Page 1

Installation Instructions

)

Bulletin 873C Ultrasonic Proximity Sensor

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

CAUTION: Solid-state devices can be susceptible to radio frequency (RF) interference depending on the power and

!

WARNING: If a hazardous condition can result from unintended operation of this device, access to the sensing area

!

the frequency of the transmitting source. If RF transmitting equipment is to be used in the vicinity of the

solid state devices, thorough testing should be performed to assure that transmitter operation is

restricted to a safe operating distance from the control equipment and its wiring.

should be guarded.

Specifications

Switching Output Analog Output

New Part Number 873C-DDNP1000E2 873C-DDAV1000E2

Old Part Number 873C-D30NP30-E2 873C-D30AP30-E2

Nominal Sensing Distance 30cm (11.8 in.) to 1m (39.4 in.)

Output Configuration N.O., PNP Analog, PNP

Operating Voltage 18-30V DC

Load Current

Minimum Load Current 1mA

Leakage Current

Voltage Drop

Repeatability

Hysteresis

Ultrasonic Frequency 200kHz

Max. Switching Frequency 5Hz

Ultrasonic Pulse Cone Angle

False Pulse Protection Incorporated

Transient Noise Protection Incorporated

Reverse Polarity Protection Incorporated

Short Circuit Protection Incorporated

Overload Protection Incorporated

Enclosure NEMA 12 and IP65 (IEC 529)

Connection Cable: 2Ćmeter (6.5 ft.) length

LED Output Energized

Operating Temperature

Shock and Vibration 30G, 10-55Hz

≤400mA ≤5mA

≤10µA

≤2.4V

±5mm in axial direction

≤15mm typical

8° (full angle)

NickelĆplated brass barrel

3Ćconductor PVC

-10°C to +60°C (-14°F to +140°F)

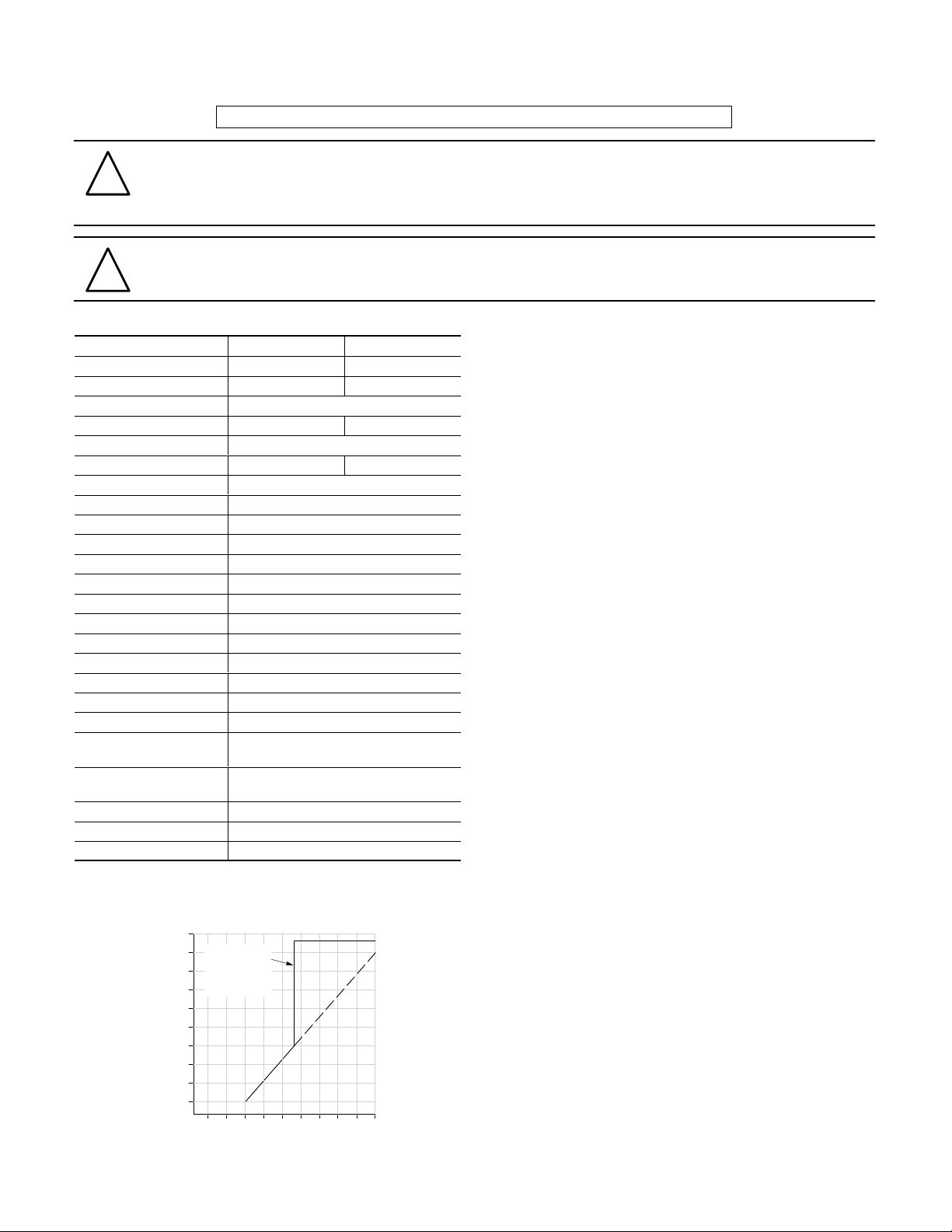

Analog Output Voltage vs. Target Distance

(Background Suppression at Maximum Distance)

10

Background

9

Suppression

Ouput Voltage (V DC)

8

7

6

5

4

3

2

1

Setpoint

(Adjustable)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Sensing Distance (meters

Description

Bulletin 873C ultrasonic sensors are solid-state devices

designed for noncontact sensing of solid and liquid objects.

The normally open switching (discrete) model features a long

sensing range which can be adjusted between 30cm (1 1.8in)

and 1m (3.3ft). All sound-reflecting objects that are within the

selected sensing range and more than 30cm from the sensor

face can be detected.

The analog model provides an output voltage that varies

linearly with target distance. For many applications, such as

monitoring the level of water in a tank or accurately positioning

a cardboard box, this technology allows a single device to do

a job that would otherwise require multiple sensors.

Each unit is housed by a plastic face and a nickel-plated brass

barrel which meet NEMA 12 and IP65 (IEC 529) enclosure

standards. It is equipped with a 2m (6.6ft) PVC cable and an

LED which glows when a target is detected.

Theory of Operation

Ultrasonic sensors emit bursts of high-frequency sound waves

which reflect or “echo” from a target. When the device detects

an echo, it energizes the load. This allows these sensors to

detect an object of any shape and material that can sufficiently

reflect an ultrasonic pulse.

Each switch senses the distance from its face to the target by

measuring the length of time required for the echo to return.

The analog model converts the time value to a DC output

voltage. The discrete model compares this time to a pre-set

value (set by the user at installation) and energizes the load

when the time drops below the threshold.

Sensing Distance

The 873C is designed to detect objects which are between

30cm (1 1.8in) and 1m (39.4in) from the sensor face. The

discrete switching model’s maximum sensing distance can be

adjusted within this range by turning the potentiometer on the

end of the sensor.

Any objects in front of the sensor must be at least 30cm from

the detector face. Objects closer than 30cm will not be

detected and will block the sound waves coming from the

sensor.

Page 2

Background Suppression and Non-Target Objects

The analog model offers a background suppression feature

which allows the sensor to ignore all objects beyond a

specified distance. This distance is set by the user at

installation by turning the potentiometer on the end of the

sensor.

Non-target objects in the sensing field can be “hidden” from

the sensor by covering them with sound-absorbent material or

by positioning them so that their echoes are reflected away

from the sensor.

Target Considerations

Because ultrasonic sensors depend on a reflected sound

wave for proper operation, the shape, material, temperature

and positioning of the target are important. These must be

selected to return the strongest echo, otherwise the sensing

distance will be reduced or the target will not be detected.

The ideal target shape is a smooth, flat surface. Rounded or

uneven objects can also be detected, but the sensing

distances and/or analog output voltages may be reduced.

An object must be close to the sensor barrel axis to be

detected because the 873C emits ultrasonic pulses in an 8_

cone. Targets must be within this cone to reflect the pulses

and activate the switch. The object’s surface must also face

directly toward the sensor to give a proper echo.

Material thinner than 0.01mm (0.0004in) and soft materials

such as fabric or foam rubber are difficult to detect by

ultrasonic technology because they are not adequately

sound-reflective.

Target temperatures must be at or below 100° C (212° F) for

reliable sensing. Targets at higher temperatures create

convection currents in the air near their surfaces, which

disturbs the reflection of the ultrasonic pulse.

Mounting Considerations

The control must be securely mounted on a firm, stable

surface or support. A mounting configuration which is unstable

or subject to excessive vibration may cause intermittent

operation.

An 873C sensor can be mounted with its sensing face flush to

surrounding surfaces. This does not effect sensing distance.

A mounting location should be chosen such that the target’s

surface faces directly toward the sensor.

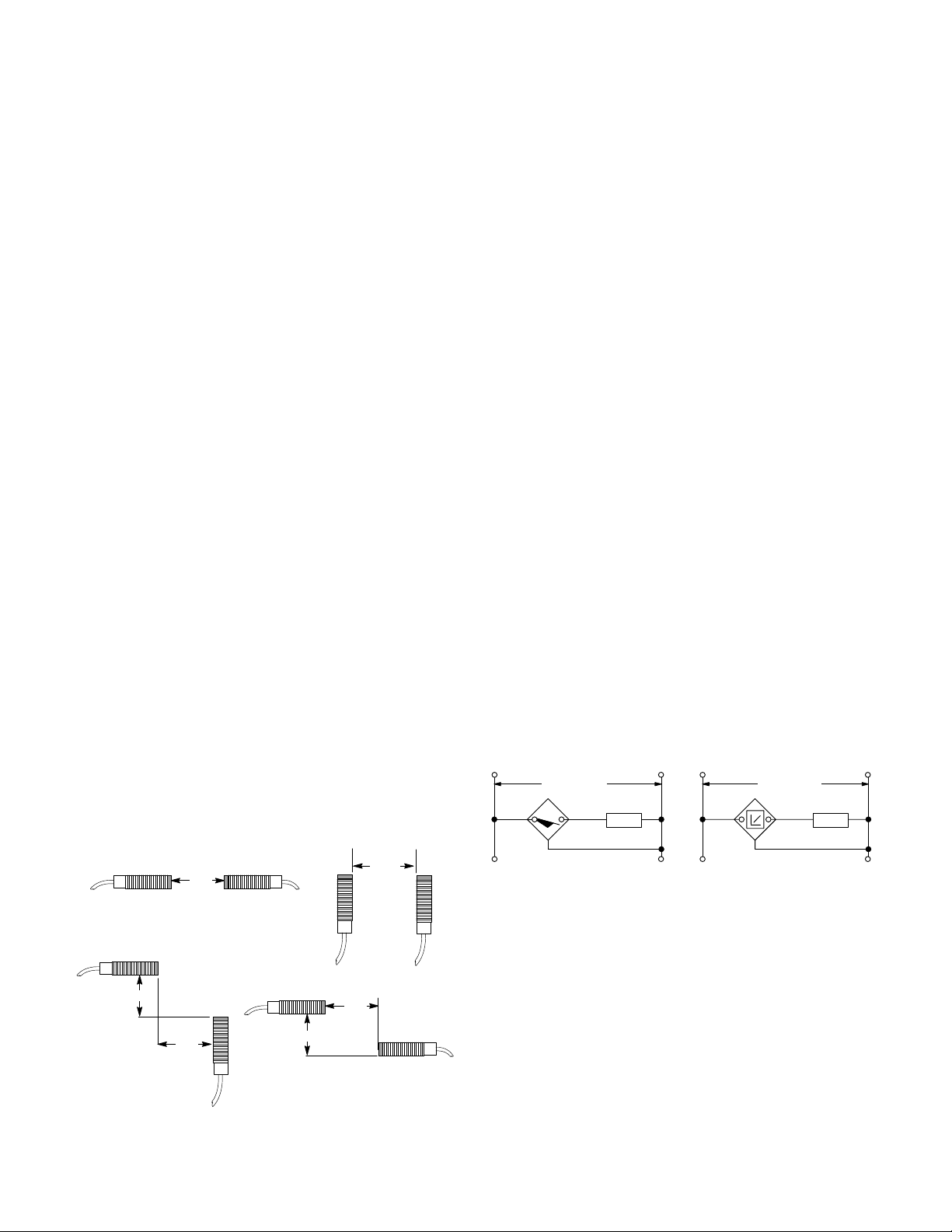

When more than one 873C is in use, the following inter-sensor

spacings must be maintained:

1.5m

6m

Environmental Factors

The output of these devices drifts approximately 0.2% per

degree Celsius of temperature change. The analog model

output voltage drops slightly as the temperature increases,

even if the target has not moved. The sensing distance of the

discrete switching model rises with increased temperature.

Strong air turbulence and convection currents can interfere

with operation of the sensor. Installation of baf fles around the

sound cone can help to reduce these effects.

Liquid splashes or heavy condensation on the face of the

sensor can interfere with proper operation. In liquid

applications, the device could be protected by relaying the

ultrasonic pulse to the surface of the liquid via a flat “bounce

panel.” Installing shielding around the sensor can also help to

reduce splash and condensation interference.

873C ultrasonic sensors are not effected by humidity, dust,

mist, or changes in atmospheric pressure.

Wiring

All external wiring should conform to the National Electric

Code and applicable local codes. Connect the proximity

switch to the power supply and load as shown in the wiring

diagrams and as described below.

1. Connect the BROWN wire from the proximity control to the

positive (+) side of the 18–30V DC supply.

2. Connect the BLUE wire from the proximity control to the

negative (–) side of the 18–30V DC supply .

3. Connect the BLACK wire from the proximity control to the

positive input of the load.

NOTE: If the positive (+) and negative (–) wires are reversed,

the switch will not operate properly . The sensor will not be

damaged because it is equipped with reverse polarity

protection.

NOTE: These switches are equipped with protection against

transient noise. However, it is recommended that the proximity

cable not be placed in the same conduit as AC power wiring.

Normally Open Switching

+ –

PNP (Sourcing)

Brn

18–30V DC

Blk

Blue

Load

–+

+ –

Analog

PNP (Sourcing)

Brn

18–30V DC

Blk

Load

Blue

–+

Wiring Switches in Series and Parallel

Series and parallel connection of this product is not

recommended.

2m

2m

3m

2m

Page 3

Alignment

The sensor can be positioned accurately using the LED on its

end, which glows with an intensity proportional to the strength

of the echo. Align the device as described below:

1. Place the target in the desired sensing position.

2. Choose a sensor location such that the surface of the

target faces directly toward the sensor. The distance

between the target and the switch must be between 30cm

(1 1.8in) and 1m (39.4in).

3. Mount the sensor on a firm, stable surface or support.

4. Apply power to the sensor as described above.

5. Turn the potentiometer on the end of the sensor fully

clockwise. This will disable the analog model background

suppression or set the discrete switching model sensing

distance to maximum. Check that the LED turns on.

6. Adjust the angle of the sensor to maximize the brightness

of the LED.

7. (Analog model only) If the analog model is sensing objects

behind the desired target, turn the potentiometer on the

end of the sensor counter-clockwise to suppress the

background objects, but not so far that the sensor no

longer detects the target.

8. (Discrete switching model only) Adjust the potentiometer

on the discrete switching model counter-clockwise until the

LED turn off, then slowly clockwise until the LED turns

back on. The sensing distance is now set at the target

location.

Dimensions—mm (inches)

LED

Adjustment Potentiometer

30.0

(1.18)

12.0

(0.47)

95.0

(3.74)

117.0

(4.61)

Accessories

Description Part Number

Mounting Brackets

Right Angle 871A-BRN30

Clamp 871A-BP30

Tilt Swivel 60-2439

Conduit adaptors 871C-N31

Page 4

Publication 46803–053–01(B)

March 1999

Printed in USA

Loading...

Loading...