Page 1

Quick Reference

Drives and Motion Accelerator Toolkit

Quick Start Summary

This quick start provides step by step instructions for

using the Drives and Motion Accelerator Toolkit to

help you design, install, operate, and maintain a drive

system. Included are selection tools, layout and wiring

drawings, and pre-configured logic and HMI files to

assist you in creating an Integrated Architecture™

solution that includes Allen-Bradley® servo drives and

PowerFlex® AC drives.

The instructions also show how the Drives and

Motion Accelerator Toolkit (DMAT) Wizard can

automate the tasks needed to build the files used in the

Integrated Architecture solution.

All the supporting files are included on the Drives and

Motion Accelerator Toolkit DVD, publication

IASIMP-SP017, including the DMAT Wizard. The

DVD provides drive selection tools; CAD drawings

for panel layout and wiring; basic status, control, and

diagnostic logic files; FactoryTalk® View ME and SE

faceplates, and more. For a copy of the DVD, contact

your local Allen-Bradley distributor or Rockwell

Automation® sales representative. With these tools and

the built-in best-practices design, the system designer

is free to focus on the design of their machine control

and not on design overhead tasks.

You can also download many of these same supporting files from the Rockwell Automation Integrated

Architecture Tools website, http://www.ab.com/go/iatools

on the Beyond Getting Started tab.

Page 2

2 Drives and Motion Accelerator Toolkit Quick Star t Summary

MOTOR

FIELD SIDE

DRIVE

PROTECTION

POWERFLEX 4

AC DRIVE

MOTOR_01

USER PROTECTED

XXXVAC SUPPLY

MAINS DISCONNECT

PROTECTION

XXAMPS

FILTERED POWER

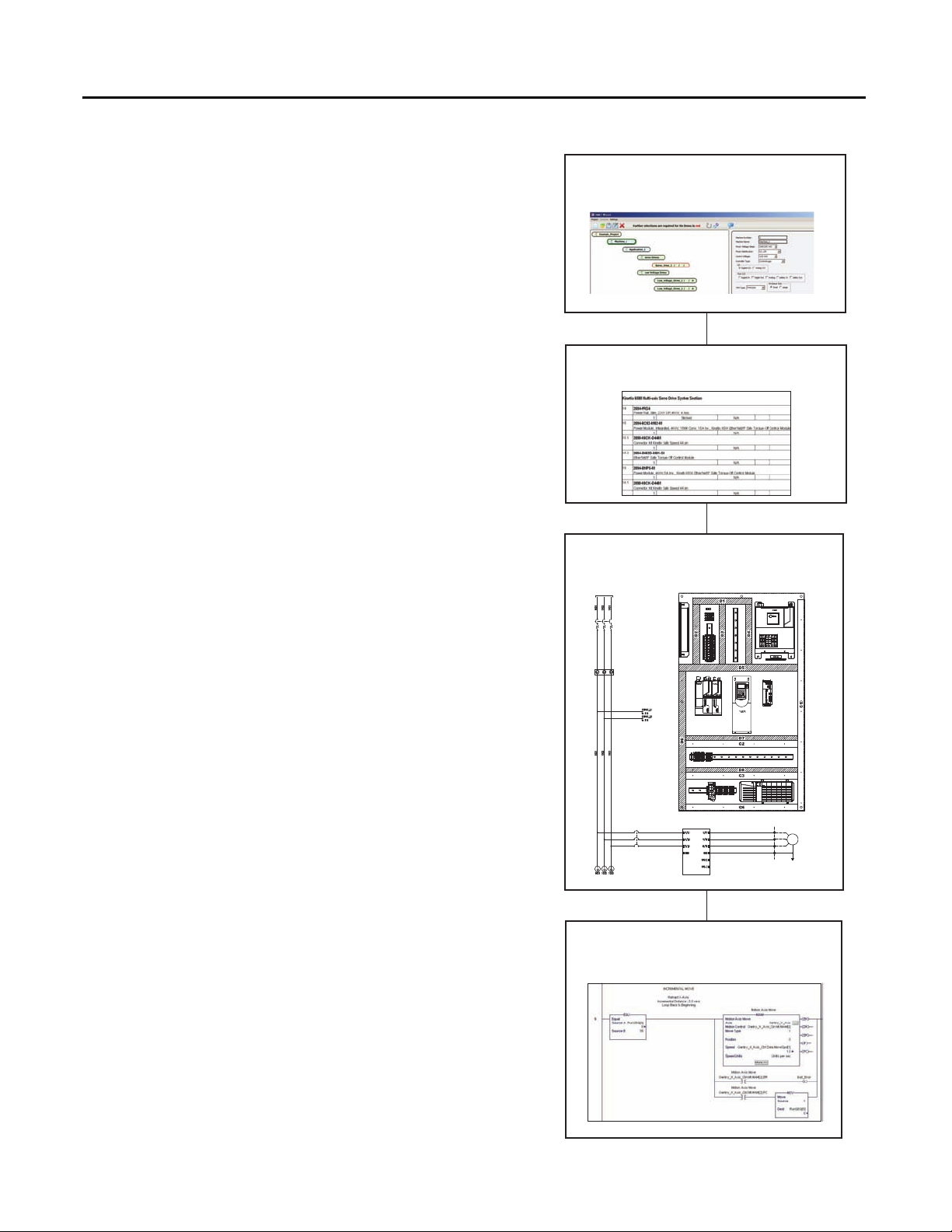

Chapter 3

System Layout and Wiring

Chapter 1

Initial System Configuration Using the DMAT Wizard

Chapter 2

Bill of Materials Completion

Chapter 4

Logic Co nfiguratio n

Quick Start Chapter Summary

Follow this path to complete your Drives and Motion

application.

Chapter 1 - Initial System Configuration Using the DMAT Wizard

In this chapter you use the Rockwell Automation DMAT

Wizard to create an initial bill of materials, assemble a system

drawing set, and create an RSLogix™ 5000 project file with a

preconfigured controller, network, drives and initial system

program logic. In addition, you are introduced to several

Rockwell Automation system configuration tools that provide

assistance in sizing your motor/drive combinations for a variety

of load, transmission, and application types.

Chapter 2 - Bill of Materials Completion

In this chapter you use Rockwell Automation ProposalWorks™

software to complete the drives and motion system bill of

materials that the DMAT Wizard created.

Chapter 3 - System Layout and Wiring

In this chapter you edit the set of layout and wiring drawings

from the DMAT drawing library that the DMAT Wizard

created.

Chapter 4 - Logic Configuration

In this chapter you edit the preconfigured logic file that the

DMAT Wizard created for your specific application.

Rockwell Automation Publication IASIMP-QS022B-EN-P - April 2012

Page 3

Drives and Motion Accelerator Toolkit Quick Start Summar y 3

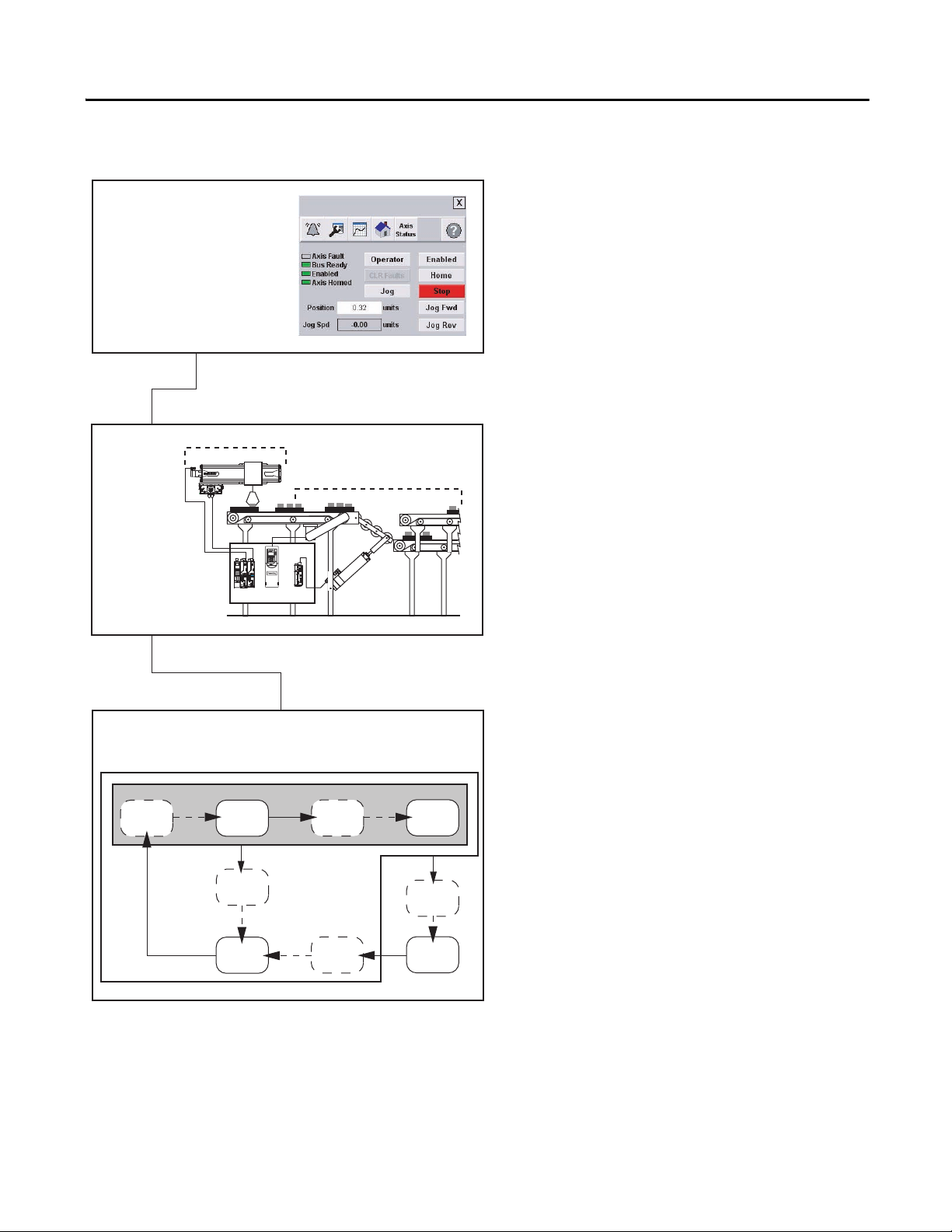

Chapter 7

Motion System Application Guide

Servo Drive

755

00300

RESETTING

IDLE

(enabled)

START

RUNNING

STOPPING

STOP

STOPPED

(disabled)

CLEARING

ABORTED

ABORTING

RESET

ABORT

CLEAR

The machine can go from any state in the shaded box to STOPPING.

The machine can go from any state

in the solid box to ABORTING.

STARTING

Chapter 7

System Application Guide

Chapter 5

FactoryTalk View ME Configuration

Chapter 6

System

Commissioning

Assembly

Packaging

Chapter 5 - FactoryTalk View ME Configuration

In this chapter you create the operator interface

application file for your system using FactoryTalk

View Studio software. The toolkit includes a

variety of preconfigured machine and device

faceplate displays providing status, control, and

diagnostics for your drives and motion system.

Chapter 6 - System Commissioning

In this chapter you download your Logix and

PanelView™ Plus applications, prepare and tune

your drive hardware, verify network

communications, and verify general operator/

program control.

Chapter 7 - System Application Guide

This chapter guides you through the preconfigured FactoryTalk View Machine Edition

application faceplates providing you with an

understanding of the status, control, and diagnostic

operation of the faceplate displays.

Rockwell Automation Publication IASIMP-QS022B-EN-P - April 2012

Page 4

4 Drives and Motion Accelerator Toolkit Quick Star t Summary

Machine

Module

Application

Module

Device

Module

PanelView Plus Terminal

Machine Faceplate

Controller Logic

HMI Application

Application

Status

Machine

Commands

Device

Commands

Device

Status

Operator

Commands

Machine Status

Device Faceplate

755

00300

X-Y Gantry

Diverter

Conveyor

Kinetix 6500

Drives

Kinetix 300

Drive

PowerFlex 753

Drive

Servo Motor Driven

Electric Cylinder

Induction Motor

X-Servo

Y-Se rvo

Assembly

Packaging

To assist you in device configuration, the Widg-O-matic machine application example is

referenced in the device configuration steps. Two servo drives are configured for the X-Y

gantry assembly section, one PowerFlex drive is configured for the conveyor, and one

Kinetix® 300 drive is configured for the packaging diverter.

Modularity Example - Machine/Application/Device Module Relationship

The machine module monitors the current state of the overall machine and based on the state and/or requests

from the HMI terminal, broadcasts out commands to both the application and device modules. The individual

modules perform a predefined task based on the command. Some of the commands may be ignored depending

on the module type.

Widg-O-matic Machine Application Example

Rockwell Automation Publication IASIMP-QS022B-EN-P - April 2012

Page 5

Drives and Motion Accelerator Toolkit Quick Start Summar y 5

Ch. 1 Example - Run the DMAT Wizard

Follow these steps to launch the DMAT Wizard and set up your wizard configuration.

1. Navigate to and select the

DMAT Wizard .exe file on the

Drives and Motion Accelerator

Toolkit DVD image.

The DMAT Wizard opens and a dialog box opens, explaining the general scope of the wizard.

2. Read the dialog box and click OK to continue wizard configuration.

The Open or Create a Project dialog box opens.

3. Click Create New to initiate a new project.

Another configuration information dialog box

opens, explaining machine, application, and drive

configuration.

4. Read configuration information dialog box and

click OK to continue.

Rockwell Automation Publication IASIMP-QS022B-EN-P - April 2012

Page 6

6 Drives and Motion Accelerator Toolkit Quick Star t Summary

Select and

delete

this drive

and cable.

Ch. 3 Example - Edit System Communication Drawings

1. Open the communication drawing for your application.

For the Widg-O-matic machine application example, the 060_120_Ethernet_Communication.dwg file is

opened.

2. Delete network devices not used in the project.

For the Widg-O-matic machine application example, one of the Kinetix 300 drives and associated cable is

deleted.

Ethernet Communication

Rockwell Automation Publication IASIMP-QS022B-EN-P - April 2012

Page 7

Drives and Motion Accelerator Toolkit Quick Start Summar y 7

Ch. 4 Example - Import and Configure Device and Application Status Logic

Follow these steps to add the device and application status information rungs to the R02_Monitor routine of

your machine program.

1. Expand the Tasks folder in your Controller Organizer.

2. Navigate to and open the R02_Monitor routine of your machine program.

For the Widg-O-matic application example, the R02_Monitor routine within the P01_WidgOmatic

program was opened.

3. Right-click Rung 13 of the R02_Monitor routine and select Import Rungs.

4. Navigate to the 4-Controller Logic folder

within the toolkit’s files folder and open the

01_Machine Logic folder.

Your personal computer’s harddrive path is

C:\Program Files\RA_Simplification\

DMAT\B-Files\4-Controller Logic.

Rockwell Automation Publication IASIMP-QS022B-EN-P - April 2012

Page 8

Ch. 5 Example - Restore and Open a Preconfigured HMI Application

IMPORTANT

Follow these steps to restore the preconfigured HMI file and open in FactoryTalk View Studio software.

1. Navigate to the HMI application files within the toolkit’s file folder and open either the

PanelView Plus 1000 or PanelView Plus 600 folder, based on the terminal size and faceplate requirements

of your application.

The Equipment Status faceplate is compatible with PanelView Plus 700 or larger terminals. To take full advantage of all

faceplates, choose the PanelView Plus 1000 folder.

Your personal computer’s harddrive path is C:\Program Files\RA_Simplification\DMAT\B-Files\

5-HMI\ME\HMI Applications.

For the Widg-O-matic machine application example, the PanelView Plus 1000 folder was selected.

PanelView Plus Terminal and Faceplates Compatibility

Application Folder PanelView Plus Terminals Supported Faceplates Displays

PVP600

PVP1000

(1) The PanelView Plus 1000 Machine, Alarm History, and Equipment Status faceplate displays are sized at 640x480 (VGA) resolution. If full-sized displays are desired, open

display, select all (objects), group, and resize group. Some text editing for new display size may also be required.

Allen-Bradley, FactoryTalk, Integrated Architecture, Kinetix, PanelView, ProposalWorks, PowerFlex, Rockwell Software, Rockwell Automation, and RSLogix are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

PanelView Plus 400

PanelView Plus 600

PanelView Plus 700

PanelView Plus 1000

PanelView Plus 1250

PanelView Plus 1500

(1)

(1)

Machine Startup Display

Machine State Diagram Display

All Device Displays

Alarm History Display

Machine Startup Display

Machine State Diagram Display

All Device Displays

Alarm History Display

Equipment Status Display

Publication IASIMP-QS022B-EN-P - April 2012

Supersedes Publication IASIMP-QR022A-EN-P - October 2010 Copyright © 2012 Rockwell Automation, Inc . All rights reserved. Printed in the U.S.A.

Loading...

Loading...