Page 1

FlexPak 3000 Digital DC Drive

Hardware Reference, Installation

and Troubleshooting

Ver sion 4.3

Instruction Manual

D2-3404-2

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

The thick black bar shown on the outside margin of this page will be used throughout this instruction manual to

signify new or revised text or figures.

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, operate, or service this equipment. Read

!

and understand this manual in its entirety before proceeding. Failure to observe this precaution

could result in severe bodily injury or loss of life.

ATTENTION:380/415 VAC-rated FlexPak drives can be configured for either 380 VAC or 415

VAC input power. Before input power is applied to the drive, verify that the control transformer

taps are set to match the input power. Follow the instructions provided in chapter 3 of this manual

to set the control transformer taps. Failure to observe this precaution could result in damage to,

or destruction of, the equipment

Reliance, FlexPak, AutoMax, and E.S.P. are trademarks of Rockwell Automation.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

©2004 Rockwell Automation. All rights reserved.

Page 3

Chapter 1 Introduction to the FlexPak 3000 Drive

1.1 Store the Drive................................................................................................. 1-1

1.2 Drive Identification Nameplate......................................................................... 1-1

1.3 Model Numbers ...............................................................................................1-2

1.4 Drive Description .............................................................................................1-2

1.5 Additional Information......................................................................................1-3

1.6 Optional Kits ....................................................................................................1-4

1.7 Getting Assistance from Reliance Electric.......................................................1-5

Chapter 2 Install and Wire the Drive

2.1 Install the Drive - Panel Layout........................................................................ 2-1

2.2 Install a Transformer .. ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ......................2-8

2.3 Install an Input Disconnect .............................................................................. 2-8

2.4 Install the Motor...................................................... ...... ....... ...... ....... ...... .........2-9

2.5 General Wiring Practices.................................................................................2-9

2.5.1 Ground the Drive and Enclosure, the Motor and the Operator's

Control Station.......................................................................................2-9

2.5.2 Recommended Lugs ...........................................................................2-17

2.5.3 Wire AC Power to the Drive................................................................ 2-18

2.5.4 Wire the DC Motor to the Drive........................................................... 2-22

2.5.4.1 Wire Motor Overload Protection............................................2-27

2.5.5 Wire the Stop Input ............................................................................2-28

2.5.5.1 Wire the COAST/STOP Digital Input .................................... 2-29

2.5.5.2 Compliance with EN 60204-1: 1992 .....................................2-29

2.5.6 Wire Optional Devices to the Drive .....................................................2-32

2.5.6.1 Logic Inputs...........................................................................2-33

2.5.6.2 Logic Outputs........................................................................ 2-33

2.5.6.3 Analog Inputs........................................................................2-33

2.5.6.4 Analog Outputs .....................................................................2-33

CONTENTS

Contents

Chapter 3 Drive Setup and Adjustment

3.1 Perform a Power Off Inspection ...................................................................... 3-1

3.2 Verify Control Transformer Tap Settings......................................................... 3-1

3.2.1 Converting a Drive for 380 VAC Input Power........................................ 3-1

3.2.2 Converting a Drive for 230 VAC Input Power........................................ 3-2

3.3 Perform a Motor Ground Check ...................................................................... 3-3

3.4 Set Jumpers .................................................................................................... 3-4

3.4.1 Set the Regulator Type (Jumper J15)................................................... 3-5

3.4.2 Setting Program Protection (Jumper J16).............................................3-6

3.4.3 Set Field Loss Detection (Jumper J20)................................................. 3-7

3.4.4 Set the Drive for the Enhanced Field Supply (Jumper J21) .................. 3-7

3.4.5 Set the Source for the Manual Mode Reference (Jumper J19)............. 3-7

3.4.6 Set the Voltage Range and Scale of an Analog Tachometer

(Jumpers J14 and J11)..........................................................................3-8

3.4.7 Set the Analog Auto Mode Reference (Jumpers J12 and J10).............3-9

3.4.8 Scale the Armature Current Feedback (Jumper 18) .............................3-9

3.4.9 Inspect Jumper J26.................. ....... ...... ....... ...... ....... ...... ....... ...... .........3-9

3.4.10Inspect the Spare 1 Jumper (J27).........................................................3-9

3.4.11Inspect the Filter Select Jumper (J28)...................................................3-9

3.4.13Inspect the Power Unit Jumper (J30)..................................................3-10

3.5 Power Up the Drive ................ ...... ...... ....... ...... ....... ...... .................................3-10

I

Page 4

3.6 Verify the Correct Direction of Motor Rotation ...............................................3-10

3.7 Determine the DC Tachometer Lead Polarity................................................3-11

3.8 Make Tachometer and Armature Feedback Zero Adjustments .....................3-11

3.9 Make Final Adjustments................................... ...... ........................................ 3 -12

Chapter 4 Troubleshooting/Diagnostics

4.1 Check for Wiring Errors....................................................................................4-1

4.2 Verify AC Line and Power Input.......................................................................4-1

4.3 Verify DC Motor Connections...........................................................................4-2

4.4 Verify Optional Kits...........................................................................................4-2

4.5 Check the Regulator LED Status.....................................................................4-3

Chapter 5 Replacement Parts

Appendix A Technical Specifications........................................................................................... A-1

Appendix B Compliance with European Union Electromagnetic Compatibility Standards..........B-1

Appendix C Recommended Parts for Integrator Drives...............................................................C-1

Appendix D Glossary Of Terms....... ...... ....... ...... ....... ...... ...... ....... ...... .........................................D-1

Index ...........................................................................................................................Index-1

II

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 5

List of Figures

Figure 1.1 – Sample FlexPak 3000 Nameplates...................................................... 1-1

Figure 1.2 – Model Number Structure ......................................................................1-2

Figure 1.3 – FlexPak 3000 Functional Block Diagram..............................................1-3

Figure 2.1 – Enclosure Mounting Minimum Clearance Distances............................ 2-1

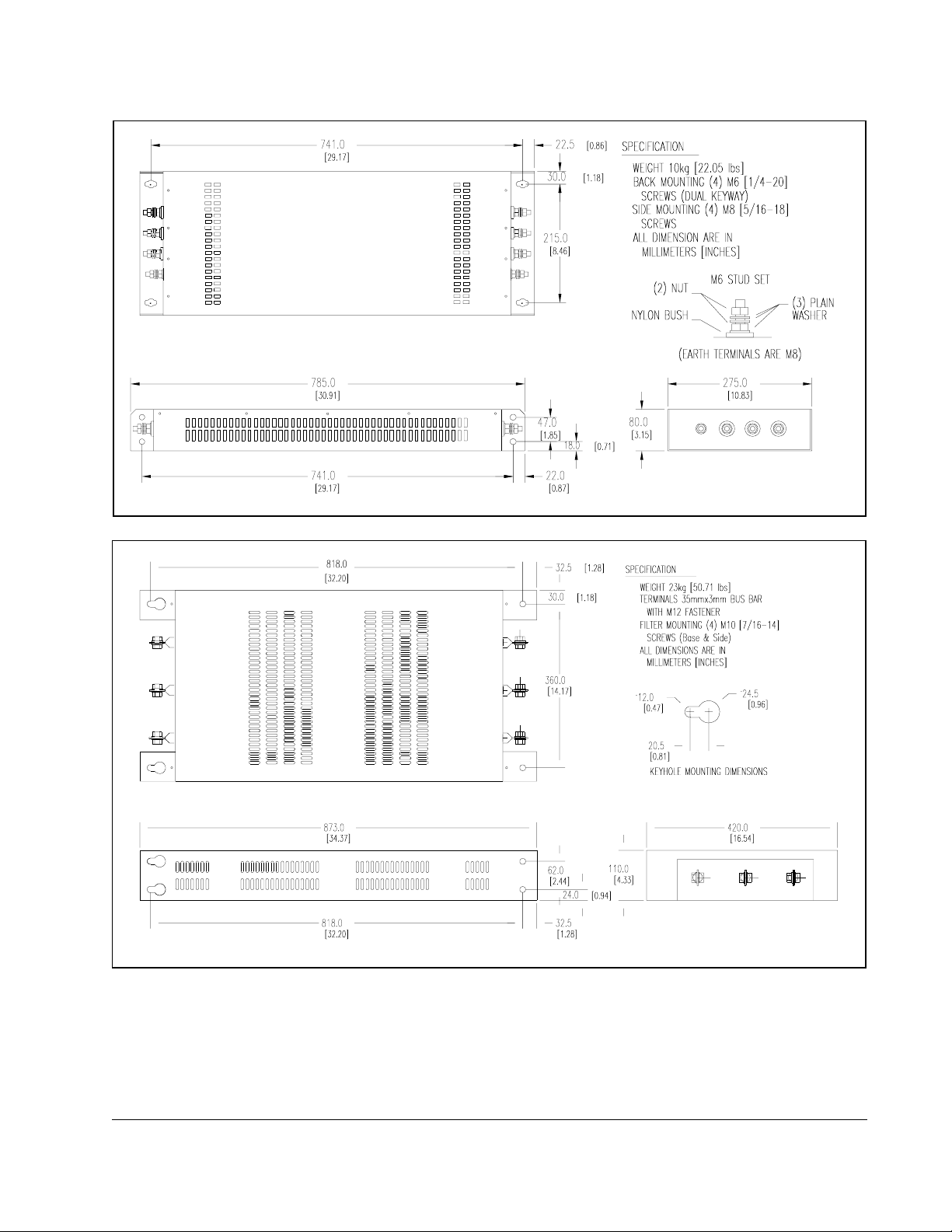

Figure 2.2 – Drive Mounting Dimensions (1.5 to 30 HP @ 230 VAC /

3 to 60 HP @ 460 VAC / 7 to 110 Amp Rated Output) ........................2-2

Figure 2.3 – Drive Mounting Dimensions (40 to 75 HP @ 230 VAC /75 to 150 HP @

460 VAC / 265 Amp Rated Output)...................................................... 2-3

Figure 2.4 – Drive Mounting Dimensions

(100 to 150 HP @ 230 VAC / 200 to 300 HP @ 460 VAC)....................2-4

Figure 2.5 – Drive Mounting Dimensions (400 to 600 HP @ 460 VAC)...................2-5

Figure 2.6 – Integrator Drive Mounting Dimensions (1.5 to 30 HP @ 230 VAC /

3 to 60 HP @ 460 VAC) ......................................................................... 2-6

Figure 2.7 – Integrator Drive Mounting Dimensions (40 to 75 HP @ 230 VAC / 75 to

150 HP @ 460 VAC) ............................................................................ 2-7

Figure 2.8 – Drive Control and Power Ground Point Locations (1.5 to 30 HP @ 230

VAC /3 to 60 HP @ 460 VAC / 7-110 Amp Rated Output)................. 2-11

Figure 2.9 – Drive Control and Power Ground Point Locations (40 to 75 HP @

230 VAC /75 to 150 HP @ 460 VAC / 265 Amp Rated Output)...........2-12

Figure 2.10 – Drive Control and Power Ground Point Locations

(100 to 150 HP @ 230 VAC / 200 to 300 HP @ 460 VAC)...............2-13

Figure 2.11 – Drive Control and Power Ground Point Locations (400 to 600 HP @

460 VAC) ............................................................................................ 2-14

Figure 2.12 – Integrator Drive Control and Power Ground Point Locations

(1.5 to 30 HP @ 230 VAC / 3 to 60 HP @ 460 VAC) .........................2-15

Figure 2.13 – Integrator Drive Control and Power Ground Point Locations

(40 to 75 HP @ 230 VAC / 75 to 150 HP @ 460 VAC) ......................2-16

Figure 2.14 – AC Line Connection Location (1.5 to 30 HP @ 230 VAC 3 to 60 HP

@ 460 VAC / 7-110 Amp Rated Output) ............................................. 2-20

Figure 2.15 – AC Line Connection Location (40 to 75 HP @ 230 VAC /75 to

150 HP @ 460 VAC / 265 Amp Rated Output)................................... 2-20

Figure 2.16 – AC Line Connection Locations (100 to 150 HP @ 230 VAC /

200 to 300 HP @ 460 VAC) ............................................................... 2-21

Figure 2.17 – AC Line Connection Locations (400 to 600 HP @ 460 VAC)...........2-21

Figure 2.18 – DC Drive Motor Field and Armature Connection Locations

(1.5 to 30 HP @ 230 VAC /3 to 60 HP @ 460 VAC / 7-110 Amp

Rated Output) .................................................................................... 2-22

Figure 2.19 – DC Motor Field and Armature Connection Locations

(40 to 75 HP @ 230 VAC /75 to 150 HP @ 460 VAC / 265 Amp

Rated Output) .................................................................................... 2-23

Figure 2.20 – DC Motor Field and Armature Connection Locations

(100 to 150 HP @ 230 VAC / 200 to 300 HP @ 460 VAC)...............2-24

Figure 2.21 – DC Motor Field and Armature Connection Locations

(400 to 600 HP @ 460 VAC) ..............................................................2-25

Figure 2.22 – DC Motor Connections (CCW Rotation Facing Commutator

End Shown)........................................................................................2-26

Figure 2.23 – Drive Cover Removal .......................................................................2-29

Figure 2.24 – Sample Regulator Board Terminal Strip Connection Diagram......... 2-30

Contents

III

Page 6

Figure 2.25 – Location of Regulator Board Terminal Strip......................................2-31

Figure 3.1 – Control Transformer Locations and Settings (380/415 VAC Drives) ....3-2

Figure 3.2 – Control Transformer Settings (230/460 VAC).......................................3-3

Figure 3.3 – Regulator Board Jumpers.....................................................................3-6

Figure 3.4 – AUTO REF Jumpers (J12 and J10)......................................................3-9

IV

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 7

List of Tables

Table 1.1 – Drive Modification Kits...........................................................................1-4

Table 2.1 – Chassis Ground Torgue Requirements............................................... 2-10

Table 2.2 – Recommended Lug Model and Part Numbers ....................................2-17

Table 2.3 – AC Line Torque Recommendations.....................................................2-19

Table 2.4 – Armature Terminal Torqure Recommendations ..................................2-27

Table 2.5 – User Device Connections to the Regulator Board Terminal Strip........ 2-32

Table 3.1 – Jumper Settings.....................................................................................3-5

Contents

V

Page 8

VI

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 9

Introduction to the FlexPak 3000 Drive

The products described in this instruction manual are manufactured by Reliance

Electric Industrial Company.

1.1 Store the Drive

After receipt inspection, repack the drive in its original shipping container until ready

for installation. To ensure satisfactory operation at startup and to maintain warranty

coverage, store the drive as follows:

• In its original shipping container in a clean, dry, safe place.

• In an ambient temperature that does not exceed 65°C (149°F) or go below -30°C

(-22°F).

• Within a relative humidity range of 5 to 95% without condensation.

• Away from a corrosive atmosphere. In harsh environments, cover the shipping/

storage container.

• At an altitude of less than 3,000 meters (10,000 ft.) above sea level.

CHAPTER 1

1.2 Drive Identification Nameplate

The FlexPak 3000 drive has a nameplate on the left side of the chassis that identifies

the specific model number design, applicable AC input power and DC output power

data. Refer to the sample nameplate in figure 1.1. All communication concerning this

product should refer to the appropriate model number information.

Figure 1.1 – Sample FlexPak 3000 Nameplates

Introduction to the FlexPak 3000 Drive

1-1

Page 10

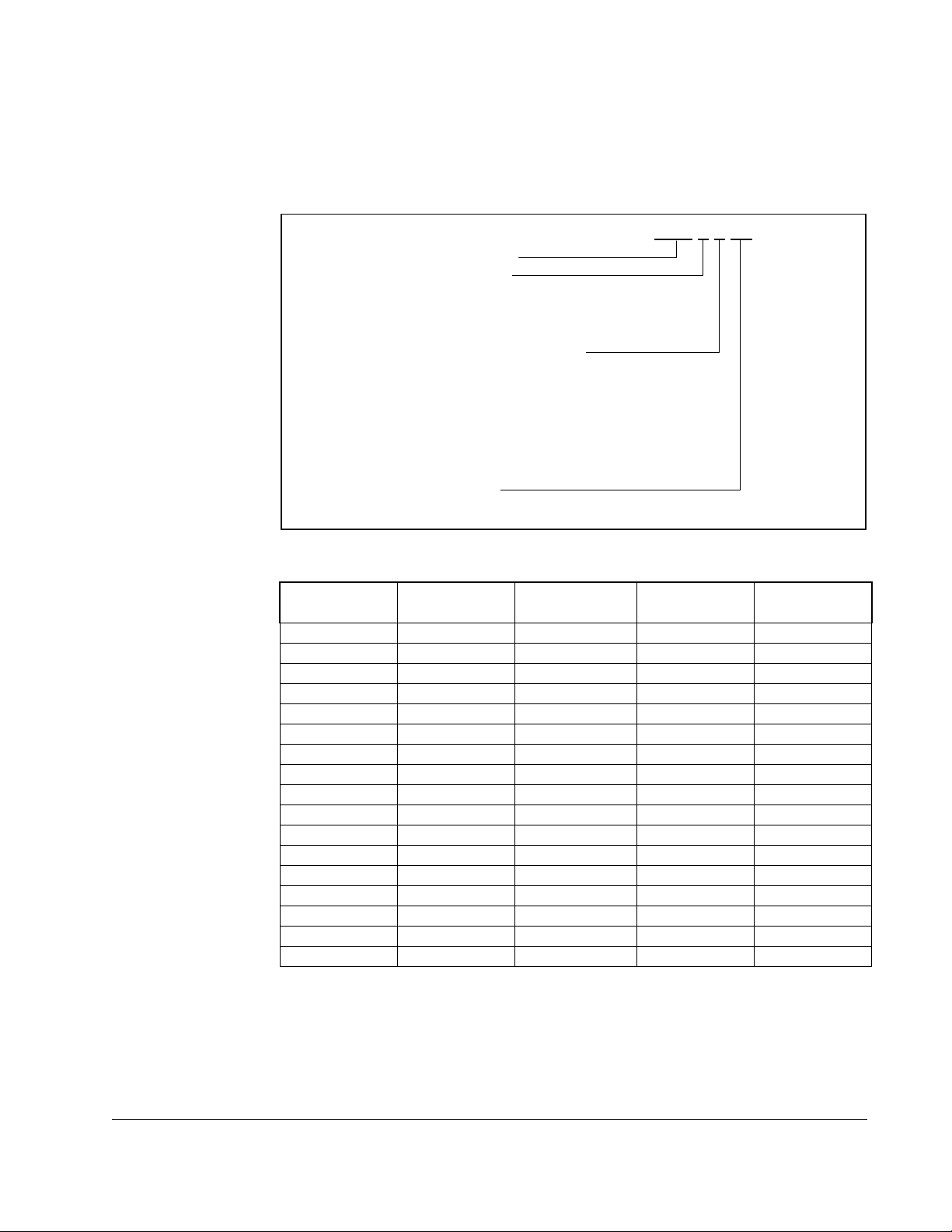

1.3 Model Numbers

Drive specific data, such as horsepower (or output current), regenerative or nonregenerative type, line voltage, chassis or enclosure type, software version and UL

certification, can be determined by the drive model number. The model number

structure is shown in figure 1.2.

Up to 300 HP, drives configured for 460 VAC input can be converted to 230 VAC input

at one half the 460 VAC horsepower rating by installing a 460 to 230 Volt Conversion

Kit (M/N 916FK0100, 1-60 HP, or M/N 916FK0200, 75-150 HP). Instruction manual

D2-3329, which is supplied with the kit, provides installation instructions. For drives

above 300 HP, contact your local Reliance Electric sales office for assistance.

For horsepower-rated drives:

Horsepower under 1000

For current-rated drives:

Rated output armature current

F = FlexPak 3000 product line

B = Regenerative drives with inverting fault breaker

R = Regenerative drives

N = Non-regenerative drives

K = Kits

150FR4042

2 = 230 volts

3 = 380/415 volts

4 = 460 volts

7 = Integrator

8 = European Power Module

0 = Chassis

7 = Integrator

Software version number 0-9, A-Z

0 = No listing

1 = U/L and C-U/L

2 = U/L, C-U/L, and CE

1.4 Drive Description

The drive is a full-wave power converter without back rectifier, complete with a digital

current minor loop and a digital major loop for armature voltage or speed regulation by

tachometer feedback. Figure 1.3 shows a block diagram of the drive.

Figure 1.2 – Model Number Structure

1-2

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 11

The drive employs a wireless construction and uses a keypad for drive setup,

including parameter adjustments and unit selection, monitoring, and diagnostics.

Multiple language capability in English, French, German, Spanish, Italian and

‘Numeric Code' is available. Reference, feedback, and metering signals can be

interfaced to the drive. The drive can be controlled locally by the Operator Interface

Module (OIM) keypad or remotely by using the terminals at the regulator board

terminal strip. You can select one of the following active control sources using the

CONTROL SOURCE SELECT key:

•KEYPAD

• TERMBLK (regulator board terminal strip)

• NETWORK (if an optional network communication board is installed)

• SERIAL (CS3000).

1.5 Additional Information

Refer to the following publications as necessary for more information.

• D2-3405 FlexPak 3000 DC Drives Software Start-up and Reference Manual

• D2-3344 FlexPak 3000 Operator Interface Module (OIM) User Guide

• D2-3348 Control and Configuration Software (CS3000)

• D2-3412 DC Contactor Use with Integrator Drives

Introduction to the FlexPak 3000 Drive

Figure 1.3 – FlexPak 3000 Functional Block Diagram

1-3

Page 12

1.6 Optional Kits

Reliance offers modification kits that broaden the application range of the drive. A

summary of these kits is presented in table 1.1. Not all kits can be used with all drive

model numbers. Refer to the Standard Drives and Control Products catalog (D-406)

for more information.

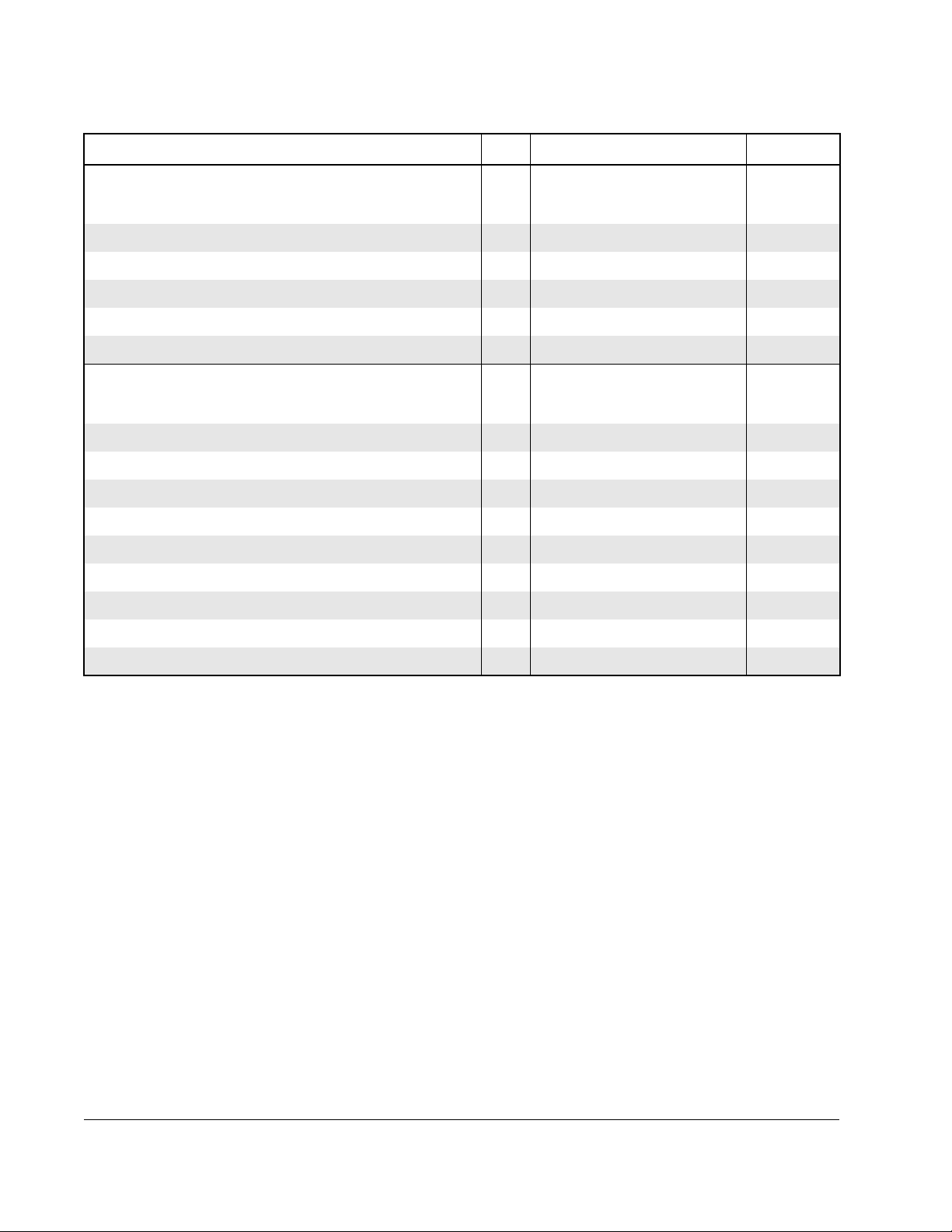

Table 1.1 – Drive Modification Kits

Name Description

Model

Number I/M Number

115 VAC Control

Interface

460 VAC to 230 VAC

Conversion Kit

AC Line Disconnect

Kit

AC Tachometer

Feedback Kit

AutoMax Network

Communication Board

Blower Motor Starter

Kit

DeviceNet

Communication Board

Converts customer-supplied 115 VAC signals to

24 VDC for operating a FlexPak 3000. Mounts

separately on the panel or can be mounted in the

bottom of a NEMA 1 enclosed drive.

Allows conversion of the 460 VAC FlexPak 3000

to a 230 VAC FlexPak 3000 at one-half the 460

VAC horsepower rating.

Allows the three-phase line to be disconnected at

the drive. Molded case switch that mounts on the

chassis of the drive or NEMA 1 enclosure.

Allows the FlexPak 3000 to accept feedback

signals from AC tachometers to a maximum

voltage of 275 VAC RMS.

Allows the FlexPak 3000 to communicate on the

Reliance AutoMax Distributed Control System

(DCS).

Provides a fused AC starter with adjustable

overload and interlocking for control of the threephase blower motor used to cool the DC motor.

Allows a FlexPak 3000 to communicate over the

open protocol DeviceNet network. Mounts inside

the FlexPak 3000 and includes terminals for

network connections. You cannot use the

AutoMax Network Communication board when

using the DeviceNet board.

917FK0101 D2-3338

916FK series D2-3329

901FK series D2-3292,

D2-3365 or

D2-3395

907FK0301 D2-3297

915FK0101 D2-3318

902FK series D2-3295

915FK1100 n/a

Drive Control

Configuration

Software for FlexPak

3000

ControlNet Network

Communication

Board

1-4

Windows-based software that allows the user to

connect any personal computer running

Microsoft Windows version 3.1 or later to a

FlexPak 3000 drive. Allows you to create, store,

upload, and download drive configurations. You

can also start and stop the drive, monitor and

change parameters through the PC, and read

and reset the drive's fault log.

Allows a FlexPak 3000 to communicate over the

ControlNet network.

FlexPak 3000 DC Drive Hardware Reference Version 4.3

2CS3000 D2-3348

915FK2101 D2-3425

Page 13

Table 1.1 – Drive Modification Kits

Name Description

Model

Number I/M Number

Dynamic Braking Kit Provides the hardware, including braking grids,

needed to provide dynamic braking on stop.

Enhanced Field

Supply Kit

Field Current

Regulator Kit

I/O Expansion Board Mounts on the FlexPak 3000 chassis and gives

Inverting Fault Circuit

Breaker Kit

NEMA 1 Conversion

Kit

Operator Interface

Module (OIM) Remote

Mounting Kit

Provides electronic field trim, field economy , and

the ability to supply 240V field voltage and other

special voltages. This kit replaces the standard

field supply.

Provides field economy, as well as preweakening of the field using a fixed reference or

field weakening for above base speed operation.

Tachometer feedback is required with this kit.

This kit replaces the standard field supply.

the FlexPak 3000 additional analog, frequency,

and digital I/O capability.

This kit is an alternative to drives supplied with

inverting fault fuses.

Converts the standard chassis to a NEMA 1

enclosure.

Allows mounting of the OIM up to five meters

from the drive.

908FK,

909FK,

912FK, and

913FK series

923FK series D2-3413

911FK series D2-3336

914FK0101 D2-3301

906FK series D2-3300 or

904FK series D2-3299 or

905FK0101 D2-3294

D2-3313 or

D2-3374

D2-3330

D2-3331

Pulse Encoder

Feedback Kit

Allows for digital pulse encoder speed feedback. 907FK0101 D2-3302

1.7 Getting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, con tac t y our local R elia nce Elec tric sale s off ice . F o r tech nic al assi sta nce , call

864-284-5444.

Introduction to the FlexPak 3000 Drive

1-5

Page 14

1-6

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 15

Install and Wire the Drive

2.1 Install the Drive - Panel Layout

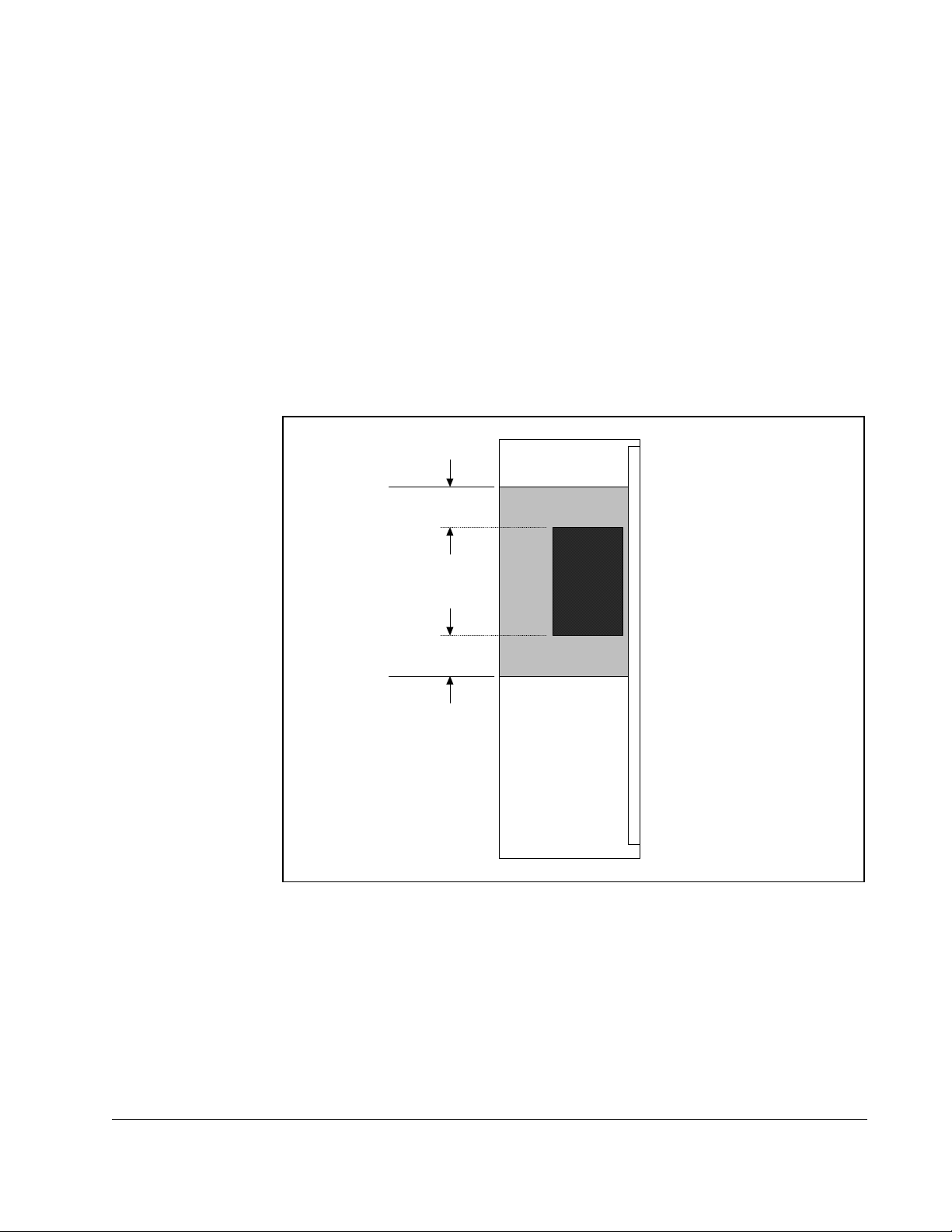

Minimum clearances must be maintained when the drive is mounted within a cabinet

as shown in figure 2.1. This allows adequate ventilation for the drive.

Regardless of these placement guidelines, the user is responsible for ensuring that

the drive's ambient temperature specification. See appendix A for more information.

Install the drive(s) in the cabinet. Refer to figures 2.2 through 2.7 for mounting

dimensions.

CHAPTER 2

Install and Wire the Drive

Figure 2.1 – Enclosure Mounting Minimum Clearance Distances

2-1

Page 16

Figure 2.2 – Drive Mounting Dimensions (1.5 to 30 HP @ 230 VAC /

3 to 60 HP @ 460 VAC / 7 to 110 Amp Rated Output)

2-2

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 17

Figure 2.3 – Drive Mounting Dimensions (40 to 75 HP @ 230 V AC /

75 to 150 HP @ 460 VAC / 265 Amp Rated Output)

Install and Wire the Drive

2-3

Page 18

Figure 2.4 – Drive Mounting Dimensions (100 to 150 HP @ 230 VAC / 200 to 300 HP @ 460 VAC)

2-4

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 19

Figure 2.5 – Drive Mounting Dimensions (400 to 600 HP @ 460 VAC)

Install and Wire the Drive

2-5

Page 20

Figure 2.6 – Integrator Drive Mounting Dimensions (1.5 to 30 HP @ 230 VAC / 3 to 60 HP @ 460 VAC

2-6

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 21

Figure 2.7 – Integrator Drive Mounting Dimensions (40 to 75 HP @ 230 VAC / 75 to 150 HP @ 460 VAC)

Install and Wire the Drive

2-7

Page 22

2.2 Install a Transformer

ATTENTION:If an input transformer is installed ahead of the drive, a

power disconnecting device must be installed between the power line

!

Input transformers step up or step down input voltage and can be either auto or

isolation transformer types. Users should consider using an isolation transformer

instead of an auto transformer for the following advantages:

• AC power line disturbances and transients are minimized by an isolation

transformer, thus reducing or eliminating possible damage to solid state

components.

• An isolation transformer provides electrical isolation for the drive from plant power

system grounds. Damaging currents may be avoided in instances where the DC

output is accidentally grounded or where the DC motor circuits are grounded.

and the primary of the transformer. If this power disconnecting device is

a circuit breaker, the circuit breaker trip rating must be coordinated with

the inrush current (10 to 12 times full-load current) of the input

transformer. Distribution system capacity above the maximum

recommended system KV A requires using an isolation transformer , a line

reactor, or other means of adding similar impedance. Failure to observe

this precaution could result in damage to, or destruction of, the equipment

ATTENTION: Connection of a drive to a transformer with a primary rating

of 2300 VAC or more may require additional input line conditioning.

Contact your local Reliance Electric sales/service office for assistance

when this is required. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

Refer to tables A.1 and A.6 for more information. Reliance offers a series of isolation

transformers suitable for use with the drive. Call you local Reliance Electric sales

office for assistance.

2.3 Install an Input Disconnect

ATTENTION:The NEC/CEC requires that an input disconnect be

provided in the incoming power line and either be located within sight of

!

Any fused disconnect or circuit breaker in the incoming AC line must accommodate a

maximum symmetrical AC fault current as indicated in Appendix A of this instruction

manual. Size the disconnect to handle the transformer primary current as well as any

additional loads the disconnect may supply.

Step 1. Install an input disconnect in the incoming power line according to the NEC/

Step 2. Wire this disconnect in the primary circuit of the drive isolation transformer (if

the drive or have provisions for a padlock. Install an input disconnect in

the incoming power line that is located within sight of the drive or that

has provisions for a padlock. Failure to observe this precaution could

result in severe bodi ly injury or loss of life.

CEC if not provided with the drive. The disconnect switch should be within

clear view of machine operator and maintenance per s onn el for easy access

and safety. An open-type switch with provisions for a padlock is

recommended.

used).

2-8

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 23

2.4 Install the Motor

Step 1. Verify that the motor is the appropriate rating to use with the drive.

Step 2. Install the DC motor in accordance with its installation instructions.

Step 3. Make sure that coupled applications have proper shaft alignment with the

driven machine or that belted applications have proper sheave/belt alignment

to minimize unnecessary motor loading.

Step 4. If the motor is accessible while it is running, install a protective guard around

all exposed rotating parts.

Step 5. Wire the motor to the drive. Refer to section 2.6.4, “Wire the DC Motor to the

Drive.”

2.5 Genera l Wiring Practices

ATTENTION:The user is responsible for conforming to the National

Electric Code (NEC/CEC) and all other applicable local codes. Wiring

!

The drive is designed for AC power entry and DC power exiting at the top and control

and signal wiring entering from the bottom.

practices, grounding, disconnects, and overcurrent protection are of

particular importance. Size and install all wiring in conformance with the

NEC/CEC and all other applicable codes. Failure to observe this

precaution could result in severe bodily injury or loss of life.

Reference signal wiring should be run in a separate conduit isolated from all AC and

DC power and control. Signal wires should not be run in parallel with high voltage or

electrically noisy conductors. Always cross such conductors at 90°. All reference

signals should be wired with either twisted double or twisted triple conductor wire, 2

twists per inch, stranded copper, AWG No. 16, 600 VAC rated, poly-vinyl chloride

insulation, with a temperature range of 40°C to 105°C (104°F to 221°F).

Tachometer feedback and other signal wiring should be run in a separate conduit

isolated from all AC and DC power and logic control. Wiring should be the same as for

the reference signals. For mounting with external contacts and solenoids, coils should

be suppressed to reduce noise.

Important: The maximum recommended wire length from the drive to the motor is

1000 feet.

2.5.1 Ground the Drive and Enclosure, the Motor and the Operator's

Control Station

You must ground both the control and power wiring.

Step 1. Locate the drive ground points as shown in figures 2.8 through 2.13.

Step 2. Run a suitable equipment grounding conductor unbroken from any drive

ground point (see step 1) to the plant ground (grounding electrode). A ring

lug is recommended at the ground point.

Install and Wire the Drive

Step 3. Connect a suitable grounding conductor from each conduit to this drive

ground point.

2-9

Page 24

Step 4. Connect a suitable equipment grounding conductor to the motor frame, the

transformer enclosure if used, and the drive enclosure. Run this conductor

unbroken to the grounding electrode.

Step 5. Connect the GND (green/ground) wire brought in with the incoming AC

power line to the drive ground point.

Step 6. Tighten chassis ground connections per table 2.1.

Table 2.1 – Chassis Ground Torgue Requirements

Hardware Size Tightening Torque

M5 18 lb/in (2 Nm)

M6 33 lb/in (3.7 Nm)

M8 100 lb/in (11.3 Nm)

M10 200 lb/in (23 Nm)

Lug with 14-10 AWG 35 lb/in (4 Nm)

Lug with 8 AWG 40 lb/in (4.5 Nm)

Lug with 6-4 AWG 45 lb/in (5.1 Nm)

2-10

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 25

Figure 2.8 – Drive Control and Power Ground Point Locations (1.5 to 30 HP @ 230 VAC /

3 to 60 HP @ 460 VAC / 7-110 Amp Rated Output)

Install and Wire the Drive

2-11

Page 26

Figure 2.9 – Drive Control and Power Ground Point Locations (40 to 75 HP @ 230 VAC /

75 to 150 HP @ 460 VAC / 265 Amp Rated Output)

2-12

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 27

Figure 2.10 – Drive Control and Power Ground Point Locations

(100 to 150 HP @ 230 VAC / 200 to 300 HP @ 460 VAC)

Install and Wire the Drive

2-13

Page 28

Figure 2.11 – Drive Control and Power Ground Point Locations (400 to 600 HP @ 460 VAC)

2-14

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 29

Figure 2.12 – Integrator Drive Control and Power Ground Point Locations (1.5 to 30 HP @ 230 VA C / 3 to 60 HP @ 460 VAC)

Install and Wire the Drive

2-15

Page 30

Figure 2.13 – Integrator Drive Control and Power Ground Point Locations (40 to 75 HP @ 230 VAC / 75 to 150 HP @ 460 VAC)

2-16

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 31

2.5.2 Recommended Lugs

g

The following describes how to interpret lug model numbers used in grounding the

drive. Refer to table 2.2 for a list of recommended lug model and part numbers.

Basic Catalog Number

Num ber of C onductors

1 = One conductor

2 = Two conductors

3 = Three conductors

Mounting H ole and Lug Material

1 = One m ounting hole, copper

2 = One m ounting hole, alum inum

3 = Two m ounting holes, copper

4 = Two m ounting holes, alum inum

5 = Four mopunting holes, copper

6 = four mounting holes. aluminum

Lug Version N um ber

01 throu

h 99

1LG 1 2 03

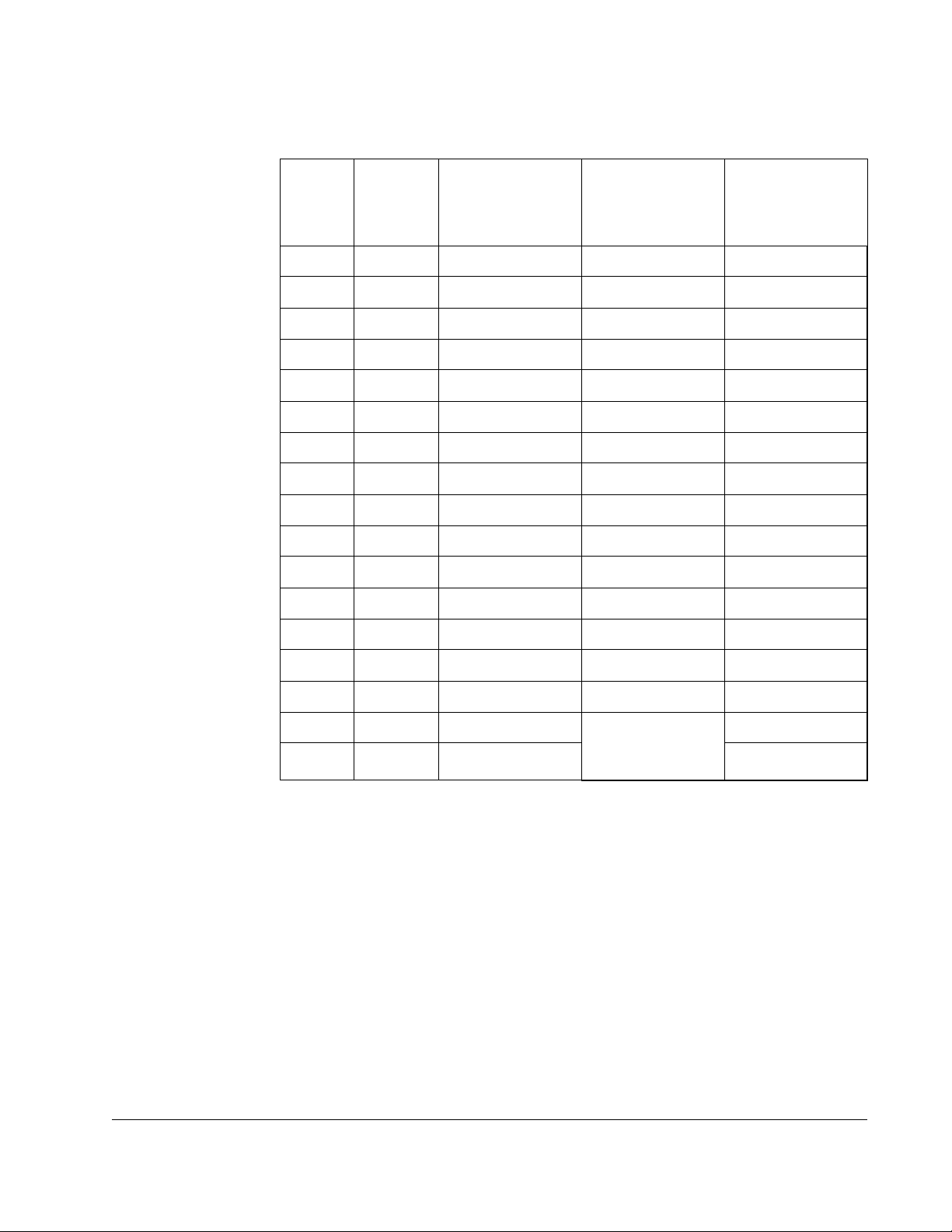

Table 2.2 – Recommended Lug Model and Part Numbers

Model

Number

1LG1101 68321-38AA 14 - 8 AWG M5 Copper

1LG1102 68321-38AB 14 - 8 AWG M6 Copper

1LG1103 68321-38AC 4 - 1/0 AWG M10 Copper

1LG1104 68321-38AD 1/0 - 4/0 AWG M12 Copper

1LG1105 68321-38AE 4/0 - 500 MCM M10 Copper

1LG1201 68321-38BA 14 - 1/0 AWG M6 Aluminum

1LG1202 68321-38BB 14 - 2/0 AWG M6 Aluminum

1LG1203 68321-38BC 6 - 250 MCM M8 Aluminum

1LG1204 68321-38BD 6 - 300 MCM M6 Aluminum

1LG1205 68321-38BE 6 - 350 MCM M10 Aluminum

1LG1206 68321-38BF 4 - 500 MCM M10 Aluminum

1LG1207 68321-38BG 300 - 800 MCM M12 Aluminum

1LG1208 68321-38BH 500 - 1000 MCM M12 Aluminum

1LG2401 68321-39BA 2 - 600 MCM M10 Aluminum

1LG2402 68321-39BB 350 - 800 MCM M10 Aluminum

1LG2403 68321-39BC 500 - 1000 MCM M12 Aluminum

1LG3601 68321-40BA 2 - 600 MCM M12 Aluminum

1.

Lugs are non-insulated screw type (solderless) for use with solid and stranded wire.

Reliance Part

Number Wire Size

Mounting

Hole Material

1

Install and Wire the Drive

2-17

Page 32

2.5.3 Wire AC Power to the Drive

ATTENTION:The user is responsible for conforming to the National

Electric Code (NEC/CEC) and all other applicable local codes. Wiring

!

Step 1. Size the AC line supply conductors for the specific drive rating and according

Step 2. Connect the AC line supply to the termination points located at the right top

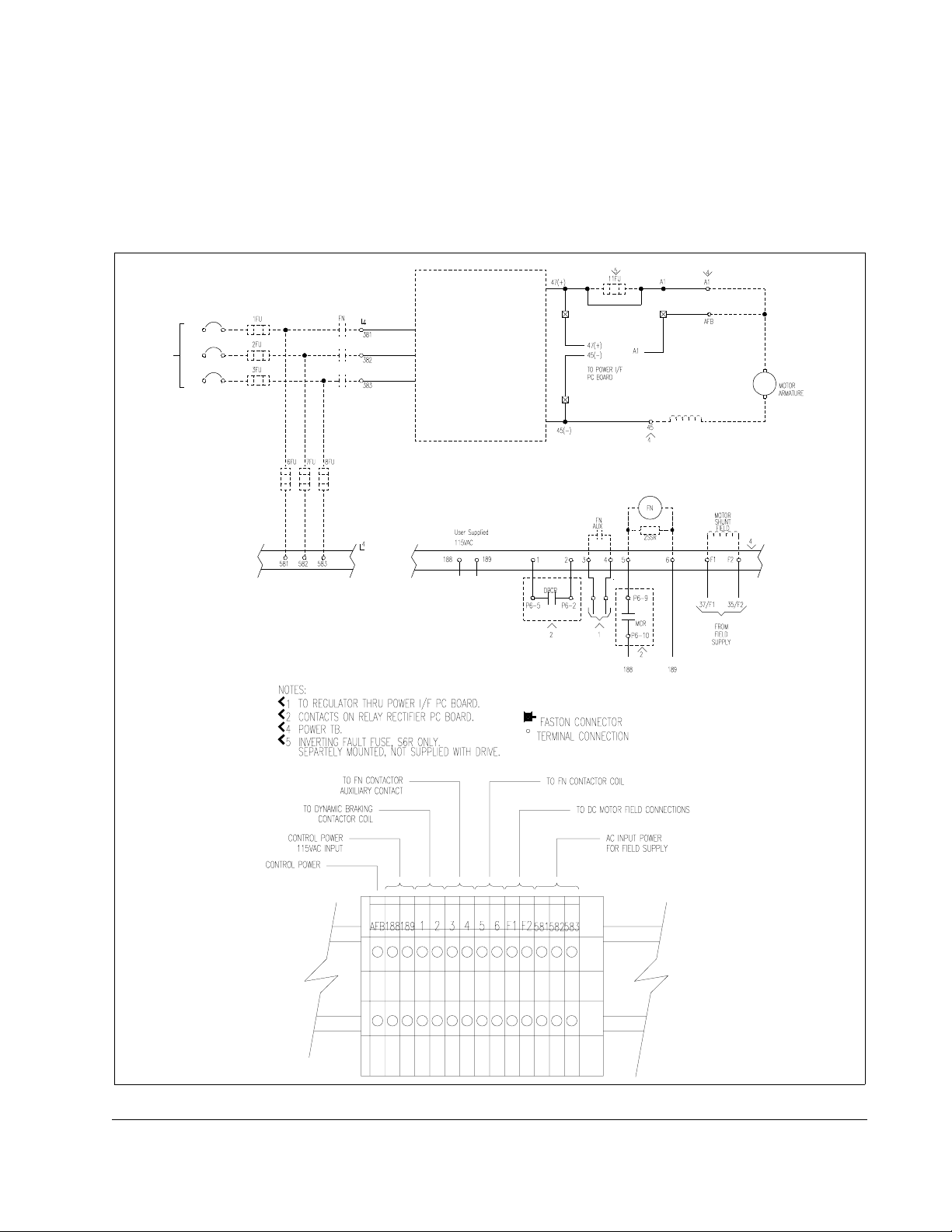

Step 3. (Integrator drives only) Connect the line fuses (1FU, 2FU, 3FU), field fuses

practices, grounding, disconnects, and overcurrent protection are of

particular importance. Size and install wiring in conformance with the

NEC/CEC and all other applicable codes. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:The drive requires a three-phase power source of either

230, 380, 415, or 460 VAC, 50 or 60 Hz. If the correct voltage is not

available, a transformer must be installed between the power source and

the drive. Do not connect the drive to a power source with available

symmetrical short circuit capacity in excess of the power source capacity

listed in Appendix A, tables A.6 and A.7. Failure to observe these

precautions could result in bodily injury or equipment damage.

to all applicable codes.

of the drive or to the disconnect. See figures 2.14 through 2.17.

(6FU, 7FU, 8FU), and the FN contactor to the drive as shown in figure 2.18.

Note that the line and field fuses must be wired as shown in figure 2.18 to

ensure proper phase relationships.

Step 4. (Integrator drives only) Connect the AC line supply to the line fuses (1FU,

2FU, 3FU).

Step 5. Tighten incoming AC line connections per table 2.3.

2-18

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 33

Table 2.3 – AC Line Torque Recommendations

AC Input

Horsepower 230 VAC 460 VAC

1.5 55 lb-in (6.2 Nm) ---------2 55 lb-in (6.2 Nm) ---------3 55 lb-in (6.2 Nm) 55 lb-in (6.2 Nm)

5 55 lb-in (6.2 Nm) 55 lb-in (6.2 Nm)

7.5 55 lb-in (6.2 Nm) 55 lb-in (6.2 Nm)

10 55 lb-in (6.2 Nm) 55 lb-in (6.2 Nm)

15 120 lb-in (13.6 Nm) 55 lb-in (6.2 Nm)

20 120 lb-in (13.6 Nm) 55 lb-in (6.2 Nm)

25 120 lb-in (13.6 Nm) 55 lb-in (6.2 Nm)

30 120 lb-in (13.6 Nm) 120 lb-in (13.6 Nm)

40 200 lb-in (22 Nm) 120 lb-in (13.6 Nm)

50 200 lb-in (22 Nm) 120 lb-in (13.6 Nm)

60 200 lb-in (22 Nm) 120 lb-in (13.6 Nm)

75 200 lb-in (22 Nm) 200 lb-in (22 Nm)

100 200 lb-in (22 Nm) 200 lb-in (22 Nm)

125 350 lb-in (40 Nm) 200 lb-in (22 Nm)

150 350 lb-in (40 Nm) 200 lb-in (22 Nm)

200 ---------- 200 lb-in (22 Nm)

250 ---------- 350 lb-in (40 Nm)

300 ---------- 350 lb-in (40 Nm)

400 ---------- 350 lb-in (40 Nm)

500 ---------- 350 lb-in (40 Nm)

600 ---------- 350 lb-in (40 Nm)

Rated Output Amps AC Input

7A 55 lb-in (6.2 Nm)

29A 55 lb-in (6.2 Nm)

55A 120 lb-in (13.6 Nm)

110A 120 lb-in (13.6 Nm)

265A 200 lb-in (22 Nm)

Install and Wire the Drive

Important: The tightening torque in the table applies to the wiring device (stud or

terminal board) provided. When an input or an output device (breaker or

lug kit) is added, refer to the kit instructions for tightening specifications.

2-19

Page 34

Figure 2.14 – AC Line Connection Location (1.5 to 30 HP @ 230 VAC 3 to 60 HP @ 460 VAC / 7-110 Amp Rated Output)

Figure 2.15 – AC Line Connection Location (40 to 75 HP @ 230 VAC /75 to 150 HP @ 460 VAC / 265 Amp Rated Output)

2-20

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 35

AC LINE

CONNECTION

AC LINE

CONNECTION

Shown Without Optional

AC Line Disconnect

Shown With Optional

AC Line Disconnect

Figure 2.16 – AC Line Connection Locations (100 to 150 HP @ 230 VAC / 200 to 300 HP @ 460 VAC)

Install and Wire the Drive

Figure 2.17 – AC Line Connection Locations (400 to 600 HP @ 460 VAC)

2-21

Page 36

2.5.4 Wire the DC Motor to the Drive

Step 1. Size the motor armature circuit conductors for the specific drive rating (see

Appendix A) and according to applicable codes. Use only copper wire rated

60/70°C or higher.

Step 2. Locate the DC motor armature and field supply leads on the drive. Refer to

figure 2.18 to 2.21.

Step 3. Connect the DC motor armature leads and the shunt field supply leads to the

drive. See figure 2.22.

Step 4. Tighten armature connections per table 2.4. Field connections should be

tightened to 9 lb-in (1.0 Nm). The tightening torque applies to the wiring

device (stud or terminal board) provided. When an input or output device

(breaker or lug kit) is added, refer to the kit instructions for tightening

specifications.

2-22

Figure 2.18 – DC Drive Motor Field and Armature Connection Locations

(1.5 to 30 HP @ 230 VAC /3 to 60 HP @ 460 VAC / 7-110 Amp Rated Output)

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 37

Figure 2.19 – DC Motor Field and Armature Connection Locations

(40 to 75 HP @ 230 VAC /75 to 150 HP @ 460 VAC / 265 Amp Rated Output)

Install and Wire the Drive

2-23

Page 38

Figure 2.20 – DC Motor Field and Armature Connection Locations

(100 to 150 HP @ 230 VAC / 200 to 300 HP @ 460 VAC)

2-24

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 39

Figure 2.21 – DC Motor Field and Armature Connection Locations (400 to 600 HP @ 460 VAC)

Install and Wire the Drive

2-25

Page 40

Figure 2.22 – DC Motor Connections (CCW Rotation Facing Commutator End Shown)

2-26

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 41

Table 2.4 – Armature Terminal Torqure Recommendations

Horsepower

Rated Drives

1.5 8-9 lb-in (.9-1.0 Nm) ------------2 8-9 lb-in (.9-1.0 Nm) ------------3 8-9 lb-in (.9-1.0 Nm) 8-9 lb-in (.9-1.0 Nm)

5 8-9 lb-in (.9-1.0 Nm) 8-9 lb-in (.9-1.0 Nm)

7.5 55 lb-in (6.2 Nm) 8-9 lb-in (.9-1.0 Nm)

10 55 lb-in (6.2 Nm) 8-9 lb-in (.9-1.0 Nm)

15 55 lb-in (6.2 Nm) 55 lb-in (6.2 Nm)

20 150 lb-in (16.9 Nm) 55 lb-in (6.2 Nm)

25 150 lb-in (16.9 Nm) 55 lb-in (6.2 Nm)

30 150 lb-in (16.9 Nm) 55 lb-in (6.2 Nm)

40 200 lb-in (22 Nm) 150 lb-in (16.9 Nm)

50 200 lb-in (22 Nm) 150 lb-in (16.9 Nm)

60 200 lb-in (22 Nm) 150 lb-in (16.9 Nm)

75 200 lb-in (22 Nm) 200 lb-in (22 Nm)

100 350 lb-in (40 Nm) 200 lb-in (22 Nm)

125 350 lb-in (40 Nm) 200 lb-in (22 Nm)

150 350 lb-in (40 Nm) 200 lb-in (22 Nm)

200 ------------- 350 lb-in (40 Nm)

250 ------------- 350 lb-in (40 Nm)

300 ------------- 350 lb-in (40 Nm)

400 ------------- 350 lb-in (40 Nm)

500 ------------- 350 lb-in (40 Nm)

600 ------------- 350 lb-in (40 Nm)

230 VAC Input 460 VAC Input

Armature Terminal Torque

Current Rated Drives Armature Terminal Torque

7A 8-9 lb-in (.9-1.0 Nm)

29A 55 lb-in (6.2 Nm)

55A 55 lb-in (6.2 Nm)

110A 150 lb-in (16.9 Nm)

265A 200 lb-in (22 Nm)

2.5.4.1 Wire Motor Overload Protection

Install and Wire the Drive

A software (internal) overload is provided that meets NEC/CEC and UL/C-UL

requirements. In addition to the software (internal) overload function, a DC motor

thermostat can be used for motor thermal overload protection. The thermostat leads

are brought out through the motor terminal box as leads P1 and P2. These two leads

must be wired to the regulator board terminal strip terminals 13 and 14.

ATTENTION: The thermostat leads to regulator board terminal strip pins

13 and 14 should be routed through a separate conduit away from motor

!

armature, field and blower motor power wiring.Failure to observe this

precaution could result in regulator board damage due to improper wiring

practices.

NOTE: The drive will not start if the circuit between terminals 13 and 14 is not made.

See figure 2.24.

2-27

Page 42

2.5.5 Wire the Stop Input

ATTENTION:The user must provide an external, hardwired emergency

stop circuit outside of the drive circuitry. This circuit must disable the

!

The FlexPak 3000 drive can be stopped by the assertion of a stop input (which can be

configured as a ramp stop, a current limit stop, or a coast/DB stop), opening a

permissive input (coast/DB interlock or customer interlock), deassertion of the

input, or in the event of a fault. Depending on the type of stop, one of two different stop

sequences

Previous to software version 4.0, once a stop sequence began, it ran to completion,

ignoring any

To the sequencing algorithm, the drive is always in one of three states: armature not

active (main contactor open), in run mode, or in jog mode. The drive is considered to

be in “run mode” if it was started by the

until the completion of a stop sequence. Note that the drive can also enter the run

mode from the jog mode if the

considered to be in “jog mode” if it was started via the

in jog mode until the completion of a stop sequence or the

causing the drive to switch from jog mode to run mode. Note that the OIM “RUNNING”

status indicates that the armature is active, either in run mode or jog mode.

system in case of improper operation. Uncontrolled machine operation

may result if this procedure is not followed. Failure to observe this

precaution could resu lt in bodily inj ury.

are executed to provide an orderly method of deactivating the armature.

RUN or JOG requests received during the stop sequence.

JOG

RUN input. The drive will remain in run mode

RUN input is asserted while in jog mode. The drive is

JOG input. The drive will remain

RUN input is asserted

Important: Only drives using software version 4.0 (and later) have the ability to

terminate a ramp/current limit stop sequence. Drives using earlier

versions of the software do not have this feature, and will ramp to stop

before a

in chapter 3 of the FlexPak 3000 Software reference manual for more

information.

The FlexPak 3000 drive can be configured to provide a coast-to-rest operational stop

without physical separation of the power source from the motor. A coast-to-rest stop

turns off the thyristor power device drivers.

In addition to the operational stop, the user must provide an external, hardwired

emergency stop external to the drive. The emergency stop circuit must contain only

hardwired electromechanical components. Operation of the emergency stop must not

depend on electronic logic (hardware or software) or on the communication of

commands over an electronic network or link.

RUN or jog request will be executed. Refer to “Stop Sequencing”

2-28

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 43

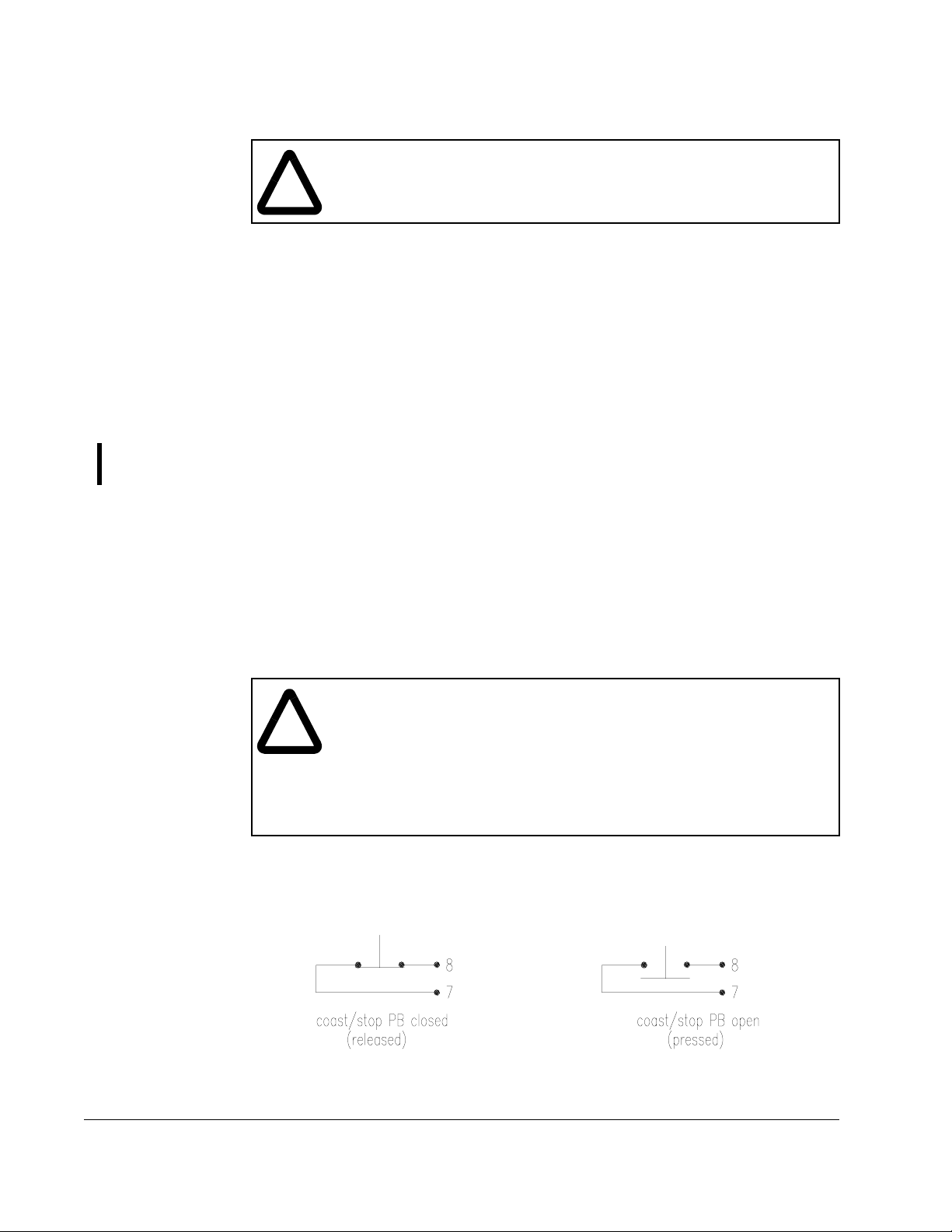

2.5.5.1 Wire the COAST/STOP Digital Input

The user must provide an external operator-accessible coast/stop pushbutton at

terminals 7 and 8 on the Regulator board to disable the machine in case of improper

operation. Uncontrolled machine operation might result if this is not done.

The customer interlock is a software-based stop function unless wired in series with

the coast/stop input. Any safety-related stops must be wired through the coast/stop

input. Use the following procedure to wire the coast/stop input.

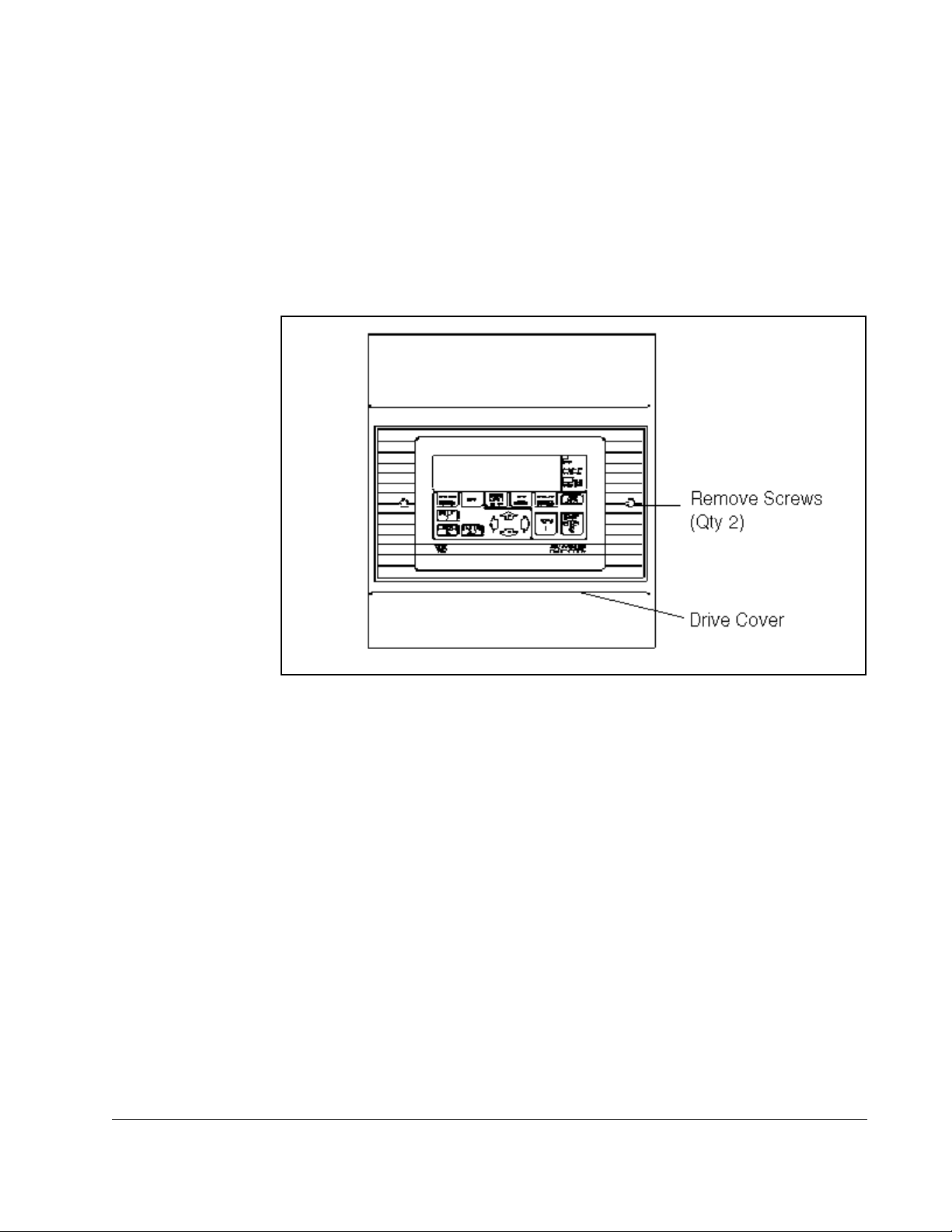

Step 1. Remove the two screws from the drive cover. See figure 2.23.

Figure 2.23 – Drive Cover Removal

Step 2. Locate the terminal strip (1 to 32) at the bottom of the regulator board. See

figure 2.25.

Step 3. Connect a normally closed Coast/Stop pushbutton to terminals 7 (+24V) and

8. See figure 2.24.

Step 4. Tighten these terminal connections to a torque not to exceed 7 lb-in (0.8

Nm).

2.5.5.2 Compliance with EN 60204-1: 1992

This section applies to users who must comply with EN 60204-1: 1992, part 9.2.5.4,

Emergency Stop.

In order to fully comply with EN60204-1: 1992, part 9.2.5.4, at least one of the stop

methods must be a category 0 stop. See section 2.6.5 for more information.

Install and Wire the Drive

2-29

Page 44

Optional Jog selector swi tc h

Start

Stop

Run

Jog

Optional Jog with

maintained contact

1

2

3

4

Run

Run

Jog

Jog

Start/Stop

1

2

3

4

2-30

Figure 2.24 – Sample Regulator Board Termin al Strip Connect ion Diagram

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 45

RS-232

Connector

Figure 2.25 – Location of Regulator Board Terminal Strip

Install and Wire the Drive

2-31

Page 46

2.5.6 Wire Optional Devices to the Drive

ATTENTION:Do not route signal wiring with power wiring in the same

conduit. This might cause interference with drive operation. Route signal

!

Refer to figures 2.24 and 2.25 and table 2.5 when wiring optional devices to the drive.

Size and install all wiring in accordance with the NEC and all other applicable local

codes.

RUN 1 (+24V) and 2

STOP 1 (+24V) and 3

JOG 1 (+24V) and 4

REV/FWD 1 (+24V) and 5

AUTO/MAN 1 (+24V) and 6

INTERLOCK 9 and 11 (+24V)

FAULT/ALARM RESET 10 and 11 (+24V)

DIGITAL INPUT 0 12 and 14 (+24V)

MOTOR THERMOSTAT 13 and 14 (+24V)

SPEED REFERENCE

POTENTIOMETER:

AUTO REFERENCE:

(+)

(-)

TACHOMETER (Analog):

High Range

Low Range

Common

METER OUTPUT 1 24 and 25 (common)

METER OUTPUT 2 25 (common) and 26

RUNNING (Indicator) 27 and 28

ALARM (Indicator) 29 and 30

NO FAULT (Indicator) 31 and 32

1.

Analog tachometer must be rated between 18 and 200 Volts/1000 RPM. The output voltage must not

exceed 250 V for a DC tachometer or 275 RMS for AC tachometers when the motor is rotating at the

value set for the TOP SP EED parameter. To calcu late the output voltage at top speed:

Tachome ter Voltage at TOP SPEED = TOP SPEED

See section 3.4.7 for information on jumpers J14 and J11.

2.

When the maximum tach voltage at top speed is 62 VDC, use terminals 22 and 23 to connect the analog

tachometer. When the maximum tach voltage at top speed is 250 VDC, use terminals 21 and 23 to

connect the analog tachometer.

wiring and power wiring in separate conduits. Failure to observe this

precaution could result in damage to, or destruction of, the equipment.

Table 2.5 – User Device Connections to the Regulator Board Terminal Str ip

User Device

• High Side (+10 ISOL)

• Wiper (+ MAN REF)

• Low Side (-MAN REF)

1

2

2

2

1000 1000

Regulator Board

Terminal Strip Numbers

16

17

18

19

20

21

22

23

x ANALOG TACH VOLTS

2-32

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 47

2.5.6.1 Logic Inputs

ATTENTION:Connecting an external power source to any of the +24

volt connections (terminals 1, 7, 11, and 14) on the Regulator board

!

The logic input circuits can be powered either from the internal +24 volt DC power

supply or from an external +24 volt DC power source. The internal +24 volt DC power

supply is available at the Regulator board terminal strip (see figure 2.16). If an

external power source is used, only the common must be connected to 24 V

COM on the Regulator board (terminal 15).

2.5.6.2 Logic Outputs

The logic output circuits are normally-open (when de-energized) relay contacts. When

energized (contacts closed) the three circuits indicate the following drive conditions.

Terminals are on the Regulator board terminal strip.

• Running Terminals 27 and 28

• Alarm Terminals 29 and 30

• No Fault Terminals 31 and 32

terminal strip will damage the drive. DO NOT connect the external power

source on the +24 volt connections on the Regulator board terminal strip.

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

2.5.6.3 Analog Inputs

The three customer analog inputs are Manual Mode Reference, Automatic Mode

Reference, and Analog Tachometer Feedback. At their full range, these inputs are

converted at 12 bits plus sign.

2.5.6.4 Analog Outputs

The two metering analog outputs are available at Regulator board terminals 24, 25,

and 26. Terminal 25 is the common connection for both output signals. The selected

signals for both meter outputs are averaged (filtered) over 100 msec to reduce meter

fluctuations.

Parameter

METER OUT 2 SELECT corresponds to terminals 25 and 26. Refer to these parameters

in Appendix B for additional drive test points that ban be configured to source Meter

Outputs 1 and 2.

METER OUT 1 SELECT corresponds to terminals 24 and 25. Parameter

Install and Wire the Drive

2-33

Page 48

2-34

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 49

Drive Setup and Adjustment

ATTENTION:Only qualified electrical personnel familiar with the

construction of this equipment and the hazards involved should install,

!

3.1 Perform a Power Off Inspection

Inspect the drive and modification kits for possible physical damage or improper

connections.

Verify that the wiring of the operator's station and the wiring to the drive is made with

sufficient bare wire to make a good electrical connection. The removal of an excessive

length of insulation may needlessly expose conductors, resulting in the possibility of

shorts or safety hazards.

adjust, operate, and/or service this equipment. Read and understand

this section in its entirety before proceeding. Failure to observe this

precaution could result in severe bodily injury or loss of life.

CHAPTER 3

3.2 Verify Control Transformer Tap Settings

Before input power is applied to the drive, verify that the control transformer taps are

set to match the input power . Note that most FlexPak 3000 drives ship from the factory

configured for 460 VA C input power (or 415 VAC for current-rated drives). These

factory settings can be changed to configure the drive for 230 VAC or 380 VAC input

power. The conversion procedures are described in sections 3.2.1 and 3.2.2.

3.2.1 Converting a Drive for 380 VAC Input Power

ATTENTION:380/415 VA C-rated FlexP ak 3000 drives can be configured

for either 380 VA C or 415 VAC input power . Before input power is applied

!

380/415 VAC-rated drives are shipped from the factory configured for 415 VAC line

input. Wire 782 is connected to terminal H1 and wire 783 is connected to terminal H3.

To configure the drive for 380 VAC operation, perform the following steps:

Step 1. Disconnect and lock out all incoming power to the drive.

Step 2. Move wire 783 to terminal H2. See figures 3.1 and 3.2 for terminal locations.

Step 3. Through the OIM, perform the Nominal AC Line Volts Adjust procedure as

to the drive, verify that the control transformer taps are set to match the

input power. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

described in section 3.9.

Drive Setup and Adjustment

3-1

Page 50

Figure 3.1 – Control T ransformer Locations and Settings (380/415 VAC Drives)

3.2.2 Converting a Drive for 230 VAC Input Power

ATTENTION:230/460 VA C-rated FlexP ak 3000 drives can be configured

for either 230 VA C or 460 VAC input power . Before input power is applied

!

Most 230/460 VAC-rated drives are shipped from the factory configured for 460 VAC

line input. For drives rated at less than 200 HP, a conversion kit (M/N 916FK0100 or

916FK0200) is required to convert FlexPak 3000 drives for 230 VAC line input. Drives

rated at 200 HP to 300 HP can be converted to 230 VAC input power by performing

the following steps. After conversion, the drive will operate at one-half the rated

horsepower (200 HP @ 460 VAC will convert to 100 HP @ 230 VAC).

Important: The following procedure applies only to drives rated at 200 HP to 300 HP.

Step 1. Disconnect and lock out all incoming power to the drive.

Step 2. Disconnect the jumpers between H2 and H3 on the control transformer. See

Step 3. Use the jumpers that were removed to connect H1 to H3 and H4 to H2, as

to the drive, verify that the control transformer taps are set to match the

input power. Failure to observe this precaution could result in damage

to, or destruction of, the equipment.

Higher horsepower drives cannot be converted for 230 VAC input power.

figure 3.2 for the location of the control transformer and the terminal

positions.

shown in figure 3.2.

3-2

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 51

Step 4. Re-connect power to the drive.

Step 5. Through the OIM, access the

the value to 230.

NOMINAL AC LINE VOLTS parameter (P.037). Set

3.3 Perform a Motor Ground Check

Drive Setup and Adjustment

Figure 3.2 – Control Transformer Settings (230/460 VAC)

ATTENTION:A megohmmeter can be used for this motor ground check,

but all conductors between the motor and the drive must be

!

The DC motor frame and conduit box should be connected to a good earth ground per

the motor instruction manual.

disconnected. The megohmmeter’s high voltage can damage the drive’ s

electronic circuits. Disconnect all conductors between the motor and the

drive before using a megohmmeter for this motor ground check. F ailure

to observe this precaution could result in damage to, or destruction of,

the equipment.

3-3

Page 52

V erify that there is no path to ground in either the DC motor armature circuit, the shunt

field circuit or the thermostat circuit. Connect one lead of an ohmmeter to the motor

frame and the other lead to the two armature leads, then to the two field leads and to

the two thermostat leads. If a reading of less than 100,000 ohms is observed, a

ground condition exists and MUST be corrected before power is applied.

3.4 Set Jumpers

ATTENTION:This equipment is at line voltage when AC power is

connected to the drive. Disconnect and lock out incoming power to the

!

The jumper settings for the FlexPak 3000 drive determine the regulator type, program

protection, field settings, references for automatic and manual modes, tachometer

voltage range, and armature feedback scaling.

There are a few guidelines for setting jumpers:

• Through the OIM, check the current jumper settings for J11, J14, and J18 in the

Correct Scaling Jumper Positions menu under Drive Information. Write down

these settings as displayed and make sure the actual settings match.

drive before proceeding. After power is removed, verify with a voltmeter

at power terminals 181, 182, and 183 that no voltage exists before

touching any internal parts of the drive. Failure to observe this precaution

could result in severe bodily injury or loss of life.

ATTENTION:Unless explicitly stated otherwise, power must be removed

before changing any jumper connection. Failure to observe this

precaution could result in damage to, or destruction of, the equipment.

• Through the OIM, check the current settings for J15, J20, and J21 in the Drive

Information menu. If these settings are correct for your system, you do not need to

change them.

Jumpers are read only on power-up, so power must be cycled for a change to a

jumper setting to be recognized by the drive.

To set the jumpers:

Step 1. Remove power from the drive.

Step 2. Remove the cover . Refer to figure 2.15 for cover remov al. You do not need to

remove the keypad.

Step 3. The jumpers are located on the Regulator board. See figure 3.3 for jumper

locations.

Step 4. Set the jumpers as described in secti ons 3.4.1 through 3.4.13. Record the

settings in table 3.1.

3-4

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 53

Table 3.1 – Jumper Settings

DEFAULT

JUMPER

SETTING FINAL SETTING

J15 (REGULATOR TYPE) SPEED

J16 (OIM PROGRAM) ENABLE

J20 (FIELD LOSS DETECT) ENABLE

J21 (FIELD SUPPLY JUMPER) B-C

J19 (MANUAL REF) POT

J14 (TACH V RANGE) 62

J11 (TACH V SCALE) 16

J10 (AUTO REF) VOLTS

J12 (AUTO REF) VOLTS

J18 (ARM I FB RB) Position 4

J26 (not used)

J27 (SPARE 1) (not used)

J28 (FILTER SELECT) (not used)

J29 (SPARE 2) (not used)

J30 (POWER UNIT) LOW

3.4.1 Set the Regulator Type (Jumper J15)

J15 determines whether the drive uses speed/voltage or torque/current regulation.

When

CURRENT is selected, only the terminal strip, the DeviceNet Communication

Board, or the AutoMax Network Communication Board can be used as a control

source. When J15 is set to

changed.

Also note that speed/voltage parameters must be set to provide overspeed protection

for the drive.

CURRENT, the drive is fixed in auto mode and cannot be

Jxx is not used. Do not

install a shorting bar

across pins of this jumper.

Drive Setup and Adjustment

3-5

Page 54

Figure 3.3 – Regulator Board Jumpers

3.4.2 Setting Program Protection (Jumper J16)

The OIM program jumper (J16) determines whether or not parameter changes can be

made through the ke ypad (OIM). Only programming options are affected by the setting

of this jumper. The OIM drive control keys (such as RUN and JOG) and the manual

speed reference are not affected.

To allow keypad parameter changes, place the jumper on pins 1 and 2 (ENABLE).

To prevent parameter changes through the keypad, place the jumper on pins 2 and 3

(DISABLE). Parameters cannot be modified through the keypad. If an attempt to

modify a parameter is made, the message “Hardware Password Protection is

Enabled” is displayed on the keypad display.

3-6

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 55

3.4.3 Set Field Loss Detection (Jumper J20)

The FIELD LOSS DETECT jumper (J20) determines whether or not a fault is

generated when a field loss occurs.

Important: Jumper J20 is ignored if the Field Current Regulator kit is installed.

Therefore, placing J20 in the DISABLE position will not disable field loss

detection. See I/M D2-3336 for more information on the Field Current

Regulator.

ATTENTION:The user must provide external field current loss detection

and inhibit drive operation via one of the drive interlocks when this jumper

!

To detect complete loss of field current, place the jumper on pins 1 and 2 (ENABLE).

When a complete loss is sensed, a fault is generated and the drive is stopped.

To ignore field loss, place the jumper on pins 2 and 3 (DISABLE). Any loss of field

current is ignored. Use the DISABLE option only when no field exists, such as with a

permanent magnet motor or when a separate field supply is used.

is positioned to DISABLE. Misapplication of this jumper can cause the

motor to run at dangerously high speeds. Provide external field current

loss detection and inhibit drive operation using one of the drive interlocks

if this jumper is positioned to disable. Failure to observe this precaution

could result in bodily injury

3.4.4 Set the Drive for the Enhanced Field Supply (Jumper J21)

Note that this jumper has no effect on the standard field supply or the optional Field

Current Regulator kit.

The FIELD SUPPLY JUMPER (J21) determines the voltage range that the drive

expects to see from the optional Enhanced Field Supply kit. Refer to I/M D2-3298 or

D2-3413 for more information on the Enhanced Field Supply.

The DC voltage range can be either from 45% to 90% or from 90% to 112.5% of AC

RMS line voltage.

To set the drive f o r a voltage range of 45% to 90%, place the jumper on pins 1and 2

(B-C).

To set the drive for a voltage range of 90% to 112.5%, place the jumper on pins 2 and

3 (A-C).

3.4.5 Set the Source for the Manual Mode Reference (Jumper J19)

ATTENTION:The drive will not operate at the correct speed if this jumper

is not set to the correct position. Failure to observe this precaution could

!

The MANUAL REF jumper (J19) determines whether the internal +10 V isolated

power supply or an external +10 V source is used for the manual mode reference.

result in damage to, or destruction of, the equipment.

Drive Setup and Adjustment

3-7

Page 56

To use the +10V power supply for the manual reference potentiometer, place the

jumper on pins 2 and 3 (POT). The supply at terminal 16 of the regulator board

terminal strip is used.

To use an external +10 V source, place the jumper on pins 1 and 2 (EXT). The

external reference is connected at terminals 17 and 18 of the regulator board terminal

strip.

Note that this input can be used as a trim on the auto mode speed reference by setting

the jumper on pins 1 and 2 (EXT).

3.4.6 Set the Voltage Range and Scale of an Analog Tachometer

(Jumpers J14 and J11)

The TACH V RANGE (J14) and TACH V SCALE (J11) jumpers set the voltage range

and scale of the analog tachometer.

Note: This jumper is ignored if an analog tachometer is not used and if FEEDBACK

SELECT is not set to DC TACH or AC TACH.

ATTENTION:The drive will not operate at the correct speed if these

jumpers are not set to the correct positions. Failure to observe this

!

precaution could result in damage to, or destruction of, the equipment.

During the quick start procedure, the drive calculates the value of the tachometer

voltage range based on the values of TOP SPEED and ANLG T A CH VOLTS/1000 and

the setting of FEEDBACK SELECT. The correct values are displayed on the Correct

Scaling Jumper Positions screen. Verify these jumper settings before performing the

self-tuning procedure.

The expected analog tachometer voltage range can be set to a maximum of 250 VDC

or 62 VDC. J11 selects the hardware circuitry to maximize the resolution over the

entire speed range.

Jumpers

Voltage J14 J11

Top Speed Tach Volts < 16 volts

Top Speed Tach Volts < 31 volts LOW 31/125

Top Speed Tach Volts < 62 volts LOW 62/250

Top Speed Tach Volts < 125 volts HI 31/125

Top Speed Tach Volts < 250 volts HI 62/250

1.

For proper operation, minimum tach voltage must be at least 18V/1000.

Note that the output voltage of the tachometer must not exceed 250 V for DC

tachometers or 275 RMS for AC tachometers when the motor is rotating at TOP

SPEED. To calculate the output voltage at top speed, multiply the two parameter

values:

1

LOW 16

3-8

Tachometer Voltage at TOP SPEED = TOP SPEED

1000 1000

See table 2.7 for tachometer connections to the Regulator board terminal strip.

FlexPak 3000 DC Drive Hardware Reference Version 4.3

x ANALOG TACH VOLTS

Page 57

3.4.7 Set the Analog Auto Mode Reference (Jumpers J12 and J10)

The AUTOREF jumpers (J12 and J10) select the type of analog auto reference to be

used when the AUTO mode is selected. J12 selects the type of signal (voltage or

milliamps). J10 selects the range. See figure 3.4 for the jumper settings.

Figure 3.4 – AUTO REF Jumpers (J12 and J10)

3.4.8 Scale the Armature Current Feedback (Jumper 18)

ATTENTION:The drive will not operate at the correct speed if this jumper

is not set to the correct position. Failure to observe this precaution could

!

The ARM I FB RB jumper (J18) scales the armature current feedback signal. The

drive calculates the value of the burden resistor needed to scale the armature current

feedback signal. The calculations are based on the values of MOTOR RATED ARM

AMPS, MAXIMUM CURRENT and CT Turns Ratio.

result in damage to, or destruction of, the equipment.

The OIM displays the correct position of the jumper during the quick start procedure.

Verify this jumper setting before performing the self-tuning procedure.

3.4.9 Inspect Jumper J26

ATTENTION:Jumper J26 is for Reliance use only. The user must not

change the status of this jumper . Misapplication of this jumper can cause

!

J26 is intended for use by Reliance factory personnel only . Verify that it is set as listed

in table 3.1.

the motor to run at dangerously high speeds. Failure to observe this

precaution could result in severe bodily injury or loss of life.

3.4.10 Inspect the Spare 1 Jumper (J27)

J27 is not used. The position of this jumper has no effect on the drive. Verify that it is

set as listed in table 3.1.

3.4.11 Inspect the Filter Select Jumper (J28)

J28 is not used. Do not install a jumper block on this jumper.

3.4.12 Inspect the Spare 2 Jumper (J29)

J29 is not used. The position of this jumper has no effect on the drive. Verify that it is

set as listed in table 3.1.

Drive Setup and Adjustment

3-9

Page 58

3.4.13 Inspect the Power Unit Jumper (J30)

ATTENTION:The drive can operate at excessive armature voltage and

speed if J30 is improperly set to the LOW position when it should be set

!

Important: An optional Power Interface module, f or drives which are powered from a

Jumper J30 must be set to “HI” if the drive nameplate indicates that the AC line input

voltage is 690 Vrms. Otherwise, J30 must be set to “LOW”.

Improper setting of jumper J30 can cause the drive to operate at the wrong speed if

configured as a voltage regulator, nuisance AC line voltage high/low alarms and

incorrect armature and AC line voltage displays. J30 is not supplied with U.S. Drives.

to HI.

690 Vrms AC line, is available only on drives manufactured by Reliance

Electric Dierikon, Switzerland. In order to operate properly with this new

power I/F module, a hardware jumper (J30) was added to the regulator

board. This jumper must be set according to the type of power interface

module installed in the drive. Jumper positions are labeled “LOW” and

“HI”.

3.5 Power Up the Drive

Apply AC power to the drive after you complete the power off inspection, motor ground

check, and drive setup procedures.

See the OIM instruction manual for the displays during power-up.

3.6 Verify the Correct Direction of Motor Rotation

ATTENTION:The user must provide an external operator-accessible

coast/stop pushbutton at terminals 7 and 8 on the Regulator board to

!

Step 1. Disconnect and lock out all incoming power to the drive.

Step 2. Verify the operation of the Coast/Stop pushbutton using an ohmmeter. When

disable t he machine in case of improp er operation. Uncon trolled machine

operation might result if this is not done. F ailure to observe this precaution

could result in severe bodily injury or loss of life.

ATTENTION:If tachometer rotation is incorrect, sudden and rapid

acceleration may result, which can cause overspeed of the drive. F ailure

to observe this precaution could result in bodily injury.

the pushbutton is pressed, the ohmmeter should read infinite ohms (open);

when released, it should read 0 (short).

3-10

Step 3. Turn power to the drive ON.

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 59

Step 4. After power-up, select ARMATURE VOLT for FEEDBACK SELECT by taking

the following path from the main menu to access this parameter:

Speed/Voltage Loop (SPD)

Speed/Voltage Loop (SPD) Feedback

Refer to the FlexPak 3000 Software Reference manual for more information

on changing parameter values.

Step 5. Initiate a JOG command to verify that the motor is rotating in the desired

direction for the Forward command.

Step 6. If the direction of rotation is incorrect, stop the drive and then disconnect and

lockout or tag power to the drive.

Step 7. T o change the direction of motor rotation, re verse the connection of the motor

armature leads A1 and A2.

Important: Wrong rotation direction can be caused by incorrect wiring of the field (F1

and F2).

3.7 Determine the DC Tachometer Lead Polarity

Step 1. Turn power to the drive ON.

Step 2. After power-up, select ARMATURE VOLT for FEEDBACK SELECT by using

the following an OIM path from the main menu to access this parameter:

Speed/Voltage Loop (SPD)

Speed/Voltage Loop (SPD) Feedback

Refer to the FlexPak 3000 Software Reference manual for more information

on changing parameter values.

Step 3. Select the forward direction (as indicated above the Forward/Reverse key on

the OIM).

Step 4. Initiate a JOG command.

Step 5. Use a voltmeter on the tachometer leads to determine the lead polarity for

the forward direction of rotation. Label the tachometer leads accordingly (+

and -).

Step 6. Verify that the (+) tachometer lead is connected to terminal 21 or 22, and that

the (-) tachometer lead is connected to terminal 23. If the (+) tachometer lead

is not connected to terminal 21 or 22, stop the drive. Disconnect and lockout

or tag power to the drive. Reverse the connection of the tachometer leads.

3.8 Make Tachometer and Armature Feedback Zero

Adjustments

This section describes zero adjustments that compensate for signal drift when

tachometer or armature feedback is used. See the OIM instruction manual for

instructions on changing these parameter values.

Drive Setup and Adjustment

3-11

Page 60

ATTENTION:The incorrect setting of the parameters described below

can cause an overspeed condition. These parameters must be set by a

!

Step 1. Stop the drive.

Step 2. Check the value of the output parameter ARMATURE VOLTAGE (P.289).

Step 3. Adjust ARM VOLTAGE ZERO (P.205). If ARMATURE VOLTAGE was more

Step 4. Repeat steps 2 and 3 until ARMATURE VOLTAGE is zero.

Step 5. Record the final value of ARM VOLTAGE ZERO in table 3.1.

Step 6. Check the value of output parameter ANALOG TACH FEEDBACK (P.291).

Step 7. Adjust ANALOG TACH ZERO (P.202). If ANALOG TACH FEEDBACK was

Step 8. Repeat steps 2 and 3 until ANALOG TACH FEEDBACK is zero.

qualified person who understands the significance of setting them

accurately . V erify that the value of these parameters is accurate f or your

application. Failure to observe this precaution could result in bodily injury.

If the value is 0: Go to step 5.

If the value is not zero: Go to step 3.

than 0 (positive), adjust ARM VOLTAGE ZERO to a negative value. If it was

less than 0 (negative), adjust ARM VOLTAGE ZERO to a positive value.

If the value is 0: Go to step 9.

If the value is not zero: Go to step 7

more than 0 (positive), adjust ANALOG TACH ZERO to a negative value. If it

was less than 0 (negative), adjust ANALOG TACH ZERO to a positive value.

Step 9. Record the final value of ANALOG TACH ZERO in table 3.1.

3.9 Make Fin al Adjustments

Set the quick start parameters and perform drive self-tuning, as described in the OIM

instruction manual.

When Quick Start and self-tuning are complete, adjust the nominal AC line frequency

and volts as follows. See the OIM instruction manual for information on setting

parameters.

Step 1. The default value of parameter NOMINAL AC LINE FREQ ((P.306) is 60 Hz.

Adjust the frequency to the nominal value of the line frequency for your

application.

Step 2. The default value of parameter NOMINAL AC LINE VOLT (P.307) is 230 VAC .

Adjust the voltage to the nominal value of the line RMS voltage for your

application.

3-12

FlexPak 3000 DC Drive Hardware Reference Version 4.3

Page 61

Troubleshooting/Diagnostics

ATTENTION:Only qualified electrical personnel familiar with the

construction of this equipment and the hazards involved should install,

!

This chapter details troubleshooting and diagnostics information fro the FlexPak 3000

drive.

The OIM also provides fault and alarm detection. See the OIM instruction manual

(D2-3344) for information on the faults and alarms and possible corrective actions.

4.1 Check for Wiring Errors

adjust, operate, and/or service this equipment. Read and understand

this section in its entirety before proceeding. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:This equipment is at line voltage when AC power is

connected. Disconnect and lock out all ungrounded conductors of the

AC power line before checking wiring. Failure to observe this precaution

could result in severe bodily injury or loss of life.

CHAPTER 4

Wiring errors and loose or grounded wiring are common problems that can inhibit

operation of a drive. Verify that the wiring has been correctly installed and that the

drive is free of loose terminations and grounded conductors.

4.2 Verify AC Line and Power Inpu t

Verify that the applied AC power is correct for the specific drive. If an isolation

transformer has been installed on the incoming AC power lines, verify its output

voltage and that it has been properly connected. Verify that the AC line fuses have

been correctly sized. The AC and DC power conductors should have been sized per

the National Electric Code (NEC) or Canadian Electric Code (CEC).

Troubleshooting/Diagnostics

4-1

Page 62

4.3 Verify DC Motor Connections

ATTENTION: A megohmmeter can be used for this motor ground check,

but all conductors between the motor and the drive must be

!

Verify that all DC motor connections are correct.

• Recheck all motor connections for tightness and correct identification.

• Verify that there is no path to ground in either the DC motor armature circuit, the