Page 1

FanMaster™ Energy Saving Package

Installation Manual (v2.xx)

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation

and Maintenance of Solid State Controls (Publication SGI-1.1 available from your

local Rockwell Automation sales office or online at

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices. Because

of this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety

considerations.

http://

WARNING: Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment, which may lead

!

to personal injury or death, property damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or economic

!

loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequences.

Shock Hazard labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may be present.

Burn Hazard labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be at dangerous

temperatures.

Rockwell Automation, Allen-Bradley, PanelView, PanelView Component, PowerFlex and MicroLogix are trademarks or registered trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual

Page 3

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Preface General Information

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

What is Contained in this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-1

Reference Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-2

Chapter 1 FanMaster Overview

FanMaster Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

FanMaster Externally Mounted Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

FanMaster Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

FanMaster Application Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Integration of FanMaster into Building Automation Systems . . . . . . . . . . . . . . . . . . . . 1-12

Chapter 2 FanMaster Installation

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table of Contents

Chapter 3 FanMaster Configuration and Start Up

Using the PanelView C600 HMI Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Gather and Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Configure the FanMaster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

View Detailed Data Log Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Start or Stop Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Clear the Data Logs and Collect Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Chapter 4 Troubleshooting

FanMaster Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

FanMaster Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Appendix A Specifications and City Climate Profiles

Drives and FanMaster Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

City Climate Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Appendix B FanMaster Diagrams

Drawing Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C FanMaster Screens and Field Descriptions

Dashboard Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Air Handler Unit Diagram Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Setup Screen #1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Setup Date and Time Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Setup Screen #2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Setup Screen #3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Supply Fan Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Return Fan Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 4

2

Fan Communication Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Cooling and Heating Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Proof of Flow Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Data Collection Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

User City Weather Data Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Data Log #1 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-15

Data Log #2 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Data Log #3 Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

System Status Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-18

Appendix D FanMaster Application Firmware Upgrades

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Upgrade the FanMaster MicroLogix 1100 Controller Application Firmware . . . . . . . . . D-1

Upgrade the FanMaster PanelView Application Firmware. . . . . . . . . . . . . . . . . . . . . . . . D-3

Restart FanMaster with the New Application Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Index

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 5

General Information

Preface

Who Should Use This Manual

What is Contained in this Manual

Manual Conventions

Use this manual if you are responsible for installing and/or operating the

Allen-Bradley® FanMaster™ Energy Saving Package (FanMaster). You

must have a thorough understanding of installation and operation of HVAC

units, Building Automation Systems (BAS) and electrical circuitry and

components in order to successfully install this product.

This manual provides installation and configuration information for the

FanMaster product only. Refer to Reference Materials on page p-2

information on associated products.

Before you begin the installation and configuration of FanMaster, it is

recommended that you read Chapter 1 - FanMaster Overview

To install and configure FanMaster, complete the instructions in each of the

following chapters, sequentially:

– Chapter 2 - FanMaster Installation

– Chapter 3 - FanMaster Configuration and Start Up

The following words are used throughout the manual to describe an action:

for

.

Word Meaning

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 6

p-2 General Information

Reference Materials

Rockwell Automation publications are available on the internet at

www.rockwellautomation.com/literature

.

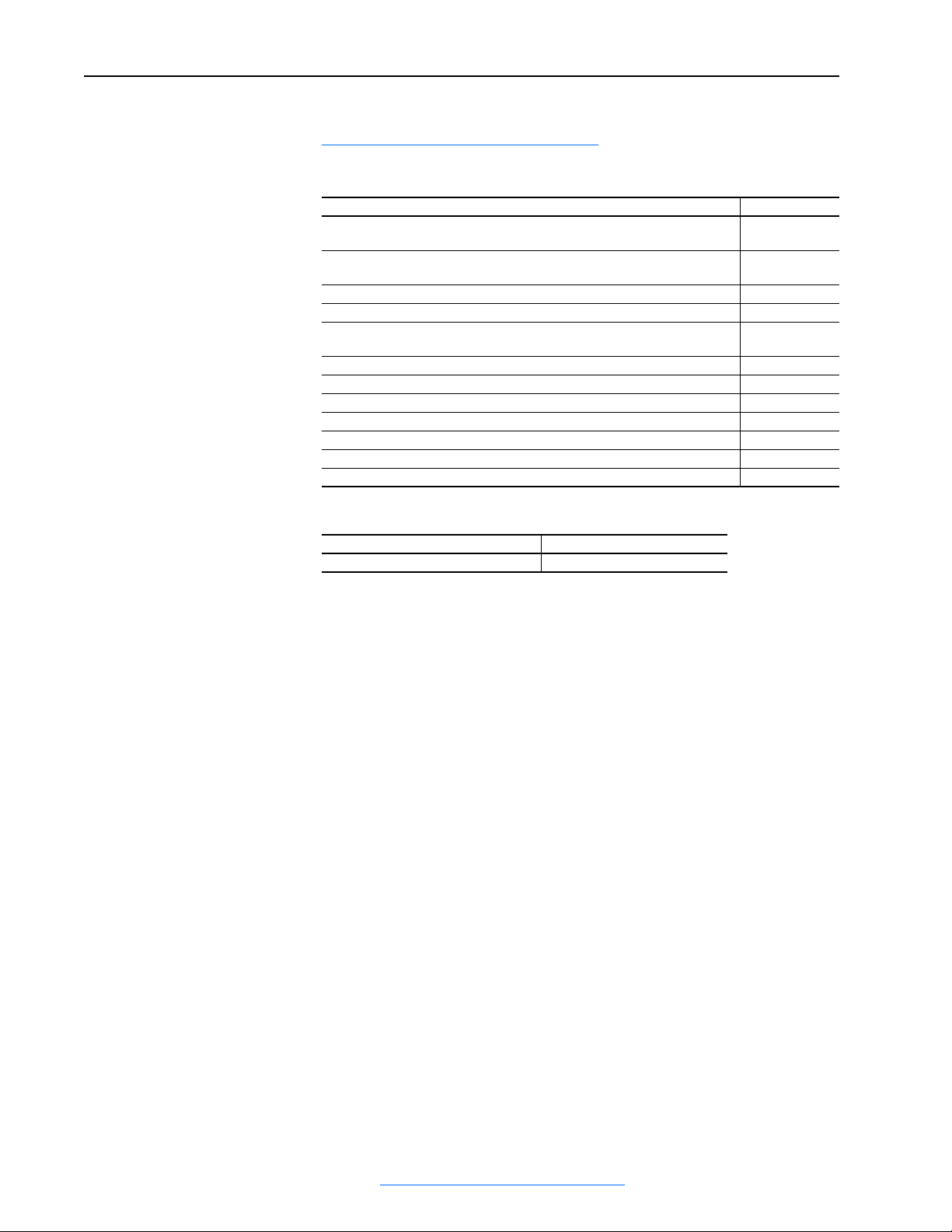

The following manuals are recommended for additional information:

Title Publication No.

PowerFlex 400 AC Drive Packages for Fan & Pump Applications Installation

Manual

PowerFlex 400 Adjustable Frequency AC Drive for Fan & Pump Applications User

Manual

PowerFlex 70 Adjustable Frequency AC Drive Installation Instructions 20A-IN009

PowerFlex 70 AC Drives User Manual 20A-UM001

PowerFlex 700 Adjustable Frequency AC Drive Frames 0…6 Installation

Instructions

PowerFlex 700 AC Drives Series B Vector Control User Manual 20B-UM002

PowerFlex 750-Series AC Drive Installation Instructions 750-IN001

PowerFlex 750-Series AC Drives User Manual 750-UM001

20-COMM-H RS-485 HVAC Adapter User Manual 20COMM-UM009

Wiring and Grounding Guidelines for PWM AC Drives DRIVES-IN001

PanelView Component HMI Terminals User Manual 2711C-UM001

MicroLogix 1100 Programmable Controllers User Manual 1763-UM001

22C-IN002

22C-UM001

20B-IN019

For Allen-Bradley Drives Technical Support:

Title Online at . . .

Allen-Bradley Drives Technical Support www.ab.com/support/abdrives

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 7

FanMaster Overview

Chapter 1

FanMaster Description

FanMaster provides a means for improving the energy efficiency of

Constant Air Volume HVAC units. Constant Air Volume HVAC units

typically draw in room air and mix it with a small amount of outside air.

This mixed air is forced by a fan through heating and/or cooling elements to

provide supply air back to the room at a temperature that makes up for

heating or cooling lost to the surrounding environment. This maintains

comfortable conditions for the building’s occupants and contents.

FanMaster improves the efficiency of a basic HVAC unit by providing the

following two additional control features:

• FanMaster replaces a fixed speed fan motor starter with a Variable Speed

AC Drive which allows the fan speed to adjust to the actual HVAC

heating and cooling loads. The Law of Affinity states that the energy

required to operate a fan decreases by the cube of the actual speed

reduction. For example, a fan running at 80% of its maximum speed

requires about 50% of the energy needed to run the fan at full speed.

And, a fan running at 50% of its maximum speed requires only about

13% of the energy needed to run the fan at full speed. FanMaster’s ability

to monitor the HVAC operation and adjust the fan speed to the required

value provides considerable opportunity for savings.

• FanMaster regulates the amount of outside air drawn into the HVAC unit

for the purpose of ventilation by monitoring the actual Carbon Dioxide

(CO

) level in the serviced space. This feature, known as Demand

2

Ventilation, maintains air quality while reducing the cost of heating or

cooling the outside air by reducing its volume.

The typical Constant Air Volume HVAC unit selected by the building's

original designer provides adequate heating, cooling, and ventilation for

worst-case conditions. The heating and cooling capacity are selected for the

coldest and hottest days anticipated and the ventilation capacity is designed

for maximum human occupancy. Since the weather is seldom at the

extremes in most locations and buildings are often occupied at less than full

capacity, FanMaster provides a savings opportunity by reducing the fan

speed and ventilation used by the HVAC unit when they are not required. In

addition, when the weather extremes do require maximum heating or

cooling or the CO

FanMaster returns the fan to its original full speed and ventilation to the

original designed value until conditions are such that it can once again

reduce the fan speed and amount of outside air ventilation.

FanMaster has been designed for installation into an existing HVAC system

with minimal interface with the existing controls. FanMaster does not

replace or interfere with the existing controls which continue to regulate

room temperature. In addition, FanMaster can also be installed and used in

an evaluation only mode (without a fan drive). This mode allows the

FanMaster energy savings calculator to provide an estimate of potential

savings, prior to performing a full installation.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

level indicates the need for maximum ventilation,

2

Page 8

1-2 FanMaster Overview

FanMaster Externally Mounted Components

Temperature Sensors

Two temperature sensing probes are provided with FanMaster. These probes

are essential to FanMaster because the measured difference in temperature

between these sensors provides the command signal for the fan speed. The

temperature sensors are typically mounted on the outside of the Constant

Air Volume HVAC unit, with the sensing probe penetrating into the air flow

inside through a hole drilled into the side of the HVAC enclosure.

The placement of the Mixed Air sensor should be selected after examining

the interior of the HVAC unit to ensure that the probe is located in a position

that will accurately measure the temperature of the combined outside and

return air before entering the heating and cooling section. Avoid a location

that is in the upper, lower or edge portion of the air stream and one which

may be unduly influenced by the air entering the unit from the outside air

damper. If the Mixed Air temperature probe does not accurately reflect the

average temperature entering the heating and cooling elements, the fan

speed will not be set properly.

The supply air sensor should be mounted from 6 inches to 5 feet

downstream of the final heating or cooling element. Because the

temperature of the air can be warmer at the top of the air stream and cooler

at the bottom, the probe should be mounted as close to the vertical center of

the air flow as possible.

Carbon Dioxide Sensor

The CO2 sensor (if installed) is usually mounted in the room return air flow

of the HVAC unit prior to mixing with outside air. Alternatively, the CO2

sensor can be mounted directly on the return air duct work serving a specific

area that is most likely to be affected by high CO2 concentrations during

occasions of high occupancy. This will ensure that FanMaster will allow full

fan speed and normal ventilation when and where it is most needed. This is

the most typical installation.

Alternatively, the CO

space in an area that is most likely to be affected by high CO

concentrations during occasions of high occupancy. This will ensure that

FanMaster will allow full fan speed and normal ventilation when it is most

needed.

It may be desirable to invest in individual CO

locations. It has been found that certain buildings lack adequate ventilation

prior to installation of FanMaster. If FanMaster seems to be running in CO

override even during periods of low occupancy, it is advised that you seek

help from an HVAC air quality professional for advice on how to best

rectify the ventilation problems.

sensor can be mounted directly in the conditioned

2

2

room monitors for critical

2

2

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 9

FanMaster Overview 1-3

Pressure Sensor (Optional)

In certain applications it may be necessary or desirable to maintain a

positive building pressure relative to the outside air. A pressure sensor can

be ordered with FanMaster which monitors the differential pressure

between the inside and outside air. When the differential pressure is lower

than a user specified setpoint, the FanMaster will override to 100% fan

speed to try to restore the desired minimum pressure differential. One

typical scenario where pressure override might occur is when a loading

dock door is opened to allow for a delivery, and additional airflow is

required to restore the pressure differential when the door closes. The sensor

requires connection to two lengths of 1/4 inch OD plastic tubing which

sample the inside and outside air pressure at their respective termination

points. You may need to experiment with the location of the tubing since

normal wind and airflow often causes localized air pressure deviations

around a building which may result in inaccurate pressure measurements.

You may find that the HVAC unit fan speed has no measurable affect on

building pressure. In this case turn off the pressure mode completely and do

not use the sensor.

When using a pressure sensor the Constant Ventilation mode described

below is not available.

Damper Position Indicator Switch

Many existing HVAC systems have a feature known as “economizer mode”

or “free cooling mode”. These systems monitor the outside air temperature

and humidity and when conditions are such that the outside air can be used

to provide cooling (instead of using the cooling element) the existing typical

system will open the outside air damper fully to allow maximum use of this

“free” cooling. FanMaster uses a Damper Position Indicator switch to

indicate when the existing control system is in economizer mode. The

switch is installed on the outside air damper in a location that causes its

contacts to close when the damper opens beyond the normal 10%

ventilation position.

In order to take full advantage of economizer mode, FanMaster increases

the speed of the fan to 100% until the existing control determines that

economizer mode is no longer appropriate. The economizer control will

then return the damper to its normal ventilation position and the contacts in

the damper position indicator switch will open. This signal is sent to

FanMaster, which allows the fan to return to its normal reduced speed and

damper override functions.

The switch must be installed in a position that will actuate when the damper

opens. It may be mounted directly on the damper blades, on the damper

actuator arms or linkage, or on the center axle of a damper blade section.

Because there are many different damper systems in use, the installation

may require fabrication of a custom linkage or mounting method if no

suitable location is available.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 10

1-4 FanMaster Overview

Fan Starter Current Sensor

This device is used only when FanMaster is installed in evaluation mode.

The current sensor device is designed such that one wire lead of the existing

fan motor passes through its center. The current sensor has a switch that

actuates when it senses current flow in the motor wire, indicating that the

fan motor has been started by the existing control system. The actuated

switch identifies when the HVAC unit fan normally runs so the FanMaster

calculator can take into account the HVAC normal hours of operation and

more accurately project monthly cumulative savings.

Fan Starter Hard-Wired Interconnection

This device is used only when FanMaster is installed with a drive.

FanMaster requires a start signal from the existing BAS system in order to

know when to start and stop the fan. The control signal on the coil of the

existing fan motor starter provides this signal. The starter coil signal is

typically 115V AC or 26V AC. Two interposing relays, one that

accommodates each of these voltages, are shipped with FanMaster (120V

AC relay already installed at position CR4). Other control voltage relays are

available from Rockwell Automation.

FanMaster Operation

Fan Speed Reduction

With the installation of FanMaster, the existing HVAC control system

continues to maintain room temperature by monitoring its own temperature

sensors and controlling the heating and cooling elements. FanMaster

provides new, independent temperature sensors mounted in the airflow of

the HVAC unit. These sensors allow FanMaster to determine if the existing

controls are requesting heating and cooling and to adjust the fan speed to a

value appropriate for the amount of heating and cooling required.

As the existing controls call for more heating or cooling (as determined by

the amplitude of the temperature differential measured before and after the

heating and cooling elements), FanMaster responds by increasing the fan

speed. As the amount of heating or cooling required decreases, the

temperature differential decreases and so does the FanMaster fan speed. If

the existing controls are not calling for heating or cooling, then there is no

temperature differential across the heating and cooling elements and

FanMaster reduces the fan speed to a user specified minimum speed.

Reducing the HVAC unit’s fan speed when not calling for maximum heating

or cooling results in significant savings in the energy required to run the fan,

according to the Law of Affinity.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 11

FanMaster Overview 1-5

Demand Ventilation Mode

A second source of energy savings is achieved by FanMaster's Demand

Ventilation mode. A typical Constant Air Volume HVAC unit is equipped

with a damper that allows a small percentage of outside air to be mixed with

the return air, maintaining an adequate CO

occupants. The damper is typically set during installation for a fixed volume

of fresh air, adequate for the worst case condition of full occupancy. The

outside air drawn in through this damper adds to the heating and cooling

load of the HVAC unit, since the outside air is seldom at the required

temperature for the building's occupants. In fact, depending on the local

conditions, the amount of heating or cooling energy which must be supplied

to this air can be quite costly.

When FanMaster reduces the fan speed as described above, it will also

reduce the amount of outside air brought into the HVAC unit. FanMaster's

demand ventilation technique monitors the amount of CO

and will override the reduced fan speed at any time the CO

above a user specified setpoint. This feature maintains an adequate level of

ventilation while reducing the cost of heating and cooling excess outside air

whenever possible.

level for the building's

2

in the return air

2

level rises

2

The energy savings can be further enhanced by an optional feature which

allows FanMaster to fully close the outside air damper up to 50% of the

time when the CO

the damper fully, FanMaster further reduces the cost of heating and cooling

the outside air. The typical outside air damper has a spring return-to-close

mechanism and the existing controls are providing a signal maintaining the

10% open position. FanMaster provides an adjustable duty cycle electrical

relay which can interrupt the electrical signal to the damper allowing it to

close up to 50% of the time. This feature is overridden automatically by the

demand ventilation mode when the CO

setpoint.

level does not require additional ventilation. By closing

2

level exceeds the user specified

2

Variable Ventilation Mode

This mode allows FanMaster to reduce the HVAC unit fan speed and

includes the option of allowing the damper to be overridden and closed 50%

of the time, exactly as with the Demand Ventilation mode. The difference is

that with the Variable Ventilation mode there is no CO

speed and damper operation are never overridden by the demand for

additional ventilation. This mode is designed for spaces such as warehouses

or manufacturing with limited occupancy or staffing relative to the volume

of the space and thus no opportunity for buildup of excessive CO

sensor and the fan

2

.

2

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 12

1-6 FanMaster Overview

Constant Ventilation Mode

Constant Ventilation mode can be used in specific applications requiring a

relatively constant flow of outside air be maintained for ventilation at all

times. This mode is not recommended for most installations as it precludes

the savings which may be realized by reducing the quantity of outside air

brought into the HVAC system. This is also the most difficult installation

due to the need to redirect the control signals for the outside damper control

into FanMaster and make new interconnections from FanMaster to the

outside air damper actuator.

If this mode of operation is enabled, FanMaster will continue to reduce the

fan speed to realize savings according to the Law of Affinity, but it will also

modulate the outside air damper open as the fan slows down in order to

maintain the same approximate quantity of outside air flow into the

building.

Estimated Savings Calculator

The FanMaster control system contains a calculator that provides an

estimate of the energy savings achieved by the reduction in fan speed and

reduction in outside air heating and cooling. The calculator uses the settings

provided by the user at startup and actual operating conditions, combined

with historical weather data for your selected location, to provide the

estimated cost savings achieved by FanMaster. The estimated energy costs

to run the HVAC unit with and without FanMaster are compared to

determine the savings.

FanMaster Application Considerations

Two State Heating or Cooling Control

Two state control of heating or cooling is used when the actual amount of

heating or cooling applied by the existing HVAC unit is fixed. That is, the

heating or cooling element is either on or off. FanMaster allows for the

selection of two state control for either heating or cooling or both. When

FanMaster is configured for two state control, it will run the fan at the

configured minimum speed when the temperature sensors detect that

heating and cooling are off, and will run the fan at the configured maximum

speed when the temperature sensors detect that heating or cooling is on.

This mode allows FanMaster to achieve energy savings during the time the

HVAC unit is idle and to allow maximum performance when the HVAC unit

is actively heating or cooling.

When in two state mode, the “Delta T Min” setup values for cooling and

heating determine when the fan speed transitions from “Min” to “Max”

speed. A typical value of five degrees is acceptable for most installations.

The “Delta T Max” setup values for cooling and heating have no effect on

operation in this mode, nor do any “SA (supply air) Override” settings.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 13

FanMaster Overview 1-7

Proportional Heating and Cooling Control

Proportional control of heating or cooling is used when the actual amount of

heating or cooling applied by the HVAC unit is variable. That is, the heating

or cooling element is modulated by a mechanical or electrical valve. The

valve modulates how much heating or cooling is provided and is adjusted by

the existing control system to meet the actual demand. FanMaster allows for

the selection of proportional control for either heating or cooling or both.

When selected, FanMaster runs the fan at the minimum speed when the

temperature sensors detect that heating and cooling are off, and will vary the

fan from its minimum to its maximum speed proportional to the temperature

differential detected by the temperature sensors in the air flow before and

after the heating or cooling elements. This mode allows FanMaster to

achieve energy savings during the time the HVAC unit is idle and to

modulate the fan speed based on the amount of heating or cooling requested

by the existing control system, achieving an optimum energy requirement

based on the heating or cooling load.

When in proportional mode, the “Delta T Min” and “Delta T Max” setup

values for cooling and heating determine the slope of the fan speed increase.

A typical value of five degrees for “Delta T Min” is acceptable for most

installations. The “Delta T Max” setup value should be adjusted so that the

fan can achieve its maximum speed when the proportional valve controlling

heating or cooling is at 100%. The HVAC unit manufacturer can provide the

design delta T (temperature rise) of the specific unit for both heating and

cooling modes of operation. The heating delta T is typically higher than the

cooling delta T. If the unit is older or the delta T data is unavailable,

FanMaster can be initially run with the default values. The actual delta T

values of the unit can be determined by using the existing temperature

control setpoints to force the unit into a full heating or full cooling mode.

Adjust the room temperature to a very high or low setpoint and allow the

HVAC unit to run at 100% heating or cooling for about 30 minutes or until

the maximum delta T can be observed on the FanMaster System Status

screen. Perform this test for both heating and cooling. Use the actual

measured delta T values for the “Delta T Max” settings for heating and

cooling.

TIP: Although the maximum fan speed is adjustable, there is seldom a

reason to adjust this value to less than 100%. The only exception would be

for a system that is oversized to the point that the full horsepower capacity

of the fan is not required under any conditions. This could occur if the size

of the area heated or cooled is reduced after installation or if the HVAC unit

is oversized for other reasons. In this case, the maximum fan speed can be

safely reduced, provided that adequate capacity remains for extremely hot

or cold days. For reference, a reduction of the maximum speed to 95% will

deliver 95% of the airflow with a fan energy cost reduction of 16%. A

reduction to 90% reduces the fan energy cost by 23%.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 14

1-8 FanMaster Overview

Supply Air Low Limit / High Limit Override

The supply air limit override setup values allow you to configure FanMaster

to run the fan at full speed as the supply air temperature reaches a low or

high limit. The default values are suitable for use in most cases. It is

desirable to limit the supply air temperature extremes to protect the HVAC

equipment. Increasing the fan speed to 100% as the temperature approaches

limits will provide this protection.

The supply air low temperature limit specifies the supply air temperature

below which FanMaster will run the supply air fan at full speed (100%) to

avoid freezing up the cooling system.

The supply air high temperature limit specifies the temperature above which

FanMaster will run the supply air fan at full speed (100%) to avoid

overheating the heating system.

In many installations the supply air limit overrides will never take effect

because the system is not capable of achieving the override temperature

limits under normal conditions. Also, the override temperatures will never

be used in two state heating or cooling systems since the fan is already at

maximum speed when the delta T exceeds the delta T minimum

temperature value.

Outside Air Damper Override

Additional savings can be achieved if the installation includes an outside air

damper with spring return-to-close, the existing system provides a signal to

open the damper to its normal outside air position (typically 10%), and the

supply override relay can be wired in a manner that interrupts the existing

control signal.

Systems Without Outside Air Dampers

FanMaster can be used with HVAC systems that do not have an outside air

damper. Even though no savings can be realized by reducing outside air,

reduced fan speeds will still provide energy savings.

Heating Only or Cooling Only HVAC Systems

The setup screens provide the ability to indicate whether or not heating or

cooling elements are used in the HVAC system. Setting these fields to “No”

indicates that heating or cooling is not available and will disable that portion

of the FanMaster operation and savings calculator.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 15

FanMaster Overview 1-9

Multi-Stage Heating or Cooling Systems

If the HVAC system has heating or cooling elements which turn on in more

than one step (e.g., low heat or high heat) FanMaster should be configured

for proportional control. This will allow the fan to run at minimum speed if

the heating and cooling are off. The fan will step to a medium speed at low

heating or cooling and step to maximum speed at high heating or cooling.

The heating and cooling Delta T Max fields should be set to a value that

ensures that the fan actually achieves maximum speed when high heat and

high cool are on.

HVAC Systems With No Return Air (100% Outside Air)

HVAC systems that draw all the air from the outside are also known as

Makeup Air Units (MAU) and are not suitable for FanMaster installations.

FanMaster control algorithms cannot determine proper fan speeds for these

type systems and cannot be used.

HVAC Systems with Electric Heating Elements Instead of Gas

FanMaster control algorithms work with either gas or electric heating

elements; both on-off or modulating types. The FanMaster energy

calculator calculates heating costs based on the user provided cost per

MMBTU of gas. If the HVAC unit has electric heating, an acceptable

estimation of heating costs can be achieved by setting a value for gas cost to

double the prevailing utility rate (electric heat is typically twice the cost of

gas). This will allow the calculator to estimate the cost of electric heat and

thus the savings values as well. Note that the FanMaster energy calculator

results are presented for informational purposes only, and do not affect the

actual control of the fan speed.

City Climate Data

If one of the pre-loaded cities in the FanMaster database does not provide a

comparable climate for the installation location, data for a “custom city”

can be entered during configuration.

A Compact Disk containing weather data for approximately 2000 locations,

both US and worldwide, can be obtained from the National Oceanic and

Atmospheric Administration (NOAA) at this URL:

http://ols.nndc.noaa.gov/plolstore/plsql/

olstore.prodspecific?prodnum=C00515-CDR-A0001

A list of cities in the weather database on the CD is found at this URL:

http://www.ncdc.noaa.gov/oa/documentlibrary/ewdcd/

ewdstations-wmo.pdf

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 16

1-10 FanMaster Overview

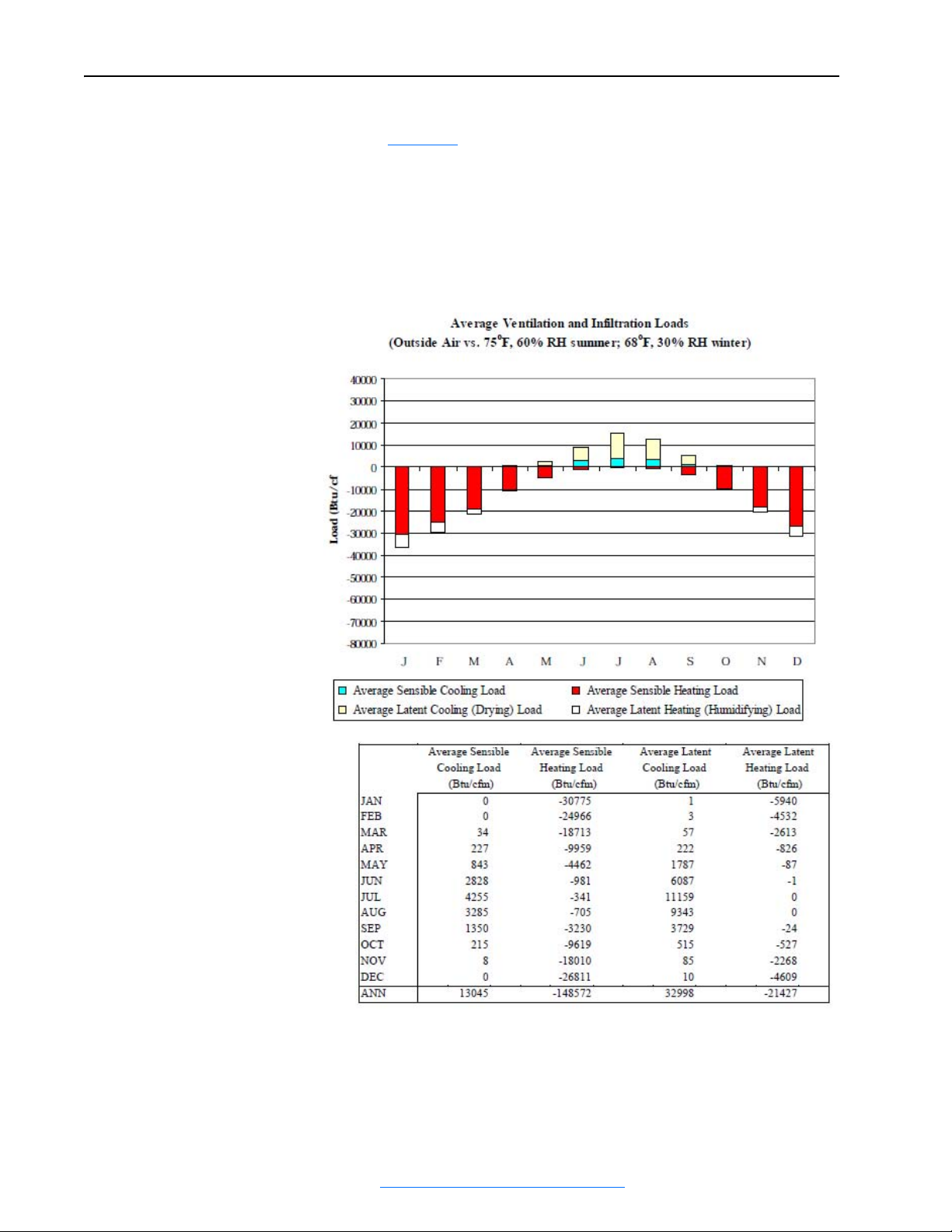

The data set for each location on the CD contains a diagram and chart, as

shown in Figure 1.1

data to be entered into the custom user data screen. The data presents the

BTU’s per CFM of ventilation air for each month of the year for the selected

location. The energy calculator multiplies the average required BTU's per

CFM times the estimated CFM ventilation of the HVAC unit. The resultant

BTU's are multiplied by the utility costs to estimate required energy costs,

both with and without FanMaster active.

Figure 1.1 Sample NOAA City Weather Data

below. The tabulated monthly data in the chart is the

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 17

FanMaster Overview 1-11

Specific Setup Values

This section provides additional information for setting up specific

FanMaster configuration fields. The values entered in these fields help the

energy calculator to perform a more accurate estimate of energy savings and

are not used by the basic control algorithm and will not affect actual

savings.

• Heating Efficiency % - Use the manufacturer’s data sheet for the HVAC

unit to determine this efficiency. This value is a measure of how

efficiently the BTU capacity of the fuel purchased is converted into an

actual BTU delivered to the heated room. This value may be listed as an

AFUE (Annual Fuel Utilization Efficiency) rating. If this value is not

available, you may simply use the default value of 87% or adjust the

value up or down about 10% based on the age of the equipment (older

units typically having a lower efficiency).

• Minimum Damper Pos % - This value can best be approximated by

visually determining the angle or degree of openness of the outside air

damper in normal operation. 0% represents a damper fully closed and

100% represents a damper fully open. Typically, the damper will be

controlled by the existing HVAC or BAS system to about 10% open. If

desired, you can use a protractor to determine the actual angle and

convert it to a percentage, taking into account that dampers often appear

to be several degrees off-vertical when fully closed due to their

overlapping position. This value ultimately determines the percentage of

the total unit flow which is outside air and thus requires heating and

cooling to bring to a suitable room temperature.

Because the regulating effect of damper position on the volume of

airflow is very difficult to determine under the best of conditions, the

actual flow volume of outside air can only be roughly approximated by

this setting. However, a change in the setting of 1 or 2 percent will have a

10 or 20 percent effect in the estimations of the heating and cooling

BTU’s saved by FanMaster; so try to be as accurate as possible. This

value is used in the estimation of savings only and therefore does not

affect the actual realized savings.

• CO

Demand Setpoint ppm - If the CO2 sensor reports a value greater

2

than the setpoint, FanMaster allows the HVAC fan to increase to 100%

and will stop any override of the normal damper position. Outside air has

a typical range of 300 to 400 ppm CO

returns the interior CO

will once again reduce the fan speed to the programmed level. ASHRAE

standard 62-1989 recommends an indoor air ventilation standard of 20

cfm per person of outdoor air or a CO

Legal CO

time of exposure. Rockwell Automation recommends that you seek

guidance from appropriate federal, state, and local regulating bodies for

further information.

limits set forth by OSHA are considerably higher and vary by

2

level to the setpoint minus 50 ppm FanMaster

2

. When the added outside air

2

level which is below 1000 ppm.

2

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 18

1-12 FanMaster Overview

• Pressure Low Limit InWC - This value sets the minimum inside vs.

outside air pressure. If the differential is below this value (in a negative

direction) the fan speed will increase to 100%. The default value of

-0.010 means the outside air pressure is just slightly higher than the

inside air. If necessary, adjust this value so that the fan only goes into

override speed when building doors are opened or if some other factor

requires periodic additional airflow. Do not set this value such that

FanMaster is in continuous override. You may find that the HVAC unit

fan speed has no measurable affect on building pressure. In this case turn

off the pressure mode completely and do not use the sensor.

Integration of FanMaster into Building Automation Systems

FanMaster provides an alarm contact for monitoring of faults by an existing

building automation system (BAS). This contact is normally closed when

FanMaster is operating properly. If power is not supplied to FanMaster or if

FanMaster detects certain conditions (see FanMaster Alarms on page 4-2

for a complete list) the fault contact will open. The alarm panel lamp on the

FanMaster unit will also be illuminated if any of the alarm conditions are

detected. The alarm contact and alarm lamp will return to normal when the

fault condition has returned to a normal state.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 19

General Precautions

FanMaster Installation

ATTENTION: Only qualified personnel familiar with Heating,

Ventilating and Air Conditioning (HVAC) systems, adjustable

!

frequency AC drives and associated instrumentation and

machinery should plan or implement the installation, start-up and

subsequent maintenance of the system. Failure to comply may

result in personal injury and/or equipment damage.

ATTENTION: The following information is merely a guide for

proper installation. Rockwell Automation cannot assume

!

responsibility for the compliance or the noncompliance to any

code, national, local or otherwise for the proper installation of

this product or associated equipment. A hazard of personal injury

and/or equipment damage exists if codes are ignored during

installation.

Chapter 2

ATTENTION: FanMaster is a HVAC fan motor control device

that when integrated with HVAC building automation systems

!

and any other control devices does not provide limits for or

protection against loss of freeze status, high temperature, high

static, carbon dioxide/indoor air quality, smoke and fire, and/or

flood control signals. All persons responsible for applying this

equipment must satisfy themselves that the intended application

of this equipment is acceptable.

ATTENTION: National Codes and Standards (NEC, VDE,

BSI, etc.) and local codes outline provisions for safely installing

!

electrical equipment. Installation must comply with

specifications regarding wire types, conductor sizes, branch

circuit protection and disconnect devices. Failure to do so may

result in personal injury and/or equipment damage.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 20

2-2 FanMaster Installation

Installation Considerations

Consider and plan for the following when installing FanMaster for

integration with an AHU:

• The existing BAS control supply fan start/stop signal. Two relays are

provided for interfacing to the BAS fan start/stop signal. The relay

installed in the FanMaster enclosure accommodates a 120V AC signal.

A second relay is shipped loose and accommodates a 24V AC signal. If

a signal other than 24V or 120V AC is used, you must purchase and

install the appropriate relay separately. The Allen-Bradley 700-HK

family of relays provides coil voltages from 6V AC…240V AC or 6V

DC…48V DC. More information is provided on the Allen-Bradley web

site at: http://www.ab.com/en/epub/catalogs/12768/229240/229266/

229643/229701/tab3.html

• The existing BAS outside air damper position control signal (used with

constant ventilation option only). FanMaster provides I/O connections

for a 4…20 mA signal only. If the BAS control signal is 0…10V DC or

0…135 Ohms, a converter adapter must be purchased separately for

both the input and output signals.

• When installing FanMaster with a Variable Frequency Drive, the

following firmware revisions must be used:

– PowerFlex 400, v1.004 and later

Installation Requirements

– PowerFlex 70EC v3.001 and later

– PowerFlex 700VC v4.001 and later

– PowerFlex 753 v1.005 and later

Power Source for FanMaster

120V AC, 10 Amp (min.) grounded service.

Tools Required for Installation

• Variable speed drill

• Sheet metal drill bits

• Various screwdrivers

• Various wrenches (open, socket and/or torque)

• Conduit cutting and bending tools (optional, for permanent

installations)

Wiring Specifications

Important:All power, I/O and signal wiring is customer supplied.

All wire to be Stranded, copper, 600V/105 °C (194 °F) insulation.

Terminal(s) Description Max. Wire Size Min. Wire Size Torque

L, N Power 10 AWG 22 AWG 1.0 N•m (9.0 lb•in)

GND Ground 6 AWG 16 AWG 2.3 N•m (20.4 lb•in)

– I/O and Signal 12 AWG 22 AWG 0.6…0.8 N•m (4.5…7.1 lb•in)

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 21

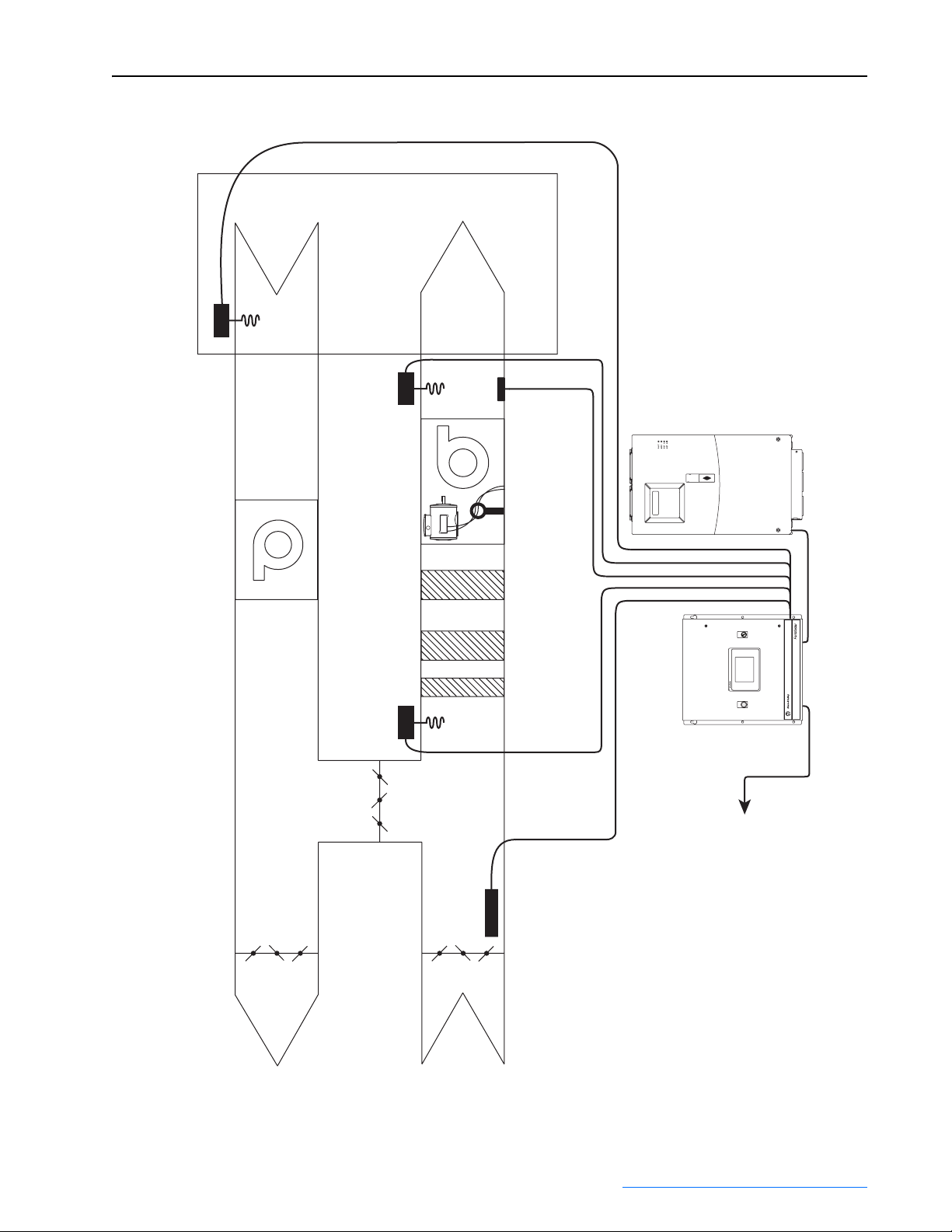

Figure 2.1 Typical FanMaster and Drive Installation

FanMaster Installation 2-3

Carbon Dioxide Sensor

Air

Return

Air

Supply

Conditioned Space

AC Drive

700VC, or 753

PowerFlex 400, 70EC,

Supply Air

Tem p Tr ans

Supply Fan

(if used)

BAS Start/Stop Control

Fan Motor Current Switch

Optional Return Fan

OVERRIDE

FANMASTER

OFF ON

PanelView C600

FAULTED

FANMASTER

Mixed Air

Temp Trans

FanMaster

Switch

Damper Position

Air

Exhaust

Air

Outside

To Input Power Source

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 22

2-4 FanMaster Installation

Installation

Install the Instruments on the AHU

Refer to Figure 2.1 on page 2-3 the for guidance on instrument locations.

Important:Instrument cables must be no longer than 3200 m (10499 ft) for

4…20 mA signals using a minimum of 20 AWG wire and 200

m (656 ft) for digital signals using a minimum of 20 AWG

wire.

Supply Air Temperature Transmitter

• Using the two screws and mounting flanges provided on the enclosure,

mount the supply air temperature transmitter to the outside of the AHU

sheet metal cover, in the middle of the supply air plenum. Placement

must be after the heating and cooling exchangers.

Important: Verify that the transmitter probe is installed in a position

that does not cause contact with any internal equipment

and that no internal equipment will be damaged while

drilling the insertion and mounting holes.

Mixed Air Temperature Transmitter

• Using the two screws and mounting flanges provided on the enclosure,

mount the mixed air temperature transmitter to the outside of the AHU

sheet metal cover, in the middle of the mixed air plenum. Placement

should be in a position where the outside air and return air are equally

mixed and the temperature reflects the average temperature entering the

heating and cooling exchangers.

Important: Verify that the transmitter probe is installed in a position

that does not cause contact with any internal equipment

and that no internal equipment will be damaged while

drilling the insertion and mounting holes.

Carbon Dioxide Sensor

• Using the two screws and mounting flanges provided on the enclosure,

mount the carbon dioxide sensor in the return air plenum. Placement

must be prior to the mixing of outside air with the return air.

Important: The carbon dioxide sensor will not operate properly

below 0° C (32° F).

Important: Verify that the sensor probe is installed in a position that

does not cause contact with any internal equipment and

that no internal equipment will be damaged while drilling

the insertion and mounting holes.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 23

Damper Position Indicator Switch

FanMaster Installation 2-5

• If your installation does not

position indicator switch with the following considerations:

– The damper position switch must be installed in a location that

allows the switch to detect the damper position (e.g., on the damper

actuator crank arm).

– The damper position switch must be set to “closed” when the

outside air damper is open 5 degrees beyond the normal minimum

position for your installation.

Current Switch

• If you are installing an evaluation unit only, clamp the current switch

around any one of the supply fan motor leads.

use constant ventilation, install the damper

Install the Drive (If Applicable)

If you are installing a FanMaster evaluation unit only, continue with Install

the FanMaster Enclosure on page 2-7.

Important:If your are installing a PowerFlex 400, Style A, NEMA/UL

Type 3R, 4 and 12 drive with a factory installed HOA switch

and a speed potentiometer, you must place a jumper between

terminal 35 on TB1 in the drive enclosure and terminal 8 on the

drive signal terminal block. The Auto Start contact is not

required on this drive.

Important:If you are installing a PowerFlex 400, Style A, NEMA/UL

Type 1 drive, the optional inputs may be installed with the

exception of the Hand/Auto, Auto Start and Speed Reference

inputs.

Important:The FanMaster configuration and startup procedure (Chapter 3)

will set all necessary parameters in the PowerFlex 400 drive to

the correct settings. Therefore, those sections of the PowerFlex

400 drive installation and/or user manual which refer to setting

or configuring parameters should be ignored during

installation.

Important:PowerFlex 70EC, 700VC and 753 drives require manual

configuration of specific drive communication parameters

before completing the FanMaster configuration and startup

procedure. These steps are included later in this chapter.

Therefore, those sections of the PowerFlex 70EC, 700VC or

753 drive installation and/or user manual which refer to setting

or configuring parameters should be ignored during

installation.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 24

2-6 FanMaster Installation

This publication provides specific steps for interconnecting the drive and

FanMaster. For detailed drive spacing, lifting, mounting, grounding and

other detailed installation instructions, refer to the following publications:

PowerFlex 400 AC Drive

• PowerFlex 400 AC Drive Packages for Fan & Pump Applications

Installation Manual, publication 22C-IN002.

PowerFlex 70EC AC Drive

• PowerFlex 70 Adjustable Frequency AC Drive Installation Instructions,

publication 20A-IN009.

PowerFlex 700VC AC Drive

• PowerFlex 700 Adjustable Frequency AC Drive Frames 0…6

Installation Instructions, publication 20B-IN019.

PowerFlex 753 AC Drive

• PowerFlex 750-Series AC Drive Installation Instructions, publication

750-IN001.

For detailed information on how to properly wire and ground drives and

determine maximum motor cable lengths, refer to:

• Wiring and Grounding Guidelines for PWM AC Drives, publication

DRIVES-IN001.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 25

FanMaster Installation 2-7

Install the FanMaster Enclosure

Environment

• The NEMA/UL Type 1 enclosure is rated for an operating temperature

range of 0°…40°C (32°…104°F).

Important: The NEMA/UL Type 1 enclosure must be mounted in a

clean, dry location. Contaminants such as oils, corrosive

vapors and abrasive debris must be kept out of the

enclosure. These enclosures are intended for indoor use

primarily to provide a degree of protection against contact

with enclosed equipment. These enclosures offer no

protection against airborne contaminants.

• The NEMA/UL Type 4 enclosure is rated for an operating temperature

range of -23°…40°C (-10°…104°F).

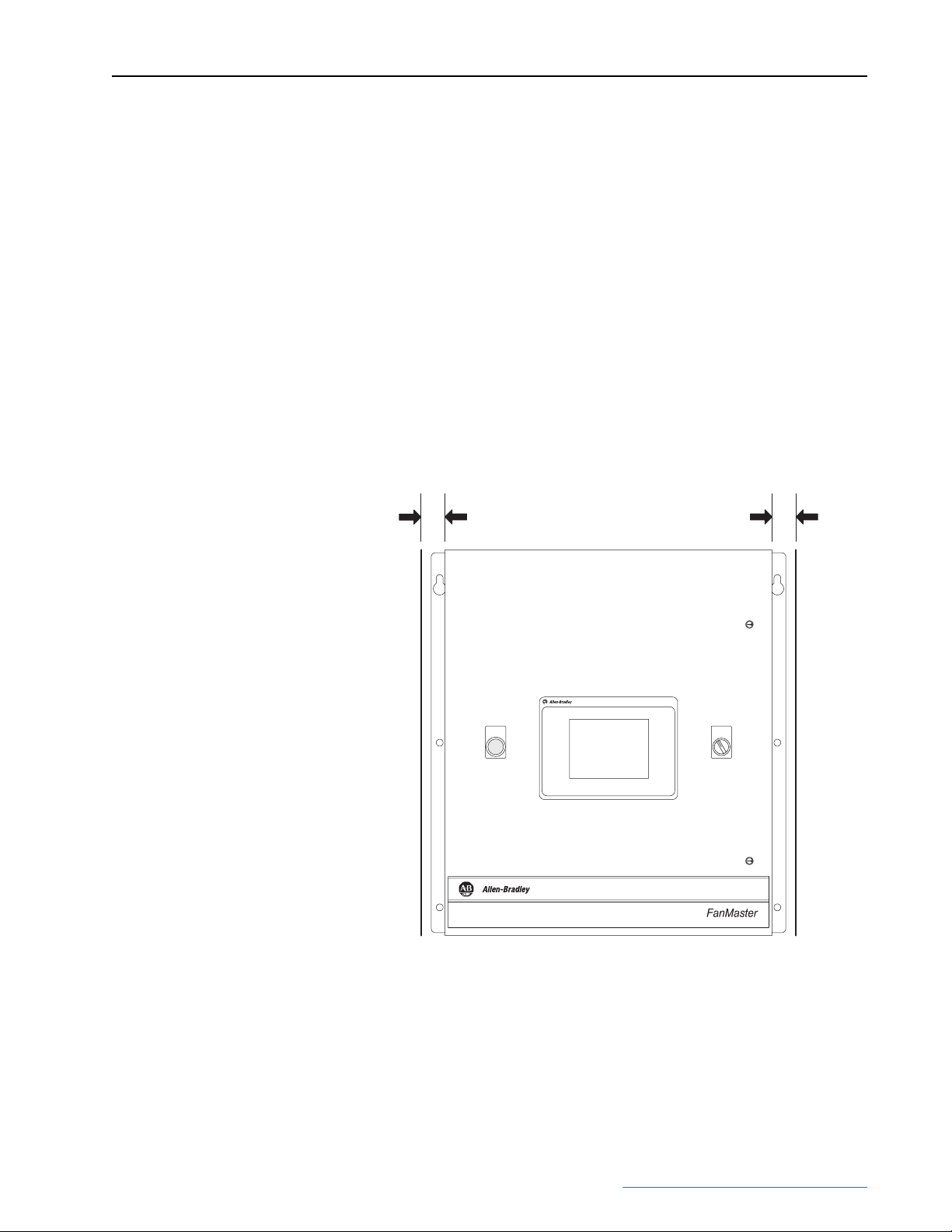

Figure 2.2 Enclosure Minimum Mounting Clearances

25.4 mm

(1.0 in.)

FANMASTER

FAULTED

PanelView C600

NEMA/UL Type 1 Enclosure Shown

25.4 mm

(1.0 in.)

FANMASTER

OVERRIDE

OFF ON

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 26

2-8 FanMaster Installation

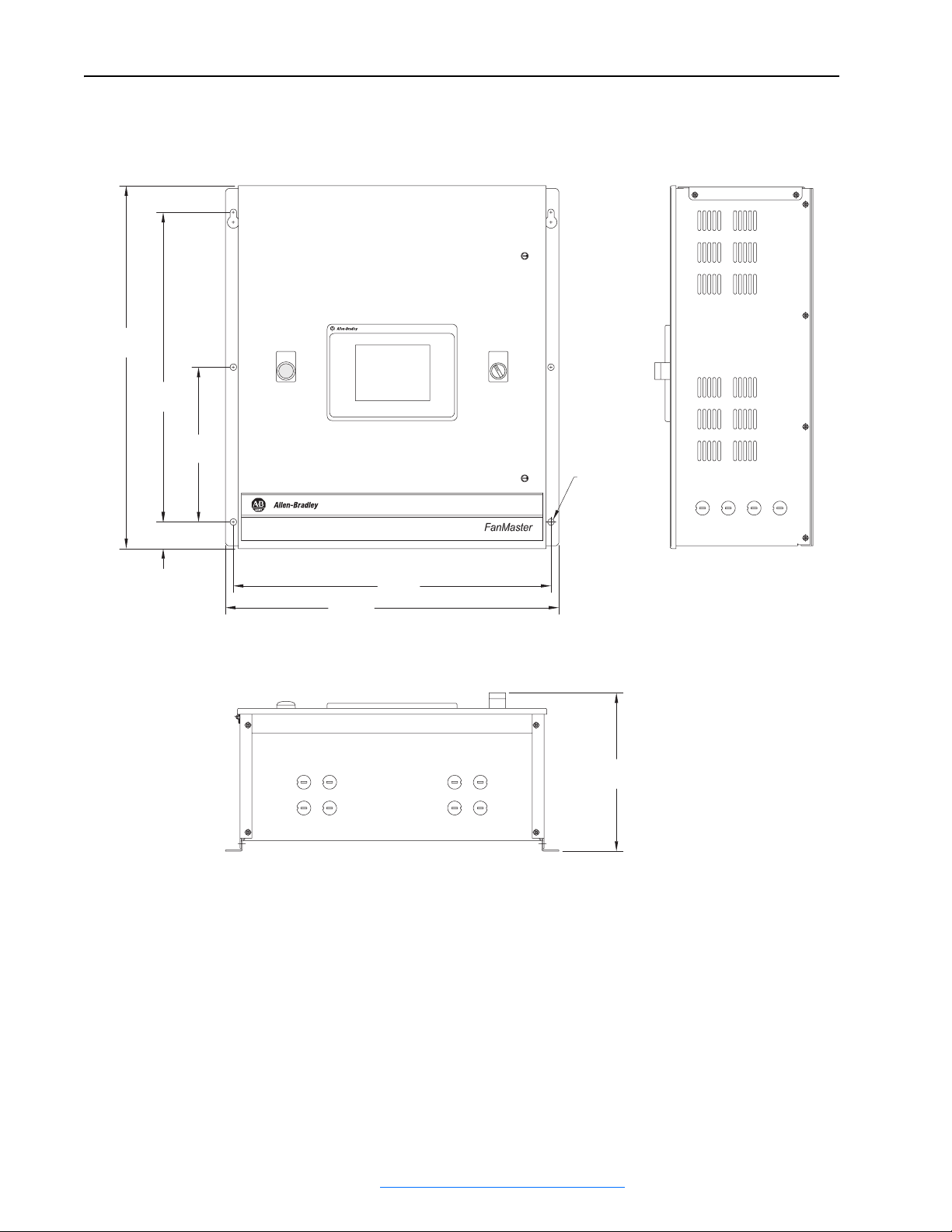

Figure 2.3 NEMA/UL Type 1 FanMaster Enclosure Dimensions

Dimensions are in mm and (inches).

580

(22.84)

495.3

(19.50)

42.40

(1.67)

247.65

(9.75)

FANMASTER

PanelView C600

FANMASTER

FAULTED

508.00

533.40

(21.00)

(20.00)

OVERRIDE

OFF ON

Ø10.4 (0.41)

Through

Mounting Holes

Typ. 6 Places

253.24

(9.97)

Side View

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Bottom View

Page 27

18.00

(0.72)

646.00

(25.45)

19.00

(0.75)

610.00

(24.00)

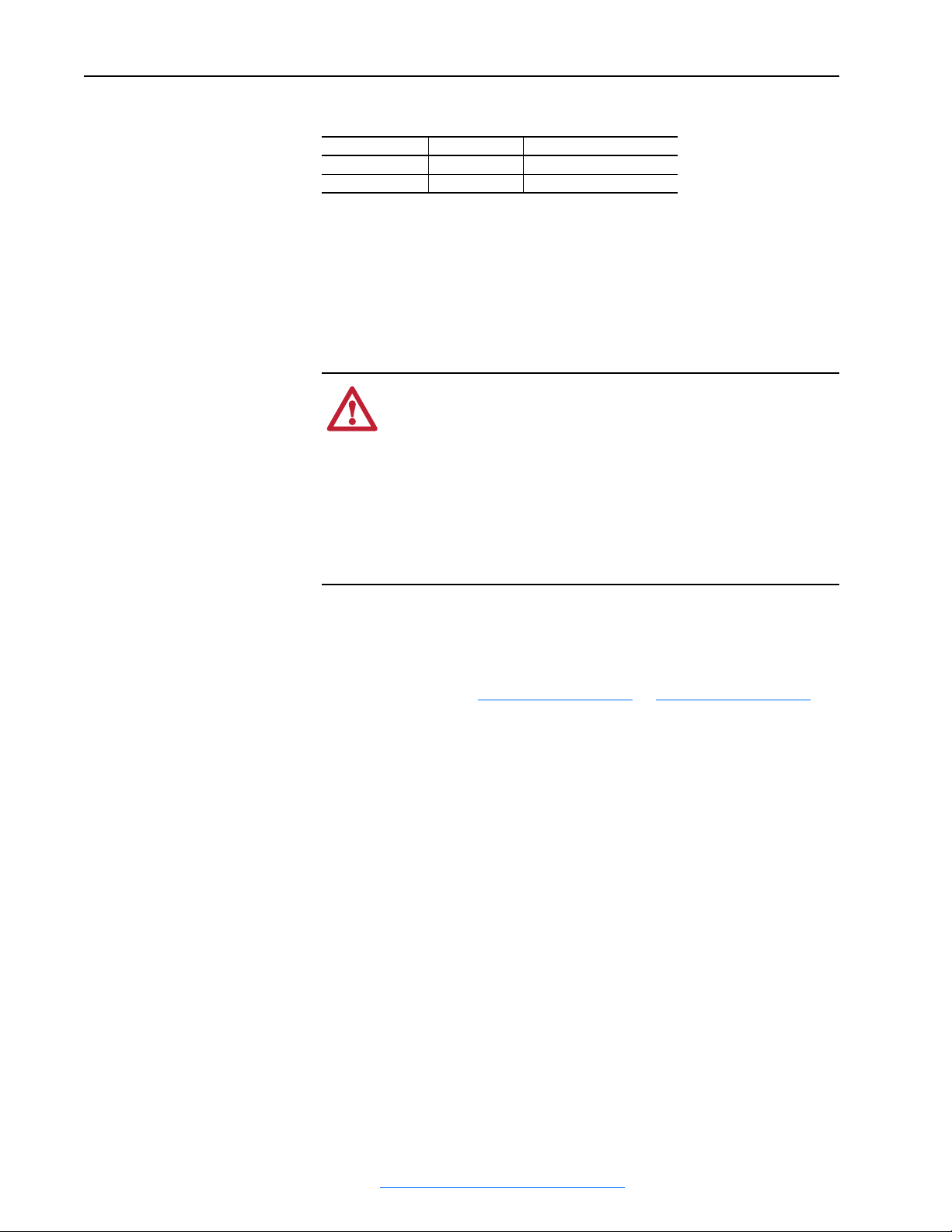

Figure 2.4 NEMA/UL Type 4 FanMaster Enclosure Dimensions

Dimensions are in mm and (inches).

610.00

(24.00)

572.00

(22.50)

Clearance for Ø 9.5 (3/8)

Mounting Hardware

Typ. 4 Places

673.00

FANMASTER

FAULTED

FANMASTER

OVERRIDE

OFF ON

(26.50)

FanMaster Installation 2-9

291.00

(11.47)

231.00

(9.10)

203.00

(8.00)

Side View

Bottom View

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 28

2-10 FanMaster Installation

FanMaster Enclosure Weights

Enclosure Enclosure Only Enclosure and Packaging

NEMA/UL Type 1 21.0 kg (46 lb) 26.3 kg (58 lb)

NEMA/UL Type 4 36.3 kg (80 lb) 41.7 kg (92 lb)

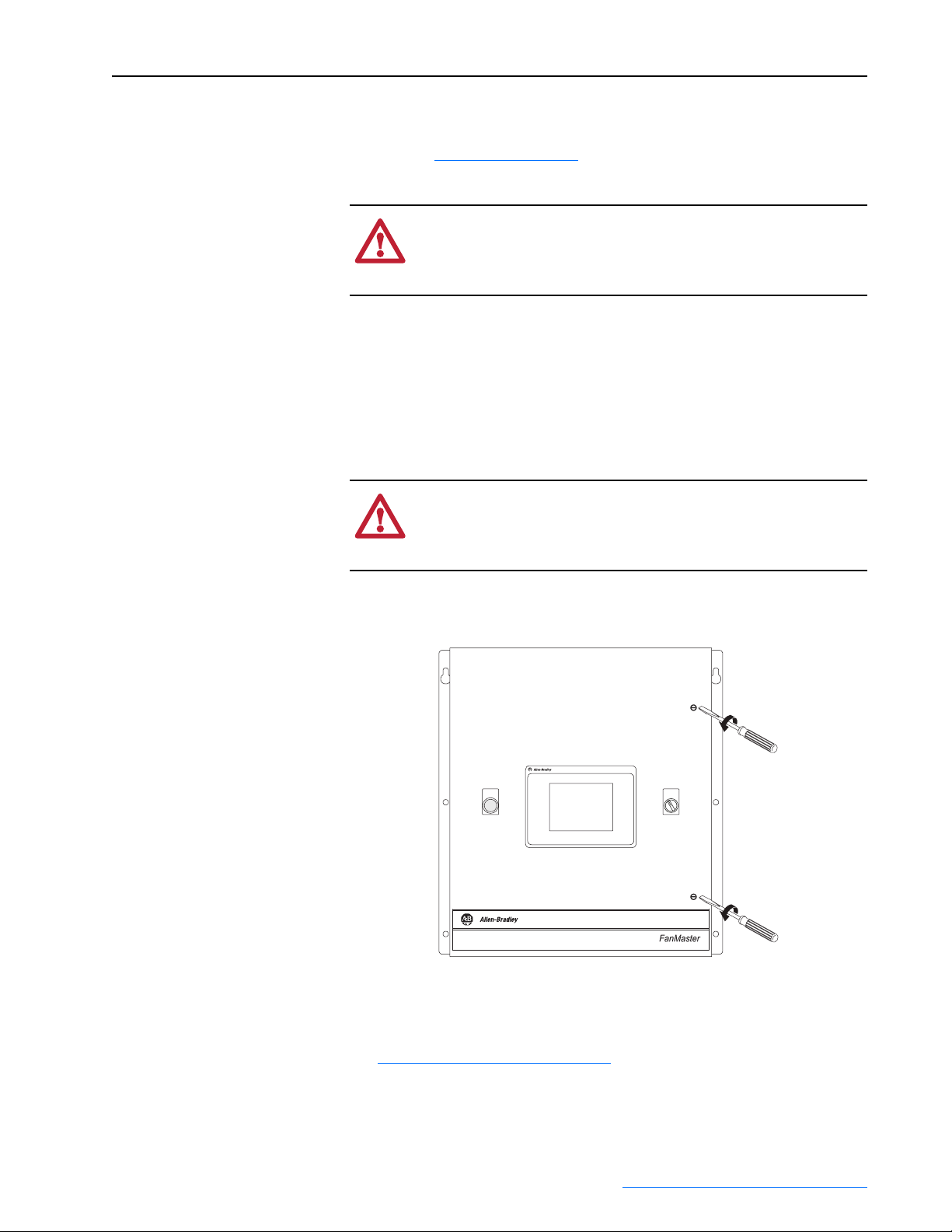

Lifting Instructions

The dimensions and weights provided above must be taken into

consideration when lifting and mounting the enclosure. Use the proper

equipment to safely lift and hold the weight of the enclosure while

mounting.

ATTENTION: To guard against possible personal injury or

equipment damage…

!

• Inspect all lifting hardware for proper attachment before

lifting the enclosure.

• Do Not allow any part of the enclosure or lifting mechanism

to make contact with electrically charged conductors or

components.

• Do Not allow personnel or their limbs directly underneath the

enclosure when it is being lifted and mounted.

Mounting Instructions

1. Verify the hole pattern on the panel to which the enclosure will be

mounted. Refer to Figure 2.3 on page 2-8

2. For NEMA/UL Type 1 enclosures, insert, but do not fully tighten, one

bolt in one of the top holes in the panel. The bolt must be fully threaded

into the panel before hanging the enclosure.

3. For NEMA/UL Type 1 enclosures, lift the enclosure and place onto the

bolt installed in the panel.

4. Install the remaining bolts into the panel and fully tighten all bolts.

or Figure 2.4 on page 2-9.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 29

FanMaster Installation 2-11

Wire the FanMaster and Drive (if Installed)

Refer to the FanMaster Diagrams contained in Appendix B for wiring and

connection details.

ATTENTION: Do not route signal and control wiring with

power wiring in the same conduit. This can cause interference

!

with operation. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

1. For permanent installations, determine where conduit will be routed and

prepare the FanMaster enclosure for conduit connections.

– For NEMA/UL Type 1 enclosures, remove the metal plugs in the

pre-located openings in the enclosure for conduit connections.

– For NEMA/UL Type 4 enclosures, drill the desired openings in the

enclosure to accommodate conduit connections.

ATTENTION: Protect the contents of the enclosure from metal

chips and other debris while removing the conduit opening plugs.

!

Failure to observe this precaution could result in damage to, or

destruction of, the equipment.

2. Open the FanMaster enclosure and verify that circuit breaker 1 (CB1) is

in the “off” position.

PanelView C600

FANMASTER

FAULTED

NEMA/UL Type 1 Enclosure Shown

FANMASTER

OVERRIDE

OFF ON

3. Route the power wires through the appropriate conduit (if used) and

connect to terminals L, N and G on terminal block 1 (TB1). Refer to

Wiring Specifications on page 2-2

for power wire size.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 30

2-12 FanMaster Installation

Important:For each installed instrument, allow for the appropriate cable

length necessary to reach the FanMaster I/O terminals in the

enclosure. Refer to Wiring Specifications on page 2-2

control wire size.

4. Wire the supply air temperature transmitter according to the

manufacturer’s instructions, route through the appropriate conduit (if

used) and connect the control wires to terminals 100, 102, 123 and 124

on TB2 in the FanMaster enclosure.

5. Wire the mixed air temperature transmitter according to the

manufacturer’s instructions, route through the appropriate conduit (if

used) and connect the control wires to terminals 100, 102, 125 and 126

on TB2 in the FanMaster enclosure.

for

6. Wire the CO

through the appropriate conduit (if used) and connect the control wires

to terminals 100, 102, 127 and 128 on TB2 in the FanMaster enclosure.

7. Wire the damper position indicator switch according to the

manufacturer’s instructions, route through the appropriate conduit (if

used) and connect the control wires to terminals 100 and 105 on TB2 in

the FanMaster enclosure.

8. If you are installing an evaluation unit, connect the control wires for the

supply fan current switch to terminals 100 and 109 on TB2 in the

FanMaster enclosure.

9. For FanMaster evaluation unit installations, continue with step 24 on

page 2-18. For installations with a drive complete the appropriate steps:

– PowerFlex 400 Drive (below)

– PowerFlex 70EC, 700VC or 753 Drive on page 2-13

PowerFlex 400 Drive

Important: A 120 Ohm terminating resistor (provided with the drive)

sensor according to the manufacturer’s instructions, route

2

must be connected to pins 4 and 5 of the RJ45

two-position terminal block adapter on the return air

drive. If a return air drive is not installed, the terminating

resistor must be connected to pins 4 and 5 of the RJ45

terminal block on the supply air drive. Refer to Figure

B.8 on page B-9 for details.

Important: The communication cable maximum length should not

exceed 500 m (1,640 ft).

a. Wire the RJ45 terminal block adapter and terminating resistor to

TB3 in the FanMaster enclosure and connect it to the PowerFlex

400 drive.

b. Continue with step 10 on page 2-14

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

.

Page 31

FanMaster Installation 2-13

PowerFlex 70EC, 700VC or 753 Drive

Important: When installing a PowerFlex 753 drive, the 20-COMM-H

communication adapter requires the 20-750-20COMM

carrier option module.

Important: Leave the 20-COMM-H adapter rotary node address

switches set to “00” and set the network protocol switch

to “RTU”.

2

3

8

RTU

N2

P1

4

6

7

1

0

9

2

3

1

0

5

9

4

5

6

7

8

Important: The communication cable maximum length should not

exceed 500 m (1,640 ft).

a. For PowerFlex 753 drives only, install the 20-COMM-H, RS-485

HVAC adapter in the drive according to the installation instructions

in the 20-750-20COMM Option Card Installation Instructions,

publication 750COM-IN001.

b. Connect the 20-COMM-H adapter, via the RS-485 cable, to TB3 in

the FanMaster enclosure. Refer to the interconnect diagrams for the

PowerFlex 70EC (Figure B.9 on page B-10

(Figure B.10 on page B-11

) or PowerFlex 753 (Figure B.11 on

), PowerFlex 700VC

page B-12).

c. Continue with step 10 on page 2-14

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

.

Page 32

2-14 FanMaster Installation

10. Connect the normally open (“Run”) contact in the supply fan drive to

FanMaster to indicate that the supply fan motor is running.

– For PowerFlex 400 drives, connect terminal R4 on the drive relay

TB to terminal 135 on TB2 in FanMaster and terminal R5 on the

drive relay TB to terminal N on TB2 in FanMaster. Note: The relay

terminal block is on the front of the drive, below the

communication adapter.

– For PowerFlex 70EC drives, connect terminal 24 on the drive I/O

TB to terminal 135 on TB2 in FanMaster and terminal 25 on the

drive I/O TB to terminal N on TB2 in FanMaster. Note: The I/O

terminal block is on the front of the drive, below the

communication adapter.

– For PowerFlex 700VC drives, connect terminal 16 on the drive I/O

TB to terminal 135 on TB2 in FanMaster and terminal 15 on the

drive I/O TB to terminal N on TB2 in FanMaster. Note: The I/O

terminal block is on the front of the drive, to the left of the

communication adapter.

– For PowerFlex 753 drives, connect terminal R0NO on the drive

Relay TB2, on the Main Control board, to terminal 135 on TB2 in

FanMaster and terminal R0C on the drive Relay TB2 to terminal N

on TB2 in FanMaster. Note: The relay terminal block (TB2) is on

the bottom, back edge of the main control board.

11. Remove the three phase AC line supply side from the existing fan motor

starter contactor and reconnect to the drive line terminals, L1, L2 & L3.

Replace the existing wiring with new, longer wires of the same gauge

and rating if required.

12. Remove the motor output side from the existing fan motor starter

contactor and reconnect to the drive motor terminals, T1, T2 & T3.

Replace the existing wiring with new, longer wires of the same gauge

and rating if required.

13. Connect the existing BAS supply fan start/stop signal wires to terminals

159 and 160 on TB2 in the FanMaster enclosure.

Important: A 120V AC relay (700-HK32A1) is installed (labeled

CR4) in the FanMaster enclosure at the factory for the

BAS supply fan start/stop signal. If your installation

requires a relay for a 24V AC signal, you must remove the

factory installed relay and install and wire the 24V AC

(700-HK32A24) relay provided, or the appropriate relay

for your installation.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 33

FanMaster Installation 2-15

14. If the existing fan motor starter provides an auxiliary open or closed

contact when the relay is energized, normal operation of the existing

control system may not be possible without this contact. Therefore,

disconnect the wires from the fan motor started contact and connect it to

the appropriate auxiliary contact terminals provided in the FanMaster

enclosure. The FanMaster auxiliary contacts actuate when the drive is

on and turning the fan. Refer to the schematic diagram, Figure B.4 on

page B-5, for details.

15. If using constant ventilation mode, continue with step 16 on page 2-17.

The FanMaster damper control override commands the damper to close

periodically in order to reduce the amount of outside air provided to the

AHU to further reduce costs associated with cooling and heating. The

damper override contact (at terminals 119 and 120 on TB2 in the

FanMaster enclosure) can be used to operate contact relay CR3 in the

FanMaster enclosure or a customer supplied interposing relay or

solenoid to close the damper when the output is turned on. Using the

damper override contact output to energize CR3 and wiring the existing

damper control or power signals through the normally closed contact on

CR3 will close the damper when the output is on.

Make the following connections for all installations. Refer to the

schematic diagrams in Figure B.2 on page B-3

page B-5 for details:

a. Install a jumper wire between terminals 1 and 152 on TB2 in the

FanMaster enclosure.

b. Install a jumper wire between terminals 151 and 119 on TB2.

c. Install a jumper wire between terminals 120 and N on TB2.

d. Complete one of the following sets of steps below based on your

installation:

• Outside Air Damper with Electric Actuator (0…10V DC or

4…20 mA) on page 2-16

• Outside Air Damper with Pneumatic Actuator on page 2-16

• Outside Air Damper with Electric Actuator (0…135 Ohm) on

page 2-16

and Figure B.4 on

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 34

2-16 FanMaster Installation

Outside Air Damper with Electric Actuator (0…10V DC or

4…20 mA)

The existing outside air damper has an electric actuator with a

0…10V DC or 4…20 mA control signal:

i. Remove the (+) control wire from the actuator (+) terminal and

connect it to terminal 155 on TB2 in the FanMaster enclosure.

ii. Wire terminal 153 on TB2 to the actuator (+) terminal.

iii. Test the system and make sure that operation does not cause an

alarm in the existing system which may cause an HVAC

shutdown due to opening the 4…20 mA loop or other failure to

follow command alarm.

Outside Air Damper with Pneumatic Actuator

The existing outside air damper has a pneumatic actuator with a mA

to Pressure controller (I to P):

i. Either remove the (+) control wire from the I to P and connect

through the relay as in steps “i. a.” and “i.b.” above, or obtain an

electrically actuated pressure valve which expels the pneumatic

actuator control air when the valve is actuated. Use the

FanMaster damper relay to switch power for the pressure valve

(separately sourced AC or DC power is required).

Outside Air Damper with Electric Actuator (0…135 Ohm)

The existing outside air damper has an electric actuator with a

0…135 ohm control signal:

i. Remove the (+) power supply wire from the actuator and

connect it to terminal 155 on TB2 in the FanMaster enclosure.

ii. Wire terminal 153 on TB2 to the actuator (+) power supply

terminal.

Important: The installer must determine and ensure the proper

operation of this contact when used to force the damper

closed.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 35

FanMaster Installation 2-17

16. (Optional - required when using the constant ventilation option rather

than the default demand ventilation option.) If FanMaster will be used

to control the outside air damper for constant ventilation control,

connect the damper position control wires to the appropriate terminals

on the drive.

Important: The analog output terminal used on the drive must be set

for a 4…20 mA signal only. Verify that the appropriate

drive DIP switch or jumper is properly set for a 4…20

mA signal or component damage may occur. Refer to the

appropriate drive User Manual for details. If the control

signal is 0…10V DC or 0…135 Ohms a converter adapter

must be purchased separately and be installed for both the

input and output signals.

– For PowerFlex 400 drives, connect the damper position control

wires to terminals 14 (-) and 15 (+) in the drive.

– For PowerFlex 70EC drives, connect the damper position control

wires to terminals 22 (-) and 23 (+) in the drive.

– For PowerFlex 700VC drives, connect the damper position control

wires to terminals 6 (-) and 7 (+) in the drive.

– For PowerFlex 753 drives, connect the damper position control

wires to terminals Ao0– and Ao0+ on TB1 in the drive.

17. (Optional - required when using the constant ventilation option rather

than the default demand ventilation option.) If FanMaster will be used

to override the BAS control of the outside air damper, connect the

damper position command signal wires to terminals 100, 102, 218 and

219 on TB2 in the FanMaster enclosure.

Important: Terminals 100, 102, 218 and 219 on TB2 of the

FanMaster unit accept a 4…20 mA signal only. If the

control signal is 0…10V DC or 0…135 Ohms, a

converter adapter must be purchased separately and be

installed for both the input and output signals.

18. For PowerFlex 400, style A, NEMA/UL Type 3R, 4 & 12 drives only,

jumper TB1-35 in the drive enclosure to drive signal terminal 8.

19. For PowerFlex 400 drives with full feature bypass only, connect

terminals 61 and 162 on FanMaster TB2 to terminals 34 and 36 on TB1

in the enclosure as shown.

20. For PowerFlex 400 drives with a full feature bypass and speed pot only,

install a new switch contact, part number 800F-X10, on the Hand Off

Auto switch in the “Auto” position. The switch snaps into place on the

second switch level on the right side of the switch as viewed from the

rear. Connect a wire from PF400 terminal 11 to the top of the switch.

Connect a wire from the bottom of the switch to PF400 terminal 8.

Verify that the switch contact closes when “Auto” is selected.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 36

2-18 FanMaster Installation

21. (Optional) If a dry contact output from FanMaster that closes on a high

CO

level is required for connection to a BAS CO2 alarm device,

2

connect the signal wires from the CO

terminals 117 and 118 on TB2 in the FanMaster enclosure.

22. (Optional) If a dry contact output from FanMaster that opens when

FanMaster faults is required for connection to a BAS annunciation

device, connect the signal wires from to the annunciation device to

terminals 121 and 122 on TB2 in the FanMaster enclosure.

23. (Optional) If your AHU currently utilizes a flow switch or pressure

sensor and requires a proof of flow dry contact output from FanMaster,

connect the signal wires from the contact to terminals 100, 102, 218 and

219 on TB2 in the FanMaster enclosure.

24. A heater is included in the FanMaster NEMA/UL Type 4 enclosure to

allow for maintaining the proper temperatures for the equipment in the

enclosure. Use the adjustment knob on the heater unit to set the

temperature to about 5°C (40°F).

25. Apply power to FanMaster by setting CB1 in the FanMaster enclosure

to the “on” position.

alarm annunciation device to

2

26. Close and secure the cover on the FanMaster enclosure.

27. Replace or close any drive or BAS control panel covers.

28. Complete the procedures in Chapter 3- FanMaster Configuration and

Start Up.

Allen-Bradley® FanMaster™ Energy Saving Package Installation Manual - Publication FANM-IN001B-EN-P – December, 2009 PN-65329

Page 37

Chapter 3

FanMaster Configuration and Start Up

This chapter contains the steps necessary to configure and start up

FanMaster. Typical values are provided as defaults where applicable. The

default values may not be valid for your installation and, if left unchanged,

may affect the calculated energy savings results. Verify all values in Tabl e

3.A on page 3-2 prior to completing the configuration procedures.

Using the PanelView C600 HMI Terminal

The PanelView C600 HMI terminal is a touch sensitive operator interface

that is used to monitor and program the controller in the FanMaster via a