Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

IMPORTANT

Ultrasonic Single Analog Output Sensors

Specifications

Model 873P-D18-400-D4 873P-D18-900-D4 873P-D18-2200-D4 873P-D30-2500-D4 873P-D30-3500-D4 873P-D30-6000-D4

Certifications cULus Listed and CE Marked for all applicable directives

Rated Sensing Distance

Teachable Sensing Range

Blind Zone

Beam Angle ±8° ±7° 14° ±1° 15° ±2°

Sensitivity Adjustment Push button

Linearity <1% of full scale value

Resolution 1 mm (0.04 in.) 2 mm (0.08 in.) 3 mm (0.12 in.) 2 mm (0.08 in.) 4 mm (0.16 in.) 6 mm (0.24 in.)

Accuracy 0.1% of sensing range

Hysteresis <1% of full scale value

Ripple 5%

Current Cons umption ≤50 mA

Output Type

Transducer Frequency 300 kHz 200 kHz 150 kHz 112 kHz 75 kHz

Response Time 500 ms 600 ms

Time Delay before Availability ≤900 ms ≤1400 ms

Electrical Protection Polarity reversal, transient noise, short circuit, overload

Minimum Load (analog voltage) 3 kΩ

Maximum Current (analog voltage output) 40 mA

Temperature Range -20…+60° C (-4…+140° F) -20…+70° C (-4…+158° F)

Temperature Compensation Yes

Temperature Drift ±5%

Housing Material Plastic—PBT

Active Head Material Epoxy—glass resin

Ingress Protection Rating IP67 (EN 60529)

AV–Analog voltage (0…10V DC) or AI–Analog current (4…20 mA)

Metallic target 100 x 100 mm (3.94 x 3.94 in.)

Metallic target 200 x 200 mm (7.87 x 7.87 in.)

Metalic target 400 x 400 mm (15.75 x 15.75 in.)

50…400 mm

(1.97…15.7 in.)

100…400 mm

(3.94…15.7 in.)

0…50 mm

(0…1.97 in.)

AV or AI

100…900 mm

(3.94…35.4 in.)

100…900 mm 200…2200 mm 200…2500 mm 250…3500 mm 350...6000 mm

0…100 mm

(0…3.94 in.)

200…2200 mm

(7.87…88.6 in.)

0…200 mm 0…200 mm 0…250 mm 0...350mm

200…2500 mm

(7.87…98.4 in.)

250…3500 mm

(9.87…137.8 in.)

350…6000 mm

(13.8…236.2 in.)

Operating Volt age Catalog Numbers

12…30V DC 873P-D30AI-2500-D4, 873P-D30AI-3500-D4, 873P-D30AI-6000-D4

873P-D18AV-400-D4, 873P-D18AI-400-D4,

15…30V DC

873P-D18AV-900-D4, 873P-D18AI-900-D4,

873P-D18AV-2200-D4, 873P-D18AI-2200-D4, 873P-D30AV-2500D4, 873P-D30AV-3500-D4, 873P-D30AV-6000-D4

The 873P sensor is a one set point mode with a

maximum sensing range from the factory.

Rockwell Automation 873P-IN005A-EN-P—October 2014

Page 2

2 873P Ultrasonic Single Analog Output Sensors

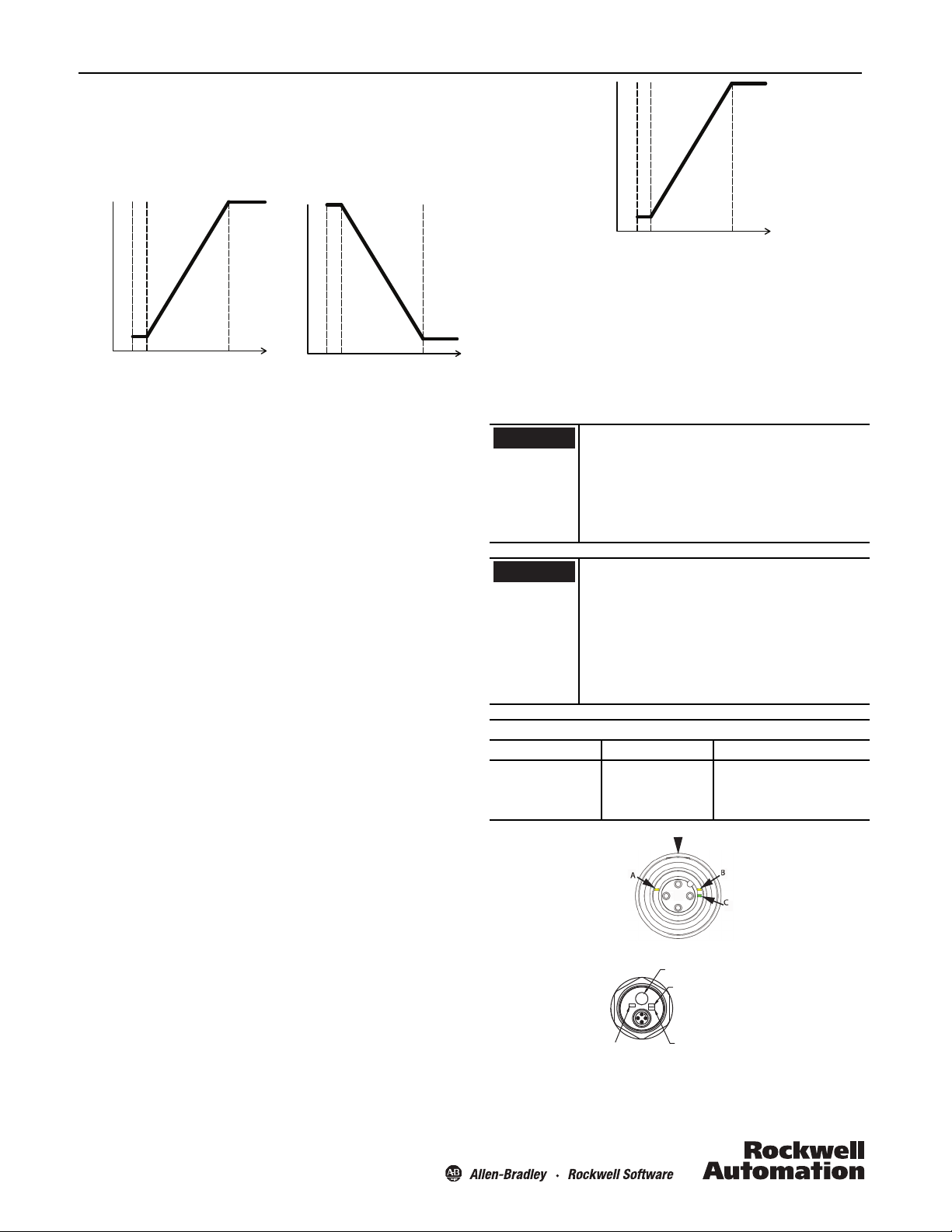

20 mA/

10V DC

Rising

Ramp

Pin 4

(BK)

Blind Zone

4 mA/

0V DC

mmP2P1BZ

20 mA/

10V DC

Falling

Ramp

Pin 4

(BK)

Blind Zone

4 mA/

0V DC

mmP1P2BZ

20 mA/

10V DC

Rising

Ramp

Pin 4

(BK)

Blind Zone

4 mA

0V DC

mmP1=P2Minimum

Sensing

Distance

BZ

Window Mode

In this sensing mode, you teach the sensor a near set point and far

set point within the defined sensing range of the sensor. P1 and

P2 define the analog output slope. P1 determines the 4 mA/0V DC

position and P2 determines the 20 mA/10V DC position. The

analog output is scaled between the two taught set points.

Rising ramp: current or voltage values increase as the target

distance increases from the sensor.

1. Place the target at the desired set point.

2. Press and release the teach button. The yellow and green LEDs

flash simultaneously, indicating that the sensor has learned the

set point.

3. Keeping the target in the same position, press and release the

teach button. The yellow LED blinks twice to indicate that the

sensor is ready for use. The minimum sensing distance is

indicated in the Specifications table.

Falling ramp: current or voltage values decrease as the target

distance increases from the sensor.

Set Point 1 (P1)

1. Place target at the desired near/far set point.

a. The near set point first yields a rising ramp.

b. The far set point first yields a falling ramp.

2. With the target still in place, press the teach button, then

release.

The yellow and green LEDs flash simultaneously, indicating that

the first set point P1 is now set. The sensor is waiting for the last

set point.

Set Point 2 (P2)

1. Place the target at the desired far/near set point.

2. Press the teach button and release. The sensor is ready to

operate.

One Set Point Mode

In this sensing mode, a set point is taught in the defined sensing

range. The working range of the sensor becomes the minimum

sensing distance to a user-taught set point. Depending on where

the set point is taught, the output will turn ON when the target

passes between the minimum sensing distance of the sensor and

the taught set point. The analog output is scaled between those

two set points. When using the One Set Point mode, it is only

possible to configure the sensor for rising ramp analog

output. It is not possible to configure the sensor for a falling

ramp.

IMPORTANT

When configuring the sensor for One Set Point

mode, it is very important that the target is at the

exact same distance for both the first and second

push of the teach button. If the target (or sensor)

has moved even slightly, the detected ranges will

be different for the two pushes of the teach

button, and the sensor will be configured for

Window Mode.

IMPORTANT

The green and yellow LEDs flash asynchronously

for about two seconds indicating there is no

target present within the sensing range of the

sensor and therefore no set point to teach. When

this happens, the 873P ignores this teach

attempt and restores its previous settings. By

comparison, when an object is detected during

the teach, the yellow and green LEDs flash

synchronously and continue flashing until the

second push of the teach button.

Single Analog Output Indicator LED Functions

LED Color Function

AYellow Output state

B Yellow Teach function

C Green ECHO LED/ Teach function

M18 LEDs

(Yellow)

Output state

Teach button

4

(Yellow)

Teach

123

(Green)

Echo/teach

Yellow LED A

output state

Rockwell Automation 873P-IN005A-EN-P—October 2014

M30 LEDs

Teach button

Yellow LED B

Teach function

AB

C

Green LED C

Echo LED/teach function

Page 3

873P Ultrasonic Single Analog Output Sensors 3

Single Analog Output

Operating Mode

Green LED

(Alignment)

Yellow LED A

(Output) Yellow LED B (Teach)

Standard Operation

Target present ON ONor OFF OFF

Target absent ON/OFF ON or OFF OFF

Green LED indicates that an echo is reflected back to the

sensor by an object, not necessarily the target. Its primary use

if for alignment.

If rising ramp

If falling ramp

Other Functions

Hold Function

The Hold function inhibits sensor operation and holds the output

to its present state.

Analog Output: If the HOLD pin is connected to the NEG, the

ultrasonic wave emission is stopped and the analog output is

frozen in the present state. If the SYNC pin is connected to the

POS or not connected, the sensor operates normally.

Lockout Feature for Teach Button

The lockout feature locks the push button to prevent unwanted

teaching of the sensor.

Lock Teach Button: Press the teach button for eight seconds,

until the yellow LEDs A and B flash alternately with the green LED

C. Release the teach button. The push button is now locked.

Unlock Teach Button: Press the teach button for eight seconds,

until the yellow LEDs A and B flash alternately with the green LED

C. Release the teach button. It is once again possible to teach the

sensor.

Synchronization of Ultrasonic Sensors

In this mode, all sensors are connected to a same output on the

PLC. A SYNC pulse simultaneously drives all sensors connected to

the output on the PLC. When mounting the sensors, attention

must be paid to a minimum distance between the sensors; said

distance varies depending on the type(s) of sensors used (see

below). The target must be positioned at the same distance from

each synchronized sensor; the target position should overall be

flat. When mounted correctly, the synchronized sensors perform

like a single sensor with an extended detection angle.

How it Works:

Connect Pin 2 (white) to all the sensors you want to synchronize.

All sensors will trigger at the same time. Any eventual crosstalk

signal related to a longer sensing distance will be ignored. An

external synchronization pulse controls the sensors.

All minimum distances depend on target distance and material.

“T” is the pulse time period applied on the SYNC wire; “Width”

refers to the pulse width.

• 400 mm Sensing Range Sensors

T ≥ 4 msec

500 μsec ≤ Width ≤ 1 msec

Minimum distance between sensors: 50

• 900 mm Sensing Range Sensors

T ≥ 7.5 msec

500 μsec ≤ Width ≤ 1 msec

Minimum distance between sensors: 30

…100 mm.

…50 mm.

• 2200 mm Sensing Range Sensors

T ≥ 17.5 msec

500 μsec ≤ Width ≤ 1 msec

Minimum distance between sensors: 30

…40 mm.

• 2500 mm Sensing Range Sensors

T ≥ 25 msec

500 μsec ≤ Width ≤ 5 msec

Minimum distance between sensors: 100 mm for working

distances up to 1.5 m, and 50 mm for distances greater than

1.5 m. Target material also affects these distances.

• 3500 mm Sensing Range Sensors

T ≥ 35 msec

500 μsec ≤ Width ≤ 5 msec

Minimum distance between sensors: 100 mm for working

distances up to 1.5 m, and 50 mm for distances greater than

1.5 m. Target material also affects these distances.

• 6000 mm Sensing Range Sensors

T >=60 ms

500 usec<=Width<= 1 msec

Minimum distance between sensors is 200 mm. Target material

also affects these distances.

Beam Diagrams

50…400 mm Sensing Range

150

100

50

-50

Parallel displacement [mm]

-100

-150

300

250

200

150

100

-100

Parallel displacement [mm]

-150

-200

-250

-300

200…3500 mm

400

350

300

250

200

150

100

-50

-100

-150

Parallel displacement [mm]

-200

-250

-300

-350

-400

0

0 100

50

0

-50

0 500

50

0

0 1000

Target 100*100 mm

Target 25 mm dia.

Target 100*100 mm

Target 25 mm dia.

Target 100*100 mm

(3.93)

(7.87)

Distance [mm (in.)]

Target 25 mm dia.

Target 25 mm dia.

(19.68)

Distance [mm (in.)]

Target 25 mm dia.

Target 25 mm dia.

(39.3)

200

1000

(39.3)

300

(11.8)

Target 200*200 mm

Target 200*200 mm

Target 200*200 mm

1500

(59.0)

Target 200*200 mm

Target 200*200 mm

Target 200*200 mm

2000

(78.7)

Distance [mm (in.)]

3000

(118.1)

(15.7)

400

2000

(78.7)

100…900 mm Sensing Range

-100

Parallel displacement [mm]

-150

-200

500

(19.6)

200…2500 mm Sensing Range200…2200 mm Sensing Range

Parallel displacement [mm]

2500

(98.4)

6000 mm

600.0

500.0

400.0

300.0

200.0

100.0

-100.0

-200.0

Parallel displacement [mm]

-300.0

-400.0

-500.0

-600.0

4000

(157.4)

200

150

100

50

0

-50

300

250

200

150

100

50

0

-50

-100

-150

-200

-250

-300

0.0

0 200

0 500

1000

0

(39.4)

400

(7.87)

(15.7)

Distance [mm (in.)]

Target 25 mm dia.

Target 25 mm dia.

1000

(19.6)

(39.3)

Distance [mm (in.)]

Target 200*200 mm

Target 200*200 mm

2000

(78.7)

Distance [mm (in.)]

3000

(118.1)

1500

(59.0)

Target 200*200 mm

Target 25 mm dia.

Target 200*200 mm

Target 25 mm dia.

Target 200*200 mm

600

800

(23.6)

(31.4)

Target 200*200 mm

Target 200*200 mm

Target 200*200 mm

2000

(78.7)

Target 400*400 mm

Target 400*400 mm

5000

4000

(196.8)

(157.5)

2500

(98.4)

(236.2)

1000

(39.3)

3000

(118.1)

7000

6000

(275.6)

Rockwell Automation 873P-IN005A-EN-P—October 2014

Page 4

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

4 873P Ultrasonic Single Analog Output Sensors

Solid-state devices can be susceptible to radio

frequency (RF) interference depending on the

power and the frequency of the transmitting

source. If RF transmitting equipment is to be

used in the vicinity of the solid-state devices,

thorough testing should be performed to assure

that transmitter operation is restricted to a safe

operating distance from the sensor equipment

and its wiring.

ATTENTION

If a hazardous condition can result from

unintended operation of this device, access to

the sensing area should be guarded.

3

(0.12)

M12x1

14

(0.55)

93.2

(3.67)

19.2

(0.76)

2.5

(0.098)

57.5

(2.26)

M18x1)

8.3

(0.33)

3

(0.12)

M12x1

10

(0.39)

99.8

(3.93)

18.2

(0.72)

2

(0.08)

69.6

(2.74)

M30x1.5)

10

(0.39)

8.5

(0.33)

3

(0.12)

M12x1

10.4

(0.41)

100

(3.94)

19.5

(0.77)

1

(0.04)

38.8

(1.53) dia.

M30x1.5)

Wiring Diagrams

HOLD/

SYNC

2

3

1

4

4-20 mA

LOAD

-+

-+

Analog Current

IMPORTANT

Dimensions [mm (in.)]

HOLD/

SYNC

2

3

1

4

0-10 VDC

LOAD

-+

-+

Analog Voltage

M18

M30

M38

Rockwell Automation maintains current product environmental information on its website at

http//www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

Allen-Bradley and Rockwell Automation are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies.

.

Publication 873P-IN005A-EN-P—10000678913 Ver 01—October 2014

Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the USA.

Loading...

Loading...