Page 1

USER GUIDE

PUBLICATION RSSQL-UM001H-EN-P-April 2011

Supersedes Publication RSSQL-UM001G-EN-P

Page 2

●

●

●

●

●

Copyright

Contact Rockwell

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support

Copyright Notice

© 2011 Rockwell Automation Technologies, Inc. All rights reserved.

This document and any accompanying Rockwell Software products are copyrighted by

Rockwell Automation Technologies, Inc. Any reproduction and/or distribution without prior

written consent from Rockwell Automation Technologies, Inc. is strictly prohibited. Please

refer to the license agreement for details.

Trademark Notices

FactoryTalk, Rockwell Automation, Rockwell Software, the Rockwell Software logo are

registered trademarks of Rockwell Automation, Inc.

The following logos and products are trademarks of Rockwell Automation, Inc.:

RSBizWare, FactoryTalk Metrics, and FactoryTalk Transaction Manager.

Other Trademarks

Microsoft, SQL Server, Event Viewer, Windows, Windows Server 2003, and Windows

Server 2008 are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe

Systems Incorporated in the United States and/or other countries.

All other trademarks are the property of their respective holders and are hereby

acknowledged.

Warranty

This product is warranted in accordance with the product license. The product’s performance

may be affected by system configuration, the application being performed, operator control,

maintenance and other related factors. Rockwell Automation is not responsible for these

intervening factors. The instructions in this document do not cover all the details or variations

in the equipment, procedure, or process described, nor do they provide directions for meeting

every possible contingency during installation, operation, or maintenance. This product’s

implementation may vary among users.

This document is current as of the time of release of the product. However, the accompanying

software may have changed since the release. Rockwell Automation, Inc. reserves the right to

change any information contained in this document or the software at anytime without prior

notice. It is your responsibility to obtain the most current information available from

Rockwell when installing or using this product.

2

Page 3

Contents

Chapter 1 Welcome To FactoryTalk Transaction Manager 13

What Is FactoryTalk Transaction Manager? ................................. 13

What Can FactoryTalk Transaction Manager Do For Me? ................. 13

Automate Data Logging .................................................... 13

Control the Plant Floor Using Business Rules and Quality

Enforcement ................................................................. 14

Manage Recipes .............................................................. 14

Understanding FactoryTalk Transaction Manager Concepts ............. 14

Transaction Control Manager Service .................................... 15

FactoryTalk Transaction Manager Service and Control Connectors 17

Control Connectors ......................................................... 18

Enterprise Connectors ...................................................... 18

Configuration Server ........................................................ 18

Transactions .................................................................. 19

FactoryTalk ....................................................................... 19

FactoryTalk Services Platform Components ............................ 20

Intended Audience .............................................................. 21

Where Can I Go For Help? ...................................................... 22

3

Page 4

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Online Help ................................................................... 22

Product Manual .............................................................. 22

Training ....................................................................... 23

Technical Support ........................................................... 23

Get Web Support ............................................................ 24

Get Phone Support .......................................................... 24

Get Consulting Services .................................................... 24

Contact Us .................................................................... 24

Chapter 2 Installing FactoryTalk Transaction Manager 27

Before You Begin ................................................................ 27

Hardware Requirements ................................................... 27

Software Requirements .................................................... 28

Software Compatibility ..................................................... 30

Activation ..................................................................... 30

Activation Options .......................................................... 33

Installing FactoryTalk Transaction Manager Software .................... 36

Distributed FactoryTalk Transaction Manager Installations ......... 38

Chapter 3 Exploring the FactoryTalk Transaction Manager User Interface

41

Starting FactoryTalk Transaction Manager ................................. 41

Exploring the FactoryTalk Transaction Manager User Interface ........ 42

Title Bar....................................................................... 43

Menu Bar ...................................................................... 44

Toolbar ........................................................................ 45

Configuration Tree .......................................................... 46

Workspace .................................................................... 49

Status Bar ..................................................................... 50

Configuration Checklist ........................................................ 50

4

Page 5

●Contents

●

●

●

●

●

Step 1: Defining and Naming a New Configuration .................... 53

Step 2: Defining Connectors ............................................... 54

Step 3: Defining Data Points .............................................. 54

Step 4: Defining Data Objects ............................................ 55

Step 5: Defining Transactions ............................................. 55

Step 6: Verifying Transactions ............................................ 56

Miscellaneous .................................................................... 56

Viewing Configuration Properties ........................................ 56

Starting Configurations ..................................................... 57

Stopping Configurations .................................................... 58

Starting and Stopping Connectors ........................................ 58

Monitoring Configurations ................................................. 58

Understanding FactoryTalk Transaction Manager External Files ........ 60

Using the Service Console ..................................................... 61

Chapter 4 Understanding FactoryTalk Transaction Manager Services 63

Introducing FactoryTalk Transaction Manager Services .................. 63

Control Connectors ............................................................. 63

FactoryTalk Live Data ...................................................... 64

DDE ............................................................................ 64

RSLinx Classic OPC .......................................................... 65

RSView32 ..................................................................... 65

Generic OPC .................................................................. 66

Enterprise Database Connectors .............................................. 66

ODBC........................................................................... 67

Oracle OCI .................................................................... 67

Microsoft OLE DB ............................................................ 67

Enterprise Application Connectors ........................................... 67

Microsoft COM+ .............................................................. 68

Time-series Data Compression ............................................ 68

FactoryTalk Metrics ......................................................... 68

Enterprise Connector Options ................................................. 68

FactoryTalk Transaction Manager Service .................................. 69

Transaction Control Manager Service ........................................ 70

5

Page 6

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Configuration Server ............................................................ 70

Chapter 5 Defining Data Points 73

Introducing Data Points ........................................................ 73

FactoryTalk Live Data Data Points ........................................... 75

Selecting a Collection Mode ............................................... 76

Consecutive Data Point and Data Block Support ....................... 77

Selecting Timeout Properties ............................................. 78

Selecting a Substitution Option ........................................... 80

Preventing Stale and Mismatched Data ................................. 80

Specifying Quality ........................................................... 81

OPC Data Points ................................................................. 82

RSLinx Classic OPC Data Points ........................................... 82

Generic OPC Data Points ................................................... 83

RSView32 Data Points ...................................................... 83

DDE Data Points ............................................................. 84

Chapter 6 Defining Data Objects 87

Introducing Data Objects ...................................................... 87

Enterprise Database Objects .................................................. 89

Oracle Call Interface (OCI) Data Objects ............................... 89

Microsoft SQL Server Data Objects ........................................... 89

ODBC Data Objects .......................................................... 89

Enterprise Application Objects ............................................... 90

Microsoft COM+ Data Objects ............................................. 90

FactoryTalk Metrics Data Objects ........................................ 91

Enterprise Connector Error Handling ........................................ 91

Inserting and Updating Data Table Records ................................ 93

Stored Procedures ............................................................... 93

Chapter 7 Creating Transactions 95

6

Introducing Transactions ....................................................... 95

Transaction Types ............................................................... 96

Page 7

●Contents

●

●

●

●

●

Unidirectional Transactions ............................................... 97

Bidirectional Transactions ................................................. 97

Bidirectional or Unidirectional Transactions With Transaction

Bindings ....................................................................... 99

Transaction Timeout .......................................................... 101

Transaction Completion ...................................................... 102

Cached Transactions ...................................................... 102

Real-time Transactions ................................................... 102

Bidirectional Transactions ............................................... 104

Transactions With Bound Transaction Results ........................ 104

Database Triggers ......................................................... 104

Expression Editor .............................................................. 104

Logical and Mathematical Operations ................................. 105

Time Functions ............................................................ 106

Data Point Range and Advanced Functions ........................... 106

Parse Function ............................................................. 107

Chapter 8 Understanding Online Edits 111

Introducing Online Edits ..................................................... 111

Understanding Online Edit Concepts....................................... 111

Online Edits Workflow .................................................... 112

Configurations That Use Online Edits .................................. 114

Learn More About Current and Pending Edits ........................ 115

Assembling Pending Edits ................................................ 116

Canceling Pending Edits .................................................. 117

Pending Edit Alerts ........................................................ 118

Creating a Configuration That Uses Online Edits ........................ 121

Editing Data Points In a Running Configuration That Uses Online Edits

............................................................................... 121

Editing Transactions In a Running Configuration That Uses Online

Edits ......................................................................... 124

Chapter 9 Exploring Advanced Topics 131

Introducing Advanced Topics ................................................ 131

Remote User Interface ....................................................... 131

7

Page 8

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Configuring the Remote User Interface ............................... 132

Distributed Configurations ................................................... 133

Licensing Required For a Distributed Configuration ................ 133

Establishing Microsoft Windows Privileges ............................ 134

Creating a Distributed Configuration .................................. 134

Using UNC Paths ........................................................... 134

Data Point Buffering ...................................................... 135

Increasing Performance ...................................................... 138

Control System ............................................................. 138

Database .................................................................... 138

FactoryTalk Transaction Manager ...................................... 139

Hardware and Operating Environment ................................ 140

Appendix A FactoryTalk Transaction Manager Sample Applications 143

External Trigger Sample Application ...................................... 143

Contents .................................................................... 143

Running the Application .................................................. 144

Appendix B FactoryTalk Transaction Manager and Microsoft COM+ Objects147

Introducing FactoryTalk Transaction Manager and Microsoft COM+

Objects .......................................................................... 147

Creating the Remote Component .......................................... 147

Creating the Client Application ............................................. 148

Installing the Remote Component .......................................... 149

Setting Up the Remote Client ............................................... 150

Creating the Microsoft COM+ Setup Program ............................. 150

Moving the Client Sample Application ..................................... 151

Including the COM+ Enterprise Application Connector In a FactoryTalk

Transaction Manager Configuration ........................................ 152

Defining the COM+ Enterprise Application Connector .................. 152

Defining the COM+ Data Object ............................................ 153

Code Sample A (ComSampleVB) ............................................ 154

Code Sample B (ClientSampleVB) .......................................... 155

8

Page 9

●Contents

●

●

●

●

●

Appendix C Securing FactoryTalk Transaction Manager Using FactoryTalk

Security 159

About FactoryTalk Security .................................................. 159

Considerations When Using FactoryTalk Transaction Manager With

FactoryTalk Security .......................................................... 159

Specify FactoryTalk Security Permissions That Allow You To Perform

FactoryTalk Transaction Manager Tasks .................................. 162

FactoryTalk Transaction Manager Behaviors When the FactoryTalk

Security Single Sign-on User Is In Effect .................................. 165

Overview .................................................................... 166

At FactoryTalk Transaction Manager Start Up ....................... 166

When Using FactoryTalk Transaction Manager ....................... 168

Writing Product-Specific Security Privileges From a Previous Release

To a File .................................................................... 169

Map Old Product-Specific Security Privileges To the New FactoryTalk

Security Permissions ...................................................... 170

Appendix D Glossary 173

Index .................................................................. 181

9

Page 10

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

10

Page 11

Figures

Figures

Figure 1: FactoryTalk Transaction Manager Functions (1) ................... 16

Figure 2: FactoryTalk Transaction Manager Functions (2) ................... 17

Figure 3: FactoryTalk Transaction Manager Functions (3) ................... 42

Figure 4: FactoryTalk Transaction Manager Title Bar ........................ 43

Figure 5: FactoryTalk Transaction Manager Menu Bar ........................ 44

Figure 6: FactoryTalk Transaction Manager Configuration Tree ............ 47

Figure 7: Error Log File View ...................................................... 49

Figure 8: Transaction Definition View ........................................... 50

Figure 9: FactoryTalk Transaction Manager Configuration Checklist ...... 52

Figure 10: FactoryTalk Data Point dialog box .................................. 74

Figure 11: Data Object Definition dialog box .................................. 88

Figure 12: Transaction Monitor ................................................... 92

Figure 13: Transaction Definition dialog box ................................... 96

Figure 14: Expression Editor dialog box ....................................... 105

Figure 15: Online Edits Workflow diagram ................................... 113

Figure 16: Pending Edit Alerts dialog box..................................... 120

Figure 17: FactoryTalk Transaction Manager Configuration ............... 121

Figure 18: Transaction Definition dialog box ................................. 124

Figure 19: Transaction Differences dialog box ............................... 127

Figure 20: Communication scheme ............................................ 132

11

Page 12

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

12

Page 13

Chapter 1

Welcome To FactoryTalk Transaction

Manager

What Is FactoryTalk Transaction Manager?

FactoryTalk Transaction Manager (previously known as RSSql) is an

industrial transaction software engine that shares data between your shop

floor systems and your enterprise applications (for example, corporate

databases) or COM+. FactoryTalk Transaction Manager can interact with

the following shop floor systems:

Human Machine Interfaces (HMI)

Programmable Logic Controllers (PLC)

ControlLogix Controllers

Distributed Control Systems (DCS)

What Can FactoryTalk Transaction Manager Do For Me?

FactoryTalk Transaction Manager helps you to manage your manufacturing

processes by integrating the data in your control systems with enterprise

applications. The following three sections describe examples of FactoryTalk

Transaction Manager applications.

Automate Data Logging

FactoryTalk Transaction Manager can move large amounts of data in a fast

and robust manner. In addition, the software has built-in fault tolerance and

13

Page 14

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

the ability to optimize reading and writing of both control and enterprise

data. You can use the software to automate the following types of processes:

Monitoring performance of control systems such as machine usage.

Tracking product information such as Work in Progress status and raw

material availability.

Updating real-time process information such as temperature, pressure,

and alarm states.

Control the Plant Floor Using Business Rules and

Quality Enforcement

FactoryTalk Transaction Manager provides the interface for a repository of

business rules. A business rule can be any logic required to run your plant

such as product specifications or quality parameters. By placing business

rules in a database or COM+ server in a central location, the rules are easier

to manage within an enterprise system. Additionally, the software can assure

quality data to meet the requirements of today’s advanced manufacturing

companies.

Manage Recipes

FactoryTalk Transaction Manager moves data (for example, recipe

information) from a database to an HMI or control system.

Understanding FactoryTalk Transaction Manager

Concepts

FactoryTalk Transaction Manager consists of several design-time and

run-time components. This guide describes the following components in

detail: Transaction Control Manager service, FactoryTalk Transaction

Manager service, control connectors, enterprise connectors, Configuration

Server, and transactions.

14

Page 15

1 ●Welcome To FactoryTalk Transaction Manager

●

●

●

●

●

Transaction Control Manager Service

The Transaction Control Manager is a service that controls and executes

FactoryTalk Transaction Manager transactions contained in a configuration,

but with the additional functionality of the FactoryTalk Live Data control

connector embedded in it. In an edit enabled configuration, the Transaction

Control Manager replaces the separate FactoryTalk Transaction Manager

and control connector services.

15

Page 16

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

The Transaction Control Manager service can connect to Rockwell Software

products and all OPC servers; therefore, the use of this service is the

preferred method for all new FactoryTalk Transaction Manager

configurations. For more information on how the Transaction Control

Manager service functions, see the following figure.

In a configuration that uses online edits, the Transaction Control Manager

service performs the duties of the FactoryTalk Transaction Manager service.

For more information on online edits, see Chapter 8, Understanding Online

Edits (page 111).

16

Figure 1: FactoryTalk Transaction Manager Functions (1)

Page 17

1 ●Welcome To FactoryTalk Transaction Manager

●

●

●

●

●

FactoryTalk Transaction Manager Service and Control

Connectors

The FactoryTalk Transaction Manager service is used to control and execute

FactoryTalk Transaction Manager transactions contained in configurations

created prior to CPR 7 or when you have a business reason to not run the

Transaction Control Manager service. For more information on how the

FactoryTalk Transaction Manager functions, see the following figure.

Figure 2: FactoryTalk Transaction Manager Functions (2)

17

Page 18

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Control Connectors

The FactoryTalk Transaction Manager service interfaces with the industrial

control system device via a control connector. A control connector is a

Microsoft Windows 2003/XP/Vista/2008 R2 service that collects data from

a controller and sends it to the FactoryTalk Transaction Manager service in

the FactoryTalk Transaction Manager. You can use the following types of

control connectors: FactoryTalk Live Data, DDE, RSLinx Classic OPC,

RSView32, and Generic OPC. Control connectors can be used to reference

data points, or memory locations within your control or shop floor system,

such as ―tags‖ from an RSView32 application.

Enterprise Connectors

The Transaction Control Manager service and the FactoryTalk Transaction

Manager service interface with enterprise systems such as databases via an

enterprise connector service. An enterprise connector is a Microsoft

Windows 2003/XP/Vista/2008 R2 service that transfers data between the

Transaction Control Manager service or the FactoryTalk Transaction

Manager service and a database. You can use the following types of

enterprise connectors: Open Database Connectivity (ODBC), Oracle Call

Interface (OCI), Microsoft OLE DB, Microsoft COM+, Time-series Data

Compression, and FactoryTalk Metrics. Enterprise connectors can be used

to create data objects that reference elements in your enterprise system, such

as tables or stored procedures.

Configuration Server

The Configuration Server is a Microsoft Windows 2003/XP/Vista/2008 R2

service that runs continuously to provide a single interface to the

configuration (.dat) files that make up the FactoryTalk Transaction Manager

configuration. The Configuration Server simplifies access to configuration

files by filtering all changes to the files and interfacing with other

FactoryTalk Transaction Manager services. A collection of all changes that

affect a configuration are recorded in an audit trail (via either FactoryTalk

Diagnostics or the Configuration Server *.log file). For more information,

see the FactoryTalk Transaction Manager online help.

18

Page 19

1 ●Welcome To FactoryTalk Transaction Manager

●

●

●

●

●

Transactions

FactoryTalk Transaction Manager creates transactions, or discrete

operations that transfer data from your control system to/from the enterprise

system. For example, a single transaction can download data from an Oracle

database, via a stored procedure, to tags in a ControlLogix processor.

Alternately, a transaction can send multiple data points from a distributed

control system to a Microsoft SQL Server database to be logged for

reporting. Transactions can be modified at runtime; for more information,

see Chapter 8, Understanding Online Edits (page 111).

The transaction model organizes the task of data management. FactoryTalk

Transaction Manager’s flexibility provides many options for customizing all

aspects of a transaction. The software can manage many transactions at

once, allowing for sophisticated manufacturing data collection and control

applications. Using the software, you can also monitor, modify, and enable

or disable individual transactions, making the development and

implementation of an application easier.

FactoryTalk

FactoryTalk is a manufacturing information platform that integrates

plant-wide control systems and connects the enterprise with the production

facility.

Integrate - FactoryTalk eliminates both functionality gaps and overlaps

by providing common services (such as diagnostics and access to

real-time data) and by sharing plant resources (such as tags and graphic

displays) throughout a production facility.

Communicate - FactoryTalk transforms plant-floor data into useful

information and delivers it to the people who need it, from maintenance

engineers to enterprise planners.

Collaborate - FactoryTalk allows defining plant-floor resources once,

and then allows simultaneous access to those resources across system

boundaries.

19

Page 20

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

FactoryTalk Services Platform Components

With each coordinated release, additional Rockwell Software products build

on the FactoryTalk platform and integrate more of the FactoryTalk

components. All of the FactoryTalk components install together as a

platform, integrated into each FactoryTalk-enabled product's install process.

The following sections discuss the FactoryTalk Services Platform

components.

FACTORYTALK DIRECTORY

FactoryTalk-enabled products use the FactoryTalk Directory to share a

common address book, which automatically finds and provides access to

plant-floor resources, such as data tags and graphic displays. Unlike a single

database, FactoryTalk Directory provides searchable references to resources

stored anywhere across an automation system, offering the benefits of

central data storage without the risk of a single point of failure. Changes

made to the automation system automatically update across all participants

in a FactoryTalk-enabled application.

FACTORYTALK LIVE DATA

FactoryTalk Live Data manages connections between FactoryTalk-enabled

products and data servers. It notifies clients when a connection is lost,

automatically reconnects, and combines data from multiple controllers and

servers into a single group with a single data server connection. This results

in faster real-time data transfer and more reliable, efficient connections to

data servers. It also assists in redundancy support for data servers by

automatically handling detection and failovers for all FactoryTalk-enabled

products.

FACTORYTALK ADMINISTRATION CONSOLE

The FactoryTalk Administration Console is a stand-alone tool that allows

you to configure and manage FactoryTalk-enabled applications.

20

Page 21

1 ●Welcome To FactoryTalk Transaction Manager

●

●

●

●

●

FACTORYTALK AUDIT AND FACTORYTALK DIAGNOSTICS

FactoryTalk Audit and FactoryTalk Diagnostics provides the ability to log

errors, warnings, and other status messages generated throughout a

FactoryTalk-enabled system to either local logs or a central location.

FACTORYTALK SECURITY

FactoryTalk Security is intended to improve the security of your automation

system by limiting access to those with a legitimate need. FactoryTalk

Security authenticates user identities and authorizes user requests to access a

FactoryTalk-enabled system. These security services are fully integrated

into the FactoryTalk Directory and are included as part of the FactoryTalk

Services Platform that installs with many Rockwell Software products.

FactoryTalk Security replaces all of the product-specific privilege

configuration that was available in previous releases of FactoryTalk

Transaction Manager. For more information about using FactoryTalk

Transaction Manager with FactoryTalk Security, refer to Appendix C,

Securing FactoryTalk Transaction Manager using FactoryTalk Security

(page 159).

Intended Audience

We assume that you are a control engineer or database administrator and that

you are familiar most of the following:

Intel personal computers

Microsoft Windows 2003/XP/Vista/2008 R2 operating systems

DDE or OPC servers (for example, RSLinx Classic or RSView32)

Configuration of database connections such as ODBC, OCI, or

Microsoft OLE DB

Microsoft COM+

RSLinx Enterprise

21

Page 22

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

FactoryTalk View SE

Where Can I Go For Help?

Our commitment to your success starts with the suite of learning aids and

assistance we provide with FactoryTalk Transaction Manager. Consult the

following resources for additional information:

Online help

Product manual

Training

Technical support

Online Help

The online help provides general overview information, comprehensive

step-by-step procedures, quick start topics, and context-sensitive control

definitions (for example, text boxes, drop-down lists, and option buttons) for

working with all of the features in FactoryTalk Transaction Manager. You

can view online help in FactoryTalk Transaction Manager by using any of

the following methods:

select Help > FactoryTalk Transaction Manager Help on the main

FactoryTalk Transaction Manager user interface.

click Help on any FactoryTalk Transaction Manager dialog box.

click the What's This? icon in the upper-right corner of a FactoryTalk

Product Manual

You can gain immediate access to product documentation by selecting Help

> Product Manuals > FactoryTalk Transaction Manager User Guide

from within FactoryTalk Transaction Manager. Throughout this document,

a number of style conventions are used to help identify material. File menu

22

Transaction Manager dialog box, then click any control to open a

definition of that control.

Page 23

1 ●Welcome To FactoryTalk Transaction Manager

●

●

●

●

●

paths are in bold with a (>) separating the entries (e.g., go to File > New);

text you are asked to type is shown in Courier Bold (e.g., in this field, type

Work Week), and button names are shown in bold (e.g., click OK).

Training

One of the best ways to increase your proficiency at using Rockwell

Software products is to attend Rockwell Software training programs. Our

training programs can help you master the basics and show you how to

unleash the full potential of our software.

We offer a wide range of training programs, from regularly scheduled

classes conducted at Rockwell Automation facilities to custom-tailored

classes conducted at your enterprise. The size of each class is kept small

intentionally to maximize student engagement.

If you would like more information about our training programs, visit the

Rockwell Software site on the World Wide Web or contact the Rockwell

Software Training Coordinator. Our World Wide Web address and

telephone numbers appear on the inside front cover of this document.

Technical Support

Rockwell Automation’s support team of outstanding professionals provides

top-notch technical support-monitoring and tracking your experience with

our products to pave the road to your success in understanding and

improving your factory performance.

Rockwell Automation provides full support for FactoryTalk Transaction

Manager. Questions concerning installation and the use of the software are

handled by the Rockwell Automation Customer Support Center, staffed

every day - except U.S. holidays - from 8 AM to 5 PM in your time zone for

calls originating within the U.S. and Canada.

To reach the Customer Support Center, call 1 (440) 646-3434 and follow the

prompts. For calls originating outside the U.S./Canada, locate the number in

your country by visiting http://www.rockwellautomation.com/locations.

23

Page 24

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Get Web Support

For web-based product support, and for detailed information on technical support

resources, please visit http://www.rockwellautomation.com/support/.

Access the Rockwell Automation Knowledge base for 24/7 technical

information and assistance. You can also download software patches and

new software versions, ask questions via email, participate in user forums,

and access other useful problem-solving tools.

The support resources available vary depending upon the product

purchased. The latest information can be obtained from the Rockwell

Automation Technical Support website.

A current TechConnect Support contract may be required to use some online

features.

Get Phone Support

To speak with a Technical Support representative in North America, call

1-440-646-3434.

For information on how to contact Technical Support in other locations

worldwide, please visit http://www.rockwellautomation.com/support/.

A current TechConnect Support contract may be required to obtain phone

support.

Get Consulting Services

Rockwell Automation provides expert consulting and turnkey

implementation of this product. Please contact your local representative for

more information.

Contact Us

We strive to help all of our customers become successful in their

manufacturing improvement efforts. Toward this objective, we invite you to

contact your local representative or Rockwell Automation at any time that

we may be of service to you.

24

Page 25

1 ●Welcome To FactoryTalk Transaction Manager

●

●

●

●

●

25

Page 26

Page 27

Chapter 2

Installing FactoryTalk Transaction Manager

Before You Begin

You should know about the following prerequisites before you install

FactoryTalk Transaction Manager:

hardware requirements

software requirements

software dependencies

activation

activation options

See the following sections for more information.

Hardware Requirements

To use FactoryTalk Transaction Manager v10.10 effectively, your personal

computer must meet the following hardware requirements:

Intel Pentium processor (1 GHz or faster recommended) - single, dual,

or quad processors.

512 MB of RAM recommended (or more based on application

requirements).

34 MB of free hard disk space (or more based on application

requirements).

CD-ROM compatible drive.

256-color VGA graphics adapter (1024 x 768 or greater resolution).

27

Page 28

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Software Requirements

To use FactoryTalk Transaction Manager v10.10 effectively, the software

installed on your server computer must meet the following minimum

requirements.

One of the supported operating systems:

Microsoft Windows XP (Service Pack 3)

Microsoft Windows Server 2003 R2 Standard Edition (Service

Pack 2)

Microsoft Windows Vista Business (Service Pack 2)

Microsoft Windows Server 2008 R2

In order to use control connectors, you need one or more of the

following:

DDE server and/or OPC server software.

If you use the RSView32 control connector, you must have

RSView32 v7.40.00 or later.

RSView32 is not supported on Windows Server 2008 R2.

RSLinx Classic must be configured to start as a Microsoft Windows service.

In order to use enterprise connectors, you need one or more of the

28

If you use the RSLinx Classic OPC control connector, you must

have RSLinx Classic v2.52.00 or later.

following:

If you use an ODBC enterprise connector, you must have ODBC

Manager and ODBC drivers version 2.x or later.

If you use an Oracle OCI enterprise connector, you must use one of

the following types of Oracle databases:

Page 29

2 ●Installing FactoryTalk Transaction Manager

●

●

●

●

●

Oracle 9i, with ODBC driver version 9.2.1.0, and Net client

driver version 9.2.0.1.0.

Oracle 10g, with ODBC driver version 10.2.0.1.0, and Net

client driver version 10.2.0.1.0.

Oracle 11g, with ODBC driver version 11.1.0.6.0, and Net

client driver version 11.1.0.6.0.

Oracle 10g and later supports all three types of client installations (Instant client,

Runtime and Administrator install).

Oracle databases created in version 10.2.0.1.0 and later are recommended. The use

of the Oracle ODBC drivers is not recommended.

If you use a Microsoft OLE DB enterprise connector, you must

have one of the following types of Microsoft SQL Server

databases:

SQL Server 2000 (Service Pack 4), with ODBC driver

SQLSRV32.DLL version 2000.85.1117.0

SQL Server 2005 (Service Pack 3), with ODBC driver

SQLSRV32.DLL version 2000.86.3959.0 and Net client

driver SQLNCLI.dll version 2005.90.4035.0.

SQL Server 2008 R2 with ODBC driver SQLSRV32.DLL

version 6.1.7600.16385 and Net client driver SQLNCLI.dll

version 2005.90.1399.0.

If you use Microsoft COM+, your Microsoft COM+ connector and

the FactoryTalk Transaction Manager configuration using it must

reside on a computer running one of the supported systems:

Microsoft Windows XP (Service Pack 3)

Microsoft Windows Server 2003 R2 Standard Edition (Service

Pack 2)

Microsoft Windows Vista Business (Service Pack 2)

29

Page 30

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Microsoft Windows Server 2008 R2

Microsoft COM+ objects must be built using Microsoft Developer Studio 6.0.

Microsoft Windows 2003/XP/Vista/2008 R2 simple TCP/IP services

must be configured.

Microsoft Data Access Components (MDAC) is updated to version 2.8

during the FactoryTalk Transaction Manager installation.

Minimum video resolution of 1024 x 768.

Software Compatibility

FactoryTalk Transaction Manager v10.10 has been tested, and is

compatible, with the latest Rockwell Software release of the following

products:

FactoryTalk Services Platform (v2.30.01)

FactoryTalk Activation (v3.30.00)

RSView32 (v7.50.00)

FactoryTalk View SE (v5.20.00)

RSLinx Enterprise (v5.30.00)

RSLinx Classic (v2.56.00)

Activation

Rockwell Software's Windows-based software products are copy protected

and require an activation key, located in an activation file, to run the

software.

FactoryTalk Transaction Manager v10.10 supports the following activation

tools:

FactoryTalk Activation: If you are a new user, you will need to

30

activate your software using FactoryTalk Activation.

Page 31

2 ●Installing FactoryTalk Transaction Manager

●

●

●

●

●

EvRSI activation: If you are a current user upgrading to FactoryTalk

Transaction Manager v10.10, your activation is already installed and

will be used automatically.

EvRSI activation will be replaced by FactoryTalk Activation in a future release. If you

are using EvRSI activation, please contact your local Rockwell Automation Sales

office or Technical Support for information on migrating your activations to

FactoryTalk Activation.

For Rockwell Automation Technical Support in the U.S. call 1 (440) 646-3434.

Outside the U.S. see http://www.rockwellautomation.com/locations.

When you launch FactoryTalk Transaction Manager, the software checks

for the activation file. If the system fails to detect the activation file, an error

is logged to FactoryTalk Diagnostics. Refer to the FactoryTalk Activation

online help for more information about diagnostic messages (go to

x:\Program Files\Common Files\Rockwell\Help\FTActivationEN.chm,

where x: is the drive where your Rockwell Software products are located).

FactoryTalk Transaction Manager software consists of several components.

The Transaction Control Manager service and the FactoryTalk Transaction

Manager service are copy protected, which means that you can run either of

these services on only one computer, per license, at a time. The Microsoft

COM+ enterprise application connector is also copy protected. If you have

FactoryTalk Transaction Manager Professional, you may install copies of

any of the other connectors on as many computers as necessary.

ACTIVATE USING FACTORYTALK ACTIVATION

FactoryTalk Activation provides a secure, software-based system for

activating Rockwell Software products and managing software activation

files. Activation files are generated and distributed via the Internet. If an

Internet connection is not available, activation file information can be

delivered via email, fax, or phone.

FactoryTalk Transaction Manager v10.10 supports floating, concurrent

activations.

31

Page 32

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

To activate your software using FactoryTalk Activation, first determine

your activation server/client configuration:

One or more activation servers, one or more clients. You will need

to run the FactoryTalk Activation Server software on the network

computer(s) that will act as the activation server(s). You will need to

run the FactoryTalk Activation Client software on each of the client

computers. Then you will direct the client computers to the activation

server computer.

Activation server/client on each computer. You will need to run the

FactoryTalk Activation Server software on this computer. This

computer will then act as both the activation server and client.

For more information, see the FactoryTalk Activation online help.

ACTIVATE USING EVRSI ACTIVATION

EvRSI activation relied on a physical master disk that used to be supplied

with the FactoryTalk Transaction Manager product. If you are a current user

upgrading to the latest release, your activation is already installed and will

be used automatically.

For more information about EvRSI activation, refer to the Activation Help

(COPYPROT.HLP) by selecting Help > Copy Protection or by clicking

Help on any of the EvMove or Reset dialog boxes.

GRACE PERIOD

In FactoryTalk Transaction Manager v10.10, the software supports a seven

day activation grace period when a valid activation is not found. During

grace period:

When a configuration is started following an operating system reboot, a

When a configuration is started from the software itself, you are

32

message is logged to the FactoryTalk Diagnostic log every four hours

until a valid activation is found.

prompted to confirm entry into grace period mode. Upon confirmation,

a message is logged to the FactoryTalk Diagnostic log every four hours

Page 33

2 ●Installing FactoryTalk Transaction Manager

●

●

●

●

●

on the computer running the Transaction Control Manager service or

FactoryTalk Transaction Manager service until a valid activation is

found.

FactoryTalk Transaction Manager can be started an unlimited number

of times. If the grace period ends and a valid activation has not been

found, you will no longer be able to start the software.

If FactoryTalk Transaction Manager is unable to successfully obtain valid activations

(for example, a network failure occurs), the software will attempt run in grace period

for up to seven days.

Activation Options

Activating FactoryTalk Transaction Manager software is determined by two

factors: whether the control and enterprise connectors can be distributed

among several computers and the maximum number of tags (data points)

that the Transaction Control Manager service or FactoryTalk Transaction

Manager service will support.

Please keep the following in mind about FactoryTalk Transaction Manager

activation:

FactoryTalk Transaction Manager previously was sold without a restriction on

the number of tags. Although this option is no longer available, customers who

own this version can continue without a tag restriction.

Each Microsoft COM+ connector must be installed on the same computer as

the Transaction Control Manager service or FactoryTalk Transaction Manager

service and requires a separate activation.

Any FactoryTalk Transaction Manager activation must be installed on the same

computer (when using EvRSI activation) or on either a centralized or local

activation server (when using FactoryTalk Activation) that will be running the

Transaction Control Manager service or the FactoryTalk Transaction Manager

service.

33

Page 34

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

FACTORYTALK TRANSACTION MANAGER LITE

This embedded version of FactoryTalk Transaction Manager supports data

collection for RSBizWare components and allows you to create transactions

in FactoryTalk Historian Classic and FactoryTalk Metrics, which can then

be executed by the FactoryTalk Transaction Manager services. While

FactoryTalk Transaction Manager Lite is similar to FactoryTalk Transaction

Manager Professional and FactoryTalk Transaction Manager Standard, it

only supports creating and modifying data points, data objects, and

transactions defined by other RSBizWare components. FactoryTalk

Transaction Manager Lite does not support custom transactions created

outside of the RSBizWare suite. To use custom transactions in addition to

RSBizWare transactions, a FactoryTalk Transaction Manager activation is

required.

FactoryTalk Transaction Manager Lite cannot be purchased separately and does not

require a separate activation. FactoryTalk Transaction Manager Lite does not run in

Demo mode.

FACTORYTALK TRANSACTION MANAGER DEMO

FactoryTalk Transaction Manager Demo cannot be purchased separately.

This embedded version of FactoryTalk Transaction Manager runs when no

activation is installed or the software is not already running under grace

period. FactoryTalk Transaction Manager Demo is limited to two hours and

10 tags.

FACTORYTALK TRANSACTION MANAGER TRIAL

This version of FactoryTalk Transaction Manager allows you to run a

configuration that includes 50 tags for a period of seven days. After seven

days, FactoryTalk Transaction Manager servers will be shut down; these

servers can be restarted. FactoryTalk Transaction Manager Trial is not

compatible with configurations containing transactions that were created by

FactoryTalk Historian Classic or FactoryTalk Metrics.

34

Page 35

2 ●Installing FactoryTalk Transaction Manager

●

●

●

●

●

Catalog Number:

Class:

Availability:

Tag Limit:

9356-PRO2400

Unlimited Professional (1)

No

Unlimited

9356-PRO2500

Large Professional

Yes

70000

9356-PRO2450

Large Professional

Yes

32000

9356-PRO2350

Medium Professional

Yes

5000

9356-PRO2300

Medium Professional

Yes

1500

9356-PRO2200

Small Professional

Yes

300

9356-PRO2100

Small Professional

Yes

150

9356-STD2400

Unlimited Standard

No

Unlimited

9356-STD2350

FactoryTalk Transaction

Manager Standard

Yes

5000

9356-STD2300

Large Standard

Yes

1500

9356-STD2200

Medium Standard

Yes

300

9356-STD2100

Small Standard

Yes

150

9356-SQLCOMPLS

Microsoft COM+ Connector

(1), (2)

Yes

N/A

An activation is required to run this version of FactoryTalk Transaction Manager. This

activation is available with RSView32 7.30.00 or later, and FactoryTalk ViewSE

5.00.00 or later.

SUMMARY

The table below shows the level of distribution and the maximum number of

tags supported for each FactoryTalk Transaction Manager activation.

The Availability column denotes sales availability (if the product is still for

sale). "No" denotes products that are no longer available for sale.

35

Page 36

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Catalog Number:

Class:

Availability:

Tag Limit:

N/A

Trial

Free (3)

50

N/A

Demo

Free

10

N/A

FactoryTalk Transaction

Manager Lite

Free (3)

N/A

(1) Used when the software enters grace period.

(2) Sold for use with FactoryTalk Transaction Manager Professional only.

(3) With the purchase of other Rockwell Software products.

Installing FactoryTalk Transaction Manager Software

FactoryTalk Transaction Manager is installed from the FactoryTalk

Transaction Manager CD-ROM or the RSBizWare CD-ROM.

To perform the installation tasks, you must have the Windows System

Administrator privilege, and your user account must be a member of the

local administrator user group.

If you install FactoryTalk Transaction Manager on a system running Microsoft

Windows 2003/XP/Vista/2008 R2 that has not previously run Microsoft Windows

Installer (MSI), you will have to reboot the computer once the FactoryTalk Services

Platform is installed. You may also have to reboot the computer at the end of the

installation.

To install FactoryTalk Transaction Manager software, complete the

following steps:

1. Log on to your system using an account with administrator privileges.

2. Shut down any other Rockwell Software applications and services.

3. If you are installing FactoryTalk Transaction Manager from the

FactoryTalk Transaction Manager CD-ROM, use autorun.exe or

36

Page 37

2 ●Installing FactoryTalk Transaction Manager

●

●

●

●

●

setup.exe. If you are installing FactoryTalk Transaction Manager from

the RSBizWare CD-ROM, FactoryTalk Transaction Manager installs

automatically with any other RSBizWare service.

4. After you have launched the FactoryTalk Transaction Manager

Welcome Page, click Required Steps. Click each of the following

options in the order specified below, to successfully install FactoryTalk

Transaction Manager.

1. Check Operating System - Verifies your operating system and its

compatibility with the current version of FactoryTalk Transaction

Manager.

2. Install Microsoft Internet Explorer - Installs Microsoft Internet

Explorer so that you can properly view the FactoryTalk

Transaction Manager online help files. Follow the instructions that

appear on the screen. If Microsoft Internet Explorer is already

installed, skip to step 4.3.

3. View Release Notes - Displays the Release Notes, allowing you to

learn more about the current version of FactoryTalk Transaction

Manager prior to installing the software.

4. Install FactoryTalk Services Platform - Installs the FactoryTalk

Services Platform on your computer. Follow the instructions that

appear on the screen.

At the end of the FactoryTalk Services Platform installation, the FactoryTalk Services

Platform Wizard appears. Follow the instructions that appear on the screen.

5. Install FactoryTalk Activation Client - Installs the FactoryTalk

Activation Client on your computer. Follow the instructions that

appear on the screen.

6. Install FactoryTalk Transaction Manager - Installs FactoryTalk

Transaction Manager on your computer. Follow the instructions

that appear on the screen.

37

Page 38

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

7. View “How to Activate Rockwell Software Products” -

Displays information on activating Rockwell Software products.

8. Check for Product Updates - Displays the FactoryTalk

Transaction Manager Product Updates page, outlining any

software updates that may be available after this version of the

software was released.

5. After you have completed all of the required steps of the FactoryTalk

Transaction Manager installation, either click Documentation and

Extras to display an optional page (which allows you to install Adobe

Acrobat Viewer, view the FactoryTalk Transaction Manager User

Guide, Release Notes, and other related documentation, display the

Application Trigger example, and launch the FactoryTalk Transaction

Manager Live Data Migration Tool), or proceed to step 6.

6. When you have finished installing the software, remove the

FactoryTalk Transaction Manager CD-ROM from the CD-ROM drive.

Store it in a safe place.

Distributed FactoryTalk Transaction Manager

Installations

You may want to run FactoryTalk Transaction Manager or its services on

more than one computer. To run the software in a distributed mode, it must

be installed on all computers that are referenced in a configuration. For more

information, see Distributed Configurations (page 133) in Chapter

9,Exploring Advanced Topics.

38

Page 39

2 ●Installing FactoryTalk Transaction Manager

●

●

●

●

●

39

Page 40

Page 41

Chapter 3

Exploring the FactoryTalk Transaction

Manager User Interface

Starting FactoryTalk Transaction Manager

To start FactoryTalk Transaction Manager, click Start on the Task bar, then

select Programs > Rockwell Software > FactoryTalk Transaction

Manager > FactoryTalk Transaction Manager.

41

Page 42

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Exploring the FactoryTalk Transaction Manager User

Interface

When you start FactoryTalk Transaction Manager for the first time (and if it

is the first Rockwell Software product run on your computer), you are

automatically logged on to FactoryTalk Security using your

Windows-linked user account information. The system graphic appears in

the right pane (or workspace) of the FactoryTalk Transaction Manager user

interface.

For more information on FactoryTalk Security, see Appendix C, Securing

FactoryTalk Transaction Manager with FactoryTalk Security (page 159).

To view the procedures for configuring and using FactoryTalk Transaction

Manager, select Help > Quick Start.

42

Figure 3: FactoryTalk Transaction Manager Functions (3)

Page 43

3 ●Exploring the FactoryTalk Transaction Manager User Interface

●

●

●

●

●

Item:

Description:

Restore

Restores the window to its former size after minimizing or maximizing it.

Move

Repositions the window on the desktop using the arrow keys on the keyboard.

Size

Resizes the window on the desktop using the arrow keys on the keyboard.

Minimize

Shrinks the window to an icon that is located on the task bar.

Maximize

Enlarges the window to occupy the entire screen.

Close

Exits the software.

The design elements on the main FactoryTalk Transaction Manager user

interface include:

Title bar

Menu bar

Toolbar

Configuration tree

Workspace

Status bar

Title Bar

The title bar shows the FactoryTalk Transaction Manager icon, the name of

the configuration or configuration server (depending on what is selected in

the configuration tree), the product name, and the Minimize, Maximize, and

Close buttons.

Figure 4: FactoryTalk Transaction Manager Title Bar

To view the Control Menu, click the FactoryTalk Transaction Manager icon

on the title bar. The following items appear on the control menu.

43

Page 44

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Menu Bar

You can access many features from the FactoryTalk Transaction Manager

menu bar. For a description of the available shortcuts, refer to Section

Toolbar (page 45) in this chapter.

Figure 5: FactoryTalk Transaction Manager Menu Bar

The Security menu allows you to log on or log off of FactoryTalk Security,

or view your FactoryTalk Security permissions on the current configuration

server. For more information on FactoryTalk Security, see Appendix C,

Securing FactoryTalk Transaction Manager with FactoryTalk Security

(page 159).

The Configuration menu allows you to create a new configuration, set or

change properties in a configuration, access the Configuration Checklist,

delete, backup, or restore a configuration, or stop or start a configuration.

The Define menu allows you to define a connector, data object, data points,

or a transaction. In addition, you can define options for error logging and

scheduled events.

The View menu allows you to view information about the currently defined

transaction. You can view diagnostic information about the configuration

that is currently running. You can also view error log files or the system

graphic. This option allows you to switch between large and small icons,

obtain a status update, or enable or disable the toolbar or status bar.

The Tools menu allows you to create a configuration report, verify the

selected configuration, or use wizards to create data logging, duplicate data

points, or duplicate transactions. You can also use this menu to set message

and log viewer options.

The Help menu provides assistance with using FactoryTalk Transaction

Manager. From the Index of the online help system, simply enter the name

of the topic for which you want to search for information. Click the Help

44

Page 45

3 ●Exploring the FactoryTalk Transaction Manager User Interface

●

●

●

●

●

Icon:

Description:

Creates a new FactoryTalk Transaction Manager configuration.

Displays the About FactoryTalk Transaction Manager dialog box.

Displays the online help for any design element (click this button and place

the cursor on any design element).

Starts the configuration or connector currently selected in the Configuration

tree. If the edit enabled configuration has pending edits, a message displays

prompting the user to ignore the pending edits and start the configuration

anyway.

Stops the configuration or connector currently selected in the Configuration

tree.

Assembles all data point and transaction pending edits in the edit enabled

configuration. For a detailed description of assembling pending edits, refer to

the chapter Understanding Online Edits (page 111).

Opens the Pending Edit Alerts dialog box. For a detailed description of

pending edit alerts, refer to the chapter Understanding Online Edits (page

111).

graphic on the toolbar, and then place the cursor on any design element on

the system graphic for more information. The Help menu also provides

specific links for viewing the release notes, a quick start, the online books,

an error code resource, support and training,. In addition, you can use this

option to obtain FactoryTalk Transaction Manager license and version

information.

Toolbar

The toolbar contains shortcuts to several commonly used FactoryTalk

Transaction Manager functions. Each button on the toolbar is a graphical

representation of a command that is also available from the FactoryTalk

Transaction Manager menu bar.

45

Page 46

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Icon:

Description:

Verifies the selected configuration. You can verify multiple transactions and

choose to save the results to a text file.

Displays information about the current transactions in the right pane of the

application workspace.

Displays diagnostic information about the configuration that is currently

running in the right pane of the application workspace.

Displays error log information in the right pane of the application workspace.

Displays the system graphic in the right pane.

Configuration Tree

The FactoryTalk Transaction Manager user interface is divided into two

panes. The left pane is known as the Configuration tree; it is a tree view of

the current configurations.

46

Page 47

3 ●Exploring the FactoryTalk Transaction Manager User Interface

●

●

●

●

●

If you see

this icon:

A configuration is...

A connector is...

running properly; all connectors in

that configuration are running

properly. All transactions start based

on the triggering rules that you

defined.

running properly.

The top level is the Configuration Server, named for the computer on which

it is running. The second level is the configuration name. The third level

displays the Transaction Control Manager service (if the configuration uses

online edits) or the FactoryTalk Transaction Manager service. The

Transaction Control Manager service or the FactoryTalk Transaction

Manager service are followed by the control connectors and enterprise

connectors defined for the configuration. For a detailed description of the

Transaction Control Manager service’s role in a configuration that uses

online edits, see Chapter 8, Understanding Online Edits (page 111).

Figure 6: FactoryTalk Transaction Manager Configuration Tree

CONFIGURATION AND CONNECTOR STATUS

The traffic lights in the Configuration tree represent the status of

FactoryTalk Transaction Manager connectors and configurations, turning

from red to green when services are started. See the following table to

determine how each icon applies to connectors and configurations.

47

Page 48

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

If you see

this icon:

A configuration is...

A connector is...

experiencing one or more connectors

that are not functioning properly

n/a (this state does not apply to a

connector).

stopped; all of the connectors are not

running. Additionally, the

Transaction Control Manager

service or the FactoryTalk

Transaction Manager service is not

running.

not running properly.

Icon:

Status:

Description:

Running

The configuration server host computer:

Resides in the FactoryTalk Administration Console.

Is working properly (the service is running and FactoryTalk

Transaction Manager can connect to it).

Has been configured in the FactoryTalk Administration

Console so that the current user has permissions (page 162)

to communicate with it.

Unknown

The configuration server host computer:

May or may not reside in the FactoryTalk Administration

Console.

Cannot be connected to or queried in FactoryTalk

Transaction Manager.

Cannot provide any information to FactoryTalk Transaction

CONFIGURATION SERVER STATUS

The icons that are displayed in the Configuration tree represent the status of

the configuration servers. The following table shows the status icons, state,

and a description of that state:

48

Page 49

3 ●Exploring the FactoryTalk Transaction Manager User Interface

●

●

●

●

●

Icon:

Status:

Description:

Manager so that the software can determine why it is not

working properly.

No privilege

The configuration server host computer:

Resides in the FactoryTalk Administration Console.

Is working properly.

User does not have permissions (page 162) to

communicate with the Configuration Server.

Workspace

The right pane of the FactoryTalk Transaction Manager user interface is the

workspace; it displays the Transaction Definition View, the Transaction

Monitor View, the Error Log Files View, or the FactoryTalk Transaction

Manager system graphic, depending on the view option that you have

selected. The Error Log File View is displayed below.

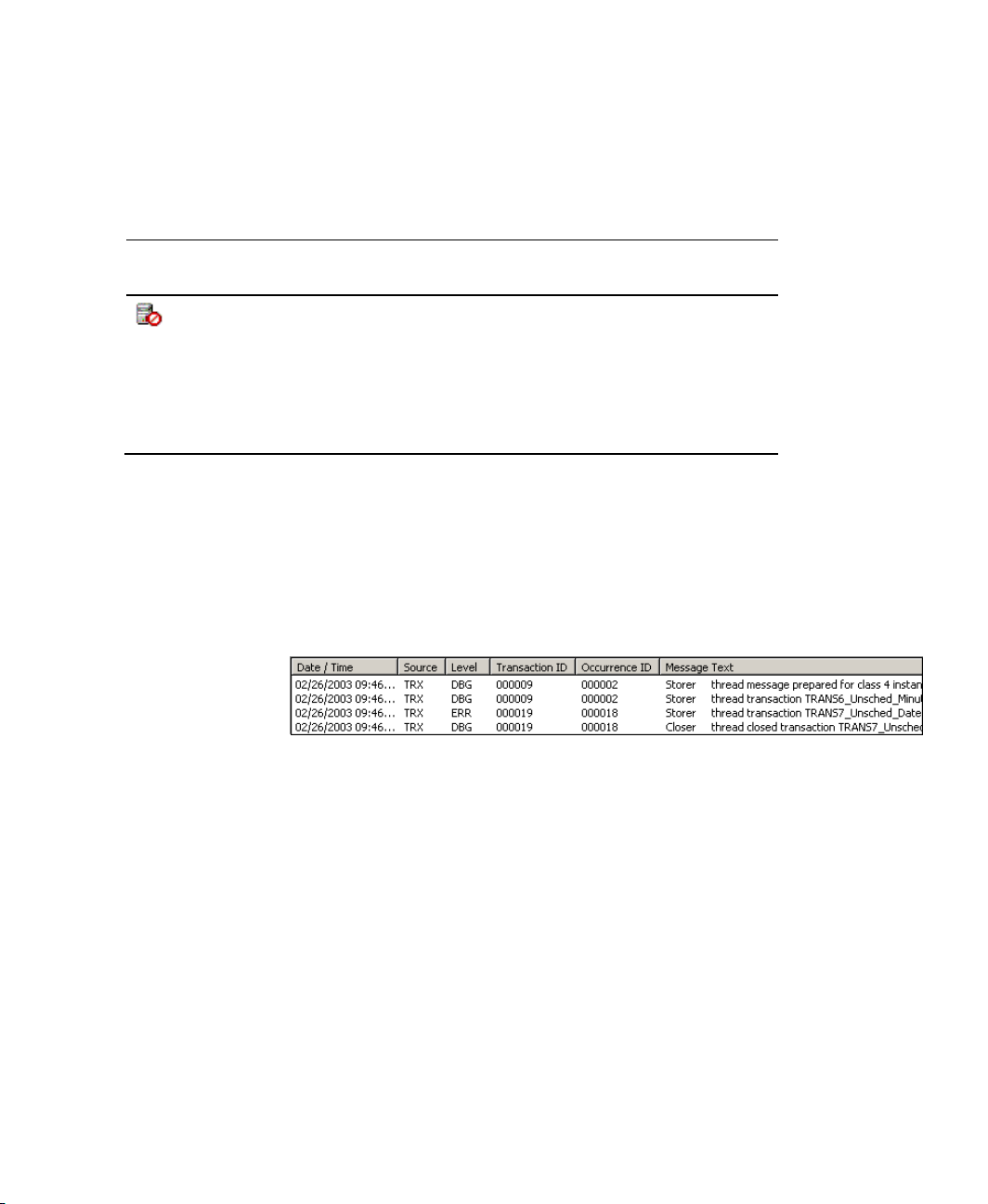

Figure 7: Error Log File View

TRANSACTION STATES

Transactions display in the Transaction Definition view. The states are

described below:

Current - The current definition of a transaction (with or without

pending edits).

Edit Pending - Changes that are made to the current transaction

definition, but not assembled.

Add Pending - A new transaction (created online), but not assembled.

49

Page 50

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

The following is an example Transaction Definition View.

Figure 8: Transaction Definition View

Status Bar

The status bar at the bottom of the main FactoryTalk Transaction Manager

user interface displays the following information:

Rows Selected (includes pending edits). The number of rows selected

before you saved, assembled or canceled pending edits.

Transactions Selected. The number of transactions selected.

Passed. The number of successful operations.

Disregarded. FactoryTalk Transaction Manager does not allow the

Failed. Operations that did not take place because of an internal error.

Configuration Checklist

A FactoryTalk Transaction Manager configuration consists of a set of

transactions that use control and enterprise connector elements required to

perform the transactions. You may create many configurations, but the

Transaction Control Manager service or the FactoryTalk Transaction

Manager service can run only one configuration at a time. Therefore, all the

50

action to be performed.

Page 51

3 ●Exploring the FactoryTalk Transaction Manager User Interface

●

●

●

●

●

transactions required to implement an application must be contained in a

single configuration.

Create a configuration using the Configuration Checklist, which lists the

required steps and displays the progress of your configuration. A green

check mark indicates a completed step, while a yellow check mark indicates

a partially completed step.

51

Page 52

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Select Configuration > Checklist or Configuration > New to begin using

the Configuration Checklist. The following figure shows the Configuration

Checklist:

This chapter is not intended to provide step-by-step directions for creating a

configuration, but to provide an overview to help you understand

configurations. The following sequence mimics the Configuration

52

Figure 9: FactoryTalk Transaction Manager Configuration Checklist

Page 53

3 ●Exploring the FactoryTalk Transaction Manager User Interface

●

●

●

●

●

Checklist. It is recommended, at least initially, that you follow this sequence

when creating configurations:

Define and name a new configuration.

Define control and enterprise connectors.

Define the data points that will be used in transactions.

Define the data objects that will be used in transactions.

Define transactions, which transfer data between data points, in the

control system and data objects.

Verify transactions.

The following sections provide additional details for each task in the

sequence. For more information, see the Quick Start in the FactoryTalk

Transaction Manager online help (select Help > Quick Start).

Step 1: Defining and Naming a New Configuration

To create a new configuration, enter a configuration name, and then click

Step 1 to open the FactoryTalk Transaction Manager Configuration dialog

box. Enter a name for the configuration and the directory path in which the

configuration (*.dat) files will reside. This directory becomes the default

location of the other files used in the configuration. Select the control and

enterprise connector service types to use in the configuration. To create a

distributed configuration, see Chapter 9, Exploring Advanced Topics (page

131).

Each configuration must have an unique name and directory path.

To create a configuration that uses online edits, you can select only the

FactoryTalk Live Data control connector. You may select any enterprise

connector. Make sure to select the Enable Online Edits check box. For more

information, see Chapter 8, Understanding Online Edits (page 111).

53

Page 54

●

●

●

●

●

FactoryTalk Transaction Manager User Guide

Step 2: Defining Connectors

To begin defining a connector, select the service to define from the

drop-down list of connector services. Click Step 2 to open the Connector

Definition dialog box. This dialog box allows you to configure

communication and security settings for the Microsoft Windows

2003/XP/Vista/2008 R2 services.

You can create multiple control or enterprise connectors in a configuration,

but you can create only one connector of each type on each host computer. A

FactoryTalk Transaction Manager Professional activation is required to

distribute connectors.

Only one instance of the Transaction Control Manager service or the FactoryTalk

Transaction Manager service can be used by a configuration.

The connector service uses the Microsoft Windows user name and password

assigned to the connector when it runs on the host computer.

In general, control connectors must run on the computer that contains the

data server to which they will communicate. This is not the case with some

OPC servers that support DCOM or OPC used in a FactoryTalk architecture.

After this step is complete (and you exit the Configuration Checklist), the

configuration displays in the Configuration tree. Click the plus sign next to a

configuration to expand it. Each connector service that is used by the

configuration displays. Individual control and enterprise connectors display

under the connector services. The Configuration tree displays all

configurations recognized by each registered configuration server.

Step 3: Defining Data Points

From the Configuration Checklist, define the data points in the control

system that you wish to use in a configuration. For more information about

data points, see Chapter 5, Defining Data Points (page 73). If you have

multiple control connectors, you must configure them individually. Select

the connector for which you wish to add or edit points, then click Step 3. In

a configuration that uses online edits, you can perform Step 3 on the

54

Page 55

3 ●Exploring the FactoryTalk Transaction Manager User Interface

●

●

●

●

●

Configuration Checklist while the configuration is running. For information

about distributing control connectors and remote browsing capabilities, see

Chapter 9, Exploring Advanced Topics (page 131).

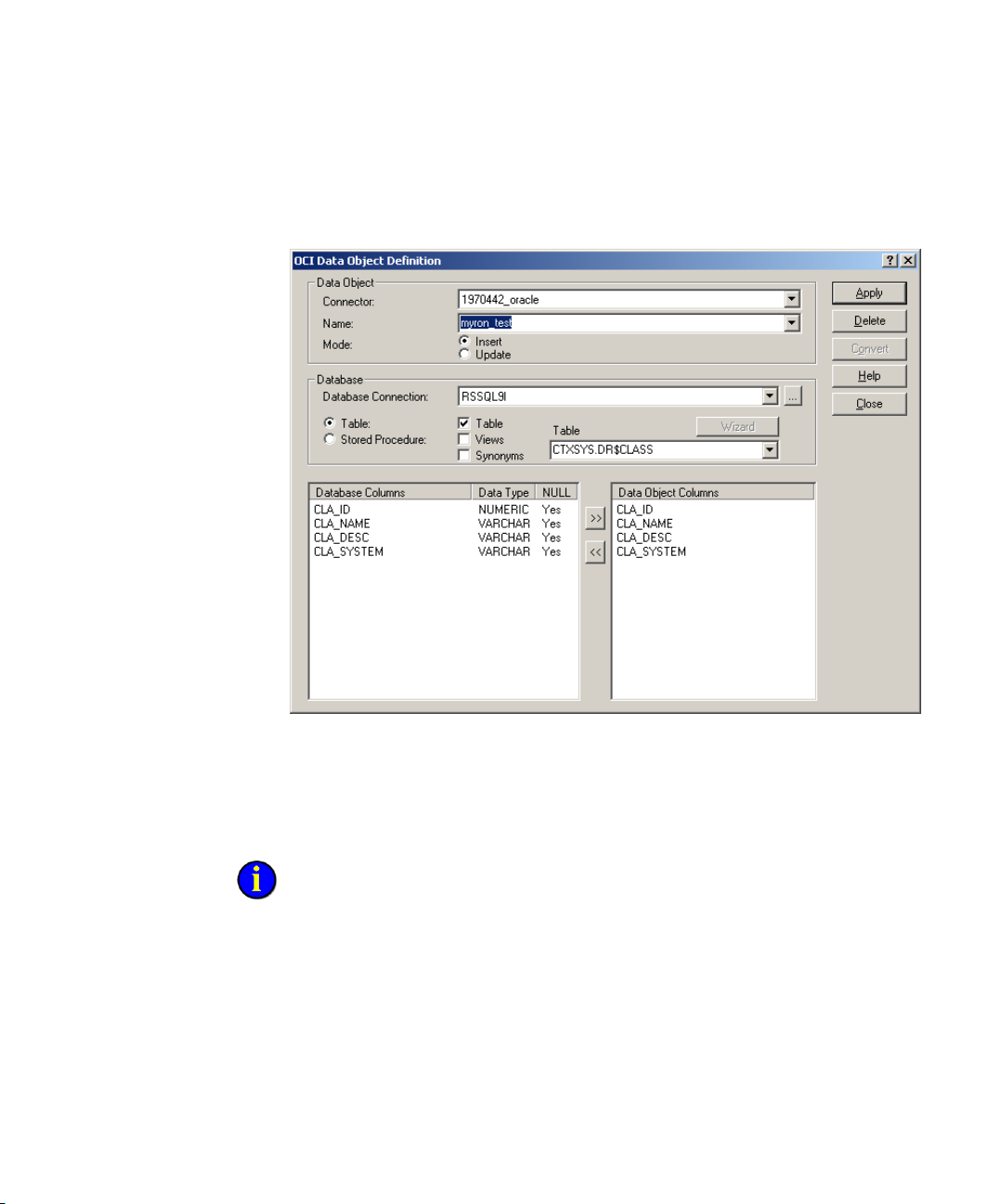

Step 4: Defining Data Objects

To begin defining a data object, select the enterprise connector to define

from the dropdown list. Click Step 4 to configure connections to the

database and create a data object. For more information about enterprise

connectors, see Chapter 6, Defining Data Objects (page 87).

From the Data Object Definition dialog box, select the table, view, or

connection (or appropriate enterprise object for your type of connector) to

configure the data object to use. Depending on the connector type, different

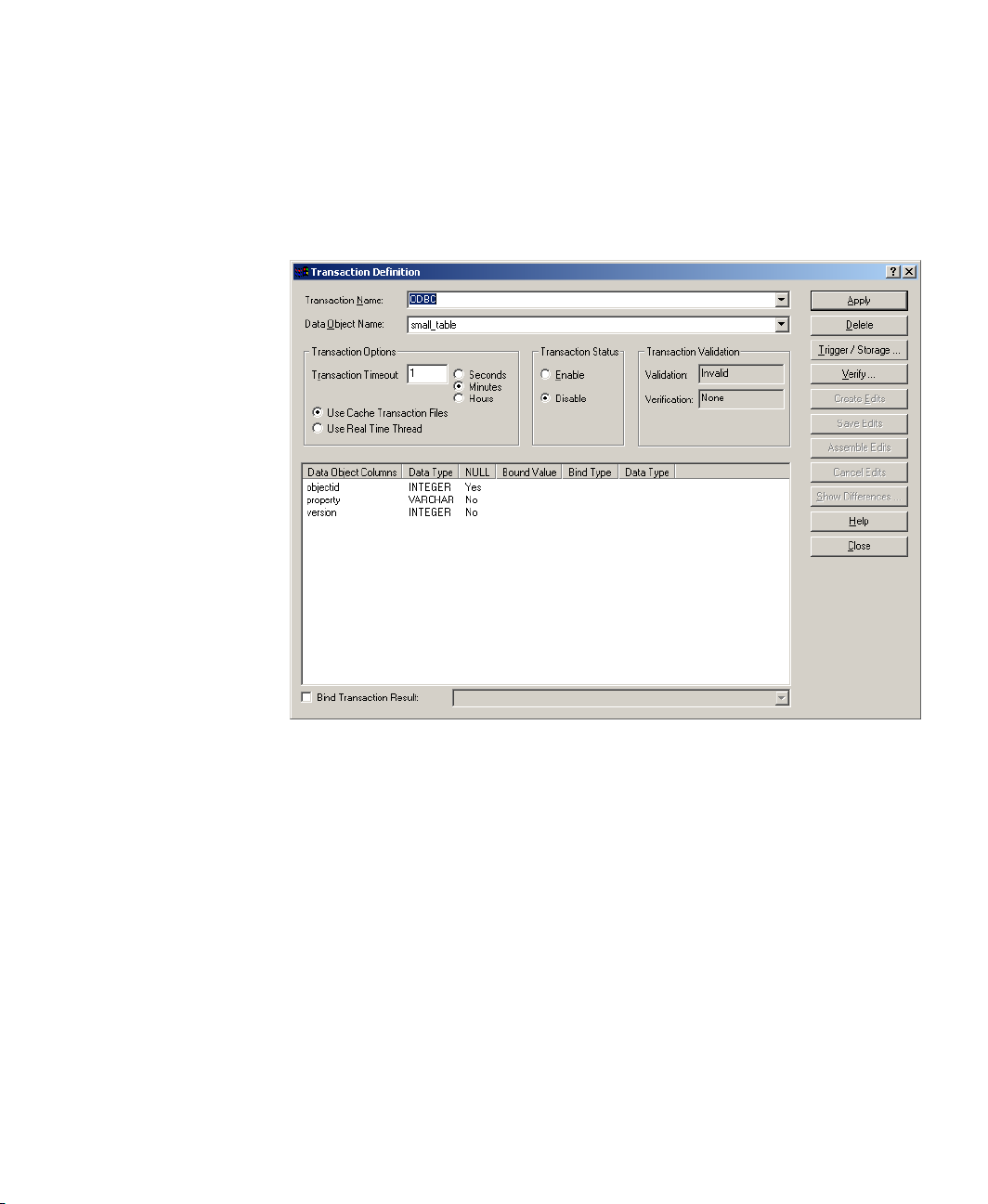

properties display, such as whether to insert or update the rows in the table