Page 1

Installation Instructions

Sensor

Operating Voltage

10.8-30V DC

/

MAR/

873E RightSoundt Ultrasonic Opposed Mode Sensors

S Continuously adjustable emitter amplitude with instability

indicator allows for simple optimized adjustment over 2

inch to 30 inch sensing range.

S Ideal solution for sensing clear objects or materials

including glass and plastic bottles.

S Highly immune to ambient sonic and electrical noise.

S Popular right angle package allows through hole mounting

as well as 18mm threaded mounting hubs on the sensor

nose and base.

S Highly visible 360

top of the sensor.

S Designed to Rugged Food Industry Standards: enclosure

rated for 1200psi washdown as well as NEMA 4X, 6P and

IP67 water ingress standards.

S Receivers come with both NPN (sinking) and PNP

(sourcing) outputs; output logic switchable via polarity of

receiver power wiring; simplified product selection…

Select a 6.5 foot cable or a 6 inch pigtail quick-disconnect

and cordset and you’re ready to start sensing!

S 10.8–30V DC operation with protections for short circuit,

overload, reverse polarity, false pulse and transient noise

Description

RightSound Bulletin 873E sensors are opposed mode

ultrasonic sensors consisting of an emitter and a receiver.

The receiver is microprocessor based to provide advanced

temperature stability and noise immunity. A red instability

indicator LED is used to signal the operator when an

unreliable sensing condition is present due to low or high

emitter sound levels or of adverse environmental conditions.

Green power LEDs indicate power status to the emitter and

receiver. A yellow output energized LED indicates when the

receiver output is on. Precise tuning of the receiver to the

emitter minimizes interference from ambient noise sources.

A major advantage of the RightSound sensor is the emitter

volume control. The emitter volume control allows the

operator to correctly adjust the volume for the sensing

distance (distance from the emitter to the receiver) and other

variables of a given application (i.e., target speed and

spacing, etc.). For further details on this subject, please refer

to page 4 of this document, Application Information.

The sensing of clear objects, which can be difficult to do

reliably with photoelectric controls, is made highly reliable

with RightSound ultrasonic sensors. RightSound sensors

have been designed for demanding environments, especially

those of the Food and Beverage Industry. The NORYL

housings are extremely rugged and are rated for 1200psi

washdown and NEMA 4X and 6P standards. The acoustic

faces of the emitter and receiver are made of FDA compliant

silicone rubber for maximum durability and water ingress

protection.

RightSounds require 10.8V DC to 30V DC power. Receivers

come with both NPN current sinking and PNP current

sourcing outputs. Both outputs are rated 100mA. The receiver

has the ability to operate in either a normally open or normally

closed mode. The modes are selected by the polarity of

receiver supply voltage (see Wiring Diagrams on page 2).

When the receiver is in the normally open mode, the output

conducts when the receiver hears a RightSound emitter.

_

indicators conveniently mounted at the

When the receiver is in the normally closed mode, the output

conducts when the sonic beam from the emitter is blocked or

not present.

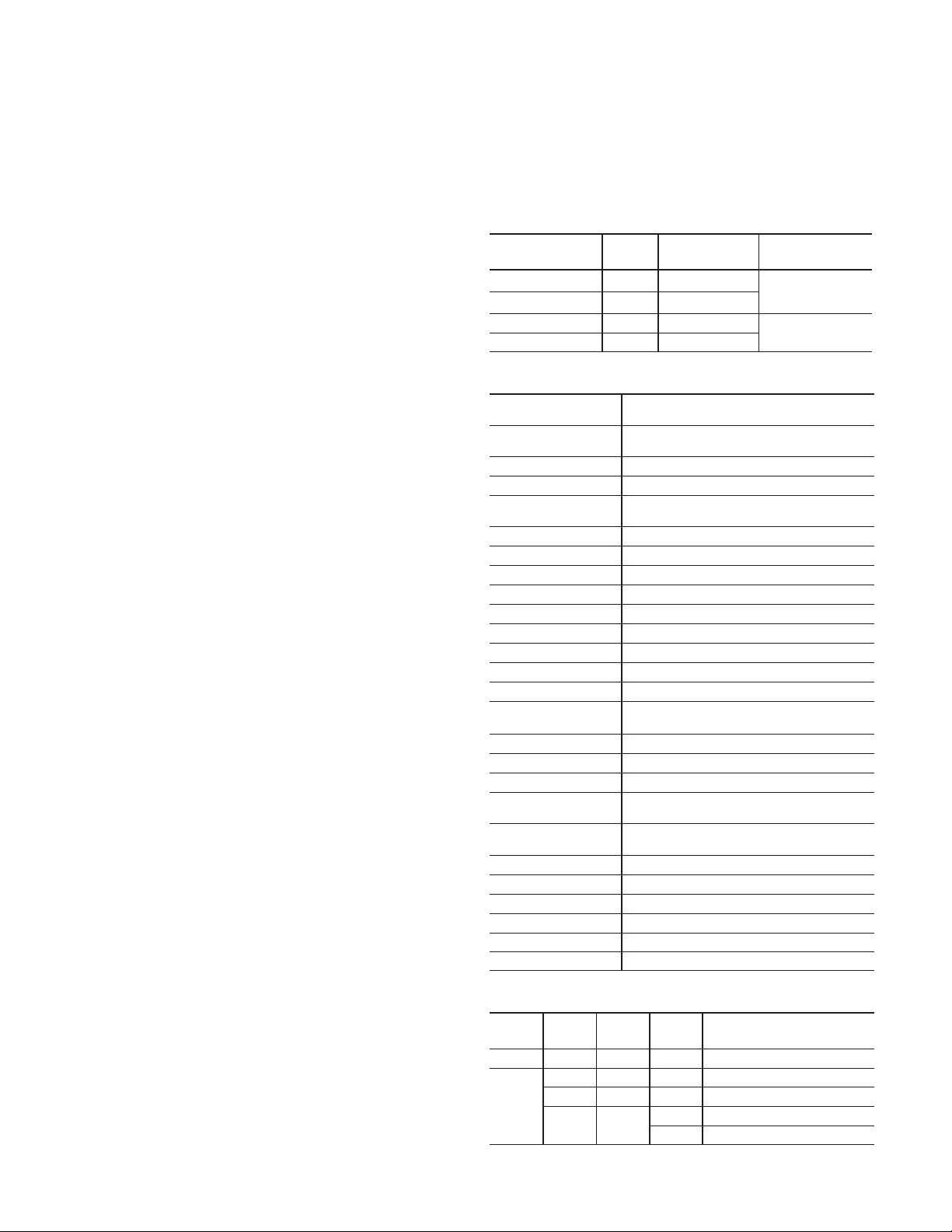

Selection Guide

Sensor Operating Voltage

Bulletin Number

873E-EDZZ0750A2 Emitter 2m (6.5ft) Cable 300V 10.8-30V DC

873E-EDZZ0750F4 Emitter Micro Style QD

873E-RDTT0750A2 Receiver 2m (6.5ft) Cable 300V

873E-RDTT0750F4 Receiver Micro Style QD

Type

Termination

Supply Current

20mA @ 20_C

100mA @ -25_C

10.8-30V DC

10mA

Specifications

Emitter 873E-EDZZ0750A2 (2m (6.5ft) 300V cable)

873E-EDZZ0750F4 (4Ćpin DC micro style QD pigtail)

Receiver 873E-RDTT0750A2 (2m (6.5ft) 300V cable)

Sensing Mode Opposed

Sensing Range 50mm to 750mm (2in to 30in)

Unit Protection False Pulse, Transient Noise, Short Circuit, Overload,

Operating Voltage 10.8-30V DC

Output Type NPN/PNP

Output Mode Normally Open/Normally Closed

Load Current 100mA max.

Leakage Current 0.1mA max.

Response Time <2.5ms

PowerĆup Delay <300ms

Max. Switching Frequency 125Hz

Ultrasonic Frequency 200-240kHz

Ultrasonic Pulse Cone

Housing Material Noryl

Sensing Face Material FDA compliant silicone rubber

LED Indicators See table below

Operating Environment NEMA 4X, 6P, IP67 (IEC529); 1200psi (8270kPa)

Connection Cable: #22 AWG PVC, 2m (6.5ft)

Vibration 20G, 10-55Hz (nonĆoperational)

Operating Temperature

Storage Temperature

Operating Humidity Not to exceed 95%, noncondensing

Approvals UL, c-UL, and CE marked for all applicable directives

Standards IEC 60947-5-2, EN60947-5-2

873E-RDTT0750F4 (4Ćpin DC micro style QD pigtail)

Reverse Polarity

(+/-) 5_

Angle

washdown

QD: 4Ćpin DC micro style male receptacle on pigtail

-25_C to +70_C (-13_F to +158_F)

-40_C to +85_C (-40_F to +185_F)

LED Indicator Lights

Sensor

Type

Emitter Ċ Green On Sensor powered

Receiver

Label Color State Status

PWR Green On Sensor powered

OUT Yellow On Output is conducting

MAR

SCP

Red

On Unreliable sensing condition

Flashing Output in overload or short circuit

Page 2

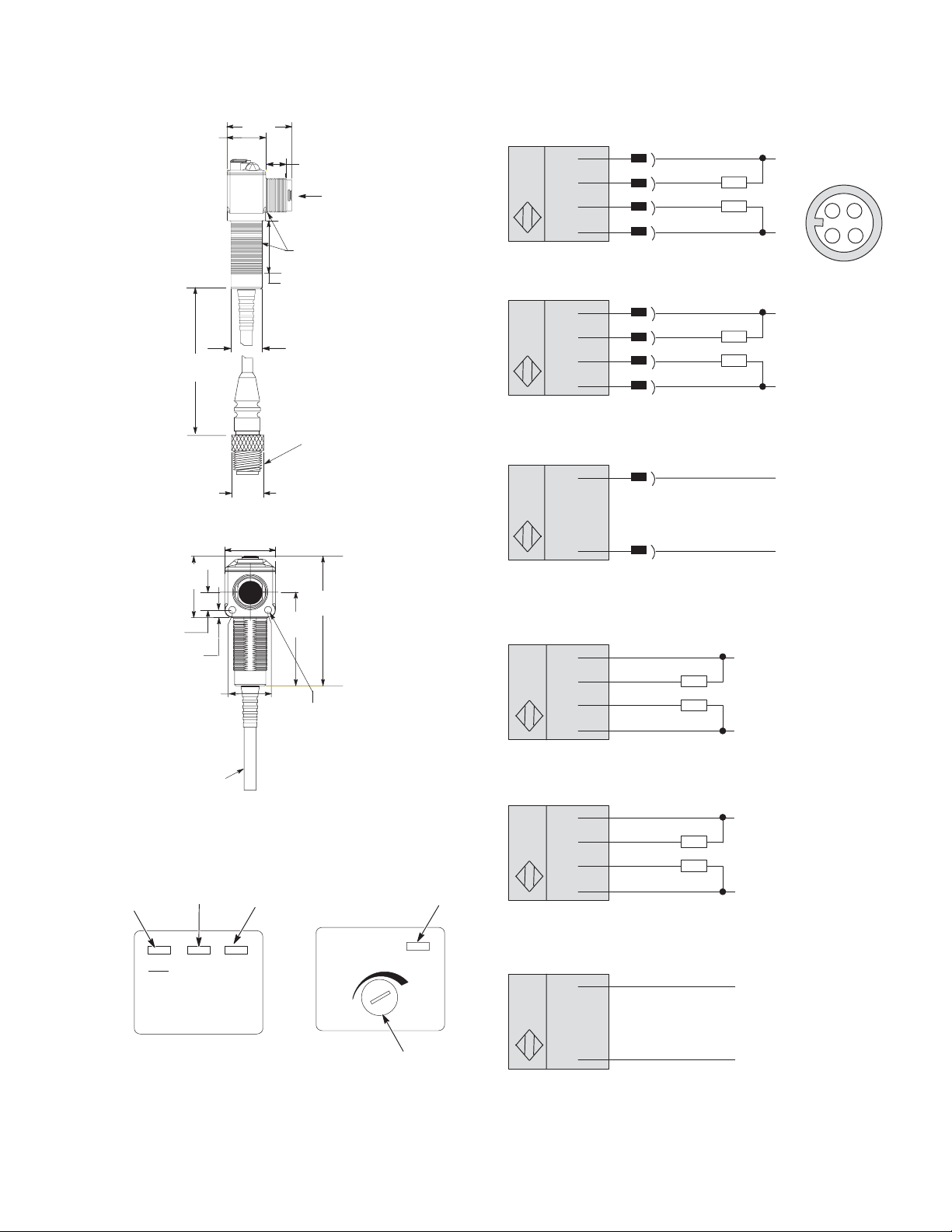

Dimensions—mm (in)

20.5

(0.81)

152/165

(6.0/6.5)

32.7

(1.29)

9.6

(0.38)

4

(0.16)

19

(0.75)

2m (6.56ft)

cable

LED and Adjustment Locations

RightSound Ultrasonic

Receiver

Red LED

Stability/Protection

Yellow LED

Output

35.1

(1.38)

(0.40)

M18 X 1.0

Thread

26.5

(1.04)

16.5

(0.65)

Micro

QuickĆDisconnect

14.48

(0.57)

27

(1.06)

49.7

(1.96)

3.6 (0.145) dia.

Clearance for #6-32 Screw

(2 places)

Green LED

Power

10

Emitter/Receiver

Face

69

(2.72)

RightSound Ultrasonic

Emitter

Green LED

Power

Wiring Diagrams

Receivers with Quick-Disconnect

Normally Open Configuration

1

Brown

2

White (NPN)

4

Black (PNP)

3

Blue

QuickĆDisconnect

Normally Closed Configuration

3

Blue

2

White (NPN)

4

Black (PNP)

1

Brown

QuickĆDisconnect

Emitter with Quick-Disconnect

Brown

1

Blue

3

QuickĆDisconnect

Receivers with Cable

Normally Open Configuration

Brown

White (NPN)

Black (PNP)

Blue

Cable

Normally Closed Configuration

Blue

White (NPN)

Black (PNP)

Brown

Cable

+10.8-30V DC

1324

-

+10.8-30V DC

-

+10.8-30V DC

-

+10.8-30V DC

-

+10.8-30V DC

-

MAR

SCP

PWROUT

1 Turn Knob

Vol ume

Brown

Blue

+10.8-30V DC

-

Cable

2

Emitter with Cable

Page 3

Specifications

1 Brown

34

3A

Coupling Nut NickelĆPlated Brass

Connector Molded oilĆresistant polyurethane body

Contacts Gold over nickelĆplated brass

Cable OilĆresistant PVC jacket, 22AWG conductors, 300V, UL recognized and

Cable O.D. 4/c = 5mm (0.21in)

Temperature

CSA certified

5/c = 6.5mm (0.25in)

-20_C to +105_C (-4_F to +221_F)

Features

Dimensions—mm (in)

Dimensions are approximate.

Illustrations are not drawn to scale.

42

(1.7)

Straight Female

S UL recognized and CSA certified

S Ratcheting coupling nut (on 4-pin DC cordsets)

S Highly visible yellow PVC jacket offers good oil and

chemical resistance

Selection Guide

Female Connector (Sensor End) Cable

Face View of Female Connector Style Wire Color Wire Rating LengthĊm (ft)

2 (6.5) 889D-F4AC-2

12

34

Straight

2 White

3 Blue

4 Black

22AWG

300V

5 (16.4) 889D-F4AC-5

10 (32.8) 889D-F4AC-10

15

(0.57)

Catalog Number

3

Page 4

Application Information

Operating Distance Selection

Operating distance is defined as the distance from the emitter

face to the receiver face. The maximum operating distance is

based on installing the control in a clean environment. Normal

industrial environments actually range from moderately dusty

to extremely dirty. In these environments, greater sensor

response may be required which can be obtained by reducing

the operating distance of the control or by increasing the

volume adjustment of the emitter (turn clockwise).

Application Precautions

With very small separation between the emitter and the

receiver, it may be necessary to misalign the receiver by

about 5_ off axis to reduce the effect of reflections.

The product may not function correctly if mounted too close to

high energy ultrasonic sources (such as ultrasonic welders or

cleaners). If such sources are present, set a blocking target

so that the red margin indicator just turns off and then activate

the welder or cleaner. If the margin indicator turns on or

flashes, greater physical separation between the sensors and

the noise source is required.

CAUTION: Care should be taken to

prevent applying force to the

emitter/receiver face. This can

damage the sensor.

Adjacent Pairs of Emitters/Receivers

When emitter/receiver pairs are used in close proximity,

precautions must be taken to prevent crosstalk (the response

of a receiver to the wrong emitter). Emitters should always be

pointed in the same direction so that the sonic beams are

parallel to each other.

A minimum spacing of 5cm (2in) must be maintained between

adjacent pairs for emitter-receiver separations of up to 15cm

(6in). Add 1cm (0.4in) of adjacent pair spacing for every

additional 10cm (4in) of emitter-receiver separation beyond

15cm (6in).

Alignment

1. Connect load(s) to the receiver.

2. Apply 10.8–30V DC power to the emitter and receiver.

The GREEN indicator must turn ON on both emitter and

receiver.

3. Position the receiver sensing face opposite the emitter

sensing face, with a separation of no more than 30I.

Center the acoustic beam by aligning the emitter and

receiver on the same axis.

4. If the RED indicator is ON, adjust the transmitter

SENSITIVITY until the RED indicator light turns OFF.

5. Breaking the acoustic beam with a target object will now

cause the output to switch, as indicated by the YELLOW

indicator.

In certain applications, the sensing target will break the center

of the acoustic beam, halfway between the transmitter and

receiver controls. With smaller sensing targets (a surface less

than 1/2I wide), it may be necessary to position the

transmitter and receiver controls so that the target breaks the

acoustic beam closer to the face of the transmitter or receiver.

If the sensing target is large (a surface wider than 1I), greater

noise immunity may be obtained by increasing the sensitivity

setting further, but not to the point where the RED indicator

lights when the target is present.

In general, operation with the RED indicator illuminated either

when the target is present or absent should be avoided by

adjusting the sensitivity setting smaller (counterclockwise) if

the RED indicator illuminates when the target is present or

greater (clockwise) if the RED indicator illuminates when the

target is absent.

Warranty

Rockwell Automation/Allen-Bradley does not supply warranty

information with documentation that ships with products.

Warranty information can be found in the Sensors catalog in

the “General” section. This can be reached via the Internet at

www.ab.com/catalogs.

Installation

The controls should also be set up away from sources of

powerful airflow (such as fans or blowers) and away from

powerful direct heat sources (such as space heaters or open

ovens).

The control must be securely mounted on a firm, stable

surface or support. A mounting which is subject to excessive

vibration or shifting may cause intermittent operation.

Wiring

All external wiring should conform to the National Electrical

Code and applicable local codes. See wiring diagrams for

external connections.

Publication 75009–119–01(C)

June 2001

4

Loading...

Loading...