Page 1

Installation

Manual

FD86N

Drive Systems

Enclosure

Hardware

Page 2

Important User

Information

The illustratio ns shown in thi s guide are intended sole ly for purposes of e xample. Since

there are many variables and requirements associated with any particular installation,

Rockwell Automation Drive Systems does not assume responsibility or liability (to

include intell ectual prope rty liabil ity) for a ctual use ba sed upon th e examples show n in

this publication.

Reproduction of the contents of this copyrigh ted publication, in whole or i n part, without

written permission of Rockwell Automation is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION:

that can lead to pe rs ona l injury or death, prope rt y damage, or economic

!

Attention statements help you:

identify a hazard

•

avoid the hazard

•

recognize the consequenc es

•

Important: Identifies information that is critical for successful application and

CENTERLINE

Torx is a trademark of Text ron Inc.

loss.

understanding of the product.

is a trademark of Rockwell International or its subsidiaries.

Identifies i nformation about pr actices or circ umstances

Page 3

Publication S-3062 – November 1997

Table of Contents

Preface

Who Should Use this Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-1

Purpose of this Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-1

Safety Precautions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-1

How to Use this Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-2

Contents of this Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-2

Related Documentation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-3

Conventions Used in this Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . .

P-3

Drive Systems Receiving

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-3

Rockwell Automation Drive Systems Support

. . . . . . . . . . . . . . . . . .

P-4

Local Product Support

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-4

Technical Product Assistance

. . . . . . . . . . . . . . . . . . . . . . . . . . .

P-4

Chapter 1

Overview of the FD86N

Enclosure

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

What is the FD86N Enclosure?

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

Standard Features of the FD86N Enclosure

. . . . . . . . . . . . . . . . . . .

1-1

Standard Options of the FD86N Enclosure

. . . . . . . . . . . . . . . . . . . .

1-2

Bulletin 2300 MCC Compatibility

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

Chapter 2

Installing the FD86N Enclosure

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Before You Begin

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Unpackin g the Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Handling the Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Storing the Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Site Planning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2

Space Requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2

Support Requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2

Entry and Exit Provisions for Wiring

. . . . . . . . . . . . . . . . . . . . . .

2-2

Lifting the Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3

Anchoring and Mounting the Enclosure

. . . . . . . . . . . . . . . . . . . . . .

2-5

Joining Control Enclosure Sections

. . . . . . . . . . . . . . . . . . . . . . . . .

2-5

Joining Control Enclosures to Bulletin 2100 MCCs

. . . . . . . . . . . . .

2-6

Protecting Ventilated Control Enclosure Equipm ent

During Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7

Removing Lifting Angles

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7

Installing Conduit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7

Installing a Typical Bus Bar Assembly

. . . . . . . . . . . . . . . . . . . . . . .

2-8

Installing a Pull Box to a Bus Bar Enclosure

. . . . . . . . . . . . . . . . . . .

2-9

Installing an Equipment Enclosure to the FD86N Enclosure

. . . . .

2-10

Installing an Air Conditioning Unit to the FD86N Enclosure

. . . . . .

2-11

Installing a Mechanical Door Interlock Link between

FD86N Enclosures

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12

Page 4

toc–ii

Table of Contents

Publication S-3062 – November 1997

Chapter 3

Joining Bus Bar Assemblies

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

Before You Begin

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

Splicing Single Bus Bar Assemblies

. . . . . . . . . . . . . . . . . . . . . . . . .

3-1

Splicing Parallel Bus Bar Assemblies

. . . . . . . . . . . . . . . . . . . . . . . .

3-2

Installing Bus Bar Tabs for Incoming Power

. . . . . . . . . . . . . . . . . . .

3-3

Making Connections to Drop Tabs

. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5

Joining Bus Bar Enclosures

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7

Installing DC Bus Bar Connections to a Bulletin2100 MCC

. . . . . . .

3-8

Installing DC Bus Bar Adapter Connections to an

SA3000 or SB3000

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9

Installing the Ground Cables between FD86N Enclosures

. . . . . . .

3-10

Connecting the Incoming Ground Bus

. . . . . . . . . . . . . . . . . . . . . . .

3-11

Chapter 4

Maintenance

Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

Protecting Ventilated Control Enclosures Du ring Mai ntena nce

. . . . .

4-1

Cleaning the Filter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

Replacing Cabinet Light Bulbs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

Page 5

Publication S-3062 – November 1997

Table of Illustratio ns

Figure P.1

Typical Dimension Sheet

. . . . . . . . . . . . . . . . . . . . . . . .

P-2

Figure 1.1

Typical 3FD86N Enclosure with Standard Options

. . . . .

1-3

Figure 2.1

Minimum Sling Angle Requirement

. . . . . . . . . . . . . . . . .

2-3

Figure 2.2

Typical Lifting (End View)

. . . . . . . . . . . . . . . . . . . . . . . .

2-4

Figure 2.3

Typical Lifting (Front Views)

. . . . . . . . . . . . . . . . . . . . . .

2-4

Figure 2.4

Joining Enclosure Sections (End Panel Outside Views)

.

2-5

Figure 2.5

FD86N Enclosure with End Plates for Connection

to a Bulletin 2100 MCC

. . . . . . . . . . . . . . . . . . . . . . . . . .

2-6

Figure 2.6

Installing a Bus Bar Assembly to an FD86N Enclosure

.

2-8

Figure 2.7

Installing a Pull Box to a Bus Bar Enclosure

. . . . . . . . . .

2-9

Figure 2.8

Installing an Equipment Enclosure to the

FD86N Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10

Figure 2.9

Installing an Air Conditioner to the Left or Right End of the

FD86N Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11

Figure 2.10

Installing a Mechanical Door Interlock Link between

FD86N Enclosures

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12

Figure 3.1

Splicing Single Bus Bar Assemblies

. . . . . . . . . . . . . . . .

3-1

Figure 3.2

Splicing Parallel Bus Bar Assemblies

. . . . . . . . . . . . . . .

3-2

Figure 3.3

Typical Installation of Incoming AC Bus Bar

Tabs (Staggered)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3

Figure 3.4

Typical Installation of Incoming AC Bus Bar Tabs (Inline)

3-3

Figure 3.5

AC Bus Bar Tab Hardware Orientation

. . . . . . . . . . . . . .

3-4

Figure 3.6

Typical 4

Drop Tab Connections

. . . . . . . . . . . . . . . . . .

3-5

Figure 3.7

Typical 6

Drop Tab Connections

. . . . . . . . . . . . . . . . . .

3-6

Figure 3.8

Installing a Sheet Metal Joiner for Bus Bar Enclosures

(FD86N to FD86N)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7

″

″

Page 6

toi-ii

Table of Illustrations

Publication S-3062 – November 1997

Figure 3.9

Installing a Sheet Metal Joiner on an Overhead Cable

Routing Box (FD86N to SA3000 or SB3000)

. . . . . . . . . .

3-7

Figure 3.10

Installing DC Bus Bar Connections from the

FD86N Enclosure to an MCC

. . . . . . . . . . . . . . . . . . . . . .

3-8

Figure 3.11

Installing the DC Bus Bar Adapter Connections between an

SA3000 or SB3000 and a DC Bus Bar Assembly

on the FD86N Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . .

3-9

Figure 3.12

FD86N Enclosure to FD86N Enclosure Ground Cable

Location and Hardware Orientation

. . . . . . . . . . . . . . . .

3-10

Figure 3.13

Connecting Incoming Ground Bus Bar Assembly Cables

to the FD86N Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . .

3-11

Figure 3.14

Grounding Hardware Connections

. . . . . . . . . . . . . . . . .

3-12

Page 7

Publication S-3062 – November 1997

Preface

Preface

Please read this preface to familiarize yourself with the rest of this

Who Should Use this Manual

Purpose of this Manual

Safety Precautions

manual. This preface describes:

who should use this manual

•

the purpose of this manual

•

safety precautions

•

how to use this manual

•

contents of this manual

•

conventions used in this manual

•

drive system rece iving informatio n

•

how to contact Rockwell Automation support

•

Use this manual if you are responsible for installing or handling the

FD86N enclosure.

This manual provides installation instructions for the FD86N

enclosure, including instruction on:

unpacking, handling, lifting, and storage

•

site planning

•

installing equipment such as pull boxes and equipment enclosures

•

joining bus bar assemblies

•

maintaining the enclosure

•

These general precautions apply to the FD86N enclosure and its

respective drive systems.

ATTENTION:

system, the products used in the system, and the

!

associated machinery should plan or implement the

installation, startup, and maintenance of the system.

Failure to comply can result in personal injury and/or

equipment damage.

Only those familiar with the drive

Page 8

P-2

Preface

Publication S-3062 – November 1997

How to Use this Manual

This manual presents i nformation in the order in which it is typically needed

Contents of this Manual

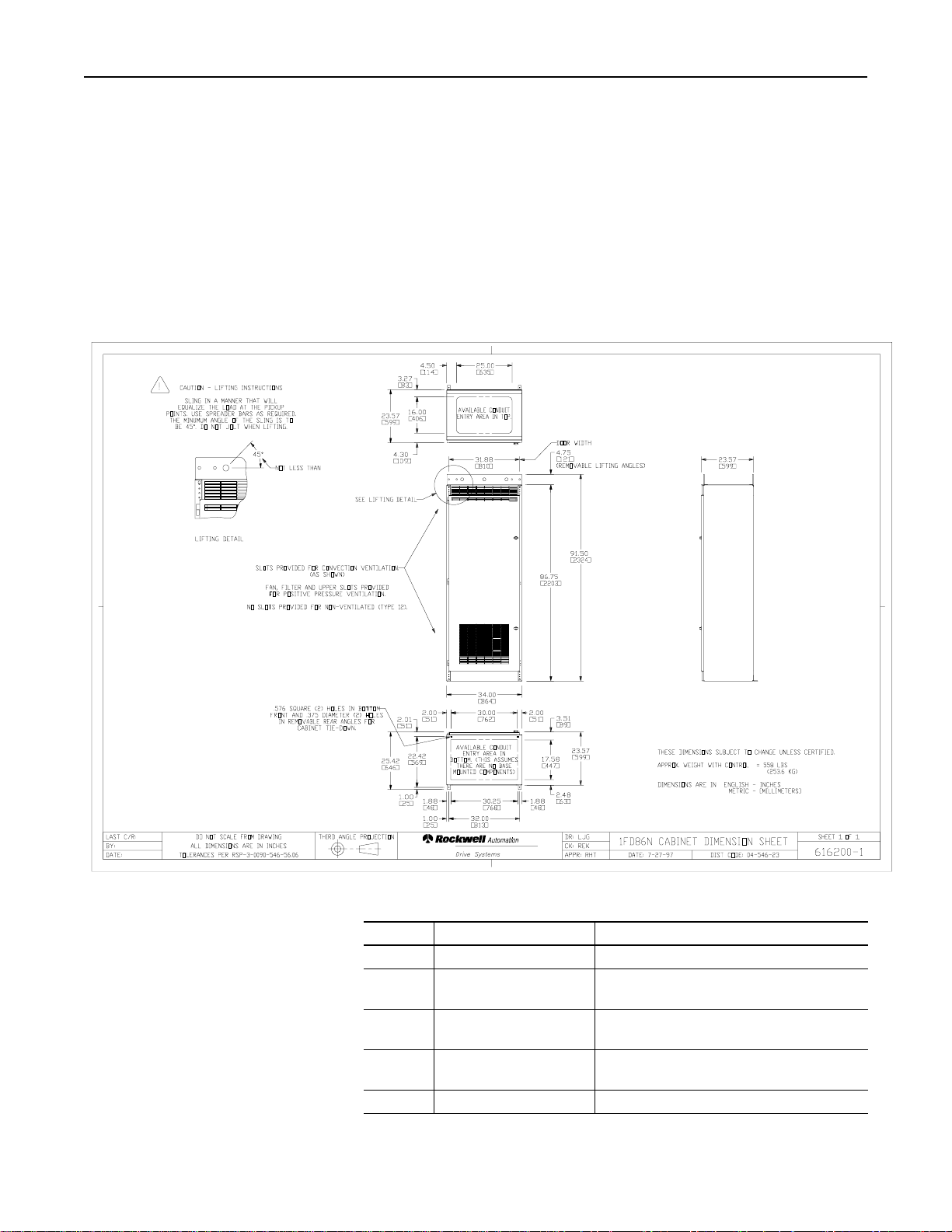

Figure P.1

Typical Dimension Sheet

Chapter

Title

Contents

Preface

Purpose, background, and scope of this manual

1

Overvi ew of the F D86N

Enclosure

General information about the FD86N enclosure

2

Installing the FD86N

Enclosure

Procedures for installing the FD86N enclosure

3

Joining Bus Bar Assemblies

Procedures for installing bus splices and ground

cables

4

Maintenance

Procedures for maintaining the FD86N enclosure

during installation.

Occasionally , t his manual requires you t o refer to your wiring sc hematic or

Dimension Sheet for information specific to your system. Check your

wiring package for these drawings. A sample Dimension Sheet is shown in

Figure P.1.

Page 9

Preface

P-3

Publication S-3062 – November 1997

Related Documentation

Conventions Used in

this Manual

Throughout this manual, these methods of showing information are used:

Drive Systems Receiving

For

Read This Document

Document Number

Additional information on joining

and splicing together Bulletin 2100

CENTERLIN

E™

MCCsInstructions—Joining and

Splicing Vertical Sections

2100-5.1

Details on receiving, handling, and

storing Bulletin 2100

CENTERLINE MCC

s

Instructions—Receiving,

Handling, and Storing Motor

Control Centers

2100-5.5

Details on joining and splicing

together Bulletin 2300 products

(Bulletin 2300 products are

packaged by Drive Systems in

Bulletin 2100

MCCs)Bulletin 2300 Family of Drive

Systems Hardware Installation

Manual

2300-5.1

Articles on

NEMA

standards for

motor control centers

Instructions for the Handling,

Installation, Operation, and

Maintenance of Motor Control

Centers

ANSI/NEMA

ICS-

2.3

Articles on safety procedures and

installation of machines and the

wiring between component

machines

National Electrical Code

ANSI/NFPA

70-1993

Bulleted li sts, such as this one, pr ovide information, not procedures.

•

Numbered lists provide procedures in sequential steps.

•

Other documents or sections to which you are referred are in italics.

•

This symbol followed by the word “ATTENTION” indicates

•

circumstances th at can lead t o personal i njury, death, property damage,

or economic loss:

!

The word “Important” indicates information that is critical for

•

successful application and understanding of the product.

The prefix of th e FD86N part number—1, 2, or 3—indicates how many

•

bays are in the cabinet.

Y ou, the cus tomer, are r esponsible for thoroughly i nspecting the equipment

before accepting t he shipment from the frei ght company. Check the items

that you receive against your purchase order. If any items are damaged, it

is your responsibility to refuse delivery until the freight agent has noted the

damage on the freight bill. Should you discover any concealed damage

during unpacking, you are responsible for notifyi ng the freight agent. Lea ve

the shipping contai ner intact and request that t he freight agent make a visual

inspection of the equipment.

Page 10

P-4

Preface

Publication S-3062 – November 1997

Rockwell Automation Drive

Systems Support

Rockwell Automation offers support services worldwide, with Sales/

Local Product Support

Technical Product Assistance

Support Offices, authorized distributors, and authorized Systems

Integrators located throughout the United States, plus Rockwell

Automation representatives in every major country in the world.

Contact your local Rockwell Automation representative for:

sales and order support

•

product technical training

•

warranty support

•

support service agreements

•

If you need to cont act Rockwell Automation for tec hnical assistance, please

review the product information in the appropriate product manual first.

Then call your local Rockwe ll Automation repres entative. F or the quickes t

possible response, have the catalog numbers of your products available

when you call.

Page 11

Publication S-3062 – November 1997

Chapter

1

Overview of the FD86N Enclosure

Introduction

What is the FD86N Enclosure?

Standard Features of the

FD86N Enclosure

This chapter provides general information about the FD86N enclosure.

The control enclosure described in this manual is a Rockwell

Automation Drive Systems product.

The FD86N enclosure is of deadback construction and can consist of

one or more encl osures fastened together . Enclosures f astened together

form a rigid, free-standing enclosure lineup assembly designed to

accommodate a drive system.

Standard overhead AC or DC bus distribution assemblies can be

mounted on the FD86N enclosure. Pull boxes can be mounted on the

distribution or bus bar assembly for user conduit entry.

The cabinet meets or exceeds the requi reme nts of the latest publ i shed

standards , including:

UL 50

•

UL 508

•

UL 508A

•

CAN/CSA C22.2 No. 14

•

NEMA 250

•

The Type 12 cabinet has been tested and approved by UL.

A typical FD86N enclosure is shown in 1.1.

FD86N enclosure features include:

bolt-together construction

•

enclosure color ANSI 49 medium light gray

•

a white control panel

•

padlockable door latches

•

hinged, removable doors

•

dimensionally aligns with Bulletin 2100 CENTERLINE motor

•

control center (MCC) design

grounded doors

•

Page 12

Overview of the FD86N Encl osure

1-2

Publication S-3062 – November 1997

Standard Options of the

FD86N Enclosure

FD86N enclosures can include:

Bulletin 2100 MCC Compatibility

electrical door interlocks

•

mechanical door interlocks

•

air conditioning (end panel mounted)

•

hood mounted equipment enclosure

•

provisions for standard overhead AC and DC bus assemblies

•

a safety ground bus

•

interior lighting

•

The FD86N enclosure connects to any Bulletin 2100 motor control

center that:

is at least 20 ″ deep with a power bus and control bus (if supplied)

•

mounted at a depth of 16.94″ from the front of the cabinet

has 1.5″ high base channels (total MCC height is 91.5″)

•

To connect to a Bulletin 2100 MCC, the FD86N must have the end panel

with cutouts for connection to another MCC.

Page 13

Overview of the FD86N Encl osure

1-3

Publication S-3062 – November 1997

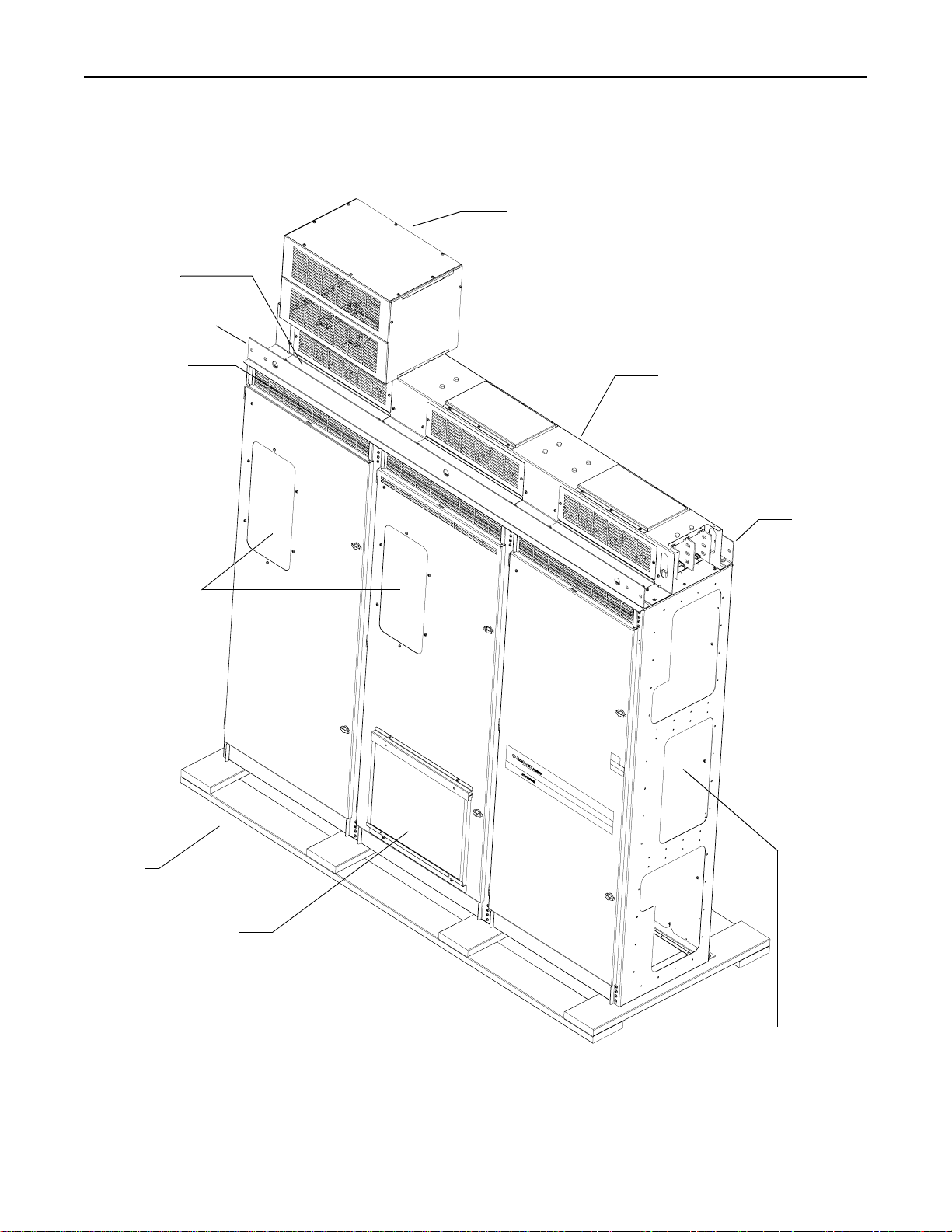

Figure 1.1

Typical 3FD86N Enclosure with Standard Options

Conduit Cover

Lifting Angle

Operator Interface

Skid

Filter

Pull Box

Lifting Angle

Panels

Bus Bar Assembly

Ventilation Slots

(Convection and Positive

Pressure Only)

End Panel Cutouts

(Pattern shown here is for

connection to another FD86N

enclosure)

(Positive Pressure Only)

Page 14

Overview of the FD86N Encl osure

1-4

Publication S-3062 – November 1997

This page intentionally left blank.

Page 15

Publication S-3062 – November 1997

Chapter

2

Installing the FD86N Enclosure

Introduction

Before You Begin

Unpacking the Enclosure

Handling the Enclosure

Storing the Enclosure

This chapter provides procedures for unpacking and installing the

FD86N enclosure. It also pro vides procedures for fastening enclo sures

together, installing conduit , an d installing bus assemblies, pull boxe s,

equipment enclosures, and air conditioning units to the enclosure.

Before you begin enclosure installation, be sure to have:

3

⁄

For skid hardware: Socket or box wrenches for ″ hardware.

•

For all enclosure hardware: Drive bit for recessed 6-lobe, Torx™

•

type screw.

Do not remove the encl osure’s protective wra ppin g until it reaches its

final installation site. If packing must be removed for acceptance

inspection, reinstall and reseal the packing after inspection.

8

Note: When removing the protective wrapping, avoid marring the

enclosure surfac e.

While removing packing materials, find and save the packing slip.

FD86N enclosures are shipped on individual skids that have forklift

access. Do not remove skids until the equipment reaches its final

installation site and is ready to be lifted into position for anchoring.

ATTENTION: Ensure that the load rating of the

lifting devic e is suf f icien t to safely hand le the loa d.

!

The FD86N enclosure must be kept upright and under protectiv e cover .

Shipping cov erings are not suit able for outdoo r or unprotected sto rage.

!

Refer to the shipping weights on the packing slip.

ATTENTION: If the enclosure is rem oved from

the skids for storage , brace and block the enclo sure

until it is permanently secured.

Page 16

2-2

Installing the FD86N Enclosure

Publication S-3062 – November 1997

Site Planning

When preparing the installation site for the enclosure, you must provide:

Space Requirements

Support Requirements

Entry and Exit Provisions for Wiring

Adequate space for the enclosure and associated equipment.

•

Adequate support for the enclosure and associated equipment.

•

Entry and exit provisions for the wiring.

•

You must have enough clearance around the enclosure to provide

unrestricted v entilation and room t o service the equi pment. Recommended

clearance requirements are:

Front: 36″ (914.4 mm)

•

Back: None

•

Ends: 18″ (457.2 mm)

•

T op (including installed equ ipment, such as pull boxes): 12 ″ (304.8 mm)

•

Adhere to the requir ements of National Electrical Code Arti cle 110-16 and

any local regulations or codes when determining appropriate clearances.

If your install ation does not pro vide t he minimum cl earance s liste d abo ve,

contact Rockwell Automation Drive Systems, especially if you plan to

mount control enclosures end-to-end or if the end will be against a wall.

Additional cooling might be required.

Forced-ventilated enclosures require space for unrestricted movement of

air at the inlet and exhaust openings. Non-ventilated enclosures require

space for con vective c ooling at the exposed surfac es. Where space is critical,

discuss the requirements with Rockwell Automation Drive Systems.

Control enclosures must be firmly fastened to a rigid struc ture or

foundation. The structure must be able to support the weight of the

equipment and rigid enough to preve nt excessive resonant vib ration. Mating

surfaces must be smooth and even to avoid deformation or stress.

See your Dimension Sheet for conduit entry and exit locations.

Page 17

Installing the FD86N Encl osure

2-3

Publication S-3062 – November 1997

Lifting the Enclosure

For lifting instructions, see the Dimension Sheet for your enclosure and

Figure 2.1

Minimum Sling Angle Requirement

45° Minimum

Sling

Lifting Angle

Enclosure

Figures 2.1, 2.2, and 2.3.

ATTENTION:

the enclosure can be top-heavy. Exercise caution.

!

When lifting the enclosure:

Use slings for pickup points.

•

Use slings with load-rated safety hooks or shackles.

•

Use the proper s lings to ensure t hat the load is equalized at all lift points.

•

Use spreader bars (see Figure 2.3) and padding to prevent damage to

•

the enclosure and enclosed equipment.

Do not pass ropes or cables through the lifting angle support holes.

•

Use rigging lengths that compensate for any unequal weight di stribution

•

of the load and that support the enclosure in an upright position.

The angle between the riggi ng and enclos ure must be at least 45°. This

•

reduces tension on the slings and compression on the lifting angles.

Keep enclosure upright.

•

Do not jolt the enclosure.

•

ATTENTION:

the skids, brace and block the enclosure until it is

permanently secured.

When detaching skids, be aware that

When the enclosure is removed from

ATTENTION:

equalized at the pickup points. Use spreader bars as

!

required. Minimum sling angle is 45°.

ATTENTION:

damage the enclosure, especially if it encloses heavy

equipment.

Lift the sling so that the load is

Tilting the FD86N enclosure can

Page 18

2-4

Installing the FD86N Enclosure

Publication S-3062 – November 1997

Figure 2.2

Typical Lifting (End View)

Sling

Typical End View

Lifting Angle

Figure 2.3

Typical Lifting (Front Views)

4 Point Pickup

6 Point Pickup

8 Point Pickup

Sling

Lifting Angle

Sling

Lifting Angle

Sling

Lifting Angle

Sling

Spreader Bar

Page 19

Installing the FD86N Encl osure

2-5

Publication S-3062 – November 1997

Anchoring and Mounting the

Enclosure

Before final anchoring of the enclosure, make sure the equipment is level

Joining Control

Enclosure Sections

Figure 2.4

Joining Enclosure Sections (End Panel Outside Views)

Left End

Right End

Back

Front

Front

Back

: Preferred Joining Locations

and fully supporte d at all anchor points . Use s teel s hims as neces sary. If it

is not lev el and supported, the enclosure or controls can be distorted, caus ing

wiring stresses, broken components, or improper environmental sealing.

Refer to your Dimension Sheet to determine mounting requirements and

mounting hole locations.

For multi-enclosure control lineups, you might need to join enclosure

sections in the field. Holes are provided in the end panels for this pur pose.

T o join th e enclosure sect ions, install M6×16 or ¼-20×½″ thread-forming

screws in at least ten holes as equally spaced around the perimeter of the

end panel as is practical. Note which holes are clearance holes and which

holes are thread -forming holes to determin e which way to insert the screws.

See Figure 2.4 for preferred joining configuration.

If you are joining Type 12 enclosures, apply a bead of general purpose

rubber sealant aro und the per ime ter of the cutou ts betwe en th e enclo sures

before installing the fasteners. Install fasteners around the cutouts, using

all available hole locations.

Page 20

2-6

Installing the FD86N Enclosure

Publication S-3062 – November 1997

Joining Control Enclosures to

Bulletin 2100 MCCs

For multi-enclosure control lineups, you might need to join enclosure

Figure 2.5

FD86N Enclosure with End Plates for Connection to a

Bulletin 2100 MCC

: Preferred Joining Locations

Left End

Right End

Back

Front

Front

Back

Note: The Bulletin 2100

MCC

must

have 1.5

high base channels.

sections in the field. Holes are provided in the end panels for this pur pose.

T o join the enclosu re sections, install M6 × 16 or ¼-20×½″ thread-forming

screws in at leas t twelve holes as equally sp aced around the perimeter of

the enclosure as is pra ctical. Join enclos ures by insert ing fasten ers through

the clearance holes of the FD86N into the thread-forming holes in the MCC

enclosure. See Figure 2.5 for preferred joining configuration.

Refer to publications 2300-5.1, 5100-5.1, and 2100-5.5 for MCC

installation information .

″

Page 21

Installing the FD86N Encl osure

2-7

Publication S-3062 – November 1997

Protecting Ventilated Control

Enclosure Equipment

During Installation

During installation and maintenance, the enclosure doors will be open,

Removing Lifting Angles

Installing Conduit

which could allow airborne particles into the enclosure. Ensure that the

environment is clean and free of airborne particles. If there are airborne

particles, co ver the encl osure to prot ect the elect rical contro l equipment in

the enclosure.

During normal operation with the doors closed and covers installed,

enclosures with pos itive pressure ventilation and filters protect equipment

from airbor ne particles.

Lifting angles can be remo ved when installati on is complete. Lifting angles

are secured with ½-13x1-½″, Grade 5 hex head cap scr e ws, l ock w a shers,

and flat washers. Remove the hardware and discard the lifting angles if

desired. Replace all hardware into the hood of the control enclosure.

ATTENTION:

hardware that secures the lifting angles has sealant

!

Your Dimension Sheet shows where conduit can be installed.

If you need to drill or cut openings in the enclosure, take care to prevent

damage to internal components or the enclosure itself.

!

under the flat washer. If you remove the lifting angles

on T ype 12 enclosur es, apply a gen eral purpo se rubber

sealant under al l of the fla t washers when the hardw are

is reinstalled.

ATTENTION:

from debris (metal chips) ca used b y dril ling or sa wi ng.

ATTENTION:

interior of the cont rol enclosur e must be va cuumed out

and wiped clean with a dry cloth.

If the enclosure is Type 12, the

Internal electro nics must be protected

When installation is complete, the

Page 22

2-8

Installing the FD86N Enclosure

Publication S-3062 – November 1997

Installing a Typical

Bus Bar Assembly

Hardware needed:

Figure 2.6

Installing a Bus Bar Assembly to an FD86N Enclosure

Front View

Rear View

Bus Bar Assembly

FD86N Enclosure Hood

Bus Bar Assembly

FD86N Enclosure

Hood

Lift Points (for Bus Bar

Assembly Only)

Typical 4 per Assembly

Five M6 or ¼-20 thread-forming screws per enclosure bay.

•

To install a bus bar assembly to the FD86N enclosure:

1. Place the bus bar assembly over the cutouts on the top of the FD86N

enclosure. Use the lifting points shown in Figure 2.6. Do not lift the

bus bar assembly using a hook in the bus bar holes.

2. Align the mounting holes. Refer to Figure 2.6.

3. Fasten the bus bar assembly to the FD86N enclosure using the M6 or

¼-20 thread-forming screws.

Page 23

Installing the FD86N Encl osure

2-9

Publication S-3062 – November 1997

Installing a Pull Box to a

Bus Bar Enclosure

Hardware needed:

Figure 2.7

Installing a Pull Box to a Bus Bar Enclosure

Split Access Cover

Top Access Cover

Bus Bar Enclosure

Typical 27

High Pull Box

Typical 9

High Pull Box

Typical 18

High Pull Box

Cutout

Typical Pull Box

(Access Covers

Removed)

Split Access Cover

Six M6 or ¼-20 thread-forming screws.

•

To install a pull box to the bus bar enclosure:

1. Remove the split or top access cover from the pull box. Refer to

Figure 2.7.

2. Place the pull box on the bus bar enclosure over the cutout.

3. Align the mounting holes. Refer to Figure 2.7.

4. Fasten the pull box to the b us bar enclosure using the M6 or ¼-20 thread-

forming screws.

5. Reinstall the access covers.

″

″

″

Page 24

2-10

Installing the FD86N Enclosure

Publication S-3062 – November 1997

Installing an Equipment

Enclosure to the

FD86N Enclosure

Hardware needed:

Figure 2.8

Installing an Equipment Enclosure to the FD86N Enclosure

Split Access Cover

Top Access Cover

FD86N Enclosure Hood

Typical 27

High

Equipment Enclosure

Typical 9

HIgh

Equipment Enclosure

Typical 18

High

Equipment Enclosure

Cutout

Typical Equipment

Enclosure (Access Covers

Removed)

Split Access Cover

Eight M6 or ¼-20 thread-forming screws.

•

To install an equipment enclosure to the FD86N enclosure:

1. Remove the split or top access cover from the equipment enclosure.

Refer to Figure 2.8.

2. Place the equipment enclosure on the FD86N enclosure over the

appropriate cutout.

3. Align the mounting holes. Refer to Figure 2.8.

4. Fasten the equipment enclosur e to the FD86N enclosu re using the M6

or ¼-20 thread-forming screws.

5. Reinstall the access covers.

″

″

″

Page 25

Installing the FD86N Encl osure

2-11

Publication S-3062 – November 1997

Installing an Air Conditioning

Unit to the FD86N Enclosure

To install an air conditioning unit on the FD86N enclosure:

Figure 2.9

Installing an Air Conditioner to the Left or Right End of the

FD86N Enclosure

FD86N Enclosure

Air Conditioning

Unit

Power Cord

Feed-Through Hole

1. Cut the plug from the power cord. Strip the wires as needed.

2. Run the power cord through the feed-through hole in the end panel.

3. Mount the air conditioner using the 16 pie ces of hardw are supplied on

the FD86N enclosure. Refer to Figure 2.9.

4. Connect the air conditioning wiring to the terminal board provided in

the FD86N enclosure. See your wiring schematic for connections.

Page 26

2-12

Installing the FD86N Enclosure

Publication S-3062 – November 1997

Installing a Mechanical Door

Interlock Link between

FD86N Enclosures

To install a mechanical door interlock link between FD86N enclosures,

Figure 2.10

Installing a Mechanical Door Interlock Link between

FD86N Enclosures

Connector Block

Square Shaft

M5-8 Hex Head Screw

(Supplied)

refer to Figure 2.10.

Page 27

Publication S-3062 – November 1997

Chapter

3

Joining Bus Bar Assemblies

Introduction

Before You Begin

Splicing Single Bus Bar Assemblies

Figure 3.1

Splicing Single Bus Bar Assemblies

Flat Washer, Conical

Washer, and Nut

Bolt and Flat Washer

Splice Bar

Bus Bar

Splice Bar

Front of FD86N Bus Bar Enclosure

Top Down View

This chapter pr ovides the in structions fo r splicing b us bars, joining bus

bar assemblies, and connecting ground buses and cables.

Before you begin this procedure, be sure to have these tools:

Socket and box wrenches for ½″ hardware.

•

Torque wrench with ½″ socket.

•

Drive bit for recessed 6-lobe, Torx type screws (M6 x 16).

•

T orque all spl ice connections to be tween 45 and 55 lb-ft (61 to 75 Nm).

To splice single bus bar assemblies together:

1. V erify that this spl ice hardwar e is present. Al l hardware is grade 5.

½-13 hex nuts

•

½″ conical washers

•

½″ flat washers

•

½-13 x 1-¾ hex head cap screws

•

ATTENTION: Use the hardware supplied with the

bus bar splice assembly.

!

2. Verify that contact surfaces are free of dirt and debris.

3. See Figure 3.1 for installation.

Page 28

3-2

Joining Bus Bar Assemblies

Publication S-3062 – November 1997

Splicing Parallel Bus Bar

Assemblies

To splice parallel bus bar assemblies together:

Figure 3.2

Splicing Parallel Bus Bar Assemblies

Flat Washer, Conical

Washer, and Nut

Bus Bar

Splice Bar

Bolt and Flat Washer

Splice Bars

Front of FD86N Bus Bar Enclosure

Top Down View

1. Verify that this splice hardware is p resent. All h ardware is grade 5.

½-13 hex nuts

•

½″ conical washers

•

½″ flat washers

•

½-13 x 2-¼ hex head cap screws

•

ATTENTION: Use the har dware furnished with the

bus bar splice assembly.

!

2. Verify that contact surfaces are free of dirt and debris.

3. See Figure 3.2 for installation.

Page 29

Joining Bus Bar Assembli es

3-3

Publication S-3062 – November 1997

Installing Bus Bar Tabs for

Incoming Power

Incoming bus b ar tabs might hav e been mounted upside do wn for shipment.

Figure 3.3

Typical Installation of Incoming AC Bus Bar Tabs (Staggered)

Figure 3.4

Typical Installation of Incoming AC Bus Bar Tabs (Inline)

Typical Incoming Bus Bar T ab

Flat Washer, Conical

Washer, and Nut

Bus Bar

Bolt and Flat Washer

Front of FD86N Enclosure

Typical Incoming Bus Bar T ab

Flat Washer, Conical

Washer, and Nut

Bus Bar

Bolt and Flat Washer

Front of FD86N Enclosure

Reinstall bus bar tabs in the upright position as sho wn in Figures 3.3 and 3.4.

Important: Use the hardware furnished with the bus bar tabs.

To install bus bar tabs for incoming power connections:

1. Verify that contact surfaces are free of dirt and debris.

2. See Figure 3.5 for installation and for correct bolt orientation.

Page 30

3-4

Joining Bus Bar Assemblies

Publication S-3062 – November 1997

Figure 3.5

AC Bus Bar Tab Hardware Orientation

Typical Bus Bar Tab

Flat Washer, Conical

Washer, and Nut

Bolt and Flat Washer

Bus Bar

Front of FD86N Enclosure

Side View

Page 31

Joining Bus Bar Assembli es

3-5

Publication S-3062 – November 1997

Making Connections to

Drop Tabs

To make connections to drop tabs:

Figure 3.6

Typical 4

Drop Tab Connections

Drop Tabs

-16 Hex Head

Cap Screw

Front

Drop Tab

Single Hole

Connector Strap

Front

Front View

Single Hole

Connector Straps

Flat Washer

″ Flat Washer

″ Lock Washer

″ Hex Nut

-16 Hex Head

Cap Screw

Flat Washer

″ Flat Washer

″ Lock Washer

″ Hex Nut

1. Verify that contact surfaces are free of dirt and debris.

2. For 4″ drop tabs, see Figure 3.6 for installation and correct bolt

orientation.

For 6″ drop tabs, see Figure 3.7 for installation and correct bolt

orientation.

″

3

⁄

8

3

⁄

8

3

⁄

8

3

⁄

8

″

3

⁄

8

3

⁄

8

″

3

⁄

8

3

⁄

8

3

⁄

8

3

⁄

8

Page 32

3-6

Joining Bus Bar Assemblies

Publication S-3062 – November 1997

Figure 3.7

Typical 6

″

Drop Tab Connections

Drop Tabs

-16 Hex Head

Cap Screw

Drop Tab

Double Hole

Connector Strap

Front View

Wire Lug

Connection

Flat Washer

″ Flat Washer

″ Hex Nut

-16 Hex Head

Cap Screw

Flat Washer

″ Flat Washer

″ Lock Washer

″ Hex Nut

″ Lock Washer

3

⁄

3

⁄

8

″

3

⁄

3

⁄

8

3

⁄

8

3

⁄

8

3

⁄

8

″

3

⁄

8

8

8

3

⁄

8

3

⁄

8

Page 33

Joining Bus Bar Assembli es

3-7

Publication S-3062 – November 1997

Joining Bus Bar Enclosures

Hardware needed: M6 or ¼-20 thread-forming screws.

Figure 3.8

Installing a Sheet Metal Joiner for Bus Bar Enclosures (FD86N to FD86N)

Figure 3.9

Installing a Sheet Metal Joiner on an Overhead Cable Routing Box

(FD86N to SA3000 or SB3000)

Bus Bar Enclosure

Sheet Metal Joiner

Bus Bar Enclosure

M6 or ¼-20

Thread-Forming Screw

FD86N Overhead Cable

Routing Box

Sheet Metal Joiner

SA3000 or SB3000

Bus Bar Enclosure

M6 or ¼-20

Thread-Forming Screw

T o join bus bar enclosures from an FD86N enc losure to FD86N enclosure,

see Figure 3.8.

To join bus bar enclosures from an FD86N enclosure to an SA3000 or

SB3000, see Figure 3.9.

Page 34

3-8

Joining Bus Bar Assemblies

Publication S-3062 – November 1997

Installing DC Bus Bar

Connections to a

Bulletin 2100 MCC

To join DC bus bars to an MCC:

Figure 3.10

Installing DC Bus Bar Connections from the FD86N Enclosure to an MCC

Bolt and Flat Washer

Flat W asher , Coni cal

Washer, and Nut

Bus Bar

Top Down View

Bus Tab

MCC

FD86N Enclosure

Front of Enclosures

Note: Bus depth in the

MCC

must be 16.94

from the front of the cabinet.

1. Remove the supplied hardware from the bus tab.

2. Make the bus connection between the FD86N enclosure and MCC.

3. Reinstall the hardware, oriented as shown in Figure 3.10.

″

Page 35

Joining Bus Bar Assembli es

3-9

Publication S-3062 – November 1997

Installing DC Bus Bar Adapter

Connections to an SA3000 or

SB3000

To join DC bus bar adapters to an SA3000 or SB3000:

Figure 3.11

Installing the DC Bus Bar Adapter Connections between an SA3000 or SB3000 and

a DC Bus Bar Assembly on the FD86N Enclosure

Top Down View

Front View

Supplied Hardware

Supplied Hardware

Supplied

Hardware

SA3000 or SB3000

FD86N Enclosure

SA3000 or SB3000

Overhead Bus Bar (+)

SA3000 or SB3000

Overhead Bus Bar (–)

Straps from

MCC

1. Remove the supplied hardware from the bus bar. Refer to Figure 3.11.

2. Make the bus bar adapter con nection between SA3000 and SB3000 and

the FD86N enclosure.

3. Reinstall the hardware, oriented as shown in Figure 3.11.

Important: Figure 3.11 sho ws connecti ons to a parallel b us bar.

If you hav e a single bus b ar, i nstall the single bus bar

between the bars of the adapter.

Page 36

3-10

Joining Bus Bar Assemblies

Publication S-3062 – November 1997

Installing the Ground Cables

between FD86N Enclosures

To install the ground cables between FD86N enclosures, see Figure 3.12

Figure 3.12

FD86N Enclosure to FD86N Enclosure Ground Cable Location and

Hardware Orientation

Bolt and Flat Washer

Flat Washer, Conical

Washer, and Nut

Ground Cables

for ground cable loc ation and har dwar e orienta tion. The con trol encl osure

ground bus can be mounted at the top or the bottom of the control panel.

Page 37

Joining Bus Bar Assembli es

3-11

Publication S-3062 – November 1997

Connecting the Incoming

Ground Bus

To connect the incoming ground bus, see figures 3.13 and 3.14.

Figure 3.13

Connecting Incoming Ground Bus Bar Assembly Cables to the FD86N Enclosure

Ground Cables

Pull Box

Control Mounting Panel

(Front of Cabinet)

Ground Bus

Note: Use the jumper and hardware fu rnished with the bus bar assembly.

Page 38

3-12

Joining Bus Bar Assemblies

Publication S-3062 – November 1997

Figure 3.14

Grounding Hardware Connections

Flat Washer

Nut

Ground Cable

Lock Washer

Flat Washer

Bolt

Bolt

Control Mounting Panel

Lock Washer

Flat Washer

Ground Cable

Grounding Washer

Ground Bus

Page 39

Publication S-3062 – November 1997

Chapter

4

Maintenance

Introduction

Protecting Ventilated Control

Enclosures During Maintenance

Cleaning the Filter

Maintenance of the FD86N enclosure consists of protecting the

enclosures during installation and cleaning the filter periodically.

During maintenance, the enclosure doors will be open, which could

allow airbo rne particles into the enclosur e. Ensure that the envi ronment

is clean and free of airb orne particles. If there are airborne particles,

cover the enclosure to protect the electrical control equipment.

During normal operation with the doors closed and covers installed,

enclosures with positive pressure ventilation and filters protect

equipment from airborne particles.

ATTENTION: If the cabinet includes forced

ventilation and filters, the filters must be cleaned or

!

replaced periodic ally to ensure proper ven tilation of the

contained equipment. The air f ilt ers are was hable. The

filter media functions in dry form— do not apply oil or

adhesive sprays t o the filter.

Replacing Cabinet Light Bulbs

1. Remove the filter from the cabinet.

2. If the filter is contaminat ed by oily or greasy su bstances, cle an the

filter with a detergent soluti on. A void use of stro ng alkali solutions.

3. Flush the filter thoroughly with clea n water. You can flush the f ilter

by either :

Immersing the filter in clean water.

•

Spraying the filter with a fine spray. Spray the filter in the

•

direction opposite of air flow.

4. Shake excess water from the filter.

5. Replace the filter in the cabinet.

Replacement filters can be ordered from your local Rockwell

Automation Drive Systems parts source. Request part number

616209-3FLT.

Replace cabinet light b ulbs with b ulbs of 60W or lowe r power tha t are

sized for the supplied voltage.

Page 40

4-2

Maintenance

This page intentionally left blank.

Publication S-3062 – November 1997

Page 41

Index

A

air conditioning unit

B

C

D

E

F

G

H

I

L

M

N

P

S

installing, 2-11

anchoring enclosure, 2-5

ground

bus, 3-11

cables, 3-10

bus bar

enclosure

installing a pull box, 2-9

installing

adapter connections to

SA3000, 3-9

SB3000, 3-9

assembly, 2-8

joining

assemblies, 3-1

enclosures, 3-7

splicing

parallel assemblies, 3-2

single assemblies, 3-1

tabs

installing for incomi ng

power, 3-3

conduit, installing, 2-7

control enclosures

joining sec tions, 2-5

joining to MCCs, 2-6

handling, 2-1

installing, 2-1

interlock link, installing, 2-12

lifting, 2-3

angle, 2-3

removing, 2-7

sling angle requirements, 2-3

MCC, 2-6

mechanical door interlock link

installing, 2-12

mounting, 2-5

multi-enclosure control

line-ups, 2-5, 2-6

National Electrical Code

requirements, 2-2

dimension sheet sample, P-2

drop tabs, connections to, 3-5

equipment enclosure,

installing, 2-10

filter

cleaning, 4-1

replacement, 4-1

pull box, installing to a bus bar

enclosure, 2-9

SA3000, 3-9

SB3000, 3-9

space requirements, 2-2

non-ventilated enclosure, 2-2

ventilated enclosure, 2-2

storing, 2-1

support requirements, 2-2

Publication S-3062 – November 1997

Page 42

I-2 Index

T

U

V

W

Type 12 enclosures, 2-5, 2-6, 2-7

unpacking, 2-1

ventilated enclosures

protecting, 2-7, 4-1

wiring

entry and exit provisions, 2-2

Publication S-3062 – November 1997

Page 43

Page 44

Rockwell Automation helps its customers receive a superior return on their investment by bringing

together leading brands in industrial automation, creating a broad spectrum of easy-to-integrate

products. These are supported by local technical resources available worldwide, a global network of

system solutions providers, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Australia • Austria • Ba hrain • Belgium • Bolivia • Brazil • B ulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croa tia • Cyprus

Czech Republic • Denmark • Dom inican Republic • Ecuador • Egypt • El Salvador • Finland • France • Ger many • Ghana • Greece • Guatemala • Honduras • Hon g Kong

Hungary • Iceland • India • Indonesia • Iran • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico

Morocco • TheNetherlands • New Zealand • Ni geria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puer to Rico • Qatar • Romania • Russia

Saudi Arabia • Sin gapore • Slovakia • South Africa, Republic of • Spain • Sweden • Switzerland • Taiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates

United Kingd om • United States • Ur u guay • Venezuela

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000, Fax: (1) 414 382-4444

Rockwell Automation Drive Systems, 6400 West Enterprise Drive, Mequon, WI 53092 USA, Tel: 414 512-8200

Rockwell Automation Drive Systems, 24703 Euclid Avenue, Euclid, OH 44117-1786 USA, Tel: 216 266-7000

Publication S-3062 — November 1997 S-3062

©1997 Rockwell International. All Rights Reserved. Printed in USA

Loading...

Loading...