Page 1

USER GUIDE

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Supersedes Publication PLTMT-UM001L-EN-P-June 2013

Page 2

Contacting Rockwell

Copyright Notice

Trademark Notices

Other Trademarks

Warranty

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/overview.page

© 2014 Rockwell Automation Technologies, Inc. All Rights Reserved.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation,

Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation, Inc. is

strictly prohibited. Please refer to the license agreement for details.

FactoryTalk, FactoryTalk Activation, FactoryTalk Diagnostics, FactoryTalk Directory, FactoryTalk Live Data,

FactoryTalk Metrics, FactoryTalk Services Platform, FactoryTalk Transaction Manager, FactoryTalk

VantagePoint, FactoryTalk ProductionCentre, Report Expert, Rockwell, Rockwell Automation, Rockwell

Software, and RSBizWare are trademarks of Rockwell Automation, Inc.

Any Rockwell Automation logo, software or hardware not mentioned herein is also a trademark, registered or

otherwise, of Rockwell Automation, Inc.

For a complete list of products and their respective trademarks, go to

http://www.rockwellautomation.com/rockwellautomation/legal-notices/overview.page?%23tab4#/tab4.

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows,

Windows ME, Windows NT, Windows 2000, Windows Server, Windows XP, Windows 7, Windows Vista, and

Windows 8 are either registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in

the United States and/or other countries.

ControlNet is a registered trademark of ControlNet International.

DeviceNet is a trademark of the Open DeviceNet Vendor Association, Inc. (ODVA)

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

This product is warranted in accordance with the product license. The product’s performance may be affected

by system configuration, the application being performed, operator control, maintenance, and other related

factors. Rockwell Automation is not responsible for these intervening factors. The instructions in this

document do not cover all the details or variations in the equipment, procedure, or process described, nor do

they provide directions for meeting every possible contingency during installation, operation, or

maintenance. This product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the accompanying software may

have changed since the release. Rockwell Automation, Inc. reserves the right to change any information

contained in this document or the software at any time without prior notice. It is your responsibility to obtain

the most current information available from Rockwell when installing or using this product.

Page 3

Welcome to FactoryTalk Metrics

Getting Started

Collecting Performance Data

Table of Contents

Chapter 1

What Is FactoryTalk Metrics? ................................................................... 9

Features and Benefits .................................................................................. 10

Intended Audience ...................................................................................... 10

Where Can I Go for Help? ....................................................................... 12

Get Web Support ................................................................................... 12

Get Phone Support ................................................................................ 13

Get Consulting Services ....................................................................... 13

Contact Us .............................................................................................. 13

Chapter 2

The RSBizWare Architecture .................................................................. 15

Importing Sample Data to the RSBizWare Database......................... 16

Connecting to the Information Services Manager .............................. 17

Using the Information Services Manager in Internet Explorer .. 17

Using the Information Services Manager in the Configuration

Console ..................................................................................................... 18

Getting Started with the Configuration Console .......................... 19

The Plant Model .......................................................................................... 20

Configuring the Plant Model .............................................................. 21

Loading Sample Activity Areas ........................................................... 23

Chapter 3

Collecting Part Count Data When the Metrics Server Manager Is

Stopped .......................................................................................................... 25

OEE Rating ................................................................................................... 27

Fault Metrics Ratings ................................................................................. 28

Mean Time Between Failure ............................................................... 28

Mean Time To Repair .......................................................................... 29

Configuring Activity Area Schedules ..................................................... 29

Time Patterns ......................................................................................... 29

Configuring Time Patterns ............................................................ 30

Configuring Work Day Time Patterns ....................................... 34

Configuring Work Week Time Patterns .................................... 36

Composites and Schedule Exceptions ............................................... 38

Configuring Composites and Schedule Exceptions ................. 39

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 3

Page 4

Table of Contents

Configuring OEE Performance Parameters For Activity Areas ...... 41

Configuring Data Collection .............................................................. 44

Configuring Cycle Time ...................................................................... 44

Configuring a Part ID/Cycle Time Lookup List ...................... 47

Configuring Part Id ............................................................................... 50

Configuring Summarization Criteria ............................................... 52

Configuring Part Count ....................................................................... 55

Configuring Part Count Using an Unscheduled Data Point 58

Configuring Part Count Using an Unscheduled Data Point

and a FTTM Expression ................................................................. 58

Configuring Part Count Using a FTTM Expression On a

Scheduled Basis ................................................................................. 59

Configuring a Formula .................................................................... 60

Availability ............................................................................................... 63

Configuring Scheduled Availability ............................................. 65

Configuring Monitored Availability ............................................ 73

Configuring Running State ............................................................ 78

Generating Performance Parameter Events ..................................... 81

Viewing Performance Parameter Events for an Activity Area .......... 81

System-generated Events ...................................................................... 83

User-defined Events .............................................................................. 85

Manual Events ........................................................................................ 88

The Recycle Bin ...................................................................................... 89

Configuring User-defined Performance Parameter Events .............. 90

Configuring the Event Data Summary ............................................. 90

Event Data Summarization Types ................................................ 92

Configuring the Event Trigger ........................................................... 93

Event Trigger Types ......................................................................... 96

Configuring the Event Value .............................................................. 99

Event Value Types ......................................................................... 101

Using the Expression Editor ....................................................... 104

Creating Event Value Reason Code Lookup Lists ................ 109

Configuring the Machine State / Faults ........................................ 111

Configuring the Reporting ............................................................... 113

Advanced Properties ................................................................................ 115

Scheduled Part Count Collection Parameters ............................. 115

4 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 5

Table of Contents

Automated Configuration

System-generated Event Data Summarization ............................. 116

Availability Interpretation Options ............................................... 117

Performance Data Trending Rate ................................................... 118

Machine States .......................................................................................... 118

Machine States at the Sample Enterprise ...................................... 120

Prioritizing Machine States .............................................................. 122

Configuring Machine States ............................................................. 123

Mapping Machine States to User-defined Events ....................... 125

Determining Availability and Running State From Machine State

.................................................................................................... 126

Configuring FactoryTalk Metrics to Perform Downtime Tracking ...

126

Running Versus Downtime .............................................................. 128

User-defined Downtime Events ...................................................... 129

Machine State ...................................................................................... 130

Reviewing the Status of Performance Parameters Events ............... 131

Start Data Collection .............................................................................. 133

Stop Data Collection ............................................................................... 134

Manual Data Collection ......................................................................... 134

Chapter 4

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 5

FactoryTalk Metrics UDT ..................................................................... 139

UDT Tags and FactoryTalk Metrics Performance Parameters 140

Setting up Communication Between a ControlLogix Controller and

FactoryTalk Metrics ................................................................................ 143

Configuring RSLinx Enterprise ....................................................... 144

Importing the FactoryTalk Metrics UDT to the ControlLogix

Controller ............................................................................................. 148

Creating Tags Based on the FactoryTalk Metrics UDT ........... 150

Creating FactoryTalk Transaction Manager and FactoryTalk

Metrics Configurations ..................................................................... 154

Configuration Types ..................................................................... 154

Configuration Flow ...................................................................... 154

Guidelines for Modifying Imported Performance Parameters 168

Page 6

Table of Contents

Analyzing FactoryTalk Metrics

Data

Chapter 5

Create a New RSBizWare Report ........................................................ 171

Insert Text, Pictures, and Hyperlinks .................................................. 172

Save the Report ......................................................................................... 174

Move the Report and Set Report Permissions ................................... 175

Add a Saved Report Object to the Report .......................................... 177

Adjust the Time Range For a Time-based Report Object ........ 180

Configure the Report Object To Use Global Credentials ............. 182

Create a New Chart ................................................................................. 185

Step 1: Plan the Chart ........................................................................ 186

Step 2: Select the Data On Which To Report ............................. 187

Step 3: Choose a Chart Type ........................................................... 187

Step 4: Describe the Data .................................................................. 187

Step 5: Select Summary or Detail .................................................... 188

Step 6: Select the Fields To Be Charted ........................................ 189

Step 7: Enter the Chart Title ........................................................... 190

Step 8: Filter the Data ........................................................................ 190

Step 9: Insert Your New Chart Into the Report ......................... 193

Create a New Text Report Object ....................................................... 194

Step 1: Start the Text Report Object Wizard .............................. 194

Step 2: Select the Data On Which To Report ............................. 194

Step 3: Group the Records ................................................................ 195

Step 4: Sort the Records .................................................................... 196

Step 5: Format the Table ................................................................... 197

Step 6: Name the Report Object ..................................................... 199

Step 7: Filter the Data ........................................................................ 199

Step 8: Insert Your New Table Into the Report .......................... 199

Create an OEE Box Chart...................................................................... 200

Step 1: Add a Chart to the Report .................................................. 200

Step 2: Select an Activity Area ......................................................... 201

Step 3: Specify the Layout of the Chart ......................................... 202

Step 4: Create a Filter ......................................................................... 203

Step 5: Customize the OEE Bar Colors ........................................ 205

Step 6: Preview Your OEE Box Chart ........................................... 207

Create a FactoryTalk Metrics Detail Chart ....................................... 207

Export the Report to HTML ................................................................ 210

6 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 7

Table of Contents

Customizing RSBizWare Charts

and Tables

Advanced Reporting Topics

Load the Report From File ..................................................................... 211

Chapter 6

Customizing Charts ................................................................................ 213

Working With the Component Parts of a Chart ....................... 214

Resizing a Component ................................................................. 215

Moving a Component .................................................................. 215

Deleting a Component ................................................................. 215

Editing the Chart Title or Text Field ....................................... 215

Changing Chart Component Properties ................................. 216

Working With Chart “Pens” ........................................................... 216

Customizing Text Report Objects ....................................................... 217

Show and Hide Columns .................................................................. 217

Resize Table Columns ....................................................................... 218

Aggregate, Group, Format, Sort, Chart, and Rename Columns .....

.................................................................................................... 218

Aggregate ......................................................................................... 220

Group ............................................................................................ 220

Format ............................................................................................ 220

Sort ............................................................................................ 221

Chart ............................................................................................ 221

Rename ............................................................................................ 221

Quick Filter .......................................................................................... 221

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 7

Chapter 7

The Excel Add-in ..................................................................................... 223

Scheduling Report Objects and Reports ............................................. 227

Schedule a Report Object .................................................................. 228

Schedule a Report ............................................................................... 231

View the History of the Scheduled Task ....................................... 235

Analyzing Non-RSBizWare Data ........................................................ 236

Create an External Data Source....................................................... 236

Report Data Sources ........................................................................... 237

Step 1: Start the Report Data Source Wizard ......................... 237

User-derived Fields .................................................................................. 241

Create Detailed Derived Fields ........................................................ 243

Create Summary Derived Fields ...................................................... 247

Page 8

Table of Contents

FactoryTalk Metrics Icon

Definitions

Object Permissions

Report Data Sources

Configuring Reports ................................................................................ 250

Chapter 8

Plant Model Element State Icons ......................................................... 253

Performance Parameter Event State Icons ......................................... 254

Chapter 9

Filter permissions ..................................................................................... 258

Report permissions ................................................................................... 258

Report data source permissions ............................................................. 259

Report object permissions ...................................................................... 259

Appendix A

Workcell History ...................................................................................... 261

Event History ............................................................................................ 263

Machine State Data.................................................................................. 264

8 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 9

What Is FactoryTalk Metrics?

Welcome to FactoryTalk Metrics

In this chapter you will learn about the following:

• What Is FactoryTalk Metrics? (page 9)

• Features and Benefits (page 10)

Chapter 1

• Intended Audience (page 10)

• Where Can I Go for Help? (page 12)

Companies in the discrete and repetitive manufacturing industries

are being challenged by management to maximize production from

existing lines, to meet required cycle times and delivery dates for

each product, and to reduce costs. To meet this challenge,

production management is striving to operate the equipment at its

highest efficiency.

Real-time identification of production assets that fail to reach the

required standard is critical to maintaining world-class efficiency. A

thorough understanding of the details behind production

performance will allow you to identify sources of production

inefficiencies, and to maximize asset utilization.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 9

The RSBizWare software is a suite of tools and services aimed at

increasing your manufacturing floor effectiveness and profitability

with solutions that target performance analysis and improvement,

and with data acquisition and integration. FactoryTalk Metrics is

just one of the applications that are available within the RSBizWare

software. FactoryTalk Metrics builds on the report, analysis, and

management capabilities of the RSBizWare software by providing a

Page 10

Chapter 1 Welcome to FactoryTalk Metrics

Features and Benefits

Intended Audience

powerful, yet simple set of tools to analyze the performance of

production assets.

FactoryTalk Metrics provides ratings - Overall Equipment

Effectiveness (OEE), Mean Time Between Failure (MTBF), and

Mean Time to Repair (MTTR) - that allow you to evaluate the

performance of your production assets. A production asset (or

activity area) can be anything from a single piece of equipment to a

complete manufacturing plant. These ratings provide a simple way

to determine quickly whether a production asset is performing

adequately, based on data collected from the control system.

FactoryTalk Metrics offers the following features and benefits:

• Rich reporting, graphing, analyzing, and querying

functionality providing a complete and easy-to-use solution for

performance analysis.

• High-level analysis tools to easily identify poorly performing

assets, including the ability to drill into the underlying detail to

identify the causes of production inefficiencies.

• The ability to evaluate every production asset based on OEE,

MTBF, and MTTR ratings.

• The ability to isolate each asset so that its rating is not affected

by upstream or downstream performance.

• The ability to connect most of the OEE parameters to either a

data point or a formula, providing flexibility in the

configuration of the OEE rating.

• The ability to embed a report object in any Microsoft ActiveX

container, such as Visual Basic or Internet Explorer.

10 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

The FactoryTalk Metrics User Guide is designed to help you

understand how to access and use the FactoryTalk Metrics product.

This document focuses on the end-user functions of FactoryTalk

Page 11

Welcome to FactoryTalk Metrics Chapter 1

Metrics and does not cover the installation and operation of

underlying system services.

This document is intended for the following types of users of the

RSBizWare software:

• RSBizWare administrators

RSBizWare administrators configure the RSBizWare system

so that it can capture performance data for use by report

designers and report users.

They should be familiar with:

• Control systems, process information (line and plant), and

databases.

• Microsoft Windows operating system.

• The location and structure of databases.

• Report designers

Report designers create the reports that will be used by report

users.

They should be familiar with:

• Process information (the physical representation of the

production line and plant).

• Microsoft Windows operating systems.

• Query logic (how to write a database query).

• Web publishing tools.

• The location and structure of databases.

• Report users

Report users make use of the reports created by the report

designer to perform their jobs.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 11

Page 12

Chapter 1 Welcome to FactoryTalk Metrics

technical support resources, please visit the support site.

Where Can I Go for Help?

Get Web Support

They should be familiar with:

• Microsoft Windows operating systems.

Consult the following resources for additional information about

the product:

• Release Notes

The release notes contain current information about the

product, including hardware and software requirements, new

features, known and fixed anomalies.

• RSBizWare Administration Guide

The administration guide helps the RSBizWare administrator

install and configure the software as well as understand the

architecture of the RSBizWare suite and its components.

• Online help

The online help provides general information and step-by-step

procedures for working with the product.

• Rockwell Automation Support Center

The support center provides a variety of services, such as

trainings, webinars, and online support that will improve your

experience using the RSBizWare suite.

TIP

For web-based product support, and for detailed information on

Access the Rockwell Automation Knowledge base for 24/7 technical

information and assistance. You can also download software patches

and new software versions, ask questions via email, participate in

user forums, and access other useful problem-solving tools.

The support resources available vary, depending on the product

purchased. The latest information can be obtained from the

Rockwell Automation Technical Support website.

12 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 13

Welcome to FactoryTalk Metrics Chapter 1

Get Phone Support

Get Consulting Services

Contact Us

A current TechConnect Support contract may be required to use

some online features.

To speak with a Technical Support representative in North

America, call 1-440-646-3434.

For information on how to contact Technical Support in other

locations worldwide, please visit the support site.

A current TechConnect Support contract may be required to obtain

phone support.

Rockwell Automation provides expert consulting and turnkey

implementation of this product. Please contact your local

representative for more information.

We strive to help all of our customers become successful in their

manufacturing improvement efforts. Toward this objective, we

invite you to contact your local representative or Rockwell

Automation at any time that we may be of service to you.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 13

Page 14

Chapter 1 Welcome to FactoryTalk Metrics

14 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 15

The RSBizWare Architecture

Chapter 2

Getting Started

Before you walk through the examples and tutorials that are

discussed in this book, it is assumed that the RSBizWare

administrator has installed, configured, and started the RSBizWare

server on the server computer.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 15

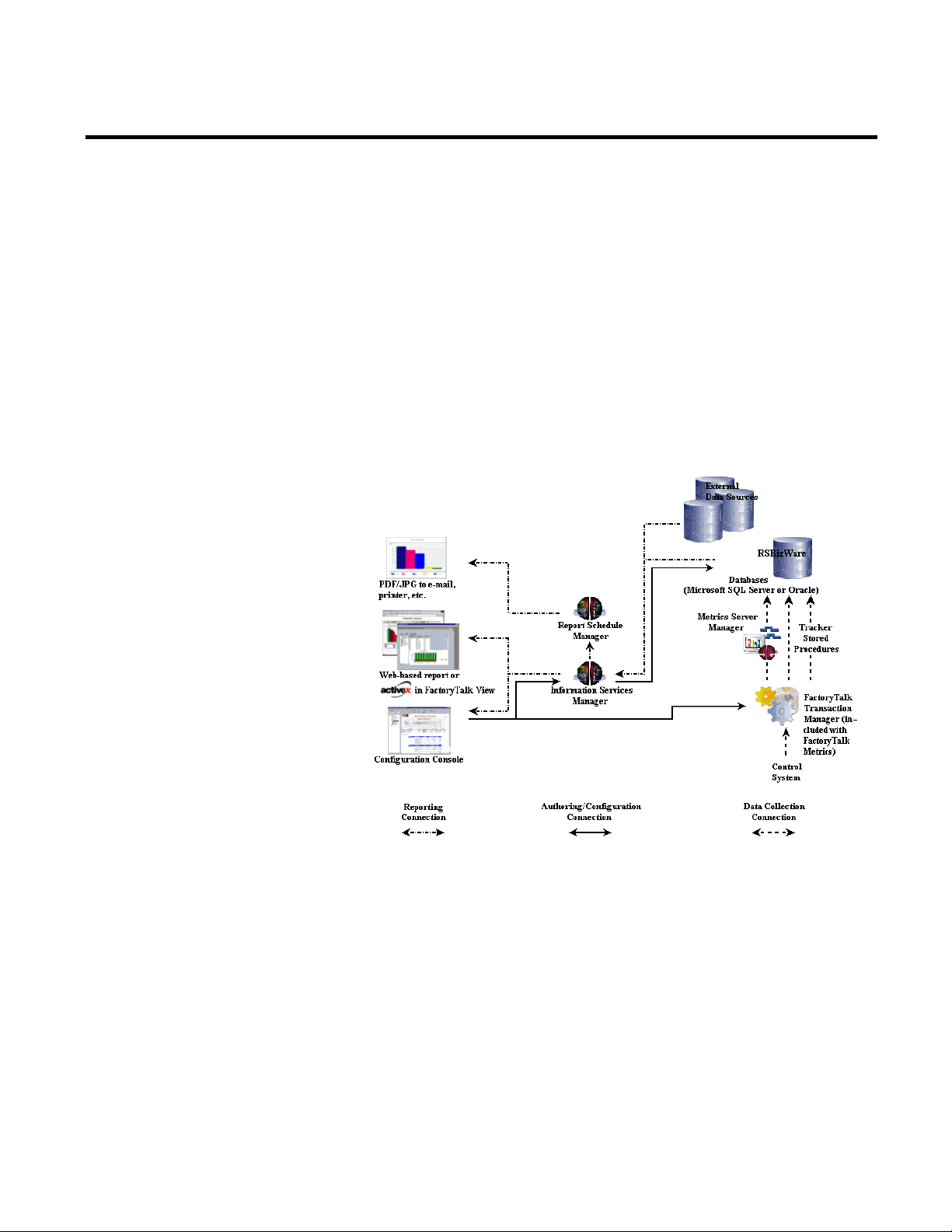

The RSBizWare architecture is a scalable, multi-tiered, distributed

architecture consisting of a data collection subsystem, an Oracle or

SQL Server database repository, the Information Services Manager,

and clients. Rockwell Automation’s FactoryTalk Transaction

Manager is the embedded engine that collects data from the control

system(s), and the Metrics Server Manager logs it to the predefined

RSBizWare database repository. There are several types of clients,

including the Configuration Console and the Internet Explorer

Web client.

Page 16

Chapter 2 Getting Started

Importing Sample Data to the RSBizWare Database

The RSBizWare architecture can be configured to run on a single

computer, or it can be distributed across multiple computers. In the

simplest case, the Configuration Console, the Information Services

Manager, the RSBizWare administrative tools used by the

RSBizWare administrator, the database, the Metrics Server

Manager, and the FactoryTalk Transaction Manager data collection

engine run on a single computer. In a distributed setting, these

components may reside on separate computers. Clients connect to

the Information Services Manager using TCP/IP, so they can be

deployed over a LAN, WAN, intranet, or the Internet. The

scalability of the RSBizWare architecture allows many clients to

connect to a single server.

You may import the FactoryTalk Metrics sample data so that you

can use it as a reference and/or for demonstration purposes.

To import the sample data into the RSBizWare database:

1. Go to Start > All Programs > Rockwell Software >

FactoryTalk Tools > Database Wizard.

The Database Load and Update Wizard appears.

2. Click Next.

The Product and Database Connection page appears.

3. In the ODBC DSN list, select your ODBC data source.

4. In the User text box, type the user name of your RSBizWare

database owner.

5. In the Password box, type the password of your RSBizWare

database owner.

6. Click Connect.

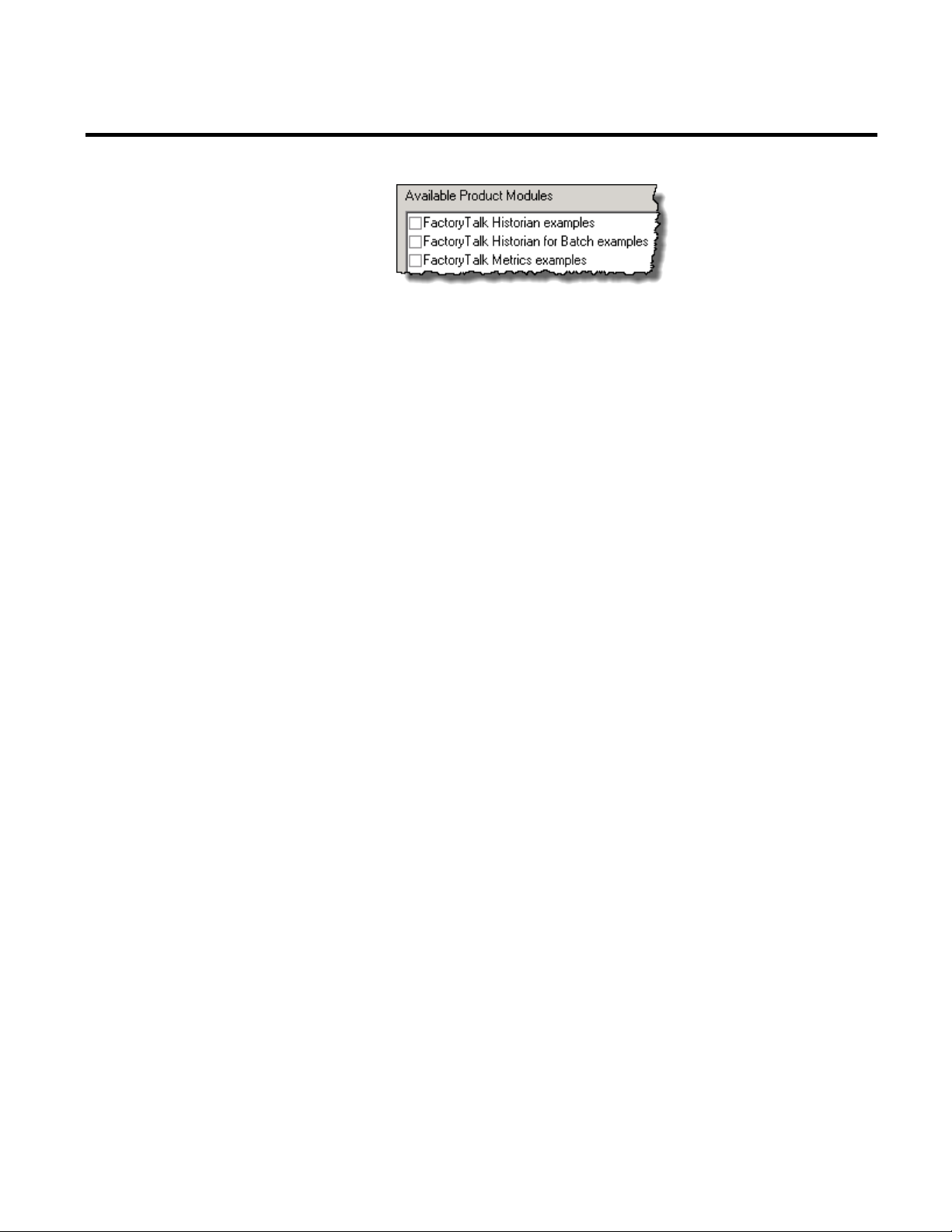

Under Available Product Modules, a list of sample data

appears.

16 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 17

Getting Started Chapter 2

Connecting to the Information Services Manager

Using the Information Services Manager in Internet Explorer

7. Select the data that you want to import.

8. Click Finish.

The Processing page with the import status appears.

After the import is complete, the Completing the Database

Load and Update Wizard page appears.

9. Click Close.

RSBizWare reports created by the report designer are saved to the

Information Services Manager, and are available online over a

TCP/IP network. If you wish to create and edit RSBizWare reports

using Microsoft Internet Explorer, you need to run the

Configuration Console.

Using Microsoft Internet Explorer to view RSBizWare reports, you

can connect to the Information Services Manager without having

the RSBizWare software installed on your computer. Instead, the

server hosts a special Web page, the Quick Web, to give you access to

the RSBizWare reports stored on the server. This option only allows

you to view RSBizWare reports.

To access the Quick Web, open Internet Explorer, type the Web

address for the Information Services Manager computer, and press

Enter on your keyboard.

The Web address is made up of the name of the server computer and

the HTTP port number used by the server computer, separated by a

colon.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 17

Page 18

Chapter 2 Getting Started

Using the Information Services Manager in the Configuration Console

For example, if you were attempting to connect to a server computer

named

would use the following address:

rsi-rockwell that uses the default HTTP port 8080, you

http://rsi-rockwell:8080.

Please contact your RSBizWare administrator for the specific

Information Services Manager Web address to which you should

connect.

The first time you try to use the Quick Web, you need to download

several ActiveX controls from the server computer. The download

will begin automatically.

After you have downloaded the ActiveX controls from the

Information Services Manager, you may be prompted to log on. If

prompted, type the user name and password for the account that

your RSBizWare administrator has authorized for you, and then

click OK. A connection to the RSBizWare server is established.

If you wish to configure your plant model, manage the collection of

control system data, and/or edit RSBizWare reports, you should

connect to the Information Services Manager via the Configuration

Console. Your RSBizWare administrator needs to assign a

FactoryTalk Metrics Author license and the appropriate privileges

to you, to enable you to perform these functions.

You need to have the client software installed on your computer to

run the Configuration Console. To install the Configuration

Console from the RSBizWare DVD, select the Minimal installation

option.

To start the Configuration Console:

1. Go to Start > All Programs > Rockwell Software >

RSBizWare > Configuration Console.

18 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

The RSBizWare Login dialog box appears.

Page 19

Getting Started Chapter 2

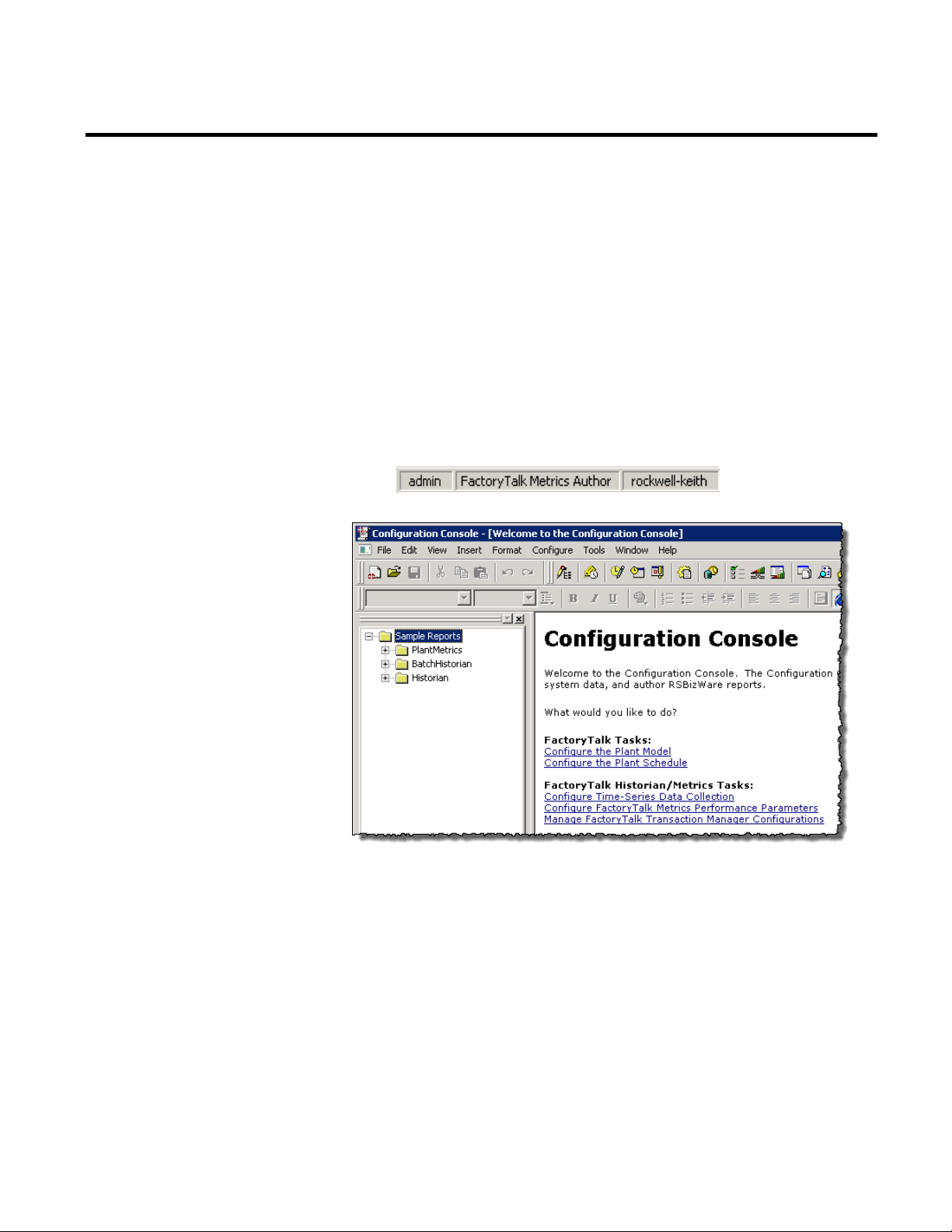

Getting Started with the Configuration Console

2. If prompted, type the user name and password for the account

that your RSBizWare administrator has authorized for you,

type the name of the server computer where the Information

Services Manager is running in the Server box, and then click

Login.

A client session with the RSBizWare server is established.

The status bar at the bottom of the client application shows

your user name, the activations that have been assigned to you,

and the Information Services Manager to which you are

connected.

The Configuration Console user interface is made up of two main

components:

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 19

• The Report Explorer pane on the left.

The Report Explorer is a hierarchical navigation tool used for

organizing the RSBizWare reports that have been saved for

future use. The Report Explorer contains the reports saved in

the Information Services Manager to which you are connected

and for which you have been granted view permissions. Your

Page 20

Chapter 2 Getting Started

selection is made.

workcell in the line).

location.

location at which products are manufactured.

Enterprise

The highest-level activity area, typically representing the business.

The Plant Model

ability to modify and delete the reports listed in the Report

Explorer depends on the licenses and features that you have

been assigned by your RSBizWare administrator, and the

permissions that you have been granted by the creator of each

individual report.

• The report design and display work area on the right.

When you click an item in the Report Explorer, the specified

RSBizWare report appears in this area. The work area is a

region where report designers can create and modify reports.

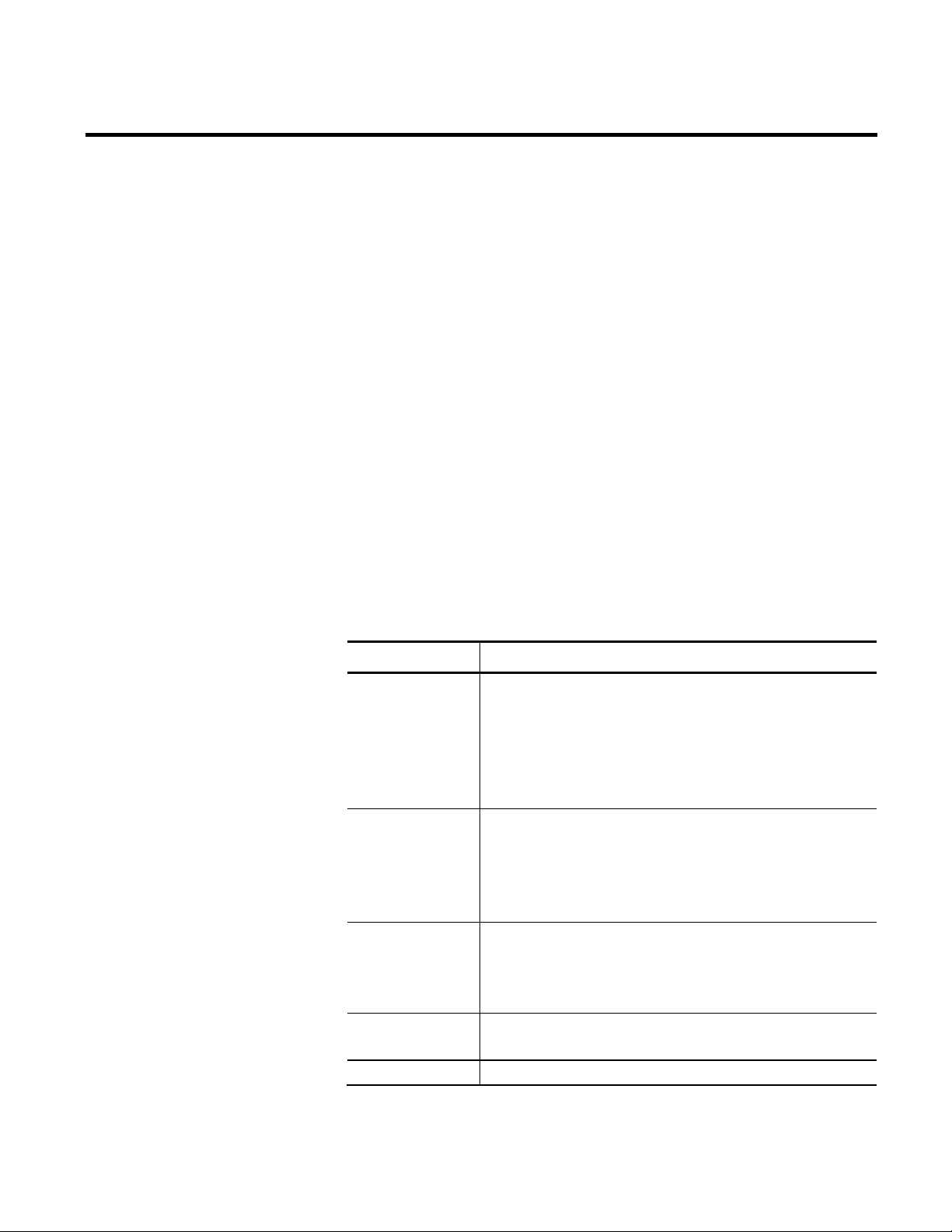

The plant model is made up of activity areas - enterprises, sites, areas,

lines, and workcells - as well as of equipment and labor resources.

The activity areas are based on the terms defined by the Instrument

Society of America (ISA) S95 standard in order to provide common

terminology for improved communication and integration between

control systems and enterprise systems.

Item Description

Workcell A location and/or group of equipment used to perform work in a

manufacturing process. The operations in a manufacturing process

are performed at workcells. A workcell is typically a physical

location and a primary resource (e.g., a machine); however, it may

also represent a logical grouping of primary resources from which a

Line A collection of one or more workcells that are combined to perform

work. The workcells in a line are either physically located close to

one another, or are related to one another in the production process

(the production result of the first workcell in a line feeds the second

Area A physical, geographical, or logical grouping of lines and/or

workcells within a site, typically representing a main production

capability (e.g., electronic assembly) within a manufacturing

Site A group of areas, lines, and workcells representing a geographical

20 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 21

Getting Started Chapter 2

To create and edit the plant model, you must be granted the

Activity Areas (page 23)".

Configuring the Plant Model

The plant model may be used by all RSBizWare applications in your

organization (FactoryTalk Metrics, FactoryTalk Historian Classic,

and FactoryTalk Scheduler). The enterprises, sites, areas, lines, and

workcells in your plant model are the subjects of your performance

parameter evaluation. For implementations of RSBizWare that

incorporate the FactoryTalk Scheduler application, the plant model

also includes capacity, which is the property of an activity area

describing its availability over time. The performance parameters

can also be configured for resources.

NOTE:

Organize Plant Model privilege by your RSBizWare administrator.

If you want to have access to sample data, see "Loading Sample

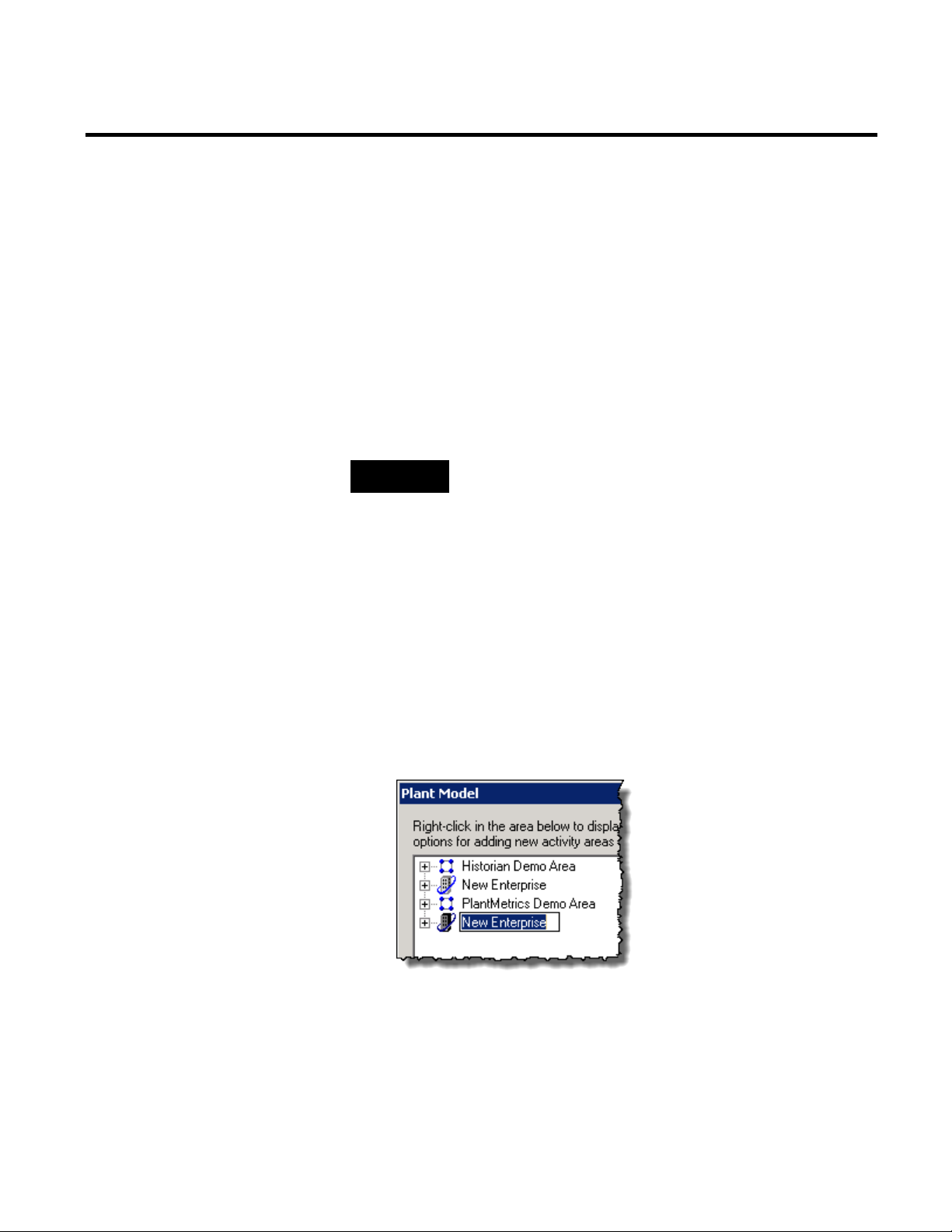

To configure the plant model in the Configuration Console:

1. On the Configure menu, click Plant Model.

The Plant Model dialog box appears.

2. Right-click in the area under the plant model tree, and then

click New Root Enterprise.

A new enterprise is added to the tree.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 21

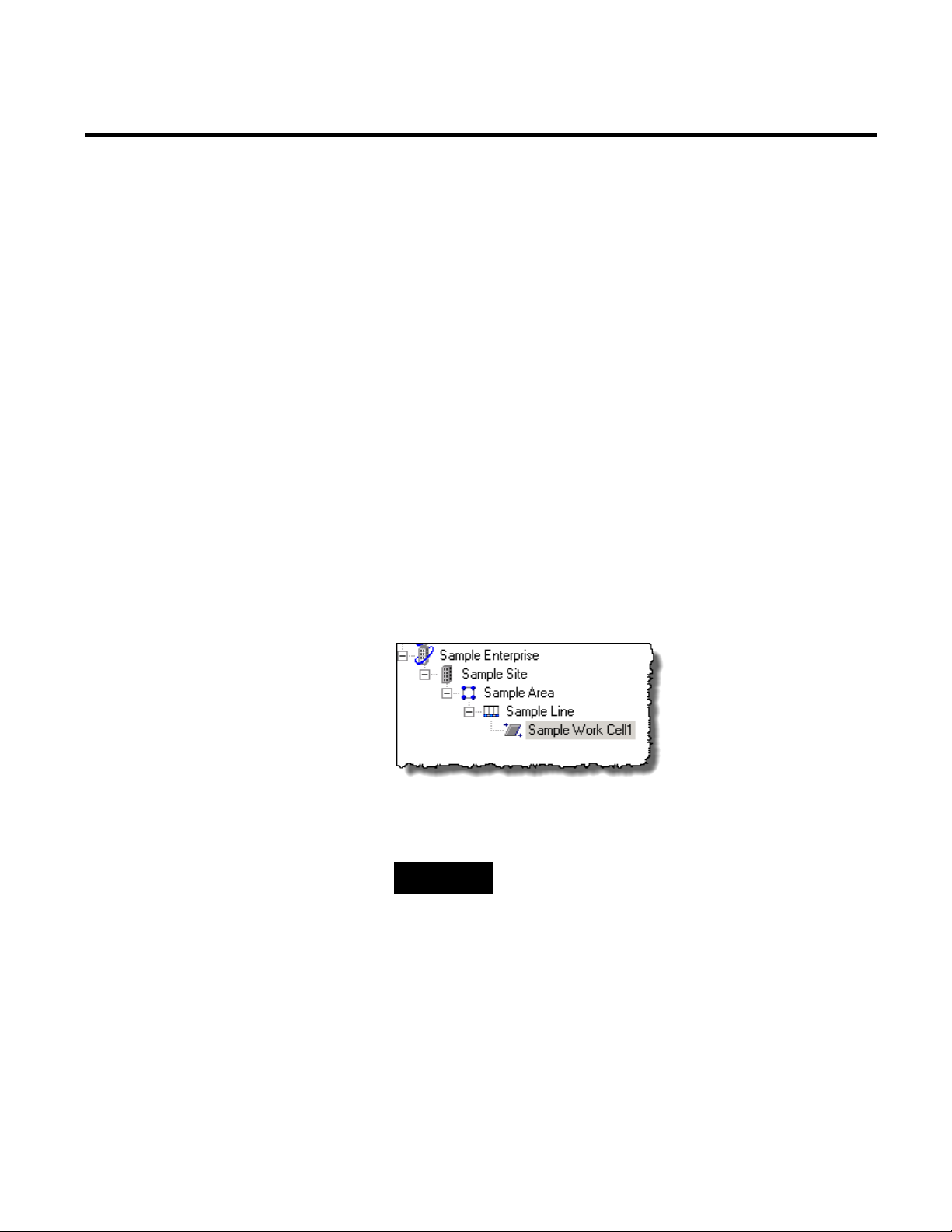

3. Change the default name to

Sample Enterprise, and then press

Enter.

4. Right-click Sample Enterprise, and then click New Activity

Area > Site.

Page 22

Chapter 2 Getting Started

them with time patterns.

A new site is added to the tree.

5. Change the default name to

Sample Site.

6. Right-click Sample Site, and then click New Activity Area >

Area.

A new area is added to the tree.

7. Change the default name to

Sample Area.

8. Right-click Sample Area, and then click New Activity Area >

Line.

A new line is added to the tree.

9. Change the default name to

Sample Line.

10. Right-click Sample Line, and then click New Activity Area >

Work Cell.

A new workcell is added to the tree.

11. Change the default name to

Sample Work Cell 1.

22 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

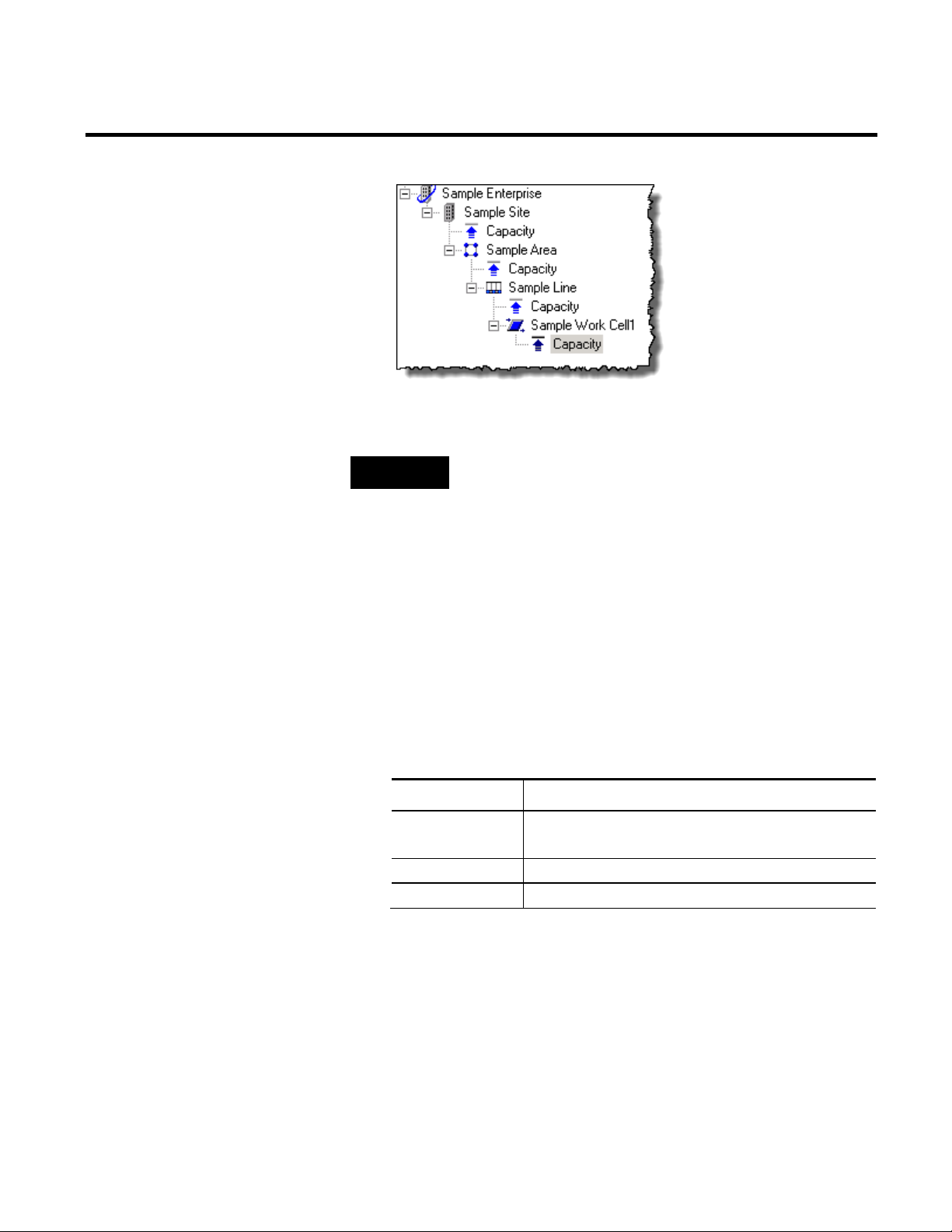

12. Right-click each activity area that you have created, and then

click Add Capacity.

TIP

The capacity of an activity area describes its availability over

time.

Add capacity for your activity areas so that you can associate

Page 23

section "Clean installation: supported installation scenarios".

Item

Description

configured for your RSBizWare SQL Server database.

User

Type the user name of your RSBizWare database.

Password

Type the password for the RSBizWare database user.

Loading Sample Activity Areas

13. Click OK.

Getting Started Chapter 2

NOTE

Follow these steps on the database server computer, on which Report

Expert is installed. For more information, see the Administration Guide,

To load FactoryTalk Metrics sample data:

1. Go to Start > All Programs > Rockwell Software >

FactoryTalk Tools > Database Wizard.

The Database Load and Update wizard appears.

2. On the Welcome page, click Next.

3. On the Product and Database Connection page, provide the

following information:

ODBC DSN Select the name of the ODBC data source that you have

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 23

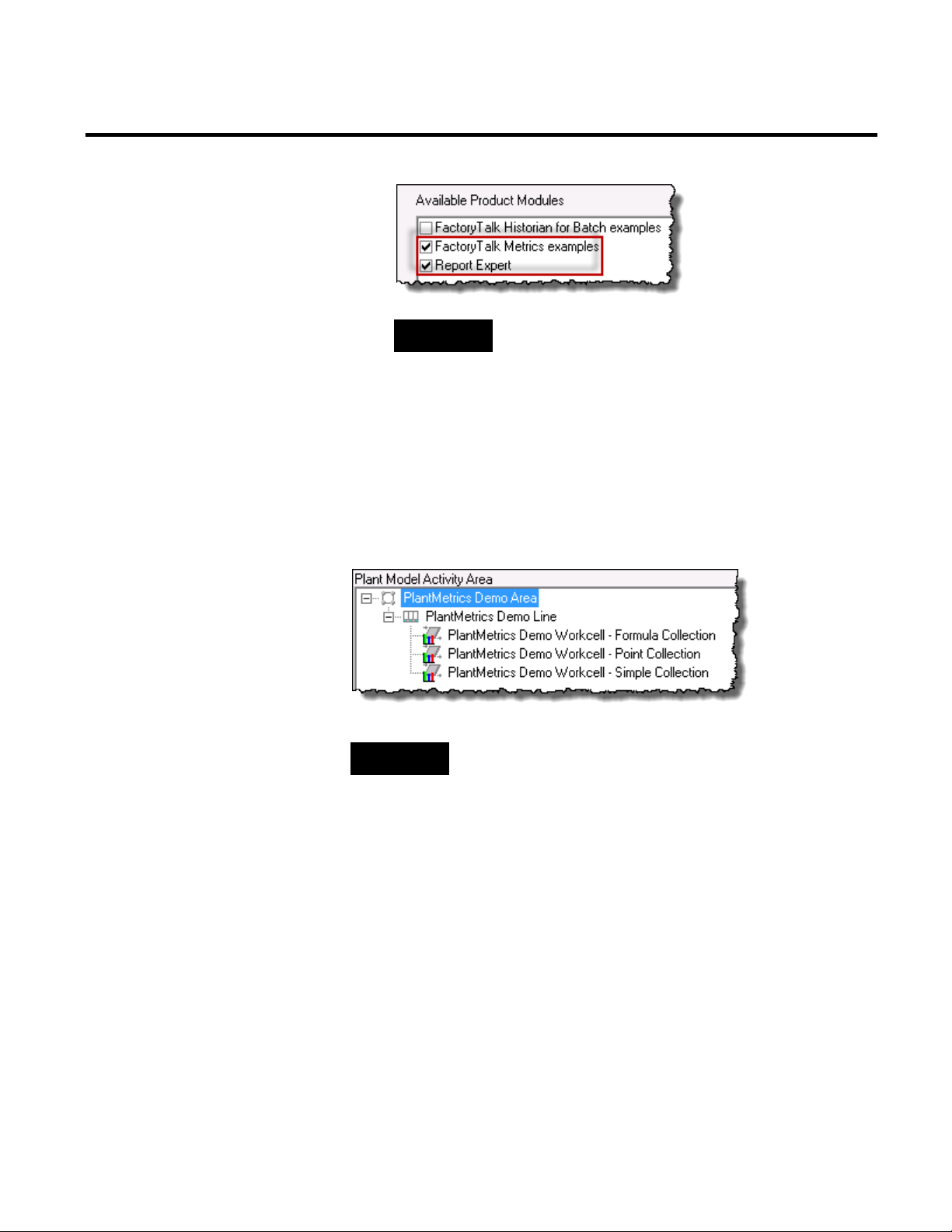

4. Click Connect. The Available Product Modules list is

populated with FactoryTalk components.

5. Under Available Product Modules, select these options:

Page 24

Chapter 2 Getting Started

Metrics and Report Expert sample data.

Parameters.

TIP

Select both options so that you have access to FactoryTalk

6. Click Finish to load data.

7. Click Close to exit the wizard.

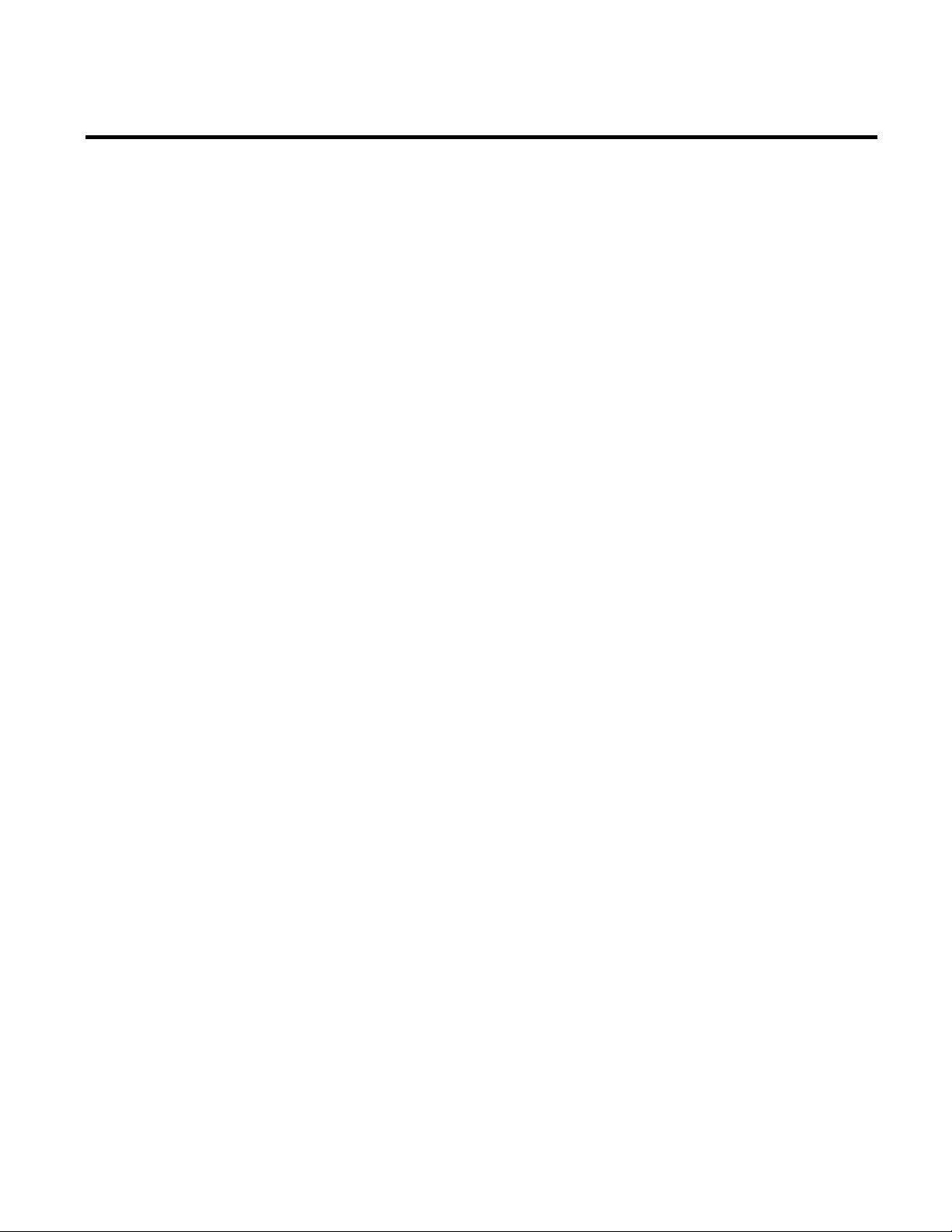

Now you can examine the OEE performance parameters that are

configured for sample activity areas. The activity areas are listed in

the Manage Performance Parameters dialog box, under

PlantMetrics Demo Area.

TIP

To open the Manage Performance Parameters dialog box, on the

Configure menu, click FactoryTalk Metrics > Performance

24 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 25

Collecting Part Count Data When the Metrics Server Manager Is Stopped

Chapter 3

Collecting Performance Data

The primary functions of FactoryTalk Metrics are collecting and

analyzing production data to provide performance ratings for every

activity area. Before the report designer can create performance

rating reports for the report user, the RSBizWare administrator

must set up the application to collect data from the control system.

This chapter will help you understand the two key categories of

ratings used to evaluate the performance of a production asset, and

understand how to identify and configure the data points that will

be used to collect the production data necessary to calculate

performance ratings.

We will:

• Define the OEE and Fault Metrics ratings.

• Configure the FactoryTalk Metrics application, including

plant model configuration, time pattern configuration, time

pattern exception configuration, composite time pattern

configuration, and performance parameter configuration.

• Start and stop data collection.

• Perform manual data collection.

The examples in "Analyzing FactoryTalk Metrics Data (page 171)"

will help you understand how to analyze the data that is collected in

FactoryTalk Metrics.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 25

In version 7.0 of FactoryTalk Metrics a change was made to the way

the data collection is initialized. Prior to this it was possible to have

partial FactoryTalk Transaction Manager .rsl files (still stored on

Page 26

Chapter 3 Collecting Performance Data

disk when data collection started) processed as current data values.

This approach could lead to inaccurate count information being

recorded in the event of a part count reset in the control system. The

most serious effect of this issue was observed when the counter used

in a FactoryTalk Metrics part count formula was reset, and the

resulting formula evaluated to a negative number. The change

required that the initial data used as a baseline for calculations all

come from the same time period. In certain environments with

continuous counters that do not get reset, this change could result in

the loss of count data that was collected erroneously in previous

versions. The data collected this way can account for part counts

that were produced since the last time the Metrics server was

running.

In order to accommodate customers that found this data useful, the

Metrics Server Manager settings file

(PlantMetricsServerSettings.xml) can be configured so that it

forces the Metrics Server Manager to initialize its data in the pre-7.0

manner.

The file is located in the <ProgramFiles>\Rockwell

Software\RSBizWare folder. It contains the

InitializeFromSingleTimestamp tag. The tag is set by default to 1.

The default value causes the Metrics Server Manager to process data

in the standard way to prevent the inclusion of older data. If you

change the value to

0, the Metrics Server Manager will process data

regardless of its timestamp. This change may be appropriate for

some production environments, but in others may lead to incorrect

values being logged for count information.

For more information on the Metrics Server Manager settings file,

refer to "The Metrics Server Manager settings file" in the RSBizWare

Administration Guide.

26 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 27

Collecting Performance Data Chapter 3

OEE Rating

FactoryTalk Metrics uses the OEE (Overall Equipment

Effectiveness) model to measure the performance of manufacturing

equipment. The OEE model yields a single performance rating for

every activity area (workcell, line, area, or plant) being monitored,

thereby providing a simple way to determine quickly if an activity

area is performing adequately. The OEE value can be used to assess a

single machine’s performance over time, or to compare the

performance of machines.

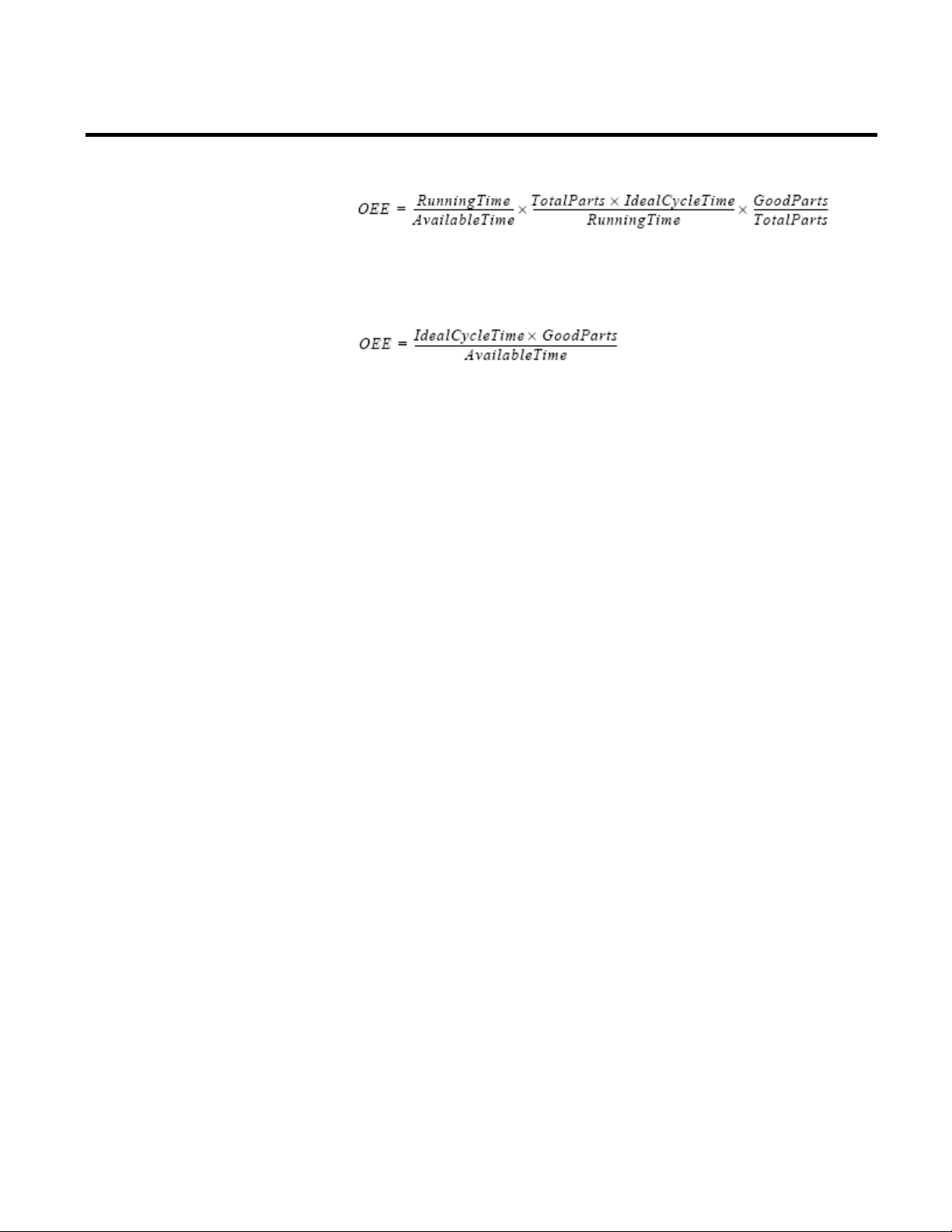

Three components contribute to the OEE value:

• Availability

The ratio of running time to available time.

Available time may be defined by a schedule, or modified by

planned downtime events such as preventive maintenance.

Available time may also be modified by events such as being

starved for parts or being blocked by a downstream process.

Availability = RunningTime / AvailableTime

• Throughput

The performance of a machine when it is running compared to

its ideal cycle time.

The ideal cycle time depends upon the product being

produced, and is measured in units of seconds per part.

Throughput = (TotalParts x IdealCycleTime) / RunningTime

• Quality

The percentage of good parts that are produced.

GoodParts = TotalParts – Scrap

Quality = GoodParts ⁄ TotalParts

The OEE calculation that is used by FactoryTalk Metrics is the

product of these three components:

OEE = Availability × Throughput × Quality

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 27

Page 28

Chapter 3 Collecting Performance Data

Fault Metrics Ratings

Mean Time Between Failure

This reduces to:

FactoryTalk Metrics gathers and stores all of the raw data necessary

to make this calculation for specific time periods, as well as by

activity area, by part number, and by shift. All of the individual

components of the calculation are stored and available for analysis.

OEE is a valuable method of analyzing performance, because it is

widely recognized and can be applied to any type of industry, factory,

or machine. However, it is merely the default efficiency calculation

performed by FactoryTalk Metrics, and additional or alternate

calculations can be implemented. Furthermore, FactoryTalk Metrics

supports the collection of detailed event data, which can be used to

analyze the specific causes of inefficiencies.

FactoryTalk Metrics uses the Fault Metrics ratings to measure the

reliability of manufacturing equipment. These metrics provide a

simple way to determine quickly if an activity area is performing

reliably. The Fault Metrics values can be used to assess a single

machine’s reliability over time, or to compare the reliability of

machines to each other.

MTBF = Uptime ⁄ FaultCount

Mean Time Between Failure (MTBF) is the ratio of running time to

the total number of failures. It measures the average amount of time

when a piece of equipment was in a running state between failures.

MTBF is a derived field that contains aggregate functions and, as

28 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 29

Collecting Performance Data Chapter 3

Area (page 81)”.

To define time patterns, configure composites, and schedule exceptions,

RSBizWare administrator.

Mean Time To Repair

Configuring Activity Area Schedules

Time Patterns

such, can only be used in summary report objects and cannot have

aggregate functions applied.

MTTR = FaultTime ⁄ FaultCount

Mean Time to Repair (MTTR) is the ratio of the time spent in a

failure state to the total number of failures. It measures the average

amount of time when a piece of equipment was in a failure state.

MTTR is a derived field that contains aggregate functions and, as

such, can only be used in summary report objects and cannot have

aggregate functions applied.

NOTE

To collect fault metrics for an activity area, you will need to create

custom events for the workcell. For information on creating custom

events, see “Viewing the Performance Parameter Events for an Activity

FactoryTalk Metrics allows you to create time patterns that will be

used to calculate the amount of available time for an activity area.

The OEE calculation is based on available time, so the calculation

will not be accurate unless the available time is defined accurately.

It is not necessary for you to use a time pattern to define available

time for an activity area; however, if you do, the OEE calculation for

the activity area will not be negatively impacted by the periods of

time when the activity area is scheduled to be unavailable (e.g.,

weekends or evenings).

NOTE

you must be granted the Manage Time Pattern privilege by your

A time pattern defines the availability of an activity area over time,

which repeats as necessary during the activity area schedule. We can

define the following durations of repeating periods:

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 29

Page 30

Chapter 3 Collecting Performance Data

Configuring Time Patterns

• Day

A time pattern for a 24-hour day.

• Week

A time pattern for a standard 7-day week.

• Custom

A time pattern for arbitrary duration, e.g., a 14-day cycle or an

8-hour shift.

A time pattern is composed of a default value and a series of time

spans. The default value defines the value of the time pattern during

intervals where no time span is specified. Each time span specifies

the start time, end time, value (e.g., Available, Unavailable), and the

optional report name for the span. The default value for the time

pattern and the value for the time span can be a named state, a

numeric value, or another time pattern. Named states are simply a

set of values (e.g., 1, 0) to which you have applied descriptions (e.g.,

Available, Unavailable).

The sample time patterns available with FactoryTalk Metrics consist

of three 8-hour shift periods, each with a 30-minute break

(Unavailable), that make up the work day. The time pattern applies

Monday through Friday, and the facility is closed (Unavailable)

during the weekends.

The ability to reference other time patterns allows you to build time

patterns from other time patterns.

In the following tutorials you will create sample shift time patterns

in the Configuration Console: a Work Day time pattern that is

made up of shifts, and a Work Week time pattern made up of five

Work Days.

30 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 31

Collecting Performance Data Chapter 3

To configure time patterns:

1. On the Configure menu, click Time Pattern.

The Time Patterns dialog box appears.

2. On the File menu, click New Folder.

A new folder is added to the Time Patterns tree.

3. Change the default name to

My Time Patterns, and then press

Enter.

4. Right-click My Time Patterns, and then click New Time

Pattern.

A new time pattern is added to the My Time Patterns folder.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 31

Page 32

Chapter 3 Collecting Performance Data

5. Change the default name to Shift A, and then press Enter.

In the right pane of the dialog box, the default settings of your

new time pattern are displayed.

TIP

The State value type set to Unavailable indicates that any

periods of time that are not listed as Available in the Time

Spans list will be considered Unavailable.

6. Clear the Lock Times check box.

The shift times will be relative to the start and end times

specified in the Work Day time pattern.

7. Under Duration, click

.

The Time Pattern Duration dialog box appears.

8. Under Duration Type, select Custom, and set the duration to

8 Hours.

9. Click OK.

10. Under Report Name, type

32 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Shift A.

Page 33

Collecting Performance Data Chapter 3

shift time”.

11. Under Time Spans, right-click the area and then click New

Time Span.

The Time Span dialog box appears.

12. Make sure that the value type is set to State and the value is set

to Available.

13. Set the start time of the shift to

NOTE

Since the shift times are relative, the start time in this example means

0:00, and the end time to 4:00.

“the start time of the shift”, and the end time means “4 hours into the

14. Click OK.

The new time span appears under Time Spans.

15. Repeat steps 11-14, and create another time span with the start

time set to

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 33

4:30, and the end time set to 8:00.

Page 34

Chapter 3 Collecting Performance Data

unavailable shows 0 capacity in the time pattern chart.

Configuring Work Day Time Patterns

NOTE

Since the default value of the time pattern is Unavailable, the

half hour between the time spans is considered unavailable,

because it has not been defined as available. A time span that is

16. Under Time Patterns, right-click Shift A, and then click

Duplicate.

A copy of the shift is added to the tree.

17. Change the name of the shift to

18. Under Report Name, type

Shift B.

Shift B.

19. Under Time Patterns, right-click Shift B, and then click

Duplicate.

A copy of the shift is added to the tree.

20. Change the name of the shift to

21. Under Report Name, type

Shift C.

Shift C.

34 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

To configure a Work Day time pattern:

1. In the Time Patterns dialog box, right-click My Time

Patterns, and then click New Time Pattern.

A new time pattern is added to the tree.

2. Change the default name to

Work Day.

Page 35

Collecting Performance Data Chapter 3

3. Under Time Spans, right-click the area and then click New

Time Span.

The Time Span dialog box appears.

4. Under Value Type, select Time Pattern.

With the Time Pattern option, you will create a time pattern

for a particular shift.

5. Under Value, select Shift A.

6. Set the start time to

0:00 (midnight), and the end time to 8:00

(AM).

7. Click OK.

8. Under Time Spans, right-click the area and then click New

Time Span.

The Time Span dialog box appears.

9. Under Value Type, select Time Pattern.

10. Under Value, select Shift B.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 35

Page 36

Chapter 3 Collecting Performance Data

Configuring Work Week Time Patterns

11. Set the start time to 8:00 (AM), and the end time to 16:00 (4

PM).

NOTE

Type the time in the 24-hour format.

12. Click OK.

13. Under Time Spans, right-click the area and then click New

Time Span.

The Time Span dialog box appears.

14. Under Value Type, select Time Pattern.

15. Under Value, select Shift C.

16. Set the start time to

16:00 (4 PM), and the end time to 24:00

(midnight).

36 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

To configure a Work Week time pattern:

1. In the Time Patterns dialog box, right-click My Time

Patterns, and then click New Time Pattern.

A new time pattern is added to the tree.

2. Change the default name to

3. Under Duration, click

Work Week.

.

The Time Pattern Duration dialog box appears.

4. Under Duration Type, select 1 Week.

Page 37

Collecting Performance Data Chapter 3

Value Type

Time Pattern

Value

Work Day

Start

Tuesday 0:00

End

Wednesday 0:00

For this item:

Select:

Value Type

Time Pattern

Value

Work Day

Start

Wednesday 0:00

End

Thursday 0:00

5. Click OK.

6. Under Time Spans, right-click the area and select New Time

Span.

The Time Span dialog box appears.

7. Under Value Type, select Time Pattern.

8. Under Value, select Work Day.

9. Under Start, select

10. Under End, select

Monday 0:00 (Monday at midnight).

Tuesday 0:00 (Tuesday at midnight).

11. Click OK.

12. Repeat steps 6-11, and create the following time spans:

Time span for Tuesday

For this item: Select:

Time span for Wednesday

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 37

Page 38

Chapter 3 Collecting Performance Data

Value Type

Time Pattern

Value Type

Time Pattern

Value

Work Day

Start

Friday 0:00

End

Saturday 0:00

Composites and Schedule Exceptions

Time span for Thursday

For this item: Select:

Value Work Day

Start Thursday 0:00

End Friday 0:00

Time span for Friday

For this item: Select:

38 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Your My Time Patterns folder should contain now the

following time patterns:

A composite is a base time pattern that is associated with an activity

area. A time pattern defines the normal schedule for the activity area,

and a composite may have exceptions that define any changes to the

normal schedule. These exceptions may be outages (unavailable

times) such as holidays or planned maintenance periods, or

Page 39

Collecting Performance Data Chapter 3

Configuring Composites and Schedule Exceptions

additional available times such as overtime hours or extended

seasonal hours.

In this tutorial you will use your Work Week time pattern created

in "Configuring Work Week Time Patterns (page 36)", as the base

time pattern for your Sample Line and Sample Work Cell 1

created in "Configuring the Plant Model (page 21)". You will also

schedule an exception for the New Year's Day.

To configure a composite and schedule exceptions:

1. On the Configure menu, click Composite Time Pattern.

The Composite Time Patterns dialog box appears.

2. Under Elements, expand the Sample Enterprise item until

you get to the Sample Line item.

3. Expand Sample Line, and then click Capacity.

4. In the right pane of the dialog box, under Exceptions,

right-click the area and select New.

The Exception dialog box appears.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 39

Page 40

Chapter 3 Collecting Performance Data

the arrows to move them under Application.

The activity area for which you are scheduling an exception (in

this tutorial it is Sample Line), is listed in the right pane of the

dialog box, under Application.

TIP

Exceptions are created for the activity areas that are listed under

Application.

If you want to add several activity areas to the exception that

you are configuring, select them under Elements, and then use

40 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

5. Under Description, type

New Year’s Day.

6. Leave the default values under Value Type (State) and Value

(Unavailable).

7. Under Start Date, select

8. Under End Date, select

Friday, January 02, 2015 at 0:0.

Saturday, January 03, 2015 at 0:0.

Page 41

Collecting Performance Data Chapter 3

Configuring OEE Performance Parameters For Activity Areas

9. Click OK.

The new exception appears under Exceptions in the

Composite Time Patterns dialog box.

After you have created a plant model and a time pattern, and

associated the time pattern with activity areas in the plant, you can

set additional parameters that will be used to measure the OEE

rating and gather custom events for these activity areas.

FactoryTalk Metrics provides a great deal of flexibility in

configuring the parameters that will be used to measure the OEE

rating of an activity area. At a minimum, you must provide the

following information:

• The FactoryTalk Transaction Manager configuration that will

be the link to the control system.

• The amount of time it should take the activity area to produce

one good part (ideal cycle time).

• The control system counter keeping track of production

counts.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 41

Page 42

Chapter 3 Collecting Performance Data

RSBizWare administrator.

For more sophisticated configurations, you can define other key

parameters and custom events. You can connect many of the

parameters either to a data point in the control system or to a

formula. Depending on the sophistication of your control system,

you can use a combination of data points and formulas. This tutorial

illustrates the different methods that you can use to configure

performance parameters.

NOTE

To configure OEE performance parameters for an activity area, you must

be granted the Manage Performance Parameters privilege by your

Use the Configuration Console to configure the performance

parameters.

To select an activity area for configuration:

1. On the Configure menu, click FactoryTalk Metrics >

Performance Parameters.

The Manage Performance Parameters dialog box appears.

2. In the tree, select the activity area for which you want to

configure performance parameters.

For this tutorial, select your Sample Work Cell 1.

42 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

3. Click Configure.

The Configure Performance Parameters dialog box appears.

Page 43

Collecting Performance Data Chapter 3

In this dialog box you can configure the parameters that will be

used to collect performance data and measure the OEE rating

for the activity area.

The upper section of the dialog box provides basic information

on the activity area that you have selected, and the following

options that you can use with your activity area:

• Enable Manual Activity Area

Select this option if you want to create a manual workcell.

This indicates that the activity area can be configured

without data points assigned.

For more information, refer to "Configure FactoryTalk

Metrics Data Collection Parameters" in the Configuration

Console Online Help.

If the FactoryTalk Transaction Manager configuration

associated with this activity area is running and enabled for

online edits, you can edit the performance parameters of the

selected activity area without stopping the configuration. If

the configuration is running and not enabled for online

edits, you cannot make changes to the configuration until

the configuration is stopped.

The FactoryTalk Transaction Manager Live Data

Migration Tool allows you to enable configurations that are

not currently enabled for online edits. For additional

information about editing a running configuration and

using the FactoryTalk Transaction Manager Live Data

Migration Tool, refer to the Online Edits Tutorial in the

FactoryTalk Transaction Manager online help.

• Enable Data Collection for this Plant Model Activity

Area

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 43

Page 44

Chapter 3 Collecting Performance Data

which the Configuration Console is connected.

Configuring Data Collection

Configuring Cycle Time

Select this option if you want to start the data collection for

the activity area that you have selected.

NOTE

Enabling the data collection for the activity area also consumes

one workcell license for the Information Services Manager to

To configure the Data Collection:

• In the list, select a FactoryTalk Transaction Manager

configuration for data collection.

Make sure you have a FactoryTalk Transaction Manager

configuration defined in the Service Console. For more

information, see the RSBizWare Administration Guide,

"Configuring data collection".

How do I access the dialog box?

1. On the Configure menu, click FactoryTalk Metrics >

Performance Parameters.

The Manage Performance Parameters dialog box appears.

2. Select the activity area for which you want to associate

machine states, and then click Configure.

The Configure Performance Parameters dialog box appears.

3. If necessary, select the FactoryTalk Transaction Manager

configuration for the activity area.

4. In the left pane of the dialog box, click Cycle Time Part Id.

44 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 45

Collecting Performance Data Chapter 3

The Ideal Cycle Time parameter is part of the Throughput value in

the OEE equation. It indicates the time, in seconds, which the

activity area should take to produce a single good part. It can have a

decimal value. If the activity area produces parts faster than the ideal

cycle time, the OEE rating will improve. If the activity area produces

parts slower than the ideal cycle time, the OEE rating will

deteriorate.

To configure the Ideal Cycle Time:

Under Ideal Cycle Time, in the Cycle Time Type list, select one of

the following options:

• Use a single Ideal Cycle Time

Select this option if the activity area always takes the same

amount of time to produce each part, regardless of what type

of part is being produced. Parts that take longer than the

specified cycle time will negatively impact the OEE rating.

In the Cycle Time box, specify the part production time in

seconds.

• Use a PartId/Cycle Time List

Select this option if you want to improve the accuracy of the

OEE rating. With this option, the application uses the

specified lookup list to find the Ideal Cycle Time for the type

of part that is being produced. This assumes that the activity

area always takes the same amount of time to produce a certain

type of part.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 45

Page 46

Chapter 3 Collecting Performance Data

Lookup List (page 47)".

In the Lookup list, select the lookup list that you want to use:

• Click Create List to create a new list.

• Click Edit List to modify the list that you have selected.

TIP

For more information on creating and editing Part

Id/Cycle Time lists, see "Configuring a Part ID/Cycle Time

• Monitor an Unscheduled data point for Ideal Cycle Time

Select this option to obtain the most accurate ideal cycle time.

With this option, the control system specifies the amount of

time it should take to produce a good part.

You can either only select a data point or first select a data

point as the ideal cycle time event trigger, and then set the

actual ideal cycle time using a FactoryTalk Transaction

Manager expression:

46 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

1. Click Select.

The Select Data Point dialog box appears.

2. Under Filtering Tools, in the FT Transaction Manager

Topic/Device list, select the device from which you want

to load data points.

3. At the top of the dialog box, click Refresh Points.

The Data Points area at the bottom of the dialog box is

populated with data points for the selected device.

4. Double-click the data point that you want to use.

The data point appears in the Data Point box in the

Configure Performance Parameters dialog box.

Page 47

Collecting Performance Data Chapter 3

Clear.

Configuring a Part ID/Cycle Time Lookup List

TIP

To delete the data point that you have selected, click

5. (Optional) Set the actual ideal cycle time using a

FactoryTalk Transaction Manager expression:

1. Select the Use a FactoryTalk Transaction Manager

Expression to determine the Ideal Cycle Time value

check box.

2. Click Edit.

The Expression Editor - Ideal Cycle Time Expression

dialog box appears.

3. Create or modify the expression that you want to use.

If you use a FactoryTalk Transaction Manager

expression, the only data point it can reference is the one

that you have provided in the Data Point box.

How do I access the dialog box?

1. On the Configure menu, click FactoryTalk Metrics >

Lookup Lists > Part Id/Cycle Times.

The Part Id/Cycle Time Lookup List dialog box appears.

2. Do either of the following:

• Click Add.

• Select a lookup list, and then click Edit.

The Part Id/Cycle Time List Configuration dialog box

appears.

Use the Part Id/Cycle Time List Configuration dialog box to

configure a Part Id/Cycle Time Lookup List and its parameters:

• Default cycle time for Total Parts.

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 47

Page 48

Chapter 3 Collecting Performance Data

Configuring the Default Cycle Time for Total Parts

Configuring Ideal Cycle Time Values for Individual Part Ids

• Cycle times for individual Part Ids.

Click the links below to learn how to:

• Configure the default cycle time for Total Parts. (page 48)

• Configure the ideal cycle time values for individual Part Ids.

(page 48)

• Manage Part Id configurations. (page 49)

• Import the cycle time values for individual Part Ids. (page 49)

To configure the default Cycle Time for Total Parts:

1. In the List Description box, type a name for the new Part

Id/Cycle Time lookup list.

The name will be displayed in the Part Id/Cycle Time Lookup

list in the Part Id/Cycle Time section of the Configure

Performance Parameters dialog box.

2. In the Default Cycle Time box, type a value for the default

cycle time for Total Parts in seconds.

To configure the Ideal Cycle Time values for individual Part Ids:

1. Under Part Ids and Cycle Times, click Add.

2. The Part Id/Cycle Time Values dialog box appears.

48 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

3. In the Part Id box, type the name of the Part Id for which you

want to set the cycle time.

Page 49

Collecting Performance Data Chapter 3

Managing Part Id Configurations

Importing Cycle Time Values for Individual Part Ids

4. In the Cycle Time box, type an ideal cycle time value in

seconds.

5. Click OK.

The Part Id and its cycle time value appear under Part Ids and

Cycle Times in the Part Id/Cycle Time List Configuration

dialog box.

6. Repeat the steps for other Part Ids for which you want to set

individual ideal cycle time values.

To manage Part Id configurations:

• To edit a Part Id configuration, click the Part Id item under

Part Ids and Cycle Times, and then click Edit.

The Part Id/Cycle Time Values dialog box appears.

• To delete a Part Id configuration, click Delete.

To import Part Id configurations:

1. Create a text file with Part Id configurations.

2. In the file, type the data in the order in which it will be

displayed in the dialog box, that is:

<Part Id>,<Ideal cycle time>

3. Separate each chunk of data with a comma, for example:

AAA,2

4. Save the file in the .csv format.

5. Under Previous Import File Path, click Import.

If there are Part Id configurations defined in the dialog box,

the following message appears:

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 49

Page 50

Chapter 3 Collecting Performance Data

Configuring Part Id

6. Click Yes.

The Open dialog box appears.

7. Navigate to the file that you want to import, and then click

Open.

The table under Part Ids and Cycle Times is populated with

the data imported from the file.

How do I access the dialog box?

1. On the Configure menu, click FactoryTalk Metrics >

Performance Parameters.

The Manage Performance Parameters dialog box appears.

2. Select the activity area for which you want to associate

machine states, and then click Configure.

The Configure Performance Parameters dialog box appears.

3. If necessary, select the FactoryTalk Transaction Manager

configuration for the activity area.

4. In the left pane of the dialog box, click Cycle Time Part Id.

50 Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014

Page 51

Collecting Performance Data Chapter 3

The Part Id parameter tells FactoryTalk Metrics what type of part is

being produced by the activity area. Changes in the Part Id value

allow FactoryTalk Metrics to track what type of part is being

produced. If you always know what kind of part the activity area is

producing, you can obtain the OEE ratings for the activity area

sorted by part.

To configure the Part Id:

Under Part Id, in the Part Id Type list, select one of the following

options:

• Do not monitor Part Id

Select this option if the application does not have information

about the types of parts the activity area is producing. The

OEE rating for the activity area will always be based on all

parts produced by the activity area.

• Use a single Part Id

Select this option if the activity area produces only one type of

part, and the OEE rating for the activity area will always be

associated with that particular type of part.

In the Part Id box, type the part ID.

• Monitor an Unscheduled data point for Part Id

Rockwell Automation Publication PLTMT-UM001M-EN-P-June 2014 51

Page 52

Chapter 3 Collecting Performance Data

Clear.

Configuring Summarization Criteria

Select this option if you want to monitor a data point in the

control system to determine the type of part being produced.

Changes in the Part Id value allow FactoryTalk Metrics to

track operation conditions to the type of part being produced.

If FactoryTalk Metrics knows what kind of part the activity

area is producing, you can obtain the OEE rating for the

activity area when it is producing a specific type of part:

1. Click Select.

The Select Data Point dialog box appears.

2. Under Filtering Tools, in the FT Transaction Manager

Topic/Device list, select the device from which you want

to load data points.

3. At the top of the dialog box, click Refresh Points.

The Data Points area at the bottom of the dialog box is

populated with data points for the selected device.

4. Double-click the data point that you want to use.

The data point appears in the Data Point box in the

Configure Performance Parameters dialog box.

TIP

To delete the data point that you have selected, click

How do I access the dialog box?