Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

ATTEN TI ON : Rockwell Automation Bulletin

2090 feedback cables provide connections

for both 5…12V and 7…12V encoder power

supplies. Only one of these connections

should be used. Simultaneous connection

to different power supplies may result in

damage to the servo drive and encoders.

842HR Sine Cosine/Serial Encoders

Size 25, High Resolution Auxiliary Servo Feedback

Description

Bulletin 842HR is a 15-bit serial/sine cosine encoder. Targeted for

high performance digital servo drive systems that require

absolute feedback for position control and high resolution

incremental feedback for speed control.

Rockwell Automation’s sine cosine high performance encoders

provide commutation, speed regulation and position control all

in one device. Absolute position values of up to 15 bit combined

with incremental resolution up to 2 million counts per turn.

Features

• Absolute feedback for position control

• High resolution Incremental feedback for speed control

• Commutation

• Sine cosine differential interface

• Digital bi-directional RS-485 interface

• Compatible with Hiperface® interface

• Internal diagnostic functions

Benefits

• High performance motor or auxiliary feedback

• High accuracy and resolution

•Low bandwidth

• Maximum noise immunity

• One interface for all servo motor applications

• Standalone housing (suitable for mounting external to a servo

motor

Hiperface is a registered trademark of SICK Stegmann Gmb H

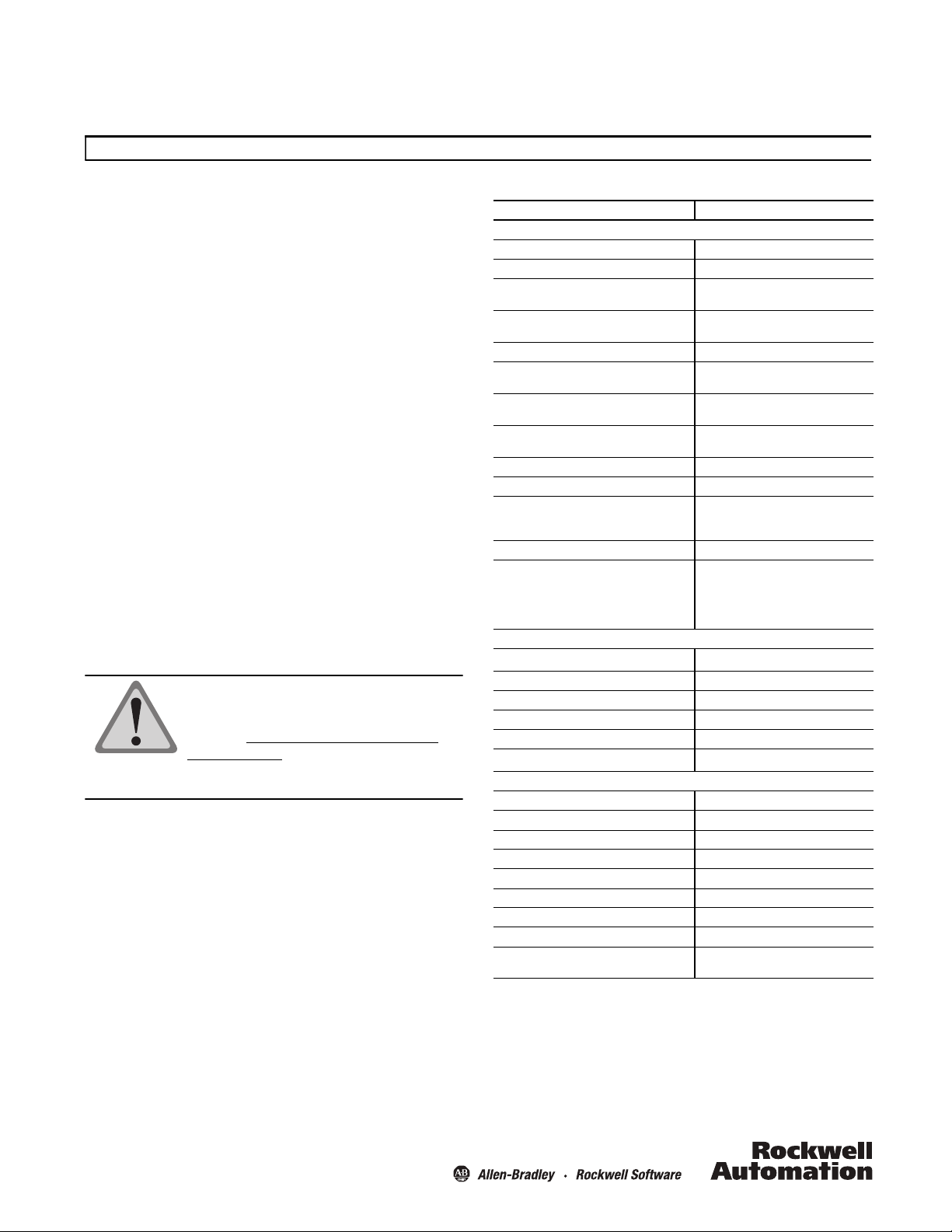

Specifications

Certifications CE Marked for all applicable directives

Electrical

# of sine/cosine cycles per revolution 1,024

Code format for absolute position value Binary

Code direction with clockwise rotation viewed

from shaft end

# of steps per revolution

(Single 842HR-S)

# of revolutions (Multi 842HR-M) 4,096

Error limits for the digital absolute value via RS

485

Error limits in evaluating the 1,024 signals,

integral non-linearity

Non-linearity within a sine/cosine period,

differential non-linearity

Output frequency for sine/cosine signals 0…200 kHz

Operating voltage range 7…12V; 5…12V

Max. operating current, no load

5…12V Supply

7…12V Supply

Available memory on EEPROM 128 bytes

Interface signals

Process data channel = SIN,

REFSIN, COS, REFCOS

Parameter channel = RS 485

Mechanical

Max. angular acceleration

Max. operating speed 6,000 RPM

Operating torque, max. 3.5 oz-in

Starting to rque, max. 5 oz-in

Shaft loading Radial 35 lb; Axial 40 lb

Life of ball bearings

Environmental

Housing Aluminum

Operating Temperature—C (F) -20…+85° (-4…185°)

Storage Temperature—C (F) -30…+90° (-22…194°)

Humidity 90%

Shock 30 g/11 ms

Vibrat ion 20 g/10…2 KHz

Protection IP66 (IEC 60529)

Approximate Weight 481 g (17 oz)

EMC

Inrush current with 5…12 V supply can be as high as 1 Amp

If applying the electronic type label, in connection with numeric controllers, attention

should be paid to Patent EP 425 912 B 2; Application of the electronic type label in

connection with speed regulation is exempt.

Condensation not permissible

To DIN EN 60068-2-27

To DIN EN 60068-2-6

With mating connector inserted

Increasing

32,768

± 90 angular seconds

± 45 angular seconds

± 7 angular seconds

180 mA

80 mA

Analog, differential

Digital

5

rad/sec

9

rotations

2

5 x 10

3.6 x 10

DIN EN 61000-6-2

DIN 6100-6-3

1

Page 2

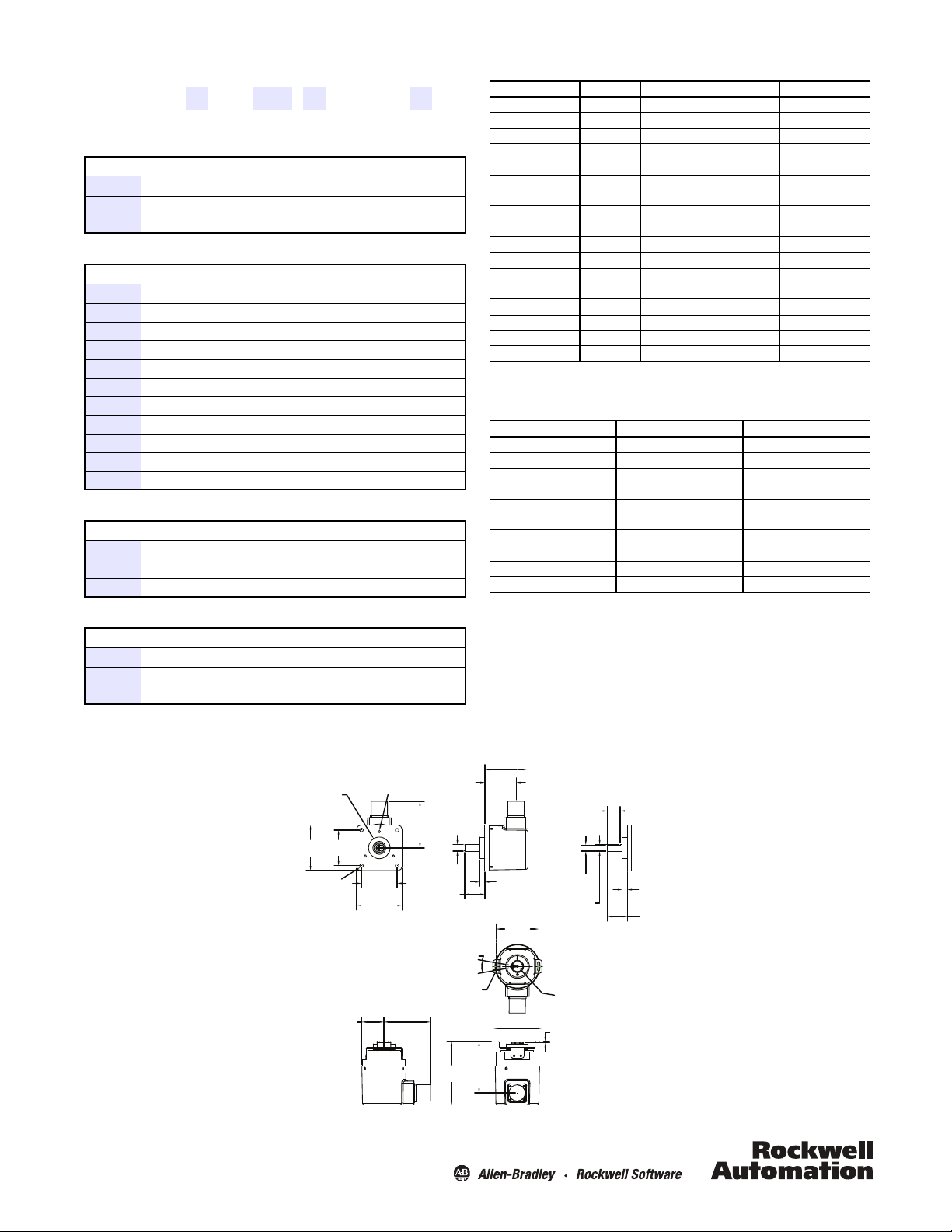

Product Selection

842HR — SJ DZ 115FWY2

abc d

a

Number of Turns

Code Description

S Single-turn (1 turn)

M Multi-turn (4096 turns)

b

Mounting Configuration (Note)

Code Description

DZ Square Flange, 3/8 inch solid shaft

DN Square Flange, 3/8 inch solid shaft with flat

A1 Hub Shaft, 15 mm blind hollow shaft

A2 Hub Shaft, 1/2 inch blind hollow shaft

A3 Hub Shaft, 12 mm blind hollow shaft

A4 Hub Shaft, 10 mm blind hollow shaft

A5 Hub Shaft, 3/8 inch blind hollow shaft

A6 Hub Shaft, 8 mm blind hollow shaft

A7 Hub Shaft, 1/4 inch blind hollow shaft

A8 Hub Shaft, 6 mm blind hollow shaft

c

Power Supply

Code Description

1 5…12V DC

2 7…12V DC

Output Terminations: M23 17-Pin

Pin No. Function Explanation Wire Color

1 SINE Process Data Channel Black

2 REFSINE Process Data Channel White/Black

3 COSINE Process Data Channel Red

4 REFCOSINE Process Data Channel White/Red

5 Data + RS-485 parameter channel G reen

6 Data - RS-485 parameter channel White/Green

9DC + Input5V Supply Voltage Gray

10 DC Return Ground Connection White/Gray

11 DC + Input 9V Sup ply Voltage Orange

13 N.C.

14 N.C.

15 N.C.

16 N.C.

17 N.C.

7 CASE Case Ground Brown

8N.C.

12 DC Return Ground Connection

Pin 12 internally tied to Pin 10.

Output Termination: MS 10-Pin

Pin No. Function Wire Color

A+VSRed

B Common Blue

C Ref SIN Brown

DRef COSBlack

EData +Grey

FData -Green

G SIN White

HCOSPink

I Not used

J Case Case

d

Connector Options

Code Description

2 MS 10- Pin

DM23 17-Pin

Approximate Dimensions [mm (in.)]

8-32 UNC-28 0.18 (9.57) min.

3 places 120° apart

66.5

(2.62)

4 places

52.3

(2.06)

on a 47.63 (1.875) B.C.

52.3

(2.06)

66.5 (2.62)

Square Flange, Solid Shaft

32.5

(1.28)

68.4 (2.7)

68.4

(2.7)

9.51 (0.3746)

9.51 (0.3744)

31.75 (1.25)

31.74 (1.24)

5.3 (0.21) Dia.

29.6

(1.16)

93.0

(3.7)

20°

3.3

(0.13)

75.5

(3.0)

63.4 (2.5)

46.4

(1.8)

7.6

(0.30)

63.0

(2.48)

72.0 (2.83)

19.1

(0.75)

8.71

(0.34)

9.51 (0.3746)

9.51 (0.3744)

Solid Shaft with Flat

15 (0.59) is max. bore size

smaller bores require collets

1.97

(0.08)

7.6

(0.30)

29.6

(1.16)

Hub

Shaft

2

Page 3

Accessories

Description Cat. No.

M23 17-pin Cables 2090-XXNFMF-Sxx

MS 10-pin Cables 842HR-CA-2-yy

Flexible Coupling 845-FC-x-x

2090-XXNFMF-Sxx

Pre-wired cable to an M23 DIN 17-pin connector for the encoder.

The other end of the cable is flying leads.

Flexible Couplings

xx = Cable Length

01 1 m

02 2 m

03 3 m

04 4 m

05 5 m

07 7 m

09 9 m

12 12 m

15 15 m

20 20 m

25 25 m

30 30 m

Note: Consult manufacturer’s drive manual for maximum

recommended cable length.

842HR-CA-2-yy

Pre-wired cable to an MS 10-pin connector for the encoder. The

other end of the cable is flying leads.

yy = Cable Length

01 1 m

03 3 m

05 5 m

10 10 m

20 20 m

30 30 m

High Performance Flexible Coupling

845–FC–B–B

Description

High performance flexible couplings are used to connect two

shafts, and help to reduce the effects of misalignment between

the shafts. Flexible couplings are offered in the high performance

version, with nonconductive inserts. They are of the flexible

curved beam helical type with clamping screw at both ends.

Specifications

Parallel Offset 0.51 mm (0.02 in) max.

Angular Offset 10° max.

Axial Compliance 1.58 mm (0.06 in) max.

Construction Aluminum with a fiberglass insert

Available catalog numbers for this encoder:

845-FC-B-B

845-FC-B-C

845-FC-B-R

845-FC-B-T

845-FC-A-B

845-FC-R-B

Product Selection

845 — FC — B—B

ab

a

Smallest Bore Diameter

Code Description

A1/4 inch

B3/8 inch

R6 mm

T 10 mm

b

Largest Bore Diameter

Code Description

A1/4 inch

B3/8 inch

C1/2 inch

R6 mm

T 10 mm

3

Page 4

Approximate Dimensions [mm (in.)]

X

YZ

AT TE N T IO N : The shielded cables, output

devices, and power supplies must be properly

grounded. All National Electric Code and

applicable local codes and ordinances must be

observed when wiring the system.

Angle

Parallel

Offset

AT TE N T IO N : Rigidly coupling the encoder

shaft to the machine shaft will cause a failure

in either the bearings of the encoder or the

bearings of the machine shaft.

High Performance Flexible Coupling

Dimension

Code

X 6.4 (0.25) 9.5 (0.375) 12.7 (0.50) 6 1 0

Y 30.56 (1.20) Dia.

Z 32 (1.25)Long

ABCRT

Flexible Shaft Couplings

Bore Size Code Letter

10000011167 Ver 01

September 2012

Loading...

Loading...