Page 1

Allen-Bradley

9/Series CNC

Mill

Operation and

Programming

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that

each application and use meets all performance and safety requirements,

including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples shown

in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control(availablefromyour

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or in

part,without writtenpermissionofAllen-Bradley Company,Inc.isprohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

WARNING: Tells readers where people may be hurt if

procedures are not followed properly.

CAUTION: Tells readers where machinery may be damaged or

economic loss can occur if procedures are not followed properly.

Warnings and Cautions:

- identify a possible trouble spot

- tell what causes the trouble

- give the result of improper action

- tell the reader how to avoid trouble

Important: We recommend that you frequently back up your application

programs on an appropriate storage medium to avoid possible data loss.

PLC is a registered trademarkof Allen-Bradley Company, Inc.

Paramacro and PALaretrademarks of Allen-Bradley Company, Inc.

Page 3

Summary of Changes

9/Series Mill

Operation and Programming Manual

October 2000

New Information

RevisionBars

The following is a list of the larger changes made to this manual since its

last printing. Other less significant changes were also made throughout.

Error Message Log

Paramacro Parameters

Softkey Tree

Error Messages

We use revision bars to call your attention to new or revised information.

A revision bar appears as a thick black line on the outside edge of the page

as indicated here.

Page 4

Chapter

1-2

Page 5

Table of Contents

Index (General)

9/Series Mill

9/Series PALReference Manual

Operation and Programming Manual

Chapter 1

Using This Manual

1.0ChapterOverview 1-1..........................................................

1.1Audience 1-1................................................................

1.2ManualDesign 1-1............................................................

1.3ReadingthisManual 1-3........................................................

1.4Terms and Conventions 1-4......................................................

1.5Warnings,Cautions,and ImportantInformation 1-5......................................

1.6RelatedPublications 1-5........................................................

Chapter 2

Basic Control Operation

2.0ChapterOverview 2-1..........................................................

2.1OperatorPanelOperations 2-1....................................................

2.1.1Keyboard 2-3.............................................................

2.1.2CalculatorFunction 2-4......................................................

2.1.3Softkeys 2-8..............................................................

2.1.4CRT 2-10................................................................

2.1.5Portable OperatorPanel 2-11...................................................

2.2The MTB Panel 2-12............................................................

2.3SoftwareMTB Panel{FRONTPANEL} 2-15............................................

2.4PowerProcedures 2-21..........................................................

2.4.1Turning Power On 2-21.......................................................

2.4.2TurningPower OFF 2-22.....................................................

2.5ControlConditions atPower-Up 2-23................................................

2.6EmergencyStopOperations 2-24...................................................

2.6.1Emergency StopReset 2-24...................................................

2.7Access Control 2-25............................................................

2.7.1Assigning Access Levelsand Passwords 2-26......................................

2.7.2Password ProtectableFunctions 2-29............................................

2.7.3EnteringPasswords 2-31.....................................................

2.8ChangingOperatingModes 2-33...................................................

2.9Displaying Systemand MachineMessages 2-37........................................

2.9.1Clearing ActiveMessages {CLEAR ACTIVE} 2-40....................................

2.10The Input Cursor 2-41..........................................................

2.11 {REFORMMEMORY} 2-41.......................................................

2.12Removingan Axis (Axis Detach) 2-43...............................................

2.13TimeParts CountDisplay Feature 2-43..............................................

Chapter 3

Offset Tables and Setup

3.0ChapterOverview 3-1..........................................................

3.1Tool OffsetTable{TOOLGEOMET}and {TOOLWEAR} 3-1...............................

3.1.1ToolOffsetDimensionalParameters 3-2..........................................

i

Page 6

Table of Contents

Index (General)

9/Series PALReference Manual

Operation and Programming Manual

3.1.2SettingTool OffsetTables 3-5..................................................

3.1.3SettingOffset DataUsing {MEASURE} 3-9........................................

3.1.4ToolOffsetRange Verification 3-10...............................................

3.2Changingthe ActiveToolOffset{ACTIVEOFFSET} 3-12..................................

3.3WorkCoordinateSystemOffsetTables {WORKCO-ORD} 3-14..............................

3.3.1SettingWorkCoordinateSystemTables 3-15.......................................

3.4BackingUp OffsetTables 3-17.....................................................

3.5Programmable ZoneTable 3-21....................................................

3.6SingleDigitFeedrate Table 3-23....................................................

9/Series Mill

Chapter 4

Manual/MDI Operation Modes

4.0ChapterOverview 4-1..........................................................

4.1ManualOperatingMode 4-1......................................................

4.1.1J ogging an Axis 4-2........................................................

4.1.2Continuous Jog 4-3.........................................................

4.1.3IncrementalJog 4-3........................................................

4.1.4HPG Jog 4-4.............................................................

4.1.5ArbitraryAngle Jog 4-5......................................................

4.1.6J og Offset 4-6.............................................................

4.1.7ResettingOvertravels 4-6.....................................................

4.2MechanicalHandleFeed(Servo Off) 4-8.............................................

4.3Removingan Axis(AxisDetach) 4-8................................................

4.4ManualMachineHoming 4-8.....................................................

4.5MDIMode 4-11................................................................

4.5.1MDI Basic Operation 4-12.....................................................

Chapter 5

Editing Programs Online

5.0ChapterOverview 5-1..........................................................

5.1Selectingthe ProgramToEdit 5-2..................................................

5.2EditingPrograms at theControl(Online) 5-3..........................................

5.2.1 Movingthe Cursor {STRINGSEARCH} andCursorSize {CHAR/WORD} 5-5................

5.2.2EnteringCharactersand Blocks 5-7.............................................

5.2.3Changingand Inserting{MODIFY INSERT} 5-7.....................................

5.2.4Erasing Characters and Blocks 5-11.............................................

5.2.5Sequence Numbers{RENUMPRGRAM} 5-13.......................................

5.2.6Merging Part Programs {MERGEPRGRAM} 5-15....................................

5.2.7ExitingEditMode{EXITEDITOR} 5-16............................................

5.3 Programming Aids {QUICK VIEW} 5-17............................................

5.3.1Selectinga QuickViewPlane 5-19...............................................

5.3.2Using {QPATH+ PROMPT}SamplePatterns 5-20....................................

5.3.3G--code FormatPrompting{GCODEPROMPT} 5-24..................................

5.3.4 Mill Cycle Format Prompting 5-26...............................................

ii

Page 7

Table of Contents

Index (General)

9/Series Mill

9/Series PALReference Manual

Operation and Programming Manual

5.4Digitizing a Program(Teach) 5-28...................................................

5.4.1Linear Digitizing 5-30.........................................................

5.4.2 Digitizing anArc (3 Points) 5-32.................................................

5.4.3Digitizingan Arc Tangentat End Points 5-34........................................

5.5Deleting Program{DELETE PRGRAM} 5-37..........................................

5.6RenamingPrograms{RENAMEPRGRAM} 5-38........................................

5.7Displayinga Program {DISPLYPRGRAM} 5-39........................................

5.8CommentDisplay{PRGRAMCOMENT} 5-40..........................................

5.9CopyingPrograms{COPYPRGRAM} 5-41............................................

5.10Selecting theProtectable PartProgram Directory 5-43...................................

5.10.1ProtectedProgramEncryptionandDecryption 5-46..................................

5.10.2StoringEncryption/DecryptionTable to BackupMemory 5-49..........................

Chapter 6

Editing Part Programs Offline (ODS)

6.0ChapterOverview 6-1..........................................................

6.1Selectingthe PartProgram Application 6-2...........................................

6.2EditingPart Programs OffLine 6-2.................................................

6.3Interfacing the WorkstationwiththeControl 6-5........................................

6.4DownloadingPart Programs fromODS 6-5...........................................

6.5UploadPartProgramsto ODS 6-12.................................................

Chapter 7

Running a Program

7.0ChapterOverview 7-1..........................................................

7.1SelectingSpecial Running Conditions 7-1............................................

7.1.1Block Delete 7-1...........................................................

7.1.2MiscellaneousFunctionLock 7-2..............................................

7.1.3Sequence Stop{SEQSTOP} 7-2...............................................

7.1.4Single Block 7-4..........................................................

7.2Selecting a Part ProgramInputDevice 7-5............................................

7.3Selectinga Program 7-6.........................................................

7.4Deselecting a Part Program 7-9...................................................

7.5 ProgramSearch {SEARCH} 7-10...................................................

7.6 SearchWith Recall {MID ST PRGRAM} 7-13..........................................

7.7BasicProgramExecution 7-17.....................................................

7.7.1 {QUICK CHECK} 7-19........................................................

7.7.2Axis Inhibit Mode 7-20.......................................................

7.7.3Dry RunMode 7-21.........................................................

7.7.4Part Production/AutomaticMode 7-23............................................

7.8Interrupted ProgramRecover {RESTRT PRGRAM} 7-25..................................

7.9Jog Retract 7-28...............................................................

7.10BlockRetrace 7-31............................................................

iii

Page 8

Table of Contents

Index (General)

9/Series PALReference Manual

Operation and Programming Manual

9/Series Mill

Chapter 8

Display and Graphics

8.0ChapterOverview 8-1..........................................................

8.1Selection ofAxisPositionDataDisplay 8-1...........................................

8.2PAL DisplayPage 8-22..........................................................

8.3ChangingLanguages 8-23........................................................

8.4Graphics 8-24.................................................................

8.4.1Selectingthe Programfor Graphics 8-24..........................................

8.4.2Running Graphics 8-25......................................................

8.4.3DisablingGraphics 8-27......................................................

8.4.4Changing Parameters 8-27....................................................

8.4.5Graphics in Single-Block 8-33..................................................

8.4.6ClearingGraphics Screen 8-33.................................................

8.4.7DisplayingMachineInformation in Graphics 8-33....................................

8.4.8Zooming Graphics 8-33......................................................

8.6PowerTurn-onScreen 8-37.......................................................

8.7ScreenSaver 8-39.............................................................

Chapter 9

Communications

9.0ChapterOverview 9-1..........................................................

9.1Setting Communications 9-1......................................................

9.1.1SettingCommunication Port ParameterValues 9-1...................................

9.1.2Communication PortParameters 9-3.............................................

9.2Inputting PartPrograms from a Tape Reader 9-9.......................................

9.3Outputting Part Programs to aTape Punch 9-13.........................................

9.4VerifyingPartProgramsAgainstSource Programs 9-17...................................

9.5ErrorConditions(Inputting and OutputtingPartPrograms) 9-18..............................

Chapter 10

Introduction to Programming

10.0ChapterOverview 10-1.........................................................

10.1Tape Format 10-1.............................................................

10.2ProgramConfiguration 10-6......................................................

10.2.1Program Names 10-8.......................................................

10.2.2Sequence Numbers 10-9....................................................

10.2.3CommentBlocks 10-10.......................................................

10.2.4Block Delete andMultiLevel Delete 10-10.........................................

10.2.5End ofBlock Statement 10-11..................................................

10.3UsingSubprograms 10-12........................................................

10.3.1Subprogram Call (M98) 10-13..................................................

10.3.2Main and SubprogramReturn(M99) 10-14.........................................

10.3.3Subprogram Nesting 10-16....................................................

10.4WordFormatsand Functions 10-17.................................................

iv

Page 9

Table of Contents

Index (General)

9/Series Mill

9/Series PALReference Manual

Operation and Programming Manual

10.4.1 Minimumand MaximumAxisMotion (ProgrammingResolution) 10-21.....................

10.5WordDescriptions 10-22.........................................................

10.5.1A_ L_ ,R_ ,C_ (Quick Plus andRadius-Chamfer Words) 10-22..........................

10.5.2Axis Names 10-22.........................................................

10.5.3D --and H-- Words (ToolOffsets) 10-22............................................

10.5.4F--words(Feedrate) 10-23....................................................

10.5.5G --codes(PreparatoryFunctions) 10-24..........................................

10.5.6I ,J,and K IntegrandWords 10-30.............................................

10.5.7M --codes(MiscellaneousFunctions) 10-30........................................

10.5.7.1Auxiliary MiscellaneousFunction(B--word) 10-37..................................

10.5.8N--words(Sequence Numbers) 10-37............................................

10.5.9O --words(ProgramNames) 10-37..............................................

10.5.10P ,L(MainProgramJumps and SubprogramCalls) 10-37.............................

10.5.11S--word(SpindleSpeed) 10-38................................................

10.5.12T--words(Tool Selection) 10-40................................................

Chapter 11

Coordinate Systems Offsets

11.0 Chapter Overview 11-1.........................................................

11.1 Machine CoordinateSystem(Absolute) 11-1..........................................

11.1.1MotionintheMachineCoordinateSystem(G53) 11-2.................................

11.2 Preset Work Coordinate Systems (G54-59.3) 11-4......................................

11.2.1AlteringWork Coordinate Systems (G10L2) 11-7....................................

11.3 Work Coordinate System ExternalOffset 11-9.........................................

11.3.1AlteringExternalOffset(G10L2) 11-11............................................

11.4 Offsetting the WorkCoordinateSystems 11-13..........................................

11.4.1CoordinateOffsetUsing ToolPosition(G92) 11-13....................................

11.4.2OffsettingCoordinateZero Points(G52) 11-16.......................................

11.4.3 {SET ZERO}Offset 11-18.....................................................

11.4.4Jogging an Offset 11-19.......................................................

11.4.5CancelingCoordinateSystem Offsets (G92.1) 11-20..................................

11.4.6Canceling Selected Coordinate System Offsets (G92.2) 11-21..........................

11.5 PAL Offsets 11-22..............................................................

Chapter 12

Overtravels and Programmable Zones

12.0ChapterOverview 12-1.........................................................

12.1HardwareOvertravels 12-2......................................................

12.2Software Overtravels 12-3.......................................................

12.3Programmable Zone2 (G22,G23) 12-5..............................................

12.4Programmable Zone3 (G22.1,G23.1) 12-7...........................................

12.5Resetting Overtravels 12-13.......................................................

v

Page 10

Table of Contents

Index (General)

9/Series PALReference Manual

Operation and Programming Manual

9/Series Mill

Chapter 13

Coordinate Control

13.0ChapterOverview 13-1.........................................................

13.1Rotating theCoordinateSystems 13-1...............................................

13.1.1RotatingtheCurrentWorkCoordinateSystem(G68, G69) 13-2.........................

13.1.2External Part Rotation 13-6...................................................

13.2PlaneSelection(G17, G18, G19) 13-11...............................................

13.3Absolute/IncrementalModes (G90,G91) 13-12.........................................

13.4Inch/Metric Modes (G20,G21) 13-13................................................

13.5Scaling 13-14.................................................................

13.5.1Scaling and AxisPosition DisplayScreens 13-17....................................

13.5.2Scaling Magnification Data Screen 13-17..........................................

13.5.3Scaling Restrictions 13-19....................................................

Chapter 14

Axis Motion

14.0 Chapter Overview 14-1.........................................................

14.1 PositioningAxes 14-1..........................................................

14.1.1 Rapid PositioningMode (G00) 14-1.............................................

14.1.2 Linear Interpolation Mode(G01) 14-3...........................................

14.1.3 CircularInterpolationMode (G02, G03) 14-5......................................

14.1.4 HelicalInterpolation Mode (G02, G03) 14-10.......................................

14.1.5 PositioningRotary Axes 14-12.................................................

14.1.6 CylindricalInterpolation 14-14..................................................

14.1.7 PALAxisMover 14-20.......................................................

14.2 PolarCoordinate Programming (G15, G16) 14-21.......................................

14.2.1 Polar ProgrammingSpecial Cases 14-25.........................................

14.3 AutomaticMotionToand From Machine Home 14-29....................................

14.3.1 Automatic MachineHoming(G28) 14-29.........................................

14.3.2 Automatic ReturntoMachineHome(G28) 14-30....................................

14.3.3 AutomaticReturn From MachineHome (G29) 14-32.................................

14.3.4 MachineHome Return Check (G27) 14-33........................................

14.3.5 Returnto AlternateHome(G30) 14-34...........................................

14.4 Dwell (G04) 14-35.............................................................

14.4.1 Dwell- Seconds 14-36......................................................

14.4.2 Dwell- Number of Spindle Revolutions 14-36......................................

14.5 ProgrammableMirrorImage(G50.1- G51.5) 14-36......................................

14.5.1 Manual MirrorImage 14-38...................................................

14.6 AxisClamp 14-39..............................................................

14.7Feed to HardStop(G24) 14-40....................................................

vi

Page 11

Table of Contents

Index (General)

9/Series Mill

9/Series PALReference Manual

Operation and Programming Manual

Chapter 15

UsingQuickPathPlust

15.0 Chapter Overview 15-1.........................................................

15.1 Using QuickPath Plus 15-1......................................................

15.2 Linear QuickPath Plus 15-3......................................................

15.3 CircularQuickPathPlus(G13,G13.1) 15-7...........................................

Chapter 16

Using Chamfers and Corner Radius

16.0 Chapter Overview 16-1.........................................................

16.1 Chamfers and CornerRadius 16-1.................................................

Chapter 17

Spindles

17.0 Chapter Overview 17-1.........................................................

17.1 Controlling Spindle (G12.1,G12.2, G12.3) 17-1........................................

17.2 Spindle Orientation (M19) 17-3...................................................

17.3 Spindle Direction(M03,M04,M05) 17-5.............................................

17.4 Synchronized Spindles 17-6.....................................................

17.4.1Using theSpindleSynchronizationFeature 17-7...................................

17.5SpecialConsiderations forSpindle Synchronization 17-9.................................

Chapter 18

Programming Feedrates

18.0 Chapter Overview 18-1.........................................................

18.1 Feedrates 18-1...............................................................

18.1.1 Feedrates Applied During CutterCompensation 18-2................................

18.1.2 Inverse TimeFeed Mode (G93) 18-4..........................................

18.1.3 Feed--Per--MinuteMode(G94) 18-5...........................................

18.1.4 Feed--Per--RevolutionMode (G95) 18-5.........................................

18.1.5 Rapid Feedrate 18-6......................................................

18.1.6 Feedrate Overrides 18-7...................................................

18.1.7 Feedrate Limits (Clamp) 18-8................................................

18.2Feedratesto ControlTorque Adaptive Feed (G25) 18-9..................................

18.3SpecialAMPAssignedFeedrates 18-12..............................................

18.3.1Single DigitF--words 18-12...................................................

18.3.2External Feedrate Switch 18-13...............................................

18.4Automatic Acceleration/Deceleration(Acc/Dec) 18-14....................................

18.4.1ExponentialAcc/Dec 18-15...................................................

18.4.2Linear Acc/Dec 18-16.......................................................

18.4.3S--CurveAcc/Dec 18-17.....................................................

18.4.4ProgrammableAcc/Dec 18-18.................................................

18.4.5Precautions on CornerCutting 18-20............................................

18.4.6Spindle Acceleration(Ramp) 18-22..............................................

vii

Page 12

Table of Contents

Index (General)

9/Series PALReference Manual

Operation and Programming Manual

18.4.7Short Block Acc/Dec G36, G36.1 18-22.........................................

9/Series Mill

Chapter 19

Dual---axis Operation

19.0 Chapter Overview 19-1.........................................................

19.1 Dual--axisOperation 19-1.......................................................

19.1.1 Parking a DualAxis 19-3...................................................

19.1.2 Hominga DualAxis 19-4...................................................

19.1.3 Programminga Dual Axis 19-5...............................................

19.1.4 OffsetManagementfora DualAxis 19-7.......................................

Chapter 20

Tool Control Functions

20.0 Chapter Overview 20-1.........................................................

20.1 Programming a T--word 20-1.....................................................

20.2 Tool LengthOffsetFunction(G43,G44,G49) 20-3......................................

20.2.1 Activating Tool Length Offsets 20-8............................................

20.2.2ToolLength Offset(TLO)Axis Selection(G43.1,G44.1) 20-9...........................

20.3 RandomTool 20-11............................................................

20.4 ProgrammingAlterations of the Offset Tables (G10L10 -- G10L13) 20-18.......................

20.5 AutomaticTool Life Management 20-19..............................................

20.5.1ToolDirectoryData 20-20....................................................

20.5.2Assigning DetailedTool Data 20-25.............................................

20.5.3 Programming Data andBacking Up Tool ManagementTables (G10L3, G11) 20-29............

20.5.4 Programming UsingTool Management 20-33......................................

Chapter 21

Cutter Diameter Compensation (G40, G41, G42)

21.0 Chapter Overview 21-1.........................................................

21.1 Active CutterCompensation 21-3..................................................

21.2 CutterCompensationGenerated Blocks G39,G39.1 21-7................................

21.3 CutterCompensation(Type A) 21-10................................................

21.3.1 CutterCompensation TypeA EntryMoves 21-10...................................

21.3.2 CutterCompensation Type AExitMoves 21-14....................................

21.4 CutterCompensation (Type B) 21-20...............................................

21.4.1 CutterCompensation TypeB EntryMoves 21-20...................................

21.4.2 CutterCompensation TypeB Exit Moves 21-24...................................

21.5 Tool PathDuring CutterCompensation 21-30..........................................

21.6 CutterCompensationSpecial Cases 21-35............................................

21.6.1 Changing CutterCompensation Direction 21-35....................................

21.6.2 TooMany Non-Motion Blocks 21-39............................................

21.6.3 Corner MovementAfterGeneratedBlocks 21-41...................................

21.6.4 Changing CutterRadiusDuringCompensation 21-43................................

21.6.5 MDIor Manual MotionDuringCutterCompensation 21-46.............................

viii

Page 13

Table of Contents

Index (General)

9/Series Mill

9/Series PALReference Manual

Operation and Programming Manual

21.6.6 Moving To/From Machine Home 21-48..........................................

21.6.7 Changing or OffsettingWork Coordinate System 21-49...............................

21.6.8 Block Look-Ahead 21-50....................................................

21.7 Error Detection for CutterCompensation 21-51.........................................

Chapter 22

Using Pocket Milling Cycles

22.0 Chapter Overview 22-1.........................................................

22.1 Pocket Milling RoughingCycle(G88.1) 22-1..........................................

22.1.1 RectangularPocketRoughingUsing G88.1 22-2.................................

22.1.2 RectangularPocketEnlargingUsingG88.1 22-5...................................

22.1.3 SlotRoughingUsing G88.1 22-8..............................................

22.1.4 CircularPocketRoughingUsingG88.1 22-10......................................

22.1.5 CircularPocketEnlargingUsingG88.1 22-13......................................

22.2 Pocket Milling FinishingCycle (G88.2) 22-15..........................................

22.2.1 RectangularPocketFinishingUsingG88.2 22-16...................................

22.2.2 CircularPocketFinishingUsing G88.2 22-19......................................

22.2.3 SlotFinishingUsingG88.2 22-20..............................................

Chapter 23

Using Post Milling Cycles

23.0 Chapter Overview 23-1.........................................................

23.1 PostMilling Roughing Cycle (G88.3) 23-1............................................

23.1.1 RectangularPostRoughingUsingG88.3 23-2.....................................

23.1.2 CircularPostRoughingUsingG88.3 23-5.......................................

23.2 PostMilling Finishing Cycle (G88.4) 23-7............................................

23.2.1 RectangularPostFinishingUsingG88.4 23-8.....................................

23.2.2 CircularPostFinishingUsing G88.4 23-11.......................................

Chapter 24

Using Hemisphere Milling Cycles

24.0 Chapter Overview 24-1.........................................................

24.1 Hemisphere MillingRoughing Cycle (G88.5) 24-1......................................

24.1.1 Concave Hemisphere RoughingUsingG88.5 24-2.................................

24.1.2 Convex Hemisphere RoughingUsingG88.5 24-5..................................

24.2 Hemisphere MillingFinishing Cycle (G88.6) 24-7.......................................

24.2.1 Concave Hemisphere Finishing UsingG88.6 24-8.................................

24.2.2 Convex Hemisphere Finishing UsingG88.6 24-10..................................

Chapter 25

Irregular Pocket Milling Cycles

25.0 Chapter Overview 25-1.........................................................

25.1 IrregularPocket Milling 25-1.....................................................

25.1.1 IrregularPocketRoughing(G89.1) 25-2.........................................

ix

Page 14

Table of Contents

Index (General)

9/Series PALReference Manual

Operation and Programming Manual

25.1.2 IrregularPocketFinishing(G89.2) 25-10..........................................

9/Series Mill

Chapter 26

Milling Fixed Cycles

26.0 Chapter Overview 26-1.........................................................

26.1 Milling Fixed Cycles 26-2........................................................

26.2 Positioningand Hole MachiningAxes 26-4...........................................

26.3 Parameters 26-7.............................................................

26.4 Milling Fixed Cycle Operations 26-8................................................

(G73):Deep HolePeck DrillingCycle with Dwell 26-9....................................

(G74):Left-HandTapping Cycle 26-10................................................

(G74.1):Left-HandSolid-Tapping Cycle 26-12...........................................

(G76): Boring Cycle,SpindleShift 26-15.............................................

(G80): Cancel or EndFixed Cycles 26-18............................................

(G81): Drilling Cycle,No Dwell/RapidOut 26-18........................................

(G82): DrillCycle,Dwell/Rapid Out 26-20............................................

(G83): Deep Hole Drilling Cycle 26-21...............................................

(G84): Right-HandTapping Cycle 26-23.............................................

(G84.1):Right-HandSolid-TappingCycle 26-25.........................................

(G85): Boring Cycle, No Dwell/FeedOut 26-28........................................

(G86): Boring Cycle, SpindleStop/Rapid Out 26-30.....................................

(G87): Back BoringCycle 26-32...................................................

(G88): Boring Cycle, SpindleStop/ManualOut 26-34....................................

(G89): Boring Cycle, Dwell/FeedOut 26-36...........................................

26.5 Altering Milling Fixed Cycle Operating Parameters 26-38..................................

26.6 Examples of Drilling Cycles 26-40..................................................

Chapter 27

Skip, Gauge, and Probing Cycles

27.1 Chapter Overview 27-1.........................................................

27.2 External Skip,Gauge,and ProbeFunctions 27-1.......................................

27.2ExternalSkip Functions (G31codes) 27-2..........................................

27.3 Tool GaugingExternalSkip Functions (G37 codes) 27-4.................................

27.4 Hole Probing (G38) 27-8.......................................................

27.5 ParallelProbingCycle(G38.1) 27-12................................................

27.6 Probing ParametersTable 27-15..................................................

27.7 Adaptive Depth (G26) 27-18......................................................

x

Page 15

Table of Contents

Index (General)

9/Series Mill

9/Series PALReference Manual

Operation and Programming Manual

Chapter 28

Paramacros

28.0 Chapter Overview 28-1.........................................................

28.1 Paramacros 28-1.............................................................

28.2 ParametricExpressions 28-2.....................................................

28.2.1 Basic MathematicalOperators 28-2............................................

28.2.2 Mathematical Function Commands 28-4........................................

28.2.3 ParametricExpressions asG-- or M--Codes 28-6..................................

28.3 Transferof ControlCommands 28-7................................................

28.3.1 ConditionalOperators 28-7..................................................

28.3.2 GOTOand IF-GOTOCommands 28-8.........................................

28.3.3 DO-ENDand WHILE-DO-END Commands 28-10...................................

28.4 ParameterAssignments 28-12...................................................

28.4.1Local Parameter Assignments 28-12............................................

28.4.2 CommonParameters 28-15..................................................

28.4.3 SystemParameters 28-15...................................................

28.4.4 PALParameters 28-33......................................................

28.4.5Shared Dual-ProcessParameters(#7100 -7199) 28-35..............................

28.5 Assigning ParameterValues 28-36.................................................

28.6 Macro CallCommands 28-44.....................................................

28.6.1Non-Modal ParamacroCall(G65) 28-45..........................................

28.6.2Modal Paramacro Call (G66) 28-46.............................................

28.6.3Modal Paramacro Call (G66.1) 28-48............................................

28.6.4AMP-definedG-CodeMacroCall 28-50..........................................

28.6.5AMP-DefinedM-CodeMacroCall 28-51..........................................

28.6.6AMP-DefinedT--, S--, and B--Code MacroCall 28-51.................................

28.6.7Nesting Macros 28-52.......................................................

28.7 Macro OutputCommands 28-54...................................................

Chapter 29

Program Interrupt

29.0 Chapter Overview 29-1.........................................................

29.1 Enabling and Disabling Interrupts (M96/M97) 29-1......................................

29.2 InterruptRequestConsiderations 29-4..............................................

29.3 InterruptTypes 29-5...........................................................

29.4The InterruptProgram 29-8......................................................

Chapter 30

Using a 9/Series Dual-processing System

30.0ChapterOverview 30-1.........................................................

30.1Defining ofa Dual- processing System 30-1...........................................

30.2Operating a Dual-processingSystem 30-2............................................

30.3SynchronizingMultiplePartPrograms 30-7...........................................

30.4SpindleControlfor Dual-- processing Systems 30-12.....................................

xi

Page 16

Table of Contents

Index (General)

9/Series PALReference Manual

Operation and Programming Manual

30.5 Using Interference Checking with a Dual-process Mill 30-12................................

30.5.1Measuring InterferenceBoundaries 30-16.........................................

30.5.2Entering InterferenceValuesManually 30-19......................................

30.5.3Entering InterferenceValuesthroughProgramming (G10L5 and G10L6) 30-21...............

30.5.4Backing UpInterference Tables 30-23...........................................

30.6Shared Axes onDual--processing Systems 30-26.......................................

30.6.1Operatinga SharedAxis 30-26.................................................

30.6.2Switchinga Shared Axistoa DifferentProcess 30-28................................

30.6.3Settingup aShared Axis 30-29................................................

30.7DualAxes ona Dual--processingSystem 30-31.........................................

30.7.1Decoupling a Dual Axis Group 30-32...........................................

30.7.2IndependentlyProgramming Dual Axis Members 30-33...............................

9/Series Mill

Chapter 31

Using Transfer Line Cycles

31.0ChapterOverview 31-1.........................................................

31.1TransferLine Cycles 31-2.......................................................

31.1.1Using TransferLine Cycles 31-3..............................................

31.1.2Selectingthe ProgramtoEditorCreate 31-6....................................

31.1.3Creatinga Transfer LinePartProgram 31-9.......................................

31.1.4EditingPartPrograms 31-12..................................................

31.1.5Reloading Part Program Templates 31-17.........................................

31.1.6Running theCycles 31-25...................................................

31.2Understandingthe QuickViewTemplates 31-25.........................................

Appendix A

Softkey Tree

AppendixOverview A-1............................................................

Understanding Softkeys A-1.........................................................

Describing Level1 Softkeys A-3......................................................

UsingtheSoftkeyTree A-3.........................................................

Appendix B

Error and System Messages

Overview B-1...................................................................

Appendix C

G-code Tables

AppendixOverview C-1............................................................

G-codeTables C-1...............................................................

xii

Page 17

Table of Contents

Index (General)

9/Series Mill

9/Series PALReference Manual

Operation and Programming Manual

Appendix D

Allen-Bradley 7300 Series CNC Tape Compatibility

AppendixOverview D-1............................................................

G-codeCompatibility Considerations D-1................................................

M-code Compatibility Considerations D-3...............................................

Offset Compatibility Considerations D-4.................................................

Additional Feature Compatibility Considerations D-6........................................

9/Series G-codesApplicabletothe 7300 SeriesCNC D-9....................................

7300 Series Features NotSupported D-10...............................................

xiii

Page 18

Table of Contents

Index (General)

9/Series PALReference Manual

Operation and Programming Manual

9/Series Mill

xiv

Page 19

1

Using This Manual

Chapter

1.0

ChapterOverview

1.1

Audience

1.2

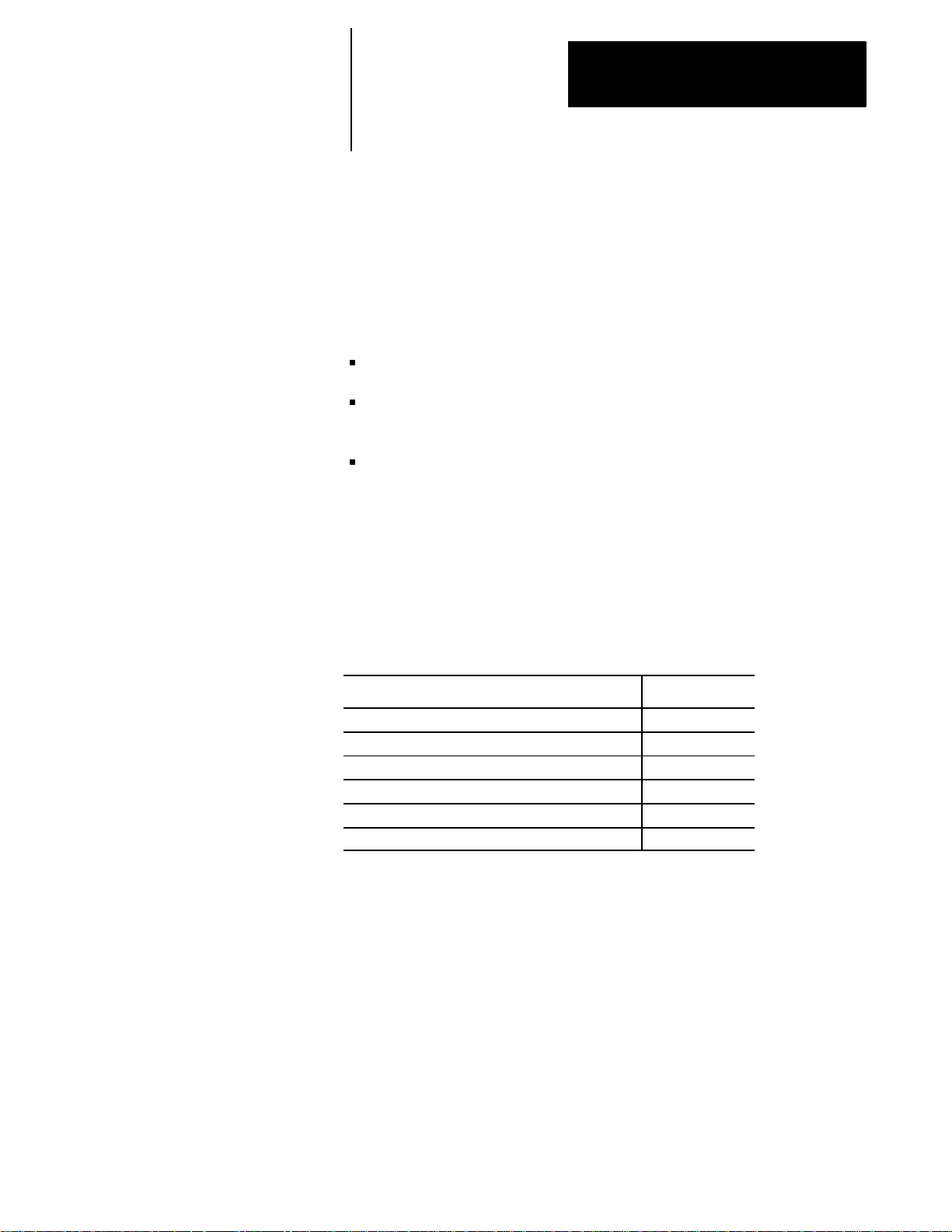

Manual Design

This chapter describes how to use this manual. Major topics include:

how the manual is organized and what i nformation can be found in it.

how this manual is written and what fundamentals are presumed to be

understood by reader.

definitions for certain key terms.

We intend this manual for use by those who program and/or operate any one

of the family Allen-Bradley 9/Series CNCs. We assume that a person has

some familiarity with the operation and programming of a CNC.

We divided the manual this way:

For information about: Refer to:

howto operatethe control chapters3 -- 9

howto programthe control chapters10 -- 29

softkeys appendixA

errorand operatormessagesin alphabeticalorder appendixB

standardG-codesused to programthe control appendixC

theAllen-Bradley7300 SeriesCNC tape reader appendixD

We placed section headings in the left margin of each page, and included

illustrations and examples as aids in programming and operating the

control.

Table 1.A provides a summary of each chapter.

1-1

Page 20

Chapter 1

Describesthefixedcycles(cannedcycles)fordrillingoperationsandtheG-wordsandparameter

s

usedtodefinethem.

Using This Manual

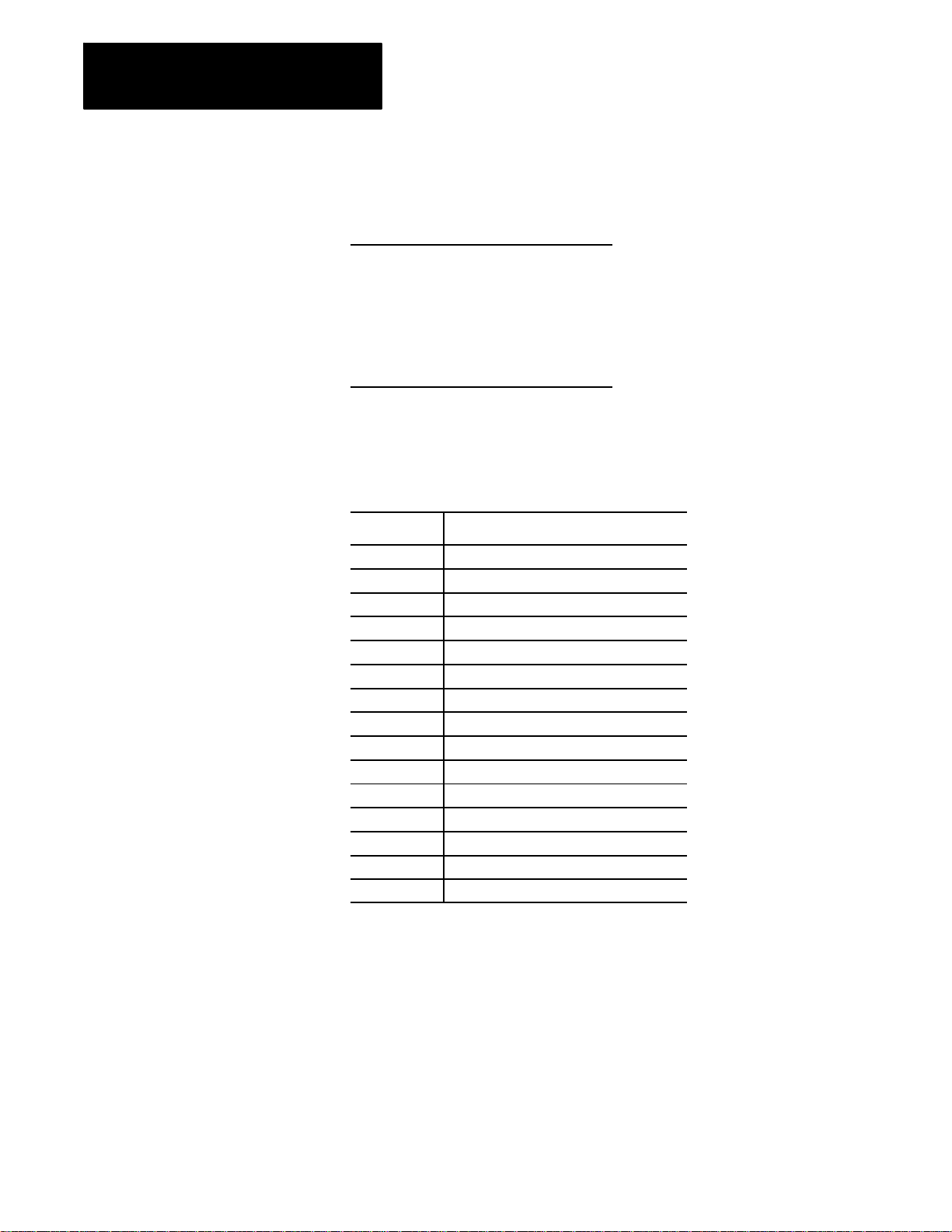

Table 1.A

Manual Organization

Chapter Title Summary

1 ManualOverview Manualoverview,intendedaudience, definition of key terms, how toproceed.

2 BasicControlOperation Abrief descriptionofthe control’sbasic operationincluding powerup, MTBpanel, operatorpanel,

accesscontrol,and E-STOP.

3 Offset Tablesand Setup Basicsetupof theoffsettable,other initialoperatingparameters.

4 Manualand MDIOperation Howto use the manualoperate modeincluding,homingthe machine,jog hand-wheel,jog

continuous,and jogincrement. Alsocovered are thebasics forMDI operation.

5 Editing ProgramsOn Line Howto create,edit,andsave a partprogramonline.

6 EditingPartProgramOffLine Howto create,edit,and save a partprogramsfromODS offline.

7 Runninga Program Howto selectand execute a programautomatically. Thiscovers programcheckingas well as part

production. Alsodetails on specialrunning conditions.

8 Displays/Graphics Howto access and interpret the differentposition displays. How to use theQuick Check and Active

Programgraphicsfeatures.

9 Communications Communications withperipheral devices. Includes sectionson communication port parameters,

inputtingand outputting AMP,PAL,Offsets, and programs.

10 Introduction toProgramming Tape format,structure and formatofthe programminglanguage forthe control.

11 CoordinateSystemOffsets Machine coordinate system,PresetWorkcoordinate systems,PAL offsets, and external offsets

12 Overtravels and Programmable

Zones (G22,G23)

13 CoordinateControl Describesabsolute/incrementalmodes, inch/metric modes,radius/diameter modes,and scaling

14 Axis Motion G-wordsdefinehow the toolis positioned tothe endpointof a move. Alsosectionson automatic

15 QuickPath Plus DescribesQuickPathPlus programming

16 UsingChamfersand Corner Radius Describesthe ,C-and ,R-wordsprogrammed forchamfering and cornerradius

17 Spindles Describesspindle speedcontrol,spindleorientation,spindledirection,and VirtualC axis

18 Programming Feedrates Describesacc/dec,AMP-assignedfeedrates,feedrate control,shortblock acc/dec

19 DualAxis Operation Describesparking,homing,programming,offsetmanagementfora dual axis

20 ToolControl Selectinga tool. Activatingand deactivatingtoollength offsets. Alsotool controlfeaturessuch as

21 CutterCompensation Describesthe Tool Tip RadiusCompensation feature (TTRC) thatoffsets fordifferenttooldiameters.

22 Using Pocket Milling Cycles

23 Using PostMillingCycles

24 Using HemisphereMilling Cycles

25 Using IrregularPocketMilling Cycles

26 Milling Fixed Cycles

27 Skipand Gauging Cycles Describesthe 9/Series Probing features. Includesthe toolmeasuring gauge feature.

28 Paramacros Describesparamacrosincluding calling,arithmetic functions,looping,decision making

29 ProgramInterrupts Describesthe programinterruptfeature. This feature is used tocalla subprogramor paramacro

30 DualProcessing Systems Necessaryinformationon capabilitiesand programmingmethods fordual processing systems.

31 Transfer Line Cycles Describes operationand programmingofT-Line-9part programtemplatesfortransferlinecontrols.

Hardwareand softwareovertravels, programmable zone 2 (G22,G23), programmable zone 3

(G22.1,G23.1),and resetting overtravels

machinehome,dwell,mirroring, and axis clamp

RandomTooland ToolLife Management.

Describesthe fixed cycles (cannedcycles) for drillingoperations and theG-wordsandparameters

programwhenevera signal correspondingto thatprogramis sent toPALby the operator.

1-2

Page 21

Chapter 1

Using This Manual

Table 1.A (cont.)

Manual Organization

Appendix Title Summary

AppendixA Softkeys Describes softkeysand theirfunctionsforsoftkeylevels 1 and 2. Alsothe softkeytreedisplaying all

levelsof softkeysand theirlocationis shown.

AppendixB Errorand OperatorMessages Analphabetical listingof 9/Seriessystemmessages withbrief descriptions.

AppendixC Gand M Code Tables Liststhe G-codesusedto programthe control.

AppendixD A-B7300 SeriesCNC TapeReader Detailed7300 Series CNC tapecompatibility featuredeveloped on the control.

1.3

Reading this Manual

To make this manual easier to understand, we included these explanations

of terms and symbols:

All explanations, illustrations, and charts presented are based on

standard CNC functions. Operations may differ from the basic

information provided in this manual depending on the configuration of

the machine tool. For details, refer to the manuals prepared and supplied

by the system installer.

Some of the softkey functions may be purchased as optional features.

This manual assumes that all of the optional features have been

purchased.

Explanations and illustrations are presented based on the movement of

the cutting tool on a fixed workpiece.

The control allows the use of any alphabetic character for expressing a

numerically controlled axis. This manual uses X, Y, and Z for the first,

second, and third axes on the basic coordinate system respectively. I, J,

and K represent the integrand words for the axes.

The term AMP is an abbreviation for Adjustable Machine Parameters.

These parameters are used to configure a control to a specific machine.

Setting of AMP is usually done by the system installer.

Key names designated between the [ ] symbols are found on the

operator panel.

Key names designated between the { } symbols are softkeys found

below the CRT.

Switch and button names on the standard MTB panel are designated

between the < > symbols.

1-3

Page 22

Chapter 1

Using This Manual

The term PAL is an abbreviation for Programmable Application Logic.

This is a ladder logic program that processes signals between the CNC

and the machine. It is usually programmed by the system installer.

System Characteristics:

Metric

Absolute

IPM

1.4

Terms andConventions

To make this manual easier to read and understand, we shortened the full

product names and features. Shortened terms include:

AMP — Adjustable Machine Parameters

Backup — Memory storage area not requiring battery maintenance

CNC — Computer Numerical Control

CPU — Central Processing Unit (the computing part of the control)

CRT — Cathode Ray Tube (the control’s monitor screen)

the control — the 9/230, 9/240, 9/260 or 9/290 CNC

ESTOP — Emergency Stop

Flash memory — programmable, non-volatile memory

HPG — Hand Pulse Generator

I/O — Input/Output

MDI — Manual Data Input

modal — an operating condition that remains in effect on the control

until cancelled or replaced

MTB — Machine Tool Builder

ODS — Offline Development System

PAL — Programmable Application Logic

RAM — Random Access Memory resident on the 9/240

softkeys — the row of keys directly below the screen

1-4

system installer — the company or contractor responsible for installing

this control on the machine

Page 23

Chapter 1

Using This Manual

1.5

Warnings, Cautions, and

Important Information

1.6

Related Publications

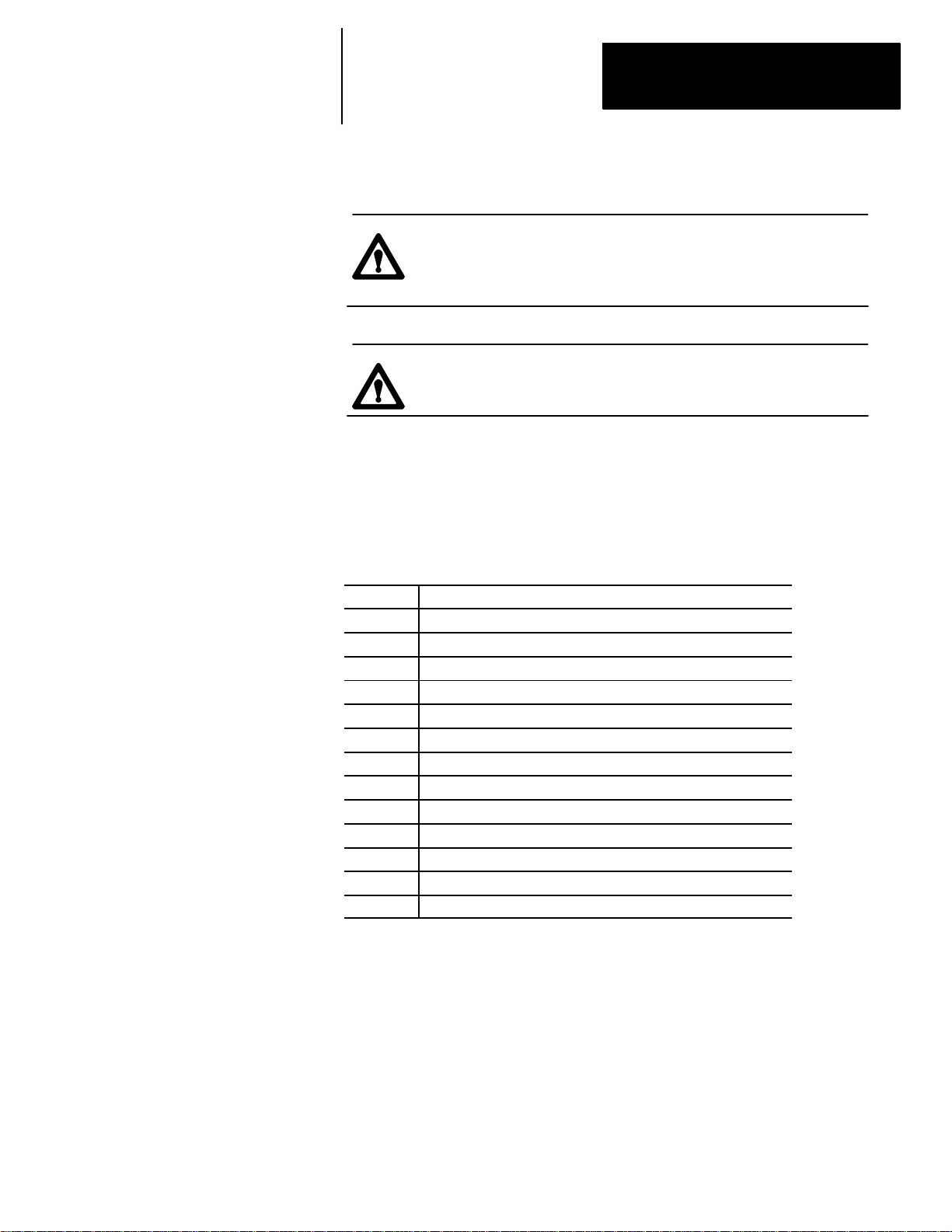

We indicate information that is especially important by the following:

WARNING: indicates circumstances or practices that can lead

to personal injury as well as to damage to the control, the

machine, or other equipment.

CAUTION: indicates circumstances or practices that can lead

to damage to the control or other equipment.

Important: indicates information that is necessary for successful

application of the control.

9/SeriesDocumentation

Pub.No. Document Name

8520-4.3 9/SeriesCNCPALReference Manual

8520--5.1.1 9/SeriesCNC Lathe Operationand Programming Manual

8520--5.1.3 9/SeriesCNC Mill Operationand Programming Manual

8520--5.1.4 9/SeriesCNC GrinderOperation and Programming Manual

8520-5.1.5 9/SeriesDataHighway PlusCommunicationModule UserManual

8520-5.1.6 9/SeriesMMS/EthernetCommunicationModuleUser Manual

8520--5.2 9/SeriesCNC OCI UserManual Supplement

8520-6.2 9/SeriesCNCIntegrationand MaintenanceManual

8520-6.4 9/SeriesCNCAMP ReferenceManual

8520-6.5 T-Line-9 TransferLine QuickStartGuide

8520--6.6 9/SeriesCNC OCI Installation Manual

8520--6.7 9/SeriesCNC OCI APIDeveloper’sGuide

MCD-5.1 Offline DevelopmentSystemUser’s Manual

END OF CHAPTER

1-5

Page 24

Chapter 1

Using This Manual

1-6

Page 25

Chapter

2

2-1

BasicControl Operation

2.0

ChapterOverview

This chapter describes how to operate the Allen-Bradley 9/Series control,

including:

Topic: On page:

MTBpanel 2-12

{FRONT PANEL} 2-15

Power-up 2-23

Emergencystops 2-24

Access control 2-25

Changingmodes 2-33

Displaysystem and messages 2-37

Inputcursor 2-41

{REFORM MEMORY} 2-41

Removingan axis 2-43

Timepartcount 2-43

We also tell you about the control conditions automatically assumed at

power up.

2.1

Operator Panel Operations

Use the operator panel to perform these operations:

display a part program

display control status and tool position

edit a part program

display and enter tool offset data

display the status of input/output signals

display and enter programmable zone boundaries

set the level of protection of part programs, tool offset data, AMP data,

etc.

Use the operator panel to perform many other operations. We describe

these operations in the remaining chapters of this manual.

Page 26

Chapter 2

2-2

Basic Control Operation

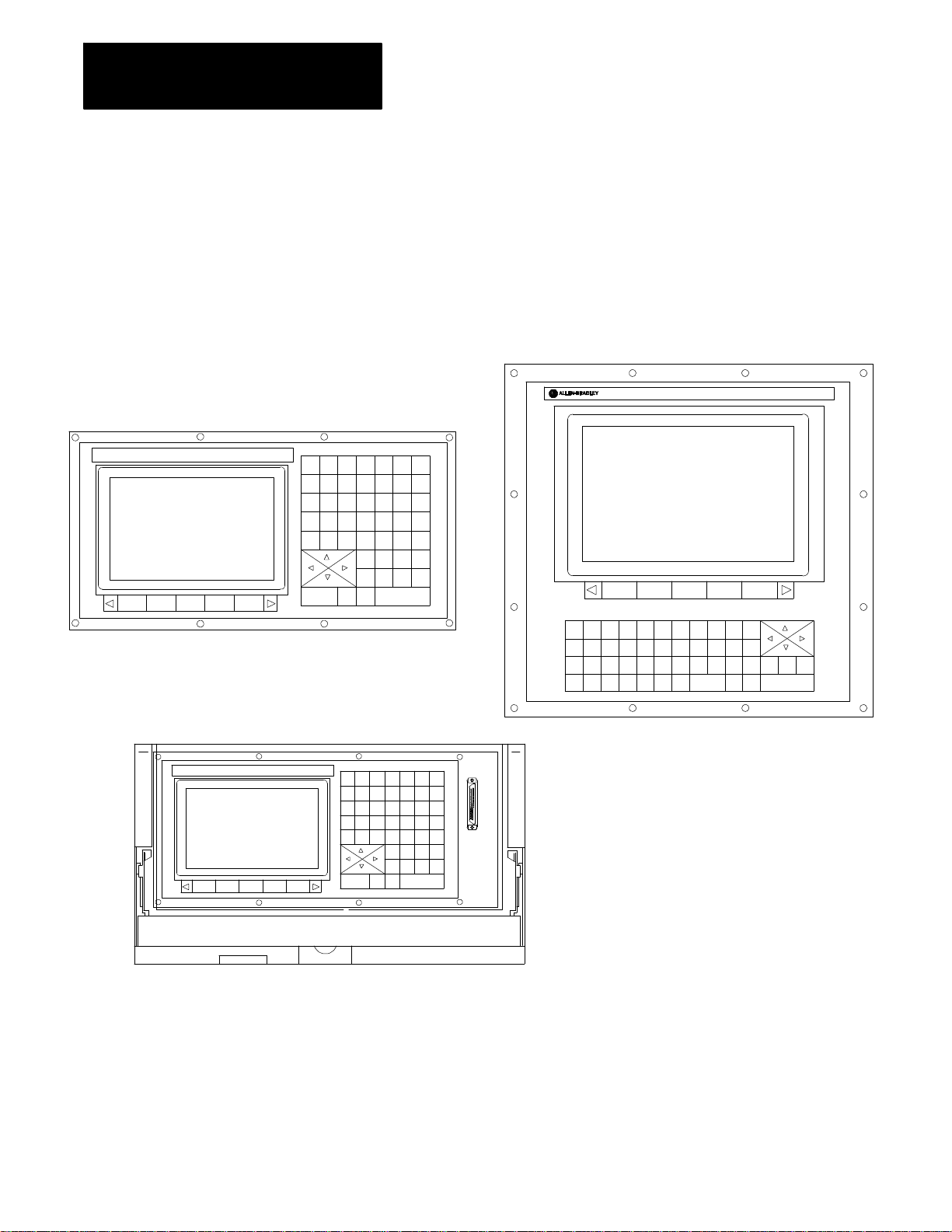

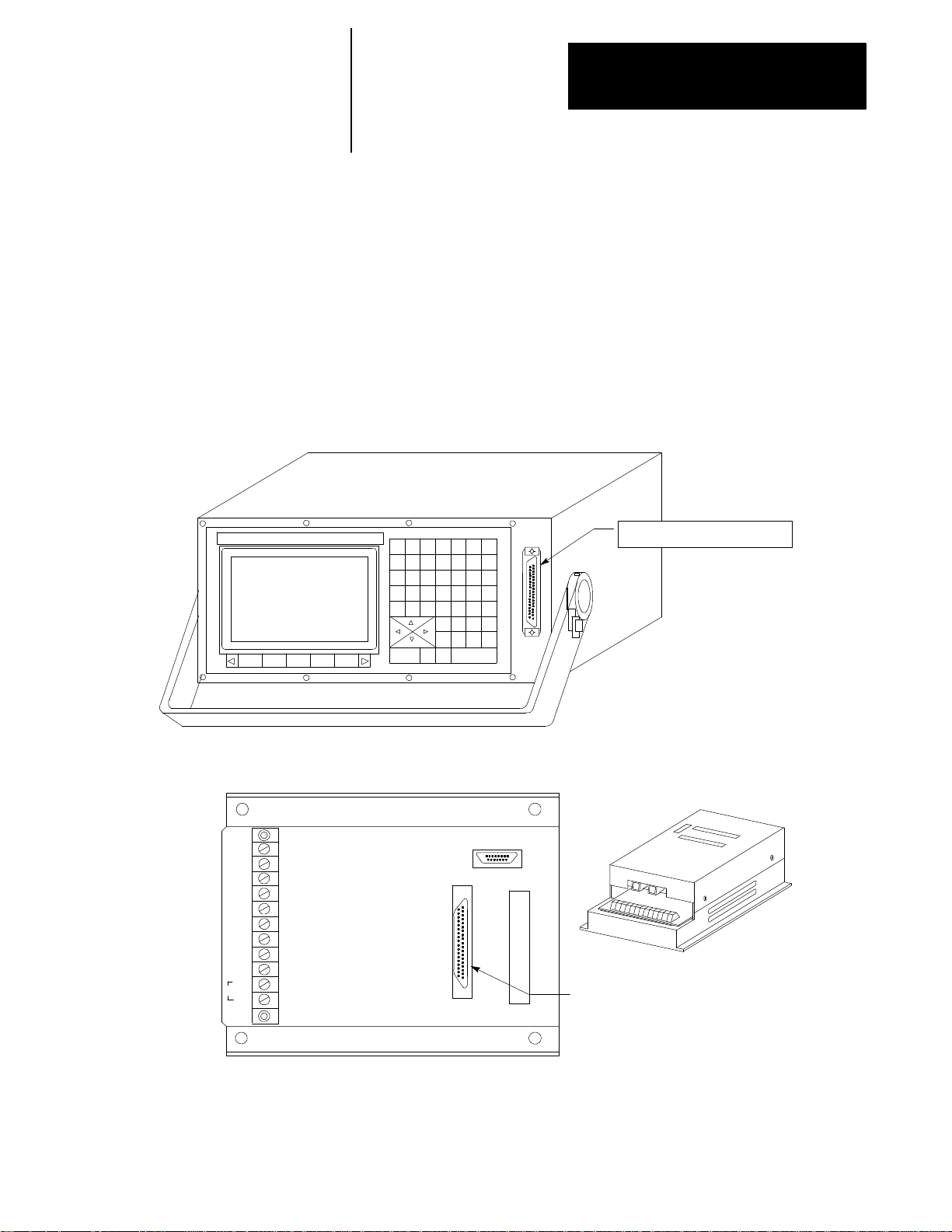

Figure 2.1 shows the different operator panels available. The color

operator panel has identical keys and softkeys in a slightly different

configuration. The portable operator panel has the same key locations as

the monochrome operator panel but can be removed from the 9/Series I/O

ring.

Figure 2.1

Operator Panels

9/SERIES

Monochrome Operator Panel

Removable Operator Panel

9

78

456

123

.

0:

N

+

_

$

=

CALC

!

G

O

X

P

_

I

F

Z

Y

A

W

R

M

Q

K

J

SHIFT

#

D

H

,

?

E

B

C

L

C

&

SP

T

S

[

]

SELECTSELECT

DISP

DEL

EOB

)

(

LINE

PROC

ColorOperatorPanel

(CRTand FlatPanel)

CAN

TRANSMIT

RES

CNTRL

19436

Page 27

Chapter 2

2-3

Basic Control Operation

2.1.1

Keyboard

Table 2.A explains the functions of keys on the operator panel keyboard.

In this manual, the names of operator panel keys appear between [ ]

symbols.

Table 2.A

Key Functions

Key Name Function

Addressand NumericKeys Usethese keys toenter alphabeticand numeric

characters. Ifa key has twocharactersprintedon it,

pressingit normallyentersthe upperleft character.Holding

downthe [SHIFT] key while pressingit entersthelower

rightcharacter.

CursorKeys • , • ,• , •

[SHIFT] and • or •

[SHIFT] and • or •

CalculationKey[CALC] Pressingthiskey enables a calculatortype function on the

Delete Key [DEL] Pressingthiskey deletes thecharacterto theleftofthe

[SHIFT] and [DEL] Pressingthis key deletesall keyed-indata currently

[CAN] Clearthemostrecently generated,activeerrormessage

Transmit Key [TRANSMIT] Thedata enteredand displayed ontheinput linesis sent to

BlockReset [RESET] Thisperforms a block reset. See page 2-4 .

ControlReset[RESET] +

[SHIFT]

DisplaySelect

[DISP SELECT]

End of Block [E.O.B.] Usethiskey to enteran End of Blockcharacterwhen

[PROC SELECT] This keyis used for dual processlathe systemsonly.

[SHIFT] and [• ] Pressthe [SHIFT] keywhile holding down the[• ]

Usethese keys tomove the cursorleft,right,up and down

inthe data displayarea (lines4-21)of thescreen. We

refertothese keys as theleft,right,up, and downcursor

keys respectively.

Pressthe rightor leftcursorkeys while holdingdown the

[SHIFT] keyto move thecursor rightand lefton any

lineon which thatdata is being input. (normallyscreen

lines2-3).

Pressthe up ordown cursorkeywhile holding down the

[SHIFT] keyto roll thedisplay page forwardor

backwards.

control. Basicmathematicalexpressionsmay be evaluated

usingthis feature. For details,see page2-4.

cursoron inputlines.

displayedon input lines.

thecontrolwhen the [TRANSMIT] keyispressed,for

examplea password ora programblock.

Pressingthe resetkey whileholding down the shiftkey

performs a controlreset. See page 2-4 fordetails.

Usethis key todisplay the differentaxis positiondisplay

softkeys.

editinga programor when writingan MDIprogram.

Pressingthiskey toggles thecontrolfrom processto

process.

softkeytojump to theonline searchmonitorscreen. Press

thesekeys again toreturntothe previousscreen.

Page 28

Chapter 2

2-4

Basic Control Operation

Reset Operations

Block Reset

Use the block reset feature to force the control to skip the block execution.

To use the block reset function, program execution must be stopped. If

program execution stops before the control has completely finished the

block execution, a block reset aborts any portion of that block that has not

been executed. If program execution stops after the complete block

execution (as in the case of single block execution or a M00 etc.), the

control aborts the execution of the entire following block.

Press

[RESET] key on the operator panel to perform a block reset.

Control Reset

You can return the control to the default parameters, clear any

programming errors, and cancel any MDI commands by executing a

control reset. After you execute a control reset, any active program resets

to the first block; any programmed offsets or rotations of the coordinate

systems reset to default, and any MDI command is discarded. All of the

operating parameters return to the standard AMP-assigned values,

including any AMP-assigned G-codes active at power-up (except

Inch/Metric which remains in its last programmed state at control reset).

2.1.2

Calculator Function

Press the

[SHIFT] key to execute a control reset.

[RESET] key on the operator panel while holding down the

The 9/Series control is equipped to evaluate simple mathematical

expressions during the course of operation or programming.

To use the calculator function, line 2 of the screen must be blank. There

can be no prompt on the input line of the screen when you attempt to do

calculations. This completely disables any calculation operation when in

MDI mode. If you attempt to enter the calculator function while another

prompt is active, the control generates the error message “CANNOT

CALCULATE - PROMPT PRESENT.”

Use the calculator function as follows:

1. Press the

[CALC] key on the operator panel. The “CALC:”prompt

appears on the input line of the screen (line 2).

2. Enter a mathematical equation on the input line by pressing the

desired keys on the operator panel.

3. Press the

[TRANSMIT] key to evaluate the expression. The answer to

the expression is displayed on the input line.

Page 29

Chapter 2

2-5

Basic Control Operation

Expressions entered on the input line cannot exceed a total of 25

characters. Only numeric or special mathematical operation characters as

described below can be entered next to the “CALC:”prompt. Any

character that is not numeric or an operation character you enter on the

input line generates the error message “INVALID CHARACTER.”

The largest number you can enter for a calculate function is 214748367.

You cannot enter a number larger than 10 digits. If control displays a

number that is too large (longer than 10 digits), the control displays t he

error message “NUMBER IS OUT OF RANGE”. If the number entered or

calculated is greater than 10 digits, control displays the error message

“MATHOVERFLOW.”

Any fractional numbers cannot exceed .999999 (6 decimal places). If you

exceed this number of decimal places, the control automatically rounds off.

If this seventh digit is less than 5, the control rounds down. If this seventh

digit is 5 or greater, the control rounds up.

Any data entered on the input lines can be edited as described on page

2-41.

To disable the calculator function, press the

[CALC] key again. The

“CALC:”prompt is removed from the input line.

Use the characters in Table 2.B to indicate mathematical operations.

Table 2.B

Mathematical Operators

* Multiplication

/ Division

+ Addition

- Subtraction

[] Brackets

#

GetParamacroValue

The control executes mathematical operations in this order:

1. Any part of the expression that is between the brackets [ ] is

evaluated first. The values of paramacro variables are also

substituted for the #xxxx as the first operation performed.

2. Multiplication and division are evaluated second.

3. Addition and subtraction are evaluated last.

If the same level of evaluation is performed the left most operation takes

priority.

Page 30

Chapter 2

2-6

Basic Control Operation

Example 2.1

Mathematic Expressions

Expression Entered Result Displayed

12/4*3

12/[4*3] 1

12+2/2 13

[12+2]/2 7

12-4+3 11

12-[4+3]

9

5

Table 2.C lists the function commands available with the [CALC] key.

Table 2.C

Mathematical Functions

Function Meaning

SIN Sine (degrees)

COS Cosine(degrees)

TAN Tangent (degrees)

ATAN ArcTangent(degrees)

ASIN Arc Sine (degrees)

ACOS ArcCosine (degrees)

SQRT Square Root

ABS Absolute Value

BIN Conversion fromDecimalto Coded Decimal

BCD Conversion fromCoded Decimalto Decimal

ROUND RoundingOff(nearestwhole number)

FIX Truncation Down

FUP Truncation Up

LN Logarithms(naturallog)

EXP Exponent

When you program these functions, place the value that the function is to

be performed on in brackets, for example, SIN [10]. The exception to this

is the arc tangent function. The format for ATAN requires the division of

two values. For example, ATAN [10]/[2] is used to calculate the arc

tangent of 5.

The functions in Table 2.C are executed from left to right in a program

block. These functions are executed before the control executes any

mathematical operators like addition or subtraction. This order of

execution can only be changed by enclosing operations in brackets [ ].

Operations enclosed in brackets are executed first.

Page 31

Chapter 2

2-7

Basic Control Operation

Example 2.2

Format for [CALC] Functions

SIN[2] This evaluatesthe sine of2 degrees.

SQRT[14+2] Thisevaluates thesquare rootof 16.

SIN[SQRT[14+2]]

Thisevaluates thesineof the squareroot of16.

Example 2.3

Mathematical Function Examples

Expression Entered Result

SIN[90]

SQRT[16] 4.0

ABS[-4] 4.0

BIN[855] 357.0

BCD[357] 855.0

ROUND[12.5] 13.0

ROUND[12.4] 12.0

FIX[12.7] 12.0

FUP[12.2] 13.0

FUP[12.0] 12.0

LN[9] 2.197225

EXP[2]

1.0

7.389056

Important: Precaution must be taken when performing calculations within

the brackets [ ]. The operations within the bracket are performed first, and

then the function is performed on this resultant. For example

ROUND[2.8+2.6]; The result of this is 5.0

The values in the brackets are added together first and then rounded, not

rounded and then added together.

Paramacro Variables in CALC Operations

Any paramacro variable can be accessed through the CALC function.

Include a # sign followed by the paramacro variable number. When the

calculation is performed the value of that paramacro variable is substituted

into the equation. You can not change the value of paramacro variables

with the CALC function. Local parameters are only available for the

currently active nesting level of the control (main program, or one of four

nested macro programs). You can not perform calculations that contain

any paramacro variables if the control is currently executing a program

block. The control must be in either cycle stop state, or E-Stop.

Page 32

Chapter 2

2-8

Basic Control Operation

Example 2.4

CallingParamacro Variables with the CALC Function

Expression Entered Result Displayed

2.1.3

Softkeys

#100

12/#100*3 Divide12 by the currentvalue of#100

SIN[#31*3]

Displaycurrentvalue of variable#100

and multiply by 3

Multiply the value of#31 (forthe current

localparameternesting level)by 3 and

take the sine of thatresult

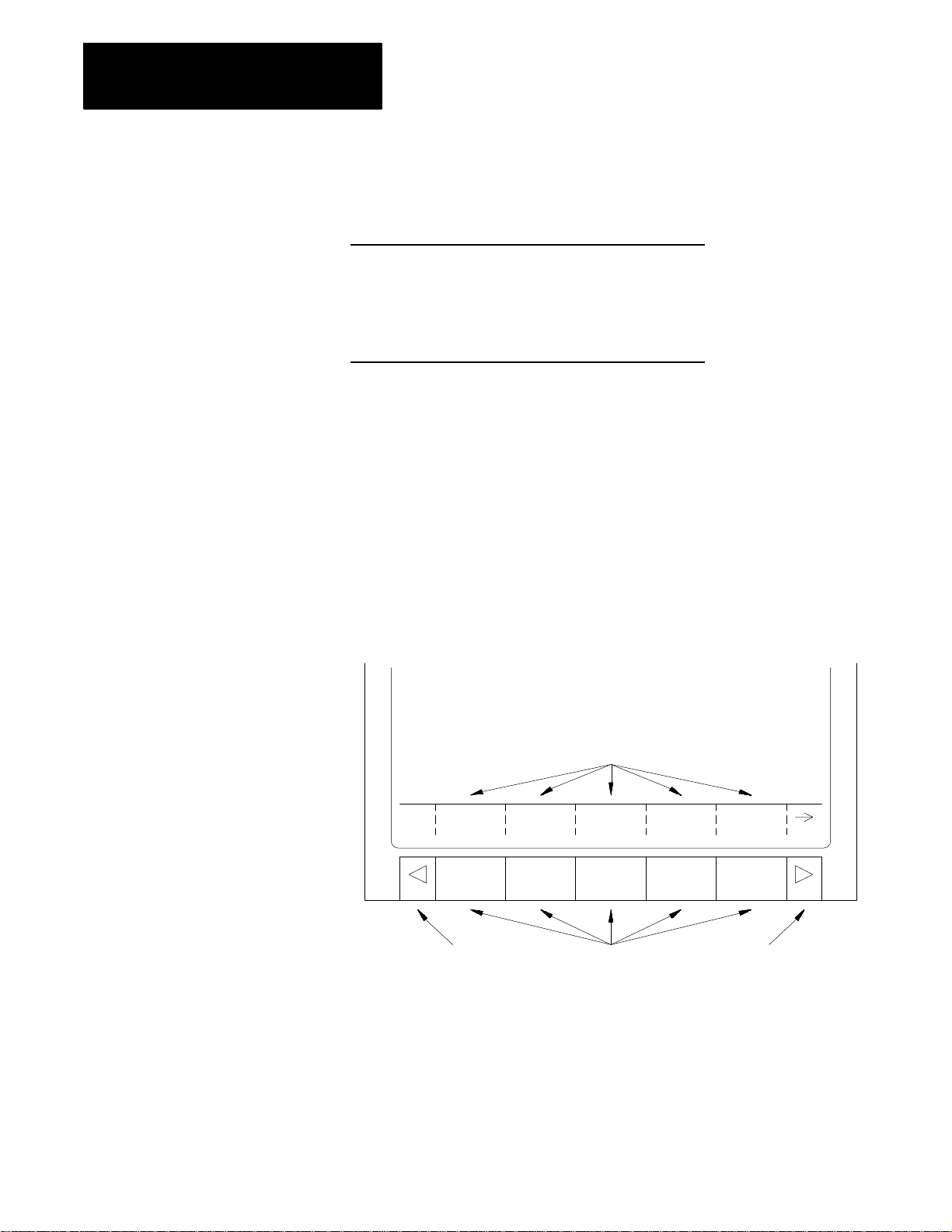

We use the term softkey to describe the row of 7 keys at the bottom of the

CRT. Each function is displayed on the CRT directly above the softkey.

Softkey names are shown between the { } symbols in this manual.

The control offers a variety of functions that can be initiated by using the

softkeys. The operator panel has 5 softkeys whose function names are

displayed in the softkey area at the bottom of the screen (lines 23-25 — see

Figure 2.2).

Figure 2.2

Softkeys

Datadisplay area

Softkey name displayarea

PRGRAM

MANAGE

Exit

OFFSET

MACRO

PARAM

Softkeys

PRGRAM

CHECK

SYSTEM

SUPORT

Continuekey

We often describe softkeys as being on a certain level, for example softkey

level 3. We use the level of the softkey to determine the location or

necessary path to reach that particular softkey function. For example, to

get to a softkey on level 3, you must press a specific softkey on level 1,

followed by a specific softkey on level 2. For a listing of all the softkeys

and their respective levels, refer to appendix A.

Page 33

Chapter 2

2-9

Basic Control Operation

Softkey level 1 is the initial softkey level the control displays at power-up.

Softkey level 1 always remains the same and all other levels are referenced

from softkey level 1.

The softkeys on opposite ends of the softkey row have a specific use that

remains standard throughout the different softkey levels.

On the: Is the:

left exitsoftkeydisplayed withthe up arrow{• }

right continuesoftkeydisplayed withthe rightarrow {• }

Use the exit softkey {• } on the far left to regress softkey levels. For

example, if you are currently on softkey level 3 and you press the exit

softkey, the softkeys change to the softkeys previously displayed on

softkey level 2. When you press the exit softkey while holding down

the shift key, the softkey display is returned to softkey level 1 regardless

of the current softkey level.

When more than 5 softkey functions are available on the same level, the

control activates the continue {

• } softkey at the far right of the softkey

area. When you press the continue softkey, the softkey functions

change to the next set of softkeys on that level.

Important: The continue softkey is not active when the number of softkey

functions on that level does not exceed 5.

For example:

(softkey level 1)

PRGRAM

MANAGE

OFFSET MACRO

PARAM

PRGRAM

CHECK

SYSTEM

SUPORT

When softkey level 1 is reached, the above set of softkeys is displayed.

Pressing the continue softkey {

• } displays the remaining softkey

functions on softkey level 1.

(softkey level 1)

FRONT

PANEL

ERROR

MESAGE

PASSWORD

SWITCH

LANG

The exit softkey is not displayed since the softkeys are already on softkey

level 1.

The softkey functions for level 1 and level 2 are explained in appendix A.

Softkey functions for level 3, or higher, are explained in the sections that

apply to their specific operations.

Page 34

Chapter 2

2-1

0

Basic Control Operation

To use a softkey function, press the plain, unmarked button directly below

the description of the softkey function.

Important: Some of the softkey functions are purchased as optional

features. This manual assumes that all available optional features have

been purchased for the machine. If an option is not purchased, the softkey

is blank.

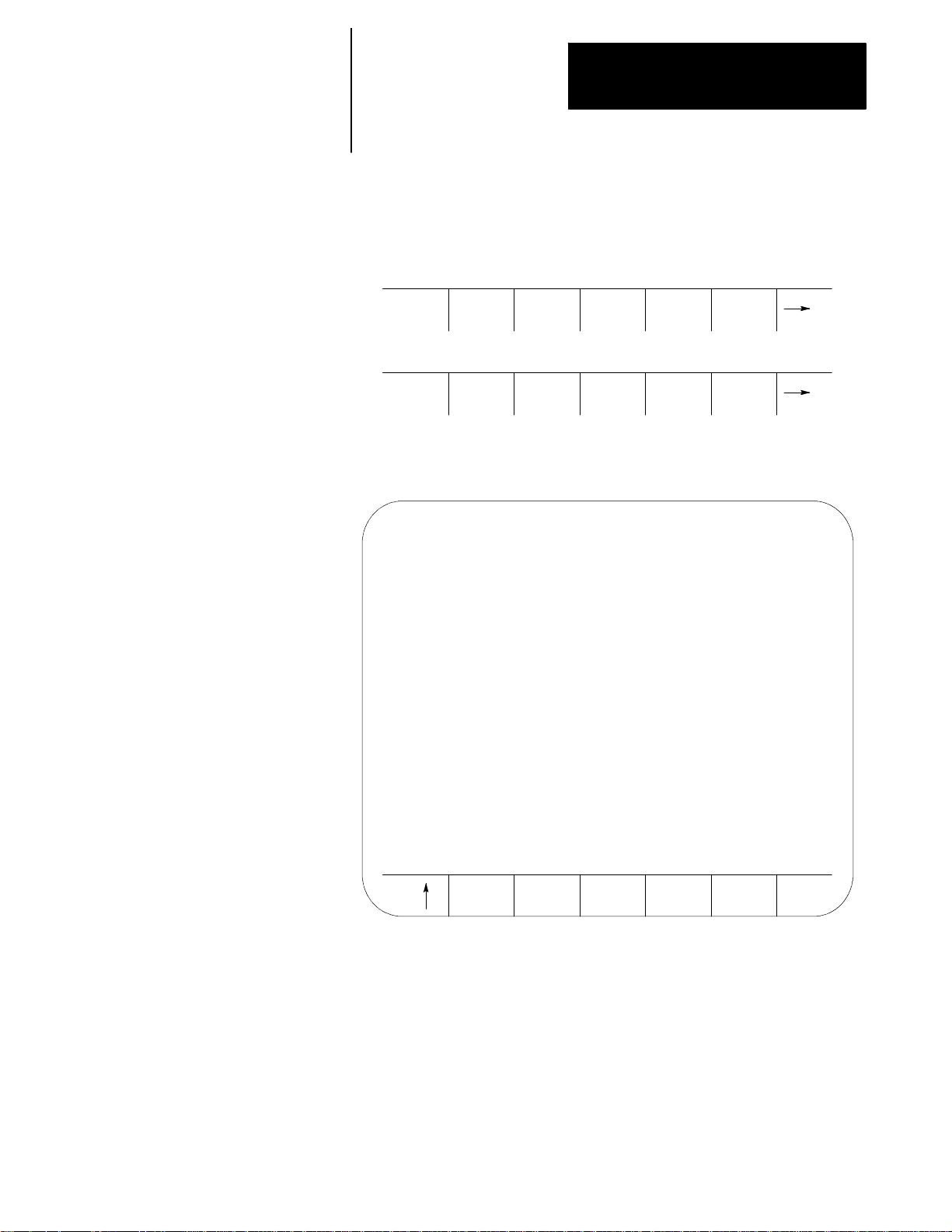

2.1.4

CRT

The control can be purchased with a 9-inch monochrome monitor or a

12-inch color monitor.

Certain lines of the screen are dedicated to displaying specific information:

Lines: Display information:

line 1

machine/

systemmessage area

lines2-3

inputlines

lines4-20

datadisplay area

lines21-22

PAL message area

lines23-25

softkeydisplayarea

Ifan erroroccurs ora message is generatedforany reason during

machineoperationor programexecution,the controldisplays the

correspondingmachine/systemmessage in thisarea. Onlythe

highestpriority,mostcurrentmessageis displayed here.

Whenyou enter datausing the keyboard,the controldisplaysthe

characters correspondingto the keyspressed untilyou press the

[TRANSMIT] key. Somescreens can onlyhave line 2 as an input

line.

The controldisplaysaxis positiondata,listingof thepart program,tool

offset data,G-,M-,H-,T-,F-,S-,and D-codes,graphics,and other

data,as determinedby theselected display. Seechapter 8.

The controldisplaysany messages generatedby the control’sPAL

programin thisarea

The controldisplaysthe currentlyavailablesoftkey functionsin this

area.

Page 35

Chapter 2

2-1

1

Basic Control Operation

2.1.5

PortableOperatorPanel

The control can be purchased with a 9-inch monochrome portable operator

panel. This panel can be attached or detached to the 9/Series I/O ring

operator panel interface assembly at any time without disrupting control

operation.

The portable operator panel is attached through a 10 ft portable operator

panel interface cable with a 3--pin D--shell connector at each end. One end

of the cable attaches to the front of the portable operator panel. The other

end attaches to the portable operator panel interface assembly. Refer to

your system installer’s documentation for details on attaching and

detaching the portable operator panel and the locations of the operator

panel interface assembly.

Removable Operator Panel

Connect Interface Assembly

(37 pin D Shell has pins)

Interface Assembly

GND12V GND5VGND 5V GND 5VCHA

GND

LH

AC

Video In CN19M

Operator Pnl. CN5

Vidoe Out CN4

Connect OperatorPanel

(37 pinD Shell has sockets)

Page 36

Chapter 2

2-1

2

Basic Control Operation

2.2

The MTBPanel

AUTO MDI MAN

Figure 2.3 shows the push-button MTB panel. Table 2.D explains the

functions of the switches and buttons on the MTB panel. Other optional or

custom MTB panels may be used. Refer to the documentation prepared by

your system installer for details.

We show button names found on the push--button MTB panel between the

< > symbols throughout this manual. The push-button MTB panel uses

defaults when you turn on power to the control. Table 2.D contains these

defaults.

Most of the switches or buttons on the MTB panel are configured by your

system installer’s PAL program. We assume that PALhas been written as

intended for normal operation. If a switch or button does not work the way

it is described in this manual, refer to documentation prepared by your

system installer.

Figure 2.3

Push-Button MTB Panel

MODE SELECT SPEED/MULTIPLY

JOG SELECT

CONT

INCR

LOWX1MEDL

X10

SPINDLESPEED

OVERRIDE

MED

X100

SPINDLE

CCW CW

ON

CYCLE

START

SINGLE

BLOCK

CYCLE

STOP

HAND HOME

AXIS

+X +4 --X

+Y TRVRS --Y

+Z - -4 --Z

MEDH

X1000

FUNCTION

F1

F3 F4

F5 F6

HIGH

X10000

F2

50 120

FEEDRATE

OVERRIDE

50 100

0

150

%

OFF

RAPID FEEDRATE

OVERRIDE

F1 25

50 100

ESTOP

RESET

OFF

19930

Page 37

Chapter 2

2-1

3

Selectstheoperationmode

Basic Control Operation

Table 2.D

Functions of the Buttons on the Push-Button MTB Panel

Switch orButton Name

MODE SELECT

JOG SELECT Selects the jogmethod tobe active in manualmode

SPEED/MULTIPLY Selectsan axis feedrateor axis feedamount multiplication ratioused in themanual mode. Each

How It Works = DefaultforPush-ButtonMTB Panel

AUTO ---- automaticmode

MANUAL-- -- manualmode

MDI---- manualdata inputmode

HANDWHEEL ---- HPG(hand pulse generator)jog

INCREMENTAL ---- incremental jog

CONTINUOUS---- continuous jog

HO M E -- -- m a c h i ne ho m e

selectionmodifiesthe activefeedrateby a value setin AMP. Modification also dependson the setting

of<JOG SELECT> asdescribedbelow:

• HANDWHEEL

Whenin handwheel jog mode,SPEED/MULTIPLYaltersthe handwheel resolutionby a factor

determinedin AMP. Yoursystem installersetsthe value for:

-LOWX1

-MEDLX10

-MEDL X100

You cannot usethevalues listedbelow forhandwheel jog:

-MEDH X1000

-HIGH X10000

• INCREMENTAL

Whenin incrementaljog mode,SPEED/M ULTIPLYaltersthe incrementaljogdistance

in AMPby yoursysteminstaller. Your systeminstallersetsa value forthe selections. The

incremental jog speed

<FEEDRATE OVERRIDE>.

• CONTINUOUS

Whenin continuous jog mode,SPEED/MULTIPLYacts as a feedrate selectionswitchwhich has

values set in AMPby yoursysteminstaller. Your systeminstaller sets a value for all 5 selections

independentlyforeach axis. <FEEDRATE OVERRIDE> can be used forspeed adjustments.

isfixed tomediumbutcan still be controlledby

byafactorset

Important: The valuesfor thedifferent<SPEED/MULTIPLY> selectionsareconfiguredby

your systeminstaller.

Page 38

Chapter 2

2-1

4

Basic Control Operation

Table 2.D

Functions of the Buttons on the Push-Button MTB Panel

Switch orButton Name

SPINDLE SPEED OVERRIDE Selects the overrideforprogrammedspindle speeds in 5%incrementswithin a rangeof 50% to120%.

SPINDLE or

SPINDLE DIRECTION

FEEDRATEOVERRIDE Selects a feedrateoverridepercentagefor thefeedrateprogrammedwith an F--wordin any of the

RAPIDFEEDRATE OVERRIDE Selects theoverride forrapid feedrates. SelectfromF1, 25%,50%, and 100% whereF1 is a rapid

EMERGENCY STOP This buttonstops machineoperationand disables the spindleand axis driveswhenpressed.

E-STOP RESET This buttonresetsan emergency stopconditionwhen pressed. Beforepressingthis buttonthe

CYCLE START The controlbegins orresumes partprogramexecution,MDI programexecution,or programcheck

CYCLE STOP The controlstopspart programexecution,MDIexecution,or programcheck when thisbuttonis

SINGLE BLOCK The controlexecutes orchecks one block ofa part programorMDIentryeach timethe