Page 1

In verting Fault Circuit Bre aker Kit

Trademarks not belonging to Rockwell Automation are property of their

respective companies.

for FlexP ak 3000 and W ebP ak 3000 Digital DC Drives

1.5 - 30 HP @ 230 V AC and 3-60 HP @ 460 VA C

Model Numbers: 906FK0101, 906FK0201, 906FK0301, 906FK0401, and 906FK0501

Instruction Manual D2-3300-2

ATTENTION:Only qualified personnel familiar with the construction and operation of this

equipment and the hazards involved should install, adjust, operate, and/or service this equipment.

!

Product Description

This instruction manual describes how to install the optional Inverting Fault Circuit Breaker kit on regenerative

FlexPak

recommended when applying regenerative drives to high inertia loads. High inertia loads are those in which

the reflected load to the motor is equal to or greater than the motor’s load, or in which the drive is frequently

regenerating power to the AC line, such as in unwind and pay-off application.

Read and understand this instruction manual in its entirety before proceeding. Failure to observe

this precaution could result in severe bodily injury or loss of life.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

3000 and WebPak 3000 drives (1.5-30 HP @ 230 VAC and 3-60 HP @ 460 VAC .) Use of this kit is

An inverting fault typically occurs as a result of a loss of the AC line. If this happens, the AC input transformer

becomes a short circuit across the motor. Since the SCRs in the bridge no longer turn off, the motor’s stored

mechanical energy is regenerated into the short circuit. The inverting fault circuit breaker interrupts the

generator action, protecting the SCR bridge and the motor.

In addition to the parts included in the kit, you must supply an appropriate mounting panel for the inverting fault

circuit breaker and provide circuit breaker wiring.

Important: If any other interlocks are required for your application, they must be connected in series to the

Customer Interlock Input along with the circuit breaker.

Table 1 – Verifying That the Inverting Fault Circuit Breaker Matches the Drive

Drive Horsepower/Voltage Rating Kit Model Number

1.5 - 2 HP @ 230 VAC

3 - 5 HP @ 460 VAC

3 - 5 HP @ 230 VAC

7.5 - 10 HP @ 460 VAC

7.5 - 10 HP @ 230 VAC

15 - 20 HP @ 460 VAC

15 - 20 HP @ 230 VAC

25 - 40 HP @ 460 VAC

25 - 30 HP @ 230 VAC

50 - 60 HP @ 460 VAC

906FK0101

906FK0201

906FK0301

906FK0401

906FK0501

FlexPak, WebPak, and Reliance are trademarks of Rockwell Automation

©2001 Rockwell International Corporation

Page 2

Table 2 – Contents of the Inverting Fault Circuit Breaker Option

Description

Inverting Fault Circuit Breaker Assembly

M5 x 10 Self-Tapping Screw

Jumper

Bus Bar

Bus Bar

Ring Lug

Wire Harness

Wire Harness

Quantity

1

4

1

1

1

1

1

1

Part Number

802273-85x

419062-100PHG

610273-30RN

610273-101A

610273-102A

68321-19D

610273-68S

610273-68R

Installing the Inverting Fault Circuit Breaker

ATTENTION:The drive is at line voltage when disconnected to incoming AC power. Disconnect,

tag, and lock out all incoming power to the drive before performing the following procedures.

!

Installing the Inverting Fault Circuit Breaker Kit involves the following processes:

• Mounting the Inverting Fault Circuit Breaker Kit

Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

• Wiring the Inverting Fault Circuit Breaker

• Removing and Replacing Fuse 11FU

• Connecting the Wire Assembly

• Checking the Circuit Breaker Settings

2

Inverting Fault Circuit Breaker Kit for FlexPak 3000 and WebPak 3000 Drives

Page 3

Mounting the Inverting Fault Circuit Breaker Kit

Step 1. Disconnect, tag, and lock out power to the drive.

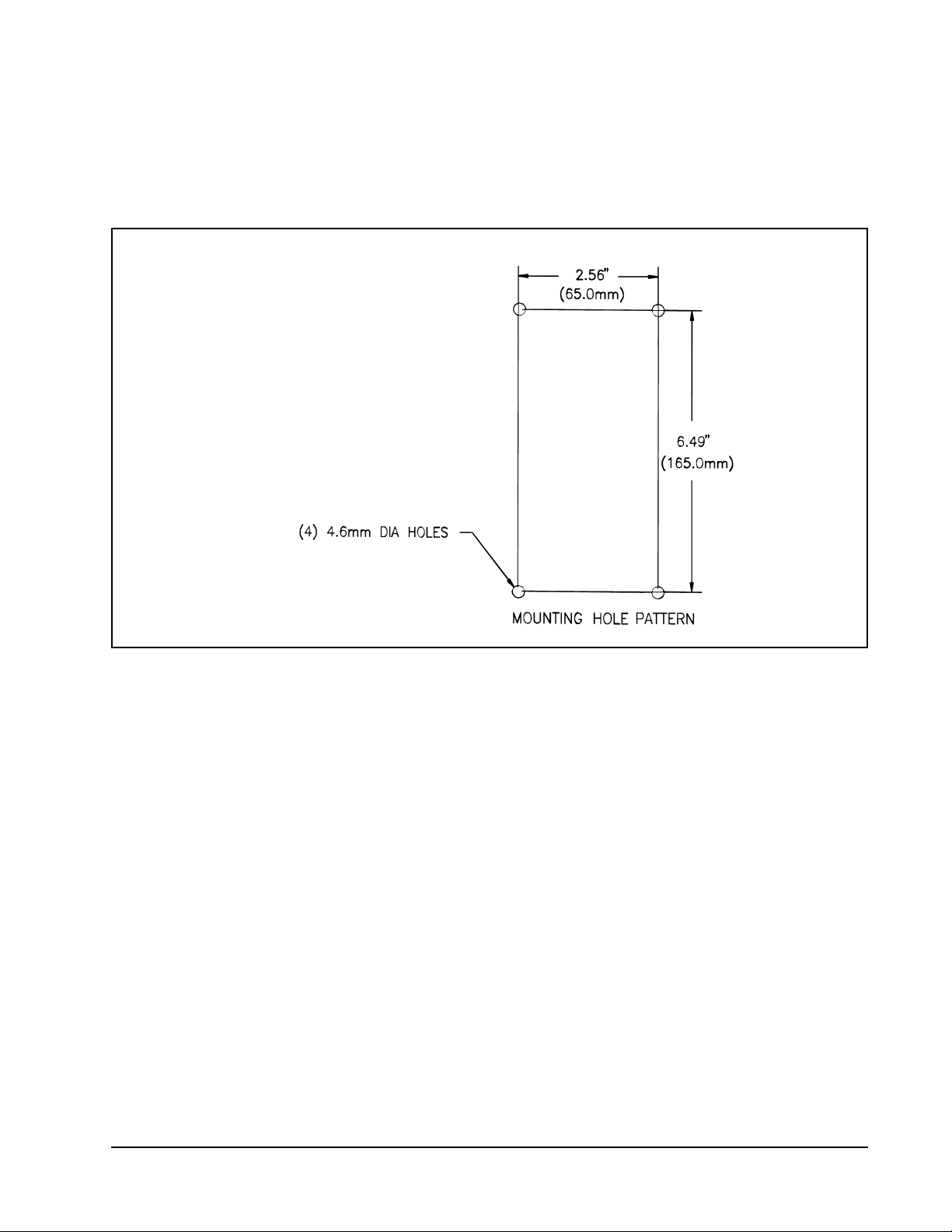

Step 2. Drill the mounting holes (4.6 mm diameter) for the circuit breaker mounting plate using the mounting

hole pattern shown in Figure 1.

Figure 1 – Inverting Fault Circuit Breaker Mounting Hole Pattern

Step 3. Mount the circuit breaker and the plate assembly with the four M5 self-tapping screws provided with

the kit.

Inverting Fault Circuit Breaker Kit for FlexPak 3000 and WebPak 3000 Drives

3

Page 4

Wiring the Inverting Fault Circuit Breaker

Step 1. Connect the motor armature lead marked A1 to the Inverting Fault Circuit Breaker terminal A1. See

Figure 2 for the location of terminal A1 on the circuit breaker.

Figure 2 – Inverting Fault Circuit Breaker Terminal Locations

Step 2. Connect the wire from the inverting fault circuit breaker terminal marked 47 (see Figure 2 for location)

to the drive motor terminal marked A1 (see Figure 3 for location).

Figure 3 – Drive Motor Terminal Block

4

Inverting Fault Circuit Breaker Kit for FlexPak 3000 and WebPak 3000 Drives

Page 5

Step 3. Connect the motor armature lead marked A2 to the drive motor terminal block (see Figure 3 for

location). If the motor has a series field, connect motor lead A2 to motor lead S1, and connect the

motor lead S2 to the drive motor terminal block marked 45.

Removing and Replacing Fuse 11FU

Step 1. Remove the drive’s front cover, then open the regulator carrier and remove the armature fuse plastic

cover over the armature fuse (11FU). Refer the drawing on the back of the carrier for the location of

11FU.

Step 2. Remove the hardware used to attach 11FU to the drive.

Step 3. Replace 11FU with the jumper/bar (part number 610273-30RN, 610273-101A, or 610273-102A)

provided with the kit. Use the hardware removed from 11FU to install the jumper/bar in place of 11FU.

Connecting the Wire Assembly

Step 1. Locate and remove the jumper wire from the 11FU terminal marked A1 and the terminal marked A1

on the Power Interface board. See Figure 4 for the location of the Power Interface board and terminal

A1 on the Power Interface board.

Figure 4 – Power Interface Board and Terminal A1 Locations

Step 2. Attach the spade connector on wire harness part number 610273-68R to the A1 terminal on the

Power Interface board. Route the other end of this wire to the inverting fault circuit breaker terminal

marked A1. Cut the wire to length as required and then terminate the end with the ring lug (part

number 68321-19D). Connect the ring lug to the A1 terminal on the inverting fault circuit breaker.

Step 3. Connect the spade connectors of the twisted pair harness (part number 610273-68S) to the male

connectors coming out of the side of the inverting fault circuit breaker. Route this harness down to the

bottom of the drive and connect it to terminals 9 and 11 on the regulator control terminal strip. See

Figure 5.

Important: If any other interlocks are required for your application, they must be connected in series to the

Customer Interlock Input (terminals 9 and 11) along with the circuit breaker.

Inverting Fault Circuit Breaker Kit for FlexPak 3000 and WebPak 3000 Drives

5

Page 6

Figure 5 – Drive Control Terminal Strip

6

Inverting Fault Circuit Breaker Kit for FlexPak 3000 and WebPak 3000 Drives

Page 7

Checking the Circuit Breaker Settings

Step 1. Visually check the setting of the circuit breaker setpoint. Set the circuit breaker settings as required.

See Table 3 for circuit breaker settings.

Table 3 – Inverting Fault Circuit Breaker Settings

Kit Model Number Drive Horsepower/Volts Required Setting

906FK0101 1.5 - 2 HP @ 230 VAC

3 - 5 HP @ 460 VAC

906FK0201 3 - 5 HP @ 230 VAC

7.5 - 10 HP @ 460 VAC

906FK0301 7.5 - 10 HP @ 230 VAC

15 - 20 HP @ 460 VAC

906FK0401 15 - 20 HP @ 230 VAC

25 - 40 HP @ 460 VAC

906FK0501 25 - 30 HP @ 230 VAC

50 - 60 HP @ 460 VAC

Step 2. Check and verify all wiring per Figure 6 before applying power to the drive. Ensure that wires are not

in contact with hot components or sharp metal edges.

Set at A (40 A)

Set at L (50 A)

Set at 2 (90 A)

Set at L (150 A)

Set at L (450 A)

Figure 6 – Inverting Fault Circuit Breaker Connection Diagram

Step 3. Set the Inverting Fault Circuit Breaker to the ON position.

Step 4. Remove the lockout and tag and reconnect power to the drive.

Step 5. Turn on power to the drive.

Kit installation is now complete.

Inverting Fault Circuit Breaker Kit for FlexPak 3000 and WebPak 3000 Drives

7

Page 8

Technical Specifications

Table 4 – Replacement Circuit Breaker Part Numbers

Kit Model Number Drive HorsePower/Voltage Rating

906FK0101 1.5 - 2 HP @ 230 VAC

3 - 5 HP @ 460 VAC

906FK0201 3 - 5 HP @ 230 VAC

7.5 - 10 HP @ 460 VAC

906FK0301 7.5 - 10 HP @ 230 VAC

15 - 20 HP @ 460 VAC

906FK0401 15 - 20 HP @ 230 VAC

25 - 40 HP @ 460 VAC

906FK0501 25 - 30 HP @ 230 VAC

50 - 60 HP @ 460 VAC

Table 5 – Inverting Fault Circuit Breaker Specifications

Kit Model

Number

906FK0101 1.5 - 2 HP @ 230 VAC

906FK0201 3 - 5 HP @ 230 VAC

906FK0301 7.5 - 10 HP @ 230 VAC

906FK0401 15 - 20 HP @ 230 VAC

906FK0501 25 - 30 HP @ 230 VAC

Drive Horsepower/

Voltage Rating

3 - 5 HP @ 460 VAC

7.5 - 10 HP @ 460 VAC

15 - 20 HP @ 460 VAC

25 - 40 HP @ 460 VAC

50 - 60 HP @ 460 VAC

Circuit Breaker

Dimensions HxWxD

6 x 4.125 x 4.12 (in)

153.4 x 105 x105 (mm)

6 x 4.25 x 4.16 (in)

153 x 115 x 106 (mm)

6 x 4.25 x 4.16 (in)

153 x 115 x 106 (mm)

6 x 4.25 x 4.16 (in)

153 x 115 x 106 (mm)

6 x 4.25 x 4.16 (in)

153 x 115 x 106 (mm)

77801-18DXA

419035-100DSA

419035-100HSA

419035-100NSA

419035-100SSA

Circuit

Breaker

Weight

4 lb

1.81 kg

4.23 lb

1.91 kg

4.23 lb

1.91 kg

4.23 lb

1.91 kg

4.23 lb

1.91 kg

Replacement Circuit Breaker

Model Number

Max

AC

Current

Rating

@ 40º C Trip Amps

Volts

50/60

Hz.

Volts

25 A 40 A 600 600

30 A 50-180 A 600 600

50 A 75-260 A 600 600

100 A 150-580 A 600 600

150 A 450-1100 A 600 600

Max

DC

Publication D2-3300-2 - February 2001

2001 Rockwell International Corporation. All rights reserved. Printed in USA.

Page 9

Page 10

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Publication D2-3300-2 – February 2001 Copyright © 2001 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...