Page 1

Field Supply Kit

for Non-Regenerative and Regenerative

FlexP ak Plus DC Drives

Model Number 14C237

Instruction Manual D2-3382

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, and/or service this

!

Product Description

The Field Supply kit provides field excitation for shunt-wound DC motors used with 1/4 to 1-1/2 HP

non-regenerative and regenerative FlexPak™ Plus DC drives. The kit is an assembly consisting of a terminal

block, a field power cube, two wiring harnesses, a support bracket, and mounting hardware.

The user must provide appropriate Field Supply wiring to the motor, based upon the motor’s field rating.

equipment. Read and understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in severe bodily injury or loss

of life.

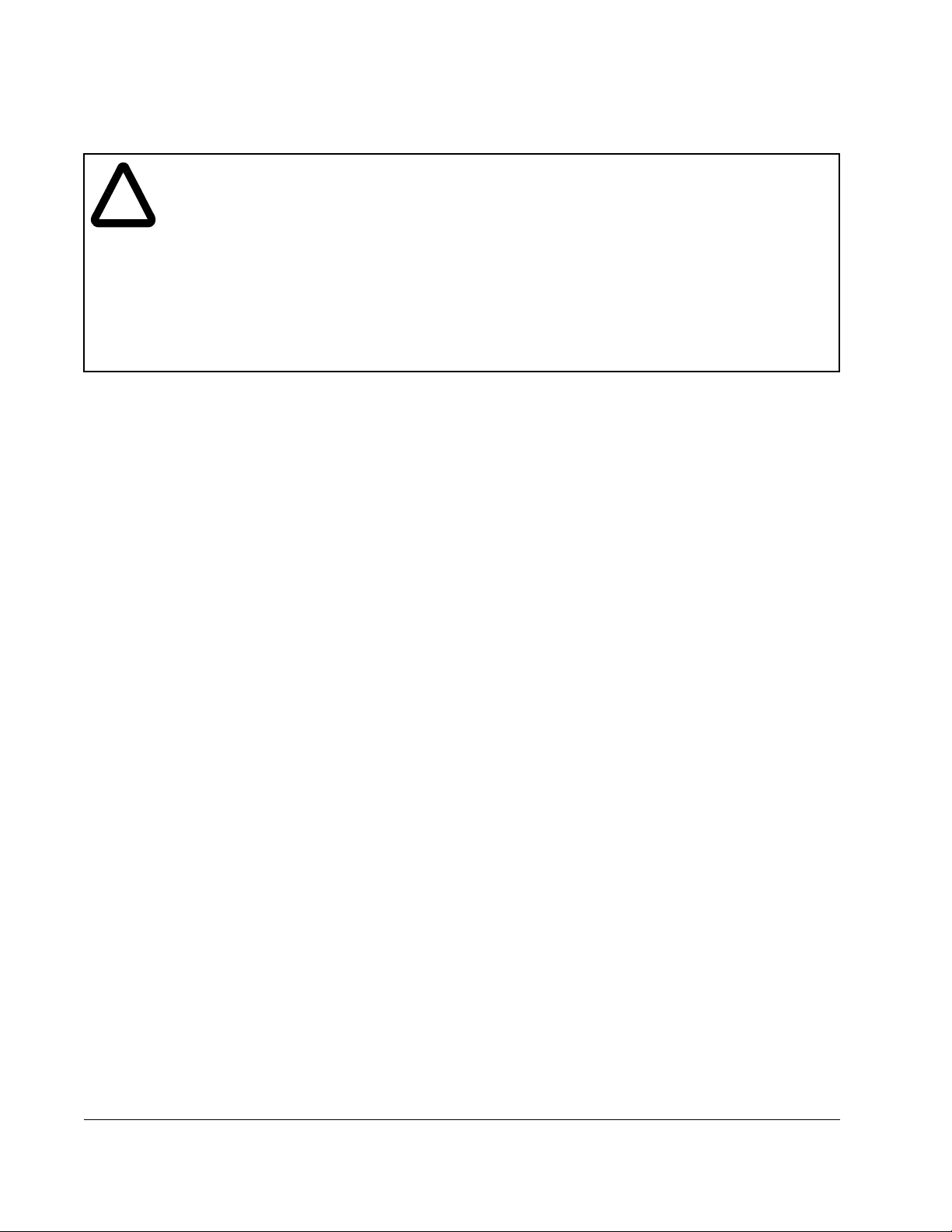

The contents of the Field Supply kit are listed in table 1.

Table 1 – Contents of the Field Supply Kit

Description Quantity Part Number

Field Supply Power Cube 1 701819-12AD

Terminal Block 2TB (32/132) 1 417620-4R

Terminal Block 2TB Section (F1/F2) 2 417621-15A

Support Bracket 1 608878-113R

Wire Jumper 51 1 608808-90SK

Wire Jumper 52 1 608808-90SL

Wire Jumper F1 1 608808-90SM

Wire Jumper F2 1 608808-90SN

6-32 Nylon Washer 1 601748-11H

Mounting Screw, 6-32 x 3/4 1 601741-61F

Mounting Screw, 8-32 x 3/8 3 601741-62C

Cup Washer 1 601748-19A

Ground Screw 1 601741-78D

Field Kit Wiring Diagram 1 705385-72

Instruction Manual 1 D2-3382

Reliance and MinPak are trademarks of Rockwell Automation.

© 1998 Rockwell International Corporation

Page 2

Installing the Field Supply in a Non-Regenerative FlexPak Plus Drive

ATTENTION:

out, and tag all sources of incoming

!

Important:

Refer to the wiring diagram included with the kit and to your FlexPak Plus drive instruction manual for help

locating and identifying drive components.

To install the Field Supply kit:

Step 1. Disconnect, lock out, and tag input power to the drive.

Step 2. Remove the drive cover.

Step 3. Verify that no voltage is present at the drive’s AC input terminals, L1 and L2.

V erify that no voltage is present at the drive’s AC input terminals, L1 and L2. Failure to observe

this precaution could resu lt in severe bodily injury or loss of life.

ATTENTION:

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

ATTENTION:

Static control precautions are required when installing, testing, servicing, or repairing this

assembly . F ailure to observe these precautions could result in damage to, or destruction of, the

equipment.

This procedure is for non-regenerative FlexPak Plus drives. See page 4 for instructions for

installation into regenerative FlexPak Plus drives.

Do not install modification kits with power applied to the drive. Disconnect, lock

power to the drive before attempting such installation.

AC

The user is responsible for conforming with all applicable local, national, and

This kit contains ESD (Electrostatic Discharge) sensitive parts and assemblies.

Step 4. Remove and set aside the drive’s auxiliary mounting bracket.

Step 5. Remove the power terminal block (1TB) and the terminal block labeled “32/132” from the terminal

block support bracket inside the drive. Leave the wires connected to the terminals.

Step 6. Remove the terminal block support bracket from the drive.

Step 7. Mount the Field Supply support bracket (with the Field Supply power cube and terminal block 2TB) in

place of the terminal block support bracket.

Step 8. Remount terminal block 1TB (removed in step 5) on the left side of the Field Supply support bracket.

Step 9. Disconnect the two wires from old terminal block 32/132. Connect them to terminals 32 and 132,

respectively, on new terminal block 2TB, as shown in figure 1 (full-wave supplies) and figure 2

(half-wave supplies). Discard the old terminal block.

Step 10. Connect wire harness 51/52 to terminal block 1TB. Connect wires F1 and F2 from the Field Supply to

terminal block 2TB on the Field Supply mounting bracket. Refer to figure 1 or 2.

Step 11. Route the user-supplied motor field wires (F1 and F2) into the drive chassis. You can use the same

conduit as the armature and motor thermostat conductors. Refer to the section on DC wiring in your

MinPak Plus DC drive instruction manual.

Step 12.

For a full-wave supply

block 2TB. See figure 1.

, connect the motor field wires to terminals F1 and F2 on Field Supply terminal

2

Field Supply Kit for Non-Regenerative and Regenerative FlexPak Plus DC Drives

Page 3

For a half-wave supply, connect motor lead F1 to terminal 51 on 1TB and motor lead F2 to terminal

F2 on 2TB. See figure 2.

Refer to the motor’s nameplate label and the technical specifications at the end of this instruction

manual to determine the appropriate field type required.

.

To F1, F2 on motor

1TB

AC

51

.

To F1 on motor

51

52

1TB

52

+

AC

Figure 1 – Connecting the Field Supply (Full-Wave)

+

–

AC

–

AC

32 132 F1

To F2 on motor

32 132 F1

2TB

F2

2TB

F2

Figure 2 – Connecting the Field Supply (Half-Wave)

Step 13. Verify that the wiring of the Field Supply is correct and all connectors are securely fastened.

Step 14. Replace the auxiliary mounting bracket removed in step 4.

Step 15. Reattach the cover to the drive.

Step 16. Apply power and test the operation of the drive.

This completes installation of the Field Supply kit in a non-regenerative FlexPak drive.

Field Supply Kit for Non-Regenerative and Regenerative FlexPak Plus DC Drives

3

Page 4

Installing the Field Supply in a Regenerative FlexPak Plus Drive

ATTENTION:

out, and tag all sources of incoming AC power to the drive before attempting such installation.

!

Important:

The Field Supply kit is shipped as an assembly mounted on a support bracket. For installation in a FlexPak

Plus regenerative drive, kit components must be removed from the support bracket and mounted internally in

the FlexPak drive.

Refer to the wiring diagram included with the kit and to your FlexPak Plus drive instruction manual for help

locating and identifying drive components.

To install the Field Supply kit:

Step 1. Disconnect, lock out, and tag input power to the drive.

V erify that no voltage is present at the drive’ s

this precaution could resu lt in severe bodily injury or loss of life.

ATTENTION:

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

ATTENTION:

Static control precautions are required when installing, testing, servicing, or repairing this

assembly . F ailure to observe these precautions could result in damage to, or destruction of, the

equipment.

This procedure is for regenerative FlexPak Plus drives. See page 2 for instructions for installation

into non-regenerative FlexPak Plus drives.

Do not install modification kits with power applied to the drive. Disconnect, lock

input terminals, L1 and L2. Failure to observe

AC

The user is responsible for conforming with all applicable local, national, and

This kit contains ESD (Electrostatic Discharge) sensitive parts and assemblies.

Step 2. Remove the drive cover.

Step 3. Verify that no voltage is present at the drive’s

Step 4. Remove and set aside the drive’s auxiliary mounting bracket.

Step 5. Remove the power cube and terminal block 2TB from the Field Supply kit support bracket. Do not

disconnect the jumpers.

Step 6. Remove the drive terminal block labeled “32/132” from the drive. Save the fasteners. Note the

connections to old terminals 32 and 132. Reconnect these to the new terminal block, 2TB, removed in

step 5. Discard terminal block “32/132”.

Step 7. Mount the field supply power cube between terminal blocks 1TB and 2TB. Use the 6-32 x 3/4 screw

and the nylon washer to mount it on the U-bar in the center of the drive chassis.

Step 8. Connect wire harness 51/52 to terminal block 1TB. Connect wires F1 and F2 from the Field Supply to

terminal block 2TB. Refer to figure 3 (full-wave supplies) or figure 4 (half-wave supplies). Use the

fasteners removed in step 6 to mount terminal block 2TB to the drive where terminal block “32/132”

was previously mounted.

Step 9. Route the user-supplied motor field wires (F1 and F2) into the drive chassis. You can use the same

conduit as the armature and motor thermostat conductors. Refer to the section on DC wiring in your

MinPak Plus DC drive instruction manual.

input terminals, L1 and L2.

AC

4

Field Supply Kit for Non-Regenerative and Regenerative FlexPak Plus DC Drives

Page 5

Step 10.For a full-wave supply , connect the motor field wires to terminals F1 and F2 on Field Supply terminal

block 2TB. See figure 3.

For a half-wave supply, connect motor lead F1 to terminal 51 on 1TB and motor lead F2 to terminal

F2 on 2TB. See figure 4.

Refer to the motor’s nameplate label and the technical specifications at the end of this instruction

manual to determine the appropriate field type required.

.

To F1, F2 on motor

1TB

AC

51

To F1 on motor

51

52

1TB

52

+

AC

Figure 3 – Connecting the Field Supply (Full-wave)

+

–

AC

–

AC

32 132 F1

To F2 on motor

32 132 F1

2TB

F2

2TB

F2

Figure 4 – Connecting the Field Supply (Half-wave)

Step 11. Verify the wiring of the Field Supply kit and that all connectors are securely fastened.

Step 12. Replace the auxiliary mounting bracket removed in step 4.

Step 13. Reattach the cover to the drive.

Step 14. Apply power and test the operation of the drive.

This completes the installation of the Field Supply kit in a regenerative FlexPak Plus drive.

Field Supply Kit for Non-Regenerative and Regenerative FlexPak Plus DC Drives

5

Page 6

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D2-3382 – November 1998 Copyright © 1998 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...