Page 1

Installation Instructions

Teth

A

7.25 dia. B.C. (to fit 8

Teth

3/8I bolt

(

Tether, 3/8 bolt on a

5V DC in, 5V DC

5-26V DC in, 5-26V

5-15V DC in, 5-15V

,

8-26V DC in

10-30V DC in, 10-30V

Bulletin 844D Blind & ThroughĆShaft Optical Incremental Encoders

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Specifications

Electrical

Code Format 2 channels with zero index

Power Requirements 120mA (no load)

Max Output Frequency 200kHz PushĆPull (120-8192 PPR)

Resolution Up to 16,384 pulses per revolution

Output Driver Capability

Mechanical

Angular Acceleration 100,000 radians/sec

Starting Torque

@ 25_C (77_F)

Running Torque

@ 25_C (77_F)

Moment of Inertia 490gcm2 (6.9 x x 10-3oz-in-sec2)

Slew Speed 3000 rpm maximum

Shaft Loading

(120-2500 PPR)

Shaft Loading

(4096-16,384 PPR)

Permissible Shaft

Radial Movement

Permissible Shaft

Axial Movement

Bore Size Supports 1/2 to 1-1/8" & 30mm shafts

Environmental

Protection NEMA Type 4, 13, IP66 (IEC 529) except

Housing Material Aluminum

Temperature

Humidity 90% noncondensing

Vibration 20g from 5 to 2000Hz

Approximate Weight 0.91kg (2lbs)

300kHz all other drivers (120-8192 PPR)

600kHz (above 8192 PPR)

3487 Line driver = "40 mA

4469 Line driver = "200 mA

7272 Line driver = "40 mA

PushĆPull Single Ended Driver = "70 mA

9.3Ncm (13inĆoz)

5Ncm (7 inĆoz)

Axial 67N (15lbs)

Radial 133N (30lbs)

Axial 44N (10lbs)

Radial 67N (15lbs)

Static +/- 0.5mm (0.02in)

Dynamic +/- 0.1mm (0.004in)

Static +/- 0.5mm (0.02in)

Dynamic +/- 0.5mm (0.02in)

terminal block connection type rated

IP40 (IEC 529) only

-20_C to 85_C (-4_F to +185_ F)ĊOperating

-30_C to 85_C (-22_F to +185_F)ĊStorage

Shock 50g for 11ms

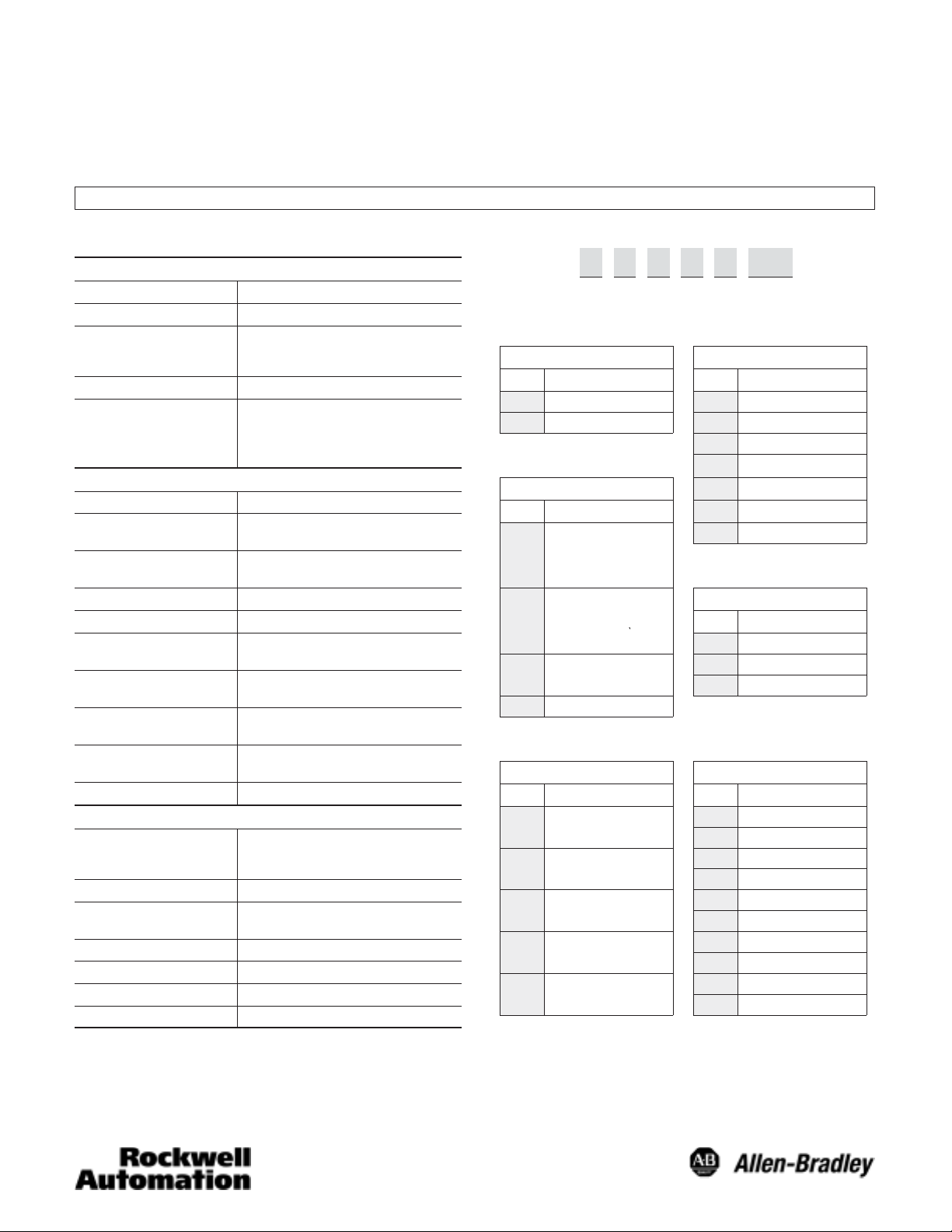

Selection

844D — A 5 A C 1 CR

a b c d e f

a

Shaft Design

Code Description Code Description

A BlindĆShaft 4 1/2in

B ThroughĆShaft 5 5/8in

6 3/4in

c

2

Mounting Configuration

7 7/8in

8 1.0in

Code Description 9 1 1/8in

I

er, 1/2I bolt on a

7.25I dia. B.C. (to fit 8

A

1/2I NEMA C face)

I

er,

5.88I dia. B.C. (to fit 4

B

1/2I NEMA C face)

Tether, 3/8I bolt on a

C

2.5-4.0I dia. radius

D AntiĆrotation pin

on a

M 30mm

Code Description

C 10Ćpin Connector

T

1 1m (3.28ft) cable

ef

Power Supply and Output Ì

Code Description Code Description (PPR)

5V DC in, 5V DC

1

2

3

4

5

Ê Shaft sizes below 1.0in include an insulating insert.

Ë Terminal block unit is not rated for fluid ingress protection (IP40 (IEC 529)

only).

Ì DLD = Differential Line Driver

Í 7272 line driver has a voltage drop of 1.9V.

Î Available with power supply and output options 1, 2, 3 and 4.

DLD out (3487)

5-26V DC in, 5-26V

DC DLD out (7272) Í

5-15V DC in, 5-15V

DC DLD out (4469)

8-26V DC in

5V DC DLD out (3487)

10-30V DC in, 10-30V

DC PushĆPull out

,

DB 120

CK 360

FW 1024

CS 2048

CR 2500

DS 4096

DR 5000

FS 8192

CV

LS

b

Shaft Size Ê

d

Connection Type

Terminal Block Ë

Resolution

10000 Î

16384 Î

Page 2

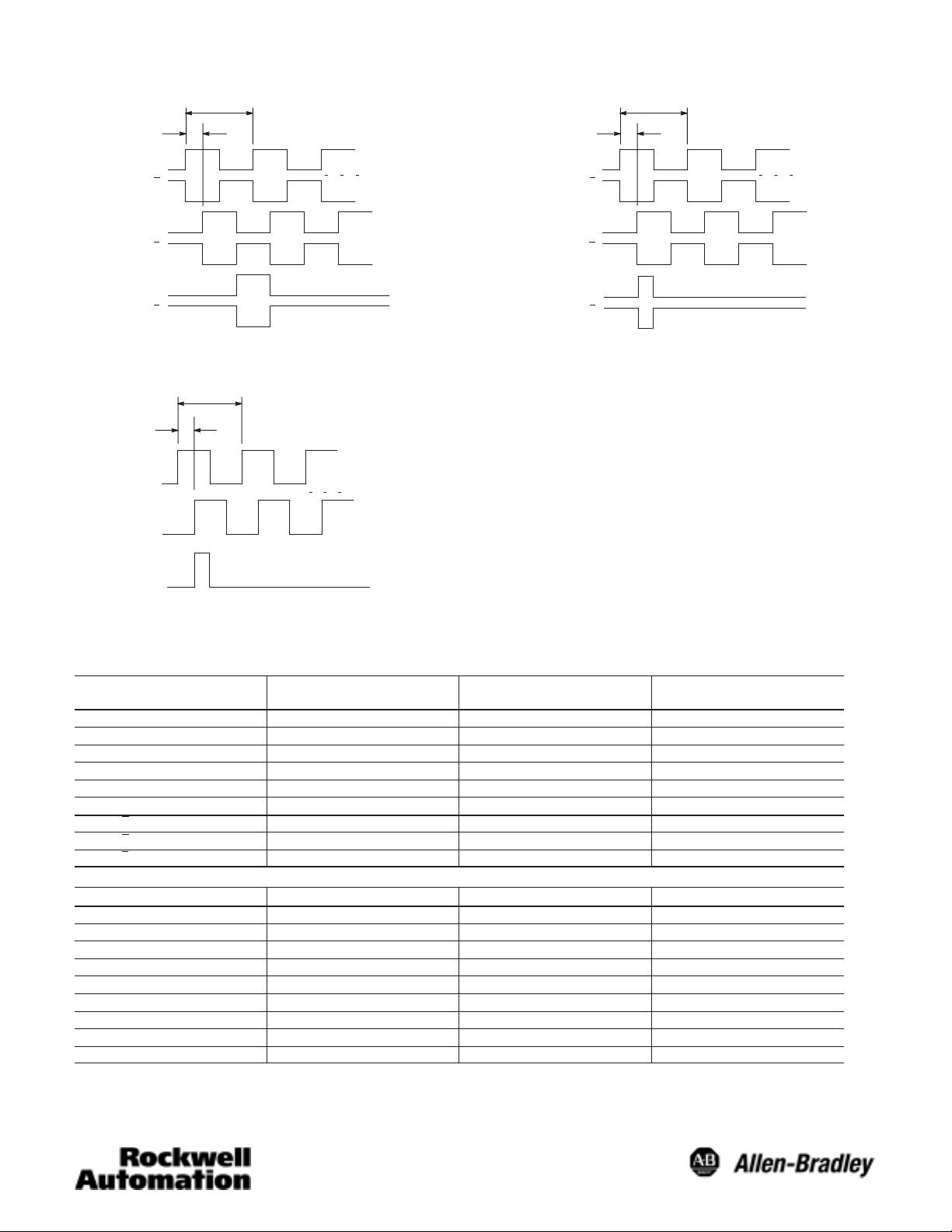

Differential Line Driver Output (for resolution v 8192 PPR)

1 Cycle

90 +/- 22°

Channel A

Channel A

Logic 1

Logic 0

Differential Line Driver Output (for resolution u 8192 PPR)

1 Cycle

90 +/- 22°

Channel A

Channel A

Logic 1

Logic 0

Channel B

Channel B

(Index) Channel Z

Channel Z

(CCW Rotation Shown)

Channel B

Channel B

(Index) Channel Z

Channel Z

PushĆPull Single End Driver Output

1 Cycle

90 +/- 22°

Logic 1

Channel A

Channel B

(Index) Channel Z

Logic 0

(CCW Rotation Shown)

Electrical Connections

Table A: Differential Line Driver Outputs

Function

Channel A Output A White 1

Channel B Output B Pink 2

Channel Z Output C Violet 7

DC+ Input D Red 3

DC Return F Blue 4

Case Ground G Green Ċ

Channel A Output H Brown 5

Channel B Output I Black 6

Channel Z Output J Yellow 8

Connector

Table B: PushĆPull Outputs

10ĆPin

Function

Channel A Output A White 1

Channel B Output B Pink 2

Channel Z Output C Violet 7

DC+ Input D Red 3

DC Return F Blue 4

Case Ground G Green Ċ

Not connected Ċ Brown Ċ

Not connected Ċ Black Ċ

Not connected Ċ Yellow Ċ

Note: 10-pin connector type MS3102R18–1P

10ĆPin Connector Shielded Cable Terminal

Shielded

Cable

Terminal

(CCW Rotation Shown)

2

Page 3

844D

Blind-Shaft Tolerance

SIze

1/2I 0.500/0.501 0.500/0.499 0.70/2.00

5/8I 0.625/0.626 0.625/0.624 0.70/2.00

3/4I 0.750/0.751 0.750/0.749 0.70/2.00

7/8I 0.875/0.876 0.875/0.874 0.70/2.00

1.0I 1.000/1.001 1.000/0.999 0.70/2.00

1 1/8I 1.125/1.126 1.125/1.124 0.70/2.00

30mm 30.000/30.025mm 30.000/29.975mm 18/50mm

844D

Through-Shaft Tolerance

Size

1/2I 0.500/0.501 0.500/0.499 0.70

5/8I 0.625/0.626 0.625/0.624 0.70

3/4I 0.750/0.751 0.750/0.749 0.70

7/8I 0.875/0.876 0.875/0.874 0.70

1.0I 1.000/1.001 1.000/0.999 0.70

1 1/8I 1.125/1.126 1.125/1.124 0.70

30mm 29.980/29.959mm 30.000/29.975mm 18mm

Dimensions—mm (inches)

Blind-Shaft Ê

Bore Mating Shaft Length

Bore Mating Shaft LengthĊmin.

Connector

Option

Cable

Option

Terminal

Option

∅89.66

(3.53)

Through-Shaft Ê

∅89.66

(3.53)

43.18

(1.70)

46.23

(1.82)

19.05 (0.75)

12.7 (0.50)

11.43 (0.45)

∅57.15

∅50.0

(1.97)

Clamp Ring

3.17 (0.125)

12.7 (0.50)

11.43 (0.45)

∅50.0

(1.97)

Clamp Ring

3.17 (0.125)

(2.25)

19.05 (0.75)

∅57.15

(2.25)

7.14

(0.28)

12.7

(0.50)

16.94

(0.673)

87.1

(3.43)

30_

6.35/6.36

(0.25)

AntiĆRotation

Pin

15_

38.1 (1.5)

87.3

(3.44)

22.4

(0.89)

(2.0)

5.59

(0.22)

51

107.5

(4.23)

76.2 (3.0)

65.0 (2.56)

23.11

(0.91)

65.53

(2.58)

#10-32UNC-28

X0.25 DP (3) Plcs

on a 3.000 B.C.

Tether Option “B”Tether Option “A”

7.14

(0.28)

12.7

(0.5)

12.7

(0.5)

5.59

(0.22)

30_

∅1.0008

1.0028

38.1 (1.5)

(3.44)

87.3

Bore

5.59

(0.22)

(1.00)

(2.00)

Tether Option “C”

18.2

87.5

(0.72)

(3.45)

51

(2.0)

76.2 (3.0)

65.0 (2.56)

25.4

50.8

13.21

(0.52)

38.10

(1.50)

∅76.2

(3.0)

12.78/12.73

(0.503/0.501)

25.4

(1.0)

85.3

(3.36)

18.16

(0.71)

65.53

(2.58)

38.1

(1.5)

∅0.218

2 Plcs

101.6

(4.0)

Ê Shown with optional anti-rotation pin.

3

Page 4

Mounting Instructions

IMPORTANT: Be sure mating shaft is chamfered and

grease-free.

1. Loosen the screw on the clamping ring with a 3/32 inch

hexagon socket wrench.

2. Slide the encoder onto the mating shaft until the tether

mount or anti-rotation pin rests on the machine surface.

The encoder should slide freely on the shaft; if not, do not

force. Check the shaft for interferences such as gouges,

burrs, rust or size.

If a mounting hole or anti-rotation pin stop already exists,

proceed to step 6.

3. Mark the mounting hole and/or anti-rotation pin stop

location.

4. Slide the encoder off. Drill and tap the marked hole to

accept the 0.375 inch x 16 (tether option B or C) or 0.5

inch x 13 (tether option A) bolt.

5. Slide the encoder back in the shaft until the tether mount

or anti-rotation pin rests on the machine surface.

6. Attach the encoder with either the 0.375 inch or 0.5 inch

bolt.

IMPORTANT: Do not stress the tether mount while

tightening the bolt.

7. Tighten the clamping ring to 8 inch-lbs.

8. Make the electrical connections according to the table

under “Electrical Connections.”

IMPORTANT: Wiring must be in accordance with the

National Electric Code and applicable local codes and

ordinances.

9. Apply the specified voltage (see Table “e” under

“Selection” on page 1 of this publication).

Visit our web site at:

http://www.ab.com/sensors

4

Publication 75008–147–01(B)

February 2003

Printed in USA

Loading...

Loading...