Page 1

INSTALLATION INSTRUCTIONS

BULLETIN 875C, 875CP, 875L CAPACITIVE PROXIMITY SENSOR

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

ATTENTION: Solid-state devices can be susceptible to radio frequency (RF) interference depending on the power

!

and the frequency of the transmitting source. If RF transmitting equipment is to be used in the vicinity

of the solid state devices, thorough testing should be performed to assure that transmitter operation is

restricted to a safe operating distance from the control equipment and its wiring.

ATTENTION: If a hazardous condition can result from unintended operation of this device, access to the sensing

!

area should be guarded.

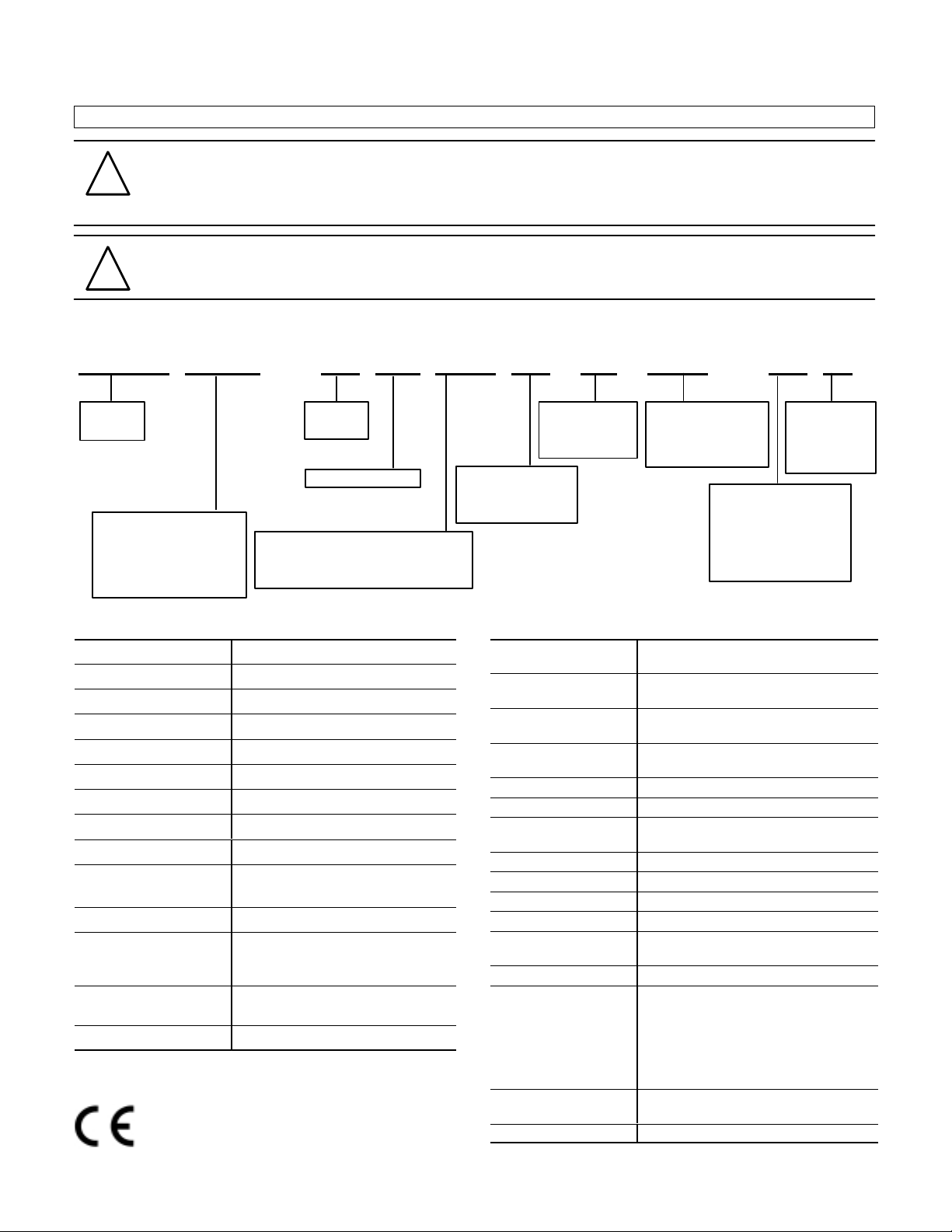

Part Number Configuration

875 CP – D M 30 N P 34 – A 2

Capacitive

Proximity

Sensor

C = Cylindrical metal body

(shielded)

CP = Cylindrical plastic body

(unshielded)

L = Limit switch style

Nominal sensing distance (in mm)

2, 5, or 10mm = shielded construction

4, 8, 20, or 30mm = unshielded construction

A=AC

D=DC

M = Smooth barrel

Specifications—AC Models

Max. Load Current 300mA

Inrush Current 2A

Leakage Current 3.5mA

Operating Voltage 20-250V

Voltage Drop <10V

Repeatability

Hysteresis

Max. Switching Frequency 15Hz

Transient Noise Protection Incorporated

Enclosure NEMA 12, IP65 (IEC 529)

Approval CE marked

Connections Cable 2Ćmeter length

Operating Temperature

Allen-Bradley capacitive sensors are manufactured and tested

to the international standard IEC 947–5–2.

≤10%

≤20%

Plastic or nickel-plated brass

2Ćconductor PVC

QuickĆDisconnect 3Ćpin micro

LEDs Green: Power

Yellow: Output

-25°C to +70°C (-13°F to +158°F)

P = PNP

N = NPN

E = Selectable

N = Normally open

C = Normally closed

E = Selectable

Specifications—DC Models

Max. Load Current 12, 18mm

Leakage Current 12mm

Operating Voltage 12mm

Voltage Drop 12, 18mm

Repeatability

Hysteresis

Max. Switching Frequency 12, 18, 30, 34mm

Transient Noise Protection Incorporated

Reverse Polarity Protection Incorporated

Short Circuit Protection Incorporated

Overload Protection Incorporated

Enclosure NEMA 12, IP65 (IEC 529)

Approval CE marked

Connections Cable 2Ćmeter length

LEDs Green: Power

Operating Temperature

Housing diameter (mm)

(cylindrical types)

Head width (mm) (limit

switch style types)

A = PVC cable

D = DC micro connector

P = Pico connector

R = AC micro connector

T = Terminal chamber

30, 34mm, limit switch style

18, 30, 34mm, limit switch style

18, 30, 34mm, limit switch style

30, 34mm, limit switch style

≤10%

≤20%

limit switch style

Plastic or nickelĆplated brass

3Ćconductor PVC

Quick-Disconnect 4Ćpin micro

3Ćpin pico

Conduit Opening 1/2Ć14 NPT internal

thread with screw

terminals

Yellow: Output

-25°C to +70°C (-13°F to +158°F)

Cable length (m)

Number of pins

Number of

terminals

200mA

400mA

0.3mA

0.1mA

10-36V

10-60V

<2V

<3V

25Hz

40Hz

Page 2

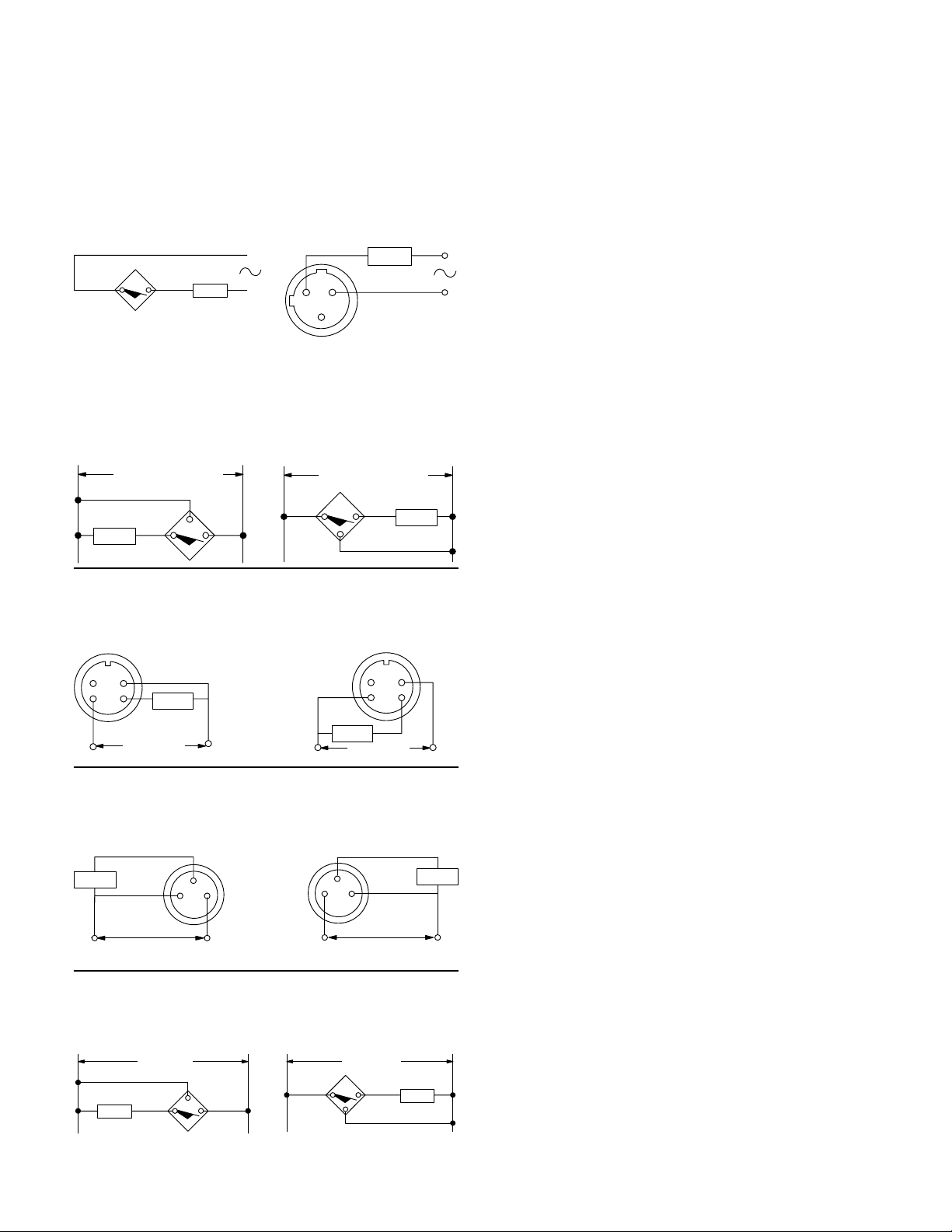

Wiring

All external wiring should conform to the National Electric

Code and applicable local codes. Connect the proximity

switch to the power supply and load as shown in the wiring

diagrams below. If the positive (+) and negative (–) wires are

reversed, the switch will not operate properly . The sensor will

not be damaged because it is equipped with reverse polarity

protection.

Wiring Diagrams for AC Switches

Cable Micro-Connector

Normally Open or Normally Closed

Black

Blue

Load

Note: Load can be switched to black wire.

3

2

1

Note: Load can be switched to pin 2.

Load

Wiring Diagrams for DC Switches

Cable

Normally Open or Normally Closed

+

NPN (Sinking)

10-36V DC (12mm)

10-60V DC (18-34mm)

Brown

+-

Load

Black

Blue

-

+ -

Micro-Connector

Normally Open or Normally Closed

NPN (Sinking)

21

34

-

Load

-+

10-60V DC

+

Pico-Connector

Normally Open or Normally Closed

NPN (Sinking)

Load

+

+-

10-36V DC (12mm)

10-60V DC (18mm)

4

31

Terminal Chamber

Normally Open or Normally Closed

+

NPN (Sinking) PNP (Sourcing)

10-60V DC

T1

+-

Load

T2

-

+ -

T3

PNP (Sourcing)

10-36V DC (12mm)

10-60V DC (18-34mm)

Brown

PNP (Sourcing)

-+

Load

-

PNP (Sourcing)

4

31

10-36V DC (12mm)

10-60V DC (18mm)

10-60V DC

T1

Black

Blue

21

34

10-60V DC

T2

T3

Load

Load

-+

+

+

Load

-

-+

-+

Wiring Switches in Series

Switches can be connected in series with a load. For proper

operation, the voltage across the energized load must be less

than or equal to the minimum supply voltage minus the

voltage drops across all sensors. The load will be energized

only when all switches are closed.

Wiring Switches in Parallel

Switches can be connected in parallel to energize a load. The

sum of the maximum leakage currents for the switches must

be less than the maximum off-state current of the load device.

The load will be energized when one or more of the switches

are closed.

Sensing Distance Adjustment

The sensing distance of an Allen-Bradley capacitive proximity

sensor can be adjusted via a twenty-turn potentiometer at the

rear of the sensor housing. Although this is a clutched

potentiometer, it does not emit an audible “click” when turned

beyond its range.

The maximum sensing distance for each sensor can be

determined using the part number configurator on page one. If

the sensing distance is set higher than the maximum, the unit

may lock in the triggered state. The minimum distance to

which each sensor can be adjusted is listed in the table below.

Nominal sensing distances are measured using a standard

target (see Target Considerations).

Minimum Adjusted Sensing Distances

12mm metal housing: 0.4mm

18mm metal housing: 1.0mm

18mm plastic housing: 2.0mm

30mm metal housing: 2.0mm

30mm plastic housing: 5.0mm

34mm plastic housing: 7.0mm

limit switch style housing: 10.0mm

This unit is not designed for reliable operation when adjusted

to distances shorter than those stated above.

Adjustment Procedure:

1. Mount the sensor on a stable surface or support (see

Mounting Considerations).

2. Apply power to the sensor per wiring diagrams (see

Wiring). Check that the green “power” LED turns on.

3. Determine a desired sensor-to-target distance which is

between the unit’s rated minimum and maximum sensing

distances (see Target Considerations and Dielectric

Constants).

4. Multiply this desired sensing distance by 1.2 and place the

target at the resulting new distance from the sensor.

Check the yellow “output” LED status.

5A.(Normally Open Models Only) If the yellow LED is off, turn

the potentiometer slowly clockwise until the LED turns on.

If the yellow LED is already on, turn the potentiometer

counterclockwise until the LED turns off, then slowly

clockwise until the LED turns on again.

5B.(Normally Closed Models Only) If the yellow LED is on,

turn the potentiometer slowly clockwise until the LED turns

off. If the yellow LED is already off, turn the potentiometer

counterclockwise until the LED turns on, then slowly

clockwise until the LED turns off again.

6. Remove the target and check that the yellow LED turns off

for normally open models and on for normally closed

models.

7. Place the target at the original desired sensor-to-target

distance determined in step 3. If the yellow LED turns on

for normally open models and off for normally closed

models, the sensor is correctly adjusted.

Page 3

Target Considerations

Standard Target

The standard target is a grounded, 1mm-thick square of mild

steel. The side lengths of a standard target are equal to either

the diameter/width of the sensor face or three times the

nominal sensing distance, whichever is greater.

Shielded vs. Unshielded

Shielded capacitive sensors can be used to sense either

conductive (metal, water) or nonconductive (wood, paper,

glass, plastic) materials. Their internal ground allows them to

detect grounded or ungrounded targets. It also makes them

more susceptible to dust and moisture in the environment than

unshielded sensors.

Unshielded capacitive sensors are used primarily to sense

grounded, conductive materials at maximum sensing

distances. They are less sensitive to nonconductive materials

than shielded sensors. This makes them able to detect

conductive materials through

a nonconductive material, such

as water inside a plastic tank. In this case, the nonconductive

material can be no thicker than the sensor’s sensing distance.

(Note: capacitive sensors cannot sense through metals.) Dust

and moisture in the atmosphere have less effect on

unshielded sensors than on shielded models.

Grounding

Targets should be grounded for most reliable sensing. If a

ground path to the target is not available, shielded sensors are

recommended. When attempting to detect nonconductive

materials with an unshielded sensor, a path to ground is

required.

Dielectric Constants

The dielectric constant is one of the material properties of a

target. Materials with higher dielectric constants are more

easily detected by capacitive sensors and are therefore

detected at greater sensing distances than those with low

constants. See page 4 for a list of common industrial materials

and their dielectric constants.

Correction Factors

Correction factors are multipliers which are determined by a

target’s mass, material, and grounding state. To calculate an

approximate sensing distance for an application, multiply the

nominal sensing distance S

by the correction factor for that

n

application’s target. The table below shows some typical

correction factors.

Correction Factors for Common Materials

Grounded metals 1.0

Ungrounded metals 0.85

Water 1.0

Glass 0.55

Paper (1 ream, 500 sheets) 0.55

Wood 0.45

Stone 0.65

Ceramic tile 0.25

PVC 0.15

Environmental Factors

Capacitive sensors can be compromised by humidity as well

as moisture on the sensor’s face. Oil or water droplets on the

sensor face can cause the unit to become unstable. Dust and

moisture in the atmosphere have less of an effect on

unshielded sensors than on shielded models.

Mounting Considerations

The control must be securely mounted on a firm, stable

surface or support. A mounting configuration which is unstable

or subject to excessive vibration may cause intermittent

operation.

Shielded vs. Unshielded

Shielded sensors can be mounted flush with surrounding

materials. Unshielded sensors must be mounted such that the

area around the sensing face is free of any material which

could trigger the sensor. Minimum clearance in all directions

should be equal to the diameter or width of the sensor.

Spacing Between Devices

When two shielded or unshielded sensors are facing each

other, they must be mounted far apart to avoid interference.

Minimum spacing should be eight times the housing diameter

or width. When two shielded sensors are mounted side by

side, the minimum distance between them must be greater

than one diameter or width. When two unshielded sensors are

mounted side by side, the distance between them should be

at least four times their diameter or width. See Dimensions

section for housing sizes.

Dimensions

Cylindrical Style

Potentiometer

and LEDs

2m

(6.5ft)

A

Potentiometer

and LEDs

M12 x 1

Thread Shld Conn. A B C D

M12x1 Y cable 12(0.47) 61.5(2.42) 40.5(1.59) N/A

M12x1 Y pico 12(0.47) 63.5(2.50) 40.5(1.59) N/A

M18x1 Y cable 18(0.71) 81.7(3.22) 60.7(2.39) N/A

M18x1 Y pico 18(0.71) 81.7(3.22) 60.7(2.39) N/A

M18x1 N cable 18(0.71) 81(3.19) 60(2.36) 20(0.79)

M18x1 N pico 18(0.71) 81(3.19) 60(2.36) 20(0.79)

M30x1.5 Y cable 30(1.18) 82(3.23) 61(2.40) N/A

M30x1.5 Y micro 30(1.18) 82(3.23) 61(2.40) N/A

M30x1.5 N cable 30(1.18) 80.5(3.17) 59(2.32) 20(0.79)

M30x1.5 N micro 30(1.18) 80.5(3.17) 59(2.32) 20(0.79)

N/A N cable 34(1.34) 85(3.35) N/A N/A

N/A N micro 34(1.34) 82(3.23) N/A N/A

B

A

B

Potentiometer

A

Potentiometer

and LEDs

M8 x 1 (pico)

M12 x 1 (micro)

and LEDs

D

C

B

C

B

mm(inches)

Limit Switch Style

120.0

NO/NC and PNP/NPN

Selector Switches

Conduit Entrance

1/2-14 NPT

30.0

(1.18)

Note:Head can be rotated in 15° increments to provide 24 sideĆ

sensing positions or rotated for top sensing.

(4.72)

15.9

(0.63)

LEDs

7.3

(0.29)

(6.5ft)

A

2m

D

60.0

(2.36)

Unshielded

Threaded

Version

Unshielded

Threaded

Version

41.5

(1.63)

41.5

(1.63)

D

D

Page 4

Dielectric Constants of Industrial Materials

This is a partial listing only . For more information, refer to the

CRC Handbook of Chemistry and Physics (CRC Press), the

CRC Handbook of T ables for Applied Engineering Science

(CRC Press), or other applicable sources.

Acetone 19.5

Acrylic Resin 2.7–4.5

Air 1.000264

Alcohol 25.8

Ammonia 15–25

Aniline 6.9

Aqueous Solutions 50–80

Bakelite 3.6

Benzene 2.3

Carbon Dioxide 1.000985

Carbon Tetrachloride 2.2

Celluloid 3.0

Cement Powder 4.0

Cereal 3–5

Chlorine Liquid 2.0

Ebonite 2.7–2.9

Epoxy Resin 2.5–6

Ethanol 24

Ethylene Glycol 38.7

Fired Ash 1.5–1.7

Flour 1.5–1.7

Freon R22 & 502 (liquid) 6.11

Gasoline 2.2

Glass 3.7–10

Glycerine 47

Marble 8.0–8.5

Melamine Resin 4.7–10.2

Mica 5.7–6.7

Nitrobenzine 36

Nylon 4–5

Oil Saturated Paper 4.0

Paraffin 1.9–2.5

Paper 1.6–2.6

Perspex 3.2–3.5

Petroleum 2.0–2.2

Phenol Resin 4–12

Polyacetal 3.6–3.7

Polyamide 5.0

Polyester Resin 2.8–8.1

Polyethylene 2.3

Polypropylene 2.0–2.3

Polystyrene 3.0

Polyvinyl Chloride Resin 2.8–3.1

Porcelain 4.4–7

Powdered Milk 3.5–4

Press Board 2–5

Quartz Glass 3.7

Rubber 2.5–35

Salt 6.0

Sand 3–5

Shellac 2.5–4.7

Shell Lime 1.2

Silicon V arnish 2.8–3.3

Soybean Oil 2.9–3.5

Styrene Resin 2.3–3.4

Sugar 3.0

Sulphur 3.4

Teflon 2.0

Toluene 2.3

Transformer Oil 2.2

Turpentine Oil 2.2

Urea Resin 5–8

Vaseline 2.2–2.9

Water 80

Wood, Dry 2–7

Wood, Wet 10–30

Capacitive Proximity Sensor Accessories

Mating Cables

The following are straight connector, 2-meter cables. Refer to

sensor catalog for other types.

AC Micro-Connector 871A–CS3–R2

DC Micro-Connector 871A–CS4–D2

DC Pico-Connector 871A–CS3–P2

Mounting Wells

12mm Delrin w/external thread 871A–WTD12

12mm Teflon w/external thread 871A–WTT12

18mm Delrin w/external thread 871A–WTD18

18mm Teflon w/external thread 871A–WTT18

30mm Delrin w/external thread 871A–WTD30

30mm Teflon w/external thread 871A–WTT30

30mm polyethylene, bolt-on type 871A–WSPE30

34mm Delrin w/external thread 871A–WTD34

34mm Teflon w/external thread 871A–WTT34

Mounting Brackets

Spring Return, stainless steel

12mm 871A–BXS12

18mm 871A–BXS18

30mm 871A–BXS30

Spring Return, anodized aluminum

12mm 871A–BXN12

18mm 871A–BXN18

30mm 871A–BXN30

Right Angle, stainless steel

12mm 871A–BRS12

12mm w/spring return bracket 871A–BRS22

18mm 871A–BRS18

18mm w/spring return bracket 871A–BRS30

30mm 871A–BRS30

30mm w/spring return bracket 871A–BRS47

Right Angle, nickel-plated brass

12mm 871A–BRN12

12mm w/spring return bracket 871A–BRN22

18mm 871A–BRN18

18mm w/spring return bracket 871A–BRN30

30mm 871A–BRN30

30mm w/spring return bracket 871A–BRN47

Clamp, plastic

12mm 871A–BP12

18mm 871A–BP18

30mm 871A–BP30

34mm 871A–BP34

Swivel/Tilt, plastic

30mm 60–2439

End Caps, plastic (unshielded models only)

12mm 871A–KP12

18mm 871A–KP18

30mm 871A–KP30

Conduit Adaptors, nickel-plated brass

12mm 871C–N13

18mm 871C–N19

30mm 871C–N31

Publication 46803–057–01(A)

March 1996

Printed in USA

Loading...

Loading...