Page 1

Deutsch

Eingangsdaten

Eingang (fest)

Temperaturbereich

Speisestrom

Ausgangsdaten

Ausgang

(kalibriert umschaltbar)

Bürde

bei Ausgangsstrom

bei Ausgangsspannung

Übertragungsfehler /

Genauigkeit

Temperaturkoeffizient

Sprungantwortzeit

Allgemeine Daten

Spannungsversorgung

Leistungsaufnahme

Betriebstemperaturbereich

Lagertemperatur

Abmessungen L/H/B mm

Isolationskoordination nach DIN EN50178, 04/98

Bemessungsspannung

Prüfspannung

Überspannungskategorie

Verschmutzungsgrad

* Tu 20 °C

PT100 2-/3-Leiter gem. EN 60751-1

(2-Leiter-Anschluss per Drahtbrücke zwischen Anschluss 2 + 3)

gemäß Best.-Nr.

0,8 mA

0...10V / 4...20mA / 0…5V

0...20mA (Werkseinstellung)

< 400 Ohm @ Versorgung ≥ 24 Vdc

> 10 kOhm

< 0,5% vom Messbereich

< 250 ppm/K vom Messbereich

< 0,7 sek

24 Vdc (±10%)

ca. 0,6 W

0...+55 °C

-25 °C...+85 °C

88 / 98 / 6,1

100 V

500 V

III

2

6. Technische Daten* 1. Allgemeine Hinweise

• Das Modul vor der Montage spannungsfrei schalten.

• Die Installation darf nur von qualifiziertem Fachpersonal

durchgeführt werden.

• Befolgen Sie alle nationalen elektrischen Bestimmungen.

Bei der Bereichsumschaltung ist auf

Schutzmaßnahmen gegen elektrostatische

Entladung (ESD) zu achten.

2. Anwendung

Die aktiven PT100/RTD analogen Signalwandler dienen zur

galvanischen Trennung und Wandlung von PT100-Signalen

in Normsignale 0(4) ... 20 mA und 0 ... (5)10 V.

Das Ausgangssignal ist über DIP-Schalter kalibriert

umschaltbar (siehe Gehäuseaufdruck).

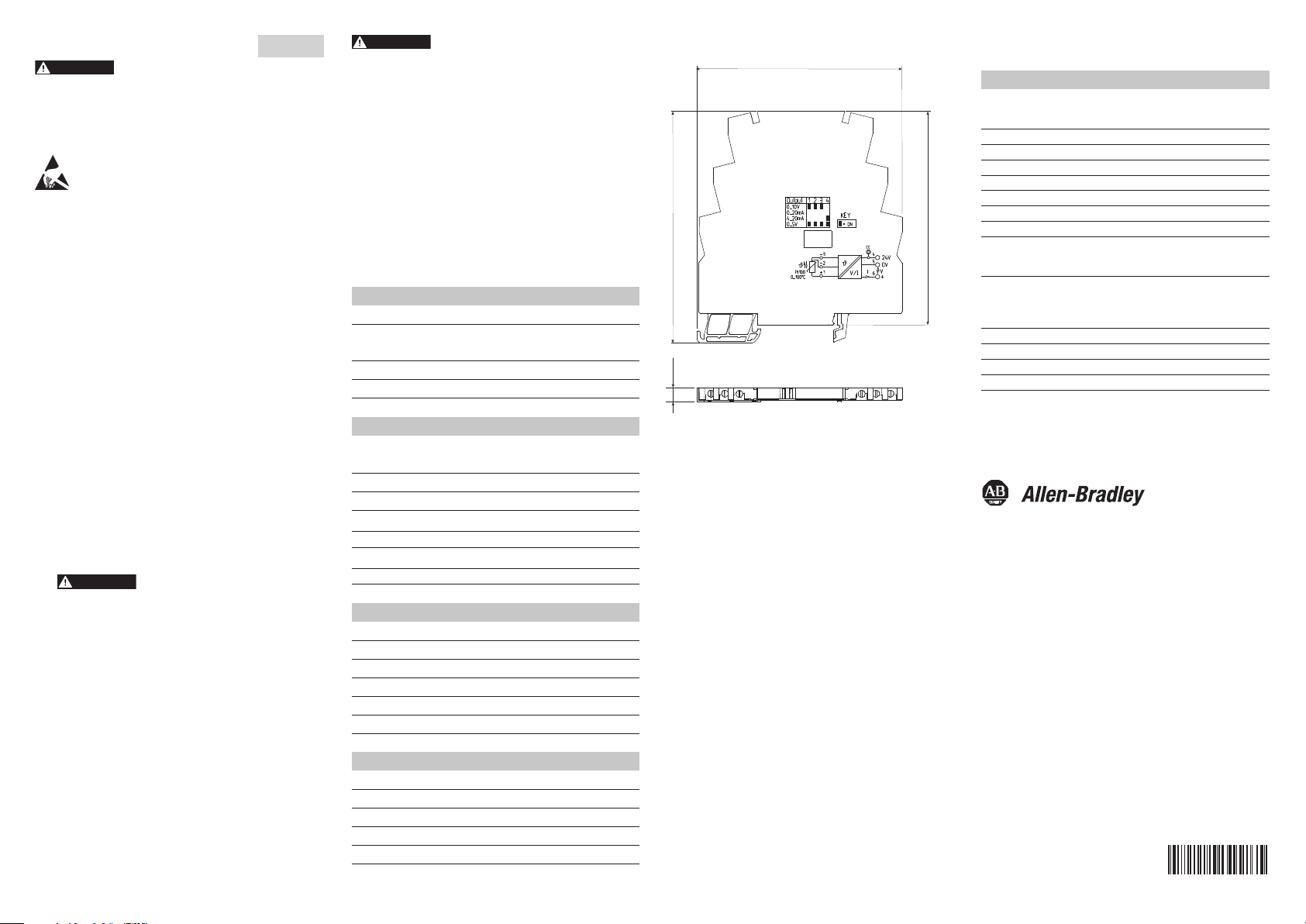

3. Konfigurierung

Stellen Sie die DIP-Schalter gemäß der Tabelle auf dem

Gehäuseaufdruck ein (Werkseinstellung 0 ... 20 mA).

4. Montage, elektrischer Anschluss

Die Analogsignalwandler werden auf TS35 Normschienen

aufgerastet und seitlich durch geeignete Endwinkel fixiert.

Klemmenbelegung siehe Gehäuseaufdruck.

Anschlussquerschnitt max. 2,5 mm

2

.

Das Produkt während des Betriebes nicht abklemmen,

solange es sich im Ex-Bereich befindet.

Das installierte Gehäuse muss mindestens eine Schutzart

IP54 nach der Richtlinie IEC 60529 erfüllen.

"Dieses Gerät darf nicht in Umgebungen mit einem

Verschmutzungsgrad größer 2 nach IEC 60664-1 installiert

werden.Alternativ kann das Gerät in einem Gehäuse mit

einer Schutzart von nicht weniger als IP64 nach der

Richtlinie IEC 60529 installiert werden."

"Steckverbinder dürfen nicht unter Spannung gezogen

werden."

T

amb

0 °C bis 55 °C

ACHTUNGACHTUNGACHTUNGACHTUNG

ACHTUNGACHTUNGACHTUNGACHTUNG

Caractéristiques d‘entrée

Entrées (fixe)

Plage de température

Courant d'alimentation

Caractéristiques de sortie

Sorties

(à calibre commutable)

Charge

pour courant de sortie

pour tension de sortie

Ondulation résiduelle

Coefficient de temp.

Fréquence limite

Caractéristiques générales

Tension d'alimentation

Puissance consommée

Plage de température

de fonctionnement

Température de stockage

Dimensions L/H/P mm

Coordination des isolements selon DIN EN50178, 04/98

Tension nominale

Tension d'essai

Classe de surtension

Degré de pollution

* Ta 20 °C

Français

PT100 2/3 fils selon EN 60751-1

(montage 2 fils par pontage filaire

entre bornes 2 et 3)

s'accorder références

0,8 mA

0...10V / 4...20mA

/ 0…5V

0...20mA (réglage d'usine)

< 400 Ohm @ Alimentation ≥ 24 Vdc

> 10 kOhm

< 0,5% de la plage de mesure

< 250 ppm/K de la plage de mesure

< 0,7 s.

24 Vdc (±10%)

env. 0,6 W

0...+55 °C

-25 °C...+85 °C

88 / 98 / 6,1

100 V

500 V

III

2

6. Caractéristiques techniques* 1. Remarques générales

• Déconnecter l’alimentation avant l’installation

• Installation uniquement par du personnel qualifié

• Respecter toutes les normes et instructions locales et

nationales en vigueur

Lors de la sélection des plages, veuillez prendre

les mesures nécessaires de protection contre les

décharges électrostatiques.

2. Utilisation

Les séparateurs actives PT100/RTD servent à la séparation

galvanique et à la conversion des signaux PT100 en signaux

normalisés 0(4) à 20 mA et 0 à (5)10 V.

Le calibre du signal de sortie se règle par commutateur DIP

(voir indication sur le boîtier).

3. Configuration

Régler les commutateurs DIP suivant le tableau imprimé sur

le boîtier (réglage usine 0 ... 20 mA).

4. Montage, raccordement électrique

Les séparateurs sont encliquetés sur des rails de norme

TS35 et fixé latéralement à l’aide d’une équerre adaptée.

Brochage : voir boîtier.

Section max. de raccordement : 2.5 mm

2

.

Ne pas déconnecter l’installation sous tension sauf si la zone

est réputée non dangereuse. Le coffret recevant les appareils

doit avoir une protection au moins IP54 selon CEI 60529.

Ce matériel est prévu pour être installé dans une zone de

degré de pollution inférieure ou égale à 2 telle que définie

dans la CEI 60664.1

Il est également possible d’installer le matériel dans un coffret

ayant un degré de protection au moins IP54 selon CEI

60529.

Ne pas séparer les connecteurs lorsqu’ils sont sous tension.

T

amb

0 °C à 55 °C

ATTENTIONATTENTION

ATTENTIONATTENTION

Page 2

931H-P2C1D-DC

Ty pe

Order No.

Qty.

Plug-In Jumper

Querverbindung

Connexion transvrsale

Plug-In Jumper, 2-pole, red 1492-CJLJ6-2-R 60

Plug-In Jumper, 3-pole, red 1492-CJLJ6-3-R 60

Plug-In Jumper, 10-pole, red 1492-CJLJ6-10-R 20

Plug-In Jumper, 41-pole, red 1492-CJLJ6-41-R 10

Plug-In Jumper, 2-pole, blue 1492-CJLJ6-2-B 60

Plug-In Jumper, 3-pole, blue 1492-CJLJ6-3-B 60

Plug-In Jumper, 10-pole, blue 1492-CJLJ6-10-B 20

Markers

Verbindermarkierer

Repérage de blocs de jonction 1492-M6X10 200

Power Supply

24 V DC Output

15 W 1606-XLP15E

30 W 1606-XLP30E

50 W 1606-XLP50E

100 W 1606-XLP100E

120 W (5 A) 1606-XLE120E

Accessories / Zubehör / Accessoires

Active Converter, PT100/RTD

931H-P2C1D-DC

Installation Instructions

Beipackinformation

Notice d’utilisation

DIR 10000043420

(Version 00)

10000043420

1. General instructions

• Disconnect power prior to installation

• Installation only by Qualified personnel

• Follow all applicable local and national electrical codes

During range selection, appropriate safety

measures against electrostatic discharge (ESD)

are to be considered.

2. Application

The PT100/RTD Active Converter is designed to galvanically

isolate and convert PT100 signals into standard signals

0(4) ... 20 mA and 0 ... (5)10 V.

The output signal is calibrated switch selectable via

DIP switches (see enclosure).

3. Configuration

Set the DIP switches according to the table printed on

the enclosure (factory setting 0 ... 20 mA).

4. Mounting, electrical connection

The signal conditioners are mounted on standard TS35

rails and fixed in position by a suitable end bracket.

For terminal assignments see enclosure.

Wire cross-section max. 2.5 mm

2

.

ATEX - Approval Rockwell Automation

UL DEMKO 09 ATEX 147279X 1201South Second Street

T II 3G Ex nAnL IIC T4 Milwaukee, Wi 53204

U.S.A.

UL Class 1, Division 2 Markings

for selected Signal Conditioners

A. “This equipment is suitable for use in Class I, Division 2,

Groups A, B, C and D hazardous locations or nonhazardous locations only or the equivalent.”

B. “WARNING: EXPLOSION HAZARD - Substitution of

components may impair suitability for use in Class I,

Division 2 environments.”

C. “WARNING: EXPLOSION HAZARD - The area must be

known to be nonhazardous before servicing/replacing

the unit and before installing or removing I/O wiring.”

D. “WARNING: EXPLOSION HAZARD - Do Not disconnect

equipment unless power has been disconnected and

the area is known to be nonhazardous.”

FOR INSTALLATION IN CLASS I, ZONE 2 LOCATIONS:

E. This equipment is to be installed into suitable enclosure,

providing a degree of protection not less than IP 54 in

accordance with IEC 60529 unless the apparatus is

intended to be afforded an equivalent degree of protection by location.

Do not disconnect while circuit is live unless area is known

to be non hazardous. The enclosure for the installation of

the apparatus shall have a protection not less than IP54 in

accordance with IEC 60529

"This device is to be installed in area of a pollution degree

of not more than pollution degree 2, as defined in IEC

60664-1. Alternatively the device may be installed into

enclosure providing a degree of protection not less than

IP 64 in accordance with IEC 60529."

“Connectors are not to be separated when they are

energized.”

T

amb

0 °C to 55 °C

English

PT 100 2-/3-Wire as in EN 60751-1

(2-Wire-Connection by putting

bridge between 2 + 3)

according Part No.

0.8 mA

0...10V / 4...20mA

/ 0…5V

0...20mA (factory setting)

<

400 Ohm @ power supply ≥ 24 Vdc

> 10 kOhm

< 0.5 % of selected range

< 250 ppm/K of selected range

< 0.7 sec.

24 Vdc (±10%)

approx. 0.6 W

0...+55 °C

-25 °C...+85 °C

88 / 98 / 6.1

100 V

500 V

III

2

6. Technical data*

Input data

Input (fix)

Temperature range

Sensor current

Output data

Output

(selectable)

Load resistance

Output current

Output voltage

Accuracy

Temperature coefficent

Response time

General data

Supply voltage

Power consumption

Operating temperature

Storage temperature

Dimensions L/H/B mm

Coordination of insulation acc. to DIN EN50178, 04/98

Rated voltage

Rated surge voltage

Overvoltage category

Contamination class

* Tu 20 °C

WARNINGWARNINGWARNINGWARNING

WARNINGWARNINGWARNINGWARNING

WARNINGWARNINGWARNINGWARNING

97,8

6,1

88

90

Loading...

Loading...