Page 1

Scheduler

Production Management

INTEGRATED PRODUCTION & PERFORMANCE SUITE

USER’S GUIDE

PUBLICATION SCHED-UM001F-EN-E–August 2007

Supersedes Publication SCHED-UM001E-EN-P

Page 2

Contact Rockwell

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support

Copyright Notice

Trademark Notices

Other Trademarks

Warranty

© 2007 Rockwell Automation Technologies, Inc. All rights reserved. Printed in USA.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation

Technologies, Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement for details.

The following logos and products are trademarks of Rockwell Automation, Inc.:

RSBizWare, FactoryTalk, FactoryTalk Activation, FactoryTalk Administration Console, FactoryTalk Automation

Platform, FactoryTalk Services Platform, RSBizWare PlantMetrics, FactoryTalk Metrics, FactoryTalk Scheduler,

RSSql, FactoryTalk Transaction Manager,

ActiveX, Microsoft, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows, Windows ME, Windows NT,

Windows 2000, Windows Server 2003, and Windows XP are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the

United States and/or other countries.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

This product is warranted in accordance with the product license. The product’s performance may be affected by system

configuration, the application being performed, operator control, maintenance and other related factors. Rockwell

Automation is not responsible for these intervening factors. The instructions in this document do not cover all the

details or variations in the equipment, procedure, or process described, nor do they provide directions for meeting every

possible contingency during installation, operation, or maintenance. This product’s implementation may vary among

users.

This document is current as of the time of release of the product; however, the accompanying software may have

changed since the release. Rockwell Automation, Inc. reserves the right to change any information contained in this

document or the software at anytime without prior notice. It is your responsibility to obtain the most current information

available from Rockwell when installing or using this product.

Version: 9.00.00 (CPR 9)

Modified: July 12, 2007 6:00 pm

ii

Page 3

Contents

1 • Welcome to FactoryTalk Scheduler 1

What is FactoryTalk Scheduler?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What is the benefit? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How is it designed?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Where do I begin?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation and startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Where can I go for help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Reference the user’s guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Get help online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Get phone support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Get Web support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Get on-site support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Get consulting services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contact us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 • The BizBikes Factory 7

Introducing BizBikes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How BizBikes are manufactured . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BizBikes business problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

How FactoryTalk Scheduler will help solve the BizBikes production problems. . . . . 8

Learn more about RSBizWare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 • The Factory Overview 11

The BizBikes manufacturing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bill of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The Manufacturing Resource Planning system . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The BizBikes manufacturing resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Process plans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Purchased components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Previously scheduled orders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 • Scheduling Features 23

Resource constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

iii

Page 4

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

Primary and additional resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Shift patterns and efficiency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Resource sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Simultaneous, Singular, and Infinite resource spanning . . . . . . . . . . . . . . . . . . . 25

Adjustable Pooled resource spanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Sequencing constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

The operation sequence numbering scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

The immediate successor operation(s) scheme . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Sequencing constraint examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Material constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fixture constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operation constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5 • Scheduling Concepts 39

Finite-capacity scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Algorithmic sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Forward sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Backward sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Bi-directional or bottleneck sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Algorithmic job selection rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Simulation-based sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Selection rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Types of rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sequencing rules: The key to good schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Operation selection rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Picking the correct rule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Predefined Job Preference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Minimum Job Tardiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Minimum Job Flow Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Maximum Facility Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Resource rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Summary of independent operation selection rules . . . . . . . . . . . . . . . . . . . . . . . 55

Summary of standard independent resource selection rules. . . . . . . . . . . . . . . . . 56

Summary of dependent selection rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Custom sequencing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6 • Using FactoryTalk Scheduler 59

Basic interactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Launch and save an application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

iv

Page 5

CONTENTS

Set the planning horizon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Attach a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Create the fcs file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Develop the shift or time patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Develop a schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

The Attributes window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

The Order Trace View window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Use operation overlap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Create named views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Unallocate and reallocate orders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Manually edit a schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

View the Project Pane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Evaluate a schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Performance metrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Schedule Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

FactoryTalk Scheduler reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7 • Schedule Analysis 87

• • • • •

Comparing different schedules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Forward scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Simulation scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Simulation setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Backward scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Bottleneck scheduling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Adding pooled resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Analysis summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Additional FactoryTalk Scheduler options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

A • Glossary 97

B • Process Plans 105

C • MRP Charts 111

SHP Red Bicycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

SHP Blue Bicycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

SSD Red Bicycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

SSD Blue Bicycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

SHP Red Finished Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

v

Page 6

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

SHP Blue Finished Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

SSD Red Finished Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SSD Blue Finished Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Handlebar Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Seat Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Pedal and Chain Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Derailleur Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Seat Post . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Handlebar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Neck Post . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

SHP Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

SSD Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

D • Time Pattern Editors 119

Time pattern types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Developing a time pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Developing exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Attaching a time pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Index 133

vi

Page 7

1

Welcome to FactoryTalk Scheduler

Welcome to FactoryTalk Scheduler, the state-of-the-art finite-capacity system that will

help you gain control of your production scheduling.

What is FactoryTalk Scheduler?

FactoryTalk Scheduler is a client/server application that is an integrated part of the RSBizWare product suite. FactoryTalk Scheduler allows you to generate a detailed, finitecapacity schedule that provides a view into the future. Through this tool, production

schedulers can identify and act on late orders; manage capacities and constraints, including labor and material; and identify the consequences of making changes, like expediting

orders. FactoryTalk Scheduler allows total resource management and, most importantly,

provides time to react to any unintended consequences.

What is the benefit?

FactoryTalk Scheduler considers all factors that reduce the ability of a production

resource to process, including shift patterns, labor/tooling/material availability, planned

maintenance, current loading, and capacities. In summary, FactoryTalk Scheduler

produces a more accurate and realistic schedule.

How is it designed?

FactoryTalk Scheduler was designed using all of the latest available software

technologies. The newest version of FactoryTalk Scheduler is written in Visual C++

Object Oriented Development. FactoryTalk Scheduler uses the ActiveX

(ADO) component of the Microsoft Data Access Components (MDAC) software

development kit to provide direct access to various database types. FactoryTalk Scheduler

provides direct connections to Microsoft SQL Server and Oracle databases. FactoryTalk

®

Scheduler has incorporated Crystal Reports

design and develop your own reports on top of the many standard reports that have

already been developed. FactoryTalk Scheduler was designed with a document-view

interface that makes it very easy for you to navigate through the screens.

for its report writer, which allows you to

®

Data Objects

®

with

Where do I begin?

You start by creating a model of the resource capacities and capabilities of a production

facility considering the scheduling objective(s) of the company. Once your model is

complete, you can select the algorithmic or simulation scheduling rules that best achieve

the defined objectives. FactoryTalk Scheduler is capable of importing product routings

and orders, from which it is simple to generate a detailed schedule. The last part allows

1

Page 8

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

you to check the schedule performance against the defined objectives and adjust the

schedule if necessary.

Since FactoryTalk Scheduler was designed to be highly configurable, your installation

may look somewhat different from the examples in this guide. The figures and dialogs

shown here are based on the tutorial example of a small manufacturing system (BizBikes,

Inc.) that produces bicycles, which is included with the FactoryTalk Scheduler software.

This example system was selected because it contains many of the key features that are

often used in a typical FactoryTalk Scheduler installation.

Intended audience

We assume that you are a manufacturing or production engineer/manager and are familiar

with the basic concepts and terms used in discrete manufacturing. You are interested in

predicting the performance of your factory or evaluating the impact of some proposed

changes. A familiarity with computers and the Microsoft

assumed. A familiarity with the concepts and terms used in simulation is also helpful.

Installation and startup

Before installing the software, we recommend that you review the product information

contained in the RSBizWare Administrator’s Guide. Then follow the step-by-step

procedures outlined in the guide (or referenced on the quick-start checklist card enclosed

in your package) to attain a successful installation and configuration of your software.

®

Windows® operating system is

The Administrator’s Guide also includes valuable information on hardware/software

requirements; reinstalling the software; activations, privileges, and permissions; and

installing and creating SQL Server databases.

Note: It is also important to review the Release Notes file located on the installation CD-ROM.

This file lists the hardware and software that is necessary to use the RSBizWare software

effectively, known issues and anomalies, and new features of the current release of the software.

Where can I go for help?

Our commitment to your success starts with the suite of learning aids and assistance we

provide with FactoryTalk Scheduler. Whether you’re new to finite-capacity scheduling or

a seasoned veteran putting a new tool to use, you’ll quickly feel at home with FactoryTalk

Scheduler.

Reference the user’s guides

Printed copies of the RSBizWare Administrator’s Guide and the FactoryTalk Scheduler

User’s Guide are distributed in the box with the software and an electronic copy of each

guide is available from the RSBizWare software installation CD-ROM or from the

2

Page 9

1 • WELCOME TO FACTORYTALK SCHEDULER

technical support group. Additionally, electronic copies of the FactoryTalk Scheduler

Customization Guide and the FactoryTalk Scheduler FDM Configuration Guide are

provided on the software CD-ROM.

• • • • •

RSBIZW

ARE ADMINISTRATOR’S GUIDE

The RSBizWare Administrator’s Guide is designed to help the administrator install and

configure the software and to understand the components that make up the RSBizWare

suite of products. The first chapter of the guide provides an overview of the software

components that make up the RSBizWare suite and describes the architecture on which

they are built. The remaining chapters describe the installation steps and the options you

have when deploying the RSBizWare software in your enterprise.

F

ACTORYTALK SCHEDULER USER’S GUIDE

The documentation set also includes the FactoryTalk Scheduler User’s Guide product

manual, which cover the product basics in easy, “click-by-click” tutorials that define and

demonstrate many of FactoryTalk Scheduler’s features.

D

OCUMENT CONVENTIONS

Throughout the guides, a number of style conventions are used to help identify material.

New terms and concepts may be emphasized by use of italics or bold; file menu paths are

in bold with a (>) separating the entries (e.g., go to File > New); text you are asked to type

is shown in Courier Bold (e.g., in this field, type Work Week), and dialog button names

are shown in bold (e.g., click OK).

Get help online

Online help is always at your fingertips! FactoryTalk Scheduler help incorporates general

overview information, comprehensive step-by-step procedures, and context-sensitive

control definitions (e.g., text boxes, drop-down lists, and option buttons) for working with

all of the software features. To view online help while running the FactoryTalk Scheduler

software:

select Help > FactoryTalk Scheduler Help from the FactoryTalk Scheduler main

menu for a full help listing,

click the Help button on any FactoryTalk Scheduler dialog to open help for that dialog

only,

click the Help button on the File toolbar, then click anywhere on the user interface to

receive help on that element, or

click the What’s This? icon in the upper-right corner of any FactoryTalk Scheduler

dialog, then on any control to receive a definition of that control.

3

Page 10

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

Get phone support

The Rockwell Automation support team of outstanding professionals provides top-notch

technical support—monitoring and tracking your experience with our products to pave the

road to your success in understanding and improving your factory performance.

Rockwell Automation provides full support for the entire RSBizWare suite of products,

which include FactoryTalk Historian Classic, FactoryTalk Metrics, FactoryTalk

Transaction Manager, FactoryTalk Scheduler. Questions concerning installation and the

use of the software are handled by the Rockwell Automation Customer Support Center,

staffed from 8

holidays—for calls originating within the U.S. and Canada.

To reach the Customer Support Center, call 1.440.646.3434 and follow the prompts. For

calls originating outside the U.S./Canada, locate the number in your country by linking to

support.rockwellautomation.com

presented from which you can locate the number to call inyour country.

W

HEN YOU CALL

When you call, you should be at your computer and prepared to give the following

information:

the product serial number and version number, which can be found in the client

software by selecting Help > About,

AM to 5 PM (in your time zone) Monday through Friday—except U.S.

and selecting the Phone/On-site link. A list will be

the type of hardware you are using,

the exact wording of any errors or messages that appeared on your screen

a description of what happened and what you were doing when the problem occurred,

and

a description of how you attempted to solve the problem.

Get Web support

In addition to phone support, the Rockwell Automation Customer Support Center offers

extensive online knowledgebases of tech notes and frequently asked questions for support

of non-urgent issues. These databases are updated daily by our support specialists.

To receive regular e-mail messages with links to the latest tech notes, software updates,

and firmware updates for the products that are of interest to you or to submit an online

support request, go to support.rockwellautomation.com

4

and select the Online link.

Page 11

1 • WELCOME TO FACTORYTALK SCHEDULER

Get on-site support

For on-site support, Rockwell Automation field support engineers are located around the

globe to provide assistance with special projects, unexpected problems, or emergency

situations. Field support engineers are available for dispatch 24x7x365 and can arrive at

many locations the same day.

To learn more about this and other support services, visit the Rockwell Automation Web

site at www.rockwellautomation.com/support

.

Get consulting services

Rockwell Automation provides expert consulting and turnkey implementation of the

RSBizWare suite. Please call your local Rockwell Automation representative for more

information.

Contact us

We strive to help all of our customers become successful in their manufacturing

improvement efforts. Toward this objective, we invite you to contact your local

representative or Rockwell Automation at any time that we may be of service to you.

Numbers for the support group are listed on the copyright page of this book.

• • • • •

5

Page 12

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

6

Page 13

2

The BizBikes Factory

Introducing BizBikes

This chapter describes a sample company, BizBikes Inc., whose

manufacturing system will be referred to in upcoming tutorial

chapters. BizBikes manufactures bicycles that are sold to

independent bicycle shops. The BizBikes factory was selected

because it contains representative key features of the RSBizWare

product suite, including FactoryTalk Historian Classic, FactoryTalk Metrics, FactoryTalk

Transaction Manager, and FactoryTalk Scheduler.

Roll up your sleeves and take a walk through the factory with us as we study the system

and how it operates. Let’s start by learning about the business environment, and then we’ll

spend some time getting familiar with the manufacturing process.

How BizBikes are manufactured

BizBikes produces bicycles in two different styles (Standard (SSD) and High Performance (SHP)) and in two different colors (red and blue). With the exception of the frames,

the two models and color variations use all the same manufactured and purchased components.

The BizBikes manufacturing facility can be broken into these logical areas:

Machining and Fabrication

Paint Shop

Subassembly

Final Assembly and Ship

There are also two Original Equipment Manufacturers (OEMs) resident on the BizBikes

campus who manufacture sprockets and seats. These finished goods are supplied to

BizBikes for final assembly.

In the machining and fabrication area, BizBikes manufactures the frames, seat posts,

handlebars, and neck post. These component parts are produced by processing raw

material through a series of work cells that cut, bend, machine, weld, and finish

components. After parts complete the machining and fabrication steps, the frames are

batched and sent to the paint shop, and the other component parts go into inventory where

they can be pulled from stock as needed to meet demand in the assembly area. In the next

stage, each bicycle is assembled based on customer order requirements with parts and

subassemblies (both manufactured and purchased) supplied from inventory. In the last

step, the bicycle (with its wheels and handlebar removed) is packed in a corrugated box

and shipped.

7

Page 14

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

BizBikes business problems

BizBikes has been losing market share to competitors due to both pricing pressure and

problems with on-time delivery. Business conditions have forced a transition from maketo-stock to make-to-order, and the bicycle shops that receive the goods are complaining

about frequent late deliveries. Thin margins and decrease in market share have produced

losses for the past two quarters. A task force was set up to analyze the problem and to

recommend a solution that will improve key performance indicators, such as lowering our

manufacturing costs, shortening our production time, and improving our on-time delivery.

Challenges:

Must quote accurately and meet delivery dates

Compete with competitor information and alternative suppliers that are readily

accessible via Internet

Must provide accurate, up-to-the-minute information on order and shop-floor resource

status to the rest of the organization

Critical to monitor, analyze, and improve the manufacturing processes through up-to-

date software and information technology

Must drive down the cost of manufacturing while maximizing resource utilization and

machine uptime

How FactoryTalk Scheduler will help solve the BizBikes production problems

Through FactoryTalk Scheduler’s finite-capacity scheduling strategies and simulationbased scheduling, the management and shop-floor teams at BizBikes now perform “whatif” analyses of the production sequences in a fraction of the time they previously spent.

Implementing FactoryTalk Scheduler in their “toolbox” allows for the generation of

realistic production scenarios that show the effects of schedule changes, maintenance

downtimes, tooling, shifts, and other key factors that determine the factory capacity and

delivery times. In minutes, FactoryTalk Scheduler generates production schedules that

used to take hours, so the teams spend their time managing the bicycle orders, not

calculating capacity.

And with FactoryTalk Scheduler’s accurate representation of the system and its operation,

the teams at BizBikes can constantly monitor the factory’s performance and make timely

decisions to increase throughput and cut the WIP, overtime, and on-hand inventory.

In the next chapter, we’ll take a look at the impact of FactoryTalk Scheduler in the

BizBikes factory by first examining their manufacturing system.

8

Page 15

Learn more about RSBizWare

See how RSBizWare solutions impact the BizBikes manufacturing system by visiting

www.software.rockwell.com/bizbikes/

For more comprehensive product information and to view application profiles of actual

companies’ successes, be sure to visit the RSBizWare Web site at

www.software.rockwell.com/rsbizware/

• • • • •

2 • THE BIZBIKES FACTORY

.

.

9

Page 16

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

10

Page 17

3

The Factory Overview

The BizBikes manufacturing system

To begin our assessment of the BizBikes factory, we’ll first examine their manufacturing

system and learn about the factory resources and processes. We will then use this model to

examine possible scenarios for improving our performance.

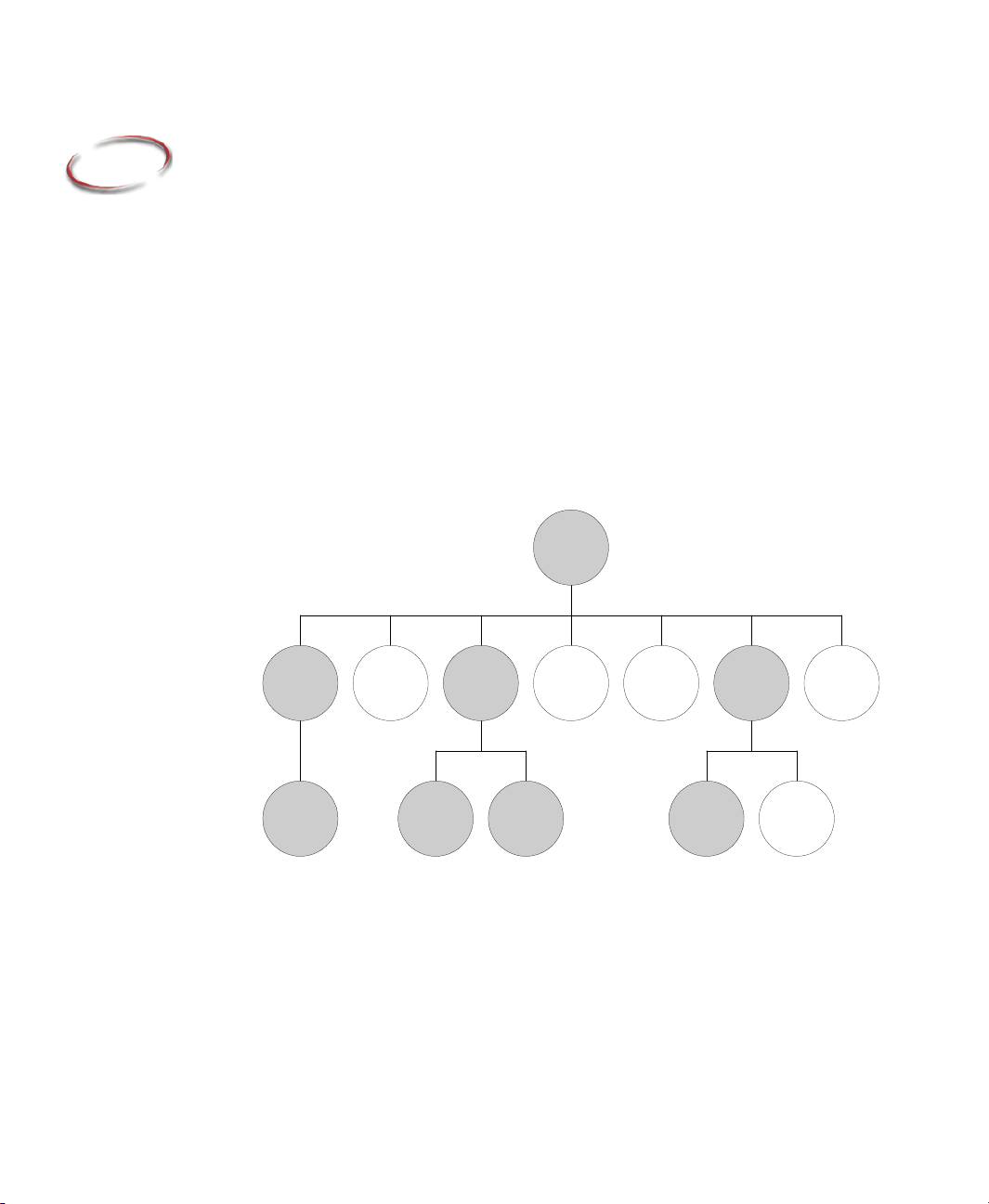

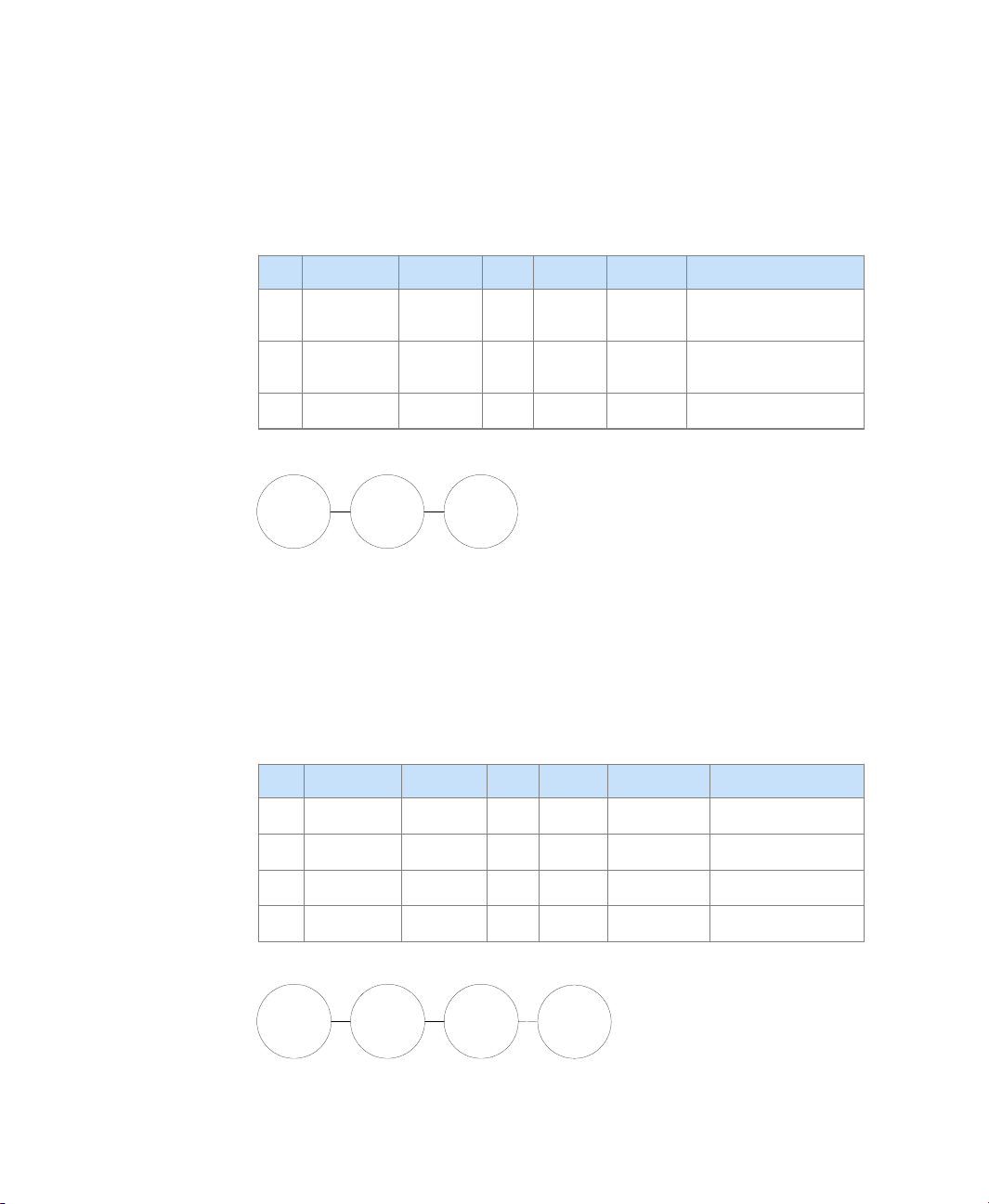

Bill of materials

The bill of materials for BizBikes contains three levels, as shown below, for a generic end

item. There are actually four end items (or BizBikes), 15 unique manufactured items, and

five purchased parts. The shaded items in the bill of materials represent manufactured

components. This generic bill of materials also includes information on manufacturing

lead times, number required per subassembly, and lot size information.

FINAL

ASSEMBLY

AND PACK

(1,1,1)

FINISHED

FRAME

(1,1,24)

FRAME

(4,1,50)

KEY: (Lead Time, Quantity, Lot Size)

PEDAL AND

CHAIN

ASSEMBLY

(3,1,60)

HANDLEBAR

(3,1,100)

HANDLEBAR

ASSEMBLY

(1,1,75)

NECK POST

(3,1,60)

WHEELS

(3,1,48)

DERAILLEUR

ASSEMBLY

(4,1,60)

SEAT POST

(3,1,100)

SEAT

ASSEMBLY

(1,1,75)

SEAT

(2,1,100)

BRAKES

(2,1,75)

The Manufacturing Resource Planning system

BizBikes employs a Manufacturing Resource Planning (MRP) system that performs

master planning and scheduling of weekly production. The MRP system consolidates

orders from multiple customers and plans the purchase and manufacturing of the

associated components. The MRP produces a set of manufacturing orders that are

released to the factory floor. These manufacturing orders are for both component parts

11

Page 18

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

(frames, handlebars, etc.) as well as final assemblies. The components are produced tostock and are consumed during the subassembly and the final assembly and pack of a

bicycle. The MRP also nets together purchased components across multiple customer

orders. The MRP netting operation generates purchase requests for component parts

(brakes, wheels, seats, etc.) based on economic order quantities and lead times. The MRP

system also plans out and issues purchase requests for materials consumed in

manufacturing component parts. The purchase requests for both component parts and raw

materials are issued to suppliers who then ship these components to our factory. In the

final assembly, we combine the manufactured and purchased components into a bicycle,

which is then packed and shipped to the customer.

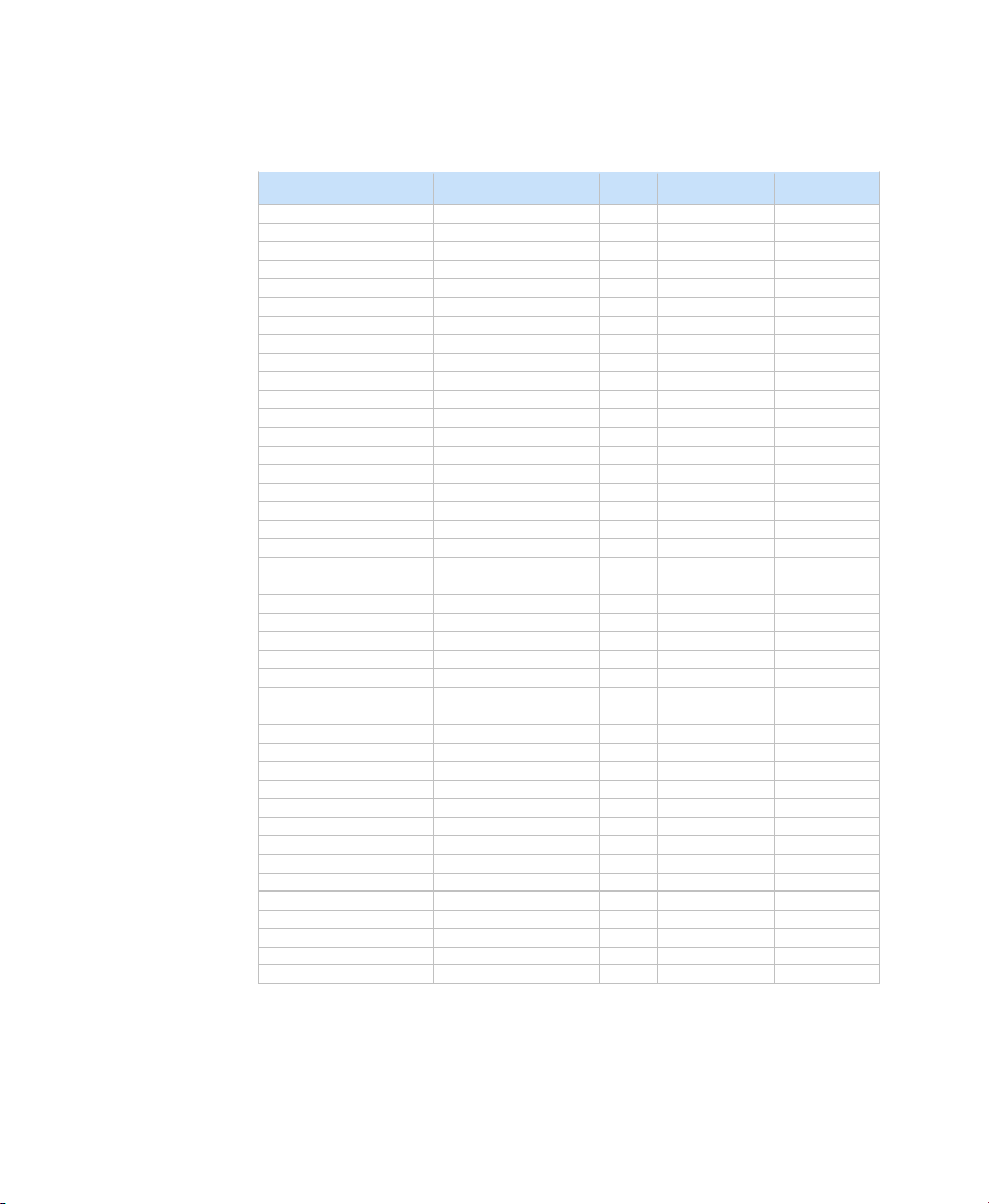

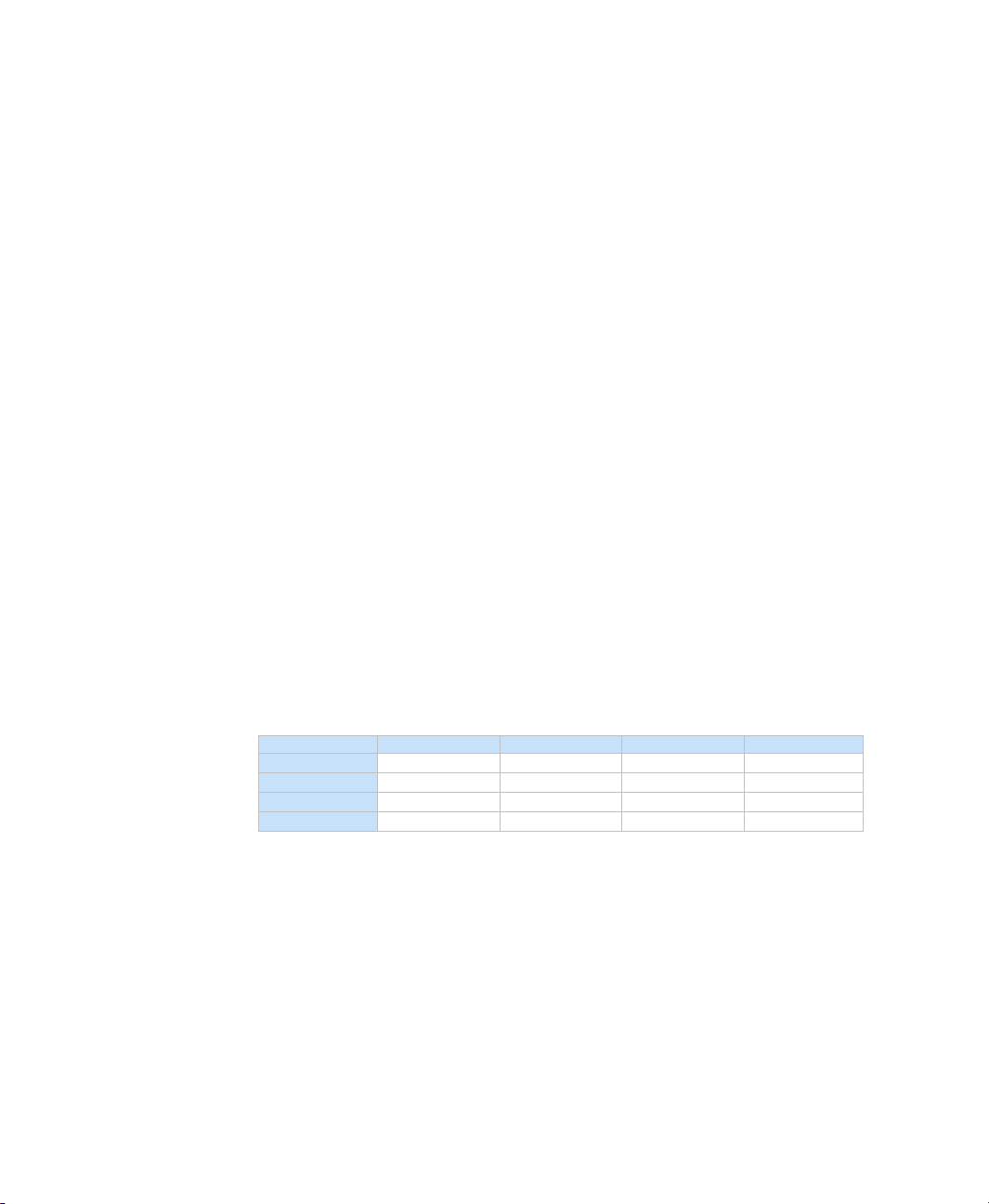

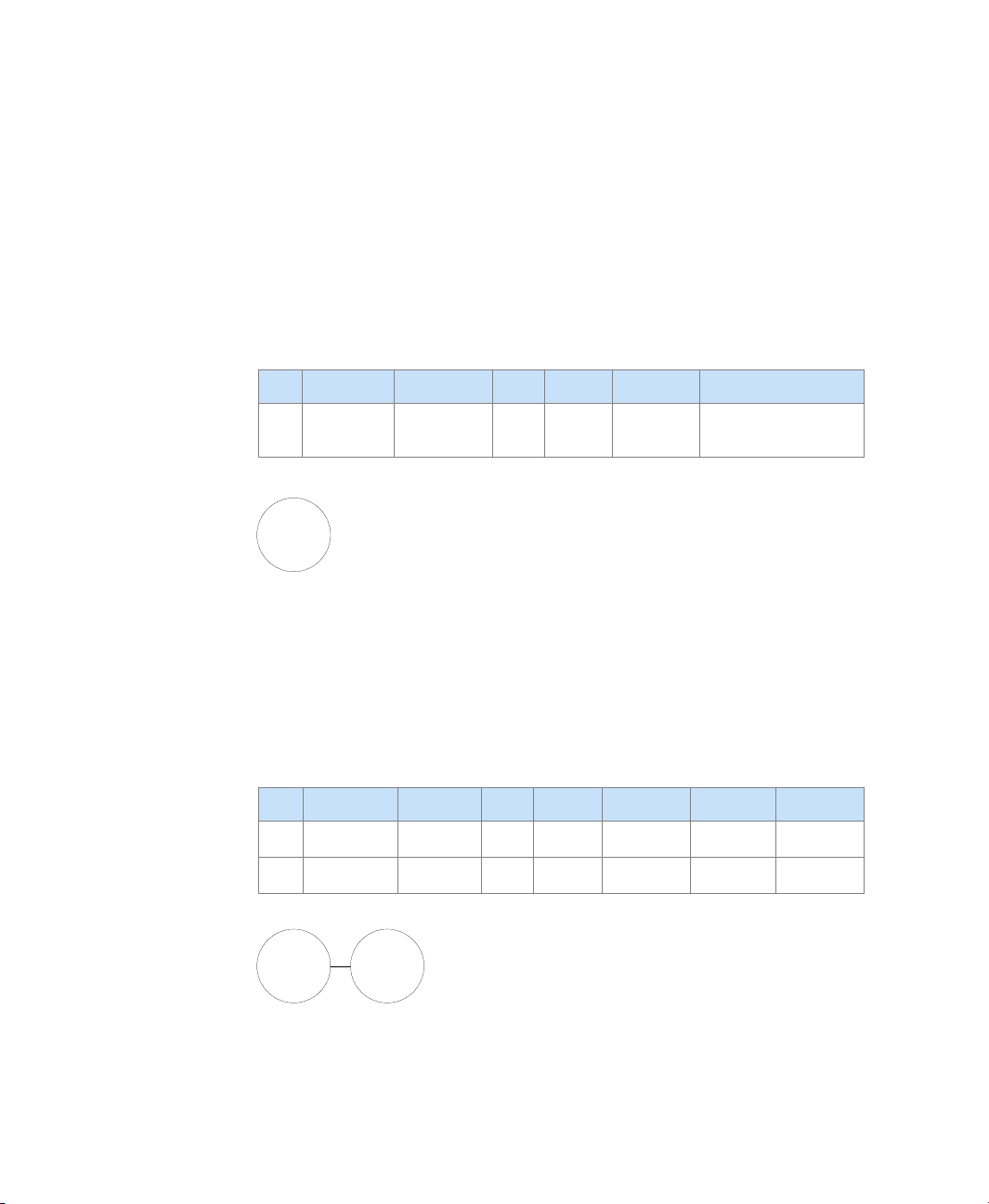

The following table shows production requirements for a typical ten-day period. These

manufacturing orders have been downloaded from the MRP and include orders for SHP

and SSD bicycles in both red and blue, along with MRP-generated orders for components

required during assembly. The 70 manufacturing orders include 33 orders for finished

BizBikes, 25 subassemblies, and 12 component parts.

12

Page 19

3 • THE FACTORY OVERVIEW

• • • • •

Order # Product Name

SHP Red 1 SHP Red Bicycle 15 2/11/03 11 PM 2/12/03 11 PM

SHP Red 2 SHP Red Bicycle 9 2/12/03 11 PM 2/13/03 11 PM

SHP Red 3 SHP Red Bicycle 8 2/13/03 11 PM 2/14/03 11 PM

SHP Red 4 SHP Red Bicycle 12 2/14/03 11 PM 2/17/03 11 PM

SHP Red 5 SHP Red Bicycle 17 2/17/03 11 PM 2/18/03 11 PM

SHP Red 6 SHP Red Bicycle 20 2/18/03 11 PM 2/19/03 11 PM

SHP Red 7 SHP Red Bicycle 9 2/19/03 11 PM 2/20/03 11 PM

SHP Red 8 SHP Red Bicycle 7 2/20/03 11 PM 2/21/03 11 PM

SHP Blue 1 SHP Blue Bicycle 11 2/10/03 11 PM 2/11/03 11 PM

SHP Blue 2 SHP Blue Bicycle 6 2/11/03 11 PM 2/12/03 11 PM

SHP Blue 3 SHP Blue Bicycle 4 2/12/03 11 PM 2/13/03 11 PM

SHP Blue 4 SHP Blue Bicycle 14 2/13/03 11 PM 2/14/03 11 PM

SHP Blue 5 SHP Blue Bicycle 11 2/14/03 11 PM 2/17/03 11 PM

SHP Blue 6 SHP Blue Bicycle 16 2/17/03 11 PM 2/18/03 11 PM

SHP Blue 7 SHP Blue Bicycle 8 2/18/03 11 PM 2/19/03 11 PM

SHP Blue 8 SHP Blue Bicycle 6 2/19/03 11 PM 2/20/03 11 PM

SHP Blue 9 SHP Blue Bicycle 15 2/20/03 11 PM 2/21/03 11 PM

SSD Red 1 SSD Red Bicycle 11 2/10/03 11 PM 2/11/03 11 PM

SSD Red 2 SSD Red Bicycle 9 2/11/03 11 PM 2/12/03 11 PM

SSD Red 3 SSD Red Bicycle 8 2/12/03 11 PM 2/13/03 11 PM

SSD Red 4 SSD Red Bicycle 14 2/13/03 11 PM 2/14/03 11 PM

SSD Red 5 SSD Red Bicycle 12 2/17/03 11 PM 2/18/03 11 PM

SSD Red 6 SSD Red Bicycle 7 2/18/03 11 PM 2/19/03 11 PM

SSD Red 7 SSD Red Bicycle 6 2/19/03 11 PM 2/20/03 11 PM

SSD Red 8 SSD Red Bicycle 12 2/20/03 11 PM 2/21/03 11 PM

SSD Blue 1 SSD Blue Bicycle 5 2/11/03 11 PM 2/12/03 11 PM

SSD Blue 2 SSD Blue Bicycle 16 2/12/03 11 PM 2/13/03 11 PM

SSD Blue 3 SSD Blue Bicycle 9 2/13/03 11 PM 2/14/03 11 PM

SSD Blue 4 SSD Blue Bicycle 12 2/14/03 11 PM 2/17/03 11 PM

SSD Blue 5 SSD Blue Bicycle 8 2/17/03 11 PM 2/18/03 11 PM

SSD Blue 6 SSD Blue Bicycle 13 2/18/03 11 PM 2/19/03 11 PM

SSD Blue 7 SSD Blue Bicycle 18 2/19/03 11 PM 2/20/03 11 PM

SSD Blue 8 SSD Blue Bicycle 15 2/20/03 11 PM 2/21/03 11 PM

SHP Red Finished Frame 1 SHP Red Finished Frame 24 2/10/03 11 PM 2/11/03 11 PM

SHP Red Finished Frame 2 SHP Red Finished Frame 24 2/13/03 11 PM 2/14/03 11 PM

SHP Red Finished Frame 3 SHP Red Finished Frame 24 2/14/03 11 PM 2/17/03 11 PM

SHP Red Finished Frame 4 SHP Red Finished Frame 24 2/17/03 11 PM 2/18/03 11 PM

SHP Blue Finished Frame 1 SHP Blue Finished Frame 24 2/10/03 11 PM 2/11/03 11 PM

SHP Blue Finished Frame 2 SHP Blue Finished Frame 24 2/13/03 11 PM 2/14/03 11 PM

SHP Blue Finished Frame 3 SHP Blue Finished Frame 24 2/17/03 11 PM 2/18/03 11 PM

SHP Blue Finished Frame 4 SHP Blue Finished Frame 24 2/19/03 11 PM 2/20/03 11 PM

SSD Red Finished Frame 1 SSD Red Finished Frame 24 2/10/03 11 PM 2/11/03 11 PM

Order

Quantity Release Date Due Date

13

Page 20

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

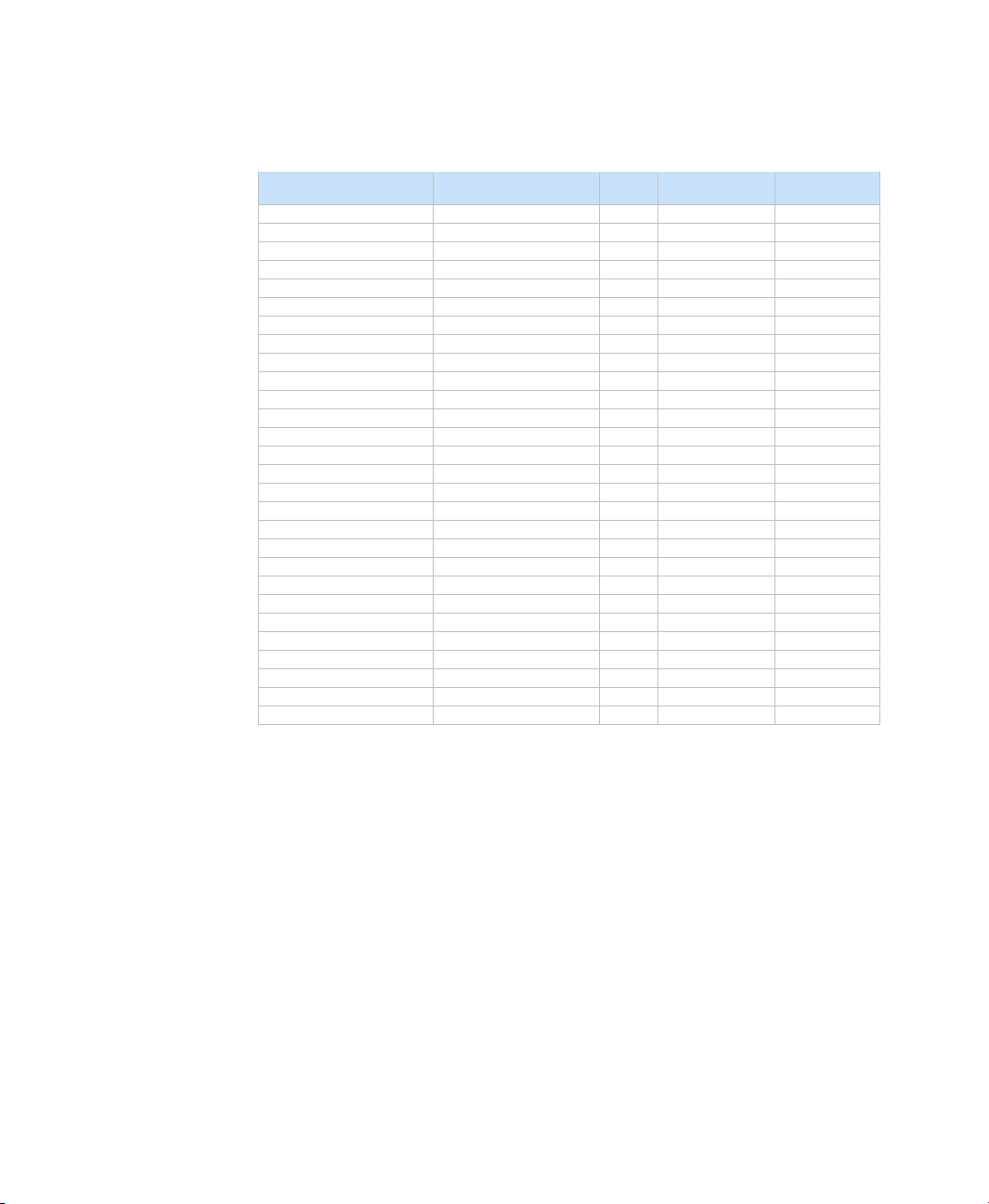

Order # Product Name

SSD Red Finished Frame 2 SSD Red Finished Frame 24 2/12/03 11 PM 2/13/03 11 PM

SSD Red Finished Frame 3 SSD Red Finished Frame 24 2/18/03 11 PM 2/19/03 11 PM

SSD Blue Finished Frame 1 SSD Red Finished Frame 24 2/11/03 11 PM 2/12/03 11 PM

SSD Blue Finished Frame 2 SSD Blue Finished Frame 24 2/13/03 11 PM 2/14/03 11 PM

SSD Blue Finished Frame 3 SSD Blue Finished Frame 24 2/17/03 11 PM 2/18/03 11 PM

SSD Blue Finished Frame 4 SSD Blue Finished Frame 24 2/18/03 11 PM 2/18/03 11 PM

Handlebar Assembly 1 Handlebar Assembly 75 2/10/03 11 PM 2/11/03 11 PM

Handlebar Assembly 2 Handlebar Assembly 75 2/12/03 11 PM 2/13/03 11 PM

Handlebar Assembly 3 Handlebar Assembly 75 2/14/03 11 PM 2/17/03 11 PM

Handlebar Assembly 4 Handlebar Assembly 75 2/17/03 11 PM 2/18/03 11 PM

Handlebar Assembly 5 Handlebar Assembly 75 2/19/03 11 PM 2/20/03 11 PM

Seat Assembly 1 Seat Assembly 75 2/10/03 11 PM 2/11/03 11 PM

Seat Assembly 2 Seat Assembly 75 2/12/03 11 PM 2/13/03 11 PM

Seat Assembly 3 Seat Assembly 75 2/14/03 11 PM 2/17/03 11 PM

Seat Assembly 4 Seat Assembly 75 2/17/03 11 PM 2/18/03 11 PM

Seat Assembly 5 Seat Assembly 75 2/19/03 11 PM 2/20/03 11 PM

Handlebar 1 Handlebar 100 2/11/03 11 PM 2/14/03 11 PM

Handlebar 2 Handlebar 100 2/12/03 11 PM 2/17/03 11 PM

Handlebar 3 Handlebar 100 2/14/03 11 PM 2/19/03 11 PM

Neck Post 1 Neck Post 60 2/11/03 11 PM 2/14/03 11 PM

Neck Post 2 Neck Post 120 2/12/03 11 PM 2/17/03 11 PM

Neck Post 3 Neck Post 60 2/14/03 11 PM 2/19/03 11 PM

SHP Frame 1 SHP Frame 50 2/10/03 11 PM 2/14/03 11 PM

SHP Frame 2 SHP Frame 50 2/11/03 11 PM 2/17/03 11 PM

SSD Frame 1 SSD Frame 50 2/11/03 11 PM 2/17/03 11 PM

SSD Frame 2 SSD Frame 50 2/12/03 11 PM 2/18/03 11 PM

Seat Post 1 Seat Post 100 2/12/03 11 PM 2/17/03 11 PM

Seat Post 2 Seat Post 100 2/14/03 11 PM 2/19/03 11 PM

Order

Quantity Release Date Due Date

14

The BizBikes manufacturing resources

The BizBikes manufacturing plant contains seven work cells (Cut, Machine, Bend, Weld,

Finish, two Subassembly areas, and two Assembly and Pack areas), and a three-person

labor pool per shift (labor required by Subassembly and Assembly and Pack). All work

cells and labor are available for two eight-hour shifts, five days a week (a 2/5 composite

shift pattern). The first shift starts at 7

and ends at 11

PM. There are no scheduled breaks in either shift. The key differences for

the processes at the various work cells are summarized below. Keep in mind that all setup

and process durations are expressed in hours.

AM and ends at 3 PM. The second shift starts at 3 PM

Page 21

3 • THE FACTORY OVERVIEW

A

SSEMBLY AND PACK

These work cells are used to assemble and pack the finished BizBikes. The setup and

process (per item) durations are part dependent. Each assembly operation requires two

labor units from the labor pool for its entire duration.

S

UBASSEMBLY

These work cells are used to assemble component parts (manufactured and purchased)

into subassemblies that are placed in stock for future required orders. The setup and

process (per item) durations are part dependent. Each subassembly operation requires one

labor unit from the labor pool for its entire duration.

F

INISH AND CUT

These work cells are utilized for operations necessary to produce the component parts

required for the subassemblies. The setup and process (per item) durations are part

dependent. These work cells are manned by a dedicated operation and do not require labor

from the labor pool.

M

ACHINE AND BEND

These work cells are utilized for operations necessary to produce the component parts

required for the subassemblies. The process (per item) durations are part dependent. These

work cells are manned by a dedicated operation and do not require labor from the labor

pool. The setup durations for these work cells are sequence dependent and defined in

matrix MM for the Machine work cell and matrix BM for the Bend work cell. These two

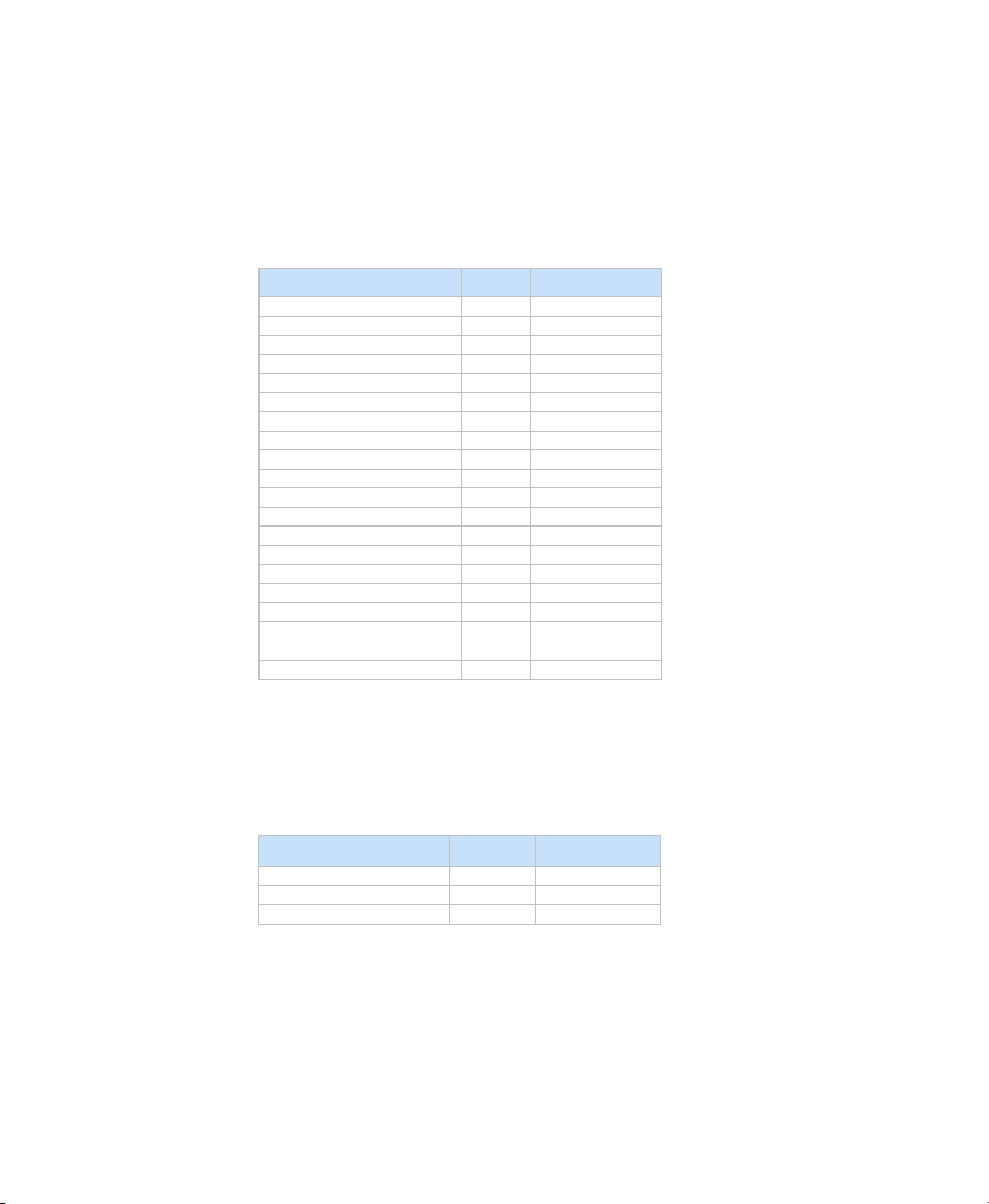

matrices are shown below.

• • • • •

Machine Setup Matrix: MM

SSD Frame SHP Frame Handlebar Neck Post

SSD Frame

SHP Frame

Handlebar

Neck Post

0.00 0.12 0.53 0.58

0.14 0.00 0.55 0.62

0.64 0.66 0.00 0.26

0.57 0.61 0.33 0.00

15

Page 22

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

This matrix shows the setup time for an operation based on the previous production lot

that was processed at this work cell. For example, if the last production lot was

Handlebar, then the setup time to produce a Neck Post is .26 hours.

Bend Setup Matrix: BM

SSD Frame SHP Frame Handlebar Neck Post

SSD Frame

SHP Frame

Handlebar

Neck Post

W

ELD

This work cell is also utilized for operations necessary to produce the component parts

required for the subassemblies. The process (per item) durations are part dependent. These

work cells are manned by a dedicated operation and do not require labor from the labor

pool. The setup duration for this work cell depends upon the frame type; i.e., we have a

different setup time for an SHP Frame and an SSD Frame. The setup time required to

change to an SHP Frame is 0.72 hours, and the time required to change to an SSD Frame

is 0.70 hours.

0.00 0.35 0.84 0.32

0.42 0.00 0.84 0.32

0.93 0.97 0.00 0.28

0.75 0.78 0.39 0.00

16

Process plans

There are eight different manufacturing order types, each with a different process plan or

routing.

F

INAL ASSEMBLY AND PACK

The process plans for assembly and packing of the SHP Red, SHP Blue, SSD Red, and

SSD Blue bicycles contain a single assembly operation. In this operation, a bicycle is

assembled from its components and subassemblies and then packaged for shipping. The

process plan for SHP Red Bicycle final assembly is summarized below.

SHP Red Bicycle Plan

Seq

#

10 Assemble

Operation Work Cell

and Pack

10

ASSEMBLE

AND PACK

Assembly

and Pack

Setup

Process

Time

0.37 0.43 Labor (2) Components required

Time

Additional

Resources

Notes

Page 23

3 • THE FACTORY OVERVIEW

The components required before this operation can be started are the manufactured parts

SHP Red Finished Frame, Handlebar Assembly, and Seat Assembly and the purchased

parts Pedal and Chain Assembly, Wheels, Derailleur Assembly, and Brakes.

F

INISHED FRAME

The process plans for a finished frame (SHP Red, SHP Blue, SSD Red, and SSD Blue)

contain two operations. The frame parts are first finished (red or blue) and then the parts

are subassembled. The finished frame is then placed in inventory where it is available for

demand from a final assembly order. The process plan for SHP Red Finished Frame is

summarized below.

SHP Red Finished Frame Plan

Seq

#

10 Finish SHP

20 Subassemble

Operation

Red Frame

SHP Frame

Work Cell

Finish 0.11 0.155 SHP Frame

Subassembly 0.19 0.083 Labor (1) Place in

Setup

Time

Process

Time

Additional

Resources

Notes

required

inventory

• • • • •

20

ASSEMBLE

FRAME

F

RAME

10

FINISH

FRAME

The process plans for a frame (SHP or SSD) contain four operations: cut, bend, machine,

and weld. The frame is then placed in inventory to be used by orders for finished frames.

The raw materials required at both the cut and weld operations have not been included in the

process plan as the material-planning replenishment process at the MRP level assures that

adequate materials will be available. The process plan for

SHP Frame

is summarized next.

17

Page 24

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

SHP Frame Plan

Seq

#

10 Cut SHP Frame

20 Bend SHP Frame

30 Machine SHP

40 Weld SHP Frame Weld WD 0.234 Place in inventory

Operation

Tubing

Tubing

Frame Tubing

Setup

Work

Cell

Time

Process

Time

Additional

Resources

Notes

Cut 0.36 0.120

Bend BM 0.154

Machine MM 0.211

10

CUT FRAME

TUBING

H

ANDLEBAR ASSEMBLY

20

BEND FRAME

TUBING

30

MACHINE

FRAME

TUBING

40

WELD

FRAME

The process plans for the handlebar assembly contain a single subassembly operation. In this operation, the previously manufactured handlebars and neck posts are assembled. The subassembly is then placed in inventory where it is available for demand from a final assembly order. The component parts required for this subassembly are a handlebar and neck post for each subassembly to be produced. The process plan for Handlebar Assembly is summarized below.

Handlebar Assembly Plan

Seq

#

Operation Work Cell

10 Assemble

Handlebar

Subassembly 0.21 0.072 Labor (1) Handlebar and Neck

Setup

Time

Process

Time

Additional

Resources

Notes

Post required;

Place in inventory

10

ASSEMBLE

HANDLEBAR

H

ANDLEBAR

The process plans for a handlebar contain three operations: cut, bend, and finish. The

completed handle is then placed in inventory to be used by orders for handlebar

assemblies. The raw materials required at the cut operation have not been included in the

process plan as the material-planning replenishment process at the MRP level assures that

18

Page 25

3 • THE FACTORY OVERVIEW

adequate materials will be available. The process plan for Handlebar is summarized

below.

Handlebar Plan

Setup

Seq

# Operation Work Cell

10 Cut

Cut 0.16 0.055

Time

Process

Time

Additional

Resources

Notes

Handlebar

Tubing

20 Bend

Bend BM 0.043

Handlebar

Tubing

30 Finish

Finish 0.14 0.088 Place in inventory

Handlebar

• • • • •

10

CUT

HANDLEBAR

TUBING

N

ECK POST

20

BEND

HANDLEBAR

TUBING

30

FINISH

HANDLEBAR

The process plans for a handlebar contain four operations: cut, machine, bend, and finish.

The completed neck post is then placed in inventory to be used by orders for handlebar

assemblies. The raw materials required at the cut operation have not been included in the

process plan as the material-planning replenishment process at the MRP level assures that

adequate materials will be available. The process plan for Neck Post is summarized below.

Neck Post Plan

Setup

Seq

# Operation Work Cell

10 Cut Neck

Cut 0.21 0.065

Time

Process

Time

Additional

Resources

Notes

Post

20 Machine

Machine MM 0.120

Neck Post

30 Bend Neck

Bend BM 0.072

Post

40 Finish Neck

Finish 0.14 0.074 Place in inventory

Post

10

CUT NECK

POST

20

MACHINE

NECK POST

30

BEND NECK

POST

40

FINISH NECK

POST

19

Page 26

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

S

EAT ASSEMBLY

The process plans for the seat assembly contain a single subassembly operation. In this operation, the previously manufactured seat post and purchased seat are assembled. The subassembly is then placed in inventory where it is available for demand from a final assembly order. The component parts required for this subassembly are a seat post and seat for each subassembly to be produced. The process plan for Seat Assembly is summarized below.

Seat Assembly Plan

Seq

# Operation Work Cell

10 Assemble

Seat and

Post

10

ASSEMBLE

SEAT AND

POST

S

EAT POST

The process plans for a seat post contain two operations: cut and machine. The completed

seat post is then placed in inventory to be used by orders for seat assemblies. The raw

materials required at the cut operation have not been included in the process plan as the

material-planning replenishment process at the MRP level assures that adequate materials

will be available. The process plan for Seat Post is summarized below.

Setup

Time

Process

Time

Additional

Resources

Notes

Subassembly 0.20 0.084 Labor (1) Seat and Seat Post

required;

Place in inventory

20

Seat Post Plan

Seq

# Operation Work Cell

10 Cut Seat

Cut 0.17 0.068

Post

20 Machine

Machine MM 0.130 Seat Post

Seat Post

10

CUT SEAT

POST

20

MACHINE

SEAT POST

Setup

Time

Process

Time

Additional

Resources

Material

Consumed

Material

Produced

Page 27

3 • THE FACTORY OVERVIEW

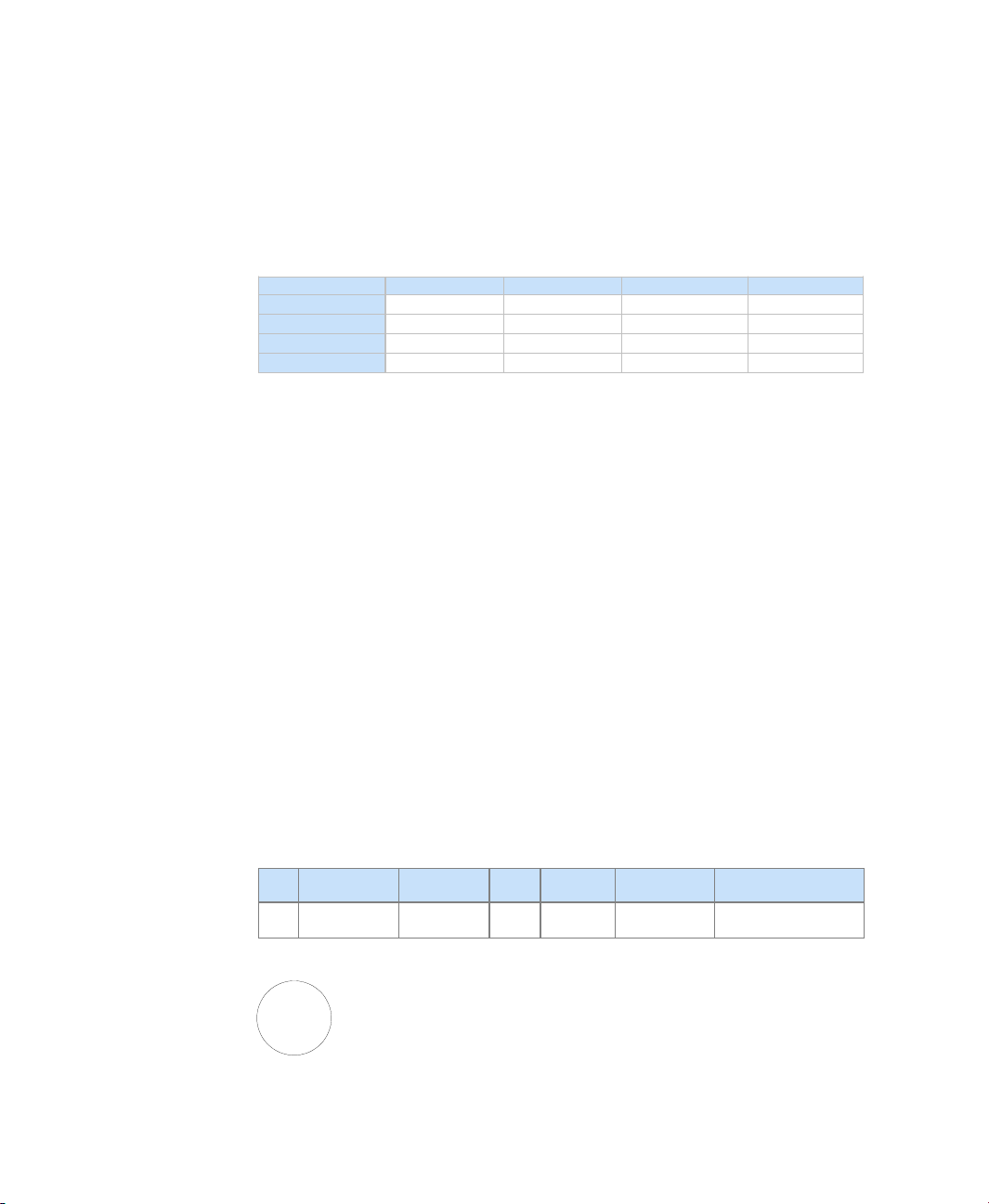

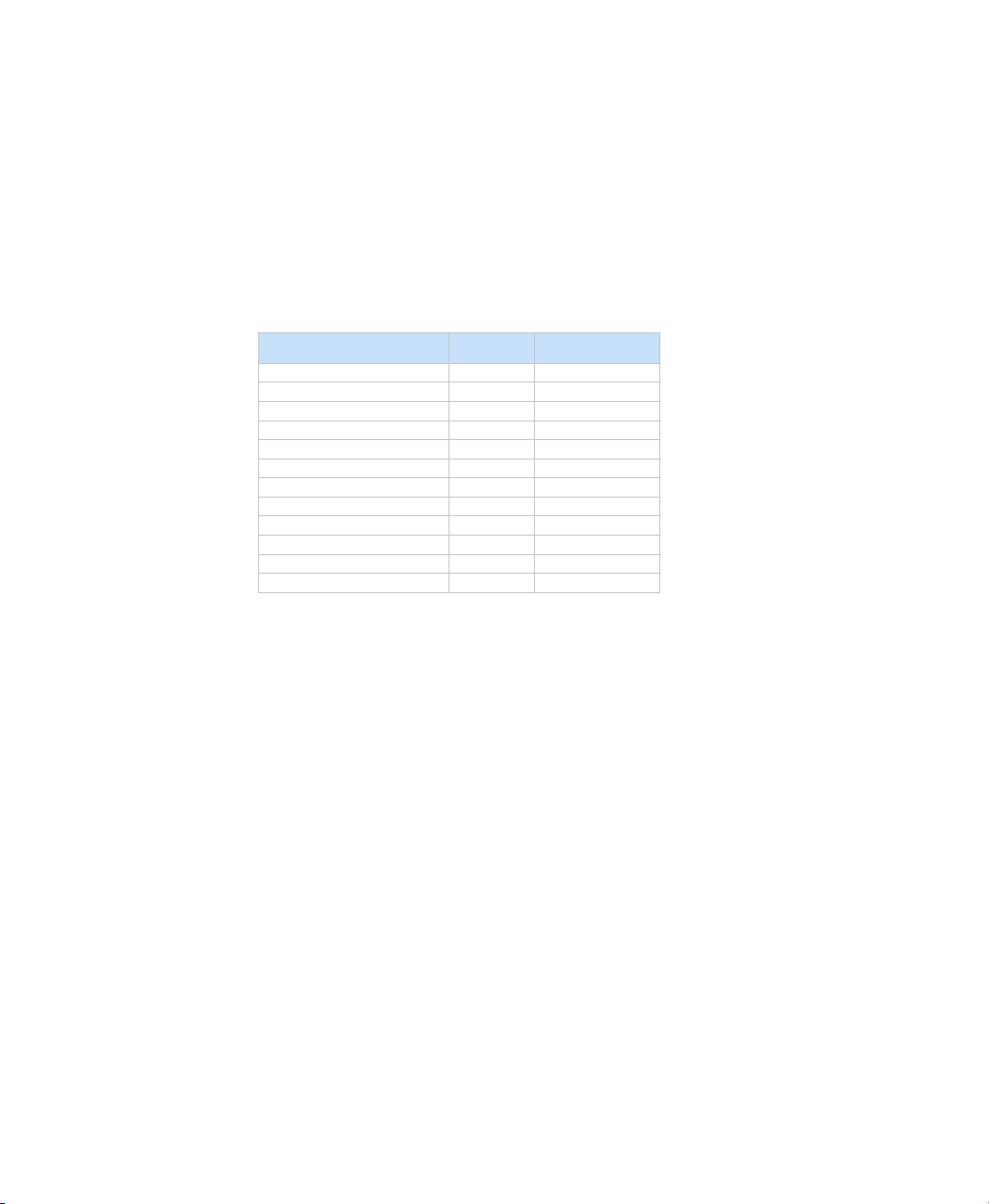

Purchased components

In addition to the manufactured components, we also have purchased components that are

used in the assembly operations. Purchase orders for these components are automatically

generated by the MRP (based on the economic lot size and lead times) to meet the

manufacturing demands. The following table summarizes the purchased components for

this same sample ten-day production period.

Material Name Quantity Date

Pedal and Chain Assembly 60 6/10/02 6:00 PM

Pedal and Chain Assembly 60 6/13/02 6:00 PM

Pedal and Chain Assembly 60 6/19/02 6:00 PM

Brakes 75 6/12/02 6:00 PM

Brakes 75 6/18/02 6:00 PM

Wheels 48 6/12/02 6:00 PM

Wheels 48 6/17/02 6:00 PM

Wheels 48 6/19/02 6:00 PM

Derailleur Assembly 60 6/12/02 6:00 PM

Derailleur Assembly 60 6/17/02 6:00 PM

Derailleur Assembly 60 6/20/02 6:00 PM

Seat 100 6/10/02 6:00 PM

• • • • •

21

Page 28

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

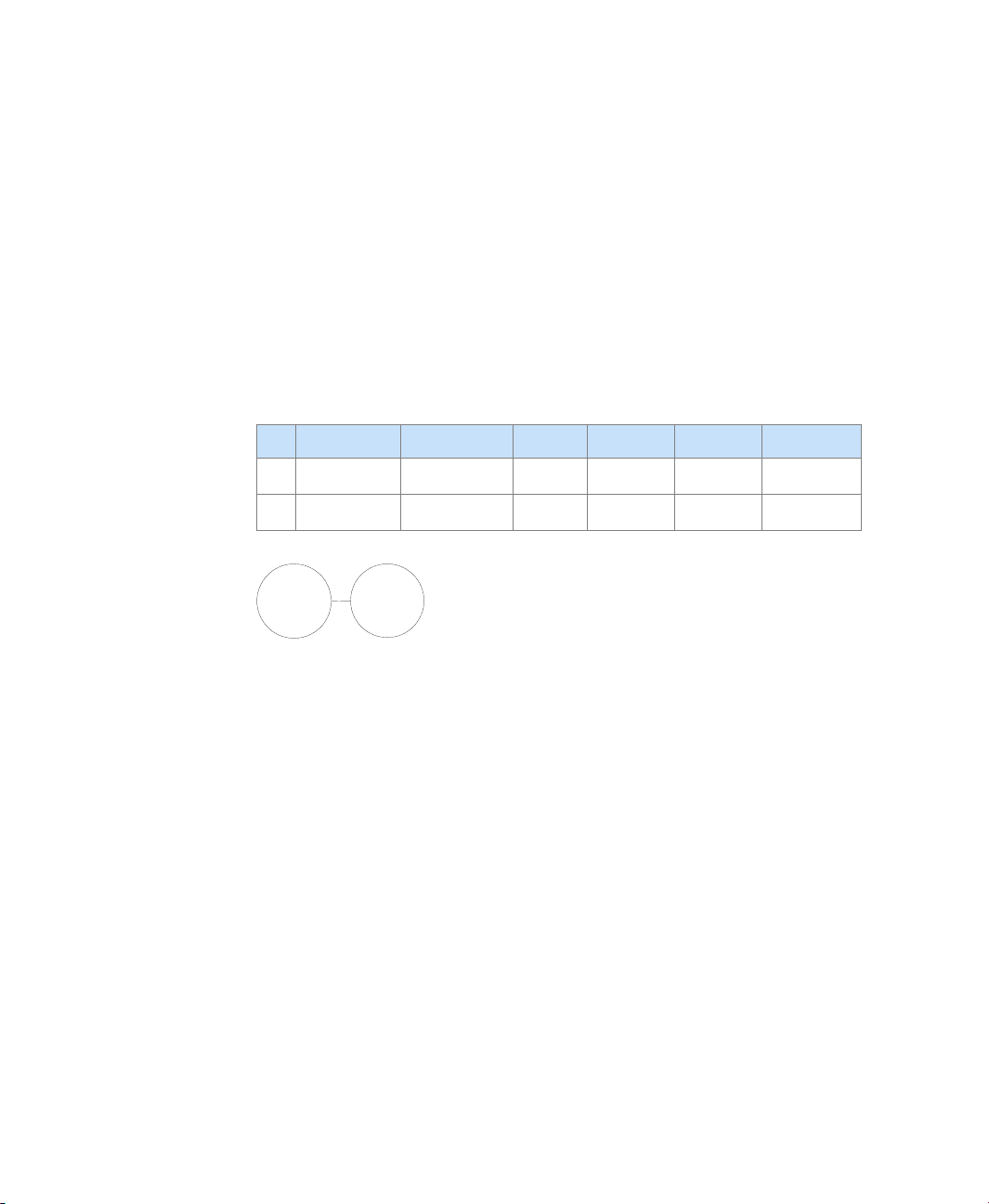

Inventories

We have a starting inventory level for both the manufactured and the purchased material.

The following table summarizes the starting inventory of these items.

Material Type Initial Quantity

SHP Red Bicycle Make 0

SHP Blue Bicycle Make 0

SSD Red Bicycle Make 0

SSD Blue Bicycle Make 0

SHP Red Finished Frame Make 8

SHP Blue Finished Frame Make 16

SSD Red Finished Frame Make 17

SSD Blue Finished Frame Make 6

Handlebar Assembly Make 27

Seat Assembly Make 36

SHP Frame Make 97

SSD Frame Make 54

Seat Post Make 127

Handlebar Make 155

Neck Post Make 118

Pedal and Chain Assembly Buy 15

Brakes Buy 50

Wheels Buy 54

Derailleur Assembly Buy 54

Seat Buy 54

22

Previously scheduled orders

Finally, we have previously scheduled orders planned for completion. These orders are

shown below.

Material Name Quantity Date

Seat Post 100 2/12/03 6:00 PM

Neck Post 60 2/12/03 6:00 PM

SSD Frame 50 2/12/03 6:00 PM

Summary

Now that we have described the BizBikes manufacturing process, we’ll use the

information in the tutorial to illustrate the features of FactoryTalk Scheduler in Chapter 4.

Page 29

4

Scheduling Features

FactoryTalk Scheduler provides a wide range of features for modeling constrained

scheduling systems. There are four basic categories of modeling constraints available—

resource, sequencing, material, fixture, and operation. We will discuss the major

features for each of them and use the BizBikes tutorial from Chapter 3 to demonstrate

examples.

Resource constraints

FactoryTalk Scheduler provides full support for the scheduling of constrained resources

with four distinct resource types:

Singular

Infinite

Simultaneous

Adjustable Pooled

The resource types differ in the functionality that they provide in modeling a wide variety

of production environments.

The Singular resource is the most commonly used type. It represents a single machine,

person, device, jig, fixture, or any resource that is constrained and has a capacity of one.

Tuto rial

Bend, Cut, Finish, Machine, Weld, Subassembly, and Assembly and Pack, as each

resource can only perform one operation at a time.

The Infinite resource type provides the ability to represent resources that have an

unlimited capacity. The most common example is a subcontractor or a drying area.

Although a subcontractor has a theoretical infinite capacity, it still requires time to

complete the task and may work only a single shift.

Tuto rial

The Simultaneous resource type represents resources that may have the ability to handle

multiple activities. It is further restricted in that if a Simultaneous resource processes

multiple activities at the same time, all the activities must be synchronized. This means

that they must all start and end at the same time. The significance of this feature is best

described by considering a kiln with a capacity measured in cubic feet. The kiln can be

used to process any number of parts, as long as the volume of the parts does not exceed

the kiln capacity. The synchronized restriction means that once you load and start the kiln,

you must finish that process before it can be used to process any additional parts. You can

: For our tutorial system, we will model the resources as Singular in work cells

: We will not use this resource type in our tutorial system.

23

Page 30

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

also restrict what operations can be processed at the same time by requiring that certain

operation attributes match before they can be processed together.

Tuto rial

The Adjustable Pooled resource type is most often used to represent pools of like

resources, any one of which fulfills the requirement of the task or operation being

performed. Typical examples are labor pools, totes, fixtures, or space. The number of

units of an Adjustable Pooled resource can vary during the operation span. We will

elaborate on this difference shortly.

Tuto rial

: We will not use this resource type in our tutorial system.

: The labor pool in our tutorial will be modeled as an Adjustable Pooled resource.

Primary and additional resources

Each operation to be scheduled must have a single primary resource for the entire duration

of the operation. Operation durations can be separated into three phases. Normally, these

are referred to as setup, process, and teardown. Additional resources can be specified for

the entire operation or for an individual phase of the operation. There is no limit on the

number of additional resources that an operation may require. However, as the number of

additional resources increases, the scheduling problem becomes more complex. This will

result in more time being required to develop a solution.

Shift patterns and efficiency

You can associate shift patterns, preventive maintenance, downtimes, etc., with any

resource. In addition to shift patterns, you can also associate an efficiency, expressed as a

fraction, with Singular, Infinite, and Simultaneous resources. Typically, this efficiency

would be defaulted to 1.0. By changing the efficiency, you can speed up or slow down

those operations that use the resource.

24

Resource sets

FactoryTalk Scheduler schedules to either a resource or a resource set. A resource set

contains one or more resources. When a resource set contains multiple resources, the

resources are typically of the same type, although it is not required. Likewise, it is not

required that the names used for resource sets differ from those of resources, but this is the

most common naming convention. Furthermore, a resource may be included in more than

one set.

Tuto rial

Machiner, Welder, and Labor. You might note that although Labor is a single resource, it

will have a capacity greater than one. We also have two resource sets, Subassembly Areas

and Assembly and Pack Areas, each with two resources. The two subassembly resources

are called Subassembly Area 1 and Subassembly Area 2. The two assembly resources are

: In our tutorial system, we will have six resources: Bender, Cutter, Finisher,

Page 31

4 • SCHEDULING FEATURES

called Assembly and Pack Area 1 and Assembly and Pack Area 2. We will associate a 1/5shift pattern with all the resources.

The combination of the availability of required resources and resource efficiencies

determine both where and how FactoryTalk Scheduler places an operation on the planning

board during the scheduling process. A resource becomes unavailable for use by an

operation in a given time period if it is currently being used by another operation or if it is

in an off-shift state.

Simultaneous, Singular, and Infinite resource spanning

Consider an operation that requires two hours of processing time on a Singular resource.

Assume that the resource is continuously on-shift starting at 7

shift the rest of the day. Also assume that there are no other operations currently using the

resource. If the operation were unable to start until 12:30

would schedule the operation from 12:30

PM to 2:30 PM, taking a continuous two-hour

span of time. However, if the operation were unable to start until 2

Scheduler would schedule the operation to start at 2

PM on the current day, where it would

process for one hour. It would then resume processing the next day at 7

the two-hour operation by 8

AM.

AM until 3 PM and is off-

PM, FactoryTalk Scheduler

PM, FactoryTalk

AM to complete

• • • • •

When an operation crosses a time where a resource is in an off-shift state or at a reduced

efficiency, it is called spanning. If an operation requires several secondary resources with

different shift patterns, the spanning can become quite complicated. However, as long as

all the required resources are Simultaneous, Singular, or Infinite types, no other operations

can use these resources during the span time of the scheduled operation. Note that if one

of these resources is a Simultaneous type, other operations may use any excess capacity.

Adjustable Pooled resource spanning

Adjustable Pooled resources differ not only in the manner in which resource spanning is

allowed, but also because you can elect to not allow certain types of spanning for

individual Adjustable Pooled resources. We’ll first discuss the default spanning mode.

The spanning behavior of Adjustable Pooled resources is best illustrated with an example.

The diagram below shows the availability profile of a labor resource. This profile

represents a 2/5 shift pattern with three workers available during the first shift (7

PM), two available during the second shift (3 PM to 11 PM), and none available during the

3

third shift. Note that the diagram shows that there is currently an operation, represented by

the white area, which has been allocated one labor unit from 10

AM to 9 PM on Day 1.

AM to

25

Page 32

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

7 101 4 7101 4 710

AM PM AM

Let us assume that FactoryTalk Scheduler is going to schedule an operation that requires a

primary resource that is available 24 hours a day and currently is not being used during

Days 1 or 2. This operation also requires two units of labor during its six-hour operation

time. If the operation were available to start on or before 9

scheduled during the first day. For example, if the operation could start at 8

be scheduled from 8

AM of Day 1, it could be

AM, it would

AM to 2 PM, as shown below.

26

7 101 4 7101 4 710

AM PM AM

Adjustable Pooled resources not only allow spanning, but they also allow the number of

labor units to vary, which will pace the operation. Thus, Adjustable Pooled resources are

often used to model resources where the pace or efficiency of the operation is based on the

number of workers currently available. Again, this is best illustrated using an example.

Let’s assume that we want to schedule the same six-hour operation as before. If the

operation could not start until 1

PM on Day 1, it would be scheduled from 1 PM to 10 PM,

Page 33

4 • SCHEDULING FEATURES

as shown below. Although this operation time is six hours, this particular process spans a

nine-hour period because it’s paced by the labor availability.

7 101 4 7101 4 710

AM PM AM

• • • • •

Between 1

is assumed to be at 100% efficiency during that time. However, between 3

PM and 3 PM, there are two units of the resource available. Thus, the operation

PM and 9 PM,

there is only one unit of labor available. The operation will continue during this six-hour

period at 50% efficiency, which accounts for an additional three hours of operation time.

During the last hour of the operation, the efficiency returns to 100% because two labor

units are available.

The spanned operation time can also include periods when there are no units available,

resulting in a zero efficiency during that time. The total number of units requested must be

available when the operation starts. For example, if the operation could not begin until

PM of Day 1, the start of the operation would have to be delayed until 9 PM on Day 1 and

4

would finish at 11

7 101 4 7101 4 710

AM PM AM

AM on Day 2, as shown below.

27

Page 34

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

Although the operation could start at 4 PM, there is only one unit of labor available from

PM to 9 PM, so the scheduled start of the operation would be at 9 PM when there are two

3

units available. From 9

the first two hours of the operation. From 11

units available, resulting in zero efficiency. The last four hours of the operation occur at

100% efficiency with two units available from 7

You also have the option of specifying a minimum number of units that must be available

for the operation to continue (the default is zero). This minimum value must be fewer than

or equal to the total number of units requested. Let’s consider the same six-hour operation

with a minimum equal to the total number, or two units. If the operation cannot start until

PM on Day 1, it would be scheduled from 1 PM to 9 AM of Day 2, as shown below. This

1

particular process spans a 12-hour period because it requires two units during the entire

operation. Thus, it spans the time from 3

PM to 11 PM, the operation is at 100% efficiency—accounting for

PM of Day 1 to 7 AM of Day 2, there are no

AM to 11 AM of Day 2.

PM to 9 PM where there is only one unit available.

28

7 101 4 7101 4 710

AM PM AM

Consider an example where the total number of units required is five and the minimum

number of units is three. The operation could not start until there were five units available,

and it would continue as long as there were three or more units available, although it

would occur at a lower efficiency if there were only three or four units available during

that time. If the operation is started and there is a point where there are fewer than three

units available, the operation will span (at zero efficiency) this time until there are at least

three units available, at which time it would resume.

As mentioned earlier, you can also elect to not allow certain types of spanning for specific

Adjustable Pooled resources. If you make this election, it will allow spanning to occur

during off-shift states, but it will not allow spanning where the resource is unavailable

because it is being used by another operation.

Page 35

Sequencing constraints

Sequencing constraints are normally a part of the product or job routing and determine the

sequence in which operations can be performed. Many systems have simple or straight

routings where the sequence is simply determined by the order in which the operations are

listed. The first operation must be completed before the second one can start, the second

completed before the third can start, and so on. Other systems allow parallel or concurrent

operations in their routings. These types of systems often include assembly or disassembly operations. The most difficult sequencing constraints are found in systems where routings are represented as networks. These types of routings are most frequently found in

maintenance operations.

FactoryTalk Scheduler provides complete support for all types and combinations of

sequencing constraints. There are two different ways to describe sequencing constraints:

using an operation sequence numbering scheme or using an immediate successor

operation(s) scheme. The two methods cannot be used together in the same application.

All sequencing constraints for a given application must be described using the same

scheme.

The operation sequence numbering scheme

The operation sequence numbering scheme has the following format:

• • • • •

4 • SCHEDULING FEATURES

XX.YY.YY.YY…

where:

XX is the standard integer operation sequence number and will be referred to as the

root operation number

YY is the integer suffix that can be appended to the basic number, separated by the

decimal character “.”

You can append as many suffixes as needed to represent your routings accurately. The

rules used by FactoryTalk Scheduler to determine the sequence of operations are:

1. If the operation sequence number consists of only a root operation number (only XX),

then all operations with lower root numbers (ignoring all suffixes) must precede that

operation. Conversely, all operations with higher root numbers (ignoring all suffixes)

must succeed that operation. Note that it is possible to have one or more operations

with the same root number, with or without suffixes.

2. If the operation sequence number consists of a root operation number and one or more suffixes, then:

all operations with lower root numbers and the same exact suffixes must precede

that operation,

29

Page 36

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

all operations with lower root numbers and a fewer number of suffixes must

precede that operation, as long as the remaining suffixes match,

all operations with lower root numbers and the same suffixes, but with additional

appended suffixes must precede that operation, and

the converse defines the operations that succeed that operation.

The immediate successor operation(s) scheme

The operation number in the immediate successor operation scheme does not include any

sequence information. The sequence of operations is determined by specifying an

additional operation field, called the immediate successor operation attribute. The rules

for this scheme are:

each operation in a routing must have a unique job step number,

the operation numbers cannot include suffixes,

the immediate successor operation attribute field defines the immediate successor

operation job step number,

if an operation has no successor, the immediate successor operation attribute field is

left blank, and

if an operation has multiple successors, the job step numbers are separated by the “&”

character.

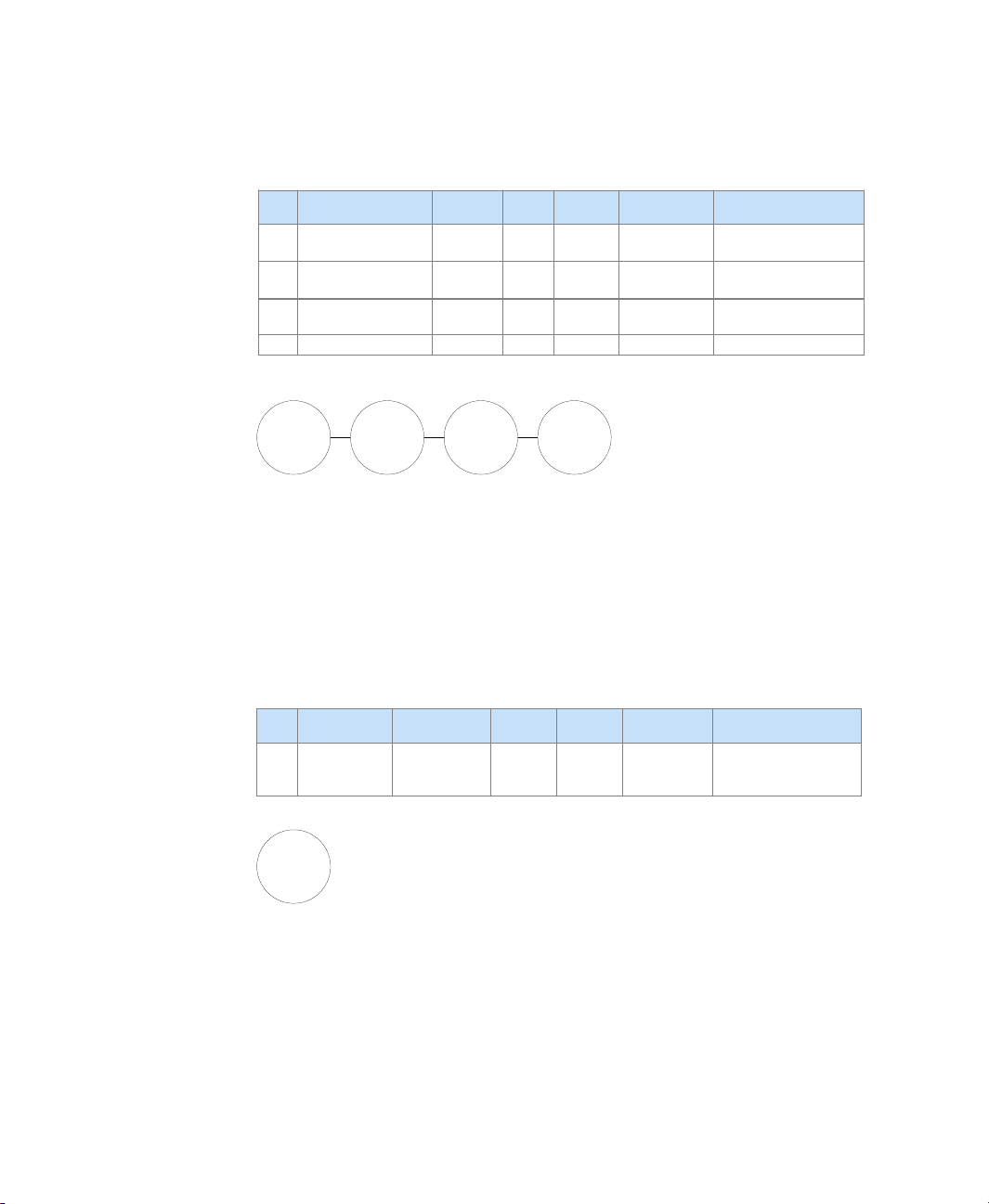

Sequencing constraint examples

A set of examples will best explain these rules and illustrate the differences between the

two schemes. In the following examples, we include both a routing diagram to illustrate

the operation sequence numbering scheme and a successor table to illustrate the

immediate successor operation scheme. In most of the examples, the operation numbers

will be different. In those examples, both operation numbers will be displayed in the

routing diagrams, with the immediate successor operation numbers in parentheses “( )”.

Both operation numbers will also be included in the successor table. The operation

sequence numbering scheme operation numbers will be labeled as OSN scheme operation

number, and the immediate successor operation scheme operation numbers will be labeled

as ISO scheme operation numbers.

30

If you have simple straight-line routings with no assembly or disassembly, then you only

need to use root operation numbers. You can also describe one operation assembly or

disassembly routing using only root operation numbers. Our first example shows two

parallel operations, labeled 10, which can be performed independently, but both need to

be completed before the last operation, labeled 20, can be started.

Page 37

4 • SCHEDULING FEATURES

10

(10)

20

(30)

10

(20)

Immediate Successor Table

OSN Scheme Operation

Number

10 10 30

10 20 30

20 30

ISO Scheme Operation

Number

Immediate Successor

Operation Number

The second example extends the previous one by allowing two sets of parallel operations.

In this example, the first two operations, labeled 10, can be performed independently, but

both need to be completed before the next two operations, labeled 20, which can be

performed independently.

• • • • •

10

10

(20)

OSN Scheme Operation

Number

10 10 30 & 40

10 20 30 & 40

20 30 50

20 40 50

30 50

20

(30)

30

(50)

20

(40)

Immediate Successor Table

ISO Scheme Operation

Number

Immediate Successor

Operation Number

31

Page 38

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

The third example illustrates how to use the numbering schemes to allow a series of

operations to be performed independently, as would normally be the case in typical

industrial routings. This example has both assembly and disassembly features. In this

example, the first two operations with the “1” suffix can be performed independent of the

first two operations with the “2” suffix. You can use any value for a suffix, as shown in the

disassembly portion of the example, where we skip to a “5” suffix.

10.1

(10)

10.2

(30)

OSN Scheme Operation

Number

10.1 10 20

20.1 20 50

10.2 30 40

20.2 40 50

40.1 60 100

40.2 70 100

40.5 80 90

45.5 90 100

40.1

20.1

(20)

20.2

(40)

30 50 60 & 70 & 80

50 100

30

(50)

Immediate Successor Table

ISO Scheme Operation

Number

(60)

40.2

(70)

40.5

(80)

50

(100)

45.5

(90)

Immediate Successor

Operation Number

32

The fourth example shows a complicated bill of materials that requires several assembly

operations at different levels. This numbering scheme illustrates the flexibility of

representing complex routing structures.

Page 39

4 • SCHEDULING FEATURES

• • • • •

10.1.1.1

(10)

10.1.1.2

(30)

10.1.2

(50)

10.1.3

(70)

20.1.1.1

(20)

20.1.2

(60)

OSN Scheme Operation

Number

10.1.1.1 10 20

20.1.1.1 20 40

10.1.1.2 30 40

30.1.1 40 110

10.1.2 50 60

20.1.2 60 110

10.1.3 70 80 & 90

20.1.3.1 80 100

20.1.3.2 90 100

30.1.3 100 110

40.1 110 130

40.2 120 130

50 130

20.1.3.1

(80)

20.1.3.2

(90)

30.1.1

(40)

30.1.3

(100)

Immediate Successor Table

ISO Scheme Operation

Number

40.1

(110)

40.2

(120)

Immediate Successor

Operation Number

50

(130)

33

Page 40

FACTORYTALK SCHEDULER USER’S GUIDE

• • • • •

The final example illustrates a non-traditional network routing structure. Project

management and maintenance environments frequently use these types of networks. This

example illustrates the flexibility of the two numbering schemes.