Page 1

8510 AC Spindle

Drive System

Programming Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1

available from your local Allen-Bradley Sales Office or online at http://

www.ab.com/manuals/gi) describes some important differences between

solid stateequipmentand hard-wired electromechanical devices.Because of

this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to

use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important:Identifiesinformation that is especially important for successful

application and understanding of the product.

Shock Hazard labels may be located on or inside the drive to

alert people that dangerous voltage may be present.

SCANport is a trademark of Rockwell Automation.

PLC is a registered trademark of Rockwell Automation.

COLOR-KEYED is a registered trademark of Thomas & Betts Corporation.

IBM is a registered trademark of International Business Machines Corporation.

Windows 95 is a registered trademark of Microsoft Corporation.

Page 3

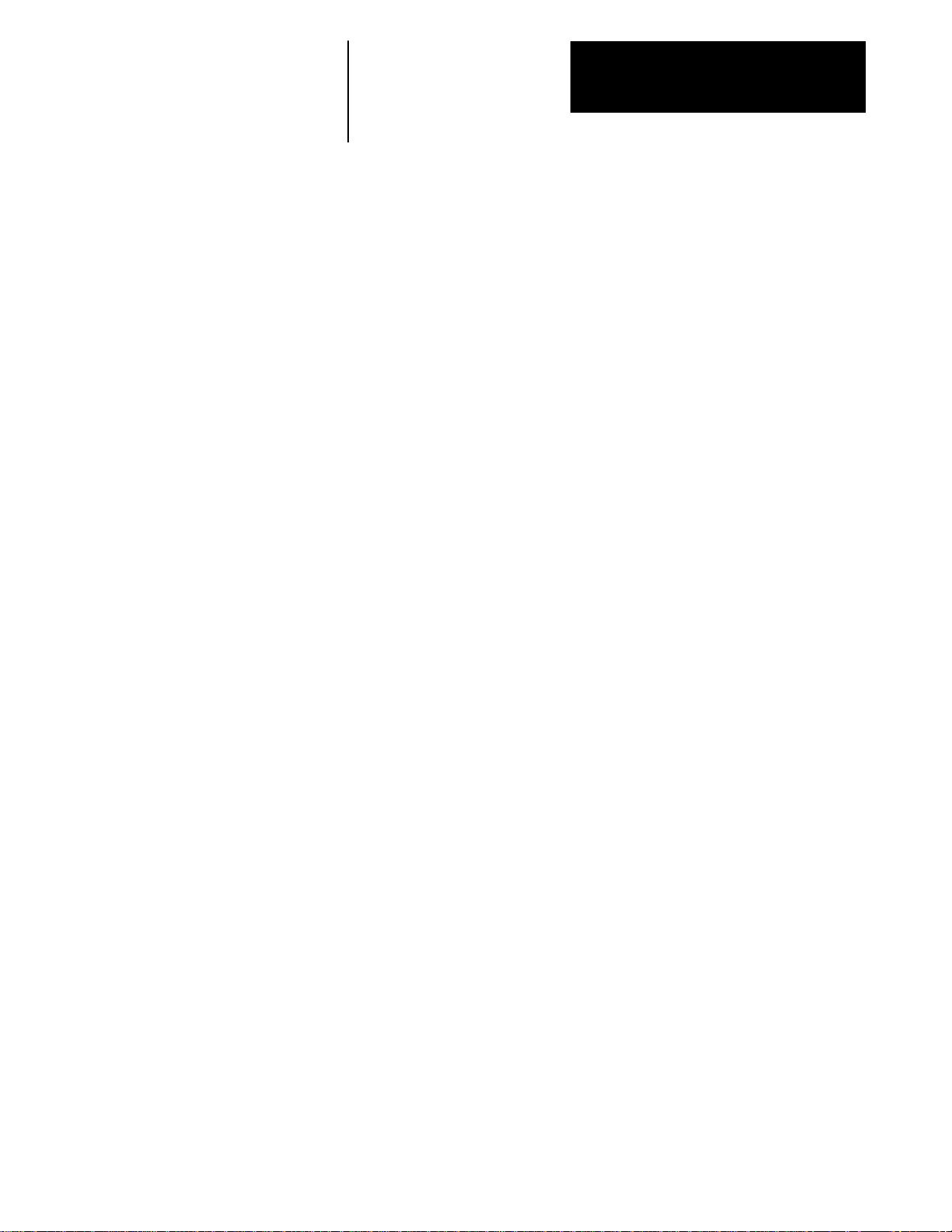

Introduction Chapter 1

Chapter Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Format and Conventions 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Capabilities 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Description 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Description and Operation 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing the DRIVE SETUP Menu 1-7. . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Key Combinations 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Programming 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Chapter 2

Chapter Objectives 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRIVE SETUP Menu 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR RANGES Menu 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOTOR SELECT Menu 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARAMETER SET Menu 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRIVE TUNING Menu 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORIENT SETUP Menu 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANALOG OUTPUT Menu 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

8510 Programming Manual

Drive Tuning Chapter 3

Chapter Objectives 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning Introduction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning Requirements 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spindle/Servo Mode Tuning 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

“Per Unit” System Description 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spindle Orient Mode Tuning 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Record Appendix A

i

Page 4

Chapter

1

Introduction

Chapter Objectives This chapter explains the programming/setup system of the 8510. Included

is an explanation of the display, control features and general programming

to help you use and understand the 8510 programming system.

Introduction In addition to the standard metering and diagnostic functions explained in

the 8510 User Manual, the keypad and display are also used for programming all of the drive setup parameters through the DRIVE SETUP menu.

Menu Format and Conventions The menu system is based on the 16 character by 2 line display used in the

8510. The menu is arranged in a tree format to allow easy access to any

item. Menu items will be shown on the display two different ways:

1) UPPER CASE letters (capitals) indicate the item is a menu heading

with a group of sub-menus or parameter names below it.

2) Initial Capital letters indicate the item is the name of a parameter.

To help differentiate input/output names, programmable parameters and

programmable values printed in this manual, the following conventions

will be used.

Input and Output Names will appear in Initial Capital Letters

Programming Display Text will appear in italics

Menu Names will appear with ALL CAPITALS

Parameter Names will appear with Initial Capital Letters

Programmable Parameter Values will appear in “quotes”

Programming Capabilities The DRIVE SETUP menu is used to define the electrical configuration and

tune the dynamic performance of the 8510. The drive can be programmed

to provide optimum machine response for a variety of mechanical system

configurations and application requirements. The following paragraphs

explain some of the capabilities.

1. When used with a multi-speed spindle gearbox, a unique set of all

programmable parameter values can be set for each gear range. Up to

four gear ranges can be used. During drive operation, two discrete

inputs are used to select the appropriate gear range parameter set.

Tip: In applications that do not use gear boxes, the gear range data sets

can be used to optimize drive performance under widely varying load

conditions, to change the drive configuration for different operations, or

to increase the number of parameter setpoints that are available.

1-1

Page 5

Chapter 1

Introduction

2. When two speed, wide constant power range motors (1327AD series)

are used, unique parameter sets are used for the low speed and high

speed windings. The two speed motors can be combined with up to a

three speed gearbox for a total of six unique sets of programmable

parameters. During drive operation, a single discrete input will select

the appropriate motor speed range and speed range parameter set.

3. Within each gear range/motor winding data set, discrete inputs can

select one of three primary operating modes; spindle, servo or torque.

For each of these modes there are independent sets of parameter data

values to control the velocity command source and scaling along with

the system dynamics. Also, within servo mode, two different velocity

scaling ranges can be selected.

Gear Range Data Sets

A Gear Range Data Set is a grouping of parameters that define a gear

range/motor winding configuration. A typical gear range data set consists

of the following:

Data Set for Standard Motor or Low Speed Winding on a Dual Winding Motor

- Overall System Configuration

- Standard Motor or Low Speed Motor Winding Parameter Set

- Spindle Mode Configuration and Tuning

- Servo Mode Configuration and Speed Range Select

High Range Tuning

Low Range Tuning

- Torque Mode Configuration and Tuning

- Spindle Orient Configuration and Tuning

Data Set for High Speed Winding on a Dual Winding Motor

- Overall System Configuration

- High Speed Motor Winding Parameter Set

- Spindle Mode Configuration and Tuning

- Servo Mode Configuration and Speed Range Select

High Range Tuning

Low Range Tuning

- Torque Mode Configuration and Tuning

- Spindle Orient Configuration and Tuning

Tip: To simplify initial drive setup, a Copy Data command is available

(GEAR RANGES menu). After programming a complete gear range/motor

winding data set, this command can copy the data set to any other gear

range/motor winding data set. The programmer then makes changes as

required to the copied data set.

1-2

Refer to GEAR RANGES Menu in Chapter 2 for further information.

Page 6

Chapter 1

Introduction

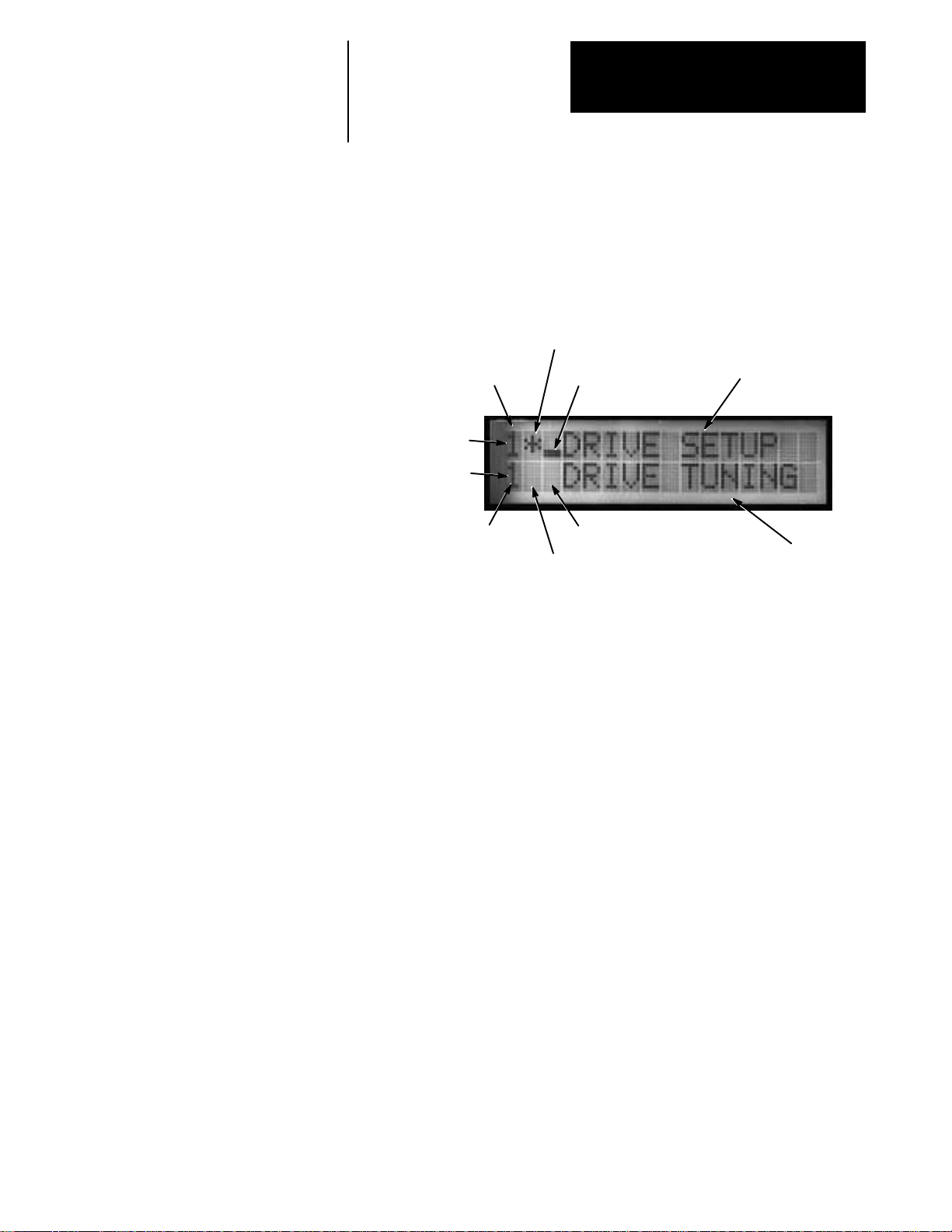

Display Description The 8510 display which is used for programming, as well as status and

diagnostic messages consists of a 16 character, 2 line, LCD (Liquid

Crystal) display. The display is divided into several different sections as

shown in Figure 1.1.

Figure 1.1

LCD Display

Motor Winding

Selected by Digital

Gear Range

Selected by Digital

Inputs

Line 1, Character 1

Line 2, Character 1

Inputs

Menu Level

Indicator

Menu Information

Gear Range

Selected for

Programming

(when applicable)

Menu Level

Indicator (when

applicable)

Motor Winding

Selected for Program-

ming

(when applicable)

Menu Information

Line 1, characters 1 & 2 – are used to display the gear range and motor

winding data set that is currently selected by the digital inputs and is being

used for drive operation. Character 1 will show the selected gear range

(1-4) and if a 2 speed motor is used, character 2 will show the motor

winding (H = high speed winding, L = low speed winding).

Line 1, character 3 – is a variable length bar (moving from the bottom up)

that represents the current depth (level) in the menu system.

Line 1, characters 4-16 – are used to display the name of the current menu

level or selected parameter. The menu options or parameter value

associated with the item displayed on line 1 will be displayed on line 2.

Line 2, characters 1 & 2 – are used to display the gear range and motor

winding data set that is currently selected for programming. Character 1

will show the selected gear range (1-4) and with 2 speed motors, character

2 will show the motor winding (L or H).

Line 2, character 3 – a variable length bar (moving from the bottom up)

that represents the current depth (level) in the menu system that has been

selected. For each level the user moves down, another bar is added to the

display.

Line 2, characters 4-16 – used to display the options that are available at

the current menu level or the value of the parameter that has been selected.

1-3

Page 7

Chapter 1

Introduction

Keypad Description and Operation When programming in the DRIVE SETUP menu, the 8510 keypad will

have expanded functions not found in the DISPLAY TYPE menu.

Figure 1.2

8510 Keypad and Display

Display

Keypad

Pressing this key will cause the display to change to the

previous menu level within the DRIVE SETUP menu section.

If the top item of the menu (see Figure 2.2) is shown, the

Mode key will have no effect. If a parameter name and value

are displayed, pressing this key will cause the system to exit

that parameter without saving the displayed value. This key

effectively aborts a selection.

Pressing this key once will cause the parameter or sub-menu

names shown on line 2 of the display to increment to the

next possible choice for the menu listed on line 1. If this key

is pressed and held, the display will continuously index

through the possible selections until the key is released.

When scrolling through a list of sub-menu or parameter

names and the end of the menu list is reached, it will roll

over to the beginning and continue to increment. When

scrolling through parameter value selections, the

incrementing will stop at the end of the list and will not roll

over.

If line 2 is displaying the numerical value of a parameter, a

cursor will be displayed under the least significant digit.

When the Scroll + key is pressed, the value of this digit will

be increased. Pressing and holding this key will cause the

value to increment continuously until the maximum limit for

this parameter value is reached. The scrolling stops at the

maximum limit. The value will not roll over.

1-4

continued

Page 8

Chapter 1

Introduction

Scroll +

(continued)

To simplify programming large values, the cursor can be

moved one digit to the left by simultaneously pressing the

Scroll + and Scroll – keys. Pressing and holding both keys

will cause the cursor to continue indexing to the left. After

reaching the most significant digit position, it will roll over

to the least significant digit position.

Tip: The quickest method to program large values is to scroll

the first digit to the correct value, index the cursor one digit

to the left and scroll to set the value of the second digit, and

repeat the process for the other digits. Scrolling the value of

a specific digit will only change the value of digits at or to

the left of the cursor.

The function of this key is identical to the Scroll+ key except

that it causes the display to decrement rather than increment.

If a menu name is shown on line 1, pressing this key will

cause the sub-menu or parameter shown on line 2 of the

display to become the active menu or parameter. This

sub-menu or parameter name will move to line 1 and the new

menu choices or parameter value will be shown on line 2.

If a parameter name is shown on line 1 and the parameter

value is on line 2, pressing Select will cause the displayed

parameter value to be stored in RAM. This value is also used

as the current operating parameter value. After the parameter

value has been stored in RAM, the display will return to the

previous menu display with the parameter name on line 2 of

the display.

If the Mode key is used to return the display to the previous

menu display, any parameter value changes will not be stored

in RAM.

Important: All parameter value changes are initially stored

in RAM. To save the data to EEPROM it is necessary to exit

the DRIVE SETUP menu and return to the DISPLAY TYPE

menu. Upon exiting DRIVE SETUP, all parameter changes

are automatically stored into EEPROM. If power is removed

from the drive or the drive is reset before the changes have

been stored in EEPROM, these changes will be lost. When

data is being written to the EEPROM, the “←” symbol will

momentarily show as character 3 on line 2 of the display.

continued

1-5

Page 9

Chapter 1

Introduction

Select

(continued)

Any time a parameter name is selected, the parameter value

that is initially shown on line 2 is the value that is currently

stored in RAM as the operating parameter value.

To speed system setup, it is possible to change the value of

any parameter while the drive is operating. When a parameter value is changed and the Select key is pushed, there is a

time delay of about 0.75-1.0 second before the value is used

in drive operation. Changes to the specified motor or drive

type or to the analog output definition will only become effective when the value changes are actually stored in EEPROM the next time the Enable input is energized.

Important: When trying to change parameters while the

drive is operating and then observe the resultant operation,

verify that the actual operating gear range and motor winding

selected by the drive inputs (and shown in characters 1 & 2

of line 1 of the display) matches the programming gear range

and motor winding shown by characters 1 & 2 of line 2. If

they do not match, any parameter changes will be made to a

different gear range data set, resulting in no effect on current

drive operation and possible erratic operation when the other

data set is used.

ATTENTION: Changing certain parameter values can result in

!

significantly different drive operation characteristics, such as

reversing direction of rotation or changing the motor speed for a

specific input command level. If parameters are changed while

the drive is operating, the user is responsible for assuring that

the changes in operating characteristics that result from these

changes will not result in unsafe machine operating conditions

1-6

Page 10

Chapter 1

Introduction

Accessing the DRIVE SETUP Menu To help guard against access to the drive setup programming parameters by

untrained personnel, a special key combination is required to access the

DRIVE SETUP menu. To access this menu, simultaneously press and hold

the Mode, Scroll + and Scroll – keys for about 3 seconds. The DRIVE

SETUP menu and a second bar at character 3 of line 1 will be displayed.

This menu allows access to all of the drive setup parameters that are

needed to integrate the motor and drive to the machine. The programmer

will be able to:

- Select and define gear ranges

- Select the motor

- Select the drive and set basic configuration parameters

- Dynamically tune the drive

- Setup spindle orient

- Configure the analog outputs

Exiting the DRIVE SETUP Menu

Upon completion of setup, pressing and holding the Mode and Scroll –

keys will return the display to the DISPLAY TYPE menu.

Important: Exiting DRIVE SETUP and returning to the DISPLAY TYPE

menu is the only

way to cause all parameter value changes to be written to

EEPROM for permanent storage.

Default Data

When the drive is shipped from the factory, default values are programmed

for most of the drive configuration data. The values that are chosen will

result in relatively low performance operation up to about half speed with

most types of systems.

Important: There are three parameters that have no default value assigned.

Two of these parameters must be programmed by the user before trying to

enable the drive or the drive will fault. These parameters are l) MOTOR

SELECT– Catalog Num and 2) PARAMETER SET – ELECT CONFIG –

Drive Cat Num. The third parameter, ORIENT SETUP – FEEDBACK

DEFN – Encoder Lines, must be programmed before attempting to use the

drive to perform spindle orient.

1-7

Page 11

Chapter 1

Introduction

Programming Key Combinations Several functions are implemented through the use of specific

combinations of multiple keys.

n Access to the DRIVE SETUP menu is accomplished by simultaneously

pressing and holding the Mode, Scroll +, and Scroll – keys for about 3

seconds.

n Pressing Mode and Scroll – simultaneously will cause the system to

change to the first display screen in the DRIVE SETUP menu. Pressing

these keys again will exit the DRIVE SETUP menu and return the

display to the DISPLAY TYPE menu.

Important: Exiting DRIVE SETUP and returning to the DISPLAY TYPE

menu is the only

way to cause all parameter value changes to be written

to EEPROM for permanent storage.

n When programming numerical values for a programmable parameter, the

cursor can be indexed one digit to the left by simultaneously pressing

Scroll + and Scroll –.

Remote Programming Program Upload/Download

Initially, during normal drive integration, the drive is programmed using

the integral keypad and display and all programmed data is stored in the

EEPROM on the I/O Board. The I/O board contains an RS-232 port that

allows offline software to access this EEPROM data.

A file transfer utility, Catalog Number 8510SA-SFTU, that runs on a DOS

based, IBM

compatible personal computer, will allow the contents of the

EEPROM to be uploaded through the RS-232 port and stored in a file in

the computer. This same utility can download this data file to the EEPROM

of another drive to duplicate the original drive setup. This allows rapid

setup of machines that are in series production by simply downloading the

drive setup from a master file. Also, a user can maintain files for each drive

in the facility and quickly duplicate the original drive setup in case the

setup is accidentally changed.

Offline Programming

A spindle drive configuration software package, Catalog Number

8510SA-SSDC, allows complete offline configuration programming of the

8510 drive. This software runs as part of the Allen-Bradley Offline

Development System (ODS) software that is used to configure the 9/Series

CNC and IMC motion controller hardware. It also requires a DOS based,

IBM compatible personal computer. Rather than using the integral keypad

and display on the drive, a full screen display and complete keyboard can

be used to enter all drive configuration data. The data file is then

downloaded via the RS-232 port into the 8510 drive. To make the final

adjustment of the analog input calibration and the drive gains, it may be

necessary to use the integral drive programming keypad.

1-8

Page 12

Chapter

2

Programming

Chapter Objectives Chapter 2 provides a detailed look at the programming associated with the

DRIVE SETUP menu found in the 8510. Included are complete

descriptions of the various parameters that can be programmed during

drive setup.

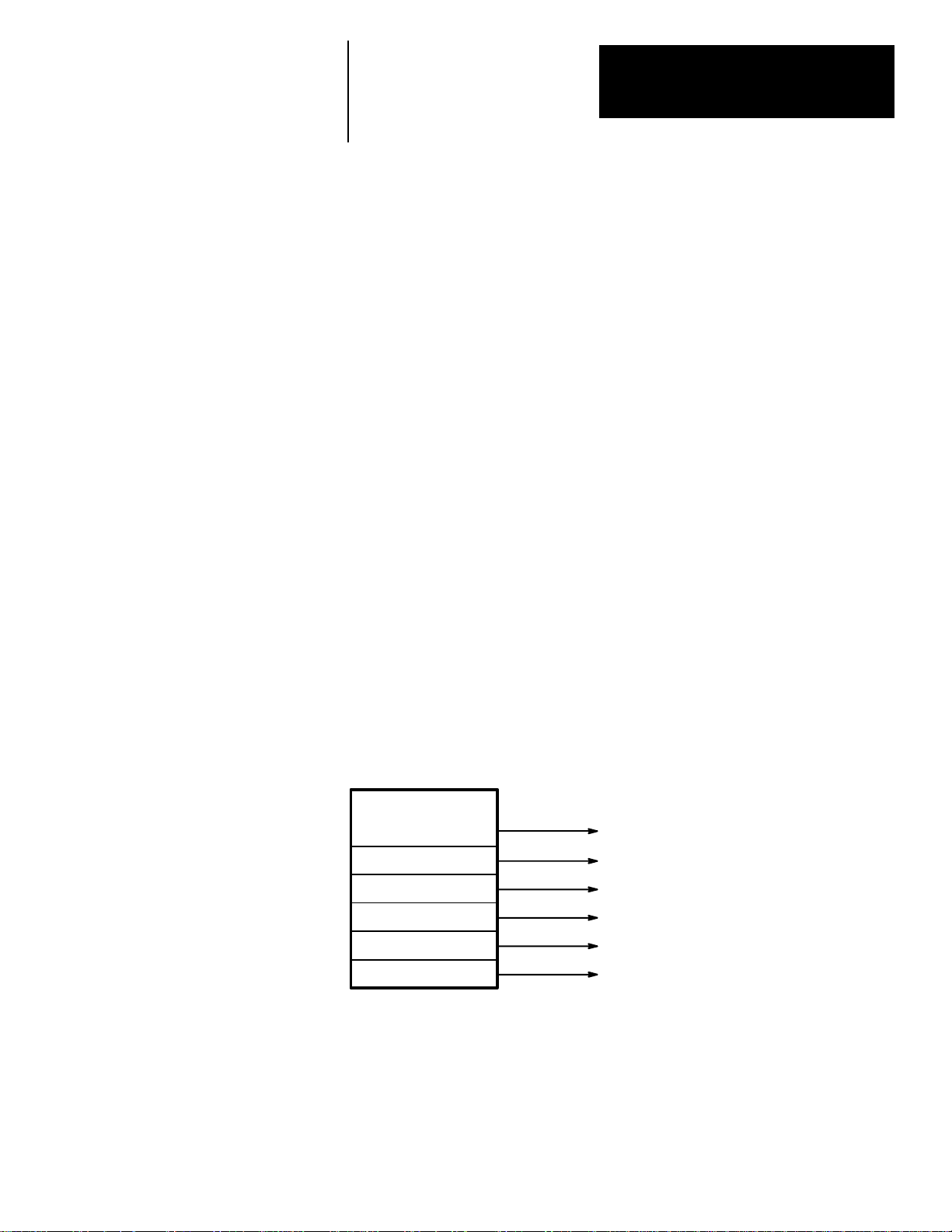

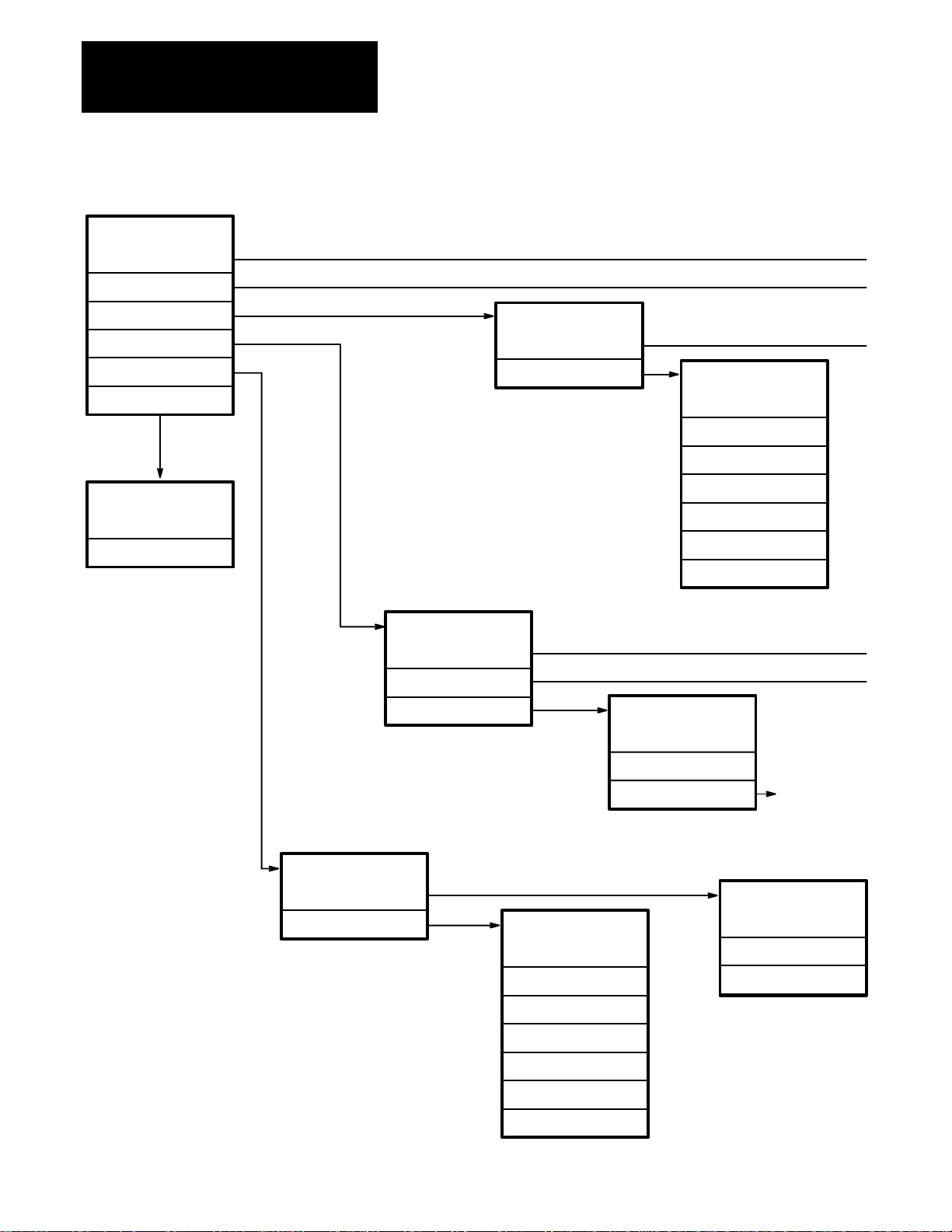

DRIVE SETUP Menu The DRIVE SETUP menu (see Figure 2.1) is the top level of the setup

parameters. The menu is accessed by simultaneously pressing and holding

the Mode, Scroll +, and Scroll – keys for about 3 seconds.

An overall view of the complete DRIVE SETUP menu is shown in

Figure 2.2.

The remaining sections in this chapter provide detailed parameter

descriptions used when programming. After most descriptions, a data

format will be provided. This indicates the entry format expected by the

programming system or the scroll choices that are available. Refer the page

numbers provided in Figure 2.1 to help locate specific programming

information.

Figure 2.1

Drive Setup Menu Tree

DRIVE SETUP

GEAR RANGES

MOTOR SELECT

PARAMETER SET

DRIVE TUNING

ORIENT SETUP

ANALOG OUTPUT

See Page 2-12

See Page 2-14

See Page 2-14

See Page 2-18

See Page 2-29

See Page 2-32

2-9

Page 13

Chapter 2

Programming

DRIVE SETUP

GEAR RANGES

MOTOR SELECT

Figure 2.2

DRIVE SETUP Menu Tree

PARAMETER SET

DRIVE TUNING

ORIENT SETUP

ANALOG OUTPUT

ANALOG OUTPUT

Output #1

Output #2

DRIVE TUNING

SPINDLE MODE

SERVO MODE

TORQUE MODE

PARAMETER SET

ELECT CONFIG

SPINDL PRESET

SPINDL PRESET

Overspd Trip

Acc Rate #1

Acc Rate #2

Low Torq Lmt

At–Set–Speed

Speed Detect

Load Detect

TORQUE MODE

Torque Enable

2-10

ORIENT SETUP

FEEDBACK DEFN

ORIENT TUNE

ORIENT TUNE

Position Data

Preset Angle

Orient Speed

Orient Start

In-Position

Dir From Stop

Hold Position

Max Speed

ANALOG CAL

A

FEEDBACK DEFN

Encoder Type

Encoder Lines

Encdr Phasing

Page 14

Chapter 2

Programming

GEAR RANGES

ELECT CONFIG

Drive Cat Num

Motor Phasing

Cmnd Phase #1

Cmnd Phase #2

Enable Torque

SERVO MODE

Analog In #

A/D Conv Type

MOTOR SELECT

Catalog Num

Select Range

SET RATIOS

Copy Data

Default Data

SET RATIOS

Spindle Revs

Motor Revs

SPINDLE MODE

Cmnd Source

ANALOG CAL

Max Cmnd Spd

A

ANALOG CAL

HI SPD RANGE

LO SPD RANGE

A

ANALOG CAL

MEASURE INPUT

PROGRAM VALUE

A

LO SPD RANGE

Max Cmnd Spd

Servo P Gain

Servo I Gain

Droop In Run

Speed Cal

HI SPD RANGE

Max Cmnd Spd

Servo P Gain

Servo I Gain

Droop In Run

Droop In Hold

Speed Cal

PROGRAM VALUE

Zero Volt In

Max +Volt In

Spindl P Gain

Spindl I Gain

Speed Cal

MEASURE INPUT

Zero Volt In

Max +Volt In

2-11

Page 15

Chapter 2

Programming

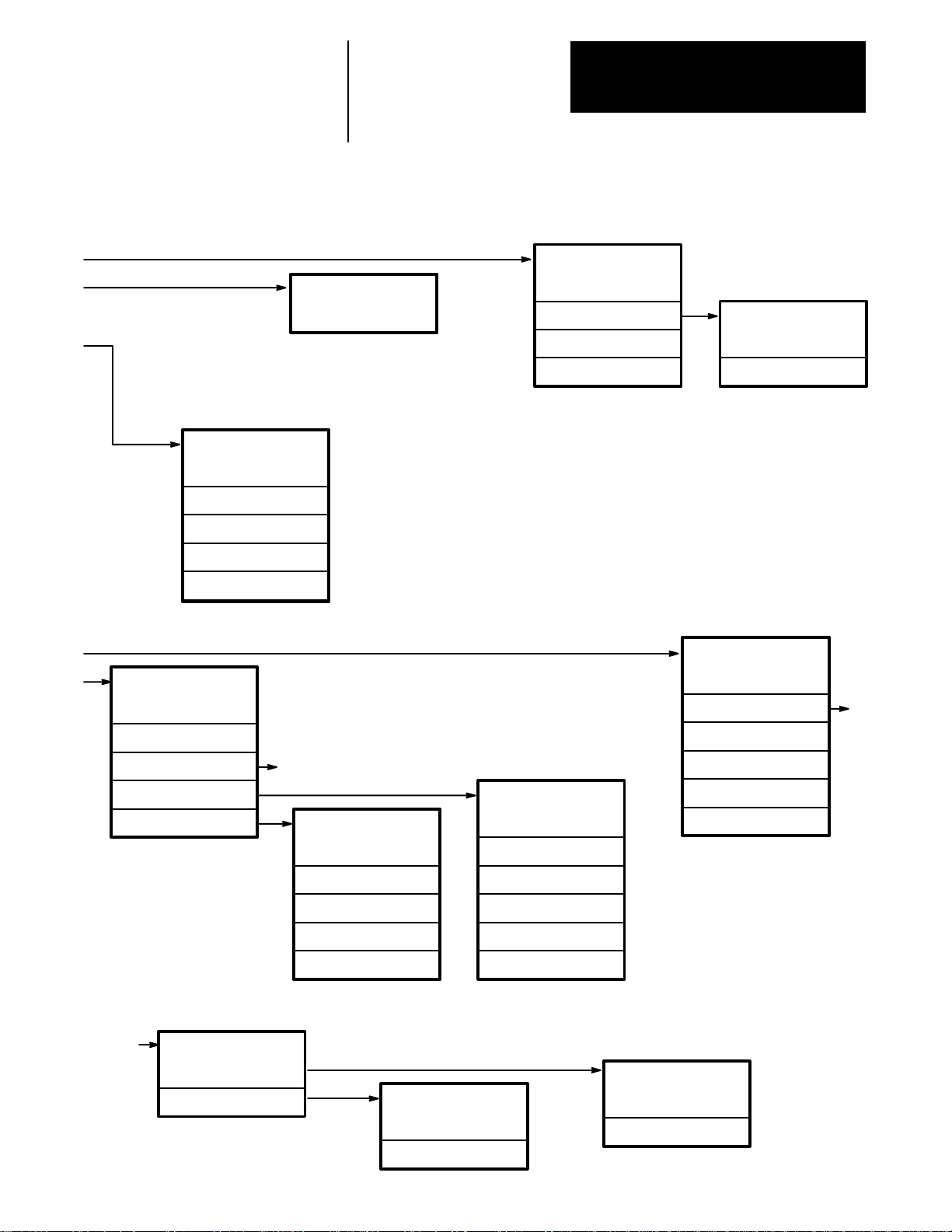

GEAR RANGES Menu This menu allows the gear ranges to be defined and selected for

programming. Refer to Figure 2.3 for an example of the GEAR RANGES

menu and the paragraphs that follow for parameter explanations.

Figure 2.3

GEAR RANGES Menu Tree

GEAR RANGES

Select Range

SET RATIOS

Copy Data

Default Data

SET RATIOS

Spindle Revs

Motor Revs

The two Gear Range Active inputs define which gear range data set is

currently being used for motor control. However, these inputs do not select

the gear range data set that can currently be programmed. The GEAR

RANGES menu is used to select the gear range data set to program.

• The first character of the first line of the display shows the gear range

data set that is selected as the operating

data set.

• The first character of the second line of the display shows the gear range

data set that has been selected for programming

.

Select Range

This parameter allows selection of the gear range data set that is to be

programmed. The programming gear range has two parts - the physical

gear range and the motor winding. If dual winding motors are used, the

parameters must be programmed for both the low and high speed windings

in each gear range.

2-12

The physical gear range is shown in character 1, line 2 of the display, with

the motor winding (dual winding motors only) shown in character 2. Dual

winding motors use an L or an H to designate the Low and High speed

windings. The second position will be blank if a motor is not selected or a

single speed motor is being used. A scroll sequence is used to select the

low speed and high speed motor windings for a particular gear range before

advancing to the next gear (i.e. 1L, 1H, 2L, 2H, etc.). With dual winding

motors, only three physical gear ranges can be used since only 6 data sets

are stored.

Possible Choices: 1, 2, 3, 4, 1L, 1H, 2L, 2H, 3L, 3H

Default Value 1

Page 16

Chapter 2

Programming

SET RATIOS

This item defines the gear range ratio.

Spindle Revs

This parameter defines half of the gear ratio. The gear ratio must be

expressed as a ratio of two whole numbers and is stated as the number of

spindle revolutions for a certain number of motor revolutions. Enter the

number of spindle revolutions here.

Data Range: 00000 to 30000

Default Value: 00001

Motor Revs

The Motor Revs parameter programs the other half of the gear ratio. This

parameter defines the number of motor revolutions required for the

number of spindle revolutions specified above. For Example: a 4.3333:1

speed reduction would be specified as Spindle Revs = 3 and Motor Revs =

13.

Data Range: 00000 to 30000

Default Value: 00001

Copy Data

This parameter allows data from a previously programmed gear range to be

copied to the gear range that is currently selected for programming. When

selected, the bottom line can be scrolled through the gear ranges starting at

“RANGE: 1.”

Possible Choices: NO COPY, RANGE: 1, RANGE: 2, . . ., RANGE: 3H

Default Value: NO COPY

Default Data

Default Data will cause all data stored in the gear range currently selected

for programming to be reset to the factory default values. This parameter is

used to confirm that reset is desired.

Possible Choices: NO, YES

Default Value: NO

2-13

Page 17

Chapter 2

Programming

MOTOR SELECT Menu This menu (Figure 2.4) selects the motor that will be used with this drive.

Figure 2.4

MOTOR SELECT Menu Tree

MOTOR SELECT

Catalog Num

Catalog Num

This parameter lists the available spindle motors. Simply select the catalog

number of the motor being used. If a motor was previously selected, that

number will be displayed. If a motor was not previously selected, the

display will show “NONE SELECTED.”

Important: The default parameters do not include the motor type. This

parameter must be programmed before attempting to enable the drive or a

fault will occur.

Data Format: 1327AB-AFL-15

Default Value: NONE SELECTED

PARAMETER SET Menu The PARAMETER SET menu allows the selection and programming of

basic drive configuration parameters and preset parameters.

Figure 2.5

PARAMETER SET Menu Tree

PARAMETER SET

ELECT CONFIG

SPINDL PRESET

SPINDL PRESET

Overspd Trip

Acc Rate #1

Acc Rate #2

Low Torq Lmt

At–Set–Speed

Speed Detect

Load Detect

ELECT CONFIG

Drive Cat Num

Motor Phasing

Cmnd Phase #1

Cmnd Phase #2

Enable Torque

2-14

Page 18

Chapter 2

Programming

ELECT CONFIG

This menu allows the user to select electrical configuration parameters for

programming.

Drive Cat Num

This parameter lists the available drive catalog numbers for selection.

Simply select the catalog number of the drive being used. If a catalog

number had previously been entered, it will be displayed. If a catalog

number was not previously selected, the display will show “NONE

SELECTED.”

Important: The default parameters do not include the drive type. This

parameter must be programmed before attempting to enable the drive or a

fault will occur.

Possible Choices: NONE SELECTED, 8510A-A04, 8510A-A06, 8510A-A11,

8510A-A22

Data Format: 8510A-A04

Default Value: NONE SELECTED

Motor Phasing

This parameter allows the electrical phase sequence of the motor control

loops to be reversed without physically changing the wiring to the motor.

If incorrectly set, the motor may run slowly or oscillate between forward

and reverse rotation.

Possible Choices: FORWARD, REVERSE

Default Value: FORWARD

Cmnd Phase #1

Cmnd Phase #1 allows the polarity of Analog Input #1 to be reversed

inside the drive without reversing the actual wiring.

Possible Choices: FORWARD, REVERSE

Default Value: FORWARD

Cmnd Phase #2

Cmnd Phase #2 allows the polarity of Analog Input #2 to be reversed

inside the drive without reversing the actual wiring.

Possible Choices: FORWARD, REVERSE

Default Value: FORWARD

Enable Torque

Determines whether or not the drive will produce motor holding torque

when the Drive Enable command is On, but the Forward and Reverse

Run commands are both Off or On. The “With Run” selection means that

one of the Run commands must be present before the motor will produce

torque.

Possible Choices: WITH RUN, WITHOUT RUN

Default Value: WITH RUN

2-15

Page 19

Chapter 2

Programming

SPINDL PRESET

Selects the various Spindle Mode parameters and performance detectors.

Overspd Trip

Sets the overspeed trip point . The drive will shut down at this point and

cause the motor to coast to a stop. Set this parameter at least 10% higher

than expected maximum speed to avoid nuisance trips.

Data Range: RPM 00000 to 30000

Default Value: 08000

Acc Rate #1

Sets the acceleration rate ramp generator for the ramp rate that is used in

spindle mode when the Accel/Decel Rate Select input is turned Off. The

rate is defined in seconds/1000 rpm of speed change. This accel/decel

rate is achieved only if the required torque does not exceed the torque

limit level.

Data Range: S/KRPM 000.00 to 009.99

Default Value: 001.00

Acc Rate #2

Sets the acceleration rate ramp generator for the ramp rate that is used in

spindle mode when the Accel/Decel Rate Select input is On. The rate is

defined in seconds/1000 rpm of speed change. This accel/decel rate is

achieved only if the required torque does not exceed the torque limit

level.

Data Range: S/KRPM 000.00 to 009.99

Default Value: 001.00

Low Torq Lmt

This parameter sets the level of torque limit used when the Low Torque

Limit Select input is On. The torque is defined as a percent of the

continuous rated torque of the specific motor/drive combination and

cannot exceed the peak torque capacity of the motor (1.2 x 30 minute

motor rating).

Data Range: % 000 to 250

Default Value: % 025

At-Set-Speed

This parameter determines how close the actual speed must be to the

commanded speed before the At Speed Indicator output is On. The data is

stated as a percent of the commanded speed. If the percent of commanded

speed gives a value less than 25 rpm, then a fixed ±25 rpm band is used

for the test.

Data Range: % 000 to 100

Default Value: % 010

2-16

Page 20

Chapter 2

Programming

Speed Detect

The Speed Detect parameter determines the speed at which the Speed

Level Indicator output changes state. If the motor speed is above this

programmed level, the output is Off.

Data Range: RPM 00000 to 30000

Default Value: 00300

Load Detect

The Load Detect parameter determines the commanded torque level at

which the Load Level Indicator output changes state. If the torque

command exceeds this programmed level, the output is On. The data

defines the torque as a percent of the continuous rated torque of the

specific motor/drive combination and cannot exceed the peak torque

capacity of the motor (1.2 x 30 minute motor rating).

Data Range: % 000 to 250

Default Value: % 125

2-17

Page 21

Chapter 2

Programming

DRIVE TUNING Menu This menu allows selection of the drive setup and tuning procedure for

each of the different operating modes. Refer to Figure 2.6.

Figure 2.6

DRIVE TUNING Menu Tree

DRIVE TUNING

SPINDLE MODE

SERVO MODE

TORQUE MODE

TORQUE MODE

Torque Enable

Max Speed

ANALOG CAL

SERVO MODE

Analog In #

A/D Conv Type

ANALOG CAL

A

HI SPD RANGE

LO SPD RANGE

LO SPD RANGE

Max Cmnd Spd

Servo P Gain

Servo I Gain

Droop In Run

Speed Cal

SPINDLE MODE

Cmnd Source

ANALOG CAL

Max Cmnd Spd

A

Spindl P Gain

Spindl I Gain

Speed Cal

HI SPD RANGE

Max Cmnd Spd

Servo P Gain

Servo I Gain

Droop In Run

Droop In Hold

Speed Cal

A

2-18

ANALOG CAL

A

MEASURE INPUT

PROGRAM VALUE

PROGRAM VALUE

Zero Volt In

Max +Volt In

MEASURE INPUT

Zero Volt In

Max +Volt In

Page 22

Chapter 2

Programming

SPINDLE MODE

This menu selects the various setup and tuning procedures needed to set the

operating parameters that are used when the Spindle/Servo Mode Select

input is Off.

Cmnd Source

This parameter is used to specify the source of the speed command. The

command can be from Analog Input #1 or from the optional 16 Bit

Digital Speed Command/Orient Position inputs on connector CN10. If

the digital inputs are used, the data can be in binary or BCD format. In

binary mode, maximum speed equals 2

16

– 1 or 65,535 counts. 1 LSB =

Max Cmnd Spd / 65535. In BCD mode, maximum speed equals 9,999

counts. In this mode, 1 LSB = Max Cmnd Spd / 9999. The digital inputs

can be used for either orient position command or spindle speed

command, but not both.

Possible Choices: ANALOG, 4 DIGIT BCD, 16 BIT BINARY

Default Value ANALOG

ANALOG CAL

This menu allows selection of two alternative methods to calibrate the

analog input channel. This sequence is not required if digital speed

commands are being used.

MEASURE INPUT

Allows selection of the steps required to calibrate the analog input by

actually measuring the value of the applied signal voltages. This is the

preferred method for calibrating the analog input.

Zero Volt In

This parameter requires the user to input the command voltage that is

equal to the zero speed command. When the Select key is pressed, the

control will read the input voltage on Analog Input #1 and use that as

the zero speed reference value. The display will function as a

voltmeter to show the voltage being read on the analog input.

Data Range: VOLT 00.000 to ±09.999

Default Value 0.000

Max +Volt In

This parameter requires the user to input the positive command

voltage that is equal to the maximum speed command. When the

Select key is pressed, the control will read the input voltage on Analog

Input #1 and use that as the maximum speed command reference

value. The display will function as a voltmeter to show the voltage

being read on the analog input.

Data Range: VOLT 00.000 to 10.000

Default Value 10.000

2-19

Page 23

Chapter 2

Programming

PROGRAM VALUE

This menu allows selection of the steps required to calibrate the analog

input by presetting the display as a normal scrolled variable. Use this

calibration method if the actual command voltages are not available.

Zero Volt In

This parameter requires the user to program the value of the command

voltage that is equal to the zero speed command.

Data Range: VOLT 0.000 to ±9.999

Default Value 0.000

Max +Volt In

This parameter requires the user to program the value of the command

voltage that is equal to the maximum speed command.

Data Range: VOLT 00.000 to 10.000

Default Value 10.000

Max Cmnd Spd

Defines the maximum motor speed that is to correspond to the maximum

input command. The maximum motor speed can be programmed to any

level required by the application (but less than the maximum allowable

for the motor/drive combination) and achieve full scale speed command

resolution at that speed.

Data Range: RPM 00000 to 30000

Default Value 03000

The tuning parameters in the 8510 drive are based on the “per unit” system.

For this drive the base quantities are defined as follows:

1 p.u. Torque = Peak Motor Torque

1 p.u. Velocity or Velocity Error = Motor Base Speed

1 p.u. Inertia = Time to accelerate to 1 p.u. Velocity with 1 p.u. Torque

Refer to Chapter 3 for a detailed description of drive tuning and the use of

the “per unit” system in determining optimum drive tuning parameters.

Spindl P Gain

The velocity loop proportional gain used in the spindle mode is set with

this parameter. This data is programmed in Per Unit Torque / Per Unit

Velocity Error or % Torque / % Velocity Error.

Data Range: 000.0 to 200.0

Default Value 005.0

2-20

Page 24

Chapter 2

Programming

Spindl I Gain

The velocity loop integral gain used in the spindle mode is set with this

parameter. This data is programmed in Per Unit Torque / Per Unit

Velocity Error/second or % Torque / % Velocity Error / second. The units

for this parameter are 1/seconds.

Data Range: 1/S 00.00 to 50.00

Default Value 00.20

Speed Cal

This parameter allows exact matching of the speed command to the actual

motor speed. When an analog input equal to the maximum spindle speed

command is supplied from the CNC, the Scroll keys can be used to adjust

the motor speed until the displayed actual speed matches the commanded

speed. Press the Select key to store the setting.

This could be considered a fine tuning of the Max Cmnd Spd parameter.

As the appropriate Scroll key is pressed, a multiplier factor for the Max

Cmnd Spd parameter is incremented in 0.04% steps. There is a time delay

of approximately one second after the multiplier is changed until it can be

observed in the system operation. During this operation, the display is

operating as a digital speed meter showing current motor speed.

Reprogramming the Max Cmnd Spd parameter will reset this multiplier to

zero.

Data Range: RPM 00000 to 30000

Default Value 0.00%

SERVO MODE

This menu selects the various setup and tuning procedures needed to set the

operating parameters that are used when the Spindle/Servo Mode Select

input is On.

Analog In #

Analog In # determines which analog input is going to be used for the

velocity command in servo mode. If the drive is to operate in torque

mode, Analog Input #1 must be used for the velocity command.

Possible Choices: INPUT #2, INPUT #1

Default Value INPUT #2

2-21

Page 25

Chapter 2

Programming

A/D Conv Type

This parameter determines which A/D converter will be used with the

servo mode analog input signal. The standard A/D converter is a 10 bit

converter with auto-ranging capabilities that gives an effective 14 to 17

bits resolution for positioning applications.

However, for large command changes, the autoranging function

introduces a time delay. The full input range of +10 volts to –10 volts is

broken into 32 equal steps of 0.625 volts. Within one increment, A/D

conversions are made in 0.8 ms. To shift the input level one increment

requires 0.8 ms. For a maximum input change from +10 volts to –10

volts, the maximum delay is 26.4 ms. The optional A/D converter is a full

14 bit, high speed converter providing an input sample every 0.8 ms. This

converter must be used for precision continuous path contouring

applications and very high response positioning applications.

Possible Choices: STANDARD, 14 BIT LINEAR

Default Value STANDARD

ANALOG CAL

This menu allows selection of two alternative methods to calibrate the

analog input channel.

MEASURE INPUT

Allows selection of the steps required to calibrate the analog input by

actually measuring the value of the applied signal voltages. This is the

preferred method for calibrating the analog input.

Zero Volt In

This parameter requires the user to input the command voltage that is

equal to the zero speed command. When the Select key is pressed, the

control will read the input voltage on the input selected by the Analog

Input # parameter and use that as the zero speed reference value. The

display will function as a voltmeter to show the voltage being read on

the analog input.

Data Range: VOLT 00.000 to ±09.999

Default Value 0.000

Max +Volt In

This parameter requires the user to input the positive command

voltage that is equal to the maximum speed command. When the

Select key is pressed, the control will read the input voltage on the

input selected by the Analog Input # parameter and use that as the

maximum speed command reference value. The display will function

as a voltmeter to show the voltage being read on the analog input.

Data Range: VOLT 00.000 to 10.000

Default Value 10.000

2-22

Page 26

Chapter 2

Programming

PROGRAM VALUE

This is a menu title that allows selection of the steps required to

calibrate the analog input by presetting the display as a normal scrolled

variable. Use this calibration method if the actual command voltages are

not available.

Zero Volt In

This parameter requires the user to program the value of the command

voltage that is equal to the zero speed command.

Data Range: VOLT 0.000 to ±9.999

Default Value 0.000

Max +Volt In

This parameter requires the user to program the value of the command

voltage that is equal to the maximum speed command.

Data Range: VOLT 00.000 to 10.000

Default Value 10.000

HI SPD RANGE

This menu selects the various setup and tuning parameters that are used

when the Spindle/Servo Mode Select input is On and the Servo Input

Scaling Low/High input is On. Also, the velocity loop tuning parameters

set for this mode will be used when the drive is performing the spindle

orient operation.

Max Cmnd Spd

Defines the maximum motor speed that will correspond to the

maximum input command. The maximum motor speed can be

programmed to any level required by the application (but less than the

maximum allowable speed for the motor/drive combination) and

achieve full scale speed command resolution at that speed. Typically

this parameter would be used for C axis rapid traverse, solid tapping

operation, or possibly precision spindle orient operations from the CNC

and would be set to a relatively low speed.

Data Range: RPM 00000 to 30000

Default Value 00084

The tuning parameters in the 8510 drive are based on the “per unit” system.

For this drive the base quantities are defined as follows:

1 p.u. Torque = Peak Motor Torque

1 p.u. Velocity or Velocity Error = Motor Base Speed

1 p.u. Inertia = Time to accelerate to 1 p.u. Velocity with 1 p.u. Torque

Refer to Chapter 3 for a detailed description of drive tuning and the use of

the “per unit” system in determining optimum drive tuning parameters.

2-23

Page 27

Chapter 2

Programming

Servo P Gain

The velocity loop proportional gain used in the servo mode is set with

this parameter. This data is programmed in Per Unit Torque / Per Unit

Velocity Error or % Torque / % Velocity Error.

Data Range: 000.0 to 200.0

Default Value 5.00

Servo I Gain

The velocity loop integral gain used in the servo mode is set with this

parameter. This data is programmed in Per Unit Torque / Per Unit

Velocity Error/second or % Torque / % Velocity Error / second. The

units for this parameter are 1/seconds.

Data Range: l/S 00.00 to 50.00

Default Value 00.20

Droop In Run

Droop In Run sets a maximum limit on the effective low frequency

velocity loop gain that the integrator can generate during normal

running mode operation. This parameter limits stick-slip motion during

very low speed C axis operation. The data is expressed in Per Unit

Velocity Error / Per Unit Torque or % Velocity Error / % Torque.

Data Range: 0.000 to 7.999

Default Value 0.001

Droop In Hold

Sets a maximum limit on the effective low frequency velocity loop gain

that the integrator can generate when the spindle is within the

in-position error band limit during spindle orient operation. This can

allow accurate positioning without excess stick-slip motion. The data is

expressed in Per Unit Velocity Error / Per Unit Torque or % Velocity

Error / % Torque.

Data Range: 0.000 to 7.999

Default Value 0.001

2-24

Page 28

Chapter 2

Programming

Speed Cal

The Speed Cal parameter allows exact matching of the speed command

to the actual motor speed in order to precisely set position loop gain.

When the velocity command from a closed position loop move

commanded by the CNC is input to the drive, the Scroll keys can be

used to adjust the motor speed until the exact following error value

required in the CNC is achieved. Press the Select key to store the

setting.

This could be considered a fine tuning of the Max Cmnd Spd parameter.

As the appropriate Scroll key is pressed, a multiplier factor for the Max

Cmnd Spd parameter is incremented in 0.04% steps. There is a time

delay of approximately one second after the multiplier is changed until

it can be observed in the system operation. During this operation, the

display is operating as a digital speed meter showing current motor

speed. Reprogramming the Max Cmnd Spd parameter will reset this

multiplier to zero.

Data Range: RPM 00000 to 30000

Default Value 0.00 %

LO SPD RANGE

This menu selects the various setup and tuning parameters that are used

when the Spindle/Servo Mode Select input is On and the Servo Input

Scaling Low/High input is Off.

Max Cmnd Spd

Defines the maximum motor speed that will correspond to the

maximum input command. The maximum motor speed can be

programmed to any level required by the application (but less than the

maximum allowable speed for the motor/drive combination) and

achieve full scale speed command resolution at that speed. Typically

this parameter would be used to obtain maximum resolution for C axis

contouring mode and would be set to a very low speed.

Data Range: RPM 00000 to 30000

Default Value 00030

The tuning parameters in the 8510 drive are based on the “per unit” system.

For this drive the base quantities are defined as follows:

1 p.u. Torque = Peak Motor Torque

1 p.u. Velocity or Velocity Error = Motor Base Speed

1 p.u. Inertia = Time to accelerate to 1 p.u. Velocity with 1 p.u. Torque

Refer to Chapter 3 for a detailed description of drive tuning and the use of

the “per unit” system in determining optimum drive tuning parameters.

2-25

Page 29

Chapter 2

Programming

Servo P Gain

The velocity loop proportional gain used in the servo mode is set with

this parameter. This data is programmed in Per Unit Torque / Per Unit

Velocity Error or % Torque / % Velocity Error.

Data Range: 000.0 to 200.0

Default Value 5.00

Servo I Gain

The velocity loop integral gain used in the servo mode is set with this

parameter. This data is programmed in Per Unit Torque / Per Unit

Velocity Error/second or % Torque / % Velocity Error / second. The

units for this parameter are 1/seconds.

Data Range: l/S 00.00 to 50.00

Default Value 00.20

Droop In Run

Droop In Run sets a maximum limit on the effective low frequency

velocity loop gain that the integrator can generate during normal

running mode operation. This parameter limits stick-slip motion during

very low speed C axis operation. The data is expressed in Per Unit

Velocity Error / Per Unit Torque or % Velocity Error / % Torque.

Data Range: 0.000 to 7.999

Default Value 0.001

Speed Cal

The Speed Cal parameter allows exact matching of the speed command

to the actual motor speed in order to precisely set position loop gain.

When the velocity command from a closed position loop move

commanded by the CNC is input to the drive, the Scroll keys can be

used to adjust the motor speed until the exact following error value

required in the CNC is achieved. Press the Select key to store the

setting.

This could be considered a fine tuning of the Max Cmnd Spd parameter.

As the appropriate Scroll key is pressed, a multiplier factor for the Max

Cmnd Spd parameter is incremented in 0.04% steps. There is a time

delay of approximately one second after the multiplier is changed until

it can be observed in the system operation. During this operation, the

display is operating as a digital speed meter showing current motor

speed. Reprogramming the Max Cmnd Spd parameter will reset this

multiplier to zero.

Data Range: RPM 00000 to 30000

Default Value 0.00 %

2-26

Page 30

Chapter 2

Programming

TORQUE MODE

This menu selects the steps needed to set up torque mode operation. When

operating in torque mode, the motor must be connected to a speed

controlled load or an external speed regulator must be used. Otherwise, the

motor will be accelerated at a constant commanded torque level until the

drive faults on overspeed.

Important: Torque Mode operation requires the use of the 14 bit A/D

converter that is part of I/O Board versions -Cx or -Dx. To make Torque

Mode work, it is necessary to set the SERVO MODE – A/D Conv Type

parameter to “14 BIT LINEAR.”

Torque Enable

This parameter is used to enable or disable torque mode operation. When

torque mode is enabled, the drive can operate in torque mode whenever

the proper input command is given to activate it. When torque mode is

programmed to the enabled condition, the internal low accel/decel ramp

control will be disabled and the Accel/Decel Rate Select input will be

assigned a new function. Torque mode will now be activated when the

Accel/Decel Rate Select is On. Otherwise, when this input is Off, the

drive operates as a normal velocity control drive in the selected mode.

Possible Choices: DISABLE, ENABLE

Default Value DISABLE

Max Speed

Defines the motor speed that will cause an overspeed fault when in torque

mode. It is determined by the speed requirements of the application.

Data Range: RPM 00000 to 30000

Default Value 03000

ANALOG CAL

This menu allows selection of two alternate methods to calibrate Analog

Input #2. The torque mode Torque Command can only be applied to this

input. The spindle mode or servo mode velocity commands must be

applied to Analog Input #1.

MEASURE INPUT

Allows selection of the steps required to calibrate the analog input by

actually measuring the value of the applied signal voltages. This is the

preferred method for calibrating the analog input.

Zero Volt In

This parameter requires the user to input the command voltage that is

equal to the zero torque command. When the Select key is pressed, the

control will read the input voltage on Analog Input #2 and use that as

the zero torque reference value. The display will function as a

voltmeter to show the voltage being read on the analog input.

Data Range: VOLT 00.000 to ±09.999

Default Value 0.000

2-27

Page 31

Chapter 2

Programming

Max +Volt In

This parameter requires the user to input the positive command

voltage that is equal to the maximum torque command. When the

Select key is pressed, the control will read the input voltage on Analog

Input #2 and use that as the maximum torque command reference

value. The display will function as a voltmeter to show the voltage

being read on the analog input.

Data Range: VOLT 00.000 to 10.000

Default Value 10.000

PROGRAM VALUE

This menu allows selection of the steps required to calibrate the analog

input by presetting the display as a normal scrolled variable. Use this

calibration method if the actual command voltages are not available.

Zero Volt In

This parameter requires the user to program the value of the command

voltage that is equal to the zero torque command.

Data Range: VOLT 0.000 to ±9.999

Default Value 0.000

Max +Volt In

This parameter requires the user to program the value of the command

voltage that is equal to the maximum torque command.

Data Range: VOLT 00.000 to 10.000

Default Value 10.000

2-28

Page 32

Chapter 2

Programming

ORIENT SETUP Menu The ORIENT SETUP menu (Figure 2.7) is used for configuring and tuning

the drive to properly perform the spindle orient function. If spindle orient is

being performed by the CNC, this setup is not required.

Figure 2.7

Orient Setup Menu Tree

ORIENT SETUP

FEEDBACK DEFN

ORIENT TUNE

ORIENT TUNE

Position Data

Preset Angle

Orient Speed

Orient Start

In-Position

Dir From Stop

Hold Position

FEEDBACK DEFN

Encoder Type

Encoder Lines

Encdr Phasing

FEEDBACK DEFN

This is a menu title for defining the feedback type and electrical

configuration for use in spindle orient.

Encoder Type

The basic type of feedback device that is being used to provide spindle

position data is determined with this parameter. If a normal encoder with

quadrature A and B channel square wave outputs and a marker channel is

being used, select “OPTICAL PULSE.” The encoder must meet the

electrical specifications defined in the 8510 User Manual. If the high

resolution magnetic feedback offered with the 8510 is being used, select

“MAGNET ANALOG.” The alternate choices are not currently valid.

Important: When this parameter has been changed and stored, it will not

become effective until AC power is removed from the drive and then

reapplied.

Possible Choices: OPTICAL PULSE, MAGNET PULSE, MAGNET ANALOG

Default Value: OPTICAL PULSE

2-29

Page 33

Chapter 2

Programming

Encoder Lines

The number of lines or primary counts per revolution from the feedback

device is defined with this parameter. For an optical encoder, this is the

number of lines on the A channel of the encoder disk. For the high

resolution magnetic feedback, it is the number of teeth on the gear. This

parameter must be specified or spindle orient will not function.

Data Range: 0000 to 8192

Default Value 0000

Encdr Phasing

Allows the polarity of the feedback data to be reversed without physically

reversing the wires from the feedback device.

Possible Choices: FORWARD, REVERSE

Default Value FORWARD

ORIENT TUNE

This menu selects the items needed to setup encoder based spindle orient

operation. Refer to Chapter 3 for a more detailed description of orient

mode tuning.

Position Data

Defines the source of orient position angle command. If a preset angle is

chosen, the actual angle is specified with the following parameter. The

other choices define the format of the optional 16 bit digital input data.

Either BCD or binary formats can be chosen. If “BCD” is chosen, one

LSB = 360 degrees / 10,000 or 0.036 degrees. If binary is chosen, one

LSB = 360 degrees / 2

16

or 0.0055 degrees. The data read at the inputs is

defined in degrees of angular displacement from the zero reference of the

spindle encoder. Also, if either “BCD” or “BINARY” are selected, it is

not possible to use digital velocity commands.

Possible Choices: PRESET ANGLE, BCD INPUT, BINARY INPUT

Default Value PRESET ANGLE

Preset Angle

This parameter specifies a preset, internally stored orient position. The

data variable is expressed in degrees of angular displacement from the

zero reference of the spindle encoder.

Data Range: DEG 000.000 to 359.999

Default Value 000.000

Orient Speed

Defines the spindle rpm from which the orient sequence will start. When

the Orient Command is input, the spindle will decelerate to this speed

before beginning the orient operation.

Data Range: RPM 000 to 999

Default Value 060

2-30

Page 34

Chapter 2

Programming

Orient Start

Specifies how far before the target position that the orient deceleration

begins. The data variable is expressed in spindle degrees prior to the

target.

Data Range: DEG 000.0 to 359.9

Default Value 45.0

In-Position

In-Position specifies how close the actual spindle position must be to the

target position before the In-position output is energized. If the spindle

were to move outside of this in-position range after the output was

initially energized, the output would again turn Off. The data is expressed

in spindle degrees away from the target.

Data Range: +DEG 000.000 to 359.999

Default Value 000.250

Dir From Stop

This parameter specifies the direction of spindle rotation when

performing an orient operation from stop. The scroll selection for this

variable specifies the direction of rotation if the Zero Speed output was

On when the Orient Command was input.

If “SHORTEST” is selected, the spindle will rotate in the direction that

gives the shortest distance to the orient position. It may rotate either

clockwise or counterclockwise.

If the spindle is rotating (the Zero Speed output is not On) when the

Orient Command is input, the orient operation always continues in the

same direction of rotation as it was moving prior to receiving the

command.

Possible Choices: CCW, CW, SHORTEST

Default Value CCW

Hold Position

Determines whether or not the motor will continue to produce torque to

hold the spindle within the in-position band once the orient function has

been completed.

Possible Choices: TORQUE HOLD, TORQUE OFF

Default Value TORQUE HOLD

2-31

Page 35

Chapter 2

Programming

ANALOG OUTPUT Menu The ANALOG OUTPUT menu (see Figure 10.1) allows the analog output

signals to be properly configured. These selections will not become active

until the data has been stored in EEPROM by transitioning the Drive

Enable input from Off to On.

Figure 2.8

Analog Output Menu Tree

ANALOG OUTPUT

Output #1

Output #2

Output #1

This parameter allows Analog Output #1 to be configured for the desired

output parameter.

Possible Choices | MOTOR RPM | (Absolute Value)

MOTOR RPM (Bipolar Value)

| SPINDLE RPM | (Absolute Value)

SPINDLE RPM (Bipolar Value)

% LOAD

% TORQUE

POWER

ORIENT ERROR

Default Value | MOTOR RPM | (Absolute Value)

Output #2

This parameter allows Analog Output #2 to be configured for the desired

output parameter.

Possible Choices | MOTOR RPM | (Absolute Value)

MOTOR RPM (Bipolar Value)

| SPINDLE RPM | (Absolute Value)

SPINDLE RPM (Bipolar Value)

% LOAD

% TORQUE

POWER

ORIENT ERROR

Default Value % LOAD

2-32

Page 36

Chapter

3

Drive Tuning

Chapter Objectives Chapter 3 provides details of the principles and process of tuning the 8510

drive for optimum operation. This chapter is designed to help the user

understand the tuning process and anticipate the results of changes in

tuning parameters. In addition, the Per Unit system of measure is explained

in detail.

Tuning Introduction The purpose of tuning a drive is to achieve the required stability,

bandwidth, and stiffness. Stability is the ability of the drive to regulate

speed or position without oscillation or excessive overshoot. Bandwidth is

related to the quickness of drive response to changing commands. Stiffness

is the ability of the drive to resist external load disturbances.

Tuning closed loop feedback systems can be complicated. There is

however, an organized approach for the typical machine tool as described

below.

• P Gain is strongly related to bandwidth

• I Gain is strongly related to stiffness

• Both P and I Gains are related to stability, if either is too high, the

system will be unstable

When building identical machines in a production environment, only the

first machine should require tuning. All others should perform identically

by simply presetting the parameter values determined while tuning the first

machine.

Tuning Requirements The 8510 drive provides multiple parameter sets to allow optimum

performance to be achieved with multi-speed gearboxes, dual winding

motors, and widely varying operating conditions. Each parameter set

provides unique tuning parameters for spindle, high speed servo, low speed

servo, and spindle orient modes. Each parameter set and its respective

operating modes used in the application will require individual tuning

according to the following procedure. For best results, it is recommended

that an oscilloscope be used to observe the results of drive tuning, however,

acceptable results can often be achieved by simply observing the spindle

and listening to the drive and motor during the tuning process.

3-33

Page 37

Chapter 3

Drive Tuning

Spindle/Servo Mode Tuning The following steps describe the tuning process for spindle or servo mode.

ATTENTION: If an oscilloscope is used during start-up, tuning

!

o 1. Program the following parameters (for the mode you are using) as

or troubleshooting, it must be properly grounded. The

oscilloscope chassis may be at a potentially fatal voltage if not

properly grounded. Always connect the oscilloscope chassis to

earth ground.

When using an oscilloscope it is recommended that the test

probe ground be connected to the test point labeled “GND.”

follows (refer to Chapter 2 as necessary) :

P Gain (Servo or Spindl) – set to the default value (5.0)

I Gain (Servo or Spindl) – set to zero

o 2. Program ANALOG OUTPUT – Output #1 for “± MOTOR RPM” and

ANALOG OUTPUT – Output #2 for “% TORQUE.” While observing

the motor rpm and per cent torque via the analog outputs or test

points, adjust P Gain to achieve the desired speed of response with no

more than one overshoot.

Ideally, P Gain should be adjusted with minimum load inertia. Tuning

with maximum load inertia could result in instability with a smaller

load inertia. Lost motion between the motor and load may

intermittently decouple the load inertia from the motor. This situation

could also lead to instability if the drive were tuned for maximum

inertia.

Lowering P Gain slows response, reduces overshoot, improves

stability, and reduces torque ripple. P Gain should not be increased

beyond the required amount for acceptable system response. Too high

of a P Gain setting will amplify digital and analog system noise and

increase velocity and torque ripple. High torque ripple can overheat

the motor and deteriorate surface finish. If P Gain is increased to

extremes, the system will become unstable, oscillate at a high

frequency, and produce significant audible noise.

It will not be possible to achieve high bandwidth on high inertia

systems. The high P Gain required will cause very high torque ripple

due to digital noise amplification.

3-34

o 3. Increase I Gain to achieve the required stiffness. Ideally, I Gain

should be adjusted with maximum load inertia. Tuning with minimum

load inertia could result in an underdamped response or instability

when larger load inertia is applied.

Page 38

Chapter 3

Drive Tuning

Operating the system in its normal metal cutting mode provides a

simplified method to verify stiffness. Load changes occur due to

milling cutter tooth frequency, intermittent cuts, etc. Velocity

disturbance can be observed by monitoring the motor rpm analog

output signal. Proper stiffness can be assumed when the velocity

disturbances are acceptable.

Stiffness can be measured by applying torque to the system when it is

at rest. The shaft will move an amount proportional to the torque.

When torque is removed, the shaft will return to its original position.

Stiffness is the ratio of torque to the angle moved. The greater the

stiffness, the lesser amount a given torque will disturb the shaft

position, and the quicker the system will respond to counteract the

disturbance.

As I Gain is increased, stability will gradually decrease. Frequency of

oscillation will be relatively low and audible noise should be at a

minimum. This suggests another method for adjusting stiffness,

simply increase I Gain until instability is about to occur, then lower

the gain until the system is well damped.

o 4. When operating the 8510 in servo mode in a closed position loop

(such as during C-axis operation or spindle orient), a “stick/slip

hunting” may be observed. Increasing the Droop In Run value can

minimize this.

“Stick/slip hunting” occurs when static friction is significantly higher

than running friction. As the motor approaches the final commanded

position, the position and velocity error decrease until the

commanded torque is less then the running friction. The motion will

then stop. When the system is at zero velocity with a non-zero

position error, the velocity loop integrator will slowly increase the

motor torque until it builds to the point of breaking the static friction

lock and causing the system to move. Once motion starts, friction

immediately drops from the static level to the running level. Since the

torque being generated to overcome static friction is too high for the

lower running friction level, overshoot of the target position may

result. When motion stops in the process of reversing, static friction

again locks the system. The integrator slowly builds up torque in the

opposite direction until it breaks the friction lock and overshoots in

the opposite direction. Hunting now becomes a never ending process,

usually in the range of 0.5 to 2 Hz.

The integral gain compensator has infinite DC gain, meaning that the

smallest position error (velocity command) can be integrated up, to

eventually generate maximum torque. Droop places a limit on DC

gain and creates a threshold below which small position error cannot

generate enough torque to break the static friction lock. The never

ending cycle of stick/slip hunting is broken. Increasing the Droop In

Run parameter setting will increase the level of this threshold.

o 5. Repeat steps 1 through 4 for each gear range, motor winding, and

mode if applicable.

3-35

Page 39

Chapter 3

Drive Tuning

“Per Unit” System Description The units used to express gain are arbitrary. When tuning analog drives by

adjusting potentiometers, units are completely unknown and gain is only an

arbitrary scale on the pot. Thus, it is possible to tune drives without even

knowing the gain units.

With digital drives, parameter values must relate directly to mathematical

or computer models of the system that are implemented in the drive.

Therefore, the units must follow some defined format.

The 8510 uses the Per Unit system. This system is employed for the

following reasons:

– The Per Unit system is independent of any local system of units. Units

do not change among industries or locality.

– The Per Unit system yields gain values which are very similar over a

wide range of motor/drive sizes. Once you become familiar with typical

values for P, I, and Droop gains, nearly the same values can be expected

for a very wide variety of motor/drive sizes.

– The Per Unit system is becoming the worldwide drives industry

standard.

Per Unit System Defined

Unit Velocity, V, is defined as the motor base speed

Unit Torque, T, is defined as the motor peak torque

Unit Inertia, J, is defined as the time to accelerate to Per Unit speed at Per Unit torque

Unit Time, t, is defined as 1 Second

Example 1:

Unit motor speed is defined as base speed. The base speed of a certain

motor is 1500 rpm. How many units of speed is the motor running at when

it is rotating at 6000 rpm?

6000 rpm

1500 rpm

= 4

Note that the Per Unit speed does not have a unit

Example 2:

The peak torque of the same motor is 200 N-m (147.5 lb.-ft.). What is the

Per Unit torque when operating at 50 N-m (36.9)?

50 N-m (36.9 lb.-ft.)

200 N-m (147.5 lb.-

ft.)

= 0.25

Note that the answer is the same with torque

expressed in lb.-ft. or N-m.

3-36

Page 40

Chapter 3

Drive Tuning

Gains

The variables for gain are expressed in Per Unit. Per Unit P, I, and Droop

gains are defined as:

P is defined as T/V (units of torque produced for each unit of velocity error)

I is defined as T/V/s (units of torque change per second for each unit velocity error)

Droop is defined as V/T (units of velocity droop for each unit of torque being produced)

Example 3:

The same 1500 rpm, 200 N-m (147.5 lb.-ft.) motor will be used.

If the velocity error is 0.02 Per Unit and P = 20, what is the Per Unit

torque?

T = P x V = 20 x 0.02 = 0.4 Per Unit Torque

What is the torque expressed in N-m (lb.-ft.)?

Torque

200 N-m (147.5 lb.-

ft.)

= 80 N-m (59.0 lb.-ft.)0.4 =

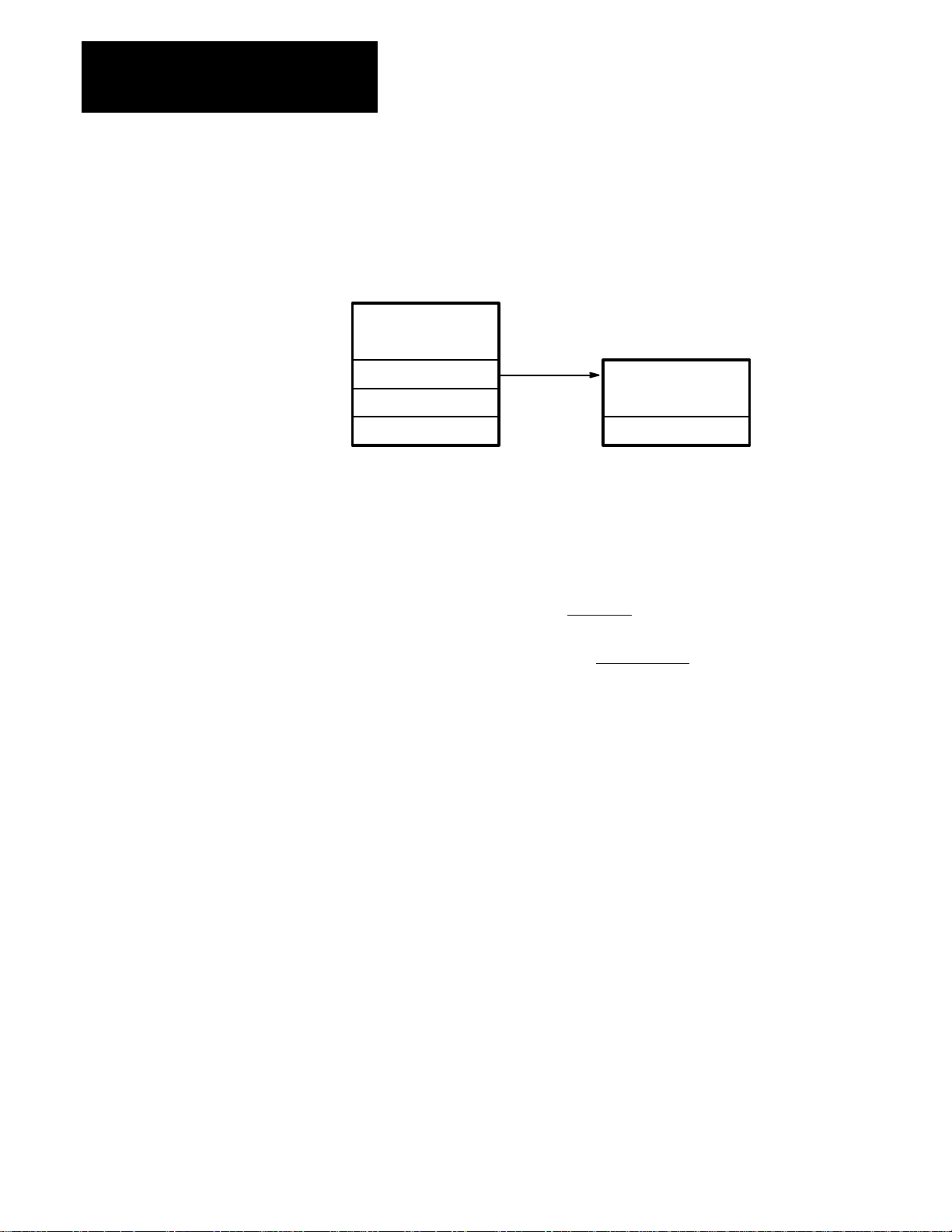

Spindle Orient Mode Tuning In the Spindle Orient Mode, the 8510 uses the Servo Mode, High Speed

Range parameter settings to control the dynamics of the velocity loop. The

position loop dynamics is controlled by the settings of the ORIENT TUNE

– Orient Speed and ORIENT TUNE – Orient Start parameters.

The actual target position is either preset by the ORIENT TUNE – Preset

Angle parameter or input through the 16 bit digital speed/position inputs.

The actual source of the orient position data is determined by the setting of

the ORIENT TUNE – Position Data parameter.

The ORIENT TUNE – Orient Speed parameter defines the spindle speed

just prior to the start of the final deceleration toward the target position.

The ORIENT TUNE – Orient Start parameter defines the number of

degrees ahead of the target spindle position where the drive begins the final

deceleration to the target position.

When the Orient Command is energized, the spindle is immediately

decelerated to the Orient Speed. When the Orient Start position is reached,

the final deceleration begins. The deceleration to Orient Speed is a simple

velocity ramp without position control. Thus, the spindle may turn as much

as one revolution at Orient Speed before the Orient Start position is

reached.

3-37

Page 41

Chapter 3

Drive Tuning

If plotted as velocity versus position, the final deceleration is a straight line

from the Orient Speed/Orient Start point to the Zero Speed/Target Position

point (see Figure 3.1). The orient position loop gain is essentially the slope

of this curve and is defined as:

The orient position loop gain that is achieved using the default values for

Orient Speed and Orient Start is:

If the velocity or position error were plotted versus time, the deceleration

would be a single exponential deceleration to the target position.

Figure 3.1

Spindle Orient Operation

Decel from

Running Speed

Kp = 6

Kp = 6

Orient

Speed

x

Orient Start

60 rpm

45.0 degrees

x

(expressed as degrees/second/degrees or radians/second)

= 8 radians/second

Orient Speed

Spindle

Speed

Spindle Position

Begin Final

Deceleration

Slope x 6 = Kp

Final Decel

Orient Start

Target

Position

3-38

Page 42

Chapter 3

Drive Tuning

Spindle Orient Tuning Process

During the final deceleration toward the target position, the drive should

not be in torque limit. When the drive is in torque limit, the actual spindle

position will fall behind the commanded spindle position, and the system is