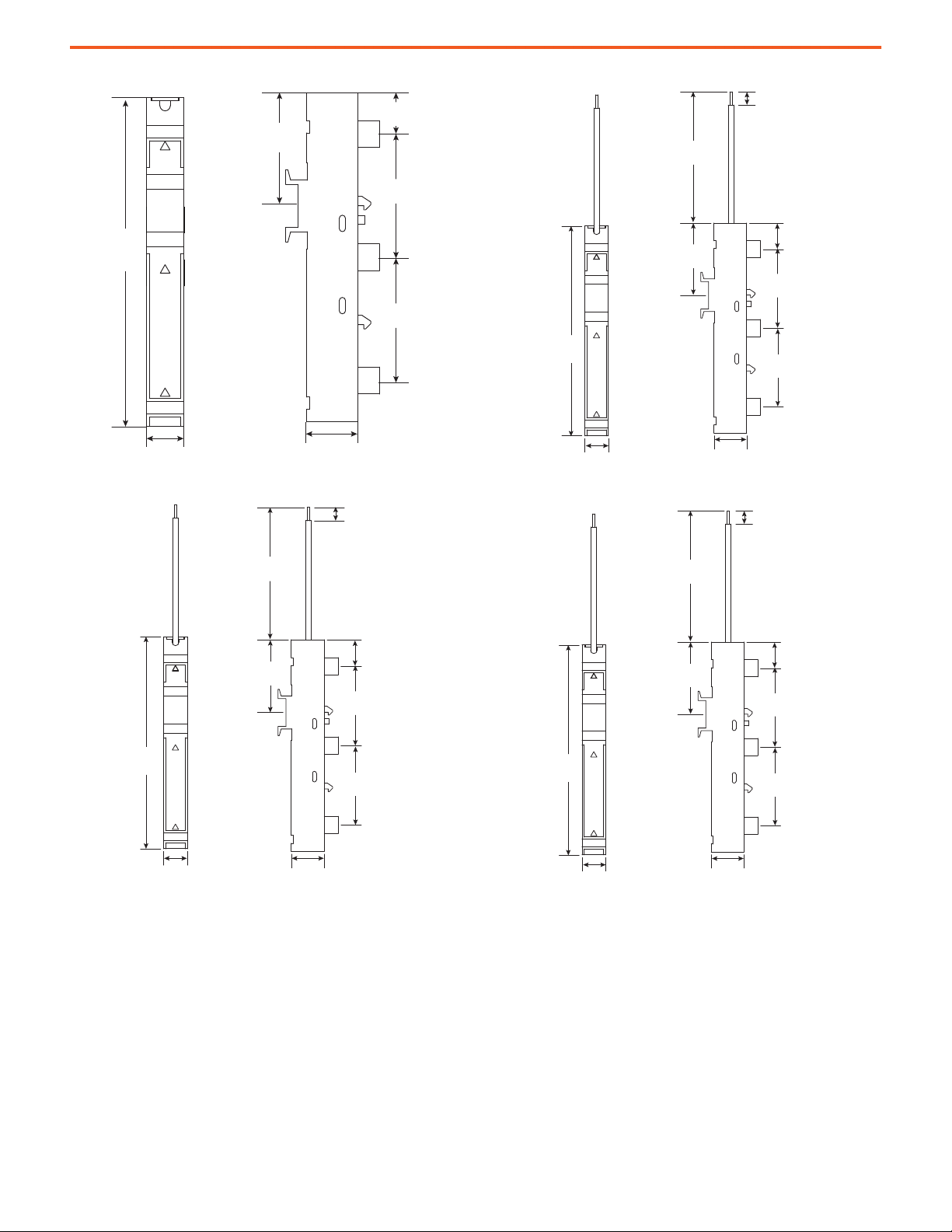

141C Crossboard® Mounting System Approximate Dimensions

160.0

(6.3)

45.0 (1.77)

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

55

(2.17)

24.5

(0.96)

160.0

(6.3)

45.0 (1.77)

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

55

(2.17)

24.5

(0.96)

120.0

(4.72)

10.0 (0.39)

Figure 5 - Cat. No. 141C-45R 3-Pole Adapter

Figure 6 - Cat. No. 141C-45R16 3-Pole Adapter

Figure 7 - Cat. No. 141C-R25, -R32, and -R45 3-Pole Adapters

10.0 (0.39)

100.0

(3.94)

20.0

60.0

(2.36)

60.0

(2.36)

(0.79)

160.0

(6.3)

45.0 (1.77)

55

(2.17)

24.5

(0.96)

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 11

Page 12

141C Crossboard® Mounting System Approximate Dimensions

45.1 (1.78) 24.5 (0.96)

46.0

(1.81)

39.8

(1.57)

160.0

(6.3)

60.0

(2.36)

20.0

(0.79)

22.3

(0.88)

60.0

(2.36)

22.5

(0.89)

62.5

(2.46)

75.0 (2.95)130.9 (5.15)

Figure 8 - Cat. No. 141C-X40 Adapter Extension Module

Figure 9 - Cat. No. 141C-23S16F Fuse Holder

12 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

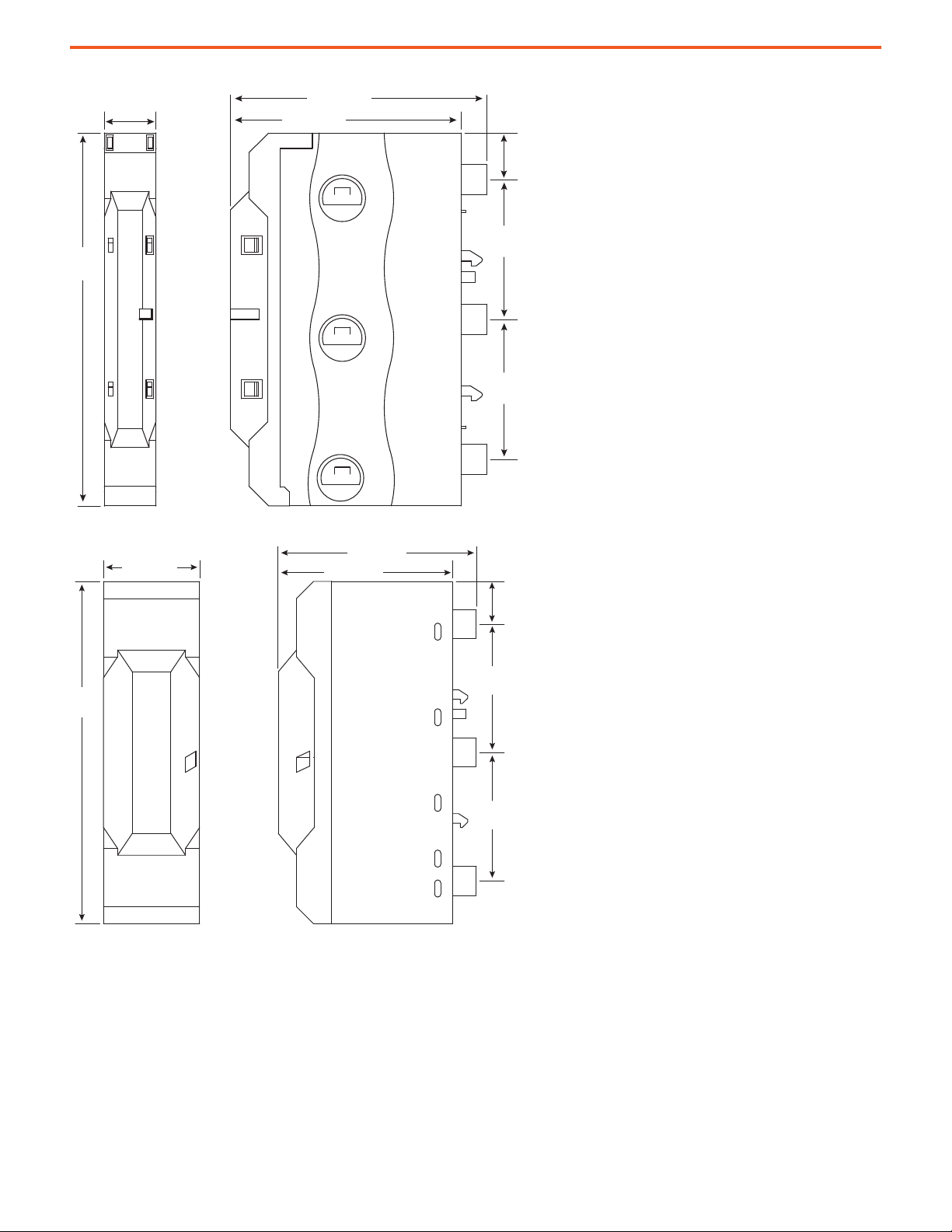

Page 13

Figure 10 - Cat. No. 141C-GGU Breaker Adapter

25.0 (0.98)

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

160.0

(6.3)

90.0 (3.54)

22.6

(0.89)

35.0 (1.38)

181.9

(7.16)

114.5

(4.51)

26.2

(1.03)

15.0

(0.59)

30.0 (1.18)

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

160.0

(6.3)

90.0 (3.54)

22.6

(0.89)

35.0 (1.38)

181.9

(7.16)

114.5

(4.51)

26.2

(1.03)

15.0

(0.59)

141C Crossboard® Mounting System Approximate Dimensions

Figure 11 - Cat. No. 141C-GHU Breaker Adapter

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 13

Page 14

141C Crossboard® Mounting System Approximate Dimensions

160.0

(6.3)

18.0

(0.71)

20.0

(0.79)

55

(2.17)

60.0

(2.36)

60.0

(2.36)

25.0

(0.98)

160.0

(6.3)

18.0

(0.71)

25.0

(0.98)

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

55

(2.17)

100.0

(3.94)

10.0 (0.39)

160.0

(6.3)

18.0

(0.71)

25.0

(0.98)

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

55

(2.17)

100.0

(3.94)

10.0 (0.39)

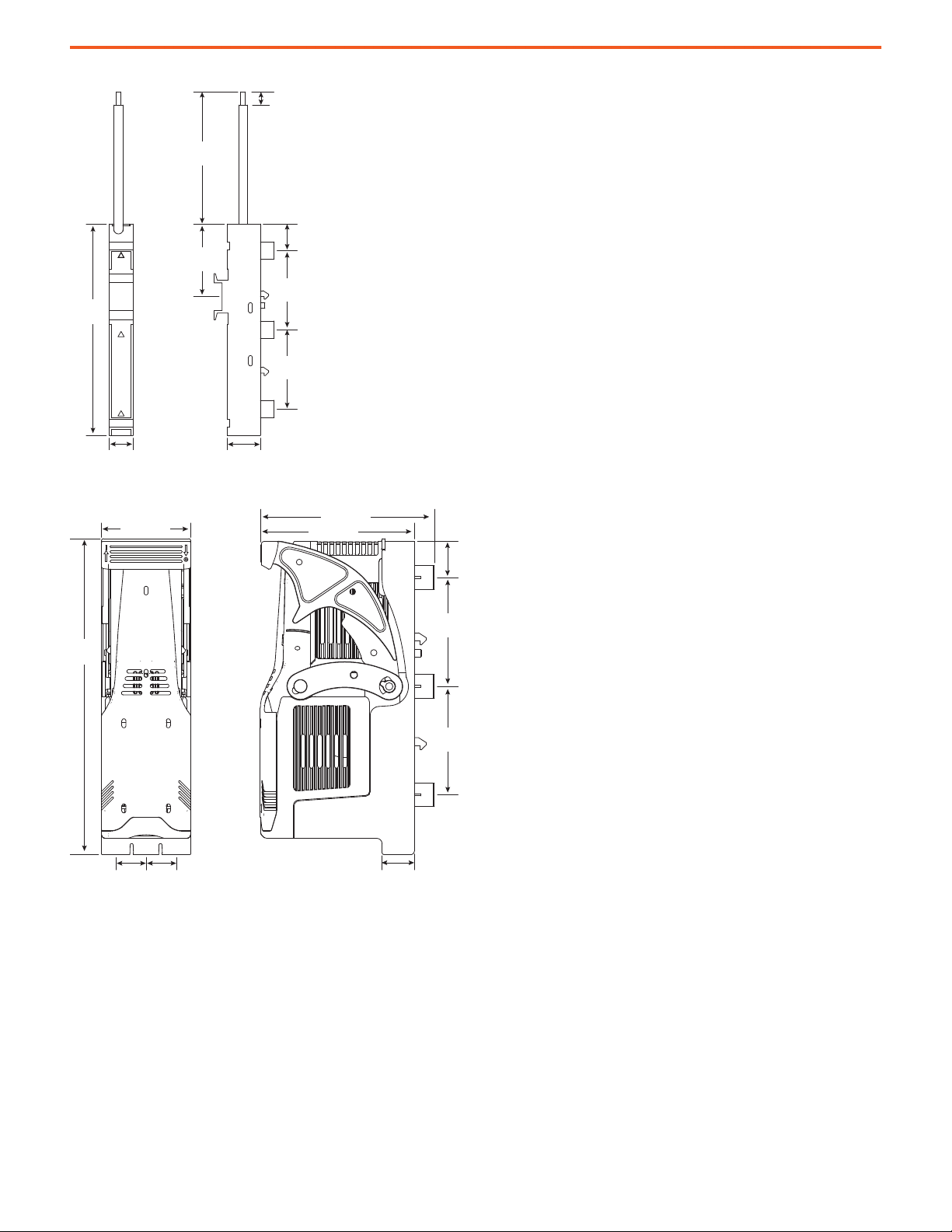

Figure 12 - Cat. No. 141C-18S 1-Pole Adapter

Figure 13 - Cat. No. 141C-181S6L1 1-Pole Adapter

Figure 14 - Cat. No. 141C-18S16L2 1-Pole Adapter

Figure 15 - Cat. No. 141C-18S16L3 1-Pole Adapter

10.0 (0.39)

160.0

(6.3)

18.0

(0.71)

60.0

(2.36)

55

(2.17)

25.0

(0.98)

60.0

(2.36)

60.0

(2.36)

20.0

(0.79)

14 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 15

Figure 16 - Cat. No. 141C-18S63L1, -L2, and -L3 1-Pole Adapters

20.0

(0.79)

60.0

(2.36)

60.0

(2.36)

18.0

(0.71)

16.6

(0.65)

49.5 (1.95)

174.5

(6.87)

16.6

(0.65)

85.0 (3.35)

95.8 (3.77)

10.0 (0.39)

100.0

(3.94)

20.0

60.0

(2.36)

60.0

(2.36)

(0.79)

160.0

(6.3)

55

(2.17)

141C Crossboard® Mounting System Approximate Dimensions

18.0

(0.71)

25.0

(0.98)

Figure 17 - Cat. No. NFD125 Fuse Switch Disconnector

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 15

Page 16

141C Crossboard® Mounting System Approximate Dimensions

Notes:

16 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 17

141A Classic Mounting System

Catalog Number Explanation

Examples that are given in this section are not intended to be used for product selection. Not all combinations produce a valid catalog

number.

Busbar Adapters

141A – C S 45 R R 16

abcdefg

ab cd

Bulletin Number Type Length Width

Code Description Code Description Code Description Code Description

141A Classic Mounting System G Standard busbar adapter S Short: 200 mm (7.87 in.) 45 45 mm (1.77 in.)

F Standard busbar adapter with terminals M Medium: 260 mm (10.2 in.) 54 54 mm (2.13 in.)

C Compact busbar adapter L Long: 320 mm (12.6 in.) 63 63 mm (2.48 in.)

72 72 mm (2.83 in.)

81 81 mm (3.19 in.)

90 90 mm (3.54 in.)

108 108 mm (4.25 in.)

110 110 mm (4.33 in.)

180 180 mm (7.09 in.)

270 270 mm (10.63 in.)

efg

Top Hat Rail Bottom Hat Rail Current Rating

Code Description Code Description Code Description

R Plastic hat rail R Rockwell Automation custom plastic rail Blank 0 A (no electrical connection)

S Plastic hat rail S Standard plastic rail 16 16 A

M Metal hat rail Blank No bottom rail 25 32 A

Screw mounting, variable

V

positions

45 63 A

125 125 A

200 200 A

250 250 A

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 17

Page 18

141A Classic Mounting System Catalog Number Explanation

Iso (Isolation) Busbar Adapters

141A – S M 45 R S 25

abcdefg

abcd

Bulletin Number Type Length Width

Code Description Code Description Code Description Code Description

141A Classic Mounting System S Iso busbar adapter S Short: 200 mm (7.87 in.) 45 45 mm (1.77 in.)

M Medium: 260 mm (10.2 in.) 54 54 mm (2.13 in.)

63 63 mm (2.48 in.)

ef g

Top Hat Rail Bottom Hat Rail Current Rating

Code Description Code Description Code Description

R Plastic hat rail R Plastic hat rail Blank 0 A (no electrical connection)

S Plastic hat rail S Plastic hat rail

25

45 45 A

Width "c" 45 mm (1.77 in.) = 25 A

Width "c" 54 mm (2.13 in.) = 32 A

Busbar Adapters for Bulletin 140G Molded Case Circuit Breakers, 140MG Motor Protection Circuit Breakers, and 140MG Motor Circuit Protectors

141A – G H T

abcd

ab cd

Bulletin Number Type Length Width

Code Description Code Description Code Description Code Description

141A Classic Mounting System

Busbar adapters for Bulletin 140G

G

and MG devices

H Frame size G, Frame size H T Top Connection

J Frame size J B Bottom Connection

K Frame size K U Universal Connection

M Frame size M

Panel Mounting Modules

141A – W M 45 R R

abcdef

ab c def

Bulletin Number Type Length Width Top Hat Rail Bottom Hat Rail

Code Description Code Description Code Description Code Description Code Description Code Description

Classic Mounting

141A

System

W

Panel mounting

module

S Short: 200 mm (7.87 in.) 45 45 mm (1.77 in.) R Plastic hat rail R Plastic hat rail

M Medium: 260 mm (10.2 in.) 54 54 mm (2.13 in.)

L Long: 320 mm (12.6 in.)

18 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 19

141A Classic Mounting System Product Selection

Product Selection

Iso Busbar Adapters

• Two-part construction

- Device Adapter Plate (DAP) (carrying the starter) snaps onto the base adapter

- Base adapter remains on busbar when exchanging starters, providing isolation from live parts

• Test position with load circuit isolated

• Optional control plug makes the starter fully pluggable

• Adapters with assigned current ratings supply the load current to the starter/load feeder by means of wire connections

• Multiple adapters can be combined to bigger platforms by use of the connection clips

• Fits on 5 mm (0.19 in.) or 10 mm (0.39 in.) thick busbars

• Meets UL 508A feeder circuit spacing requirements

Description

Iso Busbar Adapters with Wires - Short Length

• Wires on Device Adapter Plates for electrical

connection

Iso Busbar Adapters without Wires - Short Length

• Two connection clips included

Iso Busbar Adapters with Wires - Medium Length

• Wires on Device Adapter Plates for electrical

connection

Iso Busbar Adapters without Wires - Medium Length

• Two connection clips included

(1) Iso Busbar Adapters without electrical connections include two connection clips. They are intended to form bigger platforms, for example: reversing starters, starters with Smart Motor

Controllers or PowerFlex® drives.

(1)

(1)

Rated Thermal

Current I

th

25 45 (1.77)

32 54 (2.13)

45 54 (2.13) 141A-SS54RR45

45 63 (2.48)

Without

electrical

connections

25 45 (1.77)

32 54 (2.13)

45 54 (2.13)

45 63 (2.48) 141A-SM63RS45

Without

electrical

connections

[A]

Width

[mm (in.)]

45 (1.77)

54 (2.13)

45 (1.77)

54 (2.13)

63 (2.48)

Length

[mm (in.)]

200 (7.87) 2 1

200 (7.87) 1 1

260 2 1

260 1 1

Rails Pkg. Qty.

Cat. No.

141A-SS45RR25

141A-SS54RR25

141A-SS63RR45

141A-SS45R

141A-SS54R

141A-SM45RS25

141A-SM54RS25

141A-SM54RS45

141A-SM45S

141A-SM54S

141A-SM63S

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 19

Page 20

141A Classic Mounting System Product Selection

Standard Busbar Adapters

• Adapters plug directly onto the busbar

• Suitable for use with control plug

• Adapters with assigned current ratings supply the load current to the starter/load feeder by means of wire connections

• Multiple adapters can be combined to bigger platforms by use of the connection clips

• Fits on 5 mm (0.19 in.) or 10 mm (0.39 in.) thick busbars

• Meets UL 508A feeder circuit spacing requirements

Description

Standard Busbar Adapters with Wires - Short Length

• Wires for electrical connection

Standard Busbar Adapters with Flexible Busbar

Connectors - Short Length

•Metal Hat Rail

• For starters with 140MG-G/-H circuit protectors

Standard Busbar Adapters without Wires — Short

Length

• Two connection clips included

Standard Busbar Adapters with Wires — Medium

Length

• Wires for electrical connection

Standard Busbar Adapters without Wires — Medium

Length

• Two connection clips included

(2)

(2)

Rated Thermal

Current I

125 (160

Without electrical

connections

Without electrical

connections

Width

[A]

[mm (in.)]

th

16

32

63

32

63

45 (1.77)

54 (2.13)

45 (1.77) 141A-GS45RR25

54 (2.13)

54 (2.13)

63 (2.48) 141A-GS63RR45

81 (3.19)

180 (7.09)

(1)

)

270 (10.63)

45 (1.77)

54 (2.13) 141A-GS54R

72 (2.83)

81 (3.19)

45 (1.77)

54 (2.13)

54 (2.13)

63 (2.48)

45 (1.77)

54 (2.13)

63 (2.48)

Length

[mm (in.)]

200 (7.87) 2

200 (7.87) 1

200 (7.87) 1

260 (10.23) 2

260 (10.23) 1

Rails Pkg. Qty.

Cat. No.

141A-GS45RR16

141A-GS54RR16

141A-GS54RR25

141A-GS54RR45

1

1

141A-GS81SS63

141A-GS180M125

141A-GS270M125

141A-GS45R

141A-GS72S

141A-GS81S

141A-GM45RS25

141A-GM54RS25

141A-GM54RS45

141A-GM63RS45

141A-GM45S

141A-GM54S

141A-GM63S

(1) IEC Rating = 160 A

(2) Standard Busbar Adapters without electrical connections include two connection clips. They are intended to form bigger platforms; for example: for reversing starters, starters with Smart

Motor Controllers or PowerFlex drives.

20 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 21

141A Classic Mounting System Product Selection

Standard Busbar Adapters with Terminals

• Adapters plug directly onto the busbar

• Adapters ≤ 81 mm (3.19 in.) wide can be combined to bigger platforms by use of the connection clips

• Fits on 5 mm (0.19 in.) or 10 mm (0.39 in.) thick busbars

• Meets UL 508A feeder circuit spacing requirements

Description

Rated Thermal

Current I

th

(1)

25

Standard Busbar Adapters with Terminals

•Short Length

• With terminals for electrical connection

(2)

80

(1)

25

Standard Busbar Adapters with Terminals

• Medium Length

• With terminals for electrical connection

(2)

80

Standard Busbar Adapter with Terminals on Top

• With box terminals on top for electrical connection

• Wire size: 70 mm

2

(2/0 AWG)

200 108 (4.25) 222 (8.74)

• Universal mounting capability with sliding pocket nuts (M4)

Standard Busbar Adapter with Terminals on Top

• With box terminals on top for electrical connection

• Wire size: 120 mm2 (250 MCM)

250 110 (4.33) 320 (12.6)

• Universal mounting capability with sliding pocket nuts (M4)

(1) Terminal size: 6 mm2 (10 AWG). Requires a Cat. No. 141A-FTS25 spacing adapter for UL 508A applications.

(2) Terminal size: 16 mm2 (6 AWG). Requires a Cat. No. 141A-FTS63 spacing adapter for UL 508A applications.

[A]

Width

[mm (in.)]

Length

[mm (in.)]

Rails Pkg. Qty.

45 (1.77)

54 (2.13) 141A-FS54S63

63 (2.48) 141A-FS63S63

200 (7.87) 1

72 (2.83)

81 (3.19)

45 (1.77)

1

54 (2.13) 141A-FM54SS63

63 (2.48)

260 (10.23) 2

72 (2.83) 141A-FM72SS63

81 (3.19) 141A-FM81SS63

— 1

Cat. No.

141A-FS45S25

141A-FS72S63

141A-FS81S63

141A-FM45SS25

141A-FM63SS63

141A-FS108V200T

141A-FL110V250T

Busbar Adapters for Circuit Breakers

Description For Use With

Standard Busbar Adapters with Flexible

Connecting Bars for Electrical Connection

• Meets UL 508A feeder circuit spacing

requirements

– Terminal lugs for circuit breaker 140G-_-TL*

required, sold separately

Standard Busbar Adapters with Flexible

Connecting Bars for Electrical Connection

• Meets UL 508A feeder circuit spacing

requirements

– Terminal lugs for circuit breaker 140G-_-TL*

required, sold separately

Standard Busbar Adapters with Rear Connecting

Studs for Electrical Connection

• Meets UL 508A feeder circuit spacing

requirements

(1) IEC rating = 160 A

140G G-Frame

140MG G-Frame

140G H-Frame

140MG H-Frame

(Top Connection)

140G G-Frame

140G H-Frame

(Bottom Connection)

140G J-Frame

140MG J-Frame

(Top Connection)

140G J-Frame

140MG J-Frame

(Bottom Connection)

140G K-Frame

140MG K-Frame

(Top or Bottom

Connection)

140G M-Frame

140MG M-Frame

(Top or Bottom

Connection)

Rated Thermal

Current I

125 (160

125 (160

Width [mm] Pkg. Qty.

[A]

th

(1)

(1)

90 (3.54)

)

90 (3.54)

)

250 105 (4.13)

1

250 105 (4.13)

400 140 (5.51) 141A-GKU

600 238 (9.37) 141A-GMU

Cat. No.

141A-GHT

141A-GHB

141A-GJT

141A-GJB

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 21

Page 22

141A Classic Mounting System Product Selection

Accessories for Standard and Iso Busbar Adapters

Description Width [mm (in.)] Pkg. Qty. Cat. No.

Top Hat Rail s

• 35 mm (1.38 in.)

• Slides onto busbar adapters, fixation with 1 or 2 screws (included)

Control Plug

• Pull-apart terminal block allows fast and simple disconnection of control

wiring.

• Control Plug Holder included.

45 (1.77)

54 (2.13)

63 (2.48)

72 (2.83) 141A-AHS72

81 (3.19)

8 Pole 1

10 Pole 1

12 Pole 1

10

141A-AHR45

141A-AHR54

141A-AHR63

141A-AHS81

141A-APC8

141A-APC10

141A-APC12

Control Plug Holder

• Suitable for use with 8-, 10-, or 12-pole control plugs.

Spacer module for Standard or ISO busbar adapters

• For 9 mm (0.35 in.) spacing of busbar adapters.

• Use included connection clips (Cat. No. 141A-AK) for attaching the spacer

module to the busbar adapters.

• 200 mm (7.87 in.) long

Connection Clip

• For joining multiple busbar adapters and spacer modules (as spare parts only, typical required

quantity included with the adapters)

Micro Switch

• 1 N.C. Contact

• For Iso busbar adapters only. Automatically drops out the contactor when the DAP (Device Adapter

Plate) (carrying the starter) is unplugged from the base of the Iso busbar adapter.

Terminal Shroud

• Required for UL 508A applications

• For use with 25 A standard busbar adapters with terminals (Cat. No. 141A-FS…25, 141A-FM…25)

• For use with 63 A standard busbar adapters with terminals (Cat. No. 141A-FS…63, 141A-FM…63) 4

9 (0.35) 10

141A-APH

141A-AS9B

50 141A-AK

10 141A-AS

4

141A-FTS25

141A-FTS63

22 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 23

UL Fuse Bases and Fuse Holders

Description Max Voltage Rating Pkg. Qty. Cat. No.

Fuse base, 3-pole, Class CC

• For UL Class CC fuses

• 27 mm (1.06 in.) wide

• Withstand rating: 200 kA (600V)

• With spring terminals

• Meets UL 508A feeder circuit spacing requirements

Fuse base, 3-pole, Class CC with light-emitting diode (LED)

• For UL Class CC fuses

• 27 mm (1.06 in.) wide

• Withstand rating: 200 kA (600V)

• With spring terminals

• Meets UL 508A feeder circuit spacing requirements

Class J Busbar Fuse Holder

• Top or bottom connection

• For UL Class J fuses

• No tools required to change fuses

• Meets UL 508A feeder circuit spacing requirements

Class J Busbar Fuse Base

• For mounting on 10 mm (0.39 in.) wide and double-T busbars

• Top or bottom connection

• For UL Class J fuses

• Meets UL 508A feeder circuit spacing requirements

141A Classic Mounting System Product Selection

600V 30 A 1

600V 30 A 1 141A-NFHCC30L

30 A 1

60 A 1 141A-NFJ60C

100 A 1

200 A 1

400 A 1

141A-NFHCC30

141A-NFJ30C

141A-NFJ100C

141A-NFJ200C

141A-NFJ400

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 23

Page 24

141A Classic Mounting System Product Selection

Fused and Non-fused IEC Switch Disconnectors

Description Size Terminals Rating Pkg. Qty. Cat. No.

Busbar Fuse Switch

• 3-pole switch disconnector with fuses

• For D02 fuse links for D01

fuses, use reducer

For 10 x 38 NFC cylindrical

fuses

400V AC

690V AC 32 A 1 141A-NF1038

63 A

(1)

1 141A-NF0102

NH Fuse Switch Disconnector

• Connection bottom or top

• Size 00 for plugging on 5 mm (0.19 in.) or 10 mm

(0.39 in.) thick and double-T busbars.

• Sizes 1 and 2 conversion kit 141A-NFAFR5 is required

for plugging on 5 mm (0.19 in.) thick busbars.

• Size 3 only for plugging on 10 mm (0.39 in.) and

double-T busbars.

Switch Disconnector with NH Fuses

• 3-pole, bottom connections

• Multi-function handle

• Lockable in OFF position with 3 padlocks

• FLAG indicator shows the switch status

• Fuse can be changed without tools

• Applicable as main isolator according to

IEC/EN 60204-1 (main switch)

• Main switch only for utilization categories AC-23A/B

(500V/125 A), AC-23B (690V/125 A)

Non-Fused Switch Disconnector for External Rotary

Operating Handle

• 3-pole, bottom connections

• FLAG indicator shows the switch status

• Applicable as main isolator as per IEC/EN 60204-1

(main switch)

• Can also be used as an Emergency Off switch in

combination with the door coupling twist handle

• Main switch and Emergency Off switch only for

utilization categories AC-23A/B (500V/125 A) AC-23B

(690V/125 A) (additional extension shaft and door

handle required)

(1) The use of spacer module 141A-NFAD is recommended for a continuous load above 35 A.

Size 00, 200 x 106 mm

(7.87 x 4.17 in.)

Size 1, 243 x 184 mm

(9.57 x 7.24 in.)

Size 2, 288 x 210 mm

(11.34 x 8.27 in.)

Size 3, 300 x 256 mm

(11.81 x 10.08 in.)

Size 00, 200 x 106 mm

(7.87 x 4.17 in.)

Size 1, 286 x 184 mm

(11.26 x 7.24 in.)

Size 00, 200 x 106 mm

(7.87 x 4.17 in.)

Size 1, 286 x 184 mm

(11.26 x 7.24 in.)

Box terminals

2

70 mm

M10

2

120 mm

M10

2

240 mm

M12

2

240 mm

Box terminals

2

70 mm

M10

2

120 mm

Box terminals

2

70 mm

M10

2

120 mm

160 A 1

250 A 1 141A-NFD250

400 A 1

630 A 1

125 A 1

250 A 1 141A-NFD250SB

160 A 1

320 A 1

141A-NFD160

141A-NFD400

141A-NFD630

141A-NFD125SB

141A-N160SB

141A-N320SB

24 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 25

Accessories for Fused Devices

141A Classic Mounting System Product Selection

Description

Pilot Switch

• For use with Cat. No. 141A-NFD* NH-fuse switch disconnectors

• Signaling ON/OFF position of lid

• 250V AC/5 A; 30V DC/4 A

Reducer

• D02 reducer for D01 fuses

• For use with 141A-NF0102

Spacer Module

• Connectable on both sides

• 9 mm (0.35 in.) wide

• For use with 141A-NF*

Conversion Kit

• For NH-fuse switch disconnector to reduce size 1 and 2 on to 5 mm (0.19 in.)

busbars

Pkg.

Qty.

Size 1 (Series B) 1 141A-NFASNC1

Size 00, Size 2…3 1

20

Size 1 and 2 1 141A-NFAFR5

Cat. No.

141A-NFASNFD

141A-NFAR

141A-NFAD

Rotary Operating Handle

• For use with Cat. No. 141A-N160SB or 141A-N320SB non-fused switch

disconnector

•IP66

Operating Shaft

• For use with Cat. No. 141A-NDN66 or 141A-NDRY66 rotary operating handle

Pilot Switch

• For use with Cat. No. 141A-N*SB fused and non-fused switch disconnectors

• 250V AC/5 A; 30V DC/4 A

Black 1

Red/Yellow 1

290 mm (11.42 in.) 1

490 mm (19.29 in.) 1 141A-ND2

Size 00, 1

160/320 A

1 141A-NFASNC0

141A-NDN66

141A-NDRY66

141A-ND1

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 25

Page 26

141A Classic Mounting System Product Selection

H

L

W

40 (1.57)

30

(1.18)

L

L

30

(1.18)

40 (1.57)

Busbars

Height x Width

[mm (in.)]

12 x 5

(0.47 x 0.19)

15 x 5

(0.59 x 0.19)

20 x 5

(0.79 x 0.19)

25 x 5

(0.98 x 0.19)

30 x 5

(1.18 x 0.19)

12 x 10

(0.47 x 0.38)

20 x 10

(0.79 x 0.38)

30 x 10

(1.18 x 0.38)

(1) Ratings shown are based on tested conditions at an ambient temperature of 35 °C (95 °F) and a busbar temperature of 65 °C (149 °F).

Current

Rating [A]

(1)

UL Current

Rating [A]

200 150

250 —

320 362

400 — 141A-B255A 141A-B255C 141A-B255N

450 500

360 300

520 564 141A-B2010A 141A-B2010C 141A-B2010N

630 756

Length = 800 mm (31.5 in.) Length = 1200 mm (47.24 in.) Length = 2400 mm (94.5 in.)

Pkg.

Qty.

Cat. No.

Pkg.

Qty.

141A-B125A

141A-B155A 141A-B155C 141A-B155N

141A-B205A 141A-B205C 141A-B205N

3

3

141A-B305A 141A-B305C 141A-B305N

141A-B1210A 141A-B1210C

141A-B3010A 141A-B3010C 141A-B3010N

TT Busbars

Height x Width [mm (in.)] Size

Current Rating [A]

(1)

UL Current Rating

Cat. No.

141A-B125C

[A]

Pkg.

Qty.

Cat. No.

141A-B125N

12

141A-B1210N

6

Length = 2400 mm (94.5 in.)

Pkg.

Qty.

Cat. No.

TT

2

500 mm

TT

2

720 mm

(1) Ratings shown are based on tested conditions at an ambient temperature of 35 °C (95 °F) and a busbar temperature of 65 °C (149 °F).

920 1200 1 141A-BT11NZ

1175 1400 1 141A-BT12NZ

26 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 27

Busbar Supports

• 60 mm (2.36 in.) pole spacing

Description Busbar Size Pkg. Qty. Cat. No.

Busbar Support

• 3-pole with inside mounting holes

• Meets UL 508A feeder circuit spacing requirements

•1-pole

• Meets UL 508A feeder circuit spacing requirements

• includes PE and N labels

• 3-pole with inside mounting holes

• for applications according to IEC 61439-1

• approved for branch circuit applications per UL508

• 4-pole with inside mounting holes

• for applications according to IEC 61439-1

• approved for branch circuit applications per UL508

141A Classic Mounting System Product Selection

12, 20, 30 x 5 mm (0.47, 0.79, 1.18

(1)

x 0.19 in.)

or

12, 20, 30 x 10 mm

(0.47, 0.79, 1.18 x 0.38 in.)

12…30 x 5 mm (0.47…1.18 x 0.19

in.)

or

12…30 x 10 mm (0.47…1.18 x 0.38

in.)

10

141A-TU3

1 141A-TR1

141A-TR3

10

141A-TR4

Busbar Support with terminals

• 3-pole, with terminals for electrical connections

• 1.5…16 mm

2

(#16…6 AWG)

Double-T Busbar Support

• 60 mm (2.36 in.) spacing

• Meets UL 508A feeder circuit spacing requirements

(1)

Busbar End Cover

• Prevents contact with the busbar ends and prevents busbars from sliding

• The end cover can easily be clipped on the busbar support

(1) To meet UL 508A spacing requirements, this product also requires support spacers or a rear panel shroud.

12…30 x 5 mm (0.47…1.18 x 0.19

in.)

or

12…30 x 10 mm (0.47…1.18 x 0.38

in.)

3-pole 3 141A-T13

141A-TU3 or 141A-TR3

141A-TR4

141A-T13 4

10 141A-TR3F16

10

141A-TR3E

141A-TR4E

141A-T13E

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 27

Page 28

141A Classic Mounting System Product Selection

3-Pole Supply Modules

• 6…50 mm

• Flat laminated Cu conductors 7 x 4…9 x 6 mm

(0.28 x 0.16…0.35 x 0.24 in.)

• 54 mm (2.13 in.) wide

• Meets UL 508A feeder circuit spacing requirements

• Round conductors 16…120 mm

• Flat laminated Cu conductors 12 x 4 - 15.5 x 10 mm

(0.47 x 0.16…0.61 x 0.38 in.)

• 81 mm (3.19 in.) wide

For Round conductors

For Flat Conductors

Set of 3 terminals

• Meets UL 508A feeder circuit spacing requirements

• 95…185 mm

• 135 mm (5.31 in.) wide

•95…300 mm

• 135 mm (5.31 in.) wide

• Approved for branch circuit applications per UL508

• Up to 32 x 20 mm (1.26 x 0.79 in.)

• Equivalent to 625 mm

• 135 mm (5.31 in.) wide

• For round conductors

•95…300 mm

• 153 mm (6.02 in.) wide (3 single poles of 51 mm (2.01 in.) each)

• Meets UL 508A feeder circuit spacing requirements

• Requires Cat. No. 141A-BK180 or 141A-BK228 terminal cover

• For flat conductors up to 32 x 20 mm (1.26 x 0.79 in.)

• Equivalent to 625 mm2 (1250 MCM)

• 153 mm (6.02 in.) wide (3 single poles of 51 mm (2.01 in.) each)

• Meets UL 508A feeder circuit spacing requirements

• requires Cat. No. 141A-BK180 or 141A-BK228 terminal cover

Description Busbar Size Pkg. Qty. Cat. No.

2

(10…2/0 AWG)

12…30 x 5 mm

1

141A-VN370

(0.47…1.18 x 0.19 in.)

or

2

(6 AWG…250 MCM)

12…30 x 10 mm

(0.47…1.18 x 0.38 in.)

or

TT

1

141A-VN3120

12…30 x 5 mm

(0.47…1.18 x 0.19 in.)

2

(3/0 AWG…350 MCM)

or

12…30 x 10 mm

1 141A-VN3185

(0.47…1.18 x 0.38 in.)

or

TT

2

(3/0 AWG…600 MCM)

2

(1250 MCM) round conductor ampacity

1

1

141A-VN3300R

141A-VN3300F

12…30 x 5 mm

2

(3/0 AWG…600 MCM)

(0.47…1.18 x 0.19 in.)

or

12…30 x 10 mm

1 141A-VU3300R

(0.47…1.18 x 0.38 in.)

or

TT

1 141A-VU3300F

Single Terminals for Connecting to Busbars

Description Busbar Size Pkg. Qty. Cat. No.

2.5…16 mm2 (#14…6 AWG)

4…35 mm2 (#12…2 AWG)

16…70 mm2 (#6…2/0 AWG)

2

16…120 mm

(#6…250 MCM)

12…30 x 5 mm (0.47…1.18 x 0.19 in.)

12…30 x 10 mm (0.47…1.18 x 0.38 in.)

12…30 x 5 mm (0.47…1.18 x 0.19 in.)

12…30 x 10 mm (0.47…1.18 x 0.38 in.) 141A-VS235

12…30 x 5 mm (0.47…1.18 x 0.19 in.)

12…30 x 10 mm (0.47…1.18 x 0.38 in.)

12…30 x 10 mm (0.47…1.18 x 0.38 in.)

Brace Terminals

Description

•3-pole

• For connecting flat or flexible copper busbars

• Meets UL 508A feeder circuit spacing

requirements

28 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Max Terminal Space

(W x H) [mm (in.)]

55 x 28 (2.17 x 1.1)

68 x 28 (2.68 x 1.1)

30 x 10 mm (1.18 x 0.38 in.)

105 x 28 (4.13 x 1.1) 141A-VB710528F

141A-VS116

141A-VS216

141A-VS135

25

141A-VS170

141A-VS270

141A-VS2120

Busbar Size Pkg. Qty. Cat. No.

141A-VB75528F

or TT

1

141A-VB76828F

Page 29

Terminal Covers

Description Busbar Size Pkg. Qty. Cat. No.

Terminal Cover

• Finger protection when busbars supplied with single

terminals

• Attaches directly to busbars.

• Height: 180 mm (7.09 in.), Width: 54 mm (2.13 in.)

141A Classic Mounting System Product Selection

12…30 x 5 mm (0.47…1.18 x 0.19 in.)

or

12…30 x 10 mm (0.47…1.18 x 0.38 in.)

1

141A-BK1

Terminal Cover Kit

• Finger protection when busbars are supplied by Cat. No.

141A-VU3300_ supply module

• Attaches directly to busbars

• Height: 200 mm (7.87 in.)

• Depth: 90 mm (3.54 in.)

Terminal Cover Components

• Customized terminal cover width using end supports, front

shroud, and top/bottom shroud

• Shrouds can be cut to desired width

• Attaches directly to busbars

• Cat. Nos. 141A-BKH, -BKC, and -BKS must be installed

together

Width: 180 mm (7.09 in.) 1

Width: 228 mm (8.98 in.) 1 141A-BK228

Left and right supports 1

Front shroud

1100 mm (43.3 in.)

Top/bottom shroud

1100 mm (43.3 in.)

1

1 141A-BKS

141A-BK180

141A-BKH

141A-BKC

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 29

Page 30

141A Classic Mounting System Product Selection

Busbar Covers and Shrouds

Busbar Shroud Cover

• 200 x 1100 mm (7.87 x 43.3 in.), covers all three busbars

Busbar Shroud Holder

• Two required per section of Busbar Shroud Cover

Description Busbar Size Pkg. Qty. Cat. No.

12…30 x 5 mm

(0.47…1.18 x 0.19 in.)

or

12…30 x 10 mm

(0.47…1.18 x 0.38 in.)

2

10

141A-BCF1

141A-BCF1H

Single-pole Busbar Covers

• Snap-on profile for single busbars for protection against electric shock.

Single-pole Busbar Cover

• For double-T busbars

• Length: 1 m (39.37 in.); can be cut to length

Compartment Section

• Fits to Cat. No. 141A-T13 double-T busbar supports

• Length: 2400 x 48 mm (94.5 x 1.89 in.); can be cut to length

Panel Busbar Shroud

• Provides isolation between busbar and panel (required for feeder circuit

applications per UL508A)

• For use with Cat. No. 141A-TU3 supports. 240 x 810 mm (9.45 x 31.9 in)

Busbar Support Spacer — Standard

• Fits under Standard Busbar Supports, Cat. No. 141A-TU3

• Adds 20 mm (0.79 in.) to the depth of the busbar support

• Fulfills phase-to-ground spacing requirements for UL508A applications

• Panel Busbar Shroud, Cat. No. 141A-BCR, not required

12…30 x 5 mm

(0.47…1.18 x 0.19 in.)

12…30 x 10 mm

(0.47…1.18 x 0.38 in.)

Double-T

All 2

12, 20, 30 x 5 mm

(0.47, 0.79, 1.18 x 0.19 in.)

or

12, 20, 30 x 10 mm

(0.47, 0.79, 1.18 x 0.38 in.)

10

5 141A-BCT1

1 141A-BST48

10

141A-BS5

141A-BS10

141A-BCR

141A-TS3

Busbar Accessories

Description Busbar Size Pkg. Qty. Cat. No.

Busbar Connector

• System spacing 5…10 mm (0.19…0.38 in.)

• 55 mm (2.16 in.) length

Busbar Connector

• System spacing 13…20 mm (0.52…0.79 in.)

• 40 mm (1.57 in.) length

Double-T Busbar Connectors

• System Spacing 100…110 mm (3.94…4.33 in.)

• 150 mm (5.91 in.) length

Phase Separator

• For UL installation of busbar connectors

• 3-pole, including two mounts

• For use with busbar connectors

• For use with Cat. No. 141A-VC3A, -VC3B, -VC5G

30 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

12…20 x 5 mm (0.47…0.79 x 0.19 in.)

12…20 x 10 mm (0.47…0.79 x 0.38 in.)

12…30 x 5 mm (0.47…1.18 x 0.19 in.)

12…30 x 10 mm (0.47…1.18 x 0.38 in.)

Double-T Busbars

141A-BT11NZ, 141A-BT12NZ

Width: 105 mm (4.13 in.)

Width: 145 mm (5.71 in.)

Width: 200 mm (7.87 in.)

or

or

12

6

3

1

141A-VC3A

141A-VC3B

141A-VC5G

141A-PS105

141A-PS145

141A-PS200

Page 31

Panel Mounting Modules

Description Width [mm (in.)] Rails Pkg. Qty. Cat. No.

•Short Length

• 228 mm (8.98 in.) tall

• For 2-component starters

45 (1.77)

54 (2.13)

141A Classic Mounting System Product Selection

141A-WS45RR

21

141A-WS54RR

Mounting Module

• Medium Length

• 283 mm (11.14 in.) tall

• For 3-component starters that use Bulletin 193

E1 Plus™ Electronic Overload Relays

•Long Length

• 333 mm (13.11 in.) tall

• For 3-component starters that use Bulletin 193 E3™ or

E300™ Electronic Overload Relays

45 (1.77)

54 (2.13) 141A-WM54RR

54 (2.13) 2 1

21

141A-WM45RR

141A-WL54RR

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 31

Page 32

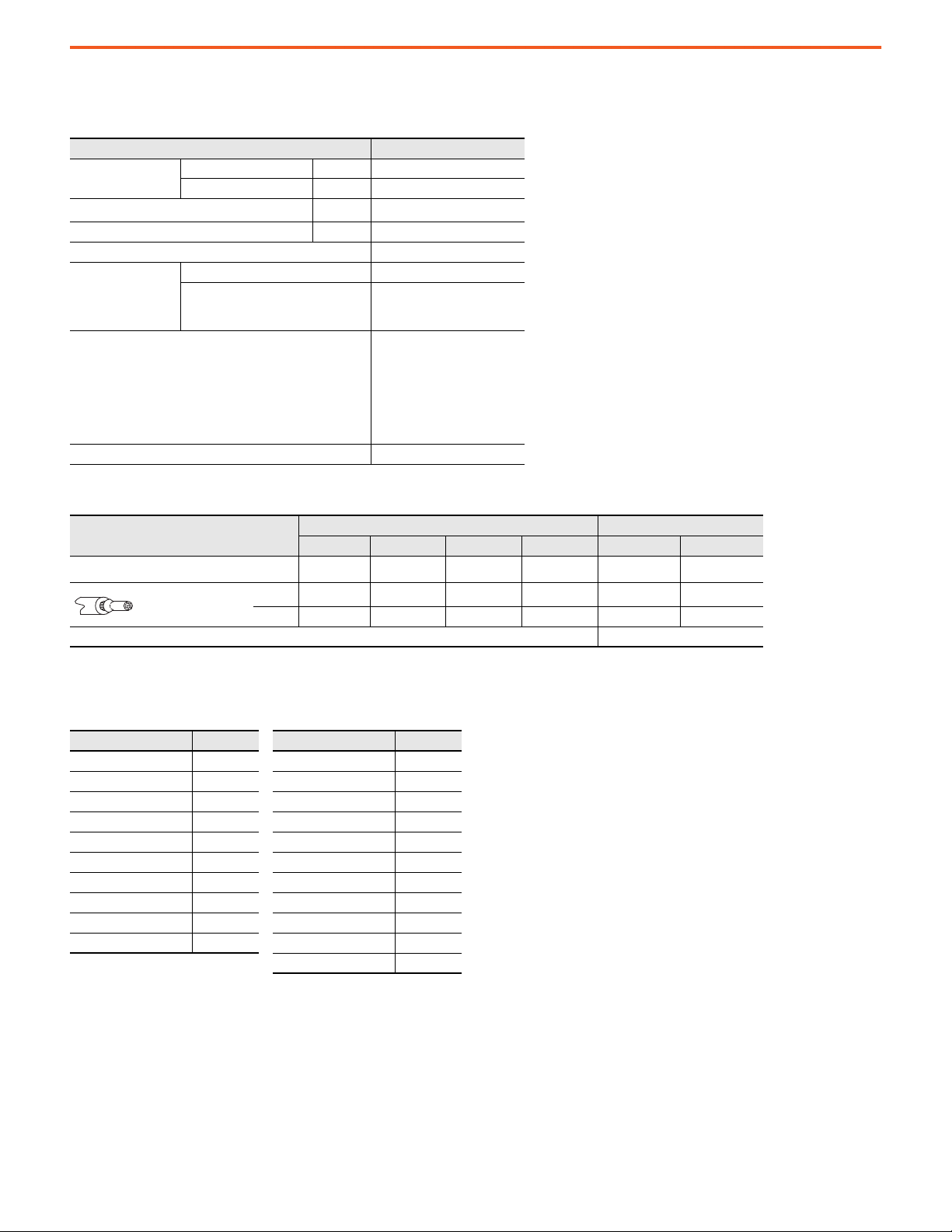

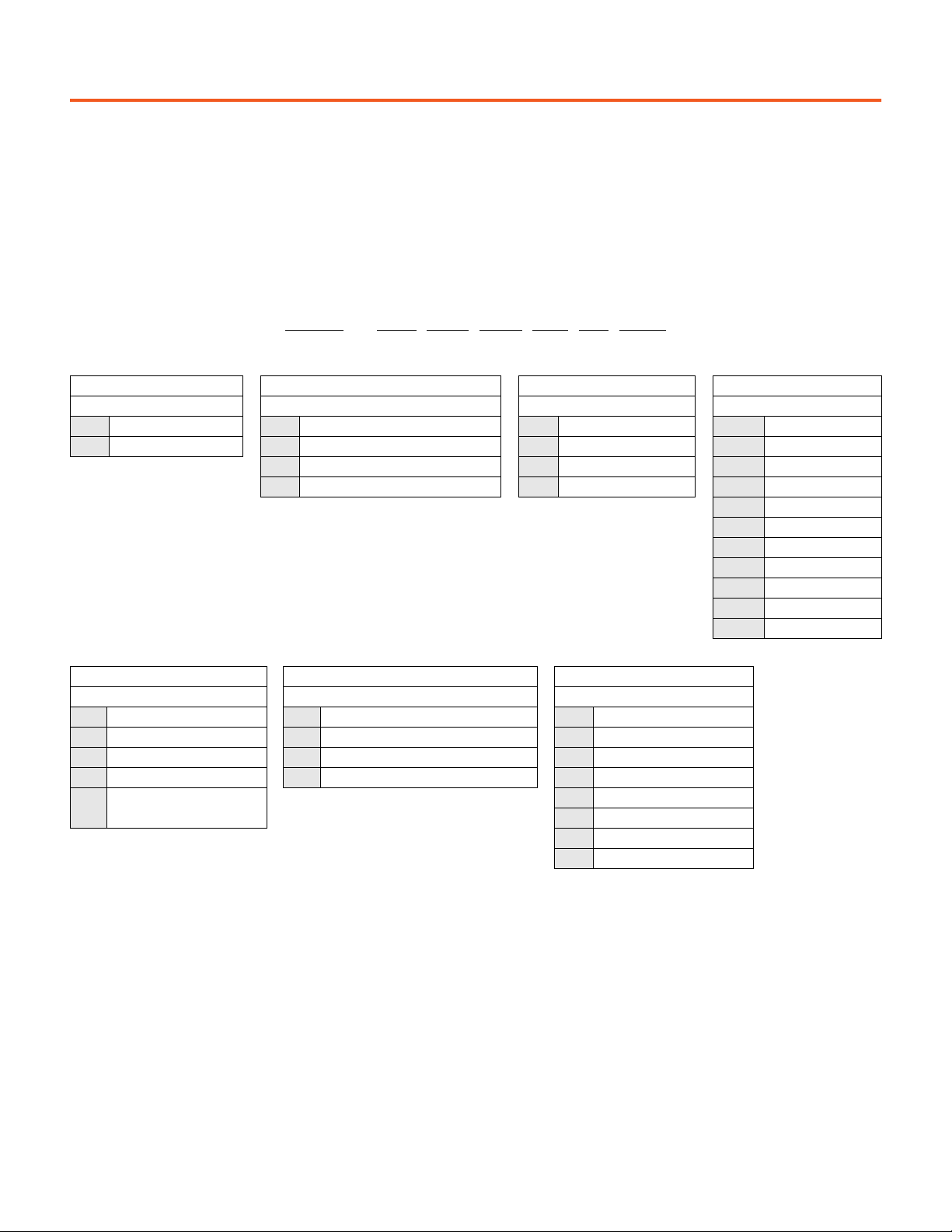

141A Classic Mounting System Specifications

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

30 K35 K40 K45 K50 K

Connuous Current [A]

Busbar Temperature Rise ΔT

Current Carrying Capacity of Copper Busbars

12 x 5 mm

(0.47 x 0.19 in.)

15 x 5 mm

(0.59 x 0.19)

20 x 5 mm

(0.79 x 0.19 in.)

25 x 5 mm

(0.98 x 0.19 in.)

30 x 5 mm

(1.18 x 0.19 in.)

12 x 10 mm

(0.47 x 0.38 in.)

20 x 10 mm

(0.79 x 0.38 in.)

30 x 10 mm

(1.18 x 0.38 in.)

TT 500 mm² TT 720 mm²

Specifications

Figure 18 - Current-carrying Capacity of Copper Busbars

32 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 33

141A Classic Mounting System Specifications

Wiring

Table 5 - Adapter Data

Iso Adapters Standard Adapters with Wire Connections Standard Adapters with Box Terminals

141A-S 141A-G 141A-F

Rated current at 60 °C I

(1)

th

stranded

solid

laminated copper

Insulation rating of conductors 105 °C (221 °F) 105 °C (221 °F) — — — —

(1) The admissible load of a complete system depends on the system topography and the application parameters. Factors of influence are ambient temperature, air circulation, busbar load,

distribution of busbar load, mix of adapters and switchgear components.

Table 6 - Supply Modules

solid

[mm

[AWG] 16…6 10…1/0 2…300 MCM 2…250 MCM No. 3/0…350 MCM

[mm

[AWG] 16…6 10…1/0 2…300 MCM 2…250 MCM — 250…600 MCM —

[mm]

[in.]

[N•m] — 8…10 12…15/ 12…15 30 30 30 30 30

[lb•in] — 71…89 106…133 106…133 266 266 266 266 266

stranded

laminated

copper

Tightening Torque

[A]326316326312532 63200 250

[mm2]

6104 610— 4 166…7035…120

[AWG] 10 8 12 10 8 — 12 6 10…2/0 2…250 MCM

2

[mm

————— 4 166…7035…120

]

[AWG] — — — — — 12 6 10…2/0 2…250 MCM

2

[mm

—————43— — — —

]

[AWG]—————1/0— — — —

Supply Adapters

141A-

TR3F16

2

1.5…16 6…50 35…150 35…120 95…185 150…300 — 120…300 —

]

2

1.5…16 6…50 35…150 35…120 95…185 150…300 — 120…300 —

]

141A-

VN370,

-CVN350

141A-

CVN3150

141A-

VN3120

141A-VN3185

141A-

VN3300R

300…600

MCM

—— — — — —

141A- VN3300F

141A-

VU3300R

—250…600 MCM—

3 x 20 x 1…

10 x 32 x 1

0.12 x 0.79 x 0.04…

0.39 x 1.26 x 0.04

—

0.12 x 0.79 x 0.04…

0.39 x 1.26 x 0.04

141A- VU3300F

3 x 20 x 1…

10 x 32 x 1

Table 7 - Class J Busbar Fuse Bases

2

]

stranded

solid

Tightening Torque

[mm

[AWG] 10…2/0 8…300 MCM 4…600 MCM

2

]

[mm

[AWG] 10…2/0 8…300 MCM 4…600 MCM

[N•m] 14…16 16…18 38…40

[lb•in] 125…142 142…160 336…355

Class J Busbar Fuse Bases

141A-NFJ100 141A-NFJ200 141A-NFJ400

6…70 10…150 16…300

6…70 10…150 16…300

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 33

Page 34

141A Classic Mounting System Specifications

AAB

CD

EF

GJH

K

Table 8 - Single Terminals

Single Terminals

141A-VS116, 141A-VS216 141A-VS135, 141A-VS235 141A-VS170, 141A-VS270

2

[mm

stranded

solid

laminated

copper

Clamping area Width x Height [mm (in.)] 7.5 x 7.5 (0.29 x 0.29) 10.5 x 11 (0.41 x 0.43) 14 x 14 (0.55 x 0.55)

Tightening Torque

\

1 conductor [mm (in.)] — 5 x 9 x 0.8 5 x 9 x 0.8

2 conductors [mm (in.)] — — 5 x 9 x 0.8

]

[AWG] 14…6 12…2 6…2/0

2

]

[mm

[AWG] 14…6 12…2 6…2/0

[N•m] 4 6 10

[lb•in] 35 53 120

2.5…16 4…35 16…70

2.5…16 4…35 16…70

Table 9 - Busbars

Attribute Value

Material E-CU blank or tinned

Busbar widths 5 or 10 mm (0.19 or 0.38 in.) thick [mm (in.)] 12, 15, 20, 25, 30 (0.47, 0.59, 0.79, 0.98, 1.18)

Tolerance of thickness [mm (in.)] +0.1/-0.3 (+0.004/-0.012)

Corner radius [mm (in.)] 0.5

Tolerance of center spacing [mm (in.)] 60 ±0.5 (2.36 ±0.02)

Standard DIN 46433

Table 10 - Busbar Specifications

Specification

Cross Section

Dimensions

Rated Current

(1)

Cat. No.

(1) For Flat busbars, replace the asterisk (*) with one of the following letters to specify the correct length: A = 800 mm (31.49 in.), C = 1200 mm (47.24 in.), N = 2400 mm (94.49 in.).

Cat. Nos. 141A-BT11NZ and 141A-BT12NZ have a length of 2400 mm (94.49 in.).

[mm

[mm] 12 x 5 15 x 5 20 x 5 25 x 5 30 x 5 12 x 10 20 x 10 30 x 10 TT 30 x 40 TT 30 x 40

[in.] 0.47 x 0.19 0.59 x 0.19 0.79 x 0.19 0.98 x 0.19 1.18 x 0.19 0.47 x 0.38 0.79 x 0.38 1.18 x 0.38 TT 1.18 x 1.57 TT 1.18 x 1.57

UL [A] 150 — 362 — 500 300 564 756 1200 1400

IEC[A]200250320400450360 520 6309601250

A B C D E F G H J K

2

60 75 100 125 150 120 200 300 500 720

]

141A-B125* 141A-B155* 141A-B205* 141A-B255* 141A-B305* 141A-B1210* 141A-B2010* 141A-B3010* 141A-BT11NZ 141A-BT12NZ

Busbar Style

34 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 35

Table 11 - UL Short-circuit Current Rating (SCCR)

• Support spacing at 800 mm (31.5 in.)

141A Classic Mounting System Specifications

Cat. No. Description

141A-B125*

141A-B1210*

141A-B205*

141A-B2010*

141A-B305*

141A-B3010*

141A-BT1*NZ TT Copper Busbar 140G-M6H3-D80 800 A 65 kA 35 kA 800 A Class T 100 kA 600 A 100 kA

141A-TU3 Busbar Support 140G-K6H3-D40 400 A 65 kA 35 kA 600 A 100 kA 600 A 100 kA

141A-CTU3 Busbar Support 140G-K6H3-D40 400 A 65 kA 35 kA 600 A 100 kA 600 A 100 kA

141A-T13 Busbar Support 140G-M6H3-D80 800 A 65 kA 35 kA 800 A Class T 100 kA 600 A 100 kA

141A-TR3E Busbar Support End Cover 140G-K6H3-D40 400 A 65 kA 35 kA 600 A 100 kA 600 A 100 kA

141A-T13E Busbar Support End Cover 140G-M6H3-D80 800 A 65 kA 35 kA 800 A Class T 100 kA 600 A 100 kA

141A-VN370 Supply Module

141A-VN3120 Supply Module 140G-K6H3-D40 400 A 65 kA 35 kA 600 A 100 kA 600 A 100 kA

141A-VN3300R Supply Module 140G-K6H3-D40 400 A 65 kA 35 kA 500 A 100 kA 300 A 100 kA

141A-VU3300R Supply Module 140G-K6H3-D40 400 A 65 kA 35 kA 500 A 100 kA 300 A 100 kA

141A-VS54136F Profile Terminals 140G-M6H3-D80 800 A 65 kA 35 kA 800 A Class T 100 kA 600 A 100 kA

141A-GHT Circuit Breaker Adapter 140G-G6* or 140MG-G8* 125 A 65 kA 25 kA — — — —

141A-GHB Circuit Breaker Adapter 140G-G6* or 140MG-G8* 125 A 65 kA 25 kA — — — —

141A-GHT Circuit Breaker Adapter 140G-H6* or 140MG-H8* 125 A 65 kA 25 kA — — — —

141A-GHB Circuit Breaker Adapter 140G-H6* or 140MG-H8* 125 A 65 kA 25 kA — — — —

141A-GJT Circuit Breaker Adapter 140G-J6* or 140MG-J8* 250 A 65 kA 25 kA — — — —

141A-GJB Circuit Breaker Adapter 140G-J6* or 140MG-J8* 250 A 65 kA 25 kA — — — —

141A-GKU Circuit Breaker Adapter 140G-K6* or 140MG-K8* 400 A 65 kA 35 kA — — — —

141A-GMU Circuit Breaker Adapter 140G-M6* or 140MG-M8* 600 A 65 kA 42 kA — — — —

141A-SS*25

141A-SM*25

141A-GS*25

141A-GM*25

141A-FS*25

141A-FM*25,

141A-SS*45

141A-SM*45

141A-GS*45

141A-GM*45

(1) 54 mm (2.13 in.) and 63 mm (2.48 in.) wide adapters only.

12 x 5 mm (0.47 x 0.19 in.)

Copper Busbar

12 x 10 mm (0.47 x 0.38 in.)

Copper Busbar

20 x 5 mm (0.79 x 0.19 in.)

Copper Busbar

20 x 10 mm (0.79 x 0.38 in.)

Copper Busbar

30 x 5 mm (1.18 x 0.19 in.)

Copper Busbar

30 x 10 mm (1.18 x 0.38 in.)

Copper Busbar

Busbar Adapter

Busbar Adapter

Busbar Adapter

Max Circuit Breaker

Cat. No.

140G-J6I3-D25

140G-J6X3-D25

140G-K6H3-D40 400 A 65 kA 35 kA 400 A 100 kA 400 A 100 kA

140G-K6H3-D40 400 A 65 kA 35 kA 500 A 100 kA 400 A 100 kA

140G-K6H3-D40 400 A 65 kA 35 kA 500 A 100 kA 400 A 100 kA

140G-K6H3-D40 400 A 65 kA 35 kA 500 A 100 kA 500 A 100 kA

140G-K6H3-D40 400 A 65 kA 35 kA 600 A 100 kA 600 A 100 kA

140G-J6I3-D25

140G-J6X3-D25

140M-C2E-B16 1.6 A 65 kA 47 kA 30 A 100 kA 30 A 100 kA

140M-C2E-C10 10 A 65 kA 30 kA 30 A 100 kA 30 A 100 kA

140M-C2E-C25 25 A 30 kA 30 kA 30 A 100 kA 30 A 100 kA

140M-D8E-C25 25 A 65 kA 30 kA 30 A 100 kA 30 A 100 kA

140M-D8E-C32

140M-C2E-B16 1.6 A 65 kA 47 kA 30 A 100 kA 30 A 100 kA

140M-C2E-C10 10 A 65 kA 30 kA 30 A 100 kA 30 A 100 kA

140M-C2E-C25 25 A 30 kA 30 kA 30 A 100 kA 30 A 100 kA

140M-D8E-C25 25 A 65 kA 30 kA 30 A 100 kA 30 A 100 kA

140M-D8E-C32 32 A 65 kA 30 kA 30 A 100 kA 30 A 100 kA

140M-F8E-C32 32 A 65 kA 30 kA — — — —

140M-F8E-C45 45 A 65 kA 18 kA — — — —

(1)

Circuit

Breaker

Rating

250 A 65 kA 25 kA 400 A 100 kA 400 A 100 kA

250 A 65 kA 25 kA 400 A 100 kA 400 A 100 kA

32 A 65 kA 30 kA 30 A 100 kA 30 A 100 kA

SCCR Max Class

480V 600V 480V 600V

CC, J, or T

Fuse

SCCR Max Class

CC, J, or T

Fuse

SCCR

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 35

Page 36

141A Classic Mounting System Specifications

General Data

Table 12 - Main Circuits

Attribute Value

Rated insulation

voltage U

i

Rated impulse withstand voltage U

Rated frequency [Hz] 50…60

Pollution degree 3

Ambient

temperature

Protection class

Standards Compliance

Certifications CE, cULus Recognized

(1) Most components comply with UL 508; there some exceptions. Consult your local

Rockwell Automation sales office or Allen-Bradley distributor.

IEC, EN [V] 690

UL, NEMA, CSA, EEMAC [V] 600

imp

Operation [ °C ( °F)] -25…+60 (-13…+140)

Transport and storage [ °C ( °F)] -50…+80 (-58…176)

Adapters and busbars IP00

Adapters and busbars mounted

on plate, connected conductors,

and usage of busbar covers

Iso adapters with device adapter

plate removed, from front

[kV] 8

IP20

IP20 B (finger proof)

•IEC/EN 61439-1

(1)

•UL 508

• CSA C22.2, No 14

Table 13 - Control Circuits

Attribute Value

Control Plugs

Rated insulation voltage U

Rated impulse withstand voltage U

Rated current at 40 °C ambient temperature I

Micro Switch

Rated insulation voltage U

Rated current

• Suitable for switching 100-C contactors

i

i

IEC, EN [V] 250

UL, NEMA, CSA, EEMAC [V] 300

imp

th

IEC, EN [V] 250

UL, NEMA, CSA, EEMAC [V] 300

[kV] 4

[A] 12

AC coil 250V

DC coil 120V

Table 15 - Standard Busbar Adapters

Cat. No. Weight [g] Cat. No. Weight [g]

141A-CC45R32 198 141A-GM63RS45 400

141A-CC54R63 218 141A-GM45S 211

141A-FM45SS25 293 141A-GM54S 277

141A-FM54SS63 349 141A-GM63S 298

141A-FM63SS63 370 141A-GS45R 200

141A-FM72SS63 408 141A-GS45RR25 302

141A-FM81SS63 429 GS54R 226

141A-FS45S25 272 GS54RR25 347

141A-FS54S63 328 GS54RR45 358

141A-FS63S63 349 141A-GS63RR45 379

141A-FS72S63 387 141A-GS72S 268

141A-FS81S63 408 141A-GS81S 289

141A-GM45RS25 313 141A-GS90M125 781

141A-GM54RS25 368 141A-GS180M125 1021

141A-GM54RS45 379 141A-GS270M125 1271

Table 16 - Standard Busbar Adapters >100 A

Cat. No. Weight [ g]

141A- FL110V250T 1200

141A- FS108V200B 1000

141A- FS108V200T 1000

Table 17 - Mounting Adapters

Cat. No. Weight [g] Cat. No. Weight [g]

141A-WL45RR 211 141A-WM54RR 211

141A-WL45RRP 240 141A-WM54RRP 234

141A-WL54RR 222 141A-WS45RR 163

141A-WL54RRP 251 141A-WS45RRP 180

141A-WM45RR 189 141A-WS54RR 204

141A-WM45RRP 212 141A-WS54RRP 221

Weights

Table 14 - Iso Busbar Adapters

Cat. No. Weight [g] Cat. No. Weight [g]

141A-SM45RS25 402 141A-SM63S 405

141A-SM45S 300 141A-SS45R 279

141A-SM54RS25 418 141A-SS45RR25 381

141A-SM54RS45 494 141A-SS54R 305

141A-SM54S 327 141A-SS54RR25 396

141A-SM63RS45 502 141A-SS54RR45 472

141A-SS63RR45 480

36 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 37

141A Classic Mounting System Specifications

Table 18 - Busbar Components

Cat. No. Weight [g] Cat. No. Weight [g]

141A-BCF1 750 141A-ND1 130

141A-BCF1H 40 141A-ND2 220

141A-BCR 800 141A-NDN66 570

141A-BCT1 380 141A-NDRY66 570

141A-BK1 144 141A-NF0102 759

141A-BK180 395 141A-NF1038 760

141A-BK228 425 141A-NFAC00A 124

141A-BK250 440 141A-NFAC1A 107

141A-BKC 420 141A-NFAC2A 109

141A-BKH 90 141A-NFAC3A 156

141A-BKS 150 141A-NFAD 61

141A-BS10 101 141A-NFAFR5 65

141A-BS5 87 141A-NFAR 1

141A-BST48 700 141A-NFASNC0 11

141A-BST76 1050 141A-NFASNC1 11

141A-CBCF1 420 141A-NFASNF 7

141A-CBCF1H 18 141A-NFASNFD 11

141A-CTS3 52 141A-NFD125SB 2190

141A-CTU3 68 141A-NFD160 1300

141A-CVN3150 575 141A-NFD250 3760

141A-CVN350 206 141A-NFD250SB 2460

141A-N160SB 2160 141A-NFD400 5500

141A-N320SB 5650 141A-NFD630 7840

141A-NFHCC30 185 141A-VB75528F 500

141A-NFHCC30L 187 141A-VB76828F 630

141A-NFJ100 3280 141A-VC3A 185

141A-NFJ200 4500 141A-VC3B 251

141A-NFJ400 6900 141A-VC3C 565

141A-NFVF1150 116 141A-VC3D 870

141A-NFVF2240 199 141A-VC5E 494

141A-NFVF3300 247 141A-VC5F 943

141A-PS105 172 141A-VC5G 1461

141A-PS145 196 141A-VN3120 485

141A-PS200 218 141A-VN3185 1140

141A-T11 158 141A-VN3300F 1619

141A-T13 591 141A-VN3300R 1540

141A-T13E 20 141A-VN370 360

141A-TR1 59 141A-VS116 21

141A-TR3 203 141A-VS135 46

141A-TR3E 21 141A-VS170 71

141A-TR3F16 285 141A-VS2120 109

141A-TR4 256 141A-VS216 23

141A-TR4E 28 141A-VS235 47

141A-TS3 131 141A-VS270 74

141A-TU3 127 141A-VU3300F 1325

141A-VB710528F 840 141A-VU3300R 1550

Table 19 - Accessories

Cat. No. Weight [g] Cat. No. Weight [g]

141A-AHR45 15 141A-APC8 29

141A-AHR54 16 141A-APH 5

141A-AHR63 16 141A-AS 75

141A-AHS72 17 141A-AS9B 20

141A-AHS81 18 141A-AS9S 38

141A-AK 1 141A-AS9W 20

141A-APC10 35 141A-CAS9B 20

141A-APC12 40 141A-FTS63 8

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 37

Page 38

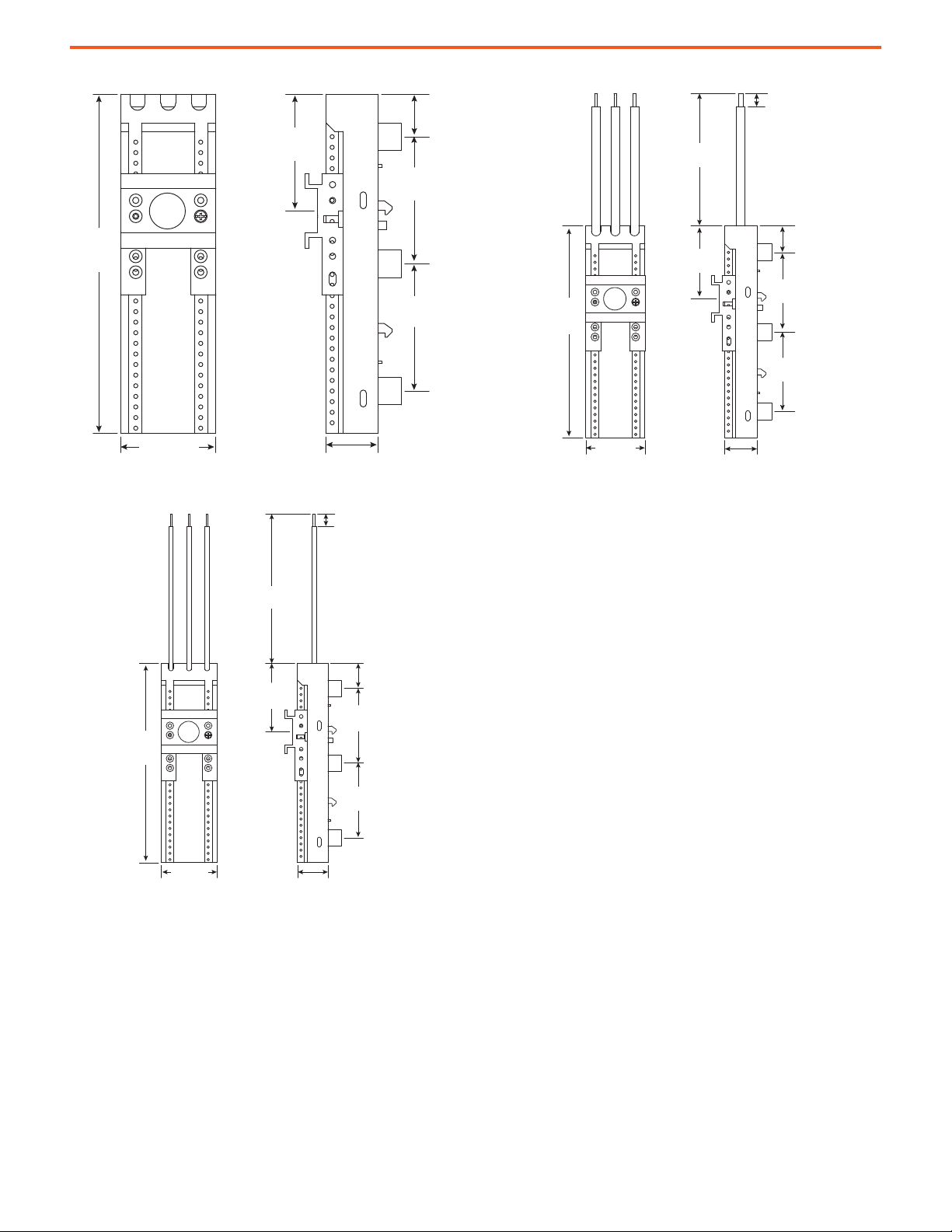

141A Classic Mounting System Approximate Dimensions

26

(1.02)

26

(1.02)

3

(0.12)

3

(0.12)

10

(0.39)

47

(1.85)

75

(2.95)

200

(7.87)

60

(2.36)

60

(2.36)

74

(2.91)

8.9

(0.35)

34

(1.33)

A

B

C

D

E

30.2

(1.19)

Free space is required to get the device adapter

placed into the parking position

Approximate Dimensions

Busbar Adapters

Dimensions are in millimeters (inches). Dimensions are not intended for manufacturing purposes.

Figure 19 - ISO Busbar Adapters

Cat. No. A B C D E Cat. No. A B C D E

141A-SS45RR25 200 (7.87) 45 (1.77) 65 (2.56) 162.5 (6.4) 73 (2.87) 141A-SM45RS25 260 (10.24) 45 (1.77) 65 (2.56) 170 (6.69) 73 (2.87)

141A-SS54RR25 200 (7.87) 54 (2.13) 65 (2.56) 162.5 (6.4) 73 (2.87) 141A-SM54RS25 260 (10.24) 54 (2.13) 65 (2.56) 170 (6.69) 73 (2.87)

141A-SS54RR45 200 (7.87) 54 (2.13) 65 (2.56) 170 (6.69) 95 (3.74) 141A-SM54RS45 260 (10.24) 54 (2.13) 65 (2.56) 170 (6.69) 95 (3.74)

141A-SS63RR45 200 (7.87) 63 (2.48) 65 (2.56) 170 (6.69) 95 (3.74) 141A-SM63RS45 260 (10.24) 63 (2.48) 65 (2.56) 170 (6.69) 95 (3.74)

141A-SS45R 200 (7.87) 45 (1.77) — 162.5 (6.4) — 141A-SM45S 260 (10.24) 45 (1.77) — 170 (6.69) —

141A-SS54R 200 (7.87) 54 (2.13) — 170 (6.69) — 141A-SM54S 260 (10.24) 54 (2.13) — 170 (6.69) —

141A-SM63S 260 (10.24) 63 (2.48) — 170 (6.69) —

38 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 39

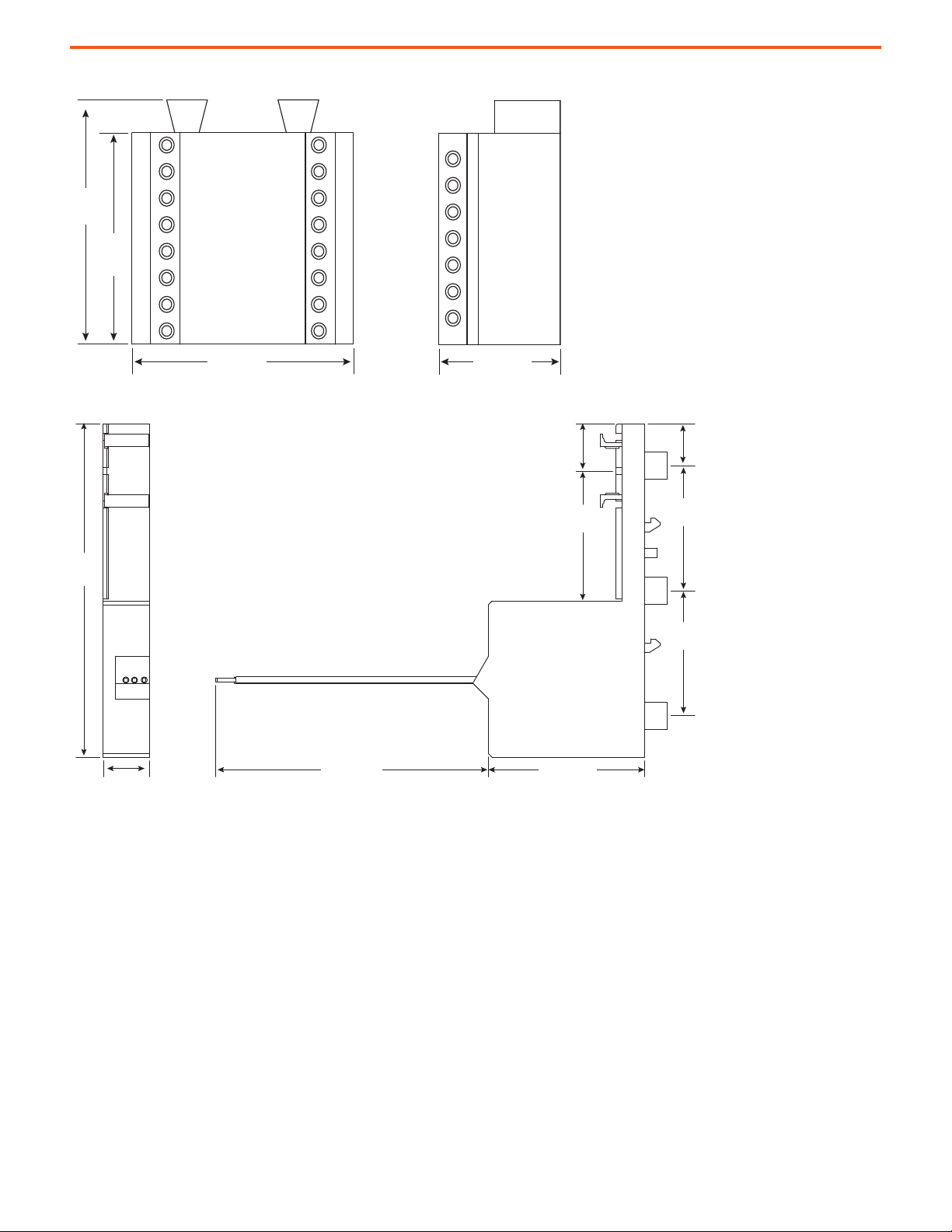

Figure 20 - Standard Busbar Adapters

30

(1.19)

72.5

(2.86)

8.5

(0.33)

27.5

(1.08)

27.5

(1.08)

37.5

(1.48)

105

(4.14)

200

(7.88)

90

(3.55)

34

(1.34)

60

(2.36)

60

(2.36)

36

(1.42)

51

(2.01)

141A-GS180M125 = 180 (7.09)

141A-GS270M125 = 270 (

10.63)

Cat. No. 141A-GS180M125

Cat. No. 141A-GS270M125

Cat. No. 141A-GS90M125

57

(2.24)

14

(0.55)

10

(0.39)

35

(1.38)

63

(2.48)

30.2

(1.19)

A

C

D

B

200

(7.87)

60

(2.36)

34

(1.33)

60

(2.36)

E

72.5

(2.85)

19.5

(0.77)

Cat. No. A B C D E

141A-GM45RS25 260 (10.24) 45 (1.77) 65 (2.56) 170 (6.69) 73 (2.87)

141A-GM54RS25 260 (10.24) 54 (2.13) 65 (2.56) 170 (6.69) 73 (2.87)

141A-GM54RS45 260 (10.24) 54 (2.13) 65 (2.56) 170 (6.69) 95 (3.74)

141A-GM63RS45 260 (10.24) 63 (2.48) 65 (2.56) 170 (6.69) 95 (3.74)

141A-GM45S 260 (10.24) 45 (1.77) — 170 (6.69) —

141A-GM54S 260 (10.24) 54 (2.13) — 170 (6.69) —

141A-GM63S 260 (10.24) 63 (2.48) — 170 (6.69) —

141A-GS45RR16 200 (7.87) 45 (1.77) 65 (2.56) 162.5 (6.4) 73 (2.87)

141A-GS54RR16 200 (7.87) 54 (2.13) 65 (2.56) 162.5 (6.4) 73 (2.87)

141A-GS45RR25 200 (7.87) 45 (1.77) 65 (2.56) 162.5 (6.4) 73 (2.87)

141A-GS54RR25 200 (7.87) 54 (2.13) 65 (2.56) 162.5 (6.4) 73 (2.87)

141A-GS54RR45 200 (7.87) 54 (2.13) 65 (2.56) 170 (6.69) 95 (3.74)

141A-GS63RR45 200 (7.87) 63 (2.48) 65 (2.56) 170 (6.69) 95 (3.74)

141A-GS45R 200 (7.87) 45 (1.77) — 162.5 (6.4) —

141A-GS54R 200 (7.87) 54 (2.13) — 170 (6.69) —

141A-GS72S 200 (7.87) 72 (2.83) 105 (4.13) — —

141A-GS81S 200 (7.87) 81 (3.19) 105 (4.13) — —

Free space is required to plug/unplug the adapter

into the busbars

141A Classic Mounting System Approximate Dimensions

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 39

Page 40

141A Classic Mounting System Approximate Dimensions

A

C

D

200

(7.87)

60

(2.36)

34

(1.33)

60

(2.36)

B

10

(0.39)

35

(1.38)

63

(2.48)

Cat. No. A B C D

Wire Size

mm

2

AWG

141A-FS45S25 200 (7.87) 45 (1.77) 65 (2.56) — 6 10

141A-FS54S63 200 (7.87) 54 (2.13) 65 (2.56) — 16 6

141A-FS63S63 200 (7.87) 63 (2.48) 65 (2.56) — 16 6

141A-FS72S63 200 (7.87) 72 (2.83) 65 (2.56) — 16 6

141A-FS81S63 200 (7.87) 81 (3.19) 65 (2.56) — 16 6

141A-FM45SS25 260 (10.24) 45 (1.77) 65 (2.56) 170 (6.69) 6 10

141A-FM54SS63 260 (10.24) 54 (2.13) 65 (2.56) 170 (6.69) 16 6

141A-FM63SS63 260 (10.24) 63 (2.48) 65 (2.56) 170 (6.69) 16 6

141A-FM72SS63 260 (10.24) 72 (2.83) 65 (2.56) 170 (6.69) 16 6

141A-FM81SS63 260 (10.24) 81 (3.19) 65 (2.56) 170 (6.69) 16 6

Free space is required to plug/unplug the adapter

into the busbars

obenen

404030302020

obenen

L2L2

30 30

20 20

40 40

50 50

60 60

80 80160160

70 70

30 30

20 20

10 10

0 0

10 10

40 40

50 50

60 60

70 70

80 80

90 90

100100

110110

120120

130130 50 50

40 40

30 30

20 20

10 10

8Nm8Nm6-706-70

L3L3L2L2L1L1

8Nm8Nm

4040 3030 2020 404030302020

4040 3030 2020

L3-40L3-40

L1-40L1-40

L3-60L3-60

16

(0.62)

44

(1.73)

108 (4.25)

60

(2.36)

60

(2.36)

222

(8.74)

60

(2.36)

9

(0.35)

max. 30 (1.18)

35

(1.38)35(1.38)

109

(4.29)

45

(1.77)

38.5

(1.51)

73

(2.87)

101

(3.97)

Cat. No. 141A-FS108V200T

4040 3030 2020 404030302020

4040 3030 2020 404030302020

80 80

90 90

80 80

210210

70 70

60 60

50 50

40 40

30 30

20 20

10 10

0 0

70 70

60 60

50 50

40 40

30 30

20 20

10 10

0 0

200200

190190

180180

170170

160160

150150

140140

130130

110110

100100

90 90

80 80

70 70

60 60

50 50

40 40

30 30

20 20

10 10

0 0

L3L3L2L2L1L1

20Nm20Nm

L3L3

L1L1

L2L2

10Nm10Nm

35-120 35-120

60

(2.36)

73

(2.87)

101

(3.97)

60

(2.36)

60

(2.36)

max. 30 (1.18)

21

(0.82)

41

(1.61)

36

(1.41)

36

(1.41)

14

(0.55)

23

(0.91)

152

(5.98)

320

(12.59)

110

(4.33)

50.5

(1.99)

Cat. No. 141A-FL110V250T

Figure 21 - Standard Busbar Adapters with Terminals

Figure 22 - Standard Busbar Adapters — Universal Adapters

40 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 41

Figure 23 - Cat. Nos. 141A-GHT, -GHB

141A-GHT (Top Connection)

141A-GHB (Bottom Connection)

200

(7.87)

211

(8.31)

6.5

(0.26)

90 (3.54)

63 (2.48)

89.8 (3.54)

62.5

(2.46)

15

(0.59)

30 (1.18)

30 (1.18)

30 (1.18)

200

(7.87)

217

(8.54)

6.5

(0.26)

90 (3.54)

63 (2.48)

89.8 (3.54)

62.5

(2.46)

15

(0.59)

30 (1.18)

30 (1.18)

30 (1.18)

141A-GJT (Top Connection)

141A-GJB (Bottom Connection)

200

(7.87)

213.8

(8.42)

35 (1.38)

35

(1.38)

8.8

(0.35)

105

(4.13)

63 (2.48)

88.5 (3.48)

55.8

(2.2)

20

(0.79)

35 (1.38)

Figure 24 - Cat. Nos. 141A-GJT, -GJB

30 (1.18)

30 (1.18)

141A Classic Mounting System Approximate Dimensions

89.8 (3.54)

217

(8.54)

200

(7.87)

30 (1.18)

90 (3.54)

62.5

(2.46)

6.5

(0.26)

15

(0.59)

63 (2.48)

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 41

Page 42

141A Classic Mounting System Approximate Dimensions

46.0

140.0

300

(11.81)

45

(1.77)

335.5

(13.2)

11

(0.43)

45

(1.77)

62

(2.44)

176

(6.93)

106.3

(4.19)

26

(1.02)

99 (3.9)

62

(2.44)

63

(2.48)

84 (3.31) 70 (2.76)

300

(11.81)

210

(8.27)

45

(1.77)

49

(1.93)

70

(2.76)

70

(2.76)

238 (9.37)

16.1

(0.63)

30.8

(1.21)

30.8

(1.21)

206.2

(8.12)

Figure 25 - Cat. No. 141A-GKU

Figure 26 - Cat. No. 141A-GMU

42 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 43

Figure 27 - Cat. No. 141A-W… Panel Mount Adapters

oben/top

Cat. No. A B C D E F

141A-WS45RR 228 (8.97) 45 (1.77) 69 (2.71) 166.5 (6.56) 210 (8.27) 35 (1.38)

141A-WS54RR 228 (8.97) 54 (2.13) 69 (2.71) 174 (6.85) 210 (8.27) 40 (1.57)

141A-WM45RR 228 (8.97) 45 (1.77) 69 (2.71) 166.5 (6.56) 265 (10.43) 35 (1.38)

141A-WM54RR 228 (8.97) 54 (2.13) 69 (2.71) 174 (6.85) 265 (10.43) 40 (1.57)

141A-WL54RR 333 (13.11) 54 (2.13) 69 (2.71) 174 (6.85) 315 (12.40) 40 (1.57)

62.5

F

30.2

(1.19)

(2.46)

42.5

(1.67)

141A Classic Mounting System Approximate Dimensions

oben/top

C

152.5

E

(6.00)

30.2

(1.19)

D

A

B

64

(2.51)

125

(4.92)

10

(0.39)

UL Fuse Bases and Fuse Holders

Figure 28 - Cat. No. 141A-NFHCC30

27

[1.06]

25

(0.99)

27.5

[1.08]

[1.34]

63

[2.48]

32

[1.26]

34

60

[2.36]

60

[2.36]

194

[7.64]

200

[7.88]

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 43

Page 44

141A Classic Mounting System Approximate Dimensions

106

[4.17]

104.5

[4.12]

189

[7.45]

37

[1.46]

95

[3.74]

194

[7.64]

34

[1.34]

60

[2.36]

60

[2.36]

200

[7.88]

184

[7.25]

57

[2.25]

57

[2.25]

225

[8.87]

46.5

[1.83]

60

[2.36]

60

[2.36]

129.5

[5.10]

59

[2.32]

111

[4.37]

83

[3.27]

45.5

[1.79]

214.5

[8.45]

6

[0.24]

243

[9.57]

262.5

[10.34]

Figure 29 - Cat. Nos. 141A-NFJ30C, -60C, and -100C

Figure 30 - Cat. No. 141A-NFJ200C

44 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 45

Figure 31 - Cat. No. 141A-NFJ400

132.5

[5.22]

76.5

[3.01]

60

[2.36]

60

[2.36]

285

[11.23]

27

[1.07]

256

[10.09]

6

[0.24]

141A Classic Mounting System Approximate Dimensions

Fused and Non-fused IEC Switch Disconnectors

Figure 32 - 141A-NF0102 and 141A-NF1038 Busbar Fuse Switches

27

[1.06]

34

[1.34]

60

[2.36]

60

[2.36]

32

[1.26]

100

[3.93]

194

[7.64]

23

[0.91]

220

[8.67]

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 45

Page 46

141A Classic Mounting System Approximate Dimensions

x x

A G

B

H

6

[0.24]

D

E

F

60

[2.36]

60

[2.36]

C

M

K

Figure 33 - 141A-NFD160 NH Fuse Switch Disconnector

34

[1.34]

60

[2.36]

200

[7.88]

60

[2.36]

97

[3.82]

189

[7.45]

194

[7.64]

106

[4.17]

87

[3.43]

37

[1.46]

Figure 34 - 141A-NFD… NH Fuse Switch Disconnector

Cat. No. A B C D E F G H K M X

141A-NFD250 184 (7.24) 243 (9.57) 128.5 (5.06) 221 (8.7) 83 (3.27) 110.5 (4.35) 45.5 (1.79) 214.5 (8.44) 44.5 (1.75) M10 57 (2.24)

141A-NFD400 210 (8.27) 288 (11.34) 145 (5.71) 268 (10.55) 97 (3.82) 124.5 (4.9) 48 (1.89) 255 (10.04) 68 (2.68) M10 65 (2.56)

141A-NFD630 256 (10.08) 300 (11.81) 159.5 (6.28) 285 (11.22) 111.5 (4.39) 139 (5.47) 48 (1.89) 267 (10.51) 76.5 (3.01) M12 81 (3.19)

46 Rockwell Automation Publication 141-TD001A-EN-P - April 2021

Page 47

Figure 35 - Cat. No.141A-NFD125SB Fuse Switch Disconnector for NH Fuses

106

[4.18]

33

[1.30]33[1.30]

27.5

[1.08]

32

[1.26]

94

[3.70]

34

[1.34]

60

[2.36]

60

[2.36]

200

[7.88]

128

[5.04]

148

[5.84]

55.5

[2.19]

144.5

[5.69]

Figure 36 - Cat. No.141A-NFD250SB Fuse Switch Disconnector for NH Fuses

141A Classic Mounting System Approximate Dimensions

286

[11.27]

83

[3.27]

60

[2.36]

60

[2.36]

57

[2.25]

184

[7.25]

57

[2.25]

27.5

[1.08]

123

[4.85]

163.5

[6.44]

194

[7.65]

61

[2.40]

225

[8.86]

Rockwell Automation Publication 141-TD001A-EN-P - April 2021 47

Page 48

141A Classic Mounting System Approximate Dimensions

77

[3.04]

34

[1.34]

34

[1.34]

60

[2.36]

60

[2.36]

200

[7.88]

29

[1.14]

154.5

[6.09]

27.5

[1.08]

106

23±0.5

[0.90±1/32"]

36

[1.42]

95

[3.74]

46

[1.81]

141A-ND1 = 220 - 440 [8.65 - 17.3"]

141A-ND2 = 440 - 640 [17.3 -25.2"]

2 - 5

[0.08 - 0.2]

Figure 37 - 141A-N160SB Non-Fused Switch Disconnector for External Rotary Operating Handle

Figure 38 - 141A-N320SB Non-Fused Switch Disconnector for External Rotary Operating Handle