Page 1

Getting Results Guide

Original Instructions

actoryTalk Batch

F

Material Manager

Getting Results Guide

FactoryTalk Batch Components 14

.00

Rockwell Automation Publication BWMTR-GR011E-EN-P - October 2020

Supersedes Publication BWMTR-GR011D-EN-P - February 2017

Page 2

FactoryTalk Batch Material Manager

personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

temperatures.

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

2

Page 3

Table of Contents

Preface

Introducing Material Manager

Introducing the Material Editor

About this manual ....................................................................................... 7

Legal Notices ............................................................................................... 7

Additional resources ................................................................................... 8

Chapter 1

What is Material Manager? ....................................................................... 11

FactoryTalk Batch Components ............................................................... 12

FactoryTalk Batch Server ..................................................................... 12

FactoryTalk Batch Recipe Editor ......................................................... 13

FactoryTalk Batch Equipment Editor ................................................. 14

FactoryTalk Event Archiver ................................................................. 14

FactoryTalk Batch Network Editor ..................................................... 15

FactoryTalk eProcedure Client ............................................................ 15

FactoryTalk eProcedure Server ........................................................... 15

FactoryTalk Batch Material Manager ................................................. 15

FactoryTalk Batch View ....................................................................... 16

Material data ............................................................................................... 17

Introduction to the Material Server ........................................................... 17

Looking at the Material Server .................................................................. 17

Set up the sample demonstrations ........................................................... 19

Configure the Network Editor ............................................................ 19

Add sample FactoryTalk Security users ............................................. 20

Configure sample permissions for FactoryTalk Security users ...... 22

Configure the sample FactoryTalk Batch Server .............................. 24

Rebuild the recipe directory ............................................................... 27

Start the FactoryTalk Batch and Material Manager Servers .................. 27

Start the sample FactoryTalk Batch Phase Simulator ............................ 29

Verify PCD communications .................................................................... 30

Summary .................................................................................................... 30

Chapter 2

Start the Material Editor ........................................................................... 31

Adding material states ...............................................................................32

Adding material types ................................................................................ 34

Adding a material class .............................................................................. 35

Adding a material ....................................................................................... 37

Adding containers ..................................................................................... 38

Associating materials with containers .................................................... 40

Creating lots................................................................................................ 41

Distributing lots to containers ................................................................. 42

3

Page 4

Table of Contents

Introducing material-enabled

phases

Introducing material-based

Running material-based recipes

Using custom code insertion

recipes

Exiting the Material Editor ........................................................................ 43

Summary ..................................................................................................... 43

Chapter 3

Open the area model .................................................................................. 45

Naming the area ....................................................................................... 46

Viewing enumeration sets ....................................................................... 46

Creating material-enabled phases ............................................................ 47

Adding material-enabled phase parameters ..................................... 50

Adding material-enabled phase report parameters ......................... 52

Defining equipment modules ............................................................ 52

Restart the FactoryTalk Batch server ........................................................ 53

Setting material container priorities ........................................................ 54

Programming a material-enabled phase .................................................. 54

Summary ..................................................................................................... 55

Chapter 4

Create a material-based operation ........................................................... 57

Creating recipe formula parameters ........................................................ 59

Assigning formula values .......................................................................... 59

Creating a unit procedure ......................................................................... 61

Enabling dynamic unit allocation ............................................................ 62

Create a procedure .................................................................................... 62

Linking phase groups ................................................................................ 68

Verifying the recipe ................................................................................... 69

Summary .................................................................................................... 70

points

4

Chapter 5

Run in simulation mode ............................................................................ 71

Running a material-based recipe ............................................................. 71

Checking inventory levels .......................................................................... 73

Using manual phase control ...................................................................... 74

Binding a material-enabled phase manually ........................................... 75

Handling split feeds ................................................................................... 76

Summary ..................................................................................................... 77

Chapter 6

When would I customize an insertion point? ......................................... 79

What library can be customized? .............................................................. 79

Creating a custom ramscustom.dll ......................................................... 80

Material manager insertion points ........................................................... 81

Page 5

Developing an implementation

plan

Binding material-based recipes

Index

Table of Contents

OnGenerateCustomLotName ................................................................... 81

OnGenerateCustomLabelName ............................................................... 82

AfterSubLotInsert ..................................................................................... 83

AfterSubLotDelete ..................................................................................... 84

AfterLotInsert ............................................................................................ 85

AfterCombinedLotInsert .......................................................................... 86

Chapter 7

Determining the system requirements ................................................... 87

Configuration requirements .............................................................. 87

Hardware and operating systems requirements .............................. 87

Security requirements ........................................................................ 88

Questions to ask about system requirements ......................................... 88

Questions to ask about the material database ........................................ 88

Questions to ask about equipment data .................................................. 89

Questions to ask about master recipe data ............................................. 89

Appendix A

Unit binding .............................................................................................. 92

Static binding ...................................................................................... 92

Creation binding ................................................................................. 92

Dynamic unit allocation ...................................................................... 93

Manual binding ................................................................................... 94

Material requirements ........................................................................ 94

Material requirements: material .................................................. 95

Material requirements: material and lot ..................................... 96

Container type ................................................................................ 97

Distributions ................................................................................. 98

Recipe phase binding ................................................................................ 99

Container binding type .................................................................... 100

Feed type ............................................................................................. 101

Automatic container binding process .............................................. 101

Summary ................................................................................................... 103

5

Page 6

Page 7

About this manual

Legal Notices

Preface

This manual introduces the basics of FactoryTalk Batch Material Manager. It

is one of a set of related manuals that describe installing, programming, and

operating the FactoryTalk Batch system.

To review FactoryTalk Batch release notes and latest information regarding

product compatibility refer to the

Center (PCDC).

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End User License Agreement (EULA)

by opening the license.rtf file located in your product's install folder on your

hard drive.

Product Compatibility and Download

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\license.rtf

Open Source Software Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses.

You can view a full list of all open source software used in this product and

their corresponding licenses by opening the oss_license.txt file located your

product's OPENSOURCE folder on your hard drive. This file is divided into

these sections:

• Components

Includes the name of the open source component, its version number,

and the type of license.

• Copyright Text

Includes the name of the open source component, its version number,

and the copyright declaration.

• Licenses

Includes the name of the license, the list of open source components

citing the license, and the terms of the license.

7

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\Help\<product

name>\Release Notes\OPENSOURCE\oss_licenses.txt

Page 8

Preface

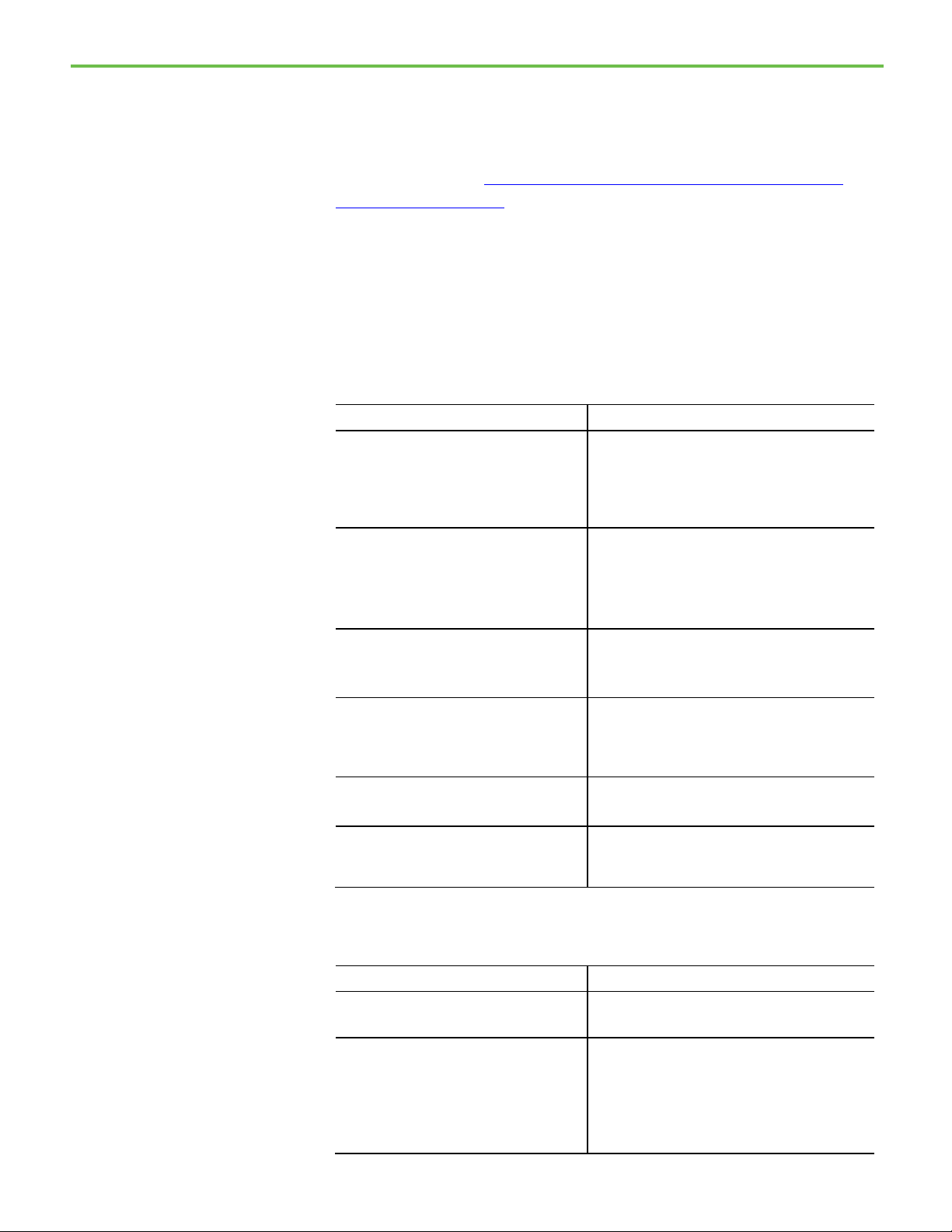

Resource

Description

Resource

Description

reference for the formulator.

Additional resources

You may obtain Corresponding Source code for open source packages

included in this product from their respective project web site(s).

Alternatively, you may obtain complete Corresponding Source code by

contacting Rockwell Automation via the Contact form on the Rockwell

Automation website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page. Please include "Open Source" as part of the request

text.

Following is a comprehensive list of documentation for the FactoryTalk®

Batch products from Rockwell Automation.

Installation, Quick Start, and Getting Results Guides

FactoryTalk Batch Components Installation and

Upgrade Guide

(BATCH-IN002)

FactoryTalk Batch View Quick Start Guide

(FTBVS-QS001)

FactoryTalk Batch View HMI Controls Quick Start

Guide

(BATCH-QS001D)

FactoryTalk Batch eProcedure® Getting Results

Guide

(BWEPRO-GR011)

FactoryTalk Batch Getting Results Guide

(BATCH-GR011)

FactoryTalk Batch Material Manager Getting

Results Guide

(BWMTR-GR011)

Provides information and procedures for FactoryTalk

Batch system installation. Includes information for

FactoryTalk Batch Material Manager, FactoryTalk Event

Archiver, and associated FactoryTalk Batch Client and

Server components.

Provides information about using FactoryTalk Batch View

to create, view, and command control recipes,

acknowledge prompts and signatures, view equipment

phases and diagnostic information, and view profile

information.

Provides a general overview of FactoryTalk Batch View

HMI Controls.

Explains the basics of FactoryTalk Batch eProcedure.

Introduces the basics of automated batch manufacturing

and the FactoryTalk Batch product components.

Introduces the basics of FactoryTalk Batch Material

Manager.

8

User Guides

FactoryTalk Batch ActiveX Controls User Guide

(BATCH-UM013)

FactoryTalk Batch Material Editor User Guide

(BWMTR-UM001)

Provides information and instructions for using the

FactoryTalk Batch ActiveX Custom Controls.

Provides access to information and procedural

instructions required to configure materials and the

containers to hold them. The material data is stored in the

material database, which is used to create materialbased recipes. This information is intended as a

Page 9

Preface

Resource

Description

Recipe Editor, View, and Phase Simulator.

your Logix 5000 controller.

reference information by the operator.

system administrator and production supervisor.

conjunction with a Human-Machine Interface (HMI).

FactoryTalk Batch Equipment Editor User Guide

(BATCH-UM004)

FactoryTalk Batch PhaseManager™ User Guide

(BATCHX-UM011)

FactoryTalk Batch Recipe Editor User Guide

(BATCH-UM006)

FactoryTalk Batch View HMI Controls User Manual

(FTBVS-UM003)

Provides information on creating and maintaining an

equipment database (area model). The area model is

stored in a file with a .cfg file extension and is available

to all other FactoryTalk Batch programs, including the

Describes the integration of the FactoryTalk Batch

software with the Studio 5000 Logix Designer®

application and the Logix 5000™ family of controllers.

The integration simplifies the configuration and

maintenance of the FactoryTalk Batch automation

system, provides better communication between the

FactoryTalk Batch Server and the Logix 5000 controller,

and significantly reduces the programming effort

required to develop the phase logic code that resides in

Provides instructions on using FactoryTalk Batch Recipe

Editor to create and configure master recipes for use in

batch automation. The interface is based on IEC 61131-3

sequential function charts to graphically organize recipes

into procedures, unit procedures, operations, and phases.

Build recipes using either the SFC format or a table-based

format.

Provides details about using FactoryTalk Batch View HMI

Controls to monitor and interact with the production

process within a FactoryTalk View SE Display Client.

FactoryTalk Batch View User Manual

(FTBVS-UM002)

FactoryTalk eProcedure Client User Guide

(BWEPRO-UM001)

FactoryTalk Event Archiver User Guide (BATCHUM012)

FactoryTalk Batch View User Guide (legacy)

(FTBVS-UM001)

Provides information and procedural instructions for

using FactoryTalk Batch View in a modern and intuitive

portal into a comprehensive batching solution for

effective operations, leveraging its own web server using

HTML5 technology to provide native connectivity into a

FactoryTalk Batch Server.

Provides information and procedural instructions

required to create and command batches using the

FactoryTalk eProcedure Client, and can be used as a

Provides information and instructions specific to the

FactoryTalk Event Archiver. Intended for use by the

Provides information and instructions on how to use

FactoryTalk Batch View to initiate and execute

FactoryTalk Batch automation processing. FactoryTalk

Batch View secured objects are located in the FactoryTalk

Diagnostics and are modified using the FactoryTalk

Administration Console. A system administrator can

customize FactoryTalk Batch View security to meet the

needs of the facility. FactoryTalk Batch View is used in

9

Page 10

Preface

Resource

Description

(BWEPRO-UM011)

Resource

Description

(BATCH-RM001)

(BATCH-RM004)

engineers and the system administrator.

reference by the instruction file author.

Administrator Guides

FactoryTalk Batch Administrator Guide

(BATCH-UM003)

FactoryTalk Batch eProcedure Administrator Guide

(BWEPRO-UM011)

FactoryTalk Batch Material Manager Administrator

Guide

Reference Guides

FactoryTalk Batch ActiveX Controls Library

Reference Guide

FactoryTalk Batch Material Server API Technical

Reference

(BWMTR-RM001)

FactoryTalk Batch PCD Programming Reference

Manual

FactoryTalk Batch Server API Reference Manual

(BATCH-RM003)

Provides instructions for configuring security and

services, and implementation and use of components not

typically accessed or used by batch operators, such as

the FactoryTalk Batch Server.

Provides procedures specific to FactoryTalk Batch

eProcedure, such as implementing security and

configuring the user-defined area Active Server Page.

Included are instructions for tasks specific to FactoryTalk

Batch, such as configuring security and services to

support FactoryTalk Batch eProcedure. Provides

instructions on the implementation and use of

components not typically accessed or used by batch

operators, such as the FactoryTalk Batch Server.

Provides information and instructions specific to

FactoryTalk Batch Material Manager. Intended for use by

the system administrator and database administrator.

Provides reference information and procedural

instructions for the FactoryTalk Batch ActiveX Custom

Controls.

Provides access to information regarding the interface

between the FactoryTalk Batch Material Server and the

FactoryTalk Batch Material Editor and FactoryTalk Batch.

It is intended to be used as a reference information by

those who want to develop custom interfaces.

Provides information and instructions about the

FactoryTalk Batch PCD interface design. It is intended to

be used as a reference guide.

Provides information regarding the interface between the

FactoryTalk Batch Server and FactoryTalk Batch View —

the Server Application Programming Interface (API). It is

intended to be used as a reference guide by those who

want to develop custom interfaces.

10

FactoryTalk Batch System Files Reference Manual

(BATCH-RM005)

FactoryTalk Batch eProcedure Instruction File

Design Reference Manual

(BWEPRO-RM001)

Provides the technical information for configuration and

maintenance of a FactoryTalk Batch system. It can be

used as a reference information for implementation

Includes information about the building of instruction

files for use in equipment database creation and recipe

development. This information is intended to be used as a

View or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

sales representative.

Page 11

What is Material Manager?

Chapter 1

Introducing Material Manager

FactoryTalk® Batch Material Manager is an integral part of the FactoryTalk

Batch suite of software components. As part of the FactoryTalk family, the

FactoryTalk Batch components increase overall plant efficiency by delivering

the visibility, control, and reporting you need to optimize manufacturing.

With coordinated execution, you can reduce scrap and rework and improve

product quality and consistency. Through real-time management of

equipment utilization, you can maximize your return on assets. By

implementing optimized recipes and procedures, you can increase your plant

capacity. By using electronic, paperless operations, you can improve your

productivity. You also reduce compliance costs by using electronic batch

record implementation, paperless manufacturing, and quality sign-offs. By

lifting the compliance burden from manufacturing, you reduce inventory

levels and cycle times, which greatly improves customer service.

The FactoryTalk Batch components ensure that plant floor operations are

optimized, giving you quick return on your net assets. New product

definitions are deployed quickly into manufacturing. Production order

information is accurate. Business and plant-level control systems are tightly

coordinated and multiple sites operate as a team. Our completely open,

configurable set of products helps you define, manage, monitor, and control

manufacturing at local, remote, or contractor plants. Best of all, you can

deploy any of the FactoryTalk Batch components wherever you need them —

one at a time or all at once — to improve productivity and plant control.

The FactoryTalk Batch components include:

• FactoryTalk Batch

• FactoryTalk eProcedure®

• FactoryTalk Batch Material Manager

As one of the FactoryTalk Batch components, Material Manager provides

plant-level material management and tracking that is tied to corporate

material management systems. Material Manager manages and tracks the use

of materials by material type, lot, and sublot. It manages and tracks vessels,

containers and pallets, as well as permanent and transient storage. It also

provides automatic support for bulk containers with multiple lots either as

composites or plug flow separated.

11

Material Manager adds material definitions to the recipes, significantly

reducing the number of recipes needed for flexible storage facilities. Material

consumption, production, and association of materials to containers and

Page 12

Chapter 1 Introducing Material Manager

FactoryTalk Batch

FactoryTalk Batch Server

vessels are automatically logged, providing complete information for forward

and backward material tracking within and across process cells.

The material recipes, called material-based recipes, allow you to define recipes

in terms of materials used, not just by plant equipment. A material-based

recipe uses material-enabled phases, which are configured in the Equipment

Editor and stored in the area model. Material-enabled phases support the

specification of a material as a means to find appropriate equipment and bind

to that equipment in a control recipe.

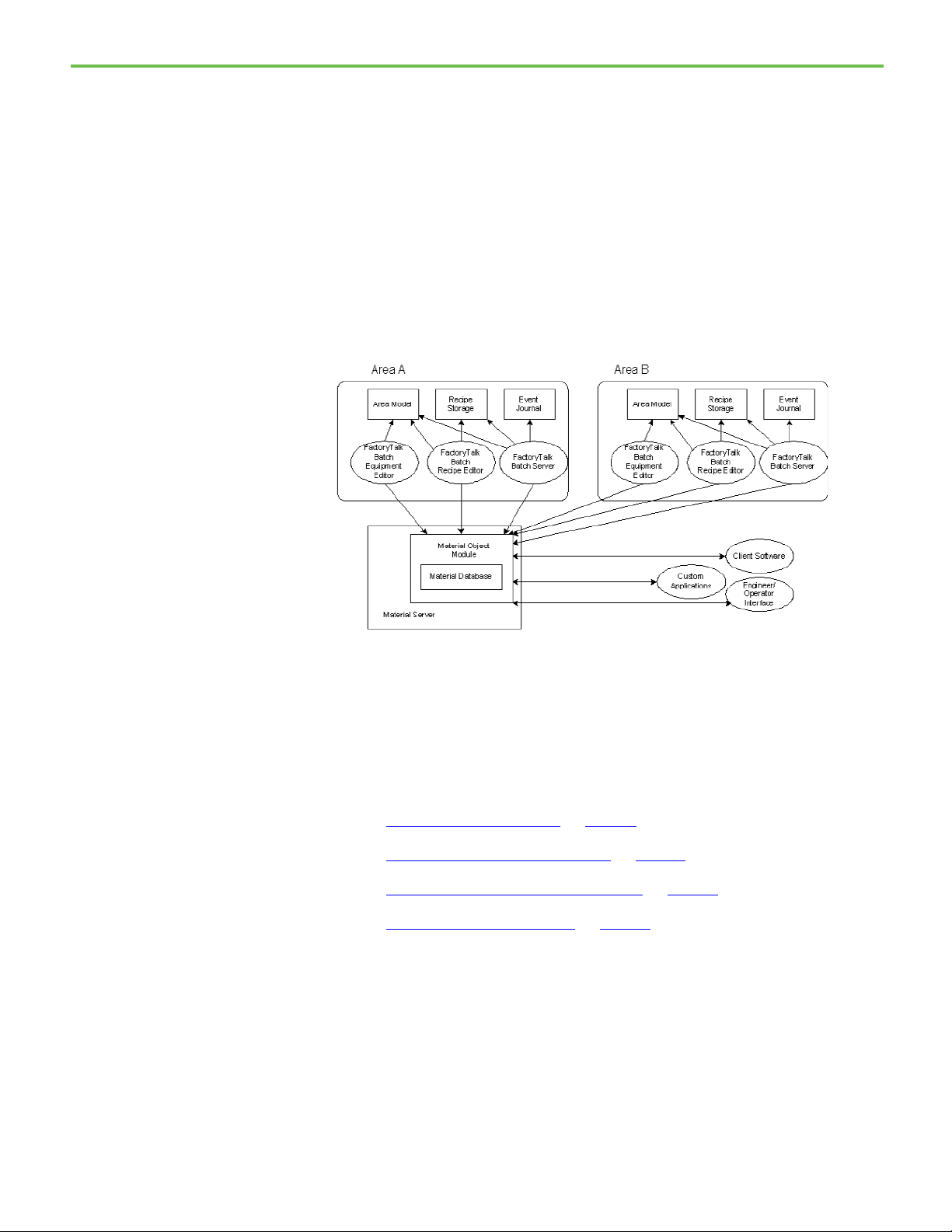

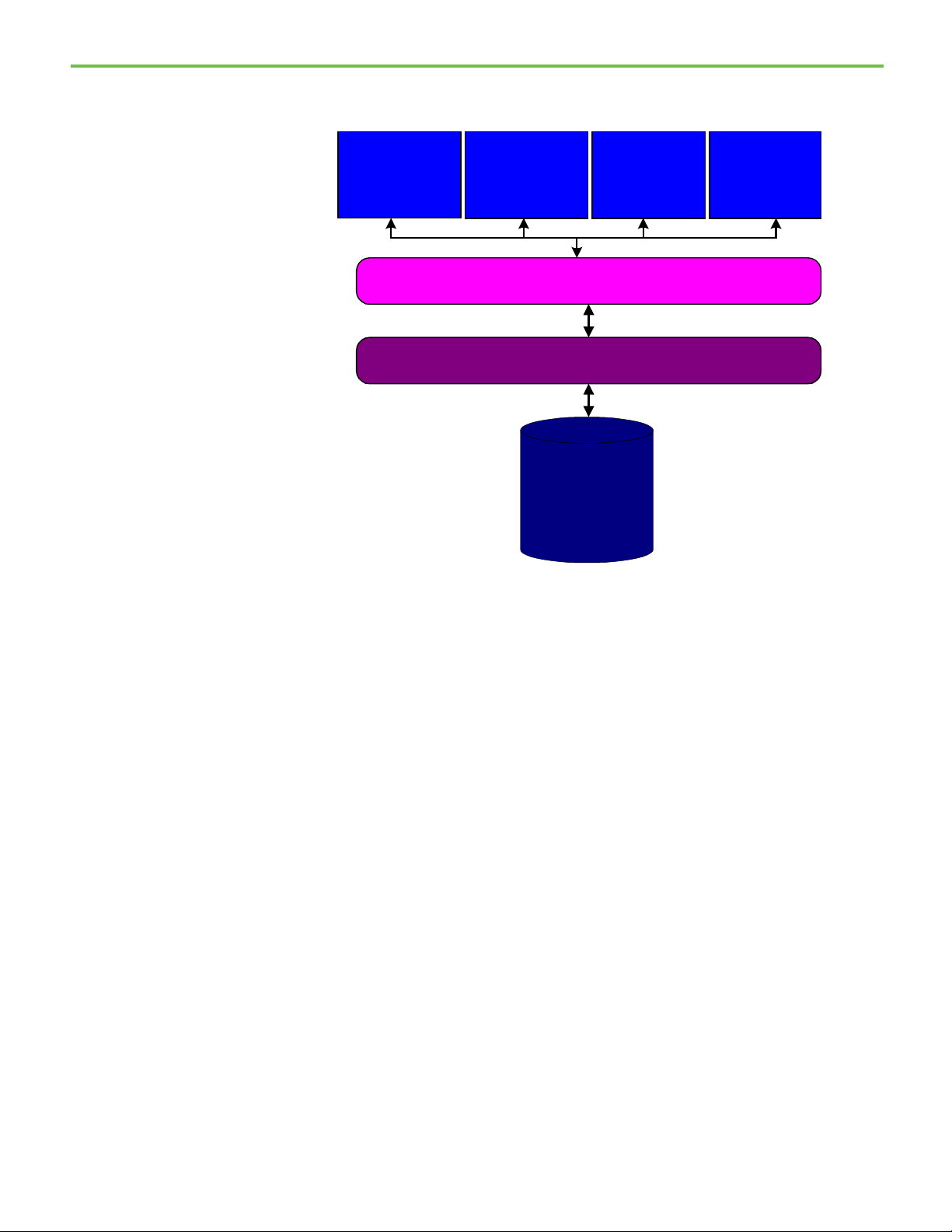

The following figure is a conceptual diagram of the elements of the materialbased recipe function and illustrates the relationships among the functional

components.

Components

FactoryTalk Batch comes with several components that interact with each

other to design, create, configure and run batch recipes.

See also

FactoryTalk Batch Server on page 12

FactoryTalk Batch Recipe Editor on page 13

FactoryTalk Batch Equipment Editor on page 14

FactoryTalk Event Archiver on page 14

The FactoryTalk Batch Server is the engine that runs FactoryTalk Batch. It is

the component that controls system information, phases and recipes. The

server allows integration with process-connected devices (PCDs) and thirdparty software packages. Prior to opening FactoryTalk Batch View, the

FactoryTalk Batch Server must be running and remain active during all batch

functions.

12

Page 13

Chapter 1 Introducing Material Manager

The FactoryTalk Batch Server operates as a Windows service, which means

that the FactoryTalk Batch Server can be configured to start automatically and

that control of the FactoryTalk Batch Server can be given to the Windows

Service Manager. Because the FactoryTalk Batch Server runs as a service, it

does not require an operator to log on to run. Therefore, logging on or off

Windows during operation does not disrupt the performance of the

FactoryTalk Batch Server.

See also

FactoryTalk Batch Components on page 12

FactoryTalk Batch Recipe Editor

The FactoryTalk Batch Recipe Editor is used to graphically create and

configure recipes.

• The interface is based on IEC 61131-3 sequential function charts (SFC)

that graphically organizes recipes into procedures, unit procedures,

operations and phases along with any applicable comments.

• In addition to the SFC view, the FactoryTalk Batch Recipe Editor offers

a table view. Table-based recipes provide a mechanism for creating

simple recipes that do not require a complex recipe structure or

elaborate transition expressions. Additionally, you can view tablebased recipes and edit all recipe parameters without having to navigate

between steps.

• The FactoryTalk Batch Recipe Editor allows you to specify sequences of

phases. The actual phase logic must be configured in the processconnected device (PCD) while the interface to the PCD must be

configured in the FactoryTalk Batch Equipment Editor.

• Recipe reports can be generated in SFC and/or descriptive format.

• If Recipe Approvals are enabled in the underlying area model, approval

signoffs are executed in the FactoryTalk Batch Recipe Editor.

• When Recipe Version Control is enabled, a version of a recipe (a read-

only, numbered snapshot of a recipe) can be saved and protected from

further editing. New work-in-progress (WIP) copies of a version allow

the recipe author to continue to make changes and updates to a recipe.

When a versioned recipe no longer matches the underlying area

model, or references a deleted or non-existent sub-recipe, it is marked

as obsolete.

See also

FactoryTalk Batch Components on page 12

13

Page 14

Chapter 1 Introducing Material Manager

FactoryTalk Batch

FactoryTalk Event Archiver

Equipment Editor

The FactoryTalk Batch Equipment Editor is a graphical interface through

which a database of process equipment is defined and maintained (an area

model).

• Components defined in the FactoryTalk Batch Equipment Editor are

used to interface with process-connected devices (PCDs) in the facility.

During recipe configuration, the area model provides a list of available

units and phase classes.

• Configure phases and commands to trigger an electronic signature

request when a report or recipe parameter is out of range (parameter

deviation), or when specific commands are executed on a batch (such

as Abort Batch or Active Step Change).

• During recipe verification, the area model confirms that the

designated equipment is capable of executing the procedures.

• During recipe execution, resource arbitration functions use the area

model to allocate equipment based on recipe and operator requests.

• The area model is available to all other FactoryTalk Batch applications.

In addition to the area model, the FactoryTalk Batch Equipment Editor allows

configuration of the following:

• Communication functions

• Electronic signatures

• Enumeration sets

• Data servers

• Recipe approvals

• Recipe version control

• FactoryTalk Event Archiver functions

See also

FactoryTalk Batch Components on page 12

The FactoryTalk Event Archiver’s purpose is to translate the FactoryTalk Batch

tab-delimited ASCII electronic batch record files to a user-specified file type.

These electronic batch record files are maintained separately for each batch

created and viewed with a word processor or spreadsheet. Many plants have

standardized on one of the many commercially available Relational Database

Management System (RDBMS) software packages. We recommend using a

high-performance database, such as SQL Server, due to their better

robustness and performance. The Archiver collects data from each electronic

batch record file and stores it in the specified RDBMS database format.

14

See also

FactoryTalk Batch Components on page 12

Page 15

FactoryTalk Batch Network

Editor

FactoryTalk eProcedure

FactoryTalk Batch Material

Chapter 1 Introducing Material Manager

The FactoryTalk Batch Network Editor is a utility that indicates where other

FactoryTalk Batch and FactoryTalk Batch Material servers are located on the

network. This network configuration allows for ease of integration with other

FactoryTalk Batch components and simplifies the process of reconfiguring a

multi-computer system. If FactoryTalk Batch Material Manager is also

installed the FactoryTalk Batch Network Editor is also used to indicate the

location of the material database.

See also

FactoryTalk Batch Components on page 12

FactoryTalk eProcedure Client

Server

Manager

The FactoryTalk eProcedure Client computer uses Internet Explorer to enable

operators to run batch recipes.

See also

FactoryTalk Batch Components on page 12

The FactoryTalk eProcedure Server provides the services to the FactoryTalk

Batch Server to enable the use of HTML instruction files. Prior to opening

FactoryTalk eProcedure Client, FactoryTalk eProcedure Server must be

running and remain active during all batch functions.

See also

FactoryTalk Batch Components on page 12

FactoryTalk Batch Material Manager is used to track material consumption in

batch recipes. It consists of two components: Material Server and Material

Editor.

15

The Material Editor provides an interface to help you create the material

database, which consists of material, lot, sublot, container, and storage

location data. The Material Server provides the communication between the

material database and the FactoryTalk Batch Server. During a batch run,

information about available containers is presented to the operator for

binding decisions. Binding is the process of mapping steps within a control

recipe to actual equipment in a plant. After a batch is run, quantities

consumed or distributed are updated in the material database for use in

inventory tracking.

Page 16

Chapter 1 Introducing Material Manager

The Material Server consists of a group of components that work together to

service various applications. The primary applications that the Material Server

services are the Material Editor, FactoryTalk Batch Server, FactoryTalk Batch

Recipe Editor, and FactoryTalk Batch Equipment Editor. Any third-party

application can also use custom solutions based on the exposed Material

Object Model (MOM).

See also

FactoryTalk Batch Components on page 12

FactoryTalk Batch View

This topic describes FactoryTalk Batch View on a Windows desktop system.

Tip: The modern FactoryTalk Batch View is an innovative and intuitive user interface for your

comprehensive batch solution. It leverages state-of-the-art web technologies with scalable

graphics for consistent visualization across all devices and form factors. The zero-install browser

simplifies administration and maintenance. As the only native client application that supports the

new features in FactoryTalk Batch and eProcedure, it is the client of the future for modern batch

solutions.

For more information about the new FactoryTalk Batch View mobile solution, view the FactoryTalk

Batch View User Manual (FTBVS-UM002).

FactoryTalk Batch View is the batch recipe initiation and execution program

used by the operator of the FactoryTalk Batch Automation Solution system to:

• Initiate and control the batch process

• Display a graphical representation of a running batch and its

associated data

Typically, FactoryTalk Batch View is intended to be used in conjunction with

an HMI.

Each FactoryTalk Batch View window can be customized to suit the needs of a

specific station:

• Specify the columns to display

• Specify the size of columns and rows

• Sort and filter on one field in certain windows

• Set the font for each FactoryTalk Batch View window

If the security is enabled for FactoryTalk Batch View, a system administrator

can use the password protection option to:

• Limit the information that is displayed

• Specify the commands that are allowed at a particular station

Using FactoryTalk Batch View, an operator can respond to electronic

signature requests that have been generated by report and recipe parameter

deviations or by a command execute request.

16

Page 17

you follow the directions for using this demonstration step by step.

Material data

Introduction to the Material

Chapter 1 Introducing Material Manager

To implement material-based recipes, you must configure three types of data:

• Material Data

Use the Material Editor to add the materials, lots, sublots, and the

containers that hold them. This data is stored in the material database.

• Equipment Data

Use the FactoryTalk Batch Equipment Editor to create materialenabled phases and then associate the resultant equipment module

with a container.

• Recipe Data

Use the FactoryTalk Batch Recipe Editor to define the materials and

amounts to use in a recipe.

There are two stages to configuring material data. First is the initial system

configuration which is the process of adding elements, such as material types,

materials, material storage containers, and storage locations that are unique

to the given installation. Once these initial elements are defined, configured,

and tested, the process of initial system configuration is considered complete.

The second stage is the on-going system upkeep, which is the process of dayto-day activities that keep the material-based recipe system current and

operational. An example of the upkeep process is the addition or distribution

of a new lot of a given material to the database.

Server

Looking at the Material Server

For ease of understanding, and for tutorial purposes, this guide refers to

configuring and using the sample files that are installed with FactoryTalk®

Batch. The SampleDemo folders contain complete area models and recipes

for a simulated plant. Before running the demonstrations:

• Configure the Network Editor to recognize the material database

• Add a FactoryTalk Security user

• Configure the FactoryTalk Batch Server to recognize the required

project directories

• Select the initialization path and file name

• Start the FactoryTalk Batch Server and the FactoryTalk Batch Phase

Simulator

Tip: This guide outlines the configuration and use of the SampleDemo2 demonstration files.

Because these files are used as an example throughout the guide, it is recommended that

The FactoryTalk Batch Material Server is a group of components that work

together to service various client applications. The primary clients that the

Material Server services are the Material Editor, FactoryTalk Batch Server,

Storage Container ActiveX control, FactoryTalk Batch Recipe Editor, and

FactoryTalk Batch Equipment Editor. Also, any third-party application can use

custom solutions based on the exposed Material Object Model (MOM). The

17

Page 18

Chapter 1 Introducing Material Manager

r

Material Client

(Client Interface)

Material Server

(Server Interface)

Material

Database

(SQL Server)

FactoryTalk Batch

Material Editor

FactoryTalk Batch

Recipe Editor &

Equipment Editor

FactoryTalk

Batch Server

Third-Party

Solutions

Material Server also interacts with SQL Server to read to and write from the

material database.

The Material Server runs with the context of a COM+ component, which is an

extension to the Component Object Model (COM). This component resides on

the client workstations and provides a rich programming model. See the

FactoryTalk Batch Material Server API Technical Reference for more information

about the material object model.

The Material Server coordinates the following functions:

Material Server Communications

• Records actions to the material database that occur during

configuration and run-time in the Activity Journal.

• Loads the material and container lists from the material database to

the Batch Server at startup for population of the area model material

and container enumeration sets.

• Loads the equipment module/container associations from the area

model into the material database.

• Communicates with the FactoryTalk Batch Server during binding.

• During Unit Binding, the FactoryTalk Batch Server communicates

with the Material Server to determine if the required materials can be

satisfied by the containers within a unit.

• During Phase Binding, the FactoryTalk Batch Server communicates

with the Material Server to get a list of containers and equipment

modules based on the material to add or distribute in the step. In

Prompted Phase Binding, the Operator selects the binding solution

18

Page 19

IMPORTANT

IMPORTANT

Chapter 1 Introducing Material Manager

from a list of container-equipment pairs. In Automatic Phase Binding,

phases are selected based on current container priority.

• In Manual Phase Binding, the FactoryTalk Batch Server communicates

with the Material Server to obtain a list of containers, lots and

equipment modules that support the required material. The list is

presented to the operator for selection of the equipment module to

bind to the material step.

• Updates the material database with actual amounts consumed or

distributed during a batch run. During an addition or distribution,

when the Feed Complete is true, the FactoryTalk Batch Server

communicates the actual amount to the Material Server. When the

Feed Complete is not true, the FactoryTalk Batch Server communicates

the actual amount to the Material Server, which in turn calculates the

difference between the promise amount and the actual amount and

sends this back to the FactoryTalk Batch Server. The FactoryTalk Batch

Server uses this difference to update the setpoint for the split feed.

This guide also describes the different binding methods and how to handle

split feeds.

Set up the sample demonstrations

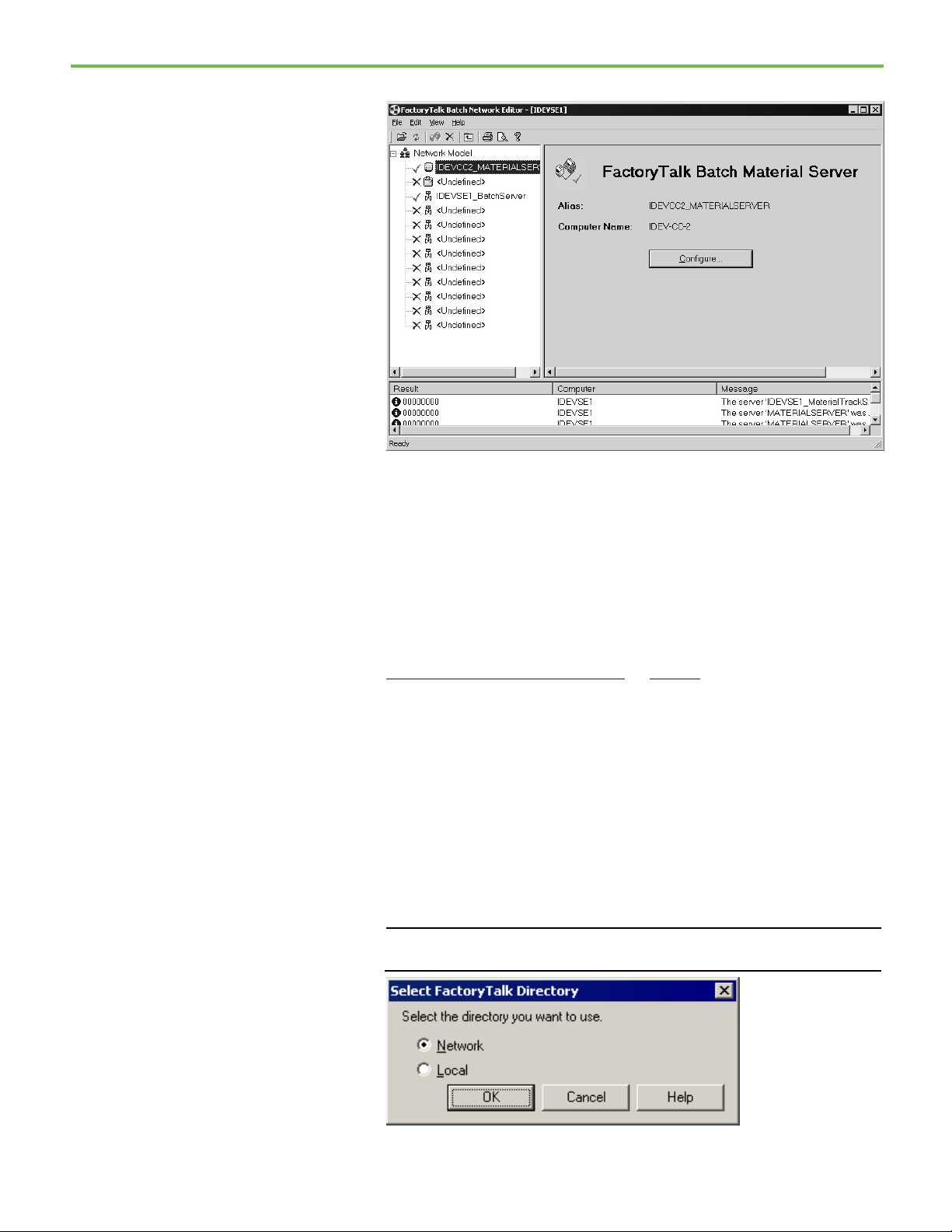

Configure the Network Editor

The installation process placed the SampleDemo1 and SampleDemo2 folders in

the BATCHCTL share on your hard drive. Within each of these SampleDemo

folders are four subfolders that contain the files for the area model. To run the

sample demonstrations, configure the Network Editor to locate the material

database, add a FactoryTalk Security user, configure the FactoryTalk Batch

Server to locate the area model, and then verify the recipes in the area model.

The default databases MaterialBasedRecipe and SAMPLE2_Materials cannot be

removed from SQL Server. You are free to add another database and use it for

production or test, but you must keep the originally installed databases intact even

though they are not being used.

Configure the Material Server with the location of the SQL database that

contains the materials for the SampleDemo2 recipes.

1. Select Start > Rockwell Software > Material Manager, and then select

Network Editor. The Network Editor window opens.

Administrator privileges are required to perform this procedure.

19

Page 20

Chapter 1 Introducing Material Manager

IMPORTANT

Add sample FactoryTalk

2. Select the Material Server.

3. Select Configure. The Configure MaterialTrack dialog box opens.

4. In the MaterialTrack Database box, type SAMPLE2_MATERIALS, and

then select OK.

5. Select Synchronize.

6. Select File > Exit, and then click Yes to exit the Network Editor.

Security users

See also

Set up the sample demonstrations on page 19

For the sample demonstrations file, create FactoryTalk user accounts for an

operator and an engineer. Create these user accounts in the FactoryTalk

Directory.

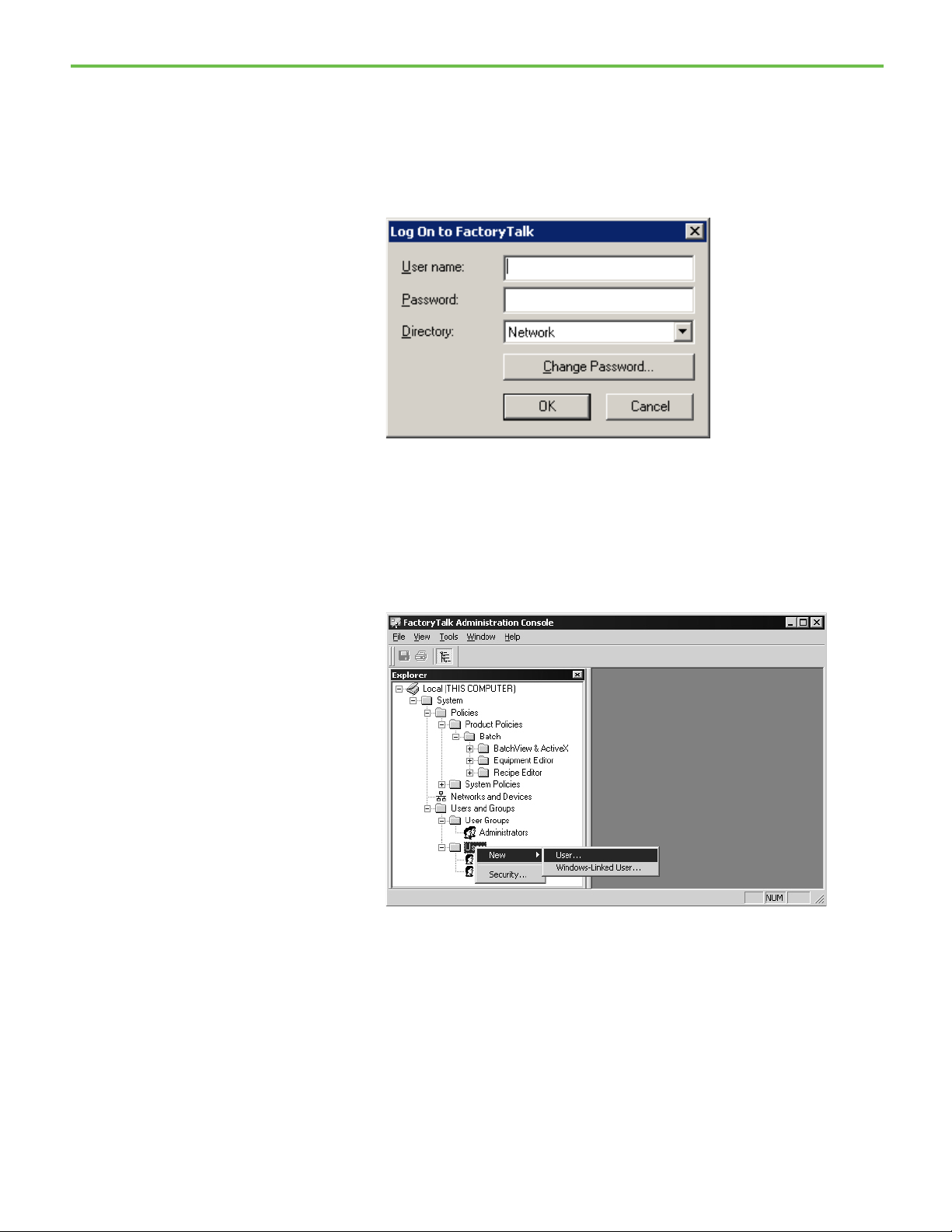

To add sample FactoryTalk Security users:

1. Select Start > Rockwell Software > FactoryTalk Administration

Console. The Select FactoryTalk Directory dialog box opens.

Administrator privileges are required to perform this procedure.

20

Page 21

2. Select Network to add this user account to the FactoryTalk Network

Directory, and select OK.

3. If not already logged on to the FactoryTalk Network Directory, the Log

On to FactoryTalk dialog box opens. In User name, type the user name

for the Administrator that was configured when the FactoryTalk

Services Platform was installed.

4. In Password, type the password for the Administrator.

5. Verify the Directory and select OK. The FactoryTalk Administration

Console window opens and displays the specified FactoryTalk

Directory.

6. Expand Users and Groups.

7. Right-click the Users folder, and select New > User to create a new

FactoryTalk Security user account in FactoryTalk Directory.

Chapter 1 Introducing Material Manager

21

Page 22

Chapter 1 Introducing Material Manager

Configure sample

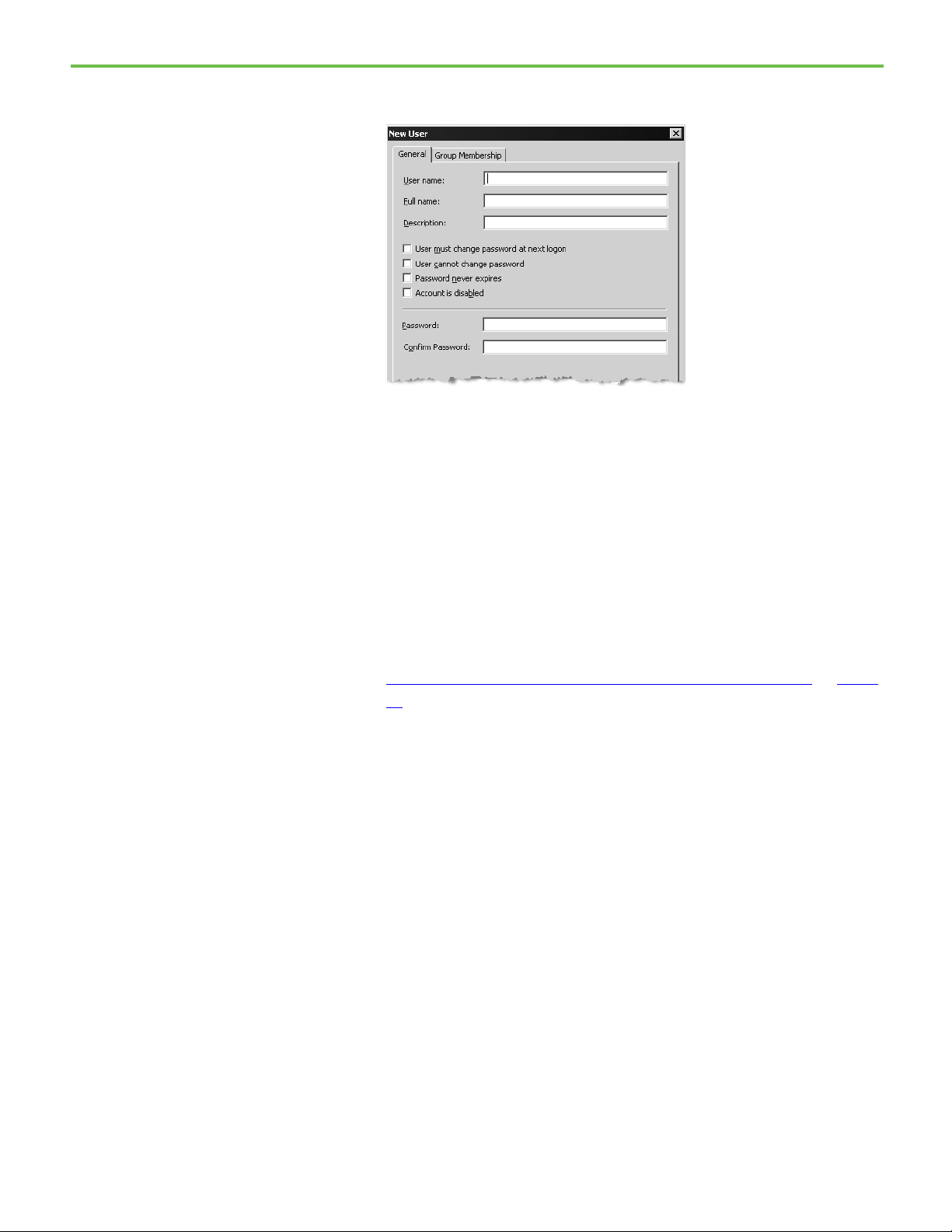

8. The New User dialog box opens and displays the General tab. In the

User name box, type OPER.

9. In Full name, type Operator.

10. In Password, type password, and confirm it by re-entering password

in the Confirm Password box.

11. Select Create.

12. Repeat steps 7-11, but this time in the User Name field, enter ENG and

in the Full Name field, enter Engineer.

13. Keep the FactoryTalk Administration Console open to configure

permissions for these FactoryTalk Security users in the next exercise.

permissions for

FactoryTalk Security users

See also

Configure sample permissions for FactoryTalk Security users on page 22

After creating the FactoryTalk security users, set up access modes for each

FactoryTalk Batch component to specify which users are permitted to view or

perform actions. Configure security settings in the FactoryTalk

Administration Console. To tighten security in the eProcedure Client, remove

the All Users group from the Full Edit policy setting.

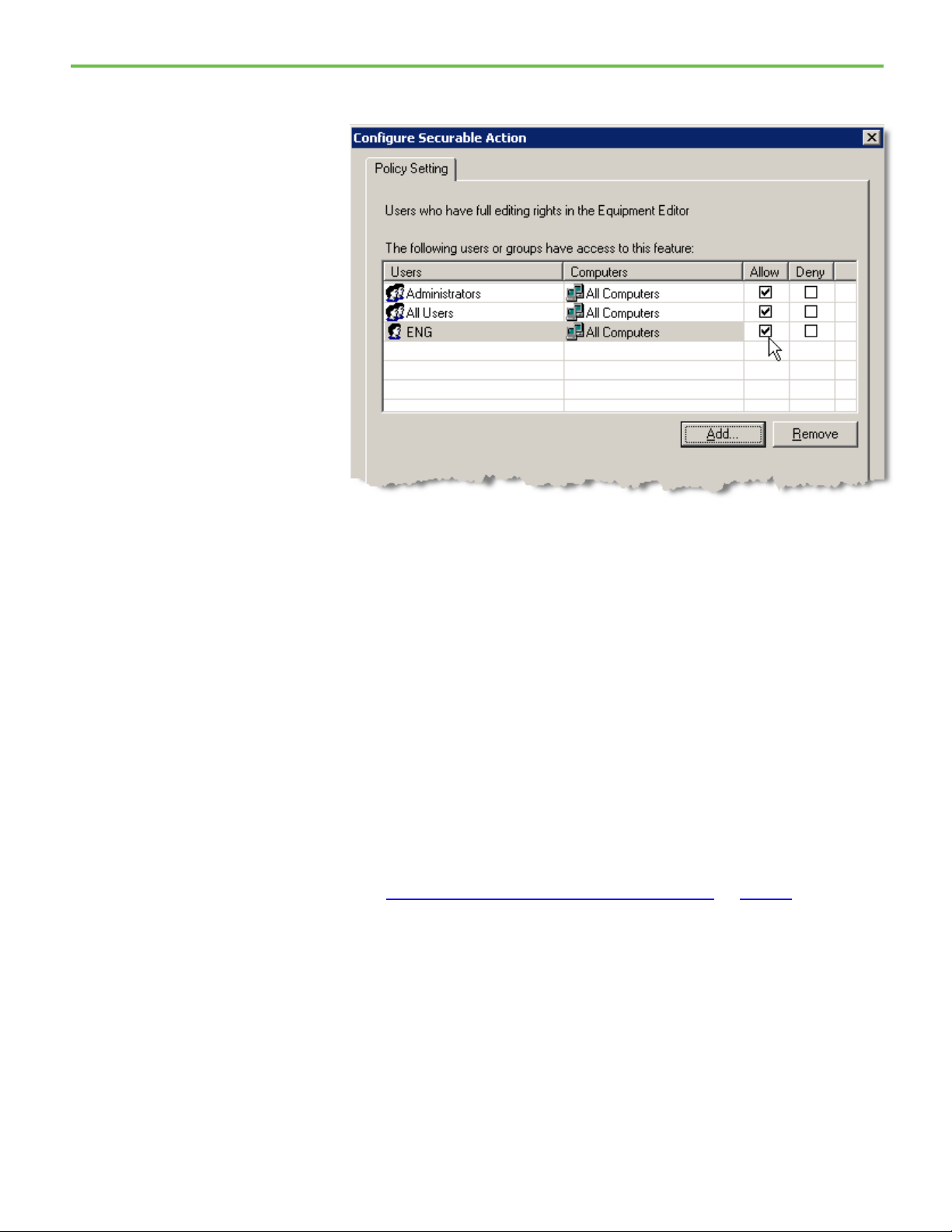

To configure sample permissions for FactoryTalk Security users:

1. In the FactoryTalk Administration Console Explorer pane, navigate to

System > Policies > Product Policies > Batch > Equipment Editor >

Access Modes.

22

Page 23

2. Right-click Access Modes, and then select Properties. The Access

Modes Properties dialog box opens.

Chapter 1 Introducing Material Manager

3. In the Full Edit row, select the Configure Security browse button. The

Configure Securable Action dialog box opens.

4. Select Add. The Select User and Computer dialog box opens.

5. In the Filter Users box, select Show All.

6. In Users, select ENG.

23

Page 24

Chapter 1 Introducing Material Manager

Configure the sample

7. Select OK. The Configure Securable Action dialog box is updated,

showing ENG in the list of Users with the Allow checkbox selected.

8. Select OK to close the Configure Securable Action dialog box.

9. In the Access Modes Properties dialog box, select View Only.

10. In the View Only row, select the Configure Security browse button.

The Configure Securable Action dialog box opens.

11. Select Add. The Select User and Computer dialog box opens.

12. In the Filter Users box, select Show All.

13. In Users, select OPER.

14. Select OK. The Configure Securable Action dialog box is updated,

showing OPER in the list of Users with the Allow checkbox selected.

15. Select OK to close the Configure Securable Action dialog box.

16. Select OK to close the Access Modes Properties dialog box.

FactoryTalk Batch Server

24

See the FactoryTalk Batch Administrator Guide for more information on security.

See also

Configure the sample FactoryTalk Batch Server on page 24

To set up the sample demonstrations, configure the FactoryTalk Batch Server

to locate the folders that contain the demonstration files and to the \Restart

and bin folders where the FactoryTalk Batch Server writes data upon system

failure. Configure the FactoryTalk Batch Server in the FactoryTalk Batch

Equipment Editor.

Page 25

IMPORTANT

IMPORTANT

instructions on defining instruction-based phases.)

Chapter 1 Introducing Material Manager

To configure the sample FactoryTalk Batch Server:

1. Select Start > Rockwell Software > Equipment Editor. The FactoryTalk

Batch Equipment Editor opens (log on to FactoryTalk if prompted).

Administrator privileges are required to perform this procedure.

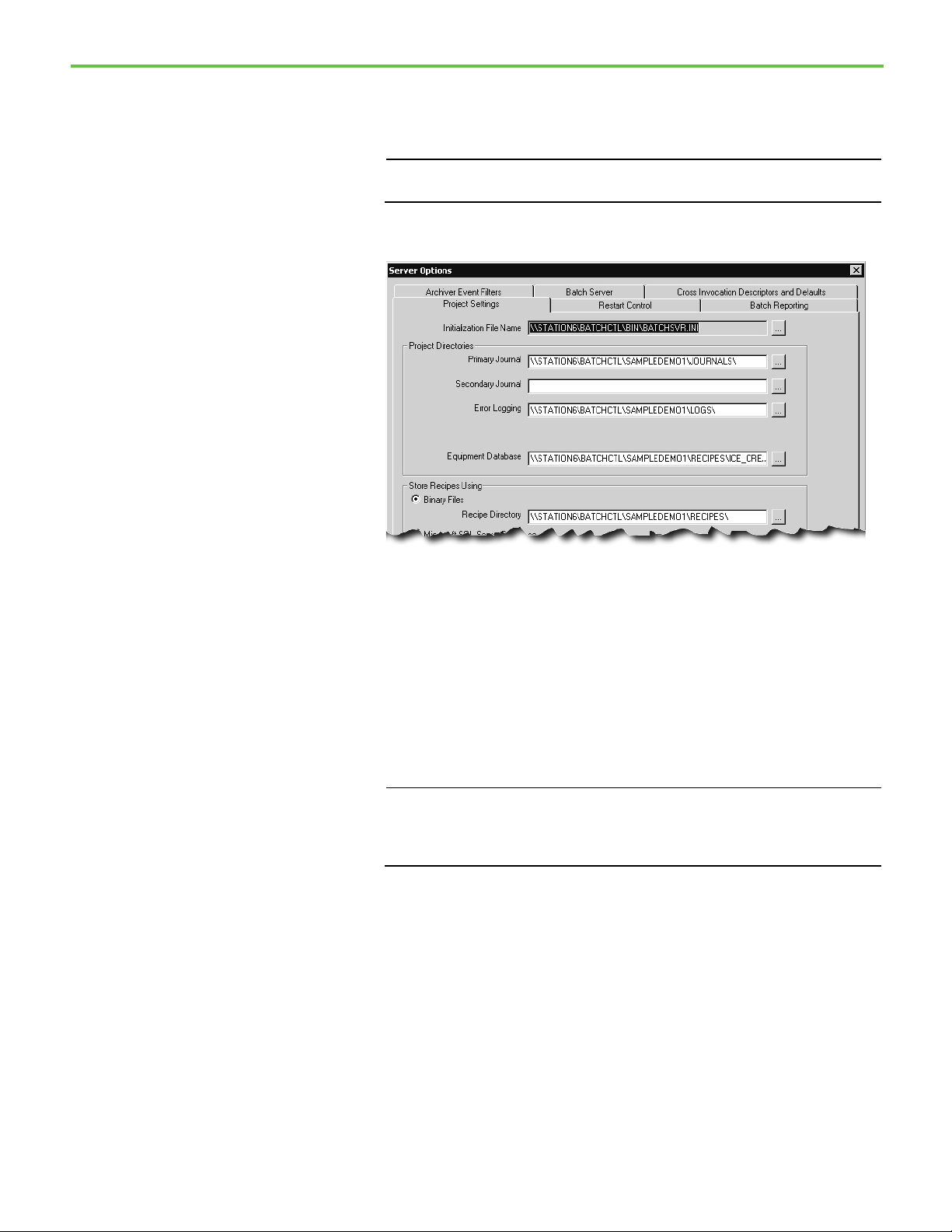

2. Select Options > Server Options. The Server Options dialog box opens

to the Project Settings tab.

3. In the Project Directories area, select the Primary Journal browse

button. The Select Directory dialog box opens.

4. From the Look in list, select the SampleDemo1\Journals folder, and

then select Open.

5. Select the Error Logging browse button. The Select Directory dialog

box opens.

6. From the Look in list, select the SampleDemo1\Logs folder, and then

select Open.

7. Click the Instructions browse button. The Select Directory dialog box

opens.

In order for the eProcedure Server to start, you must define the instruction

path and an instruction file for each instruction-based phase in the area

model. (See the FactoryTalk Batch Equipment Editor User Guide for

8. Select the Equipment Database browse button. The Select Equipment

Database dialog box opens.

9. From the Look in list, open the SampleDemo1\ Recipes folder, select

the ice_cream1.cfg file, and then select Open.

10. In the Store Recipes Using area, select Binary Files, and then select the

Recipe Directory browse button. The Select Directory dialog box

opens.

11. From the Look in list, select the SampleDemo1\Recipes folder, and

then select Open.

25

Page 26

Chapter 1 Introducing Material Manager

Options dialog box.)

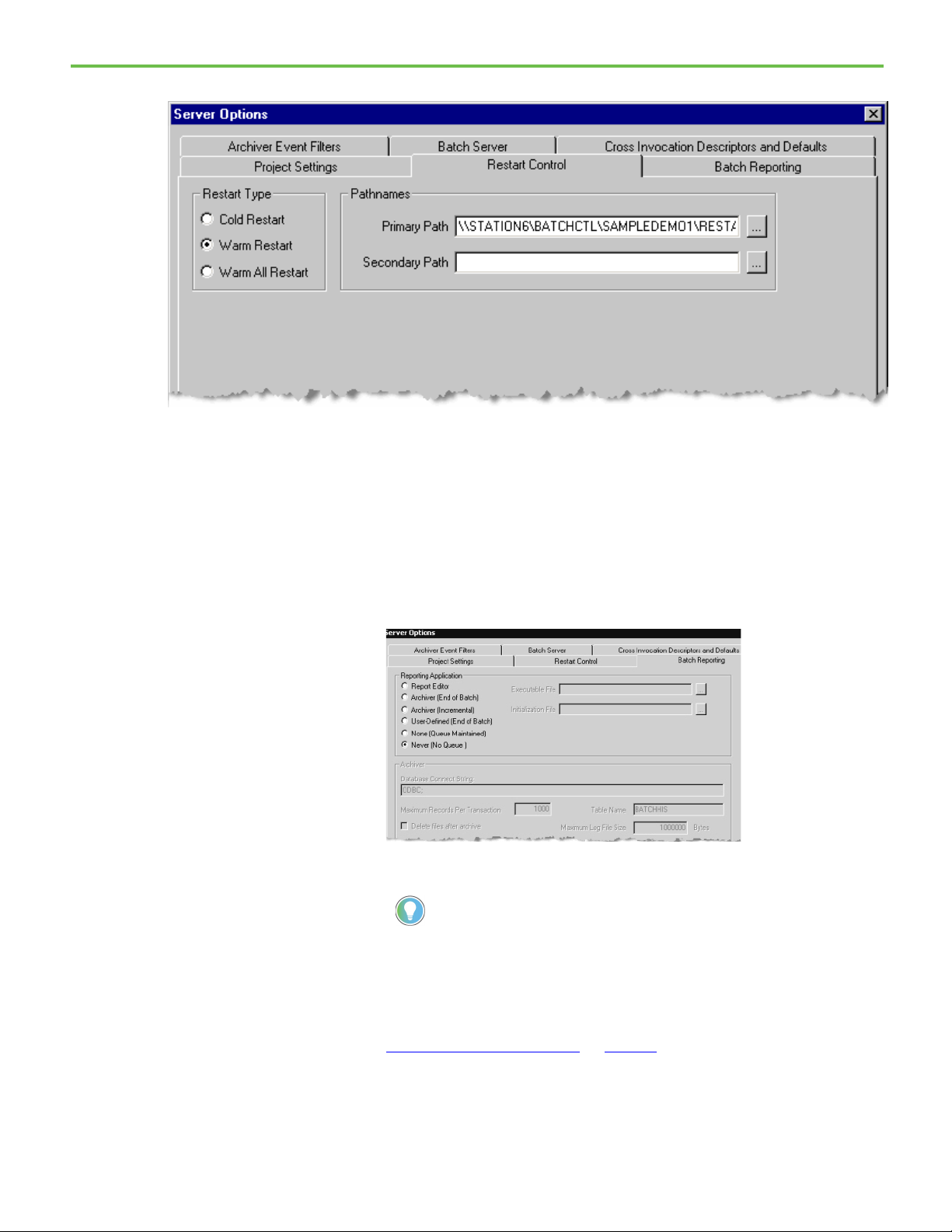

12. Select the Restart Control tab.

13. Select the Primary Path browse button. The Select Directory dialog

box opens.

14. From the Look in list, select the SampleDemo1\Restart folder, and

then select Open.

15. Select the Secondary Path browse button. The Select Directory dialog

box opens.

16. From the Look in list, select the Bin folder.

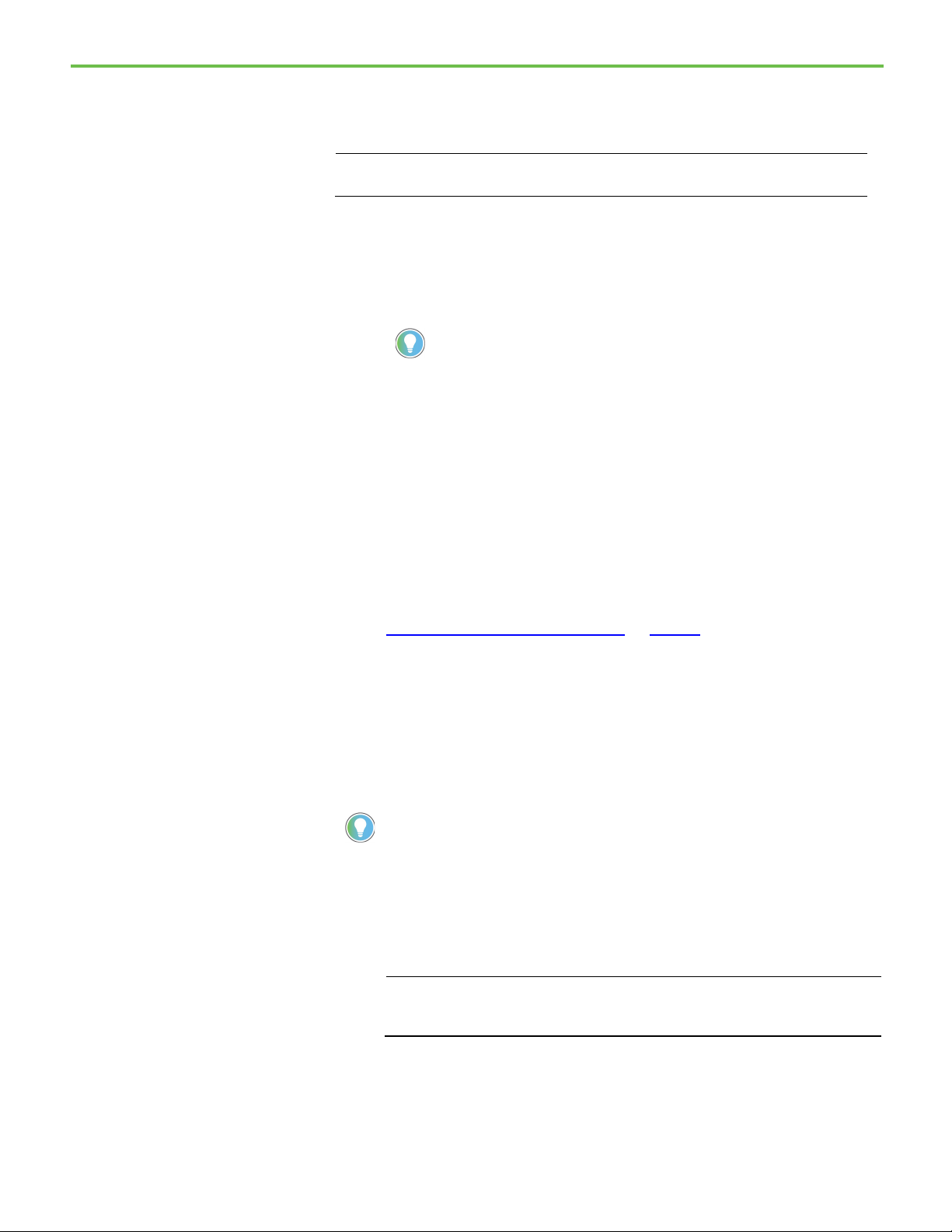

17. Select the Batch Reporting tab. Leave Never (No Queue) as the default

reporting application.

18. Select OK to close the Server Options dialog box.

19. Select File >Exit to exit the FactoryTalk Batch Equipment Editor.

Tip: These steps set up the FactoryTalk Batch Server to run the tutorial steps in this

manual. There are many other settings to consider when setting up the FactoryTalk Batch

system. (See the FactoryTalk Batch Administrator Guide for more information on the Server

See also

Rebuild the recipe directory on page 27

26

Page 27

IMPORTANT

privileges.

for more information.

IMPORTANT

Rebuild the recipe directory

Start the FactoryTalk Batch

Chapter 1 Introducing Material Manager

To run the demonstration recipes, you must rebuild the recipe directory and

verify the recipes in the area model using the FactoryTalk Batch Recipe

Editor.

Administrator privileges are required to perform this procedure.

To rebuild the recipe directory:

1. Select Start > Rockwell Software > Recipe Editor. The FactoryTalk

Batch Recipe Editor reads the area model.

Tip: If you are logged in with an account that does not have administrator privileges, rightclick Recipe Editor and select More > Run as administrator to run under elevated

2. If prompted, log on to FactoryTalk. If a message displays asking you to

verify the recipes, select Cancel.

3. Select File > Rebuild Recipe Directory. When the rebuild is complete,

select OK, and then select Yes to verify the recipes.

4. When the recipe verification is complete, select Accept to save the

recipes, and then select Close.

5. Select File > Exit to exit the FactoryTalk Batch Recipe Editor.

and Material Manager

Servers

See also

Set up the sample demonstrations on page 19

The FactoryTalk Batch and Material Manager Servers may start automatically

when the computer starts. By default, the FactoryTalk Batch Server starts in

production mode. If FactoryTalk Batch has not been activated, the tutorial can

run in demo mode. While in demo mode, the FactoryTalk Batch Server runs

for a two-hour period and then stops.

Tip: The FactoryTalk Batch Server does not start in production mode without activation. The

Material Manager Server starts automatically when the FactoryTalk Batch Server starts. See

Activating Material Manager

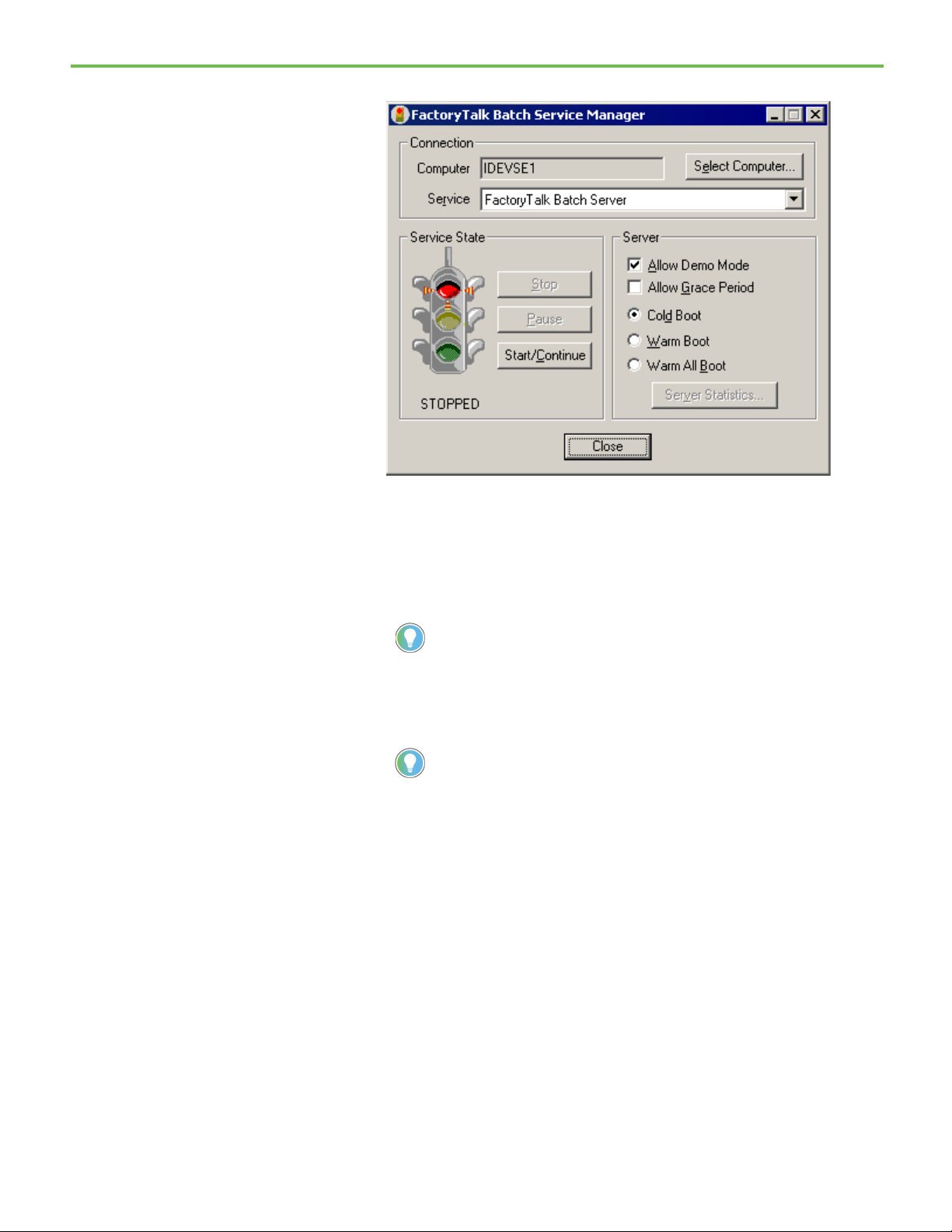

To start or restart the FactoryTalk Batch Server:

1. Select Start > Rockwell Software > Batch Service Manager.

If you are logged in with an account that does not have administrator

privileges, right-click Batch Service Manager and select More > Run as

administrator to run under elevated privileges.

27

2. In the FactoryTalk Batch Service Manager, select the FactoryTalk

Batch Server if it is not listed in the Service box.

Page 28

Chapter 1 Introducing Material Manager

displays.

Guide for installation instructions.

Cold Boot

Warm Boot

on the batch list when the server previously terminated.

Warm All Boot

3. If the FactoryTalk Batch Server is running, select Stop.

4. If the name of the computer where the FactoryTalk Batch Server is

installed does not display in the Computer box, select the Select

Computer button.

5. In the Select Computer dialog box under Enter the object name to

select, type the name of the computer where the Batch Server is

installed (or select Advanced to search for a computer). Select OK.

Tip: The FactoryTalk Batch Service Manager must communicate with the Windows Service

Manager of the selected computer to determine what services are available. There may be

a noticeable delay when establishing communications. If the Service Manager cannot

communicate with the Windows Service Manager of the selected computer, a message

28

6. From the Service list, select FactoryTalk Batch Server.

Tip: If No Batch Services displays in the list, the FactoryTalk Batch Server is not installed

on the selected computer. See the FactoryTalk Batch Components Installation and Upgrade

7. To start the FactoryTalk Batch Server in Demo mode, select Allow

Demo Mode.

8. Select the method to use for booting the server.

Restarts the FactoryTalk Batch Server in a cold state. All journal data or

recipe content is erased upon startup.

Restarts the FactoryTalk Batch Server, restoring the set of batches that were

Restarts the FactoryTalk Batch Server only if it is able to restore all of the

batches to the batch list.

9. Select the Start/Continue button. The Service State area changes from

STOPPED to START PENDING. After a few moments, RUNNING

displays and the light changes to green. The Material Server starts

automatically with the FactoryTalk Batch Server.

Page 29

Phase Simulator for more information.

see if the Phase Simulator is started.

IMPORTANT

Start the sample

FactoryTalk Batch Phase

Simulator

Chapter 1 Introducing Material Manager

The FactoryTalk Batch Phase Simulator starts automatically. Minimize

the window.

10. Select Close to close the FactoryTalk Batch Service Manager.

Tip: If conversation becomes LOST while running in Demo mode, make sure that the

Simulator is running and try starting the server(s) again. See Starting the FactoryTalk Batch

FactoryTalk Batch comes with a phase logic simulation program, referred to

as the FactoryTalk Batch Phase Simulator used to simulate the batch process

without connecting to a PCD. The Phase Simulator imitates the functionality

of a data server and can communicate with the FactoryTalk Batch Server

using OPC communication protocol. The Phase Simulator is a powerful tool

for testing, experimentation and demonstration purposes. In this guide, run

the sample demonstration using the Phase Simulator.

Tip: If the Phase Simulator is required and OPC protocol is used for communications, the

FactoryTalk Batch Server automatically starts the Phase Simulator. Check the Windows taskbar to

To run the sample demonstration correctly, open the ice_cream1.sim file in

the Phase Simulator.

To start the sample FactoryTalk Batch Phase Simulator:

1. If the Phase Simulator is already running, maximize it from the

Windows taskbar. If the Phase Simulator is not running, select Start >

Rockwell Software > Simulator. The FactoryTalk Batch Phase

Simulator opens.

Administrator privileges are required to perform this procedure.

2. Select File > Open. The Open Simulator Configuration File dialog box

opens.

3. From the Look in list, open the Program Files > Rockwell Software >

Batch > SampleDemo1 > Recipes folder. Select the ice_cream1.sim file,

and then select Open.

4. Minimize the FactoryTalk Batch Phase Simulator window.

See also

Verify PCD communications on page 30

29

Page 30

Chapter 1 Introducing Material Manager

IMPORTANT

Verify PCD communications

Use the following instructions to verify PCD communications.

Administrator privileges are required to perform this procedure.

To verify PCD communications:

1. Select Start > Rockwell Software > Batch Service Manager. The

FactoryTalk Batch Service Manager opens.

2. Make sure FactoryTalk Batch Server is selected in the Service box.

3. Select Server Details. The FactoryTalk Batch Server Details dialog box

opens.

4. Select the PCD Communications tab. The Data Server Status area

displays the status of the conversation with the OPC_SIM data server

(Phase Simulator), which should be PHASES GOOD.

5. In the Tag Verify area, select Start to begin the verify process. The tag

verification process takes several minutes.

6. When the Status box shows COMPLETED, select OK to close the

FactoryTalk Batch Server Details dialog box.

Summary

In this chapter, you:

• Set up the Network Editor and the FactoryTalk Batch Server to run the

sample demonstration

• Started the FactoryTalk Batch Server in demo mode

• Opened the .sim file in the FactoryTalk Batch Simulator to run the

sample demonstration

This chapter provided a brief overview of the capabilities of the Material

Server. (See the FactoryTalk Batch Administrator Guide for more information

about the FactoryTalk Batch Server. See the FactoryTalk Batch Material Manager

Administrator Guide for more information about the Material Server.)

The rest of this document is designed to give you a tour through Material

Manager using the sample demonstration. Follow the step-by-step

instructions to learn how to define and run material-based recipes using

Material Manager and FactoryTalk Batch software.

30

Page 31

IMPORTANT

Start the Material Editor

Chapter 2

Introducing the Material Editor

The FactoryTalk® Batch Material Editor provides an interface to help you

create the material database, which consists of several tables of data that are

stored in your Microsoft SQL Server database. The Material Editor presents

the material database as two types of data:

• Material configuration data, which defines the materials, consists of

items such as the material name, description, properties, minimum

and maximum quantity, and the default quantity.

• Material storage configuration data, which defines the containers that

hold the materials, consists of items such as the container name,

description, type, properties, and capacity.

You also use the Material Editor to create relationships between the material

and container data by assigning materials to containers and distributing lots

to the containers.

In this chapter you add new data to the SAMPLE2_MATERIALS.mdf database

that was created automatically when you installed Material Manager.

Click the Start > Rockwell Software > Material Manager > Material Editor.

Administrator privileges are required to perform this procedure.

1. Expand the Materials folder. The list of materials in the

SAMPLE2_MATERIALS material database displays in the left pane.

2. Click the Materials folder. The detailed list of materials displays in the

right pane.

31

Page 32

Chapter 2 Introducing the Material Editor

Adding material states

A material is the logical representation of a recipe ingredient, such as

cream or sugar. For each material, you create lots, which are physical

instances of a material. For example, when a new shipment of cream

arrives at the factory you add a new lot to uniquely identify that

shipment of cream. When you distribute a lot to containers, the

distributed portions become sublots, which are the physical inventory

that is stored in a container. For example, your lot of cream may be

divided into two sublots that are stored in two separate containers.

3. Collapse the Materials folder, expand the Locations folder, and then

expand the Independent Containers folder. The lists of storage

locations in the SAMPLE2_MATERIALS material database display. The

detailed list of materials remains in the right pane until you click

another folder.

The Independent Containers folder displays a list of containers, which

are repositories for inventory. In Material Manager you define

associations between materials and containers. In the area model, you

define associations between containers and equipment modules. The

FactoryTalk Batch Server uses these associations at runtime to find the

container holding the appropriate material and its associated

equipment module to bind to a material-enabled phase step.

The Locations folder contains storage locations, which are a grouping

of containers. Normally, containers assigned to a storage location have

a short life span; they might be created by one recipe and deleted by

the next. This is a common activity for a pre-weigh recipe that

distributes measured amounts of material onto pallets and then a

mixing recipe that uses the pallets as its source of material.

4. Collapse the Locations and Independent Containers folders.

To be used in a batch, both the container and the materials within the

container must be in a Ready to Use state. Any other state prevents the

material and container from being used and provides you a means to identify

offline equipment and materials. For example, you could create a lot state

called QATest and assign it to a material lot to keep it from being used while it

is being tested. To put the lot and container into use again, you would change

the state to Ready to Use.

32

Page 33

Chapter 2 Introducing the Material Editor

In this exercise, you create a container state called Maintenance so you can

keep a container from being used while it’s being repaired.

1. From the Edit menu, select States. The States Configuration dialog

box opens to the Lot tab, which shows the lot states defined in the

SAMPLE2_MATERIALS.mdf material database.

2. Select the Container tab. The container states defined in the

SAMPLE2_MATERIALS.mdf material database display.

3. Click the New State button. The Create Container State dialog box

opens.

4. In the Name box, type Maintenance.

5. In the Description box, type Out of service for maintenance.

33

Page 34

Chapter 2 Introducing the Material Editor

Adding material types

6. Click OK. The new state is added to the list. Because you didn’t assign a

controller ID, the Material Editor automatically assigned the next

available number.

Controller IDs are used throughout the Material Editor to uniquely

identify items in the material database. A PCD programmer can use

these controller IDs to access pieces of data in the material database.

7. Click Close.

Material types are used for informational and organization purposes and do

not affect the building or execution of material-based recipes. The material

types appear in a selection list when you define a material.

In this exercise, you create two new material types: Dry and Liquid.

1. From the Edit menu, select Material Types. The Material Types dialog

box opens.

34

The types defined in the SAMPLE2_MATERIALS.mdf material database

are finished, intermediate, and raw, which are the defaults (indicated

by the blue information icon) and not editable. You can add more

material types, which are editable.

2. Click the Add button. The Edit Material Type dialog box opens.

3. In the Name field, type Dry.

Page 35

Adding a material class

Chapter 2 Introducing the Material Editor

4. In the Description field, type Raw material in dry state.

Leaving Controller ID at zero forces the Material Editor to assign the

next available number.

5. Click OK. The Dry material type displays in the list.

6. Click the Add button. Add another type, Liquid, with the description

Raw material in liquid state.

7. Click OK, and then click Close.

A material class defines a group of materials that are similar. For example, a

material class called Sweetener could contain materials such as Granulated

Sugar and Corn Syrup. Material classes are used for organizational purposes

and do not affect the execution of material-based recipes.

You can use material classes to simplify the assignment of materials to storage

containers. When you define a storage location, you must indicate the

material(s) that can be stored in the container. Using material classes, you can

assign all of the members of a class of materials to a container, instead of

assigning the materials individually.

In this exercise you create a new material class for nonfat frozen yogurt

products and define properties to define the class of materials.

35

Page 36

Chapter 2 Introducing the Material Editor

1. From the Edit menu, select Material Classes. The Material Classes

dialog box opens displaying the material classes defined in the

SAMPLE2_MATERIALS.mdf material database.

The material classes display in alphabetical order. Ungrouped is the

system default, indicated by the blue information icon, and therefore

not editable.

2. Click Add. The Create Material Class dialog box opens to the General

tab.

3. In the Name box, type ICE_MILK_NON_FAT.

4. In the Description box, type Ice Milk Products - Non Fat Frozen

Yogurt.

Leaving Controller ID at zero forces the Material Editor to assign the

next available number.

5. Click Apply. The Edit Material Class dialog box opens to the General

tab.

6. Select the Properties tab, and then click the New Property button.

7. In the Material Class Property box, type butterfat_content.

8. In the Minimum box, type 2.

9. In the Maximum box, type 7.

36

Page 37

Adding a material

Chapter 2 Introducing the Material Editor

10. In the Default Value box, type 5.

11. In the EUs box, type Percent.

12. Click Apply, then select the Synchronize checkbox.

13. Click OK, click Yes to propagate the change, and then click Close.

A material is an ingredient in a recipe. For each material, you specify lots,

which are instances of a material. When you distribute a lot to containers, the

distributed portions of the lot become sublots. A sublot is physical inventory

that is stored in a container.

You are going to add a new product to your line — Chocolate Hazelnut Ice

Cream. There is already a recipe for Triple Chocolate Ice Cream that uses the

same materials you need so you only have to add Hazelnuts (raw) and

Chocolate Hazelnut Ice Cream (finished) as materials.

1. Right-click the Materials folder, and then select New Material. The

Create Material dialog box opens to the General tab.

2. In the Name box, type HAZELNUT.

3. In the Description box, type Hazelnut pieces.

4. In the Engineering Units box, type KG.

5. From the Type list, select Raw, if necessary.

6. From the Class list, select NUT.

37

Page 38

Chapter 2 Introducing the Material Editor

Adding containers

7. From the Default Lot State list, select Ready to Use, if necessary.

You can use Inventory Key to interface the material inventory with

your plant production processes. Leave Inventory Key blank for this

exercise. Leaving Controller ID at zero forces the Material Editor to

assign the next available number.

8. Click OK.

9. In the same manner, add:

• Name = IC_CHOCOLATE_HAZELNUT

• Description = Chocolate Hazelnut Premium Ice Cream

• Engineering Units = KG

• Type = Finished

• Class = ICE_CREAM_PREMIUM

• Default Lot State = Ready To Use

Containers are repositories for inventory. In the Material Editor, you create

containers and then distribute lots of materials to them. When you run a

batch, the FactoryTalk Batch Server asks the Material Server to look for

containers that meet the material requirements of the step. That container is

then selected for binding to the batch if the total inventory of the container is

greater than the defined heel property. The type of container you associate

with a material also affects the binding process, which you will read more

about in a later chapter.

Material Manager supports three different types of containers:

38

• Composite Containers hold only one material and lot at a time. As new

sublots are created and linked to a composite container, the sublots are

combined within the container. An example of a composite container

is a tank that holds multiple sublots of milk. As each sublot is added to

the container they blend together making it impossible to distinguish

Page 39

Chapter 2 Introducing the Material Editor

between the sublots. During binding the entire content of the

container is considered.

• Plug-Flow Containers hold only one material, but can hold multiple

sublots. Each sublot remains distinct when added to the plug-flow

container. Sublots that are added to a plug-flow container are available

for use in a first-in/first-out fashion. The first sublot placed in the

container is the first sublot used, then the second sublot is used, and so

on. Material Manager tracks the usage of each sublot, and recognizes

when each lot is exhausted. During binding only the first-out sublot is

considered.

• Pallet Containers hold many different materials and many sublots of

each material. Each sublot can have a label, which is the only property

unique to a sublot. All other sublot properties are inherited from the lot

properties. You can use labels to distinguish between sublots that are

unique. All sublots added to a pallet container are available at any time.

During binding, each sublot on the pallet is considered.

In this exercise, you create two new independent containers to hold

hazelnuts.

1. Expand the Material Storage Configuration folder, right-click the

Independent Containers folder, and then select New Material

Storage Container. The Create Material Storage Container dialog box

opens.

2. In the Name box, type NUT_BIN3.

3. In the Description box, type Hazelnut storage.

4. In the Capacity box, type 10000.

5. In the Heel box, type 200.

6. In the Engineering Unit box, type KG.

7. In the Container Type area, select Plug Flow.

39

Page 40

Chapter 2 Introducing the Material Editor

Associating materials with

containers

Leave the State at the default of Ready to Use and Controller ID at 0

(zero). Leaving Controller ID at zero forces the Material Editor to

assign the next available number.

8. Click OK.

9. Add a second independent container:

• Name: NUT_BIN4

• Description: Hazelnut storage

• Capacity: 10000

• Heel: 200

• Engineering Units: KG

• State: Ready_to_Use

• Container Type: Plug Flow

10. Click OK.

Now that you have defined the two new materials and containers, you need to

associate them with each other.

In this exercise you associate the HAZELNUT material with two independent

containers and the IC_CHOCOLATE_HAZELNUT material with all the

containers in a storage location.

1. Expand the Materials folder, right-click HAZELNUT, and then select

Properties. The Edit Material dialog box opens to the General tab.

2. Select the Containers tab, expand the Independent Containers folder,

select NUT_BIN3, and then click the Add button.

3. Add NUT_BIN4 in the same manner.

4. Click OK.

5. Double-click IC_CHOCOLATE_HAZELNUT. The Edit Material dialog

box opens to the General tab.

6. Select the Containers tab, select the DEEP_FREEZE storage location,

and then click the Add Location button. All the containers in the

40

Page 41

Creating lots

Chapter 2 Introducing the Material Editor

Deep_Freeze storage location are added to the Configured Containers

area.

7. Click OK.

The material that you created is merely a logical definition of a material. The

actual physical material is a lot. Each lot inherits the characteristics and

properties of the material and also includes a physical quantity and a

controller ID to identify the lot. There can be multiple lots of a single material.

Each lot is uniquely identified by its lot name.

In this exercise, you create a lot for the latest shipment of hazelnuts, which is

10,000 KG.

1. Expand the Materials folder, right-click HAZELNUT, and then select

Properties. The Edit Material dialog box opens to the General tab.

2. Select the Lots tab, and then click the New Lot button.

3. In the Lot Name box, type Hazelnut100.

4. In the Quantity box, type 10000.

Leave State at the default of Ready to Use and Controller ID at 0 (zero).

Leaving Controller ID at zero forces the Material Editor to assign the

next available number.

41

5. Click Apply.

Page 42