Page 1

FLEX 5000 Analog Isolated

Current/Voltage/HART Input

and Output Modules

Catalog Numbers 5094-IF8IH, 5094-IF8IHXT, 5094-OF8IH,

5094-OF8IHXT

User Manual

Original Instructions

Page 2

FLEX 5000 Analog Isolated Current/Voltage/HART Input and Output Modules User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential

Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory

requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 3

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Download Firmware, AOP, EDS, and Other Files . . . . . . . . . . . . . . . . . . . . 9

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

FLEX 5000 HART I/O Modules Module and Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Firmware and Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . 12

FLEX 5000 HART Module Feature Comparison. . . . . . . . . . . . . . . . . 12

Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HART Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HART-enabled I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Analog HART I/O Module

Operation in a Logix 5000

Control System

Remote I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Types of Analog I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SA Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configure Analog HART I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connection Types Available with FLEX 5000 Analog HART

I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Data Types Available with FLEX 5000 Analog HART

I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connection Over an EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . 22

Input Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Output Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Controller to Remote Analog Output Module Data

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Remote Analog Output Module to Controller Data

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Listen Only Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Protected Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

HART Device Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Protected Operations for HART Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3

Common I/O Module Features Software Configurable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fault and Status Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Module Inhibiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 3

Page 4

Table of Contents

More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Producer/Consumer Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Use CIP Sync Time with

I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Module Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Common Analog Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Rolling Timestamp of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Rolling Timestamp with the 5094-IF8IH Module . . . . . . . . . . . . 33

Rolling Timestamp with the 5094-OF8IH Module. . . . . . . . . . . . 33

Floating Point Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Module Data Quality Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Alarm Latching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Enable Latching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Unlatch Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Data Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Module Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Analog HART Input Channel

Features

Chapter 4

Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Multiple Input Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Notch Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Relationship between Notch Filter Settings and RPI Setting. . 40

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Underrange/Overrange Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Enable Process Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Configure Alarm Trigger Points . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Latch Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Unlatch Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Alarm Deadband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rate Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sensor Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Open Wire Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Over Temperature Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Field Power Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fault and Status Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 5

Digital Input Point Features Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Software Configurable Input Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Type 3-d Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Type 3-d Open Wire Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Digital Point Open Wire Condition . . . . . . . . . . . . . . . . . . . . . . . . 51

Type 3-d Short Circuit Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Digital Point Type 3-d Short Circuit Condition . . . . . . . . . . . . . . 51

4 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 5

Analog HART Output Module

Features

Table of Contents

Fault and Status Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter 6

Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Multiple Output Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Channel Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Hold for Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connection Fault Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Output Behavior Immediately After a Connection Fault. . . . . . 55

Fault State Duration After Connection Fault . . . . . . . . . . . . . . . . 55

Final Fault State Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Output State Once Connection is Re-established . . . . . . . . . . . . 56

Output Clamping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Clamp Alarming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Output Ramping/Rate Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Output Readback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

No Load Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Short Circuit Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Over Temperature Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Field Power Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Fault and Status Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 7

Common Features of HART

Integration

HART Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

HART Device Information and Identity. . . . . . . . . . . . . . . . . . . . . . . . 61

HART Device Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

HART Device Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Producer / Consumer Data Connection Type Configuration . . . . . 63

Producer / Consumer Communication of HART Device . . . . . . . . . 63

Producer / Consumer Data Configuration . . . . . . . . . . . . . . . . . . . . . 64

HART Device Configuration Change Notification. . . . . . . . . . . . . . . 64

Rolling Timestamp of Dynamic/Device Variable Data . . . . . . . . . . . 64

Execute HART Commands through Producer / Consumer Data . . 64

Execute HART Commands through Explicit Messaging . . . . . . . . . 69

Fault and Status Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Chapter 8

Configure the Module Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Create a New Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Discover Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

New Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Edit the Module Configuration Common Categories . . . . . . . . . . . . . . . 75

General Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Input Module Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Output Module Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Connection Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Module Info Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Edit 5094-IF8IH Module Configuration Categories . . . . . . . . . . . . . . . . . 78

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 5

Page 6

Table of Contents

Channels Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Ch0x Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Alarms Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Calibration Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Edit 5094-OF8IH Module Configuration Categories . . . . . . . . . . . . . . . . 82

Channels Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Ch0x Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Limits Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Calibration Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

View the Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Chapter 9

Configure HART Devices Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Create a New HART Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Discover HART Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

New Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Add HART EDD File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Update an EDD file for a specific HART device . . . . . . . . . . . . . . 90

Add an EDD file for a generic HART device . . . . . . . . . . . . . . . . . 91

Edit the Connection Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

General Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Module Definition for a Specific HART Device . . . . . . . . . . . . . . 94

Module Definition for a Generic HART Device . . . . . . . . . . . . . . 94

Variables Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Commands Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Chapter 10

Calibrate the Module Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Controller State During Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Difference Between Calibrating an Input Module and an Output Module

100

Calibrate the Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Calibrate the 5094-IF8IH Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Calibrate the Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Calibrate a 5094-OF8IH Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix A

Troubleshoot Your Module SA Power Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Module Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

FLEX 5000 Analog Isolated Input Modules Status Indicators . . . . . . . 108

FLEX 5000 Analog Isolated Output Modules Status Indicators . . . . . 110

Use the Studio 5000 Logix Designer Application for Troubleshooting

I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Warning Signal in the I/O Configuration Tree. . . . . . . . . . . . . . . . . . 111

Status and Fault Information in Module Properties Categories . . 111

Module Status on General Category . . . . . . . . . . . . . . . . . . . . . . . 112

6 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 7

Table of Contents

Module Fault Descriptions on Connection Category . . . . . . . . 112

Module Fault Descriptions on Module Info Category . . . . . . . 113

Module Diagnostics Dialog Box. . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Studio 5000 Logix Designer Application Tag Editor . . . . . . . . . . . . 114

Troubleshoot HART Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Warning Signal in the I/O Configuration Tree. . . . . . . . . . . . . . . . . 114

Status and Fault Information in Module Properties Categories . 115

Studio 5000 Logix Designer Application Tag Editor . . . . . . . . . . . . 115

CIP Error Codes for HART Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Appendix B

Module Tag Definitions Tag Name Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Access the Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5094-IF8IH Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Configuration Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Output Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5094-OF8IH Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Configuration Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Output Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

HART Device Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Output Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Appendix C

Module Diagnostic Assembly Create User-defined Diagnostic Assembly Types . . . . . . . . . . . . . . . . . . 133

Create Message Type User Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Appendix D

CIP Object Model of HART Device Object Model of HART Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Object-specific Services of Extended HART Process Device . . . . . 141

Execute_Command_CIP_Types Service (0x4C) . . . . . . . . . . . . . . . . 142

GET_HART_DEVICE_INFORMATION Service (0x4E). . . . . . . . . . 142

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 145

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 9

Preface

About This Publication This manual describes how to use FLEX 5000™ analog I/O modules in

Logix 5000™ control systems.

Make sure that you are familiar with the following:

• Use of a controller in a Logix 5000 control system

• Use of an EtherNet/IP™ network, if the analog I/O modules are installed

in a remote location from the controller that is accessible via the

EtherNet/IP network

• Studio 5000 Logix Designer® environment

Download Firmware, AOP, EDS, and Other Files

IMPORTANT

Download firmware, associated files (such as AOP, EDS, and DTM), and access

product release notes from the Product Compatibility and Download Center at

rok.auto/pcdc

Remember the following when you use FLEX 5000 Analog HART

I/O Modules:

• You cannot use FLEX 5000 I/O modules with all Logix 5000 controllers.

For example, you can use FLEX 5000 I/O modules with

CompactLogix™ 5380 and ControlLogix® 5580 controllers but not with

CompactLogix 5370 and ControlLogix 5570 controllers.

For the most current information on the Logix 5000 controllers with

which you can use FLEX 5000 I/O modules, see the product

description at rok.auto/flex5000IO

• You must use the Studio 5000 Logix Designer application, version

32.02 or later, to configure the FLEX 5000 analog HART I/O modules.

• You must use the Studio 5000 Logix Designer application, version

33.00 or later, to support ControlLogix 5580 High Availability

controllers.

.

.

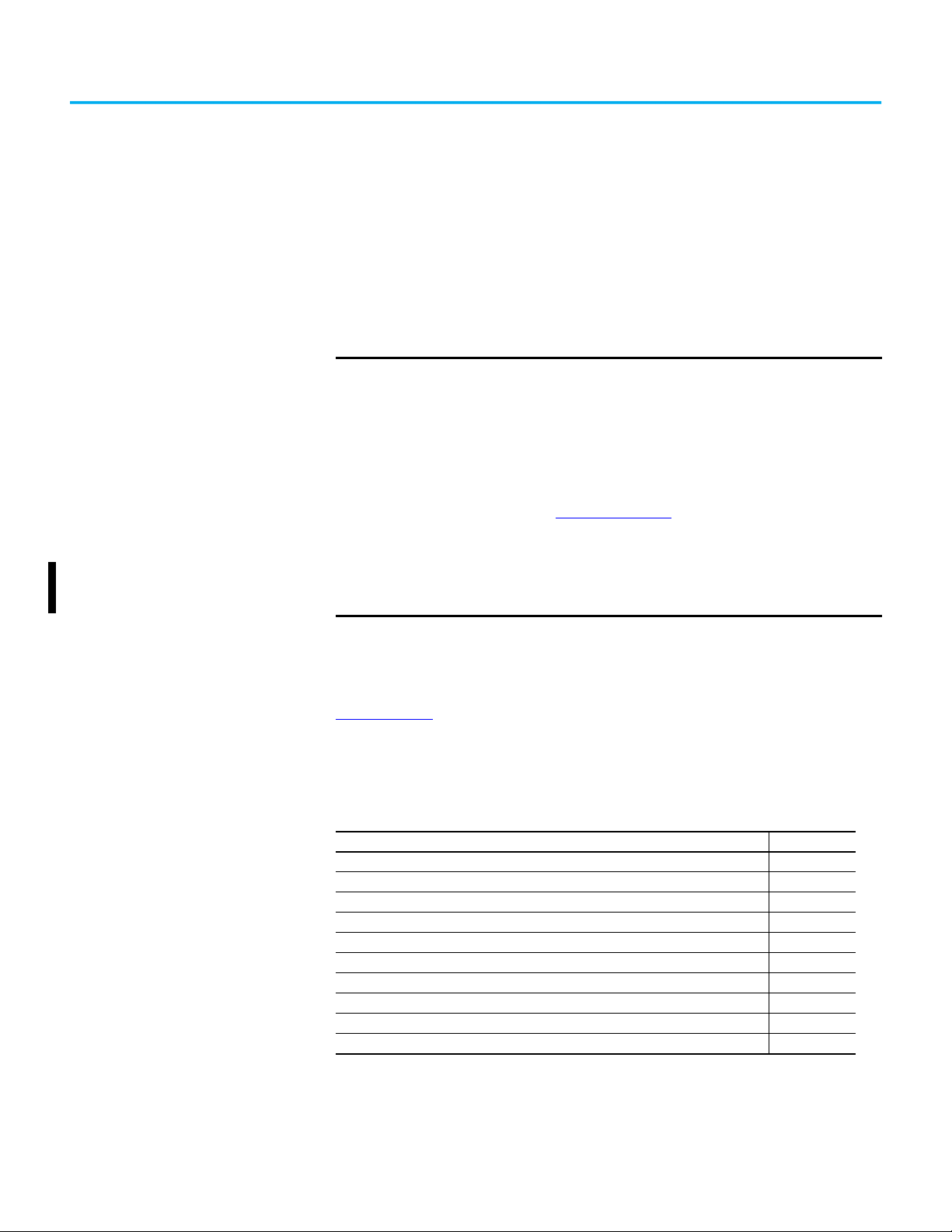

Summary of Changes This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Top ic Pa ge

Updated software version requirements 9

Added software and firmware compatibility 11

Reorganized common features 29

Updated firmware revision requirements 32

Added dedicated digital input point description 39

Added digital input point features chapter 49

Added points category description 78

Corrected Output Ch0x category descriptions 83

Added diagnostic assemblies chapter 133

Added PlantPAx HART instruction compatible device connection throughout

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 9

Page 10

Preface

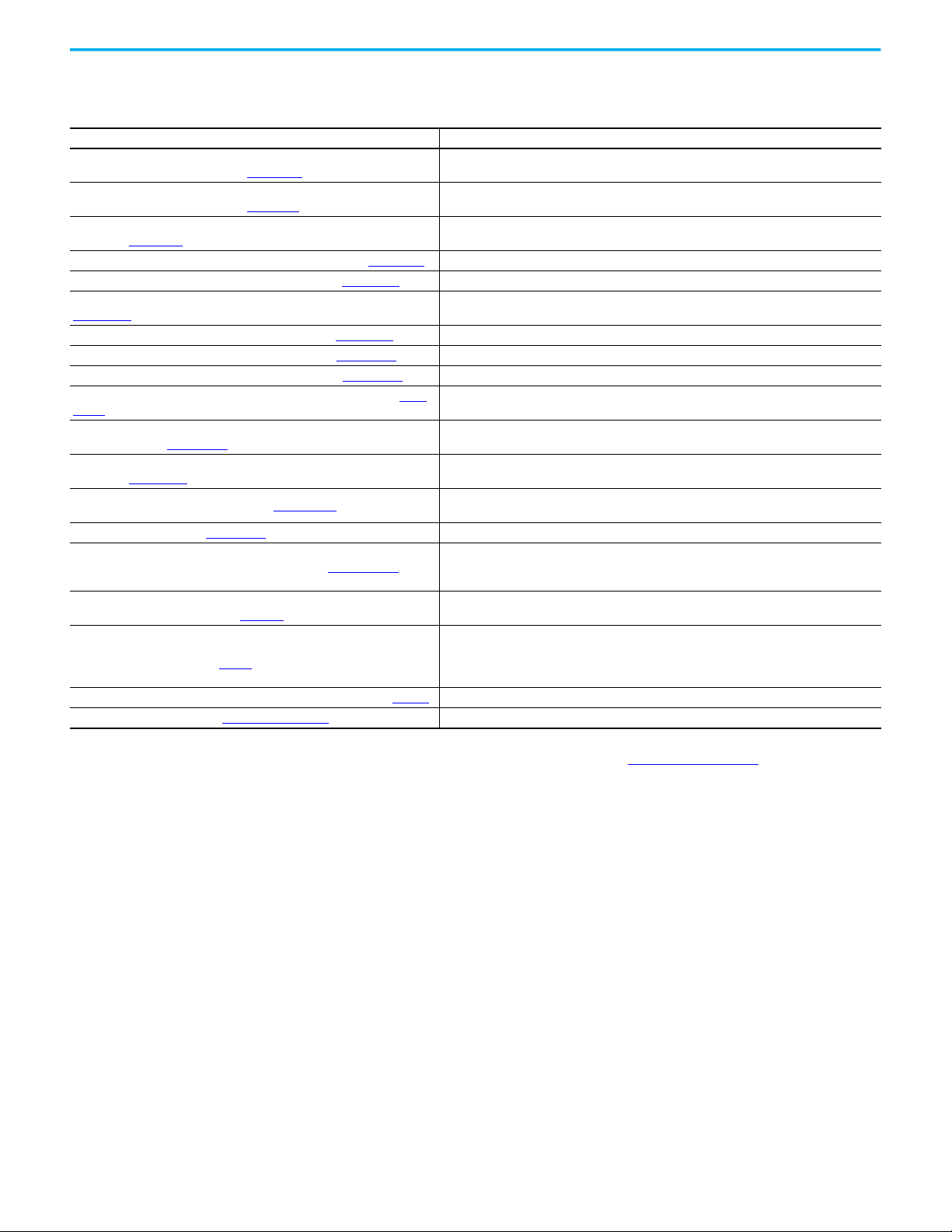

Additional Resources These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

FLEX 5000 Analog 8-channel Isolated Current/Voltage/HART Input Modules

Installation Instructions, publication 5094-IN020

FLEX 5000 Analog 8-channel Isolated Current/Voltage/HART Output Modules

Installation Instructions, publication 5094-IN021

FLEX 5000 Terminal Base Assembly Modules Installation Instructions,

publication 5094-IN010

FLEX 5000 Modules Specifications Technical Data, publication 5094-TD001

CompactLogix 5380 Controllers User Manual, publication 5069-UM001 Describes how to configure, operate, and troubleshoot CompactLogix 5380 controllers.

ControlLogix 5580 and GuardLogix 5580 Controllers User Manual, publication

1756-UM543.

FLEX 5000 Digital I/O Modules User Manual, publication 5094-UM001

FLEX 5000 Analog I/O Modules User Manual, publication 5094-UM002 Describes how to configure, operate, and troubleshoot FLEX 5000 analog I/O modules.

FLEX 5000 EtherNet/IP Adapter User Manual, publication 5094-UM005

FLEX 5000 High-speed Counter I/O Modules User Manual, publication 5094-

UM003

EtherNet/IP Communication Modules in 5000 Series Control Systems User

Manual, publication ENET-UM004

Electronic Keying in Logix 5000 Control Systems Application Technique,

publication LOGIX-AT001

EtherNet/IP Network Devices User Manual, ENET-UM006

Ethernet Reference Manual, ENET-RM002

System Security Design Guidelines Reference Manual, SECURE-RM001

Industrial Components Preventive Maintenance, Enclosures, and Contact

Ratings Specifications, publication IC-TD002

Safety Guidelines for the Application, Installation, and Maintenance of

Solid-state Control, publication SGI-1.1

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, rok.auto/certifications

Describes how to configure, operate, and troubleshoot FLEX 5000 digital I/O modules.

. Provides declarations of conformity, certificates, and other certification details.

Describes how to install and wire the 5094-IF8IH and 5094-IF8IHXT analog input modules.

Describes how to install and wire the 5094-OF8IH and 5094-OF8IHXT analog output modules.

Describes how to install and wire the terminal base assemblies for the FLEX 5000 system.

Provides specifications for FLEX 5000 EtherNet/IP adapters and FLEX 5000 modules.

Describes how to configure, operate, and troubleshoot ControlLogix 5580 and GuardLogix®

5580 controllers.

Describes how to configure, operate, and troubleshoot FLEX 5000 EtherNet/IP adapters

Describes how to configure, operate, and troubleshoot FLEX 5000 high-speed counter

modules.

Describes how to configure, operate, and troubleshoot the FLEX 5000 EtherNet/IP adapters.

Describes how to use electronic keying in Logix 5000 control system applications.

Describes how to configure and use EtherNet/IP devices to communicate on the EtherNet/IP

network.

Describes basic Ethernet concepts, infrastructure components, and infrastructure features.

Provides guidance on how to conduct security assessments, implement Rockwell

Automation products in a secure system, harden the control system, manage user access,

and dispose of equipment.

Provides a quick reference tool for Allen-Bradley® industrial automation controls and

assemblies.

Designed to harmonize with NEMA Standards Publication No. ICS 1.1-1987 and provides

general guidelines for the application, installation, and maintenance of solid-state control in

the form of individual devices or packaged assemblies incorporating solid-state

components.

You can view or download publications at rok.auto/literature

10 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

.

Page 11

Chapter 1

FLEX 5000 HART I/O Modules

Top ic Pa ge

Module Overview 13

HART Communication 13

HART-enabled I/O Modules 15

Logix 5000 controllers use FLEX 5000 analog HART I/O modules to control

devices in a control system. The controllers access the modules over an

EtherNet/IP network. FLEX 5000 analog HART I/O modules use terminal base

(TB) assemblies to connect field-side wiring.

FLEX 5000 analog HART I/O modules connect a Logix controller to your

process. HART input modules (5094-IF8IH, 5094-IF8IHXT) receive signals

from process value transmitters and convert them to corresponding

measurement values for use in the Logix controller (for example, temperature,

flow, pressure, or pH). HART output modules (5094-OF8IH, 5094-OF8IHXT)

provide current or voltage output signals that adjust the settings of valves and

other devices in accord with desired process behavior.

Module and Software Compatibility

Instruments that support the HART protocol allow several process parameters

to be measured with one field device, provide status and diagnostics

information, and allow remote configuration and troubleshooting.

FLEX 5000 analog HART I/O modules implement the Producer/Consumer

network communication model for both the module itself and the HART

devices that are attached to it. This communication is an intelligent data

exchange between modules / HART devices and other system devices in which

each module / HART device produces data without first being polled. You use

the Studio 5000 Logix Designer application, version 32.02 or later, to configure

the modules and HART devices.

Controller and programming software compatibility requirements apply when

you use FLEX 5000 standard and safety I/O modules. A module type and how it

is used affect which requirements apply.

You must also consider Logix Designer application version requirements when

you design your system. For example, you can use High Availability with only

version 33 or greater of the Logix Designer application.

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 11

Page 12

Chapter 1 FLEX 5000 HART I/O Modules

Firmware and Software Compatibility

• You must use the Studio 5000 Logix Designer application, version 32.02

or later, to configure the FLEX 5000 analog HART I/O modules.

• You must use the Studio 5000 Logix Designer application, version 33.00

or later, to support ControlLogix 5580 High Availability controllers.

• You must use module firmware 3.011 or later to support ControlLogix

5580 High Availability controller redundancy, and PlantPAx® HART

instruction compatible device connection.

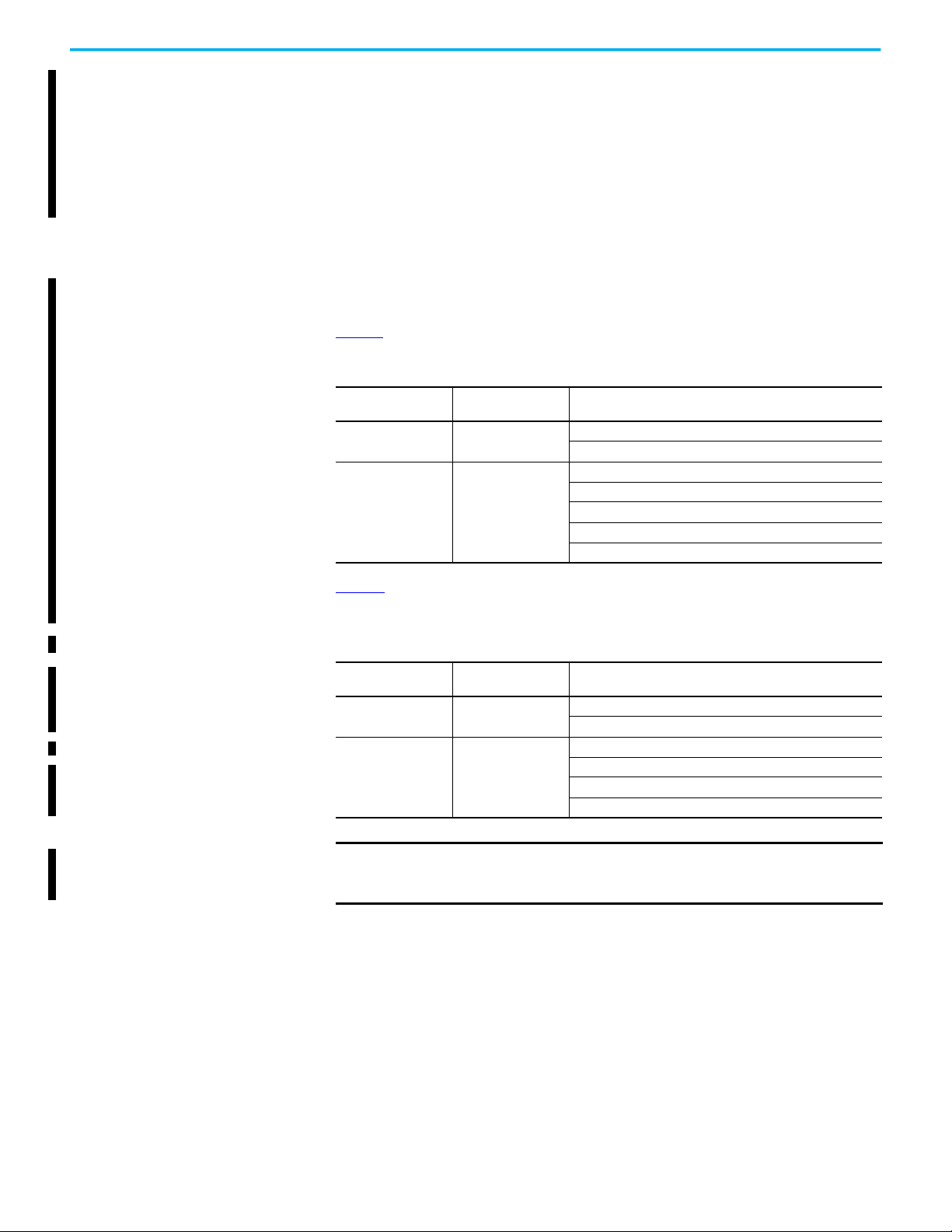

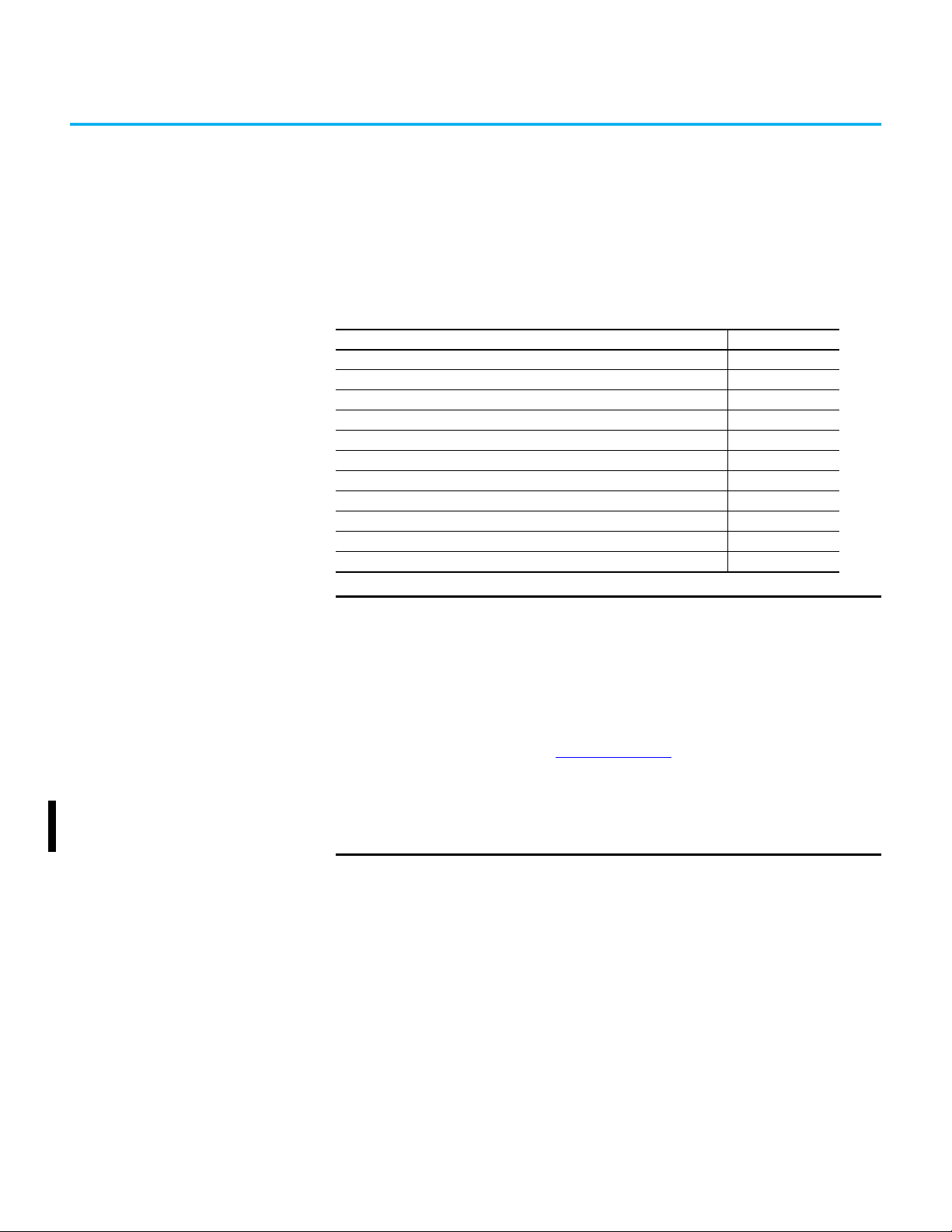

FLEX 5000 HART Module Feature Comparison

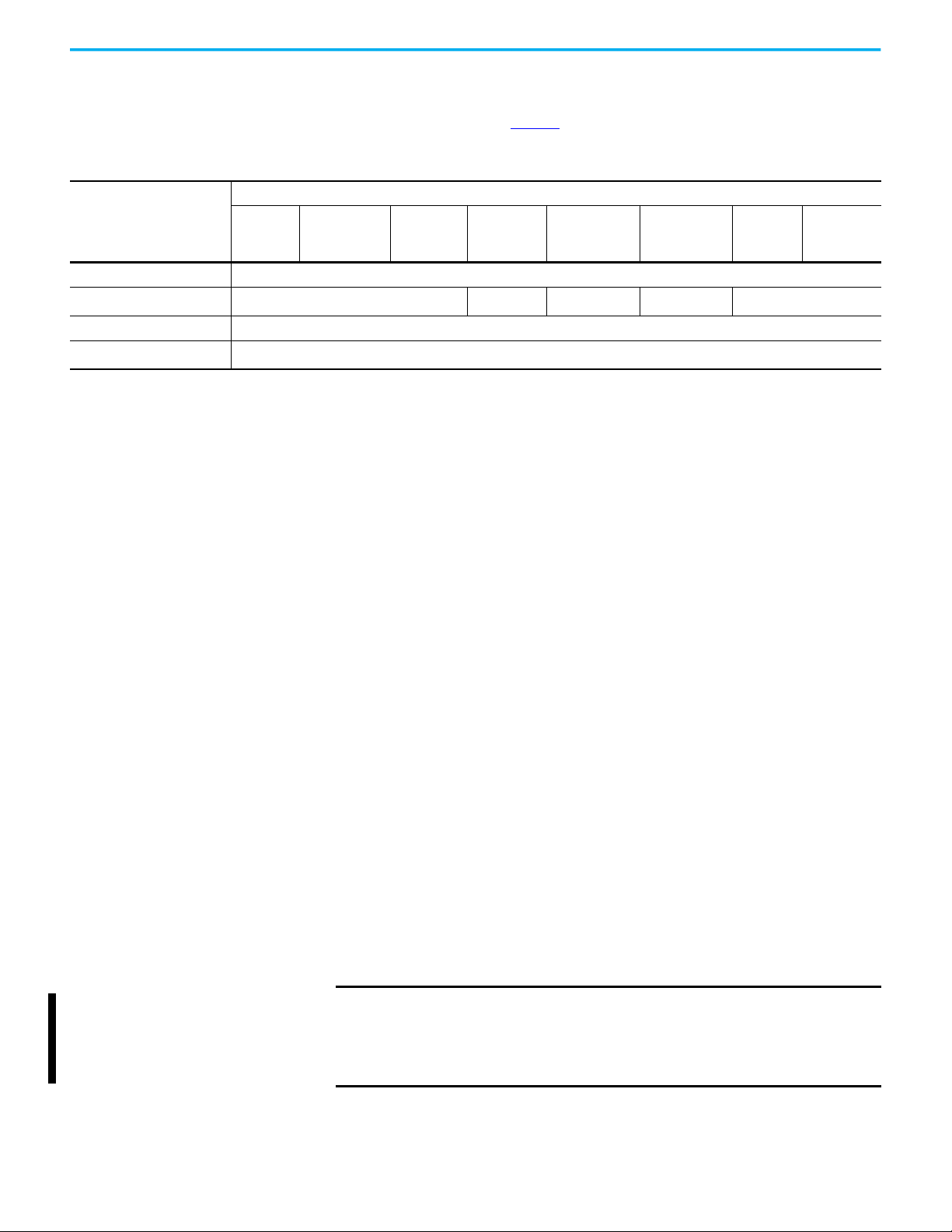

Table 1 describes the module firmware revision comparison for input modules.

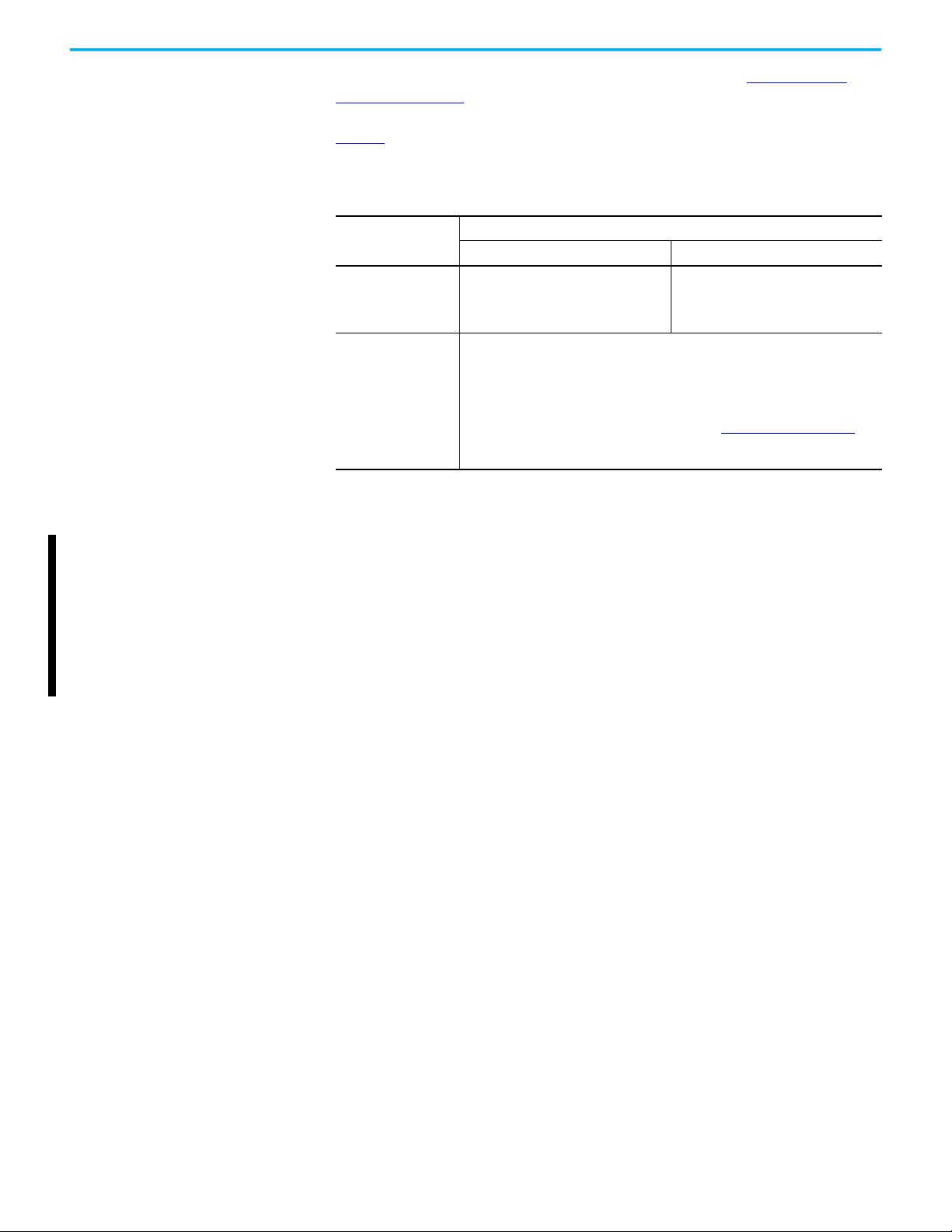

Table 1 - FLEX 5000 HART Input Module Supported Features

FLEX 5000 HART

Firmware Revision

2.0

3.0

Table 2

describes the module firmware revision comparison for output

Module

5094-IF8IH,

5094-IF8IHXT

5094-IF8IH,

5094-IF8IHXT

Supported features

Analog input

HART device connection

Analog input

HART device connection

PlantPAx HART instruction compatible device connection

Digital input (type 3 / type-3d support)

ControlLogix 5580 High Availability controller

modules.

Table 2 - FLEX 5000 HART Output Module Supported Features

FLEX 5000 HART

Firmware Revision

2.0

3.0

Module

5094-OF8IH,

5094-OF8IHXT

5094-OF8IH,

5094-OF8IHXT

Supported features

Analog output

HART device connection

Analog output

HART device connection

PlantPAx HART instruction compatible device connection

ControlLogix 5580 High Availability controller

IMPORTANT After upgrading your FLEX 5000 HART module firmware to the latest

firmware revision, you need to wait 2 to 3 minutes before the channels

reflect the upgrade and are ready to use.

12 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 13

Chapter 1 FLEX 5000 HART I/O Modules

STATUS

POWER

ANALOG 8 INPUT HART ISOLATED

5094-IF8IH

5

3

TB3I

FLEX 5000TM I/O

0 1 2 3 4 5 6 7

2

1

3

53 4

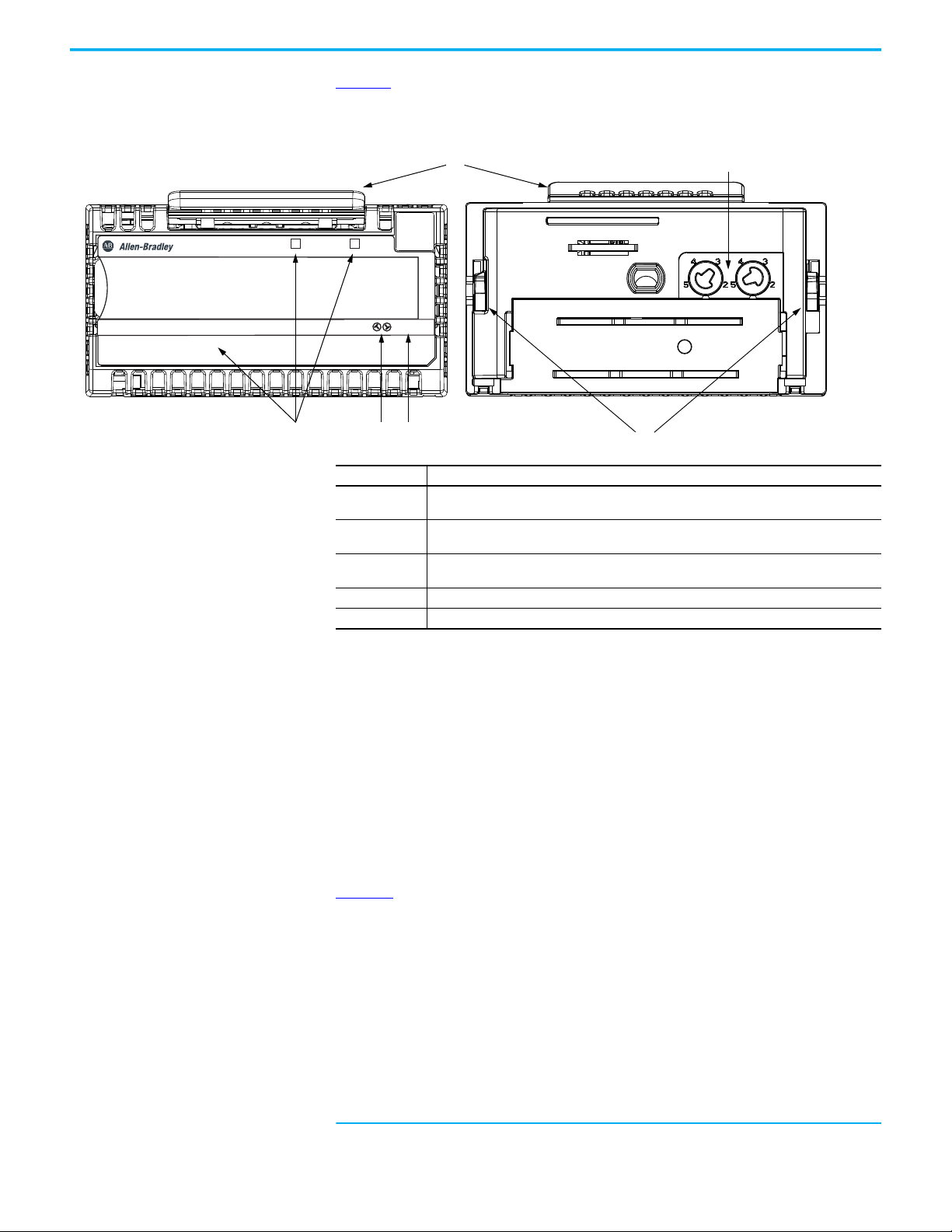

Module Overview Figure 1 shows the parts of an example FLEX 5000 analog HART I/O module.

Figure 1 - Example FLEX 5000 Analog HART I/O Module

Item Description

1

2

3

4 Ter min al b ase - Indicates the type of terminal base assembly to use with the module.

5 Latching hooks - Securely installs FLEX 5000 modules on the terminal base assembly.

Status indicators - Displays the status of communication, module health, and input/output

devices. Indicators help with troubleshooting anomalies.

Release lever - Disengages the latching hooks to allow removal of the module from the

terminal base assembly.

Module keying - Indicates the keying position the terminal base assembly must be configured

to before installing the module.

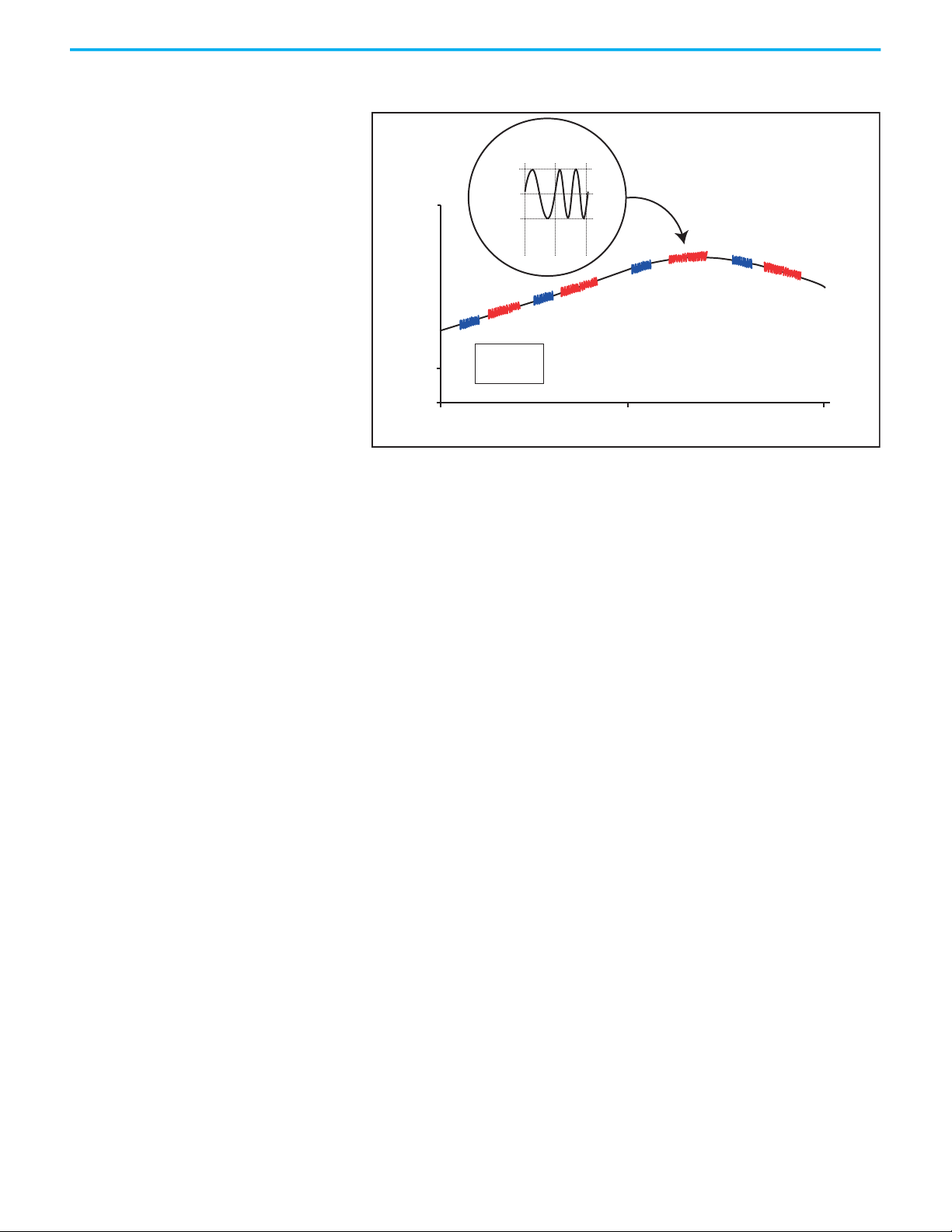

HART Communication The HART field communication protocol is widely accepted in industry as a

standard for digitally enhanced 4…20 mA communication with smart

(microprocessor-based) field devices. A digital signal is superimposed on the

4…20 mA current loop to provide two means of communication from the

device. The 4…20 mA analog channel lets the primary process variable be

communicated at the fastest possible rate while the digital channel

communicates multiple process variables, data quality, and device status. The

HART protocol lets these simultaneous communication channels be used in a

complementary fashion.

(1)

shows information about the HART protocol.

Figure 2

(1) This figure is from the HART Communication Protocol Specifications, April 2001, Revision

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 13

6.0, HART Communication Foundation. All Rights Reserved.

Page 14

Chapter 1 FLEX 5000 HART I/O Modules

The Highway Addressable Remote Transducer (HART)

protocol supports two-way digital communication,

complements traditional 4…20 mA analog signals, and

includes the following features:

• Predefined commands

– Universal command

–Common practice

– Device specific

• Large installed base

• Worldwide support

Figure 2 - HART Protocol

20 mA

Analog

Signal

4 mA

c

+0.5 mA

0.5 mA

R

Analog

Signal

0

2200

1200

Hz

Hz

“0”

“1”

R

c

HART Signal

c

R

= Command

c

= Response

R

c

R

01 2

Time (seconds)

FLEX 5000 analog HART I/O modules support the HART protocol and perform

these operations:

• Conversion of 4…20 mA analog signals to digital numeric values in

engineering units (such as kg, m, or percent) that are used in the Logix

controller.

• Conversion of digital numeric values in engineering units to 4…20 mA

analog signals to control process devices.

• Producer/Consumer network communication model directly to each

HART device.

• Automatic collection of dynamic process data from the connected HART

device. For example, temperature, pressure, flow, or valve position.

• Automatic collection of device-specific variables from the connected

HART device.

• Execution of commands through Studio 5000 Logix Designer using

input and output tags.

• Facilitation of configuration and troubleshooting of the HART field

device from your control room using FDT/DTM supported software.

With the FLEX 5000 analog HART I/O modules, both the controller and

software for device maintenance and management can access field device

data.

14 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

The FLEX 5000 analog HART I/O modules support command-response

communication protocol in a point-to-point wiring architecture.

The FLEX 5000 analog HART I/O module is the primary master device and

continuously obtains information from the connected HART devices. The

secondary master can be used for device maintenance, for example a handheld

communicator, as shown here.

Page 15

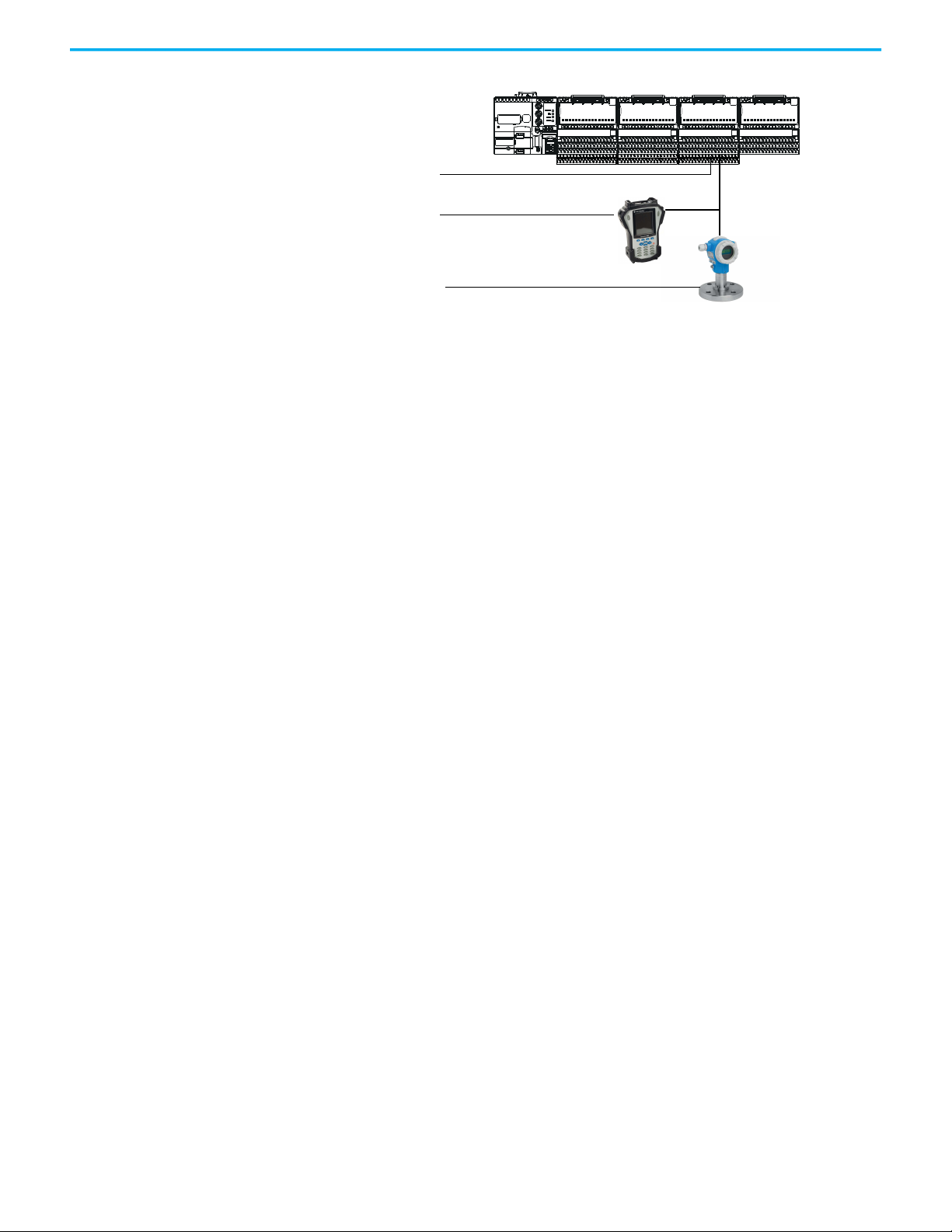

Chapter 1 FLEX 5000 HART I/O Modules

Primary master

Secondary master

(handheld communicator

as secondary master)

Slave

Most 4…20 mA transmitters are available with a HART protocol interface. The

type of data available depends on the type of instrument.

An example application is a HART enabled mass flowmeter. The standard mA

signal from the flowmeter provides one primary measurement - flow. The mA

signal with HART provides more process information. The mA signal that

represents flow is still available. The HART configuration of the flowmeter can

be set to communicate primary variable (PV), secondary variable (SV), tertiary

variable (TV), and quaternary variable (QV). These values can represent mass

flow, static pressure, temperature, total flow, and other conditions.

Dynamic variables, device-specific variables, device status, and command

execution are all available through input and output controller tags in Studio

5000 Logix Designer.

Device status information is also provided through HART.

HART connectivity provides all this information with no changes to the

existing 4…20 mA wiring.

FDT/DTM technology through HART connectivity is supported and also

provides remote configuration and troubleshooting of HART devices through

software.

HART-enabled I/O Modules

The FLEX 5000 analog HART I/O modules have built-in HART modems, so

there is no need to install external HART multiplexers or clip-on HART

modems. The 5094-IF8IH, 5094-OF8IHXT, 5094-OF8IH, and 5094-OF8IHXT

modules have separate HART modems for each channel.

HART implementation in 5094 provides a connection between the controller

and each HART device.

A HART device that is configured in a 5094 I/O module supports a configurable

connection that can include up to four Dynamic Variables, eight Device

Variables, and four HART Commands.

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 15

Page 16

Chapter 1 FLEX 5000 HART I/O Modules

Notes:

16 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 17

Chapter 2

Analog HART I/O Module Operation in a Logix

5000 Control System

Top ic Pa ge

Remote I/O Modules 17

Before You Begin 18

Types of Analog I/O Modules 18

Power the Modules 18

Ownership 19

Configure Analog HART I/O Modules 20

Input Module Operation 23

Output Module Operation 23

HART Device Operation 26

Listen Only Mode 25

Protected Operations 26

IMPORTANT

Remember the following when you use FLEX 5000 Analog HART

I/O Modules:

• You cannot use FLEX 5000 I/O modules with all Logix 5000 controllers.

For example, you can use FLEX 5000 I/O modules with

CompactLogix 5380 and ControlLogix 5580 controllers but not with

CompactLogix 5370 and ControlLogix 5570 controllers.

For the most current information on the Logix 5000 controllers with

which you can use FLEX 5000 I/O modules, see the product

description at rok.auto/flex5000IO

• You must use the Studio 5000 Logix Designer application, version

32.02 or later, to configure the FLEX 5000 analog HART I/O modules.

• You must use the Studio 5000 Logix Designer application, version

33.00 or later, to support ControlLogix 5580 High Availability

controllers.

.

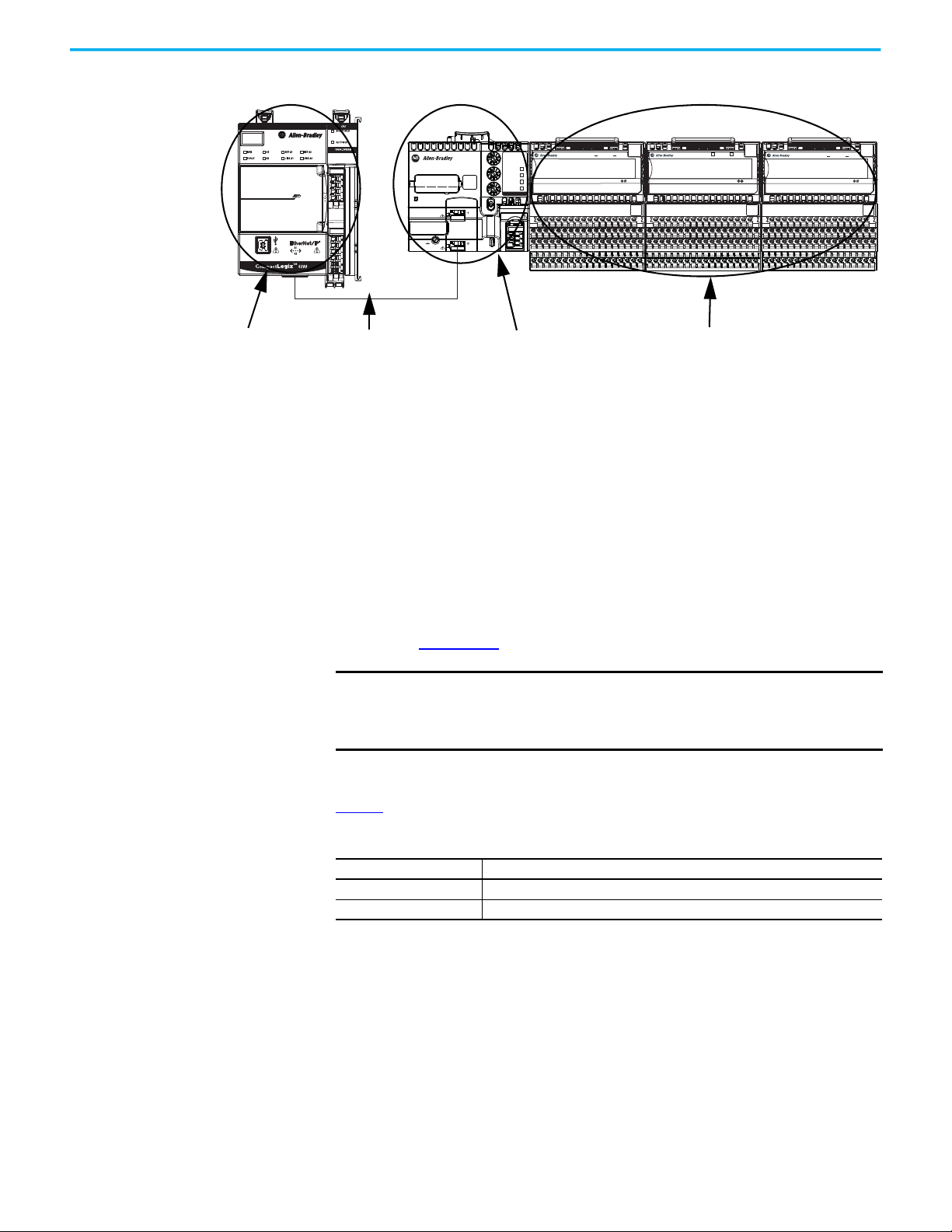

Remote I/O Modules You use FLEX 5000 analog HART I/O modules as remote I/O modules that are

accessible via an EtherNet/IP network. The modules are installed to the right

of a FLEX 5000 EtherNet/IP adapter.

Logix 5000 controllers can exchange data with the modules over the network.

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 17

Page 18

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

5069-L340ERM

EtherNet/IP Network

5094 I/O with shield bar

5094-AENTR

Figure 3 - FLEX 5000 I/O Modules in a Logix 5000 Control System

IP ADDRESS

POWER

X100

FLEX 5000TM I/O

EtherNet/IP™ Adapter

X10

STATUS

NET

LINK 1

X1

LINK 2

5094-AENTR

PRP

DLR

FLEX 5000TM I/O

ANALOG 8 OUTPUT HART ISOLATED

5094-OF8IH

0 1 2 3 4 5 6 7

STATUS

POWER

2

3

TB3I

FLEX 5000TM I/O

ANALOG 8 INPUT HART ISOLATED

5094-IF8IH

0 1 2 3 4 5 6 7

STATUS

POWER

3

5

TB3I

FLEX 5000TM I/O

ANALOG 8 OUTPUT HART ISOLATED

5094-OF8IHXT

0 1 2 3 4 5 6 7

Before You Begin Before you use your analog HART I/O module, you must complete the

following:

a. Install a FLEX 5000 EtherNet/IP adapter.

b. Install the FLEX 5000 I/O modules to the right of adapter.

c. Install an EtherNet/IP network.

d. Install the Logix 5000 controller that accesses the FLEX 5000 I/O

modules via an EtherNet/IP network.

Make sure that you have enough FLEX 5000 terminal base (TB) assemblies to

satisfy your application needs. For more information, see the FLEX 5000

Terminal Base Assembly Modules Installation Instructions,

publication 5094-IN010

.

STATUS

POWER

2

3

TB3I

IMPORTANT

TBs are not included with your module and are not available for

purchase. TBs consist of a mounting base (MB) and removable terminal

block (RTB). You must purchase MBs and RTBs separately and assemble

them together.

Types of Analog I/O Modules

Ta b l e 3 describes the types of FLEX 5000 analog HART I/O modules.

Table 3 - FLEX 5000 Analog HART I/O Modules

Cat. No. Description

5094-IF8IH, 5094-IF8IHXT 8-channel isolated current/voltage/HART input module

5094-OF8IH, 5094-OF8IHXT 8-channel isolated current/voltage/HART output module

Power the Modules FLEX 5000 analog HART I/O modules receive the following power types:

• System-side power that powers the system and lets modules transfer

data and execute logic. System-side power is also known as Backplane

power.

• Field-side power that powers field-side devices that are connected to

some FLEX 5000 I/O modules. Field-side power is also known as

SA power.

18 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 19

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

System-side power begins at the FLEX 5000 EtherNet/IP adapter and passes

across the FLEX 5000 module internal circuitry via terminal base power bus,

that is, Backplane power.

Field-side power, that is, SA power begins at the first terminal base assembly

and can be daisy chained to the next terminal base assembly on the right. You

can also install a separate field-side power source to each terminal base

assembly.

For more information on how to power FLEX 5000 analog HART I/O modules,

see the FLEX 5000 EtherNet/IP Adapter User Manual, publication 5094-

UM005.

SA Power Requirements

Take note of the following when supplying SA power to your system:

• You must limit the SA field-side power source to 10 A, max, at

18...32V DC.

• Confirm that the external module power supply is adequately sized for

the total module power bus current draw in the system.

• For example, if the total module power current draw, including current

inrush requirements, is 5 A, you can use a module power supply that is

limited to 5 A.

• You must use SELV-listed power supplies for module power if there are

functional safety modules that are connected to the FLEX 5000 I/O

family.

• Not all power supplies are certified for use in all applications, for

example, nonhazardous and hazardous environments.

• Isolated source power of up to 25 mA available from the module to

simplify the channel to channel isolation wiring for current sensors.

IMPORTANT

We recommend that you use separate external power supplies for the

adapter and the adjacent terminal base. This practice can prevent

unintended consequences that can result if you use one supply.

Ownership Every I/O module in a Logix 5000 control system must be owned by a

controller, also known as the owner-controller. When the FLEX 5000 Analog

HART I/O modules are used in a Logix 5000 control system, the ownercontroller performs the following:

• Stores configuration data for every module that it owns.

• Can reside in a location that differs from the FLEX 5000 I/O modules.

• Sends the I/O module configuration data to define module behavior and

begin operation in the control system.

Each FLEX 5000 Analog HART I/O module must continuously maintain

communication with its owner-controller during normal operation.

FLEX 5000 Analog HART I/O modules are limited to one owner-controller.

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 19

Page 20

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

Configure Analog HART I/O Modules

You must create a Studio 5000 Logix Designer application project for the

Logix 5000 controller that owns the FLEX 5000 analog HART I/O modules and

attached HART devices. The project includes module configuration data for

the FLEX 5000 Analog HART I/O modules.

The Studio 5000 Logix Designer application transfers the project to the ownercontroller during the program download. Data is then transferred to the

FLEX 5000 analog HART I/O modules over the EtherNet/IP network.

The FLEX 5000 analog HART I/O modules can operate immediately after

receiving the configuration data.

Connections

During module configuration, you must define the module. Among the

Module Definition parameters, you must choose a connection type for the

module. A connection is a real-time data transfer link between the ownercontroller and the module that occupies the slot that the configuration

references.

During HART device configuration, you must define the input and output tags

for any connected HART device.

When you download module configuration to a controller, the controller

attempts to establish a connection to each module in the configuration.

Because part of module configuration includes a slot in the FLEX 5000 I/O

system, the owner-controller checks for the presence of a module or connected

HART device there. If a module or HART device is detected, the ownercontroller sends the configuration. One of the following occurs:

• If the configuration is appropriate to the module or HART device that is

detected, a connection is made and operation begins.

• If the configuration is not appropriate to the module or HART device that

is detected, the data is rejected and the Studio 5000 Logix Designer

application indicates that an error occurred.

The configuration can be inappropriate for many reasons. For example, a

mismatch in electronic keying that helps prevents normal operation.

The owner-controller monitors its connection with a module and HART

devices. Any break in the connection, for example, the loss of power to the

FLEX 5000 I/O system, causes a fault. The Studio 5000 Logix Designer

application monitors the fault status tags to indicate when a fault occurs on a

module or HART device.

Connection Types Available with FLEX 5000 Analog HART I/O Modules

When configuring an analog HART input or output module, you must define

the module. Connection is a required parameter in the Module Definition. The

choice determines what data is exchanged between the owner-controller and

the module.

20 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 21

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

For more information on configuring the I/O modules, see Configure the

Module on page 71.

Table 4

describes the connection types that you can use with FLEX 5000 analog

HART I/O modules.

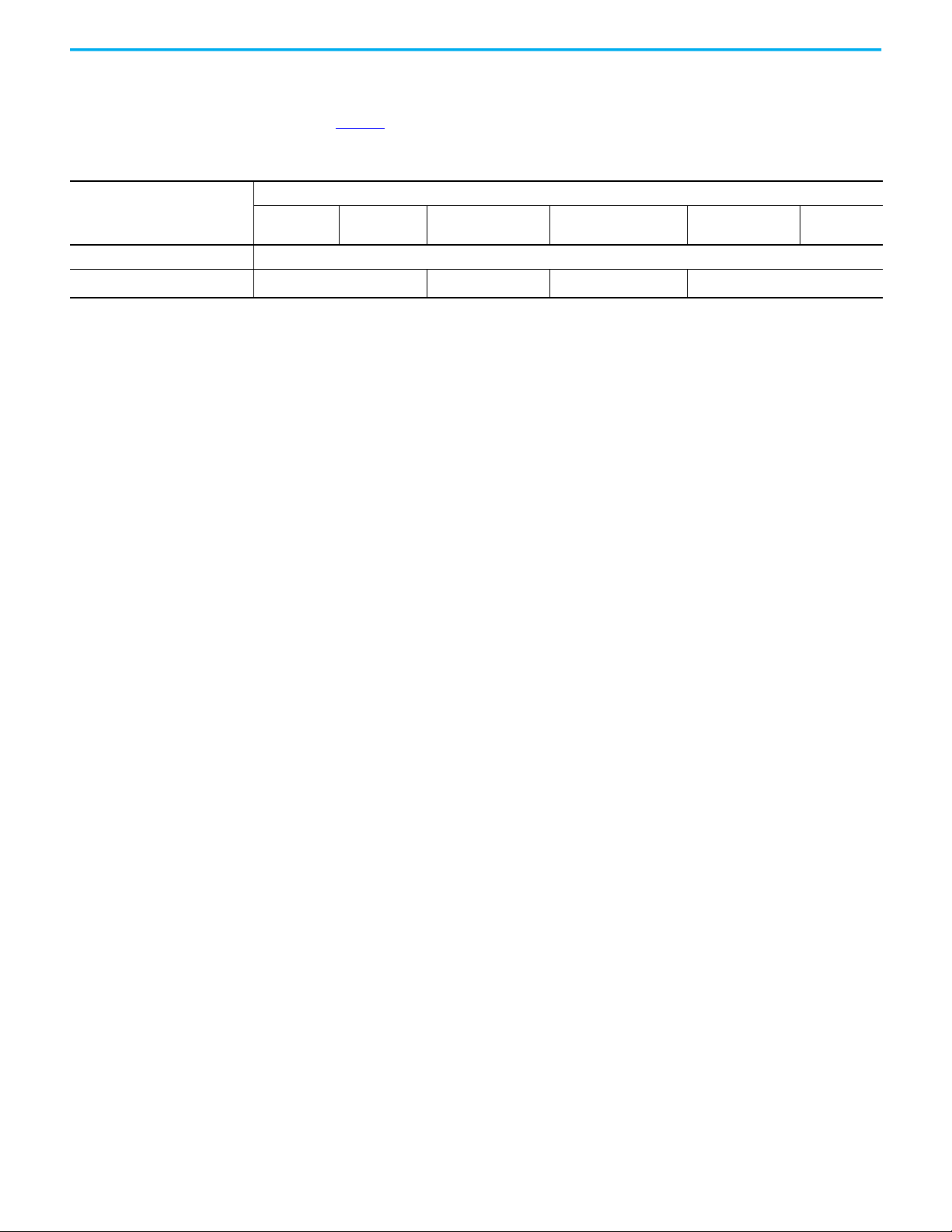

Table 4 - Connections - HART I/O Modules

Description

Connection Type

Data

Listen Only

HART Input Modules HART Output Modules

The module returns the following to the

owner-controller:

General fault data

Input data

When a Listen Only data connection is used, another controller owns the module.

A controller that makes a Listen Only connection to the module does not write

configuration for the module. It merely listens to the data exchanged with the ownercontroller.

IMPORTANT: If a controller uses a Listen Only connection, the connection must use the

Multicast option.

For more information on Listen Only connections, see Listen Only Mode

this case, all other connections to the module, for example, the connection to the

owner-controller must also use the Multicast option.

The module returns the following to the

owner-controller:

General fault data

Output data

on page 25. In

Data Types Available with FLEX 5000 Analog HART I/O Modules

The Module Definition includes a Data parameter that matches the module

type. Input modules use Input Data, and output modules use Output Data.

The available Data parameter choices are as follows:

• 5094-IF8IH and 5094-IF8IHXT – The Input Data choice is either Analog,

Analog and Discrete, or Discrete.

• 5094-OF8IH and 5094-OF8IHXT – The Output Data choice is always

Analog.

For more information on the Connection and Data parameter choices

available with FLEX 5000 I/O modules, see the Studio 5000 Logix Designer

application.

Requested Packet Interval

The Requested Packet Interval (RPI) is a configurable parameter that defines a

specific rate at which data is exchanged between the owner-controller and the

module.

You set the RPI value during initial module configuration and can adjust it as

necessary after module operation has begun. Valid RPI values for analog HART

I/O modules are 0.2…750 ms. Valid RPI values for HART devices are

500…9999.9 ms.

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 21

Page 22

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

IMPORTANT

If you change the RPI while the project is online, the connection to the

module is closed and reopened in one of the following ways:

• You inhibit the connection to the module, change the RPI value, and

uninhibit the connection.

• You change the RPI value. In this case, the connection is closed and

reopened immediately after you apply the change to the module

configuration.

For more information on guidelines for specifying RPI rates, see the

Logix 5000 Controllers Design Considerations Reference Manual, publication

1756-RM094

.

Connection Over an EtherNet/IP Network

During module and connected HART device configuration, you must

configure the Connection over EtherNet/IP parameter. The configuration

choice dictates how input data is broadcast over the network.

The FLEX 5000 analog HART I/O modules use one of the following methods to

broadcast data:

• Multicast - Multicast connections deliver information from one sender

to multiple receivers simultaneously.

Copies of one transmission are passed to a selected subset of possible

destinations.

• Unicast - Unicast connections are point-to-point transmissions between

a source node and destination node on the network.

A transmission is sent to one destination controller depending on the

module configuration.

Unicast is the default setting. We recommend that you use Unicast because it

reduces network bandwidth usage. However, if you are using a ControlLogix

5580 High Availability controller, you must use multicast.

Multicast is more efficient than sending multiple unicast streams to multiple

notes. Use multicast in the following situations:

• FLEX 5000 I/O is used in a Redundancy application

• Communication is with multiple destinations

IMPORTANT When using a ControlLogix 5580 High Availability controller, a HART

modules occupies 1 multicast connection and HART devices occupy up

to 4 multicast connections. These connections total a maximum of 5

connections per HART module and limits the adapter to a maximum of 6

HART modules.

22 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 23

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

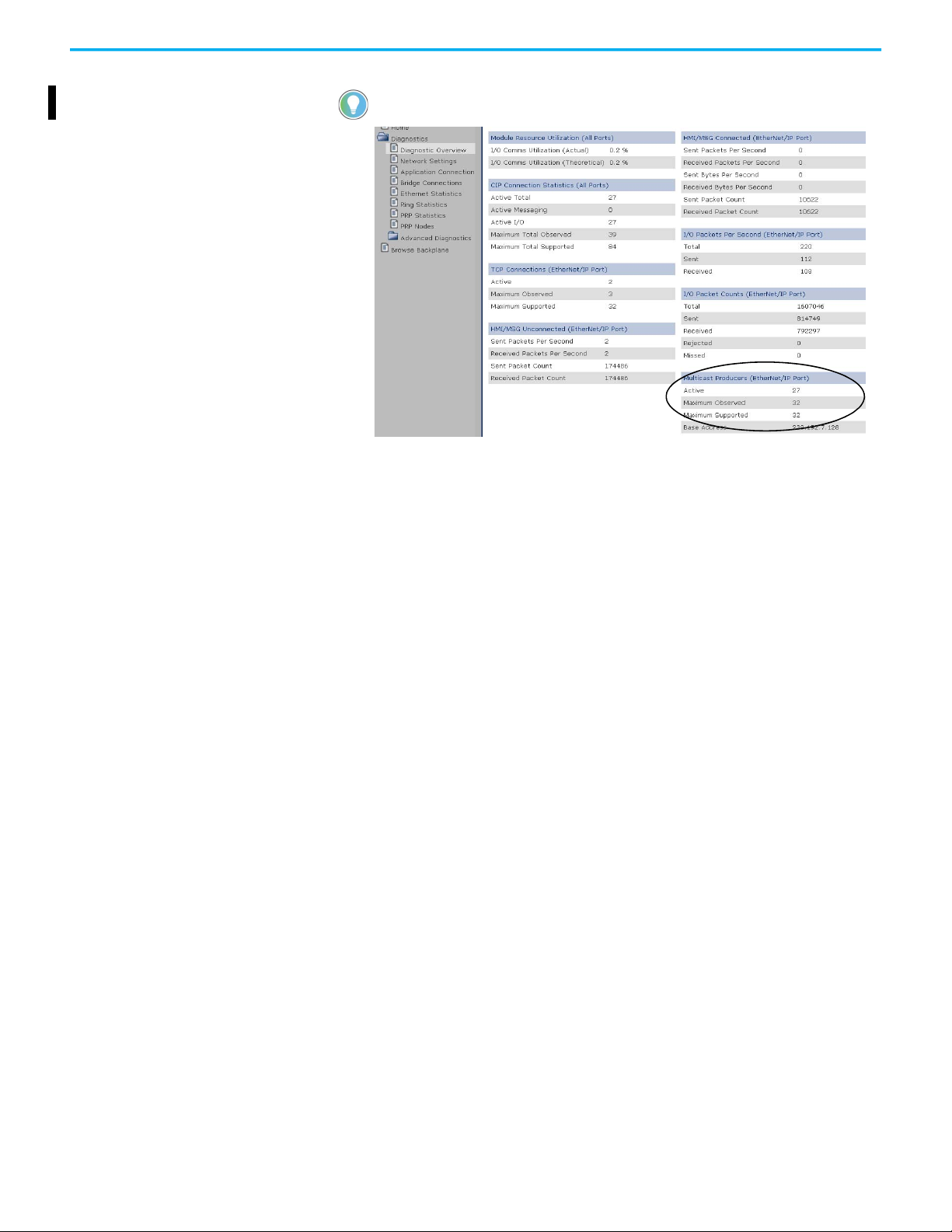

You can verify how many multicast connections are on your network by looking at

your adapter Diagnostic Overview web page.

Input Module Operation Logix 5000 controllers do not poll the FLEX 5000 analog input modules for

input data. Instead, the input modules send their input data, that is channel

and status data, at the RPI.

At the RPI, not only does the module send input data to the controller, but also

the controller sends data to the module inputs. For example, the controller

sends data to command the module to unlatch alarms or enable alarms.

FLEX 5000 analog input modules reside in a FLEX 5000 I/O system that is

accessible to a Logix 5000 controller over an EtherNet/IP network. A

FLEX 5000 EtherNet/IP adapter is the first component in a FLEX 5000 I/O

system and connects the system to the EtherNet/IP network.

FLEX 5000 analog input modules communicate input data to the FLEX 5000

EtherNet/IP adapter at the defined RPI. The input data consists of channel and

status data.

At the RPI, the following events occur.

1. The remote analog input module scans its channels for input data.

2. The module sends the data to the FLEX 5000 EtherNet/IP adapter.

3. The FLEX 5000 EtherNet/IP adapter in the FLEX 5000 I/O system sends

the data over the EtherNet/IP network.

4. One of the following:

• If the controller is directly connected to the EtherNet/IP network, it

receives the input data immediately.

• If the controller is connected to the EtherNet/IP network through

another communication module, the module sends the data to its

backplane and the controller receives it.

Output Module Operation The controller sends data to an output module at the RPI or after an

Immediate Output (IOT) instruction is executed.

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 23

Page 24

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

The RPI defines when the controller sends data to the FLEX 5000 analog

output module and when the output module reads back data. The controller

sends data to an output module only at the RPI.

At the RPI, not only does the controller send data to the output module, but

also the output module sends data to the controller. For example, the output

module sends an indication of the channel data quality.

FLEX 5000 analog input modules reside in a FLEX 5000 I/O system that is

accessible to a Logix 5000 controller over an EtherNet/IP network. A

FLEX 5000 EtherNet/IP adapter is the first component in a FLEX 5000 I/O

system and connects the system to the EtherNet/IP network.

FLEX 5000 analog output modules receive output data from a controller. The

output module also sends data to the controller.

Controller to Remote Analog Output Module Data Transmission

The controller broadcasts data to its local backplane at one of the following:

•RPI

• An IOT instruction is executed.

IMPORTANT

An IOT instruction sends data to all output modules in the system

immediately, and resets the RPI timer.

Based on the RPI rate and the length of the controller program scan, the output

module can receive and readback data multiple times during one program

scan.

When the RPI is less than the program scan length, the output channels can

change values multiple times during a program scan. The owner-controller

does not depend on the program scan to complete to send data.

These events occur when the controller sends data to a FLEX 5000 output

module.

1. Data is sent in one of the following ways:

• If the controller is directly connected to the EtherNet/IP network, it

broadcasts data to the network.

In this case, skip to step 3

.

• If the controller is connected to the EtherNet/IP network via a

communication module, the controller transmits the data to the

backplane.

In this case, proceed to step 2.

2. The EtherNet/IP communication module transmits the data to the

EtherNet/IP network.

3. The FLEX 5000 EtherNet/IP adapter in the FLEX 5000 I/O system

receives the data from the network and transmits it to the backplane.

4. The remote analog output module receives the data from the backplane

and behaves as dictated by its configuration.

24 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 25

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

Remote Analog Output Module to Controller Data Transmission

When a FLEX 5000 analog output module receives new data and the requested

data value is present on the RTB, the output module sends, or reads back a data

value back to the controller and to the rest of the control system. The data value

corresponds to the signal present at its terminals. This feature is called Output

Readback.

In addition to the Output Readback, the output module sends other data to the

controller at the RPI. For example, the module alerts the controller if a short

circuit condition exists on the module.

The following events occur when a remote FLEX 5000 analog output module

sends data to the controller at the RPI.

1. The module sends the data to the backplane.

2. The FLEX 5000 EtherNet/IP adapter in the FLEX 5000 I/O system sends

the data over the EtherNet/IP network.

3. One of the following:

• If the controller is directly connected to the EtherNet/IP network, it

receives the input data from the network without need for a

communication module.

• If the controller is connected to the EtherNet/IP network through

another communication module, the module transmits the data to its

backplane and the controller receives it.

Listen Only Mode Any controller in the system can listen to the data from an I/O module. An

owner-controller, as described in Ownership

analog I/O modules.

Other controllers can use a Listen Only connection with the analog I/O

module. In this case, the ‘listening’ controller can only listen to input data or

output readback data. The listening controller does not own the module

configuration or exchange other data with the module.

During the I/O configuration process, you can specify a Listen Only

connection. For more information on Connection options, see Input Module

Definition on page 76.

IMPORTANT

Remember the following:

• If a controller uses a Listen Only connection, the connection must use

the Multicast option. In this case, all other connections to the module,

for example, the connection of the owner-controller, must also use the

Multicast option.

• If a controller attempts to use a Listen Only connection to a module but

the owner-controller connection uses the Unicast option, the attempt at

a Listen Only connection fails.

The ‘Listen Only’ controller receives data from the module as long as a

connection between an owner-controller and module is maintained.

• If the connection between an owner-controller and the module is

broken, the module stops sending data and connections to all ‘listening

controllers’ are also broken.

• Connected HART devices cannot be added to Listen Only connections.

on page 19, exchanges data with

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 25

Page 26

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

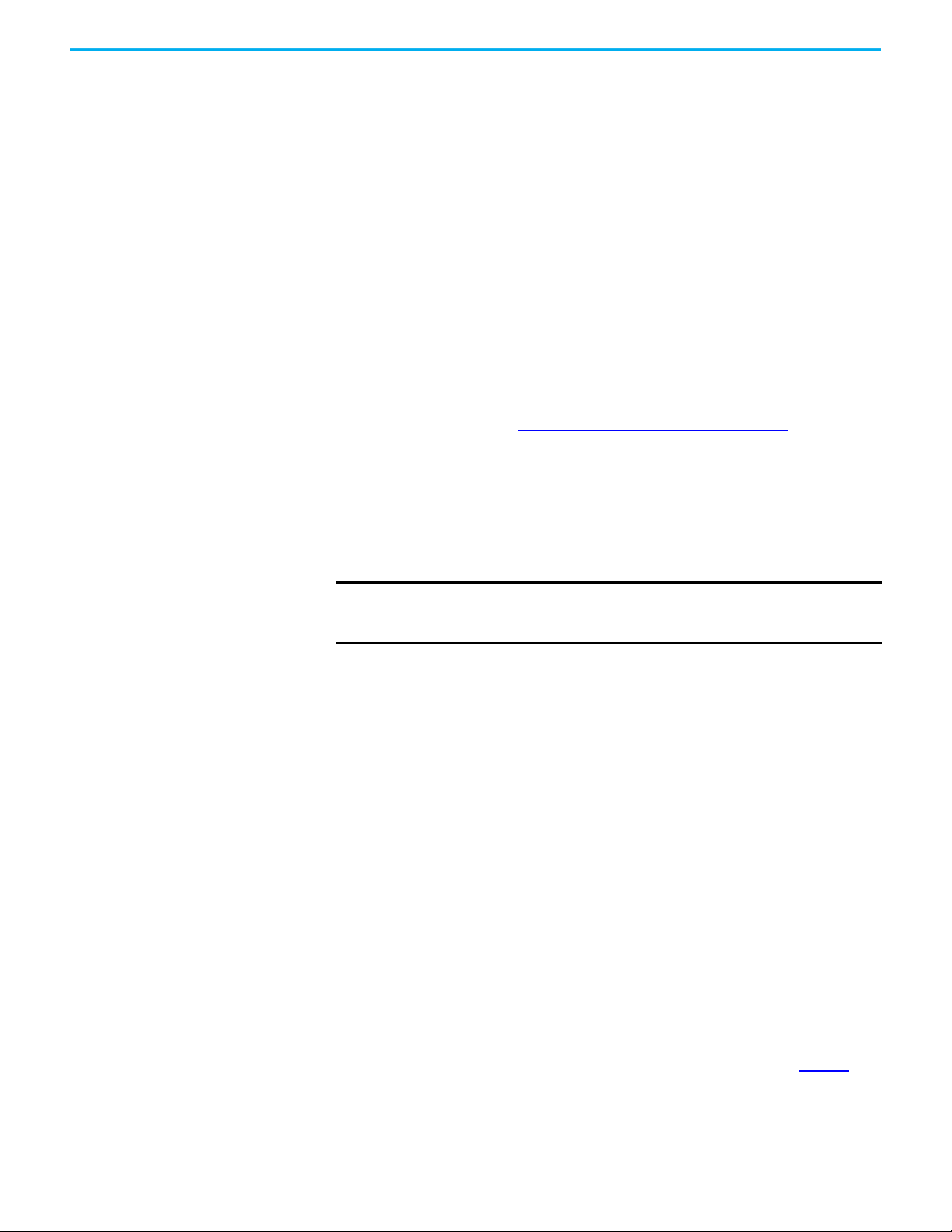

Protected Operations To maintain the secure operation of your FLEX 5000 analog HART I/O module,

operations that can disrupt module operation are restricted based on the

module operating mode. Table 5

Table 5 - Protected Operations on FLEX 5000 Analog HART I/O Modules

Current Module Operation

Connection not running Accepted

Connection running

Firmware update is in process Rejected

Calibration is in process

(1) A module calibration request is accepted when the module is connected and the owner-controller is in Program mode.

(2) The module accepts the requests and changes listed. Keep in mind, when the request or change is made, the calibration process is automatically aborted. We recommend that you wait for

the module calibration to finish before attempting any of the requests or changes.

(3) When the request is made through the Module Properties dialog box.

(4) Only requests for Listen Only connections are accepted.

(5) Configuration change is accepted in the following scenarios:

- Changes are made in the Module Properties dialog box and you click Apply.

- Changes are made in the Configuration tags and you send a Reconfigure Module MSG to the module.

(6) The difference between Rejected and Not allowed is that rejected activities can be attempted in the Studio 5000 Logix Designer application but do not take effect. The activities that are not

allowed, that is, attempts to change the Connection or Data Format used, do not occur in the Studio 5000 Logix Designer application.

For example, if you attempt to reset a module that is connected to the owner-controller, the Studio 5000 Logix Designer application executes the request and alerts you that it was rejected.

If you attempt to change the data format on a module that is connected to an owner-controller, the Studio 5000 Logix Designer application does not execute the attempted change. The

application only alerts you that the change is not allowed. In the case, if the change is attempted online, the Module Definition dialog box field that changes the data format is disabled.

(7) The change occurs after the connection is closed and reopened. You can close and reopen the connection in the following ways:

- Change the project while it is offline and download the updated project before going online again.

- Change the project while it is online and click Apply or OK in the Module Properties dialog box. In this case, before the change is made, a dialog box alerts you of the ramifications before

the change is made.

Firmware

Update

Request

Rejected

Accepted

Module Reset

Request

(1)

(2)

Module

Calibration

(3)

Request

Connection

Request

Accepted

describes the restrictions.

Activity

Configuration

Change

(4)

Accepted

(5)

Connection or

Data Format

Change

Not allowed

(6)

Electronic

Keying

Change

Accepted

RPI Change

(7)

HART Device Operation Before using the HART capabilities, be sure that:

• the I/O module and the associated field device are working properly in

the analog 4…20 mA mode.

• the channel is configured as 4…20 mA range with HART enabled.

• the field device is HART capable.

• no more than one HART field device is connected to each channel.

• Notch Filter of input channel or Ramping Rate of output channel is set to

a valid value.

Input data of HART device, that is device status, dynamic, or device variable

values and status, are sent to Logix Controller at the RPI.

At the RPI, not only does the module send input data of the HART devices to

the controller, but also the controller sends data for the HART devices to the

module. For example, the controller sends data to reset Configuration

Changed status or initiate an execution of a pre-configured HART command.

IMPORTANT If you switch the controller to Program mode or inhibit an output

module, it may cause the output channels to de-energize and the HART

device to not power up.

To power up the HART device, switch the controller to Run mode and

uninhibit the output module.

26 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 27

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

Protected Operations for HART Devices

To maintain the secure operation of your HART device, operations that can

disrupt module operation are restricted based on the module operating mode.

Table 6

describes the restrictions.

Table 6 - Protected Operations on HART Devices

Activity

Current Module Operation

Connection not running Accepted

Connection running Rejected

(1) Device Configuration change is accepted if changes are made using FTD/DTM, handheld device, and HART commands.

(2) The difference between Rejected and Not allowed is that rejected activities can be attempted in the Studio 5000 Logix Designer application but do not take effect. The activities that are not

allowed, that is, attempts to change the Connection or Data Format used, do not occur in the Studio 5000 Logix Designer application.

For example, if you attempt to reset a module that is connected to the owner-controller, the Studio 5000 Logix Designer application executes the request and alerts you that it was rejected.

If you attempt to change the data format on a module that is connected to an owner-controller, the Studio 5000 Logix Designer application does not execute the attempted change. The

application only alerts you that the change is not allowed. In the case, if the change is attempted online, the Module Definition dialog box field that changes the data format is disabled.

(3) The change occurs after the connection is closed and reopened. You can close and reopen the connection in the following ways:

- Change the project while it is offline and download the updated project before going online again.

- Change the project while it is online and click Apply or OK in the Module Properties dialog box. In this case, before the change is made, a dialog box alerts you of the ramifications before the

change is made.

- RPI changes applied to one channel applies the same change to all channels in the configuration section.

Device Reset

Request

Connection

Request

Device Configuration

Change

(1)

Accepted

Device Connection or

Data Format Change

Not allowed

(2)

Electronic Keying

Change

(3)

Accepted

RPI Change

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 27

Page 28

Chapter 2 Analog HART I/O Module Operation in a Logix 5000 Control System

Notes:

28 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

Page 29

Chapter 3

Common I/O Module Features

Top ic Pa ge

Software Configurable 29

Fault and Status Reporting 30

Module Inhibiting 30

Electronic Keying 31

Producer/Consumer Communication 31

Status Indicators 32

Use CIP Sync Time with I/O Modules 32

Module Firmware 32

Common Analog Channel Features 33

This chapter describes module features that are available on both FLEX 5000

HART input and output modules.

FLEX 5000 analog HART input modules convert an analog signal to a digital

value. For example, the modules can convert the following:

•Volts

•Milliamps

You can configure FLEX 5000 HART input modules to support digital input

signals when your application requires channel to channel isolation. The

following types of discrete device types are supported:

• Digital Input

• IEC 61131-2 Type 3-d Digital Input

For information on digital input points, see Chapter 5

FLEX 5000 analog HART output modules convert a digital value to an analog

signal. For example, the modules can convert the following:

•Volts

•Milliamps

FLEX 5000 analog HART enabled modules decodes HART information from

signal embedded within the channel.

Software Configurable You use the Studio 5000 Logix Designer application to configure the module,

monitor system operation, and troubleshoot issues. You can also use the

Studio 5000 Logix Designer application to retrieve the following information

from any module in the system:

• Serial number

Rockwell Automation Publication 5094-UM007B-EN-P - October 2020 29

Page 30

Chapter 3 Common I/O Module Features

• Firmware revision information

• Product code

•Vendor

• Error and fault information

• Diagnostic information

By minimizing the need for tasks, such as setting hardware switches and

jumpers, the software makes module configuration easier and more reliable.

Fault and Status Reporting The FLEX 5000 analog HART I/O modules report fault and status data along

with channel data. Fault and status data is reported in the following ways:

• Studio 5000 Logix Designer application

• Module status indicators

For more information on fault reporting, see the individual module feature

chapters and Appendix A, Troubleshoot Your Module

on page 107.

Module Inhibiting Module inhibiting lets you indefinitely suspend a connection, including Listen

Only connections, between an owner-controller and an analog I/O module

without removing the module from the configuration. This process lets you

temporarily disable a module, such as to perform maintenance.

IMPORTANT

You can use module inhibiting in the following ways:

• You write a configuration for an I/O module but inhibit the module to

help prevent it from communicating with the owner-controller. The

owner does not establish a connection and the configuration is not sent

to the module until the connection is uninhibited.

• In your application, a controller already owns a module, has downloaded

the configuration to the module, and is exchanging data over the

connection between the devices.

You can use module inhibiting in these instances:

• You want to update an analog I/O module, for example, update the

module firmware revision. Use the following procedure.

a. Inhibit the module.

b. Perform the update.

c. Uninhibit the module.

• You use a program that includes a module that you do not physically

possess yet. You do not want the controller to look for a module that does

not yet exist. In this case, you can inhibit the module in your program

until it physically resides in the proper slot.

Once a module is inhibited, the connections to the module and attached

HART devices are also closed and the CIP messaging to the HART

devices is disabled.

To see where to inhibit a FLEX 5000 analog HART I/O module, see page 77

30 Rockwell Automation Publication 5094-UM007B-EN-P - October 2020

.

Page 31

Chapter 3 Common I/O Module Features

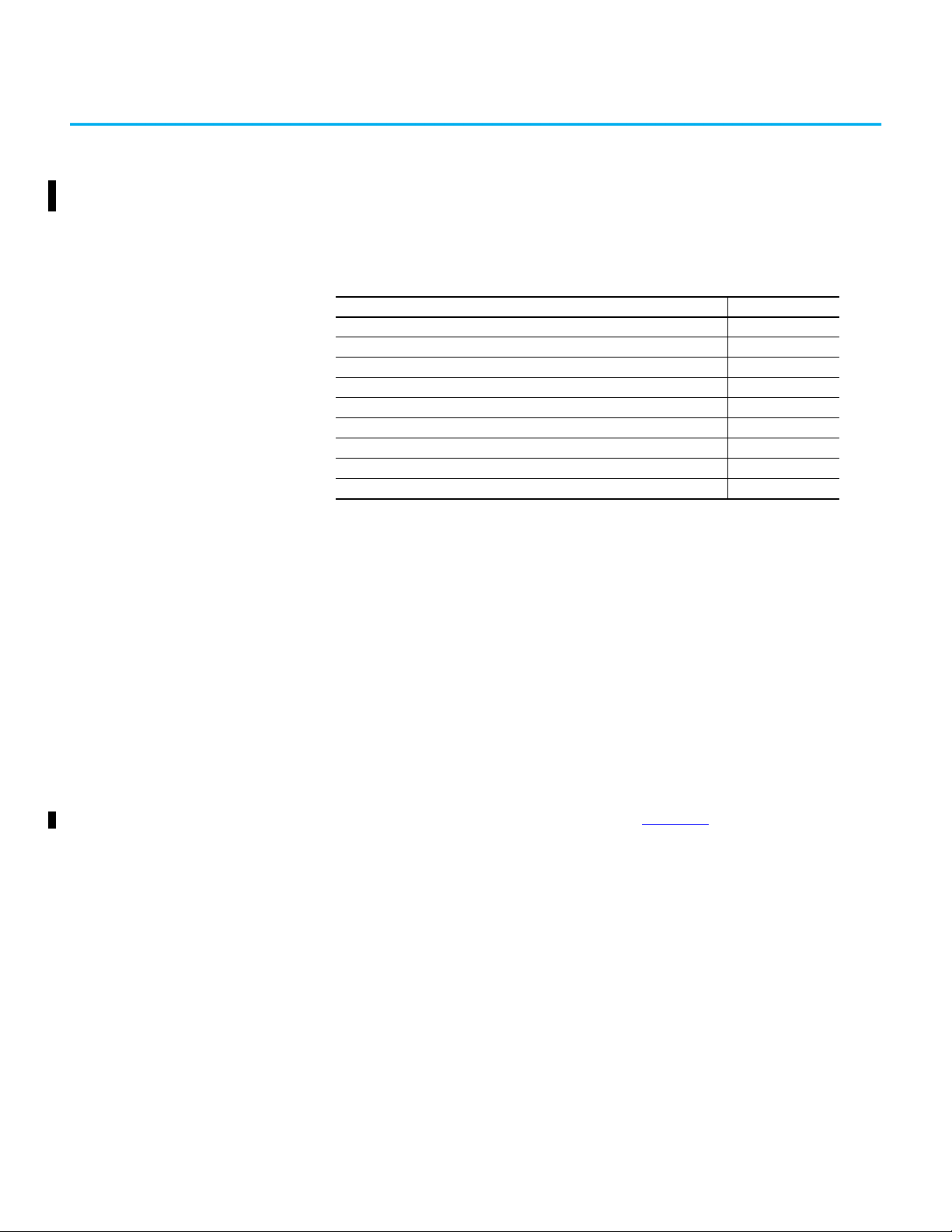

Electronic Keying Electronic Keying reduces the possibility that you use the wrong device in a

control system. It compares the device that is defined in your project to the

installed device. If keying fails, a fault occurs. These attributes are compared.

Attribute Description

Vendor The device manufacturer.

Device Type The general type of the product, for example, analog I/O module.

Product Code The specific type of the product. The Product Code maps to a catalog number.

Major Revision A number that represents the functional capabilities of a device.

Minor Revision A number that represents behavior changes in the device.

The following Electronic Keying options are available.

Keying Option Description

Lets the installed device accept the key of the device that is defined in the project when the

installed device can emulate the defined device. With Compatible Module, you can typically

replace a device with another device that has the following characteristics:

Same catalog number

Compatible Module

Disable Keying

Exact Match

Same or higher Major Revision

Minor Revision as follows:

If the Major Revision is the same, the Minor Revision must be the same or higher.

If the Major Revision is higher, the Minor Revision can be any number.

Non-XT and XT version as follows:

You can use an XT version of the module in place of a non-XT module.

You cannot use a non-XT version of the module in place of an XT module.

Indicates that the keying attributes are not considered when attempting to communicate

with a device. With Disable Keying, communication can occur with a device other than the

type specified in the project.

WAR N IN G : Be extremely cautious when using Disable Keying; if used incorrectly, this option

can lead to personal injury or death, property damage, or economic loss.

We strongly recommend that you do not use Disable Keying.

If you use Disable Keying, you must take full responsibility for understanding whether the

device being used can fulfill the functional requirements of the application.

Indicates that all keying attributes must match to establish communication. If any attribute

does not match precisely, communication with the device does not occur.

Producer/Consumer Communication

Carefully consider the implications of each keying option when selecting one.

IMPORTANT Changing Electronic Keying parameters online interrupts connections to the

device and any devices that are connected through the device. Connections

from other controllers can also be broken.

If an I/O connection to a device is interrupted, the result can be a loss of data.

More Information