Page 1

ALLEN-BRADLEY

8510 AC Spindle Drive

Connector Kits

(Cat. No. 8510SA-CABC, 8510SA-CADC)

Instructions

Introduction Connections to the motor feedback resolver that are performed inside the

motor terminal box are made through an AMP Commercial MATE-N-LOK

connector. Two sizes of connectors are used depending on the motor type.

This publication will provide the information needed to properly install

these connectors.

The connector kit to use with a specific motor type is defined below.

Motor Type Connector Kit # Pins

Single winding 1327AB Series 8510SA-CABC 16

Dual winding 1327AD Series 8510SA-CADC 10

Refer to the 8510 User Manual, publication 8510-5.1 for detailed

information about the cable required and the connector pin assignments for

each of the motor types.

Assembling the Connector/Cable The following procedure outlines the steps needed to install the connector.

1. Verify that the connector kit includes the connector body and the

correct number of pins.

2. Remove the cable insulation and strip back the shields approximately

50 mm (2”). Strip about 4 mm (3/16”) of insulation from each wire.

3. If available, use AMP crimp tool type 90123-2 to crimp the pins to the

wires. If the correct crimp tool is not available, any similar sized hand

crimp tool or pliers can be used to make the basic mechanical

connection. Solder (using rosin core solder) the wire into the connector

pin to complete the electrical connection. This assembly is shown in

Figure 1.

4. Insert the wires with (attached pins) into the connector location

specified in the 8510 User Manual. The connector pin designations are

shown in the Figure 1.

Important: Use care when orienting and inserting pins into connector.

Once pins have “snapped” into place, removal can be difficult.

Page 2

Instructions

8510 Connector Kits

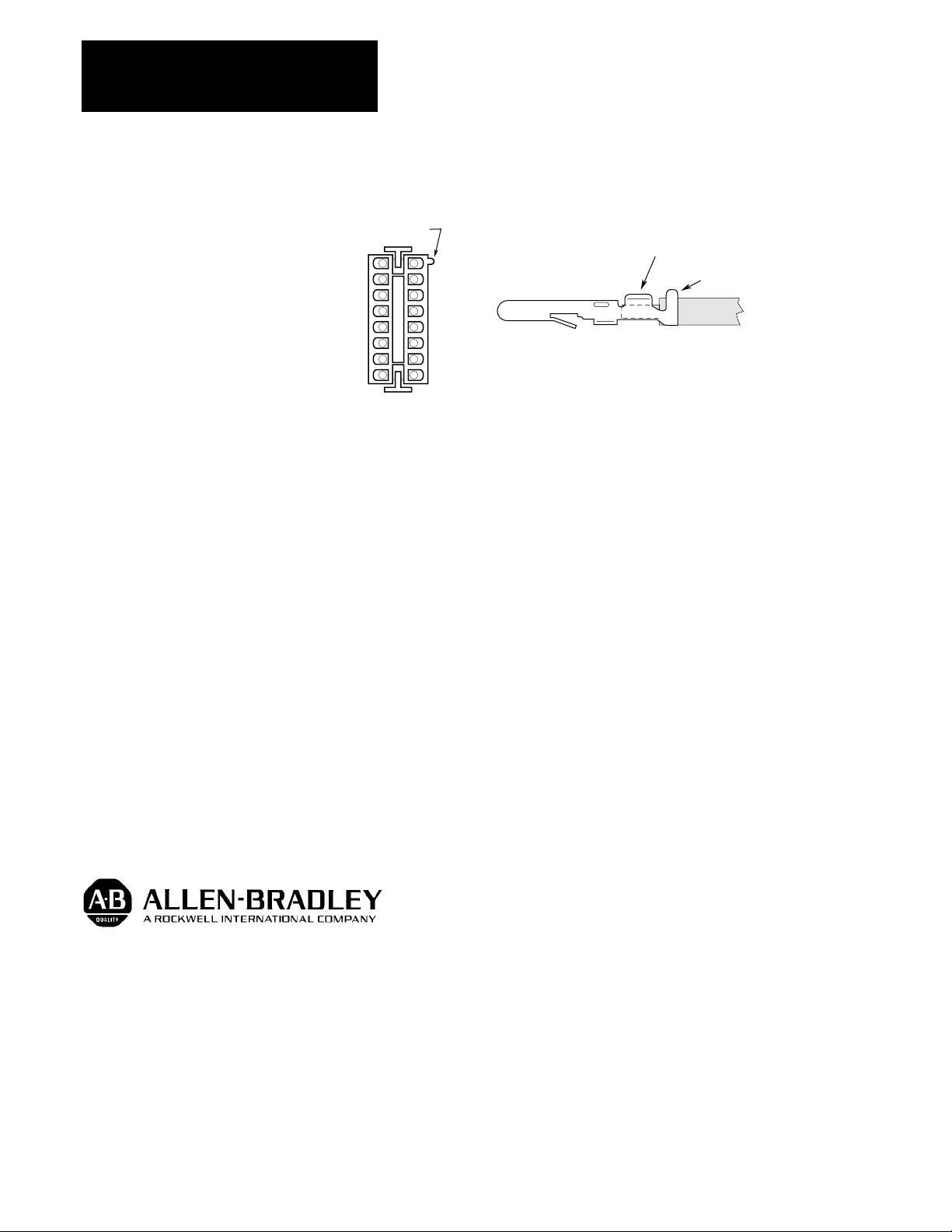

Figure 1

Connector Assembly

Pin 1

Indicator

Bend Tabs Over Stripped Wire and Solder

2

4

6

8

10

12

14

16

3

5

7

9

11

13

15

Bend Over Wire Insulation

5. When mating this connector to the motor, assure that the wires on both

connector halves are not pulling the pins to the side and out of

alignment. Check pin alignment if the connector is difficult to insert.

Allen-Bradley has been helping its customers improve productivity and quality for 90 years.

Allen-Bradley designs, manufactures and supports a broad range of control and automation

products worldwide. They include logic processors, power and motion control devices,

man-machine interfaces and sensors. Allen-Bradley is a subsidiary of Rockwell

With offices in major cities worldwide.

WORLD

HEADQUARTERS

Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204

USA

Tel: (1) 414 382-2000

Telex: 43 11 016

Fax: (1) 414 382-4444

Publication 8510-5.28 – April, 1993 P/N 152822

EUROPE/MIDDLE

EAST/

AFRICA

HEADQUARTERS

Allen-Bradley Europe

B.V.

Amsterdamseweg 15

1422 AC Uithoorn

The Netherlands

Tel: (31) 2975/43500

Telex: (844) 18042

Fax: (31) 2975/60222

International, one of the world’s leading technology companies.

ASIA/PACIFIC

HEADQUARTERS

Allen-Bradley (Hong Kong)

Limited

Room 1006, Block B, Sea View

Estate

2-8 Watson Road

Hong Kong

Tel: (852) 887-4788

Telex: (780) 64347

CANADA

HEADQUARTERS

Allen-Bradley Canada

Limited

135 Dundas Street

Cambridge, Ontario N1R

5X1

Canada

Tel: (1) 519 623-1810

Fax: (1) 519 623-8930

Fax: (852) 510-9436

Copyright 1993 Allen-Bradley Company, Inc. Printed in USA

LATIN AMERICA

HEADQUARTERS

Allen-Bradley

1201 South Second

Street

Milwaukee, WI 53204

USA

Tel: (1) 414 382-2000

Telex: 43 11 016

Fax: (1) 414 382-2400

Loading...

Loading...