Page 1

Installation Instructions

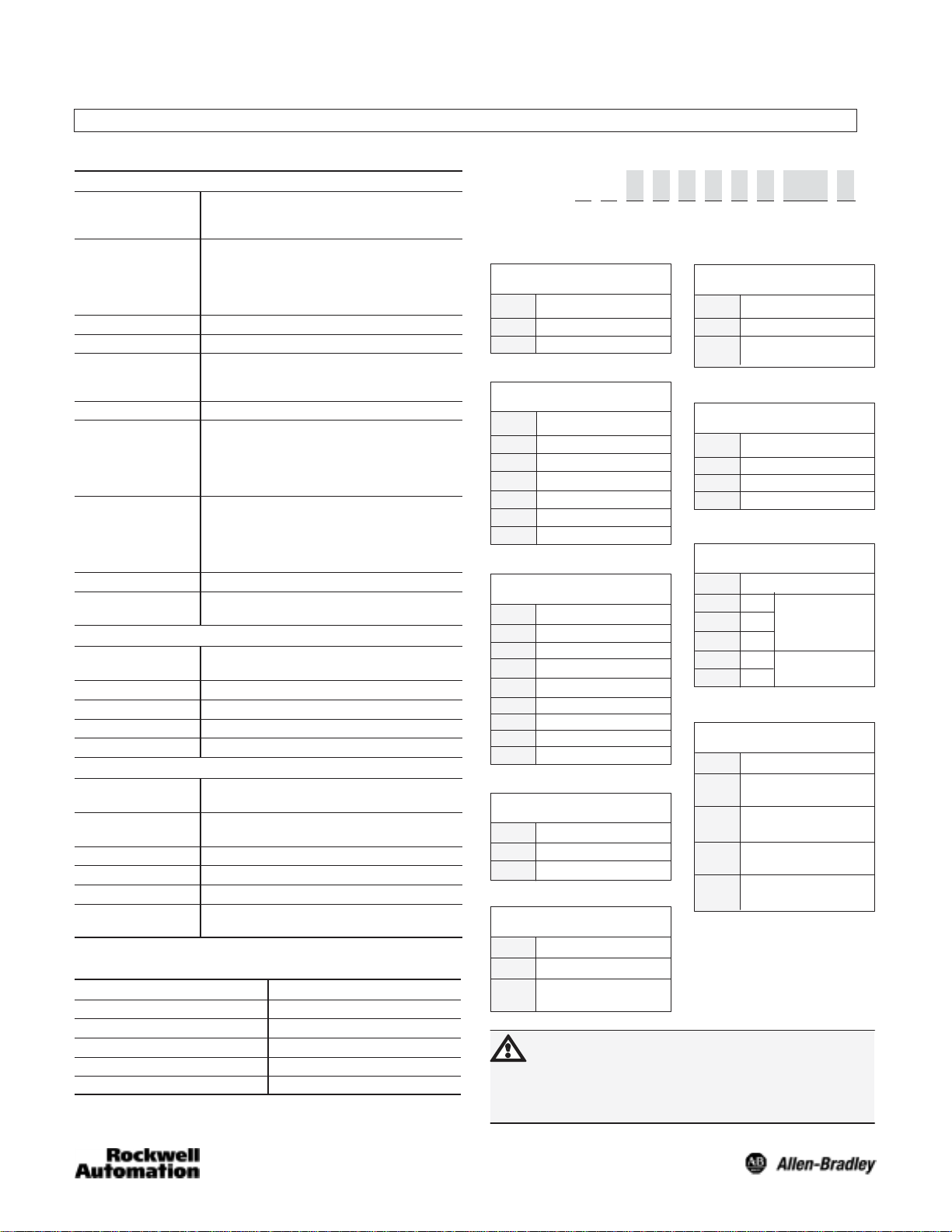

Size 25 Absolute Encoder, Bulletin 845D

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Specifications

Electrical

Code Format Binary Coded Decimal (BCD)

Resolution (Gray and Natural Binary):

Accuracy ±1 bit

Frequency Response 16K words/sec

Power Requirements Determined by catalog number:

Output Drive Capability NPN current sink = 16mA

Output Logic Parallel BCD, GRAY, or NAT BIN:

Latch Command Optional with BCD and NAT BIN only:

Direction Control Field selectable for increasing counts (CW or CCW)

Gray Code

Natural Binary

256 CPR (8 bit); 512 CPR (9 bit)

1024 CPR (10 bit)

(BCD):

360 CPR (10 bit); 1000CPR (12 bit)

5V DC ±5% @ 400mA maximum

8-24V DC @ 400mA maximum

Logic 0" = 0.0 to 0.6V DC

Logic 1" = 3.5 to 5.0V DC (TTL)

Logic 1" = 24V DC maximum

(Open collector)

Logic 0" = outputs active

(DC common)

Logic 1" = outputs latched

(+DC or open)

Reset Reset position value to zero (see Reset Pin section on

page 2). Only with shaft stationary.

Mechanical

Starting and Running

Torque

Shaft Loading Axial 89N [20lbs]; Radial 178N [40lbs]

Shaft Size 6mm, 10mm, 1/4in, 3/8in diameter

Moment of Inertia 54g-cm2 (0.3ozĆin2)

Slew Speed 5000 RPM

2.5 Ncm typical [3.5inĆoz]

Environmental

Housing NEMA Type 4, IP66 (IEC 529); NEMA Type 4X on

Temperature 0°C to +85°C (+32°F to +185°F )Ċoperating

Humidity 98%, noncondensing

Vibration 20g (58 to 150Hz)

Approximate Ship

Weight

selected models

-25°C to +90°C (-13°F to +194°F)Ċstorage

Shock 50g (11ms duration)

0.91kg (2lbs)

Accessories

Description Catalog Number

High Performance Flexible Coupling 845-FC-*-*

Measuring Wheels 845-MW-A-*

Servo Clamps 845-SC

PreĆWired Cables 845-CA-D-*

Mating Connectors 845-SCD

Selection

845D — S J D Z 1 4 B D CK 4

a b c d e f g h i

a

NEMA Rating

Code Description

NEMA 4J

X NEMA 4X

b

Mounting Configuration

Code Description

Square FlangeD

E 70mm Diameter Flange

90mm Diameter FlangeF

G Metric Servo 48mm B.C.

English ServoH

J Metric Servo 42mm B.C.

c

Shaft Options

Code Description

6mm DiameterA

B 10mm Diameter

1/4in DiameterC

Z 3/8in Diameter

6mm w/FlatK

L 10mm w/Flat

M 1/4in w/Flat

3/8in w/FlatN

d

Power Supply Options

Code Description

5V DC ±5%1

2 8-24V DC Unregulated

e

Output Configuration

Code Description

5V DC TTL Compatible4

5

NPN Open Collector

24V DC Max.

ATTENTION: The shielded cables, output devices,

and power supplies must be properly grounded. All

National Electric Code and applicable local codes

and ordinances must be observed when wiring the

system.

Latch Options

Code Description

B

Output Code Type

Code Description

G Gray Code

Code Description

CW

DW

FW

CK

CN

Connector Options

Code Description

1

2

4

5

f

No LatchA

Latch (Sink Output

Module Compatible)

g

Binary Coded DecimalD

Natural BinaryN

h

Resolution

256

512

1024

360

1000

Gray Code

Natural Binary

Binary Coded

Decimal

i

Axial Connector

(End) without Mate

Radial Connector

(Side) without Mate

Axial Connector

(End) with Mate

Radial Connector

(Side) with Mate

or

1

Page 2

Electrical Connections

Function

Pin Gray Code Natural Binary BCD (8421)

A G(0) 2

B G(1) 2

C G(2) 2

D G(3) 2

E G(4) 2

F G(5) 2

G G(6) 2

H G(7) 2

J G(8) 2

K G(9) 2

L MSB Complement Not Used 400

M Not Used Not Used 800

N Not Used Not Used Not Used

P Not Used Not Used Not Used

R Not Used Direction Control Direction Control

S Reset Reset Reset

T DC Return DC Return DC Return

U Not Used Latch Control Latch Control

V DC+ Input DC+ Input DC+ Input

0

1

2

3

4

5

6

7

8

9

1

2

4

8

10

20

40

80

100

200

Direction Pin

The Direction Pin can change function with code type. In

parallel type Gray Code encoders, its function is Most

significant Bit Complement or MSBC for short. In Natural

Binary and Binary Coded Decimal encoders, its function is

Direction Control.

Direction Control Ê

Natural Binary and BCD

A logic “1” (+DC or open) on the direction control pin will

produce increasing counts with a counter- clockwise rotation

of the shaft. A logic “0” (DC common) on the direction control

pin will produce increasing counts with a clockwise rotation of

the shaft.

Gray Code (parallel only)

Counterclockwise rotation of the shaft will produce increasing

counts. For increasing counts with a clockwise rotation, use

the Most Significant Bit Complement Pin instead of the Most

Significant Bit Pin. See Electrical Connection table for pin

designation.

ATTENTION: For parallel gray code: connecting the

MSB or MSBC to +DC will result in permanent

damage to the encoder.

Reset Pin

The shaft must be stationary before using the reset function.

Connecting the Reset Pin to +DC will reset Natural Binary and

BCD position value to zero. Connecting the Reset Pin to +DC

will reset Gray Code position value to maximum (e.g., 255,

511, 1023, etc.) if MSBC is used, to zero if MSB is used. The

reset function requires a connection to +DC for 0.1 seconds or

longer.

ATTENTION: Activating the Reset Pin results in a

change of position reading. This can cause

unexpected motion which could result in damage to

the product, equipment, or personal injury.

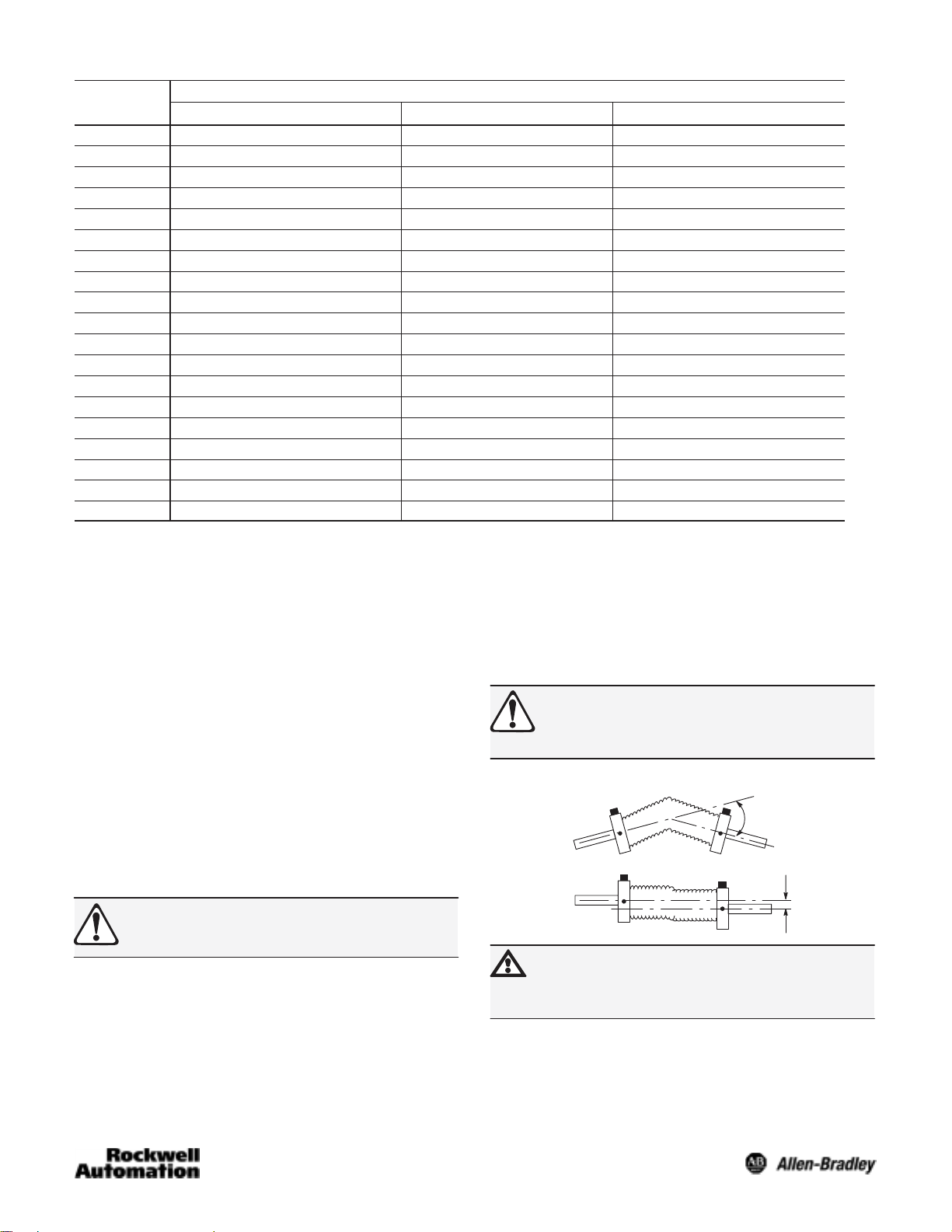

Flexible Shaft Couplings

Angle

Parallel

OffĆSet

ATTENTION: Rigidly coupling the encoder shaft to

the machine shaft will cause a failure in either the

bearings of the encoder or the bearings of the

machine shaft.

Ê Rotation is viewed from the end of the encoder shaft.

2

Page 3

Dimensions—mm (inches)

Axial Mount

Connector

58.42

(2.30)

Connector

PT02E14-19P (023)

Axial Mount

Connector

58.42 (2.30)

Connector

PT02E14-19P (023)

Axial

Mount

Connector

79.7

(3.13)

3.05

(0.12)

20.0

(0.79)

See

Table

Below

74.93

(2.95)

7.62 (0.30)

See Table Below

26.21(1.032)

26.21

(1.032)

52.40

(2.063)

58.42

(2.30)

6.35

(0.25)

(1.25) Dia.

52.40

(2.063)

66.5

(2.62) Sq.

Square Flange Mount

Connector

PT02E14-19P (023)

Axial Mount

Connector

79.7

(3.13)

Radial

Mount

Connector

20.0

(0.79

)

See Table Below

31.75

M4 x 5.0 Deep

on a 70.0 Dia.

Bolt Circle,

4 PlacesĊ90°

Apart

3.05

(0.12)

Radial Mount

Connector

6.35 (0.25)

22.86/21.59

(0.90/0.85)

31.75

(1.25) Dia.

5 (0.21) Dia.Ċ4 Mtg. Holes

10-32 UNFĆ2B X 9.6 (0.38) Deep

on a 47.6 (1.875) Dia. Bolt Circle,

3 PlacesĊ120° Apart

58.42

(2.30)

Connector

6.35

(0.25)

31.75

(1.25) Dia.

Radial

Mount

Axial Mount

Connector

74.93

(2.95)

7.62

(0.30)

See Table

Below

58.67

(2.31)

Dia.

74.93

(2.95)

7.62 (0.30)

See Table Below

58.67

(2.31) Dia.

58.42

(2.30)

31.75

(1.25) Dia.

63.5

(2.5)

Dia.

63.50

(2.50) Dia.

65.0

(2.56) Dia.

English Servo Mount

Connector

PT02E14-19P (023)

Axial Mount

Connector

Radial

Mount

Connector

2.54

(0.10)

20.0

(0.79)

M3 x 5.0 Deep on a

48.0 Dia. Bolt Circle

3 PlacesĊ120° Apart

74.93

(2.95)

7.62

(0.30)

See Table

Below

58.67

(2.31)

Dia.

Radial Mount

Connector

2.54

(0.10)

2.54

(0.10)

22.86/21.59(0.90/0.85)

31.75

(1.25) Dia.

10-32 UNFĆ2B x 9.6 (0.38) Deep

on a 47.6 (1.875) Dia. Bolt Circle,

3 PlacesĊ120° Apart

58.42

(2.30)

20.0

(0.79)

31.75

(1.25) Dia.

63.5

(2.5)

Dia.

Radial

Mount

Connector

2.54

(0.10)

M4 x 5.0 Deep on a

70.0

(2.76) Dia.

64.0 Dia. Bolt

Circle, 4 PlacesĊ

90° Apart

Metric Flange Mount

Shaft Diameter Options

Code Shaft Diameter

A or K 6mm +0.00mm, -0.013mm

B or L 10mm +0.00mm, -0.013mm

C or M 6.35(0.2499 ) +0.0000, -0.0005

Z or N 9.52 (0.3749) +0.0000, -0.0005

90.0

(3.54) Dia.

Shaft with Flat Option

19.05

(0.75)

M4 x 5.0 Deep on a

42.0 Dia. Bolt Circle

65.0

(2.56) Dia.

3 PlacesĊ120° Apart

Metric Servo Mount

Flat Dimensions

Code Dimension A"

A

K 5.3mm (0.21in)

L 9.1mm (0.36in)

M 5.5mm (0.22in)

N 8.6mm (0.34in)

3

65.0

(2.56) Dia.

Page 4

4

Publication 75008–184–01(B)

January 2005

Printed in USA

Loading...

Loading...