Page 1

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Specifications

ATTENTION

If a hazardous condition can result from

unintended operation of this device, access to

the sensing area should be guarded.

Solid-state devices can be susceptible to radio

frequency (RF) interference depending on the

power and the frequency of the transmitting

source. If RF transmitting equipment is to be

used in the vicinity of the solid-state devices,

thorough testing should be performed to

assure that transmitter operation is restricted

to a safe operating distance from the sensor

equipment and its wiring.

Installation Instructions

Ultrasonic Analog Sensors

IMPORTANT

General 300 mm Models 800 mm Models

Sensing range [mm (in.)] 30…300

(1.18…11.81)

Adjustment range [mm (in.)] 50…300

(1.96…11.81)

Blind zone [mm (in.)] 0…30 (0…1.18) 0…50 (0…0.96)

Standard target [mm (in.)] 100 x 100 (3.93 x 3.93)

Frequency Approx. 390 kHz Approx. 255 kHz

Response delay Approx. 30 ms Approx. 100 ms

Operating temperature

[C (F)]

Storage temperature [C (F)] -40…85° (-40…185°)

Electrical

Operating voltage 10…30V DC (analog voltage models are

Output current 200 mA

Current consumption <20 mA

Protection type Short-circuit, reverse polarity, overload

Output

Output type Analog: 4…20 mA/0…10V DC

Resolution 0.4 mm at max. sensing range

Repeat accuracy ±0.5% of full-scale value

Sensitivity adjustment Remote teach/optional programming

Environmental

Enclosure type rating IP67

Shock 30 g, 11 ms

Housing material Brass, nickel-plated

Connection Micro-quick disconnect

Certifications cULus listed and CE marked for all

-25…70° (-13…158°)

15…30V DC)

depending on model*

cable

applicable directives

50…800

(1.96…31.49)

70…800

(2.75…31.49)

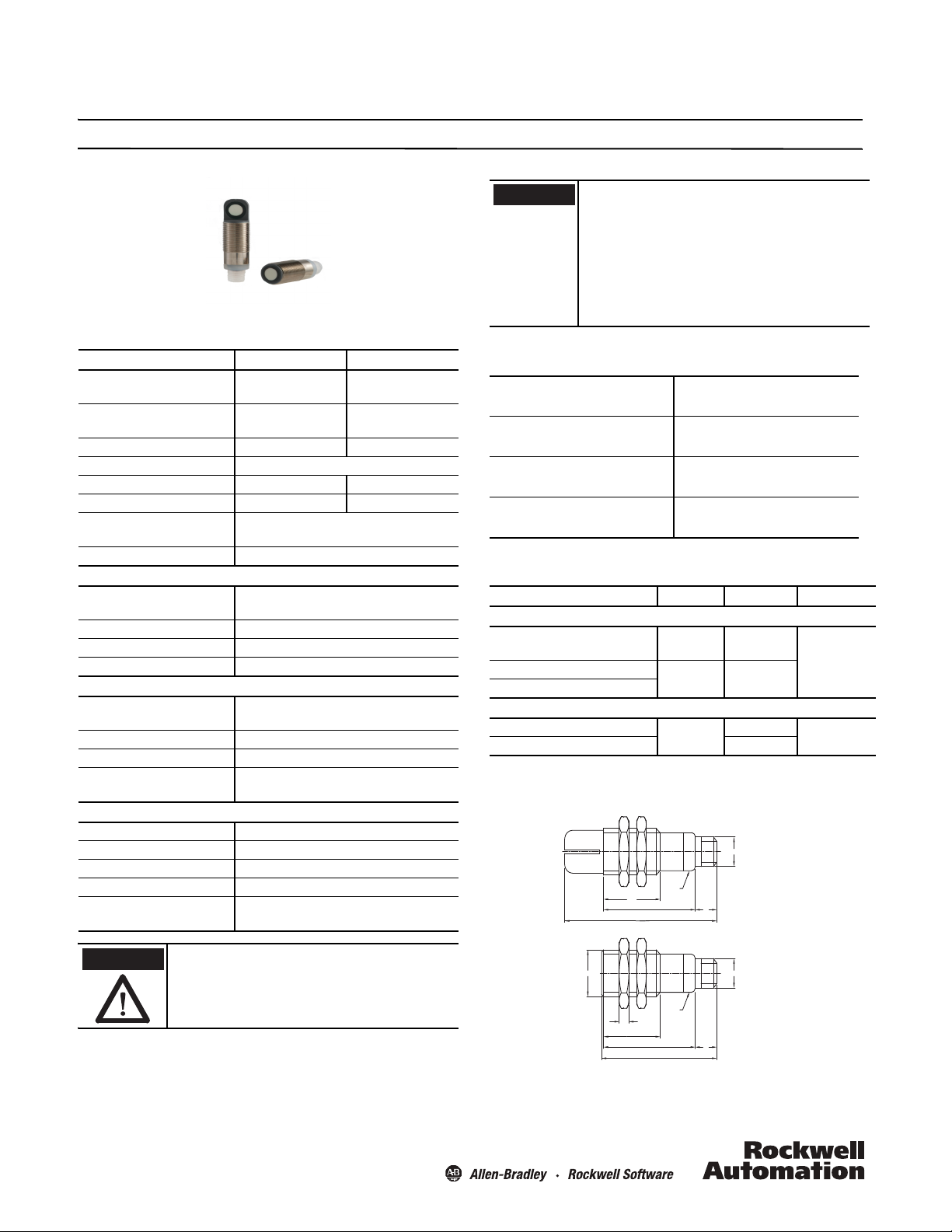

Models covered:

873M-D18AI300-D4

Analog current

873M-D18AI800-D4

Analog current

873M-D18AV300-D4

Analog voltage

873M-D18AV800-D4

Analog voltage

873M-D18RAI300-D4

Right angle, analog current

873M-D18RAI800-D4

Right angle, analog current

873M-D18RAV300-D4

Right angle, analog voltage

873M-D18RAV800-D4

Right angle, analog voltage

Indicator LED

Operating Mode Red LED Yellow LED Green LED

Tea ch Mode

Tar get det ect ed

No target detected

Target marginal (invalid teach)

Standard Mode

Target present

Target not present Off

One flash

Flashes Off

Off

Continuous

flash

On

Off

On

Dimensions [mm (in.)]

Right Angle Model

M12X1

LED

24.5

(0.96)

39.2 (1.54)

67 (26.6)

10

(0.39)

Straight Model

4

(0.16)

24.5 (0.96)

39.2 (1.54)

67.7 (2.66)

LED

10

(0.39)

M12X1M18X1

Page 2

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

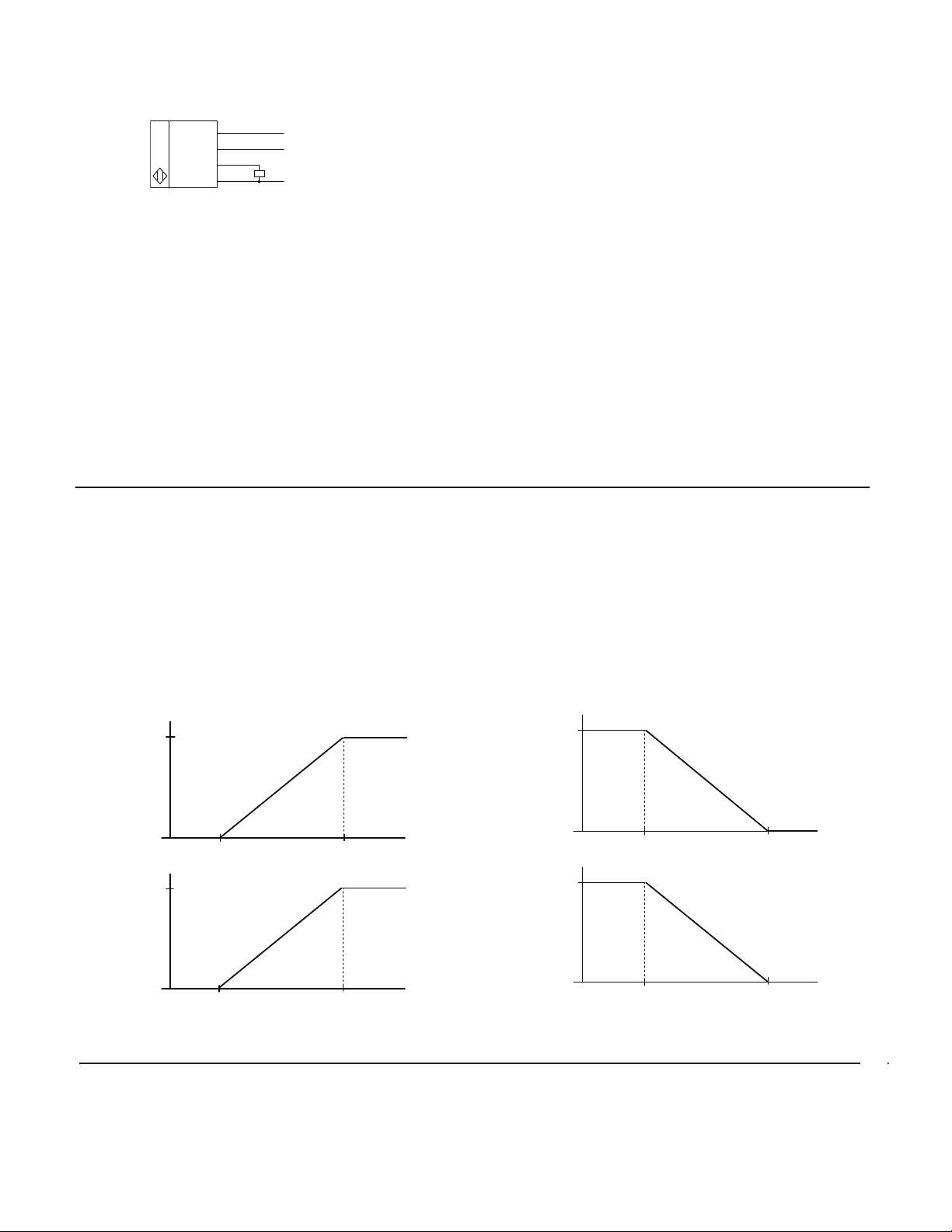

Wiring Diagram

Target Position

4

20

Set point P2Set point P1

Analog Current (mA)

Target Position

0

10

Set point P2Set point P1

Analog Voltage (V DC)

Target Position

4

20

Set point P1Set point P2

Analog Current (mA)

Target Position

0

10

Set point P1Set point P2

Analog Voltage (V DC)

1 (Brown)

2 (White)

4 (Black)

3 (Blue)

* Analog Voltage models are 15…30V DC

+10…30V DC *

Remote teach

Analog output by cat. no.

0V DC

Analog Output Characteristics

• The analog output mode returns a 4…20 mA or 0…10V DC

signal proportional to the measured value.

• The upper and lower adjustment range can be scaled to

distance-fixed window, giving the user more flexibility.

• The sensor is taught using an easy four-step remote teach

process or an optional programming cord.

• Two output functions: rising ramp and falling ramp.

Overview of Sensing and Adjustment Ranges

• When the target is beyond the far limit, or if target is absent,

the output is identical to the status at the far limit.

Setting Measurement Range

Rising Ramp: current or voltage values rise as the distance from

the target to the sensor increases.

Follow the steps below in the order they appear.

1. Place the target at the lower set point limit.

2. Using the white wire, connect to 0V DC [–] or press A1 on the

optional programming cable.

3. Place the target at the upper set limit.

4. Using the white wire, connect to 10…30V DC [+] or press A2 on

the optional programming cable

For example, if the span window is set to 4 mA at 7.62 mm (3

in.), and 20 mA at 203.2 mm (8 in.), the output will be 20 mA

when the target is anywhere at or beyond 203.2 mm (8 in.), or if

no target is present.

•In the blind zone, the output status is unpredictable because

the sensor does not have time to settle after the pulse. It is

therefore unable to accurately “hear” or interpret an echo.

•The adjustment range is where programming limits can be

stored; the sensing range is where stable sensing is possible

(see “Specifications”).

• The following example for a 300 mm sensor demonstrates the

need for both adjustment and sensing ranges:

If the blind zone were 0…30 mm, and you set a sensing

window of 50…300 mm, the output would become random/

unpredictable if the target object moved even slightly closer to

the sensor than 30 mm.

By defining the sensing range (usable but non-adjustable area

between 30 mm and 50 mm), the output is guaranteed to be

stable if the target mistakenly moves closer than the 50 mm

adjustable limit. Once the target moves into the blind zone

(closer than 30 mm) the output status becomes random/

unpredictable.

Falling Ramp: current or voltage values fall as the distance from

the target to the sensor increases.

Follow the steps below in the order they appear.

1. Place the target at the lower set point limit.

2. Using the white wire, connect to 10…30V DC [+] or press A2 on

the optional programming cable.

3. Place the target at the upper set limit.

4. Using the white wire, connect to 0V DC [–] or press A1 on the

optional programming cable.

10000231110 Ver 03

873M-IN001A-EN-P

June 2013

Loading...

Loading...