Page 1

PROCESSBOOK USER GUIDE

PUBLICATION HSEPB-UM024A-EN-E–June 2012

Supersedes Publication HSEPB-UM023A-EN-E

Page 2

●

●

●

●

●

Copyright

Contact Rockwell Automation

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support

Copyright Notice

© 2012 Rockwell Automation Technologies, Inc. All rights reserved. Printed in USA.

© 2010 OSIsoft, Inc. All rights reserved.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation Technologies, Inc. Any reproduction and/or distribution

without prior written consent from Rockwell Automation Technologies, Inc. is strictly prohibited. Please refer to the license agreement for details.

Trademark Notices

FactoryTalk, Rockwell Automation, Rockwell Software, the Rockwell Software logo are registered trademarks of Rockwell Automation, Inc.

The following logos and products are trademarks of Rockwell Automation, Inc.:

FactoryTalk Historian Site Edition (SE), FactoryTalk Historian Machine Edition (ME), RSView, FactoryTalk View, RSView Studio, FactoryTalk ViewStudio, RSView

Machine Edition, RSView ME Station, RSLinx Enterprise, FactoryTalk Services Platform, FactoryTalk Live Data, and FactoryTalk VantagePoint.

The following logos and products are trademarks of OSIsoft, Inc.:

PI System, Sequencia, Sigmafine, gRecipe, sRecipe, and RLINK.

Other Trademarks

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows, Windows ME, Windows NT, Windows 2000, Windows Server

2003, and Windows XP are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other countries.

ControlNet is a registered trademark of ControlNet International.

DeviceNet is a trademark of the Open DeviceNet Vendor Association, Inc. (ODVA).

Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation.

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

Restricted Rights Legend

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software

clause at DFARS 252.227-7013.

Warranty

This product is warranted in accordance with the product license. The product’s performance may be affected by system configuration, the application being performed,

operator control, maintenance, and other related factors. Rockwell Automation is not responsible for these intervening factors. The instructions in this document do not cover

all the details or variations in the equipment, procedure, or process described, nor do they provide directions for meeting every possible contingency during installation,

operation, or maintenance.

This product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the accompanying software may have changed since the release. Rockwell Automation, Inc.

reserves the right to change any information contained in this document or the software at anytime without prior notice. It is your responsibility to obtain the most current

information available from Rockwell when installing or using this product.

ii

Page 3

Contents

Introduction ............................................................ 1

Recent History and Requirements for FactoryTalk Historian

ProcessBook ....................................................................... 1

What's New in FactoryTalk Historian ProcessBook 3.2 ............. 1

What's New in This Release ..................................................... 2

FactoryTalk Historian ProcessBook Essentials ................... 5

What Can You View with FactoryTalk Historian ProcessBook ............ 5

Start FactoryTalk Historian ProcessBook ..................................... 6

Servers and Connections .................................................... 6

Connect to a FactoryTalk Historian Server .......................... 6

FactoryTalk Historian Security ......................................... 8

Network Errors ............................................................ 8

Displays and Connection Failure ....................................... 9

Node Identifiers for Multiple FactoryTalk Historian Servers ..... 10

Workspace .................................................................... 10

ProcessBook (.piw) ...................................................... 10

Display ..................................................................... 11

Create a New ProcessBook or Display ............................... 11

Run Mode and Build Mode ................................................. 12

Add-Ins ............................................................................ 13

Add-In Manager .............................................................. 13

Menus and Toolbars ............................................................. 14

iii

Page 4

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Command Menus ............................................................. 14

Customize Toolbars ......................................................... 15

Toolbar Buttons .............................................................. 15

Add Buttons to Toolbars ............................................... 16

Browser Toolbar ................................................................. 16

Browse ProcessBooks and Displays ....................................... 16

View Browsing History ...................................................... 17

Set a Home Page ............................................................ 17

Bookmarks and Browser History .......................................... 18

Add/Edit Bookmarks .................................................... 19

Keyboard Shortcuts ............................................................. 20

Assign a Keyboard Shortcut ................................................ 21

Remove a Keyboard Shortcut ............................................. 22

Preference Settings ............................................................. 22

General Preferences ........................................................ 23

Table of Contents Preferences............................................ 26

Display Window .............................................................. 28

Trend Preferences .......................................................... 30

Trend Elements Preferences .............................................. 32

Print ............................................................................... 33

Page Setup for Printing..................................................... 34

Print Preview ................................................................. 35

Printer Setup ................................................................. 35

Change the Language Used for FactoryTalk Historian ProcessBook .... 36

About FactoryTalk Historian ProcessBook .................................. 36

Work with a ProcessBook ........................................... 39

Basic Steps to Build a ProcessBook ........................................... 39

Create a New ProcessBook .................................................... 39

Open an Existing ProcessBook ................................................ 40

Add ProcessBook Entries ....................................................... 41

iv

Work With Multiple ProcessBooks ........................................ 41

Page 5

● Contents

●

●

●

●

●

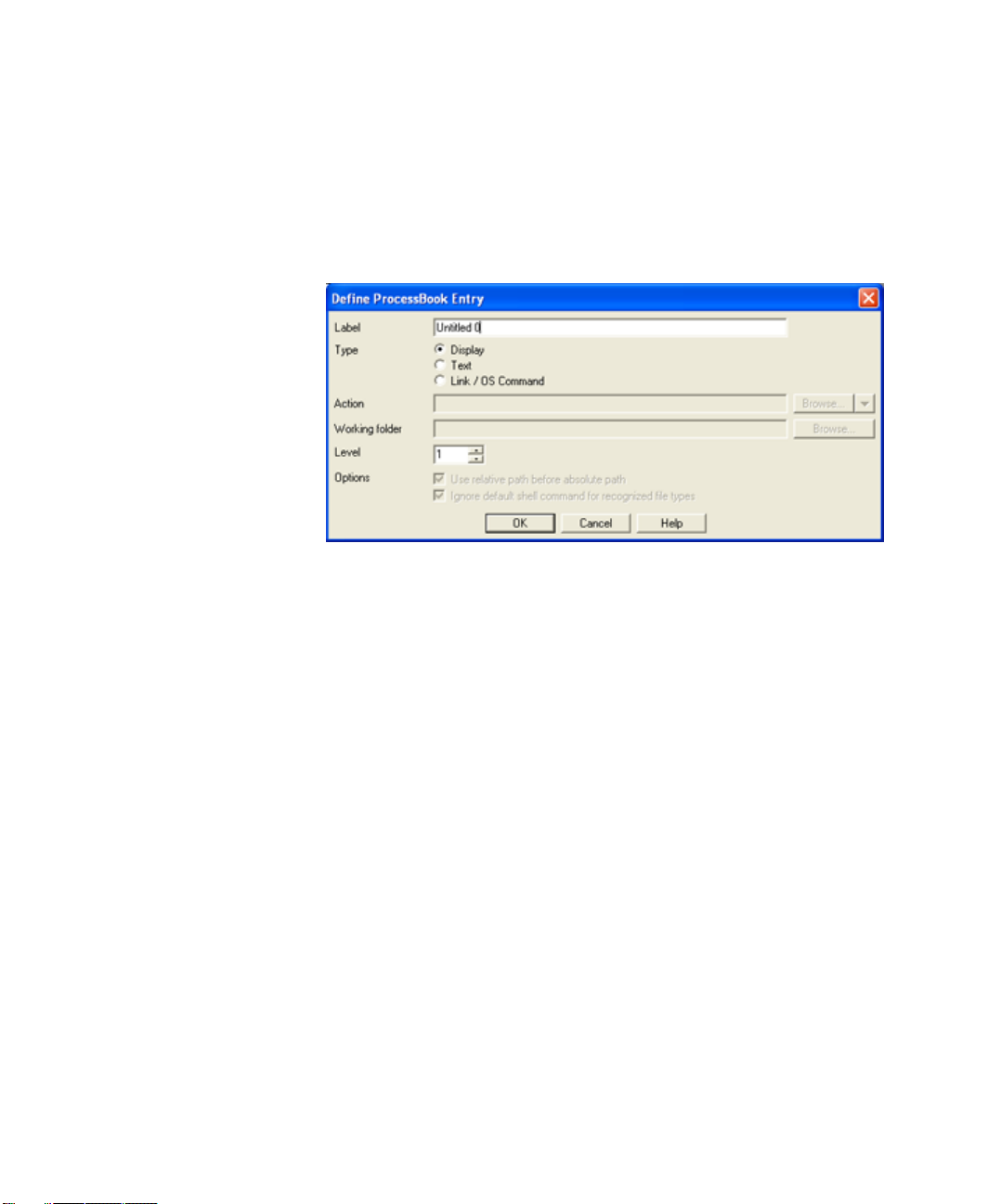

Create a Text or Display Entry ............................................ 43

Linked Display Entry ........................................................ 43

Create a Linked Display Entry ............................................. 44

Linked ProcessBook Entries ................................................ 46

Move Linked Entries ..................................................... 46

Operating System Command Entry ....................................... 46

Create an Operating System Command Entry .......................... 47

Working Directory for Operating System Commands .............. 49

Arrange ProcessBook Entries .................................................. 49

Book View..................................................................... 50

Turn Pages in Book View ............................................... 51

Resize a ProcessBook ................................................... 52

Entries in Book View .................................................... 52

Change the Name of an Entry in Book View ........................ 53

Change the Level of an Entry in Book View ......................... 53

Outline View ................................................................. 53

Collapse or Expand Outline View ..................................... 54

Rearrange Entries in Outline View ................................... 55

Change the Name of an Entry in Outline View ..................... 56

Change the Level of an Entry in Outline View ..................... 56

Copy and Paste an Entry ................................................... 57

Remove an Entry ............................................................ 57

Save a View of Your Displays .............................................. 57

Save and Close a ProcessBook ............................................ 58

Properties ........................................................................ 59

Summary Information in ProcessBook ................................... 59

FactoryTalk Historian ProcessBook File Properties .................... 60

Modify a ProcessBook Title ............................................ 61

FactoryTalk Historian ProcessBook Display Properties ............... 62

Import Files to a ProcessBook ................................................. 63

File Sharing Capability ......................................................... 64

Move a ProcessBook to Another PC .......................................... 65

v

Page 6

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Work with a Display .................................................. 67

Overview of Display Elements ................................................ 67

Static Symbols ............................................................... 67

Dynamic Symbols ............................................................ 68

Buttons ........................................................................ 68

OLE Objects .................................................................. 68

Manage Displays and Independent Display Files ........................... 69

Open a Display ............................................................... 69

Open Several Displays at One Time .................................. 70

Manage Multiple Open Displays ....................................... 70

Open Independent Display Files ...................................... 71

Browse a Display from Internet Explorer ................................ 71

Zoom Display Size ........................................................... 71

Full Screen Mode ............................................................ 72

Search for a Display ......................................................... 73

Reduce a Display to an Icon to Save Space ............................. 74

Save a Display ................................................................ 74

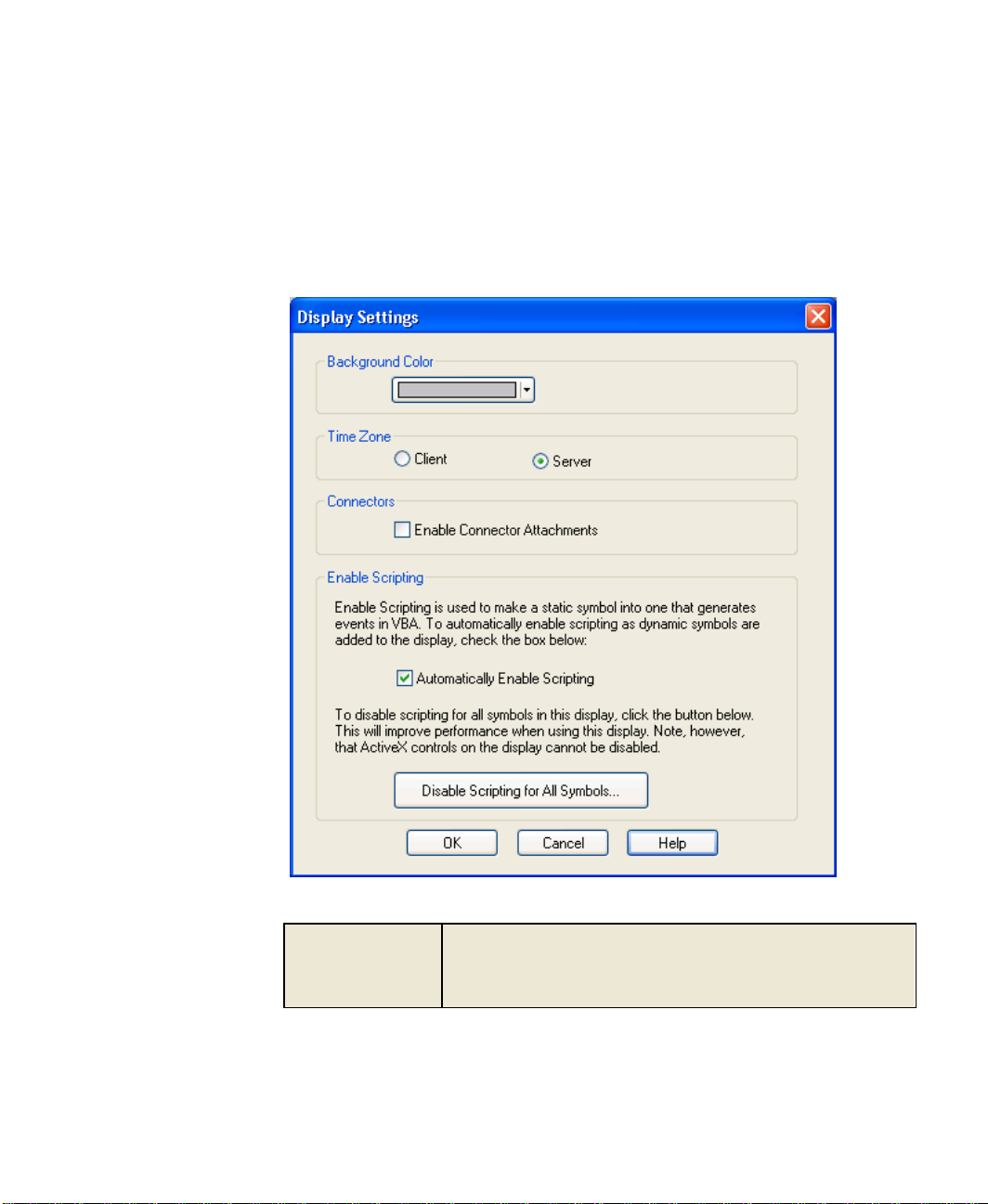

Display Settings .............................................................. 75

Display Scrolling Properties ............................................... 76

Status Bar Indicators ........................................................ 77

Drawing Tools .................................................................... 77

Organizing Symbols ......................................................... 78

Drawing Area ................................................................. 79

Drawing Grid ................................................................. 80

Set Grid Size and Grid Snap ........................................... 80

Formatting ........................................................................ 81

vi

Page 7

● Contents

●

●

●

●

●

Editable Formatting Attributes ........................................... 81

Font ............................................................................ 82

Line Color ..................................................................... 82

Fill Color ...................................................................... 83

Background Color ............................................................ 84

Line Weight ................................................................... 85

Line Style ..................................................................... 85

Line Ends ...................................................................... 86

Formatting Paintbrush ...................................................... 86

ToolTip Statistics ................................................................ 87

Time Range and Playback Toolbar ........................................... 88

Scroll Options Dialog Box .................................................. 91

Scroll Period .................................................................. 92

Scroll Period Constraints ............................................... 92

Scroll Period Time Format ............................................. 92

Change the Scroll Period ............................................... 93

Display Range ................................................................ 93

Change the Display Range ............................................. 93

The Change Display Range Dialog Box ............................... 94

Move the Display Range During Playback ........................... 94

Layers within Displays .......................................................... 95

Create Layers ................................................................ 95

Assign Symbols to Layers ................................................... 98

Layers and Composite Symbols ........................................... 98

Active Layers Status Bar ................................................... 99

Migrate Displays to Another FactoryTalk Historian Server ............. 100

Visualize Data with Symbols ...................................... 103

Trends ........................................................................... 103

vii

Page 8

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Create a Trend ............................................................. 104

Build a Trend with Multiple Plots ................................... 109

Move a Plot ............................................................. 109

Delete a Plot within a Trend ........................................ 110

Edit a Trend ................................................................ 110

Define Trend Dialog Box ................................................. 110

Display Format Tab ................................................... 112

Trace Format Tab ..................................................... 113

Layout Tab .............................................................. 115

Configure Trend Scale .................................................... 117

Trend Analysis Tools ...................................................... 118

Drag Zoom .............................................................. 119

Trend Zoom 2x In or Out ............................................. 119

Expand a Trend ........................................................ 120

Trend Cursor ........................................................... 120

Add a Trend Cursor ................................................... 121

Remove a Trend Cursor .............................................. 121

Change Time Range ....................................................... 122

How Trends Refresh ...................................................... 122

Trend Appearance ......................................................... 123

Grid Lines and Labels ................................................. 123

Grid Lines ............................................................... 123

Grid Line Labels ....................................................... 124

Value Scale Grid Lines ................................................ 124

Single and Multiple Scales for the Vertical Axis ................. 125

Time Scale Grid Lines ................................................ 126

Traces ................................................................... 127

Hide Traces ............................................................. 127

Markers .................................................................. 128

Ad Hoc Trends ............................................................. 129

Create an Ad Hoc Trend .............................................. 130

Save an Ad Hoc Trend Display ....................................... 130

OpenVMS Trends and Graphics .......................................... 131

Convert Trends ........................................................ 132

Convert Graphics ...................................................... 132

viii

Page 9

● Contents

●

●

●

●

●

XYPlots .......................................................................... 133

Draw an XYPlot ............................................................ 136

General Tab ............................................................ 137

Configure Pairings ..................................................... 139

Scale Box ................................................................ 141

Plot Time ............................................................... 142

Add a Data Set to an XYPlot ......................................... 142

Display Format Tab ................................................... 143

Plot Format Tab ....................................................... 145

Ad Hoc XYPlots ......................................................... 146

XYPlot Statistics ....................................................... 147

Linear Regression by Least Squares .................................... 150

Correlation Coefficient ................................................... 151

Interpreting an XYPlot .................................................... 152

Zoom/Revert Functions .................................................. 153

Change Time Range Feature ............................................ 156

XYPlot Cursors ............................................................. 156

Move the XYCursor from Point to Point ........................... 157

Bad Status Indicators ..................................................... 158

Out of Range Indicators .................................................. 158

Too Many Points ........................................................... 158

Examples of XYPlots ...................................................... 158

Example 1: Comparing Values for Two FactoryTalk Historian

Tags ...................................................................... 159

Example 2: Comparing Different Tags to Optimize Performance159

Example 3: Lab Comparisons ........................................ 160

Example 4: Comparing a Batch Run to a Standard .............. 161

Example 5: Comparing Two Time Ranges ......................... 161

Additional Dynamic Symbols ................................................ 162

ix

Page 10

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Values ....................................................................... 162

Add a Dynamic Value ................................................. 162

Button ....................................................................... 165

Add a Button ........................................................... 166

Bars .......................................................................... 168

Add a Dynamic Bar .................................................... 168

Bar Scales ............................................................... 171

Multi-State Symbols ....................................................... 174

Create Dynamic Multi-State Symbols .............................. 175

Static Symbols ................................................................. 177

Text Symbol ................................................................ 177

Add Text to a Display ................................................. 178

Edit a Text Box ........................................................ 178

Move a Text Block ..................................................... 179

Line Symbol ................................................................ 179

Draw a Line ............................................................. 179

Rectangle, Square, Arc, Ellipse, and Circle Symbol ................. 180

Polygon Symbol ............................................................ 181

Polyline Symbol ............................................................ 182

Graphic Symbol ............................................................ 183

Add a Graphic .......................................................... 185

Symbol Library ............................................................. 186

Use a Symbol from the Symbol Library ............................ 187

Symbol Library Options ................................................... 188

Change the Appearance of a Symbol .............................. 189

Symbol Properties ..................................................... 189

Work with Symbols ................................................. 191

Details and Annotations ...................................................... 191

Data Favorites ................................................................. 196

x

Details Window ............................................................ 191

Open Details Window ................................................. 194

FactoryTalk Historian Annotations Maintenance..................... 195

Add Annotations ....................................................... 196

Page 11

● Contents

●

●

●

●

●

Select a Default Symbol for Data Favorites .......................... 197

Search for Data Favorites ................................................ 198

Favorites Panel ............................................................ 199

Use Favorites ........................................................... 199

Import or Export Data Favorites .................................... 200

Process Drags Between FactoryTalk Historian ProcessBook and

Outside Applications .................................................. 200

Time Range Toolbar .......................................................... 201

Revert Time Range ........................................................ 201

Change the Time Range .................................................. 202

Use the Scrolling Time Range ........................................... 203

Time Forward and Back .................................................. 204

Set Time Range for Future Trends ..................................... 204

Select and Move a Symbol ................................................... 204

Select Multiple Symbols ...................................................... 205

Rotate a Symbol ............................................................... 206

Flip a Symbol ................................................................... 207

Delete a Symbol ............................................................... 207

Stacking Order ................................................................. 207

Move a Symbol Forward or Backward in the Stack .................. 208

Align Multiple Symbols ....................................................... 209

Group, Ungroup, or Regroup Symbols ..................................... 210

Connect Symbols .............................................................. 211

xi

Page 12

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Connector Symbol ......................................................... 211

Connect Two Symbols ................................................ 211

Attach a Symbol to a Connector .................................... 212

Connection Points ......................................................... 213

Add Connection Points ............................................... 214

Select Among Multiple Connection Points on One Symbol ..... 214

Delete Connection Points ............................................ 214

Move Connection Points .............................................. 214

Determine the Identifying Number of a Connection Point ..... 215

Connectors Dialog Box .................................................... 216

Connectors Dialog Box, Flow Tab ................................... 216

Configure the Flow Tab .............................................. 218

Connectors Dialog Box, Attachments Tab ......................... 219

Configure the Attachments Tab .................................... 220

Attach a Symbol as an Adjunct to a Connector ...................... 221

Attach a Symbol as an Adjunct to Another Symbol ................. 221

Move Attached Symbols Independently ........................... 223

Detect Connections and Attachments ................................. 223

Reroute a Connector Path ............................................... 224

Item Definition ................................................................ 225

Display or Change Item Definition ...................................... 225

Status Report for Dynamic Symbols ........................................ 226

Status Flags for Data.......................................................... 227

Data Streams ........................................................ 229

About FactoryTalk Historian Data .......................................... 229

FactoryTalk Historian Tags (Points) ........................................ 231

Element Relative Display (ERD) ............................................. 238

xii

FactoryTalk Historian Tag Search ...................................... 231

View Point Attributes ..................................................... 234

FactoryTalk Historian Server Data Types ............................. 235

Data from a FactoryTalk Historian System ........................... 237

FactoryTalk Historian Data Archive ................................ 237

Updates to FactoryTalk Historian Data ............................ 237

Page 13

● Contents

●

●

●

●

●

Connect to an AF Database .............................................. 239

Element Search ............................................................ 240

Add Element Relative Data to a Dynamic Symbol ................... 241

Context Path ............................................................... 243

Work with the Element Relative Display Window ................... 244

Data Sets ........................................................................ 246

PI Calculation Data Sets .................................................. 248

Create a PI Calculation Data Set ................................... 250

Intervals and Time Value ............................................ 253

Plot a Moving Average in a Trend .................................. 253

ODBC Data Sets ............................................................ 254

Create an ODBC Data Set ............................................ 255

Custom Data Sets .......................................................... 257

Placeholders................................................................ 257

Processing of Placeholder Queries ................................. 258

Design Placeholder Queries .......................................... 258

Add or Edit Placeholders ............................................. 259

Is a Data Set in Use? ...................................................... 261

Data Set Details ........................................................... 261

Add a Data Set to a Trend ............................................... 262

Time Intervals for Plotting Tags and Data Sets ...................... 264

Refresh a Trend Containing a Data Set ................................ 264

Add Data Sets to Bars or Values in a Display ......................... 265

Run FactoryTalk Historian ProcessBook When Data Sets Are

Included ..................................................................... 265

Edit a Data Set ............................................................. 266

Delete a Data Set ......................................................... 268

Copy a Data Set to Another ProcessBook ............................. 268

Loading Custom Data Sets ............................................... 269

Configure a Symbol with an AF Attribute ............................. 269

Configure the AF2.x DataSet ............................................ 271

ODBC ............................................................................ 271

xiii

Page 14

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

ODBC Driver Manager ..................................................... 271

ODBC Drivers ............................................................... 271

ODBC Data Sources ........................................................ 272

ODBC Data Access ......................................................... 272

ODBC Data Source Administrator ....................................... 273

Prepare for ODBC ......................................................... 274

Configure the ODBC Data Source ....................................... 275

Use MSQuery to Build Data Sets ........................................ 275

Assumptions About Timestamps and Data Sets ...................... 276

Stored Procedures in Queries ........................................... 276

Troubleshoot ODBC Data Sets ........................................... 277

Trace ODBC Calls .......................................................... 277

Initiate Call Tracing ................................................... 278

Delete an ODBC Driver ................................................... 278

Delete an ODBC Data Source ............................................ 278

Edit an ODBC Data Source ............................................... 279

Embedding and Linking ............................................ 281

Overview of FactoryTalk Historian ProcessBook OLE Compound

Documents ...................................................................... 281

OLE Automation in FactoryTalk Historian ProcessBook ................. 282

Object Linking and Embedding ............................................. 283

Embedded Objects ........................................................ 283

Linked Objects ............................................................. 283

Should You Link or Embed? .............................................. 284

ActiveX Controls ............................................................... 285

Add a Control .............................................................. 285

Example of Embedded and Linked Objects in a ProcessBook Display 286

Icons vs. Graphics ............................................................. 287

Embed in FactoryTalk Historian ProcessBook ............................ 287

Embed an Existing File in a Display .................................... 288

Embed a New File in a Display .......................................... 289

Windows Drag and Drop ...................................................... 289

Link a File to a Display ....................................................... 290

Dynamic and Manual Updates of a Linked Object ....................... 291

xiv

Page 15

● Contents

●

●

●

●

●

Edit, Update, or Break Links ................................................ 291

How Links Are Stored ......................................................... 292

Select a New Source Link .................................................... 292

Edit the Appearance of an OLE Object .................................... 292

Commands That Ignore OLE Objects ....................................... 293

Placement of OLE objects ................................................... 293

OLE Object Colors ............................................................. 293

Edit the Contents of OLE objects........................................... 294

Edit the Contents of an Embedded Object ............................... 294

Edit the Contents of a Linked Object ...................................... 294

Edit Contents of OLE Objects ........................................... 295

Delete an OLE Object from a Display ...................................... 295

Display an OLE Object with an Icon ........................................ 295

Convert Objects to Icons ..................................................... 296

Share ProcessBook Displays with Other Applications ................... 297

Embed a New Display in Another OLE Application .................. 298

Embed an Existing Display in Another OLE Application ............. 298

Link a ProcessBook to Another Application ............................... 299

OLE Container/Server ........................................................ 299

Visual Basic for Applications in FactoryTalk Historian

ProcessBook ......................................................... 301

VBA Commands ................................................................ 301

ActiveX Automation ........................................................... 302

What You Can Do with ActiveX Automation in FactoryTalk Historian

ProcessBook .................................................................... 302

Automation Vocabulary ...................................................... 303

Installation ........................................................... 305

System Requirements......................................................... 305

64-bit Operating Systems .................................................... 305

Upgrade from a Previous Version of FactoryTalk Historian ProcessBook306

Other FactoryTalk Historian System Client Products ................... 306

Installation Test ............................................................... 307

xv

Page 16

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Installed Files .................................................................. 307

System Administrator Notes ...................................... 309

High Availability Configuration Settings................................... 309

Recommended Connection Preference Setting ...................... 310

MDB to AF Migration .......................................................... 311

Module Relative Display Add-in ......................................... 311

Multiple Versions of FactoryTalk Historian Server or FactoryTalk

Historian ProcessBook .................................................... 312

Playback Toolbar Setting Defaults ......................................... 313

FactoryTalk Historian ProcessBook Connection to Windows NT Servers313

DEP Security .................................................................... 313

Read/Write Data Access for Users ......................................... 314

Machine Address ............................................................... 315

PROCBOOK.INI ................................................................. 315

Startup Section ............................................................ 316

Startup Example ....................................................... 320

ProcessBook View Section ............................................... 321

Conversion Section ........................................................ 322

Data Manager Section .................................................... 322

Trend Definition Section ................................................. 323

Trend Definition Example ............................................ 325

Colors Section .............................................................. 326

Time Range Scroll Section ............................................... 326

ProcessBook Level Section ............................................... 327

Display Colors Section .................................................... 328

XYPlot Definition Section ................................................ 328

Macro Protection .......................................................... 330

View Only Mode............................................................ 331

IMPPIGP.INI ..................................................................... 332

xvi

Page 17

● Contents

●

●

●

●

●

Color Section ............................................................... 332

Line Style Section ......................................................... 333

Font Section ................................................................ 334

Marker Section ............................................................. 335

Display Section ............................................................. 335

SETUPProcessBook.LOG ...................................................... 336

Supplemental Information ........................................ 337

FactoryTalk Historian Time .................................................. 337

FactoryTalk Historian Time Abbreviations ........................ 337

FactoryTalk Historian Time Expressions ........................... 338

FactoryTalk Historian Time String Examples ..................... 339

Table of Format Values ...................................................... 340

FactoryTalk Historian Point Attributes ................................ 341

Troubleshooting Tips ......................................................... 343

Display Cannot Find Data ................................................ 343

Trend Cursor Does Not Appear .......................................... 344

Trend Legend Does Not Appear ......................................... 344

Cannot Change or Save a Display ....................................... 344

Is an XYPlot Updating? .................................................... 344

Is an OLE Object in a Display Linked or Embedded? ................ 345

Linked Object Data Is Not Updating ................................... 345

ODBC Problems ................................................................ 346

Missing ODBC Trace ....................................................... 346

Missing ODBC Data Sources .............................................. 346

Technical Support and Resources ............................... 349

Technical Support ............................................................. 349

xvii

Page 18

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Knowledgebase ............................................................ 349

Worldwide Support ........................................................ 350

Training Programs ......................................................... 350

Consulting Services ....................................................... 350

TechConnect Support ..................................................... 350

Find the Version and Build Numbers ................................... 351

View Computer Platform Information ................................. 352

Index .................................................................. 353

xviii

Page 19

Chapter 1

Introduction

As the easy-to-use graphical display interface to the Rockwell Automation

FactoryTalk Historian system, FactoryTalk Historian ProcessBook makes

it possible to efficiently display real-time and historical data residing in the

FactoryTalk Historian system and other sources. Process owners use

FactoryTalk Historian ProcessBook to create interactive graphical displays

that can be saved and shared with others. Users can quickly switch between

run and build modes to create dynamic, interactive displays and populate

them with live data. They also can write scripts that automate displays and

trends by using Microsoft Visual Basic for Applications, which is

seamlessly integrated into FactoryTalk Historian ProcessBook. Rockwell

Automation also produces add-ins that perform Batch and other types of

analyses.

Recent History and Requirements for FactoryTalk Historian ProcessBook

What's New in FactoryTalk Historian ProcessBook

3.2

Enhanced Support for FactoryTalk Historian Asset Framework

Support for Module Relative Displays is discontinued and support for

FactoryTalk Historian Asset Framework (AF) is enhanced.

FactoryTalk Historian ProcessBook 3.2 removes the MRD add-in

when it is installed. Enhanced AF support includes ToolTip statistics

and support for AF data references in the Details window.

1

Page 20

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Enhancements to FactoryTalk Historian ProcessBook Display

The Playback toolbar added for v3.2 is enhanced to provide more time

controls and synchronization across multiple displays for time range

changes only. The name of the toolbar is now Time Range and

Playback toolbar to reflect the enhanced functionality.

The Bar symbol now has a scale option.

Enhanced Language Support

A Language Selection tool is added to the FactoryTalk Historian

ProcessBook preference page. This tool allows users to switch among

languages installed using the FactoryTalk Historian ProcessBook MUI

Pack. This version of FactoryTalk Historian ProcessBook has

implemented Unicode and regionalization enhancements. These

features enable you to create displays in one language and use them in

environments with different language and regional settings.

VBA Enhancements

A newer version of Visual Basic for Applications (VBA) is installed,

which addresses some security issues. In addition, support handling

UTC times through automation has been added.

What's New in This Release

FactoryTalk Historian ProcessBook v3.2 is the last version to deliver MRD

functionality.

New in version 3.2:

The Element Relative Display (ERD) (page 238) add-in is provided to

Displays can now be played back to review a specific time period

2

replace Module Relative Display. Element relative displays provide a

re-useable display that can be shared across similarly configured

elements.

using DVR-like controls.

Page 21

1 ● Introduction

●

●

●

●

●

Display navigation is enhanced with browser-based navigation

controls (page 16) that traverse, open, and bookmark displays and

workbooks.

The FactoryTalk Historian sqc Statistical Quality Control symbol is

now included with FactoryTalk Historian ProcessBook.

3

Page 22

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

4

Page 23

Chapter 2

FactoryTalk Historian ProcessBook Essentials

What Can You View with FactoryTalk Historian ProcessBook

A FactoryTalk Historian ProcessBook display entry may contain data

streams (page 229) from any or all of the following sources:

FactoryTalk Historian servers, including both point data (actual

instrument readings).

Calculations from FactoryTalk Historian data.

Other databases with ODBC connectivity.

Other databases with custom interfaces to FactoryTalk Historian

ProcessBook.

Spreadsheets, documents, schematics, graphics, photos, and other

Windows applications through OLE linking and embedding.

FactoryTalk Historian Asset Framework Servers.

VBA code.

ProcessBook displays may be linked to other displays within the same

ProcessBook, or to displays in a separate ProcessBook. You can also

include buttons that launch other applications.

5

Page 24

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Start FactoryTalk Historian ProcessBook

To begin using FactoryTalk Historian ProcessBook:

1. Launch the application.

2. Log in to a FactoryTalk Historian Server (page 6).

3. Open a ProcessBook file (page 10) or display (page 11).

Servers and Connections

FactoryTalk Historian ProcessBook is a visualization application designed

for displaying FactoryTalk Historian system data. See the PI SDK Controls

and Dialogs User Help to find comprehensive and up-to-date information

on connecting FactoryTalk Historian ProcessBook to a FactoryTalk

Historian server.

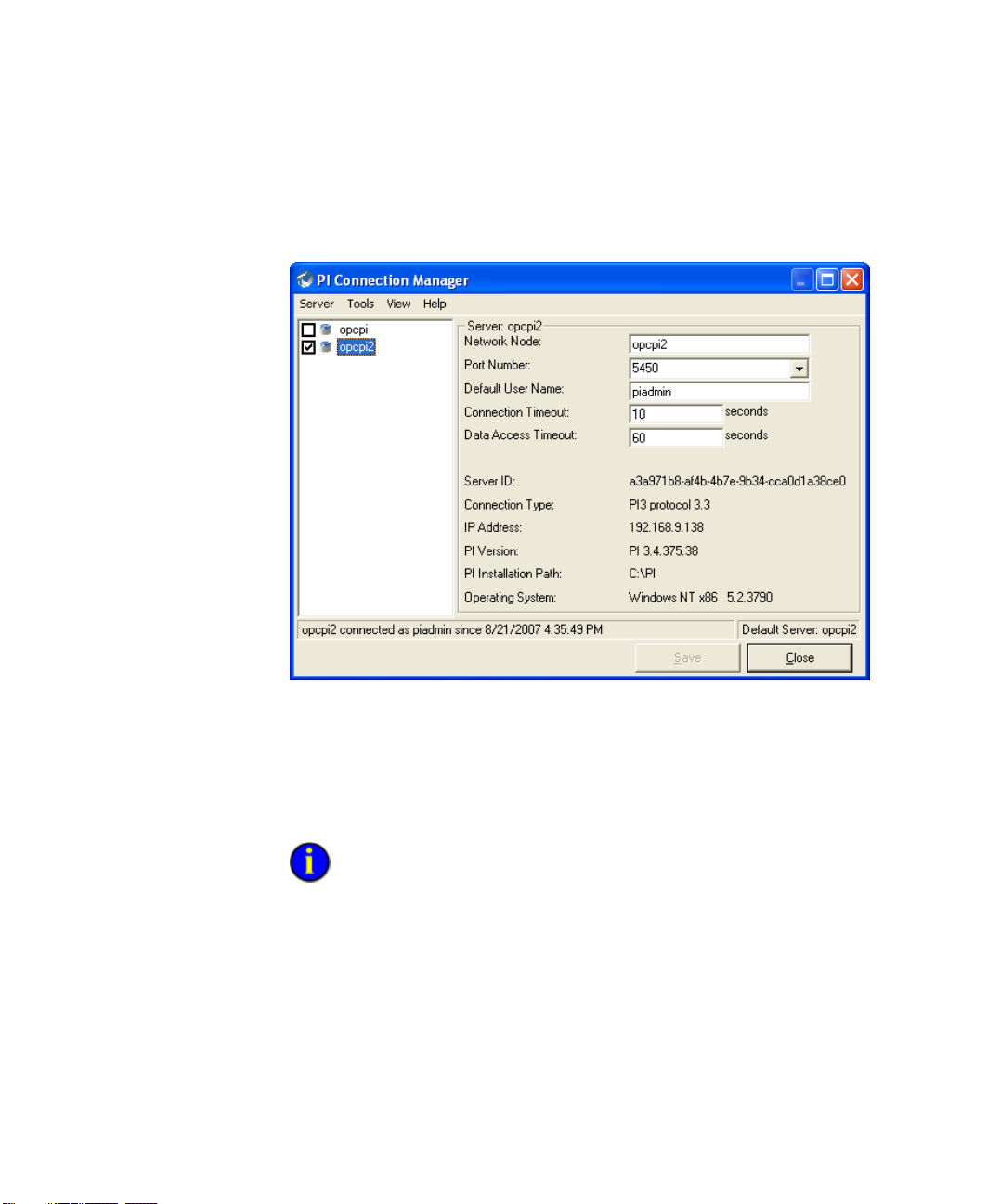

Connect to a FactoryTalk Historian Server

Use the Connection Manager to manage connections to FactoryTalk

Historian servers:

Click File > Connections. The PI Connection Manager dialog box

appears. The dialog box lists the configured servers to which you can

connect. It also shows the server you have chosen as the default server.

6

Page 25

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

A selected check box next to a server name in the Connections dialog box

indicates an open connection to the FactoryTalk Historian server.

To manage connection settings:

Click to select a check box and open a connection to a FactoryTalk

Historian server in the list. Clear a check box to close a connection.

Select a FactoryTalk Historian server in the server pane to access

connection settings.

If you select more than one server, the application tries to connect to each

server using the same user ID and password. If it fails, a new FactoryTalk

Historian Server Login dialog box appears. If you already are logged in to the

server from a different FactoryTalk Historian application, such as FactoryTalk

Historian DataLink, the application uses the user ID and password with which you

logged in. See the

PI SDK Controls and Dialogs User Help

for more detail.

7

Page 26

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

FactoryTalk Historian Security

FactoryTalk Historian ProcessBook is designed to support whatever

FactoryTalk Historian Security is configured on the FactoryTalk Historian

server.

1. When attempting to connect to a FactoryTalk Historian server, the

application first attempts to pass your FactoryTalk Security/Windows

log in credentials. The PI SDK will try to use them directly or find a

Trust for the user, domain, application or machine (per Trust

configurations).

2. If all attempts to login to the FactoryTalk Historian server using

FactoryTalk Security/Windows credentials or other machine-related

information fail, then you must have a FactoryTalk Historian ME

native security user account (not FactoryTalk Security/Windows

security-based). In this case, the PI SDK attempts to use the native

FactoryTalk Historian ME user account configured for the server.

3. If the default native FactoryTalk Historian ME user account does not

require a password, then you are automatically logged in. If the default

account does require a password, a login dialog box appears, which

expects the native FactoryTalk Historian ME user account and

password.

the

FactoryTalk Historian SE Installation and Configuration Guide

FactoryTalk Historian server.

Network Errors

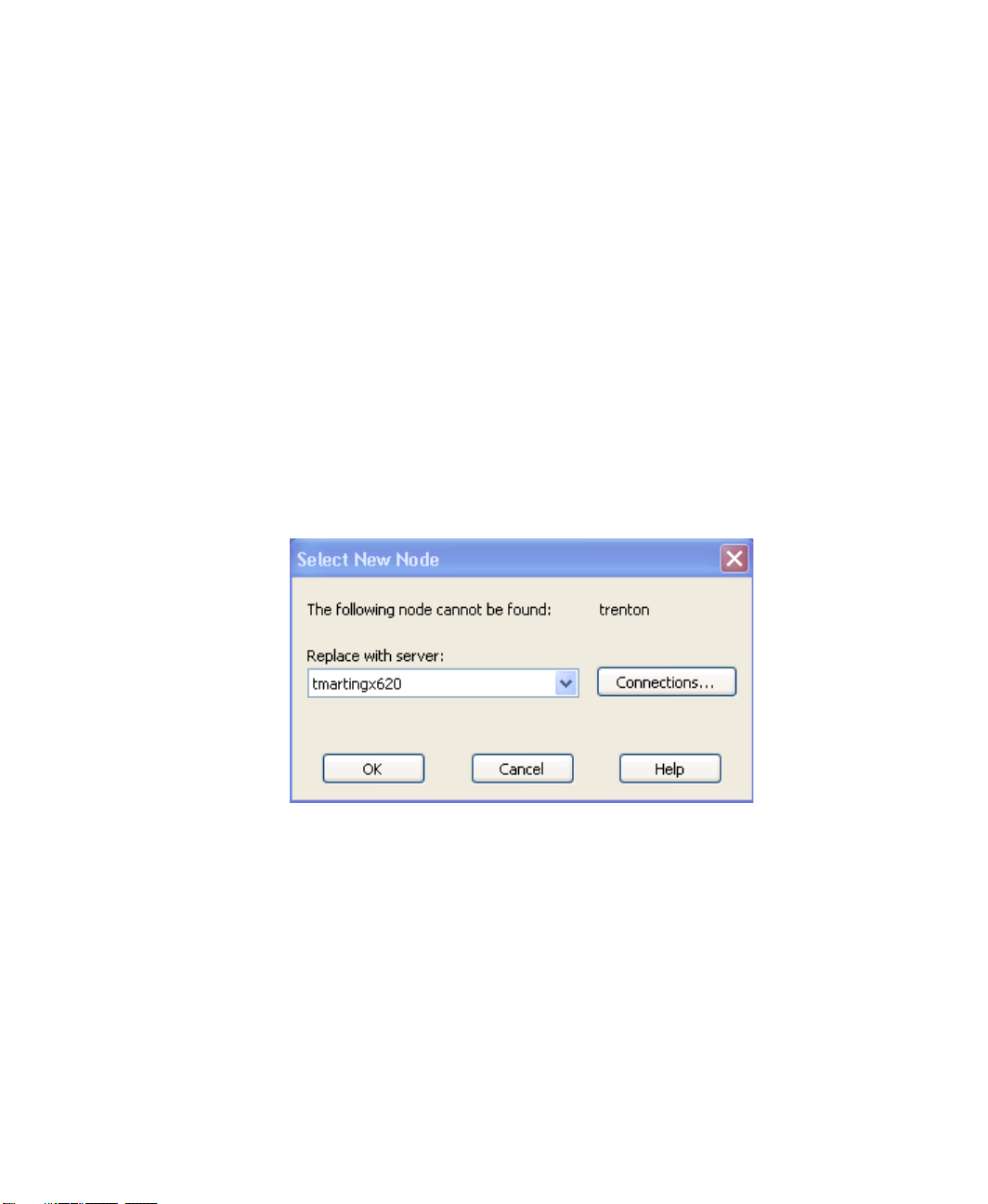

Network Errors update the Status Report (page 226) dialog box, rather

than displaying error messages on your monitor. When a display is opened

but the server is not available, only one Select New Node (page 9) dialog

box appears. The dialog box appears once for each server that is not

available.

8

For more detailed information on FactoryTalk Historian server security, see

, shipped with the

Page 27

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Displays and Connection Failure

If the connection to your data is not successful, the display (page 11) is still

drawn, but data in dynamic elements are replaced with indicators

signifying that no data is available.

Trends are labeled Invalid and no information is plotted.

Values are replaced with pound signs (###) and the message

Disconnected appears.

Bar graphs are drawn using hash marks (//////).

Multi-State symbols show the configured color for bad data.

If a server has been disconnected, and/or cannot be reached, the Select

New Node dialog box appears.

Click Connections to launch the PI Connection Manager dialog box.

From there you can choose a new server from the drop-down list of

connected servers.

9

Page 28

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Node Identifiers for Multiple FactoryTalk Historian Servers

A Node Identifier is stored with each tag name used in a display to point to

the correct server. If you define FactoryTalk Historian server nodes in the

PI Connection Manager dialog box, the identifiers are the same on each

PC on the network as long as the node names for the FactoryTalk Historian

system are the same.

Workspace

When you start FactoryTalk Historian ProcessBook, it appears as an open

window or workspace on the desktop. Depending on your settings, you

may initially see an empty workspace, or an open ProcessBook (page 10)

in either Book (page 50) or Outline (page 53) view.

Within the FactoryTalk Historian ProcessBook workspace you can open a

ProcessBook (page 10) or independent display (page 11).

ProcessBook (.piw)

In FactoryTalk Historian ProcessBook a ProcessBook is the container for

the information and analysis of the process you are monitoring. A

ProcessBook may appear as either a tabbed book - Book view (page 50), or

an outline - Outline view (page 53), and is saved as a separate file with a

.piw extension.

A ProcessBook is a collection of individual displays of data and analysis.

Use a ProcessBook to organize data from the FactoryTalk Historian system

and other sources so that you can analyze the processes you monitor or the

tasks you perform.

A ProcessBook and its displays are stored in a single file.

10

Page 29

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Display

The main unit for creating presentations of data in FactoryTalk Historian

ProcessBook is the display. A display may stand on its own (.pdi or.svg),

or it may be part of a ProcessBook (.piw) (page 10). A display contains all

the symbols used to represent an operational environment using real-time,

production data from FactoryTalk Historian as well as data from other

sources. In addition to containing this collection of data elements, the

display has its own set of features and properties that affect the collection

of data elements.

Displays can show a variety of elements, such as a schematic

representation of a production line, a plot of readings taken from a

production line, or a comparison of lab data and batch specifications.

Displays can also be linked to other ProcessBooks, displays in other

ProcessBooks, or other applications.

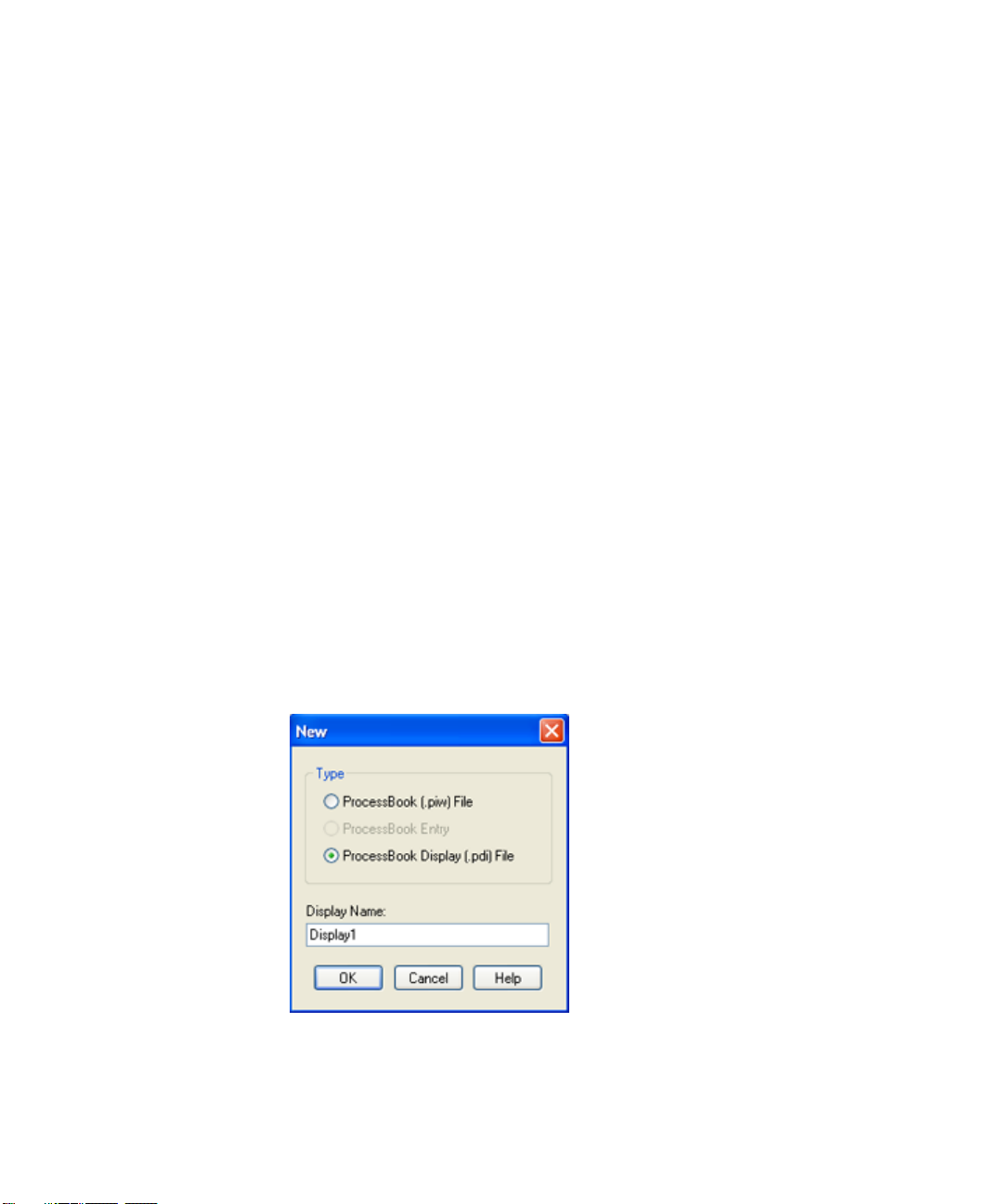

Create a New ProcessBook or Display

Use the New dialog box to create a new ProcessBook (page 39), add

ProcessBook entries (page 41), or create an independent display (page 69).

Click File > New to launch the New dialog box.

11

Page 30

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Run Mode and Build Mode

When you work with a ProcessBook or an independent display, you work

in one of two operating modes, Run mode or Build mode.

Build mode.

Most of the functions that you use when you create or modify a

ProcessBook require the Build mode pointer. Use Build mode to add,

remove, or move symbols on a display, to add, remove, or organize

entries in a ProcessBook, and for access to symbol definitions and

formatting tools.

Run mode.

It is used to open entries and execute commands once a ProcessBook

is built. You can make some changes to a display while in Run mode;

however, working in Run mode keeps you from accidentally making

permanent changes to items in a display.

You switch between modes by clicking the Run mode pointer or the

Build mode pointer , which are located on the Tools menu and the

Drawing toolbar. Your preferred mode of operation is set as a default in

your Preference settings.

clearing or selecting the Prefer Run Mode check box in the

of the ProcessBook Preferences dialog box. This is a helpful preference if you

spend most of your time building or editing displays.

12

You can choose Build or Run mode as your preferred mode of operation by

General tab

(page 23)

Page 31

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Add-Ins

By default, FactoryTalk Historian ProcessBook installs with the following

add-in components. You can load or unload these and other add-in

components by using the Add-In Manager (page 13).

AF 2.x Data Set.

Browser toolbar (page 16).

Data Favorites (page 196).

Details (page 191).

Element Relative Displays (ERD) (page 238).

ProcessBook SVG File Converter - enables you to save displays as

SVG files, which can then be used by FactoryTalk Historian

WebParts.

Time Range and Playback toolbar (page 88).

ToolTip Statistics (page 87).

FactoryTalk Historian BatchView.

You can install other add-ins with FactoryTalk Historian ProcessBook, but

they don't become available until you add additional applications:

FactoryTalk Historian BatchView

Add-In Manager

The Add-In Manager lists the Add-Ins (page 13) available in your

FactoryTalk Historian ProcessBook installation. Use this dialog box to

control whether the add-ins are loaded whenever you use FactoryTalk

Historian ProcessBook.

1. Click Tools > Add-in Manager. The Add-In Manager dialog box

appears.

13

Page 32

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Menu Bar

Function

Default

Displays when no documents are active

2. Click an available add-in from the Available Add-Ins list.

3. A description of what the add-in does appears in the Description box.

4. Under Load Behavior, select the appropriate check boxes:

Loaded/Unloaded

Loads or unloads the selected add-in. The add-in's current status

appears in the Load Behavior column at the top.

Load on Startup

Loads the selected add-in on startup of FactoryTalk Historian

ProcessBook. The add-in's current status appears in the Load

Behavior column at the top.

Command Line

Loads the selected add-in when FactoryTalk Historian

ProcessBook is started from the command prompt or from a

script.

5. Click OK to complete the action and close the dialog box.

If the add-in is unloaded and then reloaded, you must click the Revert

toolbar button to re-synchronize any symbols using the add-in.

Menus and Toolbars

Command Menus

The active components of menu bars change depending on the active

window and current selections. There are five different collections of menu

commands.

14

Page 33

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Menu Bar

Function

Book

Displays when a FactoryTalk Historian ProcessBook workbook is active

Display

Displays when a FactoryTalk Historian ProcessBook display document

is active

View-Only Book

Displays when FactoryTalk Historian ProcessBook is running in no-edit

mode and a FactoryTalk Historian ProcessBook workbook is active.

View-Only Display

Displays when FactoryTalk Historian ProcessBook is running in no-edit

mode and a display or workbook document is active.

Customize Toolbars

Toolbars may be displayed or omitted as follows:

1. Click View > Toolbars. The Toolbars tab of the Customize dialog

box appears.

2. Check the toolbars you wish to display, and click OK.

Click the Commands tab to see what buttons appear on each toolbar.

3. To move a toolbar, click the double vertical bar at the left end and

drag to the new location. If the toolbar has no move handle, click the

title bar instead.

4. To reshape a floating toolbar (one without move handles), grab one of

its edges and drag to a new shape.

Toolbar Buttons

Many of the menu commands in FactoryTalk Historian ProcessBook can

be selected by clicking a button on a toolbar. To determine the use of a

button on a toolbar, hover the mouse pointer over the button to display a

ToolTip.

15

Page 34

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

You can configure toolbars to display as view-only to omit unnecessary

buttons. View-only toolbars and others can be specified in procbook.ini

(page 315).

Add Buttons to Toolbars

You can change the icons that appear on the toolbars or create your own

custom toolbar.

1. Click View > Toolbars.

2. From the Commands tab of the Toolbars dialog box, you can select a

particular toolbar in the dialog box and drag buttons to existing

toolbars in your FactoryTalk Historian ProcessBook window.

3. While the Commands tab is open, you can also drag buttons off of a

toolbar to remove them from your window.

Browser Toolbar

The Browser add-in provides a toolbar that resembles the controls of a

typical web browser. The toolbar is automatically loaded when you install

FactoryTalk Historian ProcessBook, and allows you to navigate recentlyused ProcessBooks and displays.

Browse ProcessBooks and Displays

1. To use the Browser and Playback toolbar:

2. Click View > Toolbar Manager. The Browser and Playback

16

toolbars appear.

These toolbars are open by default when you first launch FactoryTalk

Historian ProcessBook.

Page 35

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

3. From the Browser toolbar (page 16), click either the Forward or

Back buttons to view previously opened ProcessBooks or

displays. Only displays opened during the current session of

FactoryTalk Historian ProcessBook are included in this navigation.

You can also use the Address box to open ProcessBooks and displays.

1. Click the arrow to the right of the Address box to see the last ten valid

file paths you entered. The last entry in the list is Browse.

2. Click Browse to launch an Open File dialog box where you can

browse for a file. You can also enter a URL to open a file.

View Browsing History

To view the browsing history:

1. Click the small black arrow to the right of the Back or Forward

buttons to see a drop-down box that lists the last ten

ProcessBooks and/or displays that you visited during the current

session.

2. Click an entry to return to that item.

The final entry in the list is History. Click History to open the

History tab of the Organizer window (page 18) from where you can

find an alphabetical list of all ProcessBooks and displays visited

during the current session.

Set a Home Page

The Home Page is the startup file that is defined in FactoryTalk Historian

ProcessBook preferences. It can be a .pdi (display), .piw (ProcessBook), or

a display entry.

17

Page 36

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

1. On the Browser toolbar (page 16), click the small arrow next to the

Home button .

2. From the drop-down menu, select one of the following:

1. Use Default to make PIDemo.piw your default file.

2. Use Current to set the start file to the current, active

ProcessBook or display.

Bookmarks and Browser History

The Organizer is a docking window that allows you to organize and use

bookmarks and the current session's history. By default this window is

hidden. Click the Bookmarks button on the Browser toolbar (page 16) to

make it appear.

The Organizer window has two tabs:

18

Page 37

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Bookmarks

New bookmarks are automatically added to the root level of the

bookmarks tree. You can organize the entries into a hierarchical tree

structure by dragging and dropping entries. Right-click the Bookmarks

tab to select one of the following from the context menu:

New Folder inserts a new folder at the top level of the tree or as

a subfolder of a selected folder.

Rename makes the entry name of the selected entry editable.

Edit opens a dialog box where you can enter a new name and file

path for the selected bookmark.

Select All selects every entry.

Deselect All clears every entry.

Send To File opens a Save File dialog box for the location to

store the list of bookmarks. Bookmarks are saved as XML and can

be subsequently imported. Only files/folders that are selected

(checked) in the tree are exported.

Send To E-Mail opens a pre-populated Outlook email with the

selected bookmarks ready to be sent as an attachment with the

same format as the Send to File option. Only files/folders that are

selected (checked) in the tree are exported.

Note: The Send To options are only visible if at least one

entry is checked or when right-clicking an item.

Import opens an Open File dialog box where you can select a

bookmarks file to import.

History

The tab contains an alphabetical list of all ProcessBooks and displays

you have visited during the current session. From there you can click

an entry to return to that item.

The icon of the entry indicates its file type. Hover over an entry to see

its full path in a ToolTip.

Add/Edit Bookmarks

1. On the Browser toolbar (page 16) click the Bookmark button to

open the Bookmark tab of the Organizer (page 18) window.

From there you can browse, modify, or delete stored file locations.

2. Click to add a bookmark.

19

Page 38

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

3. Click to edit a bookmark.

If the active file is already bookmarked, the same icon appears as the Edit

Bookmark icon. Click this button to edit the bookmark's label and file

path.

Keyboard Shortcuts

A keyboard shortcut is a combination of keystrokes to use for frequent

actions. Several of these are already assigned in FactoryTalk Historian

ProcessBook. They appear to the right of the corresponding menu

command on the drop-down menus.

FactoryTalk Historian ProcessBook lets you assign new combinations of

keystrokes or change existing ones.

For example you can:

Assign a keyboard shortcut for inserting symbols with one command.

Assign more than one keyboard shortcut to a specific action.

Change an existing shortcut, such as Ctrl+S, to another sequence you

prefer.

20

Page 39

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Assign a Keyboard Shortcut

To assign a keyboard shortcut:

1. Click View > Assign Shortcuts. The Shortcut Keys dialog box

appears.

2. Under Select a macro, click the appropriate macro (menu item). The

description for that item and its assigned shortcuts, if any, appears.

3. Click Create Shortcut. The Assign Shortcut dialog box appears.

21

Page 40

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

4. Under Press new shortcut key, type the key you wish to use for the

shortcut.

If you choose a combination already in use, the current assignment

appears in the dialog box. If you click OK, the previous assignment is voided.

5. Click OK.

The new shortcut appears in the Assigned shortcuts box.

If you want to reset all the keyboard shortcuts to their original positions

when FactoryTalk Historian ProcessBook was installed, click the Reset All,

and then OK.

Remove a Keyboard Shortcut

To remove a keyboard shortcut:

1. In the Shortcut Keys dialog box, under Select a macro, select the

appropriate macro (menu item command). The description for that

item and its assigned shortcuts, if any, appears.

2. Under Assigned shortcuts, select the shortcut you want to remove,

and then click Remove.

3. Click OK.

Preference Settings

You can reach the ProcessBook Preferences dialog box by clicking Tools

> Preferences. Preference settings determine how the ProcessBook entries

look, what colors are available when you draw, and whether your

ProcessBook opens in Book View (page 50) or Outline View (page 53).

22

Page 41

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Preference settings are stored in the file

procbook.ini

. Before you change the

Preference settings, consider creating a back-up copy of procbook.ini so that you

can restore FactoryTalk Historian ProcessBook to the original settings.

General Preferences

Click Tools > Preferences > General tab to configure application-wide

settings. These settings are stored in and retrieved from the [STARTUP]

section of your procbook.ini (page 315) file.

23

Page 42

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Author

Determines the name used as the creator of new files and the person

who last edited the file. See

Summary Information in ProcessBook

(page 59) for more information. This field is blank by default when

FactoryTalk Historian ProcessBook is first installed on a computer.

Startup File

The file name and path in this field determine which, if any, file is

automatically opened when the application is launched. The default

value when FactoryTalk Historian ProcessBook is first installed is

<installation path>\procbook\pidemo.piw.

Library File

The file name and path in this field determine which, if any, file is

opened when the original symbol library command is used. The

default value when FactoryTalk Historian ProcessBook is first installed

is <installation path>\procbook\symlibry.piw.

Prefer Run Mode

Determines whether ProcessBook starts up in Run mode or Build

mode by default. By default, this option is enabled when FactoryTalk

Historian ProcessBook is first installed on a computer.

Create Backup

Files

Determines whether backup files (with a .bak extension) are

automatically created when a FactoryTalk Historian ProcessBook file is

opened. By default, this option is turned off when FactoryTalk

Historian ProcessBook is first installed on a computer.

Retain snapshot

values on updating

plots

Determines whether the archive event pipe is used for updating

trends, discarding any snapshot values between stored, archive

values. This setting is stored as PB2TraceCompatibility in the

[STARTUP] section of your procbook.ini. By default, this option is

turned off when FactoryTalk Historian ProcessBook is first installed on

a computer.

Review the following for additional information:

24

Page 43

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Date and Time

Format

Settings in this area determine how time is displayed in FactoryTalk

Historian ProcessBook. Previews of each format are shown to help

you select the desired option.

The Use local Windows format option uses the current Regional

Options settings in the Windows Control Panel on the client

machine to determine how dates and times are displayed. Dates

are shown using the currently configured Short Date format and

Times are shown using the current time format settings.

The Use FactoryTalk Historian Time Format option displays

timestamps in the default FactoryTalk Historian format of ddmmm-yy HH:mm:ss.ssss, where dd is the day of the month, mmm

is a the short text abbreviation of the month name (e.g., Jan for

January), yy is the two digit year, HH is the hour in 24-hour

format, mm is the minute and ss.sss is the second, including subseconds, if present.

Default Time Zone

Determines whether timestamps reflect the time zone of the

FactoryTalk Historian server used to retrieve data (FactoryTalk

Historian server time zone), or the time zone of the local

computer (Client machine time zone), when a new display is

created. By default, the FactoryTalk Historian server option is selected

when FactoryTalk Historian ProcessBook is first installed on a

computer. This setting can also be changed and is stored with each

display.

25

Page 44

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Table of Contents Preferences

Click Tools > Preferences > Table of Contents tab to configure the

default view of Table of Contents windows for ProcessBook (PIW) files,

as well as the font applied to each level of entry in those files. These

settings are stored in and retrieved from your procbook.ini (page 315) file.

26

Page 45

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Default View

Settings in this area determine how ProcessBook entries are displayed

by default. The default is Book view.

Font Settings

The controls in this area determine the font settings applied to each

entry level in a ProcessBook. The font settings control the display of

entry names in Table of Contents windows.

The Entry level field allows you to select the level to configure.

You can only select one level at a time.

The Font field lists all the fonts installed on the computer running

FactoryTalk Historian ProcessBook.

The Size field determines the size of the text. The first time

ProcessBook is installed, the current Windows system font

determines the default font settings to use.

The Font style group determines whether text is shown in bold or

italic.

Preview

This read-only field displays font settings for each level in a

ProcessBook. Each of the 10 possible entry levels is listed and

displayed with its current font name, and style settings.

Review the following for additional information:

27

Page 46

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Display Window

Click Tools > Preferences > Display Window tab to set options that apply

to display windows. These settings are stored in and retrieved from your

procbook.ini (page 315) file.

28

Page 47

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Preserve Aspect

Ratio on resize

Determines whether display element sizes change in proportion to the

window size when a window is resized. When the check box contains

a check mark (is selected), the aspect ratio is preserved and the

display element sizes change in proportion to the window size.

Show Symbol

ToolTips

Determines whether ToolTips are displayed on display symbols.

ToolTips appear for toolbar buttons regardless of this setting's value.

By default, this option is turned on when FactoryTalk Historian

ProcessBook is first installed on a computer.

Show Value

Attributes

Determines whether icons are displayed for Value Attribute flags

(Questionable, Substituted or Annotated) on FactoryTalk Historian

data. This option is turned on when FactoryTalk Historian

ProcessBook is first installed on a computer.

Run mode scrolling

Determines the scroll bar behavior of display windows in Run mode.

Build mode

scrolling

Determines the scroll bar behavior of display windows in Build mode.

On

Display contains scroll bars all the time.

Off

Scroll bars never appear.

Automatic

Scroll bars appear when needed (this is the default setting).

Color Palette

These fields present the 16 colors selected for use throughout the

application as the basic colors for the color well control.

Use the Modify button to launch the Color dialog box, where you

can select additional colors.

Use the Reset button to return the Color Palette to system

default values.

Default Display

Background Color

Determines the default color used for new displays. The color well

control is used to select a color. This color is also set when the

Background color of the current display is changed.

Symbol Defaults

Contains fields to set the default formatting values for new symbols.

These defaults are also changed when the Formatting controls are

used and no symbols are selected.

Review the following for additional information:

29

Page 48

●

●

●

●

●

FactoryTalk Historian ProcessBook User Guide

Trend Preferences

Click Tools > Preferences > Trend tab to set default settings for new

trend symbols. These settings also apply to instant trends.

30

Page 49

2 ● FactoryTalk Historian ProcessBook Essentials

●

●

●

●

●

Display

Check or clear these options to configure what information a trend

displays by default.

AutoScale

Select this check box if you want trends to be scaled as tag values

change over time. If you do not select this check box, then trends

use the Database scale for each tag.

Plot Title

Select this check box if you want a title to display.

Value Scale Inside Axis

Select this check box to display the numeric scale inside the axis.