Page 1

Quick Start

Energy Management Accelerator Toolkit

Energy Assessment and Monitoring Methods System Configuration and

Wiring Energy Data Collector Configuration FactoryTalk EnergyMetrix

Configuration and Maintenance Local HMI Integration

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, CompactLogix, ControlLogix, FactoryTalk, FactoryTalk EnergyMetrix, PanelView Plus, Kinetix, PowerFlex, PowerMonitor, Studio 5000 Logix Designer, RSEnergyMetrix, RSLogix 5000, Rockwell Software,

Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwel l Automation are property of th eir respective compani es.

Page 3

Chapter 1

Energy Assessment and Monitoring Methods

Chapter 11

FactoryTalk View ME Energy Faceplates

FactoryTalk® EnergyMetrix™ Configuration and

Maintenance

Chapter 5 - Groups and Security Setup

Chapter 6 - Device Setup

Chapter 7 - Meter and Tag Setup

Chapter 8 - Alarm Setup

Chapter 9 - Reports and Charts

Chapter 10 - Maintenance

Chapter 4

FactoryTalk EnergyMetrix Software Installation

Chapter 3

Energy Data Collector Configuration

Chapter 2

System Configuration and Wiring

Chapter 12

Demand Control

Chapter 13

Time of Day Control

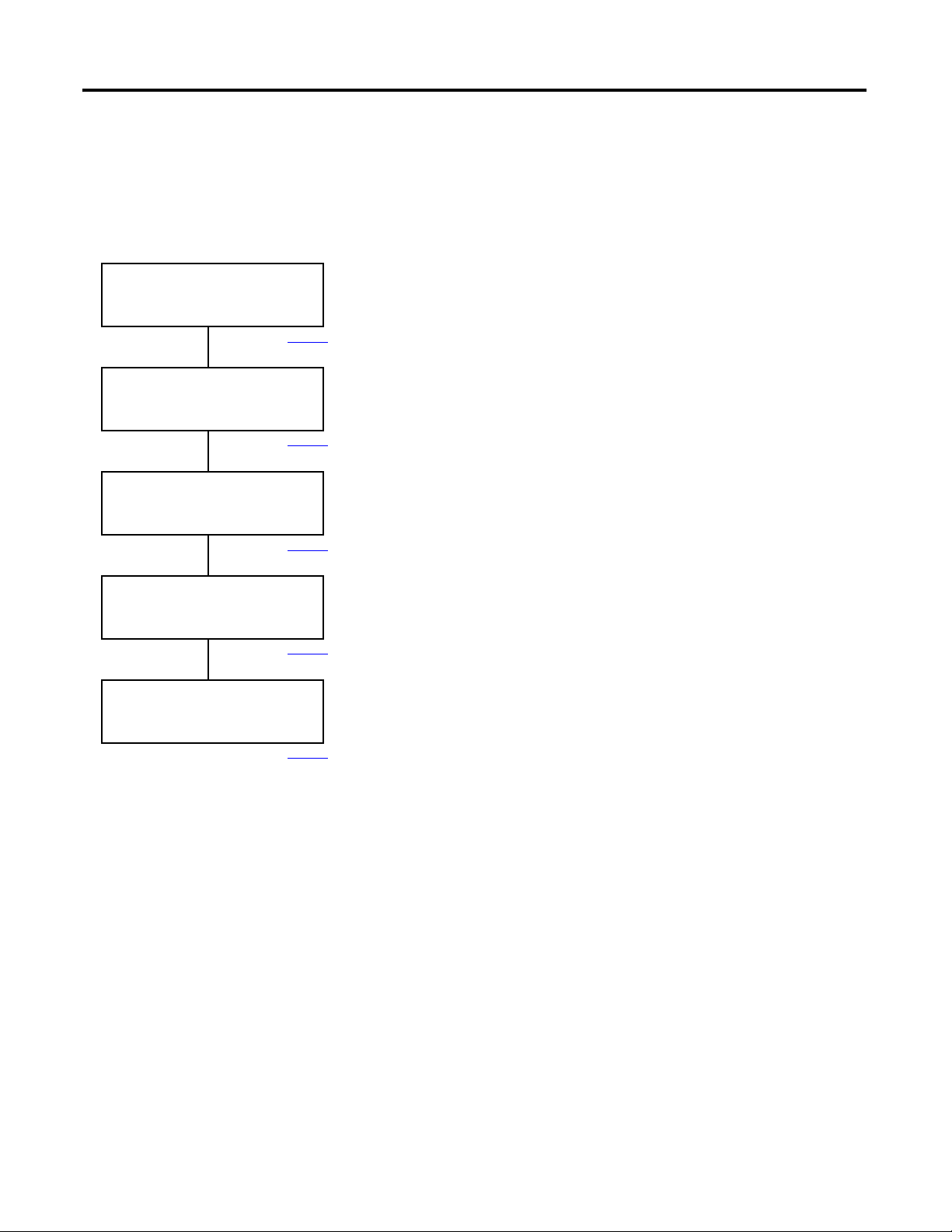

Where to Start

Follow this path to complete your energy management application.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 3

Page 4

Where to Start

Notes:

4 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 5

Energy Assessment and

Monitoring Methods

System Configuration and Wiring

Table of Contents

Preface

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Studio 5000 Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Review These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Determine Business Goals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Plant Walk-Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Energy Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Business Case for Energy Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Monitoring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

List Energy Data Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Identify Existing Energy Distribution Layouts and Metering . . . . . . . . . 33

Create Metering Layout and Name Data Collection Hardware . . . . . . 36

Create Energy Panel Layout and Wiring Drawings . . . . . . . . . . . . . . . . . . 48

Select Monitoring Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

License Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Server Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Client Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Energy Data Collector

Configuration

Chapter 3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

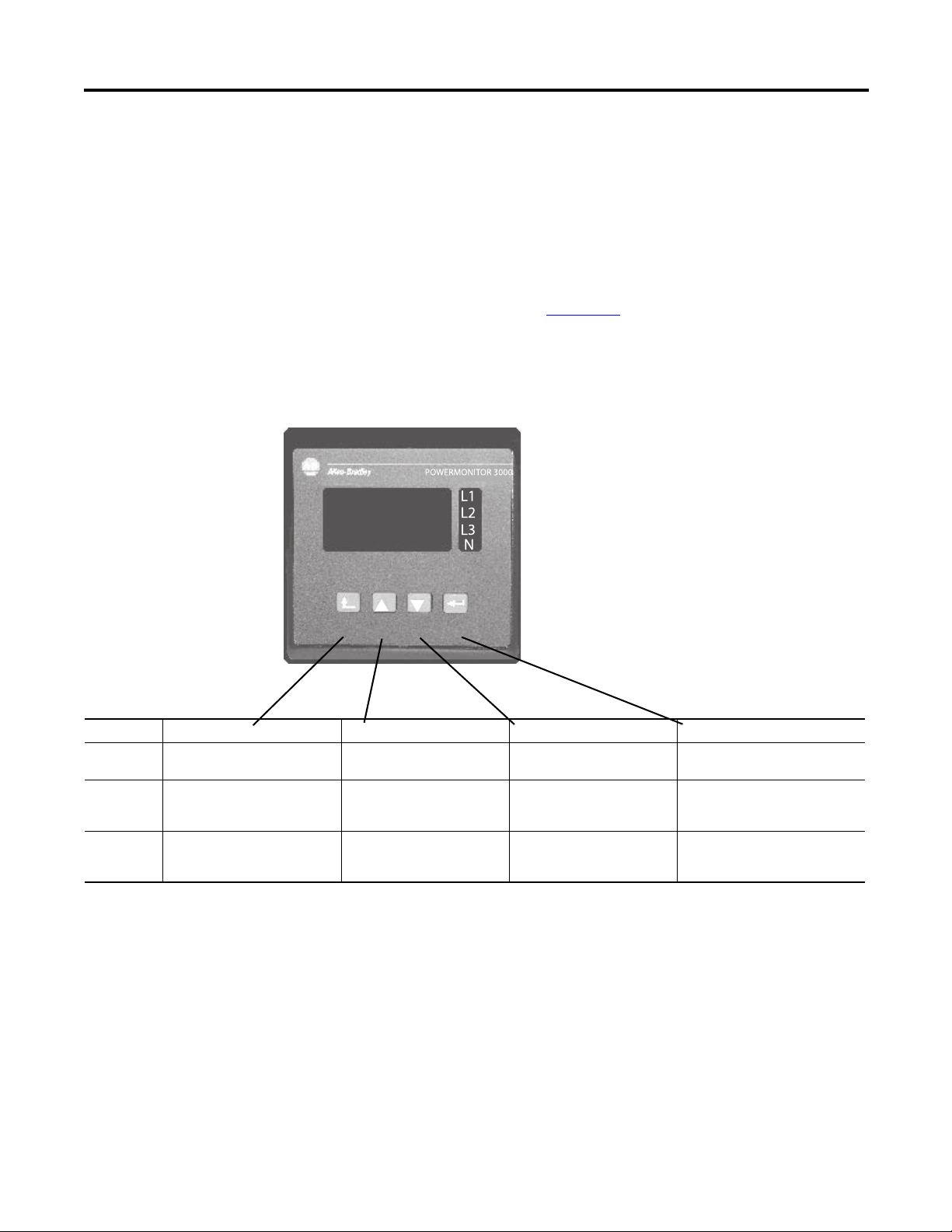

Configure a PowerMonitor 3000 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configure a PowerMonitor 1000 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Configure a PowerMonitor Wireless 250 Device. . . . . . . . . . . . . . . . . . . . 67

PC Receiver Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configure a PowerMonitor 500 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configure with the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Access the Programming Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Configure Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . 69

Configure Basic Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Configure Advanced Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Configure the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 5

Page 6

Table of Contents

FactoryTalk EnergyMetrix

Software Installation

Configure a PowerMonitor 5000 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Setup Using the Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Obtaining Access to the Configuration Pages . . . . . . . . . . . . . . . . . . . 72

How to Set Up the PowerMonitor 5000 Unit. . . . . . . . . . . . . . . . . . . 73

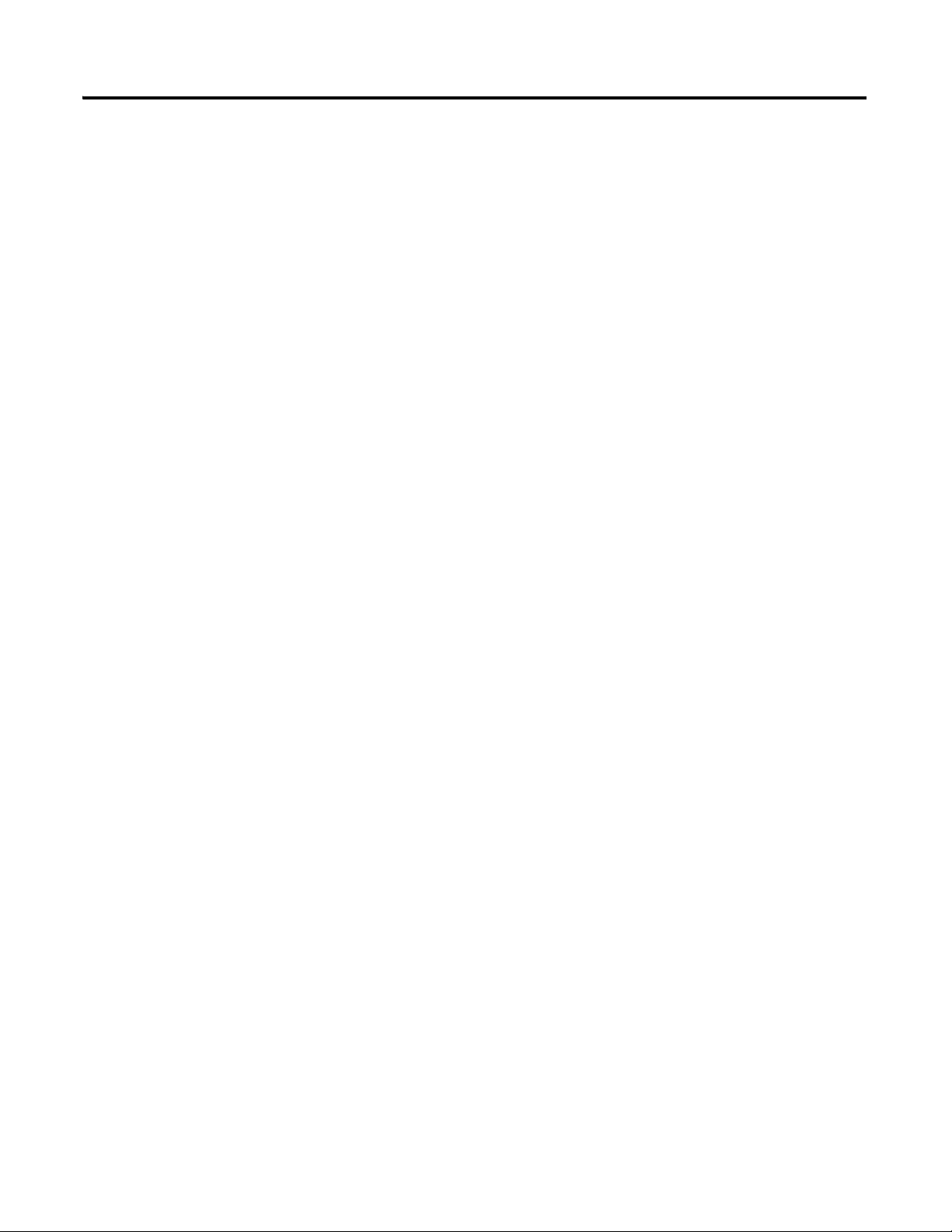

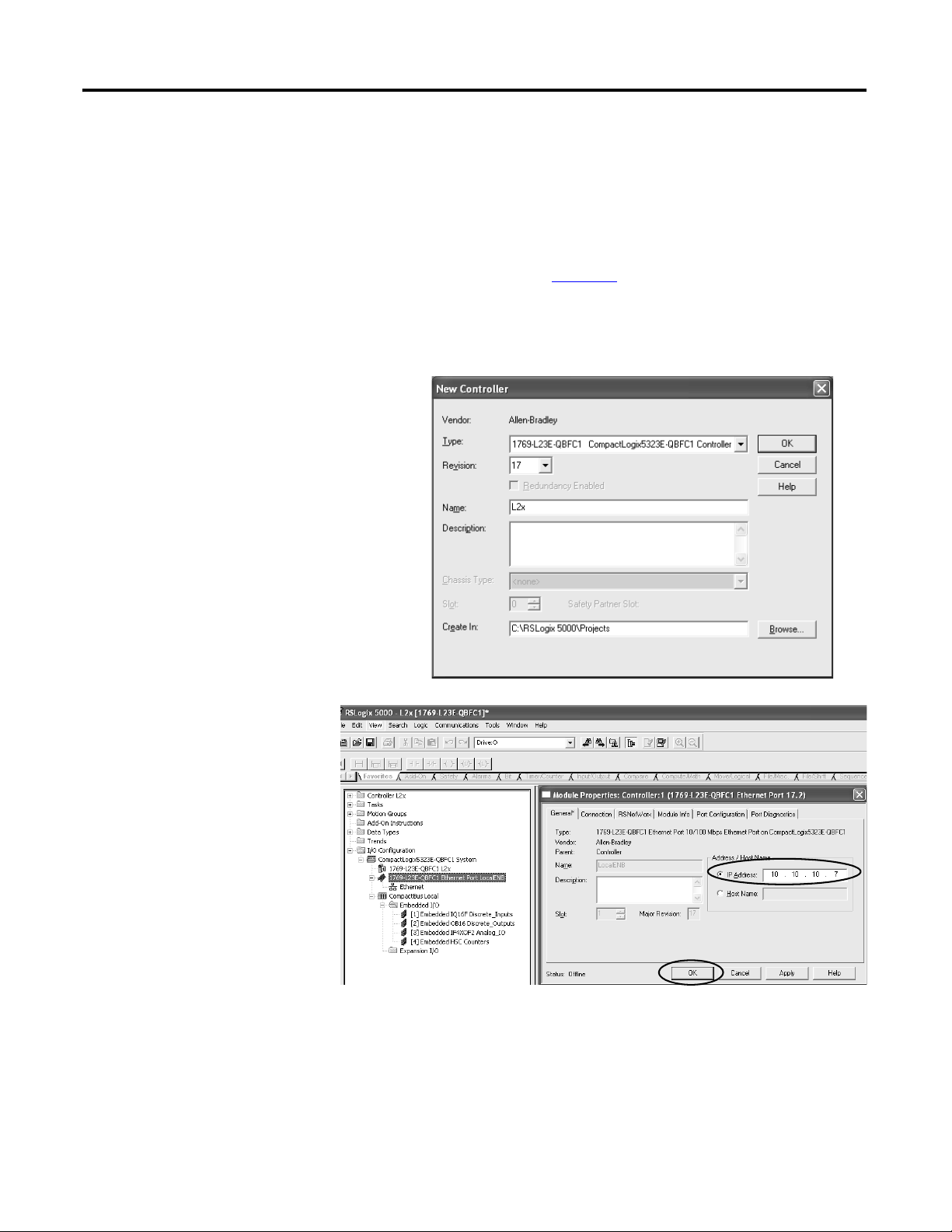

Configure a CompactLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Contents of Installation DVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Server Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Server Software Requirements for Installing FactoryTalk

EnergyMetrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Client Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Installation (64-bit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Configure Windows 2008 Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Install SQL Server 2008 R2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Enable 32-bit Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Install FactoryTalk EnergyMetrix Software Version 2.0 . . . . . . . . . . 98

Installation (32-bit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Pre-installation Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Activate FactoryTalk EnergyMetrix Software . . . . . . . . . . . . . . . . . . . . . . 102

How to Activate Your Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

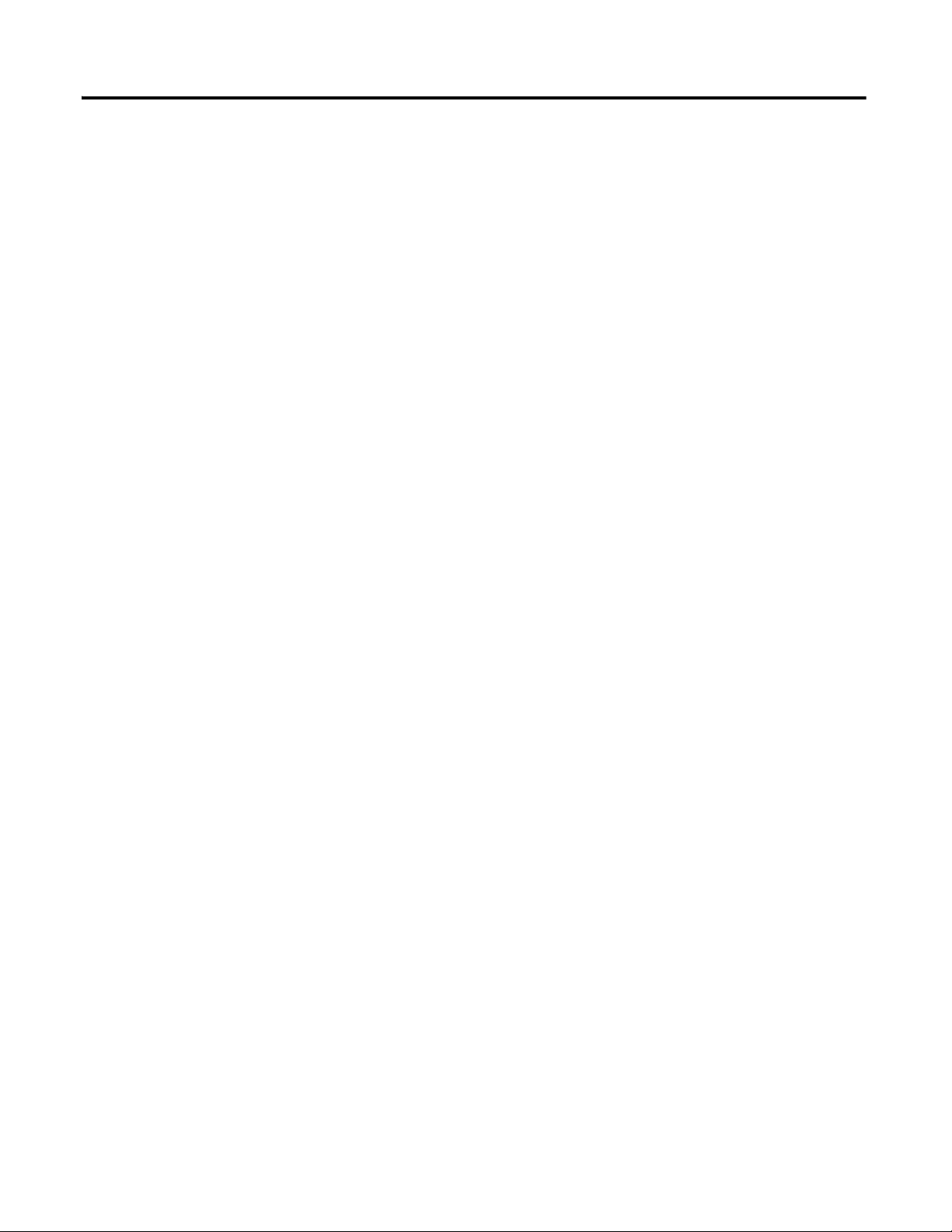

Chapter 5

FactoryTalk EnergyMetrix Groups

and Security Setup

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Creating Domains and Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configuring Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Chapter 6

FactoryTalk EnergyMetrix

Software Device Setup

6 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Overview of Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Configure Communication Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Configure a PowerMonitor Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Copy Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Page 7

FactoryTalk EnergyMetrix

Software Meter and Tag Setup

FactoryTalk EnergyMetrix

Software Alarm Setup

Table of Contents

Configure a CompactLogix Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Configure OPC Server Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Chapter 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Creating Electric Meters for PowerMonitor Devices . . . . . . . . . . . . . . . 134

Creating Energy Meters for PowerMonitor Status Inputs. . . . . . . . . . . 140

Creating Energy Meters for CompactLogix Devices . . . . . . . . . . . . . . . . 145

Creating Energy Meters for OPC Server Device . . . . . . . . . . . . . . . . . . . 150

Sharing and Moving Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Chapter 8

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Overview of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Configure an Analog Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Configure a Digital Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

View and Edit Alarm Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Configure Communication Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Configure Email Alarm Subscriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Configure SMTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

View Active Alarms and Alarm Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

FactoryTalk EnergyMetrix

Software Reports and Charts

FactoryTalk EnergyMetrix

Software and PowerMonitor

Device Maintenance

Chapter 9

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Standard Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Consumption Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Demand Analysis Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Billing Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Cost Allocation Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Power Quality Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Standard Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chapter 10

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 7

Page 8

Table of Contents

FactoryTalk View ME Energy

Faceplates

Set Up Database Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Automatic Data Repopulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Devices that Support ADR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Monitor Health of Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Using the Windows Event Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Running System Configuration Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

System Updates and Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Chapter 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Configure PowerMonitor 1000 Faceplates. . . . . . . . . . . . . . . . . . . . . . . . . 217

Configure ME PowerMonitor 500 Faceplates. . . . . . . . . . . . . . . . . . . . . . 229

Configure RSLogix5000 for the PowerMonitor 500 Unit

Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Configure FactoryTalk View ME for the PowerMonitor 500

Unit Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Configure PowerMonitor 5000 Unit Faceplates. . . . . . . . . . . . . . . . . . . . 238

Configure RSLogix5000 for the PowerMonitor 5000 Unit

Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Configure FactoryTalk View ME for the PowerMonitor 5000

Unit Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Configure ME PowerFlex Drives Faceplates . . . . . . . . . . . . . . . . . . . . . . . 248

Configure RSLogix5000 for the PowerFlex Drive Faceplate . . . . . 249

Configure FactoryTalk View ME for the PowerFlex Drive

Unit Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Configure ME E3PLUS Faceplates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

DeviceNet to EtherNet/IP Network Setup . . . . . . . . . . . . . . . . . . . . 265

Configure RSLogix5000 for the E3 Plus Faceplate . . . . . . . . . . . . . . 268

Configure FactoryTalk View ME for the E3 Plus

Module Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Configure ME E300 Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Configure RSLogix5000 for the E300 Module Faceplate . . . . . . . . 281

Configure FactoryTalk View ME for the E3 Plus

Module Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Configure ME SMC-50 Controller Faceplates . . . . . . . . . . . . . . . . . . . . . 292

Configure RSLogix5000 for the SMC-50 Controller Faceplate . . 292

Configure FactoryTalk View ME for the SMC-50 Controller

Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Configure ME CIP Motion Drive Faceplates . . . . . . . . . . . . . . . . . . . . . . 306

System Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

General Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Configure Studio 5000 Logix Designer Application for

the Kinetix Drive Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

8 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 9

Demand Control

Table of Contents

CIP Motion Energy Faceplate Overview. . . . . . . . . . . . . . . . . . . . . . . 315

Configure Device Logic for Equipment Status and Alarm

History Faceplates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Configure Equipment Status Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Configure Alarm History Faceplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Create a Runtime Application File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Transfer Runtime File to PanelView Plus Terminal . . . . . . . . . . . . . . . . 356

Run Application on PanelView Plus Terminal . . . . . . . . . . . . . . . . . . . . . 357

Chapter 12

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Control Hardware Selection and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 360

List Load Outputs and Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Create Control Panel Layout and Wiring. . . . . . . . . . . . . . . . . . . . . . 361

Logic Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

Configure Controller, Network, and I/O. . . . . . . . . . . . . . . . . . . . . . 362

Import and Configure Demand Control Program. . . . . . . . . . . . . . 364

Configure Load Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . 366

Configure PowerMonitor Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

Configure Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Save the Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

HMI Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Add Demand Faceplate to FactoryTalk View ME Application . . 369

Create a Display Navigation Button. . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Configure Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Configure Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

System Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Install System Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Download RSLogix5000 Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

Configure and Download FactoryTalk Project to

PanelView Plus Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Demand Control Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

System Application Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Faceplate Operation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Demand Controller Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Time of Day Control

Chapter 13

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

Control Hardware Selection and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 394

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 9

Page 10

Table of Contents

List Load Outputs and Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

Create Control Panel Layout and Wiring . . . . . . . . . . . . . . . . . . . . . . 395

Logic Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

Configure Controller, Network, and I/O . . . . . . . . . . . . . . . . . . . . . . 396

Import and Configure Time of Day Program. . . . . . . . . . . . . . . . . . . 398

Configure Load Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Configure Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Save the Project File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

HMI Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Add TOD Faceplate to FactoryTalk View ME Application . . . . . 402

Configure Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Configure Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

System Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Install System Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Download RSLogix5000 Project File . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Configure and Download FactoryTalk Project to

PanelView Plus Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

System Startup and Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

System Application Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

Faceplate Operation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

Custom Meter Types

Custom Units and Value Types

Energy Electric Add-On

Instructions

Digital and Analog Energy Add-On

Instructions

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Appendix B

Verify Base Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Create Base Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Verify Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Create Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Verify Value Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Create Value Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

Appendix C

CompactLogix Digital Input Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

PowerMonitor Digital Status Input Logic . . . . . . . . . . . . . . . . . . . . . . . . . 432

CompactLogix Analog Input Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Demand Calculation Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

Equipment Status Faceplate Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

Alarm History Faceplate Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

Appendix D

CompactLogix Digital Input Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 439

PowerMonitor Digital Status Input Logic . . . . . . . . . . . . . . . . . . . . . . . . . 440

CompactLogix Analog Input Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

Equipment Status Faceplate Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

10 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 11

Update Add-on Profiles

Table of Contents

Alarm History Faceplate Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Appendix E

Update the E3PLUS Add-On Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Update the SMC-50 Add-On Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Update the PowerFlex Add-On Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Update the E300 Add-On Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 11

Page 12

Table of Contents

Notes:

12 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 13

Preface

IMPORTANT

About This Publication

This quick start is designed to provide a framework for developing an energy management monitoring, analysis, and

control application for your facility. Each section guides you through the tasks you need to plan, configure, program, and

use your Rockwell Automation

named Efficient Industries Plant 1, is referenced throughout this quick start to guide you through these tasks.

To help in the design and installation of your system, application files and other information is provided on the Energy

Management Accelerator Toolkit CD, publication IASIMP-SP014. The CD provides an energy data worksheet, layout

and wiring drawings, data collection and control logic, and more. With these tools and the built-in best-practices design,

you can focus on the design of your system and not on design overhead tasks.

Before using this quick start and the CD, read the Terms and Conditions on the

CD.

The beginning of each chapter contains the following information. Read these sections carefully before you begin work in

each chapter.

• Before You Begin - This section lists the steps that must be completed and decisions that must be made before

starting that chapter. The chapters in this quick start do not have to be completed in the order in which they appear,

but this section defines the minimum amount of preparation that is required before completing the current chapter.

• What You Need - This section lists the tools that are required to complete the steps in the current chapter. This

includes, but is not limited to, hardware and software.

• Follow These Steps - This illustrates the steps in the current chapter and identifies which steps are required to

complete the examples.

energy data collection and control devices and analysis software. An example application,

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 13

Page 14

Preface

Conventions

The manual uses the following conventions.

Convention Meaning Example

Click

Double-click

Right-click

Drag and drop

Choose Choose an option from a list of options. From the Tools menu, choose Internet Options.

Select Click to highlight an item. Select the Devices folder.

Check or uncheck Click to activate or deactivate a checkbox. Check Enable device.

> Shows nested menu selections as menu name followed by menu selection. Choose File > New > Document.

Expand Click the + to the left of a given item /folder to show its contents. Expand the Main Task.

Click the left mouse button once to initiate an action. (Assumes cursor is positioned

on object or selection.)

To initiate an action, click the left mouse button twice in quick succession while the

cursor is positioned on object or selection.

To initiate an action, click the right mouse button once while the cursor is positioned

on object or selection.

Click and hold the left mouse button on an object, move the cursor to where you

want to move the object, and release the mouse button.

Click Browse.

Double-click the application icon.

Right-click the Ethernet port.

Drag and drop a task into the blank plan.

Software Requirements

You need the following software to use this toolkit.

Rockwell Automation Software Version Required For

Studio 5000 Logix Designer application 21.00 or later Power and energy management

RSLogix 5000

• ControlFlash

• BOOTP/DHCP utility

•RSLinx

FactoryTalk View Studio for Machine Edition

• FactoryTalk Services

• RSLinx Enterprise

• RSLinx Classic

Fac toryTa lk

cat. no. 9307-FTEMMENE

Energy Management Accelerator Toolkit CD IASIMP-SP014 CAD files, wiring diagrams, application

Classic

EnergyMetrix™ CD,

17.00 or later

5.0 or later PanelView Plus terminals

2.0 or later FactoryTalk EnergyMetrix software

applications

files, and other support information

14 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 15

Preface

Studio 5000 Environment

The Studio 5000 Engineering and Design Environment combines engineering and design elements into a common

environment. The first element in the Studio 5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix 5000 software and continues to be the product to program Logix5000™

controllers for discrete, process, batch, motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell Automation engineering design tools and

capabilities. It is the one place for design engineers to develop all the elements of their control system.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 15

Page 16

Preface

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation.

Resource Description

PowerMonitor 1000 Unit Installation Instructions, publication 1408-IN001 Provides information on installing, wiring, connecting, applying power and configuring the

PowerMonitor 1000 Unit User Manual, publication

1408-UM001

PowerMonitor 3000 Master Module installation instructions, publication

1404-IN007

Bulletin 1404 PowerMonitor 3000 Display Module installation

instructions, 1404-IN005

Bulletin 1404 PowerMonitor 3000 Unit User Manual, publication

1404-UM001

Bulletin 1404 PowerMonitor 3000 Unit User Manual, publication

1404-UM001D-EN-P

Bulletin 1404 Series B Ethernet Communication Release Note, publication

1404-RN008

PowerMonitor Wireless 250 Monitor User Manual, publication

1425-UM001

PowerMonitor 500 Unit User Manual, publication 1420-UM001

PowerMonitor 5000 Unit User Manual, publication

1426-UM001A

FactoryTalk EnergyMetrix User Manual, publication

FTEM-UM002

Power and Energy Management Solutions Product Overview, publication

EMSE00-BR017

Power and Energy Management Solutions Selection Guide, publication

1400-SG001

Logix Common Procedures Programming Manual, publication

1756-PM001

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification details.

http://www.rockwellautomation.com/solutions/integratedarchitecture/

Rockwell Automation Configuration and Selection Tools, available at

http://www.rockwellautomation.com/en/e-tools/

Power Monito r 1000 unit.

Provides information on setting up communication with the PowerMonitor 1000 unit by using other

applications and controllers.

Provides information on selecting an enclosure, installing, and wiring the PowerMonitor 3000 master

module.

Provides information on installing and wiring the PowerMonitor 3000 display module.

Provides information on setting up communication with the PowerMonitor 3000 master module,

firmware version 3.0 or later, by using other applications and controllers.

Provides information on setting up communication with the PowerMonitor 3000 master module, prior to

firmware version 3.0, by using other applications and controllers.

Provides information on using the PowerMonitor 3000 module with EtherNet/IP communication.

Provides information on installing, wiring and setting up communication with the PowerMonitor

Wireless 250 unit.

Provides information on installing, wiring and setting up communication with the PowerMonitor 500

unit.

Provides information on installing, wiring and setting up communication with the PowerMonitor 5000

unit.

Provides information on how to use FactoryTalk EnergyMetrix, a modular, scalable, web-enabled, client/

server energy information and management application.

Provides an overview of the Rockwell Automation suite of energy management services and solutions,

includ ing hardware and software, for

monitoring, analyzing, controlling, and optimizing energy systems.

Provides information on selecting energy management ser vices and solutions, including hardware and

power management software.

Provides information on programming Logix 5000 controllers, including managing project files,

organizing tags, programming and testing routines, and handling faults

Provides general guidelines for installing a Rockwell Automation industrial system.

Provides information on integrated architecture tools and resources including accelerator toolkits.

These online tools install on your personal computer so that you can quickly access information on our

products.

• CrossWorks

• Industrial Computer Selector

• Operator Inter face Selection Tool

• Programmable Controller Family Selector

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

16 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 17

Chapter

Plant Walk-Through

Energy Assessment

Determine Business Goals

page 18

page 18

page 19

Business Case for Energy Monitoring

page 23

Monitoring Methods

page 24

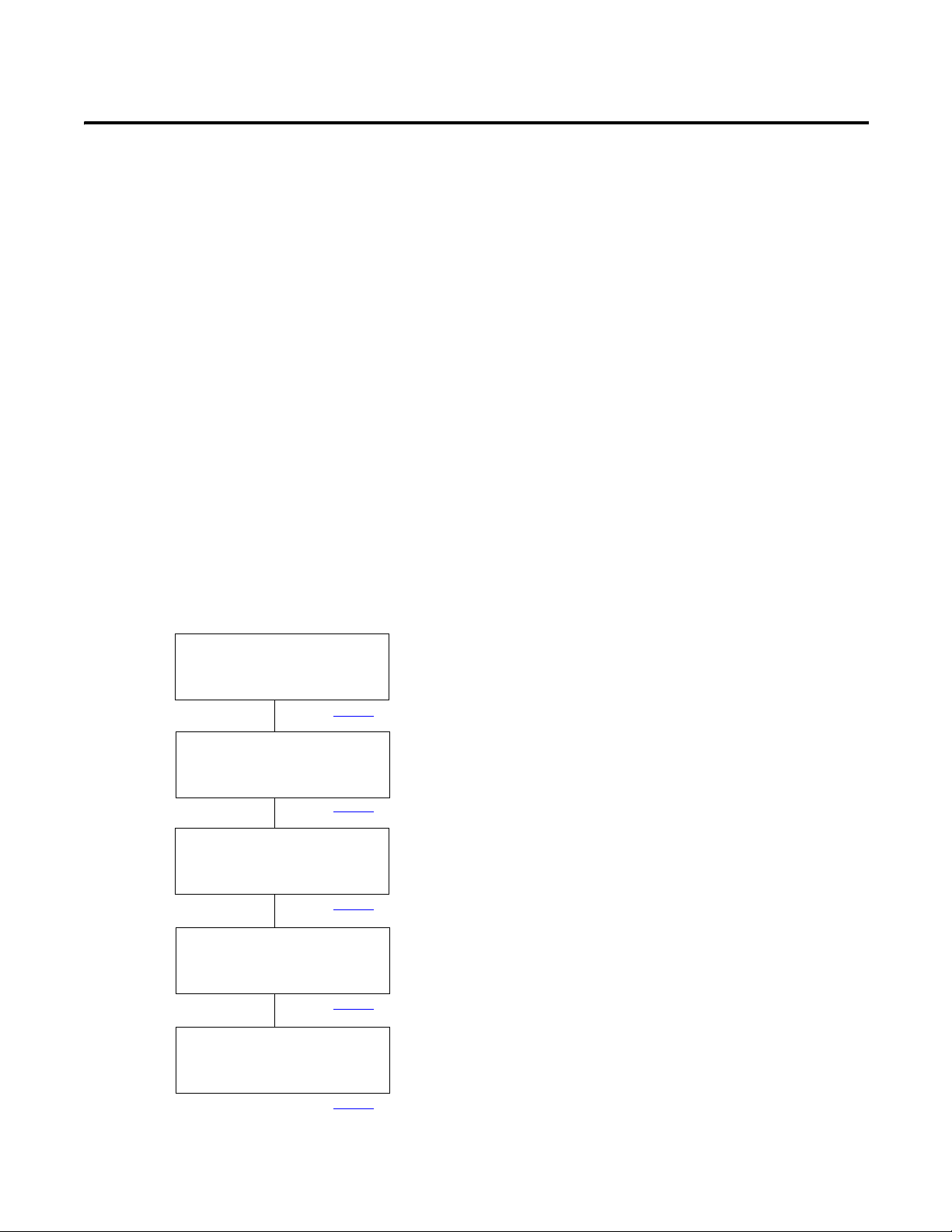

Energy Assessment and Monitoring Methods

Introduction

This chapter introduces the fundamentals of creating an energy management plan that will help you to:

• determine your business goals.

• perform a plant walk-through.

• perform an energy assessment.

• understand the business case for energy monitoring.

• review the monitoring methods available when applying Rockwell Automation energy management hardware and

software products.

1

Review These Steps

Review these concepts to create an energy management plan for your facility.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 17

Page 18

Chapter 1 Energy Assessment and Monitoring Methods

Determine Business Goals

Business today has changed and it added a color - green. Not only do you need to meet your business and production goals,

but global dynamics are forcing you to pursue energy reductions. Many companies can help reduce energy consumption at

their manufacturing facilities when a plan is implemented.

Determining your business goals is the first step in understanding and developing the scope of your energy and power

management application. Your business goals may include:

• Energy cost reduction

• Operating equipment efficiency

• Usage based cost accounting

• Downtime reduction through power quality monitoring

• Sustainable production initiatives

• Driving energy cost accountability to the energy user

• Identifying and justifying energ y cost savings projects

Plant Walk-Through

After determining your business goals, conduct a walk-through of your plant or campus. This will help you to identify the

largest energy consumption uses and events.

To maximize the efficiency of the walk-through, gather pertinent facility documentation that is available.

• Facility one line diagrams for electricity, gas, water, steam, air, and other fuels

• Production equipment layout

• Electric power equipment list

• Other energy equipment documentation including boilers, air compressors, HVAC equipment, and process cooling

equipment

• Energy meters and monitoring equipment

Plant walk-through steps include:

1. Listing large energy consuming equipment and processes.

2. Listing typical time of use or duty cycle.

3. Listing operational or production dependencies.

4. Identifying applications using variable speed drives.

5. Reviewing operation of air compressors, boilers, and chillers

18 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 19

Energy Assessment and Monitoring Methods Chapter 1

Energy Assessment

The assessment process is a detailed analysis of the data collected during the walk-through. Identifying opportunities for

energy savings and developing the return on investment for these projects is critical. Energy assessments should identify not

only opportunities, but savings, project costs, and payback calculations. Projects should also be categorized as awareness or

behavior changes, minor cost, and capital. This approach will help prioritize the steps in the energy savings plan.

Collect and Analyze Utility Bills and Rate Schedules

An important part of the energy assessment is to collect and analyze your current utility rate schedules and bills. This

typically includes electric, natural gas, water, and sewer. Other fuels consumed may include fuel oil, propane, or steam.

Understanding your bill is crucial in executing an appropriate energy management plan to maximize your energy savings

investment.

Energy rate schedules from your local utilities can include, but are not limited to, line item charges such as:

• Demand Charges - A variable monthly or yearly charge for the highest amount of energy consumed over a fixed

period, typically 15 minutes. This charge can contribute significantly to overall energy costs.

• Energy Charge - A variable monthly charge for the total energy that is consumed. This charge typically includes on-

peak and off-peak rates, contracted minimums, alternative charges, ratchet demand penalties, or other special terms.

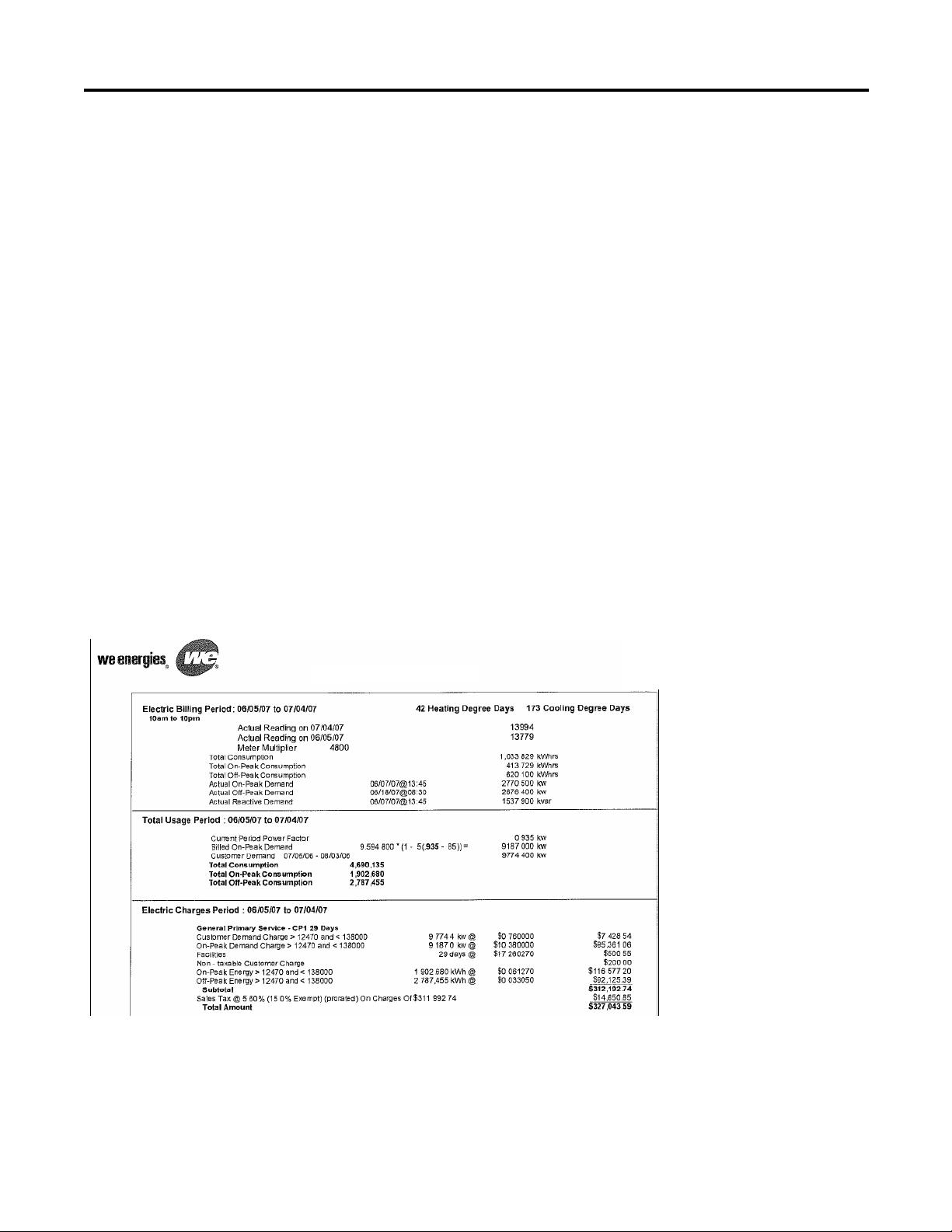

Here is an example of an electric bill and electric rate schedule. You can see that time-of-use and on-peak demand needs can

significantly increase your overall energy costs.

Sample Electric Bill

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 19

Page 20

Chapter 1 Energy Assessment and Monitoring Methods

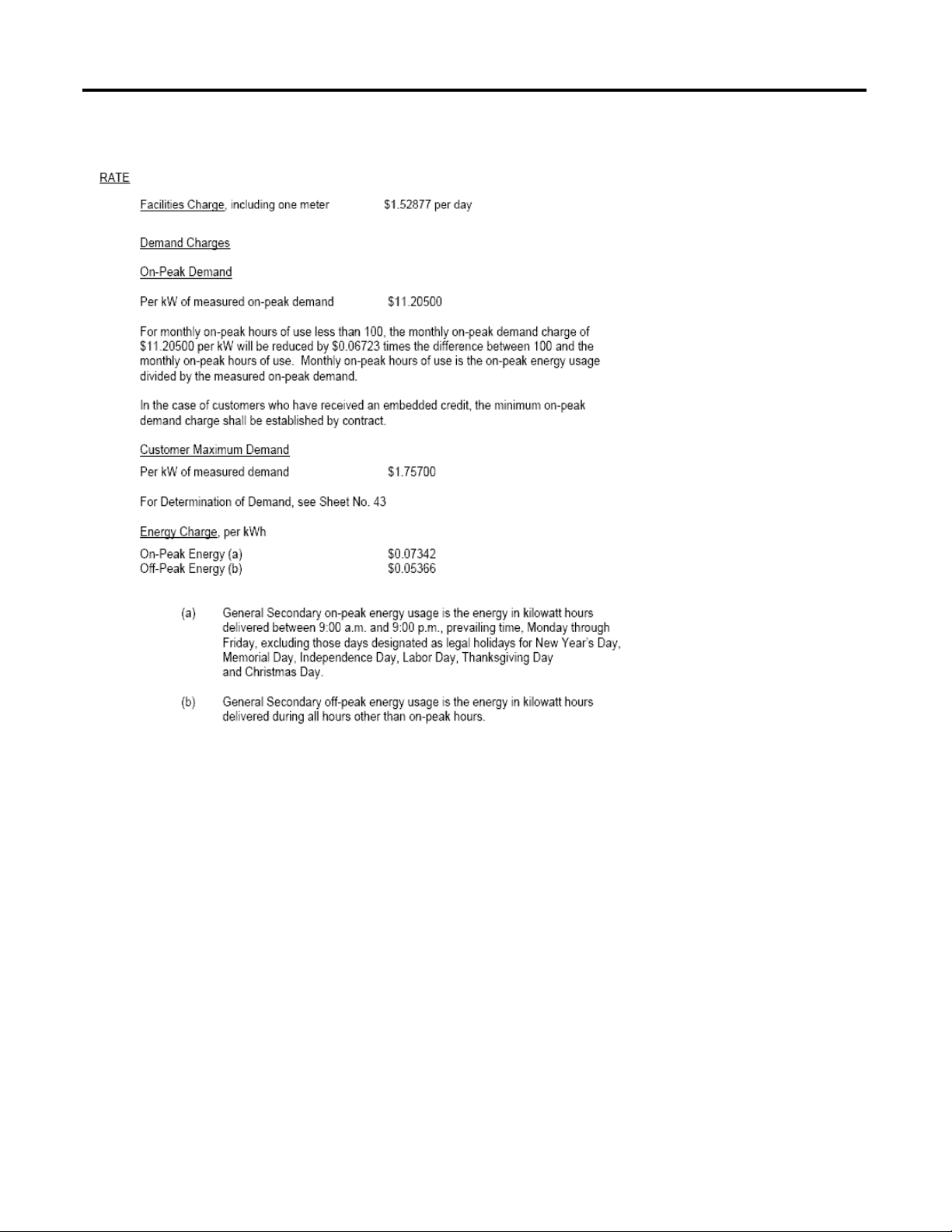

Sample Rate Schedules

20 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 21

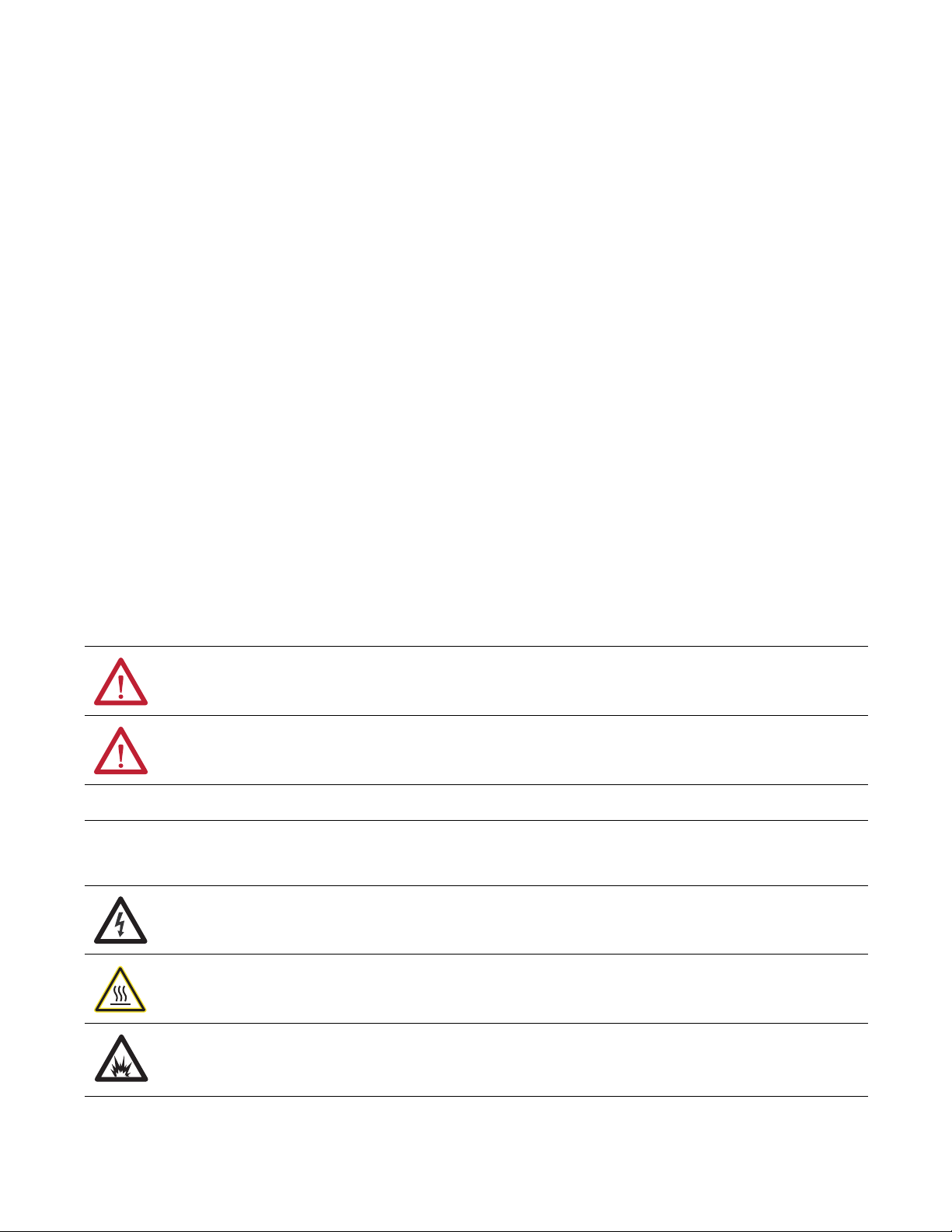

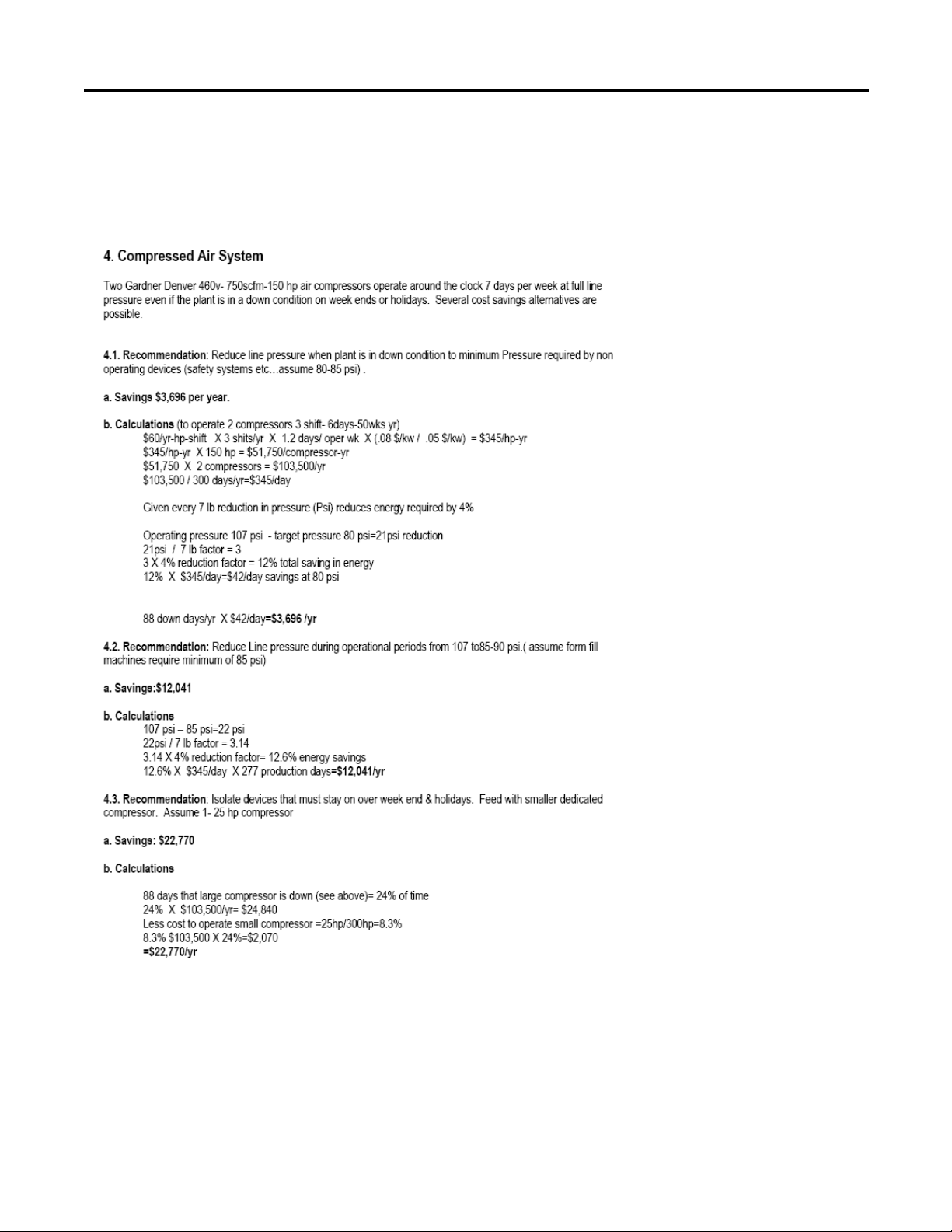

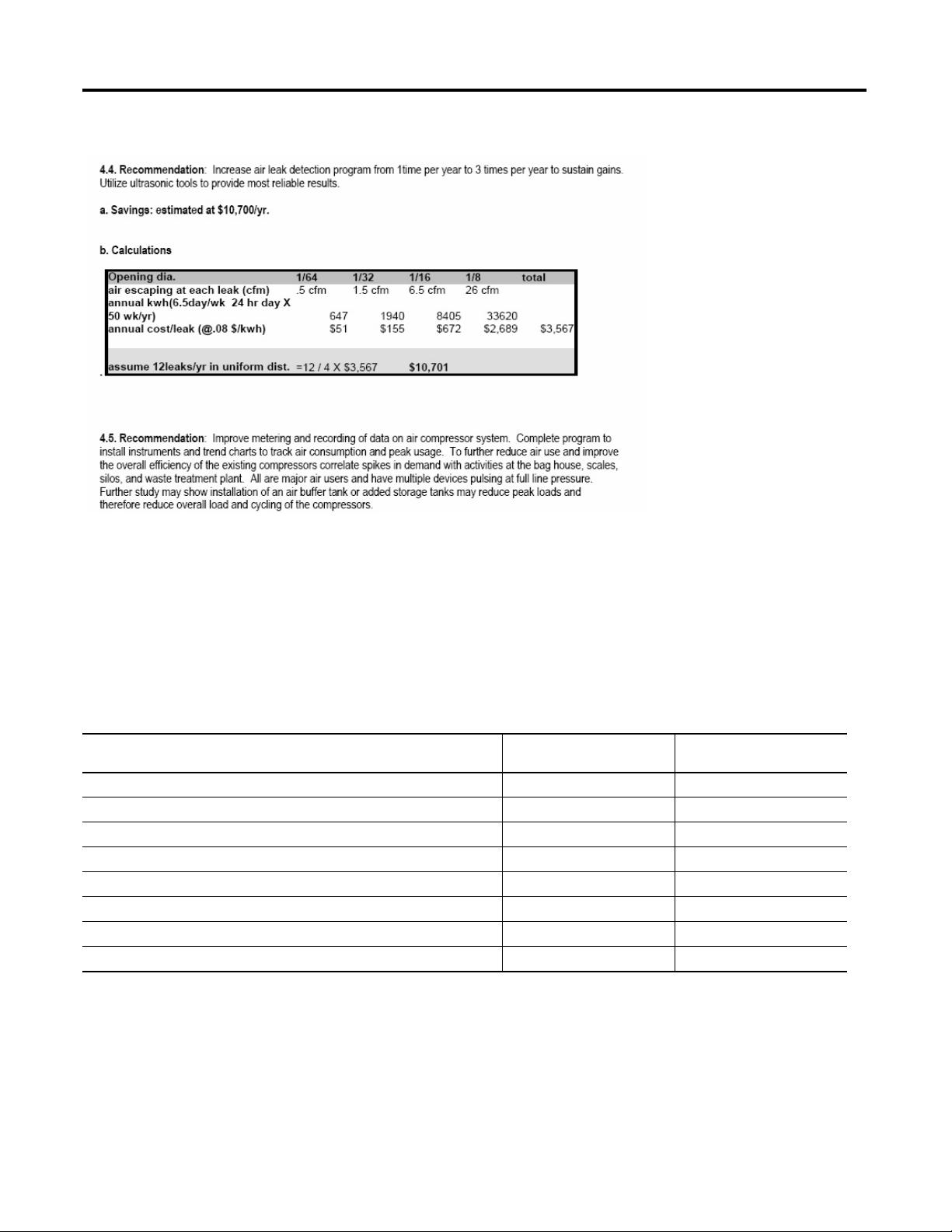

Sample Energy Assessment

Here is an example of a compressed air plant system assessment.

Sample Energy Assessment Document

Energy Assessment and Monitoring Methods Chapter 1

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 21

Page 22

Chapter 1 Energy Assessment and Monitoring Methods

How Rockwell Can Help

Rockwell Automation has a team of engineers that are experienced in conducting energy assessments for energy sources

including, but not limited to, electricity, gas, water, air, and steam.

To help you identify energy cost savings opportunities, Rockwell Automation can perform a general energy assessment that

will help you create a sustainable plan. If the scope of your needs is more extensive, a comprehensive assessment can be

performed to best fit your requirements.

Rockwell Automation Energy Assessment Options

Energy Assessment Option

Utility usage review • •

Energy saving project identification • •

Operations analysis of savings opportunities • •

Utility usage review •

Detailed energy usage analysis •

Rates and tariffs analysis •

Detailed quotations for sustainability projects •

Prioritization of projects •

(1) Request a 1400-AUD services quote from your local Rockwell Automation distributor or the Rockwell Automation custom support and maintenance team.

(2) Request 1400-ATT services quote from your local Rockwell Automation distributor or the Rockwell Automation custom support and maintenance team.

General

2 to 3 Days

(1)

Comprehensive

2 to 3 Weeks

(2)

To view a sample assessment, refer to the Energy and Utilities Site Assessment document in the Support Information

section on the Energy Management Accelerator Toolkit CD.

22 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 23

Energy Assessment and Monitoring Methods Chapter 1

Business Case for Energy Monitoring

Energy monitoring makes energy usage data visible so that it is included in the planning and execution of a business strateg y

along with other management information. Because utility bills can be a significant portion of business expense, it is

important to understand how energy is used. Implementing a monitoring plan will help your business set goals for energy

reduction that will translate into cost savings.

Typical energy users evolve through a number of energy awareness phases.

Ignorance is Expensive

In the first phase, energy is not considered a significant expense or important management information. Operations uses

energy and accounts payable pays for it. Management begins to notice the higher costs and sets goals for energy reduction.

If operation managers are not aware of the energy cost of their operations, energy savings will not be captured.

Metering the Envelope

In the second phase, energy monitoring is installed on the plant main feeds. Electricity, natural gas, water, and other feeds

are recorded. The investment is relatively low. The monitoring system generates shadow bills to verify the utility billing.

Major users of energy are identified. The relationship between operating schedules and plant demand becomes clearer. A

few energy saving opportunities are identified and cost savings generated. However, monitoring only the entire plant has

limitations addressed in the next phase.

Submetering the Processes

In this phase, submeters are installed on process lines and utility equipment such as air, compressors, and boilers. This phase

requires a higher level of investment but provides a more detailed view of energy usage. Reports run daily or weekly provide

a direct line of sight to the impact of operations decisions. Energy use can be correlated with key production indicators to

identify peak producers and opportunities for improvement. Operations can be benchmarked within a plant or across an

enterprise. More cost-saving opportunities are identified. Historical data is used to accurately forecast energy use, providing

the basis for negotiating more favorable rates from energy providers. The same data is used in justifying capital projects to

improve efficiency and further reduce energy usage, cost, and waste. Energy accountability grows.

Controlling Energy Use and Demand

The volume and accuracy of energy use information gathered in the preceding phases is useful in determining the next

steps. Perhaps an automated demand control system would be effective in increasing energy efficiency and sustainability.

Opportunities for heat recovery and onsite generation may be identified. Potential trouble spots might be avoided that

would minimize unnecessary downtime.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 23

Page 24

Chapter 1 Energy Assessment and Monitoring Methods

Monitoring Methods

Rockwell Automation power monitors and controllers collect data from your plant floor that can be used by

FactoryTalk EnergyMetrix software for monitoring and analysis.

FactoryTalk EnergyMetrix software provides monitoring and reporting tools to help you understand usage patterns,

optimize processes, and reduce utility costs in your organization. You can use these tools to monitor electrical loads,

consumption, power quality, analyze demand, and generate billing and cost allocation reports.

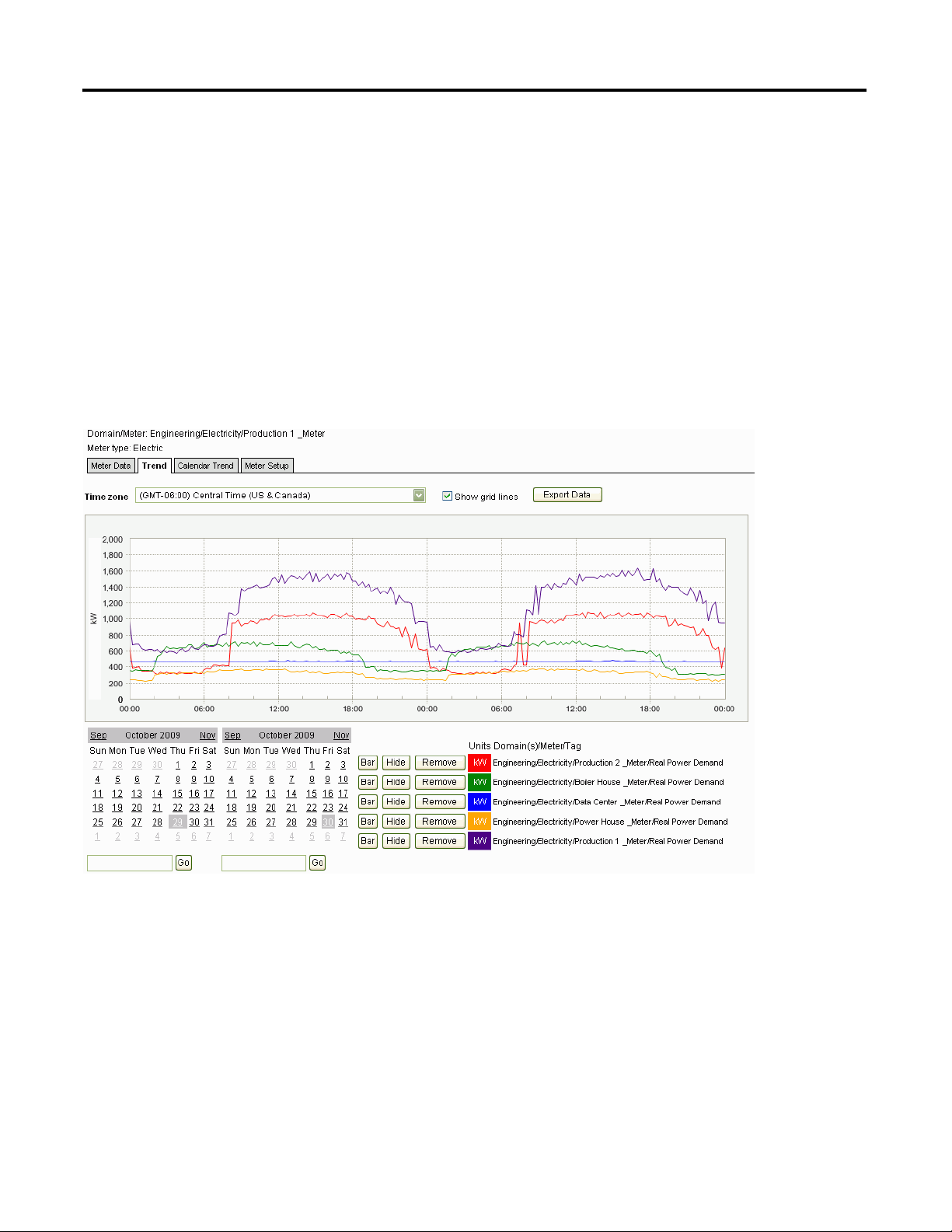

Load Profiling

Load profiling is a method where electrical loads are monitored or profiled. Load profiling helps to identify peak demands

so that you can reschedule loads accordingly to reduce energy costs.

24 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 25

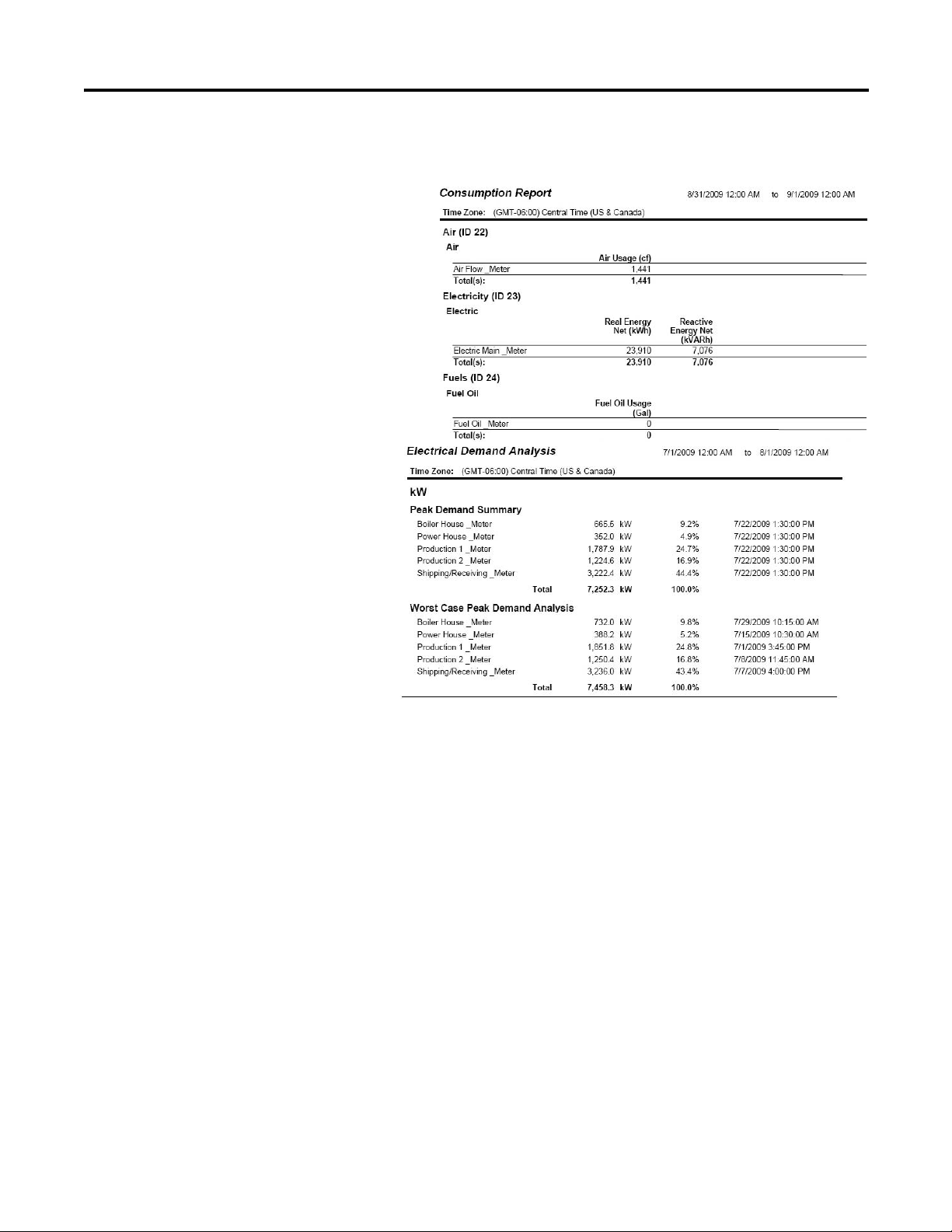

Consumption Reporting

Consumption reporting typically monitors periodic

utility usage, production, or other key performance

indicators, and assists with the early detection of

production/equipment problems such as leaks,

inefficiencies, and production problems.

Demand Analysis

Demand analysis monitors the electrical

demand of plant areas so that you can make

energy saving production scheduling or demand

control decisions.

Energy Assessment and Monitoring Methods Chapter 1

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 25

Page 26

Chapter 1 Energy Assessment and Monitoring Methods

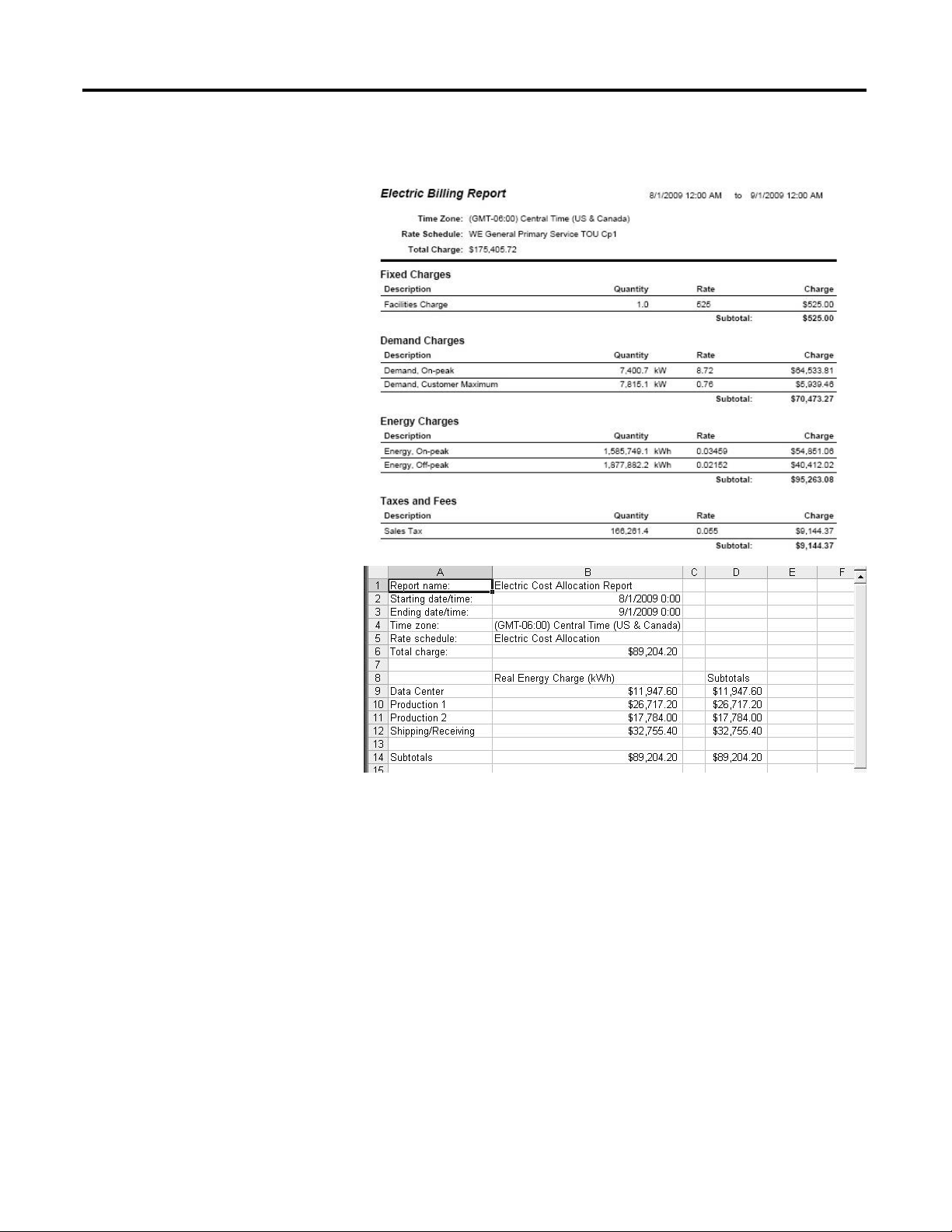

Shadow Billing

Shadow billing generates a replication of a

monthly bill from your energy provider

for comparative billing analysis and

potential energy cost recovery.

Cost Allocation

Cost allocation monitoring lets you

allocate energy costs based on actual usage

that is based on production area

submetering rather than other

measurements such as square footage

allocation. Effective cost allocation helps

drive energy accountabilities to the user.

26 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 27

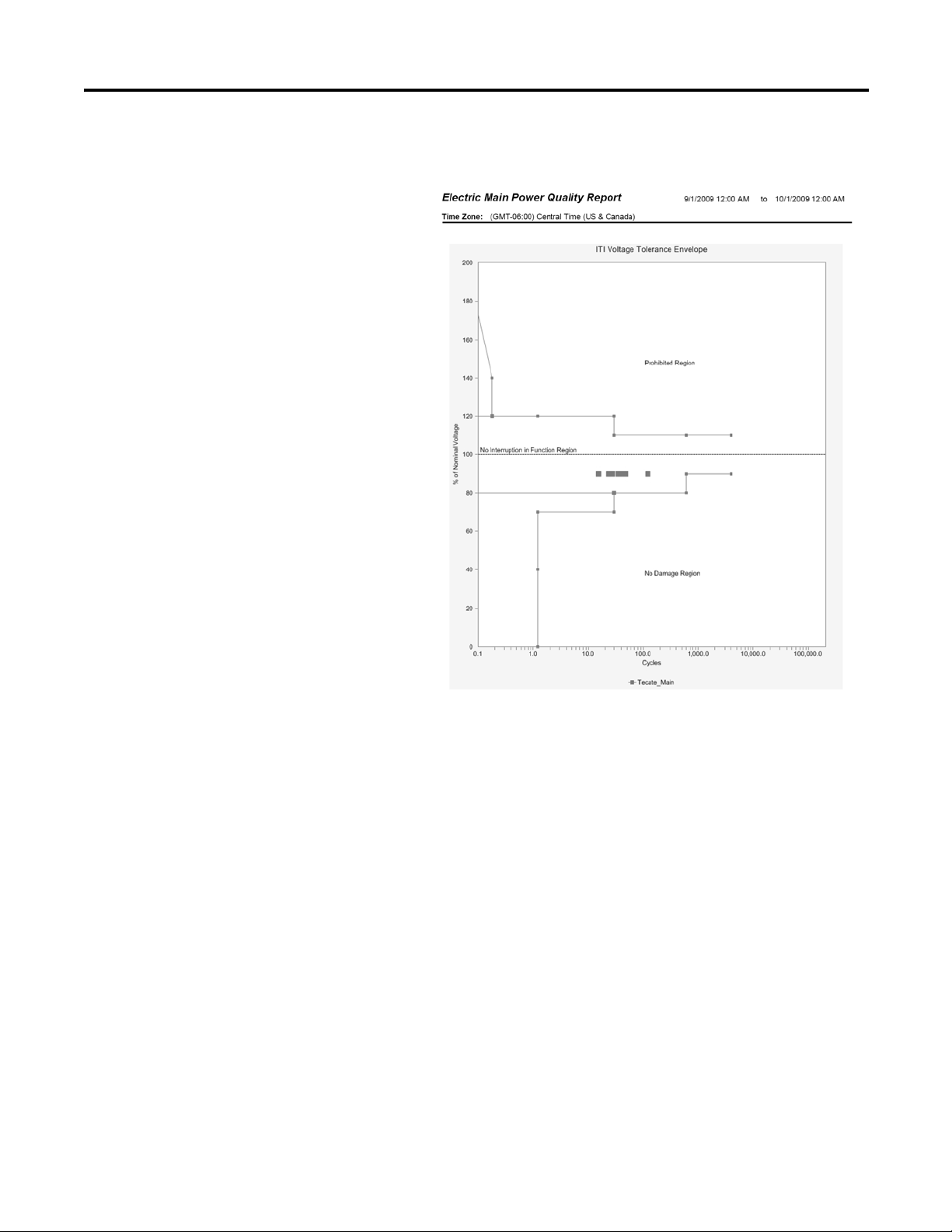

Power Quality

Power quality monitoring lets you capture power

quality events or conditions that could cause a

production shutdown like voltage sags, swells, and

brownouts.

Energy Assessment and Monitoring Methods Chapter 1

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 27

Page 28

Chapter 1 Energy Assessment and Monitoring Methods

Notes:

28 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 29

Chapter

TIP

2

System Configuration and Wiring

Introduction

In this chapter, you will do the following:

• List energy data points based on your business goals and energy monitoring plan.

• Identify your existing energ y meters and distribution systems.

• Select data collection hardware and create a meter layout.

• Create panel layouts and wiring for your data collection hardware.

• Select required software.

To help you with system configuration, an industrial plant example, named Efficient Industries Plant 1, is referenced in this

and subsequent chapters.

Before You Begin

Complete an energy assessment and review monitoring methods in Chapter 1.

What You Need

• Personal computer with internet access for downloading software and files

• AutoCAD program to open the .dwg files or Adobe Acrobat Reader software to open.pdf files

Use AutoCAD Electrical to take advantage of advanced features.

• Energy Management Accelerator Toolkit CD, publication IASIMP-SP014, or visit the Integrated Architecture

Tools and Resources website at http://www.ab.com/go/iatools

• Power and Energ y Management section of the Industrial Controls catalog, available at http://www.ab.com/catalogs/

• Microsoft Excel software

to download toolkit files

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 29

Page 30

Chapter 2 System Configuration and Wiring

page 31

page 33

List Energy Data Points

Identify Existing Energy Distribution

Layouts and Metering

page 36

page 48

Create Metering Layout and Name Data

Collection Hardware

Create Energy Panel Layout and Wiring

Drawings

page 52

Select Monitoring Software

Follow These Steps

Follow this path to layout your energy panel and wiring, and select monitoring software.

30 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 31

System Configuration and Wiring Chapter 2

List Energy Data Points

You will now review your business goals and energy monitoring plan, then enter your data points in the Energy Data

Wo r k s h e e t .

Review Business Goals and Energy Monitoring Plan

1. Review the business goals that you created in Chapter 1.

The Efficient Industries Plant 1 example, referenced throughout this quick start, is a midsized plant with two

production areas. These are the business goals of the example plant:

• Reduce electrical energy demand charges

• Improve electrical energy efficiency through power quality monitoring

• Reduce fuels and steam energy usage by running boilers in accordance with production demand schedules

• Reduce air compressor energy use

• Provide energy cost allocation to production areas, shipping and receiving, and the data center

2. Review your monitoring plan based on the initial energy assessment findings.

These are the monitoring goals of the Efficient Industries Plant 1 example:

• Monitor electrical main power quality

• Track electrical consumption of production 1, production 2, shipping/receiving, boiler house, and data center

• Monitor gas main, boiler house gas, fuel oil, and propane fuel usage

• Monitor steam, air, and water flow

Enter Energy Data Points in Energy Data Worksheet

Enter your energy data points in the Energy Data Worksheet. The procedure demonstrates how to enter data points using

the Efficient Industries Plant 1 example.

1. Browse to the System Layout and

Wiring folder on the Energy

Management Accelerator Toolkit

CD image.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 31

Page 32

Chapter 2 System Configuration and Wiring

2. Right-click Energy Data Worksheet and open the file.

When opening the spreadsheet, select Enable Macros.

3. Click the Energ y Point tab in the worksheet and enter

an energy type and name for the first energy data

point in your system.

a. Select a cell in the Energy Type column and click

the pull-down list icon.

b. Choose an Energy Type.

For the Efficient Energy Plant 1 example, choose

Electricity.

c. Select a cell in the Name column and enter a name

for the energy data point.

For the Efficient Energy Plant 1 example, Electric

Main is entered as the first Electricity data point.

4. Repeat step 3 for each data point with the same energy

type selected in step 2.

For the Efficient Energy Plant 1 example, the

Electricity energy point listing should look like this.

5. Repeat steps 3 and 4 for the remaining energy types in

your system.

For the Efficient Energy Plant 1 example, the

completed energy point listing should look like this.

32 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 33

System Configuration and Wiring Chapter 2

Identify Existing Energy Distribution Layouts and Metering

Follow these steps to help identify your existing energy distribution and metering systems.

1. Gather existing electrical distribution single line drawings and label electricity data point substations and

distribution points.

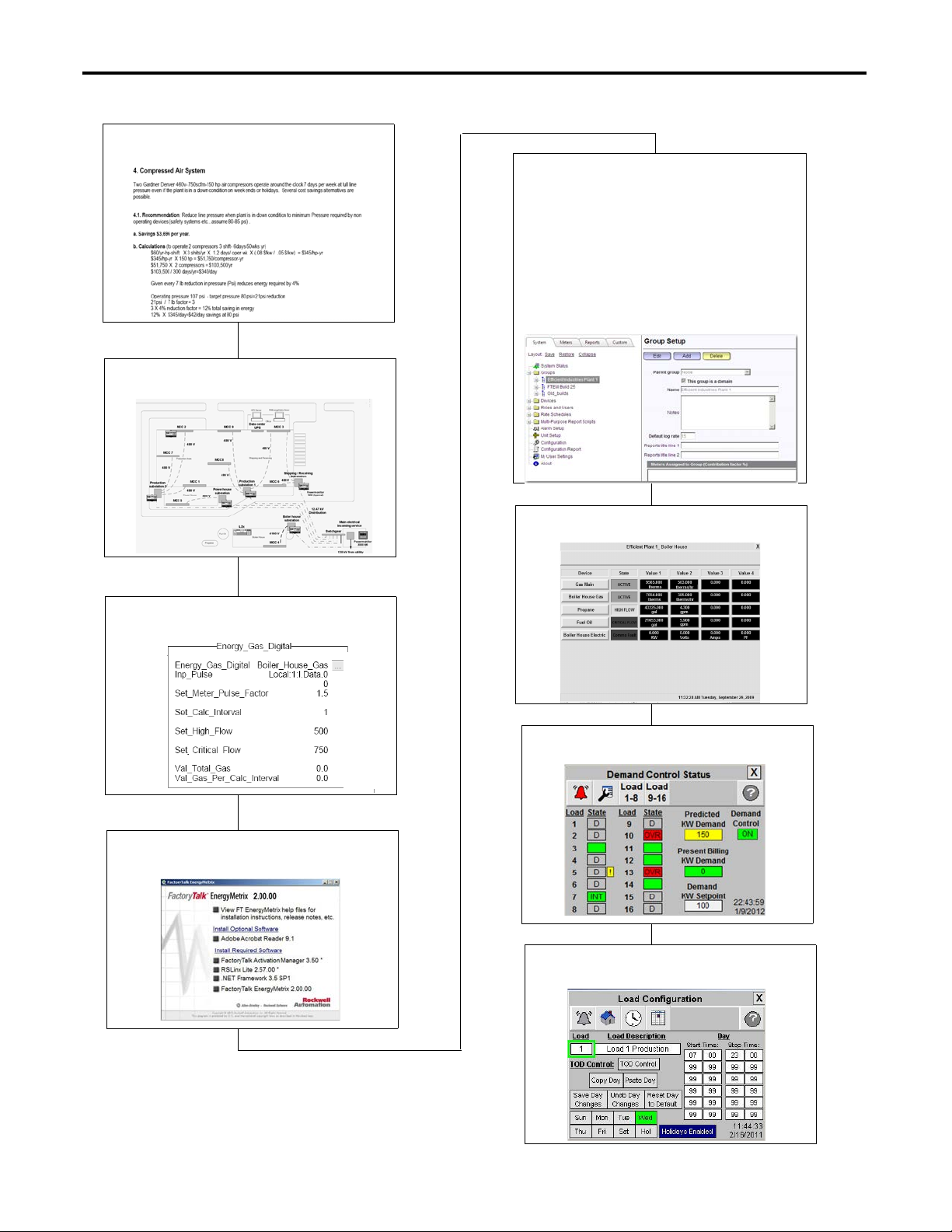

Efficient Industries Plant 1 Example - Electrical Single Line Drawing Example

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 33

Page 34

Chapter 2 System Configuration and Wiring

2. Gather or create the electrical distribution plant layout.

Efficient Industries Plant 1 Example- Electrical Distribution Layout

34 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 35

3. Gather or create other energy distribution plant layouts.

Efficient Industries Plant 1 Example - Other Energy Distribution Plant Layouts

System Configuration and Wiring Chapter 2

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 35

Page 36

Chapter 2 System Configuration and Wiring

Create Metering Layout and Name Data Collection Hardware

In this section, you will create a metering layout, then select and name your data collection hardware using the Energy Data

Worksheet. The information entered in the worksheet will be used later in the FactoryTalk EnergyMetrix software

configuration chapters.

Create a Metering Layout and Select Data Collection Device Classes

Follow these steps to create a metering layout of your energy data collection devices.

1. Add PowerMonitors to your Electrical Distribution Layout drawing based on the electricity energy data points listed

in the Energ y Data Worksheet.

For the Efficient Industries Plant 1 example, these devices are added to the drawing:

• One PowerMonitor 3000 for the Electric Main to monitor power quality

• Five PowerMonitor 1000 devices to monitor electric consumption and demand for various plant departments, as

listed in the Energy Data Worksheet

36 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 37

System Configuration and Wiring Chapter 2

2. Browse to the System Layout and Wiring folder on your Energy

Management Accelerator Toolkit CD image and open the Energy Data

Wo r k s h e e t .

3. Click the FactoryTalk EnergyMetrix tab and select a Device Class for each PowerMonitor added to the layout.

The device classes will be used in later chapters when configuring devices in FactoryTalk EnergyMetrix software and

also determine the energy meter tag names.

a. Select a cell in the Device Class column

and click the pull-down list icon.

b. Choose the appropriate PowerMonitor

device class for each data point based on

the Device Class Selection table.

Device Class Selection

Device Class Energy Data Point Metering Requirements

PowerMonitor 1000 on EtherNet/IP Select this device class for:

PowerMonitor 3000 on EtherNet/IP Select this device class for:

PowerMonitor W250 Select this device class for:

PowerMonitor 500 on Serial Select this device class for:

PowerMonitor 500 on EtherNet/IP Select this device class for:

PowerMonitor 5000 on Ethernet/IP Select this device class for:

• electricity data points requiring only consumption and demand monitoring.

• other energy data points in close proximity to a PowerMonitor 1000 device that can

provide a digital contact output, for example, an existing utility meter with a pulse

contact output.

A maximum of two energy status inputs are provided on the PowerMonitor 1000 device.

• electricity data points requiring consumption, demand, and power quality monitoring.

• other energy data points in close proximity to a PowerMonitor 3000 device that can

provide a digital contact output, for example, an existing utility meter with a pulse

contact output.

A maximum of two energy status inputs are provided on the PowerMonitor 3000 device.

electricity data points requiring consumption monitoring in a wireless communication

network

electricity data points requiring consumption monitoring

• electricity data points requiring consumption monitoring

• can also be used for demand monitoring

• electricity data points requiring consumption, demand, and power quality monitoring.

• other energy data points in close proximity to a PowerMonitor 5000 device that can

provide a digital contact output, for example, an existing utility meter with a pulse

contact output.

A maximum of four energy status inputs are provided on the PowerMonitor 5000 device.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 37

Page 38

Chapter 2 System Configuration and Wiring

For the Efficient Industries Plant 1 example, the electricity energy data point listing would look like this.

4. Identify other digital energy data points in close proximity that you can connect to the status inputs of the

PowerMonitors.

For the Efficient Industries Plant 1 example, the air flow digital pulse meter is near the Production 2 electrical

substation so it can connect to the PowerMonitor 1000 named Production 2.

5. Select a Device Class and Meter Type on the FactoryTalk EnergyMetrix tab of the Energy Data Worksheet for the

PowerMonitor status inputs identified in step 4.

a. Select the appropriate PowerMonitor Device Class.

b. Select PM Status Input for the Meter Type.

For the Efficient Industries Plant 1 example, the entries for the air flow data point would look like this.

38 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 39

System Configuration and Wiring Chapter 2

6. Identify other small groups (<3) of digital energy points in close proximity that can be collected by the digital status

inputs of the PowerMonitor 1000 device.

This is a lower cost alternative to a CompactLogix™ controller with a few digital inputs.

For the Efficient Industries Plant 1 example, the gas main and water main digital meters are somewhat isolated in the

corner of the production area near MCC 2. A PowerMonitor 1000 named MCC 2 is added to capture these two

digital meter inputs.

7. Select a Device Class and Meter Type on the FactoryTalk EnergyMetrix tab of the Energy Data Worksheet for the

PowerMonitor status inputs identified in step 6.

a. Select a PowerMonitor 1000 Device Class.

b. Select PM Status Input for the Meter Type.

For the Efficient Industries Plant 1 example, the entries for the gas main and water main data points would look like

this.

8. Identify other larger groups of digital and analog energy data points in close proximity that can connect to an L23

CompactLogix controller data collection device.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 39

Page 40

Chapter 2 System Configuration and Wiring

The L23 CompactLogix controller can collect up to 16 digital inputs and 4 analog inputs.

For the Efficient Industries Plant 1 example, the remaining digital and analog energy data points are in the Boiler

House so a CompactLogix controller is added to the metering layout.

9. Select a Device Class and Meter Type on the FactoryTalk EnergyMetrix tab of the Energy Data Worksheet for the

digital and analog energ y inputs identified in step 8.

a. Select ControlLogix

on Ethernet for the Device Class.

b. Select L2x Input for the Meter Type.

For the Efficient Industries Plant 1 example, the entries for the CompactLogix digital and analog energy data points

would look like this.

10. Identify and list any energy data points to be collected from an OPC server.

For the Efficient Industries Plant 1 example, Data Center energy consumption will be collected by an OPC server in

the office area. The personal computer for the FactoryTalk EnergyMetrix server is also in this location. All energy

data collection devices and the FactoryTalk EnergyMetrix server are connected to an EtherNet/IP network.

40 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 41

System Configuration and Wiring Chapter 2

11. Select a Device Class and Meter Type on the FactoryTalk EnergyMetrix tab of the Energy Data Worksheet for the

OPC server data point identified in step 10.

a. Select OPC Server on Ethernet for the Device Class.

b. Select OPC for the Meter Type.

For the Efficient Industries Plant 1 example, the entry for the OPC server data point would look like this.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 41

Page 42

Chapter 2 System Configuration and Wiring

Select Data Collection Hardware

Follow these steps to select your data collection hardware.

1. Browse to the System Layout and Wiring folder on the Energy

Management Accelerator Toolkit CD image and open the Energy Data

Wo r k s h e e t .

2. Click the FactoryTalk EnergyMetrix tab then choose or enter energy device

catalog numbers.

a. Select a cell in the Cat. No. column and click the pull-down list icon.

b. Choose the appropriate Cat. No. for each data point based on the PowerMonitor and CompactLogix Device

Selection table.

To use a nonstandard energy device, select the blank at the bottom of the list and enter the catalog number.

Device Cat. No. Description Communication

1408-EM1A-ENT Provides kWh data, energy log, and status log only.

PowerMonitor 1000 on Ethernet

PowerMonitor 3000 on Ethernet

PowerMonitor W250 1425-D1002-MOD PowerMonitor Wireless,100A,300V Delta Serial or Ethernet (using

1408-EM2A-ENT Provides kWh, kVARh, kVAHh data, demand and

1408-EM3A-ENT

1404-M505x-ENT

1404-M605x-ENT

1404-M805x-ENT

1425-D1002-MOD-480 PowerMonitor Wireless,100A,480V Delta

1425-W1003-MOD PowerMonitor Wireless,100A,300V Wye

1425-D2002-MOD PowerMonitor Wireless,200A,300V Delta

1425-W2003-MOD PowerMonitor Wireless, 200A,300V Wye

1425-D5002-MOD PowerMonitor Wireless, 500A, 300V Delta

1425-D5002-MOD-480 PowerMonitor Wireless, 500A, 480V Delta

1425-W5003-MOD PowerMonitor Wireless, 500A, 300V Wye

1425-D10002-MOD PowerMonitor Wireless, 1000A, 300V Delta

1425-W10003-MOD PowerMonitor Wireless, 1000A, 300V Wye

1425-D20002-MOD PowerMonitor Wireless, 2000A, 300V Delta

1425-D20002-MOD-480 PowerMonitor Wireless, 2000A, 480V Delta

1425-W20003-MOD PowerMonitor Wireless, 2000A, 300V Wye

(2)

projected demand values plus energy min/max, load

factor, and status log.

Provides same parameters as catalog number 1408EM2A-ENT plus separate voltage, current, frequency,

and power factor parameters.

(3)

Provides full consumption and demand value

parameters, ten configurable setpoints, %THD, and

K-factor harmonic analysis.

(2)(3)

Provides same parameters as catalog number 1404M505x-ENT plus waveform capture capability, and

41st order harmonic analysis.

(3)

Provides same parameters as catalog number 1404M605x-ENT plus transient detection and capture,

and 63rd order harmonic analysis.

Ethernet

Ethernet

a serial to Ethernet

gateway).

42 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 43

System Configuration and Wiring Chapter 2

Device Cat. No. Description Communication

PowerMonitor 500

(1)

1420-Vy Power Meter Indicator No Comm

1420-VyP Power Meter - Pulse (digital) Output

1420-VyA Power Meter - Analog Output

1420-Vy-ENT EtherNet/IP Power Meter Ethernet

1420-VyP-ENT EtherNet/IP Power Meter - Pulse (digital) Output

1420-VyA-ENT EtherNet/IP Power Meter - Analog Output

1420-Vy-485 Serial Power Meter Serial

1420-VyP-485 Serial Power Meter - Pulse (digital) Output

1420-VyA-485 Serial Power Meter - Analog Output

PowerMonitor 5000 1426-M5E Power Quality Meter Ethernet

1426-M5E-ENT Power Quality Meter with 2nd Ethernet Port

1426-M5E-CNT Power Quality Meter with ControlNet Port

1426-M5E-DNET Power Quality Meter with DeviceNet Port

1769-L23E-QB1B Provides 16 DC inputs/16 DC outputs

CompactLogix L23 Controllers

1769-L23E-QBFC1B Provides 16 DC inputs/16 DC outputs plus:

4 analog inputs

Ethernet

2 analog outputs

4 high speed counters

(1) The y in the catalog number designates device voltage, where 1 = 240V ACV-LL120V ACV-LN/208V ACV-LL and 2 = 400V ACV-LN and 690V ACV-LL.

(2) Preferred devices for use with this toolkit.

(3) The x in the catalog number designates device power, where A=120/240 VAC and B= 24 VDC.

For the Efficient Industries Plant 1 example, the catalog numbers for the data collection devices would look like this.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 43

Page 44

Chapter 2 System Configuration and Wiring

TIP

Name Data Collection Hardware

Follow these steps to create or select device names, meter types, and meter tag names for each energy data point. These

names will be used later in the FactoryTalk EnergyMetrix software configuration chapters.

1. Click the FactoryTalk EnergyMetrix tab on the Energy Data Worksheet.

2. Enter a device name for each energy data point.

It is recommended that you name the device with the same name as the energy data point when possible. If a device

collects multiple energy data points, use a name related to the most significant data point or unique location.

For the Efficient Industries Plant 1 example, the device names for the first six PowerMonitor devices and the data

center are the same as the energy data point names.

For the Efficient Industries Plant 1 example, the PowerMonitor 1000 device named MCC 2 collects two energy data

points, the Gas Main and the Water Main. The CompactLogix device collecting one digital and three analog inputs

is named L2x.

44 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 45

System Configuration and Wiring Chapter 2

3. Review meter names.

The meter names are autopopulated in the worksheet based on energy data point names.

4. Choose Electric as the Meter Type for all the PowerMonitor devices.

5. Select or enter meter tag names for each data point based on the Energy Type and Meter Type shown in the table.

Energy Type Meter Type Meter Tag Names

Electric

Electricity

PM Status Input

L2x Input

OPC

Natural Gas PM Status Input

L2x Input

OPC

Fuel Oil PM Status Input

L2x Input

OPC

Propane PM Status Input

L2x Input

OPC

Steam PM Status Input

L2x Input

OPC

Air PM Status Input

L2x Input

OPC

Water PM Status Input

L2x Input

OPC

Real Energy Net

Reactive Energy Net

Reactive Power Demand

Real Energy Net

Natural Gas Usage

Fuel Oil Usage

Propane Usage

Propane Usage

Air Usage

Water Usage

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1) If there is only one energy data point of a particular energy type then select the meter tag name listed in the

table. If there is more than one energy data point with the same energy type then select a blank meter name

and type [EnergyDataPointName] [EnergyType] Usage, for example, Boiler House Natural Gas Usage.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 45

Page 46

Chapter 2 System Configuration and Wiring

For the Efficient Industries Plant 1 example, the meter type and meter tag name listing would look like this.

Assign CompactLogix Input Addresses

Follow these steps to assign CompactLogix hardware input addresses and corresponding PLC-5 mapped tags to the

energy data points.

1. Click the CompactLogix tab on the Energy Data Worksheet.

2. Enter an L2x address for each energy data point that is connected to a CompactLogix controller.

a. Select a cell in the L2x column and click the pull-down list icon.

b. Choose the L2x digital hardware address to which the energy data point is wired.

Digital Input addresses are Local:1:I.Data.0 through Local:1:I.Data.15.

Analog Input addresses are Local:3:I.CH0 through Local:3:I.CH3.

46 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 47

System Configuration and Wiring Chapter 2

TIP

3. Select the corresponding PLC-5 mapped address for the energy data point.

a. Select a cell in the PLC-5 Address column and click the pull-down list icon.

b. Choose a PLC-5 File 10 address to which the energy data point will be mapped for communicating with

FactoryTalk Energ yMetrix software.

It is recommended that you assign consecutive PLC-5 addresses in a single file to simplify mapping.

Refer to page 86

for details on mapped PLC-5 addresses.

For the Efficient Industries Plant 1 example, the Compactlogix and PLC-5 address assignments would look similar

to this.

Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014 47

Page 48

Chapter 2 System Configuration and Wiring

Create Energy Panel Layout and Wiring Drawings

The toolkit provides energy data collector panel layout and wiring drawings in DWG, DXF, and PDF file formats to help

you plan the layout of your energy system. The files are organized by device (CompactLogix, PM1000, PM3000,

PMW250, PM500, and PM5000). The drawings include power and control wiring.

If you do not have CAD software, use the pdf files to build your system drawings.

Use CAD Drawings from Toolkit

Follow these steps to access the AutoCAD drawings for each device in your Energy Data Worksheet.

1. Browse to and open the System

Layout and Wiring folder on the

Energy Management Accelerator

To ol ki t C D i ma g e.

2. Navigate to the desired files based

on your device and file format

(DXF, DWG, or PDF).

3. Add the required files to your project or copy them to your project folder.

The drawings were created using AutoCAD Electrical. The project files are included in the DWG folder. The path

references in the project file are the default AutoCAD Electrical installation path.

48 Rockwell Automation Publication IASIMP-QS016C-EN-P - October 2014

Page 49

System Configuration and Wiring Chapter 2

Panel Layout Drawings

The AutoCAD Electrical project includes several panel-layout drawings for the PowerMonitor 1000, PowerMonitor 3000,

and CompactLogix data collector devices. Choose an appropriate drawing as a starting point. Add or remove components

as needed.

This example shows an energy panel layout with a PowerMonitor 3000 device.