Page 1

Allen-Bradley

9/Series CNC

Grinder

Operation and

Programming

Manual

Page 2

Important User Information

Because of the variety of uses for theproducts described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation, and Maintenance of Solid-State Control (availablefrom your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen-Bradley Company, Inc., is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies i nformation about practices or

circumstancesthat can lead to personal injury or death, property

damage or economic loss.

Attention statements help you to:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is critical for successful application

and understanding of the product.

PLC is aregistered trademarkof Allen-Bradley Company,Inc.

DataHighway Plus, DH+, IMC,PAL, PLC-5, Paramacro, QuickCheck,QuickPath Plus, and Quick View

aretrademarks of Allen-Bradley Company,Inc.

IBM is aregistered trademarkof International Business MachinesCorporation.

MS-DOS isatrademark of Microsoft.

PC ATand PCXT are trademarksof International Business Machines Corporation.

Page 3

Summary of Changes

9/Series Grinder

Operationand ProgrammingManual

October 2000

New Information

RevisionBars

The following is a list of the larger changes made to this manual since its

last printing. Other less significant changes were also made throughout.

Error Message Log

Paramacro Parameters

Softkey Tree

Error Messages

We use revision bars to call your attention to new or revised information.

A revision bar appears as a thick black line on the outside edge of the page

as indicated here.

Page 4

Chapter

1-2

Page 5

Table of Contents

Index (General)

9/Series Grinder

9/Series PALReferenceManual

Operationand ProgrammingManual

Chapter 1

Using This Manual

1.0 Chapter Overview 1-1.................................................................

1.1 Audience 1-1.......................................................................

1.2 Manual Design 1-1...................................................................

1.3 What This Manual Contains 1-2..........................................................

1.4 Reading This Manual 1-3...............................................................

1.5 Terms and Conventions 1-4.............................................................

1.6 Warnings, Cautions, and Important Information 1-4............................................

1.7 Related Publications 1-5...............................................................

Chapter 2

Operating the Control

2.0 Chapter Overview 2-1.................................................................

2.1 Operator Panel Operations 2-2...........................................................

2.1.1 Using theKeyboard 2-3............................................................

2.1.2 Softkeys 2-5....................................................................

2.1.3 Using theCRT 2-7...............................................................

2.2 The MTB Panel 2-8..................................................................

2.3 Software MTB Panel {FRONT PANEL} 2-11..................................................

2.4 Powering the Control 2-18...............................................................

2.4.1 Turning On Power 2-18.............................................................

2.4.2 Turning Off Power 2-20.............................................................

2.5 Control Conditions at Power-Up 2-20.......................................................

2.6 Emergency Stop Operations 2-22..........................................................

2.6.1 Emergency StopReset 2-22.........................................................

2.7 Access Control 2-23...................................................................

2.7.1 Assigning Access Levels and Passwords 2-24............................................

2.7.2 Password Protectable Functions 2-27...................................................

2.7.3 Storing PasswordList to Backup Memory 2-30............................................

2.7.4 Entering Passwords 2- 31...........................................................

2.8 Changing OperatingModes 2-32..........................................................

2.9 Control and Block Reset 2-36.............................................................

2.10 Displaying System and Machine Messages 2-37..............................................

2.10.1 Clearing ActiveMessages {CLEAR ACTIVE} 2-40.........................................

2.11TheInput Cursor 2-41.................................................................

2.12 {REFORM MEMORY} 2-42.............................................................

2.13 Removing an Axis(Axis Detach) 2-43......................................................

2.14 Time Parts Count Display Feature 2-44.....................................................

2.15 Calculator Function 2-48...............................................................

Chapter 3

Offset Tables and S etup

3.0 Chapter Overview 3-1.................................................................

3.1 Wheel Length Offset Tables{WHEEL GEOMET} 3-1...........................................

3.2 Dresser/Wheel RadiusOffsets {RADIUS TABLE} 3-4...........................................

3.3 Dresser/Wheel Orientation {RADIUS TABLE} 3-8.............................................

i

Page 6

Table of Contents

Index (General)

9/Series PALReferenceManual

Operationand ProgrammingManual

3.3.1 Dresser Orientations 3-9...........................................................

3.3.2 Grinding Wheel Orientations 3-10.....................................................

3.4 Entering Offset Data {WHEELGEOMET} or {RADIUS TABLE} 3-11.................................

3.5 Set Offset Data Using{MEASURE} 3-16.....................................................

3.6 Changing the Active Dresser/Wheel Offset {ACTIVE OFFSET} 3-17.................................

3.7 Work Coordinate System Offset Table{WORK CO-ORD} 3-18.....................................

3.7.1 Entering Work CoordinateSystem Data 3-19.............................................

3.8 Backing Up Offset Tables 3-23............................................................

3.9 Programmable Zone Table 3- 25...........................................................

3.10 Single-Digit Feedrate Table 3-27..........................................................

3.11Tool Offset Range Verification 3-29........................................................

9/Series Grinder

Chapter 4

Manual/MDI Operation Modes

4.0 Chapter Overview 4-1.................................................................

4.1 Manual OperatingMode 4-1.............................................................

4.1.1 Jogging an Axis 4-2..............................................................

4.1.2 ContinuousJog 4- 3...............................................................

4.1.3 Incremental Jog 4-3..............................................................

4.1.4 HPG Jog 4-4...................................................................

4.2 Arbitrary Angle Jog 4-5................................................................

4.3 Manual Gap Elimination 4-6.............................................................

4.4 ResettingOvertravels 4-9..............................................................

4.5 Mechanical Handle Feed (Servo Off) 4-10....................................................

4.6 Removing an Axis (AxisDetach) 4-10......................................................

4.7 Manual MachineHoming 4-11............................................................

4.8 MDI Mode 4-13.......................................................................

4.8.1 MDI Basic Operation 4-14..............................................................

Chapter 5

Editing Programs On Line

5.0 Chapter Overview 5-1.................................................................

5.1 Selecting a Program to Edit 5-1..........................................................

5.2 Editing Programs at the Control (on line) 5-3.................................................

5.2.1 Moving the Cursor {STRING SEARCH} 5-5...........................................

5.2.2 Entering CharactersandBlocks 5-7...................................................

5.2.3 Changing and Inserting {MODIFY INSERT} 5-7...........................................

5.2.4 Erasing Characters and Blocks 5-10....................................................

5.2.5 Sequence Numbers {RENUM PRGRAM} 5-13..........................................

5.2.6 Merging Part Programs {MERGE PRGRAM} 5-15..........................................

5.2.7 ExitingEdit Mode 5-15.............................................................

5.3 Programming Aids QuickView 5-16........................................................

5.3.1 Using {QPATH+PROMPT} Sample Patterns 5-19..........................................

5.3.2 G Code Prompting {G CODE PROMPT} 5-23.............................................

5.3.3 Grinding CyclePrompting {GRINDR PROMPT} 5-25........................................

5.3.4 Selectinga QuickView Plane 5-27.....................................................

5.4 Digitizing a Program (Teach) 5-28..........................................................

ii

Page 7

Table of Contents

Index (General)

9/Series Grinder

9/Series PALReferenceManual

Operationand ProgrammingManual

5.4.1 Linear Digitizing 5-31..............................................................

5.4.2Digitizing an Arc (3Points) 5-33.......................................................

5.4.3 Digitizing An Arc Tangent at End Points 5-35.............................................

5.5 Deleting A Program {DELETE PRGRAM} 5-37................................................

5.6 Renaming Programs {RENAME PRGRAM} 5-38..............................................

5.7 Displaying a Program {DISPLY PRGRAM} 5-39...............................................

5.8 Comment Display {PRGRAM COMENT} 5-40................................................

5.9 Copying Programs {COPY PRGRAM} 5-41..................................................

5.10 Selecting theProtectable Part Program Directory 5-42..........................................

5.10.1 Protected Program Encryption and Decryption 5-45........................................

5.10.2 Storing Encryption/Decryption Table toBackup Memory 5-48.................................

Chapter 6

Editing Part Programs Off Line (ODS)

6.0 Chapter Overview 6-1.................................................................

6.1 Selecting the Part Program Application 6-2..................................................

6.2 Editing Part Programs Off Line 6-3........................................................

6.3 Connecting theWorkstation to the Control 6-5................................................

6.4 Downloading Part Programs from ODS 6-6..................................................

6.5 Uploading Part Programs to ODS 6-12.....................................................

Chapter 7

Running a Program

7.0 Chapter Overview 7-1.................................................................

7.1 Selecting Special Running Conditions 7-1...................................................

7.1.1 Block Delete 7-2.................................................................

7.1.2 MiscellaneousFunction Lock 7-2.....................................................

7.1.3 Sequence Stop {SEQ STOP} 7-2.....................................................

7.1.4 Single Block 7-4.................................................................

7.2 Selecting a Part Program Input Device 7-5..................................................

7.3 Selecting a Program 7-6...............................................................

7.4 De-Selecting a Part Program 7-9.........................................................

7.5 ProgramSearch{SEARCH} 7-10..........................................................

7.6 Search With Recall {MID ST PRGRAM} 7-13.................................................

7.7 Basic Program Execution 7-16............................................................

7.7.1 {QUICK CHECK} 7-18.............................................................

7.7.2 Axis Inhibit Mode 7-20.............................................................

7.7.3 Dry Run Mode 7-21...............................................................

7.7.4 Part Production/Automatic Mode 7-22..................................................

7.8 Interrupted Program Recover {RESTRT PRGRAM} 7-24.........................................

7.9 Jog Retract 7-27......................................................................

7.10 Block Retrace 7-30...................................................................

iii

Page 8

Table of Contents

Index (General)

9/Series PALReferenceManual

Operationand ProgrammingManual

9/Series Grinder

Chapter 8

Display and Graphics

8.0 Chapter Overview 8-1.................................................................

8.1 Selection of Axis PositionData Display 8-1..................................................

8.2 PALDisplay Page 8-22.................................................................

8.3 Changing Languages 8-23...............................................................

8.4 Graphics 8-24.......................................................................

8.4.1 Selectingthe Program for Graphics 8-24................................................

8.4.2 Running Graphics 8-25.............................................................

8.4.3 DisablingGraphics 8-27............................................................

8.4.4 Changing Parameters 8-27..........................................................

8.4.5 Graphics in Single-Block 8-33........................................................

8.4.6 Clearing GraphicsScreen 8-33.......................................................

8.4.7 DisplayingMachine Information in Graphics 8-33..........................................

8.4.8 Zooming Graphics 8-33.............................................................

8.6 Power Turn-on Screen 8-37..............................................................

8.7 Screen Saver 8-39....................................................................

Chapter 9

Communications

9.0 Chapter Overview 9-1.................................................................

9.1 Setting Communications 9-1............................................................

9.1.1 SettingCommunication Port ParameterValues 9-1........................................

9.1.2 Communication Port Parameters 9-3..................................................

9.2 InputtingPartProgramsfrom a Serial Peripheral 9-9...........................................

9.3 OutputtingPart Programs to a Serial Peripheral 9-13............................................

9.4 Verifying Part Programs Against Source Programs 9-16..........................................

9.5 Error Conditions (Inputting and Outputting Part Programs) 9-18....................................

Chapter 10

Introduction to Programming

10.0 Chapter Overview 10-1................................................................

10.1 Tape Format 10-2....................................................................

10.2 Program Configuration 10-6.............................................................

10.2.1 Program Names 10-8.............................................................

10.2.2 Sequence Numbers 10-9...........................................................

10.2.3 Comment Blocks 10-10.............................................................

10.2.4 Block Delete and Multi Level Delete 10-11...............................................

10.2.5 End of BlockStatement 10-12........................................................

10.3 Using Subprograms 10-12...............................................................

10.3.1 Subprogram Call (M98) 10-13........................................................

10.3.2 Main and Subprogram Return (M99) 10-14...............................................

10.3.3 Subprogram Nesting 10-15..........................................................

10.4 Word Formats and Functions 10-17........................................................

10.4.1Minimumand Maximum AxisMotion (Programming Resolution) 10-20..........................

10.5 Word Descriptions 10-21................................................................

10.5.1 Axis Names 10-21................................................................

iv

Page 9

Table of Contents

Index (General)

9/Series Grinder

9/Series PALReferenceManual

Operationand ProgrammingManual

10.5.2 A_L_,R_,C_ (QuickPath Plus Words) 10-21..............................................

10.5.3 F Words (Feedrate) 10-22...........................................................

10.5.4 G Words (Preparatory Functions) 10- 23.................................................

10.5.5. I J K Integrand Words 10-28.........................................................

10.5.6 M Words (MiscellaneousFunctions) 10-29...............................................

10.5.7 N Words (Sequence Numbers) 10-34...................................................

10.5.8 O Words (Program Names) 10-34.....................................................

10.5.9 P,L(Main Program Jumps and Subprogram Calls) 10-35.....................................

10.5.10 S Word (Spindle Speed) 10-35.......................................................

10.5.11TWords (Length, Radius, and Orientation Offsets) 10-36...................................

Chapter 11

Coordinate Control

11.0Chapter Overview 11-1................................................................

11.1Machine (Absolute) Coordinate System 11-2.................................................

11.1.1 Motion in the Machine Coordinate System (G53) 11-3......................................

11.2PresetWorkCoordinate Systems (G54-59.3) 11-4.............................................

11.2.1 Altering Work Coordinate Systems (G10L2) 11-8..........................................

11.3WorkCoordinate System External Offset 11-10................................................

11.3.1Altering External Offset (G10L2) 11-11..................................................

11.4Offsetting the Work Coordinate Systems 11-13................................................

11.4.1 Coordinate Offset Using Wheel Position(G92) 11-14........................................

11.4.2 Offsetting Coordinate Zero Points (G52) 11-17............................................

11.4.3 {SETZERO}Offset 11-18...........................................................

11.4.4 JogOffset 11-19..................................................................

11.4.5 Canceling Coordinate System Offsets (G92.1) 11-20........................................

11.4.6 Canceling Selected Coordinate System Offsets (G92.2) 11-22.................................

11.5 PAL Offsets 11-22.....................................................................

11.6Rotating the CoordinateSystems 11-23.....................................................

11.6.1 Rotating the Current Work Coordinate System (G68, G69) 11-24...............................

11.6.2 External Part Rotation 11-28.........................................................

11.7 Plane Selection (G17, G18, G19) 11-33.....................................................

11.8 Overtravels and Programmable Zones 11-34..................................................

11.8.1 Hardware Overtravels 11-36.........................................................

11.8.2 SoftwareOvertravels 11-36..........................................................

11.8.3Programmable Zone 2 (G22, G23) 11-38................................................

11.8.4Programmable Zone 3 (G22.1, G23.1) 11-40.............................................

11.8.5 Resetting Overtravels 11-43.........................................................

11.9Absolute/Incremental Modes (G90, G91) 11-44................................................

11.10Inch/Metric Modes (G70, G71) 11-45......................................................

11.11 Radius/Diameter Modes (G07, G08) 11-46..................................................

11.12 Scaling 11-48.......................................................................

11.11.1 Scaling and Axis Position Display Screens 11-51..........................................

11.11.2 Scaling MagnificationData Screen 11-52................................................

11.11.3 Scaling Restrictions 11-54..........................................................

v

Page 10

Table of Contents

Index (General)

9/Series PALReferenceManual

Operationand ProgrammingManual

9/Series Grinder

Chapter 12

Axis Motion

12.0 Chapter Overview 12-1................................................................

12.1 PositioningAxes 12-1.................................................................

12.1.1 Rapid Positioning Mode (G00) 12-2...................................................

12.1.2 Linear Interpolation Mode (G01) 12-3..................................................

12.1.3 Circular Interpolation Mode (G02, G03) 12-5.............................................

12.1.4 Positioning Rotary Axes 12-9........................................................

12.1.5 PALAxis Mover 12-11..............................................................

12.2 QuickPath Plus 12-11..................................................................

12.2.1 Linear QuickPathPlus 12-13.........................................................

12.2.2 Circular QuickPath Plus (G13, G12.1) 12-17..............................................

12.3 Chamfering and Corner Radius 12-22.......................................................

12.4 AutomaticMotion To and From Machine Home 12-27...........................................

12.4.1 Automatic Machine Homing (G28) 12-28................................................

12.4.2 Automatic Return to Machine Home(G28) 12-29..........................................

12.4.3 Automatic Return from Machine Home (G29) 12-30........................................

12.4.4 Machine Home Return Check (G27) 12-32...............................................

12.4.5 Move ToAlternate Home (G30) 12-33..................................................

12.5 Spindle Speed Control 12-34............................................................

12.5.1 Surface Grinder, No S--word 12-35....................................................

12.5.2 Surface Grinder, S--word for Wheel Speed 12-36..........................................

12.5.3 Cylindrical Grinder, S--word for Part Speed 12-37..........................................

12.5.4 Cylindrical Grinder, S--word for WheelSpeed 12-40........................................

12.5.5 Notes on Constant Surface Speed Mode(G96) 12-42.......................................

12.5.6 CSS Axis Selection 12-45..........................................................

12.5.7 CSS Examples 12-46..............................................................

12.5.8 RPM SpindleSpeed Mode (G97) 12-51.................................................

12.6 Part or Wheel Spindle Orientation (M19) 12-51................................................

12.7 Feedrates 12-53......................................................................

12.7.1 Feedrates AppliedDuring Dresser/Wheel Radius Compensation 12-54...........................

12.7.2 Feed Per MinuteMode (G94) 12-56....................................................

12.7.3 Feed Per Revolution Mode (G95) 12-56.................................................

12.7.4 Rapid Feedrate 12-57..............................................................

12.7.5 Feedrate Overrides 12-58...........................................................

12.7.6 Feedrate Limits (Clamp) 12-59.......................................................

12.7.7 Rotary AxisFeedrates 12-60.........................................................

12.8 Special AMPAssigned Feedrates 12-61.....................................................

12.8.1 Single-Digit F--words 12-61..........................................................

12.8.2 External Deceleration Feedrate Switch 12-62.............................................

12.9 AutomaticAcceleration/Deceleration 12-63...................................................

12.9.1 Exponential Acc/Dec 12-64..........................................................

12.9.2 Linear Acc/Dec 12-65..............................................................

12.9.3S--CurveAcc/Dec 12-66............................................................

12.9.4 Programmable Acc/Dec 12-67........................................................

12.9.5 Precautions on Corner Grinding 12-69..................................................

12.9.6 Spindle Acceleration (Ramp) 12-71....................................................

vi

Page 11

Table of Contents

Index (General)

9/Series Grinder

9/Series PALReferenceManual

Operationand ProgrammingManual

12.9.7Controlling Spindles (G12.1,G12.2, G12.3) 12-71..........................................

12.9.8 Spindle Orientation (M19, M19.2, M19.3) 12-72...........................................

12.9.9 Spindle Direction (M03, M04, M05) 12-74................................................

12.9.10 Short Block Acc/Dec Check G36, G36.1 12-75...........................................

12.10 Dwell (G04) 12-78....................................................................

12.10.1 Dwell - Seconds 12-78............................................................

12.10.2 Dwell - Number of Spindle Revolutions 12-78............................................

12.11MirrorImage (G50.1, G51.1) 12-79........................................................

12.12 Axis Clamp 12-82....................................................................

12.13 Dual Axis Operation 12-82..............................................................

12.12.1 Parking a Dual Axis 12-84..........................................................

12.12.2 Homing a Dual Axis 12-85..........................................................

12.12.3Programming a DualAxis 12-86......................................................

12.12.4 Offset Management for a Dual Axis 12-88..............................................

Chapter 13

Wheel Length Offsets

13.0 Chapter Overview 13-1................................................................

13.1 T Words and Wheel LengthOffsets 13-1....................................................

13.1.1 SelectingWheel Length Offsets (T Word) 13-2...........................................

13.1.2 Activation of Wheel Length Offsets 13-4................................................

13.2Programming Changes to Wheel Geometry and Radius Offset Tables (G10L10) 13-5...................

Chapter 14

Angled-Wheel Grinding

14.0 Chapter Overview 14-1................................................................

14.1 Angled-Wheel GrinderConfiguration Assumptions 14-1.........................................

14.2 Determining the Wheel Angle 14-2........................................................

14.3 Angled-Wheel Mode ( G15,G16.3 and G16.4) 14-4............................................

14.3.1 Normal Angled-Wheel Grinding Mode (G16.3) 14-6........................................

14.3.2 Two Step Angled-Wheel GrindingMode (G16.4) 14-9......................................

14.3.3 Angled-Wheel Transform Off (G15) 14-11................................................

14.4 Position Displays for Angled-Wheel Grinders 14-12.............................................

14.5 Manual Motion on an Angled-Wheel Grinder 14-14.............................................

14.6 Homing an Angled-Wheel Grinder 14-15.....................................................

14.7 Plane Selectionon Angled-Wheel Grinders 14-15..............................................

14.8 Offsets on an Angled-Wheel Grinder 14-16..................................................

14.9 Overtravels and Programmable Zones on an Angled-Wheel Grinder 14-17............................

Chapter 15

Dresser/Wheel Radius Compensation

15.0 Chapter Overview 15-1................................................................

15.1 Introduction to Dresser/Wheel RadiusCompensation 15-2.......................................

15.2Programming Compensation (G40, G41, G42) 15-5...........................................

15.2.1 Application Schemes 15-5..........................................................

15.2.2 CompensationBlock Format 15-12....................................................

15.3 Generated Compensation BlocksG39, G39.1 15-15............................................

vii

Page 12

Table of Contents

Index (General)

9/Series PALReferenceManual

Operationand ProgrammingManual

15.4 Type A Compensation Paths 15-17.........................................................

15.4.1 Type A Compensation EntryMoves 15-17...............................................

15.4.2 Type A Compensation Exit Moves 15-20................................................

15.5 Type B Compensation Paths 15-27.........................................................

15.5.1 Type B Compensation EntryMoves 15-27...............................................

15.5.2 Type B Compensation Exit Moves 15-30................................................

15.6 Path During Compensation 15-37..........................................................

15.7 Special Compensation Cases 15-42.......................................................

15.7.1 Changing Compensation Direction 15-42................................................

15.7.2 TooManyNon-Motion Blocks 15-46....................................................

15.7.3 Corner Movement After Generated Blocks 15-49...........................................

15.7.4 Changing Dresser/Wheel Radius During Compensation 15-51.................................

15.7.5 MDI or Manual MotionDuring Dresser/Wheel Radius Compensation 15-55........................

15.7.6 Moving To/From Machine Home 15-57..................................................

15.7.7 Changing or Offsetting Work Coordinate System in Dresser/Wheel RadiusCompensation 15-58........

15.7.8 Block Look-Ahead 15-59............................................................

15.8 Error Detection 15-60..................................................................

9/Series Grinder

Chapter 16

Surface Grinding Fixed Cycles

16.0 Chapter Overview 16-1................................................................

16.1 Surface Grinding Considerations 16-2......................................................

16.2 Surface Grinding Parameters 16-8........................................................

16.3 G81 or G81.1 Reciprocation Without CrossPick orPlunge 16-13...................................

16.4 G82 or G82.1 PlungeGrinding (Slot) 16-14...................................................

16.5 G83 or G83.1 Incremental Plane Grinding (Axis 1) 16-16.........................................

16.6 G84 or G84.1 Incremental Plane Grinding (Axis 2) 16-19.........................................

16.7 G85 or G85.1 Continuous Plane Grinding (Axis 1) 16-20.........................................

16.8 G86 or G86.1 Continuous Plane Grinding (Axis 2) 16-23.........................................

Chapter 17

Cylindrical Grinding Fixed Cycles

17.0 Chapter Overview 17-1................................................................

17.1 Cylindrical Grinding Considerations 17-3....................................................

17.2 Cylindrical Grinding Parameters 17-9......................................................

17.3 G81 or G81.1 Reciprocation Without Plunge 17-11.............................................

17.4 G82 or G82.1 Incremental Face Grinding (Axis 1) 17-12..........................................

17.5 G83 or G83.1 Incremental Plunge Grinding (Axis 2) 17-16........................................

17.6 G84 or G84.1 Multi-pass Face Grinding (Axis 1) 17-20...........................................

17.7 G85 or G85.1 Multi-pass Diameter Grinding(Axis 2) 17- 23........................................

17.8 G86 or G86.1 Shoulder Grinding 17-26.....................................................

17.9 G87 or G87.1 Shoulder Grinding With Face Plunge 17-28........................................

17.10 G88 or G88.1 Shoulder Grinding With DiameterPlunge 17-30....................................

17.11G89orG89.1 Multi-Step Plunge with Blend 17-32.............................................

17.11.1G89for Normal Single-Step Grinders 17-38.............................................

17.11.2G89for Two-StepGrinders 17-39.....................................................

17.11.3Micro-FeedDuring the G89/G89.1 Cycles 17-40..........................................

viii

Page 13

Table of Contents

Index (General)

9/Series Grinder

9/Series PALReferenceManual

Operationand ProgrammingManual

Chapter 18

Turning Operations

18.0 Chapter Overview 18-1................................................................

18.1 Single Pass Turning Cycles 18- 1.........................................................

18.1.1 Single Pass O.D. and I.D. Roughing Cycle (G20) 18-2......................................

18.1.2 Single Pass Rough FacingCycle (G24) 18-7............................................

18.2 Single Pass ThreadGrinding 18-12........................................................

18.2.1 Considerationsfor Thread Grinding 18-12...............................................

18.2.2 Single Pass Threading Mode (G33) 18-14...............................................

18.2.3 Single Pass Var iableLeadThreadingMode (G34) 18-19.....................................

Chapter 19

Skip and Gauge Probing Cycles

19.0 Chapter Overview 19-1................................................................

19.1 External Skip Functions (G31 codes) 19-2..................................................

19.2 Wheel GaugingExternal Skip Functions (G37 Codes) 19-3......................................

Chapter 20

Paramacros

20.0 Chapter Overview 20-1................................................................

20.1 Parametric Expressions 20-1............................................................

20.1.1 Basic Mathematical Operators 20-2...................................................

20.1.2 Mathematical Function Commands 20-3................................................

20.1.3 Parametric ExpressionsasG-- or M --codes 20-6..........................................

20.2 Transfer of Control Commands 20-7.......................................................

20.2.1 Conditional Operators 20-7.........................................................

20.2.2 GOTO and IF-GOTOCommands 20-9.................................................

20.2.3 DO-END and WHILE-DO-END Commands 20-10..........................................

20.3 Parameter Assignments 20-12............................................................

20.3.1 Local ParameterAssignments 20-13...................................................

20.3.2 Common Parameters 20-15..........................................................

20.3.3 System Parameters 20-16...........................................................

20.3.4 PALParameters 20-37.............................................................

20.4 Assigning ParameterValues 20-39.........................................................

20.5 Backing Up ParameterValues 20-47........................................................

20.6 Macro Call Commands 20-48.............................................................

20.6.1 Non-Modal Paramacro Call (G65) 20-50.................................................

20.6.2 Modal Paramacro Call (G66) 20-50....................................................

20.6.3 Modal Paramacro Call (G66.1) 20-52...................................................

20.6.4 AMP-DefinedG-Code MacroCall 20-54................................................

20.6.5 AMP-DefinedM-Code MacroCall 20-55................................................

20.6.6 AMP-DefinedT -, S-, and B-Code Macro Call 20- 56.........................................

20.6.7 NestingMacros 20-57..............................................................

20.7 Macro Output Commands 20-59...........................................................

ix

Page 14

Table of Contents

Index (General)

9/Series PALReferenceManual

Operationand ProgrammingManual

9/Series Grinder

Chapter 21

In-process Dresser

21.0 Chapter Overview 21-1................................................................

21.1 Offset Generation While Dressing 21- 2.....................................................

21.1.1 Plane Selection for the In-process Dresser Offset 21-4.....................................

21.1.2 Maintaining Dresser Offsets 21-6.....................................................

21.2 Activatingthe In-process Dresser 21-7.....................................................

21.3 On-line In-process Dresser Parameters 21-8.................................................

21.4 Calibratingthe In-process Dresser 21-12.....................................................

Chapter 22

Program Interrupts and Dressing Interrupts

22.0 Chapter Overview 22-1................................................................

22.1 Program Interrupts 22-1................................................................

22.1.1 Enabling/Disabling Program Interrupts (M96, M97) 22-2.....................................

22.2 Dressing Interrupts 22-10................................................................

22.2.1 Operator Request for Dressing Interrupt 22-10............................................

22.2.2 Auto-Dressing Request during Grinding Cycle (D word) 22-10.................................

22.2.3 Dressing Interruptthrough Pre-DressRequest 22-11........................................

22.2.4 Dressing InterruptExecution 22-1 1....................................................

22.3 The Interrupt Program (P word) 22-13.......................................................

22.4 Interrupt Request Considerations 22-15.....................................................

Appendix A

Softkey Tree

Appendix Overview A-1...................................................................

Understanding Softkeys A-1................................................................

Describing Level 1 Softkeys A-3............................................................

Using the SoftkeyTr ee A-3................................................................

Appendix B

Error and System Messages

Overview B-1..........................................................................

Appendix C

G-Code Table

Overview C-1..........................................................................

x

Page 15

Using This Manual

Chapter

1

1.0

ChapterOverview

1.1

Audience

1.2

Manual Design

This chapter describes how to use this manual. Major topics include:

how the manual is written and what fundamentals are presumed to be

understood by the reader

how the manual is organized and what information can be found in it

definitions for certain key terms

We wrote this manual for operators and programmers who use

Allen-Bradley controls. We assume that you are familiar with the basic

operation and programming of a CNC.

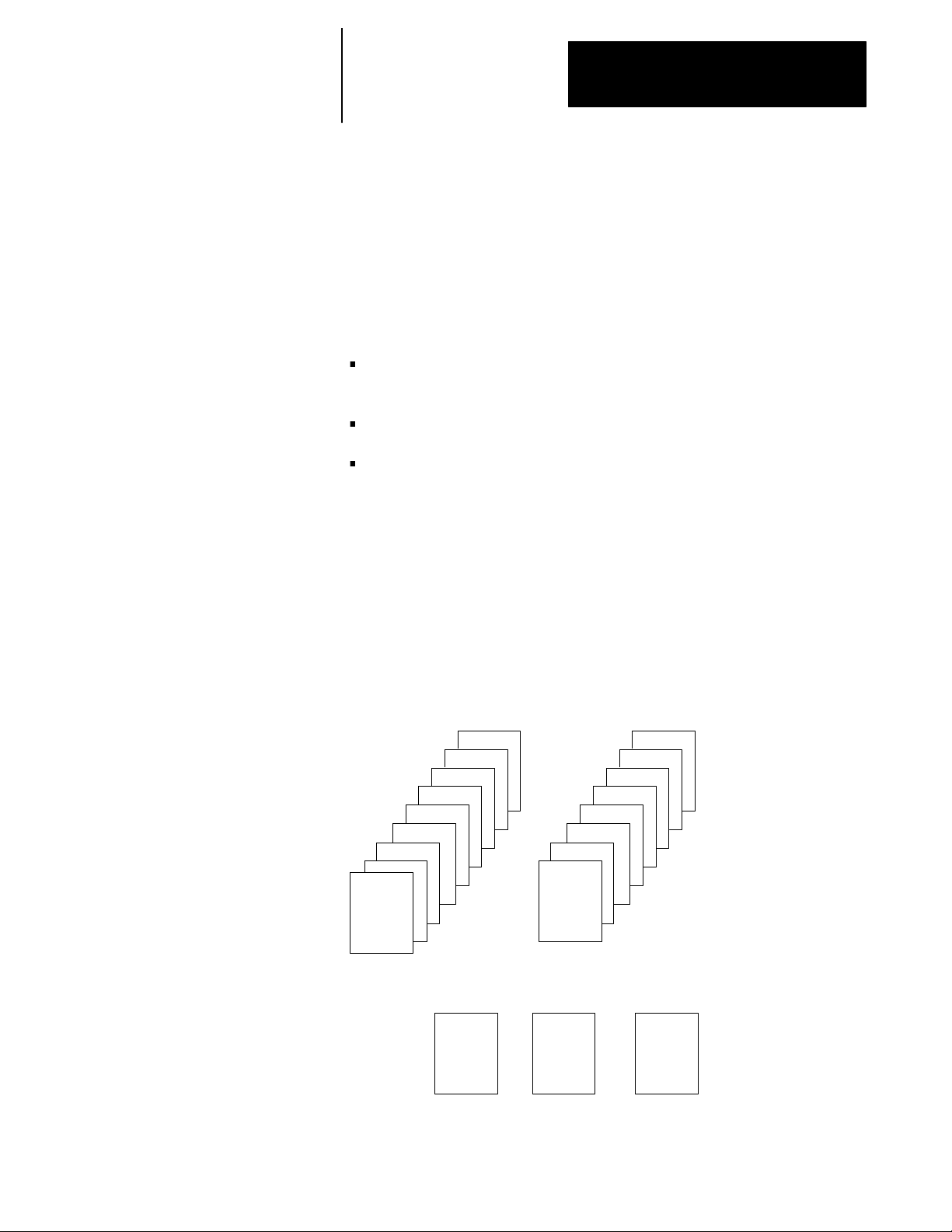

This manual has a basic operation section, a programming section and

three appendices:

How tooperate thecontrol

Chapter9

How toprogram thecontrol

Chapter22

Chapter2

SoftkeyList

Appendix

A

Chapter10

Errorand Operator

MessageList

Appendix

B

G-Code List

Appendix

C

11963-I

1-1

Page 16

Chapter 1

Using This Manual

1.3

What This Manual Contains

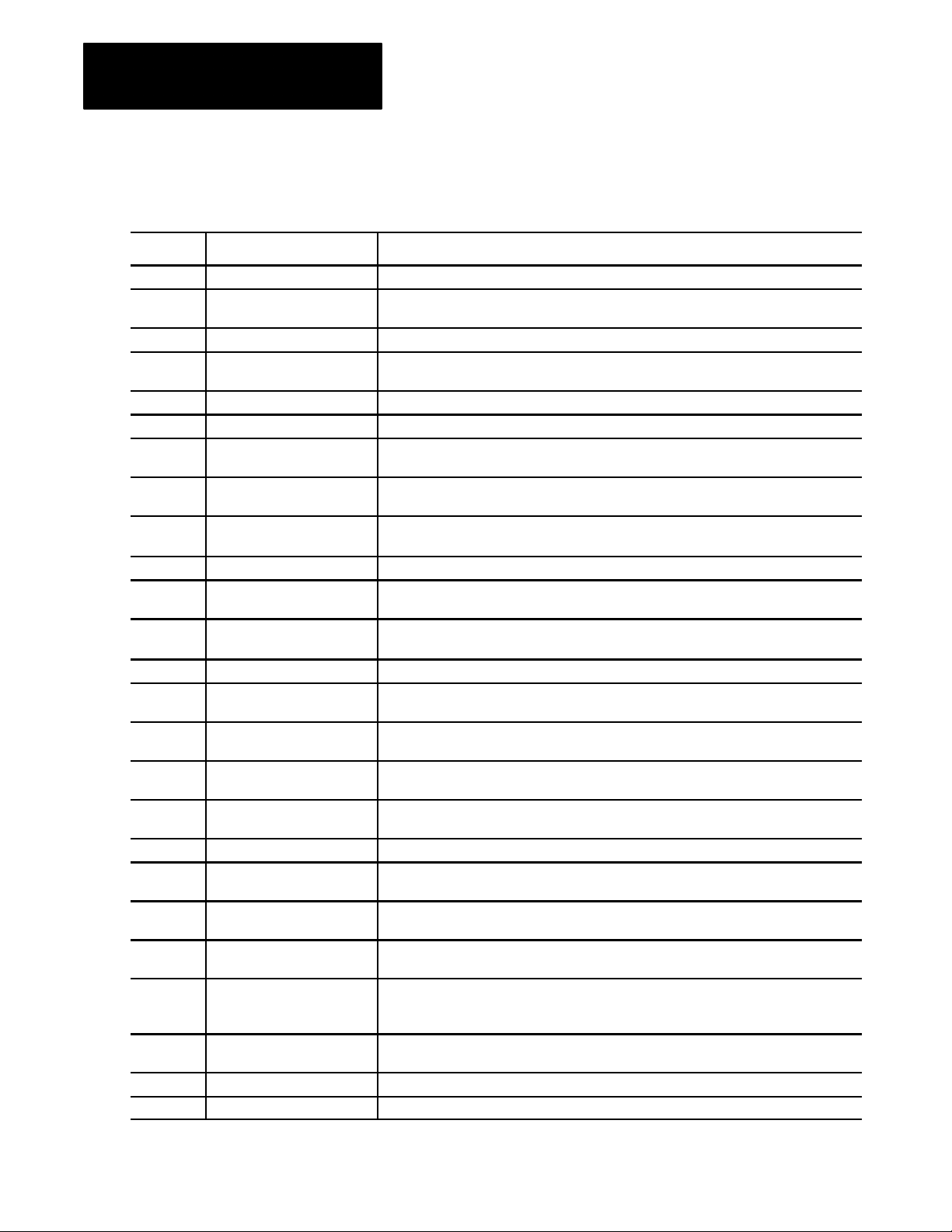

Chapter Title Summary

1 ManualOverview Manualoverview,intendedaudience, definitionof keyterms,howto proceed.

2 Operatingthe Control Abriefdescriptionofthe control’s basicoperation includingpower-up,MTBpanel,operator

3 OffsetTablesand Setup Basicsetup ofthe offsettable, otherinitial operatingparameters.

4 ManualandMDI Operation How touse themanual operatemode, including homingthe machine,jog hand-wheel,jog

5 EditingPrograms How tocreate,edit,and saveapart programon line.

6 EditingPart ProgramOffLine Howto create,edit, andsave a partprogram fromODS offline.

7 Running aProgram How toselect andexecute aprogram automatically. This coversprogram checkingas well

8 Displaysand Graphics How toaccess andinterpret thedifferentposition displays. How touse theQuickCheck

9 Communications Communicationswith peripheraldevices. Includes sections on communication port

10 Introductionto Programming Tapeformat,structureandformatofthe programminglanguage forthe control.

11 CoordinateControl The differentcoordinatesystemsand offsetstothem. Also sections on plane selection,

12 Axis Motion G-wordsthat definehowthe wheelis positionedtothe endpointof amove. Also sections

13 Wheel LengthOffset Selectinga wheel. Activatingand deactivatingwheel lengthoffsets.

14 AngledWheelGrinding Descriptionand use ofcylindrical grinderswith anangled wheel. The angledwheel is a

15 Dresser/wheelRadius

Compensation

16 SurfaceGrinding Cycles Description anduse of thefixed cycles (cannedcycles) forsurfacegrinders andthe

17 CylindricalGrindingCycles Descriptionand use ofthe fixedcycles(canned cycles)forcylindrical grinders andthe

18 TurningO perations Rough contouring routinesandthreading includingtapered andmulti-lead threading.

19 SkipandGauging Cycles Descriptionand use ofthe 9/Seriesprobing features. Includedin this isthe wheel

20 Paramacros Descriptionand use ofparamacros,including calling, arithmeticfunctions,looping,decision

21 In-Process Dresser Descriptionon how thein-process dresseroperates. The in-processdresserinteraction with

22 Programinterrupts /Dressing

Interrupts

AppendixA Softkeys Adescription ofsoftkeys andtheir functionsfor softkeylevels 1and 2. Alsothe softkeytree

AppendixB Error andOperator Messages Analphabetical listingof 9/Serieserror/warningmessages, eachwith a briefdescription.

AppendixC G-Code Tables Alisting of theG-codes usedto programthe 9/Seriescontrols.

This table contains a brief summary of each chapter.

panel,access control,and E-STOP.

continuous,and jog increment. Also coveredare thebasics forMDI operation.

aspartproduction. Also detailson special runningconditions.

and Active Programgraphics features.

parameters,inputting andoutputting AMP, PAL

overtravels,absolute/incremental andinch/metric modes.

on spindlecontrol,QuickPath Plus

non-orthogonalwheel axis.

Adescription ofthe dresser/wheelradius compensationfeature thatoffsetsfor different

dresser/wheeldiameters.

G-wordsandparametersusedto definethem.

G-wordsandparametersusedto definethem.

measuringgauge feature.

making,etc.

featuressuch asoffsettablesand thein-process dressestable arealso covered.

Adescription ofthe programinterrupt anddressing interruptfeatures. These featuresare

usedtocall asubprogram orparamacro programwhenever a signalcorresponding tothat

programissent toPAL bythe operatoror requestedbya grindercycle.

displayingalllevels ofsoftkeysandtheir locationis shown.

™ programming, dwell,andmirroring.

™,Offsets,andprograms.

1-2

Page 17

Chapter 1

Using This Manual

1.4

Reading This Manual

To make this manual easier to understand, we included these explanations

of terms and symbols:

All explanations, illustrations, and charts presented are based on

standard CNC functions. Operationscan differ from the basic

information provided in this manual depending on the configuration of

your grinder machine controlled by the CNC. For details, see the

manuals prepared and supplied by your system installer.

You can purchase some of the softkey functions and features as options

on the 9/Series control. This manual assumes you have all of the

optional features.

Explanations and illustrations assume a 2-axes cylindrical grinder

configuration. This means the movement of the grinding wheel on a

rotating part or the movement of the grinding wheel on the fixed dresser.

Explanations and illustrations were not specifically written for an angled

wheel cylindrical grinder though most will apply to the cylindrical

grinder configuration.

The control accepts several different alphabetic characters for

expressing numerically controlled axes. This manual uses Z and X for

the first and second axes on the basic coordinate system. The integrand

name for these axes is K and I respectively . Cylindrical angled wheel

grinders should also assume Z (real) and X (virtual) axes for the first

and second axis on the basic coordinate system with W (real) however,

being the actual physical wheel axis.

The term AMP is an abbreviation for Adjustable Machine Parameters.

These parameters are used to match the control to a specific machine.

AMP configuration is usually done by your system installer.

Program examples are given as radius values. Assume the control is in

radius programming mode unless stated otherwise.

Names between the [ ] symbols are keys

Names between the { } symbols are softkeys

Names between the < > symbols are switches and buttons

found on the operator panel.

found below the CRT.

found on the

standard MTB panel.

The term PAL is an abbreviation for Programmable Application Logic.

This is a ladder logic program that processes signals between the CNC

and the grinder. It is usually programmed by your system installer.

1-3

Page 18

Chapter 1

Using This Manual

1.5

Terms and Conventions

To make this manual easier to read and understand, we shortened the full

product names and features. Shortened terms include:

Term Description

AMP AdjustableMachine Parameters

backup Memorystorage areain the controlthat doesnot requirebattery powerto bemaintained

CNC Computer NumericalControl

CPU CentralProcessing Unit(the computingpart ofthe control)

CRT Cathode RayTube (thecontrol’s monitorscreen)

thecontrol the 9/240,9/260, or9/290 ComputerizedNumerical Control

Dresser/Wheel appliestoprocessesthat areinterchangeable between thedresser orgrinding wheel

EPROM Erasable Programmable Read OnlyMemory

E-STOP EmergencyStop

HPG HandPulse Generator

I/O Input/Output

MDI ManualDataInput

modal an operatingcondition thatremainsineffecton the control until canceledor replaced

MTB Machine Tool Builder

ODS OfflineDevelopment System

PAL ProgrammableApplication Logic

RAM RandomAccess Memory

softkeys therowof keysdirectlybelowthe screen

system installer the companyor contractor responsiblefor installingthis controlon the machine

1.6

Warnings, Cautions, and

Important Information

1-4

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

Information that is especially important is indicated in these ways:

ATTENTION: indicates circumstances or practices that can

lead to personal injury as well as to damage to the control, the

machine, or other equipment.

Important: indicates information that is necessary for successful

application of the control.

Page 19

Chapter 1

Using This Manual

1.7

Related Publications

For more information about Allen-Bradley controls, see these publications:

Pub.No. Document Name

8520-4.3 9/SeriesCNCPALReference Manual

8520--5.1.1 9/SeriesCNCLathe Operationand ProgrammingManual

8520--5.1.3 9/SeriesCNCMill Operationand ProgrammingManual

8520--5.1.4 9/SeriesCNCGrinder Operationand ProgrammingManual

8520-5.1.5 9/SeriesData HighwayPlusCommunicationModule User Manual

8520-5.1.6 9/SeriesMMS/EthernetCommunication ModuleUser Manual

8520--5.2 9/SeriesCNC OCI UserManual Supplement

8520-6.2 9/SeriesCNCIntegrationand MaintenanceManual

8520-6.4 9/SeriesCNCAMP Reference Manual

8520-6.5 T-Line-9TransferLineQuick StartGuide

8520--6.6 9/SeriesCNC OCI Installation Manual

8520--6.7 9/SeriesCNC OCI APIDeveloper’s Guide

MCD-5.1 OfflineDevelopmentSystem User’sManual

END OF CHAPTER

1-5

Page 20

Chapter 1

Using This Manual

1-6

Page 21

Operatingthe Control

Chapter

2

2.0

ChapterOverview

This chapter covers the basics necessary for operation of the Allen-Bradley

9/Series control. Major topics covered in this chapter include:

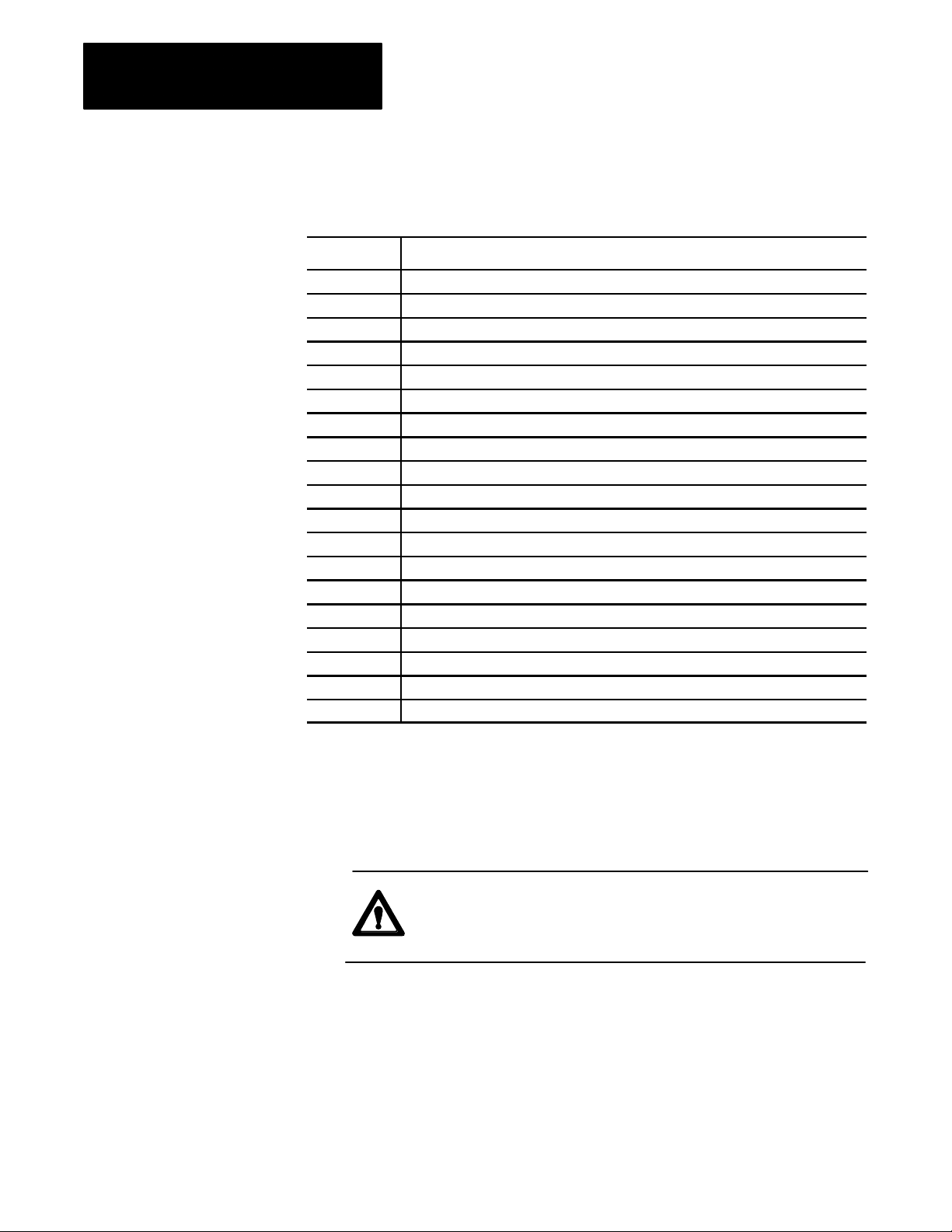

Topic: On page:

OperatorPanel Operations 2-2

UsingtheKeyboard 2-3

Softkeys 2-5

UsingtheCRT 2-7

The StandardMTB Panel 2-8

SoftwareMTB Panel{FRONT PANEL} 2-11

Poweringthe Control 2-18

TurningOnPower 2-18

TurningOffPower 2-20

ControlConditions atPower-Up 2-20

EmergencyStop Operations 2-22

EmergencyStop Reset 2-22

Access Control 2-23

AssigningAccess Levelsand Passwords 2-24

PasswordProtectable Functions 2-27

StoringPassword Listto BackupMemory 2-29

EnteringPasswords 2-30

Changing OperatingModes 2-32

ControlandBlock Reset 2-36

DisplayingSystem andMachine Messages 2-37

ClearingActive Messages{CLEAR ACTIVE} 2-40

The InputCursor 2-41

{REFORM MEMORY} 2-42

RemovinganAxis (AxisDetach) 2-43

TimeParts CountDisplay Feature 2-44

CalculatorFunction 2-48

2-1

Page 22

Chapter 2

Operating the Control

2.1

Operator Panel Operations

Use the operator panel to:

display a part program

display control status and wheel position

edit a part program

display and enter wheel offset data

display the status of input/output signals

display and enter programmable zone boundaries

set the level of protection for:

- part programs

- wheel offset data

-AMPdata

You can perform other operations by using the operator panel. They are

covered in t he remaining chapters of this manual.

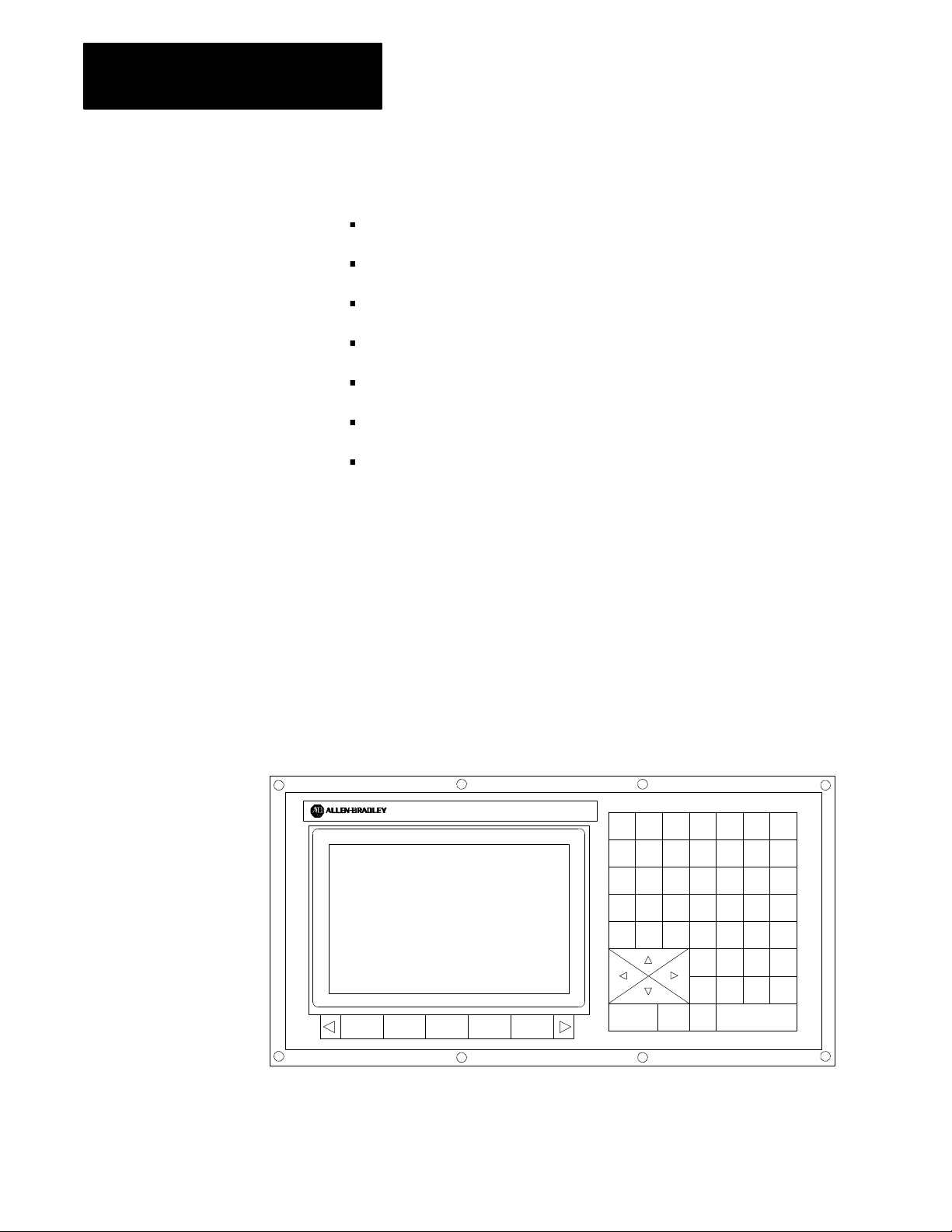

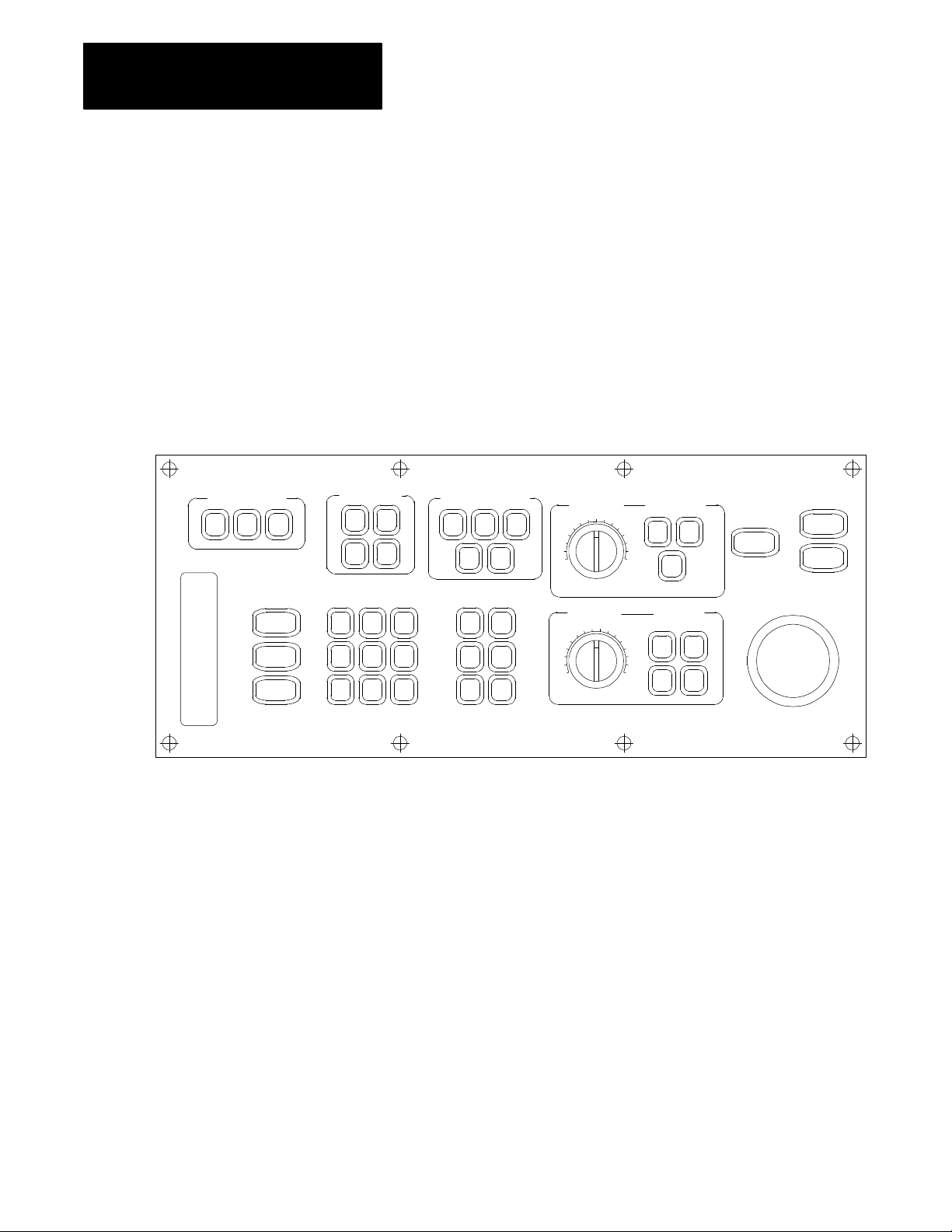

Figure 2.1 shows the monochrome operator panel.

Figure 2.1

Monochrome Operator Panel

9/SE RIES

789ONGP

456XYZQ

123IJKR

_0.ABCL

+

*

SHIFT

;

%

=:FDH

PROC

UVW

SP

E?

MST

CALC DEL CAN RES

DISP

o

]

()[

TRANSMIT

#

EOB

.

19435

2-2

Page 23

Chapter 2

Operating the Control

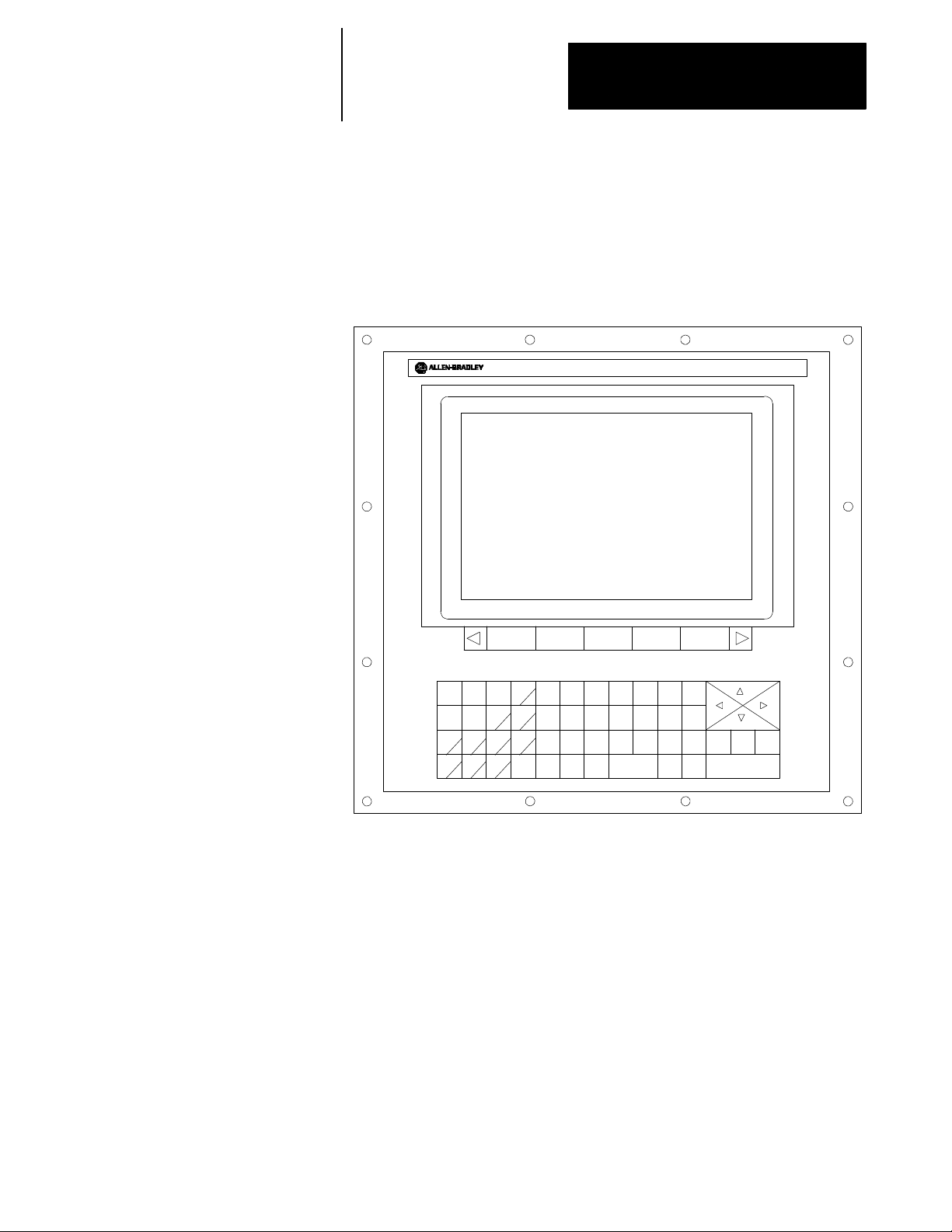

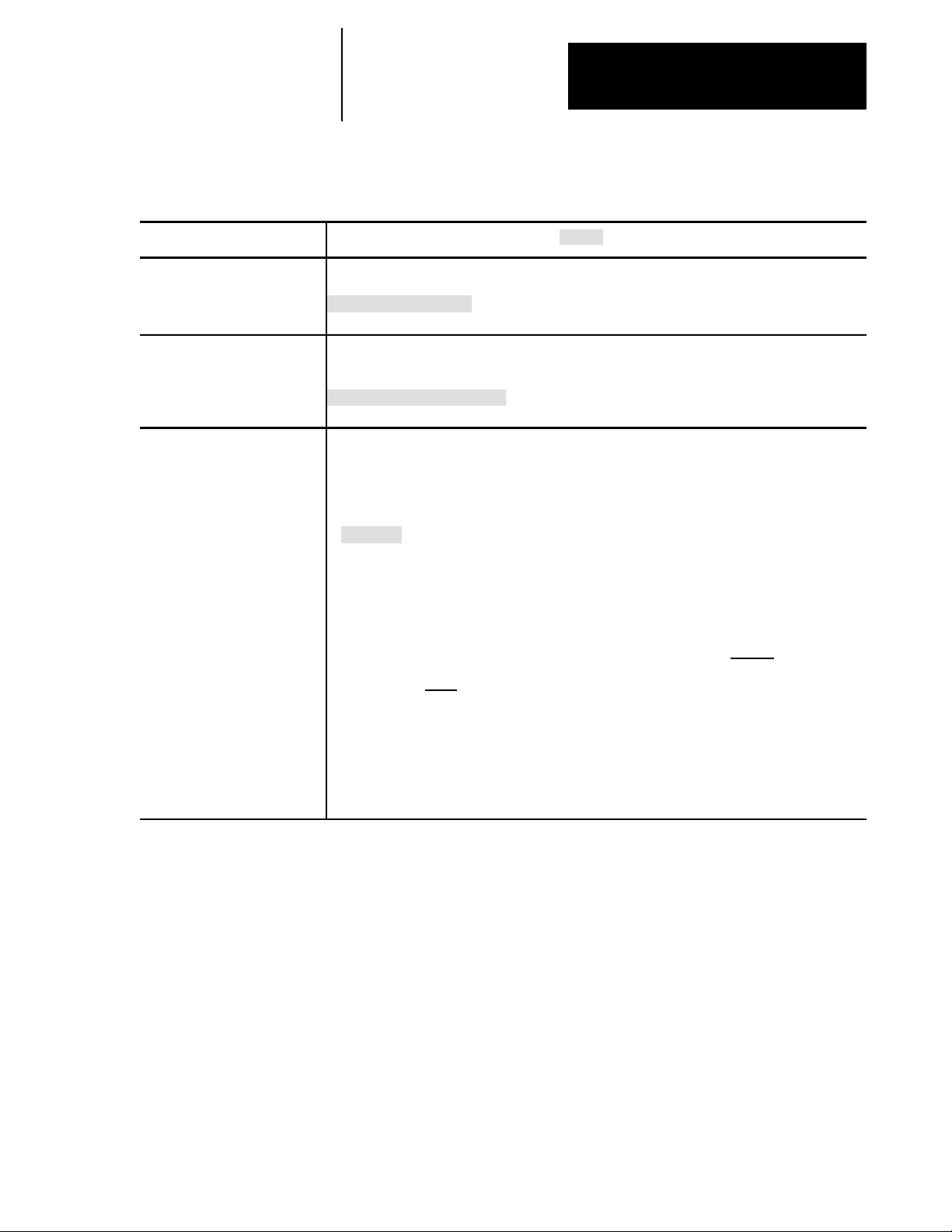

Figure 2.2 shows the color operator panel. It has keys and softkeys

identical to the monochrome operator panel in a slightly different

configuration.

Figure 2.2

ColorOperatorPanel

9/SERIES

2.1.1

Using the Keyboard

#

H

C

C

T

DISP

,

L

&

SP

DEL

(

EOB

PROC

)

CAN

LINE

TRANSMIT

RES

CNTRL

19436

?

]

.

9

6

5

0:

78

4

123

+

_

=

CALC

N

O

X

P

G

Z

Y

VU

R

Q

I

J

K

D

F

E

B

A

W

S

M

[

SHIFT

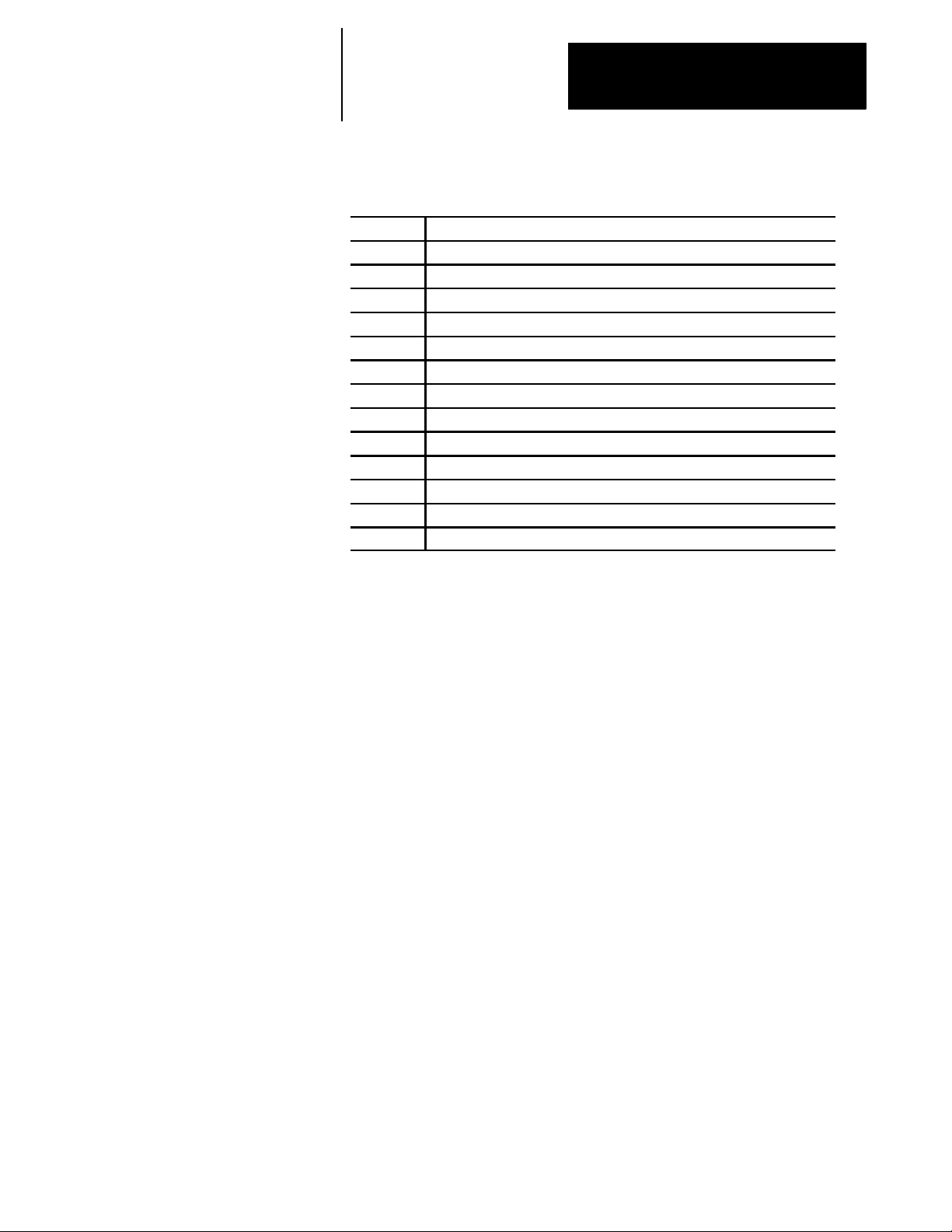

Table 2.A lists the functions of keys on the operator panel keyboard. The

names of operator panel keys appear between [ ] symbols.

2-3

Page 24

Chapter 2

Operating the Control

Table 2.A

Key Functions

Key Name Function

Addressand NumericKeys Usethese keystoenter alphabeticand numeric

characters. Ifakey hastwo charactersprinted onit,

pressingit normallyenters theupperleftcharacter.Holding

down the[SHIFT] keywhile pressingitenters thelower

rightcharacter.

CursorKeys ←,↑, →,↓

[SHIFT] and→ or ←

[SHIFT] and↑ or ↓

CalculationKey [CALC] Pressthiskeyto enablea calculator-typefunction onthe

DeleteKey[DEL] Pressthis keyto deletethe characterto theleft ofthe

[SHIFT] and[DEL] Press thiskey todeleteall keyed-indata currently

[CAN] Clearsthe mostcurrently generated,active errormessage.

TransmitKey [TRANSMIT] The dataentered anddisplayed on theinput lines(e.g., a

BlockReset [RESET] This performs a blockreset. Fordetails onBlock Reset,

ControlReset[RESET] +

[SHIFT]

DisplaySelect

[DISP SELECT]

End ofBlock[E.O.B.] Usethis keyto enteranEnd-of-Blockcharacter when

ProcessSelect

[PROC SELECT]

[SHIFT] and[⇒] Pressthe [SHIFT]key while holdingdown the[⇒]

Usethese keystomove thecursor left,right,upand down

in thedata displayarea (lines4-21) of thescreen. These

keysare referredto as theleft,right,up,anddown cursor

keys respectively.

Pressthe rightor leftcursor keyswhileholding downthe

[SHIFT] keyto movethe cursorright andlefton any

line thatdata isbeing inputon(normally screenlines 2-3).

Pressthe up anddown cursorkeys whileholdingdown the

[SHIFT] keyto rollthe displaypageforward or

backward.

control. Basic mathematical expressionscan be evaluated

usingthisfeature. For detailsonCalculator Function,see

page 2-48.

cursoron input lines.

displayedoninput lines.

passwordor a programblock) issent tothe controlwhen

you pressthe[TRANSMIT] key.

seepage2-36.

Pressthe resetkey while holdingdown theshift keyto

performa controlreset. For detailson Control Reset,see

page 2-36.

Usethiskey todisplay thedifferentaxis positiondisplay

softkeys.

editingaprogram orwhen writinganMDI program.

Usethiskey toselect thedifferentprocesses.

softkeyto jumpto theonlinesearch monitorscreen. Press

thesekeys again toreturn tothe previousscreen.

2-4

Page 25

Chapter 2

Operating the Control

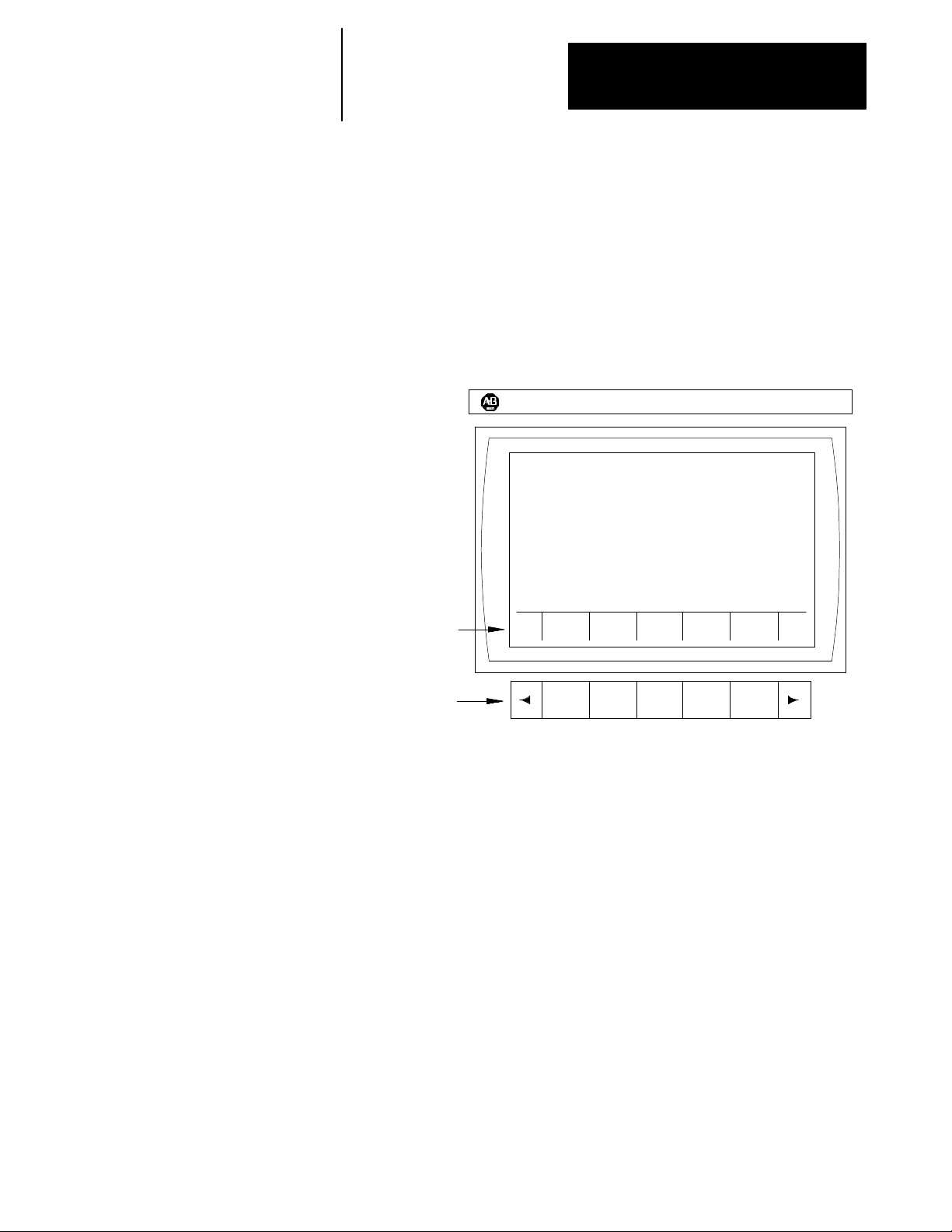

2.1.2

Softkeys

You access the various software features and functions of the control

through softkeys. Softkeys are the row of 7 keys located at the bottom of

the CRT as shown in Figure 2.3. They let you move through the control’s

software. The control displays the function of each softkey on the CRT

directly above the softkey. In this manual, softkey names appear between

the { } symbols.

Figure 2.3

Softkey and Softkey Name Locations

ALLEN-BRADLEY

Softkeynames

displayedhere

9/Series

Softkeys

11978-I

In this manual, we often describe softkeys as being on a certain level, e.g.,

softkey level 3. We use the level of the softkey to determine the location

or necessary path to reach that particular softkey. For example, to get to a

softkey on level 3, you must press a specific softkey on level 1, followed

by a specific softkey on level 2. For a listing of all of the softkeys and

their respective levels, see appendix A.

Softkey level 1 is the initial softkey level the control displays at power-up.

Softkey level 1 always remains the same, and all other levels are

referenced from softkey level 1.

The softkeys on opposite ends of the softkey row have a specific use that

remains standard throughout the different softkey levels. On the left is the

exit softkey displayed with the up arrow {

continue softkey displayed with the right arrow {

↑}, and on the right is the

→}.

2-5

Page 26

Chapter 2

Operating the Control

Use the exit softkey {↑} (on the far left) to regress softkey levels. For

example, if you are currently on softkey level 3 and you press the exit

softkey, the softkeys change to the softkeys previously displayed on

softkey level 2. When you press the exit softkey while holding down the

[SHIFT] key, the softkey display returns to softkey level 1 regardless of the

current softkey level.

When more than 5 softkey functions are available on the same level, the

control activates the continue {

→} softkey at the far right of the softkey

area. When you press the continue softkey, the softkey functions change to

the next set of softkeys available on that level.

Important: When the number of softkey functions on that level does not

exceed 5, the continue softkey is not available.

For example:

(softkey level 1)

PRGRAM

MANAGE

OFFSET MACRO

PARAM

PRGRAM

CHECK

SYSTEM

SUPORT

When you reach softkey level 1, the above set of softkeys appears. Press

the continue softkey {

→} to display the remaining softkey functions on

softkey level 1.

(softkey level 1)

FRONT

PANEL

ERROR

MESAGE

PASSWORD

SWITCH

LANG

On softkey level 1, the control does not display the exit softkey since the

softkeys are already on softkey level 1.

We explain the softkey functions for level 1 and 2 in appendix A, and level

3 or higher in the sections that apply to their specific operations.

To use a softkey function, press the plain, unmarked button directly below

the description of the softkey function.

You can purchase some of the softkey functions as optional features. This

manual assumes that you purchased all available optional features for your

machine. If you did not purchase an option, the softkey is blank.

2-6

Some features accessed through a softkey can be password protected.

When a feature is password protected, the softkey that accesses that feature

is no longer displayed.

Page 27

Chapter 2

Operating the Control

2.1.3

Using the CRT

Your control has one of these monitors:

9-inch monochrome monitor

19435

12-inch color m onitor

19436

Both have identical displays and graphics capabilities.

Certain lines of the screen are dedicated to displaying specific information:

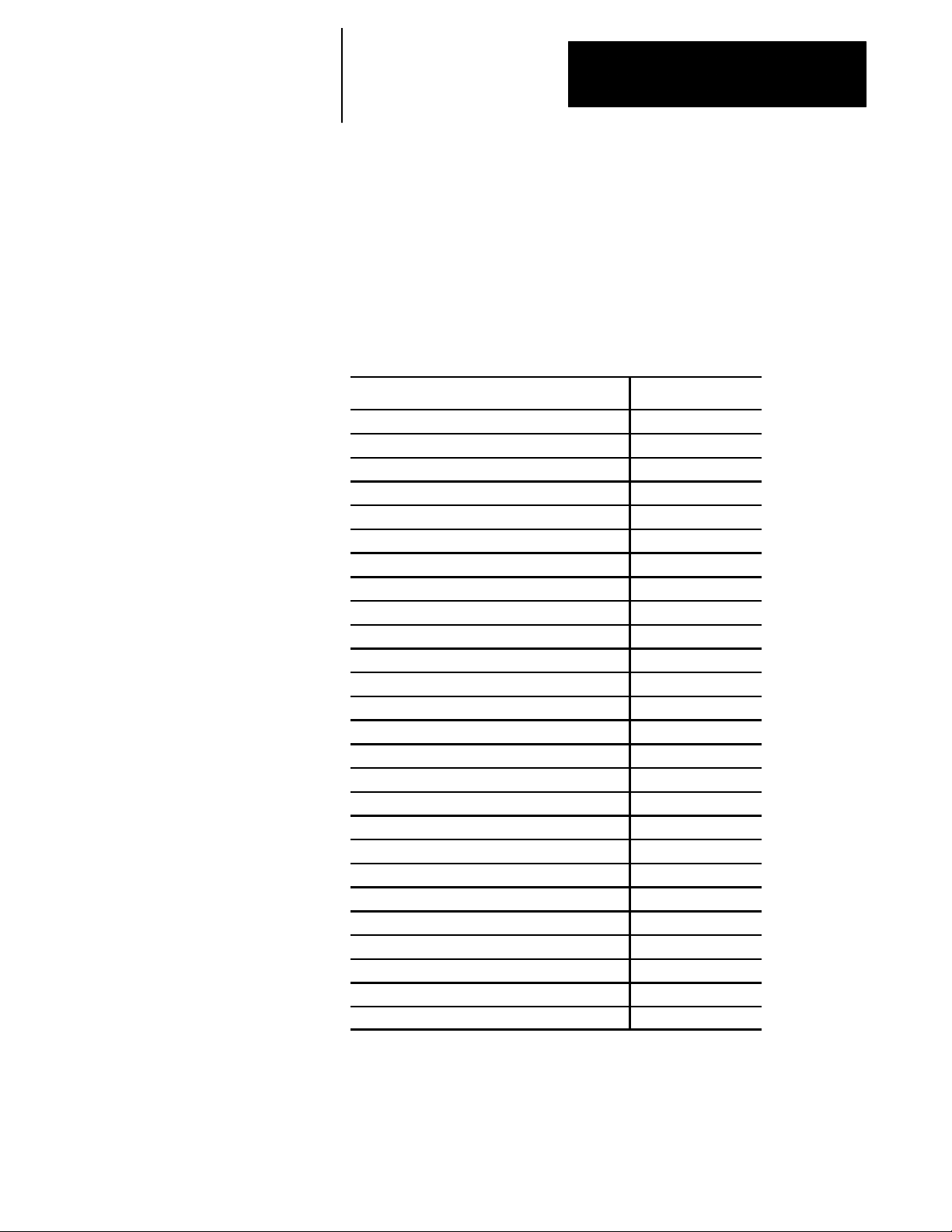

Line Area Content

1 machine/system

message

2-3 inputlines When datais enteredusingthe keyboard,the controldisplays the

4-20 data display The controldisplays axisposition data,listing ofthe partprogram,

21 -22 PALmessage The controldisplays anymessages generatedby thecontrol’s PAL

23 -25 softkeydisplay Thecontrol displaysthe currentlyavailable softkeyfunctionsinthis

Ifan error occursor amessage isgenerated foranyreason during

machineoperation orprogramexecution,the controldisplays the

corresponding machine/systemmessage inthis area. Only the

highestpriority,most currentmessage isdisplayed here.

enteredcharacters onthese linesuntilyou pressthe

[TRANSMIT] key. Somescreens canhave onlyline 2 asan

inputline.

wheel lengthoffsetdata, G/M/H/T/F/S/D codes,graphics, and

otherdata in thisarea asdetermined bythe selecteddisplay.

programin this area.

area.

2-7

Page 28

Chapter 2

Operating the Control

2.2

The MTB Panel

Figure 2.4 shows the MTB panel. Table 2.B lists the selections on this

panel. Your system may contain optional or custom MTB panels different

than the one shown below. See the documentation prepared by your

system installer for details.

We show selection names on the MTB panel between the < > symbols

when referred to in this manual. Most selections on the MTB panel are

configured by your system installer’s PAL program. This manual assumes

that PAL has been written as intended for normal operation. If a selection

does not work the way it is described i n this manual, see documentation

preparedby your system installer.

Figure 2.4

Push-Button MTB Panel

MODE SELECT SPEED/MULTIPLY

MDI MAN

AUTO

CYCLE

START

SINGLE

BLOCK

CYCLE

STOP

JOG SELECT

CONT

INCR

HOME

HAND

AXIS

+4

+X

+Y TRVRS --Y

+Z --4

LOWX1MEDL

MEDH

X1000

FUNCTION

-- X

-- Z

F1

F3 F4

F5

SPINDLE SPEED

OVERRIDE

MED

X10

X100

HIGH

X10000

FEEDRATE

F2

F6

OVERRIDE

50

0

%

100

150

SPINDLE

DIRECTION

CCW CW

OFF

RAPID FEEDRATE

OVERRIDE

F1 25

50

OFF

ESTOP

RESET

EMERGENCY

STOP

100

ON

2-8

Page 29

Chapter 2

Selectstheoperationmode

Operating the Control

Table 2.B

Selections on the MTB Panel and How They Work

Switch orButton Name

MODE SELECT

JOG SELECT Selectsthe jogmethod to beactive inmanual mode

SPEED/MULTIPLY Selects an axisfeedrateoraxis feedamount multiplicationratio usedin themanual mode. Each

How It Works = Default forPush-ButtonMTB Panel

AUTO ---- automaticmode

MANUAL ---- manual mode

MDI ---- manual datainput mode

HANDWHEEL ---- HPG (handpulse generator)jog

INCREMENTAL ---- incrementaljog

CONTINUOUS ---- continuous jog

HOME -- -- m ac hi ne h om e

selectionmodifies theactive feedrateby avalue setinAMP. Modificationalsodepends onthe setting

of<JOGSELECT> asdescribed below:

• HANDWHEEL

When inhandwheel jog mode,SPEED/MULTIPLYalters thehandwheel resolution bya factor

determined in AMP. Yoursystem installer sets thevaluefor:

-LOWX1

-MEDLX10

-MEDL X100

You cannotuse the valueslisted belowfor handwheeljog:

-MEDH X1000

-HIGHX10000

• INCREMENTAL

When inincremental jog mode,SPEED/MULTIPLYalters theincremental jog distance

in AMPbyyour system installer. Your systeminstallersetsa value fortheselections. The

incrementaljog speed

<FEEDRATE OVERRIDE>.

• CONTINUOUS

When incontinuous jog mode,SPEED/MULTIPLYacts asa feedrate selectionswitch whichhas

values setinAMP by yoursysteminstaller. Your systeminstallersetsa value forall5 selections

independentlyfor eachaxis. <FEEDRATE OVERRIDE> can beusedfor speedadjustments.

isfixed to mediumbut canstill becontrolled by

byafactor set

Important: The values for thediff erent<SPEED/MULTIPLY> selections areconfigured byyour

system installer.

2-9

Page 30

Chapter 2

Operating the Control

Table 2.B

Selections on the MTB Panel and How They Work (continued)

Switch orButton Name

SPINDLE SPEEDOVERRIDE Selectsthe overridefor programmedspindle speedsin5% incrementswithin arange of50%to 120%.

SPINDLE or

SPINDLE DIRECTION

FEEDRATEOVERRIDE Selectsafeedrateoverride percentagefor thefeedrate programmedwith an Fword in anyof the

RAPIDFEEDRATEOVERRIDE Selectsthe override forrapid feedrates. Select fromF1, 25%,50%, and 100%where F1 isa rapid

EMERGENCY STOP This button stopsmachine operationanddisables thespindle andaxisdrives whenpressed.

E-STOP RESET This button resetsan emergencystop conditionwhenpressed. Beforepressing thisbutton the

CYCLESTART The controlbegins orresumes partprogram execution,MDI programexecution,orprogram check

CYCLESTOP Thecontrol stopspart programexecution, MDIexecution,orprogram checkwhen thisbutton is

SINGLE BLOCK The controlexecutesorchecks oneblock ofa part programor MDIentry eachtime the

AXIS/DIRECTION Thesebuttons areused formanual operations. They selectanaxis anddirection when<JOG

TRVRS Hold thisbuttondownwhile executinga continuousjog move tooverride theactive feedrateand jogan

F1-F4 The functionsfor thesebuttons areassignedby thesystem installer. Refer tothe documentation

JOG RETRACT Usejogretracttojog acutting toolawayfromtheworkpiece duringautomaticorMDI program

BLOCK RETRACE To retrace thetool pathin a partprogram already executed(up to15blocks), press thisbutton.

ON Turnson power tothe control.

OFF Turns offpower tothe control.

Selectsspindle rotation,clockwise (CW),spindle stop(OFF), counterclockwise (CCW). Can be

overriddenbyany programmedspindle directioncommand.

feedratesmodes (G93/G94/G95)and thereciprocation feedrateprogrammed withan E word.

<FEEDRATE OVERRIDE> has arange of 0%to 150%ofthe programmed feedrateandalters the

programmedfeedrate in10% increments. When setto 0%, thecontrol iseffectivelyin feedhold.

feedrateoverridesetting establishedinAMP bythe system installer.

conditionthat causedthe E-Stopshould be resolved.

when thisbuttonispressed.

pressed. Ifpressed during theexecution of aprogram block acycle suspend stateoccurs.

<CYCLE START> buttonis pressedwhen single blockis active.

SELECT>isset forcontinuous,i ncremental, orhome. If <JOGSELECT> issetforhandwheel,these

buttonsselect anaxis only. Directionisthen determinedby handwheelrotation.

axisinrapid traverse.

prepared bythe systeminstaller for details.

execution.The controlcanretracethe jog movesand returnthe cuttingtool automaticallyto the

workpieceby pressing<CYCLE START>. Refer tochapter 7for moreonthis.

= Default forPush-ButtonMTB PanelHow ItWorks

2-10

Important: You can disable m any of the override switch settings by

programming the correctM code or by setting a particular paramacro

parameter. See their respective sections for details on these features.

Page 31

Chapter 2

Operating the Control

2.3

SoftwareMTB Panel

{FRONT PANEL}

The 9/Series control offers a software MTB panel that performs many of

the functions of an MTB panel. This feature uses softkeys instead of the

normal switches and buttons of a panel. If your control uses a standard

MTB panel (described on page 2-8) or some other custom MTB panel,

the requests for operations from the panel take priority. This means that

requests from the software MTB panel are ignored if a request from a

standard or custom MTB panel is sent.

The software MTB panel’s operation depends on PAL, especially if the

control uses either a standard or custom MTB panel. See the

documentation prepared by your system installer for details about using the

software MTB panel. Your system installer uses PALto disable the

{FRONT PANEL} softkey.

The software MTB panel controls these features:

Feature Function

ModeSelect Selectseither AUTO,MDI, orMANUAL modesas thecurrent operatingmode ofthe control.

Rapid Traverse Replaces thefeedrate whenexecuting acontinuous jog movewith therapid feedrate.

FeedrateOverride Selectsa feedrateoverride percentagefor thefeedrate programmedwith anFword in anyof thefeedrates modes

(G93/G94/G95)and the reciprocation feedrateprogrammed withan E word. This switchhas a rangeof 0%to

150% ofthe programmedfeedrateandalters theprogrammed feedratein 10%increments. When setto 0%,the

controlis effectively in feedhold.

Rapid FeedrateOverride Selectsthe overridefor rapidfeedrates. Select fromF1, 25%,50%, and100%,where F1is a rapidfeedrate

override setting established in AMPby your systeminstaller.

SpindleDirection Selectsspindle rotation,clockwise (CW),spindle stop(OFF), orcounterclockwise (CCW). The frontpanel is

overriddenbyany programmedspindle directioncommand.

SpindleSpeedOverride Selectsthe overridefor programmedspindle speedsin 5% increments withinarange of50% to120%.

DryRunMode Placescontrolindry runmode. This replacesfeedrates withthe dryrunfeedrates. See page7-21for details.

BlockDelete Allowsactivationofthe blockdelete feature“/ or/1”. Blockdelete 2 -9 are notavailable withthe

{FRONT PANEL}. See page7-2 fordetails.

M-FunctionLock Allowsselect M-,S-, T-, and B-codesto beignored. See page7-2 fordetails.

Optional Stop Enables ordisablesthe M01optional stopcode. When thisfeature is“ON,” an M01in a partprogram stops

automaticexecution. When thisfeatureis“OFF,”an M01ina partprogram isignored. Seepage10-31 fordetails

on M01.

SingleBlock Causes thecontrol toexecute orcheck oneblockof apart programor MDIentry eachtime you pressthe

<CYCLE START> buttonwhen thisfeature ison.

WARNING:Single blockexecution isnot possibleduring reciprocation.

Mirror Image Mirrorsthe axiscommands in thepart programaround theselected axis. See page12-79for details.

AxisInhibit Preventsaxis commandsfrombeingexecuted. The controlsimulatesaxismotiononinhibited axesusing Acc/Dec

and feedrates; however, noactual axis motionfor theinhibited axesis generated. See page 7-20for details.

(continued on next page)

2-11

Page 32

Chapter 2

Operating the Control

The software MTB panel controls these features: (continued)

Feature Function

JogtheAxes Allows manualmotions tobe performedin any oneof thejoggingmodes. You cannotperform multi-axisjogs using

thesoftware frontpanel feature. See page4-2for details.

Set Zero Changesthe wheel’scurrentposition inthe work coordinatesystem to0 for theselected axis. This isdone by

shiftingthe work coordinatesystem. See page12-89 fordetails.

BlockRetrace Allows up to15 partprogram blocksto be retraced during programexecutionandallow thewheelto automatically

re-executetheseblocks. See page 7-30for details.

Jog Retract Allowsthe wheel tobe manuallyjoggedaway fromthe partand thenautomatically returnsthe wheelto thepartby

retracingthe joggedmoves. Up to15jog movescan be remembered. See page 7-27for details.

Cycle Start The control beginsor resumespart programexecution, MDIprogram execution, or programcheck whenyou press

thisbutton.

Cycle Stop Thecontrol stopspart programexecution orprogram checkwhen youpressthisbutton. If pressedduring the

execution ofa programblock,a cycle suspendstate occurs.

WARNING:During reciprocation, pressing<CYCLE STOP>does notnecessarily stopthe reciprocatingaxis.

Software MTB Panel Screen

Use the software MTB panel screen to specify the status of the MTB

features. To access the software MTB panel screen:

1. From the main menu screen, press the

(softkey level 1)

PRGRAM

MANAGE

FRONT

PANEL

OFFSET MACRO

PARAM

ERROR

MESAGE

PASSWORD

You see the software front panel screen displaying the current status

of the alterable features:

{FRONT PANEL} softkey.

PRGRAM

CHECK

SYSTEM

SUPORT

SWITCH

LANG

2-12

Page 33

Chapter 2

Operating the Control

SOFTWARE FRONT PANEL

MODE SELECT: MDI

RAPID TRAVERSE: OFF

FEEDRATE OVR: 0%

RAPID FEEDRATE OVR: 0%

SPINDLE DIRECTION: OFF

SPINDLE SPEED OVR: 50%

DRY RUN MODE: OFF

BLOCK DELETE: OFF

M-FUNC LOCK: OFF

OPTIONAL STOP: OFF

SINGLE BLOCK: OFF

MIRROR IMAGE: X

AXIS INHIBIT: XZ

USE CURSOR FOR SELECTION

JOG

AXIS

PRGRAM

EXEC

2. Press the up and down cursor keys to selectthe feature to change.

The value of the selected feature appears in reverse video.

3. Pressthe left and right cursor keys to alter the value of the selected

feature.

When you select the mirror image and axis inhibit features, the softkey

names change to the axis names. Press the softkey that corresponds to

the axis (or axes) to which you want to assign these features.

2-13

Page 34

Chapter 2

Operating the Control

Jog Axis Screen

After accessing the software front panel screen and selecting the various

features for your application, you can use the jog axis screen to:

jog the axes of the control

shift the current work coordinate system to force the current wheel

position to be the zero point of the work coordinate system

To jog the axes of the control:

1. Press the

{JOG AXIS} softkey. The {JOG AXIS} softkey is only

available when mirror image or axis inhibit are not in reversevideo.

If one these features is in reverse video, press the up cursor key.

(softkey level 2)

JOG

AXIS

PRGRAM

EXEC

You see the jog axis screen:

PROGRAM [INCH] F 0.000 MMPM

R X 0.000 S 0.0

Z 0.000 T 0

FILENAME

SUB NAME

MEMORY MAN STOP

E-STOP

2-14

AXIS SELECT: X

JOG SELECT: CONTINUOUS

SPEED/MULTIPLY LOW

HPG NUMBER 0

SET

ZERO

JOG

AXIS +

JOG

AXIS -

Page 35

Chapter 2

Operating the Control

You can select the:

axis to jog

type of jog

speed multiply value (see manual operating mode on page 4-1)

HPG number (if HPG has been selected as the type of jog)

2. Use the up and down cursor keys to select a parameter and the left

and right cursor keys to alter the value assigned to that parameter.

3. Jog the selected axis in the selected direction by:

If jog type is: Then:

NotHPG pressthe softkeythat correspondsto thedirection onthe

selectedaxis tojog

HPG the directionof HPGrotation determinesthe directionto jog

See page 4-2 for details on jogging an axis.

Set Zero

If you want to shift the current work coordinate system to force the current

wheel position to be the zero point of the work coordinate system, press

the

{SET ZERO} softkey.

The current axis position becomes the zero point of the currently active

work coordinate system.

{SET ZERO} softkey does not function when the control is in

The

handwheel mode. See page 11-18for details on set zero operations.

ProgramExecute Screen

After accessing the software front panel screen and selecting the various