Rockwell Automation 1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789 SoftLogix General Instructions

...Page 1

Reference Manual

Original Instructions

Logix 5000 Controllers General Instructions

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, 5069

CompactLogix, Emulate 5570

Page 2

Logix 5000 Controllers General Instructions

personal injury or death, property damage, or economic loss.

IMPORTANT

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

2 Publication 1756-RM003V-EN-P - November 2020

Page 3

Topic Name

Reason

Added FBD Function element.

Added FBD Function element.

on page 478

and ULINT data types.

Added FBD Function element.

Added FBD Function element.

Equal To (EQU) on page 270

Updated the String Compare Flow Chart.

and ULINT data types.

and ULINT data types.

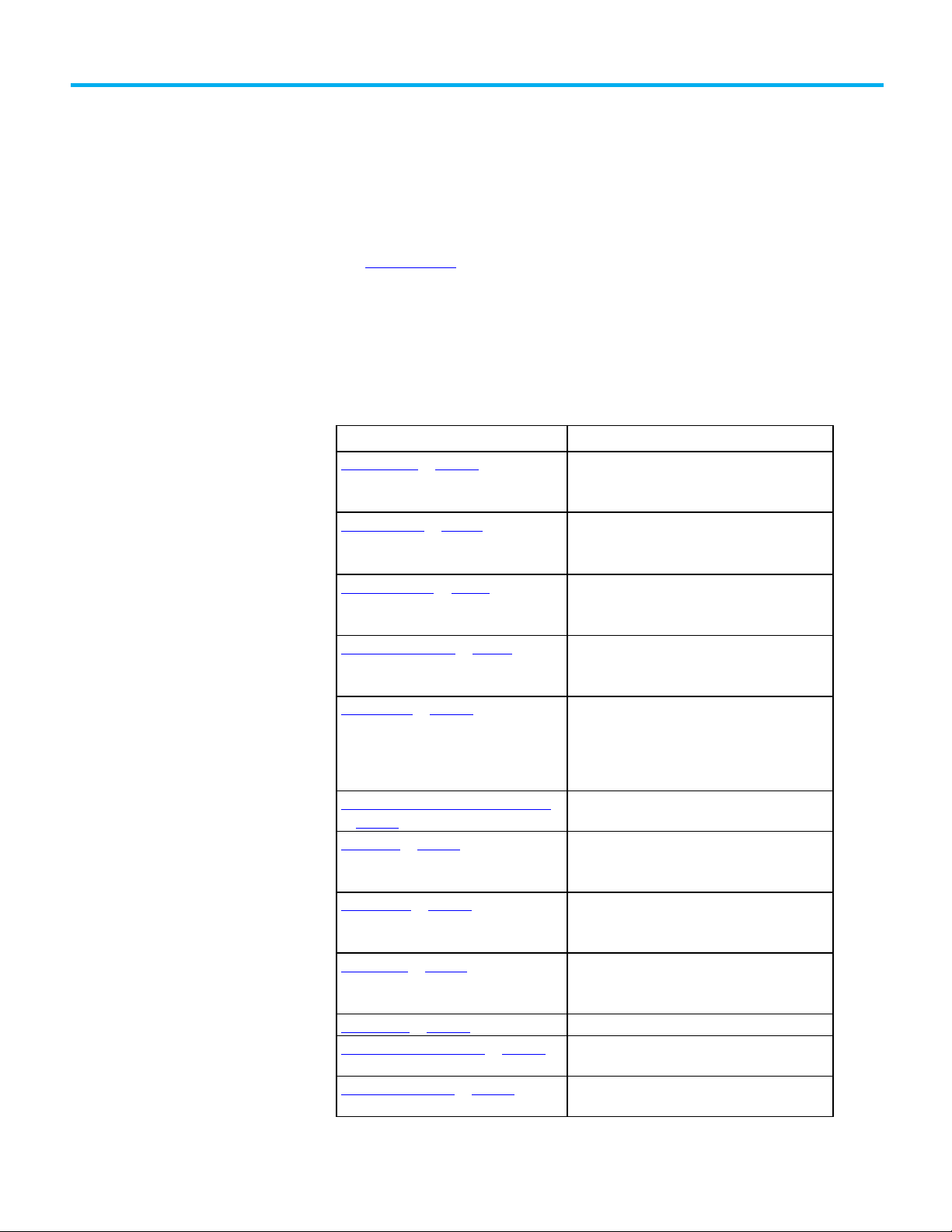

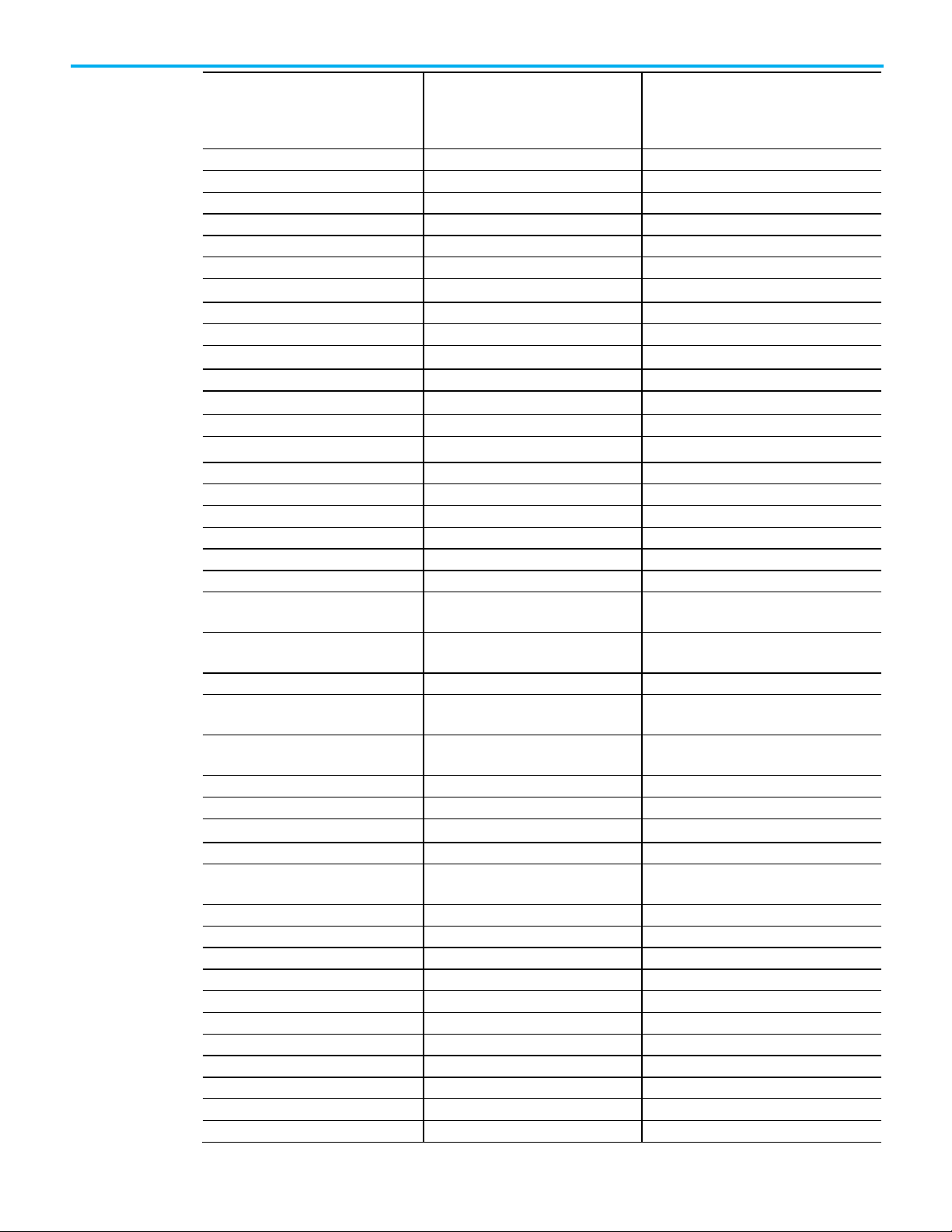

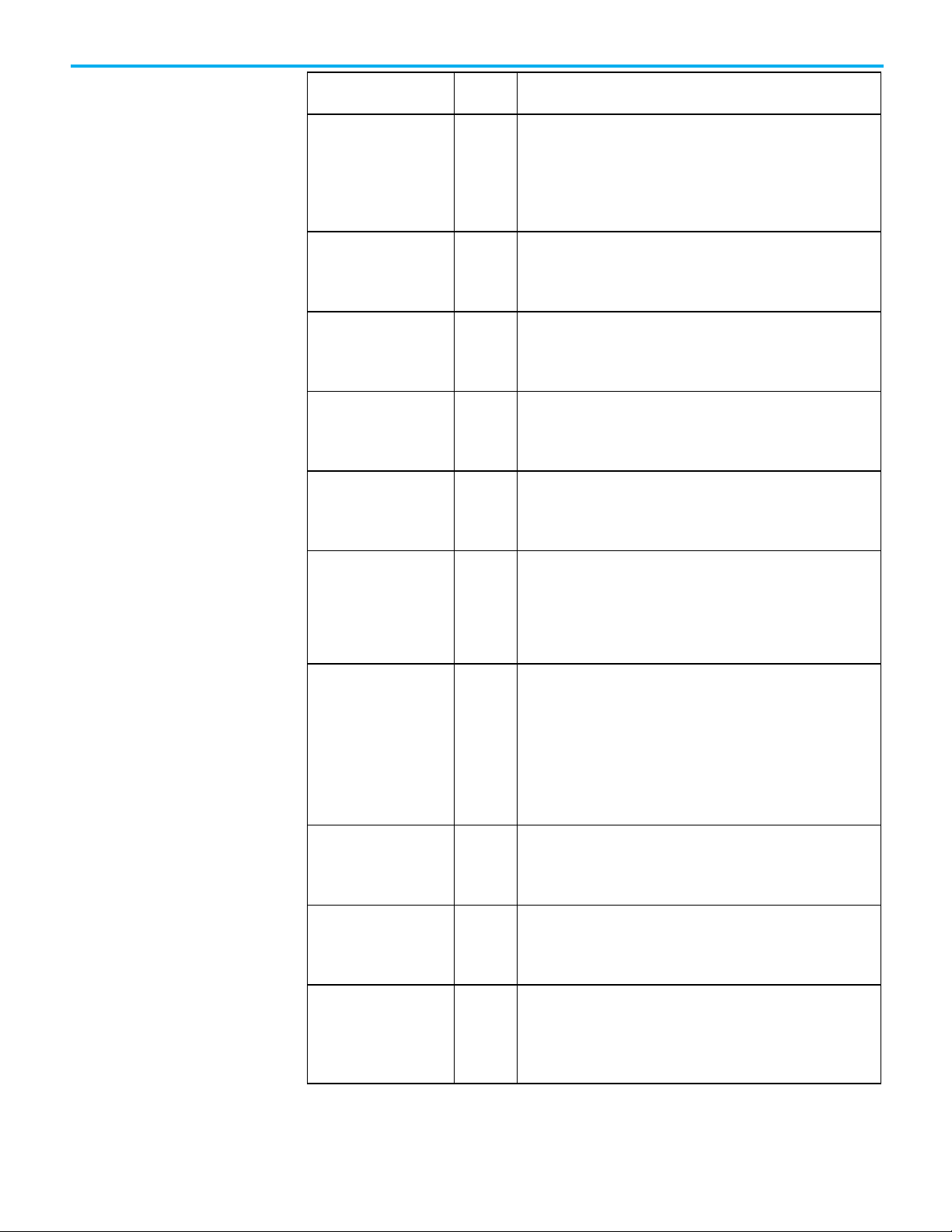

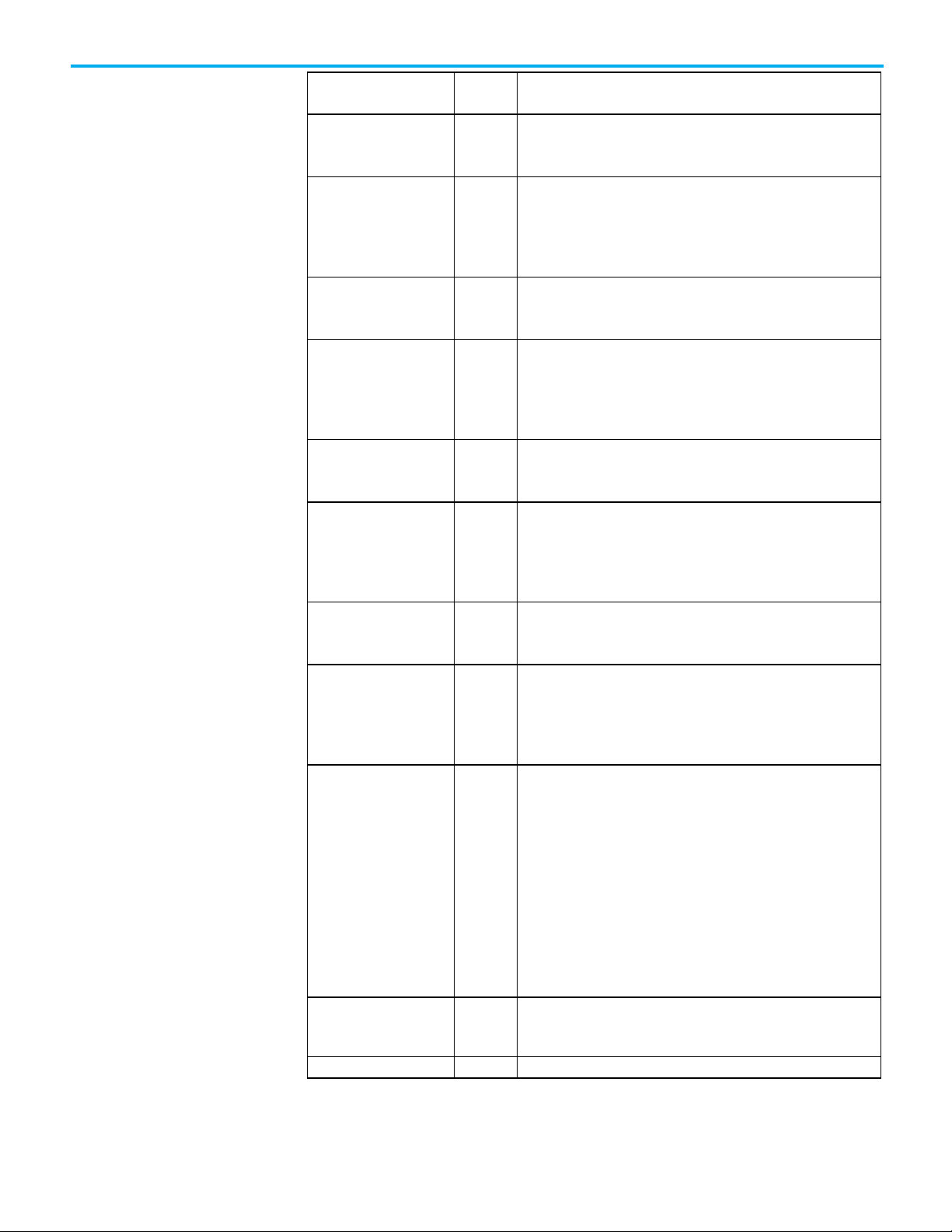

Summary of changes

This manual includes new and updated information. Use these reference

tables to locate changed information.

Global changes

The Legal noticeshave been updated.

New or enhanced features

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

Arc Cosine (ACS) on page 705 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Added FBD Function element.

Bitwise And (AND) on page 413 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Added FBD Function element.

Arc Sine (ASN, ASIN) on page 711 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Arc Tangent (ATN, ATAN) on page 717 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Compare (CMP) on page 266 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Added support for logical operators &&, ||, ^^, and !.

Added support for IsINF and IsNAN.

Copy File (COP), Synchronous Copy File (CPS)

Cosine (COS) on page 723 Added support for LINT, LREAL, USINT, UINT, UDINT

Compute (CPT) on page 356 Removed condition statement for non-LREAL

Degrees (DEG) on page 773 Added support for LINT, LREAL, USINT, UINT, UDINT

File Arithmetic and Logic (FAL) on page 488 Added support for LINT, LREAL, USINT, UINT, UDINT

Convert to Integer (FRD) on page 769 Added support for LINT, LREAL, USINT, UINT, UDINT

Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

operands converting to LREAL.

and ULINT data types.

Publication 1756-RM003V-EN-P - November 2020 3

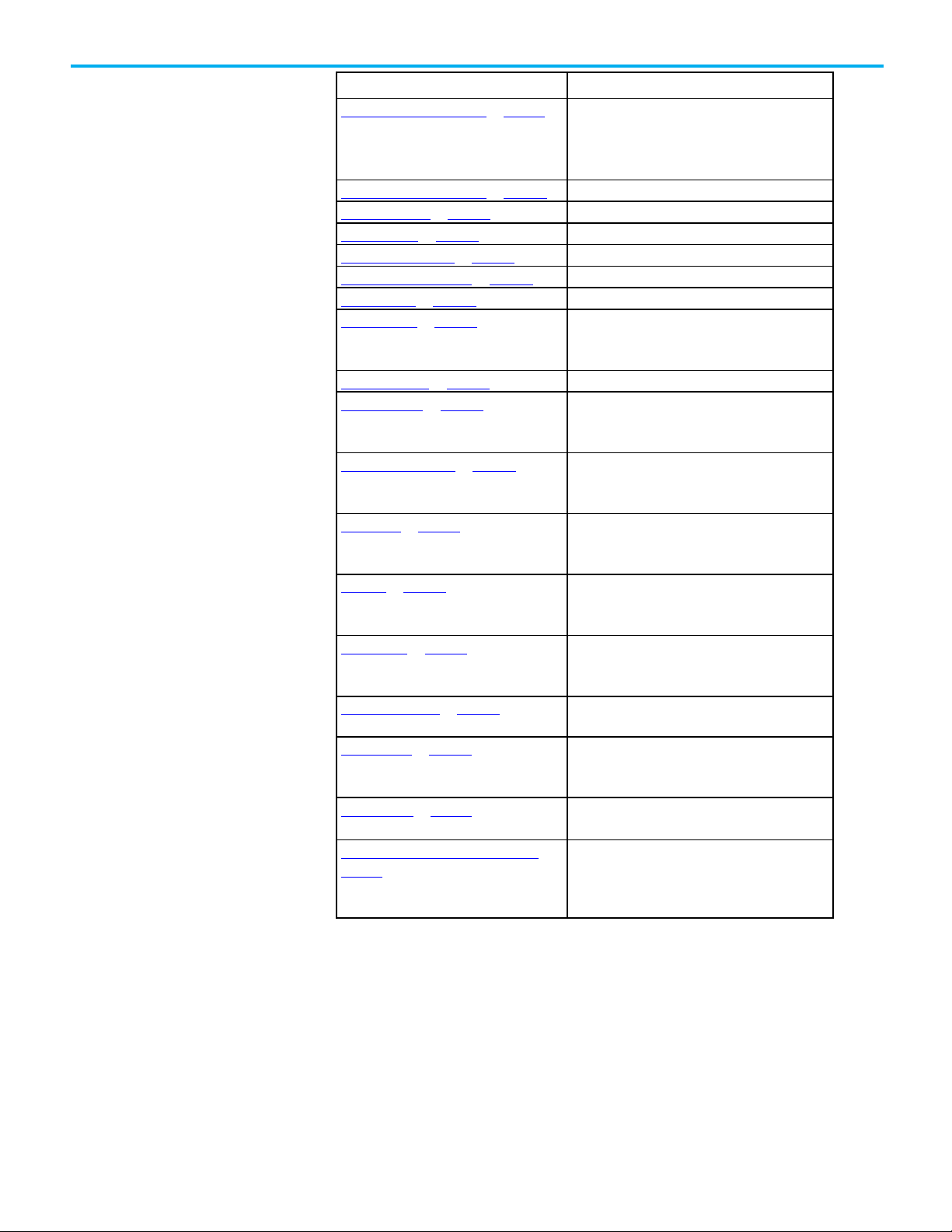

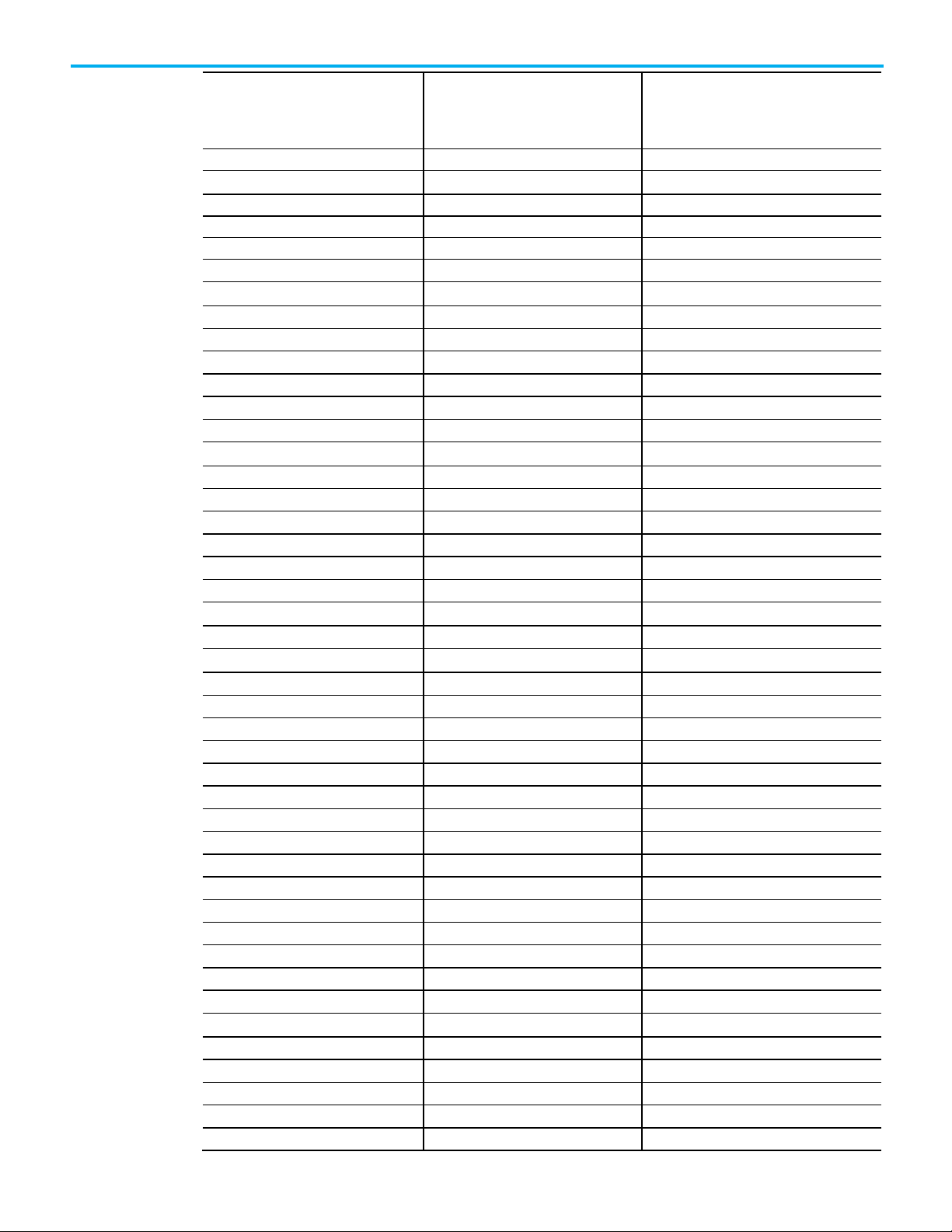

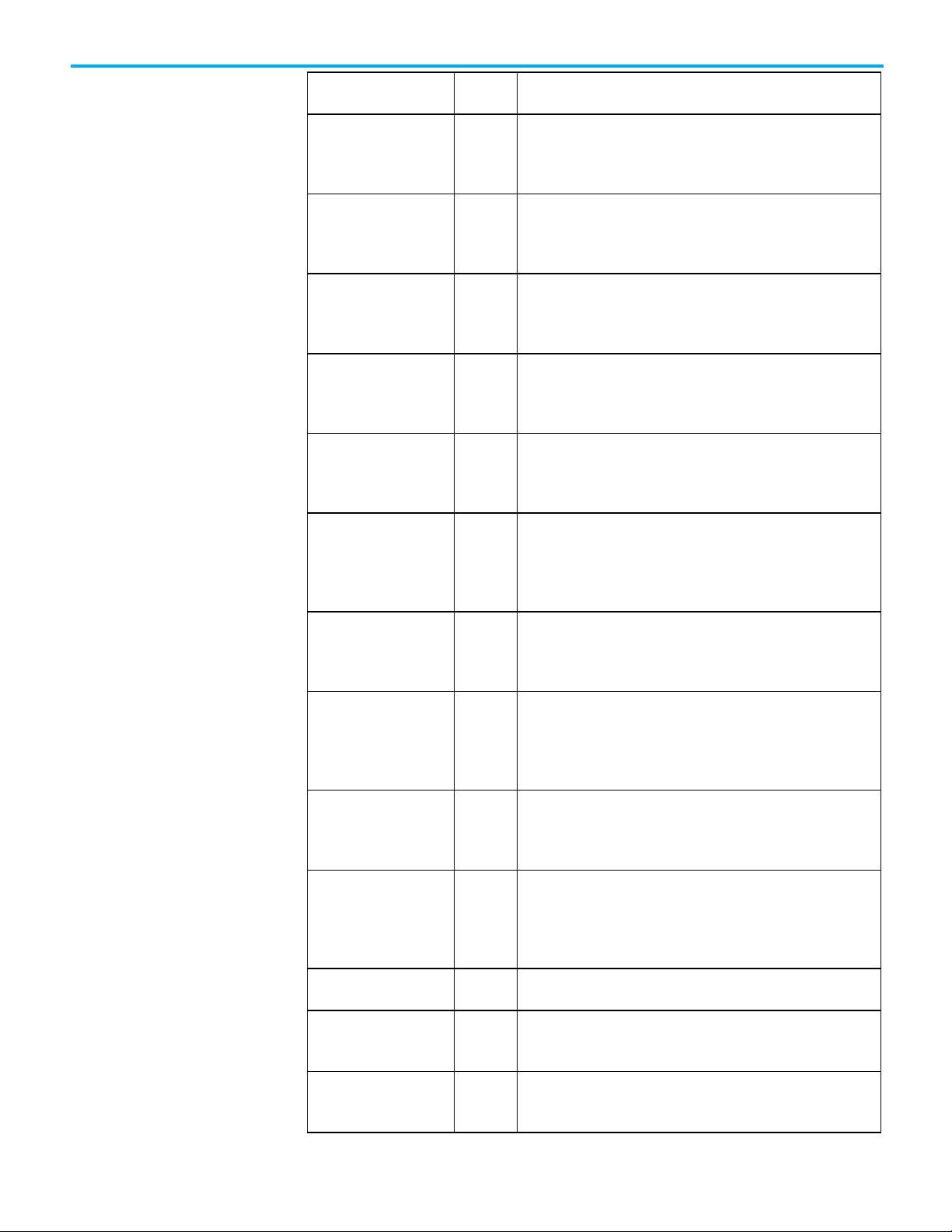

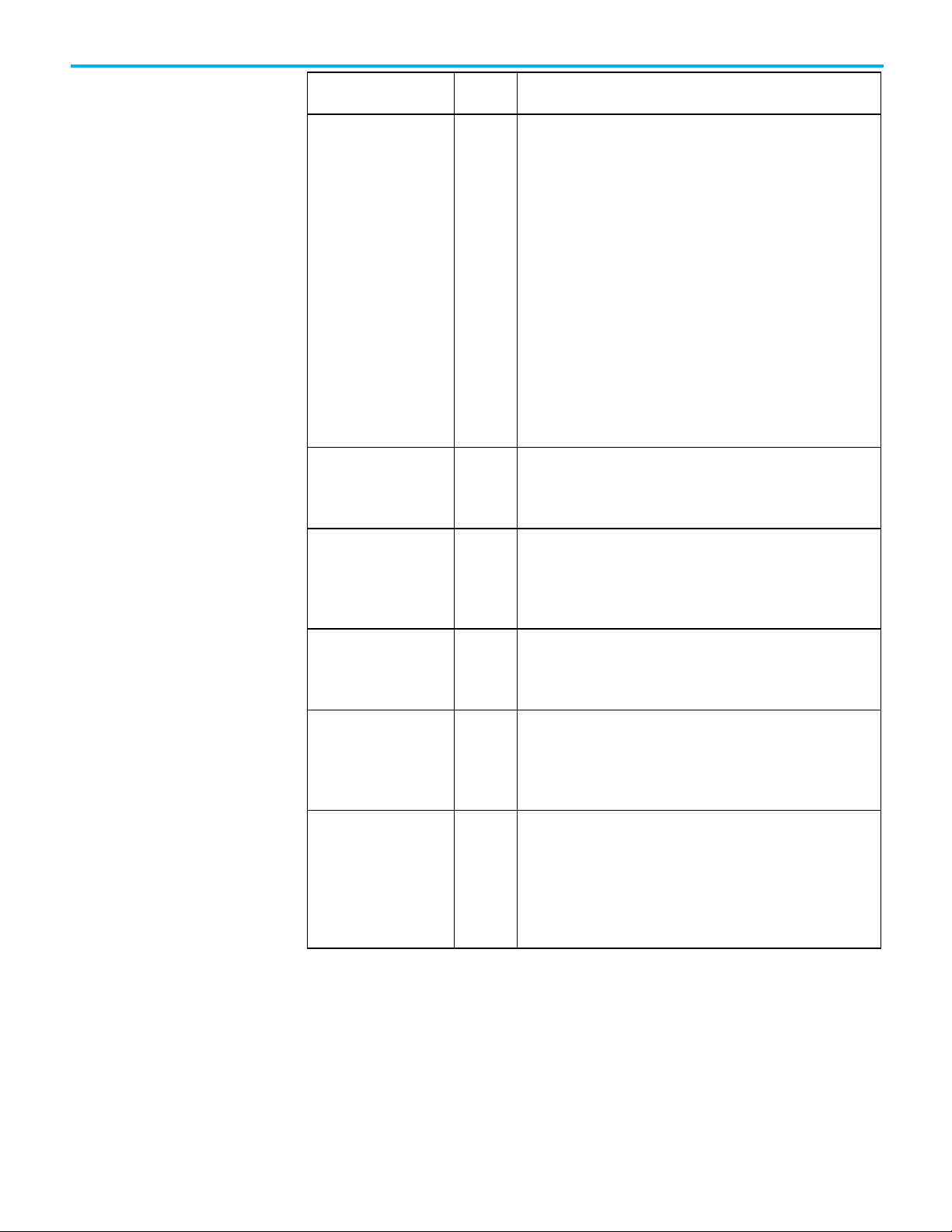

Page 4

Summary of changes

Topic Name

Reason

Is Infinity (IsINF) on page 294

New instruction.

Is Not a Number (IsNAN) on page 296

New instruction.

Less Than or Equal To (LEQ) on page 306

Updated the String Compare Flow Chart.

Less Than (LES) on page 298

Updated the String Compare Flow Chart.

Added FBD Function element.

Not Equal To (NEQ) on page 333

Updated the String Compare Flow Chart.

Added FBD Function element.

Added FBD Function element.

Added FBD Function element.

and ULINT data types.

Added FBD Function element.

Added support for IsINF and IsNAN.

File Search and Compare (FSC) on page 513 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Added support for logical operators &&, ||, ^^, and !.

Added support for IsINF and IsNAN.

Greater Than or Equal To (GEQ) on page 286 Updated the String Compare Flow Chart.

Greater Than (GRT) on page 278 Updated the String Compare Flow Chart.

Natural Log (LN) on page 749 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Bitwise Not (NOT) on page 425 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Bitwise Inclusive Or (OR) on page 432 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Added FBD Function element.

Radian (RAD) on page 779 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Added FBD Function element.

Sine (SIN) on page 729 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Tangent (TAN) on page 735 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Convert to BCD (TOD) on page 764 Added support for LINT, LREAL, USINT, UINT, UDINT

Truncate (TRN) on page 785 Added support for LINT, LREAL, USINT, UINT, UDINT

and ULINT data types.

Valid operators on page 341 Added support for logical operators &&, ||, ^^, and !.

Determine Controller Memory Information on

page 182

Added a note to indicate that this section is not

applicable to CompactLogix 5380, CompactLogix

5480, ControlLogix 5580, Compact GuardLogix 5380,

and GuardLogix 5580 controllers.

4 Publication 1756-RM003V-EN-P - November 2020

Page 5

Logix5000 Controllers General

Logix5000 Controllers Advanced Process

Logix5000 Controllers Motion Instructions

Add (ADD)

Attach to Equipment Phase (PATT)

Motion Apply Axis Tuning (MAAT)

Analog Alarm (ALMA)

Attach to Equipment Sequence (SATT)

Motion Apply Hookup Diagnostics (MAHD)

Arc Tangent (ATN, ATAN)

Derivative (DERV)

Motion Axis Fault Reset (MAFR)

ASCII Clear Buffer (ACL)

Detach from Equipment Sequence (SDET)

Motion Axis Home (MAH)

ASCII Handshake Lines (AHL)

Discrete 3-State Device (D3SD)

Motion Axis Jog (MAJ)

ASCII Read Line (ARL)

Enhanced PID (PIDE)

Motion Axis Position Cam (MAPC)

ASCII Test for Buffer Line (ABL)

Enhanced Select (ESEL)

Motion Axis Stop (MAS)

ASCII Write (AWT)

Equipment Phase Clear Failure (PCLF)

Motion Axis Time Cam (MATC)

ASCII Write Append (AWA)

Equipment Phase Command (PCMD)

Motion Axis Shutdown (MASD)

Bit Field Distribute (BTD)

Equipment Phase External Request (PXRQ)

Motion Axis Shutdown Reset (MASR)

Bit Field Distribute with Target (BTDT)

Equipment Phase Failure (PFL)

Motion Calculate Cam Profile (MCCP)

(POVR)

(MCTO)

Identifier (SASI)

Orientation (MCTPO)

Boolean AND (BAND)

Equipment Sequence command (SCMD)

Motion Change Dynamics (MCD)

Clear (CLR)

Integrator (INTG)

Motion Coordinated Stop (MCS)

Compare (CMP)

Internal Model Control (IMC)

Motion Coordinated Transform (MCT)

Convert to BCD (TOD)

JK Flip-Flop (JKFF)

Motion Direct Drive Off (MDF)

Convert to Integer (FRD)

Lead-Lag (LDLG)

Motion Direct Drive On (MDO)

Cosine (COS)

Maximum Capture (MAXC)

Motion Disarm Output Cam (MDOC)

Count down (CTD)

Modular Multivariable Control (MMC)

Motion Disarm Watch (MDW)

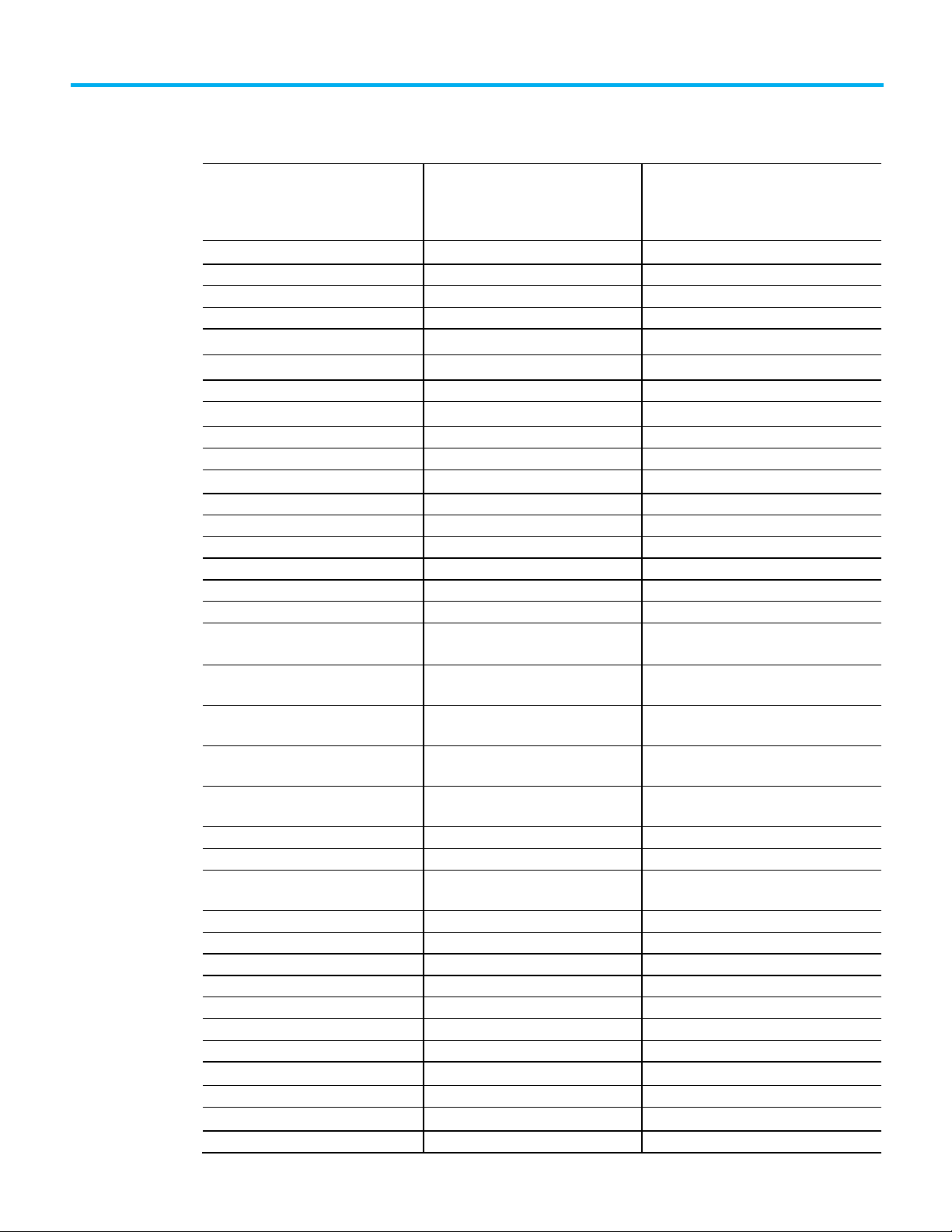

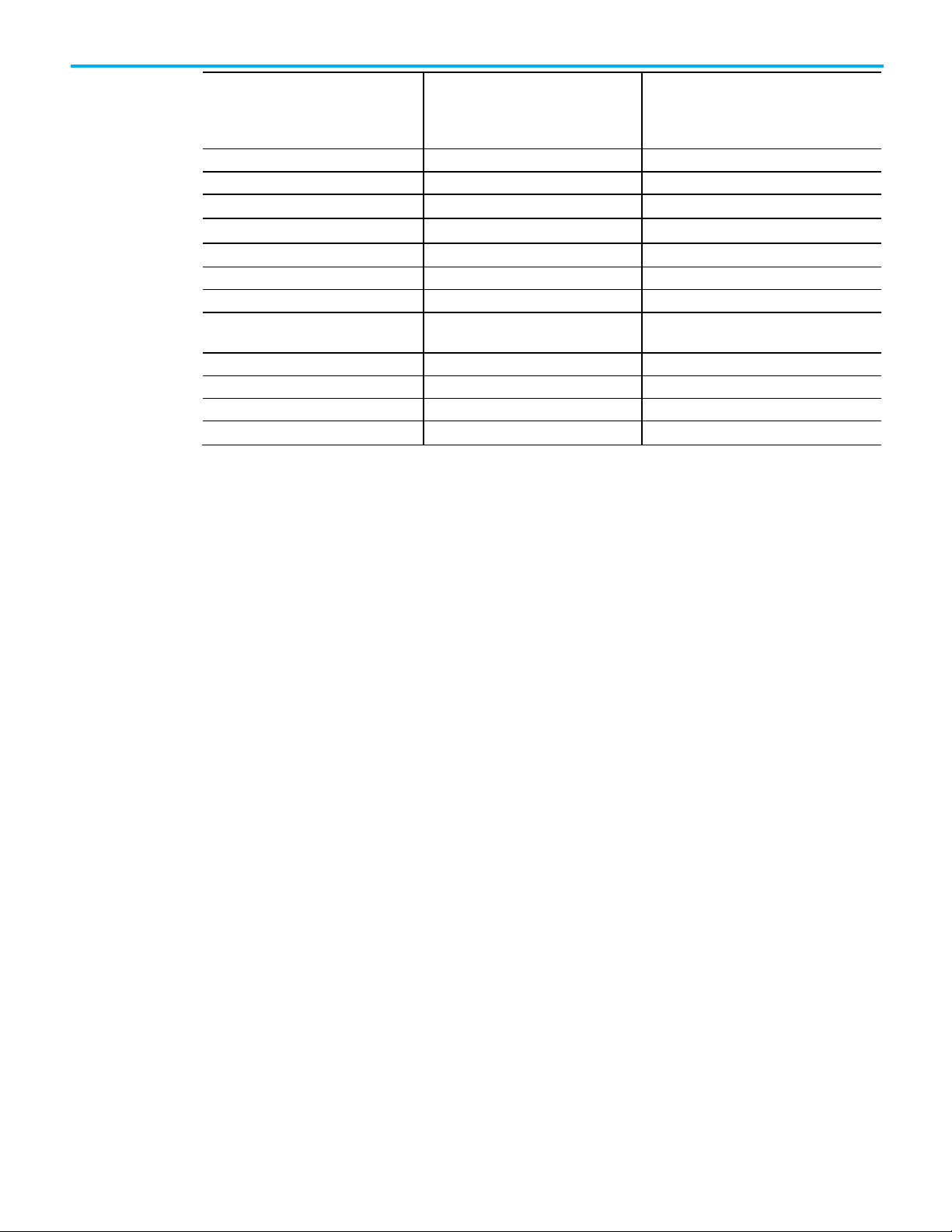

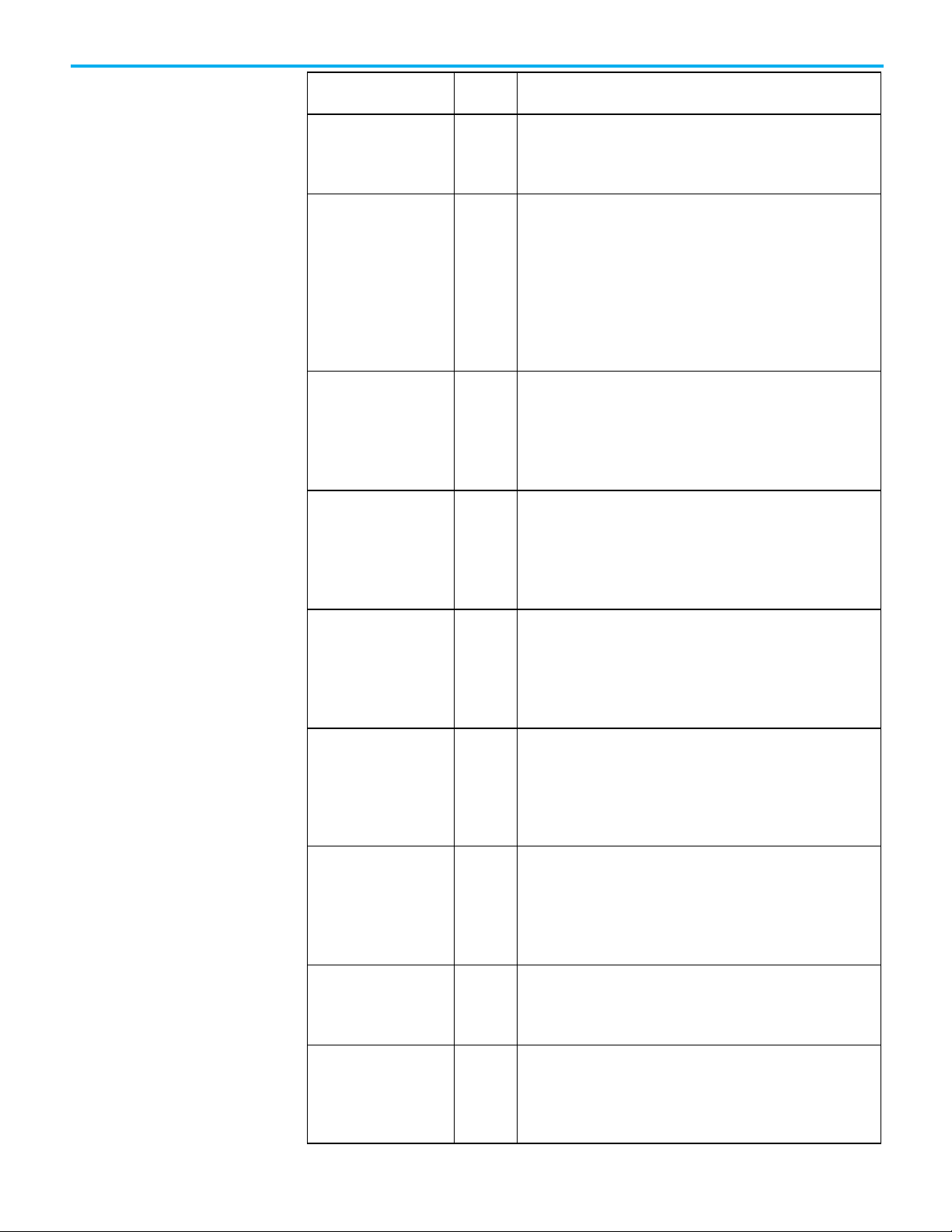

Instruction Locator

Use this locator to find the applicable Logix5000 controllers instruction

manual for each instruction.

Instructions Reference Manual 1756RM003

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Reference Manual MOTION-RM002

Absolute Value (ABS) Alarm (ALM) Master Driven Coordinated Control (MDCC)

Always False (AFI) Coordinated Control (CC) Motion Arm Output Cam (MAOC)

Arc Cosine (ACS, ACOS) D Flip-Flop (DFF) Motion Arm Registration (MAR)

Arc Sine (ASN, ASIN) Deadtime (DEDT) Motion Arm Watch (MAW)

ASCII Chars in Buffer (ACB) Detach from Equipment Phase (PDET) Motion Axis Gear (MAG)

ASCII Read (ARD) Discrete 2-State Device (D2SD) Motion Axis Move (MAM)

Bit Shift Left (BSL) Equipment Phase New Parameters (PRNP) Motion Coordinated Path Move (MCPM)

Bit Shift Right (BSR) Equipment Phase Override Command

Motion Calculate Slave Values (MCSV)

Bitwise And (AND) Equipment Phase Paused (PPD) Motion Coordinated Transform with Orientation

Bitwise (NOT) Equipment Sequence Assign Sequence

Motion Calculate Transform Position (MCTP)

Bitwise (OR) Equipment Sequence Clear Failure (SCLF) Motion Calculate Transform Position with

Boolean Exclusive OR (BXOR) Equipment Sequence Override (SOVR) Motion Coordinated Change Dynamics (MCCD)

Boolean NOT (BNOT) Function Generator (FGEN) Motion Coordinated Circular Move (MCCM)

Boolean OR (BOR) High Pass Filter (HPF) Motion Coordinated Linear Move (MCLM)

Break (BRK) High/Low Limit (HLL) Motion Coordinated Shutdown (MCSD)

Breakpoints (BPT) HMI Button Control (HMIBC) Motion Coordinated Shutdown Reset (MCSR)

Copy File (COP), Synchronous Copy File (CPS) Low Pass Filter (LPF) Motion Direct Start (MDS)

Compute (CPT) Minimum Capture (MINC) Motion Disarm Registration (MDR)

Publication 1756-RM003V-EN-P - November 2020 5

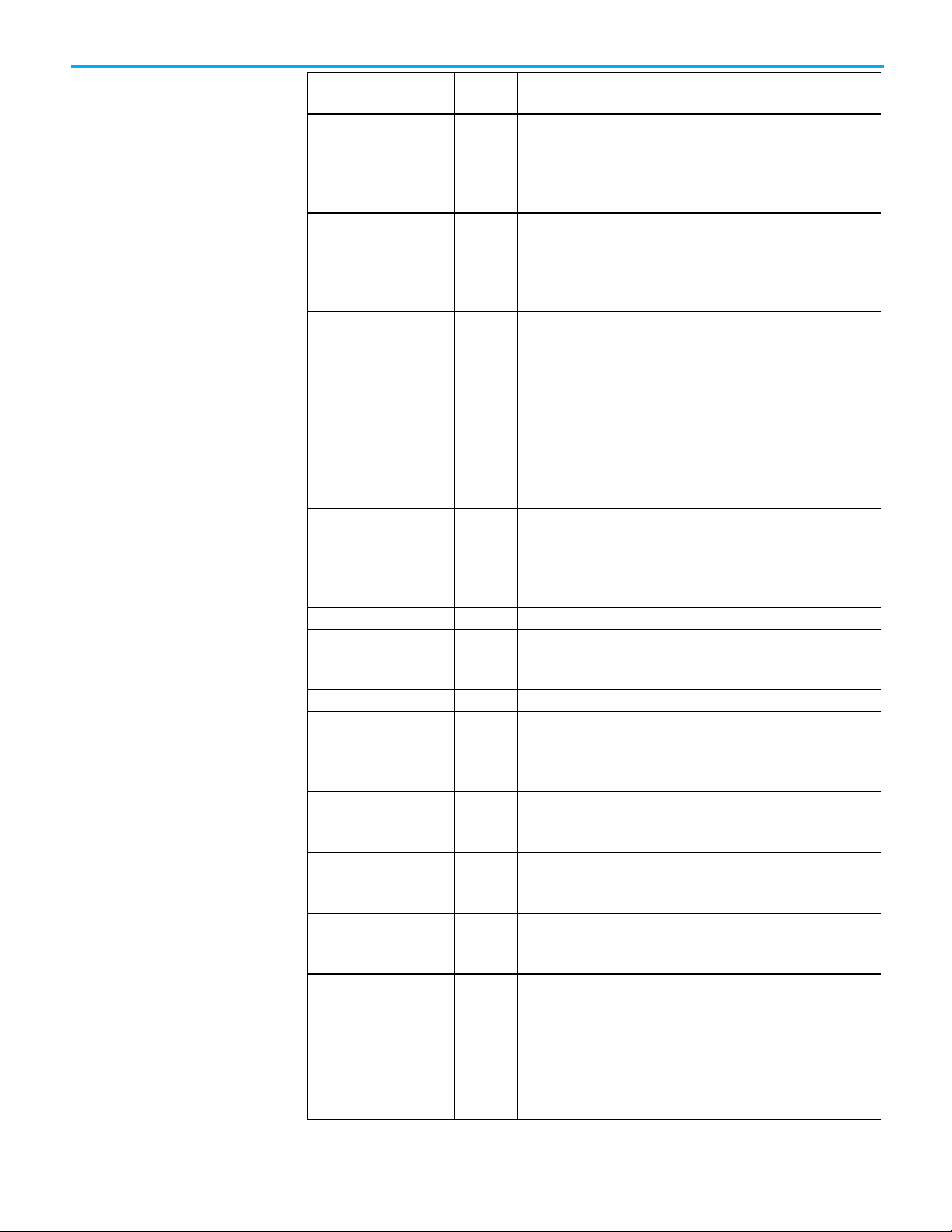

Page 6

Instruction Locator

Logix5000 Controllers General

Logix5000 Controllers Advanced Process

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Count up (CTU)

Moving Average (MAVE)

Motion Group Shutdown (MGSD)

Diagnostic Detect (DDT)

Phase State Complete (PSC)

Motion Redefine Position (MRP)

Digital Alarm (ALMD)

Position Proportional (POSP)

Motion Run Axis Tuning (MRAT)

End of Transition (EOT)

Process Dual Sensor Analog Input (PAID)

Motion Servo On (MSO)

FIFO Load (FFL)

Process Command Source (PCMDSRC)

File Average (AVE)

Process Discrete Input (PDI)

File Standard Deviation (STD)

Process Discrete Output (PDO)

File Fill (FLL)

Process Dosing (PDOSE)

File Sort (SRT)

Process Analog Fanout (PFO)

Find String (FIND)

Process High or Low Selector (PHLS)

For (FOR)

Process Interlocks (PINTLK)

(PLLS)

Value (SST)

Greater Than or Equal to (GEQ)

Process Permissives (PPERM)

(PPID)

Compensated Flow (PPTC)

Immediate Output (IOT)

Process Restart Inhibit (PRI)

Jump to Label (JMP) and Label (LBL)

Process Valve (PVLV)

and Return (RET)

Jump to External Routine (JXR)

Proportional + Integral (PI)

LIFO Unload (LFU)

Reset Dominant (RESD)

License Validation (LV)

Scale (SCL)

Limit (LIM)

S-Curve (SCRV)

Log Base (LOG)

Second-Order Controller (SOC)

Lower to Case (LOWER)

Second-Order Lead Lag (LDL2)

Masked Move (MVM)

Select (SEL)

Instructions Reference Manual 1756RM003

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Reference Manual MOTION-RM002

Count up/down CTUD Moving Standard Deviation (MSTD) Motion Group Shutdown Reset (MGSR)

Data Transition (DTR) Multiplexer (MUX) Motion Group Stop (MGS)

Degrees (DEG) Notch Filter (NTCH) Motion Group Strobe Position (MGSP)

DINT To String (DTOS) Process Analog HART (PAH) Motion Run Hookup Diagnostics (MRHD)

Divide (DIV) Process Analog Input (PAI) Motion Servo Off (MSF)

Equal to (EQU) Process Multi Sensor Analog Input (PAIM)

File Arithmetic (FAL) Process Analog Output (PAO)

File Bit Comparison (FBC) Process Boolean Logic (PBL)

FIFO Unload (FFU) Process Deadband Controller (PDBC)

File Search and Compare (FSC) Process Lead Lag Standby Motor Group

Get System Value (GSV) and Set System

Process Motor (PMTR)

Greater than (GRT) Process Proportional + Integral + Derivative

Insert String (INSERT) Process Pressure/Temperature

Is Infinity (IsINF) Process Run Time and Start Counter (PRT)

Is Not a Number (IsNAN) Process Tank Strapping Table (PTST)

Jump to Subroutine (JSR), Subroutine (SBR),

Process Valve Statistics (PVLVS)

Less Than (LES) Pulse Multiplier (PMUL)

Less Than or Equal to (LEQ) Ramp/Soak (RMPS)

LIFO Load (LFL) Rate Limiter (RLIM)

6 Publication 1756-RM003V-EN-P - November 2020

Masked Move with Target (MVMT) Selected Negate (SNEG)

Page 7

Logix5000 Controllers General

Logix5000 Controllers Advanced Process

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Master Control Reset (MCR)

Selected Summer (SSUM)

Message (MSG)

Split Range Time Proportional (SRTP)

Middle String (MID)

Totalizer (TOT)

Modulo (MOD)

Up/Down Accumulator (UPDN)

Instruction Locator

Publication 1756-RM003V-EN-P - November 2020 7

Instructions Reference Manual 1756RM003

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Masked Equal to (MEQ) Set Dominant (SETD)

Move (MOV)

Multiply (MUL)

Natural Log (LN)

Negate (NEG)

Not Equal to (NEQ)

No Operation (NOP)

One Shot (ONS)

One Shot Falling (OSF)

One Shot Falling with Input (OSFI)

One Shot Rising (OSR)

One Shot Rising with Input (OSRI)

Output Energize (OTE)

Output Latch (OTL)

Output Unlatch (OTU)

Proportional Integral Derivative (PID)

Radian (RAD)

Real to String (RTOS)

Reset (RES)

Reset SFC (SFR)

Return (RET)

Retentive Timer On (RTO)

Retentive Timer On with Reset (RTOR)

Pause SFC (SFP)

Size In Elements (SIZE)

Sequencer Input (SQI)

Sequencer Load (SQL)

Sequencer Output (SQO)

Sine (SIN)

Square Roost (SQR/SQRT)

String Concatenate (CONCAT)

String Delete (DELETE)

String to DINT (STOD)

String to REAL (STOR)

Swap Byte (SWPB)

Subtract (SUB)

Tangent (TAN)

Timer Off Delay (TOF)

Timer Off Delay with Reset (TOFR)

Timer On Delay (TON)

Reference Manual MOTION-RM002

Page 8

Instruction Locator

Logix5000 Controllers General

Logix5000 Controllers Advanced Process

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Enable (UIE)

Instructions Reference Manual 1756RM003

Timer On Delay with Reset (TONR)

Temporary End (TND)

Tracepoints (TPT)

Trigger Event Task (EVENT)

Truncate (TRN)

Unknown Instruction (UNK)

Upper Case (UPPER)

User Interrupt Disable (UID)/User Interrupt

X to the Power of Y (XPY)

Examine if Closed (XIC)

Examine If Open (XIO)

Bitwise Exclusive (XOR)

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Reference Manual MOTION-RM002

8 Publication 1756-RM003V-EN-P - November 2020

Page 9

Summary of changes

Preface

Alarm Instructions

Bit Instructions

Timer and Counter Instructions

Input/Output

Table of Contents

Instruction Locator

Studio 5000 environment ......................................................................... 17

Additional resources .................................................................................. 18

Legal Notices .............................................................................................. 18

Chapter 1

Alarm Instructions ..................................................................................... 21

Analog Alarm (ALMA) ......................................................................... 22

Digital Alarm (ALMD) ......................................................................... 46

Alarm Set Operation (ASO) ................................................................ 58

Chapter 2

Bit Instructions .......................................................................................... 63

Examine If Closed (XIC) ...................................................................... 63

Examine If Open (XIO) ....................................................................... 66

One Shot (ONS) ................................................................................... 69

One Shot Falling (OSF) ........................................................................ 71

One Shot Falling with Input (OSFI) .................................................... 74

One Shot Rising (OSR) ........................................................................ 78

One Shot Rising with Input (OSRI) .................................................... 81

Output Energize (OTE) ....................................................................... 84

Output Latch (OTL) ............................................................................. 87

Output Unlatch (OTU) ........................................................................ 89

Publication 1756-RM003V-EN-P - November 2020 9

Chapter 3

Timer and Counter Instructions .............................................................. 93

Count Down (CTD) ............................................................................. 94

Count Up (CTU) ................................................................................... 99

Count Up/Down (CTUD) ................................................................... 104

Reset (RES) ......................................................................................... 109

Retentive Timer On (RTO) ................................................................. 112

Retentive Timer On with Reset (RTOR) ............................................117

Timer Off Delay (TOF) ....................................................................... 122

Timer Off Delay with Reset (TOFR) .................................................. 127

Timer On Delay (TON) ....................................................................... 132

Timer On Delay with Reset (TONR).................................................. 137

Chapter 4

Input/Output Instructions ...................................................................... 143

Message (MSG) ................................................................................... 143

MSG Configuration Examples .......................................................... 153

Page 10

Table of Contents

Major fault types and codes ............................................................... 154

Minor fault types and codes .............................................................. 158

Message Error Codes ............................................................................... 161

Error Codes ............................................................................................... 161

Extended Error Codes ....................................................................... 162

PLC and SLC Error Codes (.ERR) ............................................................ 164

Block Transfer Error Codes ..................................................................... 165

Specify the Communication Details ................................................. 166

Specify SLC Messages ........................................................................ 174

Specify Block Transfer Messages ...................................................... 174

Get System Value (GSV) and Set System Value (SSV) ..................... 174

Immediate Output (IOT) ................................................................... 179

Access System Values ......................................................................... 182

Determine Controller Memory Information ................................... 182

DeviceNet Status Codes ..................................................................... 185

Get and Set System Data ................................................................... 188

GSV/SSV Programming Example ..................................................... 189

GSV/SSV Objects ................................................................................ 193

Access the AddOnInstructionDefinition Object ....................... 194

Access the ALARMBUFFER object .............................................. 195

Access the Axis object .................................................................. 197

Access the Controller object ....................................................... 205

Access the ControllerDevice object ............................................ 207

Access the CoordinateSystem object .......................................... 211

Access the MotionGroup object .................................................. 214

Access the Message object ........................................................... 215

Access the CST object................................................................... 215

Access the Datalog object ............................................................ 216

Access the DF1 object ................................................................... 218

Access the FaultLog object .......................................................... 220

Access the HardwareStatus object .............................................. 221

Access the Message object .......................................................... 222

Access the Module object ............................................................. 223

Access the Routine object ........................................................... 224

Access the Redundancy object ................................................... 225

Access the Program object ...........................................................227

Access the Safety object .............................................................. 228

Access the SerialPort object ....................................................... 229

Access the Task object ................................................................. 230

Access the TimeSynchronize object ........................................... 232

Access the WallClockTime object ............................................... 236

GSV/SSV Safety Objects .................................................................... 237

10 Publication 1756-RM003V-EN-P - November 2020

Page 11

Compare Instructions

Compute/Math Instructions

Table of Contents

Monitor Status Flags .......................................................................... 241

Select the Message Type ................................................................... 242

Module Faults: 16#0000 - 16#00ff ..................................................... 243

Module Faults: 16#0100 - 16#01ff ....................................................... 245

Module Faults: 16#0200 - 16#02ff ..................................................... 249

Module Faults: 16#0300 - 16#03ff ..................................................... 250

Module Faults: 16#0800 - 16#08ff ...................................................... 253

Module Faults: 16#fd00 - 16#fdff ....................................................... 253

Module Faults: 16#fe00 - 16#feff ........................................................ 254

Module Faults: 16#ff00 - 16#ffff ......................................................... 256

Specify CIP Messages ........................................................................ 257

Specify PLC-3 Messages .................................................................... 262

Specify PLC-5 Messages .................................................................... 262

Specify PLC-2 Messages .................................................................... 263

Chapter 5

Compare Instructions ............................................................................. 265

Compare (CMP) ................................................................................. 266

Equal To (EQU) .................................................................................. 270

Greater Than (GRT) ........................................................................... 278

Greater Than or Equal To (GEQ) ...................................................... 286

Is Infinity (IsINF) .............................................................................. 294

Is Not a Number (IsNAN) ................................................................. 296

Less Than (LES) ................................................................................. 298

Less Than or Equal To (LEQ) ............................................................ 306

Limit (LIM) ......................................................................................... 315

Mask Equal To (MEQ) ........................................................................ 325

Not Equal To (NEQ) ........................................................................... 333

Valid operators ................................................................................... 341

What is zero fill? ................................................................................. 342

Publication 1756-RM003V-EN-P - November 2020 11

Chapter 6

Compute/Math Instructions ................................................................... 343

Absolute Value (ABS) ......................................................................... 344

Add (ADD) .......................................................................................... 350

Compute (CPT) ................................................................................... 356

Divide (DIV) ........................................................................................ 361

Modulo (MOD) ................................................................................... 368

Multiply (MUL) ................................................................................... 375

Negate (NEG) ..................................................................................... 381

Square Root (SQR/SQRT) .................................................................. 387

Subtract (SUB) .................................................................................... 394

Page 12

Table of Contents

Move/Logical Instructions

Array (File)/Misc Instructions

FBD Functions ................................................................................... 400

Function Overloading ........................................................................ 401

Chapter 7

Move/Logical Instructions ..................................................................... 403

Bit Field Distribute (BTD) ................................................................ 404

Bit Field Distribute with Target (BTDT) .......................................... 408

Bitwise And (AND) ............................................................................. 413

Bitwise Exclusive Or (XOR) ............................................................... 419

Bitwise Not (NOT) .............................................................................. 425

Bitwise Inclusive Or (OR) .................................................................. 432

Boolean AND (BAND) ........................................................................ 439

Boolean Exclusive OR (BXOR) .......................................................... 444

Boolean NOT (BNOT) ....................................................................... 448

Boolean OR (BOR) .............................................................................. 452

Clear (CLR) .......................................................................................... 457

Masked Move (MVM) ........................................................................ 460

Masked Move with Target (MVMT) .................................................. 463

Move (MOV) ....................................................................................... 468

Swap Byte (SWPB) ............................................................................. 471

Chapter 8

Array (File)/Misc Instructions ................................................................ 477

Copy File (COP), Synchronous Copy File (CPS) ............................... 478

File Arithmetic and Logic (FAL) ....................................................... 488

File Average (AVE) ............................................................................. 506

File Fill (FLL) ....................................................................................... 510

File Search and Compare (FSC) ........................................................ 513

File Sort (SRT) .................................................................................... 528

File Standard Deviation (STD) .......................................................... 533

Size In Elements (SIZE) ..................................................................... 537

All Mode..................................................................................................... 542

All Mode Flow Chart (FSC) ................................................................ 543

Numerical Mode ................................................................................. 543

Numeric Mode Flow Chart (FSC) ...................................................... 545

Incremental Mode .............................................................................. 545

Incremental Mode Flow Chart (FSC) ................................................ 548

Array Tag ............................................................................................. 548

Standard Deviation ............................................................................ 548

12 Publication 1756-RM003V-EN-P - November 2020

Page 13

Array (File)/Shift Instructions

Sequencer Instructions

Program Control Instructions

For/Break Instructions

Special Instructions

Table of Contents

Chapter 9

Array (File)/Shift Instructions ................................................................ 551

Bit Shift Left (BSL) ............................................................................. 552

Bit Shift Right (BSR) .......................................................................... 557

FIFO Load (FFL) .................................................................................. 561

FIFO Unload (FFU) .............................................................................568

LIFO Load (LFL) .................................................................................. 575

LIFO Unload (LFU) ............................................................................ 582

Chapter 10

Sequencer Instructions ........................................................................... 591

Sequencer Input (SQI) ....................................................................... 592

Sequencer Load (SQL) ....................................................................... 596

Sequencer Output (SQO) .................................................................. 600

Chapter 11

Program Control Instructions ............................................................... 608

Always False (AFI) ............................................................................. 609

End of Transition (EOT) .................................................................... 611

Jump to External Routine (JXR) ........................................................ 614

Jump to Label (JMP) and Label (LBL) ................................................ 617

Jump to Subroutine (JSR), Subroutine (SBR), and Return (RET) . 620

Master Control Reset (MCR) ............................................................ 630

MCR Flow Chart (False) ..................................................................... 633

No Operation (NOP) .......................................................................... 634

Pause SFC (SFP) ................................................................................. 636

Reset SFC (SFR) .................................................................................. 638

Temporary End (TND) ....................................................................... 641

Trigger Event Task (EVENT) ............................................................. 644

User Interrupt Disable (UID)/User Interrupt Enable (UIE) ........... 649

Unknown Instruction (UNK) ............................................................ 652

Publication 1756-RM003V-EN-P - November 2020 13

Chapter 12

For/Break Instructions ............................................................................ 655

Break (BRK) ........................................................................................ 655

For (FOR) ............................................................................................658

Chapter 13

Special Instructions ................................................................................. 663

Data Transition (DTR) ....................................................................... 664

Diagnostic Detect (DDT) ................................................................... 667

Page 14

Table of Contents

Trigonometric Instructions

Advanced Math

Math Conversion Instructions

ASCII Serial Port Instructions

File Bit Comparison (FBC)................................................................. 675

Proportional Integral Derivative (PID) ............................................ 683

Using PID Instructions .............................................................. 689

Anti-reset Windup and Bumpless Transfer From Manual To

Auto (PID) ..................................................................................... 693

Bumpless Restart (PID) ............................................................... 694

Cascading Loops (PID) ................................................................ 694

Controlling a Ratio (PID) ............................................................ 695

Derivative Smoothing (PID) ....................................................... 697

Feedforward or Output Biasing (PID) ........................................ 697

PID Instruction Timing ............................................................... 697

Setting the Deadband (PID) ........................................................ 701

Using Output Limiting (PID) ..................................................... 702

Chapter 14

Trigonometric Instructions ................................................................... 704

Arc Cosine (ACS, ACOS) ................................................................... 705

Arc Sine (ASN, ASIN) ..........................................................................711

Arc Tangent (ATN, ATAN) ................................................................. 717

Cosine (COS) ...................................................................................... 723

Sine (SIN) ............................................................................................ 729

Tangent (TAN) .................................................................................... 735

Chapter 15

Advanced Math Instructions .................................................................. 743

Log Base 10 (LOG) .............................................................................. 743

Natural Log (LN) ................................................................................ 749

X to the Power of Y (XPY) .................................................................. 755

Chapter 16

Math Conversion Instructions ............................................................... 763

Convert to BCD (TOD) ....................................................................... 764

Convert to Integer (FRD) ................................................................... 769

Degrees (DEG) .................................................................................... 773

Radian (RAD) ...................................................................................... 779

Truncate (TRN) ................................................................................... 785

Chapter 17

ASCII Serial Port Instructions ................................................................ 793

ASCII Chars in Buffer (ACB) ............................................................. 795

ASCII Clear Buffer (ACL) ................................................................... 798

14 Publication 1756-RM003V-EN-P - November 2020

Page 15

ASCII String Instructions

ASCII Conversion Instructions

Debug Instructions

License Instructions

Instructions

Table of Contents

ASCII Handshake Lines (AHL) ......................................................... 802

ASCII Read (ARD) ............................................................................. 806

ASCII Read Line (ARL) ....................................................................... 811

ASCII Test for Buffer Line (ABL) ....................................................... 816

ASCII Write (AWT) ........................................................................... 820

ASCII Write Append (AWA) ............................................................. 825

String Types ........................................................................................ 831

ASCII Error Codes .............................................................................. 831

Chapter 18

ASCII String Instructions ....................................................................... 833

Find String (FIND) ............................................................................. 834

Insert String (INSERT) ...................................................................... 837

Middle String (MID) ......................................................................... 840

String Concatenate (CONCAT) ......................................................... 843

String Delete (DELETE) .................................................................... 849

Common Attributes for General

Chapter 19

ASCII Conversion Instructions .............................................................. 853

DINT to String (DTOS) ...................................................................... 854

Lower Case (LOWER) ........................................................................ 857

REAL to String (RTOS) ..................................................................... 860

String to DINT (STOD) ..................................................................... 862

String to REAL (STOR) ..................................................................... 866

Upper Case (UPPER) ......................................................................... 869

Chapter 20

Debug Instructions .................................................................................. 873

Breakpoints (BPT) .............................................................................. 874

Tracepoints (TPT) .............................................................................. 878

Chapter 21

License Validation (LV) .......................................................................... 883

Chapter 22

Common Attributes ................................................................................ 887

Math Status Flags .................................................................................... 887

Immediate values .................................................................................... 889

Data Conversions .................................................................................... 890

Elementary data types .............................................................................. 893

Floating Point Values .............................................................................. 896

Publication 1756-RM003V-EN-P - November 2020 15

Page 16

Table of Contents

Function Block Attributes

Structured Text Programming

Index

Index Through Arrays ............................................................................. 898

Bit Addressing ......................................................................................... 899

Chapter 23

Choose the Function Block Elements ..................................................... 901

Latching Data .......................................................................................... 902

Order of Execution .................................................................................. 903

Function Block Responses to Overflow Conditions ............................. 907

Timing Modes .......................................................................................... 907

Program/Operator Control ...................................................................... 910

Chapter 24

Structured Text Syntax ............................................................................ 915

Structured Text Components: Comments ............................................. 916

Structured Text Components: Assignments .......................................... 917

Specify a non-retentive assignment ................................................. 918

Assign an ASCII character to a string data member ....................... 919

Structured Text Components: Expressions .......................................... 920

Use arithmetic operators and functions .......................................... 921

Use bitwise operators ....................................................................... 922

Use logical operators ......................................................................... 922

Use relational operators .................................................................... 923

Structured Text Components: Instructions .......................................... 924

Structured Text Components: Constructs ............................................ 926

Character string literals .......................................................................... 926

String Types ........................................................................................ 927

CASE_OF .................................................................................................. 928

FOR_DO ................................................................................................... 930

IF_THEN ................................................................................................... 933

REPEAT_UNTIL ....................................................................................... 936

WHILE_DO ............................................................................................... 938

Structured Text Attributes ...................................................................... 940

16 Publication 1756-RM003V-EN-P - November 2020

Page 17

Studio 5000 environment

Preface

This manual provides a programmer with details about the available General,

Motion, Process, and Drives instruction set for a Logix-based controller.

If you design, program, or troubleshoot safety applications that use

GuardLogix controllers, refer to the

Instruction Set Safety Reference Manual, publication 1756-RM095.

This manual is one of a set of related manuals that show common procedures

for programming and operating Logix 5000 controllers.

GuardLogix Safety Application

For a complete list of common procedures manuals, refer to the

Logix 5000

Controllers Common Procedures Programming Manual, publication 1756PM001.

The term Logix 5000 controller refers to any controller based on the Logix

5000 operating system.

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first

element is the Studio 5000 Logix Designer® application. The Logix Designer

application is the rebranding of RSLogix 5000® software and will continue to

be the product to program Logix 5000™ controllers for discrete, process,

batch, motion, safety, and drive-based solutions.

Publication 1756-RM003V-EN-P - November 2020 17

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio

5000 environment is the one place for design engineers to develop all

elements of their control system.

Page 18

Preface

Resource

Description

http://ab.rockwellautomation.com

and other certification details.

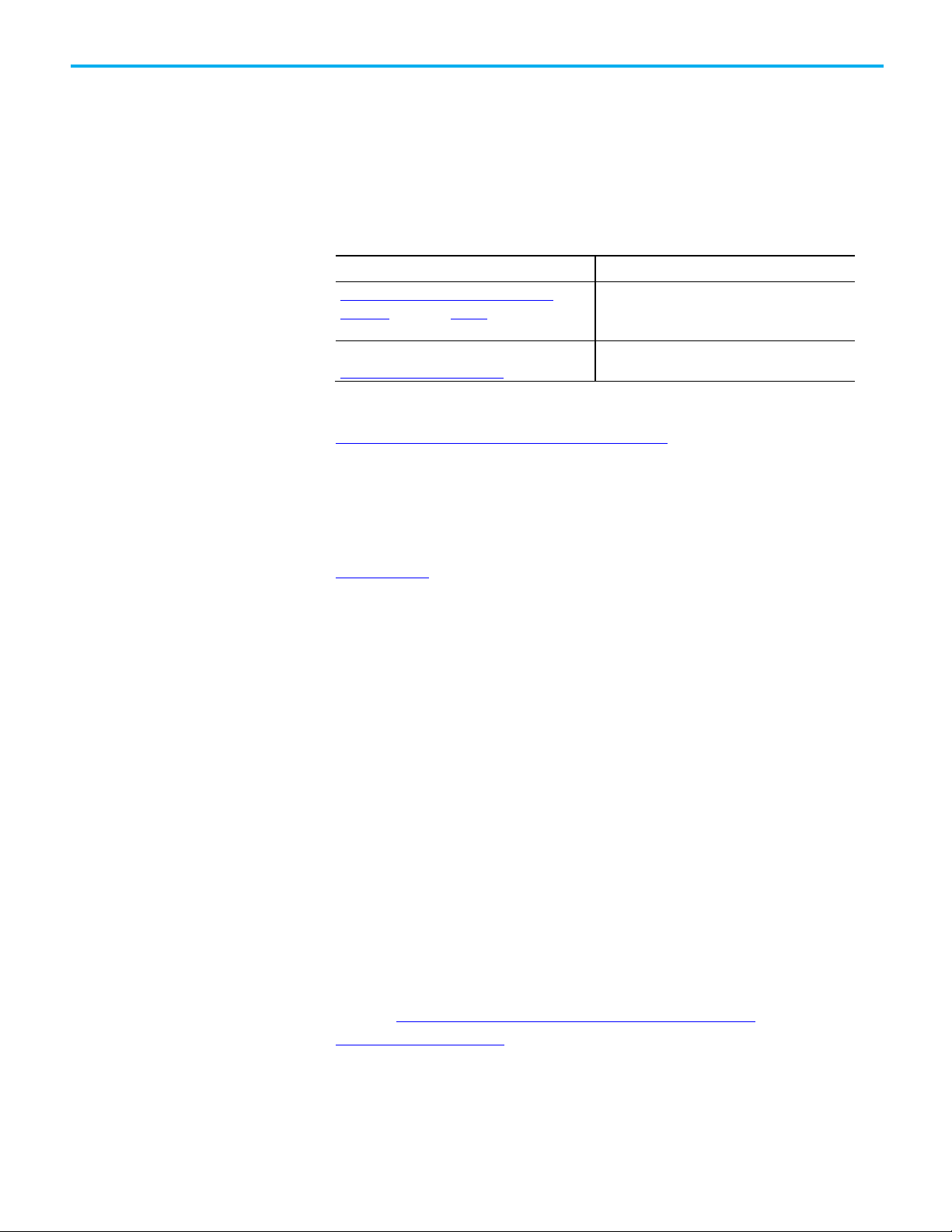

Additional resources

Legal Notices

These documents contain additional information concerning related

Rockwell Automation products.

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications webpage, available at

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates,

View or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact the local Rockwell Automation distributor

or sales representative.

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement ("EULA")

by opening the License.rtf file located in your product's install folder on your

hard drive.

18 Publication 1756-RM003V-EN-P - November 2020

Open Source Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source

packages included in this product are located at their respective web site(s).

Alternately, obtain complete Corresponding Source code by contacting

Rockwell Automation via the Contact form on the Rockwell Automation

website:

us/contact/contact.page

Please include "Open Source" as part of the request text.

A full list of all open source software used in this product and their

corresponding licenses can be found in the OPENSOURCE folder. The default

http://www.rockwellautomation.com/global/about-

Page 19

Preface

installed location of these licenses is C:\Program Files (x86)\Common

Files\Rockwell\Help\FactoryTalk Services Platform\Release

Notes\OPENSOURCE\index.htm

.

Publication 1756-RM003V-EN-P - November 2020 19

Page 20

Page 21

If:

Use the:

text,

conditions of the specified alarm set,

instruction.

Alarm Instructions

Chapter 1

Alarm Instructions

Use the alarm instructions to monitor and control alarm conditions.

The Logix-based alarm instructions instructions integrate alarming between

the RSView® SE applications and Logix 5000™ controllers.

Available Instructions

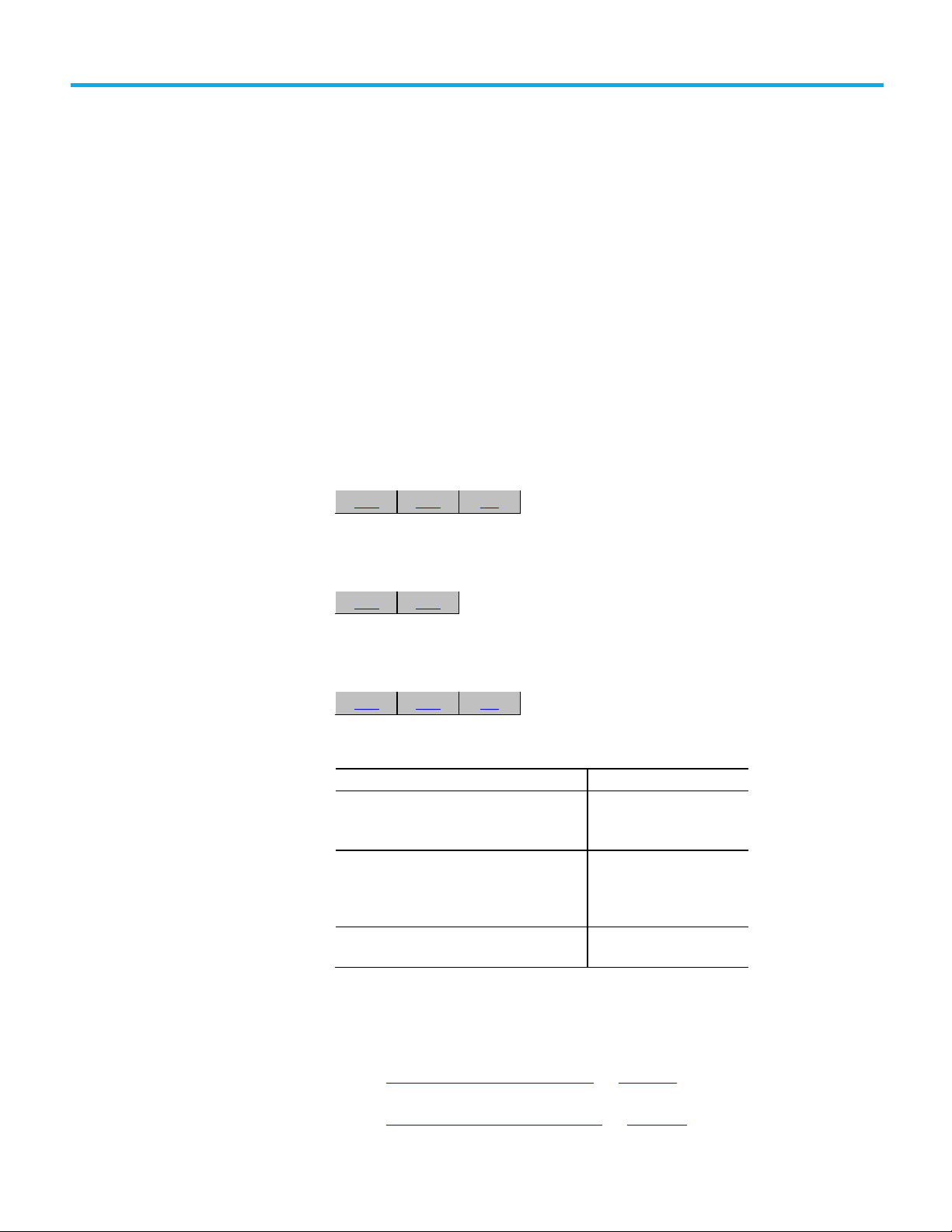

Ladder Diagram

ALMD ALMA ASO

Function Block

ALMD ALMA

Structured Text

ALMD ALMA ASO

Providing alarming for any discrete Boolean value

for a ladder diagram, function block, or structured

Providing level and rate-of-change alarming for

any analog signal for ladder diagram, function

block, diagram and structured text,

Issuing a specified operation to all alarm

Digital Alarm (ALMD)

instruction.

Analog Alarm (ALMA)

instruction.

Alarm Set Operation (ASO)

Publication 1756-RM003V-EN-P - November 2020 21

See also

Array (File)/Misc Instructions on page 477

ASCII Conversion Instructions on page 853

Page 22

Chapter 1 Alarm Instructions

Analog Alarm (ALMA)

This information applies to the CompactLogix 5370, ControlLogix 5570,

Compact GuardLogix 5370, GuardLogix 5570, Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix

5580 controllers. Controller differences are noted where applicable.

The ALMA instruction provides level and rate-of-change alarming for any

analog signal.

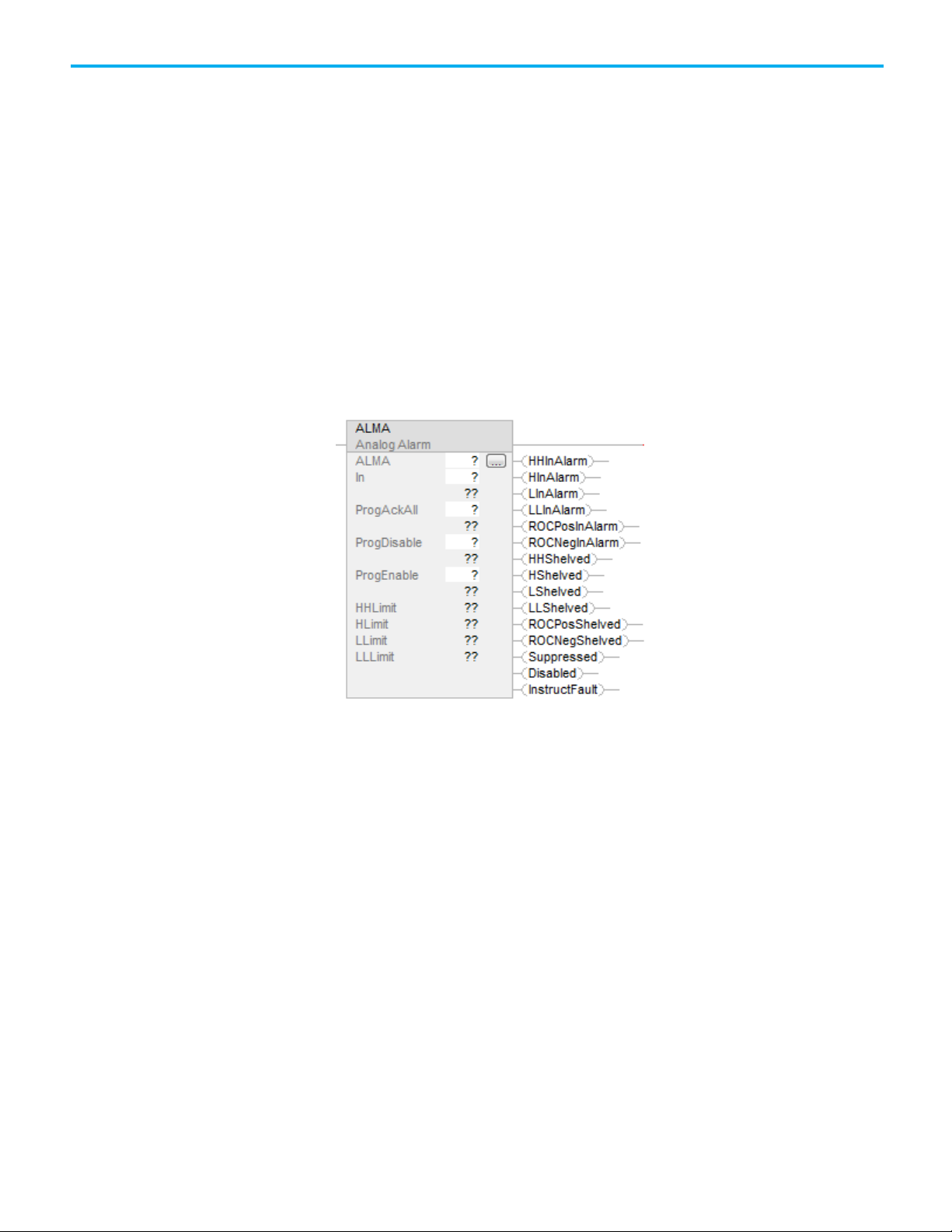

Ladder Diagram

22 Publication 1756-RM003V-EN-P - November 2020

Page 23

Operand

Type

Format

Description

ALMA

ALARM_ANALOG

Structure

ALMA structure

SINT

Function Block

Chapter 1 Alarm Instructions

Structured Text

ALMA (ALMA,In,ProgAckAll,ProgDisable,ProgEnable)

Operands

Ladder Diagram

In REAL

DINT

INT

ProgAckAll BOOL Tag

ProgDisable BOOL Tag

ProgEnable BOOL Tag

Tag

Immediate

Immediate

Immediate

Immediate

The alarm input value, which is

compared with alarm limits to

detect the alarm condition.

On transition from False to True,

acknowledges all alarm

conditions that require

acknowledgement.

When True, disables alarm (does

not override Enable Commands).

When True, enables alarm (takes

precedence over Disable

commands).

Publication 1756-RM003V-EN-P - November 2020 23

Page 24

Chapter 1 Alarm Instructions

Operand

Type

Format

Description

Operand

Type

Format

Description

SINT

require acknowledgement.

Immediate

override Enable Commands).

Input Parameter

Data Type

Description

Default is set.

Copied from instruction operand.

Function Block

ALMA tag ALARM_ANALOG structure ALMA structure

Structured Text

ALMA ALARM_ANALOG Structure ALMA structure

In REAL

DINT

INT

Tag

Immediate

The alarm input value, which is

compared with alarm limits to detect

the alarm condition.

ProgAckAll BOOL Tag

Immediate

ProgDisable BOOL Tag

ProgEnable BOOL Tag

Immediate

On transition from False to True,

acknowledges all alarm conditions that

When True, disables alarm (does not

When True, enables alarm (takes

precedence over Disable commands).

See Structured Text Syntax for more information on the syntax of expressions

within the structured text.

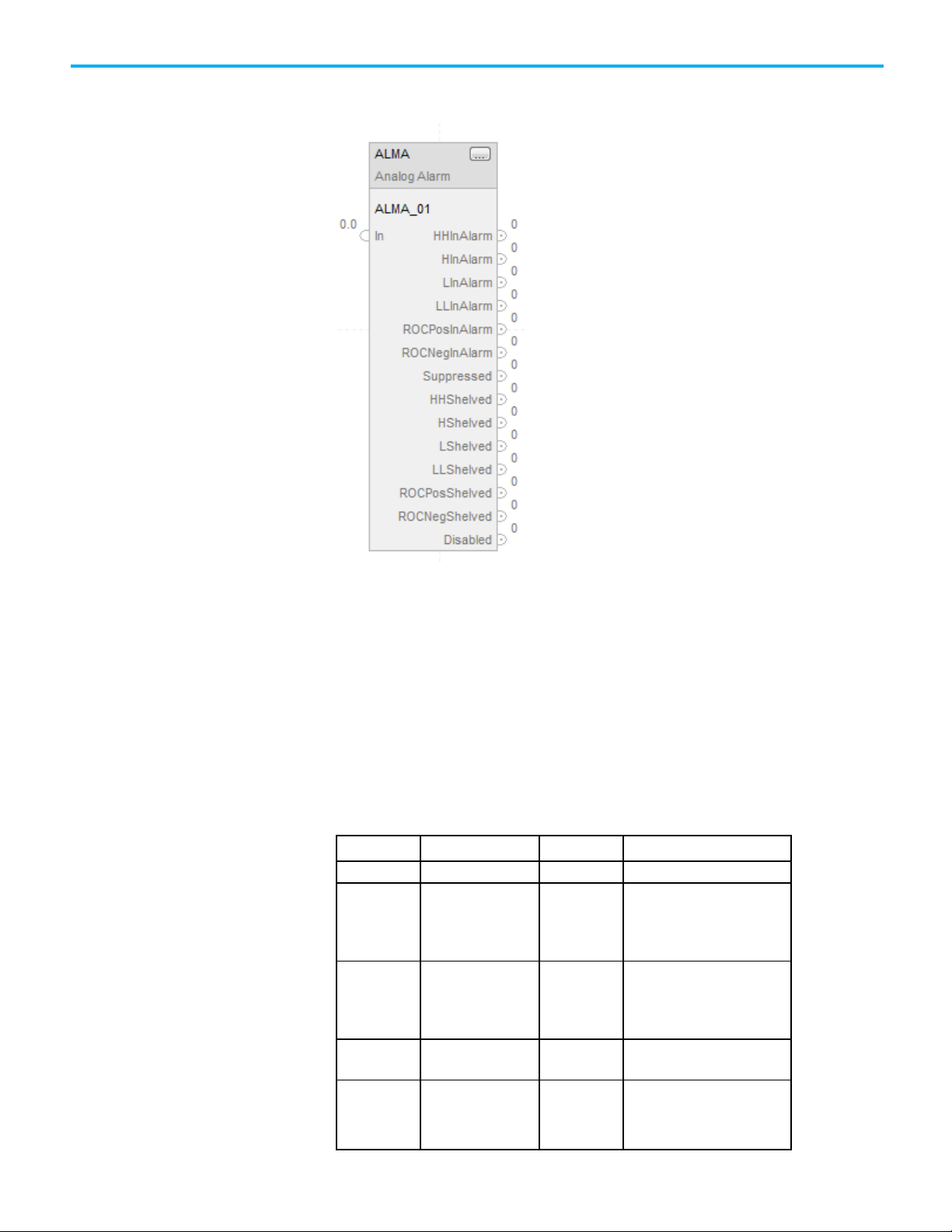

ALMA Structure

Input Parameters

EnableIn BOOL Ladder Diagram:

Corresponds to the rung state. If false, the instruction does not execute

and outputs are not updated.

Structured Text:

If false, the instruction does not execute and outputs are not updated.

Default is set.

Function Block:

If false, the instruction does not execute and outputs are not updated.

24 Publication 1756-RM003V-EN-P - November 2020

In REAL The alarm input value, which is compared with alarm limits to detect the

alarm condition.

Default = 0.0.

Ladder Diagram:

Copied from instruction operand.

Structured Text:

Page 25

Input Parameter

Data Type

Description

Default is false (good health).

Default is set.

Default is set.

Default is set.

Copied from the instruction operand.

Default is false.

Default is false.

Chapter 1 Alarm Instructions

InFault BOOL Bad health indicator for the input. The user application may set InFault to

indicate the input signal has an error. When set, the instruction sets

InFaulted (Status.1). When cleared to false, the instruction clears InFaulted

to false (Status.1). In either case, the instruction continues to evaluate In

for alarm conditions.

HHEnabled BOOL High High alarm condition detection. Set to true to enable detection of the

High High alarm condition. Clear to false to make detection unavailable for

the High High alarm condition.

Default is set.

HEnabled BOOL High alarm condition detection. Set to true to enable detection of the High

alarm condition. Clear to false to make detection unavailable for the High

alarm condition.

LEnabled BOOL Low alarm condition detection. Set to true to enable detection of the Low

alarm condition. Clear to false to make detection unavailable for the Low

alarm condition.

LLEnabled BOOL Low Low alarm condition detection. Set to true to enable detection of the

Low Low alarm condition. Clear to false to make detection unavailable for

the Low Low alarm condition.

AckRequired BOOL Specifies whether alarm acknowledgment is required. When set to true,

acknowledgment is required. When cleared to false, acknowledgment is

not required and HHAcked, HAcked, LAcked, LLAcked, ROCPosAcked, and

ROCNegAcked are always set to true

Default is true.

ProgAckAll BOOL Set to true by the user program to acknowledge all alarm conditions.

Takes effect only if any alarm condition is unacknowledged. Requires a

false-to-true transition.

Default is false.

Ladder Diagram:

Copied from the instruction operand.

Structured Text:

OperAckAll BOOL Set to true by the operator interface to acknowledge all alarm conditions.

Takes effect only if any alarm condition is unacknowledged. The alarm

instruction clears this parameter to false.

HHProgAck BOOL High High program acknowledge. Set to true by the user program to

acknowledge a High High condition. Takes effect only if the alarm

condition is unacknowledged. Requires a false -to-true transition.

Default is false.

HHOperAck BOOL High High operator acknowledge. Set to true by the operator interface to

acknowledge a High High condition. Takes effect only if the alarm

condition is unacknowledged. The alarm instruction clears this parameter

to false.

Publication 1756-RM003V-EN-P - November 2020 25

Page 26

Chapter 1 Alarm Instructions

Input Parameter

Data Type

Description

Default is false.

Default is false.

Default is false.

Default is false.

Default is false.

Default is false.

Default is false.

Default is cleared.

Default is false.

HProgAck BOOL High program acknowledge. Set to true by the user program to

acknowledge a High condition. Takes effect only if the alarm condition is

unacknowledged. Requires a false-to-true transition.

HOperAck BOOL High operator acknowledge. Set to true by the operator interface to

acknowledge a High condition. Takes effect only if the alarm condition is

unacknowledged. The alarm instruction clears this parameter to false.

LProgAck BOOL Low program acknowledge. Set to true by the user program to

acknowledge a Low condition. Takes effect only if the alarm condition is

unacknowledged. Requires a false-to-true transition.

Default is false.

LOperAck BOOL Low operator acknowledge. Set to true by the operator interface to

acknowledge a Low condition. Takes effect only if the alarm condition is

unacknowledged. The alarm instruction clears this parameter to false.

LLProgAck BOOL Low Low program acknowledge. Set to true by the user program to

acknowledge a Low Low condition. Takes effect only if the alarm

condition is unacknowledged. Requires a false-to-true transition.

LLOperAck BOOL Low Low operator acknowledge. Set to true by the operator interface to

acknowledge a Low Low condition. Takes effect only if the alarm

condition is unacknowledged. The alarm instruction clears this parameter

false.

Default is false.

ROCPosProgAck BOOL Positive rate of change program acknowledge. Set to true by the user

program to acknowledge a positive rate-of-change condition. Requires a

false-to-true transition while the alarm condition is unacknowledged.

ROCPosOperAck BOOL Positive rate of change operator acknowledge. Set to true by the operator

interface to acknowledge a positive rate-of-change condition. Requires a

false-to-true transition while the alarm condition is unacknowledged. The

alarm instruction sets this parameter to false.

ROCNegProgAck BOOL Negative rate of change program acknowledge. Set to true by the user

program to acknowledge a negative rate-of-change condition. Requires a

false-to-true transition while the alarm condition is unacknowledged.

Default is false.

ROCNegOperAck BOOL Negative rate of change operator acknowledge. Set to true by the operator

interface to acknowledge a negative rate-of-change condition. Requires a

false-to-true transition while the alarm condition is unacknowledged. The

alarm instruction clears this parameter to false.

ProgSuppress BOOL Set to true by the user program to suppress the alarm.

OperSuppress BOOL Set to true by the operator interface to suppress the alarm. The alarm

instruction clears this parameter to false.

ProgUnsuppress BOOL Set to true by the user program to unsuppress the alarm. Takes

precedence over Suppress commands.

Default is false.

26 Publication 1756-RM003V-EN-P - November 2020

Page 27

Input Parameter

Data Type

Description

Default is false.

again. It becomes unacknowledged when the shelve duration ends.

Unshelve commands take precedence over Shelve commands.

Unshelve commands take precedence over Shelve commands.

Unshelve commands take precedence over Shelve commands.

Default is false.

Chapter 1 Alarm Instructions

OperUnsuppress BOOL Set to true by the operator interface to unsuppress the alarm. Takes

precedence over Suppress commands. The alarm instruction sets this

parameter to false.

HHOperShelve BOOL High-high operator shelve. Set to true by the operator interface to shelve

or reshelve a high-high condition. Requires a false-to-true transition. The

alarm instruction clears this parameter to false.

Default is false.

Unshelve commands take precedence over Shelve commands.

Shelving an alarm postpones alarm processing. It is like suppressing an

alarm, except that shelving is time limited. If an alarm is acknowledged

while it is shelved, it remains acknowledged even if it becomes active

HOperShelve BOOL High operator shelve. Set to true by the operator interface to shelve or

reshelve a high condition. Requires a transition from false in one program

scan to true in the next program scan. The alarm instruction clears this

parameter to false.

Default is false.

Unshelve commands take precedence over Shelve commands.

LOperShelve BOOL Low operator shelve. Set to true by the operator interface to shelve or

reshelve a low condition. Requires a transition false in one program scan

to true in the next program scan. The alarm instruction clears this

parameter to false.

Default is false.

LLOperShelve BOOL Low-low operator shelve. Set to true by the operator interface to shelve or

reshelve a low-low condition. Requires a transition from false in one

program scan to true in the next program scan. The alarm instruction

clears this parameter to false.

Default is false.

Unshelve commands take precedence over Shelve commands.

ROCPosOperShelve BOOL Positive rate-of-change operator shelve. Set to true by the operator

interface to shelve or reshelve a positive rate-of-change condition.

Requires a transition from false in one program scan to true in the next

program scan. The alarm instruction clears this parameter to false.

Default is false.

ROCNegOperShelve BOOL Negative rate-of-change operator shelve. Set to true by the operator

interface to shelve or reshelve a negative rate-of-change condition.

Requires a transition from false in one program scan to true in the next

program scan. The alarm instruction clears this parameter to false.

Default is false.

ProgUnshelveAll BOOL Set to true by the user program to unshelve all conditions on this alarm. If

both shelve and unshelve are true, unshelve commands take precedence

over shelve commands.

HHOperUnshelve BOOL High-high operator unshelve. Set to true by the operator interface to

unshelve a high-high condition. The alarm instruction clears this

parameter to false. If both shelve and unshelve are true, unshelve

commands take precedence over shelve commands.

Default is false.

Publication 1756-RM003V-EN-P - November 2020 27

Page 28

Chapter 1 Alarm Instructions

Input Parameter

Data Type

Description

Default is false.

Default is false.

Default is false.

Default is false.

Default is false.

ProgEnable

BOOL

Copied from the instruction operand.

Default is false.

Default is false.

Default is true.

HOperUnshelve BOOL High operator unshelve. Set to true by the operator interface to unshelve a

high condition. The alarm instruction clears this parameter to false. If

both shelve and unshelve are true, unshelve commands take precedence

over shelve commands.

LOperUnshelve BOOL Low operator unshelve. Set to true by the operator interface to unshelve a

low condition. The alarm instruction clears this parameter to false. If both

shelve and unshelve are true, unshelve commands take precedence over

shelve commands.

Default is false.

LLOperUnshelve BOOL Low-low operator unshelve. Set to true by the operator interface to

unshelve a low-low condition. The alarm instruction clears this parameter

to false. If both shelve and unshelve are true, unshelve commands take

precedence over shelve commands.

ROCPosOperUnshelve BOOL Positive rate-of-change operator unshelve. Set to true by the operator

interface to unshelve a positive rate-of-change condition. The alarm

instruction clears this parameter to false. If both shelve and unshelve are

set, unshelve commands take precedence over shelve commands.

ROCNegOperUnshelve BOOL Negative rate-of-change operator unshelve. Set to true by the operator

interface to unshelve a negative rate-of-change condition. The alarm

instruction clears this parameter to false. If both shelve and unshelve are

true, unshelve commands take precedence over shelve commands.

ProgDisable BOOL Copied from the instruction operand.

OperDisable BOOL Set to true by the operator interface to disable the alarm. The alarm

instruction clears this parameter to false.

OperEnable BOOL Set to true by the operator interface to enable the alarm. Takes

precedence over Disable command. The alarm instruction clears this

parameter false.

AlarmCountReset BOOL Set to true by the operator interface to reset the alarm counts for all

conditions. The alarm instruction clears this parameter to false.

HHMinDurationEnable BOOL High-high minimum duration enable. Set to true to enable minimum

duration timer when detecting the high-high condition.

Default is true.

HMinDurationEnable BOOL High minimum duration enable. Set to true to enable minimum duration

timer when detecting the high condition.

Default is true.

LMinDurationEnable BOOL Low minimum duration enable. Set to true to enable minimum duration

timer when detecting the low condition.

28 Publication 1756-RM003V-EN-P - November 2020

LLMinDurationEnable BOOL Low-low minimum duration enable. Set to true to enable minimum

duration timer when detecting the low-low condition.

Default is true.

Page 29

Input Parameter

Data Type

Description

Default = 500.

Default = 0.0.

Default = 500.

Default = 0.0.

Default = 500.

Default = 500.

Chapter 1 Alarm Instructions

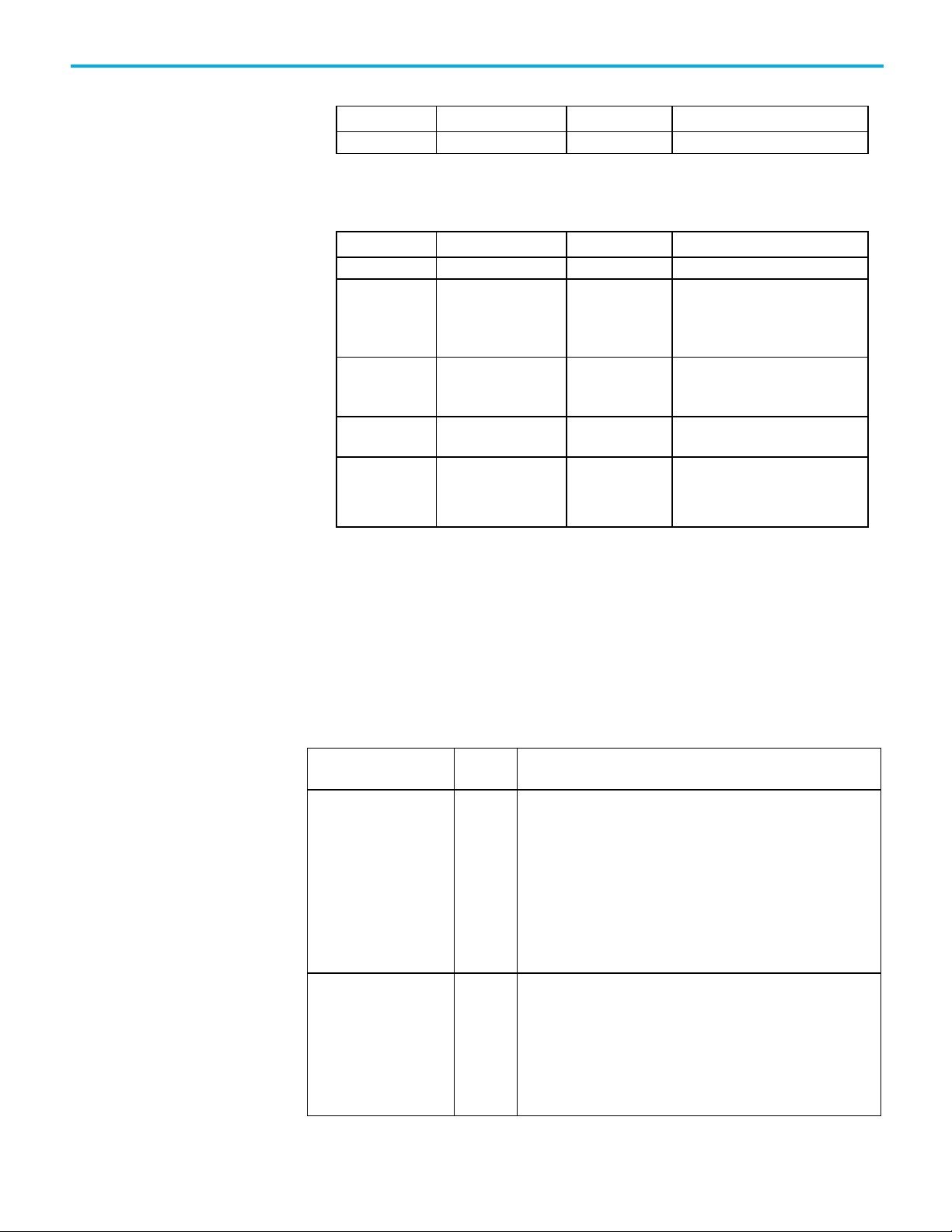

HHLimit REAL High High alarm limit.

Valid = HLimit < HHLimit < maximum positive float.

Default = 0.0.

HHSeverity DINT Severity of the High High alarm condition. This does not affect processing

of alarms by the controller, but can be used for sorting and filtering

functions at the alarm subscriber.

Valid = 1...1000 (1000 = most severe; 1 = least severe).

HLimit REAL High alarm limit.

Valid = LLimit < HLimit < HHLimit.

HSeverity DINT Severity of the High alarm condition. This does not affect processing of

alarms by the controller, but can be used for sorting and filtering

functions at the alarm subscriber.

Valid = 1...1000 (1000 = most severe; 1 = least severe).

LLimit REAL Low alarm limit.

Valid = LLLimit < LLimit < HLimit.

LSeverity DINT Severity of the Low alarm condition. This does not affect processing of

alarms by the controller, but can be used for sorting and filtering

functions at the alarm subscriber.

Valid = 1...1000 (1000 = most severe; 1 = least severe).

LLLimit REAL Low Low alarm limit.

Valid = maximum negative float < LLLimit < LLimit.

Default = 0.0.

LLSeverity DINT Severity of the Low Low alarm condition. This does not affect processing

of alarms by the controller, but can be used for sorting and filtering

functions at the alarm subscriber.

Valid = 1...1000 (1000 = most severe; 1 = least severe).

MinDurationPRE DINT Minimum duration preset (milliseconds) for an alarm level condition to

remain true before the condition is marked as InAlarm and alarm

notification is sent to clients. The controller collects alarm data as soon

as the alarm condition is detected; so no data is lost while waiting to meet

the minimum duration. Does not apply to rate-of-change conditions or to

conditions for which minimum duration detection is disabled.

MinDurationPRE only applies to the first excursion from normal in either

direction. For example, once the High condition times out, the High High

condition becomes active immediately, while a Low condition waits for

the timeout period.

Valid = 0...2147483647.

Default = 0.

ShelveDuration DINT Time duration (in minutes) for which a shelved alarm will be shelved.

Minimum time is one minute. Maximum time is defined by

MaxShelveDuration.

MaxShelveDuration DINT Maximum time duration (in minutes) for which an alarm can be shelved.

Publication 1756-RM003V-EN-P - November 2020 29

Page 30

Chapter 1 Alarm Instructions

Input Parameter

Data Type

Description

Default = 0.0.

Default = 0.0.

Default = 500.

Default = 0.0.

Deadband REAL Deadband for detecting that High High, High, Low, and Low Low alarm

levels have returned to normal.

A non-zero Deadband can reduce alarm condition chattering if the In

value is continually changing but remaining near the level condition

threshold. The Deadband value does not affect the transition to the

InAlarm (active) state. Once a level condition is active, but before the

condition returns to the inactive (normal) state, the In value must either:

drop below the threshold minus the deadband (for High and High High

conditions).

OR

rise above the threshold plus the deadband (for Low and Low Low

conditions).

The Deadband is not used to condition the Minimum Duration time

measurement.

Valid = 0 = Deadband < Span from first enabled Low alarm to the first

enabled High alarm.

Default = 0.0.

ROCPosLimit REAL Limit for an increasing rate-of-change in units per second. Detection is

enabled for any value > 0.0 if ROCPeriod is also > 0.0.

Valid = 0.0...maximum possible float.

ROCPosSeverity DINT Severity of the increasing rate-of-change condition. This does not affect

processing of alarms by the controller, but can be used for sorting and

filtering functions at the alarm subscriber.

Valid = 1...1000 (1000 = most severe; 1 = least severe).

Default = 500.

ROCNegLimit REAL Limit for a decreasing rate-of-change in units per second. Detection is

enabled for any value > 0.0 if ROCPeriod is also > 0.0.

Valid = 0.0...maximum possible float.

ROCNegSeverity DINT Severity of the decreasing rate-of-change condition. This does not affect

processing of alarms by the controller, but can be used for sorting and

filtering functions at the alarm subscriber.

Valid = 1...1000 (1000 = most severe; 1 = least severe).

ROCPeriod REAL Time period in seconds for calculation (sampling interval) of the rate of

change value. Each time the sampling interval expires, a new sample of In

is stored, and ROC is re-calculated. Instead of an enable bit like other

conditions in the analog alarm, the rate-of-change detection is enabled by

putting any non-zero value in the ROCPeriod.

Valid = 0.0...32767.0

Output Parameters

These output parameters are common to ladder logic.

30 Publication 1756-RM003V-EN-P - November 2020

Page 31

Output Parameter

Data Type

Description

Cleared to false when no Low condition exists.

Active. Cleared to false when no Low Low condition exists.

positive rate-of-change condition exists.

negative rate-of-change condition exists.

acknowledged.

Cleared to false when a High condition is not acknowledged.

rate-of-change condition is not acknowledged.

negative rate-of-change condition is not acknowledged.

acknowledged, or both.

Chapter 1 Alarm Instructions

AnyInAlarmUnack BOOL Combined alarm active and acknowledged status. Set to true when any

alarm condition is detected and unacknowledged. Cleared to false when

all alarm conditions are inactive, acknowledged, or both.

HHInAlarm BOOL High High alarm condition status. Set to true when a High High condition

is Active. Cleared to false when no High High condition exists.

HInAlarm BOOL High alarm condition status. Set to true when a High condition is Active.

Cleared to false when no High condition exists.

LInAlarm BOOL Low alarm condition status. Set to true when a Low condition is Active.

LLInAlarm BOOL Low Low alarm condition status. Set to true when a Low Low condition is

ROCPosInAlarm BOOL Positive rate-of-change alarm condition status. Set to true when a

positive rate-of-change condition exists. Cleared to false when no

ROCNegInAlarm BOOL Negative rate-of-change alarm condition status. Set to true when a

negative rate-of-change condition exists. Cleared to False when no

ROC REAL Calculated rate-of-change of the In value. This value is updated when

the instruction is scanned following each elapsed ROCPeriod. The ROC

value is used to evaluate the ROCPosInAlarm and ROCNegInAlarm

conditions.

ROC = (current sample of In – previous sample of In) / ROCPeriod

HHAcked BOOL High High condition acknowledged status. Set to true when a High High

condition is acknowledged. Always set to true when AckRequired is

cleared to false. Cleared to false when a High High condition is not

HAcked BOOL High condition acknowledged status. Set to true when a High condition is

acknowledged. Always set to true when AckRequired is cleared to false.

LAcked BOOL Low condition acknowledged status. Set to true when a Low condition is

acknowledged. Always set to true when AckRequired is cleared to false.

Cleared to false when a Low condition is not acknowledged.

LLAcked BOOL Low Low condition acknowledged status. Set to true when a Low Low

condition is acknowledged. Always true when AckRequired is cleared to

false. Cleared to false when a Low Low condition is not acknowledged.

ROCPosAcked BOOL Positive rate-of-change condition acknowledged status. Set to true

when a positive rate-of-change condition is acknowledged. Always true

when AckRequired is cleared to false. Cleared to false when a positive

ROCNegAcked BOOL Negative rate-of-change condition acknowledged status. Set to true

when a negative rate-of-change condition is acknowledged. Always set

to true when AckRequired is cleared to false. Cleared to false when a

HHInAlarmUnack BOOL Combined High High condition active and unacknowledged status. Set to

true when the High High condition is active (HHInAlarm is true) and

unacknowledged. Cleared to false when the High High condition is

inactive, acknowledged, or both.

HInAlarmUnack BOOL Combined High condition active and unacknowledged status. Set to true

when the High condition is active (HInAlarm is true) and

unacknowledged. Cleared to false when the High condition is inactive,

Publication 1756-RM003V-EN-P - November 2020 31

Page 32

Chapter 1 Alarm Instructions

Output Parameter

Data Type

Description

both.

inactive, acknowledged, or both.

positive rate-of-change condition is inactive, acknowledged, or both.

acknowledged, or both.

suppressed. Cleared to false when the alarm is not suppressed.

unshelved.

shelved. Cleared to false when high condition is unshelved.

shelved. Cleared to false when low condition is unshelved.

is shelved. Cleared to false when low-low condition is unshelved.

positive rate-of-change condition is unshelved.

MinDurationACC

DINT

Not Used. Value is always 0.

active state.

maximum count value.

active state.

LInAlarmUnack BOOL Combined Low condition active and unacknowledged status. Set to true

when the Low condition is active (LInAlarm is true) and unacknowledged.

Cleared to false when the Low condition is inactive, acknowledged, or

LLInAlarmUnack BOOL Combined Low Low condition active and unacknowledged status. Set to

true when the Low Low condition is active (LLInAlarm is true) and

unacknowledged. Cleared to false when the Low Low condition is