Page 1

Temperature Controller Communications

Functions

USER MANUAL

Bulletin No. 900-TCx

Page 2

-ii

ATTENTION

!

IMPORTANT

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. "Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls” (Publication SGI-1.1 available from your local

Rockwell Automation Sales Office or online at http://www.ab.com/

manuals/gi) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this

difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

Identifies information about practices or circumstances

that can lead to personal injury or death, property damage,

or economic loss

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Identifies information that is critical for successful

application and understanding of the product.

Publication 900-UM004D-EN-E - July 2010

Page 3

-iii

European Communities (EC)

Directive Compliance

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following standards, in

whole or in part, documented in a technical construction file:

EN 61326 EMC Requirements — Electrical Equipment for Control,

Measurement and Laboratory Use

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61010-1 Safety Requirements for

Electrical Equipment for Control, Measurement and Laboratory Use —

General Requirements. For specific information, see the appropriate sections

in this publication, as well as the Allen-Bradley publication Industrial

Automation Wiring and Grounding Guidelines For Noise Immunity,

Publication 1770-4.1.

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Publication 900-UM004D-EN-E - July 2010

Page 4

-iv

Notes:

Publication 900-UM004D-EN-E - July 2010

Page 5

Table of Contents

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -ii

European Communities (EC) Directive Compliance. . . . . . . . . . . . . -iii

EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iii

Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iii

Preface

About Communications Methods

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Safety Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Meanings of Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

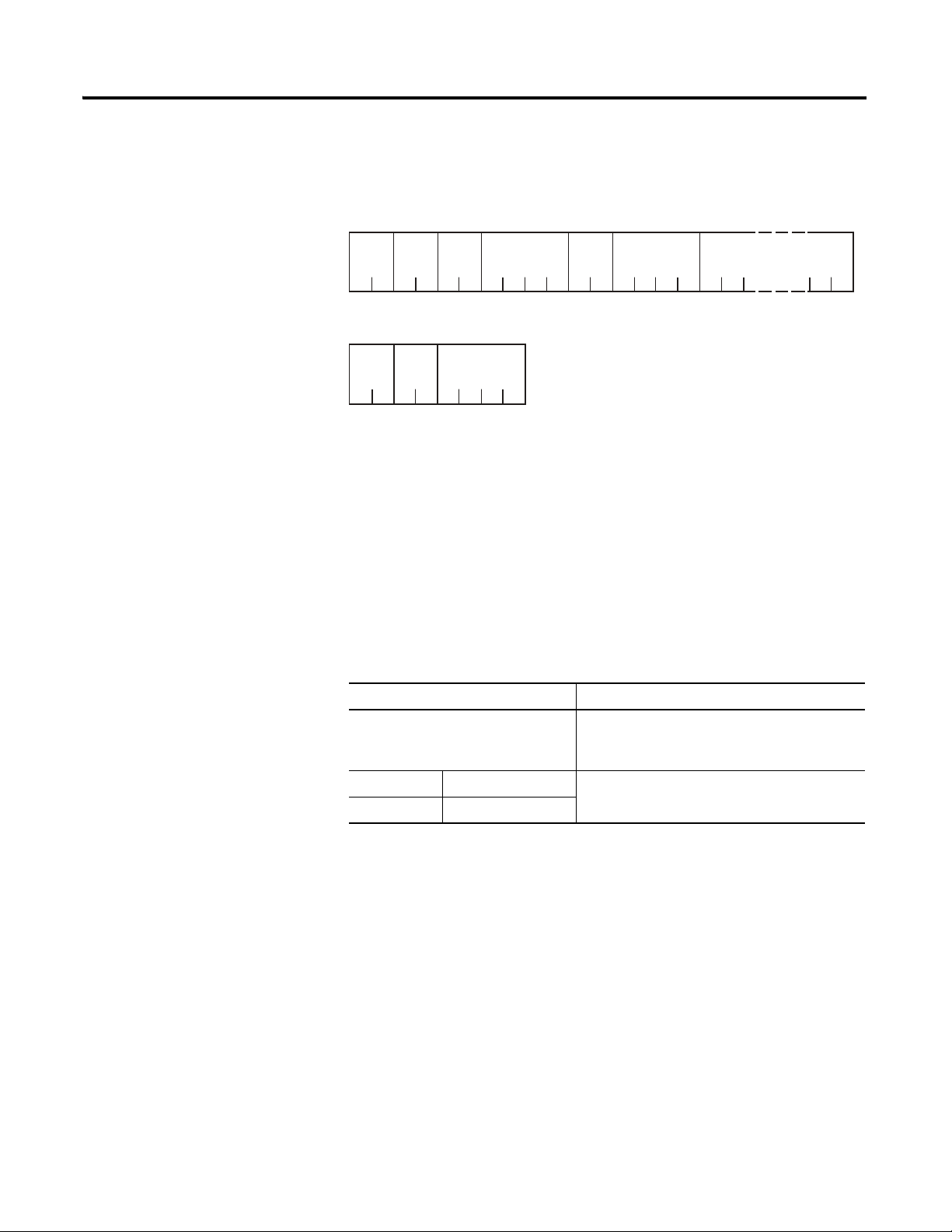

How to Read Display Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Communications Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Transmission procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

RS-232C (Applies to the 900-TC8 only). . . . . . . . . . . . . . . . . . . . 1-4

Communications parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Communications Parameter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Setting Communications Writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Chapter 2

Bulletin 900 Communications

Procedures

900-TCx (CompoWay/F)

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Command Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

BCC Calculation Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Response Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Communications Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Example of End Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Structure of Command Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

PDU (Protocol Data Unit) Structure . . . . . . . . . . . . . . . . . . . . . . 2-5

Area Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Type Code (Variable Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Number of Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

List of Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Detailed Description of Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Page 6

-ii Table of Contents

Read from Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Write to Variable Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Composite Read from Variable Area . . . . . . . . . . . . . . . . . . . . . 2-12

Composite Write to Variable Area . . . . . . . . . . . . . . . . . . . . . . . 2-13

Read Controller Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Read Controller Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Echoback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Operation Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Chapter 3

Communications Data

Modbus Communications

Procedure

Variable Area (setup range) List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Status Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Chapter 4

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Command Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Response Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Number of Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Detailed Description of the Services. . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Read Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Write Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Variable Write, Single/Operation Command. . . . . . . . . . . . . . . 4-15

Echoback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Chapter 5

Communications Data for Modbus

Publication 900-UM004D-EN-E - July 2010

Variable Area (Setting Range) List. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Appendix A

ASCII Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Page 7

Preface

ATTENTION

!

Safety Precautions

Conventions Used in This

Manual

Safety Signal Words

This manual uses the following signal word to mark safety precautions for the

Bulletin 900-TCx.

These precautions provide important information for the safe application of

the Bulletin 900-TCx Temperature Controller. You must make sure to follow

the instructions provided in all safety precautions.

Identifies information about practices or circumstances

that can lead to personal injury or death, property damage

or economic loss

Meanings of Abbreviations

The following abbreviations are used in parameter names, figures, and in text

explanations. These abbreviations mean the following:

Table P.1

Symbol Term

PV Process value

SP Set point

AT Auto-tuning

ST Self-tuning

EU Engineering unit ➊

➊ EU stands for Engineering Unit. EU is used as the minimum unit for engineering units such as °C, m, and g. The

size of EU varies according to the input type. For example, when the input temperature setting range is

–200…+1300°C, 1 EU is 1°C, and when the input temperature setting range is –20.0…+500.0°C, 1 EU is

0.1°C. In the case of analog input, the size of EU varies according to the decimal point position of the scaling

setting, and 1 EU becomes the minimum scaling unit.

P-1 Publication 900-UM004D-EN-E - July 2010

Page 8

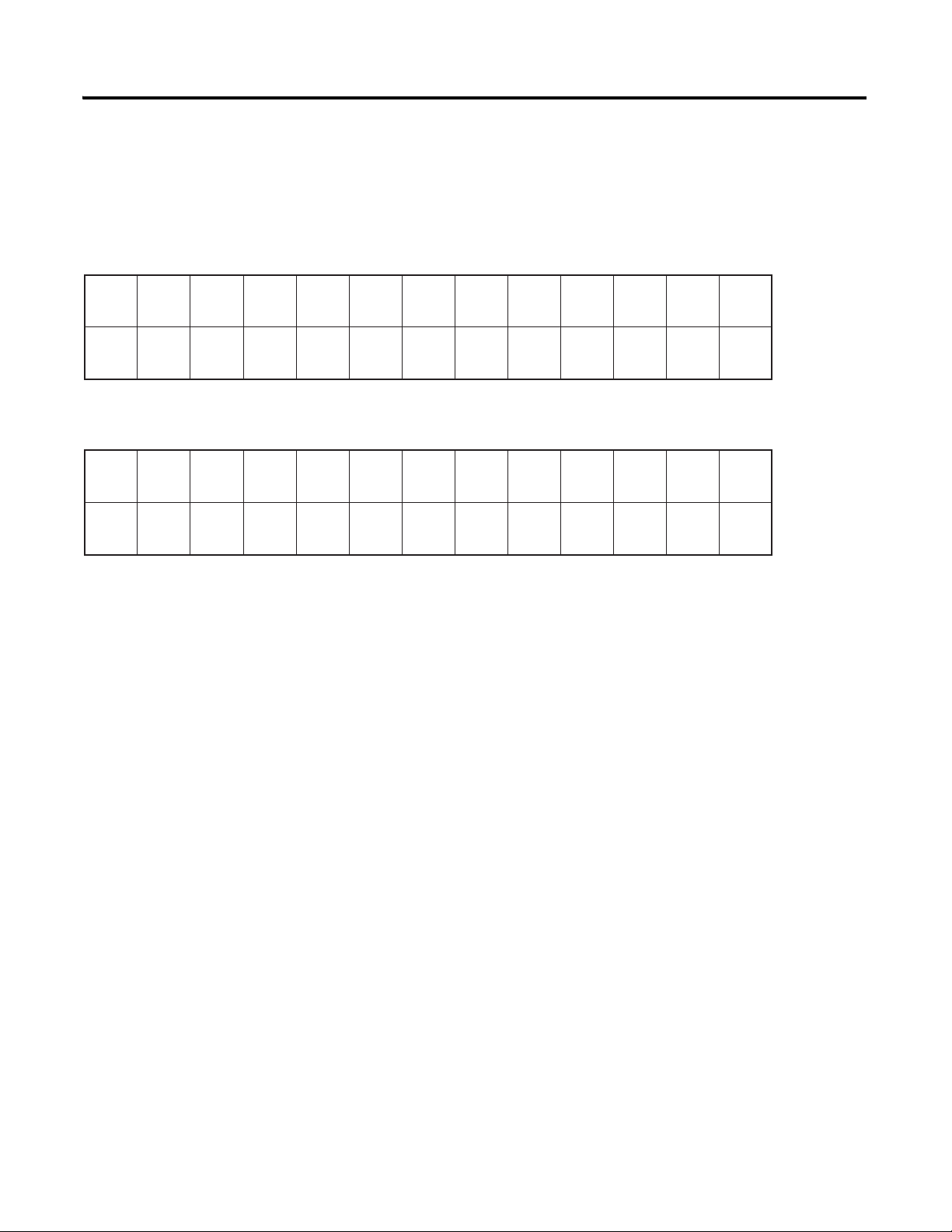

P-2 Preface

ABCDEFG

H

IJKL

M

NO

P

Q

RS T UVWX Y Z

abcdefghijklm

nopqrstuvwxyz

Symbol

Symbol

Alphabet

Alphabet

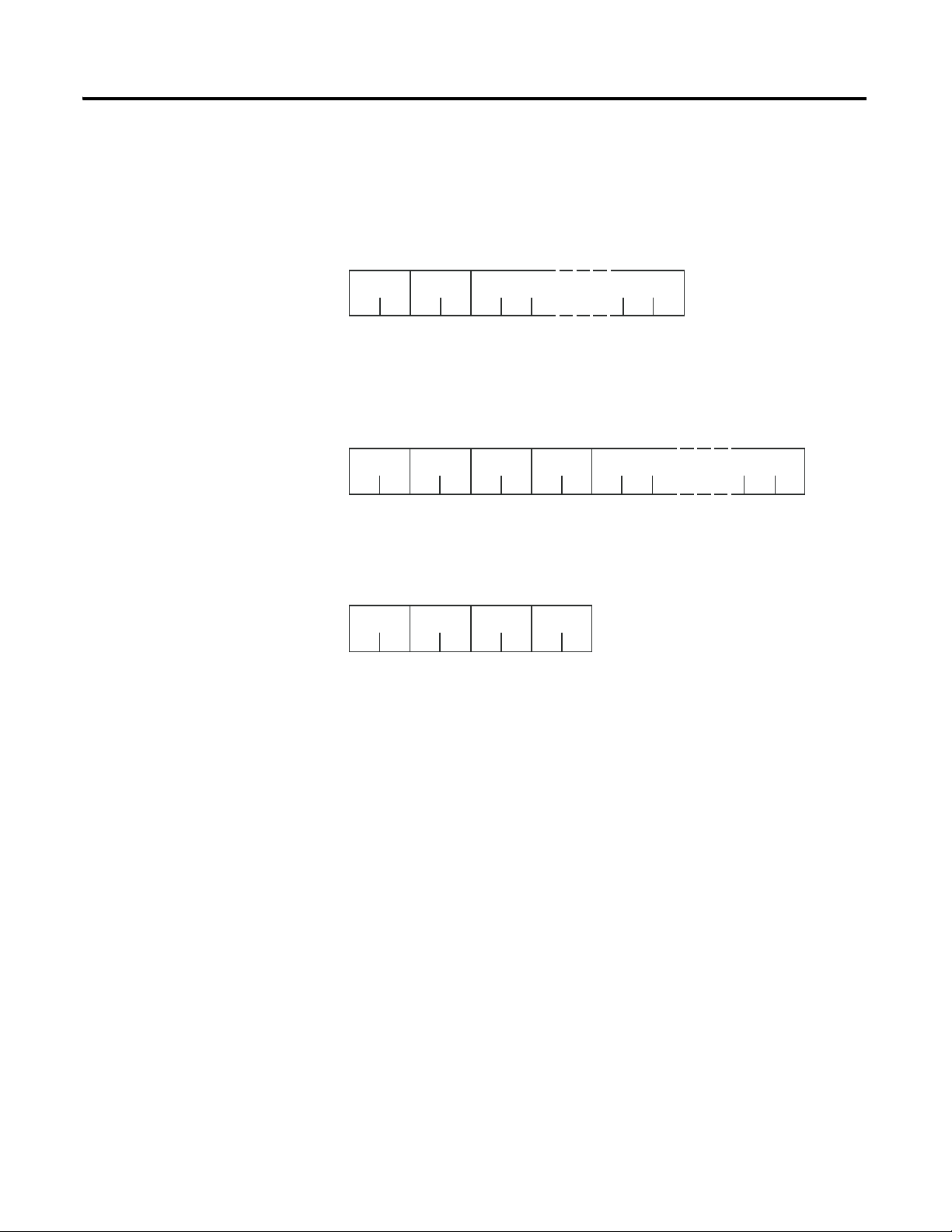

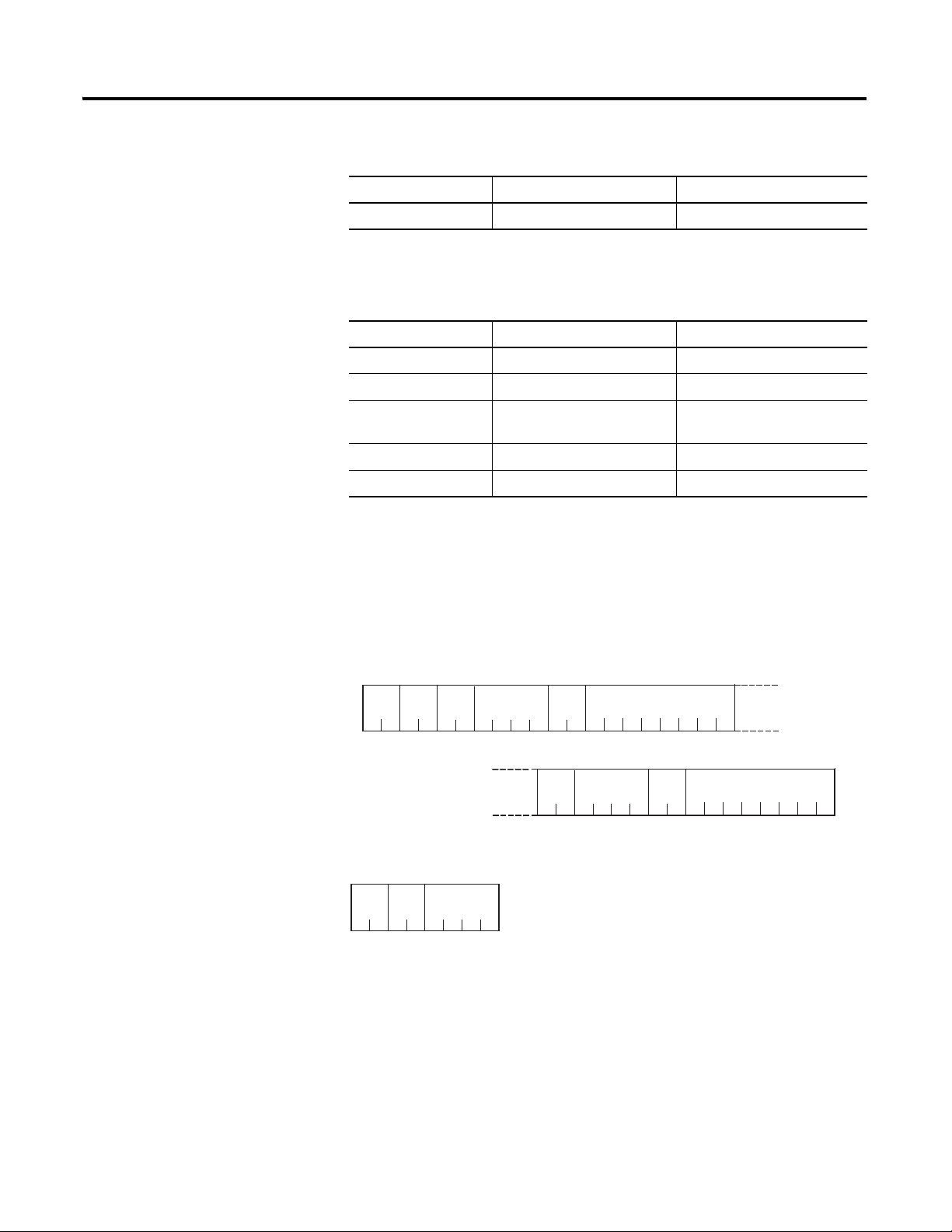

How to Read Display Symbols

The following table shows the relationship between the symbols exhibited on

the controller’s front panel displays to alphabet characters.

Publication 900-UM004D-EN-E - July 2010

Page 9

About Communications Methods

Chapter

1

Introduction

This chapter briefly describes the supported communications methods and

how to wire equipment. First-time users must read this chapter to ensure

proper installation of the equipment.

The programs for the communications functions are created on the host

device (PLC or computer), and the 900-TCx's parameters are monitored or set

from the host PLC or computer. Therefore, the description provided here is

from the viewpoint of the host device.

All Bulletin 900 Temperature Controllers offer an ASCII communications

protocol format based on CompoWay/F for general serial communications.

This format uses a standard frame format. Therefore, it can simplify

communications between 900-TCx components and the host device.

The 900-TC8, 900-TC16, and 900-TC32 controllers also have Modbus®

communication protocol. Modbus is a standard communications control

method that conforms to the Modicon Company’s RTU-mode Modbus

protocol (PI-MBUS-300 Revision J). It supports functions equivalent to the

CompoWay/F Read Variable Area, Write Variable Area, Operation Command,

and Echoback Test functions.

Simplified communications can include:

• Reading/writing of parameters

• Operation instructions

• Selection of setup levels

Communications are subject to the following condition:

• Parameters can be written only when the Communications writing

parameter is set to ON (enabled).

Modbus is a registered trademark of Schneider Electric

1-1 Publication 900-UM004D-EN-E - July 2010

Page 10

1-2 About Communications Methods

Communications

Specifications

Table 1.1

Transmission line connection➊ RS-485 : Multiple point, or RS-232C : Point to point

Communications method➊ RS-485 (2-wire, half-duplex), or RS-232C

Synchronization method Start-stop synchronization

Baud rate 1200, 2400, 4800, 9600, 19200, 38400, or 57600 bps

Communication code➋ ASCII

Data bits➋ 7 or 8 bits

Stop bits➋ 1 or 2 bits

Error detection − Parity (none, even or odd) BCC (block check

character)

− BCC with CompoWay/F (900-TC)

− CRC-16 (Cyclic Redundancy Check 16) Modbus➍

communications

Flow control None

Interface➊ RS-485/RS-232C

Retry function None

Communications buffer 217 bytes➌, 40 byte

Communications response wait

time

0 to 99 ms, default time: 20 ms

Transmission procedure

Note: Highlighted characters in the table above indicate defaults.

➊ Direct RS-232C communication is only available with the 900-TC8. However, the 900-CONVx25(B) RS232/USB

to RS485 converter can be used for 900-TC16 and 900-TC32 controllers.

➋ Communications speed, data bits, stop bits and vertical parity can each be configured independently in the

controller’s Communications Setting function group.

➌ 900-TC8, 900-TC16, and 900-TC32 Series B controllers only.

➍ The communications data length for Modbus must be 8 bits.

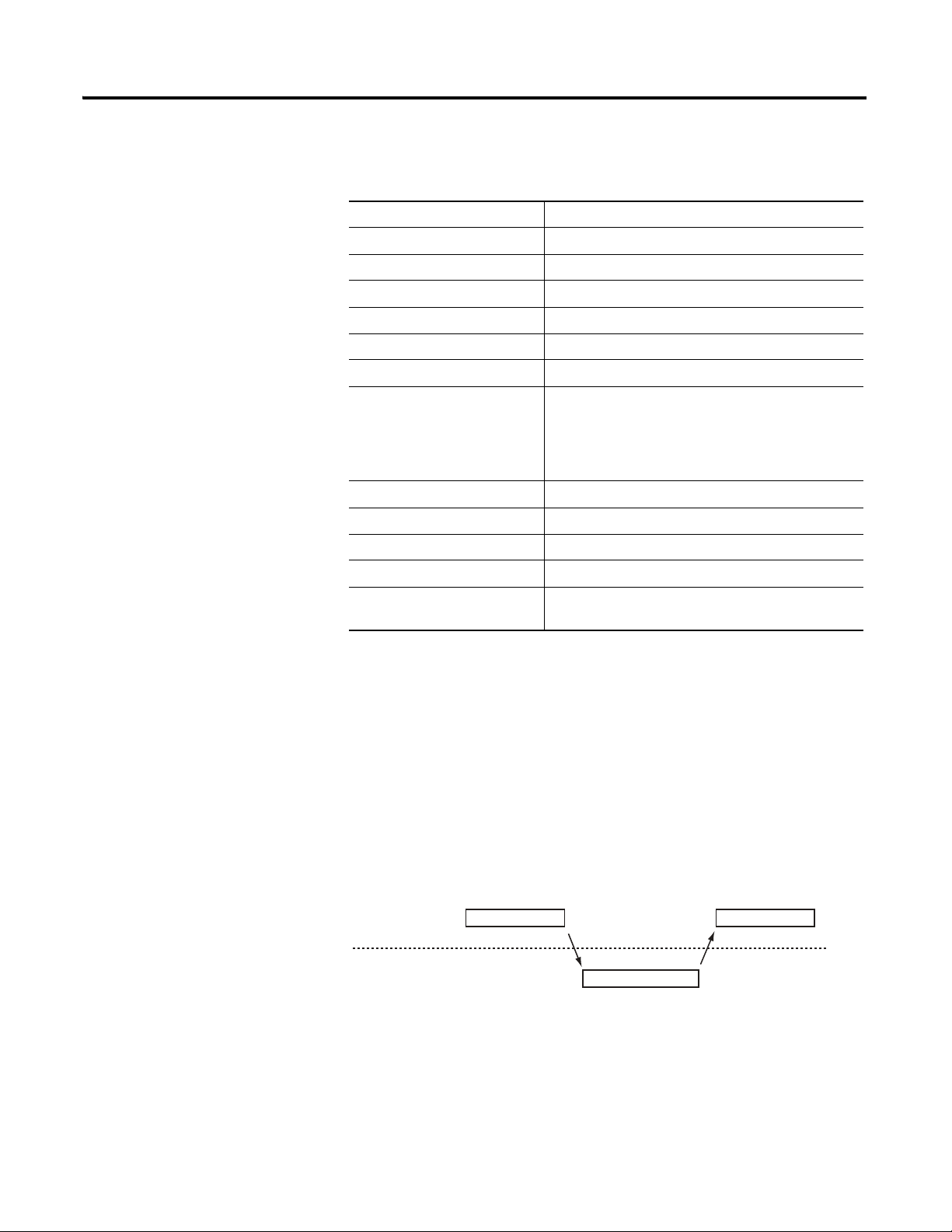

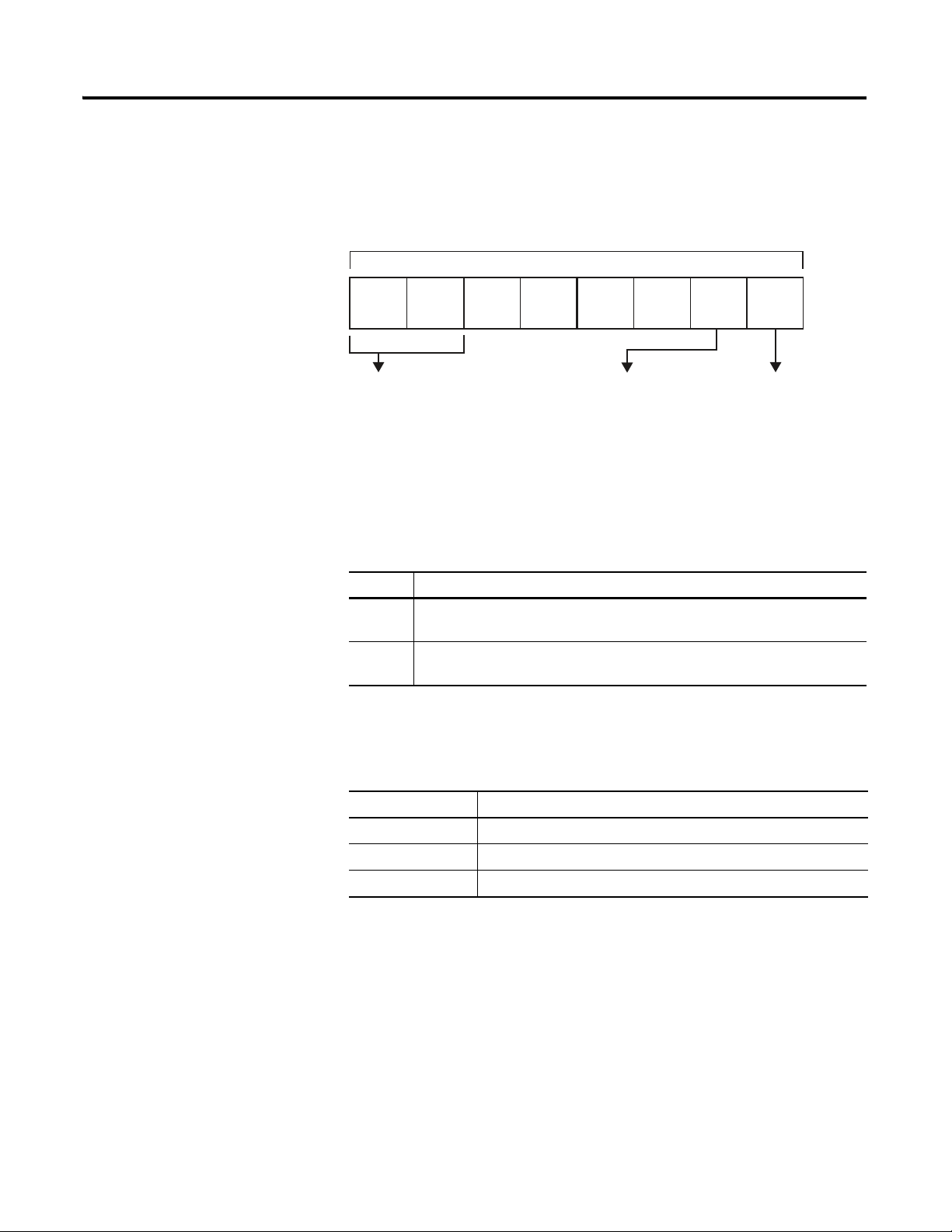

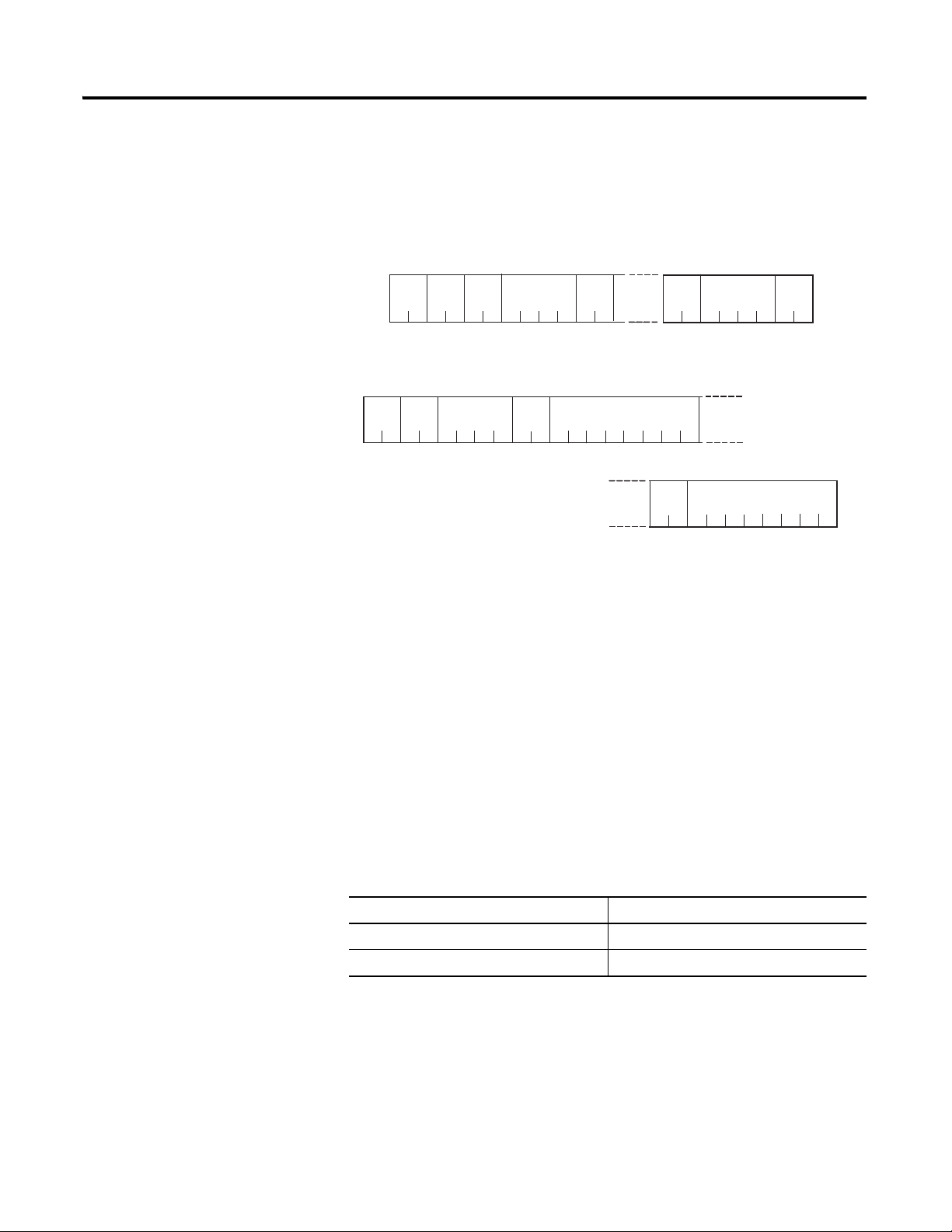

When the host device transmits a command frame, the 900-TCx transmits a

response frame that corresponds to the command frame. A single response

frame is returned for each command frame. The following diagram shows the

operation of the command and response frames.

Command Frame

Host Device

900-TCx Temperature Controller

Response Frame

Command Frame

Allow a wait time of at least 2 ms until the next command is sent after the host

device receives a response from the 900-TCx temperature controller.

Publication 900-UM004D-EN-E - July 2010

Page 11

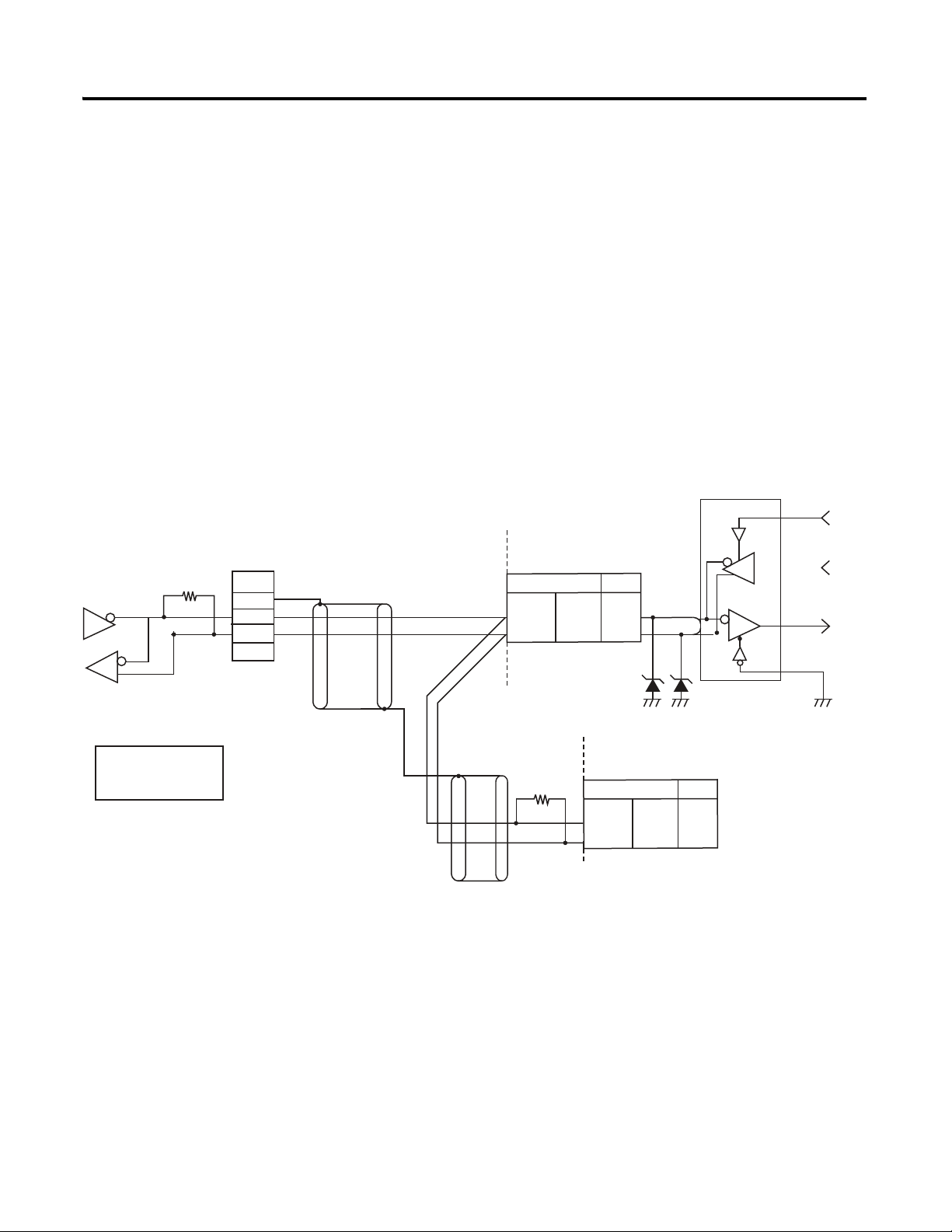

About Communications Methods 1-3

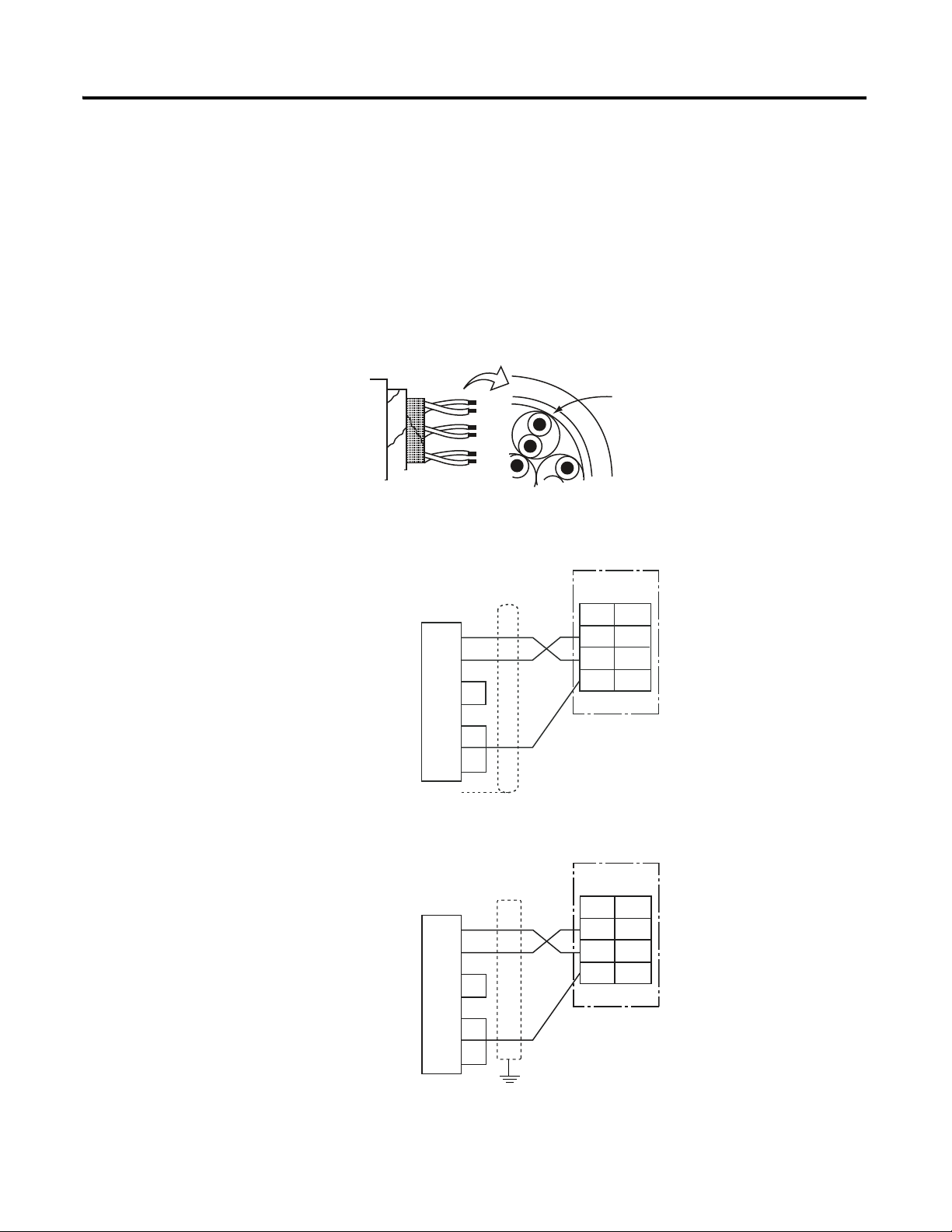

SG

FG

Abbr

_

+

900-TC32

12118

7

Pin No.

RS-485

RX

TX

Communications Transceiver

6.8V

Terminator

120Ω

(1/2W)

900-TCx

end node

RS-485

Use a terminator of resistance

120Ω = (1/2W)

Shielded cable

Both ends of the transmission line

(including the host device) must be

specified (by setting terminator ON) as

the end node. The total resistance of

the terminators must be at least 54Ω.

A<B: [1] mark

A>B: [0] space

Shielded cable

Host Device

RS-485

900-TC8/16

Abbr

A ( – )

B ( + )

900-TC32

12

11

8

7

Pin No.

900-TC8/16

Abbr

A ( – )

B ( + )

Interface

Wiring

Communications with the host device are carried out through a standard

RS-485 or RS-232C(900-TC8x) interface. Use a cat. no. 900-CONVxx

interface converter for RS232C/USB to RS485 conversion.

RS-485

• RS-485 connections can be 1:1 or 1: N. A maximum of 32 Units

(including the host device) can be connected in one-to-N systems.

• The total cable length is 500 m max.

2

• Use a shielded, twisted-pair cable #24 AWG (0.205 mm

2

(2.081 mm

) for the 900-TC8 and 900-TC16.

• Use a shielded, AWG24 to AWG18 (cross-sectional area of 0.205 to

0.823 mm2) twisted-pair cable for the 900-TC32.

)…#14 AWG

Match the communications specifications of the 900-TCx and the host device.

If a one-to-N system is being used, be sure that the communications

specifications (Refer to Communications Specifications on page 1-2) of all devices

in the system (except individual unit numbers) are the same.

This section explains how to set the 900-TCx's communications specifications.

For details on the host device, refer to publication 900-UM007*.

Publication 900-UM004D-EN-E - July 2010

Page 12

1-4 About Communications Methods

Cable Reference Diagram

900-TCxx

#24 AWG…#14 AWG

Conductor cross-section

0.205 mm to 2.081mm

22

No.

11

12

13

SD

RD

SG

RS-232C

900-TC8

Host Device

RS-232C : 25P

<

>

2

3

4

5

6

7

20

1

SD(TXD)

RD(RXD)

RS(RTS)

CS(CTS)

DR(DSR)

SG

ER(DTR)

FG

>

<

<

>

No.

11

12

13

SD

RD

SG

RS-232C

900-TC8

Host Device

RS-232C : 9P

<

>

3

2

7

8

6

5

4

SD(TXD)

RD(RXD)

RS(RTS)

CS(CTS)

DR(DSR)

SG

ER(DTR)

>

<

<

>

RS-232C (Applies to the 900-TC8 only)

• RS-232C connections are 1:1.

• The total cable length is 15m max.

• Use a shielded, AWG24 to AWG14 (cross-sectional area of 0.205 to

2.081 mm2) twisted-pair cable for the 900-TC8 and 900-TC16.

• Use a shielded, AWG24 to AWG18 (cross-sectional area of 0.205 to

0.823 mm2) twisted-pair cable for the 900-TC32.

Wiring for 25-pin RS-232 connector on host device

Publication 900-UM004D-EN-E - July 2010

Wiring for 9-pin RS-232 connector on host device

Page 13

About Communications Methods 1-5

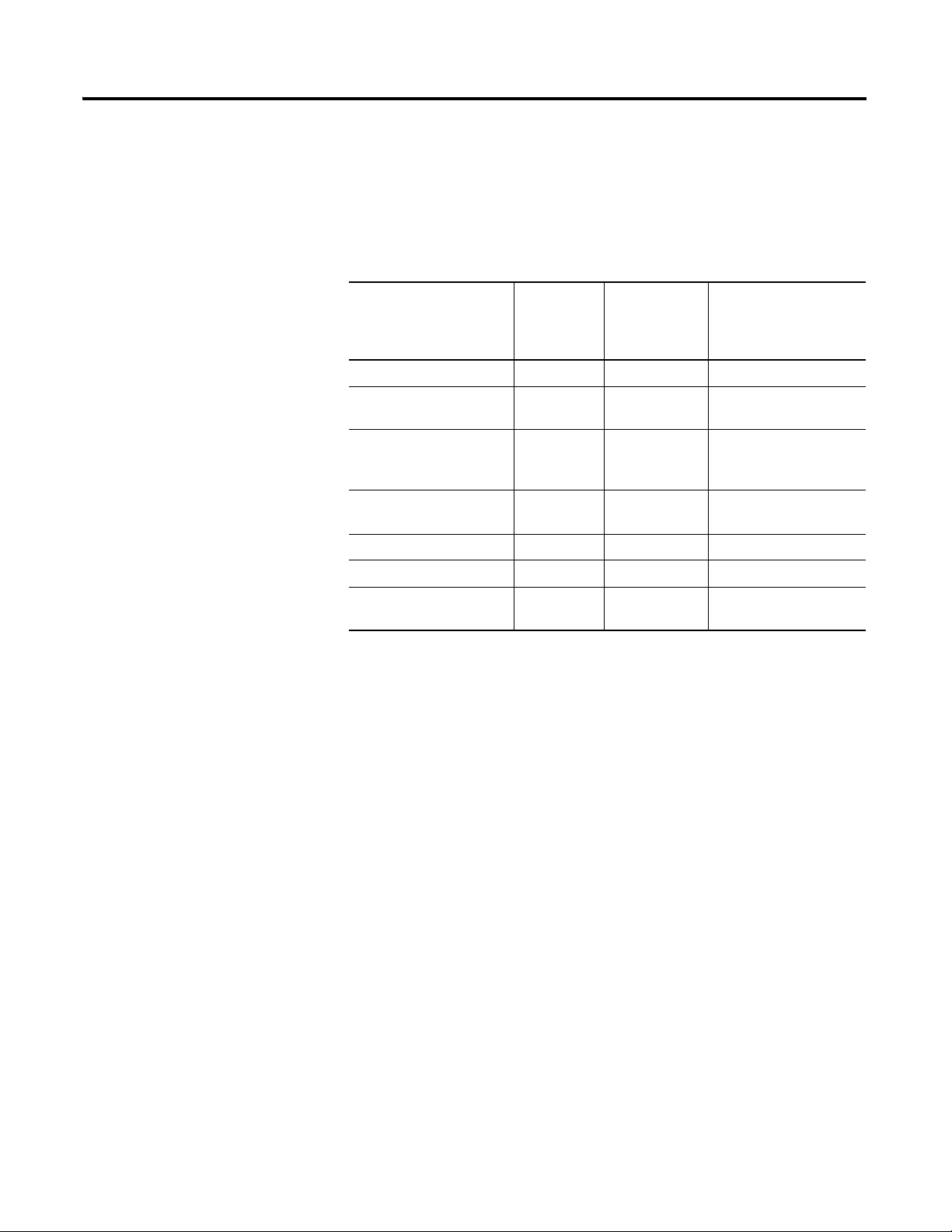

Communications

parameters

The 900-TCx's communications specifications are set/configured in the

Communications Setting function group. These parameters are set on the

900-TCx's front panel.

The table below shows the communications parameters and their ranges.

Table 1.2 Communication Parameters and Ranges

Parameter Displayed

Characters

Communication protocol psel cwf/mod

Communications unit

number

Baud rate bps 1.2 / 2.4 / 4.8 /

Communications data

length

Communications stop bit sbit 1/2 1/2

Communications parity prty None/even/odd none/even /odd

Send data wait time sdwt 0…99 0…99 ms, default time:

u-no 0…99 0, 1…99

len 7/8(bit) 7/8 (bit)

Setting Range Set Value

(Blue highlighted

characters indicate

defaults)

1 .2 / 2.4 / 4.8 /

9.6 /19.2 / 38.4

/ 57.6 (kbps)

9.6/19.2/38.4/57.6 (kbps)

20 ms

Note: Highlighted values indicate default settings.

The communications data length for Modbus must be 8 bits.

Publication 900-UM004D-EN-E - July 2010

Page 14

1-6 About Communications Methods

c

psel

cwf

c

u-no

1

c

bps

9.6

c

len

7

c

56it

2

c

prty

eVen

c

sdwt

20

Protocol selection

Communications unit

number

Communications

baud rate

Communications data

length (See note.)

Communications stop

bits (See note.)

Communications

parity

Send data wait time

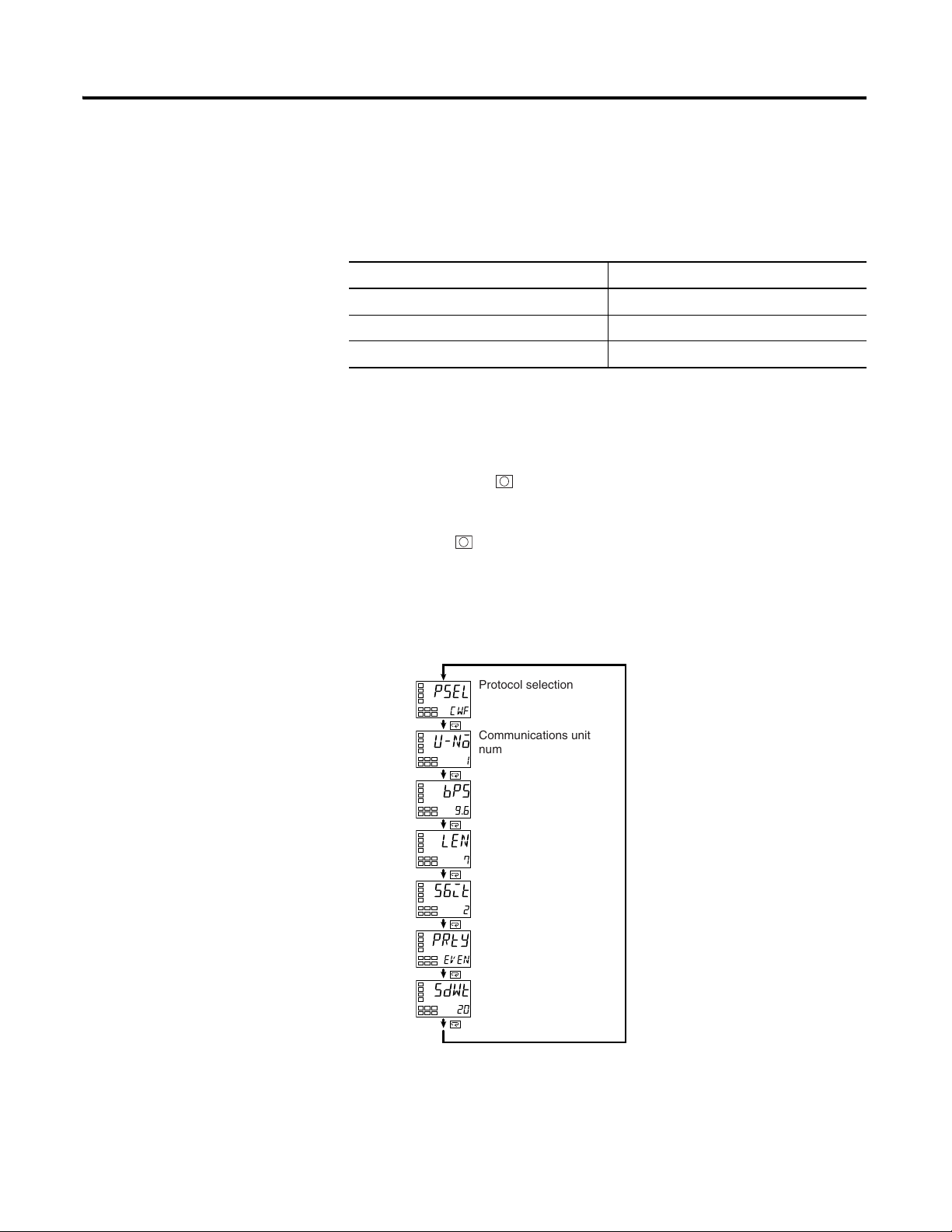

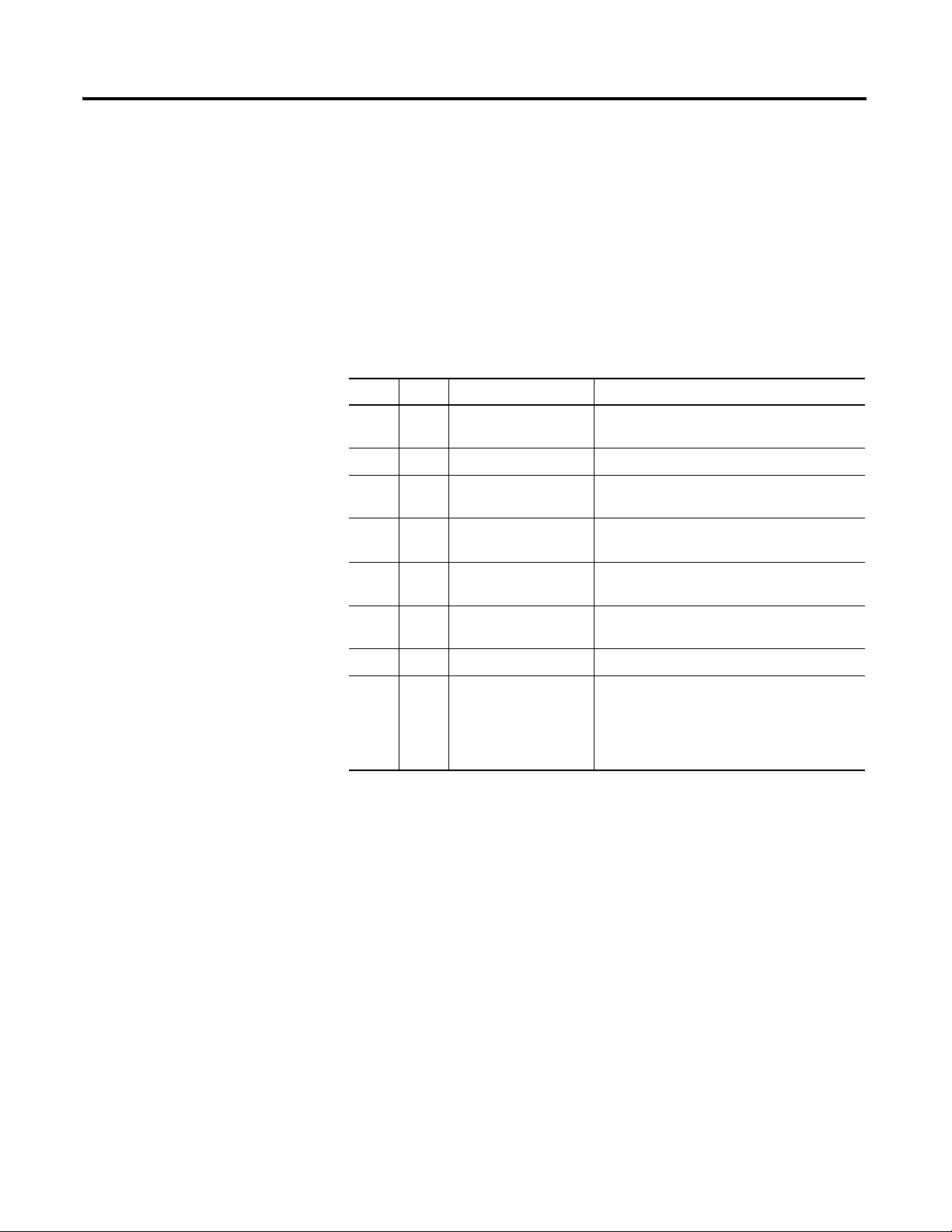

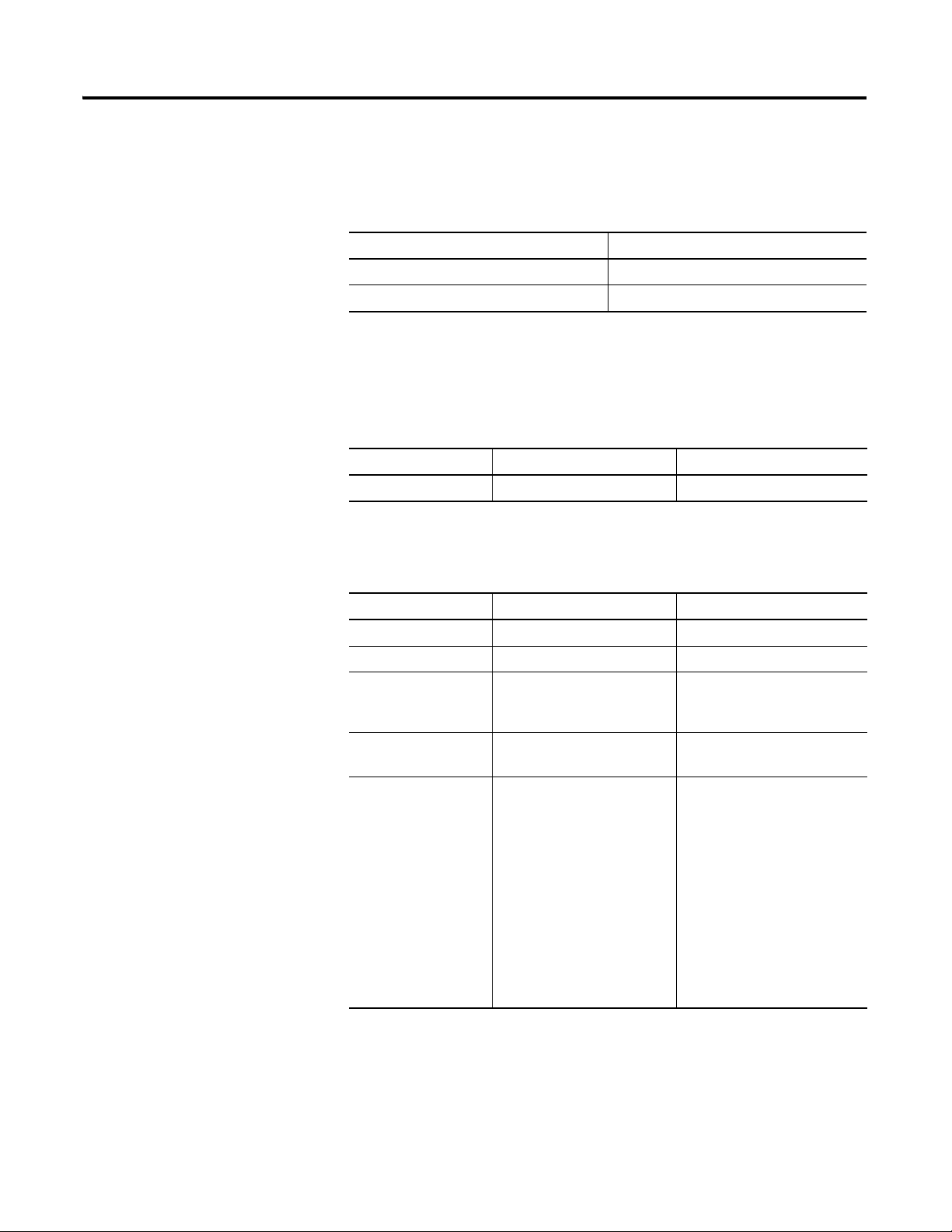

Communications Parameter

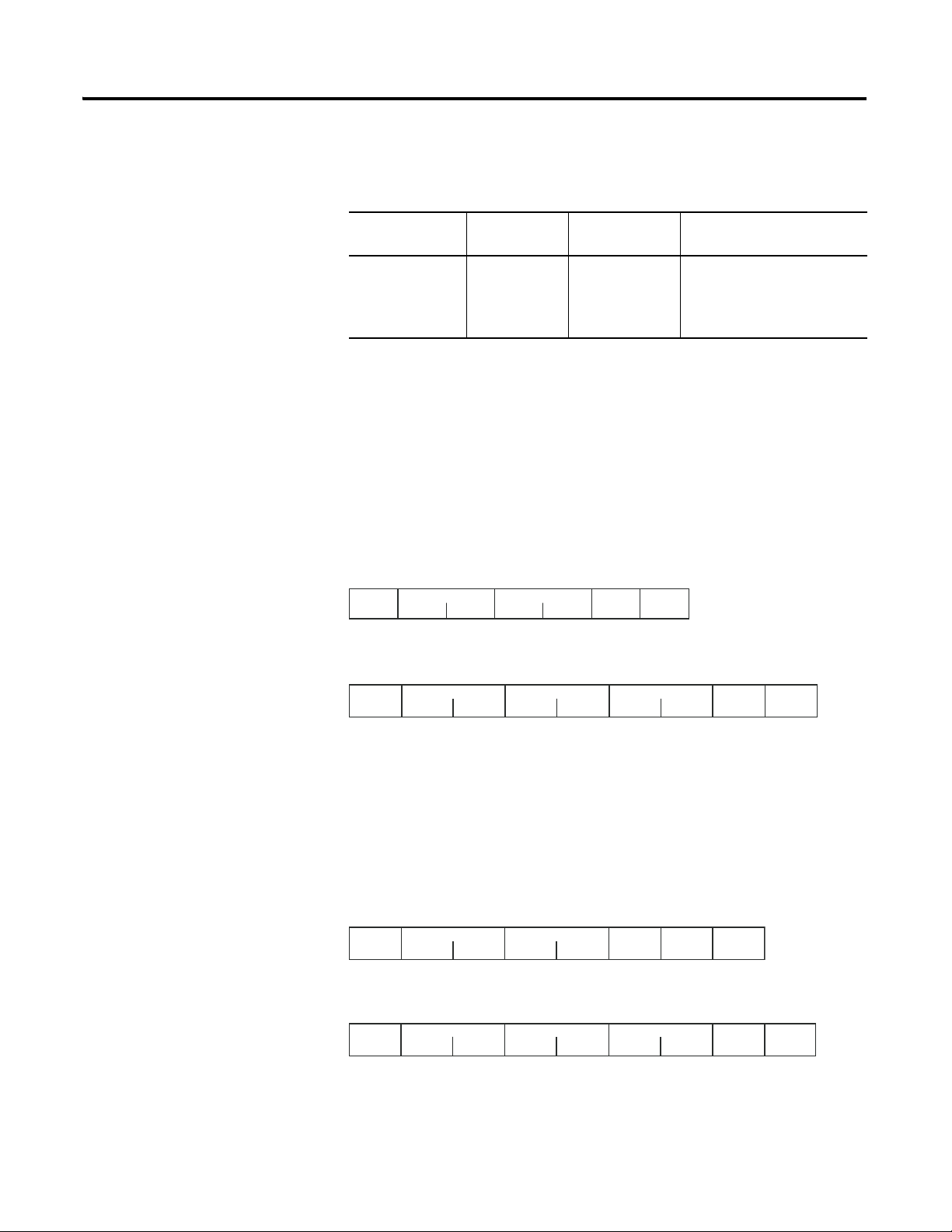

Before you carry out communications with the 900-TCx, set up

communications unit number, baud rate and other parameters by carrying out

Setup

the following procedure. For details of operations other than communications

parameter setup, refer to the applicable 900-TCx User Manual.

Table 1.3 900-TCx User Manuals

Communications Parameter Setup

Temperature Controller Model Number User Manual

900-TC8 900-UM007*

900-TC16 900-UM007*

900-TC32 900-UM007*

1. Hold down the key for at least three seconds to move from the

Operation function group to the Initial Setting function group.

2. Press the key for less than one second to move from the Initial

Setting V to the Communications Setting function group.

Publication 900-UM004D-EN-E - July 2010

3. Select the parameters as shown below by pressing the

4. Use the

D or U keys to change the parameter set values.

M key.

Note: Displayed only when the Protocol Selection is CWF (900-TC)

Page 15

About Communications Methods 1-7

Communication Parameters

Note that communications parameters are enabled after they have been

changed by resetting the controller.

• Protocol Selection (

psel)

The communications protocol can be selected. Set CompoWay/F

(900-TC) or Modbus.

• Communications unit number (

u-no )

This parameter is for setting a unique unit number for each of the

temperature controllers in the system. This unit number is set so that

the host device can identify the temperature controller when

communications are carried out with the host device. Set a unit number

within the range 0 to 99 for each temperature controller connected to

the host device on the network. Default is “1”. When two or more

temperature controllers are used, do not set them to the same unit

number Doing so will prevent normal communications operation.

• Baud rate (

bps)

This parameter is for setting the baud rate when communicating with

the host device. Set one of "1.2 (1200 bps)", "2.4 (2400 bps)", "4.8 (4800

bps)", "9.6 (9600 bps)", "19.2 (19200 bps)", "38.4 (38400 bps)", or

“57.6 (57600 bps)➊”. All units must be set to the same baud rate.

• Communications data length {

len )

This parameter is for setting the communications data length. Set either

of "7 bits" or "8 bits". All units must be set to the same communications

data length.

• Communications stop bit (

sbit )

This parameter is for setting the communications stop bit. Set either of

"1" or "2". All units must be set to the same communications stop bit

value.

• Communications parity (

prty)

This parameter is for setting the communications parity. Set one of

"none", "even" or "odd". All units must be set to the same

communications parity value.

• Send Data Wait Time (

sdwt)

The send data wait time can be set in 1-ms increments between 0 and

99 ms. The default is 20 ms.

➊ Offered with 900-TC8, 900-TC16, and 900-TC32 Series B controllers.

Publication 900-UM004D-EN-E - July 2010

Page 16

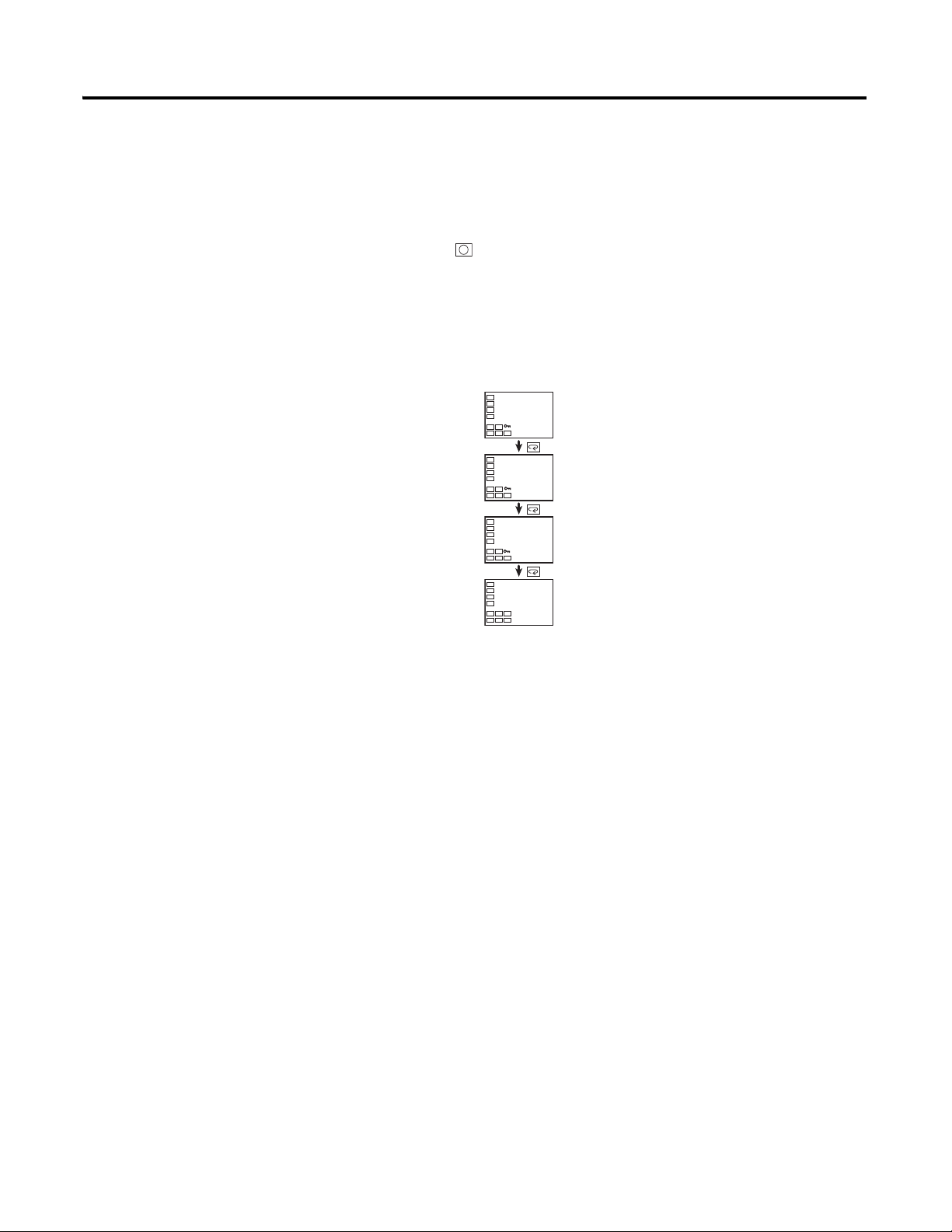

1-8 About Communications Methods

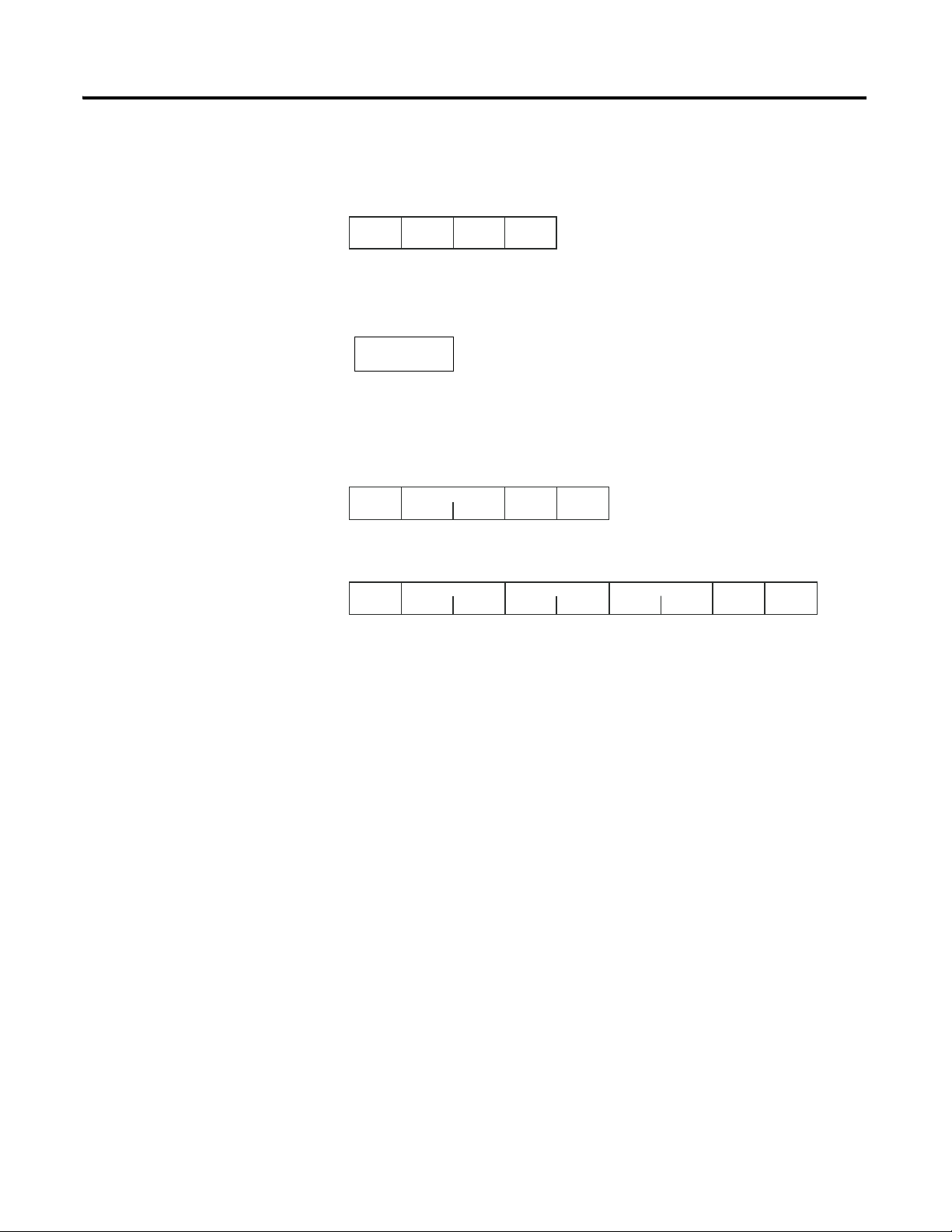

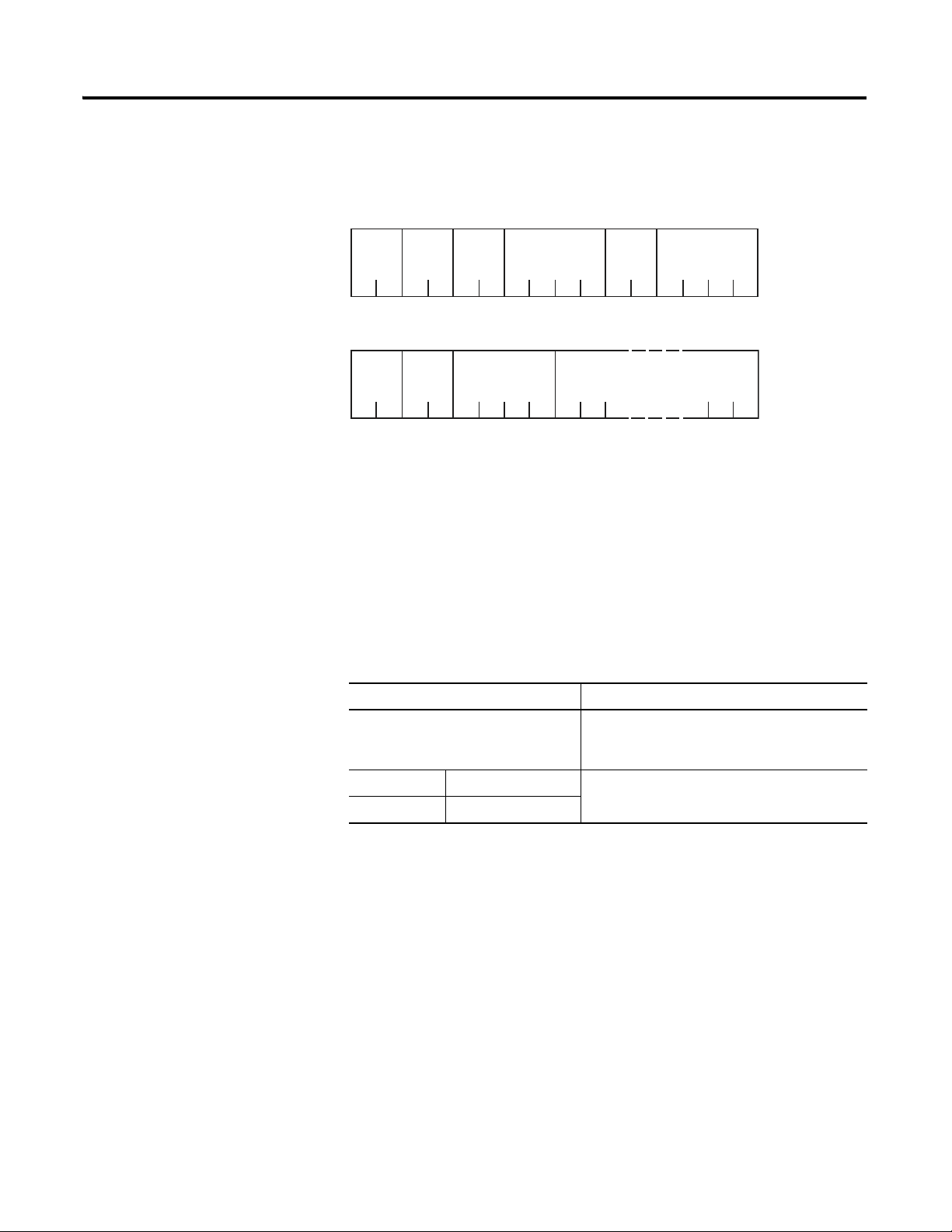

Setting Communications

Writing

Set the communications writing parameter to ON to allow the host to write to

the 900-TCx controller(s) via communications.

Parameter Setting

1. Press the key for less than one second to move from the operation

level tot he adjustment level.

2. Select the parameters as shown below by pressing the

3. Use the

D or U keys to set the communications writing parameter to

ON.

c

l.adj

c

c

cmwt

c

cmwt

Adjustment Level

Display

Displayed only once when

entering adjustment level.

AT Execute/Cancel

at

off

Communications

Writing

off

on

•

•

•

•

M key.

Publication 900-UM004D-EN-E - July 2010

Page 17

Chapter

STX

Node No.

12 2

Sub-address

0 00

SID

1

BCC Calculation Range

Tex t

Command Text

ETX

BCC

1

1

2

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Data Format

Unless otherwise indicated, numbers in this manual are expressed in

hexadecimal (with an H’ before the number: e.g., H’02). Values without the H’,

such as 00, are ASCII. The number underneath each delimiter in a frame

indicates the number of bytes.

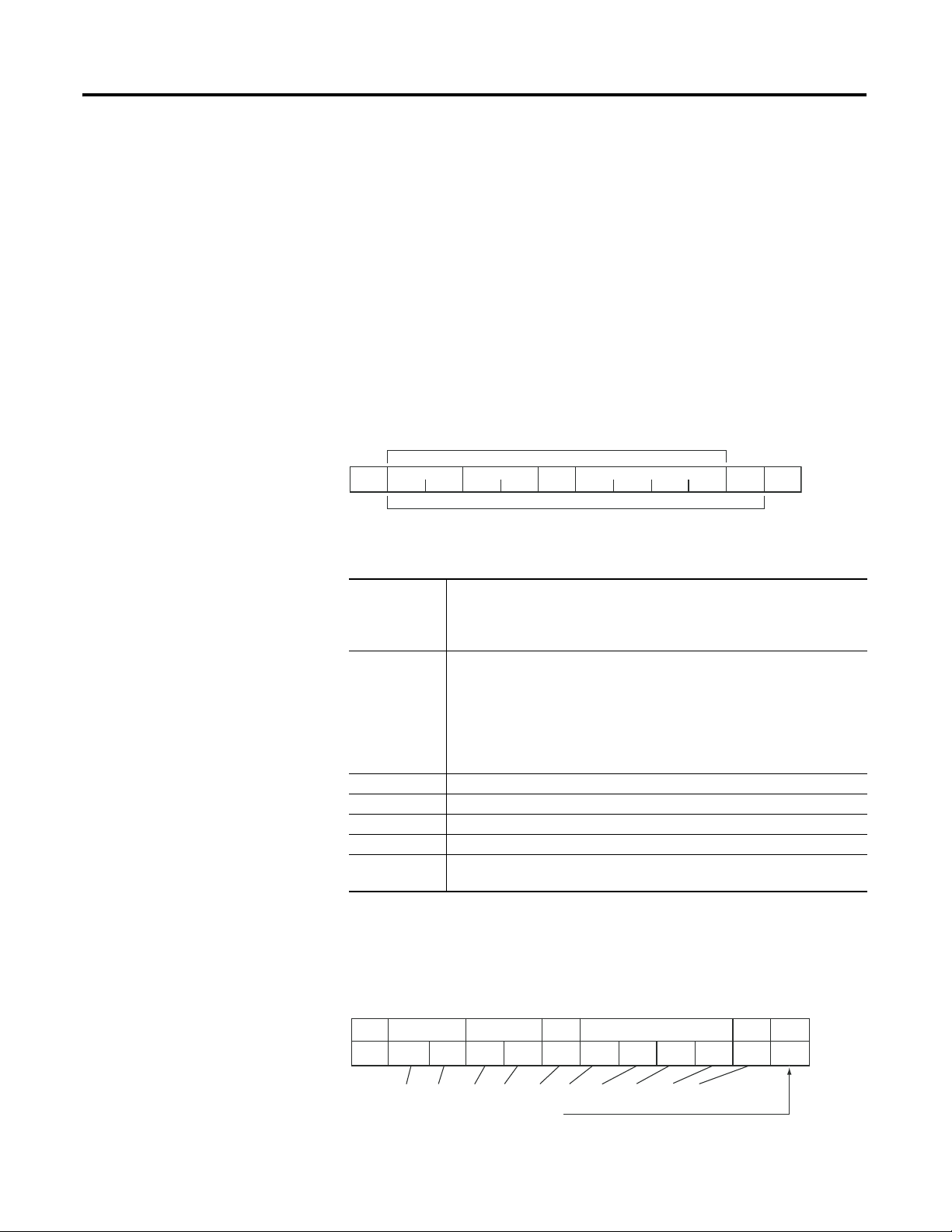

Command Frame

Table 2.1

STX This code (H’02) indicates the beginning of the communications frame

(text). Always set this character in the first byte. When STX is received

again during reception, reception is carried out again from the point

where STX was received.

Node number • This number specifies the transmission’s destination.

• Specify the 900-TCx’s communication unit number.

• A BCD value between 00 and 99 or an ASCII value of XX can be set.

• Specify XX for a broadcast transmission. No responses will be

returned for broadcast transmissions.

• No responses will be returned from node numbers other than the

ones in the above range.

Sub-address This is not used on the 900-TCx. Be sure to set the sub-address to 00.

SID (service ID) This is not used on the 900-TCx. Be sure to set the Service ID to 00.

Command text Command text area. Refer to Structure of Command Text on page 2-5

ETX This code (H’03) indicates the end of the text.

BCC Block Check Character The BCC result is found by calculating the

exclusive OR of the bytes from the node number up to ETX.

2-1 Publication 900-UM004D-EN-E - July 2010

BCC Calculation Example

The BCC (Block Check Character) is determined by calculating the exclusive

OR of the bytes from the node number up to ETX. The 8-bit result is written

to the BCC byte at the end of the frame.

STX Node No. Sub-address SID Command Text ETX BCC

02H 0(30H) 0(30H) 0(30H) 0(30H) 0(30H) 0(30H) 5(35H) 0(30H) 3(33H) 03H 35H

BCC=30H⊕30H⊕30H⊕30H⊕30H⊕30H⊕35H⊕30H⊕33H⊕03H=35H

Calculation result 35H is set to the BCC area.

The

⊕

symbol indicates exclusive OR operation and the H indicates hexidecimal code.

Page 18

2-2 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Command Text BCC

ETX

1 1

222

End CodeSub-addressNode No.

STX

1

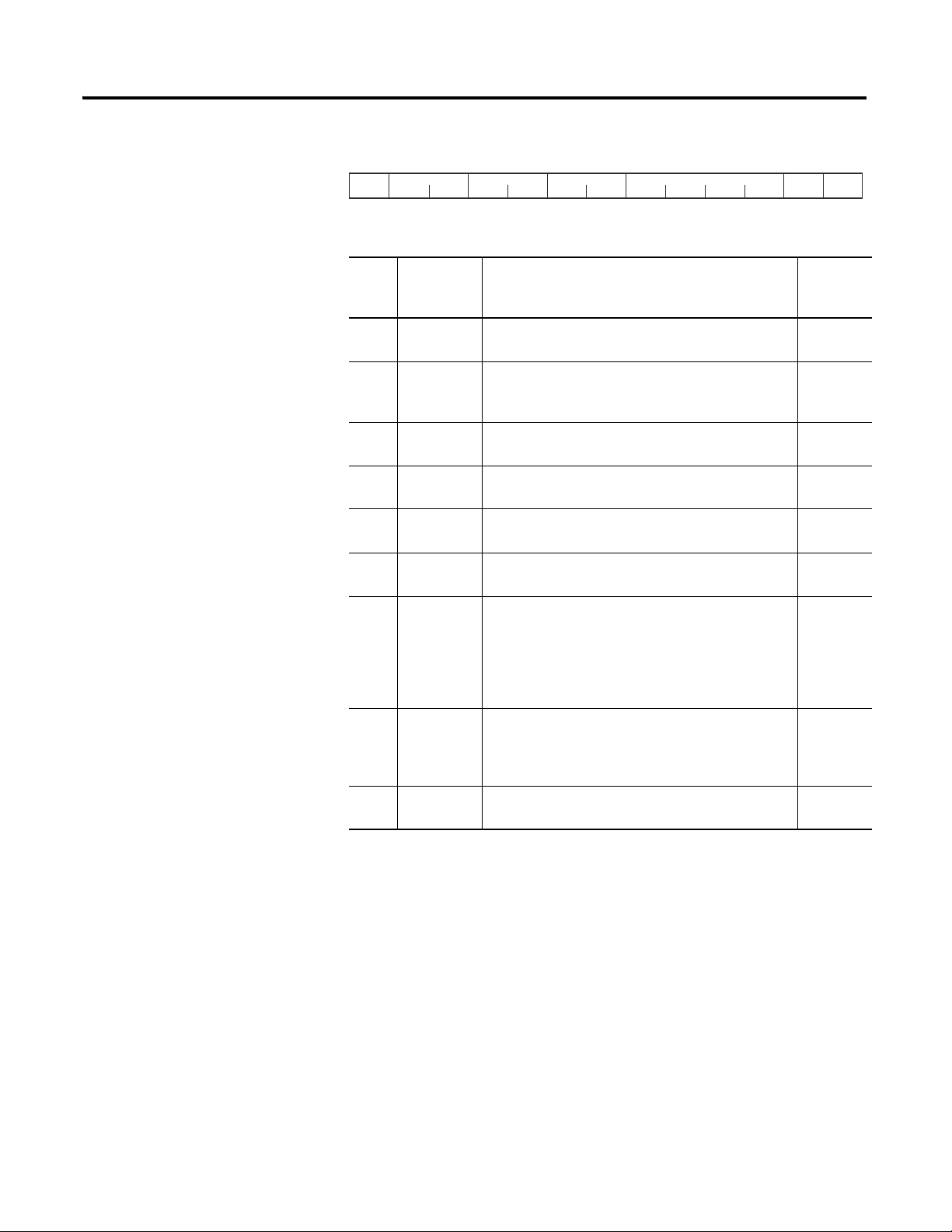

Response Frame

Table 2.2

End

Name Description Error

Code

00 Normal

The command ended normally without error. None

completion

0F FINS

command

error

The specified FINS command could not be executed.

The FINS response code should indicate why the

command could not be executed.

10 Parity error The sum total of bits whose received data is 1 does

not match the set value of Communications Parity.

11 Framing

Stop bit is 0. 1

error

12 Overrun

error

An attempt was made to transfer new data when the

reception data was already full.

13 BCC error The calculated BCC value is different from the

received BCC value.

14 Format error • The command text contains characters other than

0 to 9, and A to F. This error is not applicable to

the echoback test. (For details, see Refer

to Echoback Test on page 2-17)

• No SID and command text. Or, no command text

• MRC/SRC not included in command text

16 Sub-address

error

• Illegal (unsupported) sub-address

• No sub-address, SID and command text

• Sub-address less than two characters, and no SID

and command text

Detection

Priority

8

2

3

5

7

6

Publication 900-UM004D-EN-E - July 2010

18 Frame

length error

The received frame exceeds the fixed (supported)

number of bytes.

• The end code is returned for each command frame that was addressed

to the local node.

• No response will be returned unless the frame contained all elements up

to the ETX and BCC.

• “Error Detection Priority” indicates the priority when two or more

errors occur simultaneously.

4

Page 19

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-3

STX

Node No. Sub-address SID BCC

0 00ETX

BCC

ETX

End Code

410

Sub-address

0

Node No.

STX

Communications Data

Table 2.3 Communications Data

Communications

Specifications

CompoWay/F

(Bulletin 900-TCx)

Set (Monitor)

Value

8 digits (Hex) 2's complement Decimal point is removed and

Minus Value Decimal Point

the result is converted to

hexadecimal. Example: 105.0

Æ 1050 Æ H’000041A

Example of End Code

The following examples show an end code when a command did not end

normally.

Example 1: Illegal sub-address, and no SID and command text

Command Format:

Node No. Sub-address BCC

STX 0 A ETX

Response Format:

BCC

STX

Node No.

Sub-address

A0

End Code

16

ETX

End code is "16" (sub-address error).

This is because a sub-address was received and the sub-address error has a

higher error detection priority than the format error.

Example 2: No command text

Command Format:

Response Format:

End code is 14 (format error).

Publication 900-UM004D-EN-E - July 2010

Page 20

2-4 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

No response

BCC

ErrETXSTX

Node No.

BCC

ETX

End Code

13

Sub-address

00

Node No.

STX

Example 3: No node number provided

Command Format:

The node number is lacking one character.

Response Format:

Example 4: No sub-address, and illegal BCC

Command Format:

BCC

ETXSTX

Response Format:

Sub-address is 00 and end code is 13 (BCC error).

Publication 900-UM004D-EN-E - July 2010

Page 21

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-5

MRC SRC MRES SRES Data

MRC SRC MRES SRES

Structure of Command Text

PDU (Protocol Data Unit) Structure

An MRC (Main Request Code) and SRC (Sub-Request Code) followed by the

various required data is transferred to the command text.

Service request PDU

MRC SRC Data

The MRES (Main Response Code) and SRES (Sub-Response Code) are

transferred to the response frame following the above MRC/SRC. Data is then

transferred following the MRES and SRES.

Service response PDU (during normal operation)

If the specified command text could not be executed, the service response

PDU will contain only MRC/SRC and MRES/SRES.

Service response PDU (command text not executed)

MRES/SRES provides the response code. MRES/SRES are not output when

processing ends in a normal operation.

Area Definitions

Areas comprise only the variable area.

Publication 900-UM004D-EN-E - July 2010

Page 22

2-6 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

MSB LSB

0000

Type Code (Variable Type)

The following defines variable area type codes.

Variable type (1 byte)

Access size Area Read/Write

11: Double-word 0: Setup area 0 0: Read only

10: Word 1 : Setup area 1 1 : Read/write

The following table summarizes setup areas 0 and 1.

Table 2.4

Area Description

Setup

area 0

Setup

area 1

This area groups together the Protect, Manual Control, Operation and

Adjustment function groups.

This area groups together the Initial Setting, Communications Setting,

Advanced Function Setting and Calibration function groups.

The variable type is converted to 2-byte ASCII code and loaded to the frame.

The following table shows available variable types.

Table 2.5

Variable Type Description

CO/80 R/O (read only) parameter for setup area 0.

C1/81 R/W parameter for setup area 0.

C3/83 R/W parameter for setup area 1 .

Note: Setup area 1 has no R/O (read only) parameters. Therefore, variable

type C2 does not exist.

Addresses

Each of the variable types is appended with an address. Express addresses in

2-byte hexadecimal code, and append for the specified access size.

Publication 900-UM004D-EN-E - July 2010

Page 23

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-7

Number of Elements

The number of elements is expressed in 2-byte hexadecimal code. The range

that can be specified for the number of elements depends on the command.

Refer to Detailed Description of Services on page 2-8.

List of Services

Table 2.6

MRC SRC Name of Service Process

01 01 Read from variable

area

01 02 Write to variable area This service writes to variable areas.

01 04 Composite Read from

Variable Area

01 13 Composite Write to

Variable Area

This service reads from variable areas.

This service reads from the variable area in

the order specified by the parameters.

This service writes to the variable area in the

order specified by the parameters.

05 03 Read Controller

Attributes

06 01 Read controller status This service reads the run status of the

08 01 Echoback test This service carries out the echoback test.

30 05 Operation instructions This service carries out run/stop,

This service reads the model number and

communications buffer size.

controller.

communications writing, write mode, save

RAM data, AT (auto-tuning) execution/cancel,

multi-SP, move to protect function, move to

setup area 1 and software reset.

Note: No commands will be accepted and no responses will be returned when

a memory error (RAM error) has occurred or the controller is initializing (until

the controller recognizes the process value after the power is turned ON).

Publication 900-UM004D-EN-E - July 2010

Page 24

2-8 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Read Data

(for number of elements)

Response

Code

4

SRC

2

MRC

2

0101

Service Response PDU:

Service Request PDU:

MRC2SRC

22 2

0101

Variable

Type

Read Start

Address

4

Bit

Position

Number of

Elements

4

00

Number of elements X 8 or 4

Detailed Description of

Services

Read from Variable Area

This service reads from variable areas.

• Variable Type and Read Start Address

For details on Variable Types and Read Start Addresses, refer to Chapter

3, Communications Data.

• Bit position

Bit accessing is not supported on the 900-TCx. It is fixed to 00.

• Number of elements

Table 2.7

Number of Elements Process

0000 The read operation is not performed (read data is

not appended to the service response PDU), and

processing ends in normal completion.

Double word 0001…0019 (1…25) The read operation is carried out, and processing

Word 0001…0032 (1…50)

ends in normal completion.

Publication 900-UM004D-EN-E - July 2010

Page 25

Response code

ATTENTION

!

Normal Completion

Table 2.8

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-9

Response

Code

0000 Normal completion No errors were found.

Error Occurred

Table 2.9

Response

Code

1001 Command too long The command is too long.

1002 Command too short The command is too short.

1101 Area type error The variable type is wrong.

1103 Start address out-of-range error The read start address is out of range.

110B Response too long The number of elements exceeds the

1100 Parameter error The bit position not 00.

2203 Operation error EEPROM error

Name Description

Error Name Cause

maximum/

Alarm function:

Even though alarms are not displayed on the controller's

display, they function normally in communications.

Publication 900-UM004D-EN-E - July 2010

Page 26

2-10 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Write to Variable Area

This service writes to the controller’s variable areas.

Service Request PDU:

MRC SRC

002

1

2

Variable

Type

22

Write Start

Address

4

Bit

Position

00

2

Number of

Elements

4

Write Data

(for number of elements)

Number of elements x 8 or 4

Service Response PDU:

MRC SRC Response

0 012

22 4

Code

• Variable Type and Write Start address

For details on variable types and write start addresses, refer to Chapter 3,

Communications Data.

• Bit position

Bit accessing is not supported on the 900-TCx controller. Fixed to 00.

• Number of elements

Table 2.10

Number of Elements Process

0000 The write operation is not performed (do not

append write data to the service request PDU)

and processing ends in normal completion.

Double word 0001…0018 (1…24) The write operation is performed and processing

Word 0001…0030 (1…48)

ends in a normal completion.

Publication 900-UM004D-EN-E - July 2010

Page 27

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-11

ATTENTION

!

Response code

Normal Completion

Table 2.11

Response Code Name Description

0000 Normal completion No errors were found.

Error Occurred

Table 2.12

Response Code Error name Cause

1002 Command too short The command is too short.

1101 Area type error Wrong variable type

1103 Start address

out-of-range error

1104 End address

out-of-range error

1003 Number of elements/

data mismatch

Write start address is out of range.

The write end address (write start address

+ number of elements) exceeds the final

address of the variable area.

The number of data does not match the

number of elements.

1100 Parameter error • Bit position is other than 00.

• Write data is out of range.

3003 Read-only data Variable type CO was written to.

2203 Operation error • The Communications Writing

parameter is set to OFF (disabled).

• Attempted to write to a parameter in

setup area 1 from setup area 0.

• Attempted to write to a protect

parameter from other than protect

group.

• AT (auto-tuning) was in progress. See

note.

• EEPROM error.

Note: For details on AT (auto-tuning), see publication 900-UM007*.

Alarm function:

Even though alarms are not displayed on the

controller's display, they are all functional in

communications.

Publication 900-UM004D-EN-E - July 2010

Page 28

2-12 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

MRC SRC

0104 00

22224

00

224

Variable

type

Read

address

Bit position

Variable

type

Read

address

Bit

position

Variable

type

Response code

Variable

type

Read data

22

MRC

SRC

0104

4

Number of elements ×8 or 4

2

2

Read data

Number of elements ×8 or 4

Composite Read from Variable Area

This service reads in order the contents of specified addresses in the variable

area.

Service Request PDU

Service Response PDU

Note: The read data is read together with the variable type in the order specified by the command.

Variable Type and Read Start Address

For details on variable types and read start addresses, Refer

to Communications Data on page 2-3.

Bit Position

The 900-TCx controllers do not support bit access. Fixed to “00.”

Number of Read Data Items (Variable Type + Read Data)

Table 2.13

Read Data Length Number of Read Data Items

For double word 20 max.

For word 25 max.

Response Code

Publication 900-UM004D-EN-E - July 2010

Normal completion

Page 29

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-13

Variable

type

Write

address

Variable

type

Write data

22

MRC

SRC

0113

00

224

00

224

Write data

Write

address

Bit position

Bit

position

Number of elements ×8 or 4

Number of elements ×8 or 4

MRC SRC

0113

22 4

Response

code

Table 2.14

Response Code Name Description

0000 Normal Completion No errors were found.

Error occurred

Table 2.15

Response Code Name Description

1002 Command too short The command is too short.

1101 Area type error The variable type is wrong.

110B Response too long

1100 Parameter error Bit position is not “00”.

2203 Operation error EEPROM error.

The number of elements

exceeds the maximum.

Composite Write to Variable Area

This service reads in order the contents of specified addresses in the variable

area.

Service Request PDU

Service Response PDU

Variable Type and Write Start Address

For details on variable types and read start addresses, Refer

to Communications Data on page 2-3.

Bit Position

The 900-TCx controllers do not support bit access. Fixed to “00.”

Publication 900-UM004D-EN-E - July 2010

Page 30

2-14 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Number of Write Data Items (Variable Type + Write Data)

Table 2.16

Read Data Length Number of Read Data Items

For double word 12 max.

For word 17 max.

Response Code

Normal completion

Table 2.17

Response Code Name Description

0000 Normal Completion No errors were found.

Error occurred

Table 2.18

Response Code Name Description

1002 Command too short The command is too short.

1101 Area type error The variable type is wrong.

• Bit position is not “00”.

1100 Parameter error

3003 Read-only error

2203 Operation error

• The write data is out of the

setting range.

Variable type “CO” was written

to.

• The Communications

Writing parameter is set to

“OFF” (disabled).

• Attempted to write to a

parameter in setup area 1

from setup area 0.

• Attempted to write to a

protect parameter from

other than the protect

group.

• AT (auto-tuning) was in

progress. See note.

• EEPROM error

Publication 900-UM004D-EN-E - July 2010

Note: For details on AT (auto-tuning), see publication 900-UM007*.

Page 31

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-15

MRC SRC

0503

22

MRC SRC

0503 00D9

22 4 10 4

Response

code

Model No.

Buffer

size

Read Controller Attributes

This service reads the model number and communications buffer size.

Service Request PDU

Service Response PDU

Model Number

The model number is expressed in 10-byte ASCII. When 10 bytes are

not required, pad the remaining bytes with spaces.

Buffer Size

The communications buffer size is expressed in 2-byte hexadecimal, and

read after being converted to 4-byte ASCII.

Buffer size: 40 bytes (= H’0028)

217 bytes (= H’00D9) (900-TC8, 900-TC16,

and 900-TC32 Series B)

Response Code

Normal Completion

Table 2.19

Response Code Name Description

0000 Normal completion No errors were found.

Error Occurred

Table 2.20

Response Code Name Description

1001 Command too long The command is too long.

2203 Operation error EEPROM error.

Publication 900-UM004D-EN-E - July 2010

Page 32

2-16 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Read Controller Status

This service reads the operating and error status of the controller.

Service Request PDU

MRC SRC

0 061

2 2

Service Response PDU

MRC SRC Response

0

6

0

22 4 22

Code

1

Run

Status

Related

Informa-

tion

Publication 900-UM004D-EN-E - July 2010

Page 33

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-17

Operating status

Table 2.21

Run Status Description

00 Control is being carried out (error has not occurred in setup area 0, and the

controller is running).

01 Control is not being carried out (state other than above).

Related information

7654 3210

0

Bit position

Heater overcurrent (CT1)

Heater current hold (CT1)

AD converter error

Heater overcurrent (CT2)

Heater current hold (CT2)

Display range exceeded

Input error

Response Code

Normal Completion

Table 2.22

Response Code Name Description

0000 Normal completion No errors were found.

Error Occurred

Table 2.23

Response Code Name Description

1001 Command too long The command is too long.

2203 Operation error EEPROM error

Echoback Test

This service carries out the echoback test

Service Request PDU

MRC SRC Test Data

0081

2 2 0 to 200

Publication 900-UM004D-EN-E - July 2010

Page 34

2-18 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Service Response PDU

MRC SRC Response

Code

0801

22

Test Data

0 to 200

Test data

Set any test data within the range 0…200 bytes of user-defined test data.

Set a value for the test data within the ranges shown below according to

the communications data length.

Table 2.24

Communications Data Length Test Data

8 bits ASCII data: H’20 to H’7E, or H’A1 to H’FE

7 bits ASCII data: H’20 to H’7E

Do not set H’40. Doing so results in no response.

Response code

Normal Completion

Table 2.25

Response Code Name Description

0000 Normal completion No errors were found.

Error Occurred

Table 2.26

Response Code Name Description

1001 Command too long The command is too long.

2203 Operation error EEPROM error.

Publication 900-UM004D-EN-E - July 2010

Page 35

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-19

MRC SRC

3005

22 4

Response

code

Operation Commands

This service performs operations like the following:

• Communications Writing

•RUN/STOP

•Multi-SP

• AT Execute/Cancel

•Write Mode

•Save RAM Data

• Software Reset

• Move to Setup Area 1

Service Request PDU

Related

MRC SRC

3005

2222

Command

code

informa-

Service Response PDU

• Move to Protect Group

•Auto/Manual Switch

• Parameter Initialization

• Alarm Latch Cancel

• Invert Direct/Reverse

Operation

• Program Start

tion

Publication 900-UM004D-EN-E - July 2010

Page 36

2-20 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Command Code and related information

Table 2.27

Command

Code

00 Communications writing 00: OFF (disabled)

01 RUN/STOP 00: Run

02 Multi-SP 00: Set point 0

03 AT execute/cancel 00: AT Cancel

04 Write mode 00: Backup mode

05 Save RAM data 00

06 Software reset 00

07 Move to setup area 1 00

08 Move to protect function

09 Auto/manual switch 00: Automatic mode

Description Related Information

01: ON (enabled)

01 : Stop

01 : Set point 1

02: Set point 2

03: Set point 3

01 : 100% AT execute

02: 40% AT execute

01 : RAM write mode

00

group

01: Manual mode

0B Parameter initialization 00: Initialize to defaults

0C Alarm Latch Cancel 00: Alarm 1 latch cancel

01: Alarm 2 latch cancel

02: Alarm 3 latch cancel

03: HB alarm latch cancel

04: HS alarm latch cancel

05: OC alarm latch cancel

0F: All alarm latch cancel

0E Invert Direct/Reverse

Operation

11 Program start 00: Reset

00: Not invert

01: Invert

01: Start

Response code

Normal Completion

Table 2.28

Response

Code

0000 Normal completion No errors were found.

Name Description

Publication 900-UM004D-EN-E - July 2010

Page 37

Error Occurred

Table 2.29

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-21

Response

Code

1001 Command too long The command is too long.

1002 Command too short The command is too short.

1100 Parameter error Instruction code and related information are wrong.

2203 Operation error • The Communications Writing parameter is

Error name Cause

set to OFF (disabled). However, note that the

error is accepted regardless of the

Communications Writing parameter setting

(ON/OFF).

• The command cannot be processed. For

details, refer to Description of operating

instructions and precautions information below.

• EEPROM error

Description of operation commands and precautions:

• Communications Writing

Set the Communications Writing parameter to “ON: enabled” or “OFF:

disabled” with the related information setting. The setting can be

accepted in both setup area 0 and setup area 1. An operation error will

occur, however, if enabling or disabling communications writing is set

for an event input.

• RUN/STOP

Set control to “run” or “stop” with the related information setting. The

setting can be accepted in both setup area 0 and setup area 1. An

operation error will occur, however, if RUN/STOP is set for an event

input.

•Multi-SP

Set four set points beforehand in the Adjustment group so that you can

switch to a desired set point. The setting can be accepted in both setup

Publication 900-UM004D-EN-E - July 2010

Page 38

2-22 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

area 0 and setup area 1. An operation error will occur in the following

situations.

– When AT is being executed.

– When the Multi-SP Uses parameter is set to OFF.

– When the Multi-SP Uses parameter is set to ON but multi-SP is set

for an event input (Number of Multi-SP Uses > 0).

• AT Execute/Cancel

Set AT (auto-tuning) to “execute” or “cancel” with the related

information setting. This command can be accepted in setup area 0 only.

An “operation error” will be generated in the following instances:

– When the RUN/STOP parameter is set to “stop”

– When the command is executed in “setup area 1”

– When ON/OFF control is being used

– When 40% AT is specified during 100% AT execution.

– When 100% AT is specified during 40% AT execution.

In addition, a parameter error will occur if 40% AT is specified during

heating and cooling control.

Note: If the same type of AT execution is specified during AT execution

(e.g., if 100% AT is specified during 100% AT execution), the AT will

not be restarted and the operation will end in normal completion with

no processing.

•Write Mode

Set either the backup mode or RAM write mode with the related

information setting. The setting can be accepted in both setup area 0

and setup area 1.

The number of EEPROM (non-volatile memory) write operations is

limited. Therefore, use RAM write mode when frequently overwriting

data.

Table 2.30

Write Mode Description

The data is written to EEPROM when the parameters in the

Backup mode

RAM write mode

operation/adjustment levels (excluding read-only parameters)

are written by communications.

The data is not written to EEPROM when the parameters in the

operation/adjustment levels (excluding read-only parameters)

are written by communications. Parameters can be changed by

operating the keys on the front panel of the controller.

Publication 900-UM004D-EN-E - July 2010

Page 39

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-23

– When the mode is switched from RAM write mode to backup mode,

the parameters in the Operation/Adjustment groups (excluding

read-only parameters) are written to EEPROM.

– The RAM write mode is enabled only when the Communications

Writing parameter is set to “ON” (enabled). Consequently, when the

Communications Writing parameter setting is changed to “OFF”

(disabled), the parameters in the Operation/Adjustment groups

(excluding read-only parameters) are written to EEPROM even if the

mode is set to RAM write mode.

•Save RAM Data

This command writes the parameters in the Operation/Adjustment

groups (excluding read-only parameters) to EEPROM. The setting can

be accepted in both setup area 0 and setup area 1.

• Software Reset

Restarts processing from the point when power is turned ON. The

setting can be accepted in both setup area 0 and setup area 1.

• Move to Setup Area 1

This command moves to “setup area 1” and can be accepted at both

setup areas 0 and 1. If the “Initial Setting/Communications Protect”

parameter is set to “2,” an “operation error” will be generated, and the

move to setup area 1 will be prohibited.

When this move is carried out from setup area 0, the display indicates

the Input Type parameter in the “Initial Setting group.” When this

operation command is executed in setup area 1, the display will not

change.

• Move to Protect Group

This command moves to the “Protect group” and can be accepted only

in setup area 0.When this command is issued in setup area 1, an

“operation error” will be generated, and the move to the protect level

will be prohibited.

• Moving to Protect Group in Manual Mode

When this operation command is issued in manual mode, an

“operation error” will be generated, and the move to the Protect

group will be prohibited.

•Auto/Manual Switch

This operation command switches the mode to manual mode or

automatic mode, based on the related information setting. This

command can be accepted in setup area 0 only. An “operation error”

will be generated in the following instances:

– When the command is executed in “setup area 1"

– When auto/manual switching is disabled (not displayed)

When the Controller is switched to manual mode, the “manual

manipulated variable” will be displayed. When the Controller is switched

from manual mode to automatic mode, the Operation group’s first

parameter will be displayed. When the Controller is switched to manual

Publication 900-UM004D-EN-E - July 2010

Page 40

2-24 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

mode while already in manual mode, the command will be completed

normally and the display will not change (the contents will not be

refreshed).

• Writing Auto/Manual Status in EEPROM

The write mode determines whether the auto/manual status is written

to EEPROM.

Table 2.31

Write Mode Description

Backup mode

RAM write mode

Note: When the auto/manual mode is switched with an operation

command through communications and the Controller is in RAM write

mode, the auto/manual status is not stored in EEPROM. Consequently,

if the Controller is restarted by performing a software reset or turning

the power OFF and ON again, the auto/manual mode is set to the last

saved status.

When the auto/manual mode is switched by communications,

the auto/manual status is written to EEPROM.

When the auto/manual mode is switched by communications,

the auto/manual status is not written to EEPROM.

The status can be written with the Controller key operation.

• Switching to Manual Mode during Auto-tuning

If the mode is switched during auto-tuning (AT), the AT will be

cancelled and the Controller will be switched to manual mode.

• Parameter Initialization

The present settings are returned to the default values and written to

EEPROM. This command can be accepted in setup area 1 only. When

this command is issued in setup area 0, an “operation error” will be

generated.

• Alarm Latch Cancel

Table 2.32

Related Information Explanation (Initialization Values)

Default initialization values (Refer to Communications Data on

00

page 2-3 for details.)

(These settings are the same as the ones used when “FACT” is

selected for the setting data’s set value initialization.)

The applicable alarm latch can be cleared with the related information

setting. The setting can be accepted in both setup area 0 and setup area

Publication 900-UM004D-EN-E - July 2010

Page 41

Bulletin 900 Communications Procedures 900-TCx (CompoWay/F) 2-25

Powe r O N

Software reset command

Setting area 0 Setting area 1

“Move-to-setting

area 1” command

Control in progress Control stopped.

1. An operation error will occur if communications writing is disabled or

if an EEPROM error occurs.

• Invert Direct/Reverse Operation

Inverting or not inverting direct/reverse operation can be selected with

the related information setting. The setting can be accepted in both

setup area 0 and setup area 1. The related information specifications are

written to EEPROM according to the write mode settings. An operation

error will occur in the following situations:

– When AT is being executed.

– When inverting direct/reverse operation is set for an event input.

– When executed in manual mode.

•Program Start

The simple program function can be reset/started with the related

information setting. The setting can be accepted in both setup area 0

and setup area 1. An operation error will be generated if program start

has been set in the event input.

•Setting Areas

Control operation is executed in setting area 0. In this state, you can

perform operations that are permitted only during control or those that

cause no problems even if control is in progress. These operations

include reading PVs, writing SPs, and change RUN/STOP status.

Setting area 0, however, prohibits operations that affect control,

including writing data at the initial setting level. (Reading setting data is

always allowed.)

In setting area 1, control operation is stopped. In this state, you can

perform operations that are not allowed in setting area 0. These

operations include writing data at the initial setting level.

At power-ON, the Temperature Controller is set in setting area 0. To

move to setting area 1, use the “move-to-setting area 1” command. To

return to setting area 0, turn the power OFF and ON again, or use the

“software reset” command.

Publication 900-UM004D-EN-E - July 2010

Page 42

2-26 Bulletin 900 Communications Procedures 900-TCx (CompoWay/F)

Response Code List

Normal Completion

Table 2.33

Response

Code

0000 Normal completion No errors were found. None

Name Description Error Detection

Error Occurred

Table 2.34

Response

Code

0401 Unsupported command The service function for the relevant command is not supported. 1

1001 Command too long The command is too long. 2

1002 Command too short The command is too short. 3

1101 Area type error Wrong variable type. 4

1103 Start address out-of-range

1104 End address out-of-range

1003 Number of elements/data

110B Response too long The response length exceeds the communications buffer size (when the

Name Description Error Detection

The read/write start address is out of range. 5

error

The write end address (write start address + number of elements) exceeds

error

mismatch

the final address of the variable area.

The amount of data does not match the number of elements. 7

number of elements is greater than the maximum number of elements for

that service).

Priority

Priority

6

8

1100 Parameter error • Bit position is not “00.”

• The write data is out of the setting range.

• The command code or related information in the operation command

is wrong.

3003 Read-only error Variable type “C0” was written to. 10

2203 Operation error • The Communications Writing parameter is set to “OFF” (disabled).

• Attempted to write to a parameter in setup area 1 from setup area 0.

• Attempted to write to a protect parameter from other than the protect

level.

• Writing was carried out during AT execution.

• Processing is not possible by operation command.

• EEPROM error.

Publication 900-UM004D-EN-E - July 2010

9

11

Page 43

Communications Data

Chapter

3

Variable Area (setup range)

List

This chapter lists the details of each of the communications data in the Bulletin

900-TCx communications procedures.

For communications using a variable type not enclosed in parentheses in the

following table, the set value is double-word data (8 digits). For

communications using a variable type enclosed in parentheses, the set value is

single-word data (4 digits).

For example, variable type C0 is double-word data (8 digits), and

variable type 80 is single-word data (4 digits).

Items expressed in hexadecimal in the “Set (monitor) value” column are the

setting range for CompoWay/F (900-TC) communications. The values in

parentheses are the actual setting range.

For details of variable areas that are described not in numerical values but by

text, refer to the relevant parameter descriptions. For details concerning the

operation of these controller parameters, refer to the applicable user manual

for the specific controller (See Table 1.3 on page 1-6).

3-1 Publication 900-UM004D-EN-E - July 2010

Page 44

3-2 Communications Data

Table 3.1 Variable Type C0 (80)

Variable

Ty pe

C0 (80) 0000 Process value Temperature: Follow the specified range of the sensor. Operation

C0 (80) 0001 Status➊➋ Refer to Status Structure on page 3-13

C0 (80) 0002 Internal set point➊ SP lower limit to SP upper limit

C0 (80) 0003 Heater current 1 value

C0 (80) 0004 MV monitor (heating) Standard : H’FFFFFFCE…H’0000041A (-5.0…105.0)

C0 (80) 0005 MV monitor (cooling) H’00000000…H’0000041A (0.0 …105.0)

C0 (80) 0006 Heater current 2 value

C0 (80) 0007 Leakage current 1

C0 (80) 0008 Leakage current 2

C0 (80) 0009 Soak time remain H’00000000…H’0000270F (0…9999)

C0 (80) 000C Multi-SP monitor H’00000000…H’0000270F (0…3)

C0 (80) 000E Decimal Point

C0 (80) 000F Control Output 1

C0 (80) 0010 Control Output 2

C0 (80) 0011

C0 (80) 0012

C0 (80) 0013

Address Item (Parameter)

Name

monitor

monitor

monitor

monitor

monitor➊

ON/OFF Count

Monitor

ON/OFF Count

Monitor

Status 2 ➊➋ Refer to Status Structure on page 3-13

Status ➊➌ Refer to Status Structure on page 3-13

Status 2 ➊➌ Refer to Status Structure on page 3-13

Set (monitor) Value Function

Analog: Scaling lower limit -5%FS to scaling upper limit +5%FS

H’00000000…H’00000226 (0.0…55.0)

Heating and cooling: H’00000000…H’0000041A (0.0…105.0)

H’00000000…H’00000226 (0.0…55.0)

H’00000000…H’00000226 (0.0…55.0)

H’00000000…H’00000226 (0.0…55.0)

H’00000000…H’0000270F (0…3)

H’00000000…H’0000270F (0…9999)

Group

Advanced

Function

H’00000000…H’0000270F (0…9999)

Operation

➊ Not displayed on the controller’s display

➋ When the variable type is 80 (word access), the rightmost 16 bits are read.

➌ When the variable type is 80 (word access), the leftmost 16 bits are read.

Table 3.2 Variable Type C1 (81)

Variable

Typ e

C1 (81) 0000 Operation/adjustmen

C1 (81) 0001 Initial setting/

C1 (81) 0002 Setup change

Address Item (Parameter) Set (Monitor) Value Function

t protection

communications

protection

protection

H’00000000(0) No restrictions in Operation and

H’00000001(1) Move to Adjustment function group

H’00000002(2) Display and change of only PV" and

H’00000003(3) Display of only PV and PV/SP parameters

H’00000000(0) Move to Initial Setting/Communications

H’00000001(1) Move to Initial Setting/Communications

H’00000002(2) Move to Initial Setting/Communications

H’00000000(0) OFF (changing of setup on controller

H’00000001(1) ON (changing of setup on controller

Adjustment function groups

restricted

PV/SP parameters enabled

enabled

Setting function group enabled (move to

Advanced Setting function group

displayed)

Setting function group enabled (move to

Advanced Function Setting function

group not displayed)

Setting function group restricted

display enabled)

display disabled)

Group

Protect

Publication 900-UM004D-EN-E - July 2010

Page 45

Communications Data 3-3

Table 3.2 Variable Type C1 (81)

Variable

Typ e

C1 (81) 0003 Set Point SP lower limit to SP upper limit Operating

C1 (81) 0004 Alarm Value 1 H’FFFFF831…H’0000270F (-1999…9999)

C1 (81) 0005 Upper-Limit Alarm 1 H’FFFFF831…H’0000270F (-1999…9999)

C1 (81) 0006 Lower-Limit Alarm 1 H’FFFFF831…H’0000270F (-1999…9999)

C1 (81) 0007 Alarm Value 2 H’FFFFF831…H’0000270F (-1999…9999)

C1 (81) 0008 Upper-Limit Alarm 2 H’FFFFF831…H’0000270F (-1999…9999)

C1 (81) 0009 Lower-Limit Alarm 2 H’FFFFF831…H’0000270F (-1999…9999)

C1 (81) OOOA Alarm Value 3 ➊ H’FFFFF831…H’0000270F (-1999…9999)

C1 (81) OOOB Upper-Limit

C1 (81) OOOC Lower-Limit

C1 (81) 000D Heater burnout

C1 (81) 000E SP 0 SP lower limit…SP upper limit

C1 (81) 000F SP 1 SP lower limit…SP upper limit

C1 (81) 0010 SP 2 SP lower limit…SP upper limit

C1 (81) 0011 SP 3 SP lower limit…SP upper limit

C1 (81) 0012 Temperature input

C1 (81) 0013 Upper-limit

C1 (81) 0014 Lower-limit

C1 (81) 0015 Proportional band H’00000001…H’0000270F (0.1…999.9)

C1 (81) 0016 Integral time H’00000000…H’00000F9F (0…3999)

C1 (81) 0017 Derivative time H’00000000…H’00000F9F (0…3999) (Range when RT is “OFF”)

Address Item (Parameter) Set (Monitor) Value Function

Alarm 3 ➊

Alarm 3 ➊

detection 1

shift

temperature input

shift value

temperature input

shift value

H’FFFFF831…H’0000270F (-1999…9999)

H’FFFFF831…H’0000270F (-1999…9999)

H’00000000…H’000001 F4 (0.0…50.0) Adjust

H’FFFFF831…H’0000270F (-199.9…999.9)

H’FFFFF831…H’0000270F (-199.9…999.9)

H’FFFFF831…H’0000270F (-199.9…999.9)

H’00000000…H’0000270F (0…999.9) (Range when RT is “ON”)

Group

-ment

C1 (81) 0018 Cooling coefficient H’00000001…H’0000270F (0.01…99.99)

C1 (81) 0019 Dead band H’FFFFF831…H’0000270F

C1 (81) 001A Manual reset value H’00000000…H’000003E8 (0.0…100.0)

C1 (81) 001B Hysteresis (Heating) H’00000001…H’0000270F

(-199.9…999.9 for TC/Pt universal input models)

(-19.99...99.99 for analog input models)

(0.1…999.9 for TC/Pt universal input models)

(.01...99.99 for analog input models)

C1 (81) 001C Hysteresis (Cooling) H’00000001…H’0000270F

(0.1…999.9 for TC/Pt universal input models)

(.01...99.99 for analog input models)

C1 (81) 001D Heater burnout 2

C1 (81) 001E HS alarm 1 H’00000000…H’000001F4 (0.0…50.0)

C1 (81) 001F HS alarm 2 H’00000000…H’000001F4 (0.0…50.0)

C1 (81) 0020 Soak time H’00000001…H’0000270F (1…9999)

C1 (81) 0021 Wait band H’00000000 (0): OFF

C1 (81) 0022 MV at stop Standard: H’FFFFFFCE…H’0000041A (−5.0…105.0)

C1 (81) 0023 MV at PV error Standard: H’FFFFFFCE…H’0000041A (−5.0…105.0)

C1 (81) 0024 Manual manipulated

detection

variable

H’00000000…H’000001F4 (0.0…50.0)

H’00000001…H’0000270F

(0.1…999.9 for TC/Pt multi-input models)

(0.01…99.99 for Analog input models)

Heating and cooling: H’FFFFFBE6…H’0000041A (−105.0…105.0)

Heating and cooling: H’FFFFFBE6…H’0000041A (−105.0…105.0)

Standard: H’FFFFFFCE…H’0000041A (−5.0…105.0)

Heating and cooling: H’FFFFFBE6…H’0000041A (−105.0…105.0)

Manual

Control

Publication 900-UM004D-EN-E - July 2010

Page 46

3-4 Communications Data

Table 3.2 Variable Type C1 (81)

Variable

Typ e

C1 (81) 0025 SP ramp set value H’00000000 (0): OFF

C1 (81) 0026 MV upper limit Standard: MV lower limit + 0.1…H’0000041A (MV lower limit +

C1 (81) 0027 MV lower limit Standard: H’FFFFFFCE…MV upper limit − 0.1 (−5.0…MV upper

C1 (81) 0028 Move Protect

C1 (81) 0029 Password to Move to

C1 (81) 002A Parameter mask

C1 (81) 002B PF Key Protect H’00000000 (0): OFF

C1 (81) 002C MV Change Rate

C1 (81) 002F Heater Overcurrent

C1 (81) 0030 Heater Overcurrent

C1 (81) 0031 Extraction of Square

Address Item (Parameter) Set (Monitor) Value Function

H’00000001…H’0000270F (1…9999)

0.1…105.0)

Heating and cooling: H’00000000…H’0000041A (0.0…105.0)

limit − 0.1)

Heating and cooling: H’FFFFFBE6…H’00000000 (−105.0…0.0)

function group

Protect function

group

enable

Limit

Detection 1

Detection 2

Root Low-cut Point

H’FFFFF831…H’0000270F (−1999…9999) Protect

H’FFFFF831…H’0000270F (−1999…9999)

(Can only be set. The monitor value is always H’00000000.)

H’00000000 (0): OFF

H’00000001 (1): ON

H’00000001 (1): ON

H’00000000...H’000003E8 (0.0...100.0) Adjust

H’00000000...H’000001F4(0.0...50.0)

H’00000000...H’000001F4 (0.0...50.0)

H’00000000...H’000003E8 (0.0...100.0)

Group

Adjust

ment

ment

Note: The alarm function can also be used on units without alarm outputs. In this case, confirm alarm occurrences via the status

data.

➊The parameter will not be shown on the Controller display when alarm 3 is not assigned to an output.

Publication 900-UM004D-EN-E - July 2010

Page 47

Communications Data 3-5

Table 3.3 Variable Type C3 (83)

Variable

Typ e

C3 (83) 0000 Input Type (TC/Pt

C3 (83) 0001 Scaling Upper Limit Scaling lower limit +1…0000270F (scaling lower limit +1…9999)

C3 (83) 0002 Scaling Lower Limit H’FFFFF831 to Scaling upper limit -1 (-1999 to scaling upper limit

C3 (83) 0003 Decimal Point

C3 (83) 0004 Temperature Unit H’00000000(0): °C

C3 (83) 0005 SP Upper Limit The range of values (without decimal point) is as follows:

C3 (83) 0006 SP Lower Limit The range of values (without decimal point) is as follows:

C3 (83) 0007 PID/ ON/OFF H’00000000(0) ON/OFF

C3 (83) 0008 Standard/Heating

Address Item (Parameter) Set (Monitor) Value Function

multi-input models)

➊

Input Type (analog

input models) ➊

Position (TC/Pt

multi-input models)

Decimal Point

Position (analog input

models)

and Cooling

H’00000000 (0): Pt (−200…850°C/−300…1500°F)

H’00000001 (1): Pt (−199.9…500.0°C/−199.9…900.0°F)

H’00000002 (2): Pt (0.0…100.0°C/0.0…210.0°F)

H’00000003 (3): JPt (−199.9…500.0°C/−199.9…900.0°F)

H’00000004 (4): JPt (0.0…100.0°C/0.0…210.0°F)

H’00000005 (5): K (−200…1300°C/−300…2300°F)

H’00000006 (6): K (−20.0…500.0°C/0.0…900.0°F)

H’00000007 (7): J (−100…850°C/−100…1500°F)

H’00000008 (8): J (−20.0…400.0°C/0.0…750.0°F)

H’00000009 (9): T (−200…400°C/−300…700°F)

H’0000000A (10): T (−199.9…400.0°C/−199.9…700.0°F)

H’0000000B (11): E (0…600°C/0…1100°F)

H’0000000C (12): L (−100…850°C/−100…1500°F)

H’0000000D (13): U (−200…400°C/−300…700°F)

H’0000000E (14): U (−199.9…400.0°C/−199.9…700.0°F)

H’0000000F (15): N (−200…1300°C/

H’00000010 (16): R (0…1700°C/0…3000°F)

H’00000011 (17): S (0…1700°C/0…3000°F)

H’00000012 (18): B (100…1800°C/300…3200°F)

H’00000013 (19): Infrared temperature sensor (K 140°F/60°C)

H’00000014 (20):Infrared temperature sensor (K 240°F/120°C)

H’00000015 (21):Infrared temperature sensor (K 280°F/140°C)

H’00000016 (22): Infrared temperature sensor (K 440°F/220°C)

H’00000017 (23): 0…50 mV

H’00000018 (24): W (0... 2300°C/0...3200°F)

H’00000019 (25): PL II (0... 1300°C/0...2300°F)

H’00000000 (0): 4…20 mA

H’00000001 (1): 0…20 mA

H’00000002 (2): 1…5 V

H’00000003 (3): 0…5 V

H’00000004 (4): 0…10 V

H’00000000…H’00000001 (0…1)

H’00000000…H’00000003 (0…3)

H’00000001(1): °F

Temperature: SP lower limit + 1 to Input range upper limit

Analog: SP lower limit + 1 to Scaling upper limit

Temperature: Input range lower limit to SP upper limit - 1

Analog: Scaling lower limit to SP upper limit - 1

H’00000001(1) 2-PID Control

H’00000000(0): Standard

H’00000001 (1) Heating and cooling

−300…2300°F)

-1)

Group

Initial

setting

➊ The input type can be selected to march the connected sensor. There are two input types specifications:

Thermocouple/Resistance thermometer input and Analog input.

➋ The parameter will not be shown on the Controller display when alarm 3 is not assigned to an output.

➌ Communications parameters are enabled after they have been changed by resetting the controller.

➍ For controllers with two event inputs (events 1 and 2), this cannot be set if the number of Multi-SP uses parameter is set to 1

or 2

➎ For controllers with two event inputs (events 1 and 2), this cannot be set if the number of Multi-SP uses parameter is set to 2.

➏ PRST (program start) can be set even when the program pattern is set to OFF, but the function will be disabled.

➐ The logic of CompoWay/F (900-TC) operation command code 00 (communications writing) is not affected.

➑ The setting (monitor) range depends on the transfer output type setting. (See the setting data list for details.)

➒ P.END (program end output) can be set even when the program pattern is set to OFF, but the

function will be disabled.

➓ The output turns ON when the status of either the Control Output 1 ON/OFF Count Alarm or the Control Output 2 ON/OFF

Count Alarm turns ON.

Publication 900-UM004D-EN-E - July 2010

Page 48

3-6 Communications Data

Table 3.3 Variable Type C3 (83)

Variable

Typ e

C3 (83) 0009 ST H’00000000(0): OFF

C3 (83) 000A Control Period (heat) H’00000000 (0): 0.5

C3 (83) 000B Control Period (cool) H’00000000 (0): 0.5

C3 (83) 000C Direct/Reverse

C3 (83) 000D Alarm 1 Type H’00000000(0) Alarm function OFF

C3 (83) 000E Alarm 2 Type H’00000000(0) Alarm function OFF

C3 (83) 000F Alarm 3 Type ➋

C3 (83) 0010 Communications unit

C3 (83) 0011 Baud rate 1➌ H’00000000(0) 1.2

C3 (83) 0012 Communications data

C3 (83) 0013 Communications stop

C3 (83) 0014 Communications

C3 (83) 0015 Number of multi-SP

Address Item (Parameter) Set (Monitor) Value Function

H’00000001(1): ON

H’00000001…H’00000063 (1…99)

H’00000001…H’00000063 (1…99)

Operation

number ➌