Page 1

Installation Instructions

8720SM High Performance AC Induction

Motors

(Catalog Number 8720S M-xxxxxxxSx)

Introduction

This publication provide s installation instructi ons for the 8720SM

motors. Use this document if you are responsible for the design

and installation of 8720SM motors. Refer to the 8720MC High

Performance Drive Integration Manual (publication

8720MC-IN002x-EN-P) for performance information.

For: See page:

Complying w ith European Unio n Directives 2

8720SM AC Motor Overview 3

8720SM Receiving and Storage Information 4

Before Mounting Your Motor 5

Building Your 8720SM Motor Cables 7

Guidelines for Installing Your Motor 8

Wiring Your 8720SM Motor Power 9

Blower Motor 13

Motor Operation and Maintenance 15

Specifications 16

Dimensions 18

Motor Load Force Ratings 25

Publication 8720SM-IN001A-EN-P — February 2003

Page 2

2 8720SM High Perform a n ce AC Induction Motors

Complying with European Union Directives

If this product is installed wi t hi n the Eu rope an Uni on or EEC reg io ns

and has the CE mark, the following re g ul a ti ons apply.

EMC Directive

This unit is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatib ility (EMC) using the f ollowing s tandards, i n

whole or in part:

•

EN 50081-2 EMC - Emission Standard, Part 2 - Industrial

Environment

•

EN 50082-2 EMC - Immunity Standard, Part 2 - Industrial

Environment

•

EN 61800-3 - Adjustable Speed Electrical Power Drive Systems,

Part 3 - EMC Product Standard inclu ding specific test methods

The product described in thi s installation instructions is intended fo r

use in an industrial environment.

Low Voltage Directive

These units are tested to meet Council Directi ve 73/2 3/EEC Low

Voltage Directive. The EN 60204-1 Safety of Machinery-Electrical

Equipment of Machines, Part 1-Specification for General Requirements

standard applies in whol e or in part.

Publication 8720SM-IN001A-EN-P — February 2003

Page 3

8720SM High Performance AC Induction Motors 3

8720SM AC Motor Overview

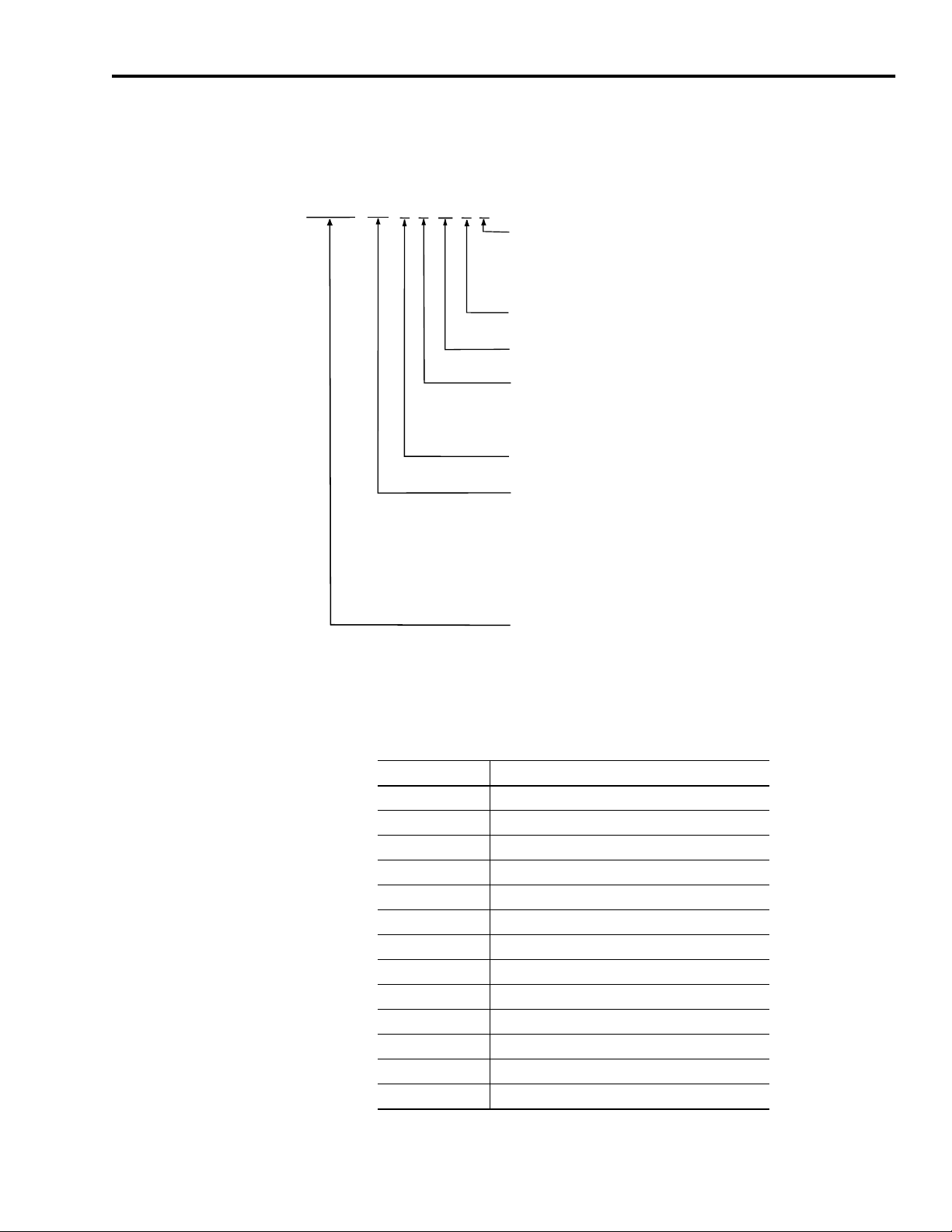

8720SM -

The 8720SM motors are high performance AC induction motors

specifically designed for use with the Allen-Bradley 8720MC Drives.

Refer to the configurator below to help identify your 8720SM motor.

xxx

x x xx S x

Feedback1

1 = SRS-660 (high resolution incremental feedback, MP-Series connector)

2 = SRM-60 (high resolution absolute feedback, MP-Series connector)

3 = SNS-60 (incremental feedback with marker)

4 = SNS-60 (incremental feedback with marker, MP-Series connector)

Speed Class

S = Standard

Curve Identification

Refer to publication 8720MC-IN002

Frame Number

1 = 112

2 = 132

3 = 132A

Winding Type

S = Single

Power

005 = 5.5 kW

007 = 7.5 kW

011 = 11 kW

015 = 15 kW

018 = 18.5 kW

022 = 22 kW

030 = 30 kW

Bulletin Number

4 = 160

5 = 180

6 = 200

037 = 37 kW

045 = 45 kW

055 = 55 kW

063 = 63 kW

075 = 75 kW

093 = 93 kW

x

-EN-P

1

Feedback options 1 and 2 apply to SERCOS mode applications. Feedback options 3 and 4 apply to Analog mode

applications.

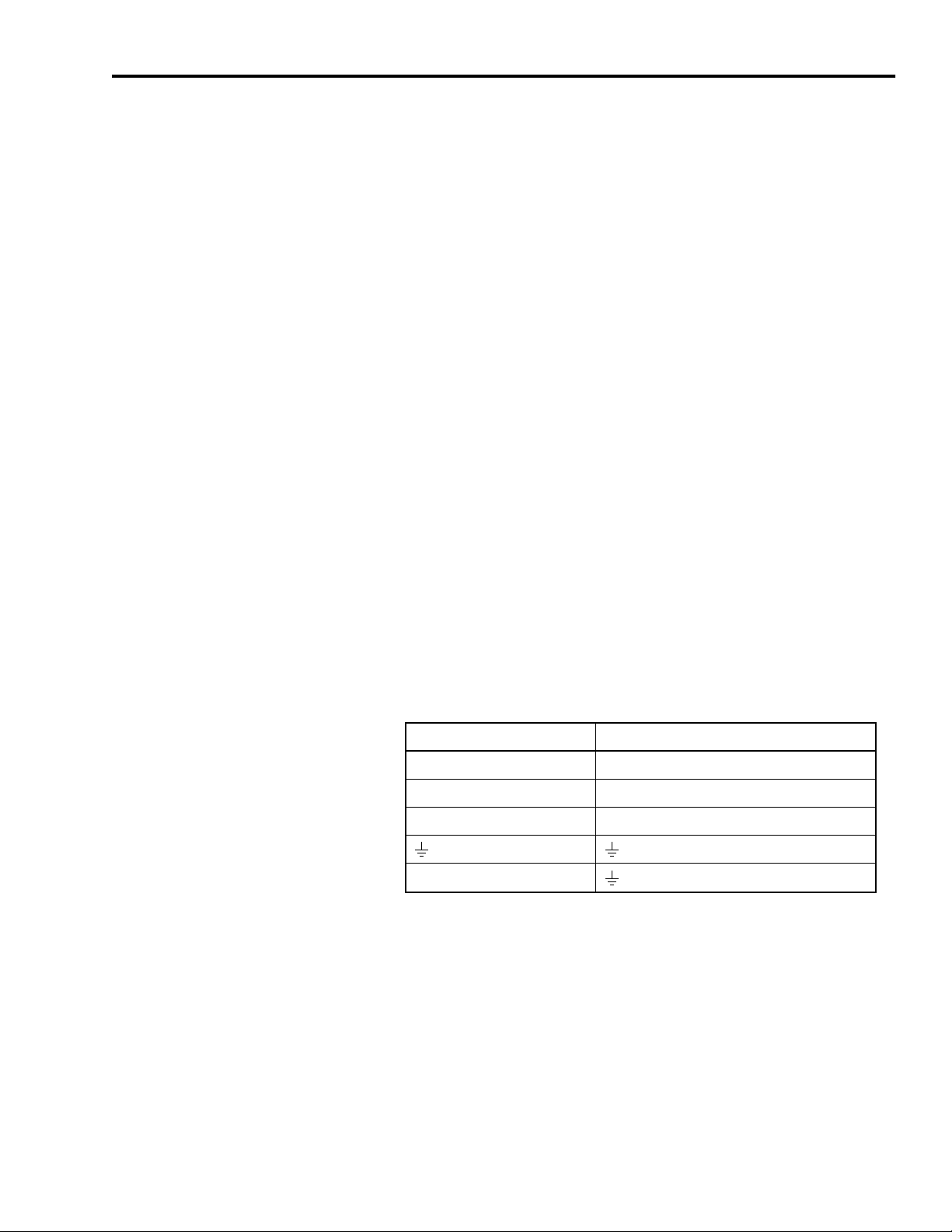

Refer to the following table to compare the motor frame number to

the motor catalog number.

Frame Catalog Number (8720SM)

DL1106 -005S1BASx, -005 S1BBSx, -005S1BCSx

DL1108 -007S1CASx, -007 S1CBSx, -007S1CCSx

DL1110 -011S1DASx, -011S1DBSx, -011S1DCSx

RDL1307 -015S2EASx, -015S2EBSx, -015S2ECSx

RDL1308 -018S2FASx, -018S2FBSx

RDL1310 -022S2GASx

RDL1611 -030S4JASx

RDL1613 -037S4KASx

DL1811 -045S5NASx

DL1813 -055S5PASx

DL1815 -063S5QASx

DL2010 -075S6SASx

DL2012 -093S6TASx

Publication 8720SM-IN001A-EN-P — February 2003

Page 4

4 8720SM High Perform a n ce AC Induction Motors

8720SM Receiving and Storage Information

The customer is responsible for inspecting the equipment before

accepting the shipme nt from the freight company. Check t he items

against your purchase order.

Handling

The 8720SM motors are equipped with lifting eye bolts. These eye

bolts are provided to assist in handling and mounting the motors. The

motors can accommodate either flange or foot mount.

ATTENTION

Eyebolts may unscrew during lifting. Check the

eyebolts to insure that they are tight. Failure to

observe this precaution could result in bodily injury.

!

Storage

Store motors in a clean, dry area protected from extreme

temperatures, moisture, shock, and vibration. Observe storage

temperatures of -20° to 80° C (-4° to 176° F) with a relative humidity

of 5 to 95%.

IMPORTANT

ATTENTION

!

The application of motors and other electrical equipment in hazardous

locations is restricted by the National Electric Code. To ensure

compliance, observe these regulations and consult with local code

inspection and enforcement agencies.

All drains are fully operable while in storage. Store

motors so that the drain is at the lowest point. Dr ains

are located in the lower po rtion of the motor c astings

on both the drive and non-drive ends of the motor.

Only qualified electrical personnel familiar with the

construction and operation of this equipment and the

hazards involved should in st al l, adjust, operate, and/

or service this equipment. Read and un de rstand this

document in its entirety before proceeding. Failure to

observe this precaution could result in severe bodily

injury or loss of life.

Publication 8720SM-IN001A-EN-P — February 2003

Page 5

8720SM High Performance AC Induction Motors 5

Before Mounting Your Motor

Before mounting your 8720SM motor, consider the following:

•

You can mount the motor horizontally or v e r tically with t h e sh aft

down or up.

•

The 8720SM motors are blower cooled with air flow from the

blower end to the drive end. The air flow must be flowing in the

direction of the arrow on the motor to provide adequate cooling.

Both air inlets and outlets must be free of obstructions. Maintain a

clearance of at least 100 mm (4 in.) at the bl ower inlet area.

•

When mounted, the motor must not be exposed to direct splash

or spray of cutting fluids or lubricatin g oils.

•

Motors include a labyrinth type shaft seal with flinger, which helps

protects against splashing. However, it will not provide protection

against flooding.

•

In an environment where high humidity is present or the motor

blower inlet air is saturated with coolant mist, make sure the

motor is mounted with the feet down and the drain holes at the

bottom of the motor are open.

•

The motors are designed for the ambient temperature i ndicated on

the nameplate. The standard motor maximum ambient is 40° C

(104° F). Locate the motor where the ambient temperature

require m ents are sat isfied and wh ere clean air has fre e access to

ventilating intake an d outlet openings . Except for machines w ith a

suitable protective enclos ure , t he locat i on should be clean and

dry.

IMPORTANT

ATTENTION

!

The cooling system on standard 8 7 20S M bl owe r

cooled motors requires that clean air is forced

through ducts which are integral to the stator frame.

It is important that you keep these ai r passages clean

and that sufficient clearance is provided on the

motor air inlets and stator duct outlets for

unrestricted air flow.

Y ou must be careful to prevent debris (such as metal

shavings and conduit knockouts) from falling into

the motor while performing any installation work

around the motor. A hazard of personal injury and/or

equipment damage exists if foreign material lodges

inside the motor.

Publication 8720SM-IN001A-EN-P — February 2003

Page 6

6 8720SM High Perform a n ce AC Induction Motors

Using Belted Driv es and Coupled Drives

Proper alignment is key for long life of bearings, shafts and belts, and

minimum downtime.

Belted Drives

If you use motor slide bases or rails, you must securely anchor them

to the foundation with the proper bolts. Make sure the motor shaft

and load shaft are parallel, and that the sheaves are aligned.

When a motor is belt coupled, the belt tension must not exceed the

radial load capabilities of the motor beari ngs. For belt drives, place the

sheave as close as possible to the motor bracket. The maximum

allowable radial load is assumed to be applied at the end of the motor

drive shaft.

IMPORTANT

Do not exceed the maximum allowable radial load

on the end of the shaft. Refer to the Radial Load

Force Ratings (Zero Axial Load) on page 25 for a

listing of radial loads .

Coupled Drives

Use flexible couplings between the motor shaft and the load shaft.

Align the motor shaft and the load shaft to values recommended for

the specific coupling before coupling is connected.

IMPORTANT

Do not exceed the maximum allowab le axial load on

the end of the shaft. Refer to the Axial Load Force

Ratings (Zero Radial Load) on page 26 for a listing of

axial loads.

Balancing the Motor

Misalignment can cause excessive vibration and damaging forces to

the shaft and bearings. During high speed operation, a small

unbalance can cause significant vibration. Make sure to accurately

dynamically balance any gears, pulleys, or couplings that are mounted

to the motor shaft. Best results are obtained by balancing after the

device is mounted to the shaft.

Publication 8720SM-IN001A-EN-P — February 2003

Motors are dynamically balanced to stay wit hi n a vibration l imit of

0.12 in./s, measured in accordance with NEMA MG-12.06. Balance is

done with a full leng th 1/2 height shaft key. A full shaft key is s hipped

Page 7

8720SM High Performance AC Induction Motors 7

with the motor. Sheave or coupling should be balanced with a 1/2

height shaft key.

Preventing Electrical Noise

Use Electromagnetic Compatibility (EMC) techniques to reduce

Electromagnetic Interference (EMI), commonly called noise. Noise

adversely impacts motor performance by inducing stray signals.

Effective techniques to counter EMI include filtering the AC power,

shielding and separating signal carrying lines, and practicing good

grounding techniques.

To help avoid EMI:

•

Filter AC power by using isolated AC power transformers or

properly installed AC line filters.

•

Physically separate signal lines from motor cabling and power

wiring. Do not r oute signal wires with motor and power wir es, or

over the vent openings of servo drives.

Building Your 8720SM Motor Cables

•

Ground all equipment using a single-point parallel ground system

that employs ground bus bars or large straps.

Refer to System Design for Control of Electrical Noise Reference

Manual (GMC-RM001x-EN-P) for information on additional electrical

noise reduction techniques.

Proper cable construction and routing improves system

ElectroMagnetic Compatibili ty (EMC). Refer to the 8720MC High

Performance Drive Installation Manual (publication

8720MC-IN001x-EN-P) for information regarding cable const ruct i on.

Publication 8720SM-IN001A-EN-P — February 2003

Page 8

8 8720SM High Perform a n ce AC Induction Motors

Guidelines for Installing Your Motor

Observe the following for installing your motor:

ATTENTION

!

•

Allow sufficient clearance in the area of the motor for it to stay

within its specified ope r ating temperature as well as protected

from direct splash or spray of cutting fluids or lubricating oils.

Refer to Before Mounting Your Motor for additional information.

•

Refer to Using Belted Drives and Coupled Drives to determine

proper installation in r ega rd to using belted and coupled drive s .

•

Mount your motor on a rigid, solid base, or foundation. Poor base

construction may cause resonances i n the motor/base assembly,

which can result in bearing failure and other motor damage. Use

the correct grade of hold down bolt s for the type of mounting.

Refer to Specifications for recommended bolt torque values.

Only qualified electrical personnel familiar with the

construction and operation of this equipment and the

hazards involved should in st al l, adjust, operate, and/

or service this equipment. Failure to observe

precaution could result in severe bodily injury or loss

of life.

•

Determine that you hav e prop erl y cons truc ted ca bles availab le fo r

your application. Refer to the 8720MC High Performance Drive

Installation Manual (publication 8720MC-IN001x-EN-P) for

information regarding cable construction.

Publication 8720SM-IN001A-EN-P — February 2003

Page 9

8720SM High Performance AC Induction Motors 9

Wiring Your 8720SM Motor Power

The procedures in this section assume yo u have installed your 8720SM

motor correctly. This section includes:

•

determining conduit box orientati on

•

wiring your motor power

•

determining your feedback connections

•

verifying thermal protector (thermostat leads) connections

Determining Conduit Box Orientat ion

The standard conduit box location for to tally enclosed motors is top

mounted for left or right conduit entry without motor disassembly.

The 8720SM motors allow rotation of the conduit box in 90 degree

increments for lead outlet at front, back, or sides.

Wiring Your Motor Power

To wire your 8720SM three-phase motor power:

1. Bring 4 wire shiel de d Be ldon VFD cable or equal to these

connections. For applic ati ons above 130A, use thick insul a tion

lead wire such as RHW-2 or equal and thread the wires through a

single grounded metal conduit.

8720SM Motor: 8720MC Drive (TB1 terminal):

U (T1) U

V (T2) V

W (T3) W

Shield

Clamp

Publication 8720SM-IN001A-EN-P — February 2003

Page 10

10 8720SM High Performance AC Induction Motors

Figure 1

8720SM-005S1BASx Thru -093S6TASx Motors

Ground Bolt

U/T1

Rotatable Conduit Box

2. Connect the shield to both the motor ground and the PE ground

on the drive with an 6 mm

the 8720MC High Performance Drive Installation Manual

(publication 8720MC-IN001x-EN-P) for the PE ground terminal on

the 8720MC drive.

ATTENTION

!

Connect an appropriate equipment grounding

conductor to the 8720MC drive ground

terminal, the motor frame, the transformer

enclosure if used, the drive electrical enclosure,

and an appropriate grounding ele ctrode.

Failure to observe these precautions could

result in severe bodily injury or loss of life.

V/T2

W/T3

2

(AWG 10) or larger conductor . Refer to

Publication 8720SM-IN001A-EN-P — February 2003

Determining Your Feedback Connections

Refer to the following ta bl e to determine the motor/integ r a te d

feedback device combination.

Motor Encoder Type Control Type

8720SM-xxxxxxxS3 and -xxxxxxxS4 Incremental sine/cosine Analog

8720SM-xxxxxxxS1 Single-turn absolute feedback

SERCOS

8720SM-xxxxxxxS2 Multi-turn absolute feedback

These feedback devices provide precision servo performance for both

spindle and power servo applications. The mo tor feedback cable

(2090-CDNFDMP-Sxx) shown in Figure 2 applies to the

8720SM-xxxxxxxS1, S2, and S4 motor configurations.

Page 11

64

(2.5)

29.5

(1.16)

83.8

(3.3)

96.52

(3.8)

(0.38)

8720SM High Performance AC Induction Motors 11

Figure 2

Motor Feedback Cable (8720SM-xxxxxxxS1, S2, and S4)

Dimensions are in millimeters (inches)

9.65

A

B

N

C

P

V

D

R

S

E

F

G

Viewed from

Connector Face

M

L

U

K

T

J

H

26.9

(1.06)

2090-CDNFDMP-S

xx

The mating right-angle P-Lok feedback connector shown in Figure 3

applies to the 8720SM-xxxxxxxS3 motor (and ships with each motor).

This connector is designed for solder joints at each termination. The

Amphenol catalog number is P3106Z2029S23. Catalog number

ST-385-16S-08D pins are also provided.

Figure 3

Motor Feedback Connector (8720SM-xxxxxxxS3)

61.7

(2.43)

34.9

(1.4)

37.29

(1.47)

1.19-18

Dimensions are in millimeters (inches)

A

B

M

T

N

S

R

J

G

H

34.9

(1.4)

C

P

D

E

F

Viewed from

Connector Face

L

K

Publication 8720SM-IN001A-EN-P — February 2003

Page 12

12 8720SM High Performance AC Induction Motors

Verifying Thermal Protector (Thermostat Leads) Connections

The 8720SM motors have three normally closed thermostats. There is

one thermostat per phase, connected in series, with leads terminated

to the feedback connector on the motor via the feedback cable. To

protect against motor overheating, make sure that you connect the

thermostats to the appropriate drive connector. Refer to the table

below for the motor and drive pins. Prior to initial startup assure that

there is very hi gh resis ta n ce b etw e en each of th e motor le ad s and the

thermal switch leads, as well as very high resistance from ground to

the thermal switch leads. The thermal protector is rated for 170° C

(338° F).

IMPORTANT

8720SM-xxxxxxxxS1, -S2, and -S4

Motor Feedback Connector Pin

RKP1-12TS+

SLP1-13TS-

Failure to conne ct the thermost ats will void the

motor warranty.

8720SM-xxxxxxxS3 Motor

Feedback Connector Pin

8720MC Connector Pin Signal

Refer to the 8720MC High Performan ce Drive Ins tallati on Manual

(publication 8720MC-IN001x-EN-P) for wiring and connector

information.

Publication 8720SM-IN001A-EN-P — February 2003

Page 13

8720SM High Performance AC Induction Motors 13

Blower Motor

Motor Blower Motor CFM @ 60 Hz

8720SM-005S1BASx, -005S1BBSx, -005S1BCSx, -007S1CASx,

-007S1CBSx, -007S1C CSx, -011S1DASx, -011S1DBS x, and -011S1DCSx

8720SM-015S2EASx, -015S2EBSx, -015S2ECSx, -018S2FASx, -018S2FBSx,

and -022S2GASx

8720SM-030S4JASx and -037S4KASx

8720SM-045S5NASx, -055S5PASx, and -063S5QASx 1117 2.00

8720SM-075S6SASx and -093S6TASx 1117 2.25

8720SM motors are blower cooled; i ncorporating an independently

powered three-phase AC blower motor that ensures continuous air

flow, regardless of the AC motor speed.

ATTENTION

!

The table below lists the necessary air flow cubic feet per minute

(CFM) requirements for the motors. The cooling inlet air must not

exceed 40° C (104° F). A llow a 101 .6 mm (4 in.) gap, minimum, at the

back of the motor to assure proper air flow.

The blower motor is typically wired to th e AC input

of the 8720MC drive and is ener gized even when the

drive is not running. Before touching blower motor

components, make sure to turn off and lock out or

tag the main power supply. Failure to observe this

precaution could result in severe bodily injury or loss

of life.

Static Pressure

(inches of water)

547 1.5

613450-1G

547 1.5

1117 1.75

613450-2E

If the blower motor dire ction of r otation is not correct the airflow will

be opposite to the arrow on the motor and it will be far lower in air

flow than what is required to cool the motor. In the standard

configuration, all 8720SM motors blow air from the blower end to the

drive end.

Publication 8720SM-IN001A-EN-P — February 2003

Page 14

14 8720SM High Performance AC Induction Motors

Connecting the Blower Motor

The specific 8720SM AC blower motor will vary depending on frame

size and enclosure. The smallest motors, 8720SM-005S1BASx thru

-022S2GASx, have a 547 CFM blower w hile the 8720SM-030S4JASx

thru -093S6TASx motors have a 1117 CFM blower. In addition:

•

The blower motors should have a fuse in each phase . The 8720SM

blower moto r should use a 1 amp, ti me dela y current limiting fuse.

A Bussmann

•

Use #16 to #18 AWG 600V hook-up wire, Alpha 3075 or 3077 or

equal.

Refer to the connection diagram supplied with each blower motor for

connection information. Figure 4 provides an example of the high, or

star, voltage 460V ac connection.

Figure 4

Blower Motor Connections

EBM Blower Connections

®

fuse (LP-CC-1) is recommended.

(Delta, 230 VAC)

W2V1U2W1V2

U1

L1 L2 L3

Low Volts

U1 = Black

U2 = Green

V1 = Blue

(Star, 460 VAC)

U2

W2

U1

V1

L1 L2 L3

High Volts

V2 = White

W1 = Brown

W2 = Yellow

V2

W1

To connect the blower motor:

1. Connect for the appropriate voltage based on the type of blower

installed.

IMPORTANT

The motor warranty conditions are violated if

you connect the blower for low voltage and

apply more than 240V ac.

2. Check that the direction of air flow is in agreement with the

direction of air flow arrows mounted on the motor. If directional

air flow is incorrect, interchange power leads L1 and L2, or U1,

and V1.

Publication 8720SM-IN001A-EN-P — February 2003

Page 15

8720SM High Performance AC Induction Motors 15

Motor Operation and Maintenance

The standard 8720SM motors are equipped with sealed deep grove

ball bearings. The motors are packed w ith the appropriate lu bricant at

the factory and do not require maintenance.

ATTENTION

Internal parts of the motor may be at line potential

even when the motor is not rotating. Make sure to

disconnect all power fr om the motor bef ore

contacting an internal part. Failure to observe this

precaution could result in bodily injury or loss of life.

!

ATTENTION

The surface of the motor may reach high

temperatures. Avoid contact with motor surfaces and

wear suitable protective equipment.

!

Repairing Your Motor

8720SM motors are high performance products and are only

authorized for repair at Rockwell Automation approved repair

facilities. Contact your local Rockwell Automation representative for

information regarding approved facilities and return procedures.

ATTENTION

!

8720SM motors are equipped with a smart feedback

device which contains detailed information specific

to that motor. You cannot replace the feedback

device supplied with the motor. Feedback devices

purchased from the supplier of the device will not

function, resulting in possible equipment damage or

personal injury.

Publication 8720SM-IN001A-EN-P — February 2003

Page 16

16 8720SM High Performance AC Induction Motors

Specifications

Environmental and Weight Specifications

Specification Description

Rated ambient temperature

Storage temperature

Environmental protection IP 55

Agency certification UL/CSA/CE

Available mounting methods flange/foot

Weight

8720SM-005S1BxSx 75 kg (165 lb)

8720SM-007S1CxSx 91 kg (201 lb)

8720SM-011S1DxSx 102 kg (225 lb)

8720SM-015S2ExSx 131 kg (289 lb)

8720SM-018S2FASx 150 kg (331 lb)

8720SM-022S2GASx 163 kg (359 lb)

8720SM-030S4JASx 226 kg (497 lb)

8720SM-037S4KASx 272 kg (598 lb)

8720SM-045S5NASx 297 kg (655 lb)

8720SM-055S5PASx 324 kg (714 lb)

8720SM-063S5QASx 350 kg (772 lb)

8720SM-075S6SASx 453 kg (999 lb)

8720SM-093S6TASx 478 kg (1054 lb)

0

°

to 40° C (32° to 104° F)

-20° to 80° C (-4° to 176° F)

IMPORTANT

The IP55 rating is based on co ntact with water sp ray.

The motor must not be exposed to direct splash or

spray of cutting fluids or lubricating oils.

Publication 8720SM-IN001A-EN-P — February 2003

Page 17

8720SM High Performance AC Induction Motors 17

Performance Specifications

The motors are available with power ratings fr om 5.5 to 93 k W (7.5 to

125 hp) and are designed to operate with the 8720MC 380 V ac to 480V

ac input invert e r s, as well as the 8720MC regener at i ve po wer supply.

The following table provides general rating information for the

8720SM motors.

Motor

8720SM-

005S1BASx 9000 13.5 32 (25.8) 53 (39.1) 5.5 (7.37) 1500 0.0165 (0.391)

005S1BBSx 9000 19.3 32 (25.8) 53 (39.1) 5.5 (7.37) 1500 0.0165 (0.391)

005S1BCSx 9000 20.2 32 (25.8) 53 (39.1) 5.5 (7.37) 1500 0.0165 (0.391)

007S1CASx 9000 20.3 48 (35.4) 72 (53.1) 7.5 (10) 1500 0.0222 (0.527)

007S1CBSx 9000 26.4 48 (35.4) 72 (53.1) 7.5 (10) 1500 0.0222 (0.527)

007S1CCSx 9000 26.4 48 (35.4) 72 (53.1) 7.5 (10) 1500 0.0222 (0.527)

011S1DASx 9000 26.8 70 (51.6) 105 (77.4) 11 (14.7) 1500 0.0272 (0.645)

011S1DBSx 9000 32.3 70 (51.6) 105 (77.4) 11 (14.7) 1500 0.0272 (0.645)

011S1DCSx 9000 32.3 70 (51.6) 105 (77.4) 11 (14.7) 1500 0.0272 (0.645)

015S2EASx 8000 33.4 96 (70.8) 143 (105.5) 15 (20.1) 1500 0.08.0 (1.92)

015S2EBSx 8000 41.5 96 (70.8) 143 (105.5) 15 (20.1) 1500 0.08.0 (1.92)

015S2ECSx 8000 48 96 (70.8) 142 (104.7) 15 (20.1) 1500 0.08.0 (1.92)

018S2FASx 8000 41.4 118 (87) 176 (129.8) 18.5 (24.8) 1500 0.0977 (2.32)

018S2FBSx 8000 47.1 118 (87) 176 (129.8) 18.5 (24.8) 1500 0.0977 (2.32)

022S2GASx 7400 48 140 (130.2) 210 (154.9) 22 (29.5) 1500 0.111 (2.63)

030S4JASx

037S4KASx

045S5NASx

055S5PASx 5000 116 350 (258) 525 (387.2) 55 (73.7) 1500 0.409 (9.7)

063S5QASx 5000 117.5 400 (294.8) 600 (442) 63 (84.4) 1500 0.468 (11.1)

075S6SASx

093S6TASx

Maximum

Speed

rpm

6000 (6500)

5800 (6500)

6000 (6500)

4500 (5000)

4000 (4500)

Rated Current

(RMS) at 1500

rpm Base Speed

Amps

1

63.1 192 (141.5) 290 (213.4) 30 (40) 1500 0.176 (4.2)

1

76.1 238 (175.40) 355 (261.8) 37 (50) 1500 0.20 (4.9)

1

93 287 (211.5) 430 (317.2) 45 (60) 1500 0.35 (8.3)

1

137 480 (353.8) 720 (531.1) 75 (100.5) 1500 0.885 (21)

1

176 590 (434.8) 890 (656.5) 93 (125) 1500 1.01 (24)

Continuous

Stall Torque

N-m (lb-ft)

1

The first value listed is for fla nge m ou nt ver sion s and th e second value (in parent hesis) is for foot mount ver sion s .

Peak

Stall Torque

N-m (lb-ft)

Motor Rated

Output

kW (hp)

Base Speed

rpm

Rotor Inertia

kg-m

2

(lb-ft2)

Publication 8720SM-IN001A-EN-P — February 2003

Page 18

18 8720SM High Performance AC Induction Motors

Mounting Bolt Specifications

Hole Diameter

mm (in.)

12 (0.47) M10-1.5 52.9 (39)

14 (0.55) M12-1.75 90.8 (67)

15 (0.59) M12-1.75 90.8 (67)

18 (0.70) M16-2.00 226.4 (167)

19 (0.74) M16-2.00 226.4 (167)

Bolt Size and

Thread

Recommended Torque

Nm (lb-ft)

Refer to the 8720MC High Perfor man ce Drive Integration Manual

(publication 8720MC-IN002x-EN-P) for additional motor performance

specifications.

Dimensions

Within this section you will find dimension drawings for the 8720SM

motors. The following notes apply to all motor dimensional drawings:

Note Description:

1 "H" Dimension will not be exceeded. Shims up to 0.5 mm (0.019 in.) thickness are usually required for coupled or geared machines .

2

3 "GA" varies +.018/-.290 mm.

4 Walls or obstructions must not encroach on air inlet space "XI" for blower or fan cooling.

5 Tolerances for flange according to DIN42948.

6 Termina l box can be rotated in 90 degree increments and mounted on top as standard.

Shaft extensions are according to Din 748. Tolerances are based on the ISO fitting system using K6 for diameters up to 50 mm (1.96 in.) and m6

for diameters above.

Publication 8720SM-IN001A-EN-P — February 2003

Page 19

8720SM High Performance AC Induction Motors 19

8720SM-005S1, -007S1, and -011S1 Dimensions (Before March 01)

The following motor dimensions are for 8720SM-005S1BASx thru

-011S1DCSx motors, 180 mm flange and 215 mm bolt circle

manufactured before March, 2001.

Figure 5

8720SM-005S1BASx thru -011S1DCSx Motor Dimensions

N

D

Motor

8720SM-

005

007

011

I2

E

AB

mm

(in.)

233

(9.17)

233

(9.17)

233

(9.17)

C

T

LA

1

H

mm

(in.)

112

(4.40)

112

(4.40)

112

(4.40)

L

Terminal Box

x1

a

e

A

mm

(in.)

HA

mm

(in.)

190

(7.48)9 (0.35)

190

(7.48)9 (0.35)

190

(7.48)9 (0.35)

K

mm

(in.)

12

(0.47)

12

(0.47)

12

(0.47)

XI

MS

Connector

AA

mm

(in.)

83.5

(3.28)

83.5

(3.28)

83.5

(3.28)

Blower

Terminal Box

3-3/16" Dia

1-5/8" Dp

AC

mm

(in.)

240

(9.44)

240

(9.44)

240

(9.44)

g1

AC

N

mm

(in.)

180

(7.08)

180

(7.08)

180

(7.08)

HA

S

F

HD

GA

H

K

LA

mm

(in.)

13

(0.51)

13

(0.51)

13

(0.51)

M

mm

(in.)

T

mm

(in.)

215

(8.46)4 (0.15)

215

(8.46)4 (0.15)

215

(8.46)4 (0.15)

P

M

AA

A

AB

C

mm

(in.)

106

(4.17)

106

(4.17)

106

(4.17)

P

mm

(in.)

250

(9.84)

250

(9.84)

250

(9.84)

Motor

8720SM-

005

007

011

S

mm

(in.)

14

(0.55)

14

(0.55)

14

(0.55)

4

XI

mm

(in.)

38

(1.49)

38

(1.49)

38

(1.49)

L

mm

(in.)

642

(25.27)

687

(27.04)

725

(28.54)

e

mm

(in.)

269

(10.59)

313

(12.32)

352

(13.85)

x1

mm

(in.)

134

(5.27)

178

(7.00)

216

(8.50)

a

mm

(in.)

203

(7.99)

248

(9.36)

286

(11.25)

2

D

mm

(in.)

38

(1.49)

38

(1.49)

38

(1.49)

E

mm

(in.)

80

(3.14)

80

(3.14)

80

(3.14)

I2

mm

(in.)

80

(3.14)

80

(3.14)

80

(3.14)

GA

mm

(in.)

41

(1.61)

41

(1.61)

41

(1.61)

3

F

mm

(in.)

10

(0.39)

10

(0.39)

10

(0.39)

g1

mm

(in.)

242

(9.52)

242

(9.52)

242

(9.52)

Publication 8720SM-IN001A-EN-P — February 2003

HD

mm

(in.)

305

(120)

305

(120)

305

(120)

Page 20

20 8720SM High Performance AC Induction Motors

8720SM-005S1, -007S1, and -011S1 Dimensions (After March 01)

The following motor dimensions are for 8720SM-005S1BASx thru

-011S1DCSx motors, 180 mm flange and 215 mm bolt circle

manufactured after March, 2001.

Figure 6

8720SM-005S1BASx thru -011S1DCSx Motor Dimensions

XI

L

Terminal Box

T

LA

I2

D

E

Motor

8720SM-

005

007

011

C

AB

mm

(in.)

233

(9.17)

233

(9.17)

233

(9.17)

1

H

mm

(in.)

112

(4.40)

112

(4.40)

112

(4.40)

x1

a

e

A

mm

(in.)

190

(7.48)

190

(7.48)

190

(7.48)

N

Y

HA

mm

(in.)

11

(0.43)

11

(0.43)

11

(0.43)

MS

Connector

K

mm

(in.)

12

(0.47)

12

(0.47)

12

(0.47)

Blower

Terminal Box

3-3/16" Dia

1-5/8" Dp

AC

mm

(in.)

240

(9.44)

240

(9.44)

240

(9.44)

C

mm

(in.)

106

(4.17)

106

(4.17)

106

(4.17)

Air Space

P

M

P

mm

(in.)

250

(9.84)

250

(9.84)

250

(9.84)

AC

X

A

AB

N

mm

(in.)

180

(7.08)

180

(7.08)

180

(7.08)

LA

mm

(in.)

13

(0.51)

13

(0.51)

13

(0.51)

S

HD

HA

H

K

M

mm

(in.)

215

(8.46)4 (0.15)

215

(8.46)4 (0.15)

215

(8.46)4 (0.15)

T

mm

(in.)

F

GA

S

mm

(in.)

14

(0.55)

14

(0.55)

14

(0.55)

Motor

8720SM-

005

007

011

XI

mm

(in.)

38

(1.49)

38

(1.49)

38

(1.49)

L

mm

(in.)

642

(25.27)

687

(27.04)

725

(28.54)

e

mm

(in.)

269

(10.59)

313

(12.32)

352

(13.85)

4

Publication 8720SM-IN001A-EN-P — February 2003

x1

mm

(in.)

134

(5.27)

178

(7.00)

216

(8.50)

a

mm

(in.)

203

(7.99)

248

(9.36)

286

(11.25)

2

D

mm

(in.)

38

(1.49)

38

(1.49)

38

(1.49)

E

mm

(in.)

80

(3.14)

80

(3.14)

80

(3.14)

I2

mm

(in.)

80

(3.14)

80

(3.14)

80

(3.14)

GA

mm

(in.)

41

(1.61)

41

(1.61)

41

(1.61)

3

F

mm

(in.)

10

(0.39)

10

(0.39)

10

(0.39)

HD

mm

(in.)

351

(13.81)

351

(13.81)

351

(13.81)

Y

mm

(in.)

156

(6.12)

156

(6.12)

156

(6.12)

X

mm

(in.)

143

(5.62)

143

(5.62)

143

(5.62)

Page 21

8720SM High Performance AC Induction Motors 21

8720SM-015S2, -018S2, and -022S2 Dimensions (250 mm Flange)

The following motor dimensions are for the 8720SM-015S2EASx thru

-022S2GASx motors, the standard “132” with 250 mm flange and 300

mm bolt circle.

Figure 7

8720SM-015S2EASx thru -022S2GASx Motor Dimensions, 250 mm Flange,

Encoder connector

XI

Terminal box blower

cooled only

Motor

8720SM-

015

018

022

AB

mm

(in.)

260

(10.23)

260

(10.23)

260

(10.23)

1

H

mm

(in.)

132

(5.19)

132

(5.19)

132

(5.19)

L

Y

T

LA

x1

e

a2

K

mm

(in.)

12

(0.47)

12

(0.47)

12

(0.47)

a

AC

mm

(in.)

279

(10.98)

279

(10.98)

279

(10.98)

a1

BA

A

mm

(in.)

216

(8.50)

216

(8.50)

216

(8.50)

m2

BA

mm

(in.)

154

(6.06)

154

(6.06)

154

(6.06)

m2

mm

(in.)

95

(3.74)

95

(3.74)

95

(3.74)

E

P

mm

(in.)

350

(13.77)

350

(13.77)

350

(13.77)

P

N

S

N

mm

(in.)

250

(9.84)

250

(9.84)

250

(9.84)

LA

mm

(in.)

17

(0.66)

17

(0.66)

17

(0.66)

AC

GA

M

A

AB

M

mm

(in.)

300

(11.81)5 (0.19)

300

(11.81)5 (0.19)

300

(11.81)5 (0.19)

Y

HD

H

K

T

mm

(in.)

S

mm

(in.)

18

(0.70)

18

(0.70)

18

(0.70)

Motor

8720SM-

015

018

022

4

XI

mm

(in.)

52

(2.04)

52

(2.04)

52

(2.04)

L

mm

(in.)

858

(33.77)

897

(35.31)

928

(36.53)

e

mm

(in.)

437

(17.20)

475

(18.70)

506

(19.92)

x1

mm

(in.)

46

(1.81)

46

(1.81)

46

(1.81)

a

mm

(in.)

365

(14.37)

403

(15.86)

435

(17.12)

a1

mm

(in.)

24

(0.94)

24

(0.94)

24

(0.94)

a2

mm

(in.)

32

(1.25)

32

(1.25)

32

(1.25)

2

D

mm

(in.)

48

(1.88)

48

(1.88)

48

(1.88)

E

mm

(in.)

110

(4.33)

110

(4.33)

110

(4.33)

GA

mm

(in.)

51.5

(2.02)

51.5

(2.02)

51.5

(2.02)

3

HD

mm

(in.)

374

(14.72)

374

(14.72)

374

(14.72)

Publication 8720SM-IN001A-EN-P — February 2003

Y

mm

(in.)

190

(7.48)

190

(7.48)

190

(7.48)

Page 22

22 8720SM High Performance AC Induction Motors

8720SM-030S4 and -037S4 Dimensions

The following motor dimensions are for the 8720SM-030S4JASx thru

-037S4KASx motors, 300 mm flange and 350 mm bolt circle.

Figure 8

8720SM-030S4JASx thru -037S4KASx Motor Dimensions

L

Y

Encoder connector

XI

x1

AC

Y

T

LA

P

HD

N

S

GA

M

H

Terminal box blower

cooled only

Motor

8720SM-

030

037

a1

BA

AB

mm

(in.)

313

(12.32)

313

(12.32)

Motor

8720SM-

030

037

1

H

mm

(in.)

160

(6.29)

160

(6.29)

S

mm

(in.)

18

(0.70)

18

(0.70)

e

a

A

mm

(in.)

254

(9.99)

254

(9.99)

XI

mm

(in.)

52

(2.04)

52

(2.04)

A

BA

mm

(in.)

170

(6.69)

170

(6.69)

x1

mm

(in.)

82

(3.22)

82

(3.22)

E

m2

mm

(in.)

95

(3.74)

95

(3.74)

a

mm

(in.)

464

(18.26)

515

(20.27)

P

mm

(in.)

400

(15.78)

400

(15.78)

a1

mm

(in.)

38

(1.49)

38

(1.49)

m2

K

mm

(in.)

14

(0.55)

14

(0.55)

4

L

mm

(in.)

989

(38.93)

1040

(40.94)

AC

mm

(in.)

332

(13.07)

332

(13.07)

e

mm

(in.)

541

(21.29)

592

(23.30)

N

mm

(in.)

300

(11.81)

300

(11.81)

2

D

mm

(in.)

55

(2.16)

55

(2.16)

AB

LA

mm

(in.)

21

(0.82)

21

(0.82)

E

mm

(in.)

110

(4.33)

110

(4.33)

K

M

mm

(in.)

T

mm

(in.)

350

(13.77)5 (0.19)

350

(13.77)5 (0.19)

3

GA

mm

(in.)

59

(2.32)

59

(2.32)

Y

mm

(in.)

190

(7.48)

190

(7.48)

Publication 8720SM-IN001A-EN-P — February 2003

Page 23

8720SM High Performance AC Induction Motors 23

8720SM-045S5, -055S5, and -063S5 Dimensions

The following motor dimensions are for the 8720SM-045S5NASx thru

-063S5QASx motors, 300 mm flange and 350 mm bolt circle.

Figure 9

8720SM-045S5NASx thru -063S5QASx Motor Dimensions

MS Connector

T

LA

E

L

XI

P

AC

g1

S

F

N

Motor

8720SM-

045

055

063

D

I2

AB

mm

(in.)

350

(13.77)

350

(13.77)

350

(13.77)

C

H

mm

(in.)

180

(7.08)

180

(7.08)

180

(7.08)

A

mm

(in.)

279

(10.98)

279

(10.98)

279

(10.98)

x1

BA

a

e

HA

mm

(in.)

15

(0.59)

15

(0.59)

15

(0.59)

m2

K

mm

(in.)

15

(0.59)

15

(0.59)

15

(0.59)

AA

mm

(in.)

70

(2.75)

70

(2.75)

70

(2.75)

Blower

Terminal

Box (4)

AC

mm

(in.)

355

(13.97)

355

(13.97)

355

(13.97)

C

mm

(in.)

121

(4.76)

121

(4.76)

121

(4.76)

AA

BA

mm

(in.)

65

(2.55)

65

(2.55)

65

(2.55)

AB

H

K

P

mm

(in.)

400

(15.78)

400

(15.78)

400

(15.78)

HD

N

mm

(in.)

300

(11.81)

300

(11.81)

300

(11.81)

LA

mm

(in.)

21

(0.82)

21

(0.82)

21

(0.82)

GA

M

mm

(in.)

350

(13.77)

350

(13.77)

350

(13.77)

M

HA

A

m2

mm

(in.)

175

(6.88)

175

(6.88)

175

(6.88)

Motor

8720SM-

045

055

063

T

mm

(in.)

5

(0.19)

5

(0.19)

5

(0.19)

S

mm

(in.)

18

(0.70)

18

(0.70)

18

(0.70)

XI

mm

(in.)

43

(1.69)

43

(1.69)

43

(1.69)

L

mm

(in.)

997

(39.25)

1048

(41.25)

1099

(43.26)

e

mm

(in.)

571

(22.48)

622

(24.48)

673

(26.49)

x1

mm

(in.)

421

(16.57)

472

(18.58)

523

(20.59)

a

mm

(in.)

520

(20.47)

571

(22.48)

622

(24.48)

D

mm

(in.)

60

(2.36)

60

(2.36)

60

(2.36)

E

mm

(in.)

140

(5.51)

140

(5.51)

140

(5.51)

I2

mm

(in.)

140

(5.51)

140

(5.51)

140

(5.51)

GA

mm

(in.)

64

(2.51)

64

(2.51)

64

(2.51)

F

mm

(in.)

18

(0.70)

18

(0.70)

18

(0.70)

g1

mm

(in.)

319

(12.55)

319

(12.55)

319

(12.55)

Publication 8720SM-IN001A-EN-P — February 2003

HD

mm

(in.)

491

(19.33)

491

(19.33)

491

(19.33)

Page 24

24 8720SM High Performance AC Induction Motors

8720SM-075S6 and -093S6 Dimensions

The following motor dimensions are for the 8720SM-075S6SASx thru

-093S6TASx motors.

Figure 10

8720SM-075S6SASx thru -093S6TASx Motor Dimensions

BA

L

x1

m2

a

e

T

LA

E

N

D

l2

C

MS Connector

Blower

Terminal

Box (4)

XI

P

g1

AA

AC

A

AB

S

8-Holes

HA

F

HD

H

K

GA

Motor

8720SM-

075

093

Motor

8720SM-

075

093

AB

mm

(in.)

396

(15.59)

396

(15.59)

T

mm

(in.)

5

(0.19)

5

(0.19)

H

mm

(in.)

200

(7.84)

200

(7.84)

S

mm

(in.)

18

(0.70)

18

(0.70)

A

mm

(in.)

318

(12.51)

318

(12.51)

XI

mm

(in.)

43

(1.69)

43

(1.69)

HA

mm

(in.)

18

(0.70)

18

(0.70)

L

mm

(in.)

1155

(45.47)

1219

(47.99)

K

mm

(in.)

19

(0.74)

19

(0.74)

e

mm

(in.)

705

(27.75)

769

(30.27)

AA

mm

(in.)

80

(3.14)

80

(3.14)

x1

mm

(in.)

499

(19.64)

563

(22.16)

AC

mm

(in.)

418

(16.45)

418

(16.45)

a

mm

(in.)

654

(25.74)

718

(28.26)

C

mm

(in.)

133

(5.23)

133

(5.23)

D

mm

(in.)

65

(2.55)

65

(2.55)

BA

mm

(in.)

82

(3.22)

82

(3.22)

E

mm

(in.)

140

(5.51)

140

(5.51)

m2

mm

(in.)

203

(7.99)

203

(7.99)

12

mm

(in.)

140

(5.51)

140

(5.51)

P

mm

(in.)

450

(17.71)

450

(17.71)

GA

mm

(in.)

69

(2.71)

69

(2.71)

N

mm

(in.)

350

(13.77)

350

(13.77)

F

mm

(in.)

18

(0.70)

18

(0.70)

LA

mm

(in.)

22

(0.86)

22

(0.86)

g1

mm

(in.)

351

(13.81)

351

(13.81)

M

mm

(in.)

400

(15.74)

400

(15.74)

HD

mm

(in.)

534

(21.02)

534

(21.02)

Publication 8720SM-IN001A-EN-P — February 2003

Page 25

8720SM High Performance AC Induction Motors 25

Motor Load Force Ratings

Motors are capable of operating with a sustained shaft load. The radial

and axial load force locations are shown in Figure 11, and the

maximum figures are in the tables.

Figure 11

Load Forces on Motor Shaft

Radial load force applied at center of shaft extension

Axial load force

The tables represent 10,000 hour L10 bearing fatigue life at various

loads and speeds. The 10,000 hour life does not account for possible

application specific life reduction that may occur due to bearing

grease contamination from external sources.

Radial Load Force Ratings (Zero Axial Load)

Motor Series

8720SM005 284 (625) 261 (575) 223 (490) 205 (450) 177 (390)

007 284 (625) 261 (575) 223 (490) 205 (450) 177 (390)

011 284 (625) 261 (575) 223 (490) 205 (450) 177 (390)

015 386 (850) 302 (665) 261 (575) 237 (520) 205 (450)

018 386 (850) 302 (665) 261 (575) 237 (520) 205 (450)

022 386 (850) 302 (665) 261 (575) 237 (520) 205 (450)

030 606 (1335) 477 (1050) 411 (905) 370 (815) 320 (705)

037 606 (1335) 477 (1050) 411 (905) 370 (815) 320 (705)

045 640 (1410) 497 (1095) 429 (945) 350 (770) 230 (505)

055 640 (1410) 497 (1095) 429 (945) 350 (770) 230 (505)

063 640 (1410) 497 (1095) 429 (945) 350 (770) 230 (505)

075 699 (1540) 540 (1190) 443 (975) 338 (745) 205 (450)

093 699 (1540) 540 (1190) 443 (975) 338 (745) 205 (450)

500 RPM

kg (lb)

1000 RPM

kg (lb)

1500 RPM

kg (lb)

2000 RPM

kg (lb)

3000 RPM

kg (lb)

Publication 8720SM-IN001A-EN-P — February 2003

Page 26

26 8720SM High Performance AC Induction Motors

Axial Load Force Ratings (Zero Radial Load)

Motor Series

8720SM005 307 (675) 228 (500) 187 (410) 161 (355) 100 (220)

007 307 (675) 228 (500) 187 (410) 161 (355) 100 (220)

011 307 (675) 228 (500) 187 (410) 161 (355) 100 (220)

015 284 (625) 200 (440) 160 (350) 135 (295) 75 (165)

018 284 (625) 200 (440) 160 (350) 135 (295) 75 (165)

022 284 (625) 200 (440) 160 (350) 135 (295) 75 (165)

030 338 (745) 239 (525) 189 (415) 157 (345) 86 (190)

037 338 (745) 239 (525) 189 (415) 157 (345) 86 (190)

045 354 (780) 230 (505) 171 (375) 87 (190) 45 (100)

055 354 (780) 230 (505) 171 (375) 87 (190) 45 (100)

063 354 (780) 230 (505) 171 (375) 87 (190) 45 (100)

075 472 (1040) 309 (680) 228 (500) 118 (260) 64 (140)

093 472 (1040) 309 (680) 228 (500) 118 (260) 64 (140)

500 RPM

kg (lb)

1000 RPM

kg (lb)

1500 RPM

kg (lb)

2000 RPM

kg (lb)

3000 RPM

kg (lb)

Publication 8720SM-IN001A-EN-P — February 2003

Page 27

8720SM High Performance AC Induction Motors 27

Publication 8720SM-IN001A-EN-P — February 2003

Page 28

For more information refer to o ur web site: www.ab.com/motion

For Allen-Bradley Technical Support information refer to: www.ab.com/support or Tel: (1) 440.646.5800

Allen-Bradley and A-B are registered trademarks of Rockwell Automation.

Bussmann is a registered trademark of Cooper Industries, Inc.

Publication 8720SM-IN001A-EN-P — February 2003

Copyright © 2003 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...