Page 1

ADMINISTRATOR’S GUIDE

Metric Line Edition

PUBLICATION FTMLE-IN001A-EN-P–August 2008

Supersedes Publication FTMLE-IN001A-EN-E

INTEGRATED PRODUCTION & PERFORMANCE SUITE

Performance & Visibility

Page 2

Contact Rockwell

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support

Copyright Notice

Trademark Notices

Other Trademarks

Warrant y

© 2008 Rockwell Automation Technologies, Inc. All rights reserved. Printed in USA.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation

Technologies, Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement for details.

Allen-Bradley, ControlLogix, FactoryTalk, PLC-2, PLC-3, PLC-5, Rockwell Automation, Rockwell Software, RSLinx,

the Rockwell Software logo are registered trademarks of Rockwell Automation, Inc.

The following logos and products are trademarks of Rockwell Automation, Inc.:

RSBizWare, the RSBizWare logo, RSLogix, FactoryTalk Activation, FactoryTalk Administration Console, FactoryTalk

Services Platform, FactoryTalk Directory, FactoryTalk Live Data, RSAssetSecurity, FactoryTalk Security, FactoryTalk

Metrics, FactoryTalk Metrics LE, RSSql, FactoryTalk Transaction Manager, RSLinx Classic, RSLinx Enterprise, SLC

500, and SoftLogix

5, SLC

Microsoft, SQL Server, Windows, Windows ME, Windows NT, Windows 2000, Windows Server 2003, and Windows

XP are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the

United States and/or other countries.

ControlNet is a registered trademark of ControlNet International.

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

This product is warranted in accordance with the product license. The product’s performance may be affected by system

configuration, the application being performed, operator control, maintenance and other related factors. Rockwell

Automation is not responsible for these intervening factors. The instructions in this document do not cover all the

details or variations in the equipment, procedure, or process described, nor do they provide directions for meeting every

possible contingency during installation, operation, or maintenance. This product’s implementation may vary among

users.

This document is current as of the time of release of the product; however, the accompanying software may have

changed since the release. Rockwell Automation, Inc. reserves the right to change any information contained in this

document or the software at anytime without prior notice. It is your responsibility to obtain the most current information

available from Rockwell when installing or using this product.

Version: 9.0.0 (CPR 9)

Modified: August 7, 2008 4:53 pm

ii

Page 3

Contents

1 • Welcome to FactoryTalk Metrics Line Edition 1

What is FactoryTalk Metrics Line Edition?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The FactoryTalk Metrics Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Benefits of FactoryTalk Metrics LE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Intended audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FactoryTalk Metrics LE administrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Where can I go for help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RSBizWare Administrator’s Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FactoryTalk Metrics User's Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Report Expert User’s Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Online Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Telephone support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Web support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

On-site support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Consulting services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Your local representative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 • Installing FactoryTalk Metrics LE 7

Installing vs. Upgrading FactoryTalk Metrics LE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing FactoryTalk Metrics LE components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Creating a new SQL Server database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Creating a SQL Server database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Creating a DSN database connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing Report Expert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install FactoryTalk Activation and licenses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing FactoryTalk Metrics LE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 • FactoryTalk Metrics LE Content 15

FactoryTalk Metrics LE UDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

UDT Data Points and FactoryTalk Metrics Performance Parameters . . . . . . . . . 16

Reports and Parameter Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

i

Page 4

FACTORYTALK METRICS LINE EDITION USER’S GUIDE

• • • • •

4 • Configuring FactoryTalk Metrics LE 25

Configuring FactoryTalk Metrics LE: New vs. Update. . . . . . . . . . . . . . . . . . . . . . . 26

Configuring the FactoryTalk Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Adding FactoryTalk users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configuring RSLinx Enterprise as the OPC Server . . . . . . . . . . . . . . . . . . . . . . . 28

Configuring the RSBizWare Service Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Loading database data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Creating the plant model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Adding the FactoryTalk Metrics LE UDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Configuring FactoryTalk Transaction Manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Registering the FactoryTalk Transaction Manager configuration for data collection 43

Configuring FactoryTalk Metrics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Modifying performance parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Configuring Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Starting data collection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5 • Viewing FactoryTalk Metrics LE Reports 49

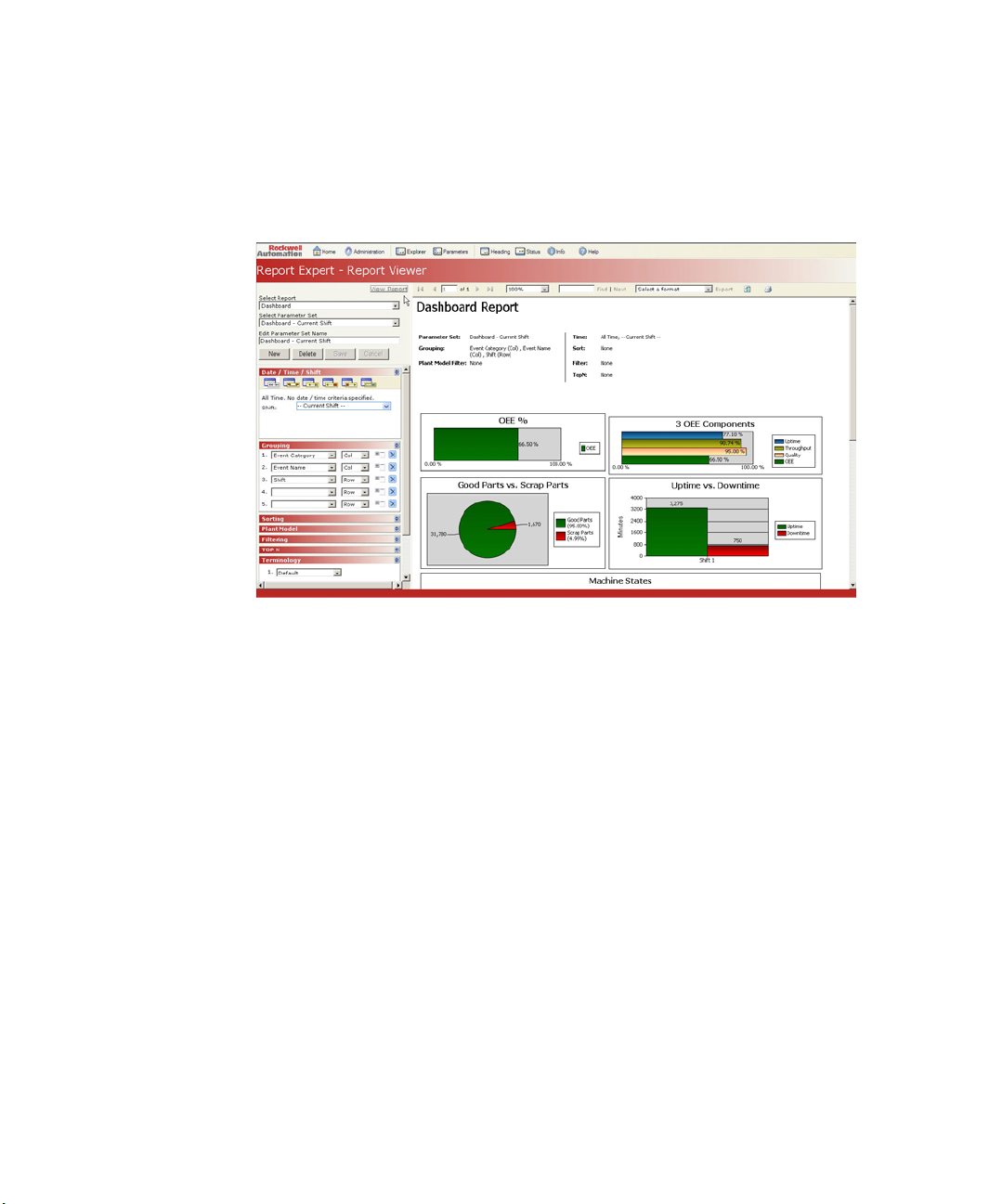

FactoryTalk Metrics LE Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Dashboard Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

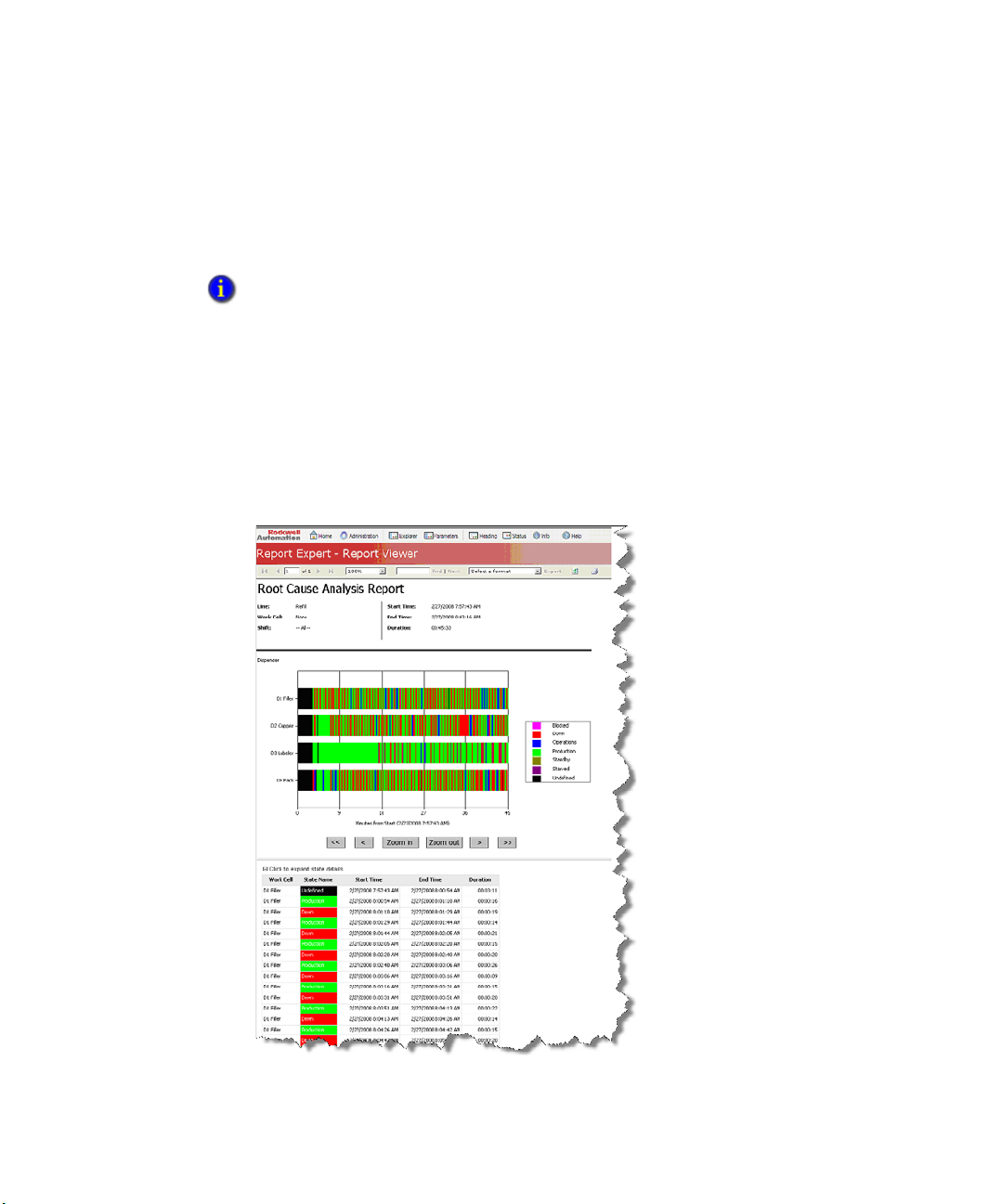

Machine State History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Dashboard widgets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Parameter settings and widgets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Index 59

ii

Page 5

1

Welcome to FactoryTalk Metrics Line Edition

What is FactoryTalk Metrics Line Edition?

FactoryTalk Metrics LE is a special edition of FactoryTalk Metrics that contains

additional components for configuring a new application and for visualizing data

collected by the application. Like FactoryTalk Metrics, FactoryTalk Metrics LE is a

performance management application that collects data about the performance of

production assets so that their efficiency can be improved.

FactoryTalk Metrics LE includes:

FactoryTalk Metrics software

Report Expert software

Microsoft SQL Server 2005 software

A FactoryTalk Metrics server license and a number of runtime user licenses

FactoryTalk Metrics LE components, which include:

The FactoryTalk Metrics LE User-Defined Type (UDT)

The FactoryTalk Metrics LE Configuration Tool

Additional Report Expert dashboard reports

This Administrator’s Guide focuses on the components that are unique to FactoryTalk

Metrics LE. All of the FactoryTalk Metrics documentation also applies to FactoryTalk

Metrics LE.

FactoryTalk Metrics LE should be considered as an alternative to FactoryTalk Metrics

under the following circumstances:

The customer has an installed base of Rockwell Automation ControlLogix controllers

that can accept a UDT data structure.

The customer is willing and able to modify their control system program(s) to

integrate the UDT and make the necessary programming changes.

The additional dashboard reports for Report Expert provided with FTMLE have value.

The UDT and Configuration Tool that are included with FTMLE are intended to

accelerate the implementation of a FactoryTalk Metrics application by providing an easy

way to connect the FactoryTalk Metrics performance parameters to the necessary data

points in the control system. This method is intended to "quick start" the application

1

Page 6

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

development, but it in no way limits the custom configuration you can perform using the

standard FactoryTalk Metrics configuration tools.

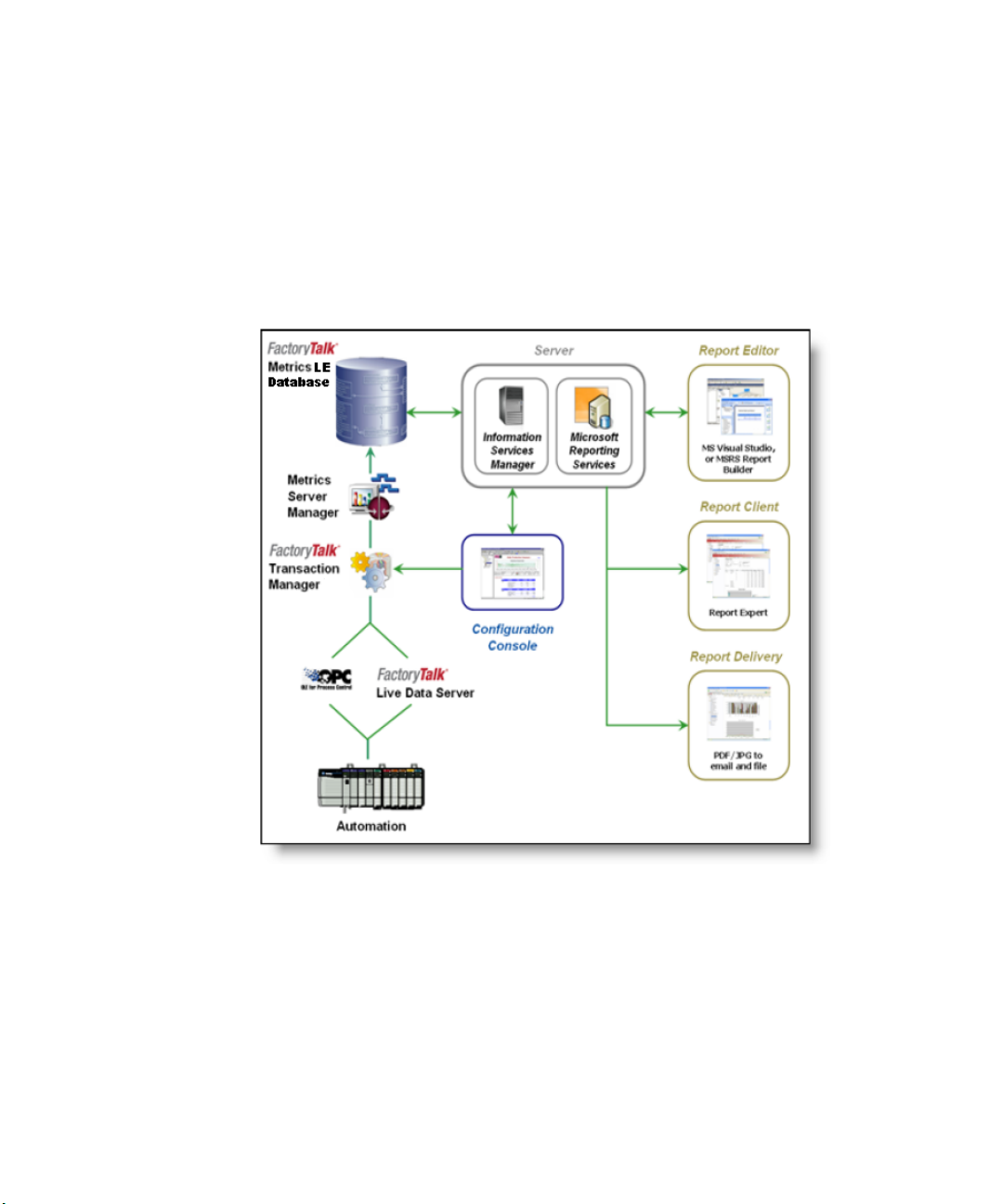

The FactoryTalk Metrics Architecture

The following diagram provides a high-level view of the FactoryTalk Metrics (and

FactoryTalk Metrics LE) architecture and its major components:

The FactoryTalk Metrics architecture is a scalable, multi-tiered, distributed architecture

consisting of a data collection sub-system, an SQL Server database repository, the

Information Services Manager, and clients.

Rockwell Automation’s FactoryTalk Transaction Manager collects data from the control

system(s) and the Metrics Server Manager logs it to the predefined database repository.

2

Page 7

1 • WELCOME TO FACTORYTALK METRICS LINE EDITION

There are different clients, including the RSBizWare Configuration Console and the Webbased report client. Users can author reports via QuickWeb, Report Expert, Microsoft

Reporting Services, or third party reporting tools.

FactoryTalk Metrics can run on a single computer, or it can be distributed across multiple

computers. In the simplest case, the RSBizWare Configuration Console, the Information

Services Manager, the Metrics Server Manager, the FactoryTalk Transaction Manager

data collection engine, and the database run on a single computer. In a distributed setting,

these components may reside on separate computers.

Clients connect to the server using TCP/IP, so they can be deployed over a LAN, WAN,

intranet, or the Internet. The scalability of the FactoryTalk Metrics architecture allows

many clients to connect to a single server.

Benefits of FactoryTalk Metrics LE

FactoryTalk Metrics LE provides the following benefits (many of which are also benefits

of FactoryTalk Metrics):

Improved Throughput. The standard reports let production management view actual

production versus rated capacity. Other reports provide information to determine if

lost production was from equipment that was being run at a reduced rate or equipment

downtime.

• • • • •

Reduced Downtime. The standard reports let the operator examine the causes of

downtime and identify the root cause of equipment breakdown or actual time taken for

activities such as changeover or setup.

Increased Line Efficiency. The Overall Equipment Effectiveness (OEE) of individual

pieces of equipment and of the overall line can be viewed with the standard reports.

Production management can use the information to focus improvement efforts on less

efficient equipment.

Better Performance Reporting. FactoryTalk Metrics LE has several Report Expert

dashboard reports that are not available in the FactoryTalk Metrics product. These

reports enhance the visualization of pertinent data for operators.

Faster Deployment. By using FactoryTalk Metrics LE, you can deploy applications

faster than you can using FactoryTalk Metrics. The FactoryTalk Metrics LE

configuration tools are applicable to customers who have an installed base of

Rockwell Automation ControlLogix processors.

Intended audience

The FactoryTalk Metrics Line Edition Administrator’s Guide is designed to help the

implementor of the FactoryTalk Metrics LE system understand how to install and

3

Page 8

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

configure FactoryTalk Metrics LE at the customer site. This document is also intended for

the following types of users:

FactoryTalk Metrics LE administrator

This is the individual who maintains FactoryTalk Metrics LE after it is installed and

configured for use. This individual should be familiar with:

Microsoft Windows operating systems

Microsoft Internet Explorer

Microsoft SQL Server 2005 (including Microsoft Reporting Services)

RSLogix 5000 programming

RSLinx Enterprise

Where can I go for help?

Consult the following resources for additional information about FactoryTalk Metrics LE:

RSBizWare Administrator’s Guide

This document is designed to help the RSBizWare administrator install and configure the

software and to understand the components that make up the RSBizWare suite of

products. The first chapter of the guide provides an overview of the software components

which included FactoryTalk Metrics

built. The remaining chapters describe the installation steps and available options when

deploying the RSBizWare software.

and describes the architecture on which they are

A printed copy of the RSBizWare Administrator’s Guide is distributed in the box with the

RSBizWare software and an electronic copy of the guide is available from the RSBizWare

software installation CD-ROM.

FactoryTalk Metrics User's Guide

This document describes how to configure and use FactoryTalk Metrics. It also applies to

FactoryTalk Metrics LE. FactoryTalk Metrics LE creates a default application that in most

cases will have to be changed, adapted, and expanded to satisfy all of the user

requirements. Refer to this document for information on how to use and configure specific

features of FactoryTalk Metrics.

A printed copy of the FactoryTalk Metrics User's Guide is distributed in the box with

FactoryTalk Metrics LE and an electronic copy of the guide is available on the

RSBizWare software installation CD-ROM.

4

Page 9

1 • WELCOME TO FACTORYTALK METRICS LINE EDITION

Report Expert User’s Guide

Report Expert is the pre-configured reporting interface to FactoryTalk Metrics LE. The

Report Expert User’s Guide is designed to help you understand how to install,

access, use, and maintain the Report Expert product.

configure,

A printed copy of the Report Expert User’s Guide is distributed in the box with the Report

Expert software and an electronic copy of the guide is available from the Report Expert

software installation CD-ROM.

Online Help

On-line Help is available within the various user interfaces provided with the product.

Telephone support

Rockwell Automation provides full support for the FactoryTalk Metrics LE product.

Questions concerning installation and the use of the software are handled by the Rockwell

Automation Customer Support Center, staffed Monday through Friday—except U.S.

holidays—from 8 AM to 5 PM Eastern time zone for calls originating within the U.S. and

Canada.

• • • • •

To reach the Customer Support Center, call 440-646-3434 and follow the instructions. For

calls originating outside the U.S./Canada, locate the number in your country by visiting

support.rockwellautomation.com

and selecting the Phone/On-site link. A list will be

presented from which you can locate and select the number to call in your country.

W

HEN YOU CALL

When you call, you should be at your computer and prepared to give the following

information:

The product version numbers, which can be found in the Report Expert software by

clicking the Info button at the top of the window.

The type of hardware you are using

The exact wording of any errors or messages that appeared on your screen

A description of what happened and what you were doing when the problem occurred

A description of how you attempted to solve the problem

Web support

In addition to phone support, the Rockwell Automation Customer Support Center offers

extensive online knowledgebases of technical notes and frequently asked questions for

support of non-urgent issues. These databases are updated daily by our support specialists.

5

Page 10

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

To receive regular e-mail messages with links to the latest technical notes, software

updates, and firmware updates for the products that are of interest to you or to submit an

online support request, visit support.rockwellautomation.com

On-site support

Rockwell Automation field support engineers are located around the globe to provide

assistance with special projects, unexpected problems, or emergency situations on-site.

Field support engineers are available for dispatch 24x7x365 and can arrive at many

locations the same day.

To learn more about this and other support services, visit the Customer Support Web site

at support.rockwellautomation.com

Consulting services

Rockwell Automation provides expert consulting and turnkey implementation of

FactoryTalk Metrics LE. Please contact your local representative for more information.

Your local representative

We strive to help all of our customers become successful in their manufacturing

improvement efforts. Toward this objective, we invite you to contact your local

representative or Rockwell Automation at any time that we may be of service to you.

and select the Online link.

.

6

Page 11

2

Installing FactoryTalk Metrics LE

FactoryTalk Metrics LE relies on several software packages that must be installed before

you install FactoryTalk Metrics LE. The list of required software packages is displayed in

the prerequisites below.

The FactoryTalk Metrics LE is based on FactoryTalk Metrics but includes some additional

Report Expert reports and tools to enable faster configuration of a FactoryTalk Metrics

application. Most of the procedures outlined in this manual are similar to the installation

and configuration required for FactoryTalk Metrics. For information about installing and

configuring FactoryTalk Metrics, refer to the RSBizWare Administrator’s Guide and the

FactoryTalk Metrics User’s Guide.

The default installation of FactoryTalk Metrics assumes that all components will be installed on

the same computer.

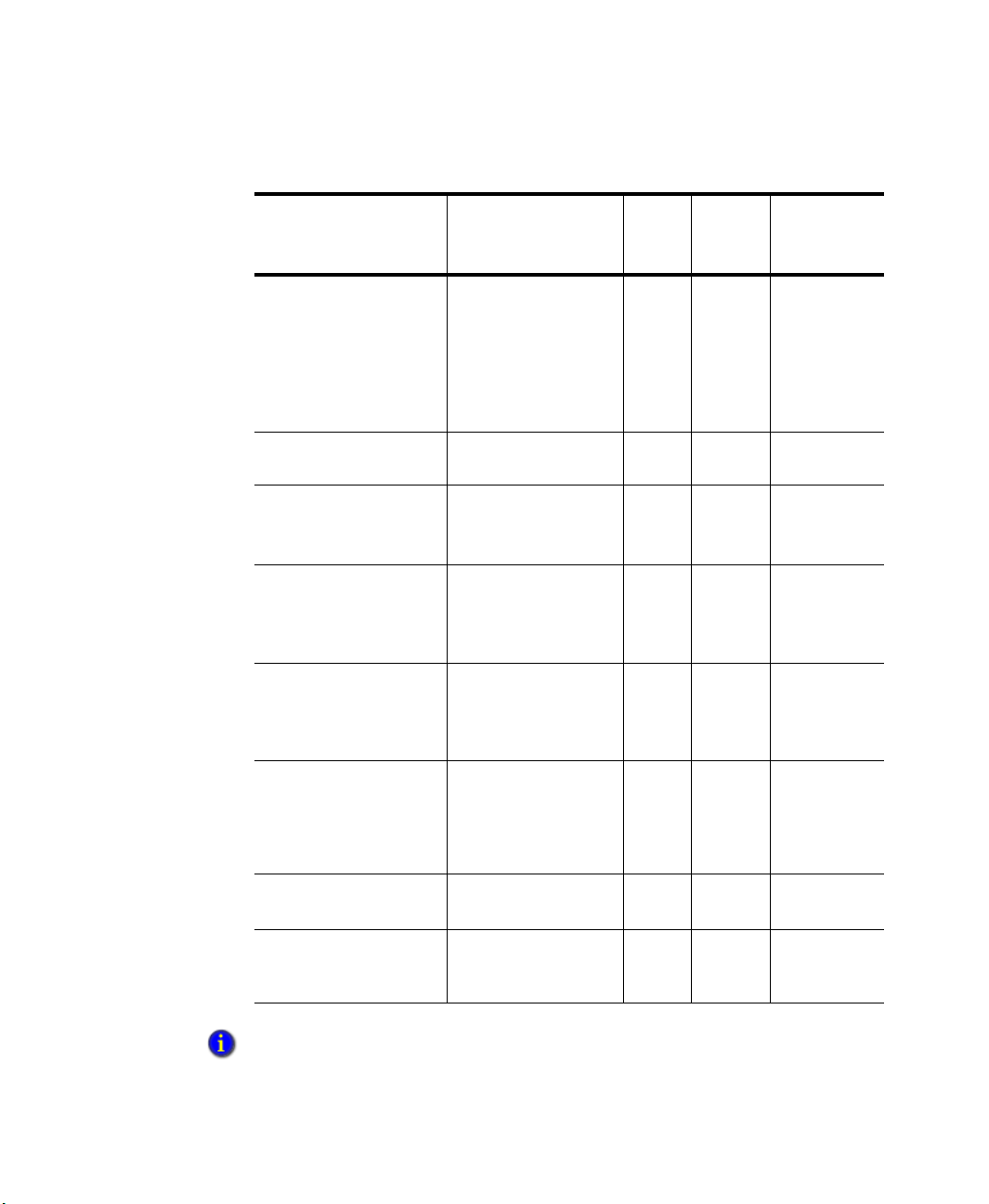

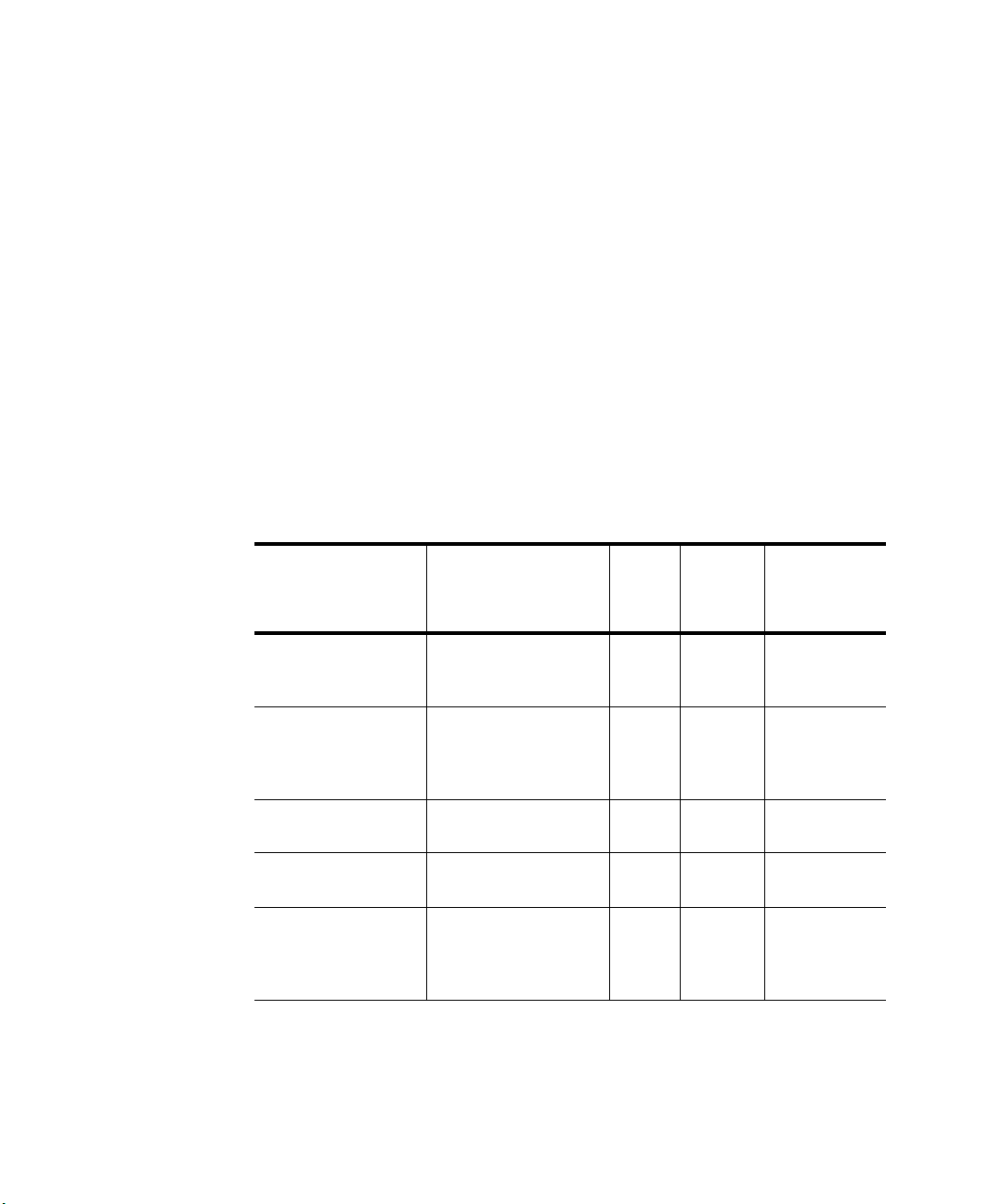

Installing vs. Upgrading FactoryTalk Metrics LE

This Administrator's Guide assumes you are installing FactoryTalk Metrics LE for

the first time on a new system. If you are upgrading an existing FactoryTalk Metrics

LE or FactoryTalk Metrics application, all of the steps in this chapter are not required.

The table below outlines the necessary steps for three different scenarios — a new

install, an update from FactoryTalk Metrics LE 8.0, and an update from FactoryTalk

Metrics 9.0. For more information about performing an upgrade, refer to the

RSBizWare Administrators Guide.

Installation Step Document Reference New

Install

Install Microsoft SQL

Server 2005 and Microsoft

Reporting Services

Microsoft SQL Server is

included with

FactoryTalk Metrics.

Refer to the

RSBizWare

Administrator’s

Guide.

9

Update

FTMLE

8.0

Update

FT Metrics

9.0

7

Page 12

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

Installation Step Document Reference New

Install

Install FactoryTalk

Services Platform

FactoryTalk Services

Platform is installed

with FactoryTalk

Metrics. Refer to the

99

RSBizWare

Administrator’s

Guide.

Install RSLogix Refer to Getting Results

with RSLogix 5000.

Install RSLinx Enterprise

Refer to the

RSLinx

9

9

Enterprise Getting

Results Guide.

Install RSBizWare 9.0 Refer to the

99

RSBizWare

Administrator’s

Guide.

Install FactoryTalk

Activation and licenses

Refer to the

RSBizWare

9

Administrator’s

Guide.

Update

FTMLE

8.0

**

**

Update

FT Metrics

9.0

*

Create database and DSN See “Creating a SQL

Server database” on

page 10 and “Creating a

DSN database

connection” on page 12.

Install Report Expert 1.10 See “Installing Report

Expert” on page 13

Install FactoryTalk

Metrics LE

* This step is required if you plan to use the FactoryTalk Metrics LE Configuration Tool to add more

workcells to an existing application.

8

See “Installing

FactoryTalk Metrics

LE” on page 14.

9

99

.

99 9

Page 13

Prerequisites

Before installing FactoryTalk Metrics LE, you must install the following software

products:

Microsoft Server 2003 operating system (Service Pack 1 or Server 2003 R2)

Microsoft SQL Server 2005 (Service Pack 2 with Microsoft Reporting Services)

FactoryTalk Metrics LE does not support Oracle.

FactoryTalk Services Platform (CPR9 version 2.10.00.117)

RSLogix (version 16) For installation information refer to Getting Results with

RSLogix 5000.

RSLinx Enterprise (version 5.00.00.100). RSLinx Enterprise will act as your OPC

Server. For installation information refer to the RSLinx Enterprise Getting Results

Guide.

RSBizware (version 9.00.00.0059) This includes:

FactoryTalk Metrics (version 9.00.0059). For installation information refer to the

• • • • •

2 • INSTALLING FACTORYTALK METRICS LE

RSBizWare Administrator’s Guide included with your FactoryTalk Metrics LE

materials.

FactoryTalk Activation Server/Client and a set of valid licenses.

Installing FactoryTalk Metrics LE components

In order to install FactoryTalk Metrics LE, you must perform the following tasks and

install the following additional components required by FactoryTalk Metrics LE:

SQL Server. Create a database to be used by FactoryTalk Metrics Line Edition. See

“Creating a new SQL Server database” on page 9.

Report Expert. Install Report Expert. See “Installing Report Expert” on page 13.

FactoryTalk Metrics LE. Install FactoryTalk Metrics LE. This loads the FactoryTalk

Metrics LE UDT (User-Defined Type), the FactoryTalk Metrics LE Configuration

Tool (which configures the performance parameters), and the additional FactoryTalk

Metrics LE reports. See “Installing FactoryTalk Metrics LE” on page 14.

Creating a new SQL Server database

Both FactoryTalk Metrics and Report Expert require a SQL Server database and DSN.

9

Page 14

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

Creating a SQL Server database

If you do not have an existing SQL Server database for FactoryTalk Metrics LE, create a

new SQL Server database and data source.

To create a SQL Server database:

1. Launch SQL Server. Select Start > All Programs > SQL Server 2005 > SQL Server

Management Studio.

2. In the Object Explorer pane, right-click Databases and select New Database.

3. In the Database name field, type the name to be given to your FactoryTalk Metrics LE

database (for example, FTMLEDB):

:

C

REATING A

Creating a new SQL Server login account is optional. You only have to create a new SQL

Server login account if you do not yet have a login account to use for SQL Server.

SQL S

ERVER LOGIN ACCOUNT

10

To create a SQL Server login account:

1. Under the Security folder in the Object Explorer pane, right-click the Logins folder

and select New Login. The Login - New dialog box appears.

2. On the General page of the dialog box, complete the following fields:

Login name. Type the name of the user (for example, FTMLEUser).

SQL Server authentication. Select this option to authenticate the new user

through SQL Server rather than Microsoft Windows.

Password. Type the user password (for example, FTMLEUser) for the SQL

Server database.

Confirm Password. Re-type the user password.

Default database. Select the SQL Server database you created for FactoryTalk

Metrics LE (for example, FTMLEDB).

Page 15

2 • INSTALLING FACTORYTALK METRICS LE

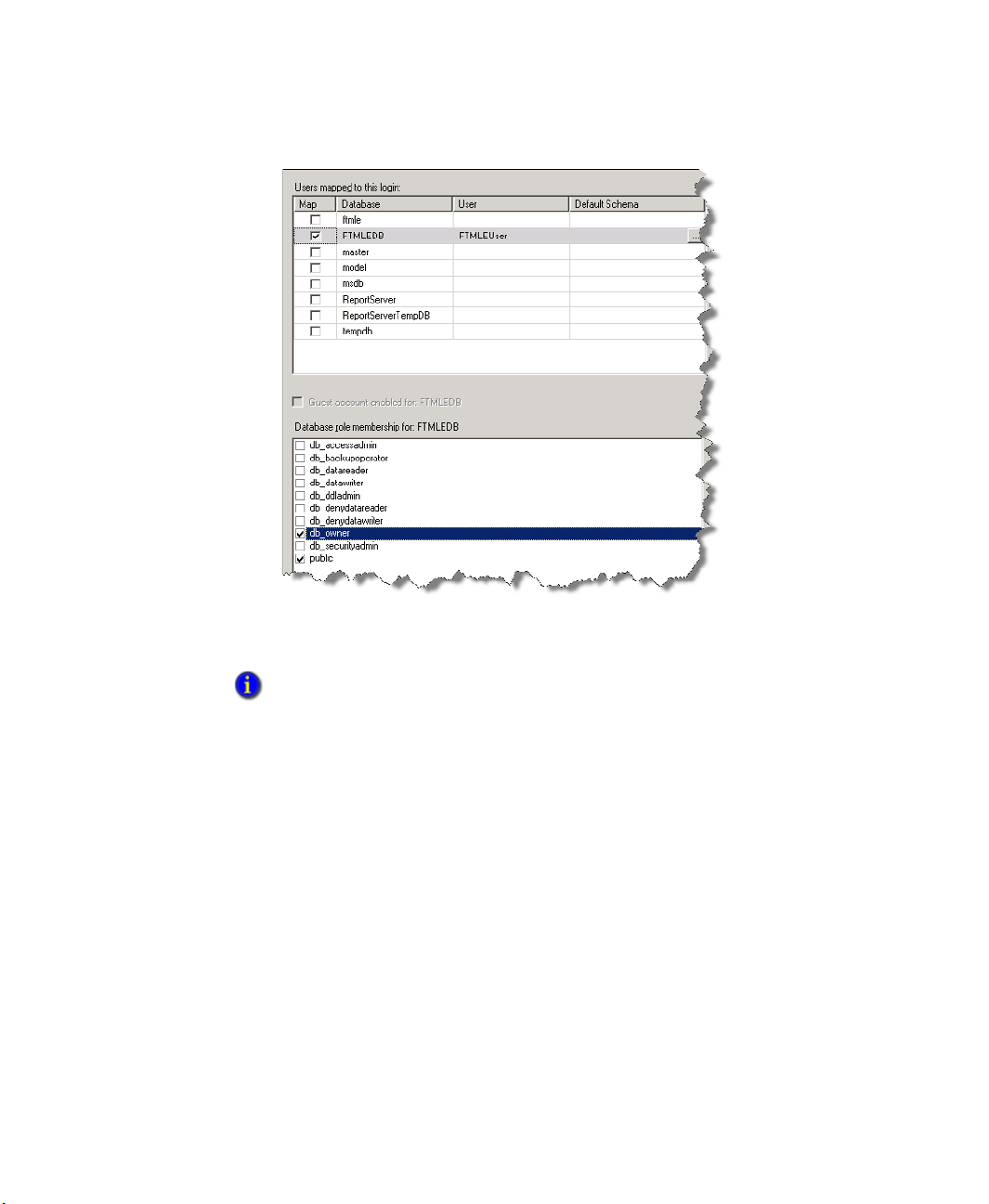

The New Login dialog box should now look like this:

• • • • •

3. In the Select a page pane on the left side of the New Login dialog box, select User

Mapping.

4. Give the user the necessary permissions on the new database:

FTMLEDB (or the name of your database). Tie the user to the newly created

FTMLEDB database. To do this, select the

Map checkbox for the FTMLEDB

database.

db_owner. Select this permission in the Database role membership for FTMLEDB

pane to grant the user administrative rights.

public. This option is selected by default.

11

Page 16

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

Select the newly

created database

(for example,

FTMLEDB).

Give the new user

db_owner and

public permissions

for the database.

The db_owner

permission lets the

user create new

tables and perform

other database

administration

functions.

• • • • •

5. Click OK. The new FactoryTalk Metrics LE user (for example, FTMLEUser) appears

under the Logins folder.

12

For help creating the SQL Server database or login account, click the Help button or refer to

the RSBizWare Administrator’s Guide.

6. Close the Microsoft SQL Server Management Studio window.

Creating a DSN database connection

1. To launch the ODBC for Windows Server 2003, select Start > All Programs >

Administrative Tools > Data Sources (ODBC). The ODBC Data Source

Administrator dialog box opens.

2. Click the System DSN tab.

3. To create a system DSN connection to this server, click Add. In the Select a driver for

which you want to set up a data source list, select the SQL Native Client driver and

then click Finish. The Create a New Datasource to SQL Server wizard page appears.

4. Complete the following fields:

Name. Type the DSN name (for example, FTMLEDSN).

Page 17

2 • INSTALLING FACTORYTALK METRICS LE

Server. Click the drop-down arrow to select the name of the computer where SQL

Server is installed.

5. Click Next.

6. Complete the following fields:

With SQL Server authentication using a login ID and password entered by

the user.

Select this option to create the database connection using SQL Server

(rather than Windows) authentication.

Login ID. Type the login id of the SQL Server user you just created (for example,

FTMLEUser).

Password. Type the password of the SQL Server user.

7. Click Next.

8. You can select the Change the default database checkbox and click the drop-down

arrow to select the database (for example, FTMLEDB).

9. Click Next. Complete the page as desired and click Finish.

It is recommended that you test the data source and verify that its connection can be

established. This verifies that the server name, login name, and password are correct. Click

Test Data Source. Once the test is successful, click OK.

• • • • •

10. When the DSN appears in the ODBC Data Servers Administration dialog box, click

OK.

Installing Report Expert

You must install Report Expert, the reporting interface to FactoryTalk Metrics LE. Install

Report Expert version 1.10.00.0007. When installing Report Expert, be sure and use the

DSN you created earlier (see

For more information on installing Report Expert, refer to the Report Expert User’s Guide.

“Creating a DSN database connection” on page 12).

Install FactoryTalk Activation and licenses

To install FactoryTalk Activation and licenses, refer to the RSBizWare Administrator’s

Guide.

13

Page 18

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

Installing FactoryTalk Metrics LE

Install FactoryTalk Metrics LE on the same computer where Microsoft SQL Server

resides. This installation process installs the FactoryTalk Metrics LE UDT, the

FactoryTalk Metrics LE Configuration Tool, and additional FactoryTalk Metrics LE

reports and parameter sets.

To begin the installation process:

1. Insert the FactoryTalk Metrics Line Edition CD-ROM into the CD/DVD drive. If your

operating system is set to the default, the FactoryTalk Metrics LE installation will

begin running automatically. If your operating system is not set to the default, browse

the CD-ROM to double-click the autorun.exe file.

2. Click Install FactoryTalk Metrics LE.

3. On the Welcome page of the installation wizard, click Next.

4. Read and accept the license agreement and click Next.

5. Complete the customer information and click Next.

6. Choose to install a complete (recommended) or custom installation of FactoryTalk

Metrics LE and click Next.

If you choose to perform a custom installation, the Custom Setup wizard page appears. As a

default, each of the features (Documentation, FactoryTalk Metrics LE Reports, FactoryTalk

Metrics LE Configuration Tool, and FactoryTalk Metrics LE ControlLogix UDT) is installed and

is necessary to make FactoryTalk Metrics LE function properly. To revise the installation of

any of the features, click the drop-down arrow next to the feature. You can opt to have the

individual features (and its subfeatures) installed on the local hard drive, installed when

required (when you first attempt to use the feature), or be made unavailable (not installed).

14

7. Click Install. The FactoryTalk Metrics LE files are copied to your computer.

8. When the installation is complete, click Finish.

9. To close the installation wizard when you are done, click Exit.

Page 19

3

FactoryTalk Metrics LE Content

FactoryTalk Metrics LE contains additional software and content which is not included in

a standard FactoryTalk Metrics installation. This content streamlines the configuration of

FactoryTalk Metrics if you have Rockwell Automation ControlLogix controllers that can

utilize a User-Defined Type.

The additional content provided with FactoryTalk Metrics LE includes:

User-Defined Type (UDT). For information on the UDT, see “FactoryTalk Metrics

LE UDT” on page 15.

Configuration Tool. The FactoryTalk Metrics LE Configuration Tool automatically

configures the performance parameters of workcells using the tag names in the UDT.

You will use the configuration tool in the next chapter. See “Configuring FactoryTalk

Transaction Manager” on page 38 and “Configuring FactoryTalk Metrics” on page 44.

Additional Report Expert reports and parameter sets. This includes a dashboard

report with several dashboard widgets which can be used to customize or create a

new dashboard report. See “Reports and Parameter Sets” on page 23.

The process of configuring and using these components is covered in Chapter 4,

“Configuring FactoryTalk Metrics LE” on page 25.

FactoryTalk Metrics LE UDT

The UDT named FTMLE_Workcell provides a comprehensive set of data points you

can use to configure FactoryTalk Metrics. The FactoryTalk Metrics LE UDT should

satisfy many customers’ data collection needs. However, FactoryTalk Metrics is not

limited to collecting tags in the UDT structure. It can collect tags from anywhere in

the control system. The UDT is provided as a convenience for data point organization

and faster configuration. Using the UDT requires the use of a compatible

ControlLogix controller.

Data point organization. The UDT organizes the data points that are typically used

for FactoryTalk Metrics data collection into a single structure that you can implement

in a Logix-based control system program.

Performance parameter configuration. The FactoryTalk Metrics LE Configuration

tool uses the data point names in the UDT to automatically configure performance

parameters for FactoryTalk Metrics workcells. Each data point is used for a particular

performance parameter.

15

Page 20

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

UDT Data Points and FactoryTalk Metrics Performance Parameters

The FactoryTalk Metrics LE Configuration tool configures FactoryTalk Metrics

performance parameters using the tag names in the UDT. Each workcell in the plant

model uses a different instance of the UDT in the control system (see “Creating the plant

model” on page 35). Each workcell will be configured identically.

The FactoryTalk Metrics LE Configuration tool configures performance parameters in a specific

manner. However, you can modify the performance parameters after you use the FactoryTalk

Metrics LE Configuration tool. As the implementor, decide whether and how to change the

performance parameters to meet the customer’s needs. You can modify workcell performance

parameters as necessary using standard methods for FactoryTalk Metrics. For more information,

see the FactoryTalk Metrics Users’ Guide.

Following are the data points in the UDT and the corresponding performance

parameters for which they will be used in FactoryTalk Metrics.

you must modify the control system program to ensure that the UDT tags contain valid

data for FactoryTalk Metrics to collect.

All UDT data points (unless otherwise noted) are used by the FactoryTalk Metrics LE

Configuration Tool to configure FactoryTalk Metrics performance parameters. If a

particular UDT data point is not used in a customer’s application, and therefore does not

contain valid control system data, you will have to modify the FactoryTalk Metrics

performance parameters. Do this after you run the FactoryTalk Metrics LE Configuration

Tool to make sure that the unused data point is not used by FactoryTalk Metrics.

As the implementor,

16

P

ART

ID

The Part ID identifies the product being produced at the workcell.The value in this field

should change when the workcell produces a different part. You must coordinate the

PartId value with the part count values in order to associate the part counts with the

correct Part Id.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

1 PartId String Part ID Unscheduled

Page 21

3 • FACTORYTALK METRICS LE CONTENT

I

DEAL CYCLE TIME

This value is the time required for one part to past through the workcell under ideal

conditions. Ideal Cycle Time is a real value and represents seconds. Usually, the Ideal

Cycle Time value changes only if the Part Id also changes.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

2 IdealCT Real Ideal Cycle Time Unscheduled

G

OOD PARTS

Good Parts is the count of the first quality parts produced by the workcell.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

3 GoodParts Integer Good Part Count Unscheduled

The GoodParts tag should act like an accumulator and increase in value. This value should

never decrease unless it is reset.

• • • • •

S

CRAP PARTS

Scrap Parts is the number of parts produced by a workcell that, for whatever reason,

cannot be categorized as good parts. From a machine efficiency point of view, these parts

have no value, and the cycle time taken to produce them at the current workcell has been

wasted.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

4 ScrapParts Integer Scrap Part Count Unscheduled

The ScrapParts tag should act like an accumulator and increase in value. This value should

never decrease unless it is reset.

17

Page 22

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

T

OTAL PARTS

The Total Parts value is automatically calculated by FactoryTalk Metrics as:

Good Parts + Scrap Parts = Total Parts

The FactoryTalk Metrics LE Configuration Tool does not use Total Parts when

configuring performance parameters and relies on FactoryTalk Metrics to calculate Total

Parts as the sum of Good Parts and Scrap Parts. If the customer’s application requires that

Total Parts be collected, you must configure Total Parts manually using the RSBizWare

Configuration Console after you run the FactoryTalk Metrics LE Configuration Tool.

S

CHEDULED AVAILABILITY

By default, the FactoryTalk Metrics Configuration tool configures Scheduled Availability

to be collected from the control system. The UDT’s Shift tag is expected to contain a

number that corresponds to the workcell’s current shift number. If Shift is greater than

zero, the workcell is assumed to be on shift and available to run.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

6 Shift Integer Scheduled Availability -

Unscheduled

Shift

18

You can create a list to convert shift values to strings by using the Configuration Console. See

the FactoryTalk Metrics User’s Guide.

R

UNNING

Running is used to determine whether or not a workcell is running. If the Running tag is

high or true, the workcell is considered to be running. Running Time is an important

component of several KPI calculations.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

7 Running BOOL Running state indicator Unscheduled

Page 23

3 • FACTORYTALK METRICS LE CONTENT

M

ONITORED AVAILABILITY

Monitored Availability can be used as a real-time override of Scheduled Availability. It is

commonly used to prevent Available Time from accumulating if the workcell is scheduled

to be available but cannot produce due to some factor that is beyond its control.

• • • • •

Line UDT Field Name Data Type FactoryTalk Metrics

use

8 Monitored_Availability BOOL Monitored Availability Unscheduled

C

USTOM EVENTS

- M

ONITORED VALUE

Scheduled/Unscheduled

The UDT contains one tag that is configured in FactoryTalk Metrics as a Monitored Value

custom event. It is assumed that this tag will always contain a meaningful value, such as

machine state code.

Line UDT Field Name Data Type FactoryTalk Metrics

use

9 Monitored_Value Integer Custom Event

(Monitored Value

type)

Using the Configuration Console, you can create a list to convert the numeric values returned by

this data point into string values for easier reporting. See the FactoryTalk Metrics User’s Guide.

Scheduled/Unscheduled

Unscheduled

19

Page 24

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

C

USTOM EVENTS

- D

IGITAL

The UDT contains an array of five Boolean values that are interpreted by FactoryTalk

Metrics as triggers for five user-defined digital events. (There are actually 32 values in the

array, but the FactoryTalk Metrics LE Configuration Tool only configures the first five.)

FactoryTalk Metrics will monitor each of these Boolean values, and each should represent

a single important event that FactoryTalk Metrics will capture (such as an e-stop,

downtime, light curtain break, product changeover, etc.). When the trigger value changes

from 0 to 1 (or low to high), that is interpreted as the start of the event. A trigger value

change from 1 to 0 (or high to low) is interpreted as the end of the event.

Once these events are configured in FactoryTalk Metrics by the FactoryTalk Metrics LE

Configuration Tool, you should edit the performance parameters to give them meaningful

names for reporting purposes. See “Modifying performance parameters” on page 45.

Digital events differ from analog events because analog events have an event value data

point (such as an event reason code) in addition to the

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

Events_Digital BOOL (32) Custom Events (with no

10 Events_Digital(0) BOOL Event Trigger

11 Events_Digital(1) BOOL Event Trigger

12 Events_Digital(2) BOOL Event Trigger

13 Events_Digital(3) BOOL Event Trigger

14 Events_Digital(4) BOOL Event Trigger

trigger data point.

Unscheduled

event values)

20

Page 25

3 • FACTORYTALK METRICS LE CONTENT

C

USTOM EVENTS

- A

NALOG

The FTMLE_Workcell UDT contains a UDT called FTMLE_AnalogEvents — an array

of one Boolean value and one Integer value. The UDT field called Events_Analog

consists of an array of five occurrences of the FTMLE_AnalogEvents UDT.

The five

triggers are interpreted by FactoryTalk Metrics as triggers for five analog events. The five

integers are interpreted as event values. Typically, reason codes for the event are provided

by the operator or control system. Each of these trigger/value pairs are independent and

should indicate that an important workcell event is occurring that FactoryTalk Metrics

should track. The trigger value should change from 0 to 1 (or low to high) when the event

to track is occurring, and should change back to 0 (or low) when the event ends. The

control system should copy an event value to the Value data point before the event ends

and the trigger returns to low. Each trigger/value pair should indicate only one distinct

event that may have multiple causes (for example, downtown operator stop, etc.). Once

these events are configured in FactoryTalk Metrics by the FactoryTalk Metrics

Configuration tool, you should edit the performance parameters to give them meaningful

names and to provide lookup lists to translate the integer values returned in the value data

points to string values for reporting. See “Modifying performance parameters” on

page 45.

• • • • •

Line UDT Field Name Data Type FactoryTalk Metrics

use

Events_Analog FTMLE_AnalogEvents[5] Custom Events (with

event values)

15 Trigger(0) BOOL Event Trigger Unscheduled

16 Value(0) Integer Event Value Scheduled

17 Trigger(1) BOOL Event Trigger Unscheduled

18 Value(1) Integer Event Value Scheduled

19 Trigger(2) BOOL Event Trigger Unscheduled

20 Value(2) Integer Event Value Scheduled

21 Trigger(3) BOOL Event Trigger Unscheduled

22 Value(3) Integer Event Value Scheduled

23 Trigger(4) BOOL Event Trigger Unscheduled

24 Value(4) Integer Event Value Scheduled

Scheduled/

Unscheduled

21

Page 26

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

F

LEX FIELDS

- S

TRING

A FactoryTalk Metrics application can have five flex fields. These fields can be an integer,

boolean, or string. Flex fields are defined system-wide for all workcells and are typically

values (such as an operator id) necessary for providing context for performance reporting.

The FactoryTalk Metrics LE Configuration Tool chooses the string tag for each flex field.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

Flex_String String(5) Flex Fields (String type) Unscheduled

35 Flex_String(0) Flex Field 1

36 Flex_String(1) Flex Field 2

37 Flex_String(2) Flex Field 3

38 Flex_String(3) Flex Field 4

39 Flex_String(4) Flex Field 5

F

LEX FIELDS

- I

NTEGER

Integer flex fields are valid flex field types and therefore are provided in the UDT.

However, this type of flex field is not used by the FactoryTalk Metrics LE Configuration

Tool. To use integer flex fields, you must configure the performance parameters manually

and change the flex field data point from the Flex_String to Flex_Integer.

22

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

Flex_Integer Int (5) Flex Fields (Integer type) Unscheduled

25 Flex_Integer(0) Flex Field 1

26 Flex_Integer(1) Flex Field 2

27 Flex_Integer(2) Flex Field 3

28 Flex_Integer(3) Flex Field 4

29 Flex_Integer(4) Flex Field 5

Page 27

F

LEX FIELDS

- B

OOLEAN

Boolean flex fields are valid flex field types and therefore are provided in the UDT.

However, this type of flex field is not used by the FactoryTalk Metrics LE Configuration

Tool. To use boolean flex fields, you must configure the performance parameters

manually and change the flex field data point from the Flex_String to Flex_Integer.

Line UDT Field Name Data Type FactoryTalk Metrics use Scheduled/Unscheduled

Flex_Real BOOL(32) Flex Fields (BOOL type) Unscheduled

30 Flex_Bool(0) Flex Field 1

31 Flex_Bool(1) Flex Field 2

32 Flex_Bool(2) Flex Field 3

33 Flex_Bool(3) Flex Field 4

34 Flex_Bool(4) Flex Field 5

Reports and Parameter Sets

• • • • •

3 • FACTORYTALK METRICS LE CONTENT

In addition to the eight report templates, 39 standard reports, and 22 standard parameter

sets that are part of the standard FactoryTalk Metrics installation, there are 10 additional

report templates, two additional parameter sets, and two additional reports included in

FactoryTalk Metrics LE. The two additional FactoryTalk Metrics LE reports are:

Dashboard Example

Machine State History

These reports can be seen in the Report Expert tree. To view the FactoryTalk Metrics LE

reports, see “Viewing FactoryTalk Metrics LE Reports” on page 49.

The two additional FactoryTalk Metrics LE parameter sets are:

Dashboard Current Shift. This parameter set contains specific grouping settings for

the dashboard reports. The time criteria is set to Current Shift.

Last 30 Minutes Current Shift. This parameter set is used for the Machine State

History report.

To make modifications to reports, see “Configuring Reports” on page 47.

23

Page 28

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

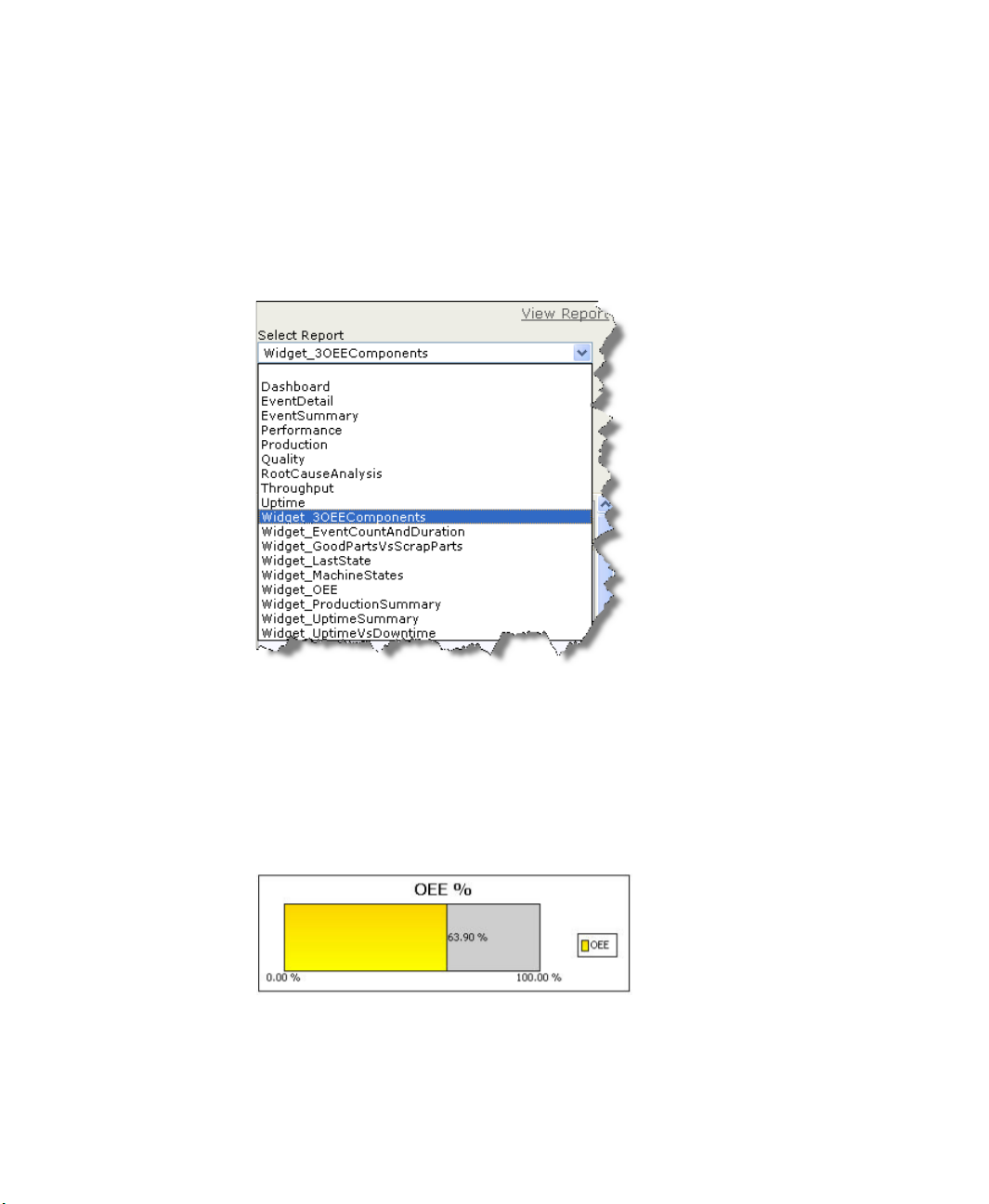

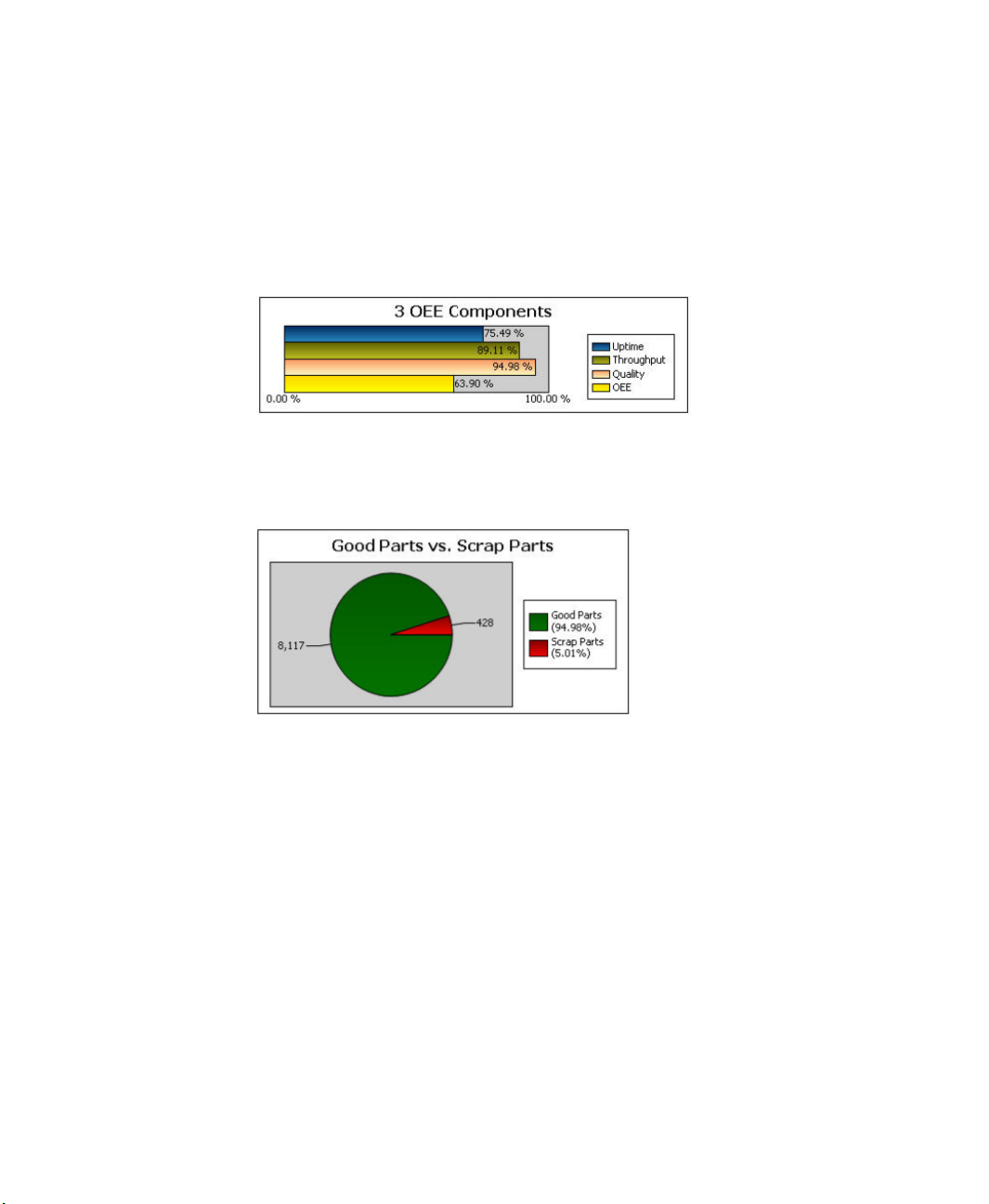

The primary additional report template is a dashboard report that contains nine dashboard

elements, or widgets. Each of the widgets is also included as a report template in Report

Expert:

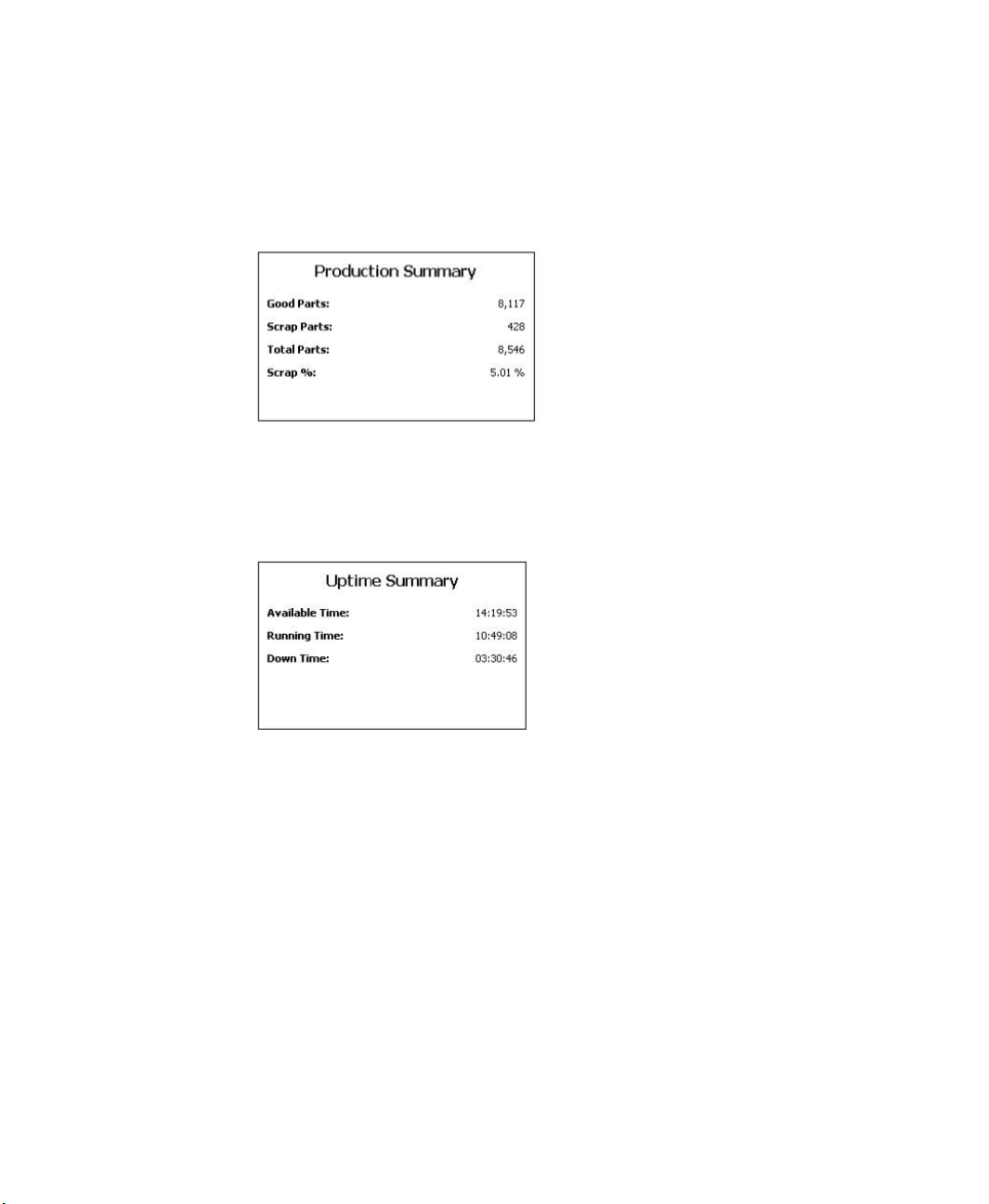

OEE %

OEE Components

Good Parts vs. Scrap Parts

Uptime vs. Downtime

Machine States

Event Count Duration

Last State

Production Summary

Uptime Summary

For specific widget information, see “Dashboard widgets” on page 53.

24

Page 29

4

Configuring FactoryTalk Metrics LE

FactoryTalk Metrics LE contains tools that are designed to reduce the time it takes to

implement a FactoryTalk Metrics system. You will use the FactoryTalk Metrics LE UserDefined Type (UDT), RSLogix 5000, RSLinx Enterprise, and the FactoryTalk Metrics LE

Configuration Tool to configure a functioning FactoryTalk Metrics LE application.

To configure FactoryTalk Metrics LE, you must modify specific information for the

following:

FactoryTalk Directory. Create users, applications, optionally define areas, create the

RSLinx Enterprise connection, and create shortcuts. See “Configuring the FactoryTalk

Directory” on page 27.

RSBizWare Service Console. Configure servers; assign privileges, licenses, and

activations; and configure flex fields. See “Configuring the RSBizWare Service

Console” on page 30.

Database data. Load the data that defines FactoryTalk Metrics LE reports into the

FactoryTalk Metrics LE database. See “Loading database data” on page 34.

Plant model. Use the RSBizWare Console to create the plant model for your facility.

See “Creating the plant model” on page 35.

FactoryTalk Metrics LE UDT. Add the FactoryTalk Metrics UDT to your

ControlLogix programs. This allows the FactoryTalk Metrics LE Configuration Tool

to use the data points in the UDT for the FactoryTalk Metrics application. See

“Adding the FactoryTalk Metrics LE UDT” on page 36.

FactoryTalk Transaction Manager. Use the FactoryTalk Metrics LE Configuration

Tool to load data as well as create and import the FactoryTalk Transaction Manager

configuration. See “Configuring FactoryTalk Transaction Manager” on page 38.

Data collection. Use the RSBizWare Service Console to register the FactoryTalk

Transaction Manager configuration for data collection. See “Registering the

FactoryTalk Transaction Manager configuration for data collection” on page 43.

FactoryTalk Metrics. Use the FactoryTalk Metrics LE Configuration Tool to

configure FactoryTalk Metrics using the data points in the UDTs in the controller

programs. See “Configuring FactoryTalk Metrics” on page 44.

Performance Parameters. Use the RSBizWare Configuration Console to modify and

customize the performance parameters as necessary using the standard FactoryTalk

Metrics capabilities. See “Modifying performance parameters” on page 45.

25

Page 30

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

Reports. Using the standard Report Expert reports, create and manage parameter sets

to satisfy your reporting requirements. Configure the report tree to add or modify

reports as necessary. See “Configuring Reports” on page 47.

When you have made all of the desired modifications, you can start data collection for the

FactoryTalk Metrics application. See “Starting data collection” on page 47.

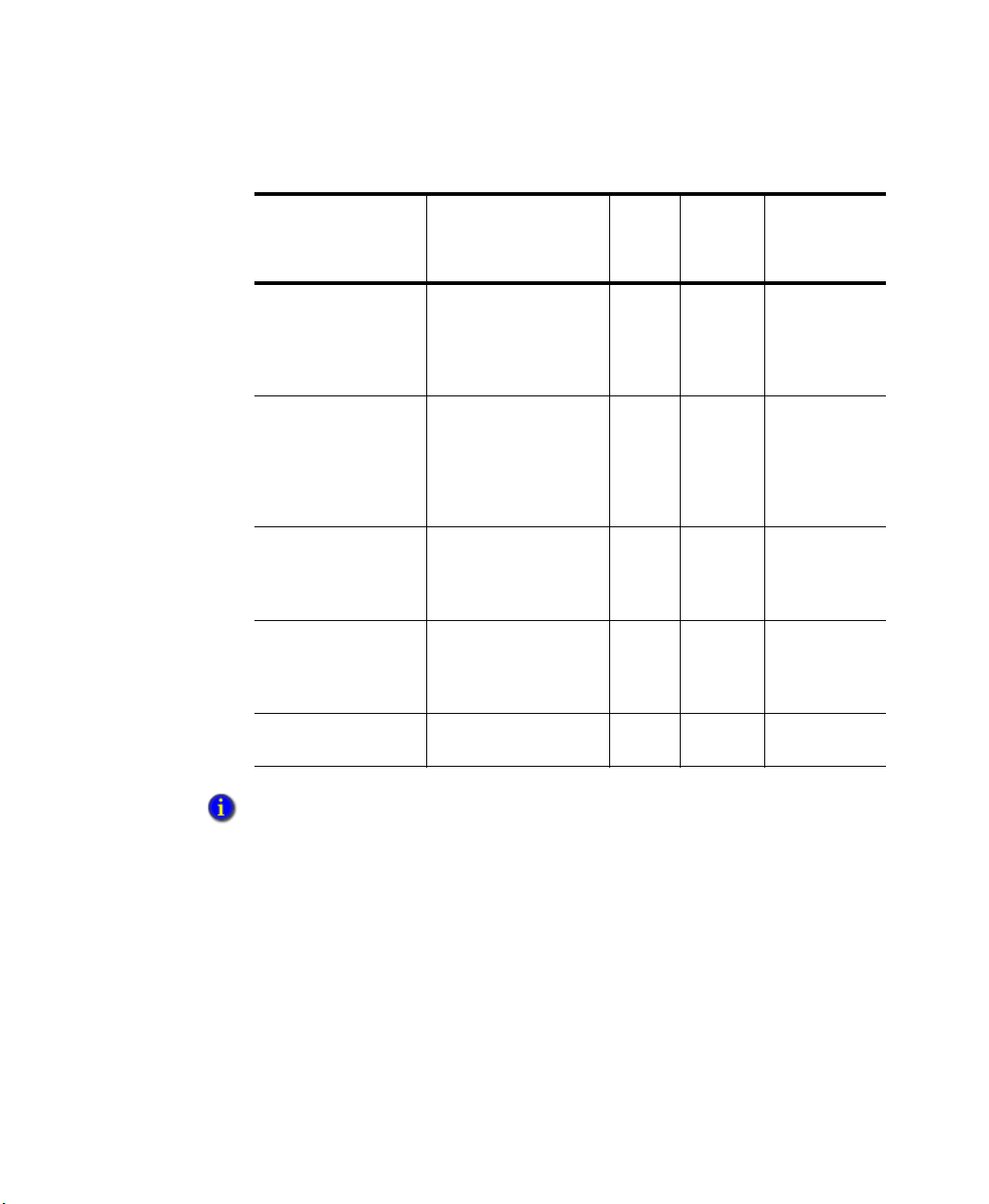

Configuring FactoryTalk Metrics LE: New vs. Update

This Administrator's Guide assumes you are configuring FactoryTalk Metrics LE for the

first time on a new system. If you are upgrading an existing FactoryTalk Metrics LE or

FactoryTalk Metrics application, all of the steps in this chapter are not required. The table

below outlines the necessary steps for three different scenarios — a new install, an update

from FactoryTalk Metrics LE 8.0, and an update from FactoryTalk Metrics 9.0. In the

update scenarios, some steps are only required if you intend to modify your existing

application to add more workcells using the FactoryTalk Metrics LE Configuration Tool.

Configuration Step Document Reference New

Install

Configure the

FactoryTalk Directory

Configure the

RSBizWare Service

Console (services,

users, and flex fields)

Load reports using the

DBWizard

Create the plant model See “Creating the plant

Import the FactoryTalk

Metrics LE UDT and

update RSLogix

programs

See “Configuring the

FactoryTalk Directory”

on page 27.

See “Configuring the

RSBizWare Service

Console” on page 30.

See “Loading database

data” on page 34.

model” on page 35.

See “Adding the

FactoryTalk Metrics LE

UDT” on page 36.

9

9

99 9

9

9

Update

FTMLE

8.0

**

**

**

Update

FT Metrics

9.0

26

Page 31

4 • CONFIGURING FACTORYTALK METRICS LE

• • • • •

Configuration Step Document Reference New

Install

Configure FactoryTalk

Transaction Manager

using the FactoryTalk

Metrics LE

Configuration Tool

Register the

FactoryTalk

Transaction Manager

configuration through

the RSBizWare Service

Console

Configure FactoryTalk

Metrics using the

FactoryTalk Metrics

LE Configuration Tool

Modify performance

parameters through the

RSBizWare

Configuration Console

Configure reports (as

needed)

See “Configuring

FactoryTalk Transaction

Manager” on page 38.

See “Registering the

FactoryTalk Transaction

Manager configuration

for data collection” on

page 43.

See “Configuring

FactoryTalk Metrics” on

page 44.

See “Modifying

performance parameters”

on page 45.

See “Configuring

Reports” on page 47.

9

9

9

9

99 9

Update

FTMLE

8.0

**

**

**

Update

FT Metrics

9.0

* This step is required if you plan to use the FactoryTalk Metrics LE Configuration Tool to add more

workcells to an existing application.

Configuring the FactoryTalk Directory

In order to configure FactoryTalk Directory for FactoryTalk Metrics LE, you must

perform the following:

Add users. Create user accounts in order for users to be able to use FactoryTalk

Metrics. See “Adding FactoryTalk users” on page 28.

Configure the OPC Server. Configure RSLinx Enterprise as the OPC server for

FactoryTalk Metrics LE. See “Configuring RSLinx Enterprise as the OPC Server” on

page 28.

27

Page 32

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

Adding FactoryTalk users

To create users who can access FactoryTalk Metrics, you must first create those users in

the FactoryTalk Directory. In the FactoryTalk Directory you can create either FactoryTalk

users or Windows-linked users. In the following steps you will create one FactoryTalk

user called FTAuthor to whom you will later grant privileges to configure FactoryTalk

Metrics.

To add users:

1. Launch the FactoryTalk Administration Console. Select Start > All Programs >

Rockwell Software > FactoryTalk Administration Console.

2. Select the Network directory and click OK.

3. Double-click the Users and Groups folder to expand it.

4. Right-click the Users folder and select New.

5. Add a FactoryTalk user (for example, “FTAuthor”).

A Windows-linked user is validated by Windows. If applicable, use Windows-linked group

accounts rather than Windows-linked user accounts. This simplifies the process if you ever

move your software to a different domain. You cannot move individual Windows-linked user

accounts from one domain to another. You can move Windows-linked group accounts to a

new domain, while retaining all of the security permissions for the group. If you change the

domain an individual Windows-linked user account belongs to, you must delete the old

account, create the new account, and then recreate all of the security permissions for the

new account.

To set up the security policy according to the customer’s needs, refer to the FactoryTalk

Security Quick Start Guide.

28

Configuring RSLinx Enterprise as the OPC Server

Configure RSLinx Enterprise as the OPC server. RSLinx Enterprise must be used as the

OPC server in order to use the FactoryTalk Metrics LE UDT in ControlLogix controllers

and the FactoryTalk Metrics LE Configuration Tool to configure FactoryTalk Metrics LE.

Other OPC servers may also be required if controllers other than ControlLogix are used as

sources for FactoryTalk Metrics LE data. When you installed RSLinx Enterprise, it

appeared in the FactoryTalk Administration Console.

C

HECKING THE PROCESSOR CONNECTIONS

1. Click the Communications tab at the bottom of the FactoryTalk Administration

Console.

2. Verify the connection to the processors. Drivers and/or devices may need to be added

to access the appropriate processors.

Page 33

4 • CONFIGURING FACTORYTALK METRICS LE

C

REATING AN APPLICATION AND SERVER FOR

RSL

INX ENTERPRISE

Create a new application for your RSLinx Enterprise OPC server and then verify the

computer hosting the server. All of the OPC servers and controllers that FactoryTalk

Metrics LE uses should be contained within a single application in the FactoryTalk

Directory.

To add an application:

1. On the Application tab, right-click the network and select New Application.

2. Type a name and description for the application (for example, “FTApp”) and click

OK. The new application appears under the network tree item at the bottom of the

FactoryTalk Administration Console.

3. Right-click the new application and select Add New Server > Rockwell Automation

Device Server (RSLinx Enterprise). The RSLinx Server Properties dialog box

opens.

4. Verify the computer name hosting the RSLinx Enterprise Server.

To configure the Redundancy and the Alarms and Events tabs as necessary, refer to the

RSLinx Enterprise Users Guide.

• • • • •

5. Click OK. The new server appears under the application.

A

DDING AREAS (OPTIONAL

)

Areas organize and subdivide a distributed network application into logical or physical

divisions. For example, separate areas might correspond with separate manufacturing

lines in a facility, separate plants in different geographical locations, or different

manufacturing processes

Adding areas to a FactoryTalk Directory application is optional.

To add areas:

1. Right-click your new application (for example, “FTApp”) and select New Area. The

New Area dialog box opens.

2. In the Name field, type a name for the new area (for example, “FTArea1”). Enter an

optional description and click OK. The new area appears under the Application tree

item.

3. Repeat steps 2 and 3 for each additional area.

29

Page 34

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

A

DDING SHORTCUTS

Add shortcuts to reference each of the ControlLogix controllers and verify the

communication.

To add shortcuts and verify their communication:

1. Click the plus sign (+) to open the new RSLinx Enterprise server you just created and

double-click the Communication Setup tree item. If necessary, maximize the

FactoryTalk Administration Console to see the entire configuration.

2. To create a new shortcut, click Add. “New Shortcut” appears.

3. Type the shortcut name to reference all data points within a specific ControlLogix

device. If one device will contain only the data points for one FactoryTalk Metrics LE

workcell, consider using the same name for both the workcell (see “Creating the plant

model” on page 35) and the shortcut (for example, “Filler”). This is the convention

used by the FactoryTalk Metrics LE Configuration Tool. If data points from more than

one workcell will be contained in one device, use some other meaningful name for the

shortcut. Create one shortcut for each device.

4. Once you name the shortcut, click the Primary tab to the right of the shortcuts and

navigate to the controller’s connection.

5. Select the controller and at the top of the dialog box, click Apply. Click Ye s to apply

the changes.

30

6. At the bottom of the dialog box, click Verify to open the Shortcut Verifier dialog box.

For help completing the dialog box, click How to use the Shortcut Verifier at the

bottom of the Shortcut Verifier dialog box.

7. At the bottom of the Communication Setup dialog box, click OK.

If multiple ControlLogix controllers are required to provide data for FactoryTalk Metrics LE,

repeat the necessary steps to add additional shortcuts.

8. Close the FactoryTalk Administration Console.

Configuring the RSBizWare Service Console

When you first configure the Service Console you must perform the following:

Configure servers. Register the Security Services Manager and Information Services

Manager and associate the Metrics Server Manager. See “Configuring servers” on

page 31.

Assign user privileges, licensing, and activation. Give FactoryTalk Directory users

FactoryTalk Metrics privileges and activations and assign workcell licenses and

Page 35

4 • CONFIGURING FACTORYTALK METRICS LE

activations to the Information Services Manager. See “Assigning user privileges,

licensing, and activation” on page 32.

Enable flex fields. FactoryTalk Metrics LE configures five flex fields. Enable the

desired flex fields. See “Enabling flex fields” on page 33.

C

ONFIGURING SERVERS

You must register the Security Services Manager, Information Services Manager and

Metrics Server Manager.

To register the servers:

1. Select Start > Programs > Rockwell Software > RSBizWare > Service Console to

open the RSBizWare Service Console.

2. If you are working with a clean installation of FactoryTalk Metrics LE, the message

“No Security Services Manager have been registered. Would you like to register one

now?” appears. If this prompt appears, click Ye s and then complete the Service

Console Registration dialog box.

If you are logged in as a Windows Administrator, you are automatically logged into the

RSBizWare Service Console. If not, you must log in using a FactoryTalk user name that is a

member of the Administrators group. See “Adding FactoryTalk users” on page 28.

• • • • •

3. Register the Information Services Manager server. Right-click the Servers tree item

(under the Security Services Manager) and select Register Server. The Service

Console Registration dialog box appears.

4. In the Server Type field, click the drop-down arrow and select Information Services

Manager and then click OK. When you expand the Servers tree item, a yellow

question mark will appear next to the Information Services Manager, indicating it is

not completely configured.

5. To complete its configuration, select the Information Services Manager tree item in

the tree and then in the Data Connection Properties on the right side of the window,

complete the following fields:

Data Sources. Select the FactoryTalk Metrics LE DSN (for example,

FTMLEDSN).

Database User ID. Enter the user id for the SQL Server database (for example,

FTMLEUser).

31

Page 36

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

Database Password. Enter the user’s password for the SQL Server database.

For more information on completing the Data Connection Properties dialog box, click Help.

6. To test the connection, click Test Connection. When the connection is successful,

click OK.

7. Click Apply and then click Ye s to restart the server.

8. When the warning message appears regarding not rebooting until the Information

Services Manager has started, click OK. The database will be initialized with the

RSBizWare schema for FactoryTalk Metrics. When this is complete, the message

“The server is running” appears at the top of the window.

9. To associate the Metrics Server Manager, under the Servers tree item, right-click the

Information Services Manager tree item and select Associate Metrics Server

Manager. Complete the Service Console Registration dialog box to associate the

Metrics Server Manager. Click the Metrics Server Manager tree item and complete

the Database Connection Properties in the pane on the right.

name, and password that you used in step 5.

For more information on configuring the RSBizWare Service Console, refer to the

RSBizWare Administrator’s Guide.

Use the DSN, user

32

A

SSIGNING USER PRIVILEGES, LICENSING, AND ACTIVATION

The FactoryTalk Metrics product activations that have been purchased must be assigned

to the server where the product is installed. In this section you will also import the

FactoryTalk users into the Service Console and assign user licenses and privileges. For

more information, refer to the RSBizWare Administrator’s Guide.

1. To assign activations to the Information Services Manager, open the Security

Services Manager, Administration, and Activations tree items. Select the desired

activations and click Assign an Activation to assign it to the Information Services

Manager. You will need to assign at least one Metrics Server Manager activation, at

least one FactoryTalk Metrics Author activation, and at least one RSBizWare Runtime

activation.

2. To synchronize the FactoryTalk Directory users with the RSBizWare database, under

the Administration tree item, select Users and Groups and click Refresh at the

bottom of the right pane. Any users or groups you created earlier will now appear.

3. To grant privileges to a user, select the user who to whom you want to grant

permission to configure FactoryTalk Metrics LE (for example, FTAuthor) and click

Edit User Properties. The Security Control dialog box appears.

Page 37

4 • CONFIGURING FACTORYTALK METRICS LE

4. Click the License & Activation tab and select FactoryTalk Metrics Author

checkbox. This allows the user to configure FactoryTalk Metrics using the

Configuration Console and the FactoryTalk Metrics LE Configuration Tool. This also

consumes one FactoryTalk Metrics Author activation. We will assume that the user is

FTAuthor. You may make as many users authors as you have FactoryTalk Metrics

Author activations.

5. Click the Privileges tab and select all of the privileges. This ensures that the user will

have the ability to perform all tasks from within FactoryTalk Metrics LE.

6. Click OK.

For more information on configuring the RSBizWare Service Console, refer to the

RSBizWare Administrator’s Guide.

E

NABLING FLEX FIELDS

Flex fields (or user-defined summarization criteria) are optional data values you can

collect from the control system to give the rest of your historical data additional context.

The standard summarization criteria include Shift and Part Id. Therefore, you can group or

sort all FactoryTalk Metrics data you collect by these values. You can define additional

flex fields at the system level. Each configured workcell can optionally collect flex field

data from the control system. At the system level you only enable, name, and define types

for flex fields available for collection. For more information about flex fields, refer to the

RSBizWare Administration Guide.

• • • • •

FactoryTalk Metrics allows up to five flex fields.

To enable flex fields:

1. In the RSBizWare Service Console under the Metrics Server Manager tree item, select

the FactoryTalk Metrics Flex-Fields tree item. The five FactoryTalk Metrics flex

fields (user-defined summarization fields) appear.

2. To enable a flex field, double-click the row of the desired flex field and select the

following options on the Configure Summarization Criteria dialog box:

Name. Flex fields are named by default (for example, "User Defined

Summarization Field 1" etc.).

If you don't change the flex field name here, the

name will appear as "User Defined Summarization Field 1" in the Performance

Parameter screen as well as in the Report Expert parameters. The name you assign

here will reference the flex field throughout the application.

Enable This Summarization Criteria. This enables the selected flex field. Flex

fields that are not enabled do not appear elsewhere in the application.

33

Page 38

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

String Value. Select this option because the FactoryTalk Metrics LE

Configuration Tool only configures the string values in the UDT for use as flex

fields. If the flex field you want to use is either numeric or boolean, you may

configure it as such here, but you will have to modify the performance parameters

that the FactoryTalk Metrics LE Configuration Tool creates to use an integer or

boolean data point for the flex field value.

3. Click OK.

4. Repeat steps 2 and 3 for each additional flex field you would like to enable (up to five

flex fields). The flex fields you enable will be included in the performance parameters

for all the workcells you define in the FactoryTalk Metrics application.

For more information about configuring the RSBizWare Service Console, refer to the

RSBizWare Administrator’s Guide.

5. Close the RSBizWare Service Console.

Loading database data

Load the data required by FactoryTalk Metrics LE into the database. This loads the

standard Report Expert data used in FactoryTalk Metrics and updates the FactoryTalk

Metrics LE database with Report Expert .dat files and the extra FactoryTalk Metrics LE

.dat file.

34

1. Launch the Database Load and Update Wizard. To do this, select Start > Programs >

Rockwell Software > FactoryTalk Tools> Database Wizard.

2. Click Next. The Product and Database Connection dialog box opens.

3. Complete the following fields:

OBDC DSN. Click the drop-down arrow and select the DSN that you created

earlier (for example, FTMLEDSN). See “Creating a DSN database connection” on

page 12.

User. Type the user name for the DSN (for example, FTMLEUser).

Password. Type the password (for example, FTMLEUser).

4. Click Connect. The Available Product Modules list appears.

5. Select

the FactoryTalk Metrics Line Edition and Report Expert check boxes.

The Report Expert schema only appears if this is a clean install and therefore Report Expert

has not been installed previously.

6. To load the data, click Finish. The data is loaded.

Page 39

7. To close the wizard, click Close.

P

LANT MODEL STRUCTURE

The default plant model structure follows S95 standards and consists of the following

hierarchy:

Enterprise

Site

Area

Line

Wo rk ce ll

Create entries in the plant model for at least the site, area, line, and workcell levels

shown because this is the plant model structure that is used in the Report Expert reports.

Typically, machines that are to be monitored by FactoryTalk Metrics are defined at the

workcell level. The FactoryTalk Metrics LE Configuration Tool only configures plant

model entries at the workcell level.

Creating the plant model

There is no default plant model configured for FactoryTalk Metrics LE. The number of

workcells you add to your plant model is limited by the size of the license purchased.

FactoryTalk Metrics LE can be purchased with 10, 25, 50, 100, 200 workcell licenses.

Therefore, you can configure your plant model as necessary with up to 200 workcells. To

use the FactoryTalk Metrics LE Configuration Tool effectively, you will create one

instance of the FactoryTalk Metrics UDT in the control system for each workcell defined

in the plant model.

• • • • •

4 • CONFIGURING FACTORYTALK METRICS LE

To add workcells:

1. Launch the RSBizWare Configuration Console. To do this, select Start > All

Programs > Rockwell Software > RSBizWare > Configuration Console.

2. Under FactoryTalk Tasks, click Configure the Plant Model. The Plant Model dialog

box appears.

3. To create an entry at the plant model’s root level, right-click anywhere in the window

and select New Root Enterprise or New Root Site. To create an entry at a lower

level, right-click an entry in the plant model, select New Activity Area, and then

select the appropriate level for the new entry.

35

Page 40

FACTORYTALK METRICS LINE EDITION ADMINISTRATOR’S GUIDE

• • • • •

4. At the workcell level of the plant model, type the name of the workcell (for

example, "Filler").

5. Add the remaining workcells for your plant model and then click OK.

For more information about configuring your plant model with additional workcells, refer to

the RSBizWare Administrator’s Guide.

Adding the FactoryTalk Metrics LE UDT

For each workcell to be included in the FactoryTalk Metrics application, you must create

an instance of the FactoryTalk Metrics LE UDT in the control system to serve as a data

source for that workcell. You must add the UDT definition to the appropriate RSLogix

5000 control program, create an instance of the UDT, and add MOV or other instructions

to the program to ensure that the UDT data points will contain valid data. For a discussion

of how each of the FactoryTalk Metrics performance parameters relates to the tags in the

UDT, see “UDT Data Points and FactoryTalk Metrics Performance Parameters” on

page 16.

All data points in the UDT, with the exception of Good Parts, are optional. Therefore, you do not

have to use all of the data points contained in the UDT. However, the FactoryTalk Metrics LE

Configuration Tool assumes you are using all of the data points and will map them to the

appropriate FactoryTalk Metrics performance parameters. You will have to manually remove the

data points that you do not use from the FactoryTalk Metrics performance parameters. See

“Modifying performance parameters” on page 45.

36

To import the UDT:

1. Launch RSLogix 5000. Select Start > All Programs > Rockwell Software >

RSLogix 5000 Enterprise Series > RSLogix 5000.

2. Open your controller program file into which you want to import the UDT.

3. Right-click the User-Defined folder and select Import Data Type to import

FactoryTalk Metrics LE UDT.

4. Browse to select the FTMLE_Workcell.L5X file and click Import.

By default the FTMLE_Workcell.L5X UDT file is located in the following location:

C:\Program Files\Rockwell Software\FactoryTalk Metrics Line Edition

5. When the file is imported two UDTs (FTMLE_AnalogEvents and FTMLE_Workcell)

appear under the User-Defined folder. You will use these data types later to create an

array of tags specifically designed to store FactoryTalk Metrics data.

Page 41

4 • CONFIGURING FACTORYTALK METRICS LE

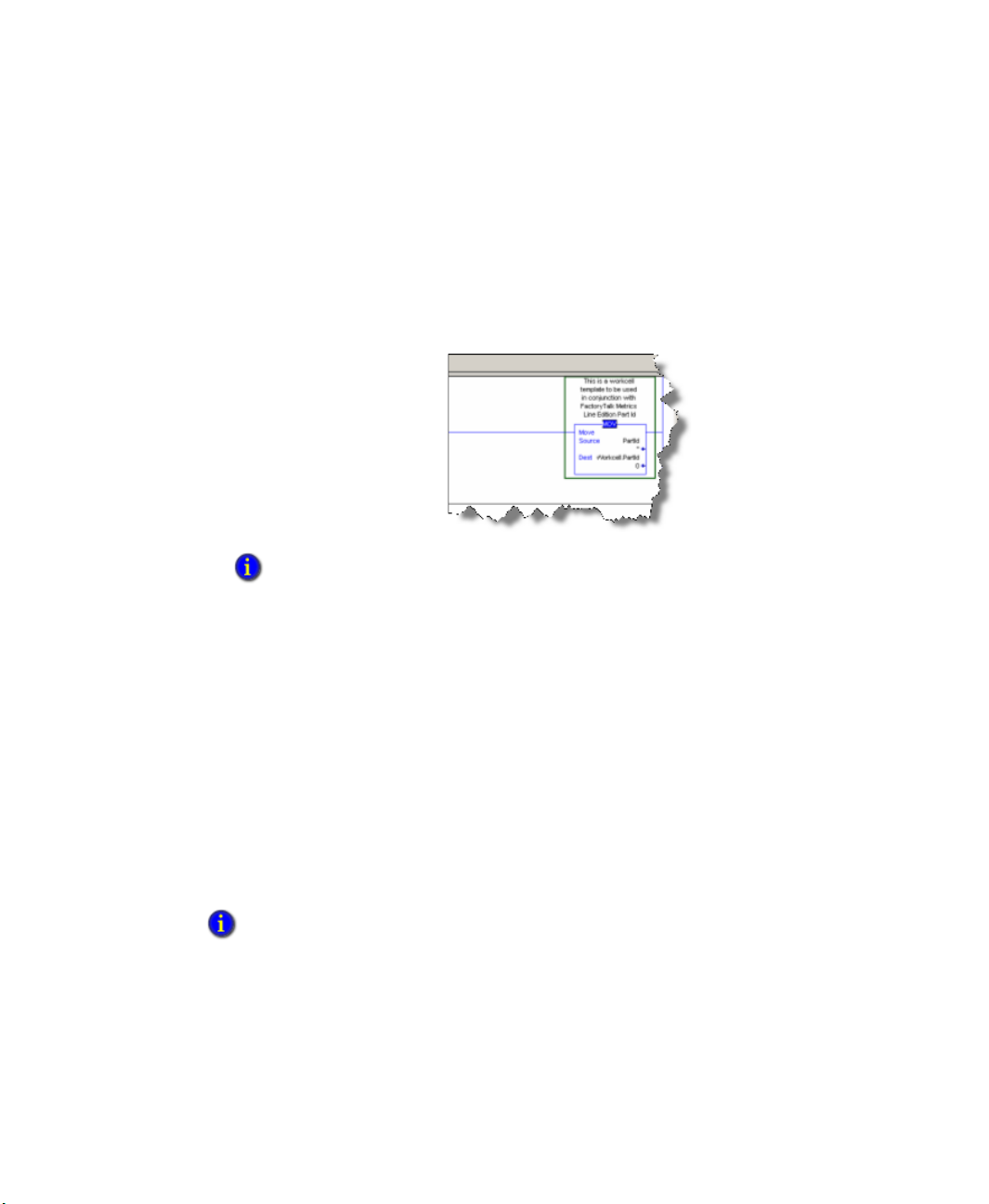

FTMLE_Workcell defines the

structure used to collect the

information for a standard

FactoryTalk Metrics workcell

and references the

FTMLE_AnalogEvent

structure.

6. To see the UDT’s tags, select the FTMLE_Workcell tree item.

If the controller program contains datapoints for more than one workcell that will be

configured in FactoryTalk Metrics LE, you can create an array of UDTs rather than creating