Page 1

ALLEN-BRADLEY

8510 AC Spindle Drive

Connector Kits

(Cat. No. 8510SA-C20S, 8510SA-C50S)

Instructions

Introduction All signal interface connections to the 8510 AC Spindle Drive are made

through Honda MR series connectors. This publication will provide the

information needed to properly install these connectors.

The interface function and the connector kit required are shown below:

Interface Function Connector Kit

Standard Digital and Analog I/O 8510SA–C50S

Resolver Feedback from Motor 8510SA–C20S

Digital Speed/Position Input 8510SA–C20S

Position Feedback for Spindle Orient 8510SA–C20S

Dual Winding Motor Control 8510SA–C20S

Refer to the 8510 User Manual, publication 8510-5.1 for detailed

information about the cable required and the connector pin assignments for

each of the above interfaces.

Assembling the Connector/Cable The following procedure outlines the steps needed to install the connector.

1. Verify that the connector kit includes the blue connector body and the

gray housing (see Figure 1).

2. Refer to the 8510 User Manual to determine the required cable type and

connector pin assignments for each interface function. The maximum

wire size that the connector terminals can accept is 24 AWG

(0.283 mm

3. Disassemble the connector by removing the 2 short screws and nuts

(see Figure 1). Since the connector contains a number of small pieces,

care should be taken during disassembly.

2

).

4. Prepare the cable and wire ends. The connector shell is relatively short,

so minimize the amount of cable insulation that is removed (or it may

be difficult to properly clamp the cable into the connector shell).

Carefully solder the wires to the connector pins with a rosin core

solder. The connector pin designations are shown in Figure 1.

5. Install cable clamp around cable(s). To allow positioning, do not

tighten clamp completely.

Page 2

Instructions

8510 Connector Kits

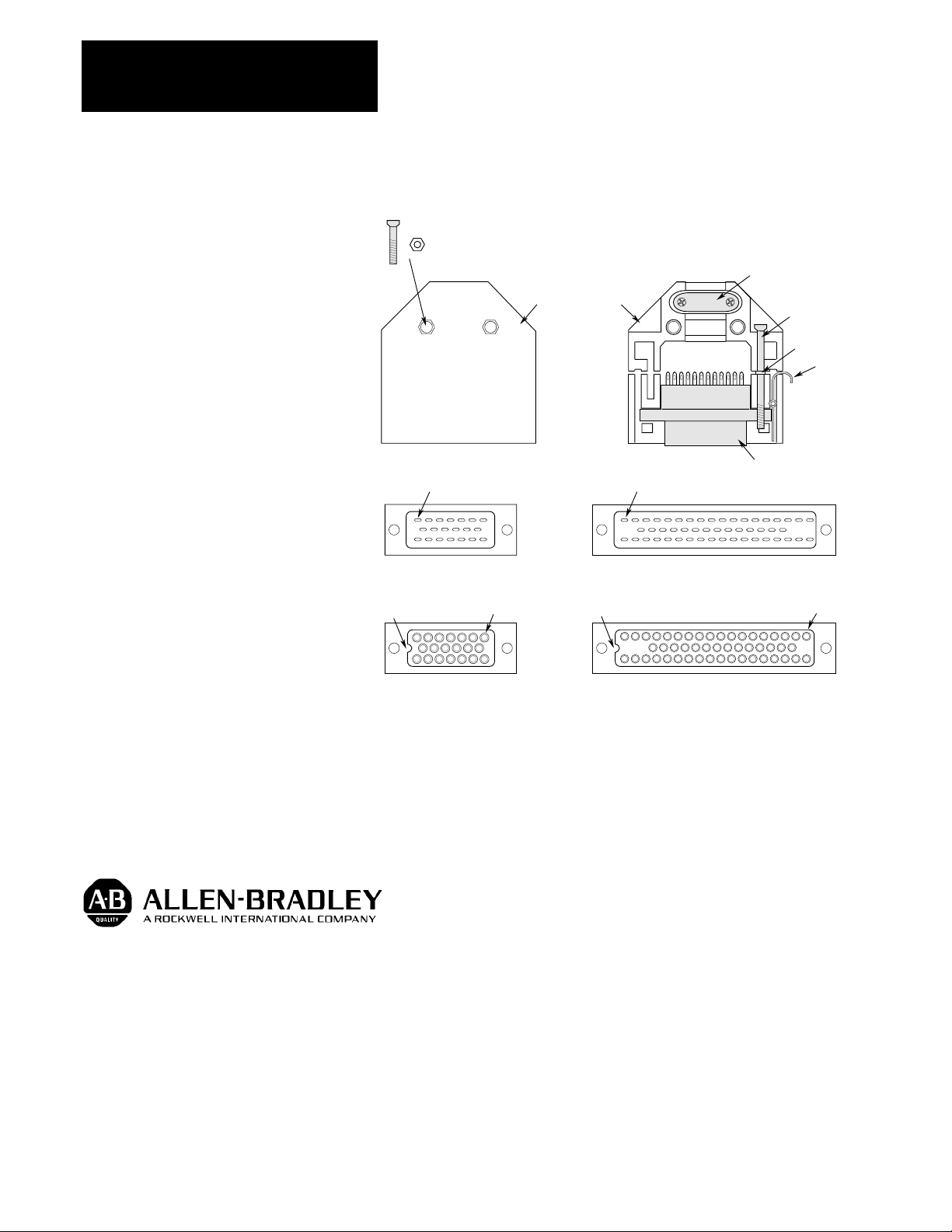

Figure 1

Connector Assembly

Short Screw & Nut

Pin 1

Cable Clamp

Connector Housing

Long Screw

Washer

Clip

Connector Body

Pin 1

Back Side of 20 Pin Connector

Locating Notch

Front Side of 20 Pin Connector

6. Place connector body into housing and slide cable clamp to position

shown. Tighten cable clamp.

7. Re-install the 2 long screws/washers, clips and assemble the connector

housing as shown in Figure 1.

With offices in major cities worldwide.

1

8

14

HONDA

1

19

33

HONDA

Back Side of 50 Pin Connector

Pin 1

Locating Notch

Pin 1

Front Side of 50 Pin Connector

Allen-Bradley has been helping its customers improve productivity and quality for 90 years.

Allen-Bradley designs, manufactures and supports a broad range of control and automation

products worldwide. They include logic processors, power and motion control devices,

man-machine interfaces and sensors. Allen-Bradley is a subsidiary of Rockwell

International, one of the world’s leading technology companies.

WORLD

HEADQUARTERS

Allen-Bradley

1201 South Second Street

Milwaukee, WI 53204

USA

Tel: (1) 414 382-2000

Telex: 43 11 016

Fax: (1) 414 382-4444

Publication 8510-5.11 – April, 1993 P/N 152821

EUROPE/MIDDLE

EAST/

AFRICA

HEADQUARTERS

Allen-Bradley Europe

B.V.

Amsterdamseweg 15

1422 AC Uithoorn

The Netherlands

Tel: (31) 2975/43500

Telex: (844) 18042

Fax: (31) 2975/60222

ASIA/PACIFIC

HEADQUARTERS

Allen-Bradley (Hong Kong)

Limited

Room 1006, Block B, Sea View

Estate

2-8 Watson Road

Hong Kong

Tel: (852) 887-4788

Telex: (780) 64347

Fax: (852) 510-9436

CANADA

HEADQUARTERS

Allen-Bradley Canada

Limited

135 Dundas Street

Cambridge, Ontario N1R

5X1

Canada

Tel: (1) 519 623-1810

Fax: (1) 519 623-8930

Copyright 1993 Allen-Bradley Company, Inc. Printed in USA

LATIN AMERICA

HEADQUARTERS

Allen-Bradley

1201 South Second

Street

Milwaukee, WI 53204

USA

Tel: (1) 414 382-2000

Telex: 43 11 016

Fax: (1) 414 382-2400

Loading...

Loading...