Page 1

Technical Publications

FactoryTalk Alarms and Events System Configuration Guide

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Supersedes Publication FTAE-RM001L-EN-E - September 2020

Original Instructions

Page 2

FactoryTalk Alarms and Events System Configuration Guide

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash will

Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and for

2

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 3

Table of Contents

What you need to get started

Overview of FactoryTalk Alarms

and Events services

Plan your system

Define device-based alarms in

Logix 5000 controllers

Chapter 1

Required software ....................................................................................... 9

Recommended hardware and supported operating systems ................. 9

Logix 5000 controllers .......................................................................... 9

Compatible firmware ........................................................................... 11

Older controllers .................................................................................. 11

How to get the information you need ....................................................... 12

Chapter 2

Choose between HMI Tag Alarm Monitoring and FactoryTalk Alarms

and Events .................................................................................................. 15

Where to start ............................................................................................ 16

FactoryTalk Alarms and Events components ........................................... 16

About monitoring for alarm conditions .................................................. 20

About device-based alarm monitoring .............................................. 20

Device-based alarm monitoring workflow ................................. 20

About server tag-based alarm monitoring ......................................... 21

Server tag-based alarm monitoring workflow ............................ 21

Choose between device-based and server tag-based alarm monitoring

..................................................................................................................... 22

Graphic objects in FactoryTalk Alarms and Events .................................23

Chapter 3

Decide what type of application you are building .................................. 25

Decide what type of alarm monitoring you need ................................... 26

Follow these steps ...................................................................................... 26

What you need ........................................................................................... 27

Install and activate FactoryTalk software ................................................ 27

Typical stand-alone system ................................................................ 27

Install FactoryTalk software ............................................................... 28

Install Microsoft SQL Server .............................................................. 28

Chapter 4

Alarm buffering during loss of connection to the controller ................ 29

Before you begin ....................................................................................... 30

What you need .......................................................................................... 30

Follow these steps ...................................................................................... 30

Define a Logix tag-based alarm ................................................................. 31

Create an alarm definition .................................................................. 31

Download the program to controller and test the alarm ..................32

Define an instruction-based alarm: digital ..............................................32

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

3

Page 4

Table of Contents

Add a device server for Logix

controllers

Add an OPC data server for

third-party controllers

Add a tag-based alarm server

or third-party controllers

Set up graphic displays

Monitor and interact with alarms

at runtime

5000, PLC-5, or SLC 500

for Logix 5000, PLC-5, SLC 500,

Configure the digital alarm and download to the controller ............32

Define an instruction-based alarm: analog .............................................. 36

Configure the analog alarm and download it to the controller ........ 36

Chapter 5

Before you begin ........................................................................................ 39

What you need ........................................................................................... 39

Follow these steps ...................................................................................... 39

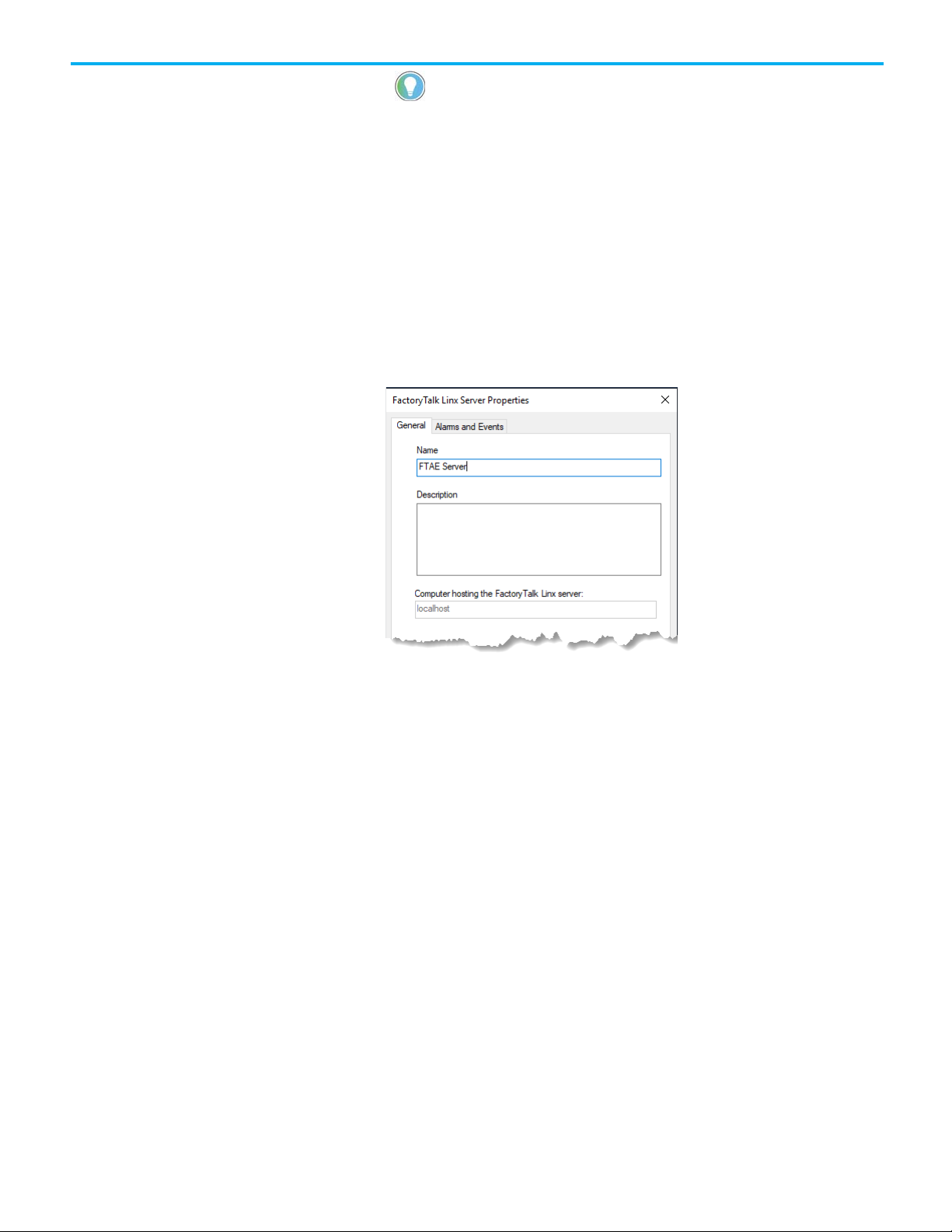

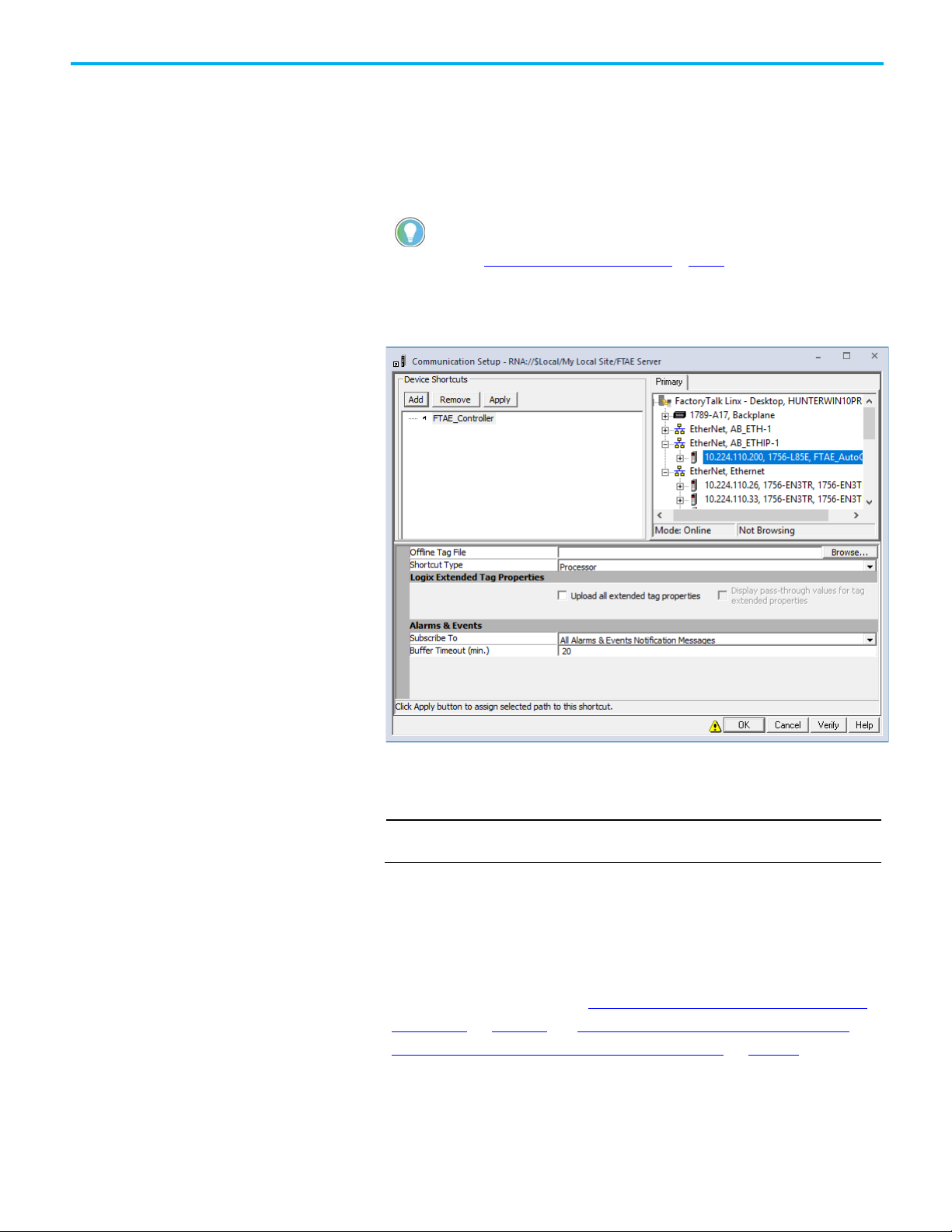

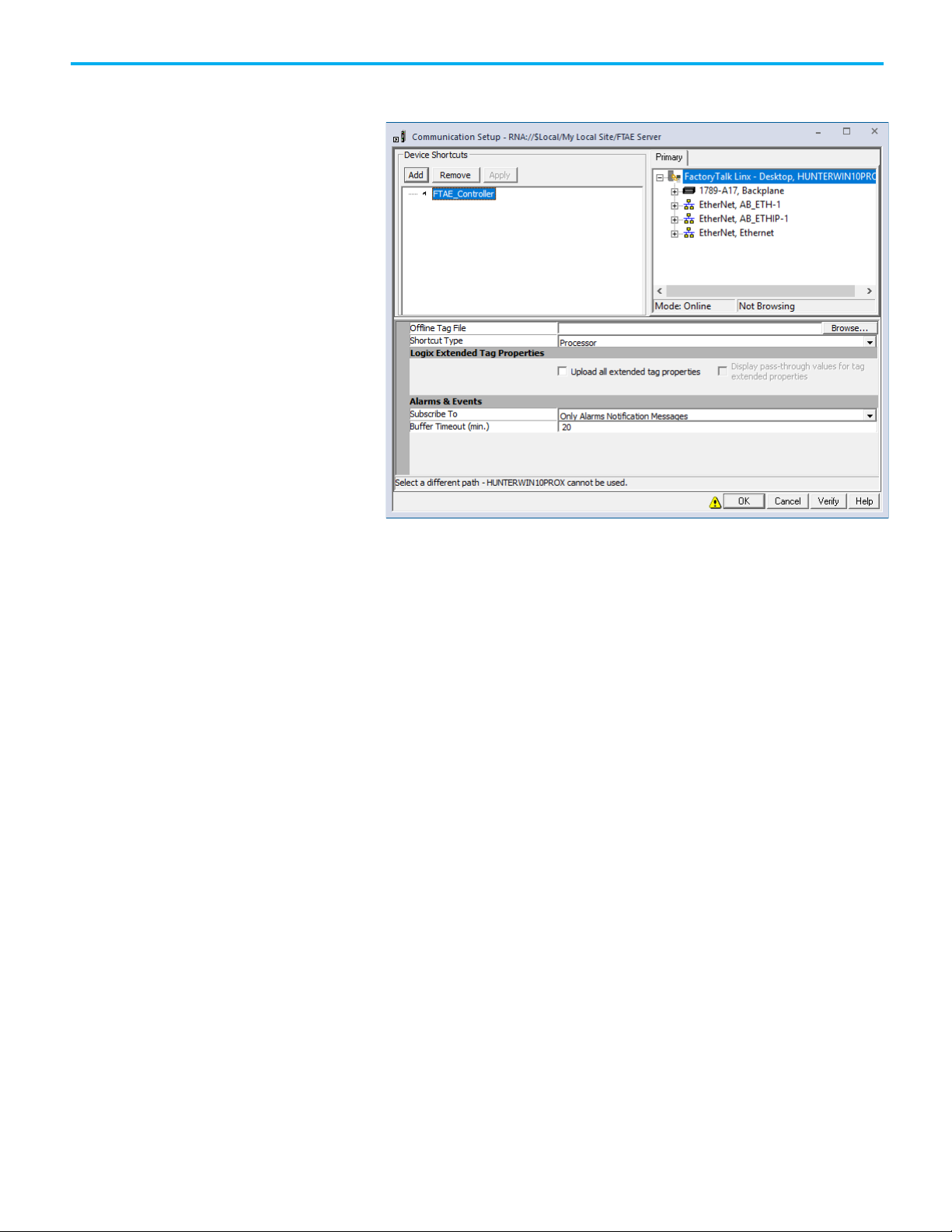

Add a device server .................................................................................... 39

Chapter 6

Before you begin ........................................................................................ 47

What you need ........................................................................................... 47

Follow these steps ...................................................................................... 47

Add an OPC data server to an application ................................................ 47

Chapter 7

Before you begin ........................................................................................ 51

What you need ........................................................................................... 51

Follow these steps ...................................................................................... 51

Create an application ................................................................................. 51

Add a data server ........................................................................................ 53

Add a Tag Alarm and Event Server ........................................................... 55

Define alarm conditions ............................................................................56

Next steps .................................................................................................... 57

4

Chapter 8

Before you begin ........................................................................................59

What you need ...........................................................................................59

Follow these steps .......................................................................................59

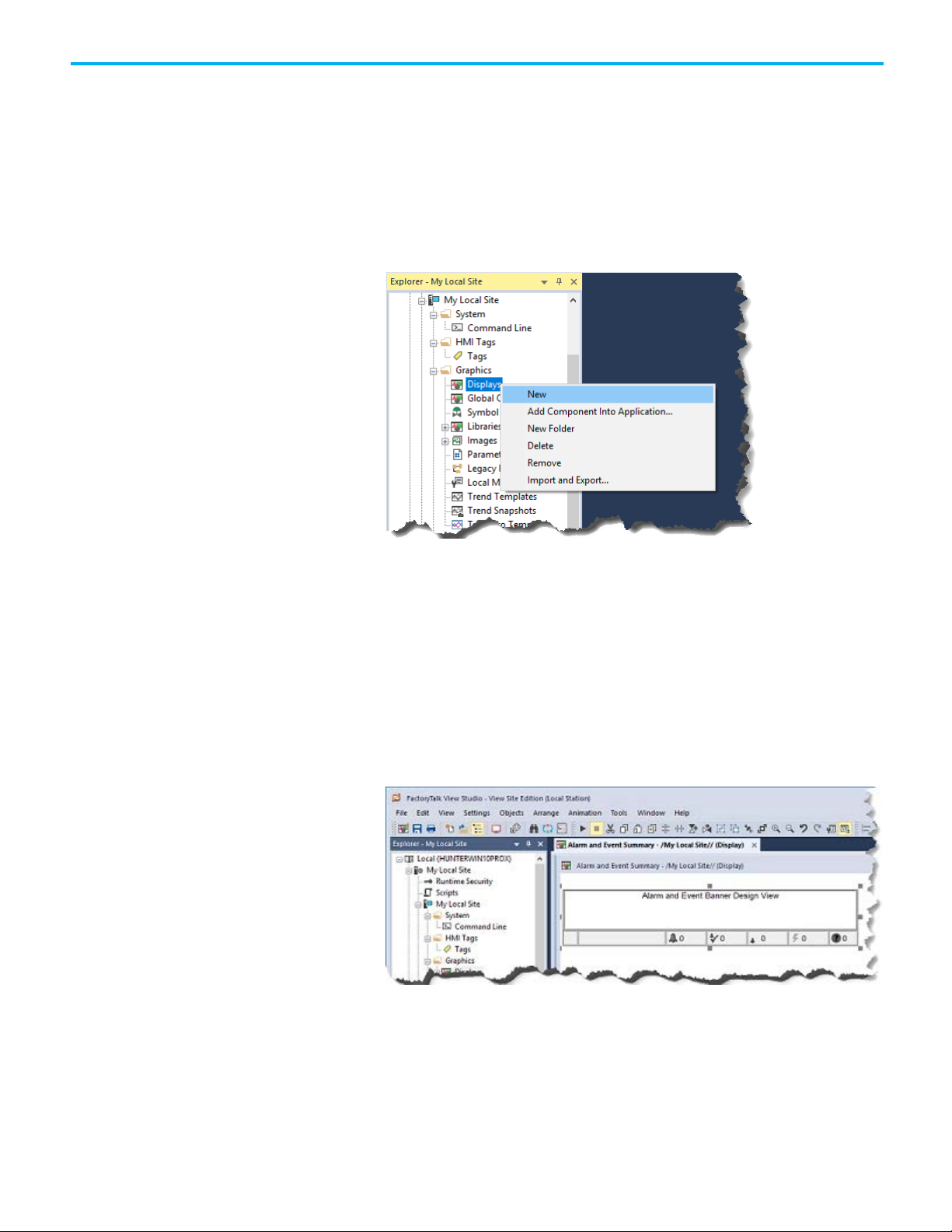

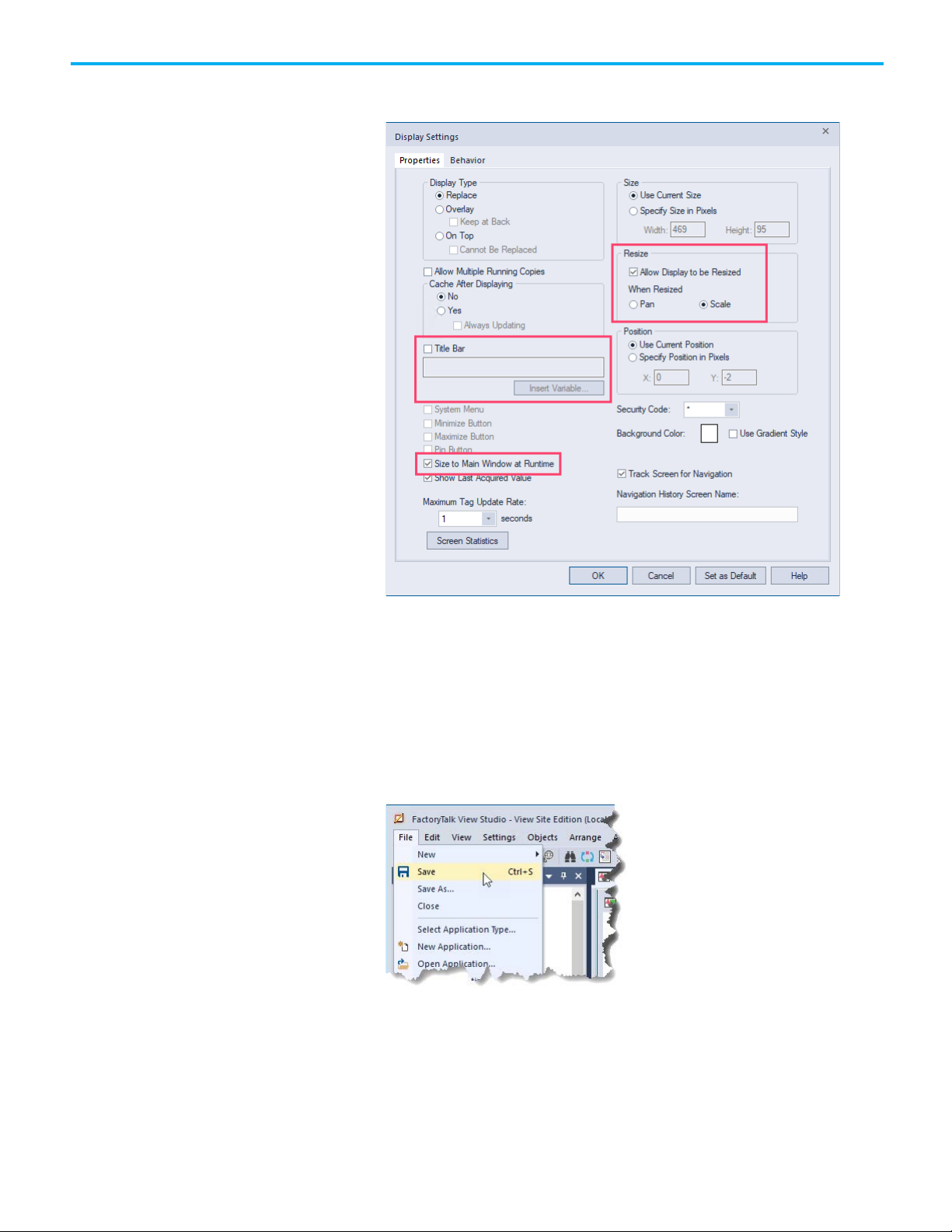

Create a graphic display ............................................................................ 60

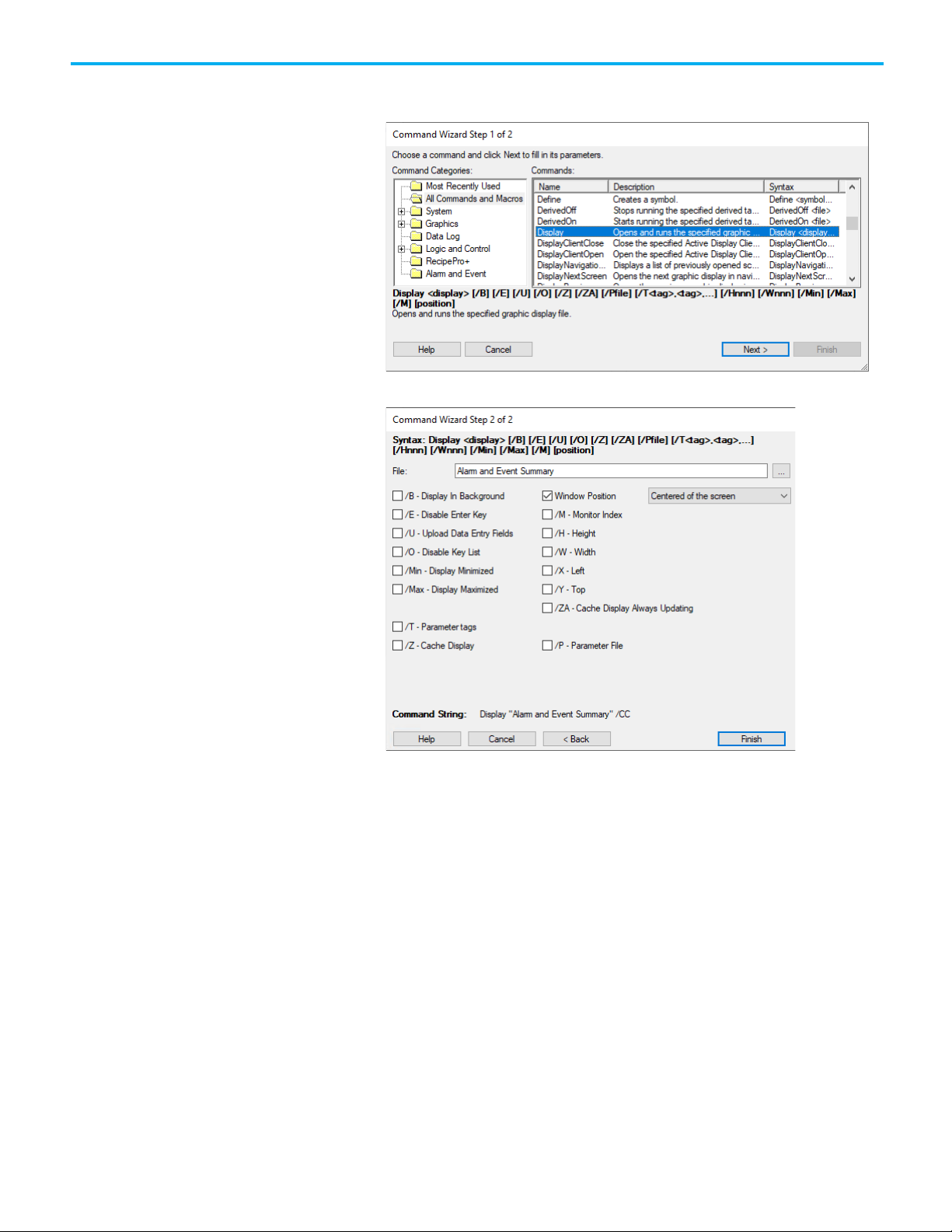

Create an Alarm and Event Summary ...................................................... 61

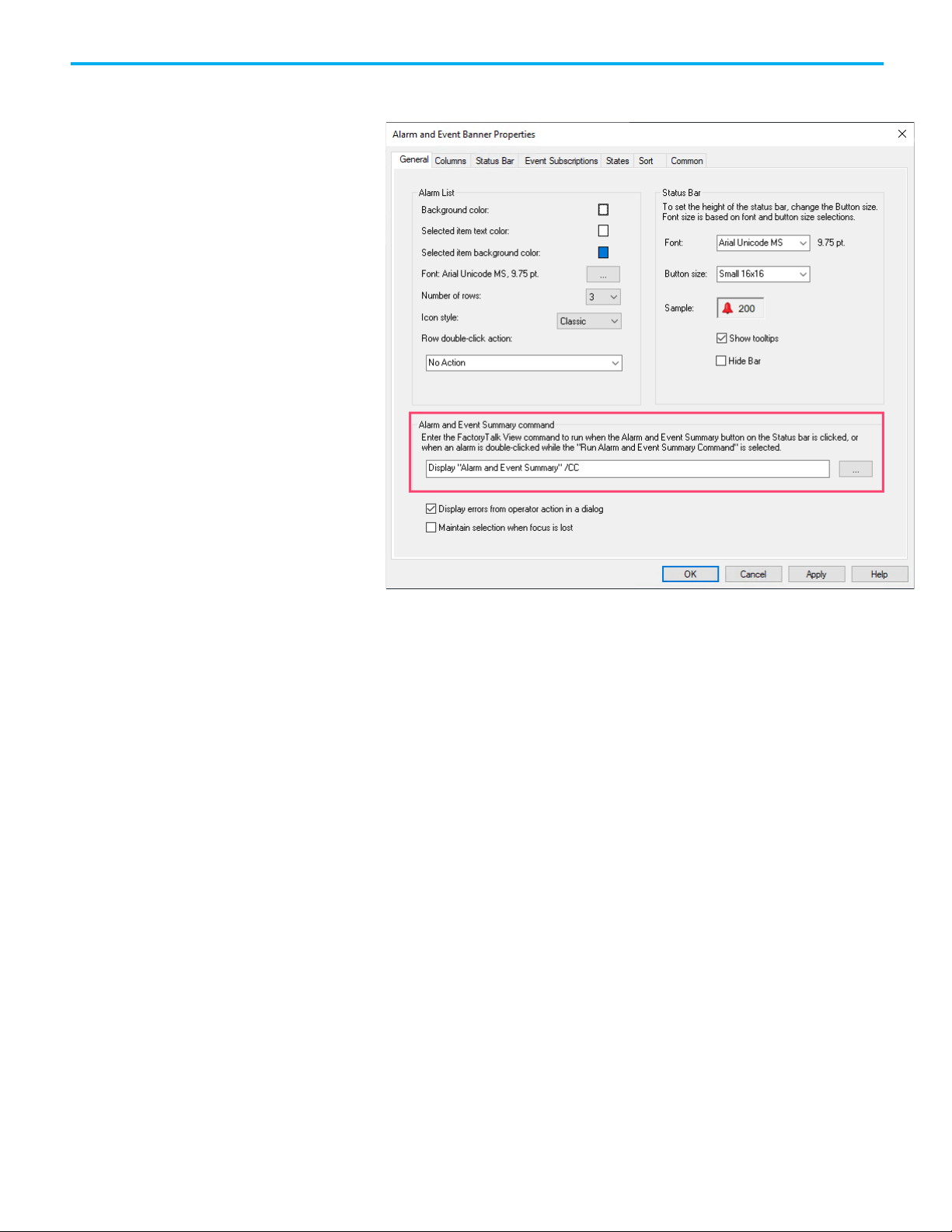

Create an Alarm and Event Banner display ............................................ 64

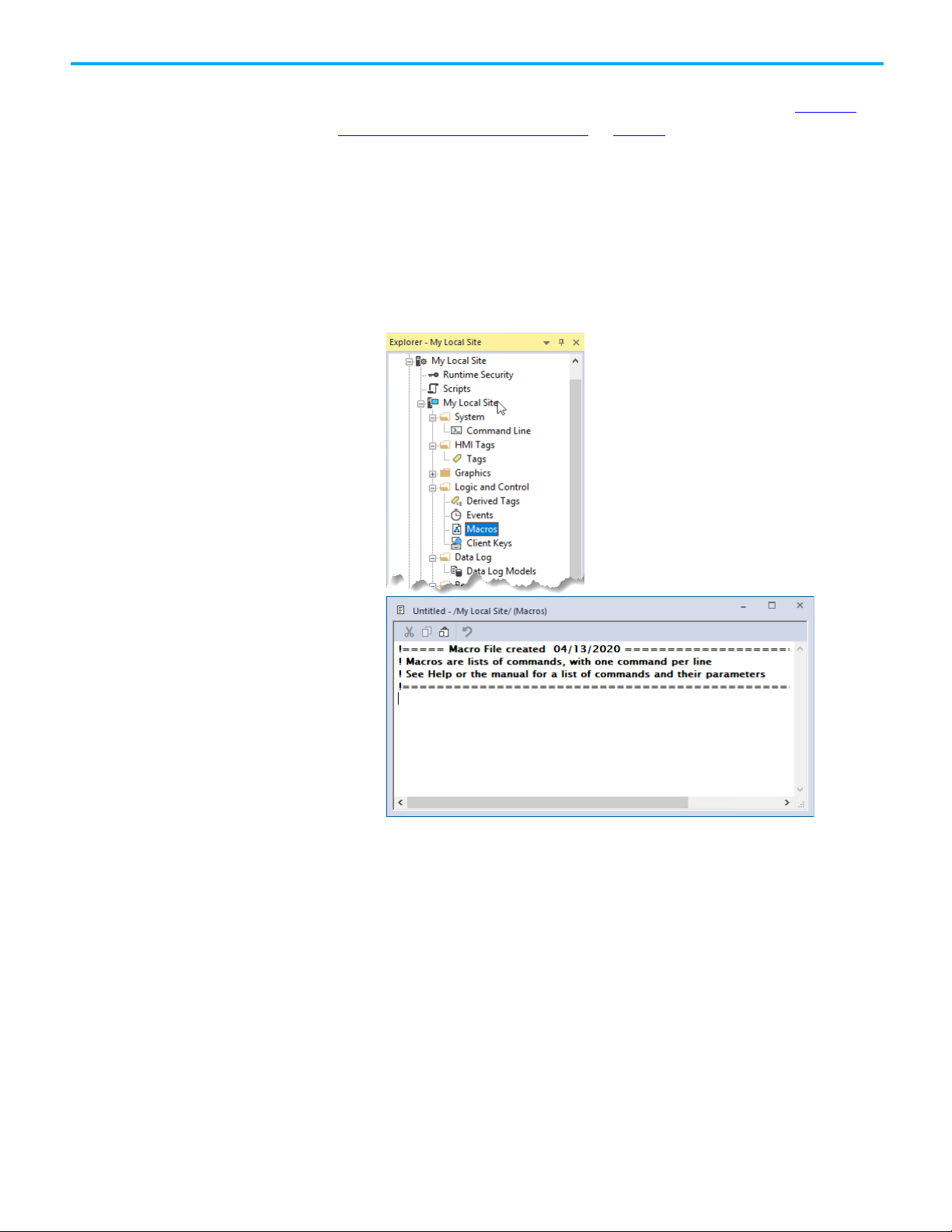

Create a startup macro for the Banner display ....................................... 69

Create an Automatic Diagnostic Event Summary .................................. 70

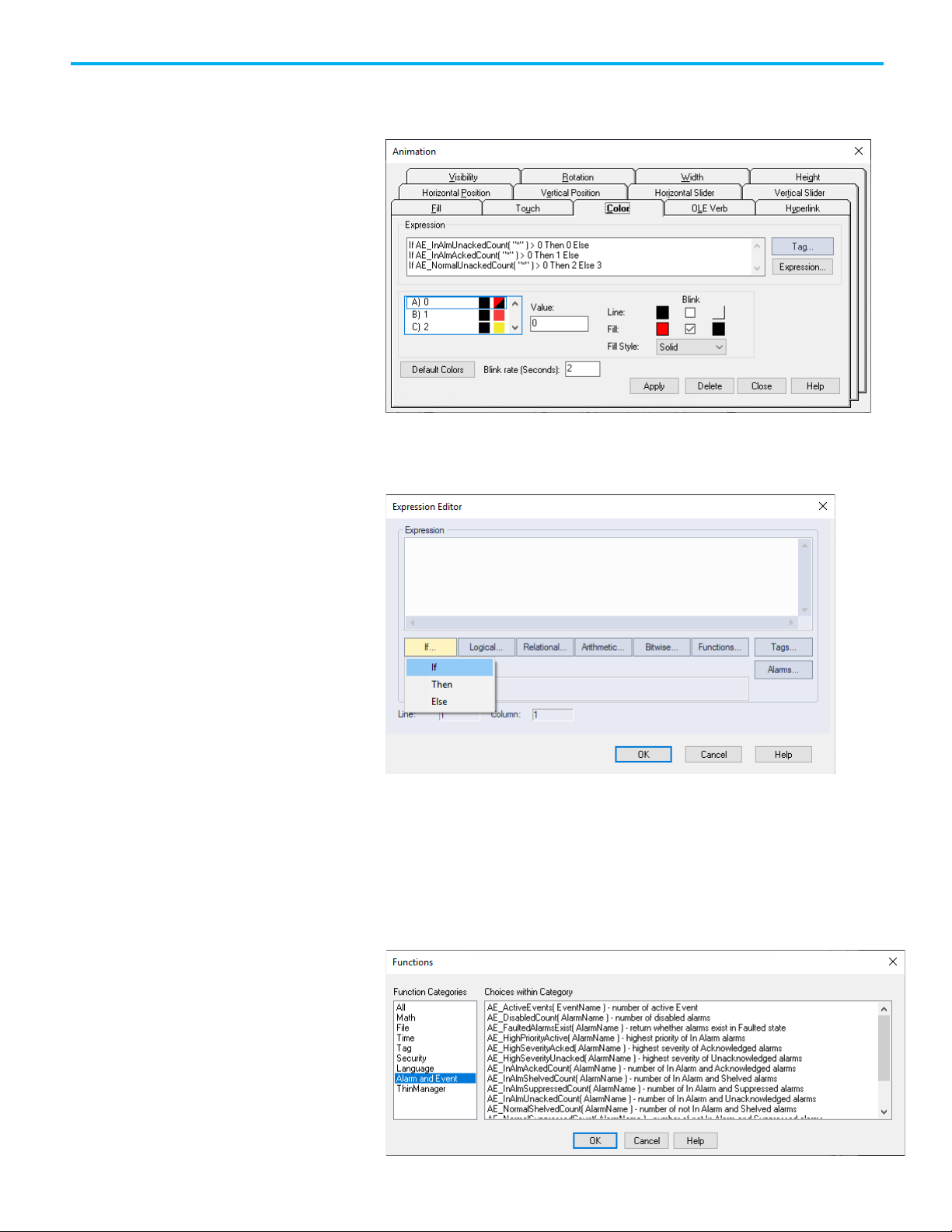

Use color animation to indicate alarm state changes ............................. 74

Next steps .................................................................................................... 81

Chapter 9

Before you begin ....................................................................................... 83

What you need .......................................................................................... 83

Follow these steps ..................................................................................... 83

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 5

Table of Contents

Set up historical alarm and

event logging

Configure redundancy for

alarms and events

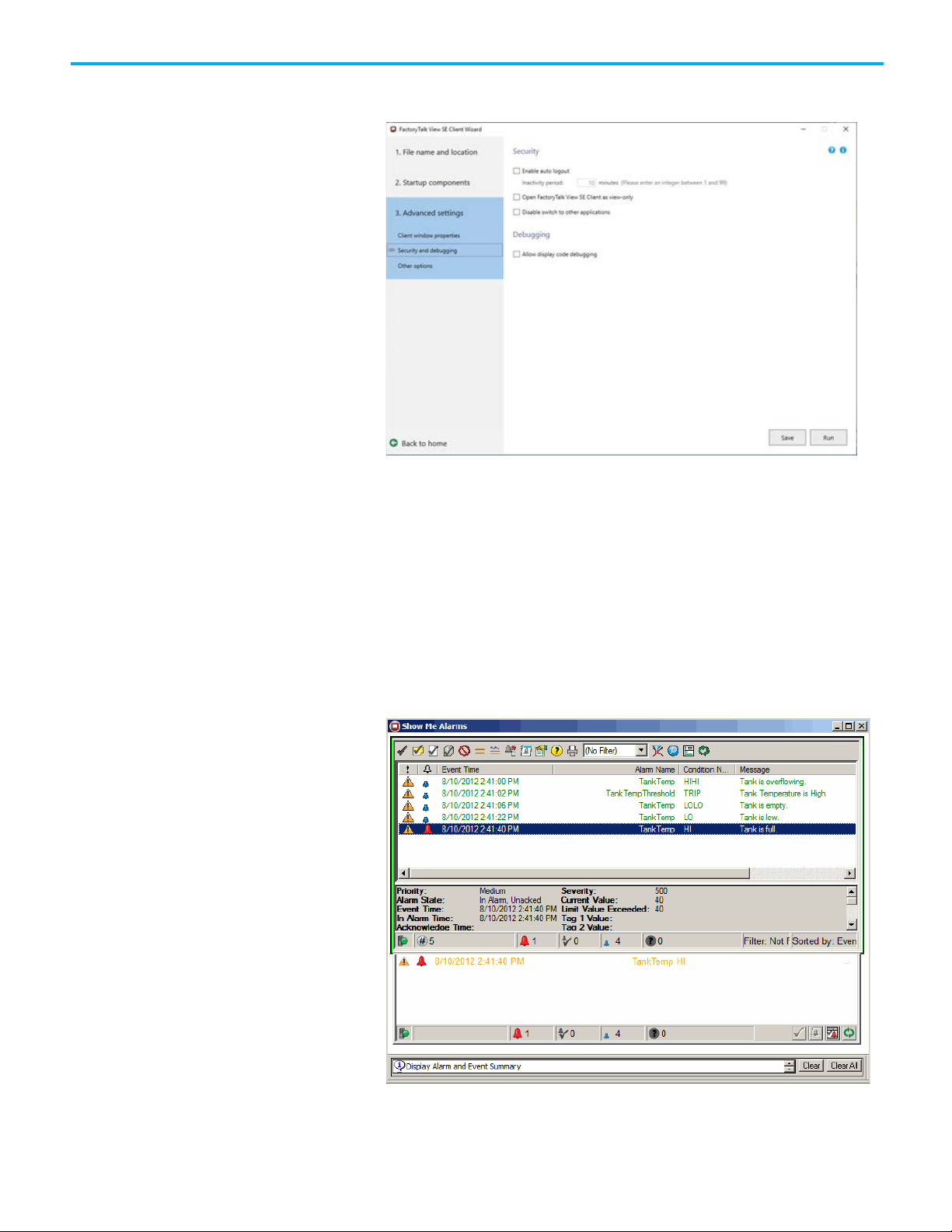

Create and then run a FactoryTalk View Client configuration.............. 83

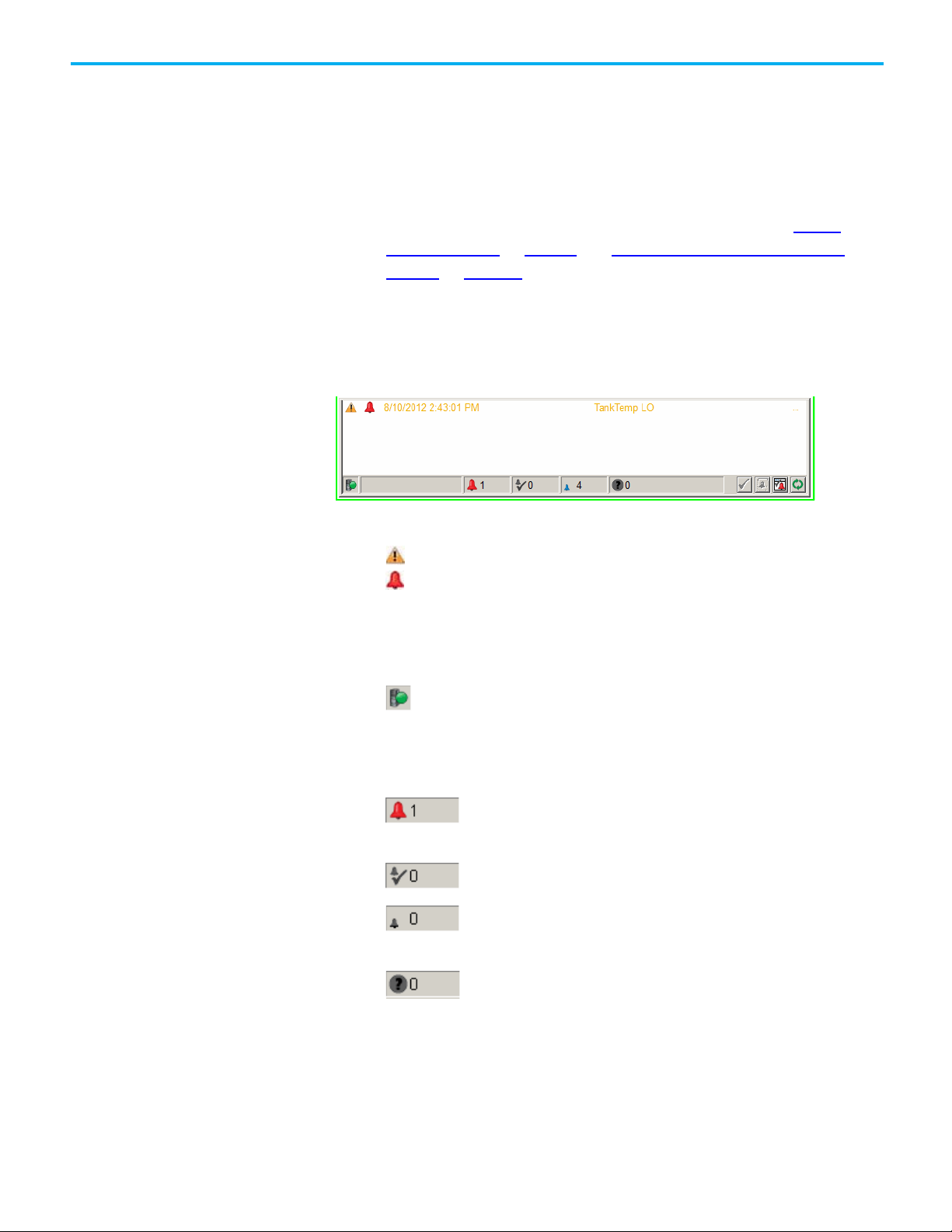

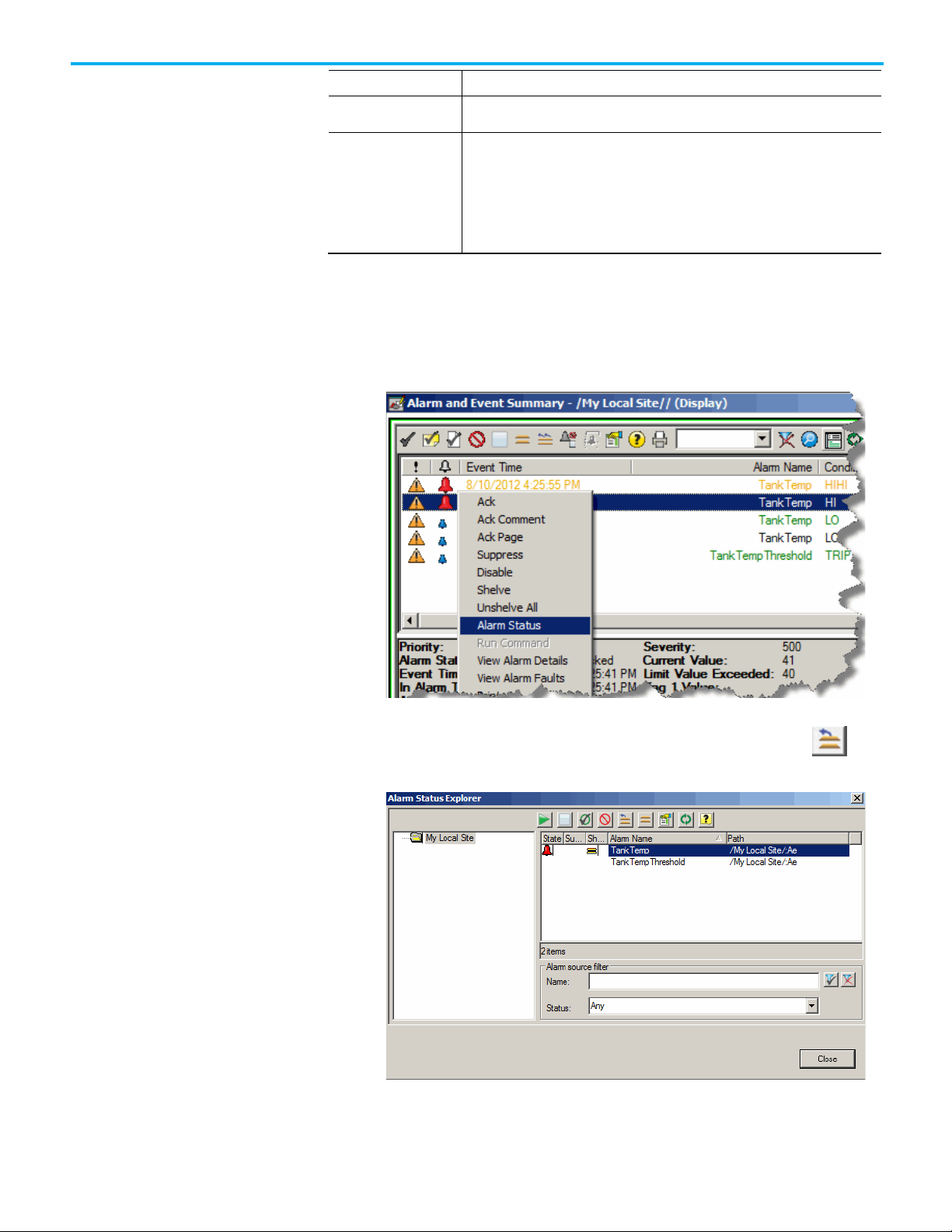

Monitor alarms and events ....................................................................... 87

Security for alarms and events ........................................................... 88

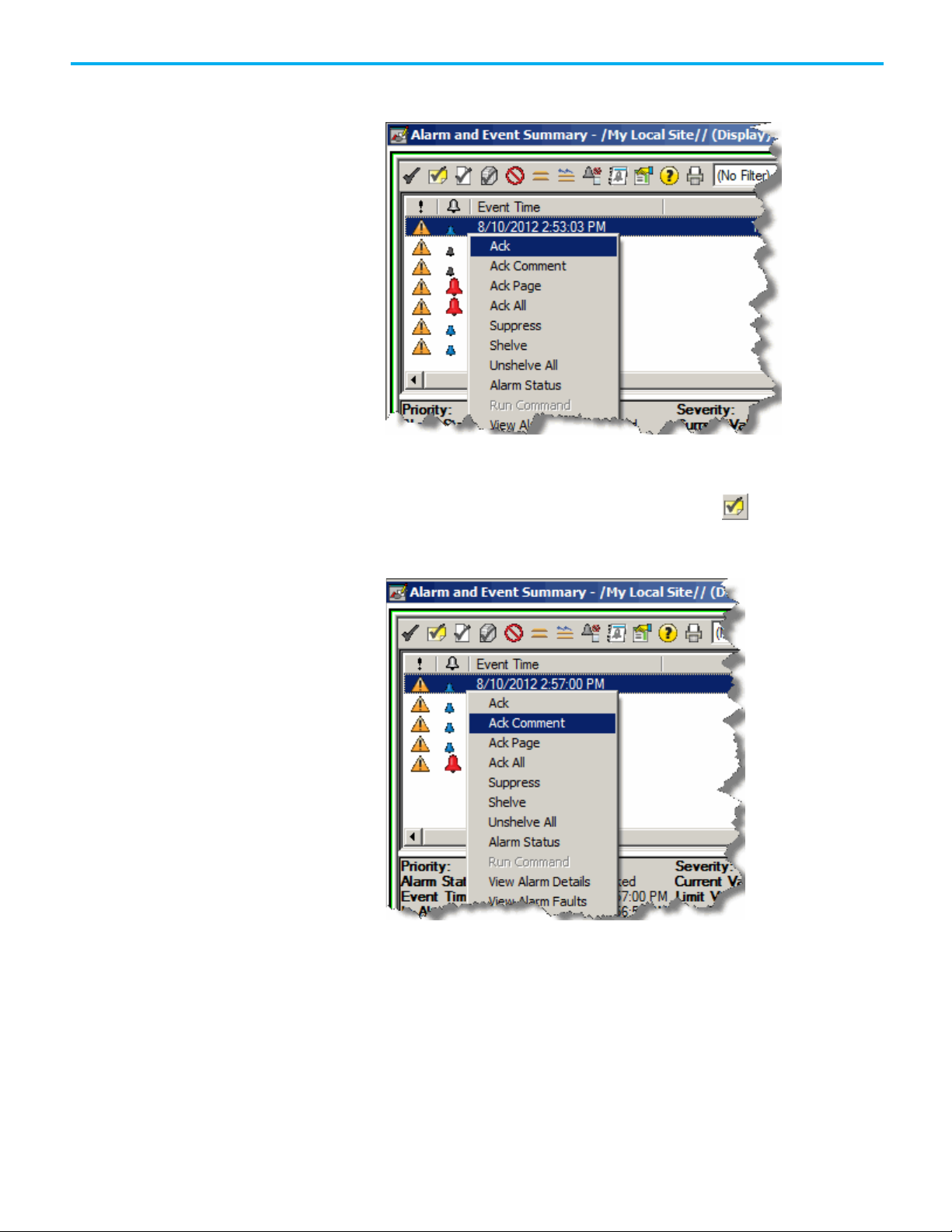

Acknowledge an alarm ........................................................................ 88

Acknowledge the selected alarm .................................................. 88

Acknowledge the selected alarm and enter a comment ............ 89

Acknowledge all of the alarms displayed on the page ................ 90

Acknowledge all of the alarms in the event list........................... 90

Disable or enable an alarm .................................................................. 91

Disable selected alarms ................................................................. 91

Enable selected alarms ................................................................. 92

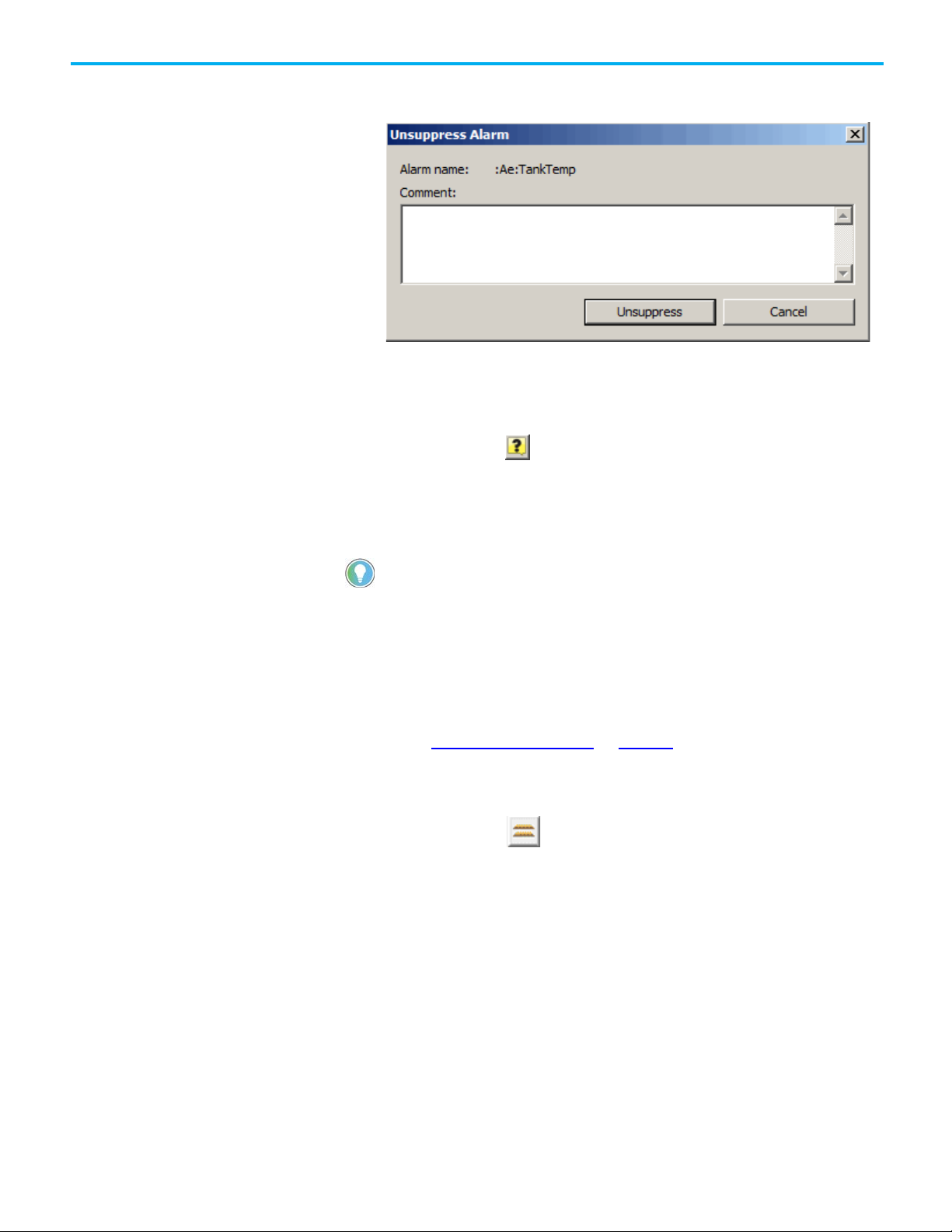

Suppress or unsuppress an alarm ....................................................... 93

Suppress an alarm ........................................................................ 94

Unsuppress an alarm .................................................................... 94

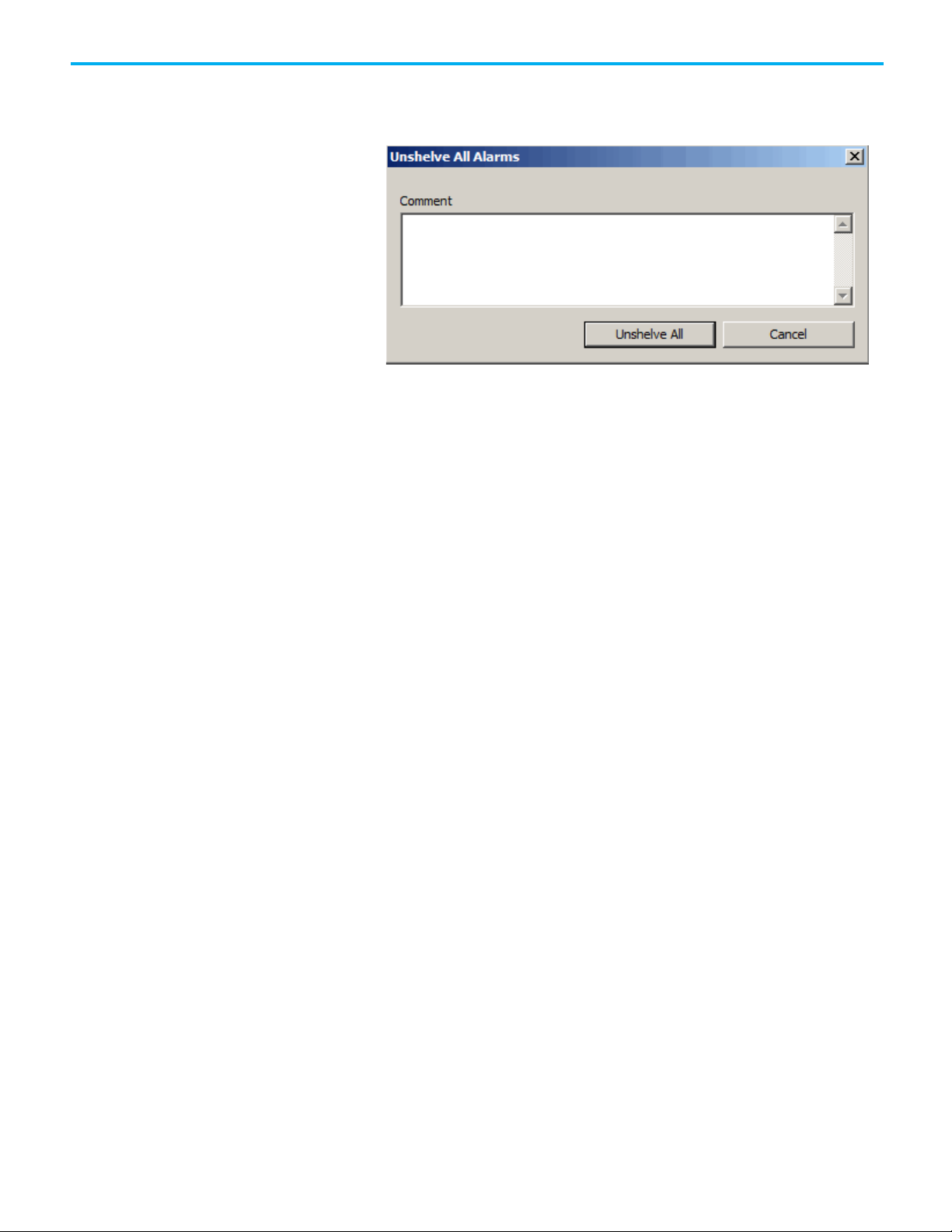

Shelve or unshelve an alarm ............................................................... 96

Shelve an alarm ............................................................................. 96

Unshelve an alarm ........................................................................ 98

Chapter 10

Before you begin ...................................................................................... 101

What you need ......................................................................................... 101

Follow these steps .................................................................................... 102

Confirm that the SQL Server software is installed ................................ 102

Add a database definition to your FactoryTalk system ......................... 102

Associate a database definition with an alarm server ........................... 105

Create an Alarm and Event Log Viewer display ..................................... 107

Create a button to open the Alarm and Event Log Viewer display . 110

Create a startup macro for the Menu Bar display .................................. 114

View historical alarm data in a FactoryTalk View SE Client ................. 115

Run the application ............................................................................ 116

Start the FactoryTalk View SE Client from within FactoryTalk

View Studio .................................................................................. 116

Chapter 11

FactoryTalk server redundancy .............................................................. 119

Develop and test your application without redundancy ...................... 119

Before you begin ...................................................................................... 119

What you need .......................................................................................... 120

Follow these steps ..................................................................................... 121

Upgrade an existing device-based alarm server .................................... 121

Upgrade an existing tag-based alarm server.......................................... 123

Check the status of an alarm server ........................................................ 124

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

5

Page 6

Table of Contents

Get started with language

switching

System performance and limits

Install FactoryTalk Alarms and

Events manually

Install SQL Server 2014 SP3

Express

Appendix A

Before you begin ...................................................................................... 127

What you need ......................................................................................... 128

Follow these steps .................................................................................... 128

Create device-based alarm messages...................................................... 128

Translate alarm messages using import and export ....................... 129

Translate alarm messages in RSLogix 5000 version 16 or earlier

....................................................................................................... 129

Translate alarm messages using RSLogix 5000 version 17 or later

....................................................................................................... 132

Create tag-based alarm messages ........................................................... 134

Enter text strings in FactoryTalk View Studio ................................. 135

Add languages to the application ............................................................ 138

Add buttons to a graphic display to switch languages at runtime ....... 139

Enter alarm messages in other languages .............................................. 143

Create a Display Client configuration file to test alarm messages ....... 152

Test alarm messages at runtime ............................................................. 154

Summary and tips for setting up language switching .......................... 157

Text that supports language switching ............................................ 157

Text that does not support language switching .............................. 157

Alarm and Event Summary and Alarm and Event Banner ............. 158

Alarm and Event Log Viewer ............................................................. 158

Appendix B

Controller specifications ......................................................................... 159

Controllers with revision 24 and later .............................................. 159

Controllers with revision 20 or earlier ............................................. 159

System sizing recommendations ............................................................ 160

Appendix C

Summary of steps .................................................................................... 163

Confirm that FactoryTalk Services Platform is installed ...................... 163

Install FactoryTalk Alarms and Events................................................... 164

Appendix D

Summary of steps .................................................................................... 165

Step 1. Open the FTView folder ............................................................... 165

Step 2. Install the .NET Framework ....................................................... 166

Step 3. Run the SQL Server Install batch file (not the .exe) ................... 166

Step 4. Configure the Windows firewall ................................................. 167

6

Appendix E

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 7

Table of Contents

Use an existing SQL Server

database

Alarm time stamping

Time synchronization

Supported SQL Server databases ........................................................... 169

Remote connections to the SQL Server database .................................. 169

Summary of steps .................................................................................... 169

Step 1. Install SQL Server Management Tools ................................. 169

Step 2. Specify Mixed Mode authentication for the SQL Server

database .............................................................................................. 170

Step 3. Configure TCP/IP protocol for the database ....................... 170

Step 4. Enable the SQL Server Browser service ............................... 170

Step 5. Configure the Windows Firewall ...........................................171

Appendix F

Overview of time keeping........................................................................ 173

Coordinated System Time (CST) ...................................................... 173

Coordinated Universal Time (UTC) .................................................. 173

Local Time (Wall Clock Time) ........................................................... 174

ALMD and ALMA alarm blocks................................................................ 175

Insert time stamps manually ............................................................ 177

Example ..................................................................................................... 177

Appendix G

Coordinate multiple controller wall clocks ............................................ 179

Install the Logix5000 Clock Update Tool ...............................................180

Start Clock Update Tool ...........................................................................180

Start the Update Tool automatically .................................................180

Use the Logix5000 Clock Update Tool ....................................................180

Synchronize devices on a schedule ......................................................... 181

Create a synchronization schedule ................................................... 181

Create a synchronization schedule............................................. 181

Remove a synchronization schedule .......................................... 182

Modify a synchronization schedule............................................ 182

Enable or disable a synchronization schedule ........................... 182

Add devices ............................................................................................... 183

Add a device ........................................................................................ 183

Remove a device ................................................................................. 184

View details about a device ................................................................ 184

Assign devices to synchronization schedules ........................................ 184

Synchronize devices manually ................................................................ 185

View the log file ........................................................................................ 185

Change the location of the log file .................................................... 186

Time stamps with tag-based alarms ....................................................... 187

Supported devices .................................................................................... 187

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

7

Page 8

Table of Contents

Reference for building a

distributed system

Language identifiers

Glossary

Legal Notices

Index

Appendix H

When installing FactoryTalk Alarms & Events ...................................... 189

Typical distributed system on a network ............................................... 189

Appendix I

Language identifiers ................................................................................ 191

Appendix J

A - C ........................................................................................................... 195

D ................................................................................................................ 196

E - P ............................................................................................................ 197

R - T ............................................................................................................ 199

Legal Notices ........................................................................................... 203

8

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 9

Chapter 1

IMPORTANT

This guide describes how to set up a local station application. However, the procedure for

and Events services.

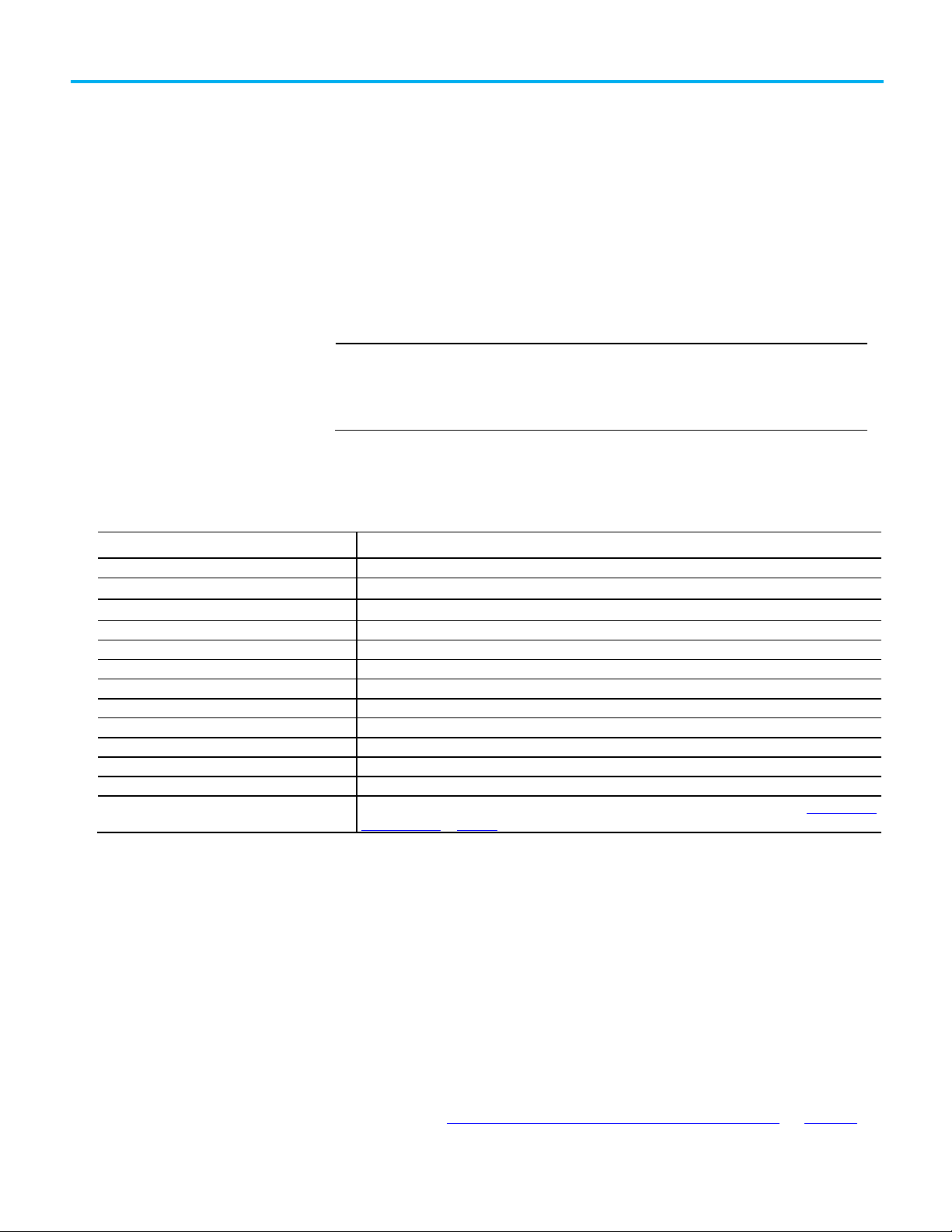

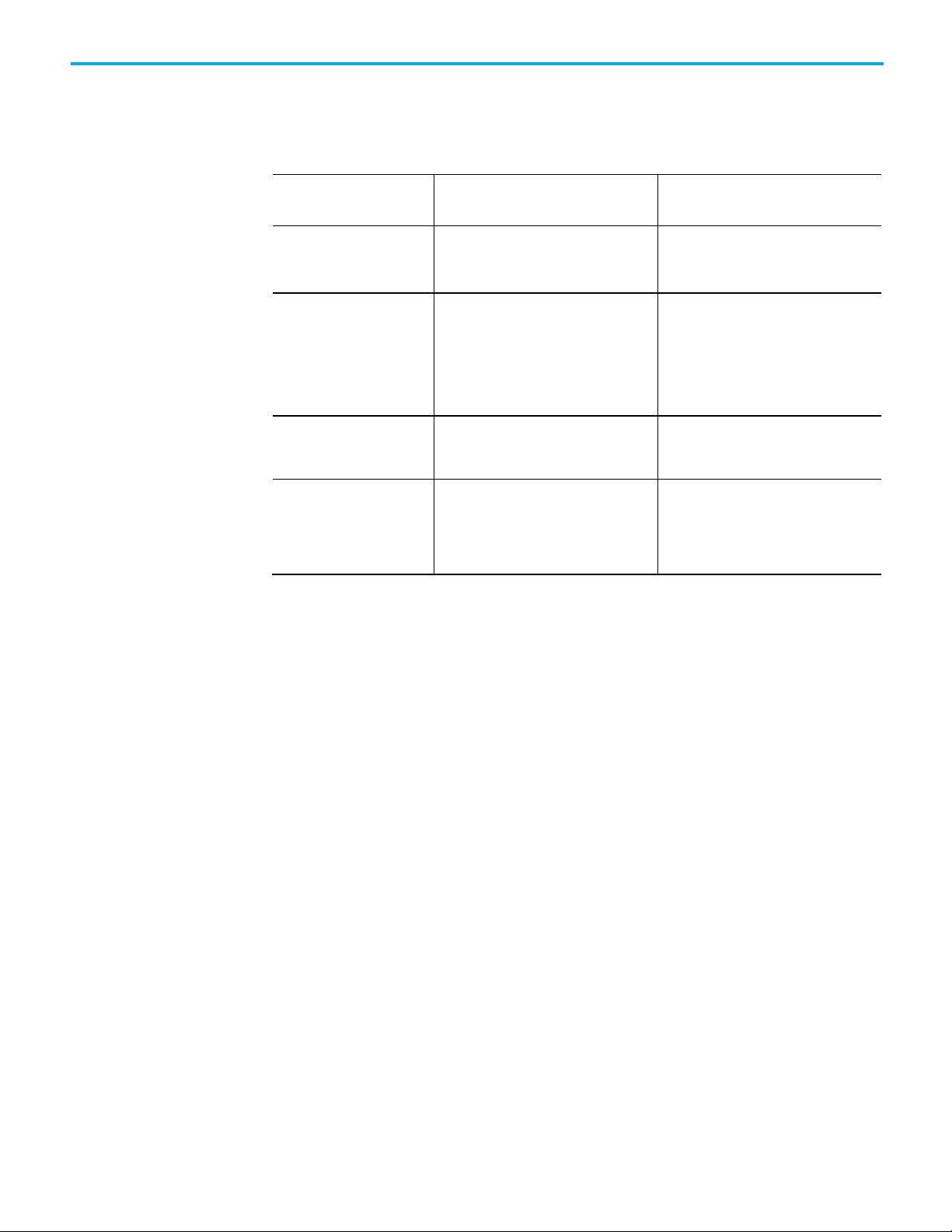

Software

Version

FactoryTalk Services Platform

2.10 or later

RSLogix 5000

16.03 or later (or the Logix Designer application version 21.00 or later)

Logix Designer

21.00 or later (or RSLogix 5000® software version 16.03 or later)

RSLogix 500

Version that supports FactoryTalk Services Platform 2.10 or later

RSLogix 5

Version that supports FactoryTalk Services Platform 2.10 or later

FactoryTalk View SE

5.00 or later

FactoryTalk View Studio

5.00 or later

RSLinx Classic (used for Logix programming)

2.50.20 or later

ControlFLASH™

4.00.09 (used to download firmware)

SoftLogix™

16.03 or later

Microsoft® SQL Server®

Version that supports FactoryTalk Alarms and Events historical logging. For more information, see Supported SQL

Server databases on page 169.

Required software

Recommended hardware

Logix 5000 controllers

What you need to get started

The FactoryTalk® System Configuration Guide describes the tasks that are

required to install, configure, and use FactoryTalk Alarms and Events services

as part of a FactoryTalk-enabled automation system. This guide also includes

references to additional documentation that provides more detail.

setting up a network station application or network distributed application is similar. This

guide provides information about the latter two applications where it is necessary. See

the Help included with the individual software products used to configure and use Alarms

T

he following software is required to configure and operate FactoryTalk

Alarms and Events services:

FactoryTalk Alarms and Events 2.10 or later (included with FactoryTalk View Site Edition and FactoryTalk® Linx™)

FactoryTalk Linx 5.00 or later

The hardware and supported operating systems that are recommended to run

and supported operating

systems

FactoryTalk Alarms and Events are the same as those recommended to run

FactoryTalk View Site Edition. For details, see the FactoryTalk View Site Edition

Installation Guide. To access the guide, in the FactoryTalk View Studio toolbar

click Help, point to Online Books, and then click Installation Guide.

The Logix 5000 controllers listed in the following table support FactoryTalk

Alarms and Events services. When you use built-in alarm instructions in

Logix 5000 controllers, these controllers require a firmware update to revision

16.20 or later (excluding 21 to 23). If you do not want to update the firmware in

your controllers, use a Tag Alarm and Event Server for software-based alarms

and events. See Decide what type of alarm monitoring you need on page 26

.

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

9

Page 10

Chapter 1 What you need to get started

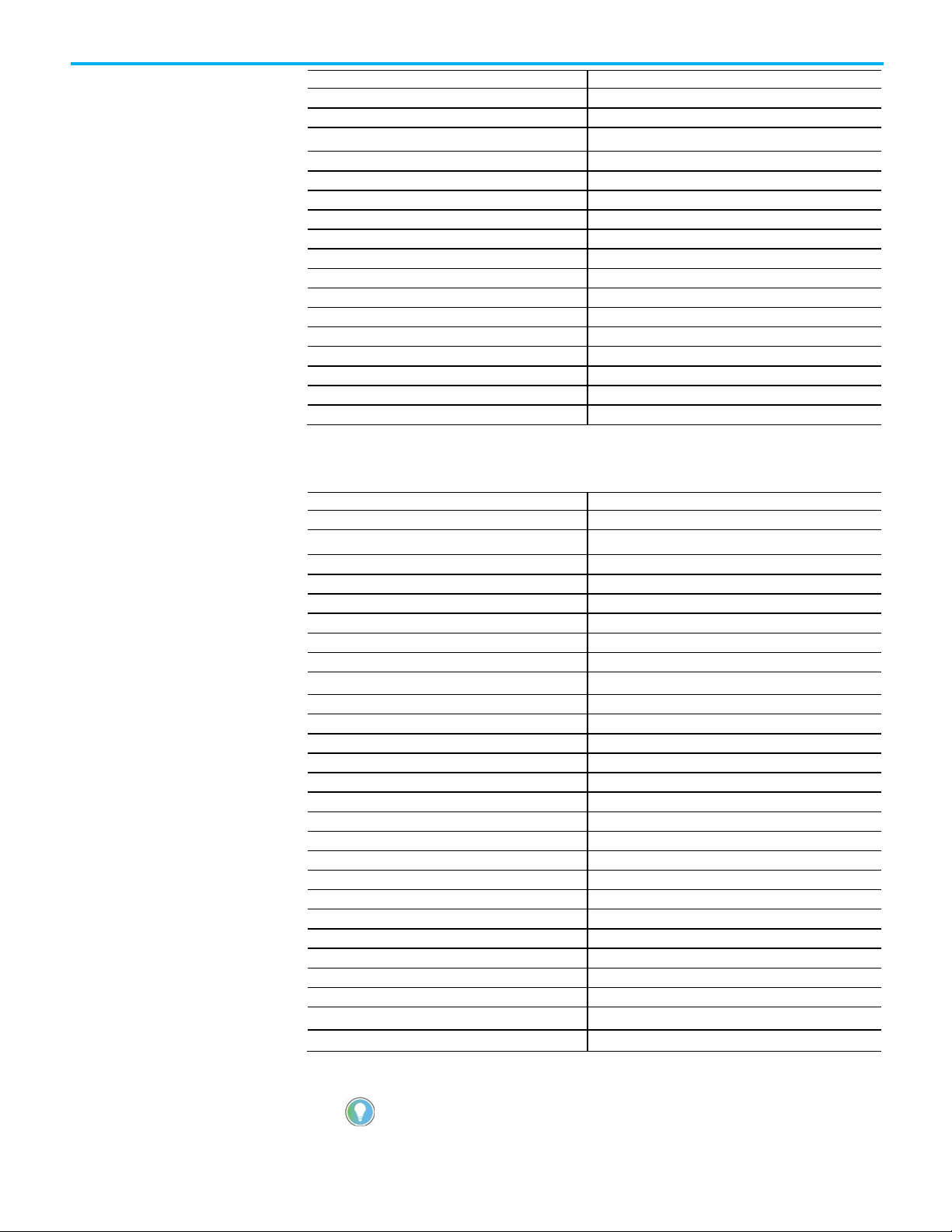

Catalog number

Name

1756-L61

ControlLogix Processor

1756-L62

ControlLogix Processor

1756-L64

ControlLogix Processor

1756-5555

5555 ControlLogix Processor

1768-L43

CompactLogix L43 Controller

1769-L31

CompactLogix L31 Controller

1769-L32C

CompactLogix L32C Controller

1769-L32E

CompactLogix L32E Controller

1769-L35CR

CompactLogix L35CR Controller

1769-L35E

CompactLogix L35E Controller

1794-L34

FlexLogix L34 Controller

1756-L61S

ControlLogix Safety Processor

1756-L62S

ControlLogix Safety Processor

PowerFlex 700S 2

DriveLogix5370

1789-L60

SoftLogix5800

EMULATE

RSLogix Emulate 5000

Catalog number

Name

ControlLogix 1756-L71 Series B

ControlLogix Processor

ControlLogix 1756-L72 Series A

ControlLogix Processor

ControlLogix 1756-L72 Series B

ControlLogix Processor

GuardLogix 1756-L72S Series B

ControlLogix Safety Processor

ControlLogix 1756-L73 Series A

ControlLogix Processor

ControlLogix 1756-L73 Series B

ControlLogix Processor

ControlLogix 1756-L73XT Series B

ControlLogix Processor

GuardLogix 1756-L73SXT Series B

ControlLogix Safety Processor

ControlLogix 1756-L74 Series A

ControlLogix Processor

ControlLogix 1756-L74 Series B

ControlLogix Processor

ControlLogix 1756-L75 Series A

ControlLogix Processor

ControlLogix 1756-L75 Series B

ControlLogix Processor

CompactLogix 1769-L16ER-BB1B

CompactLogix L16ER-BB1B Controller

CompactLogix 1769-L18ER-BB1B

CompactLogix L18ER-BB1B Controller

CompactLogix 1769-L18ERM-BB1B

CompactLogix L18ERM-BB1B Controller

CompactLogix 1769-L24ER-QB1B

CompactLogix L24ER-QB1B Controller

CompactLogix 1769-L24ER-QBFC1B

CompactLogix L24ER-QBFC1B Controller

CompactLogix 1769-L27ERM-QBFC1B

CompactLogix L27ERM-QBFC1B Controller

CompactLogix 1769-L30ER

CompactLogix L30ER Controller

CompactLogix 1769-L30ER-NSE

CompactLogix L30ER-NSE Controller

CompactLogix 1769-L30ERM

CompactLogix L30ERM Controller

CompactLogix 1769-L33ER

CompactLogix L33ER Controller

CompactLogix 1769-L33ERM

CompactLogix L33ERM Controller

SoftLogix 1789-L60

SoftLogix5800

Tip: Firmware revisions 21 to 23 do not support the new alarms functionality.

1756-L63 ControlLogix Processor

The following controllers with firmware revision 24 and later support

FactoryTalk Alarms and Events services:

ControlLogix 1756-L71S Series B ControlLogix Safety Processor

GuardLogix 1756-L73S Series B ControlLogix Safety Processor

CompactLogix 1769-L36ERM CompactLogix L36ERM Controller

10

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 11

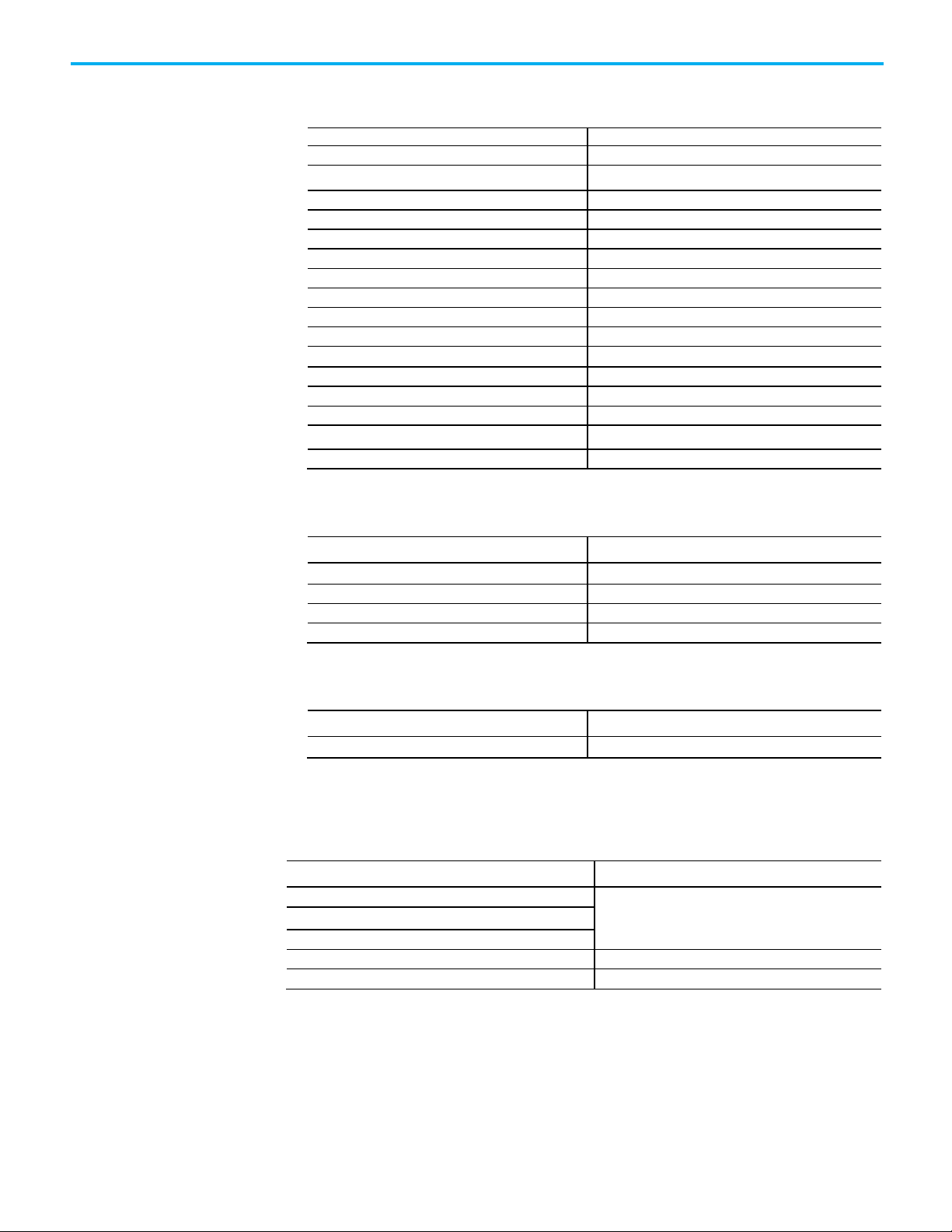

Chapter 1 What you need to get started

Catalog number

Name

ControlLogix 1756-L81E

ControlLogix Processor

ControlLogix 1756-L83E

ControlLogix Processor

ControlLogix 1756-L84E

ControlLogix Processor

ControlLogix 1756-L85E

ControlLogix Processor

CompactLogix 5069-L306ER

CompactLogix L306ER Controller

CompactLogix 5069-L306ERM

CompactLogix L306ERM Controller

CompactLogix 5069-L310ER

CompactLogix L310ER Controller

CompactLogix 5069-L310ERM

CompactLogix L310ERM Controller

CompactLogix 5069-L310ER-NSE

CompactLogix L306ER-NSE Controller

CompactLogix 5069-L320ER

CompactLogix L320ER Controller

CompactLogix 5069-L320ERM

CompactLogix L320ERM Controller

CompactLogix 5069-L330ER

CompactLogix L330ER Controller

CompactLogix 5069-L330ERM

CompactLogix L330ERM Controller

CompactLogix 5069-L340ERM

CompactLogix L340ERM Controller

Catalog number

Name

CompactLogix 5069-L380ERM

CompactLogix L380ERM Controller

CompactLogix 5069-L3100ERM

CompactLogix L3100ERM Controller

CompactLogix 1769-L37ERMO

CompactLogix L37ERMO Controller

GuardLogix 1769-L37ERMOS

CompactLogix Safety Processor

Catalog number

Name

CompactLogix 5069-L46ERMW

CompactLogix 5480 Controller

Controller

Firmware revision

ControlLogix

CompactLogix L3x and L4x

DriveLogix

ControlLogix Redundant Systems

16.60 or higher (excluding 21 to 23)

SoftLogix

16.03 or higher (excluding 21 to 23)

Compatible firmware

Older controllers

The following controllers with firmware revision 29 introduce support for

FactoryTalk Alarms and Events services:

ControlLogix 1756-L82E ControlLogix Processor

CompactLogix 5069-L340ER CompactLogix L340ER Controller

The following controllers with firmware revision 30 introduce support for

FactoryTalk Alarms and Events services:

The following controllers with firmware revision 32 introduce support for

FactoryTalk Alarms and Events services:

Automatic Diagnostics is supported only on Compact GuardLogix 5380, CompactLogix 5380, CompactLogix 5480,

ControlLogix 5580, and GuardLogix 5580 controllers, and the firmware revision must be 33 or later.

The controller firmware revisions listed in the following table are compatible

with FactoryTalk Alarms and Events services:

16.20 or higher (excluding 21 to 23)

These controllers also support FactoryTalk Alarms and Events services:

• Logix 5000 controllers that communicate with FactoryTalk Linx, using

Tag Alarm and Event Servers.

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

11

Page 12

Chapter 1 What you need to get started

How to get the information

you need

• PLC-5® and SLC™ 500 controllers that communicate with FactoryTalk

Linx (or RSLinx Classic to bridge from Ethernet to DH+™ or DH-485

networks), using Tag Alarm and Event Servers.

• Third-party PLCs that communicate with OPC® Data Servers such as

KEPWare, using Tag Alarm and Event Servers.

For more information about the products and components discussed in this

guide, the following manuals and Help files are available:

• FactoryTalk Help

• Studio 5000 Logix Designer Help (for help with developing a controller

project)

• Studio 5000 Logix Designer Online Books

• FactoryTalk View Site Edition Installation Guide

• FactoryTalk View Site Edition User Guide

• RSLinx Classic Help (for help with configuring drivers and creating

topics)

• RSLinx Classic Quick Start Guide

• FactoryTalk Linx Getting Results Guide

• FactoryTalk Linx Help

12

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 13

Chapter 2

IMPORTANT

FactoryTalk View version 10.00 is the last release to support the legacy HMI tag alarms.

and Events.

Overview of FactoryTalk Alarms and Events

services

FactoryTalk Alarms and Events was introduced with FactoryTalk Services

Platform 2.0 (CPR 9) and FactoryTalk View Site Edition 5.0 (CPR 9) to provide

a common, consistent view of alarms and events throughout a FactoryTalk

system.

Beginning with FactoryTalk Alarms and Events 2.30 (CPR 9 SR 3), devicebased and tag-based servers support redundant server configuration.

We highly recommend that you update your alarming strategy to use FactoryTalk Alarms

FactoryTalk Alarms and Events supports two types of alarm monitoring:

• Device-based alarms, including:

• Logix instruction-based alarms

Alarm instructions are programmed and then downloaded into

Logix 5000 controllers. The controller detects alarm conditions and

publishes the alarm information, which is routed to FactoryTalk

Alarms and Events.

• Logix tag-based alarms

Logix tag-based alarms associate alarm conditions with tags for

Logix 5000 controllers. Logix tag-based alarms monitor tag values

to determine the alarm condition, but they are not part of the logic

program and do not increase the scan time for a project. Logix tagbased alarms are supported only on Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and

GuardLogix 5580 controllers.

• Server tag-based alarms

If you are not using Logix 5000 controllers, or if you do not want to use

the built-in alarms or alarm instructions that are available with the

Logix Designer application, server tag-based alarm monitoring offers

the equivalent of HMI tag alarm monitoring, but with an expanded

feature set. Tag Alarm and Event servers monitor controllers for alarm

conditions through data servers and publish event information that

can be displayed and logged. Server tag-based alarm monitoring is

supported for Logix 5000 controllers, PLC-5, and SLC 500 devices

communicating through Rockwell Automation device servers

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

13

Page 14

Chapter 2 Overview of FactoryTalk Alarms and Events services

(FactoryTalk Linx), or for third-party controllers communicating

through OPC Data Servers.

FactoryTalk Alarms and Events:

• Provides a single, integrated set of alarm information.

All participating FactoryTalk products work together to provide a

consistent way to define, manage, log, and view alarm and event

information across a FactoryTalk application.

• Streamlines alarm programming and eliminates polling with devicebased alarm monitoring.

If your automation system includes Logix 5000 controllers, you can use

pre-built alarms or alarm instructions, available in the Logix Designer

application (RSLogix 5000 software version 16 or later), to simplify

coding, and then download them to the controller. Device-based alarm

monitoring eliminates the need for duplicating alarm tags in an HMI

server and requires fewer controller communication resources by

eliminating polling.

• Supports other controllers in the integrated system with server tagbased alarm monitoring.

If your automation system includes other Rockwell Automation

controllers, such as PLC-5s or SLC 500s, or if you prefer not to use the

alarms or alarm instructions with Logix 5000 controllers, softwarebased tag servers monitor controllers for alarm conditions and publish

event information.

• Monitors alarms and events from third-party controllers.

Server tag-based alarm monitoring also makes it possible to monitor

alarm conditions from third-party controllers, which communicate

through OPC Data Servers.

• Provides accurate time stamps on alarm conditions that are generated

from Logix 5000 controllers using device-based alarm monitoring.

When you use device-based alarm monitoring, timestamps are applied

immediately in the controller and are not delayed until alarms reach an

HMI server. To make sure that the timestamps on device-based alarms

are accurate, synchronize the clocks of all controllers that produce

alarms. The event time is propagated throughout the FactoryTalk

Alarms and Events system, so inaccurate timestamps can affect where

alarms are displayed in the Alarm and Event Summary or the Alarm

and Event Banner as well as reports about the alarm and event history.

For more information about synchronizing controller clocks, see

Time

synchronization on page 179.)

14

• Subscribes to and displays diagnostic events enabled by the Automatic

Diagnostics feature of Studio 5000 Logix Designer. Automatic

Diagnostics is supported only on Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 15

Choose between HMI Tag

Alarm Monitoring and

FactoryTalk Alarms and

Events

Chapter 2 Overview of FactoryTalk Alarms and Events services

GuardLogix 5580 controllers, and the firmware revision must be 33 or

later.

• Sends process data with events and messages.

You can associate up to four tags with each alarm to include process

da

ta with event information and alarm messages.

• Secures access to alarm and event operations through integration with

FactoryTalk Security.

• Generates messages for logging.

Log messages include audit messages that track operator actions,

system-related diagnostic messages, and historical alarm and event

messages.

• Shows alarm messages and status information at runtime, in

FactoryTalk View graphic displays.

HMI tag alarm monitoring and FactoryTalk Alarms and Events are two

separate alarm monitoring systems that do not share alarm information with

each other. FactoryTalk tag-based and device-based alarm information can

only be displayed in the FactoryTalk alarm and event objects. FactoryTalk

View HMI tag alarm information cannot be displayed in FactoryTalk alarm

and event objects.

If you are already using HMI tag alarm monitoring in existing applications

you can continue using it. However, to take advantage of the new features of

FactoryTalk Alarms and Events you will need to migrate your existing alarm

monitoring system to FactoryTalk Alarms and Events.

Migrate to FactoryTalk Alarms and Events if you want to:

• Use device-based alarm monitoring. You can use a Logix 5000

controller not only to detect alarms, but also to monitor alarms. This

keeps all alarm and event processing in the controller. To use devicebased alarm monitoring, add the built-in alarm instructions, available

in the Logix Designer application (or RSLogix 5000 software version 1

o

r later), to a logic project and then download the project to a Logix

5000 controller. The controller detects alarm conditions and publishes

vent information, which can be displayed and logged.

e

• Use language-switching with alarm messages. Language switching is

not supported for alarm messages when you use HMI tag alarm

monitoring in FactoryTalk View Site Edition. FactoryTalk View

Machine Edition supports language-switching with alarm messages in

version 5.0 or later.

• Take advantage of the richer feature set offered by FactoryTalk Alarms

and Events, including:

6

• Redundant software-based Tag Alarm and Event servers that

monitor controllers for alarm conditions through data servers an

publish event information that can be displayed and logged.

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

d

15

Page 16

Chapter 2 Overview of FactoryTalk Alarms and Events services

Where to start

FactoryTalk Alarms and

• Configurable Alarm and Event Summary that includes the ability to

suppress alarms directly from the summary, without the use of

separate commands.

• Alarm and Event Banner, Alarm and Event Log Viewer, and Alarm

Status Explorer objects that are hosted in graphic displays. You can

use the Alarm Status Explorer to enable or disable alarms, suppress

or unsuppress alarms, shelve or unshelve alarms, and view operato

co

mments.

• System-wide views in the Alarm and Event Banner, rather than just

the alarms in a single HMI server exposed by th

em\AlarmBanner system tag.

syst

Here is an overview of the sections covered in this guide:

1. Overview of FactoryTalk Alarms and Events services on page 13

2. Plan your system on page 25

• Set up device-based alarm monitoring

efine device-based alarms in Logix 5000 controllers on page 29

a. D

b. Add a device server for Logix 5000, PLC-5, or SLC 500 controllers

on page 39

r

e

Events components

• Set up tag-based alarm monitoring

dd an OPC data server for third-party controllers on page 47

a. A

b. Add a tag-based alarm server for Logix 5000, PLC-5, SLC 500, or

third-party controllers on page 51

3. Set up graphic displays on page 59

4. Monitor and interact with alarms at runtime on page 83

5. Set up historical alarm and event logging on page 101

6. Configure redundancy for alarms and events on page 119

16

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 17

Chapter 2 Overview of FactoryTalk Alarms and Events services

The following diagram shows a high-level view of the components of the

FactoryTalk Alarms and Events system. For more detailed information, see

FactoryTalk Alarms and Events Help.

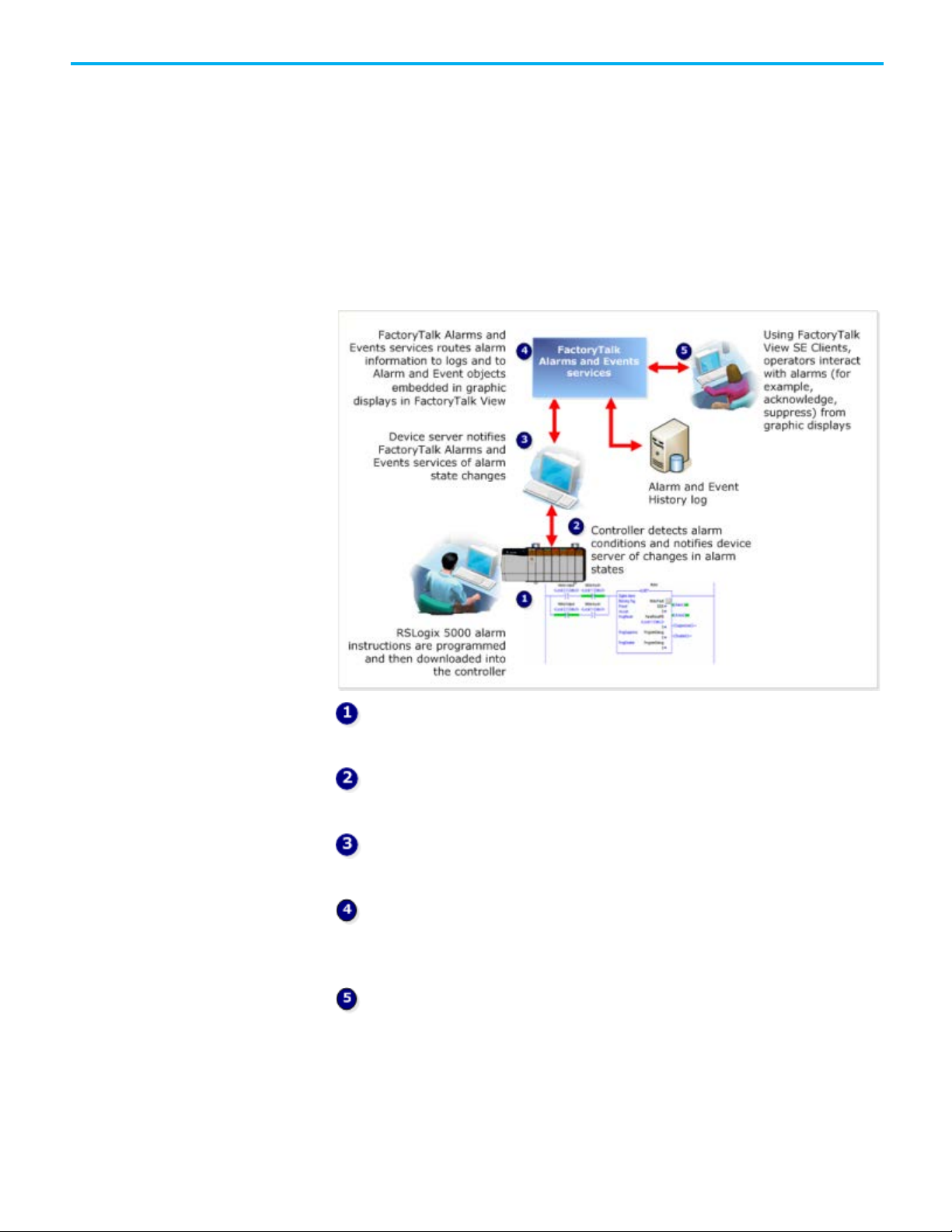

Device-based alarm monitoring

With device-based alarm monitoring that are available with the Studio 5000

Logix Designer application, pre-built alarms or alarm instructions are

configured and then downloaded into a Logix 5000 controller. The controller

detects alarm conditions and notifies alarms and events services of alarm

states. Software components publish this information to a device server. From

the device server, the information can be logged to a database and monitored

from FactoryTalk View graphic displays.

Use device-based alarm monitoring with Logix 5000 controllers, programmed

with the Logix Designer application, communicating through Rockwell

Automation Device Servers (FactoryTalk Linx).

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

17

Page 18

Chapter 2 Overview of FactoryTalk Alarms and Events services

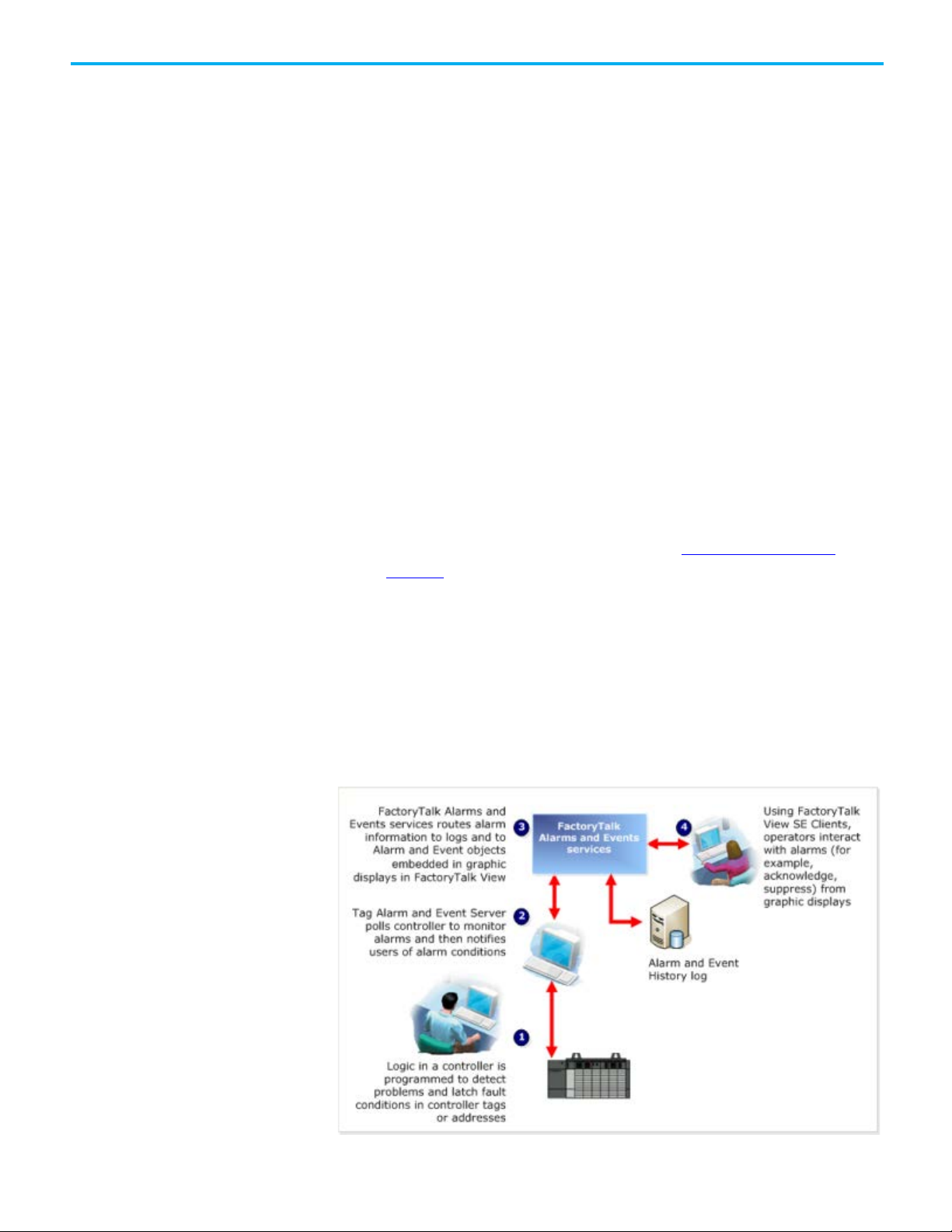

Server tag-based alarm monitoring

If you are not using Logix 5000 controllers, or if you do not want to use the

pre-built alarming available with the Logix Designer application, server tagbased alarm monitoring offers the equivalent of HMI tag alarm monitoring,

but with an expanded feature set. The server tag-based Alarm and Event

servers monitor controllers for alarm conditions through data servers and

publish event information for display and logging. These data servers serve

tags, or data items, contained in OPC-DA (Data Access) servers. Clients that

need access to data items, such as FactoryTalk View Studio and FactoryTalk

Transaction Manager, use data server application elements referenced from

the FactoryTalk Directory to locate the computers that are hosting OPC-DA

2.0 compliant data servers.

Use the server tag-based alarm monitoring for Logix 5000 controllers, PLC-5

devices, and SLC 500 devices communicating through Rockwell Automation

Device Servers (FactoryTalk Linx), or for third-party controllers

communicating through OPC data servers.

FactoryTalk Alarms and Events services

Both device-based and tag-based alarms and events are published to

FactoryTalk Alarms and Events services, which then routes the information to

FactoryTalk Alarms and Events objects hosted in FactoryTalk View, the alarm

and event history log, and to diagnostic logs and audit logs.

Alarm and Event Historian

The Alarm and Event Historian is a logging component that installs silently as

part of the FactoryTalk Alarms and Events software. It manages connections

between alarm servers and databases and logs data from each alarm server to

an alarm history database. An Alarm and Event Log Viewer allows viewing and

printing data from alarm history databases. Third-party database tools can

also retrieve, view, analyze, and print alarm history information.

To use alarm and event logging, install SQL Server separately, or use an

existing SQL Server database. See the release notes for FactoryTalk Alarms

and Events for the latest qualified versions of SQL Server.

18

Diagnostic and audit logs

FactoryTalk Diagnostics routes messages generated by FactoryTalk Alarms

and Events to Local logs on the computers hosting FactoryTalk components,

and optionally to a centralized database log. Audit messages are routed to the

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 19

Chapter 2 Overview of FactoryTalk Alarms and Events services

Local log as well and to the FactoryTalk Audit Log if FactoryTalk AssetCentre is

installed.

Alarm and event setup and monitoring

These components define alarm conditions, set up alarm servers, view and

interact with alarm conditions, and view and run reports on historical alarm

information:

• Alarm and Event Banner

Use the Alarm and Event Banner object, embedded in a FactoryTalk

View graphic display, to monitor and respond to the most seriou

arms requiring immediate attention.

al

• Alarm and Event Log Viewer

Use the Alarm and Event Log Viewer object, embedded in a

FactoryTalk View graphic display, to view, filter, and print historical

alarm information stored in SQL Server databases.

s

• Alarm and Event Summary

Use the Alarm and Event Summary object, embedded in a FactoryTalk

View graphic display, to acknowledge, disable, suppress, filter, and sort

alarms during runtime.

• Alarm Status Explorer

Use the Alarm Status Explorer object, embedded in a FactoryTalk View

g

raphic display, to enable or disable alarms, suppress or unsuppress

alarms, shelve or unshelve alarms, and view operator comments.

• Automatic Diagnostic Event Summary

Use the Automatic Diagnostic Event Summary object, embedded in a

FactoryTalk View graphic display, to suppress, unsuppress, filter, and

sort diagnostic events during runtime.

• Alarm Server Setup

Use either FactoryTalk View Studio or FactoryTalk Administration

Console to add Rockwell Automation Device Servers (as part of

configuring FactoryTalk Linx data servers) and Tag Alarm and Event

ervers to a FactoryTalk application.

S

• Database definitions

Use database definitions to define logging options from an alarm

server to a SQL Server database.

• Diagnostics Viewer

Use the Diagnostics Viewer to view, filter, and export systemgenerated diagnostic messages. Run the Diagnostics Viewer from

either FactoryTalk View Studio or FactoryTalk Administration Console.

• FactoryTalk Audit Log

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

19

Page 20

Chapter 2 Overview of FactoryTalk Alarms and Events services

About monitoring for alarm

About device-based alarm

Device-based alarm

Use the FactoryTalk Audit Log to view and manage audit messages

routed by FactoryTalk Diagnostics. To access the Audit Log, use

FactoryTalk AssetCentre software.

You can monitor for alarm conditions in either of two ways--using device-

conditions

monitoring

based alarm monitoring, or server tag-based alarm monitoring.

With device-based alarm monitoring, detection and monitoring for alarm

conditions are both done in the controller. This is in contrast to server tagbased alarm monitoring, where alarm detection occurs in the controller, but

alarm monitoring is performed by software-based servers.

monitoring workflow

larm instructions or alarms are programmed and then downloaded

A

into a Logix 5000 controller.

The controller detects alarm conditions and notifies its device server,

FactoryTalk Linx, of alarm states.

The device server extracts alarms and publishes the information to

FactoryTalk Alarms and Events services.

FactoryTalk Alarms and Events services routes the alarm information to

logs and to Alarm and Event objects embedded in graphic displays in

FactoryTalk View.

Operators interact with alarms through objects embedded in graphic

displays, such as Alarm and Event Summary, Alarm and Event Banner, and

Alarm Status Explorer.

This approach offers a number of benefits over generic methods of alarm

detection:

20

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 21

Chapter 2 Overview of FactoryTalk Alarms and Events services

About server tag-based

Server tag-based alarm

• Alarm instructions are programmed only once, and then downloaded

the controller, reducing programming effort and errors.

to

• Alarm conditions are detected more quickly.

• Real-time alarming is performed in the controller.

• HMI tags or alarms in a Tag Alarm and Event Server are not required,

reducing overhead and potential tag-mapping errors.

• Alarm states are managed, processed, and preserved by controllers,

even if a server goes down.

• Data polling is eliminated; alarm status is communicated only when

state changes, reducing network overhead and controller processing,

and improving overall system performance.

• Time stamps on alarm conditions are more accurate, because they are

applied in the controller, and not delayed until they reach the HMI

software or Tag Alarm and Event Server. Because device-based alarms

are stamped with the controller’s time, all controllers producin

al

arms must have their clocks synchronized. The event time is

propagated throughout the FactoryTalk Alarms and Events system, so

inaccurate time stamps can affect where alarms are displayed in the

Alarm and Event Summary or the Alarm and Event Banner as well as

reports based on the alarm and event history. For more information

about synchronizing controller clocks, see Time synchronization

page 179.

g

on

alarm monitoring

monitoring workflow

HMI tag alarm monitoring, offered by FactoryTalk View Site Edition (SE),

and tag-based alarm monitoring, offered by FactoryTalk Alarms and Events,

are both examples of software-based alarm monitoring.

Software-based alarm monitoring is a generic way of monitoring alarms from

legacy or third-party controllers.

With software-based alarm monitoring, alarm detection occurs in the

controller, but alarm monitoring is performed by software-based servers.

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

21

Page 22

Chapter 2 Overview of FactoryTalk Alarms and Events services

Choose between device-

Logic in a controller is programmed to detect problems and latch alarm

conditions in tags.

Alarm conditions are defined through software hosted by FactoryTalk

View Studio or FactoryTalk Administration Console.

A Tag Alarm and Event Server polls controller tags and notifies clients,

including FactoryTalk Alarms and Events, of alarm conditions.

FactoryTalk Alarms and Events services routes the alarm information to

logs and to Alarm and Event objects embedded in graphic displays in

FactoryTalk View.

Using FactoryTalk View SE Clients, operators interact with alarms

(acknowledge, disable, suppress, and other commands) from graphic displays,

such as the Alarm and Event Summary, the Alarm and Event Banner, and the

Alarm Status Explorer.

This approach has several disadvantages:

based and server tag-based

alarm monitoring

• Programming is required in both the controller, and the HMI software

or Tag Alarm and Event Server.

• Tags must be duplicated in the HMI server and mapped to the

controller. For Tag Alarm and Event Servers, controller tags must be

mapped to alarms--which can be a tedious, error-prone process.

• Alarms are detected and processed twice, first in the controller logic

and then again in the HMI software or Tag Alarm and Event Server.

• Polling between the HMI server or Tag Alarm and Event Server and

controller tags increases network overhead.

• Alarm time stamps are delayed because they are applied by the HMI

server or Tag Alarm and Event Server after polling and processing,

rather than immediately when they occur. Time stamps are not

synchronized among multiple alarm servers.

• Alarm acknowledge and enable states are held in the computer, and

not in the controller. If the computer fails, alarm state information is

lost.

Use device-based alarm monitoring with:

• Logix 5000 controllers, using downloaded alarms or alarm instructions

programmed with the Logix Designer application (or RSLogix 5000

software version 16 or later)

22

Use server tag-based alarm monitoring with:

• Logix 5000 controllers

• PLC-5, SLC 500 devices

• Third-party controllers that communicate through OPC Data Servers

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 23

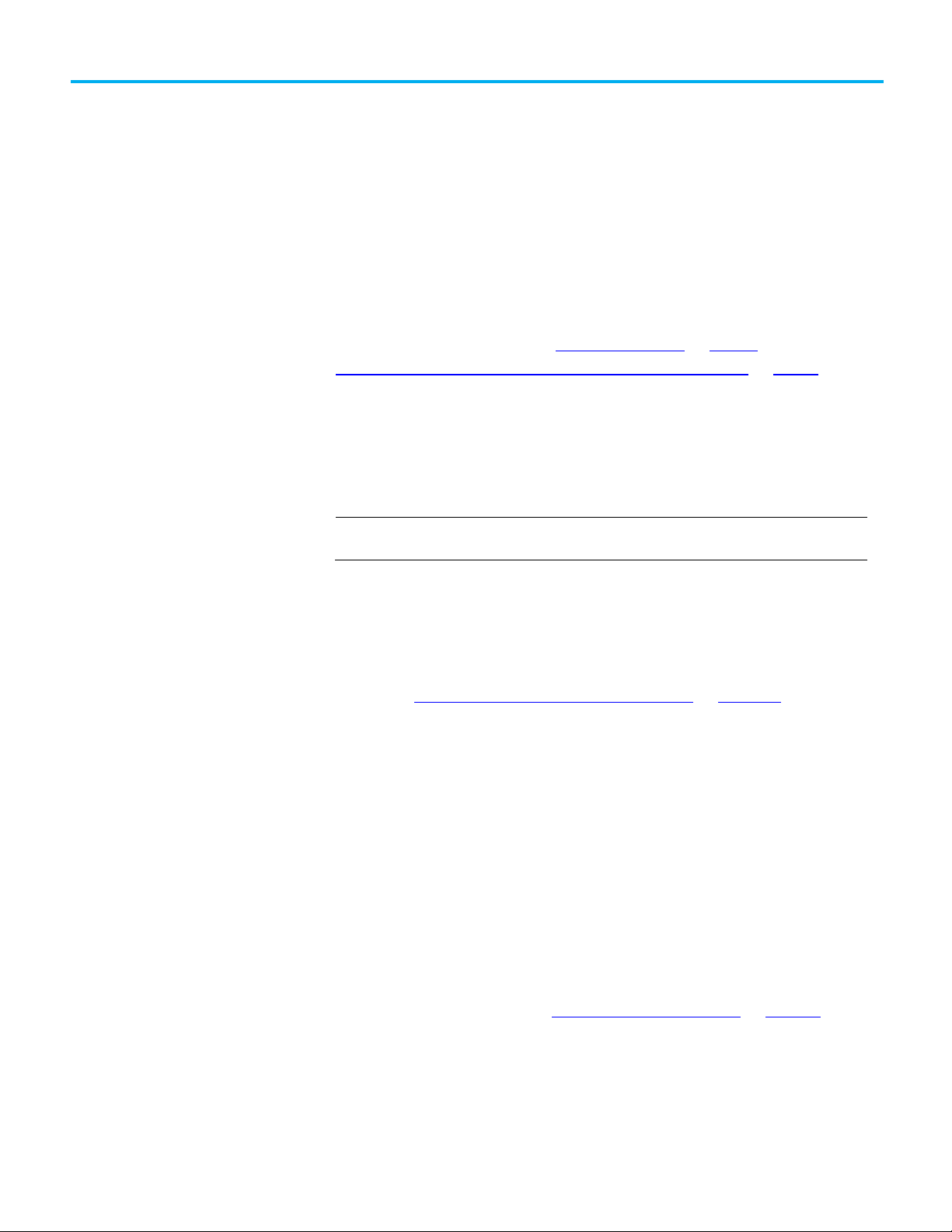

To do this

way

do it this way

Acknowledge, disable, suppress,

HMI Tag Alarm Summary

Alarm and Event Summary

View, filter, and print historical

HMI Tag Alarm Log Viewer

Alarm and Event Log Viewer

Graphic objects in

FactoryTalk Alarms and

Events

Chapter 2 Overview of FactoryTalk Alarms and Events services

FactoryTalk Alarms and Events graphic objects are on the Objects menu in the

graphics editor in FactoryTalk View Site Edition. The HMI tag alarm

monitoring objects remain available for compatibility with existing

applications.

filter, and sort alarms at runtime

Enable or disable alarms,

suppress or unsuppress alarms,

and view operator comments

Monitor and respond to the most

serious alarms that require

immediate attention

alarm information

In HMI tag alarm monitoring, you do it this

HMI Tag Alarm Summary (suppress only, using

the Execute feature)

SuppressOn and SuppressOff commands

Suppressed list

Alarm system tags Alarm and Event Banner

Alarms are logged to a proprietary format, and

can be exported to an ODBC-compliant

database.

With FactoryTalk Alarms and Events, you

Alarm and Event Summary (suppress only; to

unsuppress alarms, use the Alarm Status

Explorer)

Alarm Status Explorer

Historical alarm information is stored in

Microsoft SQL Server databases.

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

23

Page 24

Page 25

IMPORTANT

FactoryTalk Alarms and Events is not supported for use with FactoryTalk View Machine

Decide what type of

application you are building

Chapter 3

Plan your system

Before you build and deploy FactoryTalk Alarms and Events as part of a local

or network application, consider which computer hardware and operating

systems you plan to use, and where to install the various hardware and

software components. The information in this chapter offers some guidelines

as you begin planning. See also Required software on page 9

Recommended hardware and supported operating systems on page 9.

You must decide whether you are building a local station application or

network station application on a stand-alone computer, or a network

distributed application distributed across multiple computers. This system

configuration guide primarily discusses how to install, configure, and use

software on a stand-alone system.

and

Edition.

• Network distributed applications are held in a FactoryTalk Network

Directory. Participating software products can be located on multiple

computers, distributed across a network. All of the computers

participating in a particular network distributed application share

common Network Directory Server located on a network computer.

See Typical distributed system on a network on page 189

graphical overview.

The application you create in the Network Directory can be divided

into any number of areas. Each area can contain one or more sub-areas

and one or more data servers. Each area or sub-area can contain only

one HMI server. A network distributed application supports

FactoryTalk Alarms and Events redundancy.

• Network station applications are held in a FactoryTalk Network

Directory. All participating software products (except for data servers)

must be installed on the same computer. Network station applications

can connect to data servers that are located on different machines. All

of the computers participating in a particular network station

application share a common Network Directory Server located on a

network computer. See Typical stand-alone system on page 27

graphical overview.

for a

for a

a

The application you create in the Network Directory can be divided

into any number of areas. Each area can contain one or more sub-areas

and one or more data servers. A network station application consists of

only one HMI server. You can add the HMI server in the root area or

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

25

Page 26

Chapter 3 Plan your system

IMPORTANT

To use FactoryTalk Alarms and Events with a local station application, install all

applications and network distributed applications.

Tip: FactoryTalk Services Platform and FactoryTalk Alarms and Events software is installed

along with FactoryTalk View and FactoryTalk Linx software.

Decide what type of alarm

Follow these steps

within the areas you have created. A network station application

supports FactoryTalk Alarms and Events redundancy.

monitoring you need

• Local station applications are suitable for self-contained, stand-alon

rocesses that do not interact with other processes or systems. Local

p

station applications are held in a FactoryTalk Local Directory and are

accessible only from the local computer where they reside. Even if th

c

omputer is connected to a network and even if a network applicatio

esides on the same computer, the applications you create in the

r

FactoryTalk Local Directory remain self-contained and do not share

data or project elements.

Local station applications do not support areas, and all application

components and participating software products are located on a

single computer. See Typical stand-alone system on page 27

for a

graphical overview.

software on the same computer.

FactoryTalk Alarms and Events redundancy is only supported in network station

actoryTalk Alarms and Events supports two types of alarm monitoring:

F

• Device-based alarm monitoring

Built-in alarms or alarm instructions, that are available in the Logix

Designer application (RSLogix 5000 software version 16 or later), are

programmed in a logic project and then downloaded to a Logix 5000

controller. The controller detects alarm conditions and publishes event

information, which can be displayed and logged.

e

e

n

• Server tag-based alarm monitoring

Software-based tag alarm and event servers monitor controllers for

alarm conditions through data servers and publish event information,

which can be displayed and logged. Tag-based alarm monitoring is

supported for Logix 5000, PLC-5, and SLC 500 devices communicating

through Rockwell Automation device servers (FactoryTalk Linx), or for

third-party controllers that communicate through OPC Data Servers.

You can use a mix of both types of alarm monitoring. Choose server tag-based

alarm monitoring if you do not want to change the logic in your

programmable controllers, or if you do not want to update the firmware in

Logix 5000 controllers.

Follow these steps to plan your system:

• Determine network configuration

• Install and activate FactoryTalk View software

• Install FactoryTalk Linx software

26

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 27

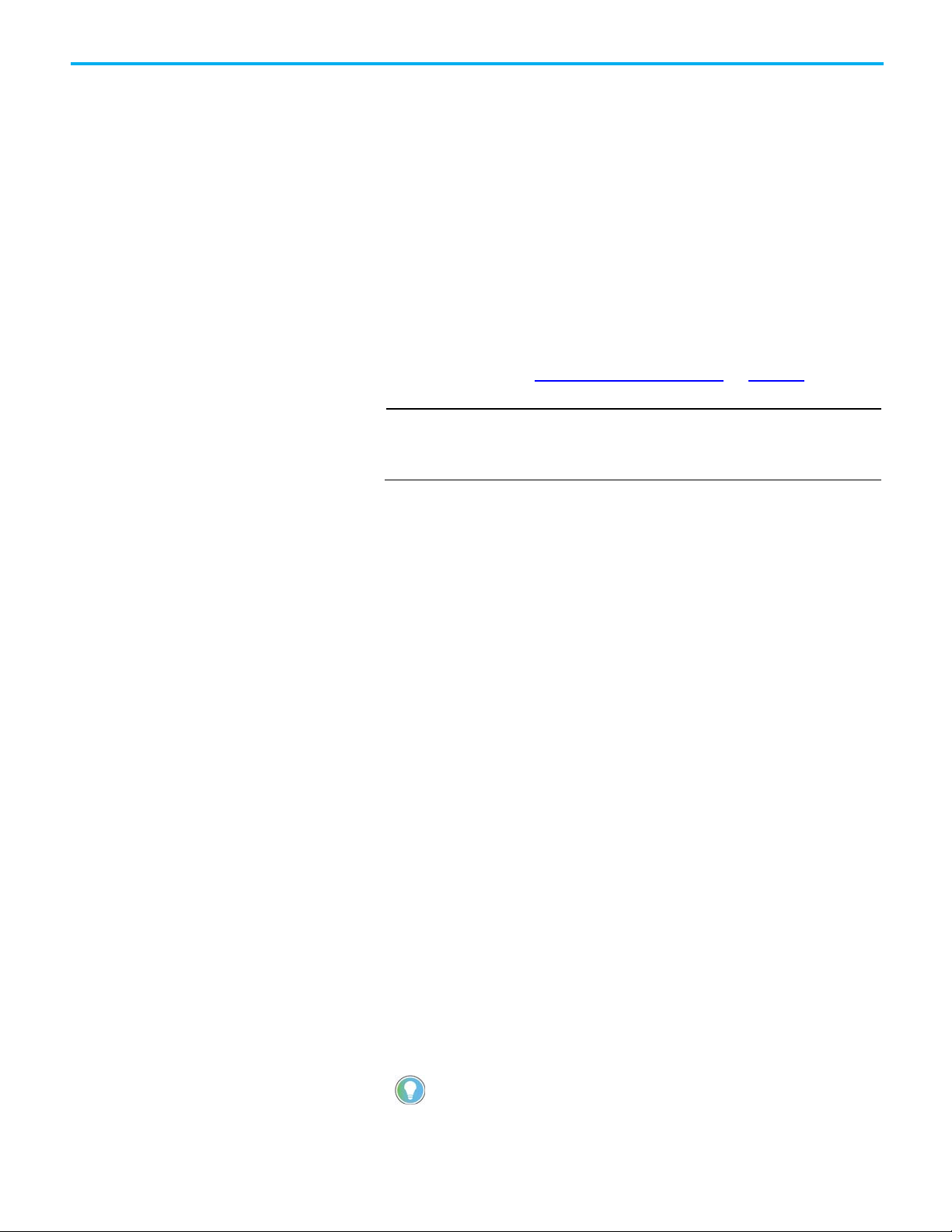

IMPORTANT

This guide describes how to set up a local station application. The procedure to set up a

Reference for building a distributed system on page 189.

What you need

Install and activate

FactoryTalk software

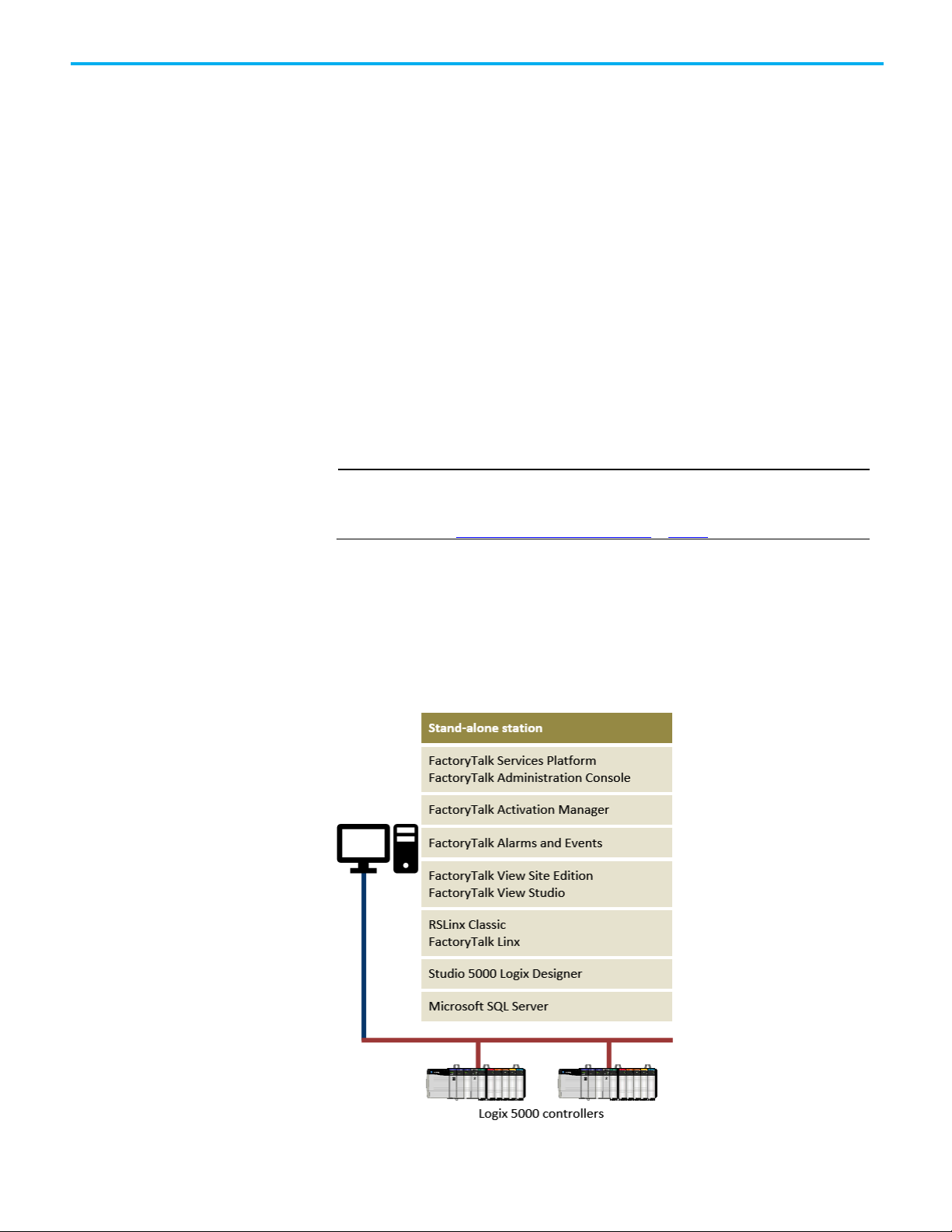

Typical stand-alone system

Chapter 3 Plan your system

• Install RSLinx Classic software

• Install and activate RSLogix software

• Update Logix 5000 firmware to V16 or later (optional if using Ta

Al

arm and Event Servers)

• (optional) Install Microsoft SQL Server 2014 SP3 Express

• Decide what type of application you are building.

• Decide what type of alarm monitoring you need.

• Install and activate FactoryTalk software.

• Update Logix 5000 firmware to revision 16.20 or later (excluding 21 to

23), if you plan to use device-based alarm monitoring and alarm

instructions that are built into Logix 5000 controllers. If you do no

lan to use device-based alarm instructions, you can skip this step and

p

use tag-based alarm monitoring with a Tag Alarm and Event Server

instead.

Follow these procedures to install and activate the software products required

for FactoryTalk Alarms and Events.

network station application or network distributed application is similar. This guide

provides additional information about the two applications where it is necessary. See also

g

t

For more information about each software product, see its respective product

Help.

To use FactoryTalk Alarms and Events with a local station application or a

network station application as part of a stand-alone FactoryTalk system,

install all software on the same computer. Use this diagram only as a starting

point--your own system will vary.

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

27

Page 28

Chapter 3 Plan your system

IMPORTANT

This guide provides additional information about network distributed applications

Tip: To take advantage of the new alarms functionality in the v24 firmware, we recommend you

revision 24 or later.

Tip: If you already have Microsoft SQL Server installed, you may need to change the configuration

SQL Server database on page 169.

Install FactoryTalk software

Install Microsoft SQL Server

For specific installation instructions, refer to the installation guide for each

product.

• To develop or run local station applications, install all the necessary

software components on one computer.

• To develop or run network station applications, install all the necessary

software components (except for data servers) on one computer.

Network station applications can connect to data servers that are

located on different machines.

• To develop or run network distributed applications, install different

ombinations of software on each computer, depending on you

c

n

eeds. For more information, see FactoryTalk Help. Click Start > All

r

Programs > Rockwell Software > FactoryTalk Tools > FactoryTalk

Help.

or network station applications where it is necessary.

To set up a FactoryTalk system, install the following software:

• FactoryTalk Services Platform

• FactoryTalk Activation

• FactoryTalk View Site Edition

• FactoryTalk Linx

• RSLinx Classic

• The Studio 5000 Logix Designer application (known previously a

s

RSLogix 5000 software)

• Update Logix 5000 firmware to revision 16.20 or later (excluding 21 to

23). If you plan to use device-based alarm monitoring see

Decide what

type of alarm monitoring you need on page 26.

I

f you plan to log historical alarm and event messages to a database, you must

install Microsoft SQL Server software on the computer you want to use for

logging. If you do not have Microsoft SQL Server software installed, see

Microsoft SQL Server 2014 SP2 Express on page 165.

options to log alarm and event messages. For configuration instructions, see Use an existing Microsoft

28

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

install FactoryTalk Services Platform v2.71 or later and update your controller firmware to

Install

Page 29

Chapter 4

Tip: Logix tag-based alarms are supported only on Compact GuardLogix 5380, CompactLogix 5380,

CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580 controllers.

Tip: If your FactoryTalk application does not include Logix 5000 controllers, or if your controllers are not

a tag-based alarm server for Logix 5000, PLC-5, SLC 500, or third-party controllers on page 51.

Alarm buffering during loss

Define device-based alarms in Logix 5000

controllers

To set up device-based alarm monitoring, you program alarms or alarm

instructions that are available with the Logix Designer application (RSLogix

5000 software version 16 or later), and download them to a Logix 5000

controller. The controller detects alarm conditions and notifies alarms and

events services of alarm states. Software components publish this information

to a device server, where it can be logged to a database, and interacted from

FactoryTalk View graphic displays.

FactoryTalk Alarms and Events can handle many different types of alarms.

The controller limits the alarms to Logix tag-based alarms and instructionbased alarms. The instruction-based alarms include digital and analog alarms.

An analog alarm instruction monitors two types of alarm conditions: Level

and Rate of Change. A server tag-based alarm supports three alarm types:

Digital, Level, and Deviation.

of connection to the

controller

Logix tag-based alarms associate alarm conditions with tags for Logix 5000

controllers. Logix tag-based alarms monitor tag values to determine the alarm

condition, but they are not part of the logic program and do not increase the

scan time for a project.

A digital alarm instruction is based on the input rung state (in ladder logic) or

on the alarm input (for function block). The trigger condition compares the

value of the tag to either zero or one.

An analog alarm defines a condition that evaluates a single analog tag against

up to four limit values (high-high to low-low) and up to two rate of change

limits (positive and negative).

programmed with the alarm instructions included in the Logix Designer application (RSLogix 5000

software version 16 or later), see Add an OPC Data Server for third-party controllers on page 47 and Add

To receive device-based alarms, the alarm server (FactoryTalk Linx)

establishes a subscription to the alarms in the Logix controller. The controller

maintains a connection to each subscriber and monitors the status of that

connection.

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

29

Page 30

Chapter 4 Define device-based alarms in Logix 5000 controllers

IMPORTANT

Firmware revision 21 to revision 23 do not support the new alarms functionality. The

buffering time unless instructed by Technical Support.

Tip: To take advantage of the new alarms functionality in the revision 24 firmware, we

your controller firmware to revision 24 or later.

Before you begin

What you need

Follow these steps

As alarm state changes occur, the controller caches information such as

timestamps, alarm state and associated tag values, and transmits the

information to all of the subscribers.

If any subscriber fails to confirm the receipt of the alarm information, or if the

connection to a subscriber is not good, the controller stores the undelivered

alarm information in a 100 KB buffer. Each subscriber has its own buffer and

communication problems with one subscriber do not interfere with alarm

delivery to other subscribers. When the buffer is full, newer alarm

information is discarded and a FactoryTalk Diagnostics message is logged.

The buffer is created when the subscriber establishes its initial connection,

and is maintained for a length of time after a subscriber loses its connection.

The length of time is specified in the Buffer Timeout setting on each

FactoryTalk Linx device shortcut. See step 3, "Create a new shortcut to the

controller," in Add a device server on page 39

.

buffer timeout setting is not available to controllers with firmware revision 24 or later. For

controllers with version 20 or earlier, we recommend that you do not change the default

• Rev

iew Plan your system on page 25

.

• Verify that you have installed and activated the software listed in the

next section under What you need on page 30

.

• Verify that the Logix 5000 firmware has been updated to revision 16 or

later (excluding revisions 21 to 23).

recommend you install FactoryTalk Services Platform software version 2.71 or later, and update

• L

ogix Designer application (RSLogix 5000 software)

• ControlFLASH

• RSLinx Classic

Follow these steps to define a digital or analog alarm:

• Plan your system

• Run Studio 5000 Logix Designer software

• Create a project

• For a digital alarm, define a boolean tag or a rung state on which to

alarm

For an analog alarm, define a analog tag on which to alarm

• Add a digital or analog alarm instruction

• Configure the digital or analog alarm properties

• Downland the project to the controller

• Test the alarm instruction

• Add a device server

• Add a data server

30

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

Page 31

Define a Logix tag-based

alarm

Create an alarm definition

Chapter 4 Define device-based alarms in Logix 5000 controllers

Use Logix tag-based alarms to send alerts about specific events or conditions.

Logix tag-based alarms are similar to instruction-based alarms that are

created using alarm instructions (ALMA and ALMD), but Logix tag-based

alarms do not affect the scan time of the project.

Tip: Logix tag-based alarms are supported only on Compact GuardLogix 5380, CompactLogix 5380,

CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580 controllers.

To define a Logix tag-based alarm:

1. On the Controller Organizer, expand the Alarm Manager folder, right-

click Alarms, and select New Alarm.

To create an alarm in Tag Editor or in the Ladder, Sequential Function

Chart, Function Block, or Structured Text editors, right-click a tag an

s

elect Add Alarm for [tag].

2. In the Name box, enter a name for the alarm.

3. In the Input box, add the input tag for the alarm. If you launch the

New Alarm dialog box from a logic editor, the Input box is populate

w

ith the tag that you right-clicked.

4. To enable the alarm, select the Required to be used and evaluated

check box. All new alarms are disabled by default.

5. Adjust other alarm settings as necessary.

d

d

An alarm definition is associated with an Add-On Instruction (AOI) or a

defined data type. When a tag is created using a data type or an AOI that has

alarm definitions, alarms are created automatically based on the alarm

definitions.

You can create an alarm definition for the following components:

• Any scalar tag or parameter of an AOI.

• Any scalar member of a user-defined data type (UDT).

• Any scalar member of a system-defined data type (SDT).

• Any scalar member of a module-defined data type (MOT).

When a tag uses a data type that has alarm definitions associated with it,

alarm conditions are automatically added for the tag based on its alarm

definitions.

When an AOI is based on an AOI definition, alarm conditions are

automatically added for the AOI instance based on the alarm definitions

associated with the AOI definition.

To create an alarm definition:

1. On the Controller Organizer, expand the Alarm Manager folder, rightclick Alarm Definitions, and select New Alarm Definition

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021

.

31

Page 32

Chapter 4 Define device-based alarms in Logix 5000 controllers

Tip: If your FactoryTalk application does not include Logix 5000 controllers, or if your controllers

third-party controllers on page 51.

Download the program to

Define an instruction-based

Configure the digital alarm

You can also right-click a scalar tag or parameter of an AOI or a scalar

member of a data type and select Add Alarm Definition.

2. In the Name box, enter a name for the alarm definition.

3. When creating an alarm definition for a UDT or AOI, in the Input box,

add an input tag. When creating an alarm definition for a data type

dd a data type member in the Input box.

a

4. To enable all instances of the alarm, select the Required to be used and

evaluated check box. All new alarms definitions are disabled by

default.

5. Adjust other settings as necessary.

You can download the program containing the Logix tag-based alarm to the

controller and test the alarm

controller and then use FactoryTalk View to test the alarm.

1. If it is not already running, start RSLinx Classic to establish

communications between the controller and the Logix Designer

application (RSLogix 5000 software version 16 or later).

2. On the Logix Designer application menu, click Communications >

Who Active.

3. Select the controller to which you want to download the project.

4. Click Download. At the prompt, click Download again. The controller

is placed in Program mode.

5. To switch the controller to run mode, click Communications > Run

Mode.

6. To test the alarm, in FactoryTalk View Studio, create a FactoryTalk

Alarms and Events graphic object (for example, Alarm and Even

ummary) to read Logix tag-based alarms with the fully qualified

S

name.

,

t

Digital tags are either on or off. They have states instead of limits. The alarm

alarm: digital

and download to the

controller

trigger condition compares the value of the tag to the configured alarm state.

An alarm can be triggered if the digital alarm is in one of these two states:

• The rung evaluation or input tag is equal to zero

• The rung evaluation or input tag is not equal to zero

This example uses the ladder logic editor that comes with the Logix Designer

application (RSLogix 5000 software) to define a digital alarm. You can also

configure digital alarms in function blocks or structured text.

Step 1. Create a rung of logic that will trigger the alarm

1. Create a new project with default settings. In this example, we use

32

Rockwell Automation Publication FTAE-RM001M-EN-E - March 2021