Page 1

Installation Instructions

Dual Probe Holder

Cat. No. EK-29000-DPH01

This document provides information to install the Allen-Bradley Dual Probe Holder. The

Dual Probe Holder is designed to combine a displacement transducer and an Allen-Bradley

9000 series sensor (velocity or accelerometer) into a single housing. The Dual Probe Holder

can be used in conjunction with the Allen-Bradley XM

provide shaft relative, case absolute, and shaft absolute measurements.

Note that the Dual Probe Holder is also functional with either one of the two sensors

installed.

For more information on the XM-121 Absolute Shaft module, refer to the XM-121 Absolute

Shaft User Guide (publication GMSI10-UM014x-EN-E). Refer to the specific sensor manual

for recommended wiring requirements and specifications for that sensor.

For information about See page

Important User Information 2

About the Dual Probe Holder 3

Installing the Dual Probe Holder 6

Replacing the Sensors in Dual Probe Holder 10

Specifications 13

®

-121 Absolute Shaft module to

Publication GMSI10-UM028A-EN-E - November 2007

Page 2

2 Dual Probe Holder

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical

equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls

(Publication SGI-1.1 available from your local Rockwell Automation sales office or online at

http:///literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage,

or economic loss.

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequences.

Labels may be located on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be located on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may be dangerous temperatures.

Publication GMSI10-UM028A-EN-E - November 2007

Page 3

Dual Probe Holder 3

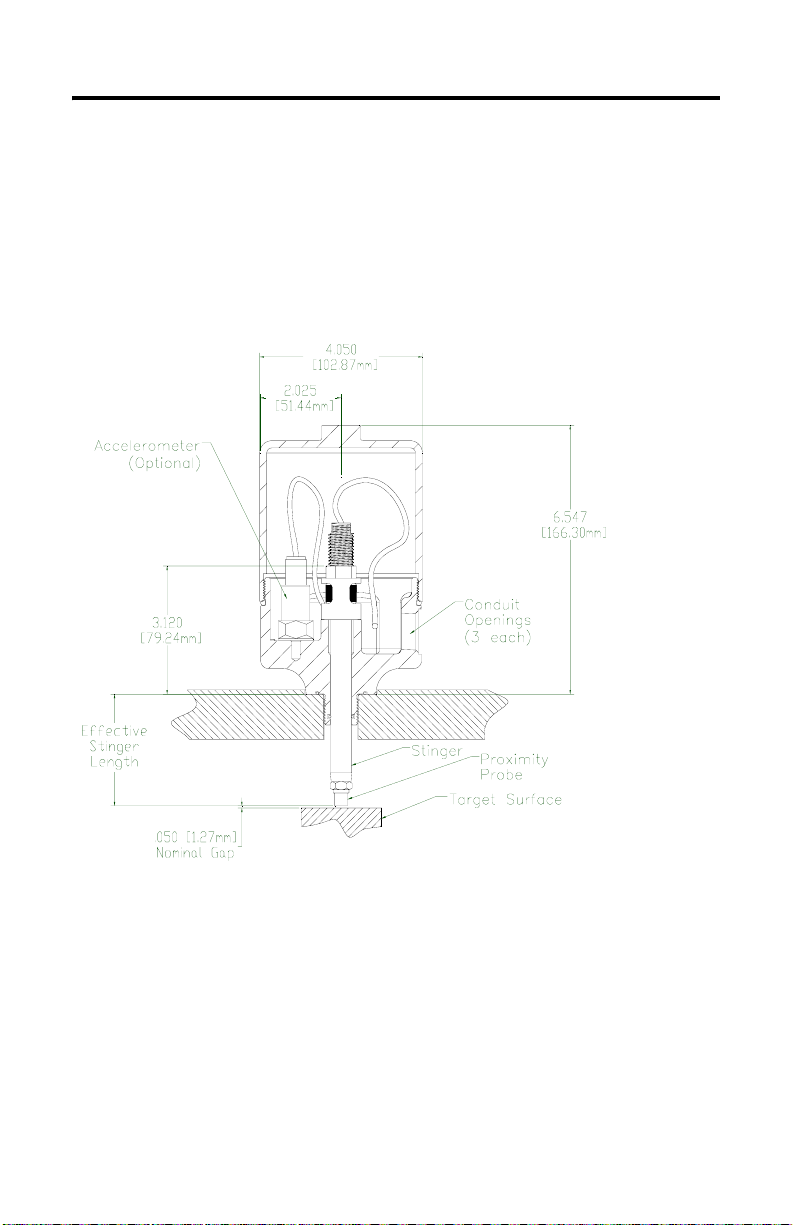

About the Dual Probe Holder

The Dual Probe Holder provides a single housing for a non-contact eddy current probe and

an Allen-Bradley 9000 series sensor. The Dual Probe Holder allows the eddy current probe

and the 9000 sensor to be installed at the same point on the same bearing half. The Dual

Probe Holder mounts on the machine casing and the installed sensors connect to a

monitoring system such as the XM-121 Absolute Shaft module.

Figure 1 Dual Probe Holder Internal Side View

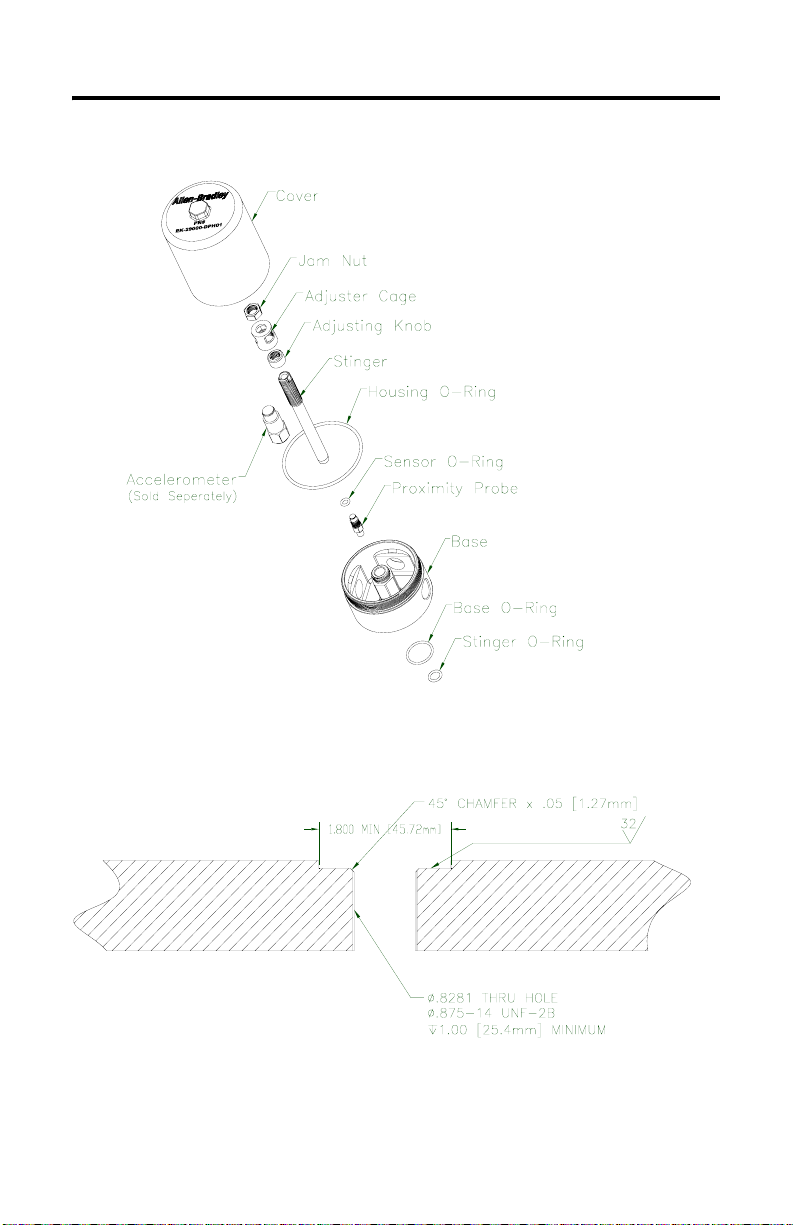

The Dual Probe Holder consists of a base that threads into the machine case, three conduit

ports for wiring connections, a stinger of optional length, o-rings, an eddy current probe, a

case vibration sensor, a jam nut, adjusting cage and knurling adjusting knob to secure the

stinger to the base to maintain the probe-to-shaft gap. And the Dual Probe Holder cover

screws onto the base of the holder. See

The location in which the probe and holder is installed determines which stinger you use.

Refer to Dual Probe Holder Ordering Information on page 5.

Figure 2 on page 4.

Publication GMSI10-UM028A-EN-E - November 2007

Page 4

4 Dual Probe Holder

Figure 2 Dual Probe Holder Exploded View

Figure 3 Mounting Requirements

Publication GMSI10-UM028A-EN-E - November 2007

Page 5

Dual Probe Holder 5

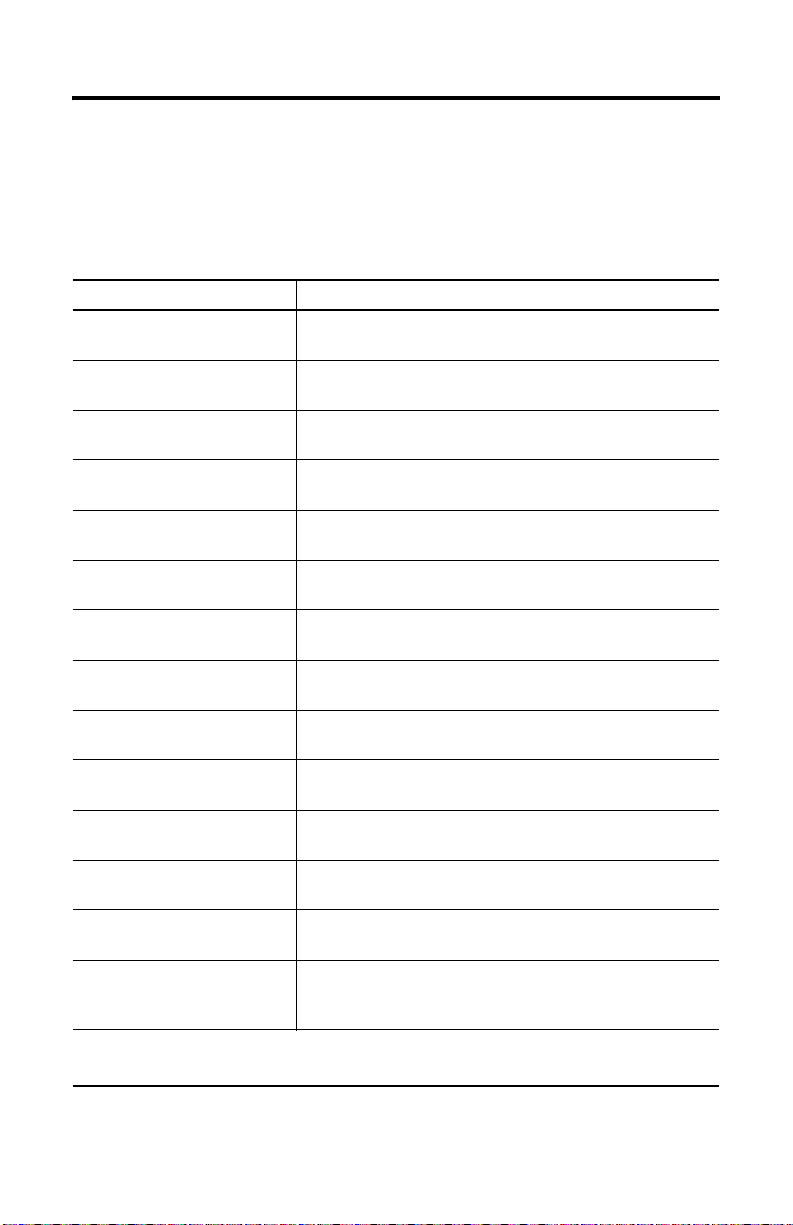

Dual Probe Holder Ordering Information

The following items are options for the Rockwell Automation Dual Probe Holder, Cat. No.

EK-29000-DPH01.

Table 1 Dual Probe Holder Items

Rockwell Automation Cat. No. Description

48772-0200 Stainless steel stinger, 2.00 to 3.00 in. (5.1 to 7.6 cm) probe

48772-0300 Stainless steel stinger, 3.00 to 4.00 in. (7.6 to 10.2 cm) probe

48772-0400 Stainless steel stinger, 4.00 to 5.00 in. (7.6 to 12.7 cm) probe

48772-0500 Stainless steel stinger, 5.00 to 6.00 in. (12.7 to 15.2 cm) probe

48772-0600 Stainless steel stinger, 6.00 to 7.00 in. (15.2 to 17.8 cm) probe

48772-0700 Stainless steel stinger, 7.00 to 8.00 in. (17.8 to 20.3 cm) probe

48772-0800* Stainless steel stinger, 8.00 to 9.00 in. (20.3 to 22.9 cm) probe

48772-0900* Stainless steel stinger, 9.00 to 10.00 in. (22.9 to 25.4 cm) probe

48772-1000* Stainless steel stinger, 10.00 to 11.00 in. (25.4 to 27.9 cm) probe

48772-1100* Stainless steel stinger, 11.00 to 12.00 in. (27.9 to 30.5 cm) probe

48772-1200* Stainless steel stinger, 12.00 to 13.00 in. (30.5 to 33.0 cm) probe

48772-1300* Stainless steel stinger, 13.00 to 14.00 in. (33.0 to 35.6 cm) probe

48772-1400* Stainless steel stinger, 14.00 to 15.00 in. (35.6 to 38.1 cm) probe

48772-9024* Stainless steel stinger, 24.00 in. (61.0 cm), for cut-to-length

* The unsupported length of stinger should not exceed 200 mm (8 in) per API 670.

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

adjustment range

applications. Probe end is not machined. The end must be machined

after stinger is cut to length.

Publication GMSI10-UM028A-EN-E - November 2007

Page 6

6 Dual Probe Holder

Table 1 Dual Probe Holder Items

Rockwell Automation Cat. No. Description

2109/30/05/1/05 2100 Series Reverse Mount 8 mm Probe with 0.5 m cable

2109/30/05/1/10 2100 Series Reverse Mount 8 mm Probe with 1.0 m cable

1442-PR-0812E0205N 1442 Series Reverse Mount 8 mm Probe with 0.5 m cable

1442-PR-0830M0505N 1442 Series Reverse Mount 8 mm Probe, Metric, with 0.5 cable

1442-PR-0812E0210N 1442 Series Reverse Mount 8 mm Probe with 1.0 m cable

1442-PR-0830M0510N 1442 Series Reverse Mount 8 mm Probe, Metric, with 1.0 cable

EK-43781I 9000A General Purpose Sensor

EK-43808I 9100VO Velocity Output Sensor

EK-43786I 9100CSA General Purpose Sensor

EK-43805I 9100T High Temperature Sensor

IMPORTANT

The Dual Probe Holder is also compatible with Bentley Nevada 3300 XL

(330105 and 330195) Series Probes.

Installing the Dual Probe Holder

This section describes the installation of the Dual Probe Holder.

Receiving, Unpacking, and Inspection

Unpack the Dual Probe Holder and inspect for possible damage during shipment. Report any

damages immediately to the local transportation agent and submit a copy to Rockwell

Automation.

Publication GMSI10-UM028A-EN-E - November 2007

Page 7

Dual Probe Holder 7

Installation

Follow the steps below to install the Dual Probe Holder. Refer to Figures on pages 3 and 4

for assistance. Make sure the machine is stopped before installing the Dual Probe Holder.

TIP

Follow API 670 requirements for surface finish and flatness, even for

non-API installations. If the surface is not properly prepared, it can reduce

the detection of higher frequencies.

Prepare Mounting Surface

1. Spot face the surface, then drill and tap a hole in the machine case where you want to

install the Dual Probe Holder.

Check Parts and (if necessary) Replace Housing and Stinger O-rings

2. Open the Dual Probe Housing cover and remove plastic bag containing adjusting

cage, adjusting knob, jam nut and o-rings.

3. Replace the installed housing and stinger Viton O-rings with Buna O-rings (supplied

in plastic bag) to meet low temperature operating conditions (see table below). If you

do not need to replace the o-rings, proceed to step 4.

placement of the o-rings.

The table below shows the required o-rings for the appropriate temperature operating

ranges.

Table 2 O-Ring Requirements

Temperature Operating Range Required O-ring

-10 to 400°F (-23 to 204°C) Viton O-ring (default)

-30 to 230°F (-34 to 110°C) Buna O-ring

Figure 3 on page 8 shows the

Publication GMSI10-UM028A-EN-E - November 2007

Page 8

8 Dual Probe Holder

Figure 3 Placement of O-Rings

Install Base on Machine

4. Install the appropriate base o-ring into the grove in the Dual Probe Holder base. See

Figure 3. Use Table 2 on page 7 to determine which o-ring to install.

5. Apply anti-seize compound to the threaded portion of the Dual Probe Holder base

and install the base into the machine casing. Tighten to 55 ft-lb (75 N-m) torque.

Install Reverse Mount Probe Stinger

6. Install the appropriate sensor o-ring onto the base of the threaded portion of the

probe. Use

7. Apply two drops of thread adhesive, such as Blue Loctite 242 (or greater), to the

probe threads.

8. Insert probe cable into the stinger and tighten probe to 66 in-lb (7.5 N-m).

Publication GMSI10-UM028A-EN-E - November 2007

Table 2 on page 7 to determine which o-ring to install.

Page 9

Dual Probe Holder 9

Install Stinger and Assemble Adjustment Mechanism

9. Screw the knurled adjusting knob down to the end of the threaded portion of the

stinger.

10. Apply a film of grease to the unthreaded surface of the stinger. Insert the stinger into

the base until the knurled adjusting knob contacts the base.

11. Install the adjusting cage and hand tighten.

12. Install the jam nut so flat portion of the stinger is above the jam nut.

Install 9000 Sensor

13. Install the 9000 series sensor into the base. Use stud or bolt (1/4-28 threads x 3/8

inch) and thread locking compound. Socket wrench can be used.

Connect Wiring

14. Connect the non-contact sensor and the 9000 series sensor to the monitoring system.

Wiring can pass through any of the three conduit holes. Refer to Wiring

Considerations on page 10. For specific wiring connections to the monitor, refer to

monitoring system’s manual.

Gap Non-Contact Sensor

15. Gap the probe. Refer to the eddy current probe manual for probe gap procedures and

specifications.

ATTENTION

16. Tighten jam nut. Use a wrench on flat portion of the stinger to ensure the stinger

does not move while tightening the jam nut. Tighten the jam nut to 35 ft-lb (48 N-m)

torque.

17. Verify gap voltage.

Do not scratch sensor tip or target surface.

Publication GMSI10-UM028A-EN-E - November 2007

Page 10

10 Dual Probe Holder

Install Cover

18. Apply a film of grease to the exposed surface of the housing o-ring (on base). Place

the Dual Probe Holder cover on the base, and hand tighten. Be sure to turn an

additional 1/2 turn to seat the enclosure seal.

Wiring Considerations

• There are three wiring holes machined in the base of the Dual Probe Holder to pass

cabling through. If a wiring hole is not needed, use a 3/4 inch plug to close the

opening. The plug will maintain a NEMA 4X rating for environmental protection.

• The field wiring must be enclosed in 3/4 inch conduit. The conduit must be sealed at

the cable entry to maintain a NEMA 4X rating.

• Protect cable ends from debris before pulling through conduit.

• Terminate the shielded wires at the monitor end to prevent ground loops.

Refer to the wiring requirements in the eddy current probe manual and the Allen-Bradley

9000 series sensor manual. In addition, refer to the monitor manual in which the sensors are

connected to for requirements specific to the monitor.

Replacing the Sensors in Dual Probe Holder

The Dual Probe Holder allows removing and installing of the sensors without disassembling

the machine. Follow the steps below to remove the sensors from the Dual Probe Holder.

Replacing Non-Contact Sensor

To remove probe from Dual Probe Holder

1. Remove the Dual Probe Holder cover.

2. Disconnect the probe lead from the extension cable.

3. Tighten the adjusting knob to hold the sensor away from the target.

4. Loosen jam nut and adjusting cage so stinger can be removed from the base. Be

careful not to move the knurled adjusting knob.

Publication GMSI10-UM028A-EN-E - November 2007

Page 11

Dual Probe Holder 11

5. Pull stinger out from base.

6. Unscrew probe and remove.

To install probe

1. Clean the threads of the stinger.

2. Install the appropriate sensor o-ring onto the base of the threaded portion of the

probe. Use Table 2 on page 7 to determine which o-ring to install.

3. Apply two drops of thread locking compound, such as Loctite 242 (or greater), to the

probe threads.

4. Insert probe cable into the stinger and tighten probe to 66 in-lb (7.5 N-m).

TIP

5. Apply a film of grease to the unthreaded surface of the stinger. Insert the stinger into

the base until the knurled adjusting knob contacts the base.

6. Install the adjusting cage and hand tighten.

To prevent the non-contact sensor from contacting the target

surface, it is advisable to rotate the knurled adjusting knob until it

bottoms out of threads.

7. Install the jam nut so the flat portion of the stinger is above the jam nut.

8. Connect the non-contact sensor to the monitoring system.

9. Gap the probe. Refer to the eddy current probe manual for probe gap procedures and

specifications.

ATTENTION

10. Tighten jam nut and verify gap voltage. Use a wrench on flat portion of the stinger to

ensure the stinger does not move while tightening the jam nut. Tighten the jam nut to

35 ft-lb (48 N-m) torque.

Do not scratch sensor tip or target surface.

Publication GMSI10-UM028A-EN-E - November 2007

Page 12

12 Dual Probe Holder

11. Apply a film of grease to the exposed surface of the housing o-ring (on base) if

needed. Place the Dual Probe Holder cover on the base, and hand tighten. Be sure to

turn an additional 1/2 turn to seat the enclosure seal.

Replacing Series 9000 Sensor

To remove 9000 sensor from Dual Probe Holder

1. Remove Dual Probe Holder cover.

2. Disconnect wiring leads.

3. Remove stud or bolt and remove sensor.

To install 9000 sensor

1. Clean housing threads.

2. Install 9000 sensor into the base. Use stud or bolt (1/4-28 threads x 3/8 inch) and

thread locking compound. Socket wrench can be used.

3. Apply a film of grease to the exposed surface of the housing o-ring (on base) if

needed. Place the Dual Probe Holder cover on the base, and hand tighten. Be sure to

turn an additional 1/2 turn to seat the enclosure seal.

Publication GMSI10-UM028A-EN-E - November 2007

Page 13

Specifications

Table 4 Dual Probe Holder Specifications

Product Feature Specification

Enclosure Dimensions See Figure 1 (page 3)

Housing Material 304 stainless steel

Adjusting Knob & Cage 303 stainless steel

Operating Temperature -51...177 °C (-60...351 °F)

Rating NEMA 4X

Weight 6.5 lb

Dual Probe Holder 13

Publication GMSI10-UM028A-EN-E - November 2007

Page 14

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using our

products. At http://support.rockwellautomation.com, you can find technical manuals, a

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of these

tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information, contact

your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation,

please review the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your module up and running:

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be

returned:

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Listen. Think. Solve, Allen-Bradley and XM are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Publication GMSI10-UM028A-EN-E - November 2007

Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...