Page 1

Reference Manual

Ethernet Design Considerations

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, ArmorBlock, CompactLogix, ControlLogix, FactoryTalk, PanelView, RSLinx, RSLo gix, Logix5000, Kinetix, FLE X, POINT I/O, PowerFlex, RSNetWorx, RSView,

SoftLogix, Stratix 2000, Stratix 5700, Stratix 6000, Stratix 8000, Stratix 8300, ArmorPOINT, POINT Guard I/O, Guard I/O, GuardLogix, Integrated Architecture, ControlFLASH, and TechConnect are trademarks of

Rockwell Automation , Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

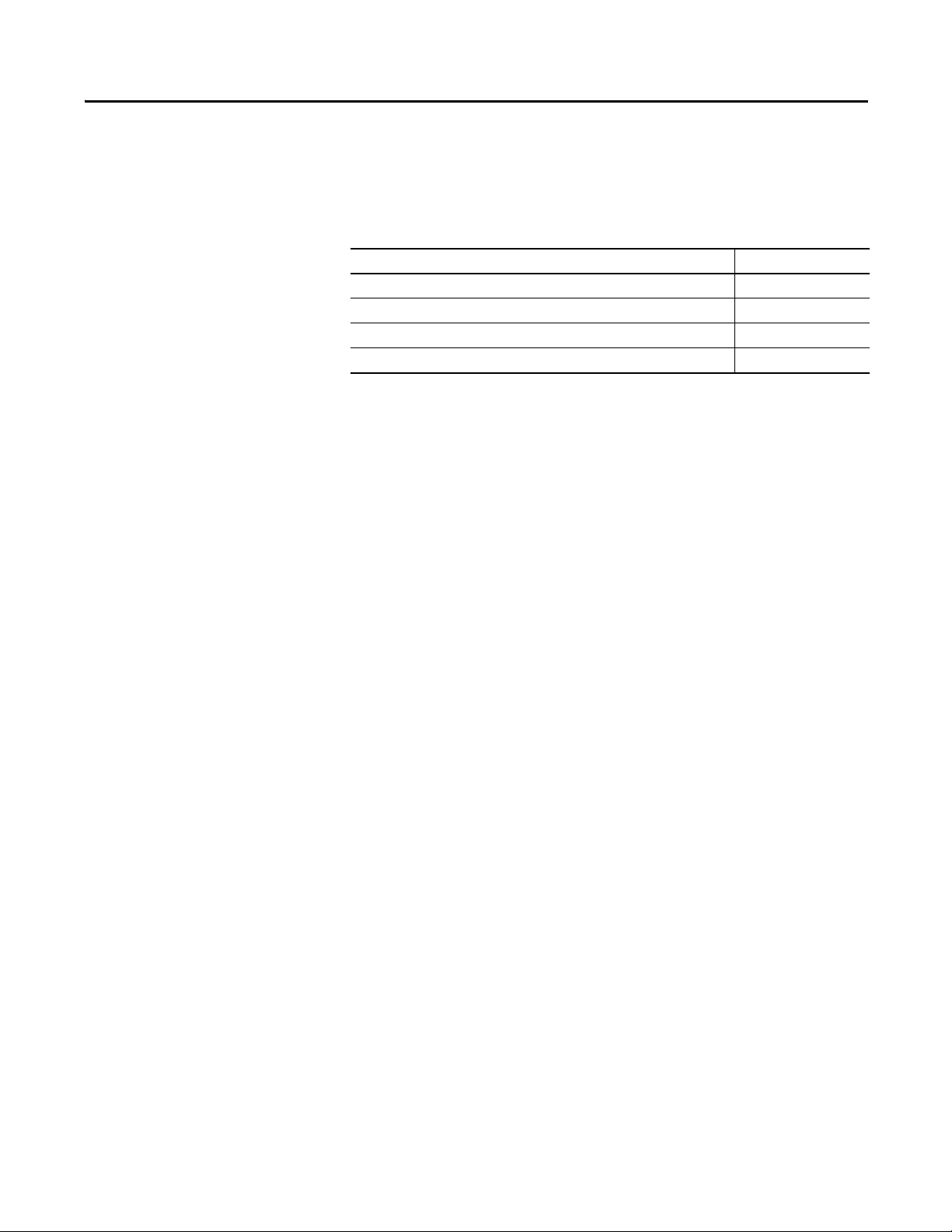

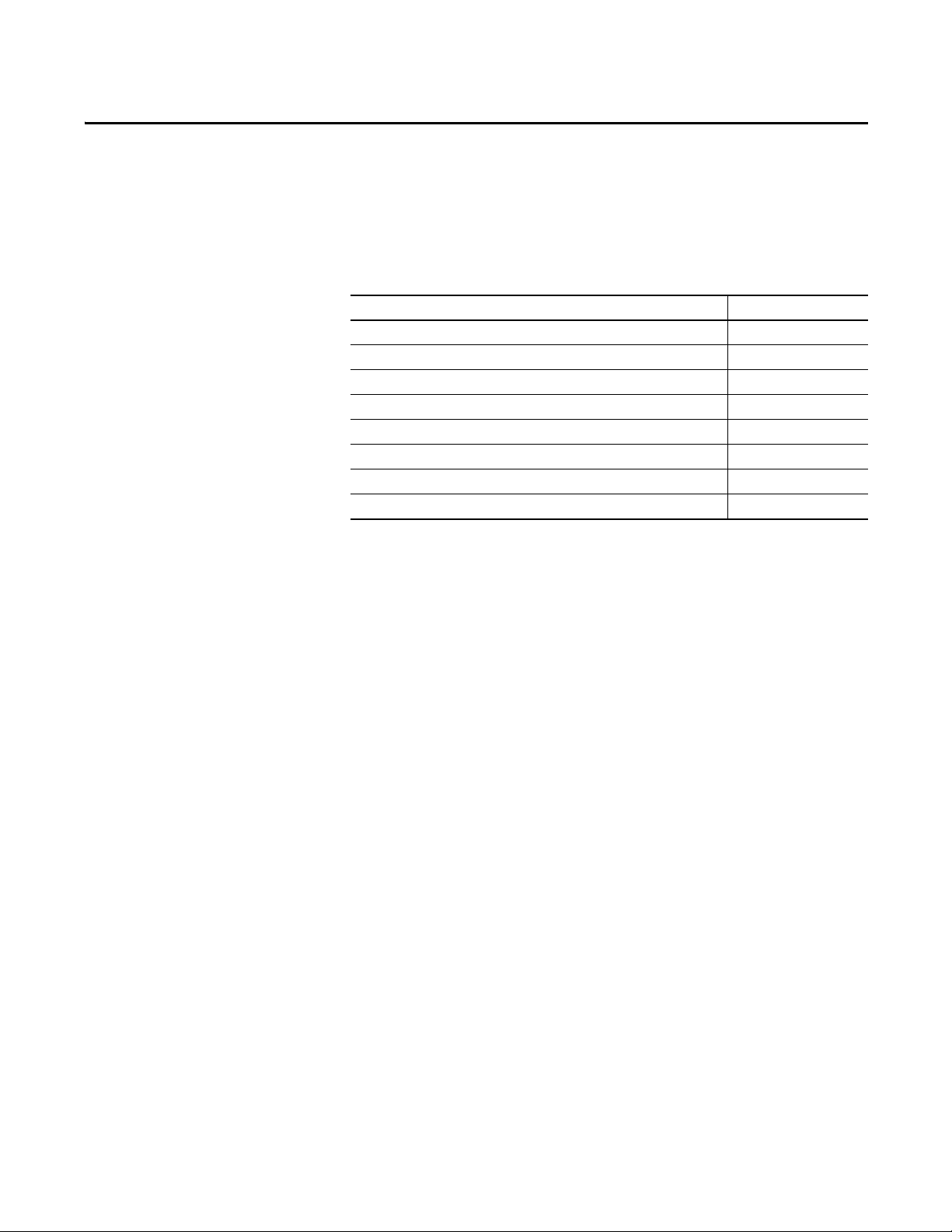

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the changes made to this revision.

Top ic Pa ge

Studio 5000™ Logix Designer application is the rebranding of RSLogix™ 5000 software 10

Updated switch selection chart 28

Updated information about network address translation (NAT) 38

Added specifications for the 1756-EN2TRXT, 1756-EN2TSC, and 9300-ENA modules 66, 67, 68

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 5

Table of Contents

Preface

EtherNet/IP Overview

Ethernet Infrastructure Components

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1

Network Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configuration Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gateway Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Subnet Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

EtherNet/IP Modules in a Control System . . . . . . . . . . . . . . . . . . . . . . . . . 19

Bridge across Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 2

Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Hubs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Repeaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Media Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Routers and Gateways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Unmanaged versus Managed Switches. . . . . . . . . . . . . . . . . . . . . . . . . . 29

Autonegotiation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Full-duplex Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ethernet Infrastructure Features

Chapter 3

Transmission Packets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Default Setting in the Studio 5000 Environment. . . . . . . . . . . . . . . . 33

Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Multicast Address Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Transmission Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Address Resolution Protocol (ARP). . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Domain Name System (DNS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Network Address Translation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Allen-Bradley Products That Support NAT . . . . . . . . . . . . . . . . . . . . 38

Virtual LANs and Segmentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

VLAN Trunking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

VLANs and Segmentation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . 44

Quality of Service (QoS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

QoS Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Resiliency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Time Calculations in a Logix5000 System . . . . . . . . . . . . . . . . . . . . . . 46

Resiliency Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 5

Page 6

Table of Contents

Spanning Tree Protocol (STP) and Rapid STP (RSTP) . . . . . . . . . . 48

EtherChannel Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Flex Links Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Resilient Ethernet Protocol (REP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Device-level Ring (DLR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Internet Group Management Protocol (IGMP). . . . . . . . . . . . . . . . . . . . . 55

Port Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Dynamic Secure MAC Address (MAC ID) . . . . . . . . . . . . . . . . . . . . . 56

Static Secure MAC Address (MAC ID) . . . . . . . . . . . . . . . . . . . . . . . . 56

Security Violations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Device Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 4

EtherNet/IP Protocol

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

TCP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

CIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

CIP Connection Message Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

CIP Connection Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Nodes on an EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

EtherNet/IP Network Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Packets Rate Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

EtherNet/IP Capacity Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Upgrade to Latest Firmware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Monitor Packet Sizes in Current Application . . . . . . . . . . . . . . . . . . . 70

Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Implicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

CIP Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

CIP Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Integrated Motion on an EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . 76

Connectivity to IT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 5

Predict System Performance

6 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

System Prediction Goals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Part One: Determine If System Has Sufficient Bandwidth

to Meet Application Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Part Two: Predict Maximum input or Output Times for

CIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Performance Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

CompactLogix 5370 Controller Example . . . . . . . . . . . . . . . . . . . . . . . 83

ControlLogix Controller Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Identify and Count Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Calculate Packets/Second . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Estimate the Fastest RPI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Page 7

Index

Table of Contents

Estimate Maximum Input or Output Times for CIP Connections . 89

Example: Predict System Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Determine If System Has Sufficient Bandwidth

to Meet Application Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Explicit Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

EtherNet/IP Module Serving as a Scanner . . . . . . . . . . . . . . . . . . . . . . 93

EtherNet/IP Modules Functioning as Adapters . . . . . . . . . . . . . . . . . 95

EtherNet/IP Modules 2 and 3 with Consumed Tags . . . . . . . . . . . . 96

Recommendations to Achieve More Throughput

in an Existing Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Estimate the Maximum Input or Output Times

for CIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Refine Estimates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 9

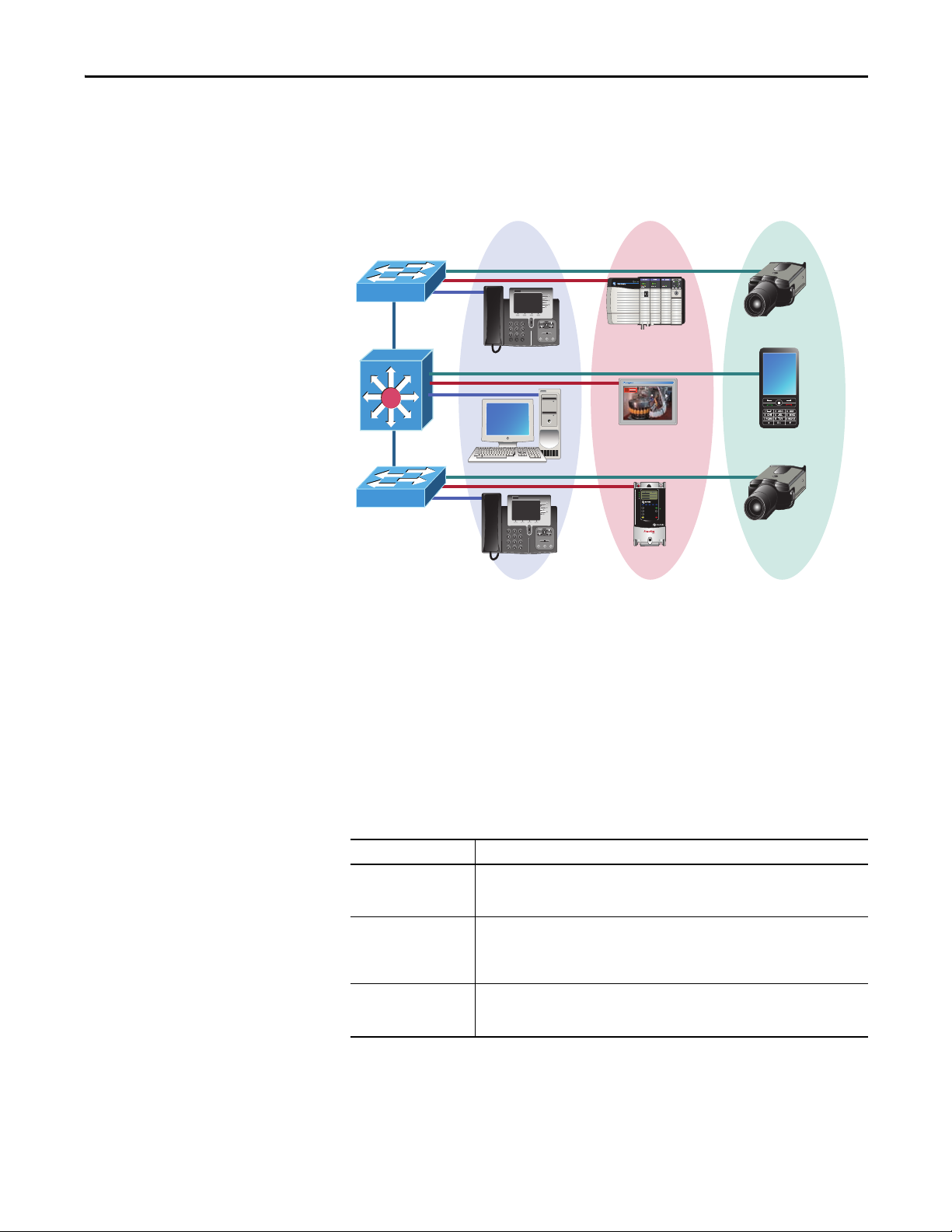

Rockwell Automation uses open network technology for seamless, plant-wide

integration. These open networks share a universal set of communication

services. As a result, information can be communicated seamlessly throughout

the plant and to and from the Internet for e-business applications.

Each Rockwell Automation network is ideal for a wide range of applications,

operates with devices manufactured by various vendors, and shares data with

industry-standard information networks.

Comparison EtherNet/IP Network ControlNet Network DeviceNet Network

Function Plant management system tie-in (material

handling) with configuration, data collection,

and control on a single high-speed network

Typical devices networked • Mainframe computers

• Programmable controllers

• Robots

• HMI

• I/O

• Drives

• Process instruments

Data repetition Large packets, data sent regularly Medium-size packets; data transmissions are

Number of nodes, max No limit 99 nodes 64 total nodes

Data transfer rate 10 Mbps, 100 Mbps, or 1 Gbps 5 Mbps 500, 250, or 125 Kbps

Typical use Plant-wide architecture

High-speed applications

Supports transmission of time critical data

between PLC processors and I/O devices

• Programmable controllers

• I/O chassis

• HMIs

• Personal computers

• Drives

• Robots

deterministic and repeatable

Redundant applications

Scheduled communication

Connects low-level devices directly to

plant-floor controllers without the use of I/O

modules

• Sensors

• Motor starters

• Drives

• Personal computers

• Push buttons

• Low-end HMIs

• Bar code readers

• PLC processors

• Valve manifolds

Small packets; data sent as needed

Supply power and connectivity to low-level

devices

Preface

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 9

Page 10

Preface

Studio 5000 Environment

The Studio 5000 Engineering and Design Environment combines engineering

and design elements into a common environment. The first element in the

Studio 5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix 5000 software and continues to be the

product to program Logix5000™ controllers for discrete, process, batch, motion,

safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. It is the one place for

design engineers to develop all the elements of their control system.

10 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 11

Preface

Additional Resources

These documents and websites contain additional information concerning

related products from Rockwell Automation.

Table 1 - ODVA Resources

Resource Description

http://www.odva.org/

http://www.odva.org/default.aspx?tabid=54

Ethernet Media Planning and Installation Manual, ODVA publication

http://www.odva.org/Portals/0/Library/Publications_Numbered/

PUB00148R0_EtherNetIP_Media_Planning_and_Installation_Manual.pdf

Network Infrastructure for EtherNet/IP: Introduction and Considerations,

ODVA publication

http://www.odva.org/Portals/0/Library/Publications_Numbered/

PUB00035R0_Infrastructure_Guide.pdf

Table 2 - Rock well Automation Resources

Resource Description

http://www.ab.com/networks/

http://www.rockwellautomation.com/services/networks/

http://www.rockwellautomation.com/services/security/

http://www.ab.com/networks/architectures.html Links to the Education series webcasts for IT and controls professionals.

EtherNet/IP Embedded Switch Technology Application Guide, publication ENET-AP005 Describes how to install, configure, and maintain linear and device-level ring (DLR)

EtherNet/IP QuickConnect Application Technique, publication ENET-AT001

EtherNet/IP Socket Interface Application Technique, publication ENET-AT002 Describes the socket interface used to program MSG instructions to communicate

EtherNet/IP Network Configuration User Manual, publication ENET-UM001 Describes how to configure and use EtherNet/IP communication modules with a

Accesses the Open DeviceNet Vendors Association (ODVA) website.

Accesses the CIP Advantage website. The website offers the following:

• CIP features and benefits

• How to get started

Describes the required media components and how to plan for, install, verify,

troubleshoot, and certify an Ethernet network.

Provides an overview of the technologies used in EtherNet/IP networks and provides

guidelines for deploying infrastructure devices in EtherNet/IP networks.

Accesses the networks and communication section of the Rockwell Automation website.

Accesses Rockwell Automation network and security services websites.

networks by using EtherNet/IP devices with embedded switch technology.

Describes EtherNet/IP QuickConnect technology. QuickConnect technology enables

EtherNet/IP devices to quickly power up and join an EtherNet/IP network.

between a Logix5000 controller via an EtherNet/IP module and Ethernet devices that do

not support the EtherNet/IP application protocol.

Logix5000 controller and communicate with various devices on the Ethernet network.

Table 3 - Cisco and Rockwell Automation Alliance Resources

Resource Description

http://www.ab.com/networks/architectures.html

Converged Plantwide Ethernet (CPwE) Design and Implementation Guide,

publication ENET-TD001

Embedded Switch Technology Reference Architectures, publication ENET-RM003

Links to the Rockwell Automation and Cisco Systems reference architecture website.

Represents a collaborative development effort from Rockwell Automation and Cisco

Systems. The design guide is built on, and adds to, design guidelines from the Cisco

Ethernet-to-the-Factory (EttF) solution and the Rockwell Automation Integrated

Architecture™. The design guide focuses on the manufacturing industry.

Provides design recommendations for connecting device-level topologies to networks

comprised of Layer 2 switches. It also covers the implementation of embedded switch

technology within the Converged Plantwide Ethernet (CPwE) Cell/Area zone.

You can view or download Rockwell Automation publications at

http:/www.rockwellautomation.com/literature/

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 11

. To order paper copies of

Page 12

Preface

Notes:

12 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 13

Chapter 1

Application

Presentation

Session

Transport

Network

Link

Physical

CIP

Control and Information

Protocol

Ethernet

MAC

Ethernet

Physical

UDP TCP

IP

IP-Multicast

EN50170

Control International

and

IF C 61158 Standard

Request for Comments

IETF

UDP/TCP/IP

IEEE 802.3

OPEN

EtherNet/IP Overview

Top ic Pa ge

Network Protocols 14

Configuration Requirements 15

EtherNet/IP Modules in a Control System 19

Bridge across Networks 20

The EtherNet/IP protocol is a multi-discipline, control and information

platform for use in industrial environments and time-critical applications. The

EtherNet/IP network uses standard Ethernet and TCP/IP technologies and an

open, application-layer protocol called the Common Industrial Protocol (CIP).

The open, application-layer protocol makes interoperability and

interchangeability of industrial automation and control devices on the

EtherNet/IP network a reality for automation and real-time control applications.

The EtherNet/IP protocol follows these standards:

• IEEE 802.3—Standard Ethernet, Precision Time Protocol (IEEE-1588)

• IETF—Internet Engineering Task Force, standard Internet Protocol (IP)

• IEC—International Electrotechnical Commission

• ODVA—Open DeviceNet Vendor Association, Common Industrial

Protocol (CIP)

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 13

Page 14

Chapter 1 EtherNet/IP Overview

Network Protocols

On the most basic level, Ethernet is a wire or cable that connects computers and

peripheral modules so that they can communicate. The actual wire used for the

network is referred to as the network medium. Beyond the physical medium, all

Ethernet networks support protocols that provide data transfer and network

management capability.

Protocol Description

Common Industrial

Protocol (CIP)

Transmission Control

Protocol/internet Protocol

(TCP/IP)

User Datagram Protocol/

internet Protocol (UDP/IP)

CIP applies a common application layer over an Ethernet network by encapsulating

messages in TCP/UDP/IP. This common application layer provides interoperability and

interchangeability of industrial au tomation and control modules on an Ethernet network.

The EtherNet/IP network supports both real-time I/O (implicit messaging) and explicit

messaging.

TCP/IP is a transport-layer protocol (TCP) and a network-layer protocol (IP) commonly

used in business environments for communication within networks and across

internetworks. The EtherNet/IP communication modules use TCP/IP for explicit

messaging. Explicit messaging is used by applications when time is not a critical factor,

such as uploading or downloading programs.

UDP is a much simpler transport protocol. It is connectionless, and provides a simple

means of sending datagrams between two modules. UDP is used by applications that

implement their own handshaking between modules and require minimal transport

service. UDP is smaller, simpler, and faster than TCP and can operate in unicast, multicast,

or broadcast mode. The EtherNet/IP communication modules use UDP/IP for real-time

I/O messaging.

CIP

CIP is a message-based, application-layer protocol. This protocol implements a

relative path to send a message from the producing modules in a system to the

consuming modules.

CIP uses the producer/consumer networking model instead of a source/

destination (master/slave) model. The producer/consumer model reduces

network traffic and increases speed of transmission.

In traditional I/O systems, controllers poll input modules to obtain their input

status. In the CIP system, digital input modules are not polled by a controller.

Instead, they produce their data either upon a change of state (COS) or at a

requested packet interval (RPI). The frequency of update depends upon the

options chosen during configuration and where on the network the input

module resides. The input module, therefore, is a producer of input data and the

controller is a consumer of the data.

The controller can also produce data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers over the Logix

backplane and over the EtherNet/IP network. This data exchange conforms to

the producer/consumer model.

14 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 15

EtherNet/IP Overview Chapter 1

Class A

Class B

Class C

Network (7 bits)

Network (14 bits)

Network (21 bits)

Local Address (8 bits)

Local Address (16 bits)

Local Address (24 bits)

Class D

Multicast Address (28 bits)

0

0

8

8

8

8

0

0

0

16

16

16

24

24

24

31

31

31

31

1

0

1

0

1

11 1

0

Configuration Requirements

All devices on Ethernet communicate by using the Ethernet address for the

device. This address is sometimes referred to as the hardware address or Media

Access Controller (MAC) address. The hardware address is a unique, six-byte

address, which is embedded in the circuitry of every device on an Ethernet

network. Every vendor of Ethernet products obtains their own unique address

range.

For a device to communicate on an Ethernet network, you must configure its

IP address, gateway address, and subnet mask.

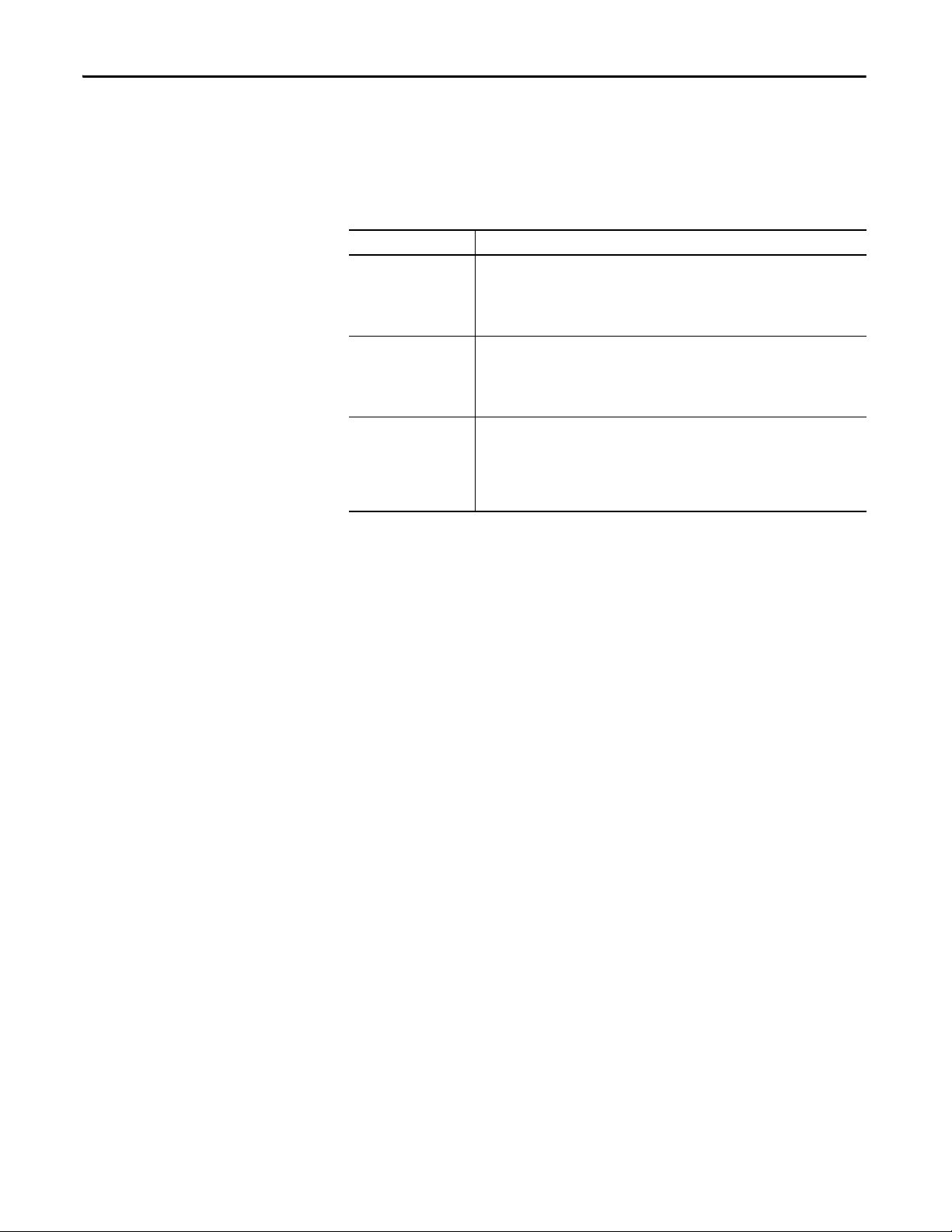

IP Address

The IP address identifies each node on the IP network or system of connected

networks. Each TCP/IP node on a network must have a unique IP address. The

IP address is 32 bits long and has a network ID part and a host ID part. Because

networks vary in size, there are four types of networks.

Network Type Application

Class A Large networks with many devices

Class B Medium-sized networks

Class C Small networks (fewer than 256 devices)

Most common for private, industrial networks

Class D Multicast addresses

The network class determines how an IP address is formatted.

16

24

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 15

Page 16

Chapter 1 EtherNet/IP Overview

Each node on the same physical network must have an IP address of the same

class and must have the same network ID. Each node on the same network must

have a different local address (host ID), thus giving it a unique IP address.

IP addresses are written as four-decimal integers (0...255) separated by periods

where each integer gives the value of one byte of the IP address.

For example, the following 32-bit IP address is written as 130.0.0.1:

10000010 00000000 00000000 00000001

Class Leftmost Bits Start Address Finish Address

A0xxx 0.0.0. 127.255.255.255

B10xx 128.0.0.0 191.255.255.255

C110x 192.0.0.0 223.255.255.255

D 1110 224.0.0.0 239.255.255.255

Public IP addresses are for computers and devices connected to the Internet.

Devices on industrial networks are not connected to the Internet, but they

communicate with each other over an EtherNet/IP network. These devices use

private IP addresses that are not routed on the Internet.

Private IP addresses typically start with 10, 172, or 192 as the first part of the

address. Private IP addresses are typically connected to the Internet through a

Network Address Translation (NAT) device.

For more information about NAT, see page 38

.

16 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 17

EtherNet/IP Overview Chapter 1

Network 1

Network 2

A

B

C

G

128.1.0.2

128.2.0.3

128.2.0.2

128.2.0.1

128.1.0.1

Gateway Address

A gateway connects individual physical networks into a system of networks.

When a node needs to communicate with a node on another network, a gateway

transfers the data between the two networks. The following figure shows

gateway G connecting Network 1 with Network 2.

When host B with IP address 128.2.0.1 communicates with host C, it knows

from C’s IP address that C is on the same network. In an Ethernet environment,

B can then resolve C’s IP address to a MAC address and communicate with C

directly.

When host B communicates with host A, it knows from A’s IP address that A is

on another network because the network IDs differ. To send data to A, B must

have the IP address of the gateway connecting the two networks. In this example,

the gateway’s IP address on Network 2 is 128.2.0.3.

The gateway has two IP addresses (128.1.0.2 and 128.2.0.3). Network 1 hosts

must use the first IP address, and Network 2 hosts must use the second IP

address. To be usable, a host’s gateway IP address must match its own net ID.

Devices with IP address switches use the default gateway address of either

192.168.1.1 or 0.0.0.0. Check your product information to determine which

gateway address applies for your device.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 17

Page 18

Chapter 1 EtherNet/IP Overview

128.1.0.1

128.2.64.1

128.2.64.3

128.1.0.2

Network 1

Network 2.1

128.2.128.1 128.2.128.2

128.2.128.3

128.2.64.4

128.1.0.1

128.2.64.1

128.2.128.1

128.2.64.2

128.2.128.2

128.1.0.2

128.2.64.3

128.2.128.3

A

B

C

G

G2

DE

Network 2.2

Subnet Mask

Subnet addressing is an extension of the IP address scheme. It enables a site to use

a single net ID for multiple physical networks. Routing outside of the site

continues by dividing the IP address into a net ID and a host ID via the IP class.

Inside a site, the subnet mask is used to redivide the IP address into a custom net

ID portion and host ID portion.

A subnet mask determines which of the 32 bits in the IP address are part of the

network ID and which are part of the unique node identification. This also

determines the size of the network or subnetwork.

Take Network 2 (a Class B network) in the previous example and add another

physical network. Selecting this subnet mask adds two additional net ID bits

providing for four physical networks.

11111111 11111111 11111111 00000000 = 255.255.255.0

Two bits of the Class B host ID have been used to extend the net ID. Each unique

combination of bits in the part of the host ID where subnet mask bits are 1

specifies a different physical network.

A second network with hosts D and E has been added. Gateway G2 connects

network 2.1 with network 2.2. Hosts D and E use gateway G2 to communicate

with hosts not on network 2.2. Hosts B and C use gateway G to communicate

with hosts not on network 2.1. When B is communicating with D, G (the

configured gateway for B) routes the data from B to D through G2.

18 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 19

EtherNet/IP Overview Chapter 1

Switch

1756-EN2T

1756 I/O Modules

1794-AENT

1794 I/O Modules

Work stat ion

1734-AENT

1734 I/O Modules

PowerFlex®

Drive

1783-ETAP

Work stat ion

1783-ETAP

1756-EN2TR

1756 I/O Modules

1769-L18ERM-BB1B Control System

1769-L33ERM Control System

PanelView™ Plus Terminal Connected

Via a 1783-ETAP EtherNet/IP Tap

1794-AENTR FLEX™ I/O Adapter

1734-AENTR POINT I/O™ Adapter

with POINT I/O Modules

Kinetix 6500 Drives

with Motors

Kinetix 350 Drive

with Motor

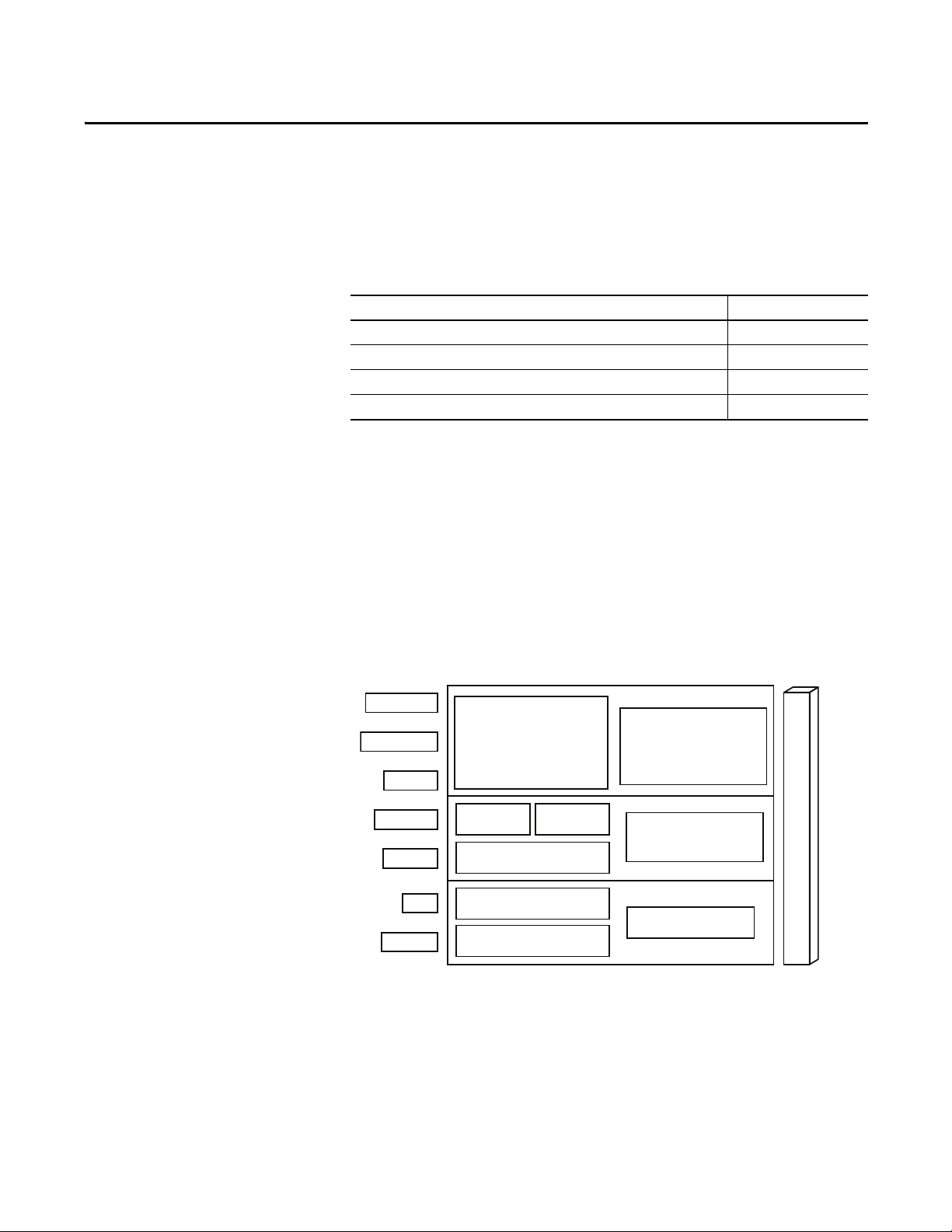

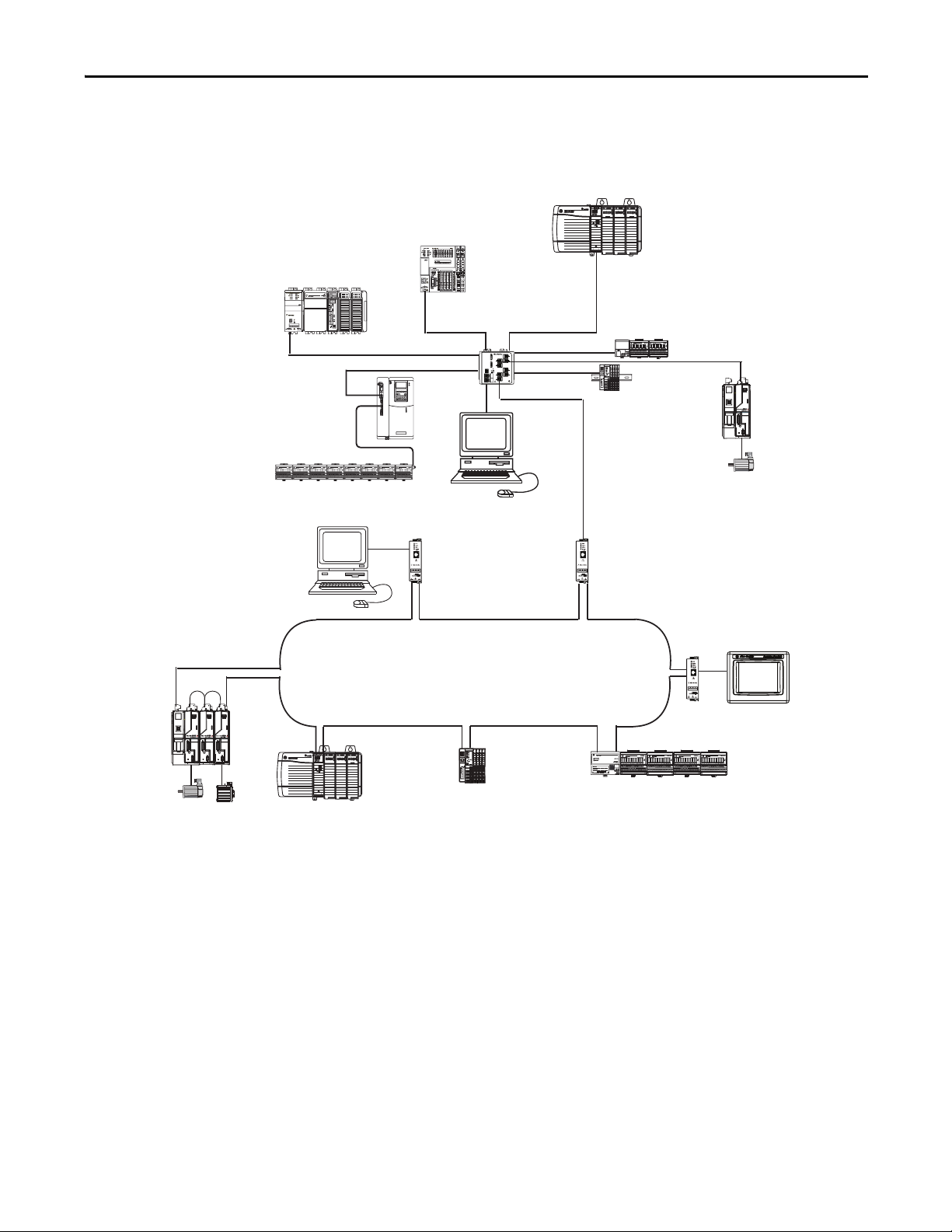

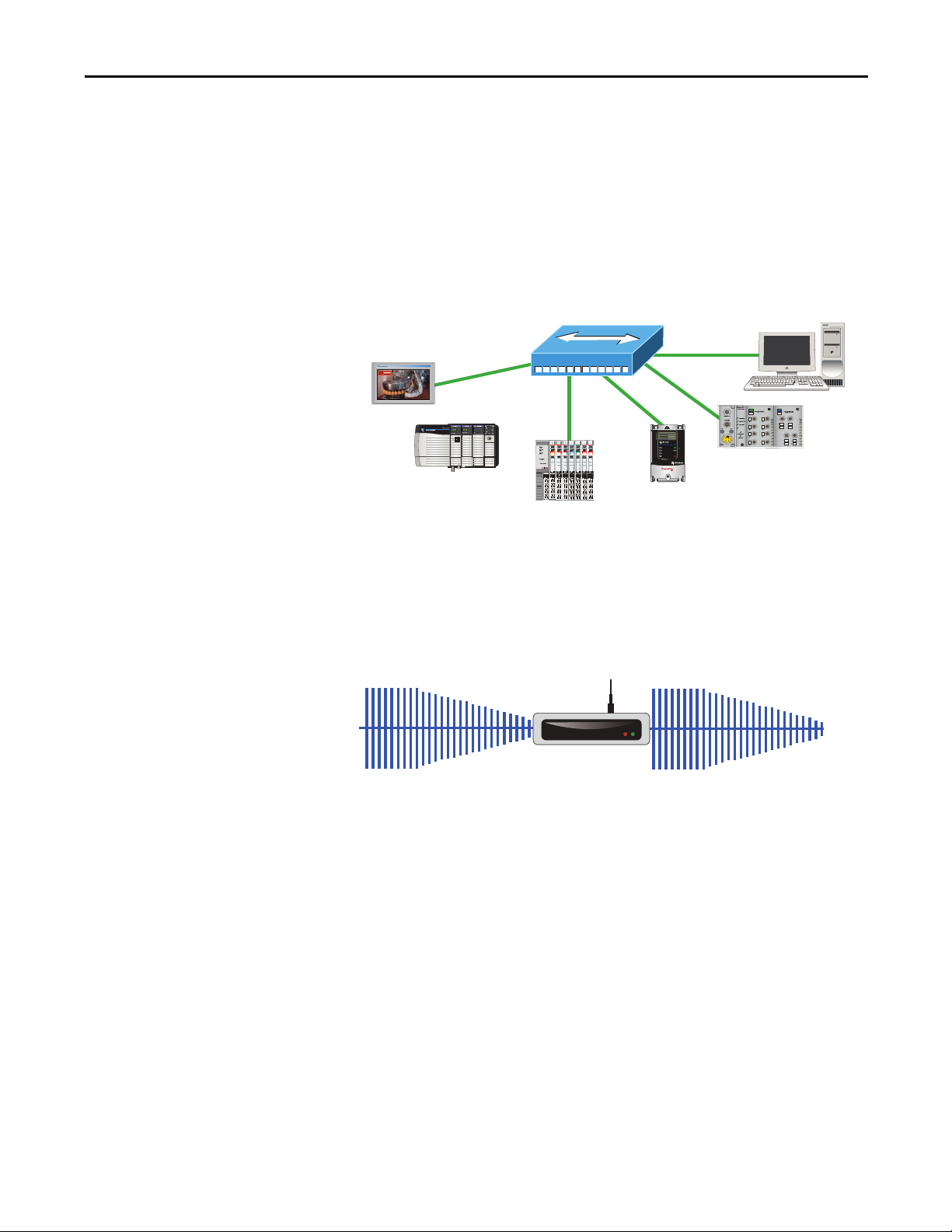

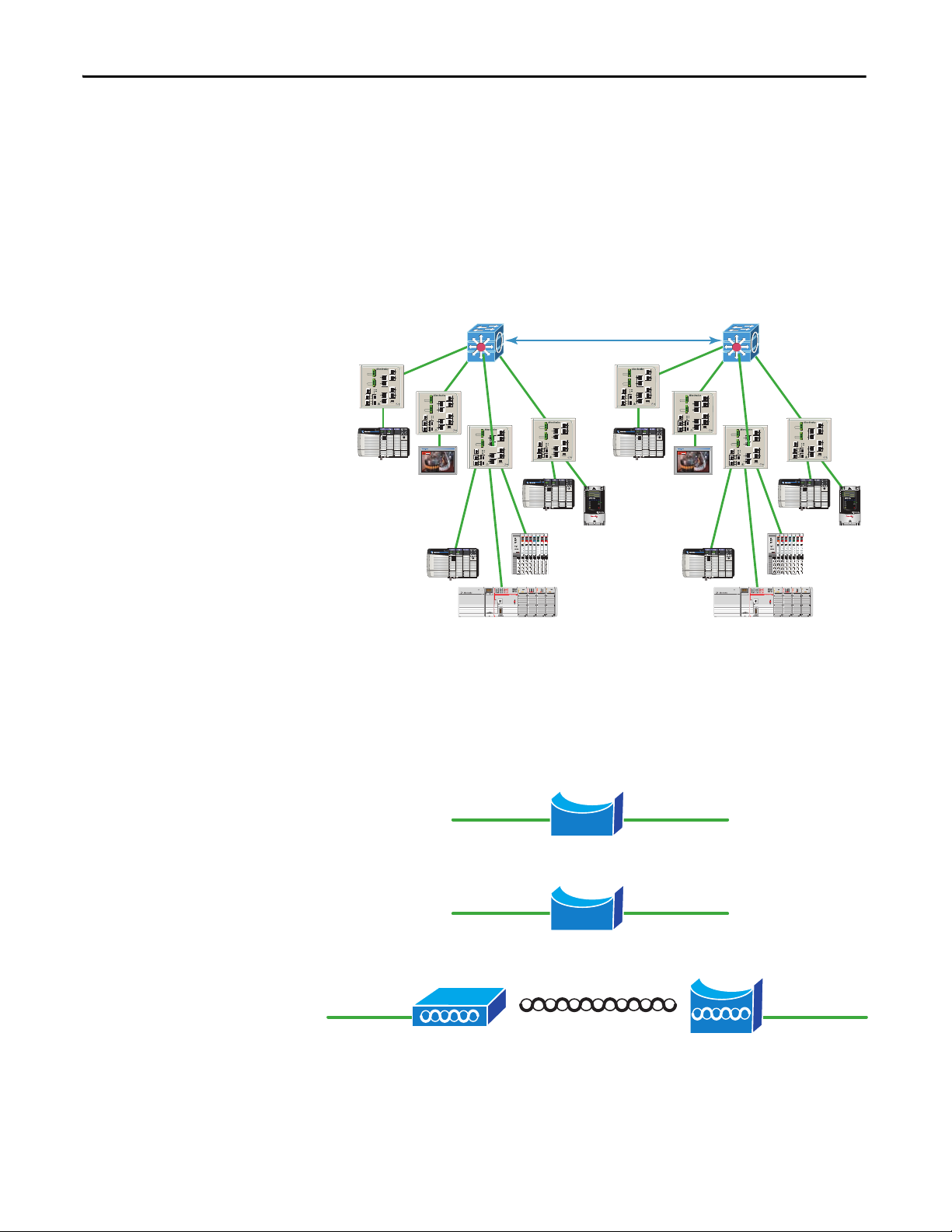

EtherNet/IP Modules in a Control System

The following diagram shows how EtherNet/IP communication modules can fit

into a control system.

In this example, the following actions can occur:

• Controllers produce and consume tags with each other.

• Controllers initiate MSG instructions to send/receive data or configure

devices.

• Controllers control I/O and drives.

• Workstations can upload/download projects to the controllers.

• Workstations can configure devices on the EtherNet/IP network.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 19

Page 20

Chapter 1 EtherNet/IP Overview

IMPORTANT

Bridge

EtherNet/IP

Panel View Pl us

Terminal

DeviceNet

Drive

Switch

Bridge across Networks

Some EtherNet/IP communication modules support the ability to bridge or

route communication through devices, depending on the capabilities of the

platform and communication devices.

You have a bridge when you have a connection between communication devices

on two networks. For example, the bridge device has both EtherNet/IP and

DeviceNet connections, enabling Device 1 on the EtherNet/IP network to

communicate with Device 2 on a DeviceNet network through the bridge.

The bridge device can be an EtherNet/IP-to-DeviceNet bridging device or a

Logix5000 system with an EtherNet/IP communication module and a

DeviceNet communication module.

CIP messages originating on this network Can bridge to this network

EtherNet/IP ControlNet DeviceNet RS-232 Serial

EtherNet/IP Yes Yes Yes Yes

ControlNet Yes Yes Yes Yes

RS-232 Yes Yes Yes Yes

In the following example graphic, a workstation configures a drive on a

DeviceNet network and bridges EtherNet/IP networks to reach the drive.

You can bridge between devices on different networks for only messaging.

You cannot bridge from one network to another for I/O control or

produced and consumed tags. This restriction applies regardless of whether

the two networks are either of the following:

• Same type, such as an EtherNet/IP network to an EtherNet/IP network

• Different types, such as an EtherNet/IP network to a ControlNet network

20 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 21

Ethernet Infrastructure Components

Top ic Pa ge

Topologies 22

Media 24

Hubs 25

Repeaters 25

Media Converters 26

Bridges 26

Routers and Gateways 27

Switche s 28

Chapter 2

The topology and cable layout of the Ethernet network is part of the physical

layer. Ethernet systems require various infrastructure components to connect

individual network segments.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 21

Page 22

Chapter 2 Ethernet Infrastructure Components

Switch

D D D

D D

Switch

Switch

SwitchSwitch

D

D

D

D

D D

Switch

D D

Switch

D D

Switch

D D

Layer 3 Layer 3

Layer 2

D D

Layer 2

D D

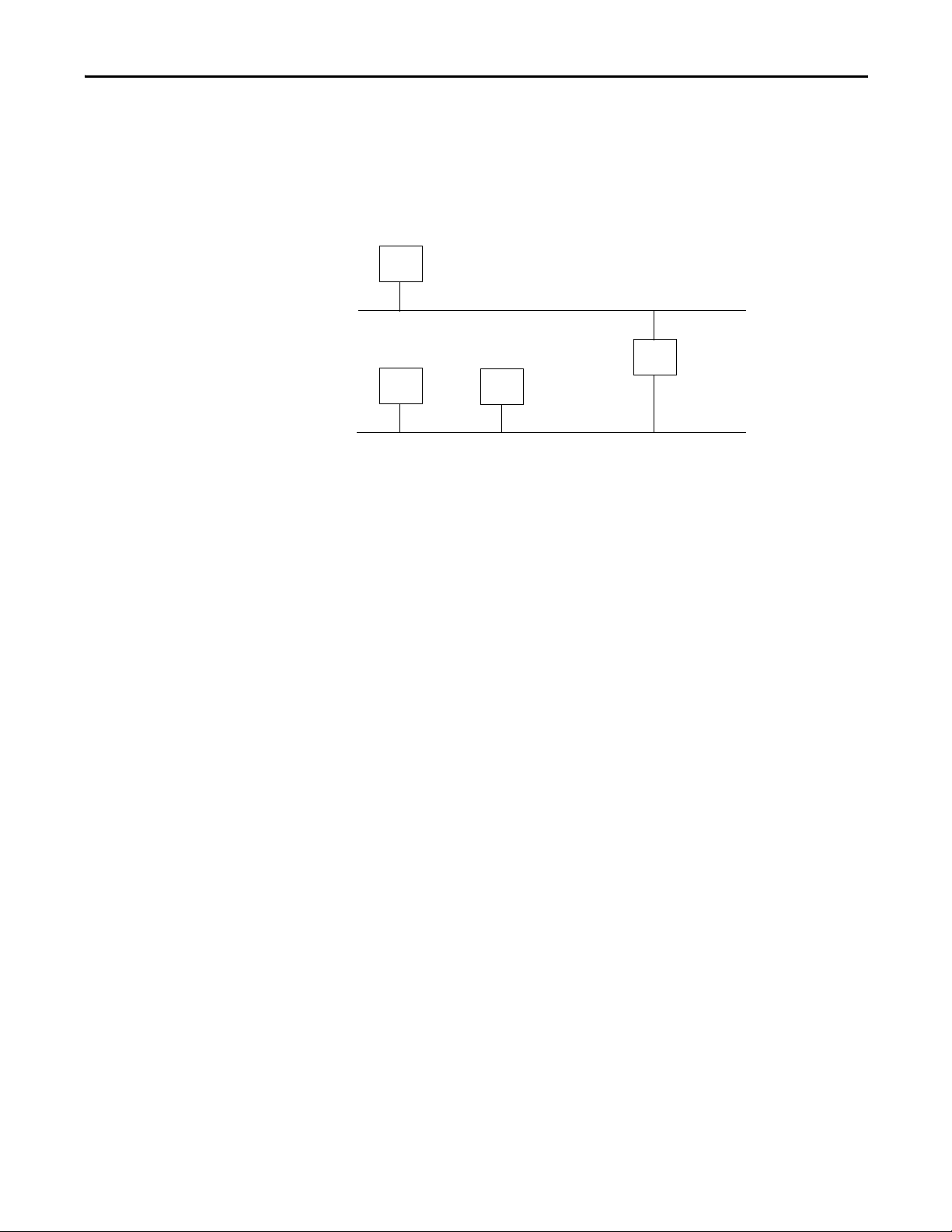

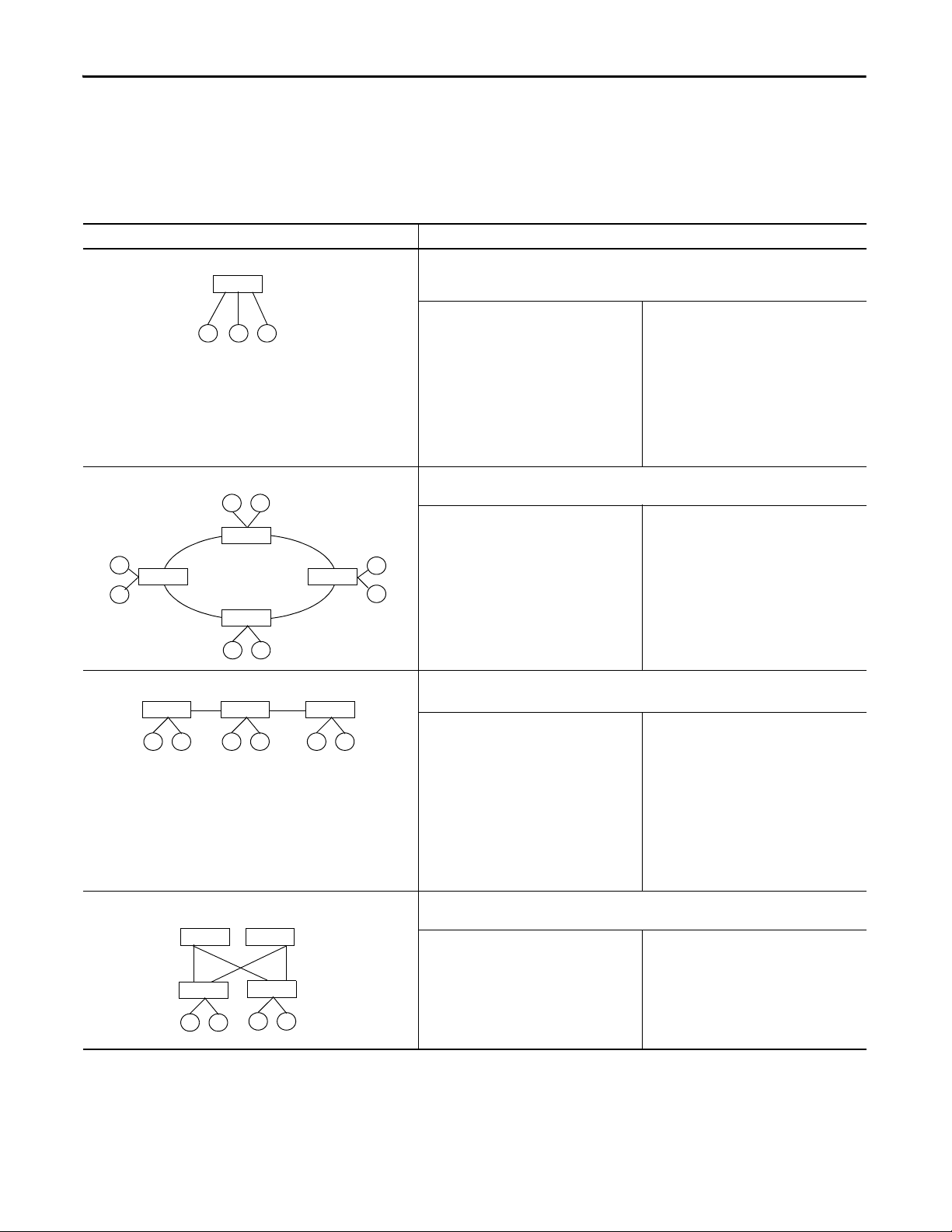

Topologies

Ethernet networks are laid out in point-to-point configurations with one cable

for each device. Ethernet networks have active infrastructures that rely on

switches. You can design a network with individual switch devices and devices

with embedded switch technology.

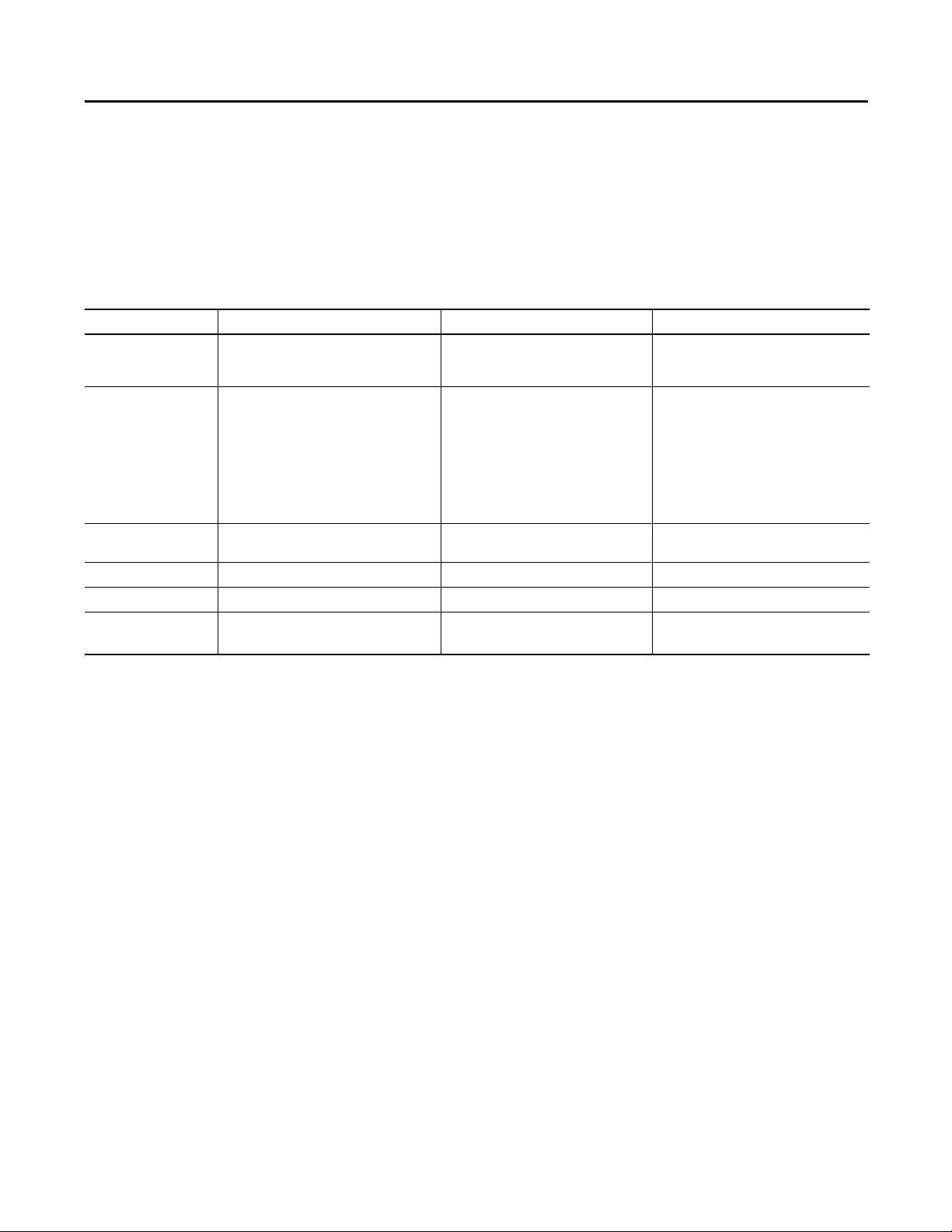

Table 4 - Topologies with an Individual Switch

Topology Description

Star The most common EtherNet/IP network topology is a star, where end devices are connected and

Ring—switch based A ring network is a single-fault tolerant ring network intended for the interconnection of automation

communicate with each other via a switch. In a star topology, nodes are typically grouped closely

together.

Advantag es

• Easy to design, configure, and implement

• Direct path between the infrastructure device

and the end device

• Remove and add devices without affecting the

rest of the network

• Increase port capacity on the switch to add

more devices

• Centralization can ease troubleshooting,

because the switch sees the activities of all of

the connected devices

devices.

Advantag es

• Ability to survive a single point of failure or a

device being powered down on the ring.

• Simplified cabling

• Ability to cover long distances with 100 m

between each copper segment

Disadvantages

• Loss of network service in case of connection

failure (no resiliency)

• Primarily the single point of failure of the

centralized sw itch

Disadvantages

• Additional configuration complexity

• Longer convergence times

• Variable number of hops can make

performance difficult to predict

Linear—switch based A linear network is a collection of devices that are daisy-chained together.

A linear topology works best for a limited number of nodes.

Advantag es

• Easy to design, configure, and implement

• Least amount of cabling

• Minimal amount of cable needed

• Ability to cover long distances with 100 m

between each link

Redundant star In a redundant star topology, every Layer 2 access switch has dual connections to a Layer 3 distribution

22 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

switch. Devices are connected to the Layer 2 switches.

Advantag es

• Resiliency from multiple connection failures

• Faster convergence to connection loss

• Consistent number of hops provide

predictable and consistent per formance

• Fewer bottlenecks

Disadvantages

• Loss of network service in case of connection

failure (no resiliency)

• Creates the potential for bottlenecks

• Variable number of hops can make

performance difficult to predict

• Powering down a device or the failure of a

device in the center of the network affects

connectivity between any of the devices on

either side

• Each link in the chain represents network

delay

Disadvantages

• Additional wiring and ports required

• Additional configuration complexity

Page 23

Ethernet Infrastructure Components Chapter 2

D

D D

D

D

D

D D

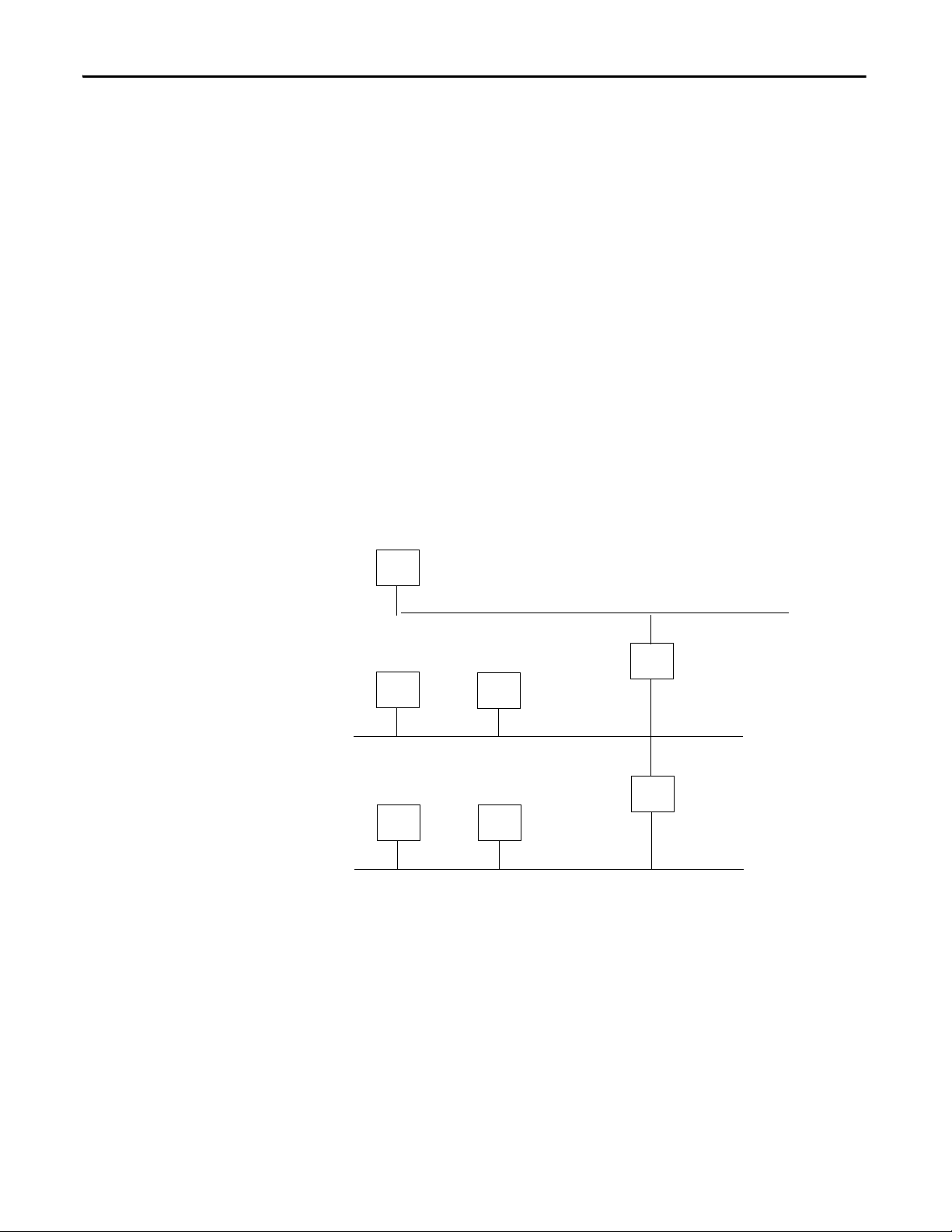

The EtherNet/IP embedded switch technology offers alternative network

topologies by embedding switches into the end devices themselves.

Table 5 - Topologies with Embedded Switch Technology

Topology Description

Device-level ring (DLR)—embedded switch A DLR network is a single-fault tolerant ring network intended for the interconnection of automation devices. This

topology is also implemented at the device level. No additional switches are required.

Advantages

• Ability to survive a single point of failure or a device

being powered down on the ring.

• Simplified cabling

• Ability to cover long distances with 100 m between

Disadvantages

• Supervisor-node configuration required

• Additional configuration complexity

• Variable number of hops can make performance

difficult to predict

each copper segment

• Very fast network convergence

Linear—embedded switch A linear network is a collection of devices that are daisy-chained together. The EtherNet/IP embedded switch technology

enables this topology to be implemented at the device level. No additional switches are required.

A linear topology works best for a limited number of nodes.

Advantages

• Easy to design, configure, and implement

• Least amount of cabling

• Minimal amount of cable needed

• Ability to cover long distances with 100 m between

each link

Disadvantages

• Loss of network service in case of connection failure (no

resilie ncy)

• Creates the potential for bottlenecks

• Variable number of hops can make performance

difficult to predict

• Powering down a device or the failure of a device in the

center of the network affects connectivity between any

of the devices on either side

• Each link in the chain represents network delay

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 23

Page 24

Chapter 2 Ethernet Infrastructure Components

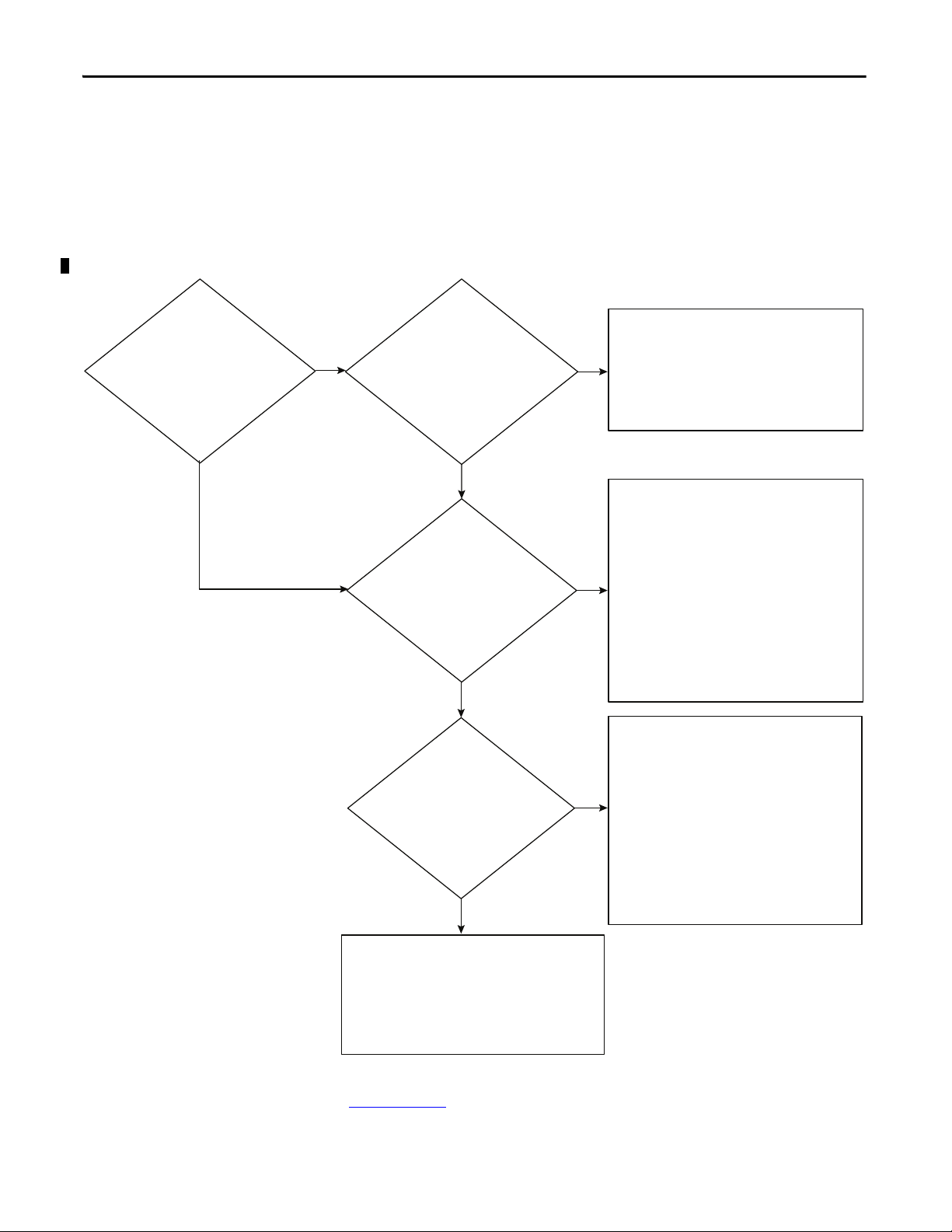

Do you have any of these:

• Long distances?

• High Magnetic fields?

• High noise?

Fiber Media

Recommendations:

• Multi-mode for general purposes, cost less

• Single-node yields higher dista nce, but

costs more

Do you have excess

amounts of any of these:

• Radiated noise?

• Conducted noise?

• Metal conduit?

Copper STP (shielded twisted pair)

Recommendations:

• Requires proper grounding

• Category 5e, 6, and 6a cables and

connectors

Copper UTP (unshielded twisted pair)

Recommendations:

• Requires proper grounding

• Category 5e, 6, and 6a cables and comectors

Yes

Yes

No

No

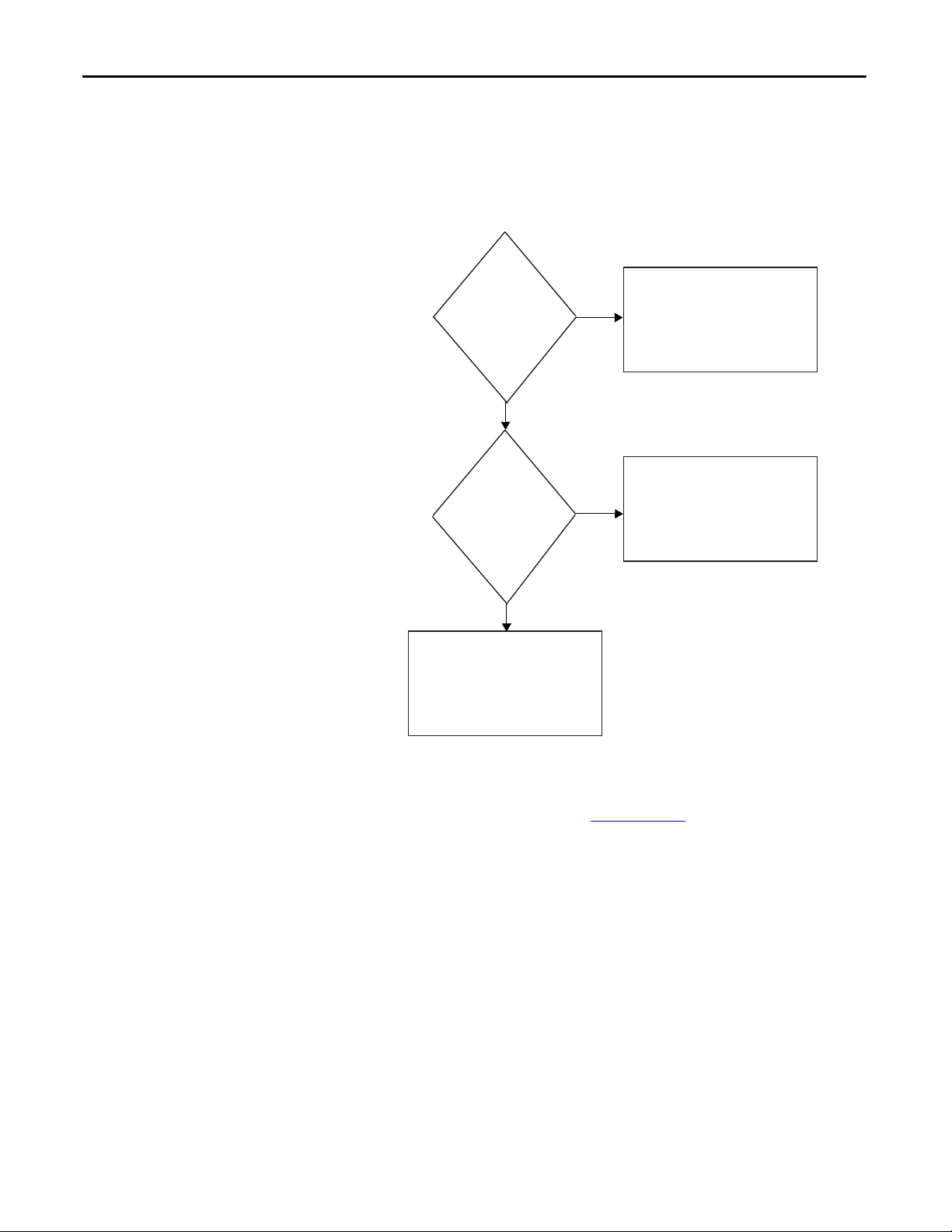

Media

The actual wire used for the network is referred to as the physical media.

Generally, shorter cable runs are less susceptible to EMI (electromagnetic

interference) and RFI (radio-frequency interference) from electrical circuits,

motors, and other machinery.

Figure 1 - Select Ethernet Media

For more information about the media options, see the Ethernet section of the

Network Media Catalog, publication M116-CA552

24 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

.

Page 25

Ethernet Infrastructure Components Chapter 2

Hub

HMI

1756 Controller

1734 POINT I/O

Power Flex

1738 ArmorPOINT® I/O

Personal computer

Repeater

Hubs

Hubs are multiport repeaters. They are based on older technology, which has

been largely replaced by network switches at Layer 2, but they are still used as

network diagnostic tools to analyze network traffic:

• A hub is at the center of a star topology.

• Hubs can connect together with a variety of media as a backbone between

hubs.

• A hub broadcasts everything it receives on any channel out all other

channels.

Repeaters

A repeater recreates the incoming signal and re-transmits it without noise or

distortion that can have affected the signal as it was transmitted down the cable.

Repeaters are generally used in older networks to increase the network length.

More modern networks use fiber media or switches to increase network length.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 25

Page 26

Chapter 2 Ethernet Infrastructure Components

Fiber Link

Ethernet

Ethernet

Ethernet

Tok en R in g

Bridge

Bridge

Ethernet Ethernet

Access Poi nt

Work Group Bridge

Media Converters

Media converters let you mix fiber and copper (twisted-pair) cables in the same

system.

Use a switch to mix media:

• Physical layer devices offer no buffering or advanced diagnostic features.

• Physical layer devices are easily overrun by an EtherNet/IP system (no

buffering = lost data).

• Layer 2 devices have buffering, QoS, and other management features.

Bridges

A bridge is a device that isolates traffic between segments by selectively

forwarding frames to their proper destination. A bridge is transparent to the

network and protocol independent. More advanced devices that perform the

same bridging function are commonly used instead of a bridge.

26 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 27

Ethernet Infrastructure Components Chapter 2

Routing Table

Network

Port

10.17.10.0

10.10.10.0

1

2

10.17.10.56

VLAN 17

Subnet 10.17.10.0

Subnet Mask

255.255.255.0

1

0

.

1

0

.

1

0

.

5

6

Default Gateway

10.10.10.1

10.17.10.1

VLAN 10

Subnet 10.10.10.0

Subnet Mask

255.255.255.0

Routers and Gateways

Routers and gateways use the network portion of IP addresses to identify the

location of networks. A routing table lets a device know from which port to

transmit a message, so the message can get to a particular network. If that

network is not directly attached to the device, it forwards the message to the next

gateway or router in the path for further routing.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 27

Page 28

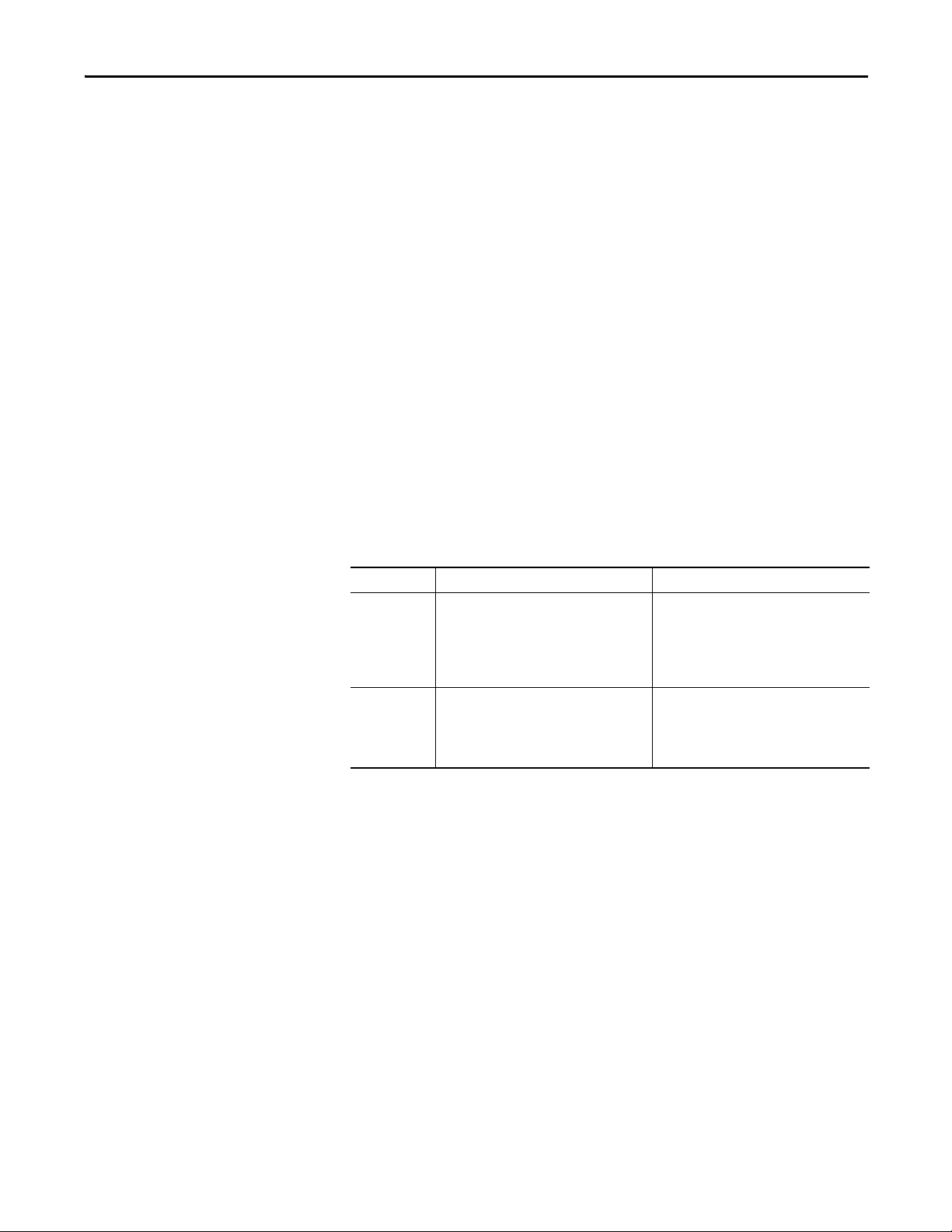

Chapter 2 Ethernet Infrastructure Components

Yes

No

Yes

No

No

Do you connect to another

network infrastructure device,

such as a switch or router?

Do you ne ed Layer 3 routin g?

Select a Stratix 8300 modular, managed switch:

• 1783-RMS06T 4 ports copper, 2 ports copper/fiber

• 1783-RMS10T 8 ports copper, 2 ports copper/fiber

Optionally, add expansion ports:

• 1783-MX08T 8 ports copper

• 1783-MX08F 8 ports fiber

• 1783-MX04S 4 ports SFP

• 1783-MX08S 8 ports SFP

• 1783-MX04E 4 ports PoE

• 1783-MX4T04E 4 ports PoE + 4 ports 10/100

Select a Stratix 8000 modular, managed switch:

• 1783-MS06T

• 1783-MS10T

Optionally, add expansion ports:

• 1783-MX08T 8 ports

• 1783-MX08F 8 ports copper

• 1783-MX04S 4 ports SFP

• 1783-MX04E 4 ports PoE

• 1783-MX4T04E 4 ports PoE + 4 ports 10/100

Do you need any of these:

• Network segmentation

• Diagnostic information

• Port security

• Traffic management

• Network resiliency

Do you need any of these?

• More than 20 ports

• More than 4 fiber ports

• More than 4 PoE ports

Select a Stratix 2000™ unmanaged switch:

• 1783-US03T01F 3 ports copper, 1 port fiber

• 1783-US05T 5 ports copper

• 1783-US06T01F 6 ports copper, 1 port fiber

• 1783-US08T 8 ports copper

Select a Stratix 5700 conf igurable, managed switch:

• 1783-BMSxxx 6 port versions

• 1783-BMSxxx 10 port versions

• 1783-BMSxxx 20 port versions

Yes

No

Yes

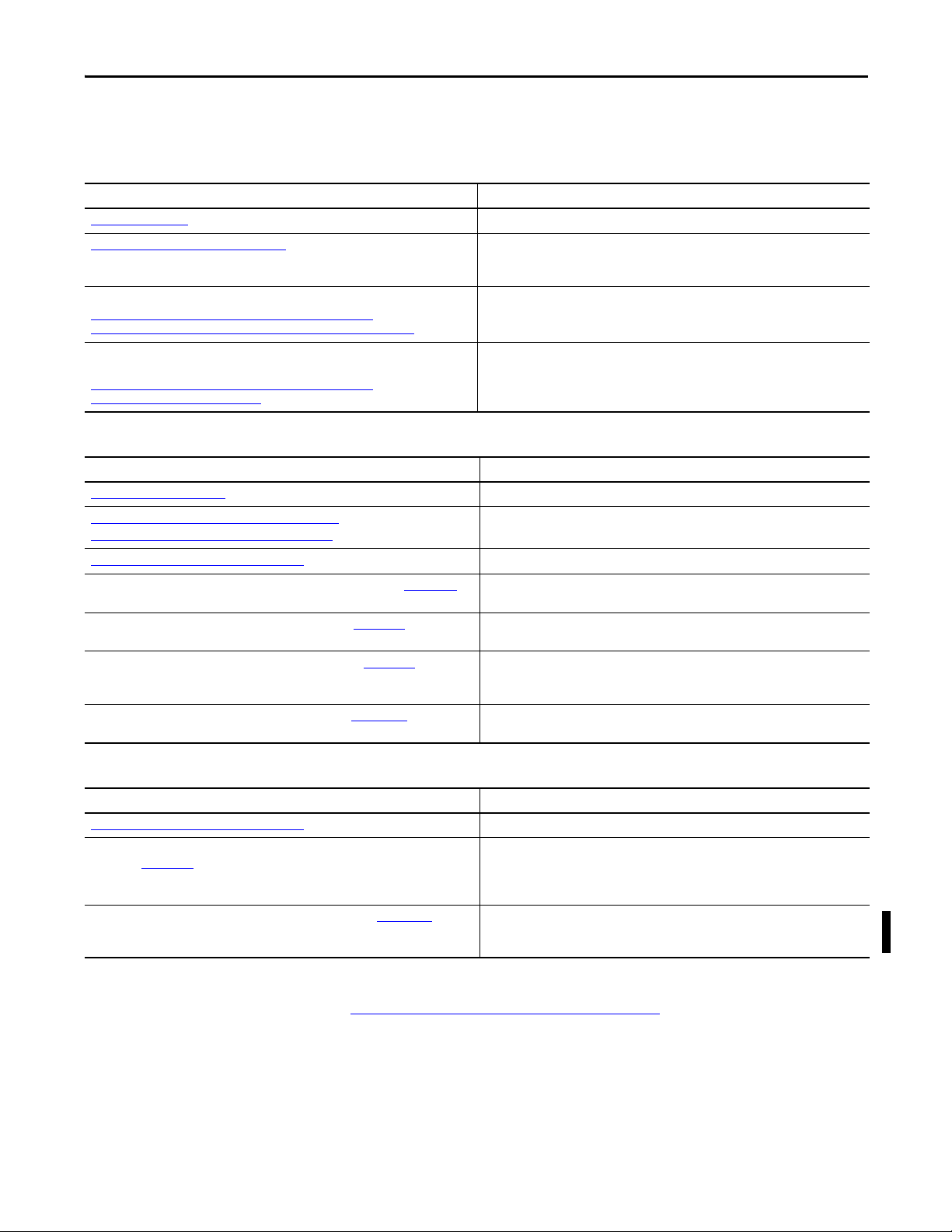

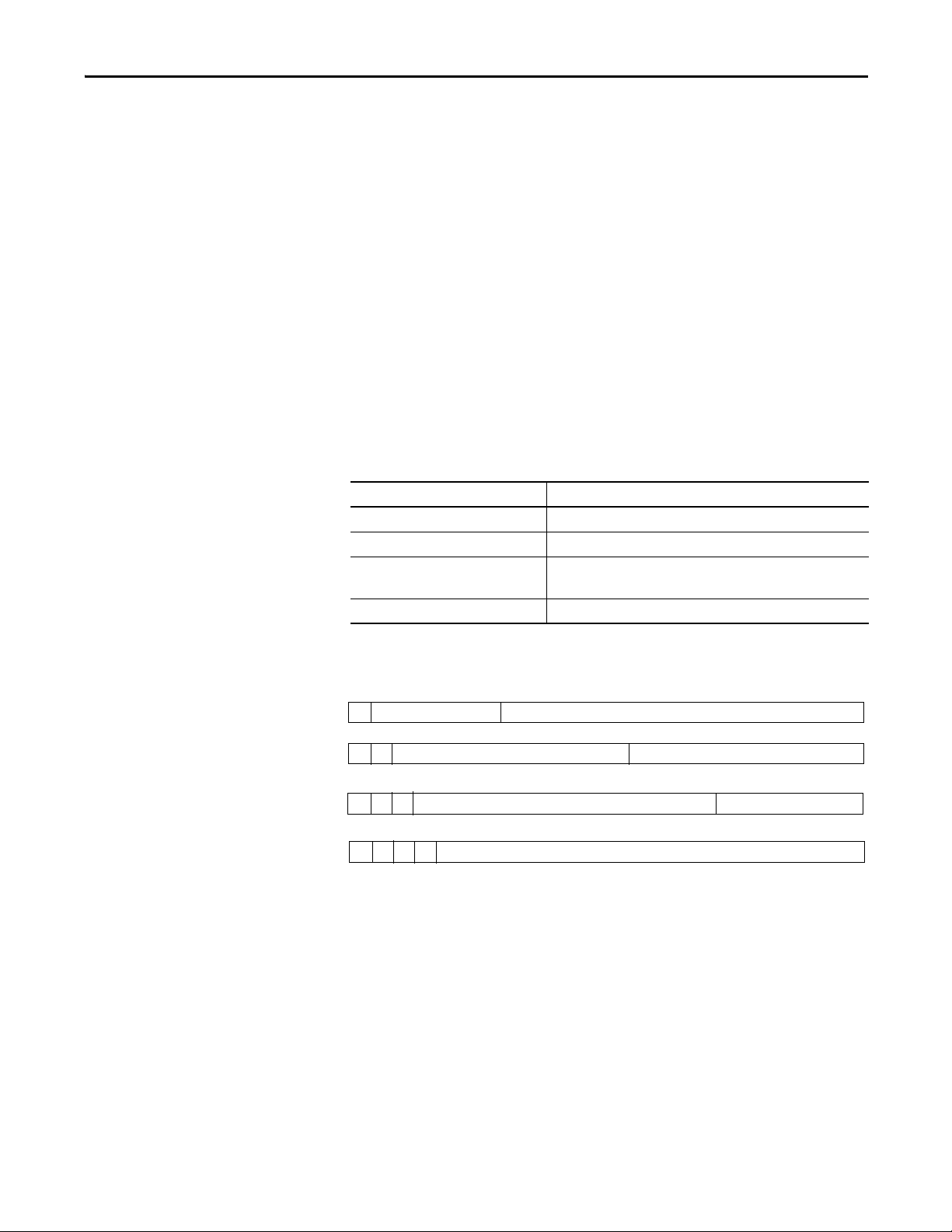

Switches

Figure 2 - Select an Ethernet Switch

Switches provide determinism and throughput required for control applications.

Industrial-rated switches are recommended for connecting computers and other

devices to each other and to higher-level networks in the network reference

architecture. Ethernet switches perform the following:

• Operate in Full-duplex mode to eliminate collisions

• Include managed switch features for advanced network functionality

For more information, see the Stratix Switch Reference Chart, publication

ENET-QR001

.

28 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 29

Ethernet Infrastructure Components Chapter 2

Unmanaged versus Managed Switches

Unmanaged switches are relatively inexpensive and simple to set up, but they do

not provide any management capabilities, security, or diagnostic information.

Therefore, they are difficult to troubleshoot.

As a general rule for unmanaged switches, make sure of the following:

• Your application does not contain I/O traffic

or

• Your application has I/O control and the following is true:

– The network is not directly connected to the IT network

– All nodes on the network are Rockwell Automation devices

– There is no potential to overload a device with traffic

Managed switches are typically more expensive than unmanaged switches and

require some level of support for initial configuration and replacement. However,

managed switches provide advanced features, which can enable better network

performance in your control system. Managed switches are able to manage

multicast traffic and provide diagnostics data, security options, and other

advanced features.

Switch Type Advantages Disadvantages

Managed • Ability to manage multicast traffic

• Diagnostics data

• Security options

• Additional advanced features

• Network segmentation features

• Network resiliency features

Unmanaged • Inexpensive

• Simple to set up

• 'No Config' replacement

• More expensive

• Requires some level of support and

configuration to start up and replace

• No network segmentation

• No dagnostic information

• No port security

• No traffic management

• No network resiliency

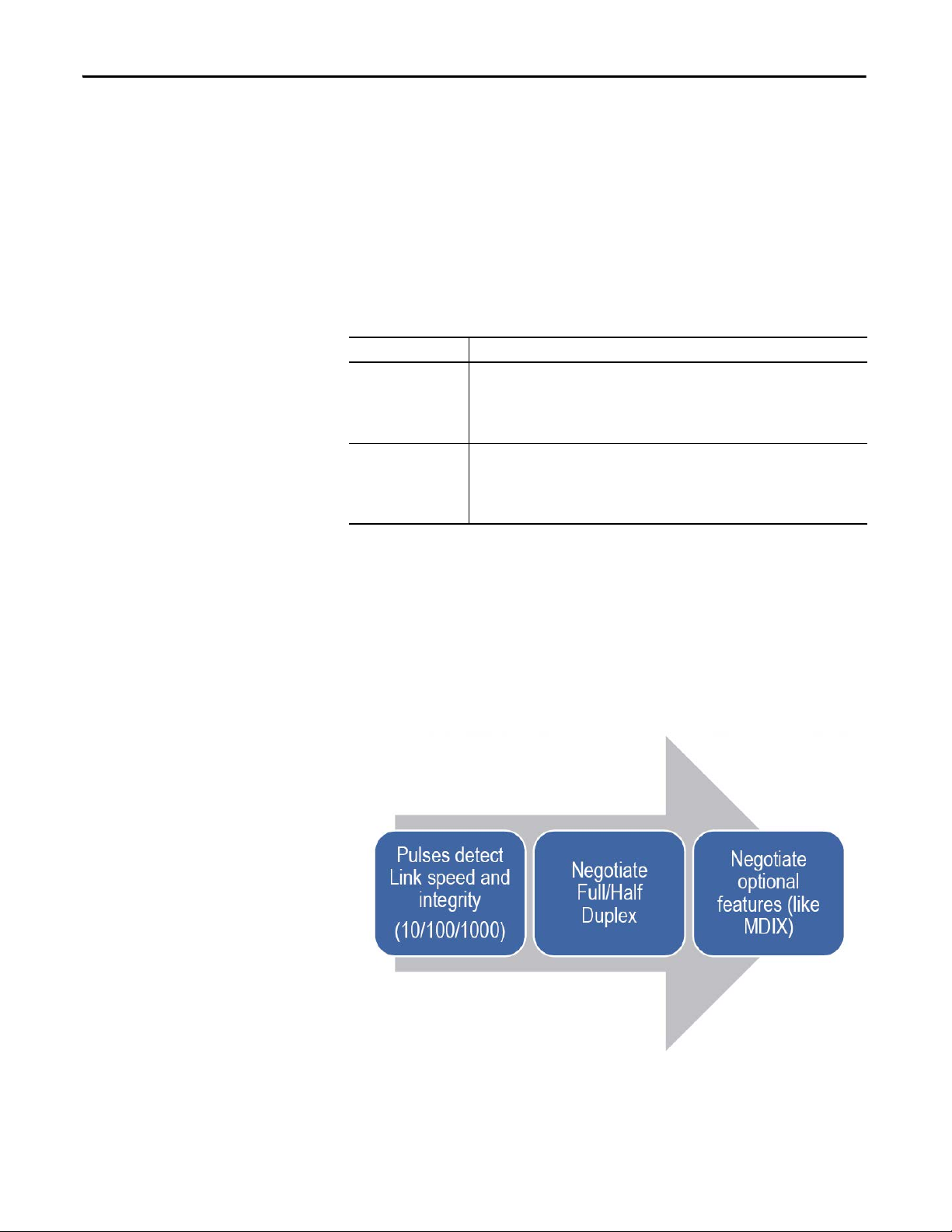

Autonegotiation

Autonegotiation lets devices select the optimal way to communicate without

requiring you to configure the devices. However, if you connect a

manually-configured device to an autonegotiation device, a high rate of data

transmission errors can occur.

All 100 Mbps devices are required to support autonegotiation, but most existing

10 Mbps devices do not. Select a switch that supports both speeds to enable you

to connect to existing devices that use the slower rate.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 29

Page 30

Chapter 2 Ethernet Infrastructure Components

Full-duplex Mode

Ethernet is based on Carrier Sense Multiple Access/Collision Detect (CSMA/

CD) technology. This technology places all nodes on a common circuit so they

can all communicate as needed. The nodes must handle collisions (multiple

devices talking at the same time) and monitor their own transmissions so that

other nodes have transmission time.

The data transmission mode you configure determines how devices transmit and

receive data.

Tran smiss ion Mo de Featu res

Full-duplex Dete rministic

• Transmit and receive at the same time

• Transmit on the transmit pair and receive on the receive pairs

• No collision detection, backoff, or retry

• Collision free

Half- duplex Nondeterministic

• One station transmits and the others listen

• While transmitting, you do not receive, as no one else is transmitting

• If someone else transmits while you are transmitting, then a collision occurs

• Any Receive-while-Transmit condition is considered a collision

Full-duplex mode eliminates collisions. Combined with the speed of the switches

available today, you can eliminate the delays related to collisions or traffic in the

switch. A a result, the EtherNet/IP network becomes a highly deterministic

network well-suited for I/O control:

• If you are autonegotiating, make sure you verify the connection.

• If you are forcing speed and duplex on any link, make sure you force at

both ends of the link. If you force on one side of the link, the

autonegotiating side always goes to half-duplex.

30 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 31

Ethernet Infrastructure Features

Top ic Page

Transmission Packets 32

Transmission Protocols 35

Network Address Translation 38

Virtual LANs and Segmentation 42

Quality of Service (QoS) 45

Resiliency 46

Internet Group Management Protocol (IGMP) 55

Port Secur ity 56

Device Commissioning 58

Chapter 3

When you use the EtherNet/IP network for time-critical control, there are

several features available in switches that are required or recommended.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 31

Page 32

Chapter 3 Ethernet Infrastructure Features

1756 Controller

Stratix Switch

Transmission Packets

Data is transmitted over the EtherNet/IP network in packets. There are

transmission methods for transporting data on the network.

Packet Type Destination Description

Unicast A single node Unicast connec tions are point-to-point transmissions between a source node and destination node on the network.

A frame is sent to a single destination.

Multicast Multiple nodes

simultaneously

Multicast connections deliver information from one sender to multiple receivers simultaneously.

Copies of a single frame are passed to a selected subset of possible destinations.

Broadcast All nodes Broadcast connections transmit information to every device on the network.

A frame is delivered to all hosts on the network.

32 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 33

Ethernet Infrastructure Features Chapter 3

Limit the amount of broadcast and multicast traffic on the supervisory control

network:

• Eliminating unwanted traffic reduces the load on devices, switches, and the

network.

• Eliminating unnecessary incoming broadcast traffic also minimizes

network load.

It is important to prevent network traffic from coming into the supervisory

control (level 2) and manufacturing operations (level 3) network from other

levels. Likewise, it is equally important to make sure that traffic on the control

system network does not get propagated into the plant enterprise network

Default Setting in the Studio 5000 Environment

The support for unicast communication and the default settings in the

Studio 5000 environment depend on the version of software. Later versions

include the unicast features of earlier versions.

Studio 5000 Version Unicast Support and Default Setting

20.01.00 Safety I/O unicast support added

Unicast default

19.01.00 Safety produce/consume unicast support added

Unicast default

18.02.00 Standard I/O unicast support added

Multicast default

16.03.00 Standard produce/consume unicast support added

Multicast default

For a compatibility chart of products see Knowledgebase answer ID 66324 at

http://www.rockwellautomation.com/knowledgebase/

.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 33

Page 34

Chapter 3 Ethernet Infrastructure Features

Layer 2

Switch

Layer 2

Switch

I/O

(producer)

Control ler

(consumer)

Switch or

Router

To P lant Net wo rk

Frames

Use multicast frames in these situations:

• Redundancy applications

• Communication with more than one destination

Multicast is more efficient than sending multiple, unicast streams to

multiple nodes.

• Video streaming

You must use unicast communication if the transmission routes through a Layer 3

device.

I/O devices generally produce at very fast rates, such as 10 ms, so it is easy to

flood the network with multicast traffic and force each end device to spend time

deciding whether to discard numerous multicast frames. If there are a lot of I/O

devices, they can easily use up a significant part of a router’s CPU time.

You must consider control network traffic propagating onto the plant

information network, as well as, plant information network traffic propagating

onto the control network. Some best practices include the following:

• Minimize device load due to unwanted IP multicast traffic

• Minimize switch load due to unwanted IP multicast traffic

• Minimize network load due to unwanted incoming IP multicast or

broadcast traffic

• Block IP multicast traffic generated within the EtherNet/IP subnet from

propagating onto the plant network

• Implement standard network troubleshooting tools

For more information, see Virtual LANs and Segmentation

Internet Group Management Protocol (IGMP)

on page 55.

on page 42 and

34 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 35

Ethernet Infrastructure Features Chapter 3

EXAMPLE

EXAMPLE

1756 Controller

1756 Controller

Device needs to send a

message to 130.151.3.4

Who has the IP address 130.151.3.4 ?

130.151.3.4

Power Flex

I have IP

address

130.151.3.4

1734 POINT I/O

Multicast Address Limit

In multicast communication, EtherNet/IP interfaces support a maximum of

32 devices that transmit multicast.

An Ethernet adapter that produces data uses a unique multicast address for

each I/O connection.

A Logix controller that produces tags uses a unique multicast address for each

produced tag.

The multicast address limit is independent of the connection limit for a device.

Not all connections require a multicast address. In the case of produced and

consumed tags, one produced tag requires one multicast address, but it also

requires one connection for each consumer. If there are multiple consumers, the

one multicast address must use multiple connections.

Transmission Protocols

The network layer (Layer 3) provides switching and routing that create logical

paths, known as virtual circuits, for transmitting data from node to node.

Routing and forwarding are functions of this layer, as well as addressing and

internetworking.

Address Resolution Protocol (ARP)

An ARP request is a broadcast message that asks ‘who has this IP address?’. The

device that has that IP address responds and the requestor adds the IP address

and hardware address pair to its ARP cache. The original device can now send the

message. This protocol enables the network to learn and adapt to changes.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 35

Page 36

Chapter 3 Ethernet Infrastructure Features

DNS Server

What is the IP address

for the PowerFlex drive?

1756 Controller

The controller needs to

send a message to the

Power Flex dri ve.

1734 POINT I/O

PowerFlex Drive

130.151.3.4

If you replace a Rockwell Automation EtherNet/IP communication module with

a new module, the new module has a different MAC ID. The ARP cache entries

in other devices are now invalid because the MAC ID corresponding to the

module's IP address has changed. This can cause a delay in reestablishing

communication with the replacement module. The delay varies depending on the

module and the network configuration in use.

When a Rockwell Automation EtherNet/IP device starts up, it issues a gratuitous

ARP that causes other devices to update their ARP caches. This generally results

in a quick recovery of communication with the replacement module (less than a

minute). However, some switches do not forward the gratuitous ARP message

onto the network, such as if the Spanning Tree Protocol is enabled on that port.

We recommend that you disable the Spanning Tree Protocol on ports to which

EtherNet/IP communication modules are directly connected, but not on ports

that are linked to other switches. In the worst case, if the gratuitous ARP is not

seen, an originating device can wait as long as 10 minutes for the ARP cache entry

to age out and be deleted.

Domain Name System (DNS)

DNS is a name resolution protocol that enables you to identify devices by names

rather than IP addresses. For DNS to work, a DNS server is configured to hold a

table of names and the associated IP addresses. When a device attempts to send a

message to a device with an unknown name, it requests the IP address of the

named device from the DNS server.

36 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 37

Ethernet Infrastructure Features Chapter 3

DNS Server

I have IP address

130.151.3.4

1756 Controller

1734 POINT I/O

PowerFlex Drive

130.151.3.4

DNS Table

Name IP Address

Controller 130.151.3.5

PowerFlex Drive 130.151.3.5

POINT I/O 130.151.3.5

The DNS server refers to its table and sends back an IP address for the requested

name. Once the client device receives the IP address for a name, it stores it in its

own table so it does not have to ask for the IP address every time. The device still

sends an ARP request if it needs to decode the IP address into a hardware address.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 37

Page 38

Chapter 3 Ethernet Infrastructure Features

Network Address Translation

Network address translation (NAT) enables a single device to act as an agent

between the public network (commonly the plant network) and the private

network (machine network). This facilitates communication between a group of

computers with preset IP addresses on a private network by mapping each preset

IP address to a valid IP address on the public network.

These are two types of NAT implementations:

• One-to-many—Multiple nodes are mapped to a single public identity to

get onto the Internet, such as in a home network. This type of

implementation conserves public IP addresses and offers some protection

against attacks from the Internet.

• One-to-one—Each node on the network translates to another identity on

another network . This type of implementation is used in manufacturing to

integrate machinery onto a larger network without requiring addressing

changes at the machine level.

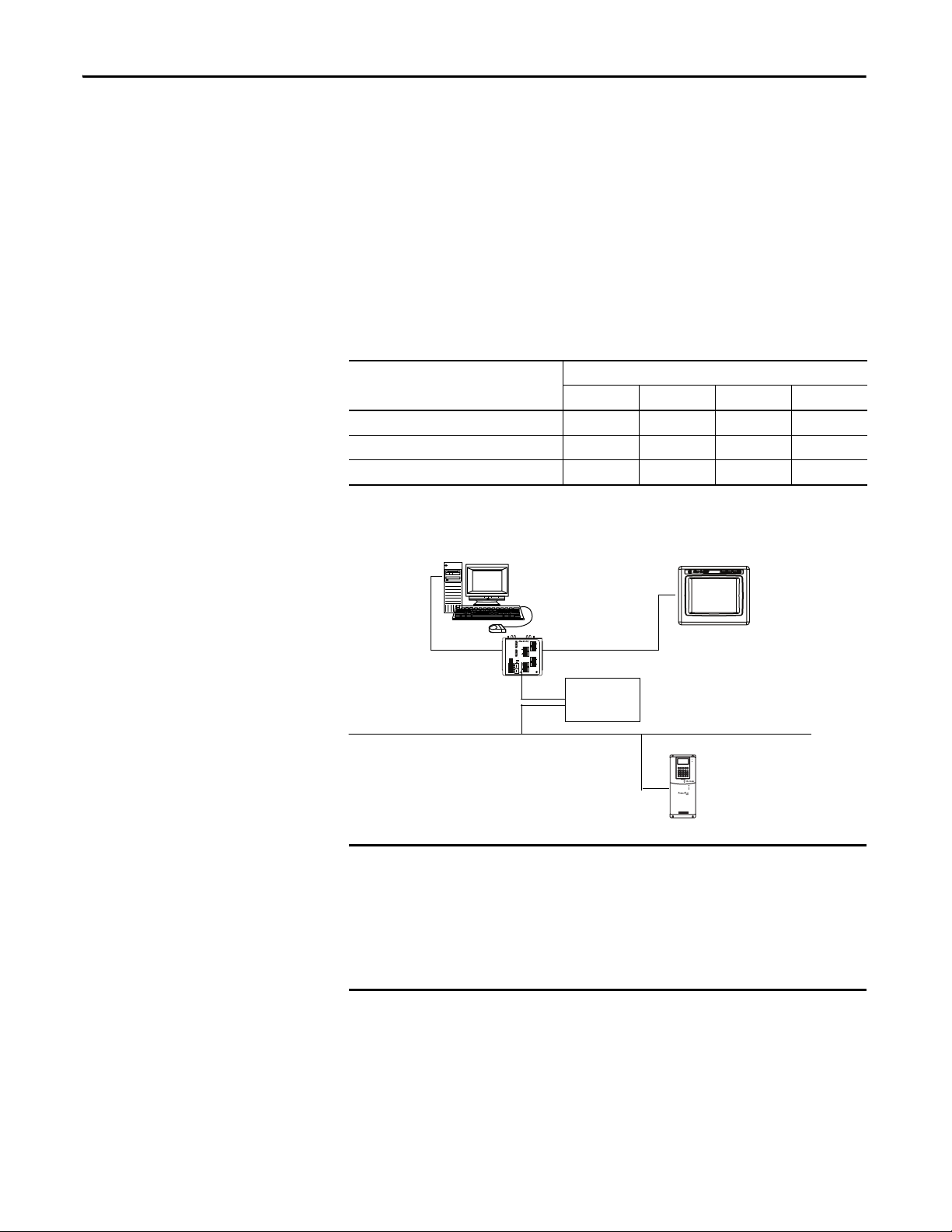

Allen-Bradley Products That Support NAT

The table summarizes features of the two products that support one-to-one NAT.

Feature 9300-ENA Device Stratix 5700 Switch

NAT architecture Standalone device Integrated into switch hardware

Performance 500 messages/s Wire-speed translations

Number of translations, max 128 128 devices or subnets

Supported network topologies Star • Star

• Redundant star

• Ring

Configuration Web interface • Device Manager Web interface

• Studio 5000 environment

• Command-line interface (CLI)

(1) One subnet translation can include translations for 16…65,000 devices.

(1)

38 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 39

Supported NAT Topologies

Logix Co ntroller

Stratix 5700 with NAT

Pane lView

POINT I/O

Plant Network

PowerFlex Drive

Compac tLogix™ 5370 Controller

PanelView Plus

Stratix 2000

Kinetix 350

9300-ENA

Figure 3 - Switch-level Ring (REP) with Stratix 5700 Switch

Ethernet Infrastructure Features Chapter 3

Figure 4 - Star with 9300-ENA Device

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 39

Page 40

Chapter 3 Ethernet Infrastructure Features

Stratix 5700 with NAT

Plant Network

Logix Controller

PanelVi ew

POINT I/O

PowerFlex Drive

Stratix 5700 with NAT

Plant Network

Logix Controller

Pane lView

POINT I/O

PowerFlex Drive

Figure 5 - Star with Stratix 5700 Switch

Figure 6 - Redundant Star with Stratix 5700 Switch

40 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 41

Figure 7 - Star with Device-level Ring

POINT I/O

Plant Network

1783-ETAP

Kinetix 5500 Drive

1783-ETAP

9300-ENA

or

Stratix 5700

with NAT

Pane lView

Logix Co ntroller

Ethernet Infrastructure Features Chapter 3

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 41

Page 42

Chapter 3 Ethernet Infrastructure Features

Switch

Controller 1

PC

I/O

Controller 2

I/O

I/O

I/O

I/O

VLAN 1 VLAN 2

Virtual LANs and Segmentation

A virtual LAN (VLAN) is a switched network segmented on a functional

application or organizational basis rather than a physical or geographical basis.

Switches filter destination MAC addresses and forward VLAN frames to ports

that serve the VLAN only to which the traffic belongs. A VLAN consists of

several end systems. These systems are either hosts or network equipment, such as

switches and routers, that are members of a single logical broadcast domain. A

VLAN does not have physical proximity constraints for the broadcast domain.

With VLANs, you can configure a switch to share two isolated networks without

the traffic from one network burdening the other. IP multicast traffic from

VLAN 1 does not reach VLAN 2. A VLAN blocks broadcast traffic and adds a

measure of security between networks.

A VLAN also gives you the ability to control access and security to a group of

devices independent of their physical location.

Table 6 - VLAN Features

Feature Description

Broadcast control Just as switches isolate collision domains for attached hosts and forward appropriate traffic out a particular port, VLANs

Security High-security users can be grouped into a VLAN, possibly on the same physical segment, and no users outside of that

Performance The logical grouping of devices prevents traffic on one VLAN from burdening other network resources. Performance

Network management You can logically move a device from one VLAN to another by configuring a port into a VLAN. The device does not have to

refine this concept and provide complete isolation between VLANs. A VLAN is a bridging domain, and all broadcast and

multicast traffic is contained within it.

VLAN can communicate with them. VLANs can also assist in securing plant-floor systems by limiting access of production

floor personnel, such as a vendor or contractor, to certain functional areas of the production floor.

within the VLAN is also improved because the VLAN acts as a dedicated LAN.

be physically disconnected from one network and reconnected to another, which can result in expensive,

time-consuming recabling.

Segmentation is the process of outlining which endpoints need to be in the same

LAN. Segmentation is a key consideration for a cell or area network.

Segmentation is important to help manage the real-time communication

properties of the network, and yet support the requirements as defined by the

network traffic flows. Security is also an important consideration in making

segmentation decisions.

42 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 43

Ethernet Infrastructure Features Chapter 3

VLAN 10 VLAN 102 VLAN 42

A security policy can call for limiting access of factory floor personnel, such as a

vendor or contractor, to certain areas of the production floor, such as a functional

area. Segmenting these areas into distinct VLANs greatly assists in the application

of these types of security considerations.

All level 0…2 devices that need to communicate multicast I/O between each

other must be in the same LAN. The smaller the VLAN, the easier it is to manage

and maintain real-time communication. Real-time communication is harder to

maintain as the number of switches, devices, and the amount of network traffic

increase in a LAN.

Typically control networks are segmented from business networks. You can also

segment networks based on function, logical layout, and traffic types. Choose

from the following options to segment control.

Table 7 - Segment Control Options

Segmentation Option Description

Physical isolation • Physically isolate networks

ControlLogix® gateway • A separate ControlLogix EtherNet/IP bridge module is dedicated to each subnet

VLANs • Ports on a managed switch are assigned to a specific VLAN

• Each network is a separate subnet creating clusters of control

• No IT involvement

• The chassis backplane provides isolation of Ethernet traffic

• Only CIP traffic can be shared between subnets

• No IT involvement

• Data is forwarded to ports within only the same VLAN

• Can require IT involvement

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 43

Page 44

Chapter 3 Ethernet Infrastruc ture Features

802.1 Q Trunk

VLAN 102

VLAN 42

VLAN 20

VLAN 102

VLAN 42

VLAN 20

VLAN Trunking

Trunking enables a VLAN to span multiple switches.

VLANs and Segmentation Guidelines

Configure separate VLANs for different work cells or areas of your plant.

Configure one VLAN for all data traffic relevant to one particular area or cell

zone. Because 80…90% of traffic is local to one cell, this is the optimal design. All

devices with multicast connections must be on the same VLAN. Within a

VLAN, multicast and unicast traffic can be mixed depending on application

requirements. The default communication type of unicast must be used for

point-to-point communication to minimize device, network, and infrastructure

loading:

• Design small cell or area zones, each with a dedicated VLAN and IP

subnet.

• Restrict data flow out of the cell or area zone unless plantwide operations

explicitly require it.

• Segment traffic types into VLANs and IP subnets to better manage the

traffic and simplify security management.

• Within the cell or area zone, use Layer 2 VLAN trunking between

switches with similar traffic types. When trunking, use 802.1Q, VTP in

transparent mode.

• Use Layer 3 distribution switches to route information between cell or area

Zone VLANs and plantwide operations in the Industrial Zone.

• Enable IP directed broadcast on cell or area zone VLANs with

EtherNet/IP traffic for easy configuration and maintenance from control

systems, such as RSLinx® software.

• Avoid large Layer 2 networks to simplify network management.

• Select switches based on the VLAN features you need:

– Stratix 6000 switches support VLANs.

– Stratix 8000 and Stratix 8300 switches support VLANs and VLAN

trunking, as well as Layer 3 switching (enables routing across VLANs

and subnets).

44 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 45

Ethernet Infrastructure Features Chapter 3

Ingress Actions Egress Actions

Classification Policing/Metering

Marking

Queue/Schedule

Congesti on Control

Distinguish traffic by

examining Layer 2/3/4

labels and QoS fields.

QoS changed depending

on trust state at port.

Make sure conformance

is to a specified rate.

DSCP-CoS or

CoS DSCP Mapping

4 queues/or with

priority scheduling

Quality of Service (QoS)

Quality of service determines how packets are marked, classified, and treated

based on traffic type. Rockwell Automation EtherNet/IP devices prioritize traffic

internally. Implementing QoS at the switch level adds another level of

prioritization. QoS does not increase bandwidth—QoS gives preferential

treatment to some network traffic at the expense of others.

Not all network traffic can be treated equally. To minimize application latency

and jitter, control data must have priority within the cell or area zone. QoS gives

preferential treatment to some network traffic at the expense of others. Control

data is more sensitive to latency and jitter than information data.

To explain how QoS works, think about the last time you boarded a plane at the

airport. As boarding time gets close, everyone starts to crowd around the gate. It

is impossible for everyone to go down the jetway to the plane at once, so the

airline establishes a boarding procedure to avoid chaos. This can be compared to

the use of QoS on an Ethernet network. The network can have motion traffic,

voice traffic, and email traffic all being transmitted at the same time over the

network.

In the airline example, first class passengers board first, followed by families with

small children, followed by frequent flyers, and followed by the coach cabin

starting at the back of the plane. Similarly, QoS lets you set up priority queues in

the managed switches on the network. In the automation example, equate

motion traffic to the first class passengers and give it the highest priority for

network usage. Voice traffic can go second (it also has low tolerance for delay),

and email traffic has the lowest priority queue. This results in the least amount of

delay possible on the motion control.

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 45

Page 46

Chapter 3 Ethernet Infrastruc ture Features

QoS Guidelines

Follow these guidelines with QoS:

• Manage the output queues based on application needs. Schedule precision

and motion control packets in the highest priority queue.

• QoS gives preferential treatment to Industrial Automation and Control

System Network traffic at the expense of other network traffic.

• QoS is integrated into the Stratix 8000 and Stratix 8300 switch

configurations.

• Deploy QoS consistently throughout Industrial Automation and Control

System Network.

Resiliency

A resiliency protocol maintains parallel links for redundancy while avoiding

loops. Network convergence time is a measure of how long it takes to detect a

fault, find an alternate path, and recover from the fault:

• During the network convergence time, some portion of the traffic is

dropped by the network because interconnectivity does not exist.

• Communication drops if the convergence time is longer than the Logix

connection timeout.

Time Calculations in a Logix5000 System

Network convergence must occur before the control system is impacted:

• Logix message instruction (MSG) time out (explicit, CIP Class 3)

• I/O connection timeout (implicit, CIP Class 1), 4 x RPI, 100 ms

minimum

• Logix Producer/Consumer connection timeout (implicit, CIP Class 1),

4 x RPI, 100 ms minimum

• Safety I/O connection timeout (implicit, CIP Class 1), 4 x RPI (default)

46 Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

Page 47

Ethernet Infrastructure Features Chapter 3

Resiliency Protocols

• Spanning Tree Protocol (STP), Rapid STP (RSTP), Multiple Instance

STP (MSTP)

– Stratix 8000 and Stratix 8300–MSTP default

– Rapid Per VLAN Spanning Tree Plus (rPVST+); Cisco Technology

• Resilient Ethernet Protocol (REP); Cisco Technology

• EtherChannel Link Aggregation Control Protocol (LACP); IEEE

• Flex Links; Cisco Technology

• Device-level ring; topology option

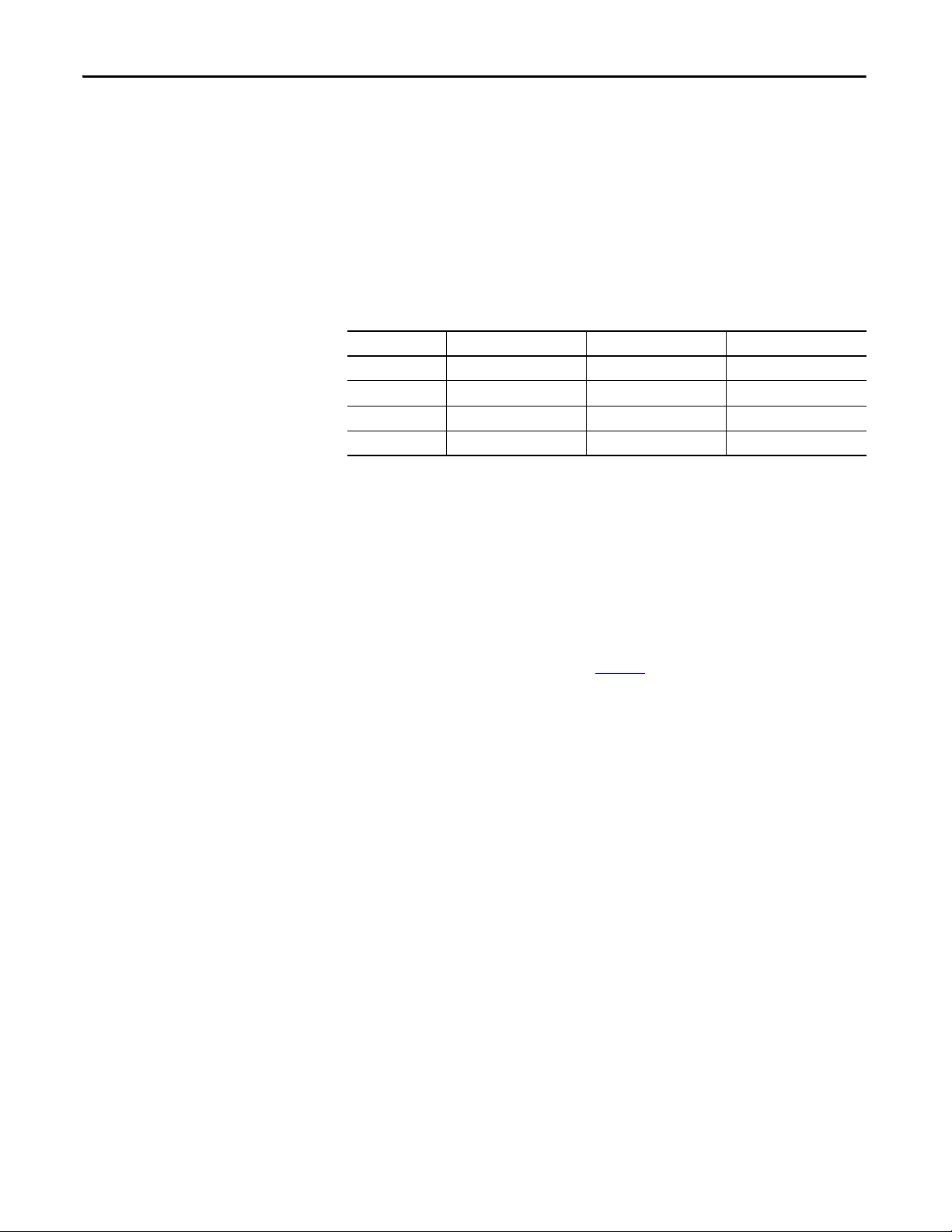

Resiliency Protocol Mixed Vendor Ring Redundant Star Network Convergence

> 250 ms

STP X X X

RSTP X X X

MSTP X X X X

PVST+ X X X

REP X X

EtherChannel X X X

Flex Links X X X

DLR X X X

Network Convergence

> 70 ms

Network Convergence

> 1 ms

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013 47

Page 48

Chapter 3 Ethernet Infrastruc ture Features

Catalyst 3750 Switch Stack

Stratix 8000

Access Sw itches

F = Forwarding

B = Blocking

B

Distribution Switches

FB F

Spanning Tree Protocol (STP) and Rapid STP (RSTP)

Spanning Tree Protocol (STP) prevents loops on the network that occur when

there is more than one open path active at once on the network. The convergence

rate can take up to 50 seconds.

Rapid Spanning Tree Protocol (RSTP) is designed for faster network

convergence and eliminates the forwarding delay on point-to-point links by using

explicit handshaking protocol. The convergence rate is significantly faster than

STP:

• Only standard protocol for network resiliency—IEEE 802.1D

• Built into Stratix 8000 and Stratix 8300 switches

• Requires redundant star or ring topology

• Provides alternate path in case of failures, avoiding loops

• Unmanaged switches do not support STP or RSTP, or any other resiliency

protocol