Page 1

USER GUIDE

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Supersedes Publication RPTEXP-UM001G-EN-P-June 2013

Page 2

Contacting Rockwell

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/overview.page

Copyright Notice

Trademark Notices

Other Trademarks

© 2014 Rockwell Automation Technologies, Inc. All Rights Reserved.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation,

Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation, Inc. is

strictly prohibited. Please refer to the license agreement for details.

FactoryTalk, FactoryTalk Activation, FactoryTalk Diagnostics, FactoryTalk Directory, FactoryTalk Live Data,

FactoryTalk Metrics, FactoryTalk Services Platform, FactoryTalk Transaction Manager, FactoryTalk

VantagePoint, FactoryTalk ProductionCentre, Report Expert, Rockwell, Rockwell Automation, Rockwell

Software, and RSBizWare are trademarks of Rockwell Automation, Inc.

Any Rockwell Automation logo, software or hardware not mentioned herein is also a trademark, registered or

otherwise, of Rockwell Automation, Inc.

For a complete list of products and their respective trademarks, go to

http://www.rockwellautomation.com/rockwellautomation/legal-notices/overview.page?%23tab4#/tab4.

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows,

Windows ME, Windows NT, Windows 2000, Windows Server-, Windows XP, Windows 7, Windows Vista,

Windows 8 are either registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in

the United States and/or other countries.

ControlNet is a registered trademark of ControlNet International.

DeviceNet is a trademark of the Open DeviceNet Vendor Association, Inc. (ODVA)

Warranty

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

This product is warranted in accordance with the product license. The product’s performance may be affected

by system configuration, the application being performed, operator control, maintenance, and other related

factors. Rockwell Automation is not responsible for these intervening factors. The instructions in this

document do not cover all the details or variations in the equipment, procedure, or process described, nor do

they provide directions for meeting every possible contingency during installation, operation, or

maintenance. This product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the accompanying software may

have changed since the release. Rockwell Automation, Inc. reserves the right to change any information

contained in this document or the software at any time without prior notice. It is your responsibility to obtain

the most current information available from Rockwell when installing or using this product.

Page 3

Chapter 1

Table of Contents

Welcome to Report Expert

Report Expert Prerequisites

Installing Report Expert

Getting Started

Features of Report Expert.......................................................................... 12

Benefits of Report Expert .......................................................................... 13

Intended Audience ...................................................................................... 13

Report Expert Establishers ................................................................... 13

Report Expert Administrators ............................................................ 14

Report Expert Users .............................................................................. 14

Where Can I Go for Help? ....................................................................... 14

Chapter 2

Hardware and Software Requirements .................................................. 18

Chapter 3

Installing or Upgrading Report Expert .................................................. 19

Removing Report Expert ........................................................................... 22

Chapter 4

Understanding the Report Expert Architecture .................................. 25

Connecting to Report Expert ................................................................... 27

Settings Specific to Internet Explorer 10 .......................................... 28

Add the Report Expert Site to the Trusted Sites Zone............ 28

Open the Report Expert Site in Compatibility View .............. 29

Navigating Report Expert.......................................................................... 29

Administration Page ............................................................................. 30

Manual Data Editor .............................................................................. 31

Parameters Page for the Editor ...................................................... 32

Editor Page ......................................................................................... 32

Report Viewer ......................................................................................... 33

Parameters Page for the Viewer ..................................................... 33

Explorer Page ..................................................................................... 34

Troubleshooting .......................................................................................... 34

Chapter 5

Understanding Report

Templates

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 3

Drillthrough ................................................................................................. 37

Report Templates ........................................................................................ 38

Dashboard ................................................................................................ 39

OEE % Widget .................................................................................. 40

Page 4

Table of Contents

3 OEE Components Widget ......................................................... 40

Last State Widget.............................................................................. 40

Production Summary Widget ....................................................... 41

Uptime Summary Widget .............................................................. 41

Fault Summary Widget ................................................................... 42

Good Parts vs. Scrap Parts Widget ............................................... 42

Uptime vs. Downtime Widget ...................................................... 43

Machine States Widget ................................................................... 43

Event Count and Duration Widget ............................................. 43

Parameter Settings and Widgets ......................................................... 44

Event All Detail ...................................................................................... 44

Event Chart ............................................................................................. 46

Event Configuration ............................................................................. 48

Event Detail ............................................................................................. 49

Event Detail Paged ................................................................................. 50

Event History String/Value ................................................................. 51

Event Overview ...................................................................................... 52

Event Summary ...................................................................................... 53

Fault 54

Performance ............................................................................................ 56

Production ............................................................................................... 59

Production Overview ............................................................................ 60

Quality ...................................................................................................... 63

Root Cause Analysis .............................................................................. 64

State Detail .............................................................................................. 65

State Summary ........................................................................................ 67

Throughput ............................................................................................. 68

Uptime...................................................................................................... 70

Query Fields .................................................................................................. 72

Raw Data ....................................................................................................... 76

Chapter 6

Understanding Parameter Sets

4 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Using the Date / Time / Shift Parameter .............................................. 77

Start and End Times .............................................................................. 78

Selecting Date/Time ............................................................................. 79

Selecting Shift ......................................................................................... 82

Page 5

Table of Contents

Using the Grouping Parameter ................................................................ 83

Selecting the Grouping Field ............................................................... 85

Selecting the Grouping Type .............................................................. 85

Selecting the Grouping Expansion Type .......................................... 87

Deleting a Grouping .............................................................................. 88

Using the Sorting Parameter .................................................................... 88

Selecting the Sorting Field ................................................................... 89

Selecting the Sorting Method ............................................................. 90

Deleting a Sorting .................................................................................. 90

Using the Plant Model Parameter ........................................................... 90

Using the Filtering Parameter .................................................................. 91

Selecting the Filtering Field and Value ............................................. 92

Deleting a Filter ...................................................................................... 93

Using the TOP N Parameter .................................................................... 93

Using the Terminology Parameter .......................................................... 94

Viewing and Generating

Reports

Editing Event and Production

Data

Chapter 7

Viewing Saved Reports on the Explorer Page ....................................... 97

Generating Reports Using the Parameters Page .................................. 97

Generating Reports with Existing Parameter Sets ......................... 98

Generating Reports with Temporarily Customized Parameter

Sets 98

Creating New Parameter Sets for Reports ....................................... 99

Viewing and Using Reports ...................................................................... 99

Navigating Reports ............................................................................. 100

Exporting Reports ............................................................................... 100

Printing Reports .................................................................................. 101

Chapter 8

Displaying Data ........................................................................................ 103

Edit Events ............................................................................................ 104

Parameter Set Information Panel .............................................. 104

Event Details Panel ....................................................................... 104

Event List Panel ............................................................................. 105

Edit Production Data ......................................................................... 107

Parameter Set Information Panel .............................................. 107

Activity Area Details Panel ......................................................... 108

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 5

Page 6

Table of Contents

Production Data List Panel ......................................................... 109

Edit Shift Information ....................................................................... 111

Parameter Set Information Panel .............................................. 111

Shift Information List Panel ....................................................... 111

Enter Data Manually .......................................................................... 112

Parameter Set Information Panel .............................................. 113

Select Area and Shift Details Panel............................................ 113

Shift Summary Panel..................................................................... 114

Creating Events ......................................................................................... 115

Creating Events From Scratch ......................................................... 115

Creating Events From Existing Events .......................................... 116

Editing Events ........................................................................................... 117

Editing the Category - Name ........................................................... 118

Editing the Start/End Time ............................................................. 119

Editing the Start/End Value ............................................................. 121

Editing the Start/End Value of Events With a Value Lookup

List 122

Editing the Start/End Value of Events without a Value

Lookup List ..................................................................................... 122

Splitting Events ......................................................................................... 123

Deleting Events ......................................................................................... 124

Editing Production Data ........................................................................ 125

Editing the Number of Good and Scrap Parts ............................. 125

Editing the Part Id .............................................................................. 126

Editing the Ideal Cycle Time ........................................................... 127

Editing the Values of the User-Defined Summarization Fields 127

Splitting Production Data ...................................................................... 129

Editing Shift Instances ............................................................................ 130

Splitting Shift Instances .......................................................................... 131

Chapter 9

Administering Report Expert

6 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Configuring Security for Report Expert ............................................. 134

Setting up Security for Report Expert Editors ............................. 134

Setting up Security for Report Expert Administrators .............. 136

Disabling Security ............................................................................... 137

Configuring Report Expert Settings .................................................... 138

Page 7

Table of Contents

Modifying the RptSetting Table ..................................................... 143

Communicating With SQL Server Reporting Services (SSRS)144

Configuring the Report Tree of the Explorer Page .......................... 146

Adding Tree Items .............................................................................. 146

Copying Tree Items ............................................................................ 148

Editing Tree Items .............................................................................. 148

Organizing Tree Items ....................................................................... 149

Deleting Tree Items ............................................................................ 149

Configuring the Quick Web ................................................................. 149

Configuring Report Subscriptions ....................................................... 150

Creating Shared Schedules in SQL Server Reporting Services

(SSRS) .................................................................................................... 151

Adding Report Subscriptions ........................................................... 151

Modifying Report Subscriptions ..................................................... 152

Deleting Report Subscriptions ......................................................... 154

Configuring Parameter Sets ................................................................... 154

Adding Parameter Sets ....................................................................... 154

Copying Parameter Sets .................................................................... 155

Modifying Parameter Sets ................................................................. 156

Deleting Parameter Sets .................................................................... 157

Configuring Terminologies ................................................................... 157

Domain Terminology ........................................................................ 157

Creating Domain Terminologies .................................................... 158

Adding Terms Terminologies .......................................................... 159

Editing Terms ...................................................................................... 160

Deleting Terms .................................................................................... 161

Copying Terminologies to Other Cultures .................................. 161

Deleting Terminologies ..................................................................... 162

Deleting Cultures from Domain Terminologies ......................... 163

Synchronizing Terminology Changes with Report Server ....... 163

Configuring the Line Order .................................................................. 164

Chapter 10

Glossary of Fields

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 7

Area 165

Availability ................................................................................................. 165

Available Time .......................................................................................... 165

Page 8

Table of Contents

Average Duration ..................................................................................... 165

Avg. Duration/Event End Num ........................................................... 165

Cycle Time Diff. ....................................................................................... 166

Cycle Time Diff. % .................................................................................. 166

Downtime .................................................................................................. 166

Duration ..................................................................................................... 166

End Time .................................................................................................... 166

End Value ................................................................................................... 167

Enterprise ................................................................................................... 167

Event Category .......................................................................................... 167

Event Comment ....................................................................................... 167

Event Count .............................................................................................. 167

Event During Num .................................................................................. 167

Event During Scheduled Time .............................................................. 167

Event End Num ........................................................................................ 168

Event Is Fault ............................................................................................. 168

Event Name ............................................................................................... 168

Event Occurrence ..................................................................................... 168

Event Occurrence Count/Id ................................................................. 168

Event Reason ............................................................................................. 168

Event Reason Code .................................................................................. 168

Event Severity ............................................................................................ 168

Event Start Num ....................................................................................... 169

Event Trigger ............................................................................................. 169

Event Trigger Expression ........................................................................ 169

Event Value ................................................................................................ 169

Event Value Expression ........................................................................... 169

Event Value Lookup List Name ............................................................ 169

Fault % ........................................................................................................ 169

Fault Count ............................................................................................... 170

Fault Metric Use ....................................................................................... 170

Fault Time .................................................................................................. 170

Faults ........................................................................................................... 170

Faults per Hour ......................................................................................... 170

Good Parts ................................................................................................. 170

Ideal Cycle Time ....................................................................................... 170

8 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 9

Table of Contents

Ideal % ......................................................................................................... 171

Ideal Parts ................................................................................................... 171

Line 171

Machine State Name ............................................................................... 171

Max Duration ............................................................................................ 171

Max. Duration/Event Start Num ......................................................... 171

Min Duration ............................................................................................ 171

Min. Duration/Event Severity .............................................................. 172

MTBF ......................................................................................................... 172

MTTR ......................................................................................................... 172

OEE % ......................................................................................................... 172

Part Description ....................................................................................... 173

PartId ........................................................................................................... 173

Quality % .................................................................................................... 173

Realized Cycle Time ................................................................................ 173

Record State ............................................................................................... 173

Reporting Value ........................................................................................ 173

Running Time ........................................................................................... 173

Scheduled Unavailable Time ................................................................. 174

Scrap % ........................................................................................................ 174

Scrap Parts .................................................................................................. 174

Shift 174

Shift Name ................................................................................................. 174

Shift Number ............................................................................................ 174

Shift Start ................................................................................................... 174

Site 175

Start Time .................................................................................................. 175

Start Value .................................................................................................. 175

State Count ................................................................................................ 175

State Name ................................................................................................. 175

TEEP ........................................................................................................... 175

Throughput % ........................................................................................... 175

Time in Event ............................................................................................ 176

Total Duration .......................................................................................... 176

Total Parts .................................................................................................. 176

Uptime ........................................................................................................ 176

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 9

Page 10

Table of Contents

Uptime % ................................................................................................... 176

Work Cell................................................................................................... 176

10 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 11

Chapter 1

Welcome to Report Expert

Report Expert is a new reporting environment based on SQL Server

Reporting Services (SSRS) for Microsoft SQL Server that allows you

to report on data generated by FactoryTalk Metrics.

Report Expert is an optional component that is installed separately

from RSBizWare and the FactoryTalk Metrics software. To use

Report Expert, you must install one of the supported versions of

Microsoft SQL Server (see "Report Expert Prerequisites (page 17)").

Read the release notes (located on your Report Expert CD) to learn

about software/hardware requirements.

Report Expert provides a web interface to view and interact with

three types of reports that display FactoryTalk Metrics data:

• Quick Web reports, which are created with the RSBizWare

and FactoryTalk Metrics report authoring tools.

• SQL Server Reporting Services reports, which are created

using the SSRS report designer tools.

• Report Expert report templates (page 38), which are specially

modified SSRS reports.

A fixed number of Report Expert report templates are installed

automatically with Report Expert. These report templates, when

combined with parameter sets you can create, will satisfy a wide

range of reporting requirements. You can also create new Report

Expert report templates using SSRS. Creating new reports is an

advanced topic that is not covered in this user guide.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 11

Page 12

Chapter 1 Welcome to Report Expert

Features of Report Expert

Report Expert provides the following features:

• Uses standard SQL Server Reporting Services (SSRS) for

Microsoft SQL Server.

• Includes SSRS for Microsoft SQL Server, and appropriate

client licenses.

• Includes value-added content not available in SSRS, such as:

• Interactive filtering using the plant model and other

FactoryTalk Metrics key fields (for example, any of the five

flex fields).

• Dynamic grouping and sorting.

• Expanded date and time filtering, including shift filtering.

• Pre-defined named filters such as Today, Yesterday, and

This Week.

• Drilldown and drillthrough.

• Allows you to:

• View Report Expert report templates, standard SSRS

reports, and Quick Web reports through a single web

interface.

• Create a custom reporting tree.

• Create parameter sets that define filtering, grouping, and

sorting behaviors and apply these to report templates to

create custom reports.

• Create and modify your own report parameter sets, as well

as save parameter sets with report templates to create

custom reports.

• Use the parameter settings interactively to perform ad-hoc

reporting.

12 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 13

Welcome to Report Expert Chapter 1

Intended Audience

• Modify standard SSRS RDL reports to take advantage of

Report Expert parameter passing (passing values from the

Report Expert parameter set into the report).

• Enter event and production data manually.

• View and modify event and production data.

• View and modify shift information.

Benefits of Report Expert

Report Expert uses an industry-standard reporting package from

Microsoft, not a proprietary reporting package from Rockwell

Automation. This means it can be much easier and more

cost-effective for you to create and maintain a reporting system.

Expertise on SSRS can be obtained from Microsoft training classes,

publications, and contractors. SSRS could be the reporting standard

for other applications in your company, allowing for easier

integration of FactoryTalk Metrics data with other data and

applications.

The user guide is designed to help you understand how to install,

configure, access, use, and maintain your Report Expert software.

The document is intended for the following three types of users:

• Report Expert Establisher (page 13)

• Report Expert Administrator (page 14)

Report Expert Establishers

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 13

• Report Expert User (page 14)

Report Expert establishers install Report Expert and set it up for use

by the administrator and other users.

They should be familiar with:

• Microsoft Windows operating systems.

Page 14

Chapter 1 Welcome to Report Expert

• Microsoft SQL Server (including SQL Server Reporting

Services (SSRS)).

• Microsoft Internet Information Services (IIS).

Report Expert Administrators

Report Expert Users

Report Expert administrators define the parameter sets and reports

accessible to Report Expert users.

They should be familiar with:

• The layout and content of the lines and plant for which the

reports will provide information.

• Microsoft Windows operating systems.

• Microsoft Internet Explorer.

• Microsoft SQL Server (including SQL Server Reporting

Services (SSRS)).

Report Expert users use the reports created by the administrator in

order to perform their job.

They should be familiar with:

• Microsoft Windows operating systems.

• Microsoft Internet Explorer.

Where Can I Go for Help?

Consult the following resources for additional information about

the product:

• Release Notes

The release notes contain current information about the

product, including hardware and software requirements, new

features, known and fixed anomalies.

• RSBizWare Administration Guide

14 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 15

Welcome to Report Expert Chapter 1

The administration guide helps the RSBizWare administrator

install and configure the software as well as understand the

architecture of the RSBizWare suite and its components.

• Online help

The online help provides general information and step-by-step

procedures for working with the product.

• Rockwell Automation Support Center

The support center provides a variety of services, such as

trainings, webinars, and online support that will improve your

experience using the RSBizWare suite.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 15

Page 16

Chapter 1 Welcome to Report Expert

16 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 17

Chapter 2

Report Expert Prerequisites

Before you install Report Expert, keep the following in mind:

• Report Expert must be installed on the same computer as SQL

Server Reporting Services (SSRS).

• Make sure you have configured your System DSN (Data

Source Name) in your ODBC Data Source Administrator.

If you have RSBizWare installed, you may already have System

DSN configured.

To verify the System DSN configuration on Microsoft Windows

Server:

1. In the file explorer, go to the following directory:

%windir%\SysWOW64\

2. Double-click odbcad32.exe.

The ODBC Data Source Administrators (32-bit) dialog box

appears.

3. Click the System DSN tab.

If the system DSN is configured, your RSBizWare database is

listed under System Data Sources.

If the System DSN is not configured, create a DSN for the

RSBizWare database on the server containing the Report

Expert web site. For more information on creating a DSN, see

the Report Expert Release Notes, section "Prerequisites for

Windows Server 2012 for FactoryTalk Metrics and Report

Expert".

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 17

Page 18

Chapter 2 Report Expert Prerequisites

Hardware and Software Requirements

For up-to-date information on hardware and software requirements

of Report Expert, refer to the Report Expert Release Notes, available

on the RSBizWare installation DVD.

18 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 19

contains information that can help identify the cause of your installation

Expert report templates, those reports in your currently installed version

Chapter 3

Installing Report Expert

This chapter describes how to install the Report Expert software.

If you are installing Report Expert, you must have the Windows

System Administrator privileges, and your user account must be a

member of the local administrator user group.

Installing or Upgrading Report Expert

IMPORTANT

If you encounter problems during the Report Expert installation and

need to call support, make sure that you have access to the log files

created during installation. These files are named Rockwell - Report

Expert 3.20 Install.log and Rockwell - Report Expert Deployment 3.0.log.

Depending on your installation options, only one of these files may

appear.

The log files are usually located in the \Documents and

Settings\username\Local Settings\Temp folder, where username is

the name of the installing user. However, this location can vary

depending on the value of the %TEMP% environment variable. This file

problem.

You must have the administrator privileges to perform any of the

following actions.

NOTE

If you are going to perform an upgrade to Report Expert 3.20, you may

want to first rename standard reports if you changed any of the reports

to meet your specific needs. If you do not rename the standard Report

To install or upgrade Report Expert on the server:

1. Close the SSRS web site, if it is open.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 19

of Report Expert will be removed and replaced by new versions of the

Report Expert report templates.

Page 20

Chapter 3 Installing Report Expert

2. Run the RSBizWare installation DVD.

The RSBizWare installation wizard appears.

3. On the Welcome page, click FactoryTalk Metrics >

Installation > Install Report Expert.

The installation program checks for installed applications.

4. On the Welcome page, click Next.

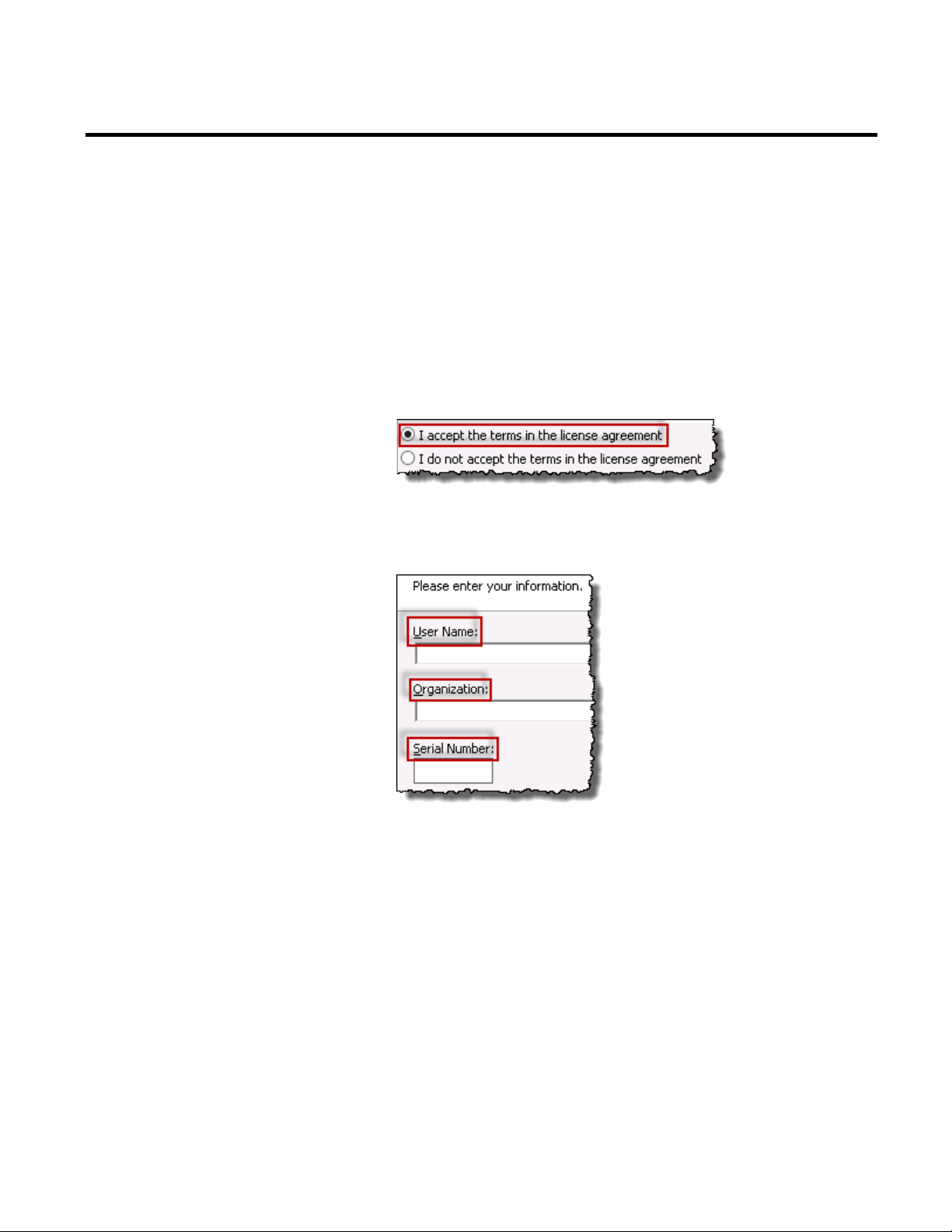

5. On the License Agreement page, click:

6. Click Next.

7. On the Customer Information page, type the following:

8. Click Next.

9. On the Setup Type wizard page, select:

• Complete, if you want to install all the features.

• Custom, if you want to install specific components.

If you choose this option, the Custom Setup page appears.

Select the components that you want to install and their

locations on the computer.

10. Click Next.

20 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 21

Installing Report Expert Chapter 3

The Virtual directory information page appears. It displays

the default virtual directory of the Report Expert web site:

http://localhost/RockwellSoftware/ReportExpert

11. Click Next.

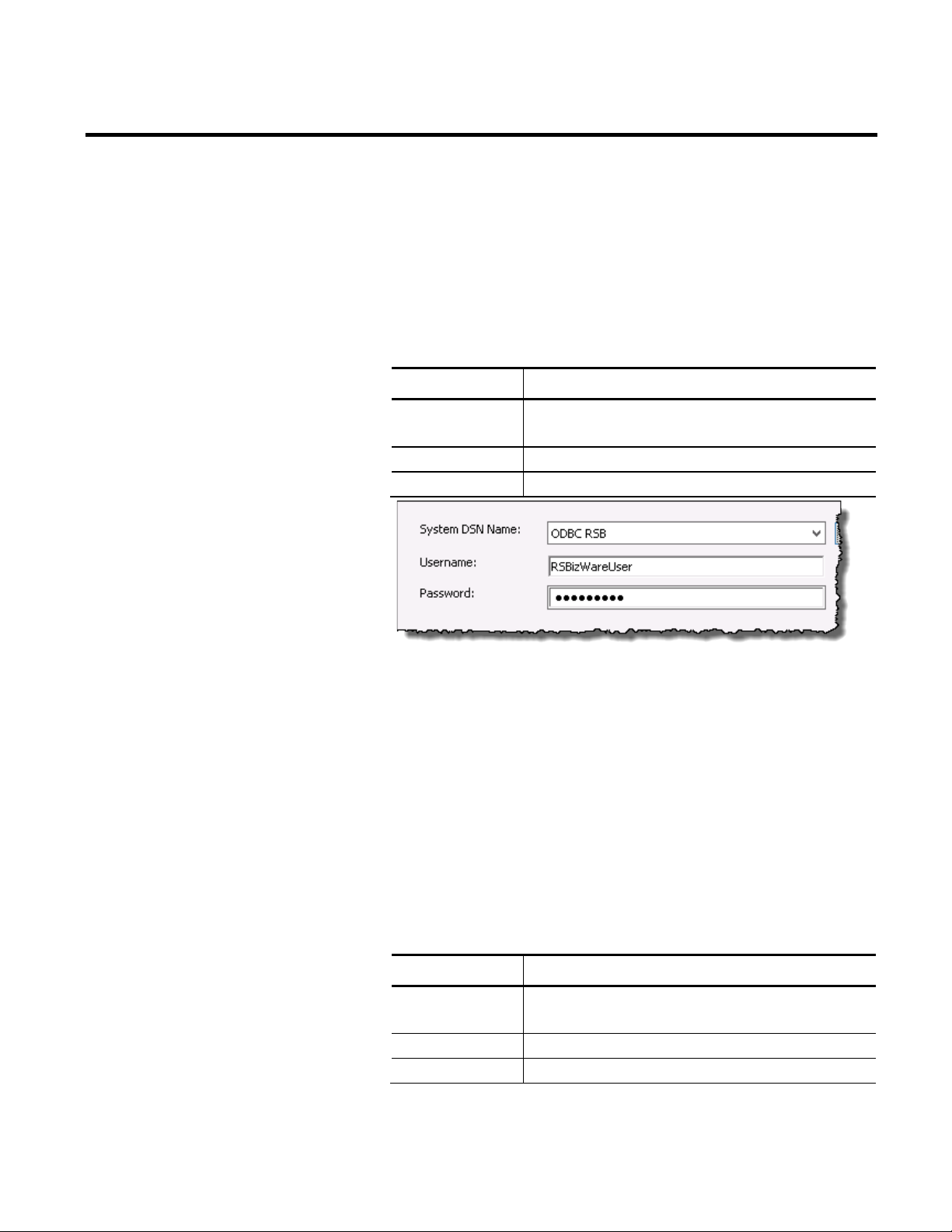

12. On the Database connection information page, provide the

following information:

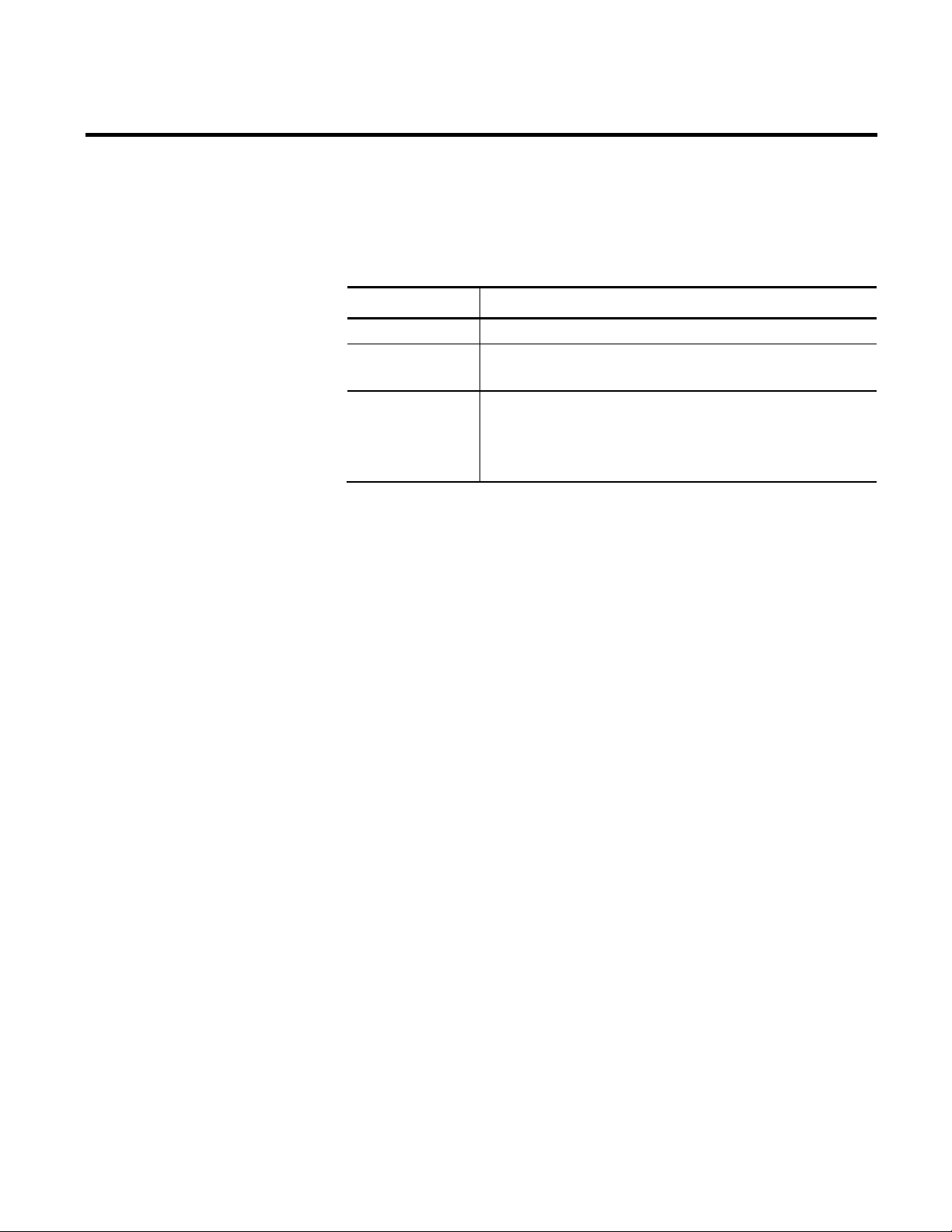

Item Description

System DSN Name Select the name of the ODBC data source that you have

configured for your RSBizWare SQL Server database.

Username Type the user name of your RSBizWare database.

Password Type the password for the RSBizWare database user.

13. Click Next.

14. On the Ready to Install the Program page, click Install.

The Installing... page presenting the installation status

appears.

15. On the InstallShield Wizard Completed page, click Finish.

The Database Load and Update wizard appears.

16. On the Welcome page, click Next.

17. On the Product and Database Connection page, provide the

following information:

Item Description

ODBC DSN Select the name of the ODBC data source that you have

configured for your RSBizWare SQL Server database.

User Type the user name of your RSBizWare database.

Password Type the password for the RSBizWare database user.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 21

Page 22

Chapter 3 Installing Report Expert

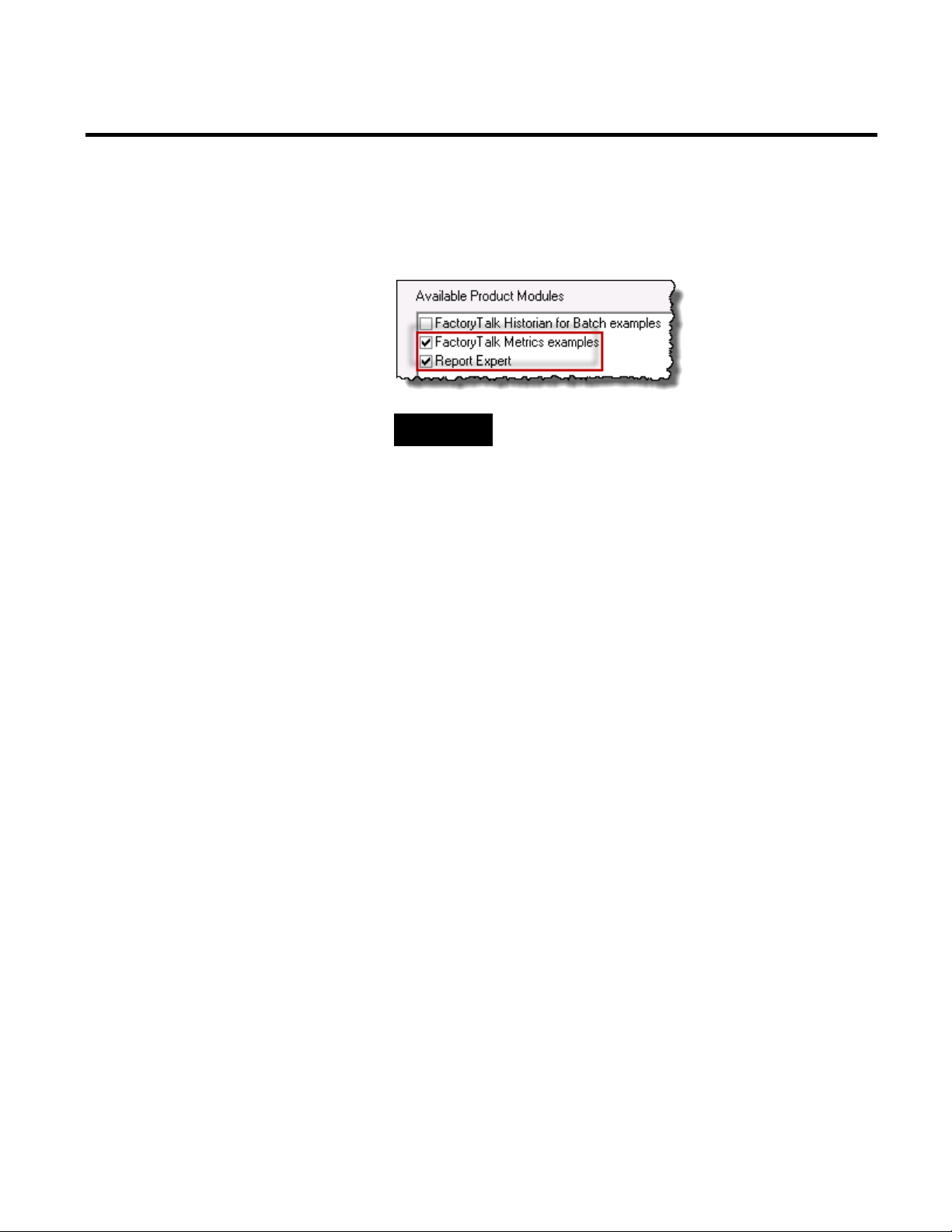

18. Click Connect. The Available Product Modules list is

populated with FactoryTalk components.

19. Under Available Product Modules, select these options:

Removing Report Expert

TIP

Select both options so that you have access to FactoryTalk

Metrics and Report Expert sample data.

20. Click Finish to load data.

21. Click Close to exit the wizard.

Before removing Report Expert, you must delete all of the scheduled

reports you created while using Report Expert. You can delete the

reports from the Subscriptions tab (see "Deleting Report

Subscriptions (page 154)") or you can stop the Microsoft SQL

Server Agent (MSSQLSERVER) service (note that

MSSQLSERVER is the default Microsoft SQL Server instance

name that needs to be replaced with an appropriate one).

To stop the SQL Server agent service:

1. Go to Start > Administrative tools > Services. The Services

dialog box appears.

2. Right-click the SQL Server Agent service, and click Stop.

To remove Report Expert from the computer:

• Run the Report Expert installation again, click Next, and then

select Remove.

• Select Start > Settings > Control Panel > Add/Remove

Programs. The Windows Add/Remove Programs utility

22 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 23

Installing Report Expert Chapter 3

appears. To remove Report Expert, select Report Expert and

click Remove.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 23

Page 24

Chapter 3 Installing Report Expert

24 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 25

Chapter 4

Getting Started

In this chapter you will learn the following:

• What are the components of the Report Expert architecture

(page 25).

Understanding the Report Expert Architecture

• How to connect to Report Expert (page 27).

• What are the components of the Report Expert web page

(page 29).

• Where Report Expert-related errors are logged (page 34).

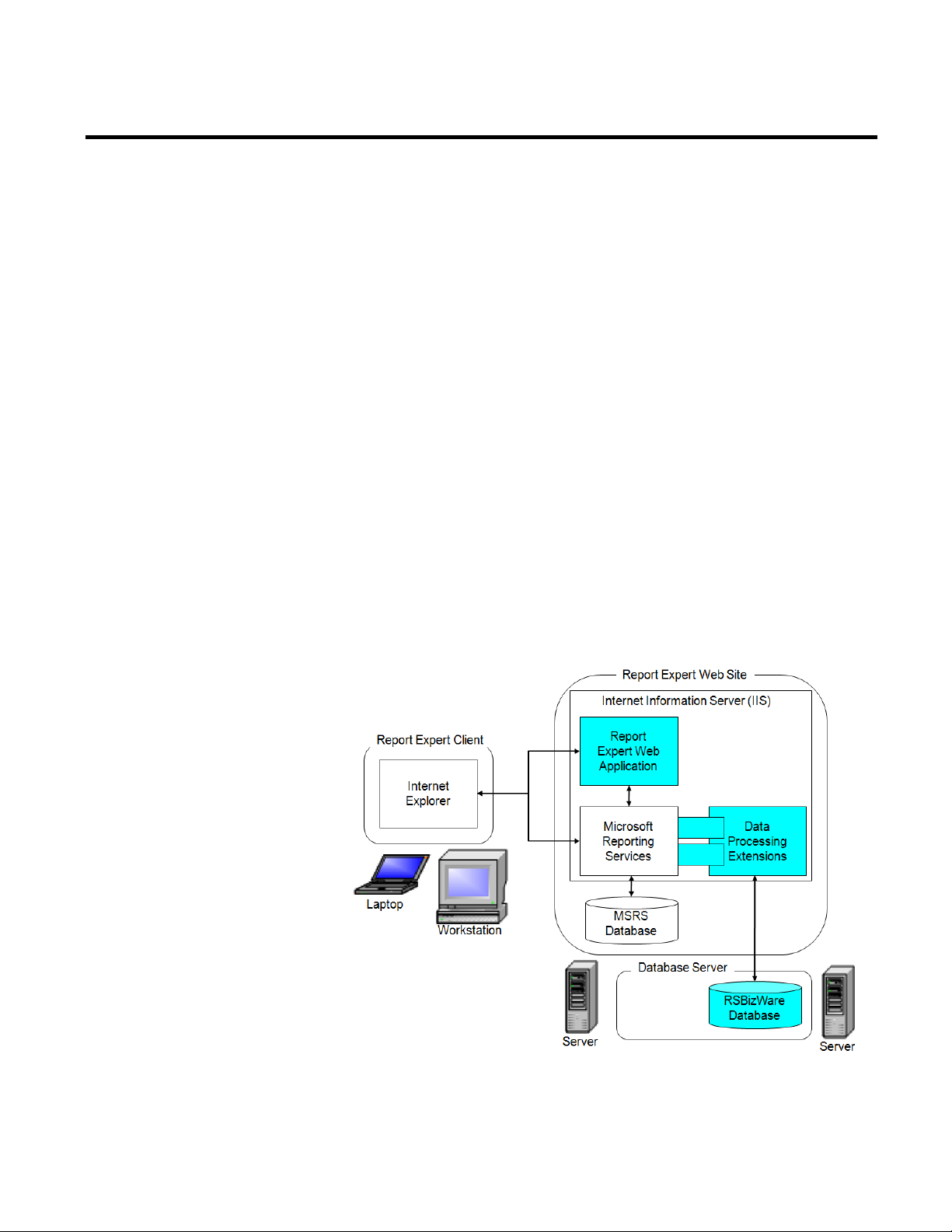

The following diagram provides a high-level architecture of Report

Expert.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 25

Page 26

Chapter 4 Getting Started

The Report Expert architecture is a scalable, multi-tiered,

distributed architecture consisting of the following main

components:

Item Description

Report Expert client (One or more.) A laptop or workstation running Internet Explorer.

Report Expert web

site

A server computer running Microsoft SQL Server with SQL Server

Reporting Services (SSRS) and Internet Information Server (IIS).

Database server A server computer running Microsoft SQL Server. This computer

contains the RSBizWare database with the FactoryTalk Metrics data

from which the content of Report Expert report templates are

derived.

The Report Expert components can be configured to run on a single

computer, or it can be distributed across multiple computers. In the

simplest case, the Report Expert web site can be installed on the

same machine as the database server and a user can access the Report

Expert client on the same server computer. In a distributed setting,

these components may reside on separate computers.

The Report Expert client connects to the Report Expert service to

view an HTML report, while it connects directly to the SQL Server

Reporting Services (SSRS) to generate a PDF or an Excel version of a

report or to print a report. The scalability of the Report Expert

architecture allows many clients to connect to a single Report Expert

web site.

The Report Expert web application interacts with the SSRS web

application. The SSRS web application uses the FactoryTalk Metrics

Data Provider (a SSRS Data Processing Extension) to retrieve

FactoryTalk Metrics data.

To generate FactoryTalk Metrics-related Report Expert report

templates, the Report Expert Service must have a connection to the

RSBizWare database containing the FactoryTalk Metrics tables and

views. In addition, SSRS need access to its own separate database at

run time.

26 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 27

Getting Started Chapter 4

NOTE

The same instance of Microsoft SQL Server can host both the SSRS

database and the RSBizWare database. However, only one instance of

Microsoft SQL Server is licensed with a FactoryTalk Metrics server.

Therefore, if you want to distribute the two databases across two

different computers, you must acquire an additional Microsoft SQL

Server license.

Connecting to Report Expert

Use Microsoft Internet Explorer to connect to Report Expert.

To start Report Expert do either of the following:

• Go to Start > All Programs > Rockwell Software > Report

Expert > Report Expert.

• Open Internet Explorer.

Go to:

http://hostcomputer:8001/rockwellsoftware/reportexpert

where hostcomputer is the name of the computer on which

Report Expert is installed.

NOTES

In order to display drill-down report data correctly, make

sure your Internet Explorer setting for refreshing pages is

set up correctly.

• In Internet Explorer 7.0, select Tools > Options.

Under Temporary Internet Files, click Settings

and select Every time I visit the webpage.

• In Internet Explorer 8.0 or 9.0, select Tools >

Internet Options. Under Browsing history, click

Settings and select Every time I visit the

webpage.

Report Expert administrators should open Report Expert in

Internet Explorer using the Run as administrator option so that the

Administration page is visible. For more details, see "Administering

Report Expert (page 133)".

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 27

Page 28

Chapter 4 Getting Started

TIP

If you use Internet Explorer 10, see "Settings Specific to Internet Explorer

10 (page 28)" to learn how to configure your browser to work with

Report Expert.

Settings Specific to Internet Explorer 10

Add the Report Expert Site to the Trusted Sites Zone

To make sure that Report Expert is displayed correctly in Internet

Explorer 10, configure the following:

• Add the Report Expert site to the Trusted sites zone. (page 28)

• Set Internet Explorer 10 to open the Report Expert site in

Compatibility View. (page 29)

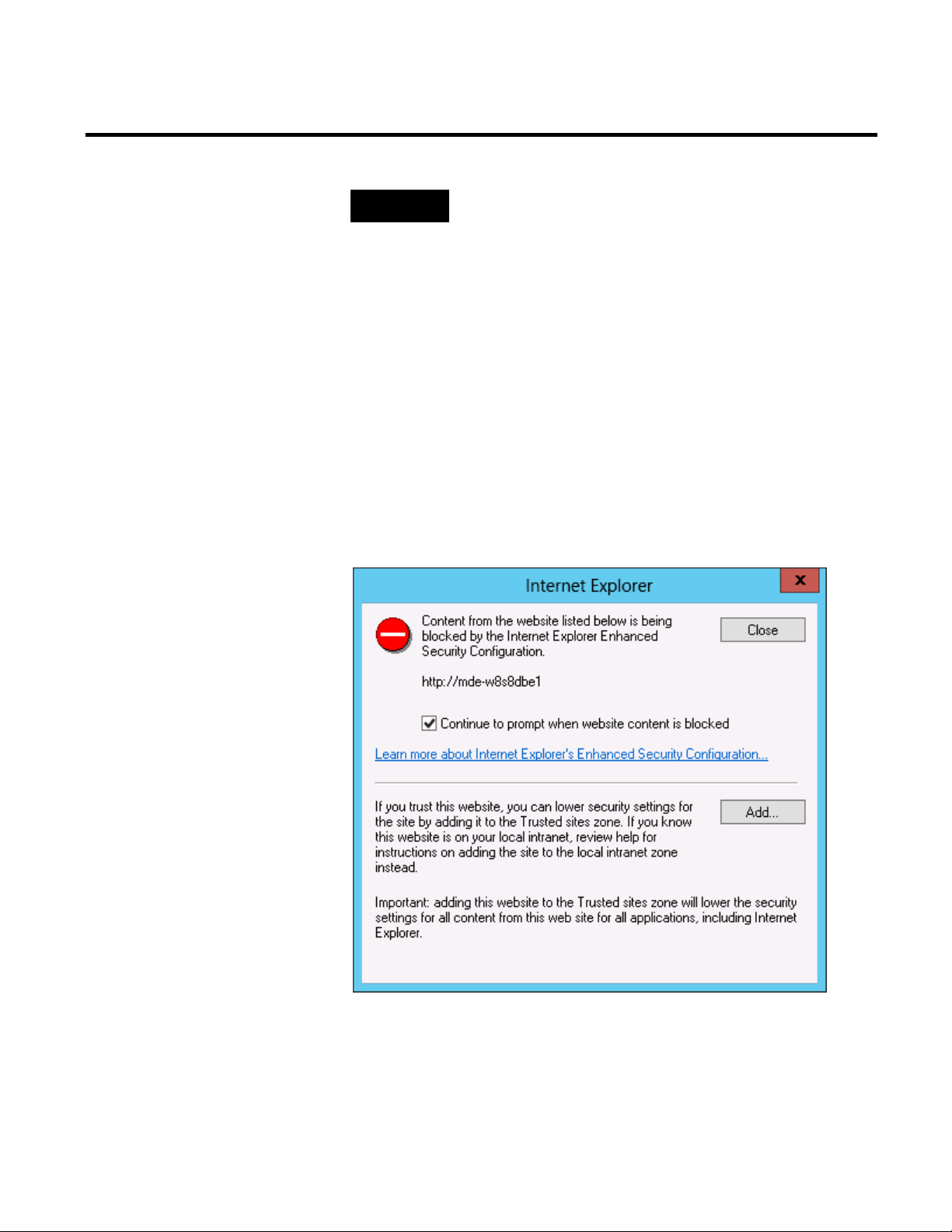

When you open the Report Expert site in Internet Explorer 10 for

the first time, the following message is displayed:

To prevent Internet Explorer 10 from blocking Report Expert, add

the Report Expert site to the Trusted sites zone.

28 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 29

Getting Started Chapter 4

To add the Report Expert to the Trusted sites zone:

1. In the dialog box displayed above, click Add.

The Trusted sites dialog box appears.

The address of the Report Expert site appears under Add this

website to the zone.

2. Click Add.

The site is added to the Websites list.

3. Click Close.

The Report Expert site is reloaded and is displayed in the

browser with its content.

Open the Report Expert Site in Compatibility View

To open the Report Expert site in Compatibility View:

1. Open Report Expert in Internet Explorer 10.

2. Right-click the window bar of Internet Explorer, and click

Menu bar.

The menu bar appears.

3. On the Tools menu, click Compatibility View settings.

The Compatibility View Settings dialog box appears.

The address of the Report Expert site appears under Add this

website.

4. Click Add.

The site is added to the Websites you've added to

Compatibility View list.

5. Click Close.

Navigating Report Expert

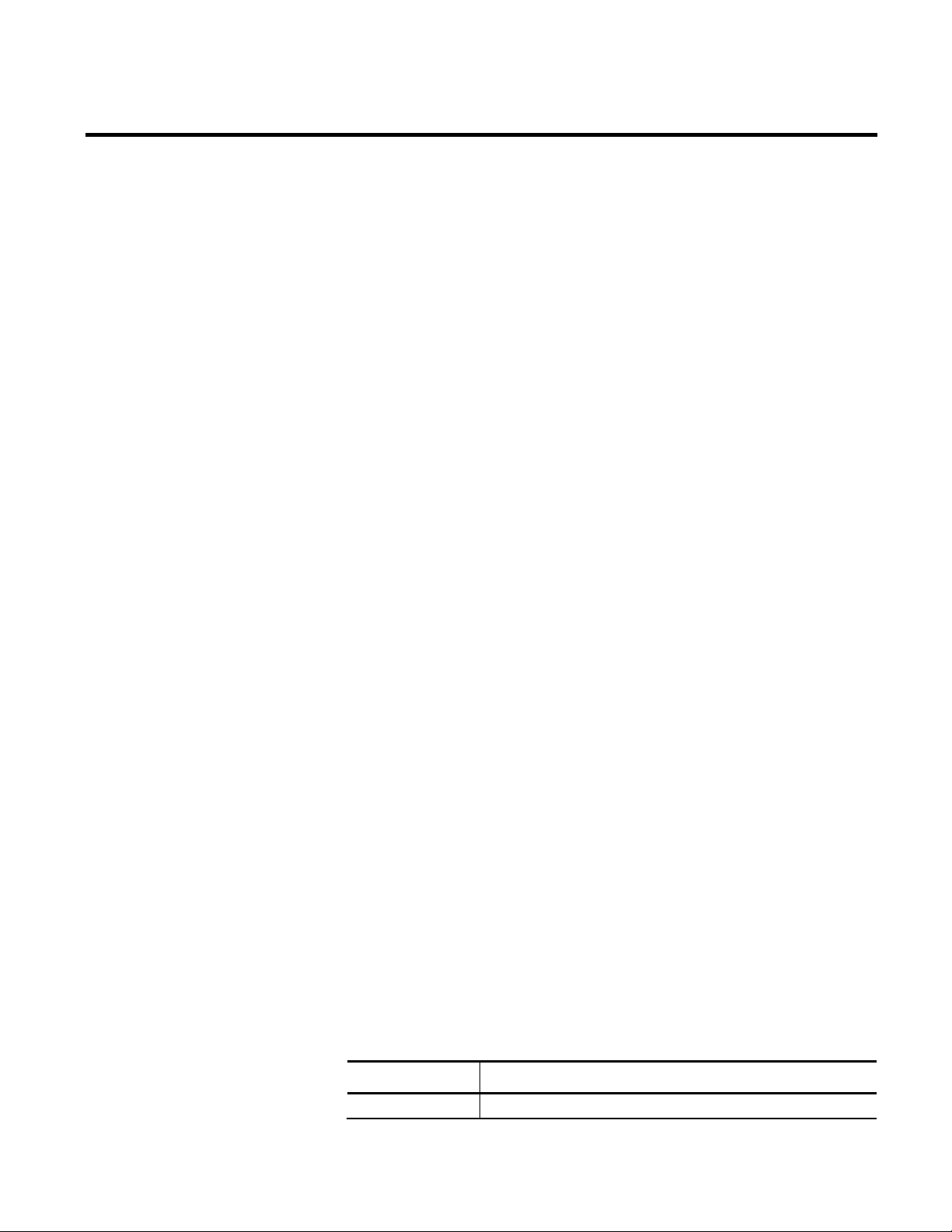

Report Expert consists of the following modules and pages:

This module: Contains these pages:

Administration Administration

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 29

Page 30

Chapter 4 Getting Started

ay or hide the red status bar at the bottom of the Report Expert

This module: Contains these pages:

Manual Data Editor

• Parameters

• Editor

Report Viewer

• Parameters

• Explorer

Use the toolbar at the top of the Report Expert page to navigate to

different areas of the product, and to control which components are

displayed.

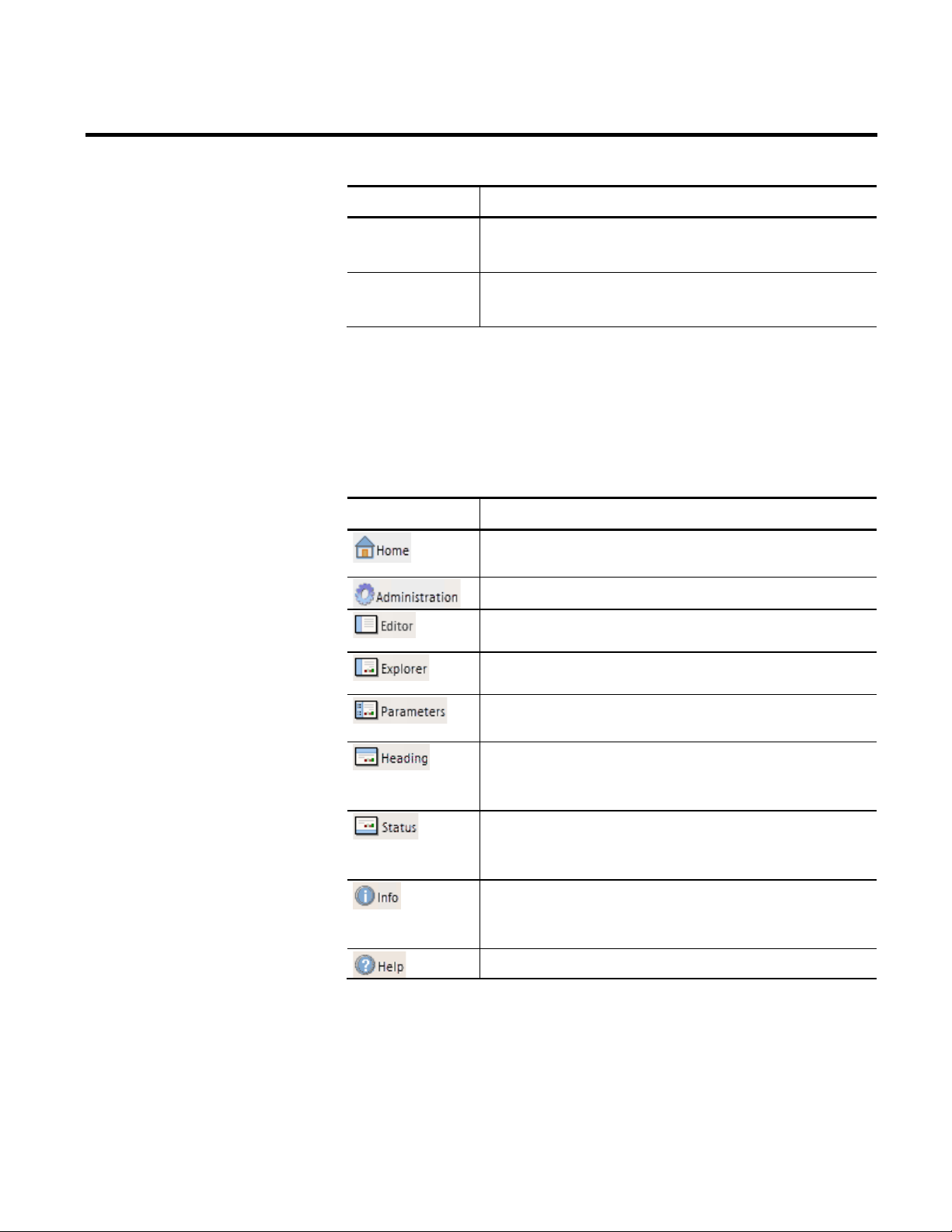

The toolbar contains the following icons:

Click this button To:

Open the Report Expert home page. By default, it is the Report

Viewer's Parameters page.

Open the Administration (page 30) page.

Open the Editor (page 32) page.

Open the Explorer (page 34) page.

Administration Page

30 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Display or hide the Parameters page for either the Manual Data

Editor (page 32) or the Report Viewer (page 33).

Display or hide the red heading bar at the top of the Report Expert

web page. The heading bar indicates your current location within

the Report Expert.

Displ

web page. The status bar shows tool tips and messages as you work

within Report Expert.

Display a new browser window containing a list of the various

components (and their version numbers) being used by Report

Expert, and the version number of Report Expert.

Display the help for Report Expert.

Page 31

Getting Started Chapter 4

On the Administration page, administrators can:

• Manage the content of the tree on the Explorer page.

• Configure the RSBizWare QuickWeb for Report Expert.

• Configure report subscriptions.

• Schedule reports for future delivery.

• Configure the way parameter sets are displayed on the web

page.

• Configure a line order for work cells.

Manual Data Editor

To open the Administration page, click

on the

Report Expert toolbar.

For more information on using the Administration page, see

"Administering Report Expert (page 133)".

The Manual Data Editor allows you to display and modify

production data from a FactoryTalk Metrics database. It consists of

the following pages:

• Parameters page (page 32).

• Editor page (page 32).

For more information on using the Editor, see "Editing Event and

Production Data (page 103)".

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 31

Page 32

Chapter 4 Getting Started

Parameters Page for the Editor

On the Parameters page, you can select operations and the

parameter sets for which you want to perform the operations.

To open the Parameters page for the Manual Data Editor for the

first time, click

To show or hide the Parameters page, click

on the Report Expert toolbar.

on the

Report Expert toolbar.

Editor Page

On the Editor page, you can perform various operations on the

production data you have selected:

• Edit events.

• Edit production data.

• Edit shift information.

32 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 33

• Enter data manually.

Getting Started Chapter 4

Report Viewer

Parameters Page for the Viewer

To open the Editor page, click

on the Report Expert

toolbar.

The Report Viewer allows you to view available reports. It consists

of the following pages:

• Parameters page (page 33).

• Explorer page (page 34).

For more information on using the Viewer, see "Viewing and

Generating Reports (page 97)".

On the Parameters page, you can associate report templates with

parameter sets and generate ad-hoc reports.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 33

Page 34

Chapter 4 Getting Started

To show or hide the Parameters page, click on the

Report Expert toolbar.

For more information on using the Parameters page, see "Generating

Reports Using the Parameters Page (page 97)".

Explorer Page

On the Explorer page, you can select a report from the tree to

automatically display that report in the display area.

To open the Explorer page, click

on the Report Expert

toolbar.

For more information on using the Explorer page, see "Viewing

Saved Reports on the Explorer Page (page 97)".

Troubleshooting

Errors for Report Expert are logged in the following locations,

depending on the task you are performing at the time of the error:

• Microsoft Event Viewer.

Errors that occur while you are running the software (with the

exception of generating reports).

To display the Event Viewer, do either of the following:

• On Microsoft Windows Server 2008 R2:

34 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 35

Getting Started Chapter 4

Go to Start > Control Panel, and then click View event

logs in the System and Security group, or select Start >

Administrative Tools > Event Viewer. The Event Viewer

window appears.

• The SSRS log.

Errors that occur when you are generating reports.

The log file is located in the following folder:

Program Files\Microsoft SQL Server\<the name of the folder of

the Reporting Services instances, for example the default name or

MSRS10_50.MSSQLSERVER for Microsoft SQL Server 2008

R2>\Reporting Services\LogFiles.

• The Report Expert service log.

Errors that occur when you are using the Editor.

The log file is located in the \Website\Logs folder of your

Report Expert installation directory, for example: c:\Program

Files (x86)\Rockwell Software\Report Expert\Website\Logs.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 35

Page 36

Chapter 4 Getting Started

36 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 37

Chapter 5

Understanding Report Templates

Report Expert includes a fixed number of report templates. These

are partial reports where the data fields to be displayed are already

defined. The data fields and behavior of these templates are fixed, so

you cannot easily change them. However, you can apply parameter

sets to report templates to change both the content and the

appearance of the resulting report.

Drillthrough

In this chapter you will learn about standard report templates that

are available with Report Expert.

You will use this information to create your own reports. See

"Viewing and Generating Reports (page 97)" for details.

For information regarding the source of all raw data used by Report

Expert, see "Raw Data (page 76)".

For a list of the report templates, the queries the report templates

use, and the fields in each of those queries, see "Query Fields (page

72)".

When you use the Report Expert drillthrough capability by clicking

a data value in a report template, the resulting report displays data

based on the new row grouping. There is a set hierarchy of data

groupings as you drill through a report. For example, if you drill

through a report that contains a week’s data for a single work cell,

the resulting report will be grouped by day.

Following is the drillthrough hierarchy for the report templates

supporting Report Expert drillthrough capability:

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 37

Page 38

Chapter 5 Understanding Report Templates

• Site

• Area

• Line

• Work Cell

• Month

• Week

• Day

• Shift

• Hour

Report templates that do not support drillthrough are identified in

the report template descriptions.

Report Templates

This section presents descriptions of the Report Expert report

templates. Depending on the type of a report template, the

descriptions may include the following information:

• The definition of the report template.

• The query on which the report template is based.

• The fields of the report template grid.

• The maximum number of rows allowed in the report template.

• The information on the drillthrough hierarchy.

• The description of the bar charts included in the report

template.

• The calculations used by Report Expert to prepare the

resulting report.

The definitions of report template fields are also available in

"Glossary of Fields (page 165)".

38 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 39

Understanding Report Templates Chapter 5

All report templates are available on the Parameters page, under

Select Report. See "Viewing and Generating Reports (page 97)" for

details.

Dashboard

The Dashboard report template is combined with the Dashboard

Current Shift parameter set. The Dashboard Current Shift

parameter set contains the following settings:

Item Description

Date/Time/Shift All Time Current Shift

Grouping Event Category (Col), Event Name (Col), Shift (Row)

Sorting None

Plant Model None

Filtering None

TOP N None

NOTE

For information on how the dashboard widgets (and this report

template) respond to changes in parameter settings, see "Parameter

Settings and Widgets (page 44)".

The Dashboard report template is comprised of the following

dashboard widgets:

• OEE % (page 40)

• 3 OEE Components (page 40)

• Last State (page 40)

• Production Summary (page 41)

• Uptime Summary (page 41)

• Fault Summary (page 42)

• Good Parts vs. Scrap Parts (page 42)

• Uptime vs. Downtime (page 43)

• Machine States (page 43)

• Event Count and Duration (page 43)

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 39

Page 40

Chapter 5 Understanding Report Templates

OEE % Widget

The OEE % widget displays the OEE % value as a horizontal bar

chart for the work cells selected over the time period selected.

The color of the bar changes depending on the OEE value. The

color values are taken from the respective Color fields in the

RptSetting table. The values which cause a change from one color to

another are also set in the RptSetting table in the Threshold fields

(see "Configuring Report Expert Settings (page 138)").

3 OEE Components Widget

Last State Widget

The 3 OEE Components widget displays the OEE % and the three

OEE components (availability, throughput, and quality) as four bars

in a horizontal bar chart.

The color of the OEE bar changes depending on the OEE value. The

color values are taken from the respective Color fields in the

RptSetting table. The values which cause a change from one color to

another are also set in the RptSetting table in the Threshold fields

(see "Configuring Report Expert Settings (page 138)").

The Last State widget displays the current machine state and the

time the machine has been in that state. The data is shown as text.

This widget is not useful if you select more than one work cell.

However, if you select more than one work cell, this widget displays

the machine state with the latest starting time.

40 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 41

Understanding Report Templates Chapter 5

Machine states are not configured so you must configure them

manually. If you do not configure machine states, this widget will

not contain data. For information on configuring machine states,

refer to the FactoryTalk Metrics User Guide.

Production Summary Widget

Uptime Summary Widget

The Production Summary widget displays the number of good parts,

scrap parts, total parts, and scrap % for all the selected work cells for

the time period.

The Uptime Summary widget displays total available time, running

time, and down time for all selected work cells for the time period.

Each is shown in the format HH:MM:SS.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 41

Page 42

Chapter 5 Understanding Report Templates

Fault Summary Widget

Good Parts vs. Scrap Parts Widget

The Fault Summary widget displays the aggregated fault-related

data: fault count, fault time, mean time between failure and mean

time to repair.

The Good Parts vs. Scrap Parts widget displays the total good parts

and scrap parts by percentage in a pie chart.

42 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 43

Understanding Report Templates Chapter 5

Uptime vs. Downtime Widget

Machine States Widget

The Uptime vs. Downtime widget displays the total uptime and

total downtime (in minutes) as a vertical bar chart. If shift is

configured for the selected work cell(s), and more than one shift is

included in the time selection, the data is grouped by shift.

The Machine States widget displays total time (in minutes) in each

of the defined machine states in pie chart format.

Machine states are not configured so you must configure them

manually. If you do not configure machine states, this widget will

not contain data. For information on configuring machine states,

refer to the FactoryTalk Metrics User Guide.

Event Count and Duration Widget

The Event Count and Duration widget displays information for

user-defined events, including the event name, total event duration

(in minutes), and total event count. Duration is shown as a vertical

bar chart, and event count as a line. The chart is grouped by event

category and event name within each category.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 43

Page 44

Chapter 5 Understanding Report Templates

With the exception of the Event Count and Duration widget, data in

Parameter Settings and Widgets

The widgets will respond to most changes you make to the Report

Expert parameters. However, not all parameter settings affect all the

widgets. In general, the widgets will respond to the following

parameters:

Item Description

Date/Time/Shift All widgets in a report template use the selected setting for time

and shift.

Plant Model All widgets in a report template use the selected setting for the

Plant Model filter.

Terminology All widgets in a report template use the selected setting for

terminology. You can use the Terminologies feature to change the

titles that appear in each widget. See "Using the Terminology

Parameter (page 94)".

If the selected widget uses the data fields in the parameter settings,

the widget will respond to the following parameters:

Event All Detail

Item Description

Sorting

the widgets is not sorted. If you select a data field in the Event

Count and Duration widget (Event Count or Event Duration), you

can sort the data in the Event Count and Duration widget. See

"Using the Sorting Parameter (page 88)".

Filtering The widgets respond to filtering, depending on the data being

filtered. If you filter on Part Id or one of the flex fields, filtering will

affect all widgets. If you filter on event category or event

description, filtering only affects the Event Count and Duration

widget. See "Using the Filtering Parameter (page 91)". Filtering

that is not appropriate for a particular widget is ignored.

NOTE

If you change grouping parameters, the widgets will not respond and an

error message will appear. Do not change the grouping parameters

(Event Category (Col), Event Name (Col), Shift (Row)) in the default

parameter set (Dashboard – Current Shift).

The Event All Detail report template displays information on every

occurrence of events. It contains more details than the Event Detail

and Event Detail Paged report templates.

44 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 45

Understanding Report Templates Chapter 5

The report does not support any grouping.

NOTE

Due to a large amount of data that can be displayed with this report we

recommend that you filter your data thoroughly to shorten the report

generation time, and/or limit the number of records to be returned with

the EventDetailExtRowLimit setting (page 138) available in the

RptSetting table.

Query: EventDetailExt.

The fields of the report template grid:

Item Description

Line

Workcell

Event Category The category of the event.

Event Name The name of the event.

Event Severity The numeric severity level assigned to the event.

Start Time The date and time that the event or state started.

End Time The date and time that the event or state ended.

Duration The length of the event, calculated as the difference between start

Start Value The value collected at the start of the event.

End Value The value collected at the end of the event.

Shift Start Time The start time of the shift during which the data was collected.

A level of the plant model (which is constructed by enterprise, site,

area, line, and then work cell).

time and end time and displayed using the format

HH:MM:SS.mmm. The calculation for this field is:

Duration = End Time - Start Time.

Shift Number The number of the shift.

Shift Name The name of the shift.

Record State The numeric state of the database record.

Event During

Information whether the event occurred during the scheduled time.

Scheduled Time

Event Start Num The numeric value collected at the start of the event.

Event End Num The numeric value collected at the end of the event.

Event During Num A numeric information on the event calculated as the difference

between Event End Num and Event Start Num. The calculation for

this field is:

Event During Num = Event End Num – Event Start Num.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 45

Page 46

Chapter 5 Understanding Report Templates

Item Description

Event Is Fault Information on whether the event is used for Faults metrics.

Event Reason Code The numeric code representing the event reason.

Event Reason The string value representing the event reason.

Event Occurrence The identifier of a single event occurrence.

PartId The ID of the part that was being produced when the event

occurred.

Event Comment The wording of a comment that you have typed for an event in the

Editor (page 115).

The drillthrough hierarchy: none.

Calculations used by Report Expert to obtain values in the resulting

report:

Event Chart

• Duration = End Time - Start Time

• Event During Num = Event End Num – Event Start Num

The Event Chart report template aggregates all event-related data. It

contains a chart which displays data of the number and duration of

all events together, and links to Event Detail reports concerning

specific events.

Query: Event.

The fields of the report template grid:

Item Description

Event Count The number of events that occurred during the reporting period.

Total Duration The total time (HH:MM:SS.mmm) in the reporting period during

which an event or state was occurring.

Min. Duration The shortest event or state occurrence.

Max. Duration The longest event or state occurrence.

Avg. Duration The average length of event or state occurrences.

Detail Link to an Event Detail report referring to a specific fault, filtered to

display only faults and grouped by event name.

46 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 47

Understanding Report Templates Chapter 5

The values of the report template and other report templates to

which the values link using the drillthrough hierarchy:

Click a value in this column: To display this report template:

Event Count Event Chart

Total Duration Event Chart

Min. Duration Event Chart

Max. Duration Event Chart

Avg. Duration Event Chart

Detail Event Detail

The report template bar charts: Event Count and Event Duration

on separate charts, and a chart that displays both these values

together.

The bar chart fields:

Event Count and Event Duration chart fields (sorted according to

the type of sorting criteria selected):

Item Description

Values Event Count and Total Duration

X axis grouping First non-page grouping parameter

Series Second non-page grouping

Event Count chart fields (sorted by Event Count):

Item Description

Value Event Count

X axis grouping First non-page grouping parameter

Series Second non-page grouping

Event Duration fields (sorted by Total Duration):

Item Description

Value Total Duration

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 47

Page 48

Chapter 5 Understanding Report Templates

Item Description

X axis grouping First non-page grouping parameter

Series Second non-page grouping

Event Configuration

The Event Configuration report template displays FactoryTalk

Metrics configuration data related to events.

Query: EventConfiguration.

The fields of the report template grid:

Item Description

Enterprise

Site

Area

Line

Work Cell

Event Category The category of the event.

Event Name The name of the event.

Machine State Name The name of the machine state associated with the event.

Severity Level The numeric severity level assigned to the event.

Fault Metric Use Defines how the event affects the calculation of Fault Metrics.

Event Trigger A textual description of the data point used as a trigger for the

Event Trigger

Expression

Event Value A text description of the data point used for the event value.

Event Value

Expression

Event Value Lookup

List Name

A level of the plant model (which is constructed by enterprise, site,

area, line, and then work cell).

event.

A FactoryTalk Transaction Manager expression used to determine

the event trigger value.

A FactoryTalk Transaction Manager expression used to determine

the event value.

A name of the value lookup list that provides descriptive names for

each event value, if there is any list associated with the event.

48 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 49

Understanding Report Templates Chapter 5

•

The report template supports the following:

Item Description

Event Detail

Sorting by

Site

• Area

• Line

• Work Cell

• Event Name

• Event Category

• Work Cell Ordered

The standard plant model filtering

Filtering by

• Event Name

• Event Category

• Terminology

The drillthrough hierarchy: none.

The Event Detail report template displays raw event data.

Query: EventDetail.

The fields of the report template grid:

Item Description

Start Time The date and time that the event or state started.

End Time The date and time that the event or state ended.

Duration The length of the event, calculated as the difference between start

time and end time and displayed using the format

HH:MM:SS.mmm. The calculation for this field is:

Duration = End Time - Start Time.

Start Value The value collected at the start of the event.

End Value The value collected at the end of the event.

Event Comment The wording of a comment that you have typed for an event in the

Editor (page 115).

The maximum number of rows in the resulting report: 5000.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 49

Page 50

Chapter 5 Understanding Report Templates

NOTE

If the data returned exceeds the maximum number of rows allowed in

the resulting report, the Max row limit reached message appears in

red above the grid. The maximum row number can be changed in the

RptSettings table. For details, see "Modifying the RptSetting Table (page

143)".

The drillthrough hierarchy: none.

Calculations used by Report Expert to obtain values in the resulting

report:

• Duration = End Time - Start Time

Event Detail Paged

The Event Detail Paged report template displays raw event data,

divided into pages.

Query: EventDetail.

The fields of the report template grid:

Item Description

Start Time The date and time that the event or state started.

End Time The date and time that the event or state ended.

Duration The length of the event, calculated as the difference between start

time and end time and displayed using the format

HH:MM:SS.mmm. The calculation for this field is:

Duration = End Time - Start Time.

Start Value The value collected at the start of the event.

End Value The value collected at the end of the event.

Event Comment The wording of a comment that you have typed for an event in the

Editor (page 115).

The maximum number of rows in the resulting report: 5000.

50 Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014

Page 51

Understanding Report Templates Chapter 5

NOTE

If the data returned exceeds the maximum number of rows allowed in

the resulting report, the Max row limit reached message appears in

red above the grid. The maximum row number can be changed in the

RptSettings table. For details, see "Modifying the RptSetting Table (page

143)".

The drillthrough hierarchy: none.

Calculations used by Report Expert to obtain values in the resulting

report:

• Duration = End Time - Start Time

Event History String/Value

The Event History String and Value report templates display

row-level data from the OEEEvent table. The difference between

the reports is that the Start Value, End Value and Reporting Value

columns are displayed as either strings or values in the Event History

String and Event History Value report templates respectively.

Query: EventDetailExt.

The fields of the report template grid:

Item Description

Line

Workcell

Shift Start Time The start time of the shift during which the data was collected.

Event Occurrence The identifier of a single event occurrence.

Event Category The category of the event.

Event Name The name of the event.

Event Reason The string value representing the event reason.

Start Time The date and time that the event or state started.

End Time The date and time that the event or state ended.

Duration The length of the event, calculated as the difference between start

A level of the plant model (which is constructed by enterprise, site,

area, line, and then work cell).

time and end time and displayed using the format

HH:MM:SS.mmm. The calculation for this field is:

Duration = End Time - Start Time.

Rockwell Automation Publication RPTEXP-UM001H-EN-P-June 2014 51

Page 52

Chapter 5 Understanding Report Templates

Event Overview

Item Description

Start Value The value collected at the start of the event.

End Value The value collected at the end of the event.

Reporting Value The string value representing the event reason.

Event Severity The numeric severity level assigned to the event.

The drillthrough hierarchy: none.

Calculations used by Report Expert to obtain values in the resulting

report:

• Duration = End Time - Start Time

The Event Overview report template displays row-level data from

the OEEEvent table.

Query: EventDetailExt.

The fields of the report template grid:

Item Description

Line

Work Cell

Event Category The category of the event.

Event Name The name of the event.

Event Reason The string value representing the event reason.

Shift Start The start time of the shift during which the data was collected.

Event Occurrence

Count/Id