Page 1

Temperature Controllers

USER MANUAL

Bulletin 900-TC8, 900-TC16, & 900-TC32

Series B

Page 2

2

Page 3

3

ATTENTION

!

Important User Information

Because of the variety of uses for the prod ucts described in this publi cation,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that

each application and use meets all performance and safety requirements,

including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Rockwell Automation does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples sho wn

in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control (available

from your local Allen-Bradley sales office), describes some important

differences between solid-state equipment and electromechanical devices

that should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Safety Precautions

Safety Signal Words

This manual uses the following signal word to mark safety precautions for the

Bulletin 900-TC8, 900-TC16, and 900-TC32 Temperature/Process

Controllers.

These precautions provide important information for the safe application of

the Temperature/Process Controller. You must make sure to follow the

instructions provided in all safety precautions.:

Identifies information about practices or circumstance s

that can lead to personal injury or death, property damage

or economic loss

Page 4

4

IMPORTANT

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Identifies information that is critical for successful

application and understanding of the product.

Trademark List

900Builder and 900BuilderLite are registered trademarks of Rockwell Automation, Inc.

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following standards,

in whole or in part, documented in a technical construction file:

EN 61326 EMC Requirements — Electrical Equipment for Control,

Measurement and Laboratory Use

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61010-1 Safety Requirements

for Electrical Equipment for Control, Measurement and Laboratory Use —

General Requirements. For specific information, see the appropriate

sections in this publication, as well as the Allen-Bradley publication

Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, Publication 1770-4.1.

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Page 5

Table of Contents

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

European Communities (EC) Directive Compliance . . . . . . . . . 1-4

Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Preface

Bulletin 900 Input & Output

Overview

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-i

Meanings of Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-i

Series B Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-ii

Series B Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-ii

900-TC8x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-ii

900-TC16x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-ii

900-TC32x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-ii

Terminal Arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-iv

Body Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-v

900-TC8, 900-TC16, & 900-TC32 Ratings . . . . . . . . . . . . . . . . . . . . P-vi

Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-vi

Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-vii

Other Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-viii

Option Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-ix

How to Read Display Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-x

Chapter 1

I/O Configurations & Main Functions. . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Main Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Controller Hardware Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

900-TC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

900-TC16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

900-TC32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Front Panels & General Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Display Meanings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Operation Indicators 1,2,3... . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Basic Keypad Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Chapter 2

Preparations

1-1 Publication 900-UM007D-EN-E - January 2011

Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

System Wiring and Installation Guidelines. . . . . . . . . . . . . . . . . . 2-4

Panel Mounting — 900-TC8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting Up the 900-TC8 Controller with the Optional Units . . . 2-9

Page 6

1-2 Table of Contents

Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Bulletin 900 Wiring Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Wiring Guidelines and Precautions. . . . . . . . . . . . . . . . . . . . . . . 2-17

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Using the Direct PC Communications Port . . . . . . . . . . . . . . . . . . . 2-30

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Chapter 3

Configuration & Basic Operation

How Function Groups Are Configured and Operating the Keys on the

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Selecting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Changing Parameters/Loading Values into Controller Memory. 3-7

Communications Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Setting Up Communications Parameter Data . . . . . . . . . . . . . . . 3-9

Initial Setup Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Configuring the Input Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Input Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Selecting °C/°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Temperature Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Configuring the SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Changing the SP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Selecting PID Control or ON/OFF Control . . . . . . . . . . . . . . . . . . 3-16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2-PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

ON/OFF Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Configuring the Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Control Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Direct/Reverse Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Assigned Output Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Auxiliary Output Opening or Closing in Alarm . . . . . . . . . . . . . . . . 3-25

Executing the ON/OFF Control Method . . . . . . . . . . . . . . . . . . . . 3-25

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

ON/OFF Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

ON/OFF Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Determining PID Constants (AT, ST, Manual Setup) . . . . . . . . . . . 3-30

AT (Auto-Tuning) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

ST (Self-Tuning). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Conditions that Start Self-Tuning (SRT) . . . . . . . . . . . . . . . . . . 3-34

Self-Tuning (ST) Stable Range . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

RT (Robust Tuning). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Manual PID Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Alarm Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Alarm Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Publication 900-UM007D-EN-E - January 2011

Page 7

Table of Contents 1-3

PV Change Rate Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Heater Burnout Alarm (HBA), Heater Short Alarm (HSA), and Heater

Overcurrent Alarm (HOA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

HBA, HSA, and HOA Alarm Detection . . . . . . . . . . . . . . . . . . 3-46

Installing Current Transformers (CT). . . . . . . . . . . . . . . . . . . . . 3-48

How to Calculate Heater Current Detection Values . . . . . . . . . 3-50

Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Heater Burnout Alarm (HBA) Setup . . . . . . . . . . . . . . . . . . . . . 3-55

HS Alarm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Heater Overcurrent Alarm Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

Moving to the Advanced Setting Function Group . . . . . . . . . . 3-60

Configure Overcurrent Detection. . . . . . . . . . . . . . . . . . . . . . . . 3-61

Set-up of the No. 3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

MV Display for Heating and Cooling Control . . . . . . . . . . . . . . . . . 3-63

System Setup/Operational Considerations. . . . . . . . . . . . . . . . . . . . 3-65

Chapter 4

Parameter Adjustments &

Application Considerations

Shifting Input Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1-Point (Uniform) Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2-Point Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

How to Calculate Input Shift Values . . . . . . . . . . . . . . . . . . . . . . 4-3

Using the 1-Point Shift Method . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Using the 2-Point Shift Method . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Alarm Functions/Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Alarm Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Standby Alarm Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Alarm Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Summary of Alarm Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Configuration of Scaling Upper-Limits and Scaling Lower-Limits for

Analog Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Executing the Heating and Cooling Control Mode . . . . . . . . . . . . . 4-12

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Dead Band (Heating and Cooling Control) . . . . . . . . . . . . . . . . 4-13

Setup of Heating and Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Using the Event Input Feature — 900-TC8 & 900-TC16. . . . . . . . 4-16

Multi-SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Selecting Multi-SP by Keypad Operation . . . . . . . . . . . . . . . . . . 4-19

Multi-SP Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Executing RUN/STOP Controller Mode Change. . . . . . . . . . . 4-23

Switching Between Auto and Manual Control . . . . . . . . . . . . . . 4-23

Controlling the Start of the Simple Program Function . . . . . . . 4-23

Control by Inverting Direct/Reverse Operation . . . . . . . . . . . . 4-24

Publication 900-UM007D-EN-E - January 2011

Page 8

1-4 Table of Contents

Switching 100% AT Execute/Cancel . . . . . . . . . . . . . . . . . . . . . 4-24

Switching 40% ATExecute/Cancel . . . . . . . . . . . . . . . . . . . . . . 4-25

Switching Setting Change Enable/Disable. . . . . . . . . . . . . . . . . 4-25

Switching Alarm Latch Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Configuring the SP Upper- and Lower-Limit Values. . . . . . . . . . . . 4-26

Set Point Limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Set Point Limit Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Executing the SP Ramp Function to Limit the SP Rate of Change 4-29

SP Ramp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

SP Ramp Application Considerations. . . . . . . . . . . . . . . . . . . . . 4-30

To Move to the Advanced Setting Function Group . . . . . . . . . . . . 4-31

Using the Key Protect Function Group . . . . . . . . . . . . . . . . . . . . . . 4-33

Key Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

PV Color Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

PV Color Change Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Alarm Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Alarm Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Loop Break Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Loop Break Alarm (LBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Performing Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Manual MV Limit Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Using the Transfer Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Transfer Output Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Using the Simple Program Function . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Simple Program Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Operation at the Program End . . . . . . . . . . . . . . . . . . . . . . . . . . 4-69

Output Adjustment Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Output Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

MV at Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

MV at PV Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

Using the Extraction of Square Root Parameter . . . . . . . . . . . . 4-77

Setting the Rate of MV Variation . . . . . . . . . . . . . . . . . . . . . . . . 4-80

Setting the PF Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

Monitor/Setting Item. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Monitor/Setting Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Counting Control Output ON/OFF Operations . . . . . . . . . . . . . . 4-87

Control Output ON/OFF Count Function. . . . . . . . . . . . . . . . 4-87

Displaying PV/SV Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-90

Publication 900-UM007D-EN-E - January 2011

Page 9

Chapter 5

Table of Contents 1-5

Parameter Functions & Definitions

Conventions Used in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

About the Parameter Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Protect Function Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Move to Protect Function Group. . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Operation/Adjustment Protection . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Initial Setting/Communications Protection . . . . . . . . . . . . . . . . . 5-4

Setting/Configuration Change Protection . . . . . . . . . . . . . . . . . . 5-4

PF Key Protect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Parameter Mask Enable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Password to Move to Protect Function Group . . . . . . . . . . . . . . 5-5

Operation Function Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

PV (Process Value) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

PV/SP – Process Value/Set Point – No. 1 Display

PV/SP – Process Value/Set Point – No. 2 Display (900-TC8) . 5-8

No. 3 Display (900-TC8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Auto Manual Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Multi-SP (Set Point 0…3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Set Point During SP Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Heater Current 1 Value Monitor. . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Heater Current 2 Value Monitor. . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Leakage Current 1 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Leakage Current 2 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Program Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Soak Time Remain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

RUN/STOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Alarm Value 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Alarm Value 2 (900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . 5-17

Alarm Value 3 (900-TC8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Upper-Limit Alarm Value 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Lower-Limit Alarm Value 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Upper-Limit Alarm Value 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Lower-Limit Alarm Value 2 (900-TC8, 900-TC16) . . . . . . . . . . 5-19

Upper-Limit Alarm Value 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Lower-Limit Alarm Value 3 (900-TC8 only) . . . . . . . . . . . . . . . 5-20

MV Monitor (Heating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

MV Monitor (Cooling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Adjustment Function Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Adjustment Function Group Display . . . . . . . . . . . . . . . . . . . . . 5-24

AT Execute/Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Communications Writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Heater Current 1 Value Monitor. . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Heater Current 1 Value Monitor. . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Leakage Current 1 Monitor (900-TC8, 900-TC16) . . . . . . . . . . 5-28

Publication 900-UM007D-EN-E - January 2011

Page 10

1-6 Table of Contents

Leakage Current 2 Monitor (900-TC8, 900-TC16) . . . . . . . . . . 5-29

Heater Burnout Detection 1 (900-TC8, 900-TC16). . . . . . . . . . 5-30

Heater Burnout Detection 2 (900-TC8, 900-TC16). . . . . . . . . . 5-31

HS Alarm 1 (900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . 5-31

HS Alarm 2 (900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . 5-32

Set Point 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Set Point 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Set Point 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Set Point 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Temperature Input Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Upper-Limit Temperature Input Shift Value,

Lower-Limit Temperature Input Shift Value . . . . . . . . . . . . . . . 5-35

Proportional Band, Integral Time, Derivative Time . . . . . . . . . 5-35

Cooling Coefficient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Dead Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Manual Reset Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Hysteresis (Heating)

Hysteresis (Cooling). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Soak Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

Wait Band. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

MV at Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

MV at PV Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

SP Ramp Set Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

MV (Manipulated Variable) Upper-Limit,

MV (Manipulated Variable) Lower-Limit . . . . . . . . . . . . . . . . . . 5-42

MV Upper-Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

MV Lower-Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

MV (Manipulated Variable) Change Rate Limit, . . . . . . . . . . . . 5-43

Extraction of Square Root Low-cut Point,. . . . . . . . . . . . . . . . . 5-44

Monitor/Setting Item Level (900-TC8) . . . . . . . . . . . . . . . . . . . . . . 5-45

Monitor/Setting Item Display 1 to 5 . . . . . . . . . . . . . . . . . . . . . 5-45

Manual Control Function Group . . . . . . . . . . . . . . . . . . . . . . . . 5-46

PV/MV (Manual MV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Initial Setting Function Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Input Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Scaling Upper-Limit, Scaling Lower-Limit, Decimal Point . . . . 5-52

Temperature Units (°C/°F) Selection. . . . . . . . . . . . . . . . . . . . . 5-53

Set Point Upper-Limit, Set Point Lower-Limit . . . . . . . . . . . . . 5-54

PID ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

Standard or Heating/Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

ST Self-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

Program Pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-57

Control Period (Heat) ,Control Period (Cool) . . . . . . . . . . . . . . 5-57

Direct/Reverse Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Alarm Type for Alarm 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

Publication 900-UM007D-EN-E - January 2011

Page 11

Table of Contents 1-7

Alarm Type for Alarm 2 (900-TC8 & 900-TC16) . . . . . . . . . . . 5-59

Alarm Type for Alarm 3 (900-TC8) . . . . . . . . . . . . . . . . . . . . . . 5-59

Alarm 1 Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

Alarm 2 Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Alarm 3 Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Transfer Output Type (900-TC8, 900-TC16). . . . . . . . . . . . . . . 5-62

Transfer Output Upper-Limit

Transfer Output Lower-Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

Linear Current Output (900-TC8, 900-TC16) . . . . . . . . . . . . . . 5-64

Number of Multi-SP Uses (900-TC8, 900-TC16) . . . . . . . . . . . 5-65

Event Input Assignment (* 1 and 2) (900-TC8, 900-TC16) . . . 5-66

Extraction of Square Root Enable (900-TC8, 900-TC16) . . . . . 5-68

Move to Advanced Setting Function Group . . . . . . . . . . . . . . . 5-68

Advanced Setting Function Group . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

Parameter Initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

Multi-SP Uses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

SP Ramp Time Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

Standby Sequence Reset Method . . . . . . . . . . . . . . . . . . . . . . . . 5-72

Auxiliary Output * Open in Alarm . . . . . . . . . . . . .(* = 1 to 3) 5-73

HB ON/OFF (900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . 5-74

Heater Burnout Latch (900-TC8, 900-TC16). . . . . . . . . . . . . . . 5-74

Heater Burnout Hysteresis (900-TC8, 900-TC16) . . . . . . . . . . . 5-75

ST (Self-Tuning) Stable Range . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

α . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

AT Calculated Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

AT Hysteresis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

Limit Cycle MV Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

Input Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

Additional PV Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-78

Manipulated Variable (MV) Display . . . . . . . . . . . . . . . . . . . . . . 5-78

Automatic Display Return Time . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

Alarm 1 Latch, Alarm 2 Latch, Alarm 3 Latch. . . . . . . . . . . . . . 5-79

Protect Function Group Move Time . . . . . . . . . . . . . . . . . . . . . 5-80

Input Error Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

Cold Junction Compensation Method . . . . . . . . . . . . . . . . . . . . 5-82

MB Command Logic Switching . . . . . . . . . . . . . . . . . . . . . . . . . 5-82

PV Color Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-82

PV Stable Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-84

Alarm 1 ON Delay, Alarm 2 ON Delay, Alarm 3 ON Delay . . 5-85

Alarm 1 OFF Delay, Alarm 2 OFF Delay, Alarm 3 OFF Delay 5-86

Input Shift Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-86

MV at Stop and Error Addition . . . . . . . . . . . . . . . . . . . . . . . . . 5-87

Auto/Manual Selection Addition . . . . . . . . . . . . . . . . . . . . . . . . 5-87

Robust Tuning (RT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-88

Heater Short Alarm (HSA) Use (900-TC8, 900-TC16) . . . . . . . 5-88

Heater Short Alarm (HSA) Latch (900-TC8, 900-TC16). . . . . . 5-89

Publication 900-UM007D-EN-E - January 2011

Page 12

1-8 Table of Contents

Heater Short Alarm (HSA) Hysteresis

(900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-89

Loop Break Alarm (LBA) Detection Time. . . . . . . . . . . . . . . . . 5-90

Loop Break Alarm (LBA) Level . . . . . . . . . . . . . . . . . . . . . . . . . 5-90

Loop Break Alarm (LBA) Band . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

Control Output 1 Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . 5-92

Control Output 2 Assignment (900-TC8 & 900-TC16) . . . . . . 5-93

Auxiliary Output 1 Assignment. . . . . . . . . . . . . . . . . . . . . . . . . . 5-93

Auxiliary Output 2 Assignment (900-TC8, 900-TC16) . . . . . . . 5-94

Auxillary Output 3 Assignment. . . . . . . . . . . . . . . . . . . . . . . . . . 5-95

Character Select LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

Soak Time Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

Alarm SP Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-97

Manual MV Limit Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-97

PV Rate of Change Calculation Period. . . . . . . . . . . . . . . . . . . . 5-98

Automatic Cooling Coefficient Adjustment. . . . . . . . . . . . . . . . 5-98

Heater Overcurrent Use (900-TC8, 900-TC16) . . . . . . . . . . . . . 5-99

Heater Overcurrent Latch (900-TC8, 900-TC16) . . . . . . . . . . . 5-99

Heater Overcurrent Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . 5-100

(900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-100

PF Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-101

Monitor/ Setting Item * (*: 1 to 5) . . . . . . . . . . . . . . . . . . . . . . 5-102

PV/SP Display Screen Selection. . . . . . . . . . . . . . . . . . . . . . . . 5-103

MV Display Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-103

PV Decimal Point Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-104

PV Status Display Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-105

SV Status Display Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-106

Display Refresh Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-106

Control Output 1 ON/OFF Count Monitor . . . . . . . . . . . . . . 5-107

Control Output 2 ON/OFF Count Monitor

(900-TC8 & 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-107

Control Output 1 ON/OFF Count Alarm Set Value

(900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-107

Control Output 2 ON/OFF Count Alarm Set Value

(900-TC8, 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-108

ON/OFF Counter Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-108

Move to Calibration Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-109

Communications Setting Function Group . . . . . . . . . . . . . . . . . . . 5-109

Protocol Setting

Communications Unit No.

Communications Baud Rate

Communications Data Length

Communications Stop Bits

Communications Parity

Send Data Wait Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-110

Publication 900-UM007D-EN-E - January 2011

Page 13

Chapter 6

Table of Contents 1-9

Troubleshooting & Error

Indication

Error Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Input Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Display Range Exceeded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

AD Converter Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Memory Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Current Value Exceeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Heater Burnout Alarm (HBA)

Heater Short Alarm (HSA)

Heater Overcurrent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Heater Burnout Alarm (HBA), Heater Short Alarm (HSA), and

Heater Overcurrent Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

900-CPOEM1 USB-Serial Conversion Cable. . . . . . . . . . . . . . . A-5

Current Transformer (CT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Approximate External Dimensions . . . . . . . . . . . . . . . . . . . . . . A-7

Sensor Input Setting

and Indication Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Control Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Calibration

Appendix B

Parameter Operations List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Function Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Setup Function Group Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Parameter Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Appendix C

Parameter Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Registering Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

User Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Calibrating Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Registering Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Calibrating Thermocouples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Calibrating 0…50 mV Analog Input. . . . . . . . . . . . . . . . . . . . . . . . . C-10

Calibrating Platinum Resistance Thermometers. . . . . . . . . . . . . . . . C-12

Calibrating Analog Input (e.g., 4…20 mA Analog Input) . . . . . . . . C-14

Calibrating an Analog Current Input (900-TC8 & 900-TC16) . C-14

Publication 900-UM007D-EN-E - January 2011

Page 14

1-10 Table of Contents

Calibrating an Analog Voltage (e.g., 1…5V DC) Input

(900-TC8 & 900-TC16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Checking Indication Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-18

Checking Accuracy of a Thermocouple or Non-Contact

Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-18

Checking Indication Accuracy of a Platinum Resistance

Thermometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-19

Analog Input (900-TC & 900-TC16) . . . . . . . . . . . . . . . . . . . . . C-20

Appendix D

Glossary

Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Index

Publication 900-UM007D-EN-E - January 2011

Page 15

Preface

Conventions Used in This

Manual

Meanings of Abbreviations

The following abbreviations are used in parameter names, figures, and in text

explanations. These abbreviations mean the following:

Table P.A

Symbol Term

PV Process value

SP Set point

SV Set value

AT Auto-tuning

ST Self-tuning

HB Heater Burnout

HS Heater Short ➊

EU Engineering unit ➋

OC Overcurrent

LBA Loop Burnout Alarm

➊ A heater short indicates that the heater remains ON even when the control output from the Temperature

Controller is OFF because the SSR has failed or for any other reason.

➋ “EU” stands for Engineering Unit. EU is used as the minimum unit for engineering units such as °C, m, and g.

The size of EU varies according to the Input Type.

For example, when the input temperature setting range is –200…+1300°C, 1 EU is 1°C, and when the input

temperature setting range is –20.0…+500.0°C, 1 EU is 0.1°C.

For analog inputs, the size of EU varies according to the decimal point position of the scaling setting, and 1 EU

becomes the minimum scaling unit.

Note: For additional definitions of terms used in this manual, refer to

Appendix D, Glossary.

P-i Publication 900-UM007C-EN-E - January 2011

Page 16

P-ii Preface

Series B Controllers

Series B Upgrades

Series B controllers have the following upgrades.

900-TC8x

Although the upgraded controllers are compatible with the previous

controllers, terminal arrangements have been changed. Terminal sizes and

panel mounting depth have not been changed.

Other changes are outlined in the following tables. Refer to the relevant pages

in the manual for details.

900-TC16x

The upgraded controllers are basically compatible with the previous

controllers. Terminal arrangements, terminal sizes, and panel mounting depth

have not been changed.

900-TC32x

Model numbers have changed accompanying the introduction of universal

input capability. The default setting of the input type parameter of the

900-TC32x (models with resistance thermometers) has been changed from a

Pt100 resistance thermometer to a K thermocouple. Make sure the setting of

the input type parameter agrees with the temperature sensor that is being used.

The terminal block has also been changed, which means the wiring methods

and terminal arrangement are different.

Publication 900-UM007C-EN-E - January 2011

Page 17

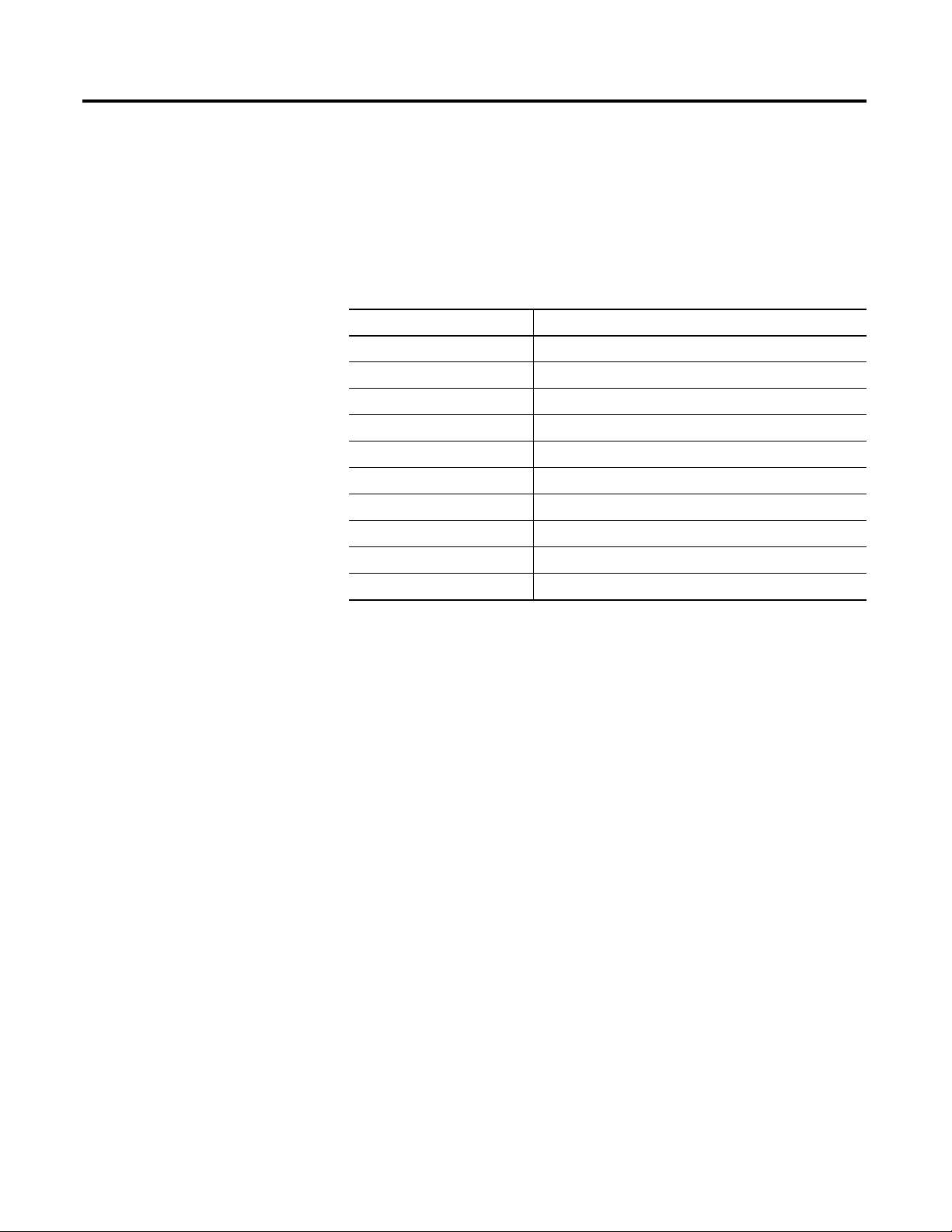

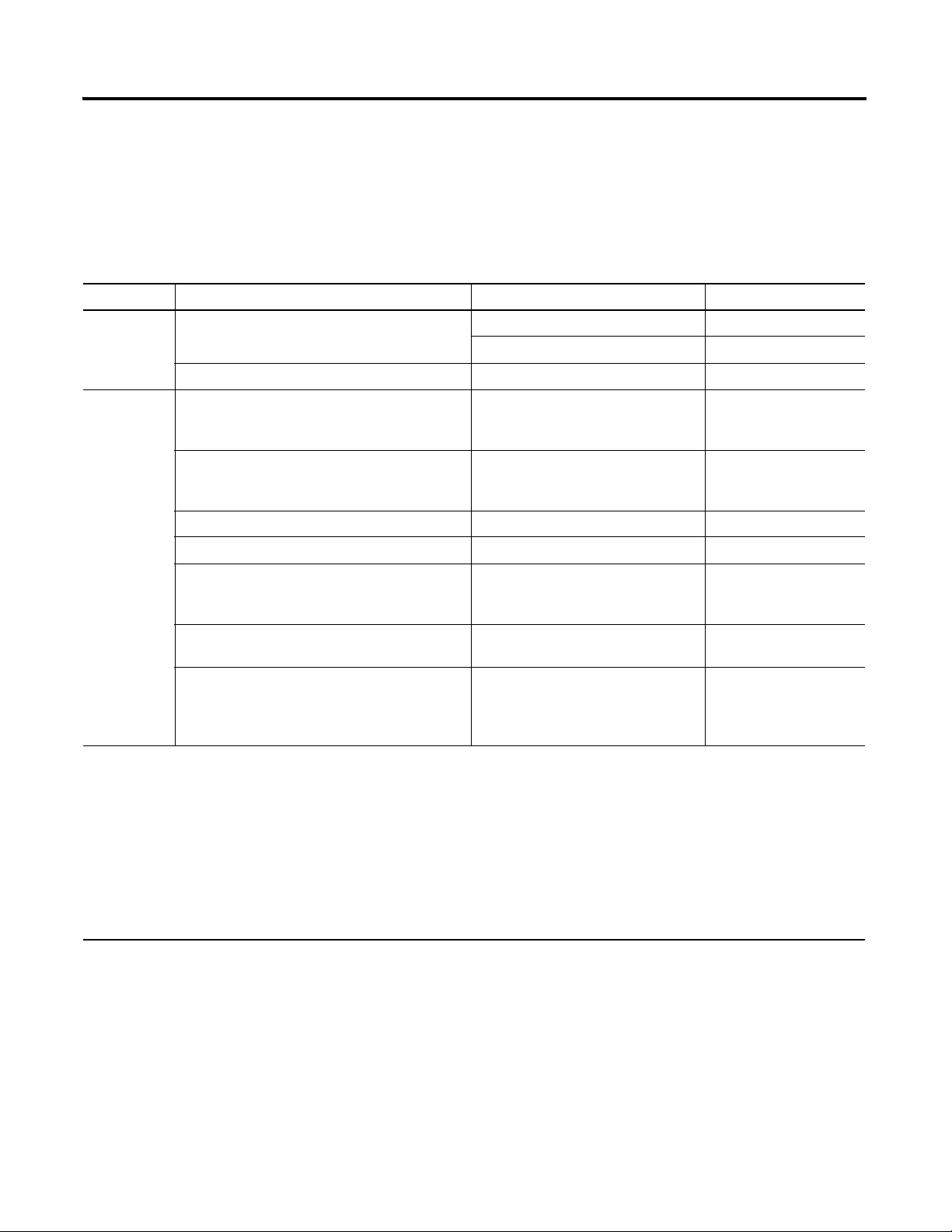

Table P.B

STOPOUT1

MANU

CMWOUT2

SUB2

SUB3

SUB1

HA

CMW STOP OUT

Preface P-iii

Series A Series B

900-TC16

900-TC8

ALM1

ALM2

ALM3

HA

OUT1

STOP

MANU

CMW

OUT2

ALM2

ALM1

HA

ALM3

OUT1

STOP

OUT2

CMW

MANU

• Number of displays: 2 (PV and SV)

ALM1

ALM2

ALM3

HA

OUT1

STOP

MANU

CMW

OUT2

• ALM indicator was changed to SUB indicator

• Number of displays: 3 (PV, SV, and MV) ➊

• ALM indicator was changed to SUB indicator.

900-TC32

• Display Segments – PV: 7 segments, SV: 7

• Character Heights – PV: 7 mm, SV: 3.5 mm

segments

CMW STOP OUT

SUB1

MANU

• Display Segments – PV: 11 segments, SV: 11

segments

• Character Heights – PV: 7.5 mm, SV: 3.6 mm

• Changes to Display Contents – “AL” LED indicator

eliminated, LED indicators and key indicator added

➊ A 2-level display is configured when shipped from the factory. A 3-level display is activated if parameters are

initialized.

Publication 900-UM007C-EN-E - January 2011

Page 18

P-iv Preface

++

−

B

+

V

mA

−

−

CT1

CT2

+

−

DO NOT

USE

DO NOT

USE

B

A

DO NOT

USE

DO NOT

USE

DO NOT

USE

One CT

Two CTs

Analog inputTC/Pt universal input

Control Output 2

Control Output 2

14

15

16

17

18

19

20

1

7

1212

1111

1010

9

8

2

4

3 5

6

InputInput

Power Power

SupplySupply

ControlControl

Output 1Output 1

AuxillaryAuxillary

Output 1Output 1

DO NOTDO NOT

USEUSE

A

B

B

Universal

TC/Pt Input

DO NOTDO NOT

USEUSE

B(+)

A(-)

RS-495

Communications

+

-

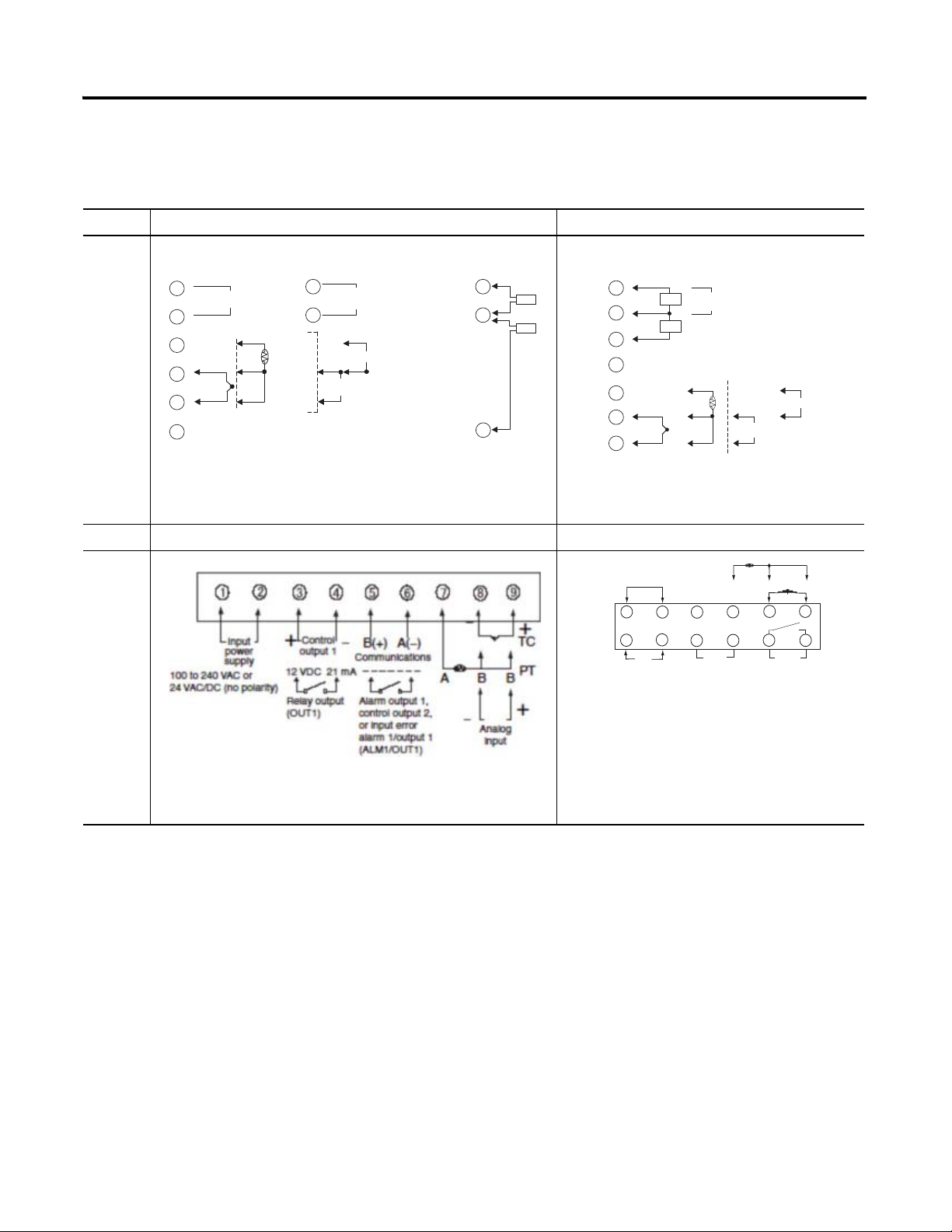

Terminal Arrangements

Table P.C — Terminal Arrangements

Series A Series B

One CT

Two CTs

14

15

19

CT1

CT2

900-TC8

Voltage output

14

Control Output 2

15

16

−

17

18

+

TC/Pt universal input

19

+

12 VDC , 21 mA

−

A

B

B

Long-life relay

output

14

Control Output 2

250 VAC, 3 A

15

(Resistive load)

−

V

+

Analog input

+

mA

−

Terminals 16...20 were changed and 1...15 were not.

900-TC16 --- No change for terminal layout

900-TC32

• 100 to 240 VAC

• 24 VAC/DC (no polarity)

Number of terminals: 9 (1 to 9)

Input terminals: 7 to 9

RS-485 communication terminals: 5 & 6

Publication 900-UM007C-EN-E - January 2011

Number of terminals: 14 (1 to 14)

Input terminals: 10 to 12

RS-485 communication terminals: 7 & 8

Page 19

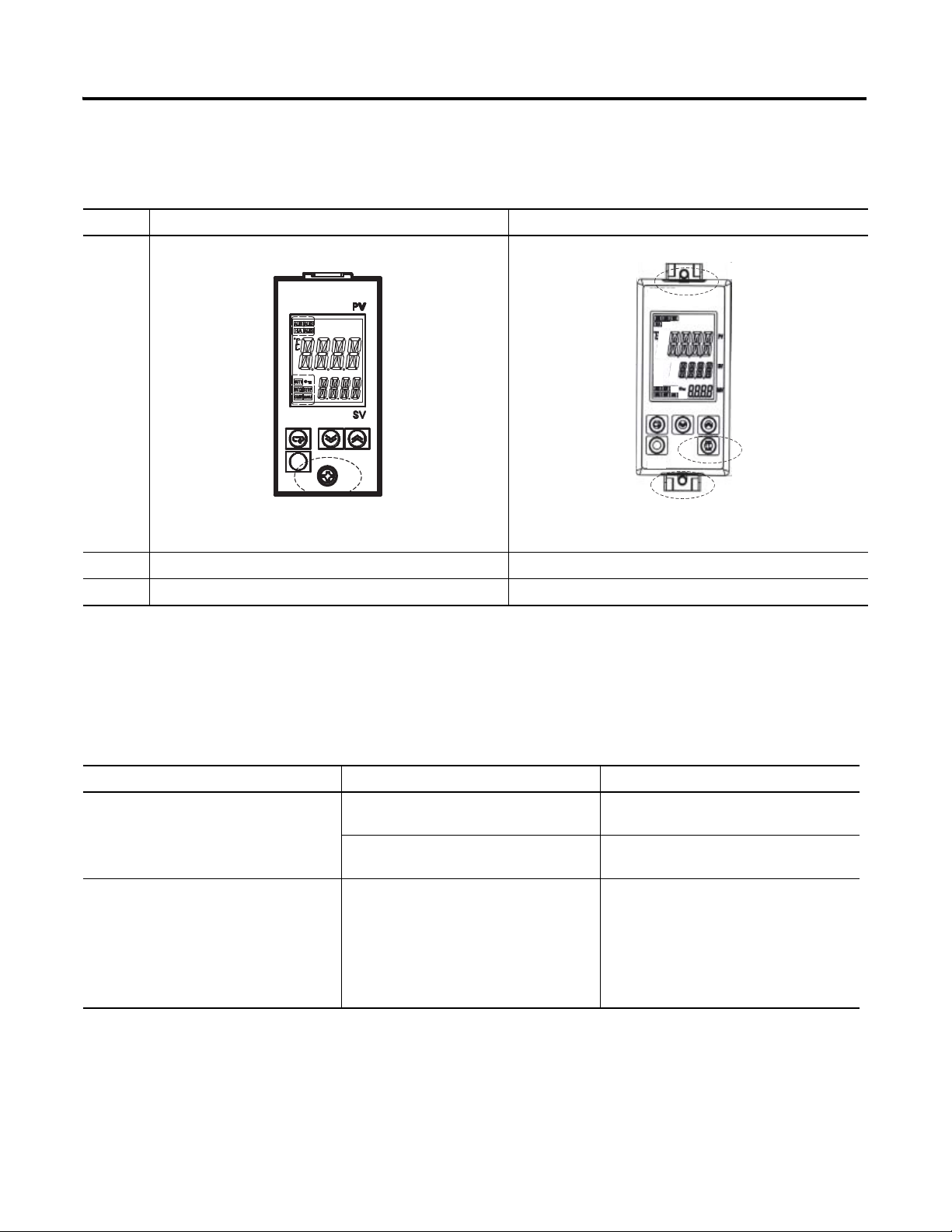

Body Removal

Table P.D — Body Removal

Series A Series B

Preface P-v

• Removal using screws

900-TC8

900-TC16 --- • No change for body removal

900-TC32 --- • No change for body removal

• Removal using hooks

900-TC8, 900-TC16, &

900-TC32 Ratings

Table P.E — 900-TC8, 900-TC16, & 900-TC32 Ratings

---

Input sensor types for thermocouple inputs

Input range for E thermocouple: 0...600 ºC

• Thermocouple: ±0.5% PV or ±1ºC,

• Platinum resistance thermometer:

Input accuracy

• Analog input: ±0.5% FS ± digit

Series A Series B

whichever is greater) ±1 digit

(±0.5%PV or ±1ºC, whichever is

greater) ± 1 digit

The following types of thermocouple input

were added: W and PLII.

Input range increased for E thermocouple:

-200...600 ºC

• Thermocouple: ±0.3% PV or ±1ºC,

whichever is greater) ±1 digit

• Platinum resistance thermometer:

(±0.2%PV or ±.08ºC, whichever is

greater) ± 1 digit

• Analog input: ±0.2% FS ± digit

Publication 900-UM007C-EN-E - January 2011

Page 20

P-vi Preface

PF Key

900-TC8, 900-TC16, &

900-TC32 Ratings

Table P.E — 900-TC8, 900-TC16, & 900-TC32 Ratings

---

Input sensor types for thermocouple inputs

Input range for E thermocouple: 0...600 ºC

• Thermocouple: ±0.5% PV or ±1ºC,

• Platinum resistance thermometer:

Input accuracy

• Analog input: ±0.5% FS ± digit

Series A Series B

whichever is greater) ±1 digit

(±0.5%PV or ±1ºC, whichever is

greater) ± 1 digit

The following types of thermocouple input

were added: W and PLII.

Input range increased for E thermocouple:

-200...600 ºC

• Thermocouple: ±0.3% PV or ±1ºC,

whichever is greater) ±1 digit

• Platinum resistance thermometer:

(±0.2%PV or ±.08ºC, whichever is

greater) ± 1 digit

• Analog input: ±0.2% FS ± digit

Influence of signal source resistance

Current outputs

Alarm outputs

Characteristics

• Thermocouple: 0.1ºC/Ω (except B,

R, S), 0.2ºC/Ω (B, R, S)

• Platinum resistance thermometer:

0.4ºC/Ω

• Current output resolution, approx.:

2,700

• 250 VAC, 1A (900-TC16 & 900-TC32) • 250VAC, 3A (900-TC16)

Table P.F — Characteristics

Series A Series B

--- PV Status Display

Front Panel

(900-TC8)

• Thermocouple: 0.1ºC/Ω (for all

specifications)

• Platinum resistance thermometer:

0.1ºC/Ω

• Current output resolution, approx.:

10,000

• 250VAC, 2A (900-TC32)

PF Key Added

Publication 900-UM007C-EN-E - January 2011

---

Inputs ---

PV/SP display selection for

three-level display

Square root extraction (for models

with analog inputs)

Page 21

Table P.F — Characteristics

Series A Series B

---

Outputs

--- MV change rate limiter

--- 40% AT

Preface P-vii

Control output ON/OFF count

alarm

Communications

Characteristics

Controls

Alarms

Other ---

Table P.G

Communication

Access Size

Communication

Service

Communications

buffer size

Baud rate

Automatic cooling coefficient

---

--- PV rate of change alarm

---

Series A Series B

Double word access only

---

40 bytes 217 bytes

38.4 kbits/s max. (900-TC08, 900-TC16)

19.2 kbits/s max. (900-TC32)

adjustment for heating/cooling

control

OC alarm (only for models with

heater burnout detection)

Inverting direct/reverse operation

using event inputs or

communications commands

Word access and double

word access

Composite Read from

Variable Area and

Composite Write to

Variable Area

57.6 kbits/s max.

External

communications

RS-485/RS-232C external

communications and communications

via 900BuilderLite ™ cannot be used at

the same time.

Publication 900-UM007C-EN-E - January 2011

RS-485/RS-232C external

communications and

communications via

900BuilderLite ™ can be

used at the same time.

Page 22

P-viii Preface

Modified section

Other Upgrades

Table P.H

Mounting Bracket

(900-TC8 only)

Terminal Cover for 900-TC16

Series A Series B

Note: The mounting bracket for the Series A

models cannot be used for Series B models.

Terminal Cover for 900-TC8

Note: The terminal covers for the Series A

models cannot be used for Series B models.

Note: The terminal covers for the Series A

models cannot be used for Series B models.

Publication 900-UM007C-EN-E - January 2011

Page 23

Preface P-ix

Option Units

(Series B Controller Compatible— One Option Unit per Controller)

This unit provides communications event input etc. functionality.

Table P.I

Bulletin No. Name Function Cat. No. (Series)

900-TC8

(Series B)

900-TC16

(Series B)

➊ Enables direct RS-232 connection to personal computer using 900BuilderLite™ software. A Cat. No. 900-CP1X cable or equivalent is

also required.

➋ Provides two event inputs. Allows selecting up to 4 different pre-configured set points, controller Run/Stop or Auto/Manual mode,

from 2 external inputs.

➌ Heater burnout is not available for 0...20 or 4…20 mA analog output style 900-TC16 controllers such as the 900-TC16AC.

➍ To obtain 57.6 k baud rate, Series B communication units must be used with any Series A or Series B 900-TC8 controller catalog

number.

➎ Series B option units must be used with Series B 900-TC16 controllers. Series A option units cannot be used with Series B controllers

and vice versa.

➏ Series B provides 57.6 K baud rate.

Communications Unit

Event Input Unit Event Input➋ 900-TC8EIM(A)

Communications and 1-Phase Heater Burnout Unit

and Heater Short

Event Input Unit with 1-Phase Heater Burnout and

Heater Short

Event Input Unit Event Input➋ 900-TC16NACEIM(B)➎

Communications Unit RS-485 communications 900-TCNACCOM(B)➎➏

Communications and 3-Phase Heater Burnout and

Heater Short Unit

Communications and Second Voltage (SSR) Output

Unit

1-Phase Heater Burnout and second voltage (SSR)

output

RS-232C communications➊ 900-TC8232 (B)➍

RS-485 communications 900-TC8COM(B)➍

RS-485 communications with

single-phase heater burnout (open) and

heater short-circuit failure detection➌

Event Input with single-phase heater

burnout (open) and heater short-circuit

failure detection➋➌

RS-485 communications with 3-phase

heater burnout (open) and heater

short-circuit failure detection

RS-485 communications and a second

voltage (SSR) output

1-Phase Heater burnout (open) and

heater short-circuit failure detection

with a second control voltage (SSR)

output

900-TC16NCOM(B)➎➏

900-TC16NEIM(B)➎

900-TC16NCOMP3(B)➎➏

900-TC16NCOMV2(B)➎➏

900-TC16P1V2(B)➎

Publication 900-UM007C-EN-E - January 2011

Page 24

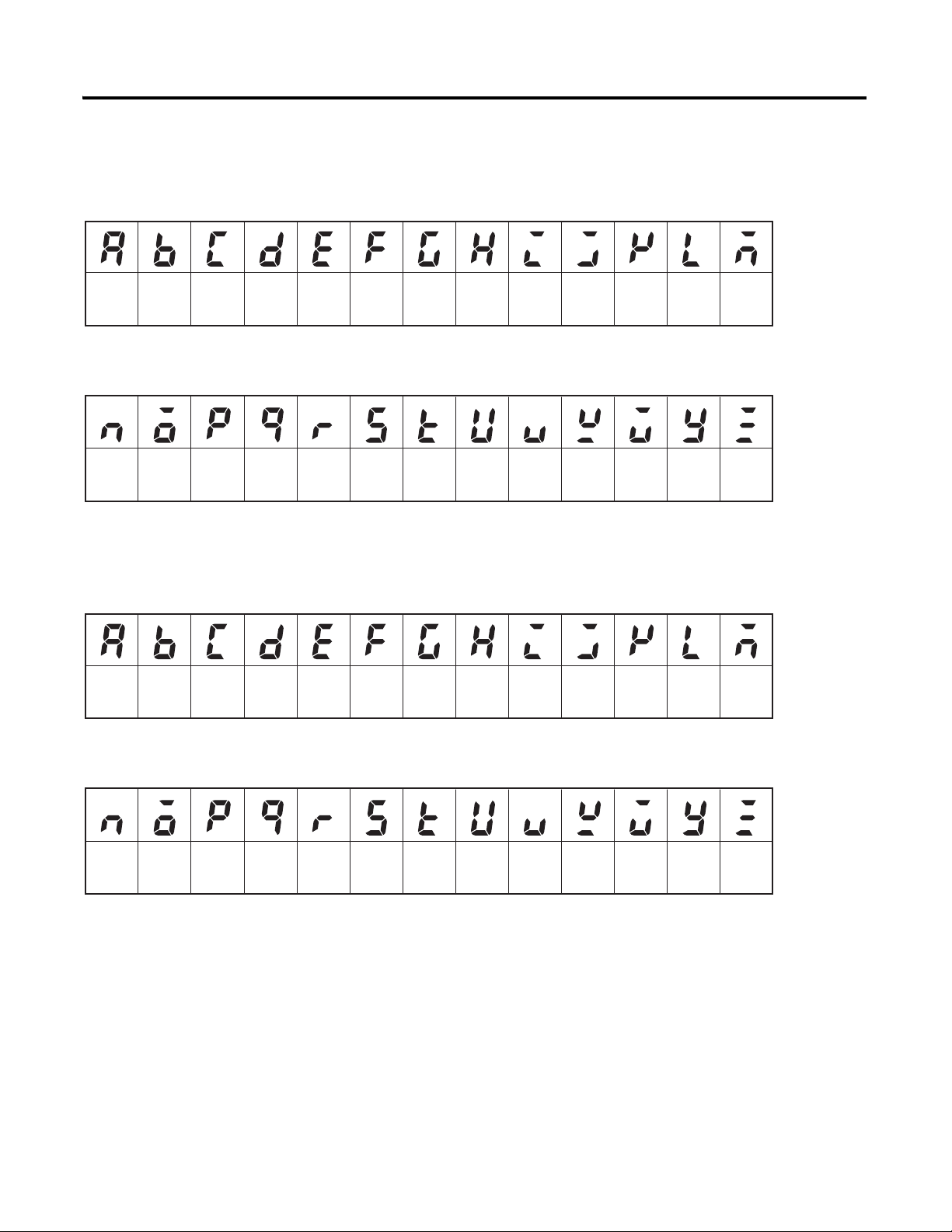

P-x Preface

ABCDEFGHI JKLM

NOPQRSTUVWXYZ

Symbol

Symbol

Alphabet

Alphabet

ABCDEFGHI JKLM

NOPQRSTUVWXYZ

Symbol

Symbol

Alphabet

Alphabet

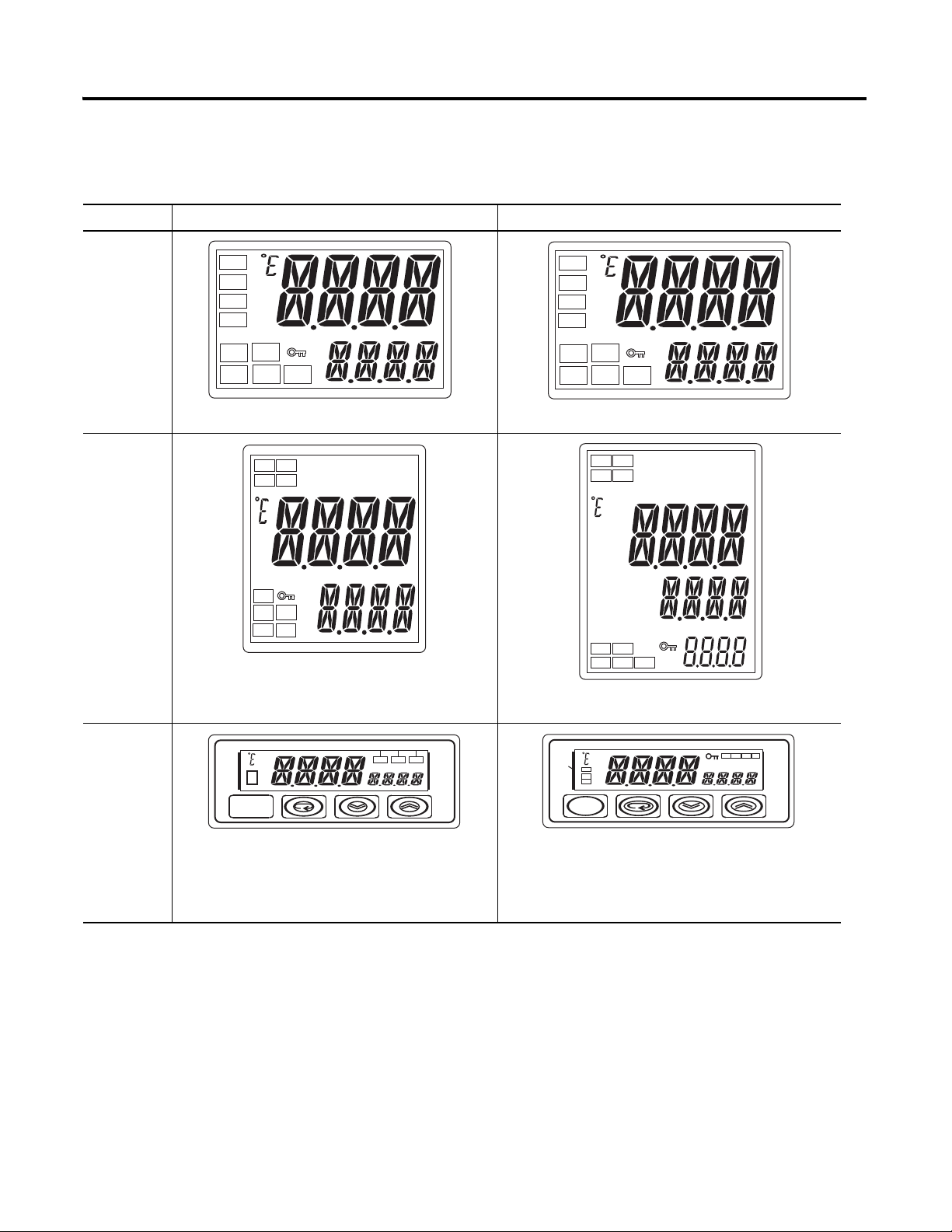

How to Read Display

Symbols

The following table shows the relationship between the symbols exhibited on

the controller’s front panel displays to alphabet characters.

Table P.J 11 — Segment Display Selection

The Character Select parameter in the Advanced Setting function group can be

turned OFF to display the following 7-segment characters.

Table P.K 7 — Segment Characters

Publication 900-UM007C-EN-E - January 2011

Page 25

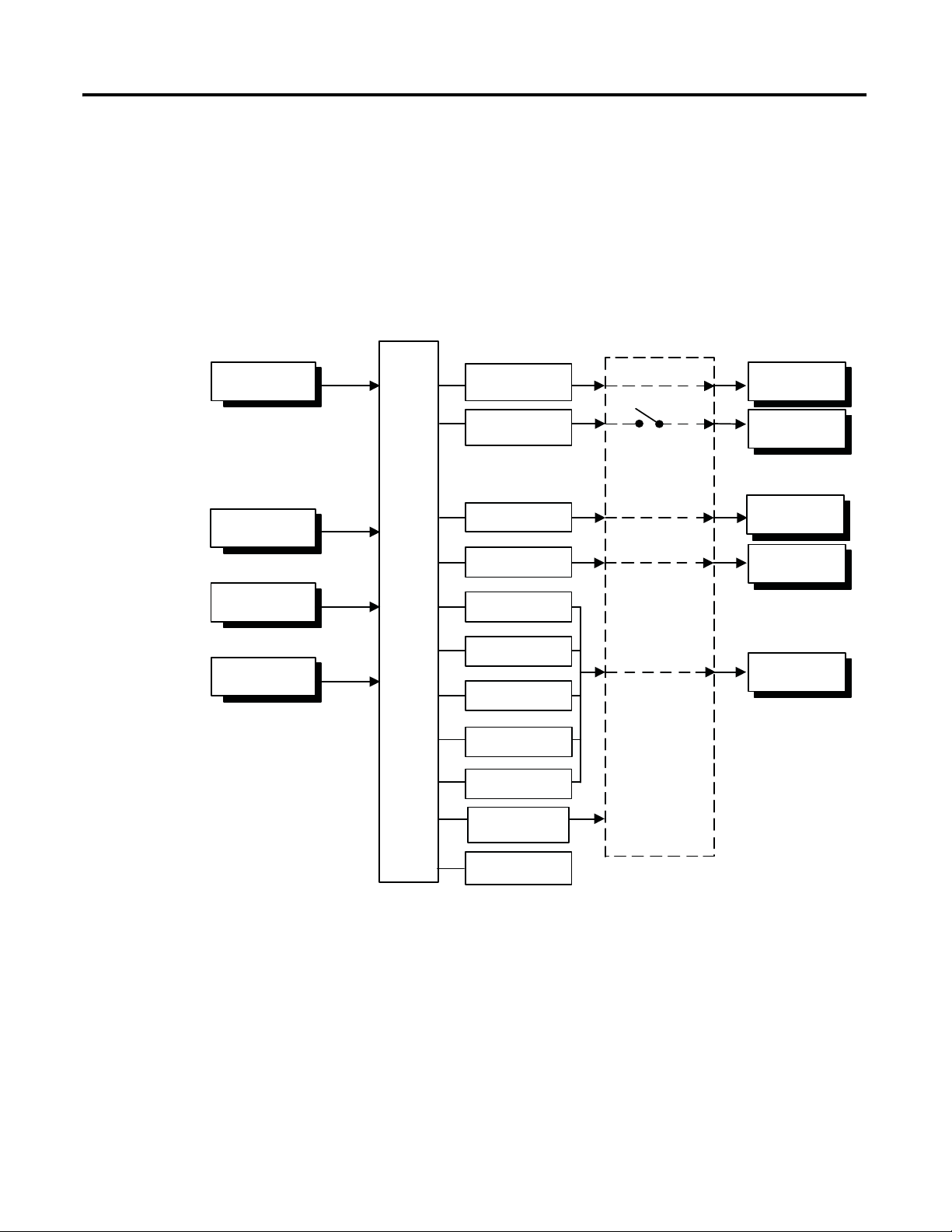

I/O Configurations & Main

Overcurrent Alarm

Temperature Input

or Analog Input

Control

Section

CT1 Input

CT2 Input

Event Inputs

2 Channels

Set point input functions

from external digital switches:

• RUN/STOP

• Program Start

• Auto/Manual

Control Output

Heating

Control Output

Cooling

Control Ouput 1

Control Ouput 2

Auxillary Output 3

Auxillary Output 2

Auxillary Output 1

Auxillary Output 3

Auxillary Output 2

Auxillary Output 1

HB Alarm

HS Alarm

Input Error

Simple Program

END Output

Communications

Function

QQ303T

Heating/Cooling

Chapter

Bulletin 900 Input & Output Overview

1

Functions

Figure 1.1 — 900-TC8 I/O Configuration

1-1 Publication 900-UM007D-EN-E - January 2011

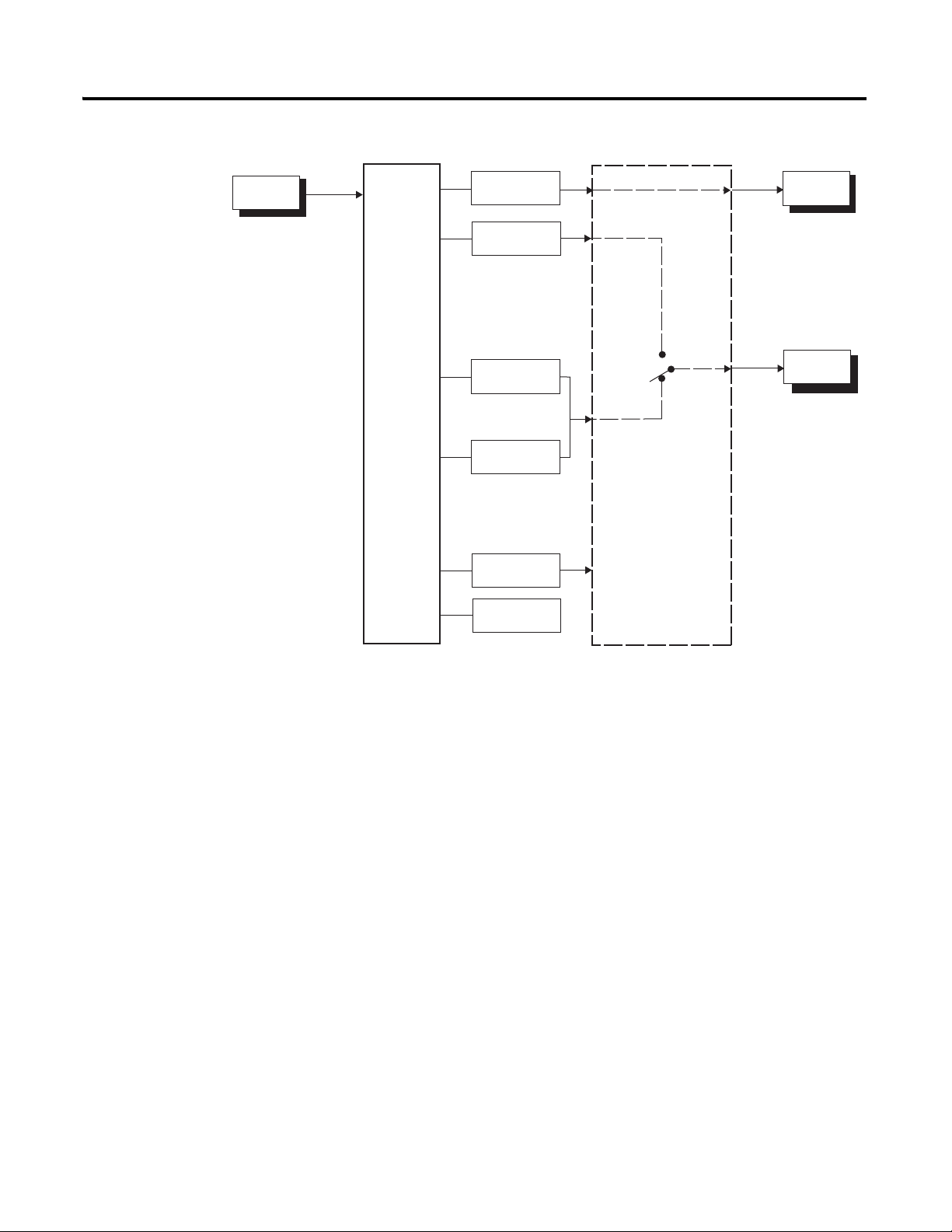

Page 26

1-2 Bulletin 900 Input & Output Overview

Temperature Input

or Analog Input

CT1 Input

CT2 Input

Event Inputs

2 Channels

Set point input functions

from external digital switches:

• RUN/STOP

• Program Start

• Auto/Manual

Control

Section

Control Output

Heating

Control Output

Cooling

Auxillary Output 2

Auxillary Output 1

Auxillary Output 2

Auxillary Output 1

Control Ouput 1

Control Ouput 2

Heating/Cooling

Overcurrent Alarm

HB Alarm

HS Alarm

Input Error

Simple Program

END Output

Communications

Function

QQ303T

Figure 1.2 — 900-TC16 I/O Configuration

Publication 900-UM007D-EN-E - January 2011

Page 27

Figure 1.3 — 900-TC32 I/O Configuration

Bulletin 900 Input & Output Overview 1-3

Temperature

Input

Control

Section

Control Output

(Heating)

Control Output

(Cooling)

Alarm 1

Input Error

Program End

Output

Communications

Function

Heating/

Cooling

Standard

Control

Output 1

Auxillary

Output 1

Bulletin 900-TC8, 900-TC16, and 900-TC32 temperature controllers allow the

user to:

• Select from thermocouple and platinum RTD temperature sensors, plus

non-contact temperature sensor and analog voltage or current inputs.

➊

• Individually assign the function for each output by changing the

configured values of the following parameters: Control Output 1,

Assignment, Control Output 2 Assignment

Assignment

➊, and Aux 3 Assignment (900-TC8).

➊, Aux 1 Assignment, Aux 2

• Select heating and cooling control in addition to standard control

• Select AT (Auto-Tuning) and ST (Self-Tuning) as tuning functions

• Use multi-SP, switch between automatic and manual operation,

start/reset the simple program function, and initiate the RUN/STOP

function according to event input.

➊

• Use the Heater Burnout Alarm (HBA) and Heater Short Alarm (HSA)

function.

➊

• Use the communications function (for units equipped with the optional

communications function modules)

• Calibrate sensor input

• Configure the color of the PV display to switch between amber, red, and

green, making the process status easy to understand at a glance.

➊ The Bulletin 900-TC32 Temperature Controller does not support this function

Publication 900-UM007D-EN-E - January 2011

Page 28

1-4 Bulletin 900 Input & Output Overview

Features

• Watertight construction (equivalent to IP66 indoor use).

• Conform to cULus/IEC safety standards and EMC standards.

Main Functions

The following introduces the main functions of the Bulletin 900-TC8,

900-TC16, and 900-TC32 temperature controllers. For details on each

function and how to use them, refer to Chapter 3 and onward.

• Input Sensor Types — The following input sensors can be connected

for temperature input:

– Thermocouple: K, J, T, E, L, U, N, R, S, B, W, PL11

– Infrared non-contact temperature sensor type: Type K thermocouple

(10…70XC), K (60…120XC), K (115…165XC), K (160…260XC)

– Platinum resistance thermometer: Pt100, JPt100

– Analog millivolt input: 0…50 mV

• High level analog inputs:

– Current input:4…20 mA DC, 0 to 20 mA DC

– Voltage input:1…5V DC, 0…5V DC, 0…10V DC

• Control Output — Control output is either an On/Off

electro-mechanical relay (EMR) ON/OFF triac output (AC only)

On/Off voltage (input to solid-state relay) output, or analog current

(DC: 4...20 mA or 0…20 mA) output

• Triac Relay Outputs

closing andopening the AC voltage circuit, thereby eliminating relay

chatter and arcing and improving durability versus an EMR. However, if

high levels of noise or surge are imposed between the output terminals,

short-circuit faults may occasionally occur. If the triac output becomes

permanently shorted, there is the danger of fire due to overheating of

the heater element. To avoid this danger, design safety into the system,

including measures to prevent excessive temperature rise and fire. Take

countermeasures such as installing a surge absorber. As an additional

safety measure, provide error detection in the control loop. Use the

Loop Break Alarm (LBA) and Heater Short Alarm (HSA) that are

provided for Bulletin 900 temperature controllers.

➊ The Bulletin 900-TC32 Temperature Controller does not support this function

➊

➊, Refer to Table 1.B or 1.D.

➊ — use semiconductors for switching when

➊,

Publication 900-UM007D-EN-E - January 2011

Page 29

Bulletin 900 Input & Output Overview 1-5

1

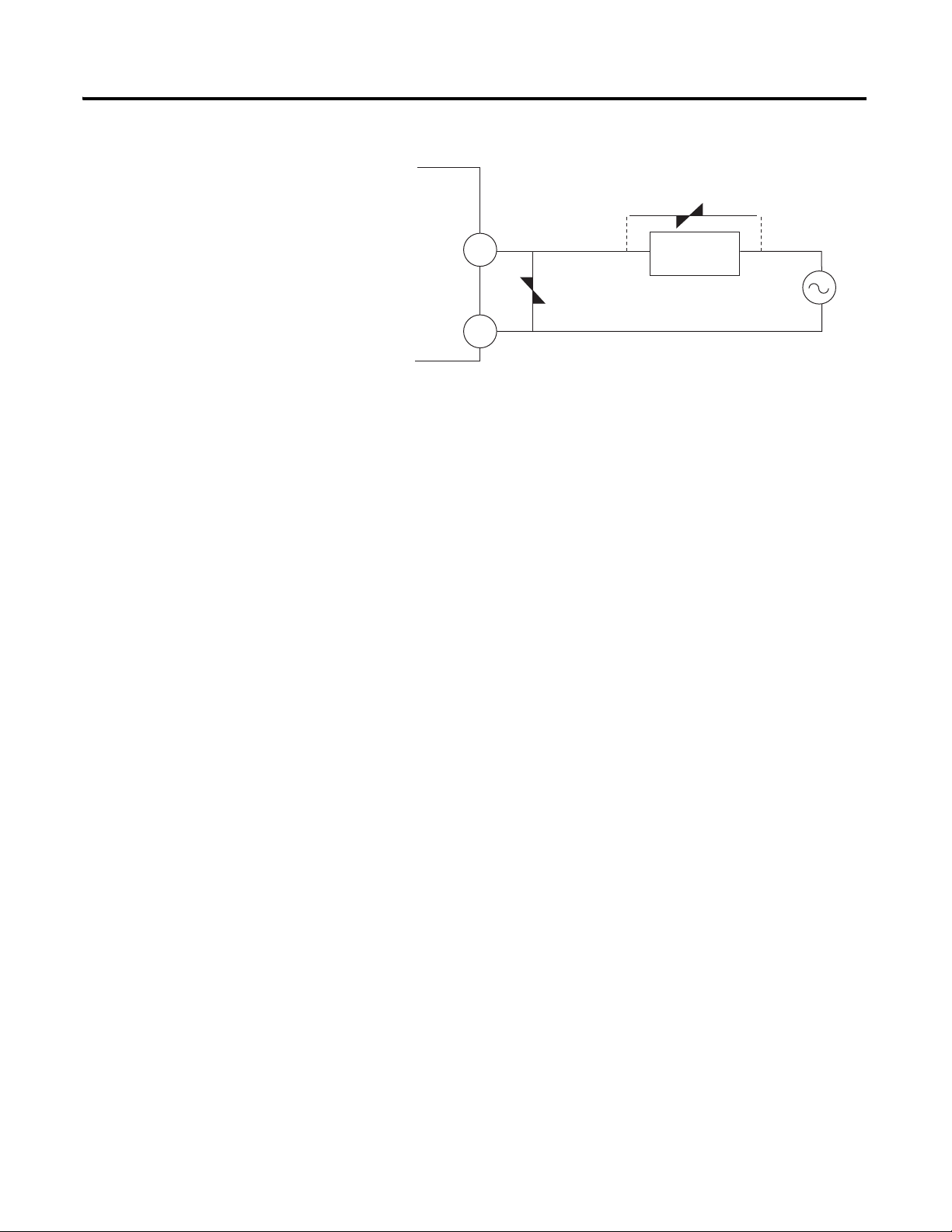

2

Triac

Relay Output

Varistor

Varistor

Inductive

Load

Figure 1.4 — Triac Diagram

Select a surge absorber that satisfies the following conditions.

Publication 900-UM007D-EN-E - January 2011

Page 30

1-6 Bulletin 900 Input & Output Overview

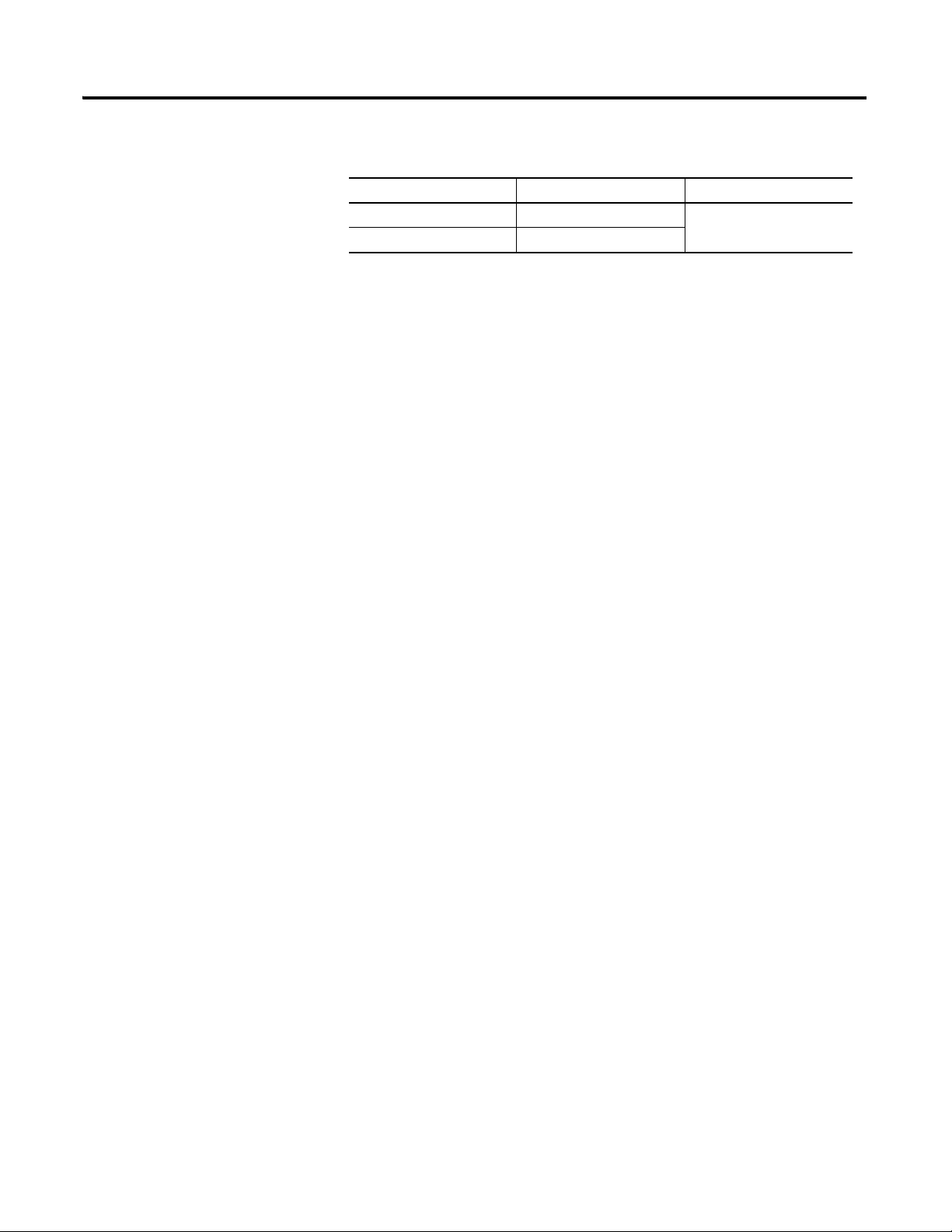

Table 1.A — Surge Absorber Selection

Voltage Used Varistor Voltage Surge Resistance

100…120V AC 240…270V

200…240V AC 440…470V

1000 A minimum

• Always connect an AC load to the triac relay output. The output will not

turn OFF if a DC load is connected.

• Alarms — Alarms are supported on the Bulletin 900 temperature

controllers. You can configure the alarm type and alarm value, or Upper

and Lower-Limit alarms.

If necessary, a more comprehensive alarm function can be achieved by

configuring the Standby Sequence, Alarm Hysteresis, Close in

Alarm/Open in Alarm and Alarm Latch ON/OFF parameters.

When the input error output is configured to ON, Alarm Output 1

turns ON when an input error occurs.

• Control Adjustment — Optimum PID constants can be configured

easily by using the AT (Auto-Tuning) and ST (Self-Tuning) parameters.

• Event Input — When the optional event input unit is mounted, the

following functions can be achieved by event input:

Multiple set point selection (multi-SP max. 4 points), RUN/STOP

mode change switching between automatic and manual operation, and

starting/stopping the simple program. Refer to Table 1.C and 1.E.

• HBA and HS Alarms — The Heater Burnout Alarm (HBA) and

Heater Short Alarm (HSA) and heater overcurrent function is

supported by selecting the appropriate controller (900-TC8) or option

module (900-TC16). Refer to Table 1.B for the TC8 and Table 1.E for

the TC16.

• Communications Function — Personal computer (PC)

communicationsare supported when the option communications unit is

mounted on the temperature controller. Refer to Table 1.C and 1.E.

Note: The PC must have 900BuilderLite software installed.

Note: 900-TC protocol is an integrated general-purpose serial

communications protocol.

Publication 900-UM007D-EN-E - January 2011

Note: Modbus is a communications control method conforming to the RTU.

Mode of Modicon Inc.'s Modbus Protocol.

Note: The 900-TC16 and 900-TC32 do not support the RS-232C interface.

Page 31

Bulletin 900 Input & Output Overview 1-7

Controller Hardware

Versions

The following tables provide a list of controller base features with associated

Cat. Nos.

Publication 900-UM007D-EN-E - January 2011

Page 32

1-8 Bulletin 900 Input & Output Overview

900-TC8

Table 1.B — Controller Versions

DIN Size

(mm)

1/8th DIN

(48 x 96 x 78)

No. of

Alarms

3

Sensor Input

Ty pe

Thermocouple

or RTD

Power

Supply

Voltage

100…240V

AC

Control

Output 1

Ty pe

Relay On/Off NA Yes (1-Phase) 900-TC8RGTH1Z25

Volts On/Off

(SSR)

Analog NA No 900-TC8ACGTZ25

Relay On/Off NA Yes (1-Phase) 900-TC8RGTH1U25

Control

Output 2

Ty pe

NA No 900-TC8RGTZ25

Volt On/Off

(SSR)

NA Yes (3-Phase) 900-TC8RGTH3Z25

NA Yes (1-Phase) 900-TC8VGTH1Z25

NA No 900-TC8VGTZ25

Triac On/Off

(3 A)

Volt On/Off

(SSR)

NA Yes (3-Phase) 900-TC8VGTH3Z25

Triac On/Off

(3 A)

Volt On/Off

(SSR)

Supports

Heater Burnout

Alarm

No 900-TC8RVGTZ25

No 900-TC8VYGTZ25

No 900-TC8VVGTZ25

No 900-TC8ACYGTZ25

No 900-TC8ACVGTZ25

Cat. No. for

Enhanced

900-TC8 Line

Analog

Current and

Voltage

Publication 900-UM007D-EN-E - January 2011

NA No 900-TC8RGTU25

24V AC/DC

100…

240V AC

Volts On/Off

(SSR)

Analog NA No 900-TC8ACGTU25

Relay On/Off NA Yes (1-Phase) 900-TC8RABH1Z25

Volts On/Off

(SSR)

Analog NA No 900-TC8ACABZ25

NA Yes (1-Phase) 900-TC8VGTH1U25

NA No 900-TC8VGTU25

NA No 900-TC8RABZ25

NA Yes (1-Phase) 900-TC8VABH1Z25

NA No 900-TC8VABZ25

Triac On/Off

(3 A)

No 900-TC8VYABZ25

Note: To implement the HBA and HSA function, a current transformer (Cat.

No. 900-CT1 or 900-CT2) is required. A current transformer is NOT

provided with the controller.

Note: When the heating and cooling function or the HBA or HSA is used,

one of the alarm outputs will be disabled for each function used.

Page 33

Table 1.C — Controller Option Units

Event Out Comms Cat. No. for Enhanced Option Units Series

— RS232 900-TC8232B B

Option Unit

— RS485 900-TC8COMB B

Yes — 900-TC8EIMA A

900-TC16

Table 1.D — Controller Versions

Bulletin 900 Input & Output Overview 1-9

DIN Size

(in mm)

1/16th DIN

Number of

Alarms

2

Sensor Input

Ty pe

Thermocouple or

RTD

Analog Current and

Voltage

Power Supply

Voltage

100…240V AC Relay On/Off 900-TC16RGTZ25

24V AC/DC Relay On/Off 900-TC16RGTU25

100…240V AC Relay On/Off 900-TC16RABZ25

24V AC/DC Relay On/Off 900-TC16RABU25

Control Output

Ty pe

Triac On/Off (3 A) 900-TC16YGTZ25

Volts On/Off (SSR) 900-TC16VGTZ25

Analog Current 900-TC16ACGTZ25

Volts On/Off (SSR) 900-TC16VGTU25

Analog Current 900-TC16ACGTU25

Triac On/Off (3 A) 900-TC16YABZ25

Volts On/Off (SSR) 900-TC16VABZ25

Analog Current 900-TC16ACABZ25

Volts On/Off (SSR) 900-TC16VABU25

Analog Current 900-TC16ACABU25

Cat. No for Enhanced

900-TC16 Line

Publication 900-UM007D-EN-E - January 2011

Page 34

1-10 Bulletin 900 Input & Output Overview

Table 1.E — Controller Option Units

DIN Size

(in mm)

1/16th DIN

Number of

Alarms

1

Heater

Burnout Event Out Comms

1-Phase HB — RS485 — 900-TC16NCOM B

— — RS485 — 900-TC16NACCOM

1-Phase HB Yes — — 900-TC16NEIM

— Yes — — 900-TC16NACEIM

3-Phase HB — RS485 — 900-TC16NCOMP3

— — RS485 Yes 900-TC16NCOMV2

1-Phase HB — — Yes 900-TC16P1V2

Voltage (SSR)

Control Output 2

Cat. No. for Enhanced

Option Units Series

➊ Series B option units must be used with Series B controllers. DO NOT use series B option units

with Series A controllers.

900-TC32

Table 1.F — Controller Versions

Sensor Input

Ty pe

Thermocouple

or RTD

Power Supply

Voltage

100…240V AC Relay On/Off Yes 900-TC32CRGTZ25

24V AC/DC Relay On/Off Yes 900-TC32CRGTZ25

Control Output

Ty pe

Volts On/Off (SSR) Yes 900-TC32CVGTZ25

Relay On/Off No 900-TC32RGTZ25

Volts On/Off (SSR) No 900-TC32CVGTZ25

Volts On/Off (SSR) Yes 900-TC32CVGTZ25

Relay On/Off No 900-TC32RGTZ25

Volts On/Off (SSR) No 900-TC32CVGTZ25

Comm Function

(RS-445)

Cat. No for Enhanced

900-TC32 Line

Publication 900-UM007D-EN-E - January 2011

Page 35

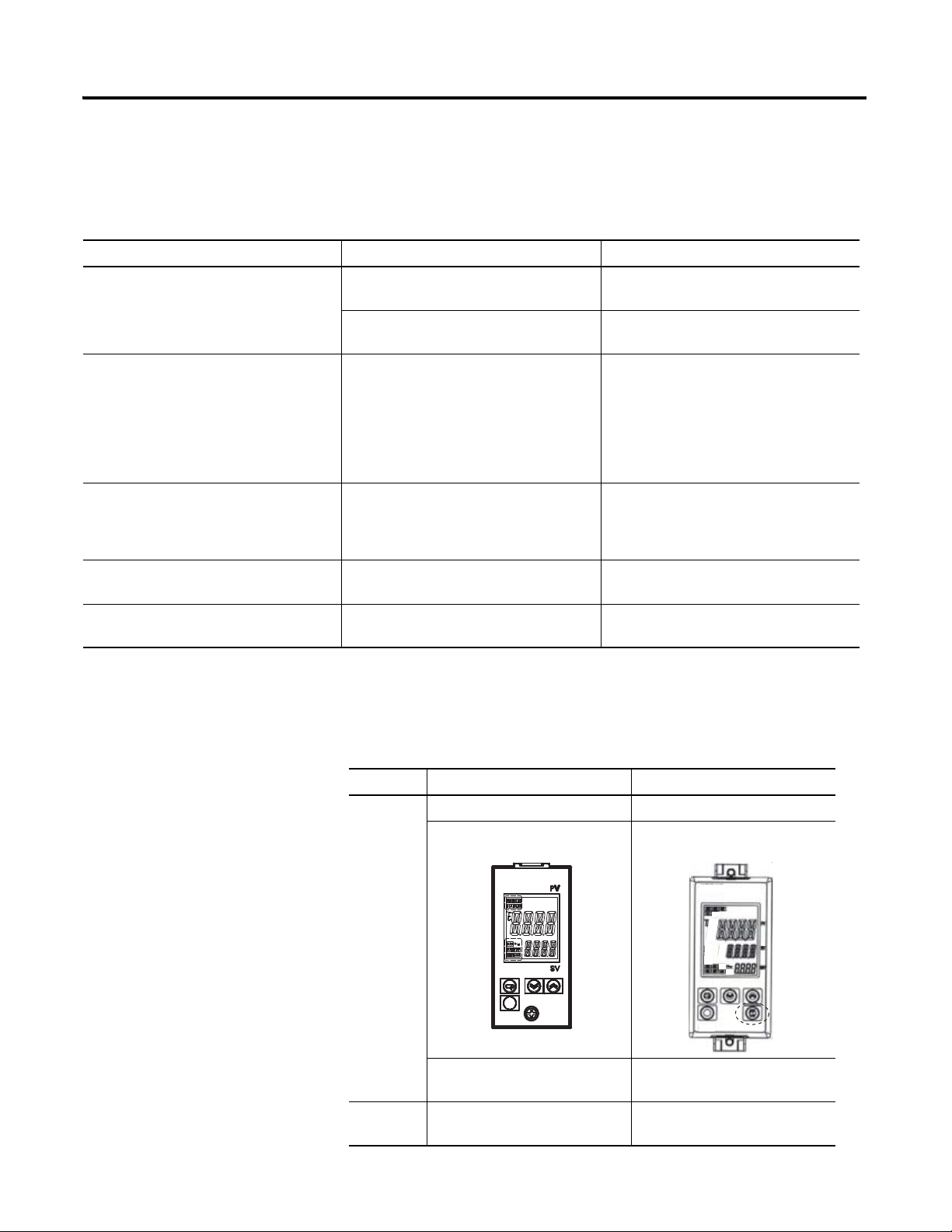

Bulletin 900 Input & Output Overview 1-11

PF

A/M

MV

SV

PV

SUB2

SUB3

STOPOUT1

MANU

CMWOUT2

SUB1

HA

Operation Indicators

Temperature Unit

Operation Indicators

Mode Key

No.1 Display

No.2 Display

No.3 Display

Up Key

Down Key

Function Key/

Auto/Manual Key

Function Group Key

Mode Key

Temperature Unit

Operation Indicators

No. 1 Display

No. 2 Display

Up Key

Function Group Key

Down Key

Front Panels & General

Functions

Figure 1.5 — Bulletin 900-TC8

Figure 1.6 — Bulletin 900-TC16

Publication 900-UM007D-EN-E - January 2011

Page 36

1-12 Bulletin 900 Input & Output Overview

SUB2

SUB3

STOPOUT1

MANU

CMWOUT2

SUB1

HA

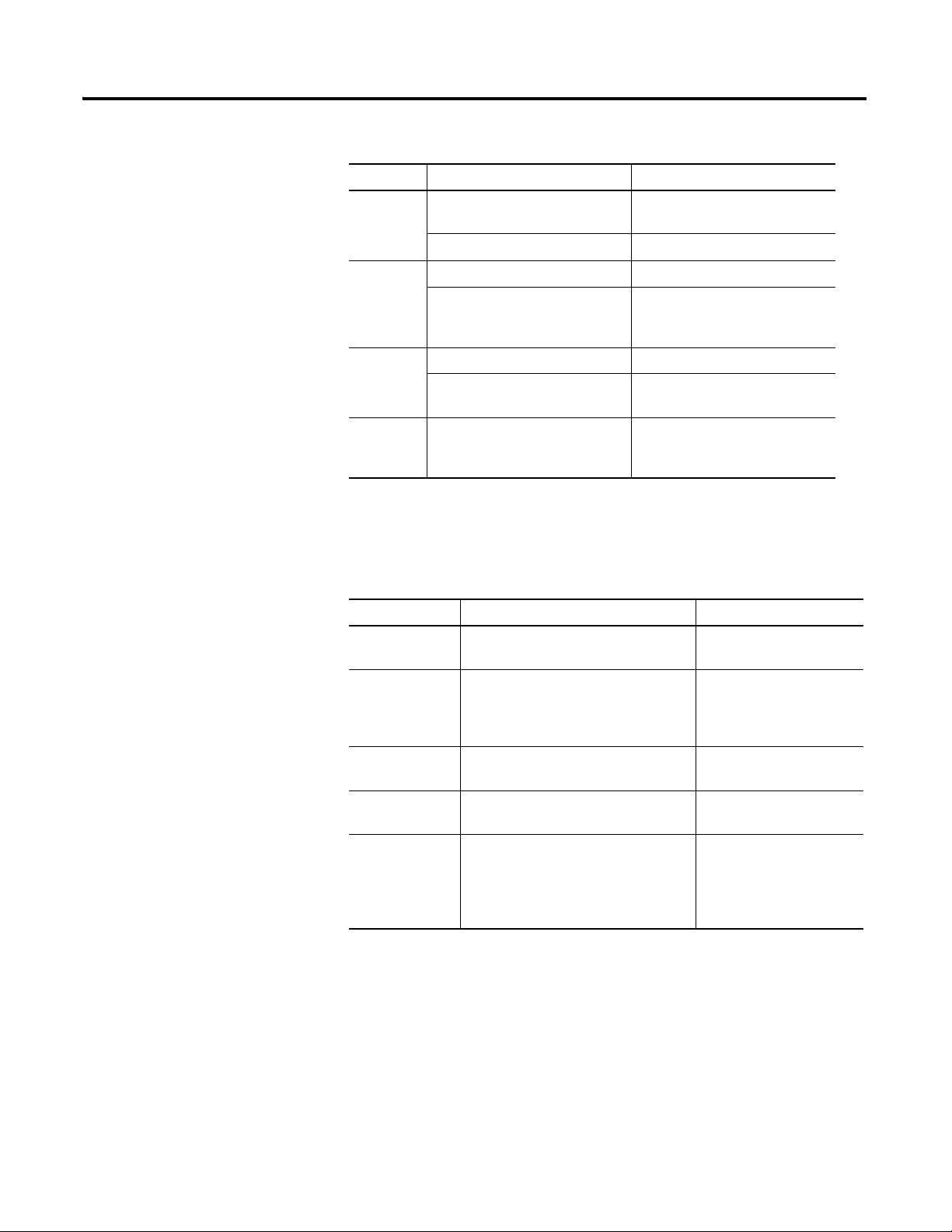

Figure 1.7 — Bulletin 900-TC32

Display Meanings

Display Meaning

No. 1 Displays the Process Value or Parameter Type during configuration. Lights for

No. 2 Displays the Set Point, parameter operation read value, manipulated variable,

No. 3

(900-TC8 only)

approximately 1 second during startup.

or during configuration, the value of the displayed (No. 1 display) parameter.

Displays MV, soak time remaining, or multi SP. Lights for approximately 1

second during startup. A 2-level display is configured when shipped from the

factory. A 3-level display is activated if parameters are initialized.

Publication 900-UM007D-EN-E - January 2011

Page 37

Bulletin 900 Input & Output Overview 1-13

Operation Indicators 1,2,3...

Operation

Indicator Definition Function

SUB 1 Sub 1 Lights when the function configured for the Auxiliary Output 1 Assignment parameter

SUB2 Sub 2 900-TC8 and 900-TC16 Only:

SUB3 Sub 3 900-TC8 Only:

HA Heater Burnout, Heater Short Alarm, Heater

OUT1 Control Output 1 Lights when the control output function assigned to control output 1 turns ON. For a

OUT2 Control Output 2 900-TC8 and 900-TC16 Only:

STOP Operation Stopped Lights when operation is stopped. During operation, this indicator lights when

CMW Communications Writing Lights when communications writing is enabled and is not lit when it is disabled.

MANU Manual Mode Lights when the auto/manual mode is configured to manual mode.

c or f

Overcurrent Detection Output Display

Key Lights when setting change protect is ON (i.e., when the up and down Keys are

Temperature Unit The temperature unit is displayed when the display unit parameter is configured to a

is ON.

Lights when the function configured for the Auxiliary Output 2 Assignment parameter

is ON.

Lights when the function is configured for the Auxiliary Output 3 Assignment

parameter is ON.

900-TC8 and 900-TC16 Only:

Lights when a heater burnout, heater short alarm, or heater overcurrent occurs.

current output, however, OFF for a 0% output only.

Lights when the control output function assigned to control output 2 turns ON. For a

current output, however, OFF for a 0% output only.

operation is stopped by an event or by key input using the RUN/STOP function.

disabled by protected status.

temperature. Indication is determined by the currently selected Temperature Unit

parameter value. When the parameter value is configured for °C, c is displayed, and

when configured for °F, f is displayed. The display flashes during self-tuning (ST)

operation.

Publication 900-UM007D-EN-E - January 2011

Page 38

1-14 Bulletin 900 Input & Output Overview

PF

A/M

+

+

+

or

Key Definition Function

Function (Auto/Manual) 900-TC8 Only:

Function Group Select Press this key to select the desired function group. The groups are selected in the following order:

Mode Select Press this key to select the various parameters within each function group. The selection of

Basic Keypad Functions

The following describes the basic functions of the front panel keys.

This is a function key. When it is pressed for at least 1 second, the function configured in the PF

Setting parameter will operate. Example: When A-M (auto/manual) is selected in the PF Setting

parameter (initial value: A-M), the key operates as an auto/manual switch, switching between

Auto Mode and Manual Mode. If the key is pressed for more than 1 second (regardless of key

release timing), the mode will switch.

Operation function group ←→ Adjustment function group, Initial Setting function group ←→

Communications Setting function group.

parameters can be reversed by holding this key down.

Up Each press of this key increments values displayed on the No. 2 (SV) display. Holding down this

key continuously increments values.

Down Each press of this key decrements values displayed on the No. 2 (SV) display. Holding down this

key continuously decrements values.

Key Combination —

Function Group and Mode Select

Key Combination —

Function Group and Up or

Function Group and Down

This key combination settings the Bulletin 900 to the Protect function group. For details on the

Protect function group, refer to Chapter 5 , Parameter Functions & Definitions.

To restrict changing parameter values and to prevent accidental or incorrect operations, these

keys require simultaneously pressing of the key along with the or key.

The key applies only to the parameter configured for the Password to Move to Protect

function group . Refer to Chapter 5 for more detailed information on this function group.

Publication 900-UM007D-EN-E - January 2011

Page 39

Preparations

Front View Side View Back View

Allen-Bradley

900-TC8

6.0

79.2

112

20

8

8

8

Allen-Bradley

All

Br

6

Chapter

2

Hardware Installation

Approximate Dimensions

The recommended panel thickness for mounting the 900-TC16 and 900-TC32

is 1 to 5 mm and the 900-TC8 is 1 to 8 mm.

Note: Dimensions are in millimeters. Dimensions are not intended to be used

for manufacturing purposes.To convert millimeters to inches, multiply

by 0.0394.

Figure 2.1 — 900-TC8

Figure 2.2 — 900-TC16

48 4

en-

2-1 Publication 900-UM007D-EN-E- January 2011

900-TC1

44.

4.

Page 40

2-2 Preparations

48

35

24

99

44.8

22

2

1 2 3 4 5 6

7 8 9 10 11 12

(48 x number of units -2.5)

45

92

92

120 min.

➊

60 min.

Figure 2.3 — 900-TC32

Panel Cutout Dimensions

Dimensions are in millimeters. Dimensions are not intended to be used for

manufacturing purposes.

Figure 2.4 — 900-TC8

Publication 900-UM007D-EN-E - January 2011

Page 41

60

min.

45

Figure 2.5 — 900-TC16

45

Figure 2.6 — 900-TC32

x60 min.

(48 number of units -2.5)

Preparations 2-3

45

Publication 900-UM007D-EN-E - January 2011

Page 42

2-4 Preparations

ATTENTION

!

• Horizontal group-mounting of two or more temperature controllers, or

mounting temperature controllers above each other may cause heat to

build up inside the temperature controllers. This will shorten their

service life. When mounting temperature controllers like this, consider

forced cooling measures, such as a cooling fan.

• If forced air cooling is used, limit cooling to the terminal block. Rapid

variation or transients in temperature at the terminal block may result in

a measurement error.

System Wiring and Installation Guidelines

Risk of Electrical Shock

• Devices are Open Type, Listed Process Control

Equipment and must be mounted in an enclosure.

• More than one disconnect switch may be required to

de-energize the equipment before servicing.

• Signal inputs are SELV, limited energy.

• To reduce risk of fire or electrical shock, do not

interconnect the outputs of different Class 2 circuits.

• Disconnect all power (including field device) before

installing and/or servicing.

• Do not touch the controller’s wiring terminals while

the power is ON. Doing so may cause an electric

shock.

Publication 900-UM007D-EN-E - January 2011

Page 43

Preparations 2-5

ATTENTION

!

• Do not allow metal fragments or lead wire scraps to

fall inside the Bulletin 900 Controller. These may cause

electric shock, fire, or malfunction.

• Never disassemble, repair, or modify the Bulletin 900

Controller with line or field device power applied.

Doing so may cause electric shock, fire, or

malfunction.

• Do not use the Bulletin 900 Controller in flammable

and explosive gas atmospheres.

• Use the Bulletin 900 Controller within the rated supply

voltage. Not doing so may cause controller damage or

fire.

• Configure all controller settings according to the

control target of the Bulletin 900 Controller. If the

settings are not appropriate for the control target, the

controller may operate in an unexpected manner,

resulting in damage to the product or personal injury.

• To maintain safety in the event of a product

malfunction, always take appropriate safety measures,

such as installing an alarm on a separate line to prevent

excessive temperature rise. If a malfunction prevents

proper control, an accident may result.

• Do not wire unused terminals.

• Make sure to observe correct polarity when wiring the

controller terminals.

• Power supply, input, output, and communication

terminals (for models with communications) have

basic insulation between them.

When double insulation is required, apply

supplemental insulation defined in IEC 60664 that is

suitable for the maximum operating voltage with

clearances or solid insulation.

Publication 900-UM007D-EN-E - January 2011

Page 44

2-6 Preparations

ATTENTION

!

• Do not use the Bulletin 900 Controller in the following

places which might exceed its specifications:

– Places subject to dust or corrosive gases (in

particular, sulfide gas, and ammonia gas)

– Places subject to high humidity, condensation, or

freezing

– Places subject to direct sunlight

– Places subject to vibration and large shocks

– Places subject to splashing liquid or oily atmosphere

– Places directly subject to heat radiated from heating

equipment

– Places subject to intense temperature changes

• To allow heat to escape, do not block the area around