Loading...

Loading...E

- Emonitor with a Gupta Single-User Database

- Emonitor with an MS SQL Networked Database

- Emonitor with an Oracle Multi-User Database

- Emulate 55702

- Energy Management Accelerator Toolkit

- Enwatch B Series

- Enwatch EK-44750C

- Enwatch EK-44750C-RK24V

- Ethernet Design Considerations

- EtherNet/IP

- Ethernet Media

- External Dynamic Brake Kit

- External Dynamic Brake Resistor Recommended Protection

F

- F1770-KFCD15

- F-6300

- FactoryTalk4

- FactoryTalk Alarms and Events

- FactoryTalk AssetCentre

- FactoryTalk AssetCentre Machine Edition

- FactoryTalk Batch3

- FactoryTalk Batch Components

- FactoryTalk Batch View2

- FactoryTalk Edge Gateway

- FactoryTalk Historian Classic2

- FactoryTalk Historian ME 2.2

- FactoryTalk Historian SE

- FactoryTalk Historian SE 3.04

- FactoryTalk Historian SE 3.01

- FactoryTalk Historian SE 4.02

- FactoryTalk Historian SE ActiveView 3.2

- FactoryTalk Historian SE DataLink 4.2

- FactoryTalk Historian SE ProcessBook 3.2

- FactoryTalk Linx2

- FactoryTalk Metrics

- FactoryTalk Metrics Line Edition

- FactoryTalk Network Manager

- FactoryTalk Report Expert

- FactoryTalk Scheduler

- FactoryTalk Security System

- FactoryTalk Transaction Manager

- FactoryTalk Translation Utility

- FactoryTalk View Machine Edition3

- FactoryTalk ViewPoint

- FactoryTalk ViewPoint Guide

- FactoryTalk View Site Edition2

- FANM FanMaster Energy Saving Package

- FD86N Drive Systems Enclosure Hardware

- FERROGARD GD2 Magnetically Actuated Interlock Switch

- Ferrotek Coded Magnetic Safety Switch Control Unit

- FLEX

- FLEX 50003

- FlexPak 3000 115

- FlexPak 3000 DC Drive

- FlexPak 3000 Digital DC Drive

- FlexPak 3000 Drive Field Current Regulator

- FlexPak 3000 Power Module

- FlexPak Plus Auxiliary Panel

- FlexPak Plus Contactor Auxiliary Contact

- FlexPak Plus DB

- FlexPak Plus DC Drive

- FlexPak Plus DC Drive Field Supply

- FlexPak Plus DC Drive Reversing Contactor

- FlexPak Plus Incoming Line CB

- FlexPak Plus M-Contactor Adapter

- FlexPak Plus/MinPak Plus Dancer Follower

- FlexPak Plus, MinPak Plus DC Drive Automatic Reversing

- FlexPak Plus, MinPak Plus DC Drive Auxiliary M-Contactor

- FlexPak Plus, MinPak Plus DC Drive Dynamic Braking

- FlexPak Plus, MinPak Plus DC Drive Torque Taper

- FlexPak Plus/MinPak Plus Tachometer Feedback

- FlexPak Plus/MinPak Plus Test Meter Adapter

- FlexPak Plus/MinPak Plus Voltage

- FlexPak Plus NRG DC Drive

- FlexPak Plus Reversing Contactor

- FlexPak-WebPak 3000 DC Drive AutoMax Network Communication Board

- Flex-WebPak 30007

- Flowmeter Dosing

G

Loading...

Loading... Loading...

Loading...Nothing found

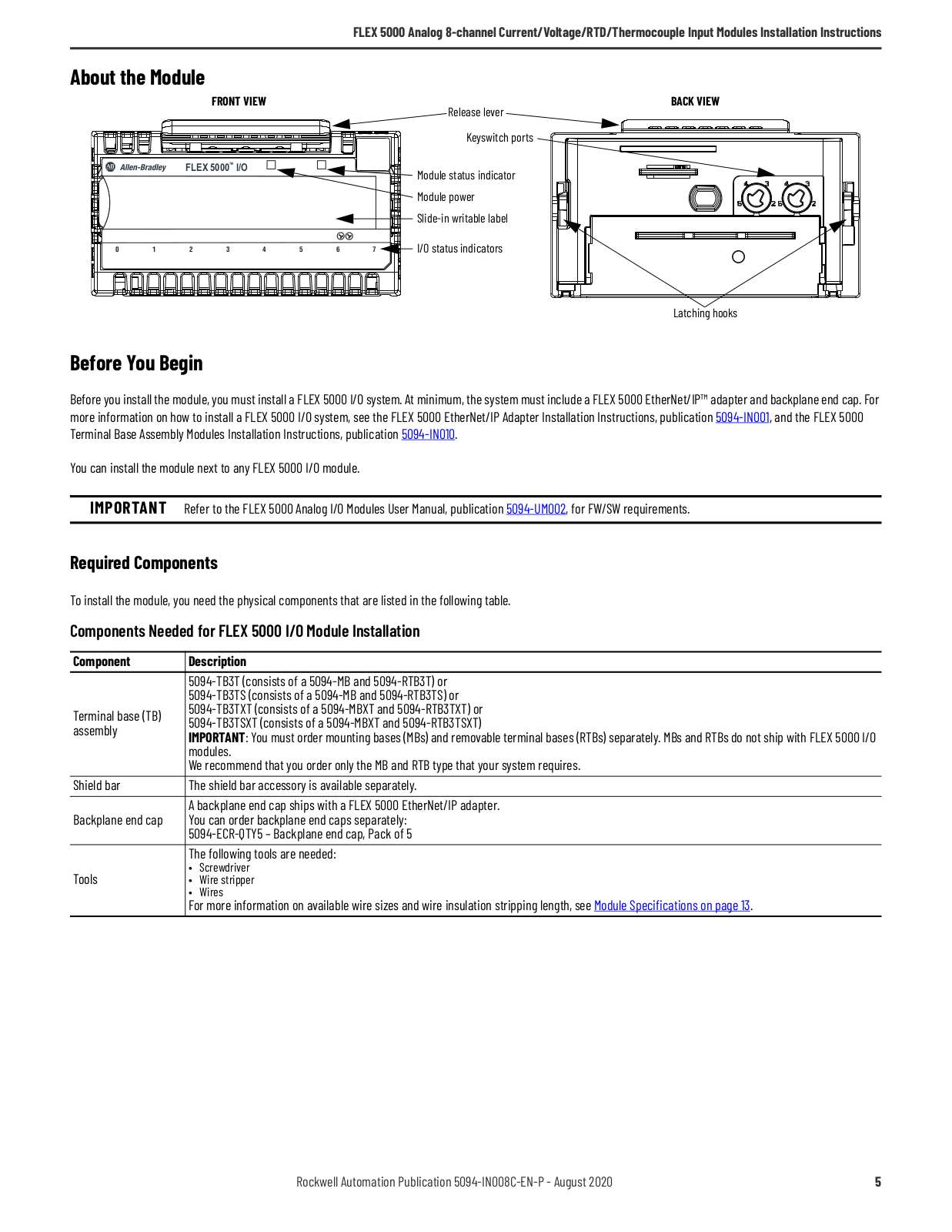

FLEX 5000

Table of contents

Loading...

Loading...Specifications and Main Features

Frequently Asked Questions

User Manual

Loading...

Loading...+ hidden pages