Page 1

Administrator Guide

F

actoryTalk Batch

Material Manager

Administrator Guide

FactoryTalk Batch Components 14.00

Rockwell Automation Publication BWMTR-UM011E-EN-P - October 2020

Supersedes Publication BWMTR-UM011D-EN-P - February 2017

Original Instructions

Page 2

FactoryTalk Batch Material Manager

personal injury or death, property damage, or economic loss.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION:

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD:

ARC FLASH HAZARD:

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

2

Page 3

About this manual

Preface

This manual provides administrator instructions for the FactoryTalk Batch

Material Manager components. It is one of a set of related manuals that

describe installing, programming, and operating the FactoryTalk Batch

system.

To review FactoryTalk Batch release notes and latest information regarding

product compatibility refer to the

Center (PCDC).

Product Compatibility and Download

3

Page 4

Preface

Legal Notices

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End User License Agreement (EULA)

by opening the license.rtf file located in your product's install folder on your

hard drive.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\license.rtf

Open Source Software Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses.

You can view a full list of all open source software used in this product and

their corresponding licenses by opening the oss_license.txt file located your

product's OPENSOURCE folder on your hard drive. This file is divided into

these sections:

• Components

Includes the name of the open source component, its version number,

and the type of license.

• Copyright Text

Includes the name of the open source component, its version number,

and the copyright declaration.

• Licenses

Includes the name of the license, the list of open source components

citing the license, and the terms of the license.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\Help\<product

name>\Release Notes\OPENSOURCE\oss_licenses.txt

You may obtain Corresponding Source code for open source packages

included in this product from their respective project web site(s).

Alternatively, you may obtain complete Corresponding Source code by

contacting Rockwell Automation via the Contact form on the Rockwell

Automation website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page. Please include "Open Source" as part of the request

text.

4

Page 5

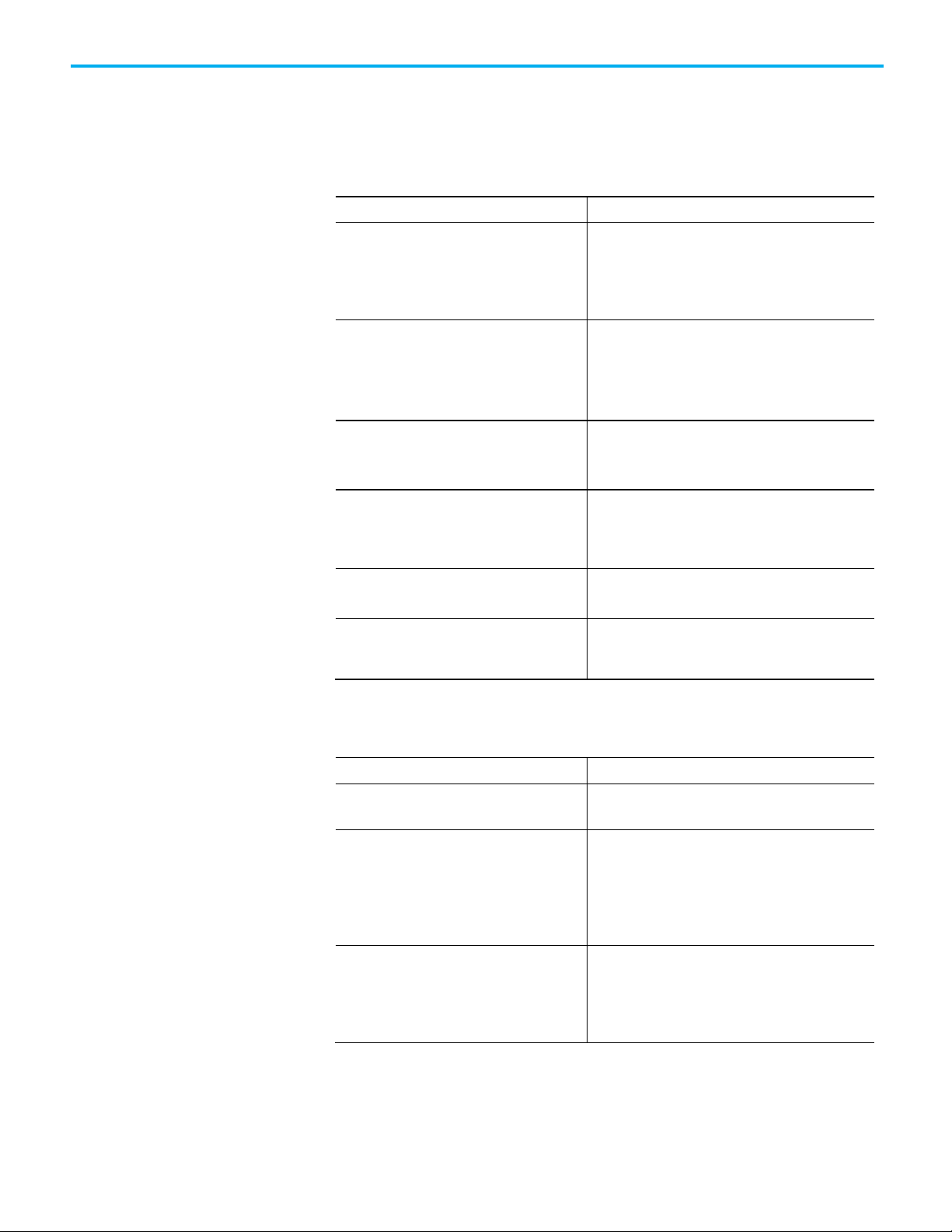

Following is a comprehensive list of documentation for the FactoryTalk®

Resource

Description

FactoryTalk Batch View Quick Start Guide

Provides information about using FactoryTalk Batch View

FactoryTalk Batch Material Manager Getting

(BWMTR-GR011)

Introduces the basics of FactoryTalk Batch Material

Resource

Description

reference for the formulator.

Recipe Editor, View, and Phase Simulator.

Additional resources

Batch products from Rockwell Automation.

Installation, Quick Start, and Getting Results Guides

Preface

FactoryTalk Batch Components Installation and

Upgrade Guide

(BATCH-IN002)

(FTBVS-QS001)

FactoryTalk Batch View HMI Controls Quick Start

Guide

(BATCH-QS001D)

FactoryTalk Batch eProcedure® Getting Results

Guide

(BWEPRO-GR011)

FactoryTalk Batch Getting Results Guide

(BATCH-GR011)

Results Guide

Provides information and procedures for FactoryTalk

Batch system installation. Includes information for

FactoryTalk Batch Material Manager, FactoryTalk Event

Archiver, and associated FactoryTalk Batch Client and

Server components.

to create, view, and command control recipes,

acknowledge prompts and signatures, view equipment

phases and diagnostic information, and view profile

information.

Provides a general overview of FactoryTalk Batch View

HMI Controls.

Explains the basics of FactoryTalk Batch eProcedure.

Introduces the basics of automated batch manufacturing

and the FactoryTalk Batch product components.

Manager.

User Guides

FactoryTalk Batch ActiveX Controls User Guide

(BATCH-UM013)

FactoryTalk Batch Material Editor User Guide

(BWMTR-UM001)

FactoryTalk Batch Equipment Editor User Guide

(BATCH-UM004)

Provides information and instructions for using the

FactoryTalk Batch ActiveX Custom Controls.

Provides access to information and procedural

instructions required to configure materials and the

containers to hold them. The material data is stored in the

material database, which is used to create materialbased recipes. This information is intended as a

Provides information on creating and maintaining an

equipment database (area model). The area model is

stored in a file with a .cfg file extension and is available

to all other FactoryTalk Batch programs, including the

5

Page 6

Preface

Resource

Description

FactoryTalk Batch PhaseManager™ User Guide

Describes the integration of the FactoryTalk Batch

FactoryTalk Batch Recipe Editor User Guide

Provides instructions on using FactoryTalk Batch Recipe

FactoryTalk Batch View HMI Controls User Manual

Provides details about using FactoryTalk Batch View HMI

FactoryTalk Batch Server.

reference information by the operator.

FactoryTalk Batch View User Guide (legacy)

Provides information and instructions on how to use

Resource

Description

FactoryTalk Batch Administrator Guide

Provides instructions for configuring security and

the FactoryTalk Batch Server.

(BATCHX-UM011)

(BATCH-UM006)

(FTBVS-UM003)

FactoryTalk Batch View User Manual

(FTBVS-UM002)

software with the Studio 5000 Logix Designer®

application and the Logix 5000™ family of controllers.

The integration simplifies the configuration and

maintenance of the FactoryTalk Batch automation

system, provides better communication between the

FactoryTalk Batch Server and the Logix 5000 controller,

and significantly reduces the programming effort

required to develop the phase logic code that resides in

your Logix 5000 controller.

Editor to create and configure master recipes for use in

batch automation. The interface is based on IEC 61131-3

sequential function charts to graphically organize recipes

into procedures, unit procedures, operations, and phases.

Build recipes using either the SFC format or a table-based

format.

Controls to monitor and interact with the production

process within a FactoryTalk View SE Display Client.

Provides information and procedural instructions for

using FactoryTalk Batch View in a modern and intuitive

portal into a comprehensive batching solution for

effective operations, leveraging its own web server using

HTML5 technology to provide native connectivity into a

FactoryTalk eProcedure Client User Guide

(BWEPRO-UM001)

FactoryTalk Event Archiver User Guide (BATCHUM012)

(FTBVS-UM001)

Administrator Guides

(BATCH-UM003)

Provides information and procedural instructions

required to create and command batches using the

FactoryTalk eProcedure Client, and can be used as a

Provides information and instructions specific to the

FactoryTalk Event Archiver. Intended for use by the

system administrator and production supervisor.

FactoryTalk Batch View to initiate and execute

FactoryTalk Batch automation processing. FactoryTalk

Batch View secured objects are located in the FactoryTalk

Diagnostics and are modified using the FactoryTalk

Administration Console. A system administrator can

customize FactoryTalk Batch View security to meet the

needs of the facility. FactoryTalk Batch View is used in

conjunction with a Human-Machine Interface (HMI).

services, and implementation and use of components not

typically accessed or used by batch operators, such as

6

Page 7

Preface

Resource

Description

FactoryTalk Batch eProcedure Administrator Guide

Provides procedures specific to FactoryTalk Batch

(BWEPRO-UM011)

Resource

Description

(BATCH-RM001)

FactoryTalk Batch PCD Programming Reference

Provides information and instructions about the

engineers and the system administrator.

reference by the instruction file author.

(BWEPRO-UM011)

FactoryTalk Batch Material Manager Administrator

Guide

Reference Guides

FactoryTalk Batch ActiveX Controls Library

Reference Guide

FactoryTalk Batch Material Server API Technical

Reference

(BWMTR-RM001)

eProcedure, such as implementing security and

configuring the user-defined area Active Server Page.

Included are instructions for tasks specific to FactoryTalk

Batch, such as configuring security and services to

support FactoryTalk Batch eProcedure. Provides

instructions on the implementation and use of

components not typically accessed or used by batch

operators, such as the FactoryTalk Batch Server.

Provides information and instructions specific to

FactoryTalk Batch Material Manager. Intended for use by

the system administrator and database administrator.

Provides reference information and procedural

instructions for the FactoryTalk Batch ActiveX Custom

Controls.

Provides access to information regarding the interface

between the FactoryTalk Batch Material Server and the

FactoryTalk Batch Material Editor and FactoryTalk Batch.

It is intended to be used as a reference information by

those who want to develop custom interfaces.

Manual

(BATCH-RM004)

FactoryTalk Batch Server API Reference Manual

(BATCH-RM003)

FactoryTalk Batch System Files Reference Manual

(BATCH-RM005)

FactoryTalk Batch eProcedure Instruction File

Design Reference Manual

(BWEPRO-RM001)

FactoryTalk Batch PCD interface design. It is intended to

be used as a reference guide.

Provides information regarding the interface between the

FactoryTalk Batch Server and FactoryTalk Batch View —

the Server Application Programming Interface (API). It is

intended to be used as a reference guide by those who

want to develop custom interfaces.

Provides the technical information for configuration and

maintenance of a FactoryTalk Batch system. It can be

used as a reference information for implementation

Includes information about the building of instruction

files for use in equipment database creation and recipe

development. This information is intended to be used as a

View or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

sales representative.

7

Page 8

Page 9

Table of Contents

Preface

Configuring Material Manager

Implementing security

Using the material activity

Network Editor

About this manual ....................................................................................... 3

Legal Notices ............................................................................................... 4

Additional resources ................................................................................... 5

Chapter 1

Identify the material database .................................................................. 11

Setting the Material Server options ......................................................... 11

Enable the automatic deletion of lots with no remaining sublots.......... 12

Chapter 2

Security settings......................................................................................... 16

Material Manager Security .................................................................. 17

Using workgroup security ......................................................................... 18

Using domain security ............................................................................... 18

Configuring the domain server .......................................................... 18

Setting security on folders or files ............................................................ 19

Adding users and user groups............................................................. 19

Change permissions on the BATCHCTL share .................................. 19

journal

Chapter 3

Enable material journaling ...................................................................... 22

Chapter 4

Open the Network Editor ..........................................................................23

Network Editor interface ..........................................................................23

Hierarchy pane .................................................................................... 24

Detail pane ........................................................................................... 24

Results pane ......................................................................................... 25

Menu bar .............................................................................................. 25

Network Editor toolbar....................................................................... 26

Status bar ............................................................................................. 26

Configure your network ........................................................................... 27

Select a network model ....................................................................... 27

Add a server ......................................................................................... 27

Remove a server................................................................................... 28

Synchronize network models ............................................................. 28

User Preferences dialog box ..................................................................... 28

User Preferences dialog box - General tab ........................................ 28

Edit colors ............................................................................................ 29

Edit the application font ..................................................................... 30

9

Page 10

Table of Contents

Troubleshooting

Change the FactoryTalk Batch

Index

Edit information tips .......................................................................... 30

User Preferences dialog box - Views tab ............................................ 31

Set report preferences ......................................................................... 31

Report printing formats ............................................................................32

Preview reports .................................................................................... 33

Print reports ......................................................................................... 33

Chapter 5

Automatic repair of batch component installation fails ......................... 35

Error: No containers match material container specification ............... 35

Error: Unable to retrieve the Promise ID ................................................. 35

Operating without a Material Server ........................................................ 35

Losing communication ........................................................................ 36

Switching to manual ........................................................................... 38

Restoring communication ................................................................. 38

Starting the FactoryTalk Batch server ................................................ 39

server user account

Chapter 6

New user account requirements for the FactoryTalk Batch Server ....... 41

Configure your FactoryTalk Batch system ............................................... 41

Server account password change locations ...................................... 42

Change the server user account for the FactoryTalk Batch Server

service ................................................................................................... 43

Change the server user account in FactoryTalk Batch COM+

applications .......................................................................................... 43

Change the server user account in My Computer properties .......... 44

10

Page 11

IMPORTANT

opens and reads the databases.

Identify the material

database

Setting the Material Server

Chapter 1

Configuring Material Manager

This chapter contains instructions for configuring FactoryTalk® Batch

Material Manager. This chapter assumes that the FactoryTalk Batch system is

configured and working properly and that Material Manager is installed.

Configure the FactoryTalk Batch Material Manager Server with the location of

the SQL database that contains the materials for the recipes.

To identify the material database

1. Navigate to Rockwell Software > Network Editor.

he Network Editor window opens with the Material Server selected

T

by default.

options

2. Select Configure. The Configure MaterialTrack dialog box opens. The

default database is materialbasedrecipe.

3. In the MaterialTrack Database box, enter the name of the database,

and select OK.

The Network Editor does not verify database names. Changes

made to the database name are immediate for the clients and

servers. If the database name is invalid, the Material Editor

will not open.

Before changing the database name, check the spelling of the

database name and synchronize the Network Editor. After

changing the database name, confirm that the Material Editor

4. Select Synchronize.

5. Select File > Exit, and then select Yes to exit the Network Editor.

et the options for the Material Server in the FactoryTalk Batch Equipment

S

Editor module.

To identify the material database

1. Click Start > Rockwell Software > Equipment Editor.

2. From the Options menu, select Server Options. The Server Options

dialog box opens to the Project Settings tab.

11

Page 12

Chapter 1 Configuring Material Manager

Enable the automatic

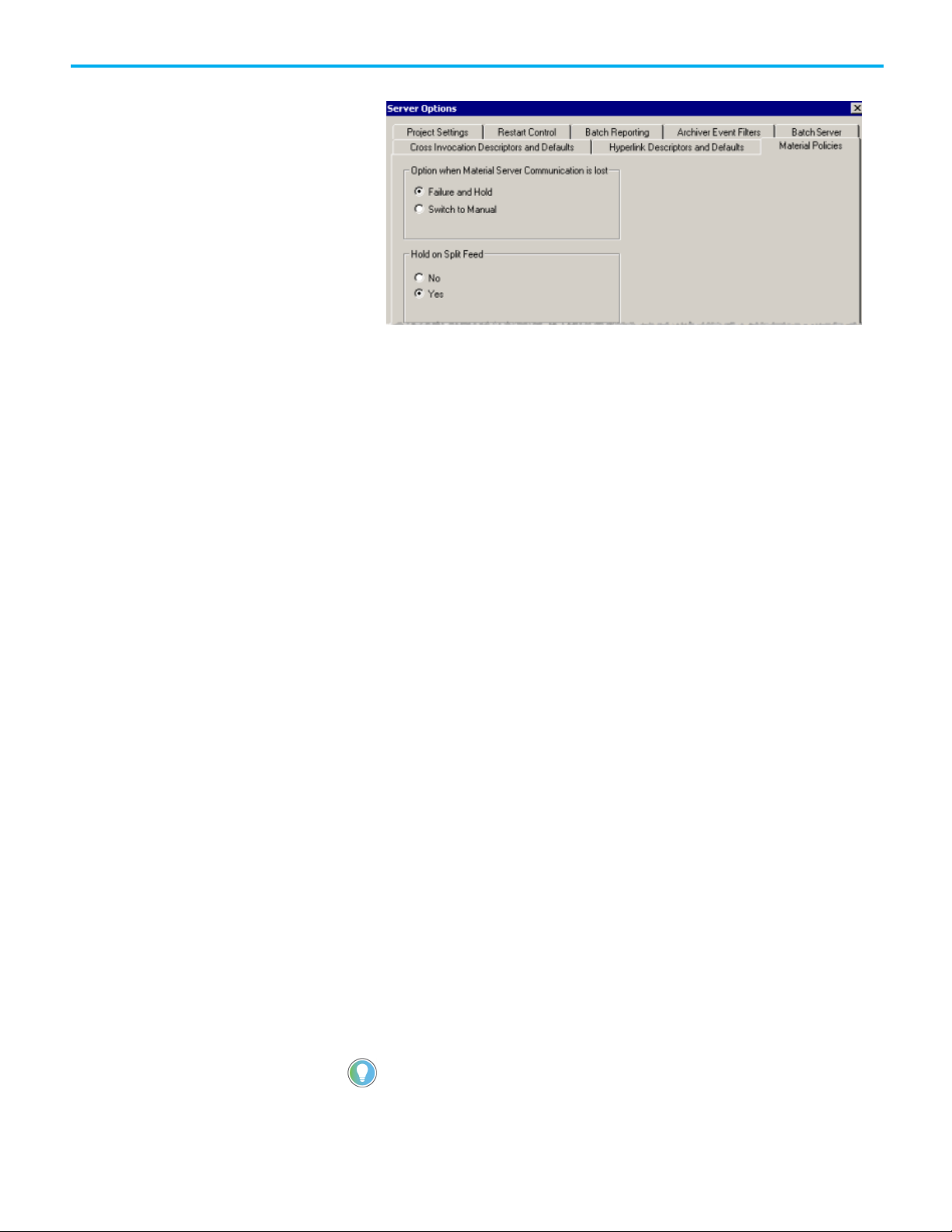

3. Select the Material Polices tab.

• Option when Material Server Comm is lost

When communication is lost between the FactoryTalk Batch and

Material Servers, you can choose to fail and hold the batch or switch

the batch to Manual mode.

• Failure and Hold indicates the FactoryTalk Batch Server places the

batch in the HELD state.

• Switch to Manual indicates the FactoryTalk Batch Server continues

to run the batch prompting the operator for decisions regarding

information normally supplied by the Material Server. (See

"Troubleshooting" for more information.)

• Hold on Split Feed

Split feeds occur when a material phase step does not add or

distribute all of the material configured by the step.

• No directs the FactoryTalk Batch Server to continue processing a

batch when a split feed occurs. If you select this option, add a

material loop to the recipe so that the binding process can select

another container for material additions. (See the FactoryTalk Batch

Recipe Editor User Guide for more information on material loops.)

• Yes directs the FactoryTalk Batch Server to hold the batch when a

split feed occurs. The Material Server calculates and sends new

AMOUNT parameters to the FactoryTalk Batch Server. To resume

processing, the operator must perform an active step change away

from the unfinished step, manually rebind the unfinished step,

perform an active step change back to the unfinished step, and then

restart the batch.

deletion of lots with no

remaining sublots

12

4. Make your selections, and then click OK.

Use the following procedure to enable the automatic deletion of lots with no

remaining sublots to free up space in the material database.

Tip: Sublots are identified as labels in Material Editor and FactoryTalk Batch View.

Page 13

Chapter 1 Configuring Material Manager

To enable the automatic deletion of lots with no remaining sublots

1. On the Material Manager Server machine, create a registry key.

• 32 bit system Registry Editor location:

[HKEY_LOCAL_MACHINE\SOFTWARE\MaterialTrack\Material

Recipe\Setup

• 64 bit system Registry Editor location:

[HKEY_LOCAL_MACHINE\SOFTWARE\Wow6432Node\MaterialTr

ack\Material Recipe\Setup

2. Create a new string value

Value to TRUE.

DeleteLotOnZeroSubLots and set the

13

Page 14

Page 15

Chapter 2

Implementing security

FactoryTalk® Batch Material Manager security controls who has permissions

for certain actions, such as viewing, adding, removing, and changing an item.

Security is set using COM+ role-based security and Windows user groups and

users.

Through the use of COM+ role-based security, administration of security for

Material Manager is greatly simplified. COM+ role-based security allows an

application to have preset user categories called roles. These roles have preset

permissions and have preset Windows user groups added to them. To

implement security, an administrator must create the preset user groups and

add the appropriate user accounts to these groups.

15

Page 16

Chapter 2 Implementing security

Security settings

This flowchart is an example of how security works for Material Manager.

16

The setup program creates a default user group and preset COM+ roles.

Domain user groups and accounts created prior to installation are added to

the roles during the installation process. Security is then implemented using

Windows user groups and users.

Tip: If you want to customize security, contact Rockwell application support

.

Page 17

client computers if you want them to be able to reference the logged messages.

Material Manager Security

Chapter 2 Implementing security

The local user group installed with Material Manager is MTUsers. This group

is assigned permissions to the MaterialBasedRecipe database in SQL Server.

The domain user account specified during the installation is added to this

group role to allow the Editor to access the database using COM+.

To use domain security, create the following user groups and accounts on the

domain prior to installation. These groups and accounts are added to the

appropriate COM+ roles during the installation and inherit the permissions of

those roles.

• MTBatchServer

User Group & COM+ Role

Add the FactoryTalk Batch user account under which the FactoryTalk

Batch Server service is running to the MTBatchServer group. The

MTBatchServer group is added to the MTBatchServer role during

installation. This is the role that the FactoryTalk Batch Server uses to

access the material database. All FactoryTalk Batch Servers have

unlimited access to Material Manager.

• MTGeneral

COM+ Role

The MTGeneral role is used internally by the Material Server to check

security and communication between clients and the server.

• MTLotAuthor

User Group & COM+ Role

The MTLotAuthor role has permission to add, edit, and delete lots. The

MTLotAuthor group is added to the MTLotAuthor role during

installation.

• MTMaterialAuthor

User Group & COM+ Role

The MTMaterialAuthor role has permission to add, edit, and delete

materials and containers. The MTMaterialAuthor group is added to

the MTMaterialAuthor role during installation.

• MTMaterialViewer

User Group & COM+ Role

The MTMaterialViewer role has permission to view items in the

Editor. The MTMaterialViewer group is added to the

MTMaterialViewer role during installation.

• Domain user account for the server

User

The domain user account specified during the installation is added to

the local group, MTUsers. This is the account under which the server

runs.

Tip: The

MaterialServer.log

computer. You must share the \Program Files\Rockwell Software\Batch folder with the

file on the Material Server cannot be viewed from a client

17

Page 18

Chapter 2 Implementing security

Tip: Services with blank passwords are not supported.

Using workgroup security

Using domain security

Configuring the domain

When FactoryTalk Batch Material Manager is installed for a workgroup, the

local user accounts, local user groups, and COM+ Roles are created and

assigned default permissions. You must customize the security settings to

meet your facility’s unique requirements as outlined in the following the

steps:

Configuring the FactoryTalk Batch Material Manager Workgroup

Server and Client Nodes

• You must define Windows user accounts and passwords on all

computers that communicate with the Material Server. You need to

configure membership in FactoryTalk Batch Material Manager user

groups on the Material Server computer only.

• Create Windows User Accounts

If you are not using the existing Windows user accounts, create new

user accounts with the appropriate rights.

• Add Windows User Accounts to Windows User Groups

Add the appropriate Windows user accounts to the FactoryTalk Batch

Material Manager user groups on the Material Server computer. The

user accounts inherit the rights and permissions of the user group to

which they are added.

server

Perform the following steps to customize the security settings and implement

domain security. This is only one possible implementation of domain

security; you may find that your specific security requirements involve other

steps.

• Create Domain User Accounts

If you are not using existing user accounts, create domain user

accounts that meet your facility’s specific security requirements. For

Domain user accounts that need access to Batch client applications,

you must add the Windows user accounts to the appropriate

FactoryTalk Directory. (See FactoryTalk Help for more information.)

• Create Domain User Groups

Create the following groups on the domain prior to installation of

FactoryTalk Batch Material Manager:

• MTBatchServer

• MTLotAuthor

• MTMaterialAuthor

• MTMaterialViewer

• MTGeneral

18

Page 19

IMPORTANT

FactoryTalk Batch Server continues writing information to log files and event journals

been written to the event journal or log file while the file is open is lost.

IMPORTANT

IMPORTANT

Setting security on folders

or files

Adding users and user

Change permissions on the

Chapter 2 Implementing security

• Add Domain User Accounts to the Appropriate Domain User Groups

Add the appropriate domain user accounts to the domain user groups.

The user accounts will inherit the rights and permissions of the user

group to which they are added.

Tip: Services with blank passwords are not supported.

You should limit log file and e vent journal (.evt) access to prevent data from

being lost. Setting security on the folders or files is one suggested method. Set

the security according to your company’s requirements.

Use Notepad to open log files. If a log file is opened with a program other than

Notepad, the FactoryTalk Batch Server may not run due to an access error.

(.

evt

) even when they are open. If a file is opened and then saved, data that may have

groups

To add Windows security on folders or files in Windows Explorer

complete the following steps.

1. In Windows Explorer, locate the folder or file.

2. Right-click the folder or file, and then select Properties.

3. Select the Security tab, and then click the Add button.

4. From the Select Users, Computers, or Groups dialog box, click

Advanced and then click Find Now.

5. Select a User or Group from the Search results: list, and then click OK.

6. Repeat for each User or Group that requires access to the folder or file.

Be sure to add the FactoryTalk Batch Server user account and then configure

the account with Full Control permissions.

7. Click OK to return to the Properties dialog box.

8. From the Group or user name: list, select a User or Group, and then

select the permissions in the Permissions area. Repeat for each User or

Group.

9. Click OK.

Change the permissions on the BATCHCTL share to tighten security by

BATCHCTL share

removing the Everyone group and adding a new group that contains all the

Windows users that need to access the share.

Include these user types in the group:

19

This new group allows applications to access the BATCHCTL share while locking out

non-domain users.

Page 20

Chapter 2 Implementing security

• The FactoryTalk Batch Server and FactoryTalk Event Archiver user.

• Windows users logged in when the FactoryTalk Batch Equipment

Editor, FactoryTalk Batch Recipe Editor and FactoryTalk Batch View

are launched.

To change permissions on the BATCHCTL share

1. In Windows Explorer, locate the Batch folder. The default location is

C:\Program Files (x86)\Rockwell Software\Batch.

2. Right-click the Batch folder, and then select Properties.

3. Select the Security tab and do the following:

a. Select Edit, select the Everyone group, and then select Remove.

b. After removing the Everyone group, select Add.

4. From the Select Users, Computers, Service Accounts, or Groups dialog

box, select Advanced and then click Find Now.

5. Select a group from the Search results list, and then select OK.

6. Select OK to return to the Properties dialog box.

7. From the Group or user name list, select a user or group, and then

select the permissions in the Permissions area. Repeat for each user or

group.

8. Select OK.

20

Page 21

Tip: You must first enable the material logging service. See Enable material journaling in the

FactoryTalk Batch Components Installation and Upgrade Guide

.

Chapter 3

Using the material activity journal

The material activity journal (MaterialBasedRecipe_MAJ) is an SQL database

that captures events specific to FactoryTalk® Batch Material

Manageroccurring during a batch run of a material-based recipe. This

Material Manager-specific data is stored in the tbActivityJournal table and is

found also in the FactoryTalk Batch event journal (.evt) file along with the

other non-Material Manager events.

Batch Event Journal Entry

Material Activity Journal Entry

When the FactoryTalk Batch Server is able to communicate with the Material

Server, the Material Manager-specific data is sent to the material activity

journal by way of a COM+ queued component that uses features of Microsoft

Message Queuing (MSMQ). This queued component enables journaling even

when lapses in database communication occur. If the Material Server is not

ready to receive data for the material activity journal, this queued component

holds the data until the Material Server is ready.

21

Page 22

Chapter 3 Using the material activity journal

IMPORTANT

Enable material journaling

If for some reason the queued component cannot pass the Material Managerspecific data to the material activity journal, the data is stored as messages in

a dead queue. If the FactoryTalk Batch Server loses communication with the

Material Server, the Material Manager-specific data appears only in the Batch

event journal (.evt) file.

Recording activity to the Material Activity Journal is off by default. To record

activity to the MaterialBasedRecipe_MAJ database, change the default value

in the Registry on the Material Server computer.

To enable material journaling

This procedure is for Material Manager users only.

1. Select Start > Run.

2. In Run, enter regedt32 and select OK. The Registry Editor opens.

3. Expand HKEY_LOCAL_MACHINE and then Software.

4. For a 64-bit computer, expand Wow6432node.

5. Navigate to the MaterialTrack > Material Recipe > Logging subkey.

22

6. Double-click the JournalActive subkey to open the Edit String dialog

box.

7. To enable material logging, in Value data, enter True and select OK.

8. Close the Registry Editor.

Page 23

IMPORTANT

Open the Network Editor

Network Editor interface

Chapter 4

Network Editor

The Network Editor is a utility that allows you to indicate where other

FactoryTalk® Batch and/or FactoryTalk Batch Material Manager Servers are

located on the network. This network configuration information simplifies

integration with other FactoryTalk products and the process of reconfiguring

a multi-computer system.

During installation, the network configuration information is completed

based on your responses. If you have multiple servers in your network, use the

Network Editor to update the location of all your servers.

The Network Editor is installed automatically with the FactoryTalk Batch and

Material Servers.

Open the Network Editor to configure your network.

Administrator privileges are required to perform this procedure.

To open the Network Editor:

• Select Start > Rockwell Software > Network Editor. The Network

Editor window opens.

The Network Editor interface has the following areas:

• Hierarchy pane

• Detail pane

• Results pane

• Toolbar

23

Page 24

Chapter 4 Network Editor

Item

Description

system was last synchronized.

Apply Changes

Saves changes made to the FactoryTalk Batch system information.

Hierarchy pane

Detail pane

• Status bar.

The Hierarchy pane provides a hierarchical view of the application servers in

your FactoryTalk Batch system. The Network Model is the parent item in the

hierarchy list, with the following application servers listed as Network Model

members: Material Server, and FactoryTalk Batch Server 1 through Batch

Server 10. The following indicators appear next to each server listed:

Indicates the server is recognized on the network

Indicates the server is not defined or recognized

Indicates there is a problem with the server or the server’s configuration

The Detail pane provides information specific to the item selected in the

Hierarchy pane.

Network Model Information

The following items are available when Network Model is selected in the

Hierarchy pane.

System Name Allows you to name your FactoryTalk Batch system. The default is

Network Model.

Network Model from Displays the name of the computer from which the FactoryTalk Batch

24

Time Stamp Displays the time of the last synchronization.

User Name Displays the Windows user ID of the person who performed the last

synchronization.

Undo Changes Undoes changes made to the FactoryTalk Batch system information that

are not applied.

Page 25

Item

Description

Item

Description

Computer Name

Displays the computer name for the selected server.

IMPORTANT

the Material Editor opens and can read the database.

Error

Indicates an error message.

Warning

Indicates a warning message.

Results pane

Menu bar

Chapter 4 Network Editor

Synchronize All Application

Servers

Initiates the synchronization of the application servers.

Application Server Information

The following items are available when a server or Undefined is selected in the

Hierarchy pane.

Alias Displays a user-defined alias for the selected application server.

Configure Allows you to specify the name of the material database when using

FactoryTalk Batch Material Manager. The default database is

MaterialBasedRecipe.

The Network Editor does not verify database names. Changes made to the database

name are immediate for the clients and servers. If the database name is invalid, the

Material Editor will not open. Before changing the database name, check the spelling

and synchronize the Network Editor. After changing the database name, confirm that

The Results pane provides information messages regarding the results of the

last synchronization. Included in the list is an icon indicating the type of

message listed, the name of the computer that performed the

synchronization, and the message generated by the synchronization process.

The table below shows icons used in the messages and explains what types of

messages they represent.

Information Represents an information message.

The menu bar contains the menus for File, Edit, View, and Help.

• File menu

From the File menu, you can select a Network Model, synchronize all

servers, print, and exit the Network Editor application.

25

• Edit menu

Page 26

Chapter 4 Network Editor

Synchronize: Allows you to synchronize your application servers.

Network Editor toolbar

Status bar

From the Edit menu, you can add or remove a server from the Network

Editor.

• View menu

From the View menu, you can show or hide the toolbar/status bar, and

refresh the Network Editor. You can also specify how data is viewed in

the panes as well as setting other user preferences.

The Network Editor includes a toolbar which allows you to perform various

functions. The buttons are enabled based on the item currently selected in the

Network Editor. As you move your cursor over a button, a tool tip displays the

button name and a detailed functional description displays in the status bar.

The Network Editor Toolbar buttons are:

Select Network Model: Allows you to select a network model from another computer.

Add Server: Allows you to add a previously undefined server.

Remove Server: Allows you to remove a server.

Up One Level: Moves you up one level in the Hierarchy pane.

Print: Prints a report for the selected item.

Print Preview: Allows you to view a report on the selected item.

Help: Opens the Network Editor help.

The status bar at the bottom of the window displays text messages on the left

side. In addition, the status bar displays one or more icons on the right side,

representing the status of the application and data.

The list of states that can be displayed in the status bar:

Database: The Network Editor is accessing data.

Server: The Network Editor is accessing other servers.

26

Printing: A report is being printed or previewed.

Processing: The Network Editor is processing data.

Waiting: The Network Editor is busy.

Page 27

Configure your network

Select a network model

Add a server

Chapter 4 Network Editor

The Network Editor allows you to configure your FactoryTalk Batch system.

You can add or remove application servers, print reports, and synchronize

your network model with another computer.

This section provides instructions for performing each of these functions.

When you select a network model, you are retrieving an existing network

model from another computer and using it as the network model for the local

computer. You must do this if you add, remove, or rename a server in your

system and need to update your network model with your existing system, or

if you want to use the network model from another computer.

To select a network model

1. Open the Network Editor.

2. In the Network Editor toolbar, click the Select Network Model button.

3. Type the computer name in the "Enter the object name to select" area,

or click the Advanced button to search for a computer.

4. Click OK.

Use the Network Editor to add a previously undefined server.

To add a server

1. Open the Network Editor.

2. In the Hierarchy pane, select the type of server to add.

3. Click Add Server.

4. In the Alias box, type an alias name. This is the name that displays in

the Network Editor.

5. In the Computer Name box, type the computer name, or use the

browse button to locate and select the computer from the list of

computers on your domain.

6. Click the Synchronize button.

7. Click OK.

27

Page 28

Chapter 4 Network Editor

Tip: It is a good idea to synchronize after adding or removing a server from the network model.

Remove a server

Synchronize network

User Preferences dialog

User Preferences dialog

Use the Network Editor to remove a server from your network model.

To remove a server

1. On the main FactoryTalk Batch server open the Network Editor and

navigate to the root network model.

2. In the Hierarchy pane, select the server to remove.

3. Click the Remove Server button.

4. Click the Synchronize button. The servers listed in the model are

updated with the new member server list.

The server you removed is not updated.

5. Log in to the server you removed and open Network Editor.

6. Repeat steps 2 through 4 to remove the server manually.

models

box

The synchronization process copies the network model data from your

computer to each of the computers included in your FactoryTalk Batch

system.

Click the Synchronize button. The Network Editor refreshes and the results of

the synchronization process display in the Results pane.

The User Preferences function allows you to customize the behavior and

appearance of the various panes and views within the Network Editor.

You can turn on information tips, change the application text/background

colors, configure the various views, and set up reports used for printing.

box - General tab

28

Page 29

Edit colors

Chapter 4 Network Editor

The General tab is used to configure the basic behavior and appearance of the

Network Editor views and dialog boxes. The selections on the General tab are

used in conjunction with other sections of the User Preferences dialog box.

In the Options area, you have the following selections:

• Use application colors: Select to assign colors, other than the current

Windows colors, to the background and text in the views.

• Use application font: Select to change the font, font style, and size

from the default Windows style.

• Information tips: Select to enable single line tips that appear when you

move the cursor over a button or field.

• Animate dialogs: Select to have dialog boxes fly out from the location

from which they are opened.

• Confirm deletion: Select to display an "Are you sure?" message when

you delete an item. Leave disabled to delete an item immediately

without confirmation.

• Confirm exit: Select to have the application ask if you want to exit.

Leave disabled to exit without a confirmation message.

29

The Network Editor defaults to the current Microsoft Windows color scheme.

You can change the color of the text and background.

To edit colors

1. Open the Network Editor.

2. From the View menu, select User Preferences.

3. On the General tab in the User Preferences dialog box, select Use

application colors.

4. Select the Colors tab.

Page 30

Chapter 4 Network Editor

Edit the application font

Edit information tips

5. Disable Use Windows colors to enable the Background color and Text

color lists.

6. Select the desired colors from the appropriate list, and then click

Apply.

The Network Editor defaults to the current Windows fonts. You can change

the display font.

To edit the application font

1. Open the Network Editor.

2. From the View menu, select User Preferences.

3. On the General tab in the User Preferences dialog box, select Use

application font.

4. Select the Font tab.

5. Select the desired font, style, and size from the appropriate lists, and

then click OK.

6. Click Apply.

7. Click OK.

Information tips appear when you move the cursor over a button or field. You

can change the font and colors of tips, and set tip timing, which determines

how soon a tip displays.

To edit information tips

1. Open the Network Editor.

2. From the View menu, select User Preferences.

3. On the General tab in the User Preferences dialog box, select

Information tips.

4. Select the Tips tab.

5. To enable the Background color and Text color lists, disable Use

Windows colors.

6. To change the tip color, select the text and background colors from the

appropriate lists, and then click OK.

7. To change the tip font, click the Change Font button. The Font dialog

box opens. Select the desired font, style, and size from the appropriate

list, and then click OK.

30

Page 31

menu, select Print Setup, select Landscape in the Orientation area, and then click OK.

User Preferences dialog

box - Views tab

Set report preferences

Chapter 4 Network Editor

8. To change the timing of information tips, use the Up and Down arrows

to change the settings in the Timing area.

• Delay determines how soon a tip displays when the cursor stops on

an area with a tip.

• Visible duration determines how long the tip is visible before

closing.

9. Click Apply.

10. Click OK.

To configure properties that are specific to each view and list in the Network

Editor, use the Views tab. For all list views, you can enable information tips,

alter the behavior of drag and drop, change the appearance of scroll bars, and

set selection options. On selected views, you can change the font style and

color, as well as the background color.

You can define a footer to print on each report page and select the font and

color (if your printer supports color printing) for the various report sections.

To set report preferences

1. From the View menu, select User Preferences. The User Preferences

dialog box opens to the General tab.

2. Select the Reports tab. The default report style for most views is

Formatted.

3. To change the type of printed report, select either List or Formatted to

the right of the appropriate report.

31

Tip: If you select the List format, set the page orientation to landscape. From the File

Page 32

Chapter 4 Network Editor

Report printing formats

4. Where available, you can select Include Related Data, and any

additional data associated with the selected item (single items only –

not lists or groups) also prints on the report.

5. In the Footer Text box, type a word or phrase to appear centered at the

bottom of each page.

6. Click Apply.

The Network Editor report printing feature allows you to print network,

server, or result pane information, in a report formatted with headers, footers

and column headings (in list reports). There are two report formats available:

formatted and list. The header (at the top of the page) consists of the report

name, while the footer (at the bottom of the page) contains the printing

date/time and the page count.

A formatted report presents the information down the page, with bold field

names as shown in this figure.

32

A list report presents the data in a columnar, spreadsheet format, with one

line per data item. The field names become column headings as shown in this

figure.

You can customize the reports by setting margins, changing font styles, and

selecting text colors. In addition, you can enter custom text that is also

included in the footer. (See "Set report preferences" for more information.)

Page 33

report preferences for instructions.

Preview reports

Print reports

Chapter 4 Network Editor

The Print Preview function of the Network Editor allows you to see how a

printed report looks before you send it to the printer.

To preview reports

1. Click the Print Preview button. The Print Preview window opens,

displaying the report as it will look when printed. The following

options are available from the Print Preview window:

• Next Page – If there is more than one page in the report, click Next

Page to view the next page of the report.

• Prev Page – Click to view the previous report pages (if there is more

than one page in the report).

• Two Page – Allows you to view two pages of a report in the same

window.

• One Page – Returns to the default preview setting of one page per

window.

• Zoom In/Out – Click Zoom In to magnify the preview page. Click

Zoom Out to reduce the size of the page in the preview window.

• Close – Closes the preview window.

2. Click Close to return to the Network Editor. You can either print the

report or make additional report configuration changes.

The Network Editor report printing feature allows you to print network,

server, or result pane information, in a report formatted with headers, footers

and column headings (in list reports).

To print reports

1. In the Network Editor’s Hierarchy pane, select the list or item(s) that

you want to print.

2. From the File menu, click Print. You could also click the Print button

or press ctrl+p to display the Print dialog box.

3. Ensure that the correct printer is selected, and click OK.

Tip: To configure heading and footer fonts and add a custom footer to your reports, see Set

33

Page 34

Page 35

Material Server in the

PCD Programming Reference Manual

.)

Automatic repair of batch

component installation fails

Error: No containers match

Error: Unable to retrieve the

Operating without a

Chapter 5

Troubleshooting

This chapter contains information specific to troubleshooting the

FactoryTalk® Batch Material Server. (See the FactoryTalk Batch Administrator

Guide for information on troubleshooting the FactoryTalk Batch Server.)

This can happen if one or more necessary folders were unintentionally moved

(in Windows explorer). For example, if the Schema folder gets moved away

from its original install path, the install package starts up automatically and

tries to ‘repair’ the problem. This ‘repair’ can clear out the Model and Server

keys in the registry, which can make the Batch client editors generate warning

dialogs because they are not able to find the Network Model.

If this happens, completely uninstall the application and then reinstall it.

material container

specification

Promise ID

This error can appear for several reasons. Here are a few things to check when

this message appears:

• The container’s state is not marked Ready to Use.

• The lot state of the sublot in the container is not marked Ready to Use.

• The material specification of the step does not match the material

specification of a sublot.

If Material Manager offers the equipment ID of container to a recipe (A) and

that container already has a Promise ID issued to another recipe (B), the

recipe (A) trying to use that container goes into Hold. The operator receives

the error: "Unable to retrieve the Promise ID". This prevents the inadvertent

dumping of two materials into the same empty container, thus (possibly)

destroying both materials.

Material Server

35

There may be a time when communication between the FactoryTalk Batch

Server and the Material Server is lost. If this occurs during a batch run, the

operator can complete the batch without the Material Server.

Tip: To run material-based recipes without the Material Server, use the upper range request codes

(11000-18000) in the phase logic. (For more information, see Unable to Communicate with

Page 36

Chapter 5 Troubleshooting

ATTENTION: If the FactoryTalk Batch Server is configured to Switch to Manual and

Losing communication

Because the Material Server cannot provide the FactoryTalk Batch Server with

information necessary for automatic binding, the operator is prompted to

select the containers/equipment modules for binding. Also, since the Material

Server populates the material database with material additions and

distributions, this task must be performed manually when the batch is

complete.

communication is lost with the Material Server, the FactoryTalk Batch Server switches to

prompt binding and presents an unfiltered list of container/equipment module pairs from

which to select binding candidates. The operator must select the container/equipment module

pair to supply the correct material to continue processing the batch.

Failure to select the correct container/equipment module pair could result in a hazardous

situation depending on the material.

When communication is good between the FactoryTalk Batch and Material

Servers, the Failed Material Server Indicator in the FactoryTalk Batch View

status bar displays

a green MT-G.

When the FactoryTalk Batch Server loses communication with the Material

Server, The Failed Material Server Indicator in the FactoryTalk Batch View

status bar displays a red MT-B.

If the FactoryTalk Batch Server is configured to Failure and Hold when

communication is lost with the Material Server, the batch is held until

communication resumes and the operator clears the failure.

If the FactoryTalk Batch Server is configured to Switch to Manual when

communication is lost with the Material Server, the batch continues to run

and the following occurs:

• All binding switches to prompt binding. Because the FactoryTalk Batch

Server cannot access the information in the material database, the lists

of equipment modules and containers are generated from the area

model. Any other information provided by the material database, such

as capacity, engineering unit, lot, and label, does not display. The

36

Page 37

Chapter 5 Troubleshooting

operator must select the equipment module and container that can

add material to or distribute material from the batch.

• The FactoryTalk Batch Server begins to use a default invalid promise

ID since the Material Server cannot send a valid promise ID, which is

used to update the inventory in the Material Editor. The actual

amounts added or distributed in the recipe must be manually updated

in the material database. In split feed situations, the FactoryTalk Batch

Server continues to update the setpoint so processing can continue.

• The FactoryTalk Batch Server records Loss of Material Tracking and

Loss of Material Server in the event journal. When the batch is

complete, the additions and distributions must be updated manually

into the material database.

(See the FactoryTalk Batch View User Guide for information on the status bar

and event journal. See the FactoryTalk Material Editor User Guide for

information on updating the material database manually.)

Possible Failure and Hold Errors

When using a Failure and Hold configuration, and a break in communication

happens after the Promise ID is required and the reporting is the first

communication that fails, the Promise ID given by the Material Server may

still exist in the material database. These "orphaned" Promise IDs can be a

problem for several reasons.

37

Page 38

Chapter 5 Troubleshooting

Loss of Material Tracking are enabled.

Switching to manual

Restoring communication

1. A distribution type promise is limited to 1 per container. An orphaned

promise of this type locks the container to other distributions.

2. Over-consumption also can be affected by this — The FactoryTalk

Batch Server may assume there are active addition promises when in

actuality this promise is no longer attached to a running phase.

Reporting only happens once the phase transitions to a STOPPED, ABORTED

or COMPLETED state.

To solve this problem, open the event journal and look for the event

description "Material Distribution Database Reporting Failed - Event Type

Material Tracking." Go to the tbPromise table and delete the Promise ID

record that was noted in the event journal entry.

Upon installation, the FactoryTalk Batch Server is configured to fail and hold

a batch when communication with the Material Server is lost. If you want to

run batches even when communication is lost, configure the FactoryTalk

Batch Server to switch to Manual mode. In Manual mode, the FactoryTalk

Batch Server prompts the operator for information normally supplied by the

Material Server.

1. Click Start > Rockwell Software > Equipment Editor.

2. From the Options menu, select Server Options. The Server Options

dialog box opens to the Project Settings tab.

3. Select the Material Policies tab.

4. Select Switch to Manual, and then click OK.

Tip: If you are using the FactoryTalk Event Archiver, select the Archiver Event Filters tab

while you are in the Server Options dialog box to verify that Loss of Material Server and

5. Exit the FactoryTalk Batch Equipment Editor.

38

When communication between the FactoryTalk Batch and Material Servers

becomes available, the action of the FactoryTalk Batch Server depends on the

setting selected on the Material Policies tab of the Server Options dialog box

in the Equipment Editor.

Page 39

Tip: If you want to limit security on the Failed Material Server Indicator dialog box, disable

FactoryTalk Batch View Security in the

FactoryTalk Batch Administrator Guide

.)

IMPORTANT

Starting the FactoryTalk

Chapter 5 Troubleshooting

• If the FactoryTalk Batch Server is configured to Failure and Hold, the

Failed Material Server Indicator in the FactoryTalk Batch View status

bar displays a green MT-G when the Material Server becomes available.

The operator must clear the failure for the batch to continue

processing. (See the FactoryTalk Batch View User Guide for more

information.)

• If the FactoryTalk Batch Server is configured to Switch to Manual, the

Failed Material Server Indicator in the FactoryTalk Batch View status

bar displays a yellow MT-S when the Material Server becomes

available. The operator must restore communication manually when

appropriate.

the Material Server Control button for specified users or groups. (See Configure

1. Double-click the Failed Material Indicator in the FactoryTalk Batch

View. The Failed Material Server Indicator dialog box opens.

2. Click the Material Server Control button. The Material Server Control

dialog box opens.

3. Select Reestablish Communication with Material Server, and then

click OK.

Be aware that the material database is not synchronized with the FactoryTalk

Batch Server and the data in the material database must be updated

manually. (See the

updating the material database manually.)

FactoryTalk Material Editor User Guide

for information on

A cold boot requires communication between the FactoryTalk Batch and

Batch server

Material Servers. If the Material Server is unavailable, the FactoryTalk Batch

Server will not start. During a cold boot, the container, material, and material

class enumerations are created based on the information in the material

39

Page 40

Chapter 5 Troubleshooting

database. Once this information becomes resident in the FactoryTalk Batch

Server, it can process a batch without the Material Server.

This material data (container, material, and material class enumerations)

resident in the FactoryTalk Batch Server is referred to as persisted data. A cold

boot refreshes this data by downloading new data from the material database

via the Material Server. A warm or warm-all boot does not refresh this data.

If you need to restart the FactoryTalk Batch Server when the Material Server is

unavailable, use either the warm or warm-all boot method. Both of these

methods ensure that the container, material, and material class enumerations

resident in the FactoryTalk Batch Server prior to the restart are restored.

(See the FactoryTalk Batch Administrator Guide for more information on the

FactoryTalk Batch Service Manager.)

40

Page 41

Tip: The user account for the FactoryTalk Batch server, Batch Archiver, eProcedure server services

and the Batch COM+ Application must be identical.

Configure your FactoryTalk

Chapter 6

Change the FactoryTalk Batch server user

account

Depending on your facility’s security requirements you may need to change

the FactoryTalk Batch server user name and password periodically. If you

change the server’s user account after installing the FactoryTalk Batch

components you must configure your FactoryTalk Batch system to use the

new server user account.

New user account requirements for the FactoryTalk Batch Server

Batch system

When creating a new user account for the FactoryTalk Batch Server, the

following requirements must be met.

• The password must be configured never to expire--if the password ever

expires, the service eventually fails to log on.

• The user account must never be disabled or deleted--if this account is

ever disabled/deleted, the service eventually fails to log on.

• The domain user account must have a unique name--if the user

account is a domain account, remove any local user accounts with the

same name.

• The user account/user group must exist on all workgroup computers--

if you want a local account to have access to resources on other

computers in a workgroup environment, you must create accounts

with the same name and password on each computer in the

workgroup.

After you create a new user account for the FactoryTalk Batch Server,

configure your FactoryTalk Batch system.

To configure your FactoryTalk Batch system

1. Configure the FactoryTalk Batch Server computer:

41

a. Add the new server user account to the batchsvr_group and

administrators group. By adding the new account to the

Page 42

Chapter 6 Change the FactoryTalk Batch server user account

Server account password

batchsvr_group it inherits all the required user rights and access

permissions.

b. If FactoryTalk Batch Material Manager is part of your system, add

the new FactoryTalk Batch Server user account to the

MTBatchServer group on the Material Server computer.

c. Add the new FactoryTalk Batch Server user account to the

FactoryTalk Batch Server service.

d. If you are running FactoryTalk Event Archiver in incremental mode,

add the new FactoryTalk Batch Server user account in the Batch

Archiver service.

e. If FactoryTalk eProcedure is part of your system, add the new

FactoryTalk Batch Server user account to the eProcedure Server

service.

f. Add the new FactoryTalk Batch Server user account to the Batch

COM object in Component Services > My Computer > COM+

Applications.

change locations

2. Configure the FactoryTalk Batch Client computer(s):

a. If you are using workgroup security, create the new FactoryTalk Batch

Server user account on all FactoryTalk Batch Client computers in the

workgroup.

b. Add the new FactoryTalk Batch Server user account to Component

Services > My Computer > Properties > COM Security on all remote

FactoryTalk Batch View computers. Configure the account with

Access Permissions: Local Access and Remote Access.

c. If eProcedure is part of your system, add the new FactoryTalk Batch

Server user account to Component Services > My Computer >

Properties > COM Security on all remote eProcedure Client

computers. Configure the account with Access Permissions: Local

Access and Remote Access.

If you change the password for the existing FactoryTalk Batch Server user

account, change the password in these locations:

• If you are using Workgroup security, change the password for the

FactoryTalk Batch Server user account on all FactoryTalk Batch

computers in the workgroup.

• Change the password for the FactoryTalk Batch Server user account in

the FactoryTalk Batch server service.

42

Page 43

Change the server user

account for the FactoryTalk

Change the server user

Batch Server service

• If you are running FactoryTalk Event Archiver in incremental mode,

change the password for the FactoryTalk Batch Server user account

to the Batch Archiver service.

• If eProcedure is part of your system, change the password for the

FactoryTalk Batch Server user account in the eProcedure Server

service.

• Change the password for the FactoryTalk Batch Server account in the

Batch COM object in Component Services > My Computer > COM+

Applications.

Chapter 6 Change the FactoryTalk Batch server user account

To change the user account for the FactoryTalk Batch Server service, complete

these steps on the server computer.

To change the server user account for the FactoryTalk Batch Server

account in FactoryTalk

service

1. Select Start > Windows Administrative Tools > Services. The Services

dialog box opens.

2. Right-click FactoryTalk Batch Server, and then click Properties. The

FactoryTalk Batch Server Properties dialog box opens.

3. On the Log On tab, select This Account and type the new user and/or

password.

4. Click OK.

• If you are using FactoryTalk Event Archiver in incremental mode,

change the user account name and/or password for the Batch

Archiver service.

• If eProcedure is part of your system, change the user account name

and/or password for the eProcedure Server service.

5. Close Services.

To change the FactoryTalk Batch Server user account in Batch COM+

applications, complete these steps on the FactoryTalk Batch Server computer.

Batch COM+ applications

43

To change the server user account in FactoryTalk Batch COM+

applications

1. Select Start > Windows Administrative Tools > Component Services.

Page 44

Chapter 6 Change the FactoryTalk Batch server user account

Tip: The new permissions are applied the next time the FactoryTalk Batch Server is started

on the computer.

Change the server user

2. Expand Component Services, Computers, My Computer and COM+

Applications.

3. Right-click Batch, and then select Properties. The Batch Properties

dialog box opens.

4. On the Identity tab, select This user and type the new FactoryTalk

Batch Server user name and/or password.

5. Click OK.

To change the FactoryTalk Batch Server user account in My Computer

properties, complete these steps on the FactoryTalk Batch Client computers.

account in My Computer

properties

To change the server user account in My Computer properties

1. Select Start > Windows Administrative Tools > Component Services.

2. Expand Component Services and Computers.

3. Right-click My Computer, and then click Properties. The My

Computer Properties dialog box opens.

4. On the COM Security tab, click the Edit Default button in the Access

Permissions area. The Access Permission dialog box opens.

5. Click the Add button to open the Select Users, Computers, or Groups

dialog box.

6. Type the new FactoryTalk Batch Server user account name and then

click OK.

7. In the Access Permission dialog box, select the new FactoryTalk Batch

Server account. In the Permissions list, select Allow for Local Access

and Remote Access.

8. Click OK twice.

9. Close Component Services.

10. Restart the computer.

44

Page 45

Index

Index

disable

Material Server Control button 38

domain

security 18

F

A

Archiver

service 41

B

Batch Server

starting 39

switching to manual mode 38

boot

cold 39

warm 39

warm-all 39

C

change

colors 29, 31

fonts 31

list view properties 31

report margins 31

view properties 31

cold boot 39

colors

change 29, 31

COM+ 15

communication

configuring Material Server 11

restoring with Material Server 38

without Material Server 35

configure

formatted reports 32

list reports 32

Network Editor 11

report footings 31

report headings 31

user preferences 28

workgroup server nodes 18

D

Failed Material Server Indicator 36

failure and hold 36

failure and hold errors 36

formatted report 32

L

list report 32

list view properties

change 31

M

manual mode

switching the Batch Server 38

material database

changing names 11

configuring Network Editor 11

Material Server

configuring communication mode 11

configuring split feeds 11

losing communication 35

restoring communication 38

Material Server Control button

disabling 38

MT-B 36

MTBatchServer 17

MT-G 36, 38

MTGeneral 17

MTLotAuthor 17

MTMaterialAuthor 17

MTMaterialViewer 17

MT-S 38

MTUsers 17

N

Network Editor

configuring material database 11

network model

synchronize 27

database

changing names 11

45

orphaned promise ID 36

O

Page 46

Index

P

U

print preview 33

promise ID

orphaned 36

prompt binding, losing communication 36

R

report preferences

set 31

reports

change margins 31

column and row preferences 31

configure footings 31

configure headings 31

S

security

Batch Server 17

domain 18

user accounts 18

user groups 18

role-based 15

roles

MTBatchServer 17

MTGeneral 17

MTLotAuthor 17

MTMaterialAuthor 17

MTMaterialViewer 17

MTUsers 17

user groups

MTBatchServer 17

MTLotAuthor 17

MTMaterialAuthor 17

MTMaterialViewer 17

workgroup 18

set

report preferences 31

user preferences 28

split feed

configuring Material Server 11

starting

Batch Server 39

synchronize 27

User Preference dialog box

change colors 29, 31

change fonts 31

change view properties 31

column and row preferences 31

edit information tips 30

list view properties 31

set 28

V

view properties 31

W

warm boot 39

warm-all boot 39

workgroup

configuring server nodes 18

security 18

T

troubleshoot

failure and hold errors 36

46

Page 47

Rockwell Automation support

Technical Support Center

Find help with how-to videos, FAQs, chat, user forums, and product notification

rok.auto/support

Knowledgebase

Access Knowledgebase articles.

rok.auto/knowledgebase

Local Technical Support Phone Numbers

Literature Library

Find installation instructions, manuals, brochures, and technical data publications.

rok.auto/literature

Product Compatibility and Download Center

Get help determining how products interact, check features and capabilities, and

rok.auto/pcdc

Use these resources to access support information.

updates.

Locate the telephone number for your country. rok.auto/phonesupport

(PCDC)

find associated firmware.

Documentation feedback

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at

rok.auto/docfeedback

.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at rok.auto/pec.