Page 1

QUICK START

ARMORSTART®

ETHERNET/IP DISTRIBUTED

MOTOR CONTROLLER

Getting Started

BULLETIN 280E, 281E AND 284E

Introduction

This guide provides the basic information required to start up an

®

ArmorStart

Controller. For detailed information on specific product features or

configurations, refer to the ArmorStart EtherNet/IP user manual,

Publication 280E-UM001*.

The user should have a clear understanding of EtherNet/IP™ network

operations, including how slave devices operate on a network and

communicate with other devices and the controller. Also, the user should

be familiar with and have access to RSLogix 5000™ revision 17.01 or later.

This programming software package is referred to often in this manual.

EtherNet/Industrial Protocol (IP) Distributed Motor

ATTENTION: This guide is intended for qualified service

personnel responsible for setting up and servicing these devices.

The user must have previous experience with and a basic

understanding of electrical terminology, configuration procedures,

required equipment, and safety precautions.

Page 2

2 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

General Precautions

In addition to the precautions listed throughout this manual, the following

statements, which are general to the system, must be read and understood.

ATTENTION: The controller contains ESD (electrostatic discharge)

sensitive parts and assemblies. Static control precautions are

required when installing, testing, servicing, or repairing the

assembly. Component damage may result if ESD control

procedures are not followed. If you are not familiar with static

control procedures, refer to Publication 8000-4.5.2, Guarding

against Electrostatic Discharge, or any other applicable ESD

protection handbooks.

ATTENTION: An incorrectly applied or installed controller can

damage components or reduce product life. Wiring or application

errors, such as undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures, may result in

malfunction of the system.

Precautions for Bulletin 280E/281E Applications

Precautions for Bulletin 284E Applications

ATTENTION: Only personnel familiar with the controller and

associated machinery should plan or implement the installation,

startup, and subsequent maintenance of the system. Failure to do

this may result in personal injury and/or equipment damage.

ATTENTION: To prevent electrical shock, open disconnect switch

prior to connecting and disconnecting cables. Risk of shock –

environment rating may not be maintained with open receptacles.

ATTENTION: The drive contains high voltage capacitors which

take time to discharge after removal of mains supply. Before

working on drive, ensure isolation of mains supply from line inputs

(R, S, T [L1, L2, L3]). Wait three minutes for capacitors to discharge

to safe voltage levels. Failure to do so may result in personal injury

or death. Darkened display light-emitting diode (LED)s are not an

indication that capacitors have discharged to safe voltage levels.

Risk of shock – environment rating may not be maintained with

open receptacles.

Publication 280E-QS001B-EN-P – February 2011

Page 3

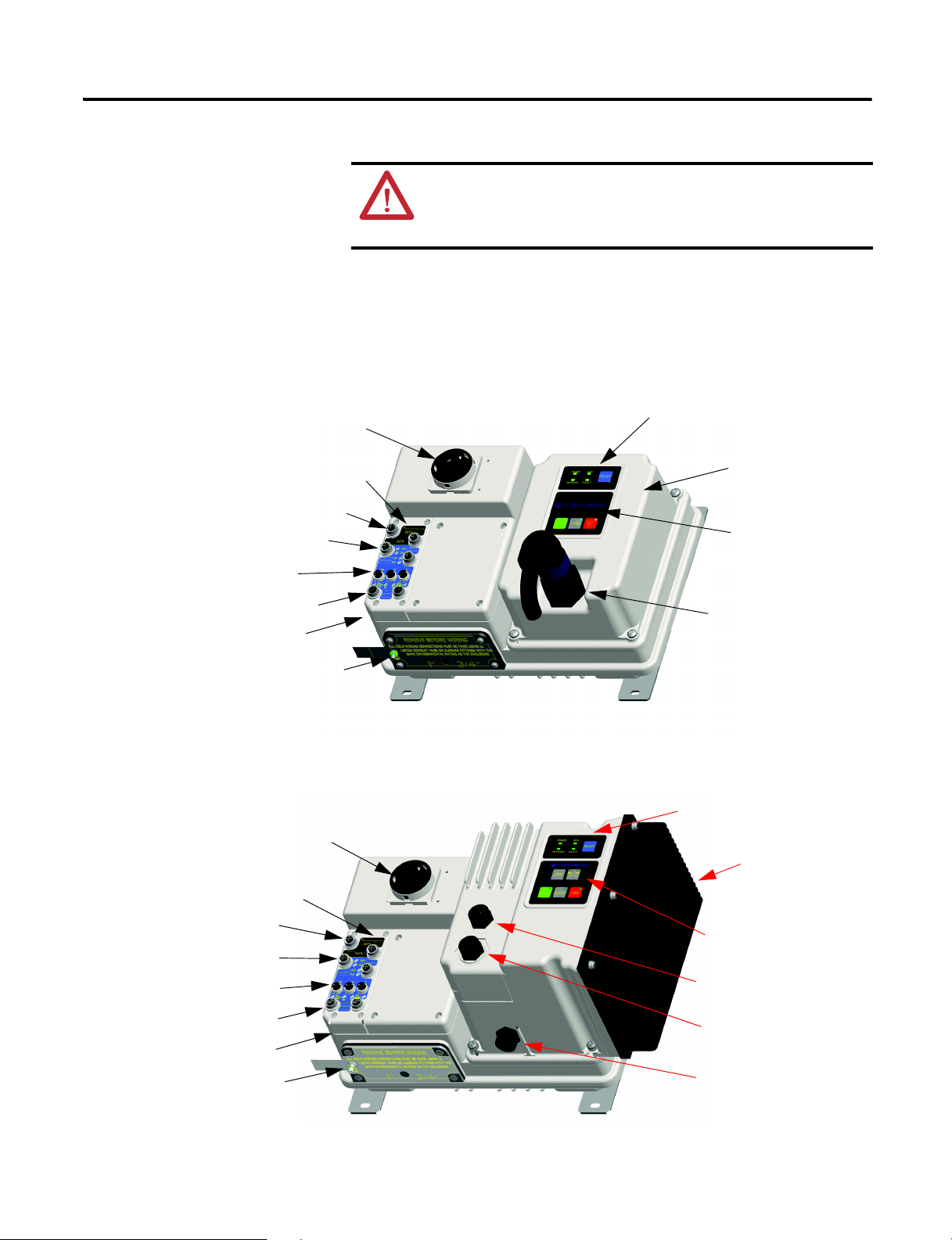

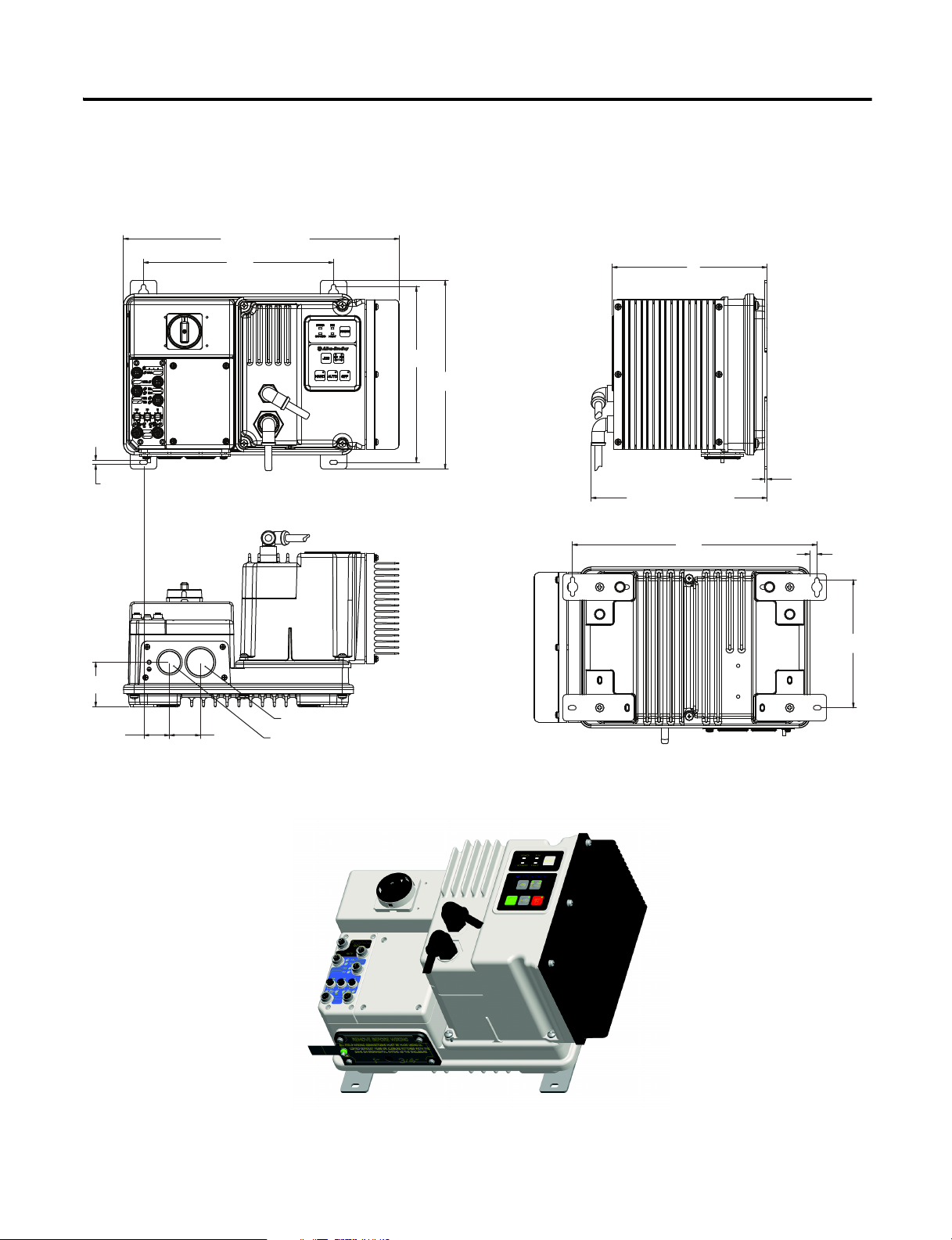

ArmorStart EtherNet/IP

LED Status

Indication and Reset

Motor Connection

4 Inputs (Micro/M12)

IP Address Notation Area

Ethernet Ports (DLR)

Local Disconnect

Ground Terminal

2 Outputs (Micro/M12)

Hand-Off-Auto Keypad

IP Address Switches

Control Module

Base Module

LED Status

Indication and Reset

Motor Connection

Source Brake Connection

4 Inputs (Micro/M12)

Ethernet Ports (DLR)

Local Disconnect

Ground Terminal

2 Outputs (Micro/M12)

IP Address Switches

IP Address Notation Area

Hand-Off-Auto Keypad

Control Module

Base Module

Dynamic Brake Connection

Features

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 3

ATTENTION: Only qualified personnel familiar with adjustable frequency

AC drives and associated machinery should plan or implement the

installation, startup, and subsequent maintenance of the system. Failure

to do this may result in personal injury and/or equipment damage.

Figure 1 – Bulletin 280E/281E ArmorStart with EtherNet/IP™

Communication Protocol

Figure 2 – Bulletin 284E ArmorStart with EtherNet/IP™ Communication Protocol

Publication 280E-QS001B-EN-P – February 2011

Page 4

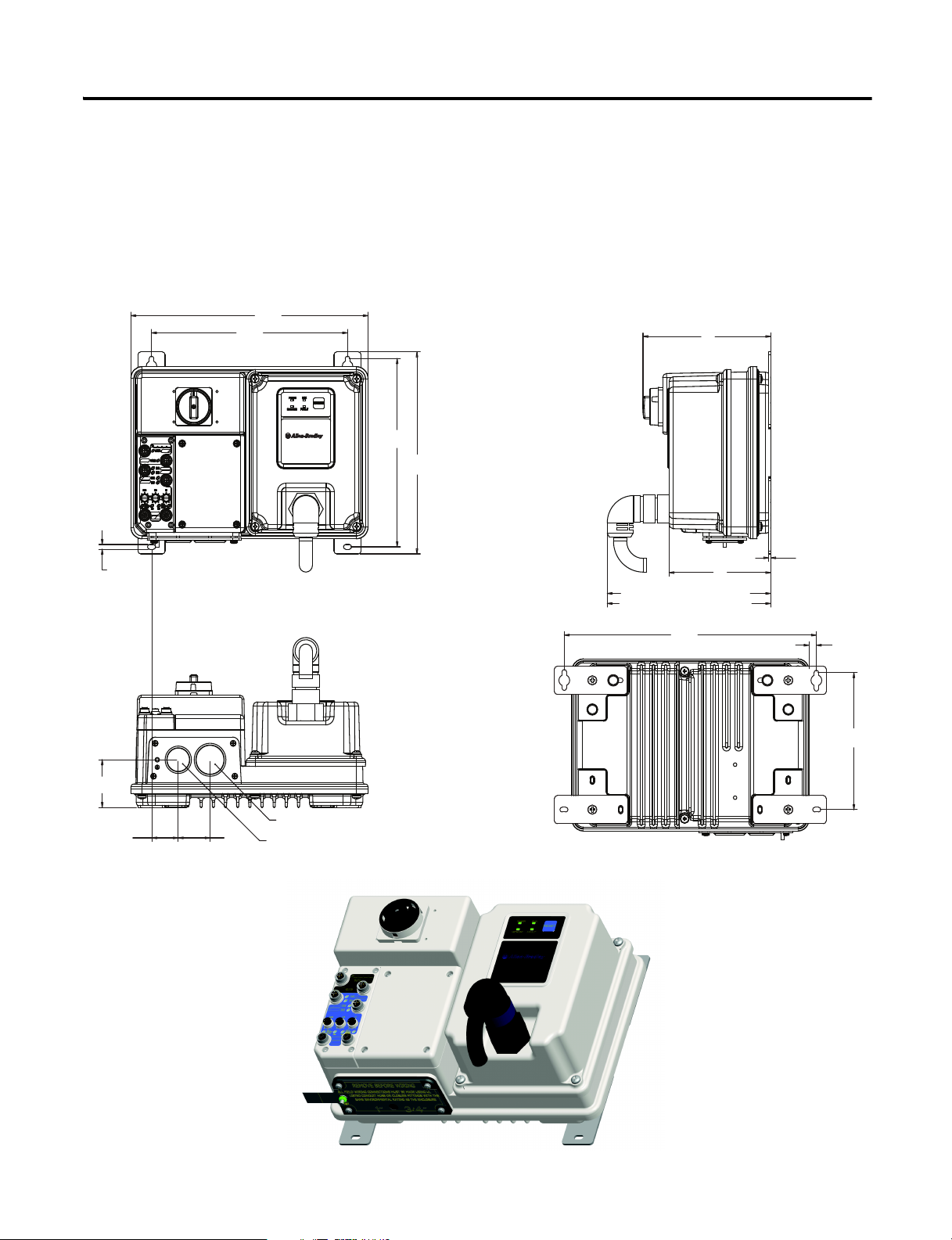

4 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

39

2[]

47

1.85[]

67,9

3[]

3,02

.12[]

373

14.69[]

11

.43[]

195

7.68[]

189

7[]

OR CONNECTION 185 [7.3] M22 CORDSETMOT

MOTOR ECTION 243 [9.57] M35 CORDSETCONN

150

6[]

351

13.82[]

0.75" CONDUIT OPENING

1" CONDUIT OPENING

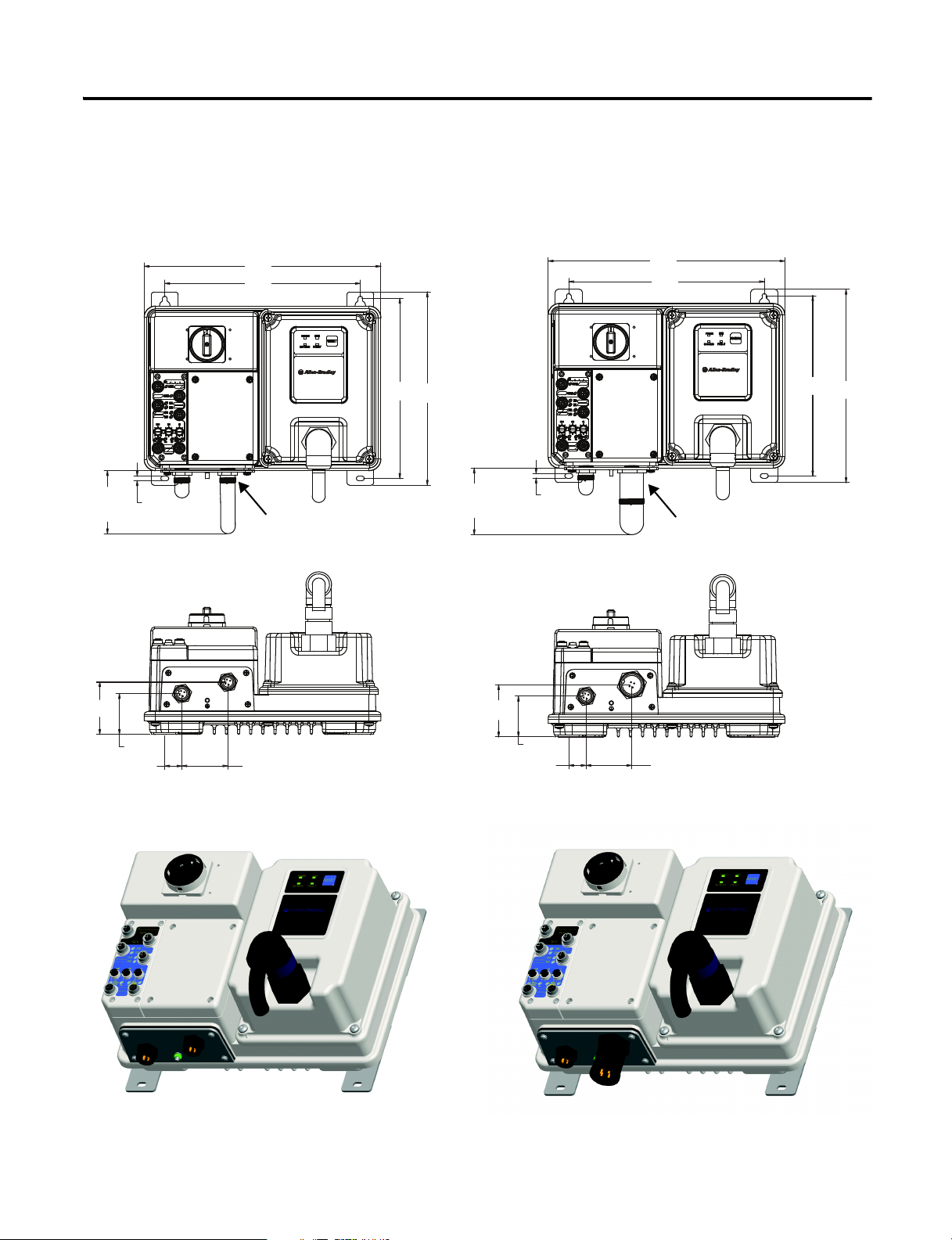

Dimensions

Conduit Gland Entrance

Dimensions are shown in millimeters (inches). Dimensions are not intended to

be used for manufacturing purposes. All dimensions are subject to change.

Figure 3 – Dimensions for Bulletin 280E/281E

Publication 280E-QS001B-EN-P – February 2011

Page 5

Conduit Gland Entrance

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

39

2[]

47

1.85[]

67,9

3[]

3,02

.12[]

373

14.69[]

11

.43[]

195

7.68[]

236

9[]

2HP or less 420.38 [16.55]

3HP or greater 444.38 [17.50]

R CONNECTION 266.9 [10.51]MOTO

0.75" CONDUIT OPENING

1" CONDUIT OPENING

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 5

Figure 4 – Dimensions for Bulletin 284E

Publication 280E-QS001B-EN-P – February 2011

Page 6

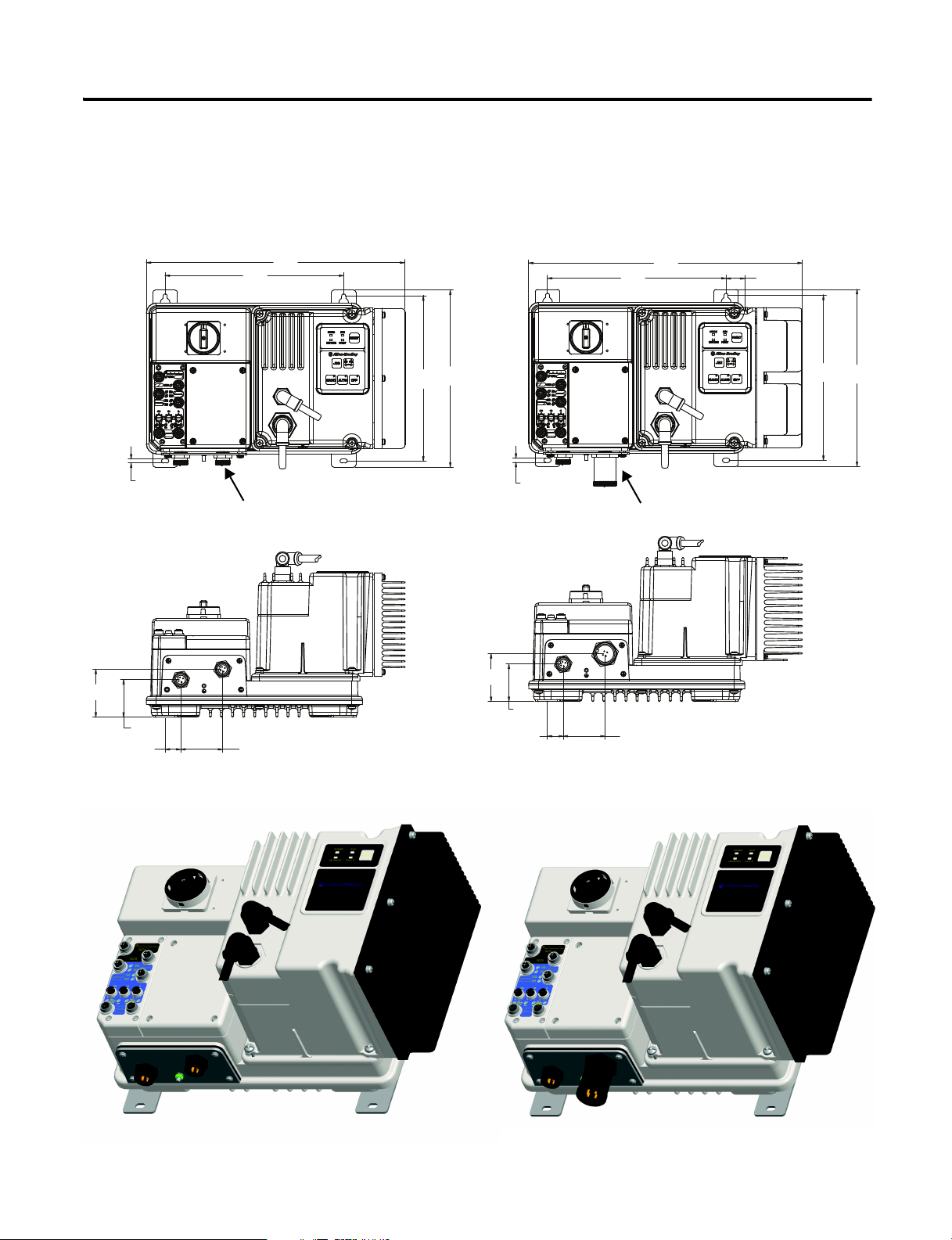

6 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

203.2

[8]

CABLE

KEEP OUT

203.2

[8]

CABLE

KEEP OUT

68

2.68[]

60,6

2[]

77,6

3[]

25,5

1[]

351

13.82[]

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

25,5

1[]

68

2.68[]

60,6

2[]

77,6

3[]

351

13.82[]

290

11.42[]

268

10.55[]

287,5

11.32[]

6,8

.27[]

10 Hp @ 480V AC

3 Hp and less @ 480V AC

25 Amp Short Circuit

Protection (M35)

10 Amp Short Circuit

Protection (M22)

ArmorConnect® Gland Connectivity

Figure 5 – Dimensions for Bulletin 280E/281E

Publication 280E-QS001B-EN-P – February 2011

Page 7

ArmorConnect Gland

68

2.68[]

60,6

2[]

77,6

3[]

25,5

1[]

419,53

16.52[]

290

11.42[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

25,5

1[]

68

2.68[]

60,6

2[]

77,6

3[]

444,38

17.50[]

290

11.42[]

30,4

1[]

287,5

11.32[]

268

10.55[]

6,8

.27[]

3 Hp or greater at 480V

2 Hp or less at 480V

25 Amp Short Circuit

Protection (M35)

10 Amp Short Circuit

Protection (M22)

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 7

Connectivity

Figure 6 – Dimensions for Bulletin 284E

Publication 280E-QS001B-EN-P – February 2011

Page 8

8 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

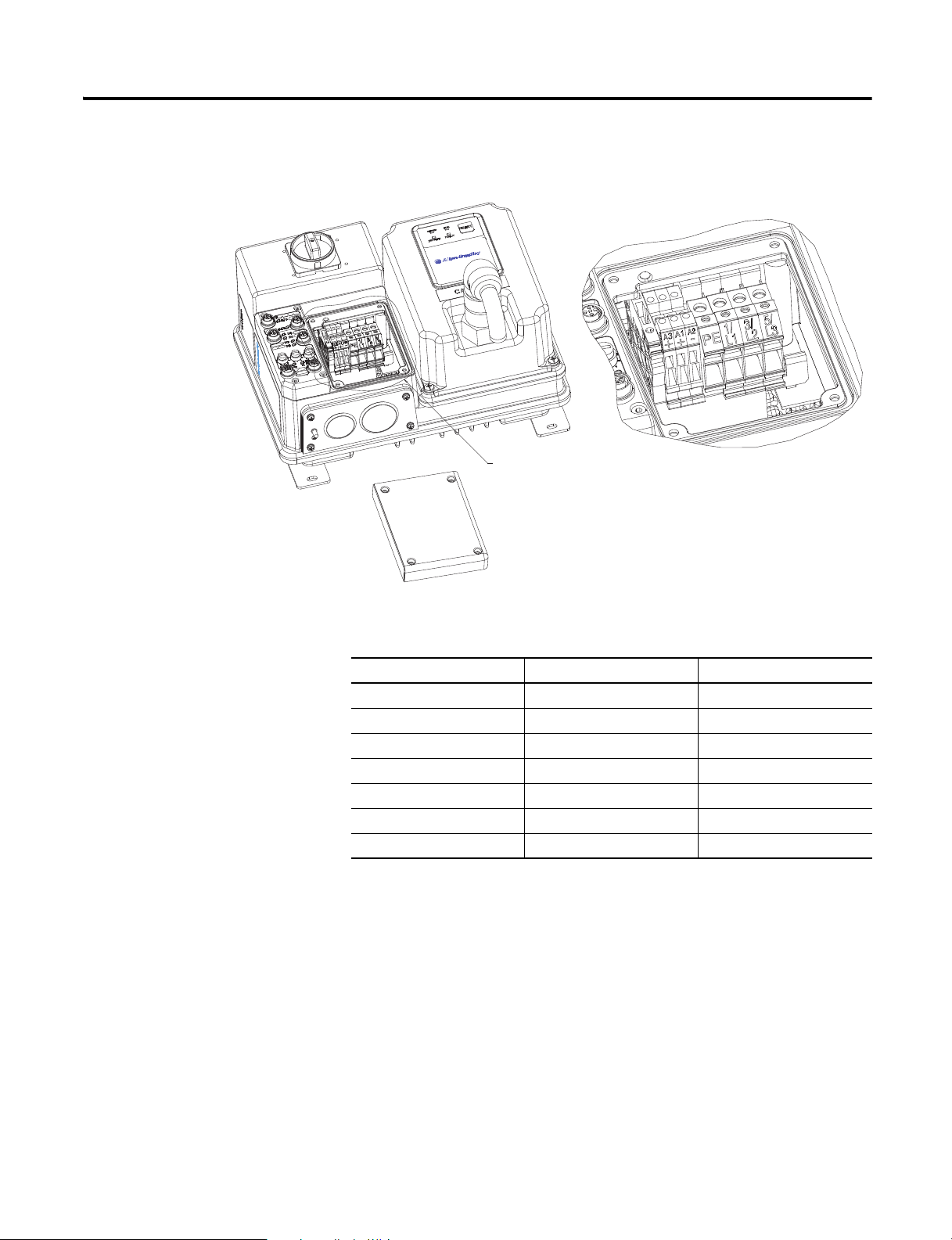

Control and Power Connections

Figure 7 – ArmorStart EtherNet/IP Power and Control Terminals

See Detail A

Detail A

Table 1 - Power, Control and Ground Terminal Designations

Terminal Designations No. of Poles Description

A1 (+) 2 Control Power Input

A2 (–) 2 Control Power Common

A3 (+) 2 Unswitched 24V Control

PE 2 Ground

1/L1 2 Line Power Phase A

3/L3 2 Line Power Phase B

5/L5 2 Line Power Phase C

Publication 280E-QS001B-EN-P – February 2011

Page 9

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 9

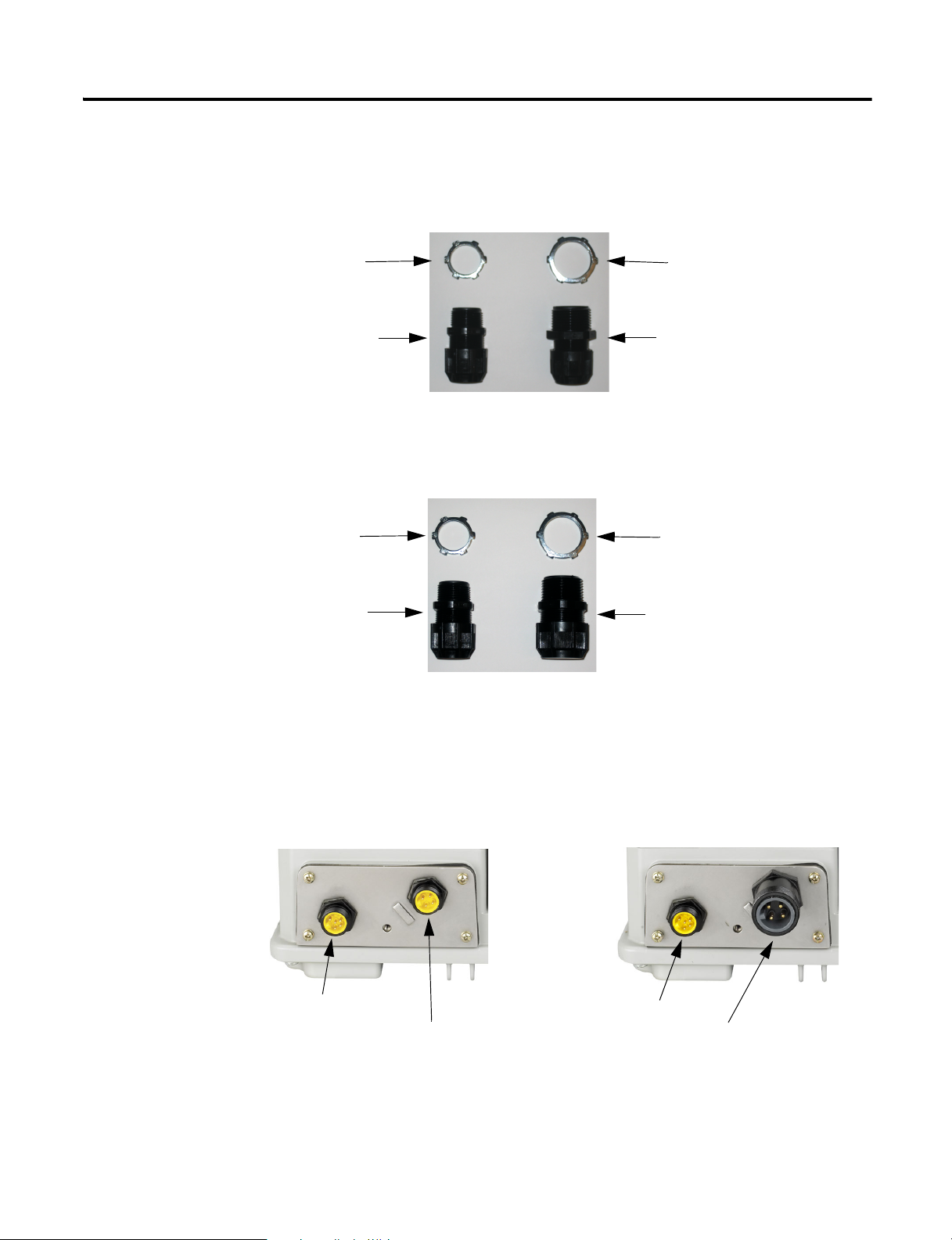

3/4 in. Lock Nut 1 in. Lock Nut

Thomas & Betts Cord Grip

Cat. No. 2931NM

3/4 in. Stain Relief Cord Connector

Cable Range: 0.31…0.56 in.

Used with Control Power Media

Cordset - Example:

Cat. No. 889N-M65GF-M2

Thomas & Betts Cord Grip

Cat. No. 2940NM

1 in. Stain Relief Cord Connector

Cable Range: 0.31…0.56 in.

Used with Three-Phase Power

Media Cordset - Example:

Cat. No. 280-PWR22G-M1

3/4 in. Lock Nut 1 in. Lock Nut

Thomas & Betts Cord Grip

Cat. No. 2931NM

3/4 in. Stain Relief Cord Connector

Cable Range: 0.31…0.56 in.

Used with Control Power Media

Cordset - Example:

Cat. No. 889N-M65GF-M2

Thomas & Betts Cord Grip

Cat. No. 2942NM

1 in. Stain Relief Cord Connector

Cable Range: 0.70…0.95 in.

Used with Three-Phase Power

Media Cordset - Example:

Cat. No. 280-PWR35G-M1

Control Power Receptacle

Three-Phase Power Receptacle

Control Power Receptacle

Three-Phase Power Receptacle

10 A Short Circuit Protection Rating 25 A Short Circuit Protection Rating

Recommended Cord Grips

Figure 8 – Cord grips for ArmorStart

Figure 9 – Cord grips for ArmorStart

Devices with 10 A Short Circuit Protection Rating

Devices with 25 A Short Circuit Protection Rating

ArmorConnect Connections

Figure 10 – ArmorConnect Receptacles

Publication 280E-QS001B-EN-P – February 2011

Page 10

10 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Factory installed ArmorConnect gland plate connections

Figure 11 – ArmorConnect Connections

Table 2 - ArmorConnect Gland Plate Conductor Color Code

Control Power Wiring

Terminal Designations Description Color Code

A1 (+) Control Power Input Blue

A2 (–) Control Power Common Black

A3 (+) Unswitched Control Power Red

PE Ground Green/Yellow

1/L1 Line Power – Phase A Black

2/L2 Line Power – Phase B White

3/L3 Line Power – Phase C Red

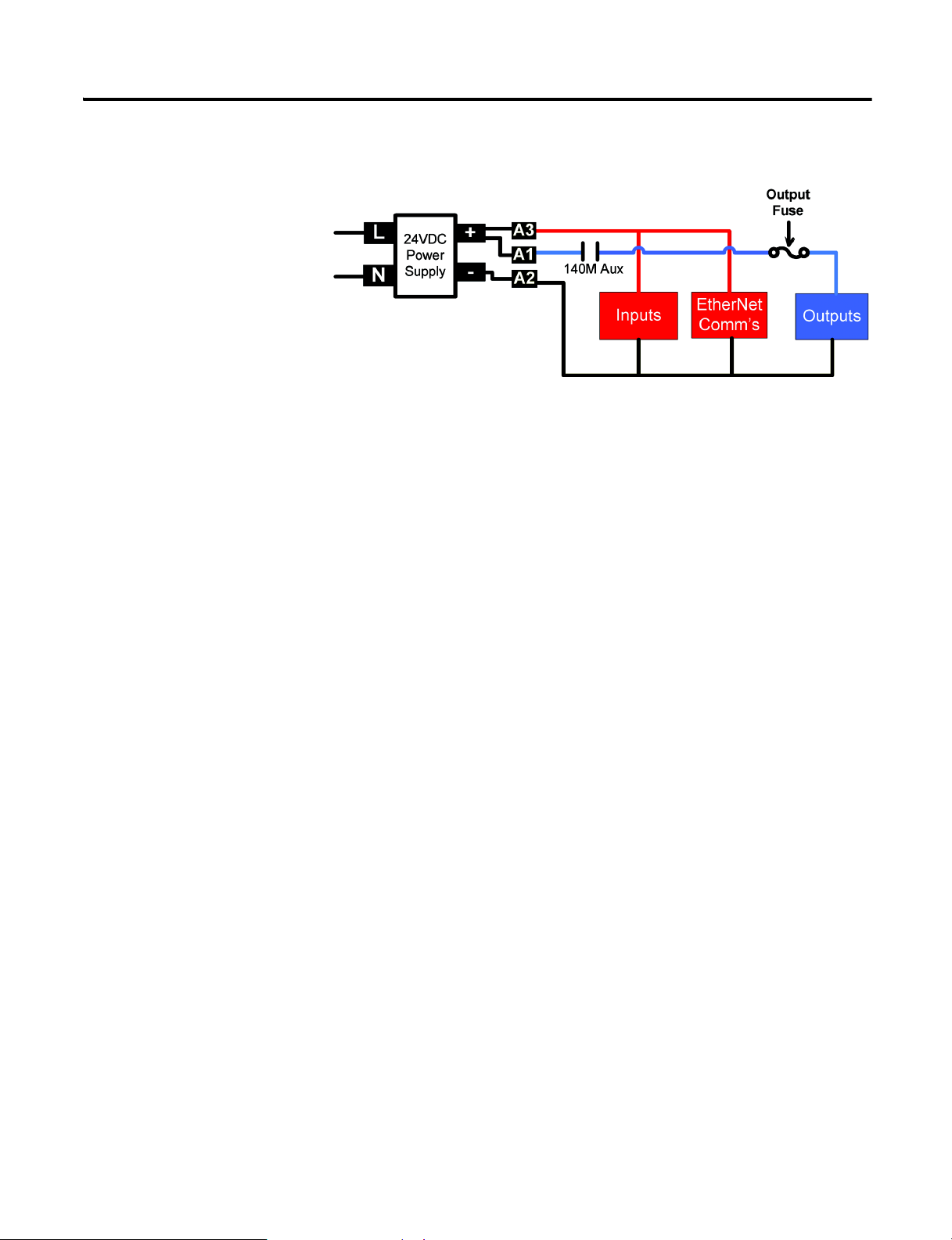

ArmorStart EtherNet/IP utilizes 24V DC control power for communications

and I/O. The control power terminal connections are labeled A1,A2, and A3.

Switched power will supply the outputs. Unswitched power will supply logic

power and sensor inputs. The diagram below provides the user an example of the

internal and external connections for proper operation.

Publication 280E-QS001B-EN-P – February 2011

Page 11

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 11

Figure 12 – Control Power Wiring Example

24V DC Control Power

• Rated Operation Voltage

– 24V DC (–15%, +10%)

• A1 = Switched +V

• A2 = Common for both switched and unswitched (–V)

• A3 = Unswitched +V

Group Motor Installations for USA and Canada Markets

The ArmorStart Distributed Motor controllers are listed for use with each other

in group installations per NFPA 79, Electrical Standard for Industrial Machinery.

When applied according to the group motor installation requirements, two or

more motors, of any rating or controller type, are permitted on a single branch

circuit. Group Motor Installation has been successfully used for many years in the

USA and Canada.

Wiring and Workmanship Guidelines

In addition to conduit and seal-tite raceway, it is acceptable to utilize cable that is

dual rated Tray Cable, Type TC-ER and Cord, STOOW, for power and control

wiring on ArmorStart installations. In the USA and Canada installations, the

following guidance is outlined by the NEC and NFPA 79.

In industrial establishments where the conditions of maintenance and

supervision ensure that only qualified persons service the installation, and where

the exposed cable is continuously supported and protected against physical

damage using mechanical protection, such as struts, angles, or channels, Type TC

tray cable that complies with the crush and impact requirements of Type MC

(Metal Clad) cable and is identified for such use with the marking Type TC-ER

(Exposed Run)* shall be permitted between a cable tray and the utilization

Publication 280E-QS001B-EN-P – February 2011

Page 12

12 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

equipment or device as open wiring. The cable shall be secured at intervals not

exceeding 1.8 m (6 ft) and installed in a “good workman-like” manner.

Equipment grounding for the utilization equipment shall be provided by an

equipment grounding conductor within the cable.

*Historically cable meeting these crush and impact requirements were designated

and marked “Open Wiring”. Cable so marked is equivalent to the present Type

TC-ER and can be used.

While the ArmorStart is intended for installation in factory floor environments

of industrial establishments, the following must be taken into consideration when

locating the ArmorStart in the application: Cables, including those for control

voltage including 24V DC and communications, are not to be exposed to an

operator or building traffic on a continuous basis. Location of the ArmorStart to

minimize exposure to continual traffic is recommended. If location to minimize

traffic flow is unavoidable, other barriers to minimize inadvertent exposure to the

cabling should be considered. Routing cables should be done in such a manner to

minimize inadvertent exposure and/or damage.

Additionally, if conduit or other raceways are not used, it is recommended that

strain relief fittings be utilized when installing the cables for the control and

power wiring through the conduit openings.

The working space around the ArmorStart may be minimized as the ArmorStart

does not require examination, adjustment, servicing or maintenance while

energized. In lieu of this service, the ArmorStart is meant to be unplugged and

replaced after proper lockout/tag-out procedures have been employed.

The Hand-Off-Auto (HOA) is a factory installed option that the user may select.

The HOA keypad may require the ArmorStart to be selected and installed as

follows if the application requires frequent use of the hand operated interface by

the equipment operator:

1. They are not less than 0.6 m (2 ft) above the servicing level and are within

easy reach of the normal working position of the operator.

2. The operator is not placed in a hazardous situation when operating them.

3. The possibility of inadvertent operation is minimized.

If the operated interface is used in industrial establishments where the conditions

of maintenance and supervision ensure that only qualified persons operate and

service the ArmorStart's operator interface, and the installation is located so that

inadvertent operation is minimized then other installation locations with

acceptable access can be provided.

Publication 280E-QS001B-EN-P – February 2011

Page 13

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 13

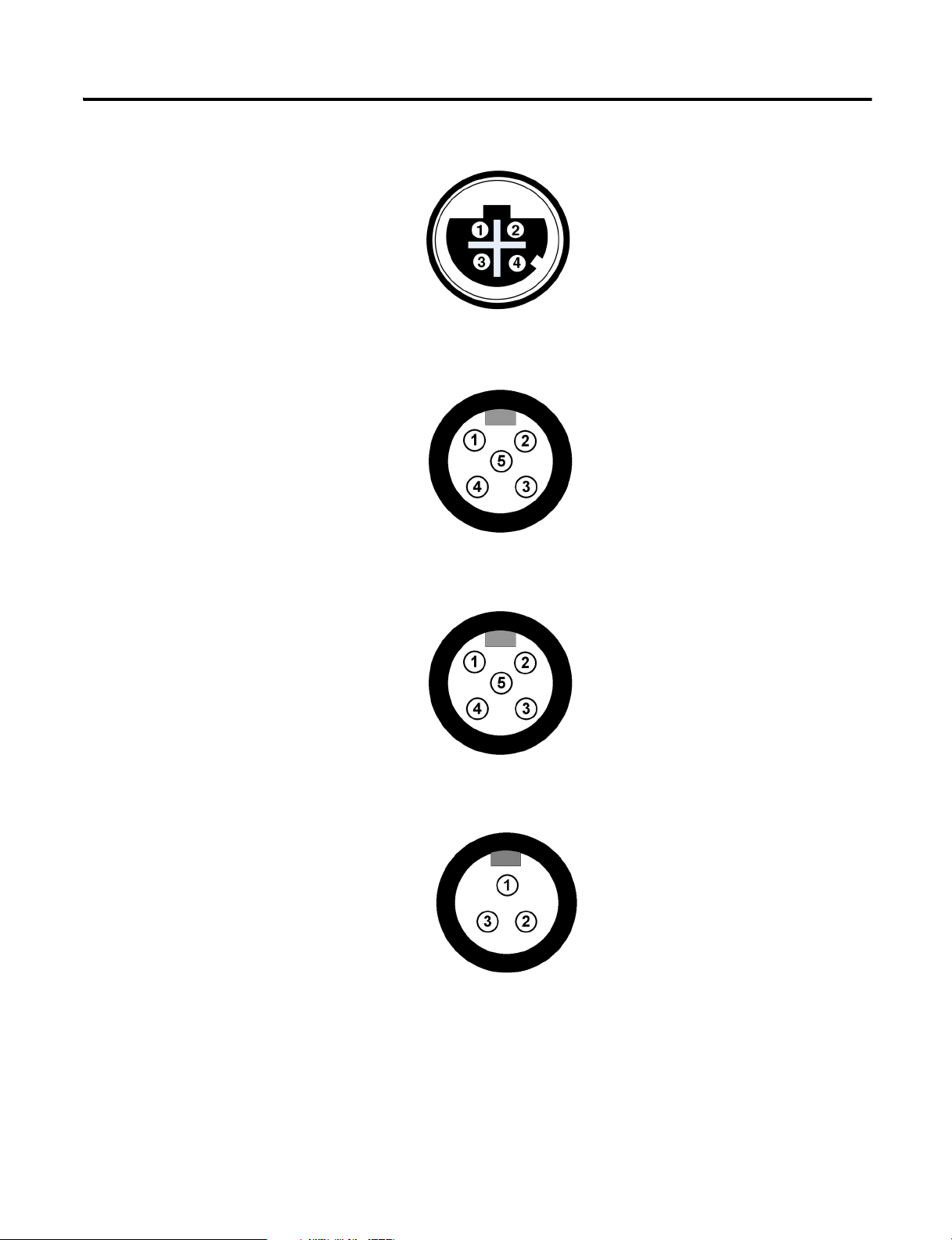

Pin 1: Tx+

Pin 2: Rx+

Pin 3: Tx–

Pin 4: Rx–

Pin 1: +24V (A3 or DNET)

Pin 2: Input 0

Pin 3: Common

Pin 4: Input 1

Pin 5: NC (no connection)

Pin 1: NC (no connection)

Pin 2: NC (no connection)

Pin 3: Common

Pin 4: Output +24V DC (A1)

Pin 5: NC (no connection)

Pin 1: GND (green/yellow)

Pin 2: BR+ (black)

Pin 3: BR- (white)

ArmorStart Receptacle Pin Outs

Figure 13 – Receptacle Connections for EtherNet/IP (M12)

Figure 14 – Receptacle Connections for Input (M12)

Figure 15 – Receptacle Connections for Output, EtherNet/IP Version (M12)

Figure 16 – Receptacle Connections for Dynamic Brake (M22) – Bulletin 284E only

Publication 280E-QS001B-EN-P – February 2011

Page 14

14 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

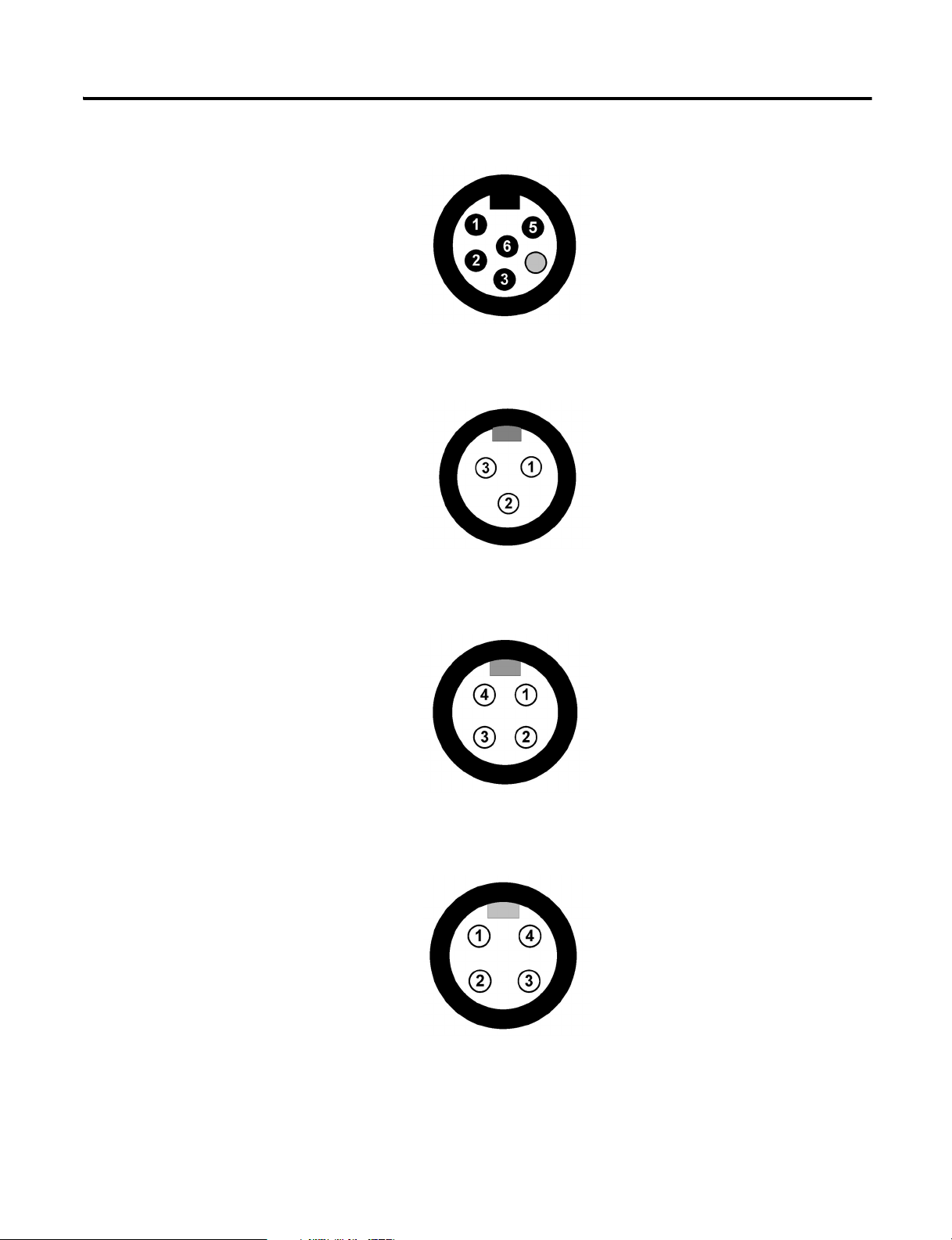

Pin 1: +24V DC unswitched (A3) (red)

Pin 2: Common (A2) (black)

Pin 3: PE (green)

Pin 4: Not used (blank)

Pin 5: +24V DC switched (A1) (blue)

Pin 6: Not used (white)

Pin 1: L1 (black)

Pin 2: GND (green/yellow)

Pin 3: L2 (white)

Pin 1: T1 (black)

Pin 2: T2 (white)

Pin 3: T3 (red)

Pin 4: Ground (green/yellow)

Pin 1: T1 (black)

Pin 2: Ground (green/yellow)

Pin 3: T3 (red)

Pin 4: T2 (white)

Figure 17 – Receptacle Connections for Incoming Control Power – 24V DC Only

Figure 18 – Receptacle Connections for Source or Control Brake – Bulletin 284E

only

Figure 19 – Receptacle Connections for Motor Connector (M22) – Bulletin 280E/

281E: 3 Hp or less and Bulletin 284E: 5 Hp or less

Figure 20 – Receptacle Connections for Motor Connector – 10 Hp or greater (M35) –

Bulletin 280E/281E only

Publication 280E-QS001B-EN-P – February 2011

Page 15

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 15

Pin 1: L1 (black)

Pin 2: L2 (white)

Pin 3: L3 (red)

Pin 4: Ground (green/yellow)

Pin 1: L1 (black)

Pin 2: Ground (green/yellow)

Pin 3: L3 (red)

Pin 4: L2 (white)

Figure 21 – Receptacle Connections for Incoming 3-Phase Power – 10 A Short

Circuit Protection (M22)

Figure 22 – Receptacle Connections for Incoming 3-Phase Power – 25 A Short

Circuit Protection (M35)

AC Supply Considerations for Bulletin 284E Units

Ungrounded and High Resistive Distribution Systems

ATTENTION: The Bulletin 284E contains protective Metal Oxide

Varistors (MOV)s that are referenced to ground. These devices

should be disconnected if the Bulletin 284E is installed on an

ungrounded and high resistive distribution system.

Disconnecting MOVs

To prevent drive damage, the MOVs connected to ground must be disconnected

if the drive is installed on an ungrounded and high resistive distribution system

where the line-to-ground voltages on any phase could exceed 125% of the

nominal line-to-line voltage. To disconnect the MOVs, remove the jumper shown

in Figure 24, Jumper Removal.

1. Before installing the Bulletin 284E, loosen four mounting screws.

2. Unplug control module from the base unit by pulling forward.

Publication 280E-QS001B-EN-P – February 2011

Page 16

16 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Remove Jumper

Figure 23 – 284E Removal of Control Module

Figure 24 – 284E Jumper Removal

ATTENTION: DO NOT remove this jumper if the unit is

equipped with an EMI filter installed.

Publication 280E-QS001B-EN-P – February 2011

Page 17

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 17

Protective IP67 Caps

Writable surface for IP address

Configuring EtherNet/IP Address

Before using the ArmorStart you may need to configure an IP address, subnet

mask, and optional Gateway address. The rotary network address switches found

on the I/O section of the ArmorStart are set to 999 and DHCP is enabled as the

factory default. The ArmorStart reads these switches first to determine if the

switches are set to a valid IP address between 1…254. When switches are set to a

valid number the IP address will be 192.168.1._ _ _ [switch setting].

The IP address can also be set using DHCP or BootP.

• If BootP is preferred, use Rockwell Automation BootP utility, version 2.3

or later, that ships with RSLogix™ 5000 or RSLinx® software.

• If DHCP is preferred, use a third party DHCP server.

This document assumes the user has set the IP address to 192.168.1.1. The user

can change this IP address to any address either statically or dynamically.

ATTENTION: To avoid unintended operation, the adapter must be

assigned a fixed IP address. If a DHCP server is used, it must be

configured to assign a fixed IP address for your adapter.

Failure to observe this precaution may result in unintended

machine motion or loss of process control.

Manually Configure the Network Address Switches

Remove the protective caps from the rotary switches. Set the network address by

adjusting the three switches on the front of the I/O module.

Figure 25 – Switches on the I/O Module

Publication 280E-QS001B-EN-P – February 2011

Page 18

18 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

This example shows the

IP address set to 163.

Factory Setting 99

DO NOT CHANGE

IMPORTANT

Figure 26 – Network Address Example

The adapter’s subnet mask will be 255.255.255.0 and the gateway address is set to

0.0.0.0. A power cycle is required for any new IP address to take effect.

If the switches are set to an invalid number (such as 000 or a value greater than

254), the adapter will check to see if DHCP is enabled. If DHCP is enabled, the

adapter requests an address from a DHCP server. If DHCP is not enabled, the

adapter will use the IP address (along with other TCP configurable parameters)

stored in non-volatile memory.

Figure 27 – Rotary Switch on Control Module

X100

8

X10

0

2

6

4

0

8

6

X1

0

2

8

6

4

2

4

Use the Rockwell Automation BootP/DHCP Utility

Publication 280E-QS001B-EN-P – February 2011

Refer to Figure 27, the ArmorStart is shipped with the control module

rotary switches set to a value of 99. DO NOT modify this setting. If

these are changed and the unit stops responding, the switches will need

to be manually set to node address 63 and power cycled.

The Rockwell Automation BootP/DHCP utility is a stand alone program that

incorporates the functionality of standard BootP software with a user friendly

graphical interface. It is located in the Utils directory on the RSLogix5000

installation CD. The ArmorStart EtherNet/IP adapter must have DHCP

enabled (factory default) to use the utility.

Page 19

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 19

IMPORTANT

DHCP IP Support

Using the Rockwell Automation Embedded Web Server

DHCP (Dynamic Host Configuration Protocol) software automatically assigns

IP addresses to client stations logging onto a TCP/IP network.

When DHCP is enabled (factory default Enabled), the unit will request its

network configuration from a DHCP/BOOTP server. Any configuration

received from a DHCP server will be stored in non-volatile memory.

ArmorStart EtherNet/IP will remember the last successful address if DHCP is

enabled. The possibility exists that the adapter will be assigned a different IP

address, which would cause the adapter to cease communicating with the

ControlLogix® controller.

Internal Web Server

ArmorStart Ethernet/IP internal web server allows you to view information and

configure the ArmorStart via a web browser. The embedded web server is used to

access configuration and status data. Security in the form of an administrative

password can be set. The default Login is Administrator. There is no password

set by default.

Caution: The user should set the password to a unique value for

authorized personnel. If the Login and password are lost you will need

to reset the device to factory defaults losing its configuration.

To access the internal web browser, open your computers internet browser and

enter the IP address of the desired ArmorStart (192.168.1.1).

Figure 28 – Internal Web Browser

Publication 280E-QS001B-EN-P – February 2011

Page 20

20 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Parameter Configuration

ArmorStart Ethernet/IP embedded web server provides the user the ability to

view and modify the device configuration without having to access RSLogix 5000.

To view the device configuration from the web server, select the Parameters

folder. For the parameter configuration, the user will login through the

Administrative Settings or when prompted.

E-mail Notification Configuration

ArmorStart Ethernet/IP internal web server will support the e-mailing of

warning and trip messages via Simple Mail Transfer Protocol (SMTP). The

configuration parameters for the SMTP Server’s IP address, user login, and port

number are configurable through the Administrative Settings page of the internal

web server. The user will configure the device name, device description, and

device trip type.

Figure 29 – E-mail Notification Configuration

Publication 280E-QS001B-EN-P – February 2011

E-mail triggers:

– When a trip occurs.

– When a trip is cleared.

– When a warning occurs.

– When a warning is cleared.

Note: “Cleared Event” e-mails will only be sent when all events have been cleared

and if an trip event e-mail has previously been sent. For example, if the device is

configured to send e-mails when a phase loss trip is detected and an overload trip

is detected, no e-mail will be sent when the overload is cleared.

Page 21

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 21

ArmorStart EtherNet/IP Add-On Profile for Logix

The Add-On Profile (AOP) must be installed in order for RSLogix 5000 to fully

support the ArmorStart EtherNet/IP product. The AOP can be downloaded

from http://www.rockwellautomation.com/support/downloads.html.

Example - Adding ArmorStart to RSLogix 5000

1. In the RSLogix 5000 tree select the Ethernet® adapter and add a new

module.

Note: The ArmorStart EtherNet/IP AOP must be installed prior to this

step.

Figure 30 – Controller Organizer

Publication 280E-QS001B-EN-P – February 2011

Page 22

22 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

2. Within the “Other” category select the ArmorStart.

Figure 31 – Select Module Box

3. Configure the new module by adding a name and the IP address.

Figure 32 – New Module Box

Publication 280E-QS001B-EN-P – February 2011

Page 23

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 23

4. Go online with the controller via RSWho and download the project to the

processor.

Figure 33 – RSWho Box

5. Open the controller tags to view the units command, status, and diagnostic

information.

Figure 34 – Controller Tags

Publication 280E-QS001B-EN-P – February 2011

Page 24

24 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Figure 35 – EtherNet/IP LED

Diagnostics

EtherNet/IP LED Status

Indication

Link 1 or 2 Status LED Description Recommended Action

Off No link established Verify network cabling, and correct, as needed.

Green Link established at 100 Mbps None

Flashing green Transmit or receive activity present at 100 Mbps None

Yellow Link established at 10 Mbps None

Flashing yellow Transmit or receive activity present at 10 Mbps None

EtherNet/IP LED status and diagnostics consists of four LEDs.

• Link Activity/Status LEDS

– Ethernet Link1 Activity/Status (Port 1) – LED Color: Bicolor

(Green/Yellow), refer to Table 3

– Ethernet Link2 Activity/Status (Port 2) – LED Color: Bicolor

(Green/Yellow), refer to Table 3

• “MOD” LED – Bicolor Red/Green represents the Ethernet Module

status, refer to Table 4

• “NET” LED – Bicolor Red/Green represents the Ethernet Network

status, refer to Table 6

Table 3 - Link 1 or Link 2 Port Activity/Status

Publication 280E-QS001B-EN-P – February 2011

Table 4 - Module Status Indicator

MOD Status LED Summary Requirement

Steady Off No power If no power is supplied to the device, the module status indicator shall be

steady off.

Steady Green Device operational If the device is operating correctly, the module status indicator shall be

steady green.

Flashing Green Standby If the device has not been configured, the module status indicator shall

be flashing green.

Flashing Red Minor fault If the device has detected a recoverable minor fault, the module status

indicator shall be flashing red.

Note: An incorrect or inconsistent configuration would be considered a

minor fault.

Steady Red Major fault If the device has detected a non-recoverable major fault, the module

status indicator shall be steady red, refer to Table 5.

Flashing Green/Red Self-test While the device is performing its power up testing, the module status

indicator shall be flashing green/red.

Page 25

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 25

Figure 36 – LED Status

Indication and Reset

Refer to Parameter 63 "Base Trip" for the Base Module Trip Status.

Table 5 - "Steady Red" MOD LED Status (Refer to Table 4 above.)

Fault Type Description

0 EEPROM Fault Non-volatile memory value out of range for a local parameter, or a write failure detected. This fault

1 Internal Comm2 The Internal communication connection has timed out. This fault is also reflected by a flashing red

2 Hardware Fault Internal diagnostics checks failed. This fault is also reflected by a solid red MOD status LED.

3 Control Module An illegal or unsupported Control Module product code or revision has been detected. Also reported

4…15 Reserved Reserved

NET Status LED Description Recommended Action

Flashes

Green-Red-Off

Solid Green The device is operating in a normal condition. No action required.

Flashing Green The device is operating in a normal condition. No action required.

Flashing Red Internal network fault has occurred. Check 3-phase and control power connections.

Solid Red The device has detected a major error that has

is also reflected by a solid red MOD status LED.

MOD status LED.

if no Control Module is detected on power up. This fault is also reflected by a solid red MOD status

LED.

Table 6 - Network LED Status Indication

The device has not completed the initialization, is

not on an active network, or may not be powered up.

rendered it incapable of working.

Check to make sure the product is properly wired

and configured on the network.

Check ethernet connections.

Troubleshooting should be done to ensure that

the control module internal switch settings are

correct. Consult factory.

Control Module LED Status and Reset

The Control Module LED status and diagnostics consists of four status LEDs

and a Reset button. The following is a brief explanation of the operation of each

LED found on the Control Module.

Table 7 - Control Module LED Status Indication

LED Definition Recommended Action

Power This LED will be illuminated solid green

when switched control power is present

and with the proper polarity.

Run This LED will be illuminated solid green

when a start command and control power

is present.

Network This bicolor LED is used to indicate the

status of the internal network connection.

Fault This LED is used to indicate the fault

status of the ArmorStart. When the unit is

faulted, the unit will respond with a

specific blink pattern to identify the fault.

Ensure 24V DC is present on A1 and A2.

Check if the local disconnect is in the OFF

position.

Ensure 24V DC is present on A1 and A3.

Check if the user is properly commanding to

RUN via Instance 162 or 166.

See Table 6, Network LED Status Indication

table above for additional information.

See Table 8 and Table 9 below for

additional information.

The “Reset Button” is a local trip reset.

Publication 280E-QS001B-EN-P – February 2011

Page 26

26 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Control Module Fault LED Indications

Table 8 - Fault LED Indicators for Bulletin 280E/281E

Blink

Pattern

1 No Short Circuit The circuit breaker (140M) has tripped. Determine cause of trip. Try to reset the circuit

2 Yes Overload The load has drawn excessive current and based

3 Yes Phase Loss The ArmorStart has detected a missing phase. Verify that 3-phase voltage is present at the line

4 — Reserved Not Used —

5 — Reserved Not Used —

6 Yes Control Pwr Loss

7 Yes Input Fault This error indicates a shorted sensor, shorted

8 Yes Over Temperature This fault is generated when the operating

9 Yes Phase Imbalance The ArmorStart has detected a voltage

10 Yes Control Power (24V DC)

11 — Reserved Not Used —

12 — Reserved Not Used —

13 No EEprom This is a major fault, which renders the

14 No Hdw Flt This fault indicates that a serious hardware

15 — Reserved Not Used —

16 — Reserved Not Used —

Auto-

Resettable

Bulletin 280E/281E

Trip Status Description Action

breaker using the disconnect handle. If the

conditions continue, check power wiring or

replace based module. This cannot be disabled.

Verify that the load is operating correctly and

the ArmorStart is properly set-up. the fault

cannot be disabled.

side connections. This fault can be disabled and

is disabled by default.

Check control voltage, wiring, and proper

polarity (A1/A2 terminal). Also, check and

replace the control voltage fuse, if necessary.

This fault can be disabled and is disabled by

default.

Correct, isolated or remove wiring error prior to

restarting the system. This fault can be disabled

and is disabled by default.

Check for blocked or dirty heat sink fins. Verify

that ambient temperature has not exceeded

40°C (104°F). 1. Clear the fault or cycle power to

the drive.

Check the power system and correct if

necessary. This fault can be disabled and is

disabled by default.

Check the state of the network power supply

(A3/A1 terminal) and look for media problems.

This fault can be disabled and is disabled by

default.

If the fault was initiated by a transient, power

cycling should clear the problem, otherwise

replacement of the ArmorStart may be required.

This fault cannot be disabled.

Check for a base/starter module mismatch. If no

mismatch exists, the ArmorStart may need to be

replaced. (Hdw Flt is the factory-enabled default

setting.) This fault cannot be disabled.

(Switched Power)

Lost (Unswitched

Power)

on the trip class selected, the device has

tripped.

The ArmorStart has detected a loss of the

control power voltage.

input device, wiring input mistakes, or a blown

output fuse.

temperature has been exceeded. This fault

cannot be disabled.

imbalance.

The 24V DC power supply is below tolerance

threshold.

ArmorStart inoperable. Possible causes of this

fault are transients induced during EEprom

storage routines.

problem exists.

Publication 280E-QS001B-EN-P – February 2011

Page 27

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 27

Table 9 - Fault LED Indicators for 284E

Bit/Blink

Pattern

1 No Short Circuit The circuit breaker (140M) has tripped. Determine cause of trip. Try to reset the circuit

2Drive

3Drive

4Drive

5Drive

6

7

8

9Drive

10

11 No Internal Comm

12 Drive

Auto-

Resettable 284E Trip Status Description Action

breaker using the disconnect handle. If the

conditions continue, check power wiring or

replace based module. This cannot be disabled.

Controlled

Controlled

Controlled

Controlled

Parameter 23

(PrFlt Reset

Mode)

Parameter 23

(PrFlt Reset

Mode)

Parameter 23

(PrFlt Reset

Mode)

Controlled

Parameter 23

(PrFlt Reset

Mode)

Controlled

Overload

(Drive Codes 7 and 64)

Phase Short

(Drive Codes 38…43)

Ground Fault

(Drive Code 13)

Stall

(Drive Code 6)

Control Pwr Loss

(Switched Power)

Input Fault This error indicates a shorted sensor, shorted

Over Temperature This fault is generated when the operating

Over Current

(Drive Codes 12 and 63)

Control Power (24V DC)

Lost (Unswitched

Power)

(Drive Code 81)

DC Bus Fault

(Drive Codes Reference

3, 4 and 5)

An excessive motor load exists 1. Reduce load so drive output current does not

1. Phase U, V, or W to Gnd. A phase to ground

fault has been detected between the drive

and motor in this phase.

2. Phase UV, UW, or VW Short. Excessive

current has been detected between these

two output terminals.

A current path to earth ground has been

detected at one or more of the drive output

terminals.

Drive is unable to accelerate motor. Increase Parameters 139…167 (Accel Time x) or

The ArmorStart has detected a loss of the

control power voltage.

input device, wiring input mistakes, or a blown

output fuse.

temperature has been exceeded. This fault

cannot be disabled.

The drive output current has exceeded the

hardware current limit.

The 24V DC power supply is below tolerance

threshold.

RS485 (DSI) port stopped communicating. Clear the fault or cycle power to the drive. If the

Power Loss - DC bus voltage remained below

85% of nominal. UnderVoltage - DC but voltage

fell below the minimum value. OverVoltage - DC

bus voltage exceeded maximum value.

exceed the current set by Parameter 133

(Motor OL Current).

2. Verify Parameter 184 (Boost Select) setting.

3. Drive rating of 150% for 1 minute.

4. Reduce load or extend Accel Time two

hundred percent or when 3 seconds has been

exceeded.

Check the wiring between the drive and motor.

Check motor for grounded phase. Check the

motor and drive output terminal wiring for a

shorted condition. Replace drive if fault cannot

be cleared.

Check the motor and external wiring to the drive

output terminals for a grounded condition.

reduce load so drive output current does not

exceed the current set by Parameter 189

(Current Limit 1).

Check control voltage, wiring, and proper

polarity (A1/A2 terminal). Also, check and

replace the control voltage fuse, if necessary.

This fault can be disabled and is disabled by

default.

If this fault occurs, the offending problem

should be isolated or removed prior to restarting

the system. This fault can be disabled and is

disabled by default.

Check for blocked or dirty heat sink fins. Verify

that ambient temperature has not exceeded

40°C (104°F).

1. Clear the fault or cycle power to the drive.

Check programming. Check for excess load,

improper Parameter 184 (Boost Select) setting.

DC brake volts set too high or other causes of

excess current. Parameter 198 (SW Current Trip)

has been exceeded, check load requirements

and Parameter 198 setting.

Check the state of the network power supply

(A3/A1 terminal) and look for media problems.

This fault can be disabled and is disabled by

default.

problem persists replace the unit.

Monitor the incoming AC line for low voltage or

line power interruption. Check the input fuses.

Monitor the AC line for high line voltage or

transient conditions. Bus overvoltage can also

be caused by motor regeneration. Extend the

decel time or install dynamic brake option.

Publication 280E-QS001B-EN-P – February 2011

Page 28

28 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Table 9 - Fault LED Indicators for 284E

Bit/Blink

Pattern

13 No EEprom

14 No Hdw Flt (PF Drive Codes

15 Drive

16 Drive

Auto-

Resettable 284E Trip Status Description Action

(PF Drive Code

Reference 100)

Reference 70 and 122)

Controlled

Controlled

Restart Retries (PF

Drive Code Reference

33)

Misc. Fault (PF Drive

Code Reference 2, 8,

29, 48 and 80)

Troubleshooting

The checksum read from the board does not

match the checksum calculated.

Failure has been detected in the drive power

section or drive control and I/O section.

Drive unsuccessfully attempted to reset a fault

and resume running for the programmed number

of Parameter 192 (Auto Rstrt Tries).

Heatsink temperature exceeds a predefined

value. The drive was commanded to write

default values to EEprom. The autotune function

was either cancelled by the user or failed.

Set Parameter 141 (Reset to Defaults) to

Option 1 “Reset Defaults”.

1. Cycle power.

2. Replace drive if fault cannot be cleared.

Correct the cause of the fault and manually

clear.

Check for blocked or dirty heat sink fins. Verify

that ambient temperature has not exceeded

40°C (104°F).

1. Clear the fault or cycle power to the drive.

2. Program the drive parameters as needed.

Restart procedure.

Introduction

The purpose of this section is to assist in troubleshooting the ArmorStart®

Distributed Motor Controller using the LED Status Display and diagnostic

parameters.

ATTENTION: Servicing energized industrial control equipment can be

hazardous. Electrical shock, burns or unintentional actuation of controlled

industrial equipment may cause death or serious injury. For safety of

maintenance personnel as well as others who might be exposed to

electrical hazards associated with maintenance activities, follow the local

safety related work practices (for example, the NFPA70E, Part II in the

United States). Maintenance personnel must be trained in the safety

practices, procedures, and requirements that pertain to their respective

job assignments.

ATTENTION: Do not attempt to defeat or override fault circuits. The

cause of the fault indication must be determined and corrected before

attempting operation. Failure to correct a control system of mechanical

malfunction may result in personal injury and /or equipment damage due

to uncontrolled machine system operation.

ATTENTION: The drive contains high voltage capacitors that take time to

discharge after removal of mains supply. Before working on drive, ensure

isolation of mains supply from line inputs (R, S, T, [L1, L2, L3]). Wait three

minutes for capacitors to discharge to safe voltage levels. Failure to do so

may result in personal injury or death.

Darkened display LEDs is not an indication that capacitors have

discharged to safe voltage levels.

Publication 280E-QS001B-EN-P – February 2011

Page 29

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 29

Faulted Display

Motor will

not Start

See

Table 10

See

Table 8

Fault

LED

Network

LED

Ye s

No

See

Tabl e 6

ATTENTION: Only qualified personnel familiar with adjustable frequency

AC drives and associated machinery should plan or implement the

installation, startup, and subsequent maintenance of the system. Failure

to comply may result in personal injury and/or equipment damage.

ATTENTION: This drive contains electrostatic discharge (ESD) –

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing this assembly. Component

damage may result if ESD control procedures are not followed. If you are

not familiar with static control procedures, refer to Allen-Bradley

®

Publication 8000-4.5.2, Guarding against Electrostatic Damage, or any

other applicable ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can result in

component damage or a reduction in product life. Wiring or application

errors, such as undersizing of the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures may result in malfunction of

the system.

Bulletin 280E/281E Troubleshooting

The following flowchart for Bulletin 280E/281E units, is provided to aid in

quick troubleshooting.

Figure 37 - Bulletin 280E/281E Control Module LED Status

Publication 280E-QS001B-EN-P – February 2011

Page 30

30 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Faulted Display

See

Tabl e 9

Fault

LED

Network

LED

Ye s

No

See

Table 6

See

Table 12

Actions

Motor will

not start

Define Nature

of the

Problem

Bulletin 284E Troubleshooting

Fault Definitions

Some of the Bulletin 284E ArmorStart Distributed Motor Controller faults are

detected by the internal hardware of the ArmorStart, while others are detected by

the internal drive. For internal drive faults, the internal hardware of the

ArmorStart simply polls the drive for the existence of faults and reports the fault

state. No fault latching is done by the internal hardware of the ArmorStart for

these faults. The PrFlt ResetMode parameter (Parameter 23) determines the

Auto Resettability of only the faults that are detected on the main control board.

The Auto Resettability of the faults that are detected in the internal drive is

controlled by internal drive parameters, refer to Table 9. The following flowchart

for Bulletin 284E units, is provided to aid in quick troubleshooting.

Figure 38 - Bulletin 284E Control Module LED Status

Publication 280E-QS001B-EN-P – February 2011

Page 31

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 31

Internal Drive Faults

A fault is a condition that stops the drive. There are two fault types.

Type Description

1 Auto-Reset/Run

When this type of fault occurs, Parameter 192 (Auto Rstrt Tries) and related

Parameter(s): 155, 193 are set to a value greater than 0, a user-configurable timer,

Parameter 193 (Auto Rstrt Delay) and related Parameter(s): 192, begins. When the

timer reaches zero, the drive attempts to automatically reset the fault. If the

condition that caused the fault is no longer present, the fault will be reset and the

drive will be restarted

2 Non-Resettable

This type of fault may require drive or motor repair, or is caused by wiring or

programing errors. The cause of the fault must be corrected before the fault can be

cleared.

Automatically Clearing Faults (Option/Step)

Clear a Type 1 Fault and Restart the Drive:

1. Set Parameter 192 (Auto Rstrt Tries) to a value other than 0.

2. Set Parameter 193 (Auto Rstrt Delay) to a value other than 0.

Clear an Overvoltage, Undervoltage or Heatsink OvrTmp Fault without

Restarting the Drive:

1. Set Parameter 192 (Auto Rstrt Tries) to a value other than 0.

2. Set Parameter 193 (Auto Rstrt Delay) to 0.

Auto Restart (Reset/Run)

The Auto Restart feature provides the ability for the drive to automatically

perform a fault reset followed by a start attempt without user or application

intervention. This allows remote or unattended operation. Only certain faults are

allowed to be reset. Certain faults (Type 2) that indicate possible drive

component malfunction are not resettable. Caution should be used when

enabling this feature, since the drive will attempt to issue its own start command

based on user selected programming.

Publication 280E-QS001B-EN-P – February 2011

Page 32

32 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

The following table describes Bulletin 284E Faults as seen in Parameters 107,

108, and 109 (Fault 1, 2 or 3).

No. Fault

F2 Auxiliary Input 1 Auxiliary input interlock is open. 1. Check remote wiring.

F3 Power Loss 2 DC bus voltage remained below

F4 UnderVoltage 1 DC bus voltage fell below the

F5 OverVoltage 1 DC bus voltage exceeded

F6 Motor Stalled 1 Drive is unable to accelerate

F7 Motor Overload 1 Internal electronic overload trip 8. An excessive motor load exists. Reduce load so drive output current does

F8 Heatsink

F12 HW OverCurrent 2 The drive output current has

F13 Ground Fault 2 A current path to earth ground has

F33 Auto Rstrt Tries Drive unsuccessfully attempted to

F38

F39

F40

F41

F42

F43

F48 Params

F63 SW OverCurrent 2 Programmed Parameter 198 (SW

F64 Drive Overload 2 Drive rating of 150% for 1 min. or

F70 Power Unit 2 Failure has been detected in the

F80 SVC Autotune The autotune function was either

OvrTmp

Phase U to Gnd

Phase V to Gnd

Phase W to Gnd

Phase UV Short

Phase UW Short

Phase VW Short

Defaulted

Ty pe

➊ Description Action

2. Verify communications.

85% of nominal.

minimum value.

maximum value.

motor.

1 Heatsink temperature exceeds a

predefined value.

exceeded the hardware current

limit.

been detected at one or more of

the drive output terminals.

reset a fault and resume running

for the programmed number of

Parameter 192 (Auto Rstrt Tries).

2 A phase to ground fault has been

detected between the drive and

motor in this phase.

2 Excessive current has been

detected between these two

output terminals.

2 The drive was commanded to

write default values to EEPROM.

Current Trip) has been exceeded.

200% for 3 sec. has been

exceeded.

drive power section.

cancelled by the user or failed.

3. Monitor the incoming AC line for low voltage or line power interruption.

4. Check input fuses.

5. Monitor the incoming AC line for low voltage or line power interruption.

6. Monitor the AC line for high line voltage or transient conditions. Bus

overvoltage can also be caused by motor regeneration. Extend the decel

time or install dynamic brake option.

7. Increase Parameters 139…167 (Accel Time x) or reduce load so drive

output current does not exceed the current set by Parameter 189 (Current

Limit 1).

not exceed the current set by Parameter 133 (Motor OL Current).

9. Verify Parameter 184 (Boost Select) setting

10. Check for blocked or dirty heat sink fins. Verify that ambient temperature

has not exceeded 40°C.

11. Replace internal fan.

12. Check programming. Check for excess load, improper programming of

Parameter 184 (Boost Select), DC brake volts set too high, or other causes

of excess current.

13. Check the motor and external wiring to the drive output terminals for a

grounded condition.

14. Correct the cause of the fault and manually clear.

15. Check the wiring between the drive and motor.

16. Check motor for grounded phase.

17. Replace starter module if fault cannot be cleared.

18. Check the motor and drive output terminal wiring for a shorted condition.

19. Replace starter module if fault cannot be cleared.

20. Clear the fault or cycle power to the drive.

21. Program the drive parameters as needed.

22. Check load requirements and Parameter 198 (SW Current Trip) setting.

23. Reduce load or extend Accel Time.

24. Cycle power.

25. Replace starter module if fault cannot be cleared.

26. Restart procedure.

Publication 280E-QS001B-EN-P – February 2011

Page 33

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 33

No. Fault

F81 Comm Loss 2 RS485 (DSI) port stopped

F100 Parameter

Checksum

F122 I/O Board Fail 2 Failure has been detected in the

Ty pe

➊ Description Action

communicating.

2 The checksum read from the board

does not match the checksum

calculated.

drive control and I/O section.

➊ See Table 9 for internal drive fault types, common symptoms and corrective actions.

Table 10 - Motor Does Not Start

Cause(s) Indication Corrective Action

No output voltage to the

motor.

Drive is Faulted Flashing red status light Clear fault.

None Check the power circuit.

27. Turn off using Parameter 205 (Comm Loss Action).

28. Replace starter module if fault cannot be cleared.

29. Set Parameter 141 (Reset To Defaults) to Option 1 (Reset Defaults).

30. Cycle power.

31. Replace starter module if fault cannot be cleared.

• Check the supply voltage.

• Check all fuses and disconnects

Check the motor.

• Verify that the motor is connected properly.

• Verify that I/O Terminal 01 is active.

• Verify that Parameter 136 (Start Source) matches your configuration.

• Verify that Parameter 195 (Reverse Disable) is not prohibiting movement.

• Press Stop

• Cycle power

• Set Parameter 200 (Fault Clear) to Option 1 (Clear Faults).

• Cycle digital input is Parameters 151…154 (Digital In x Sel) is set to Option

7, (Clear Faults).

Table 11 - Drive Does Not Respond to Changes in Speed Command

Cause(s) Indication Corrective Action

No value is coming form the

source of the command.

Incorrect reference source is

being selected via remote

device or digital inputs.

The drive Run indicator

is lit and output is 0 Hz.

None • Check Parameter 112 (Control Source) for correct source.

• Check Parameter 112 (Control Source) for correct source.

• If the source is an analog input, check wiring and use a meter to check for

presence of signal.

• Check Parameter 102 (Commanded Freq) to verify correct command.

• Check Parameter 114 (Dig In Status) to see if inputs are selecting an

alternate source. Verify settings for Parameters 151…154 (Digital In x Sel).

• Check Parameter 138 (Speed Reference) for the source of the speed

reference. Reprogram as necessary.

Table 12 - Motor and/or Drive Will Not Accelerate to Commanded Speed

Cause(s) Indication Corrective Action

Acceleration time is

excessive.

Excess load or short

acceleration times force the

drive into current limit,

slowing, or stopping

acceleration.

None Reprogram Parameter 139 (Accel Time 1) or Parameter 167 (Accel Time 2).

None • Compare Parameter 103 (Output Current) with Parameter 189 (Current

Limit1).

• Remove excess load or reprogram Parameter 139 (Accel Time 1) or

Parameter 167 (Accel Time 2).

• Check for improper setting of Parameter 184 (Boost Select).

Publication 280E-QS001B-EN-P – February 2011

Page 34

34 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

SERVICE CODE 0X05

Class Code 0x0001

INSTANCE 1

Data (USINT) 1

Table 12 - Motor and/or Drive Will Not Accelerate to Commanded Speed

Cause(s) Indication Corrective Action

Speed command source or

value is not as expected.

Programming is preventing

the drive output from

exceeding limiting values.

Torque performance does

not match motor

characteristics.

None • Verify Parameter 102 (Commanded Freq).

None Check Parameter 135 (Maximum Freq) to insure that speed is not limited by

None • Set motor nameplate full load amps in Parameter 226 (Motor NP FLA).

Table 13 - Motor Operation is Unstable

Cause(s) Indication Corrective Action

Motor data was incorrectly

entered.

None 1. Correctly enter motor nameplate data into Parameters 131, 132, and 133.

• Check Parameter 112 (Control Source) for the proper Speed Command.

programming.

• Use Parameter 227 (Autotune) to perform Static Tune or Rotate Tune

procedure.

• Set Parameter 225 (Torque Perf Mode) to Option 0 (V/Hz).

2. Enable Parameter 197 (Compensation).

3. Use Parameter 184 (Boost Select) to reduce boost level.

Cause(s) Indication Corrective Action

Digital input is not selected

for reversing control.

Motor wiring is improperly

phased for reverse.

Reverse is disabled. None Check Parameter 195 (Reverse Disable).

Cause(s) Indication Corrective Action

No input power to drive. None Check the power circuit.

Jumper between I/O

Terminals P2 and P1 not

installed and/or DC Bus

Inductor not connected.

Resetting Device to Factory Defaults

Table 14 - Drive Will Not Reverse Motor Direction

None Check Parameters 151…154 (Digital In x Sel). Choose correct input and

program for reversing mode.

None Switch two motor leads.

Table 15 - Drive Does Not Power Up

• Check the supply voltage.

• Check all fuses and disconnects.

None Install jumper or connect DC Bus Inductor.

The ArmorStart Control and Based module can be reset to factory defaults using

a Type 1 Reset service. It must be sent to the device identity object as follows. To

reset only the control module refer to Parameter 141 "Reset To Defaults".

Publication 280E-QS001B-EN-P – February 2011

Page 35

Control Module Removal

Motor Cable

30 lb•in./

3.39 N•m

Note: DeviceNet™ base module is shown.

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 35

ATTENTION: To avoid shock hazard, disconnect main power before

working on the controller, motor, or control devices.

1. Disconnect power by going to the control module and turning OFF the

At-Motor disconnect and performing lockout-tagout per your company

policy.

2. Remove motor cable.

3. Loosen the four mounting screws.

4. Unplug the Control module from the base by pulling forward.

Installation of Control Module

5. Install control module.

6. Tighten four mounting screws.

7. Install motor cable.

Figure 39 – Control Module Replacement

1

4

2

3

1

3

2

Publication 280E-QS001B-EN-P – February 2011

Page 36

36 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Output Fuse

Cat. No. W25176-155-03

Control Voltage Fuse

Cat. No. W25172-260-17

Source Control Brake Fuses

Cat. No. W25172-260-12

Figure 40 – Control Voltage and Output Fuse Replacement

Publication 280E-QS001B-EN-P – February 2011

Figure 41 – Source Brake Fuse Replacement (Bulletin 284E only)

Page 37

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 37

Bulletin 280E/281E/284E Programmable Parameters

Basic Setup Parameters

Additional configuration information and advanced settings help can be found in

the ArmorStart User Manual, Publication 280E-UM001*.

To configure the basic ArmorStart functionality refer to Table 16 below. These

are the minimum setup configurations required for Bulletin 280E/281E or

Bulletin 284E. There are additional capabilities and motor protection that are

not enabled or left at their default values.

Table 16 - Quick Parameter Setup

Bulletin 280E/281E Bulletin 284E

106 FLA Setting

107 Overload Class

108 OL Reset Level

131 Motor NP Volts

132 Motor NP Hertz

133 Motor OL Current

134 Minimum Freq

135 Maximum Freq

137 Stop Mode

138 Speed Reference

139 Accel Time 1

140 Decel Time 1

Parameter Groups

Common to Bulletin 280E/281E and Bulletin 284E Units

Basic Status Network Config Starter Protection User I/O Config Miscellaneous Config Drive I/O Config

1 Hdw Inputs

2 Network Inputs

3 Network Outputs

4 Trip Status

5 Starter Status

6 InternalLinkStat

7 Starter Command

22 Breaker Type

56 Base Enclosure

57 Base Options

58 Wiring Options

59 Starter Enclosure

60 Starter Options

61 Last Pr Fault

62 Warning Status

63 Base Trip

13 Prod Assy Word 0

14 Prod Assy Word 1

15 Prod Assy Word 2

16 Prod Assy Word 3

23 PrFlt ResetMode

24 Pr Fault Enable

25 Pr Fault Reset

26 Str Net FltState

27 Str Net FltValue

28 Str Net IdlState

29 Str Net IdlValue

30 Off-to-On Delay

31 On-to-Off Delay

32 In Sink/Source

33 OutA Pr FltState

34 OutA Pr FltValue

35 OutA Net FltState

36 OutA Net FltValue

37 OutA Net IdlState

38 OutA Net IdlValue

39 OutB Pr FltState

40 OutB Pr FltValue

41 OutB Net FltState

42 OutB Net FltValue

43 OutB Net IdlState

44 OutB Net IdlValue

8 Network Override

9 Comm Override

45 Keypad Mode

46 Keypad Disable

47 Set To Defaults

Bulletin 284E

48 Drive Control

49 DrvIn Pr FltState

50 DrvIn Pr FltValue

51 DrvIn Net FltState

52 DrvIn Net FltValue

53 DrvIn Net ltState

54 DrvIn Net ltValue

55 High Speed Enable

Units Only

Publication 280E-QS001B-EN-P – February 2011

Page 38

38 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Bulletin280E/281E

Units Only Bulletin 284E Units Only

Starter Display Drive Display Drive Setup Drive Advanced Setup

101 Phase A Current

102 Phase B Current

103 Phase C Current

104 Average Current

105 Therm Utilized

Starter Setup

106 FLA Setting

107 Overload Class

108 OL Reset Level

101 Output Freq

102 Commanded Freq

103 Output Current

104 Output Voltage

105 DC Bus Voltage

106 Drive Status

107 Fault 1 Code

108 Fault 2 Code

109 Fault 3 Code

110 Process Display

112 Control Source

113 Contrl In Status

114 Dig In Status

115 Comm Status

116 Control SW Ver

117 Drive Type

118 Elapsed Run Time

119 Tes tpoint Data

122 Output Power

123 Output Power Fctr

124 Drive Temp

125 Counter Status

126 Timer Status

128 StpLogic Status

129 Torque Current

131 Motor NP Volts

132 Motor NP Hertz

133 Motor OL Current

134 Minimum Freq

135 Maximum Freq

136 Start Source

137 Stop Mode

138 Speed Reference

139 Accel Time 1

140 Decel Time 1

141 Reset To Defaults

143 Motor OL Ret

151 Digital In 1 Sel

152 Digital In 2 Sel

153 Digital In 3 Sel

154 Digital In 4 Sel

155 Relay Out Sel

156 Relay Out Level

157 Relay Out LevelF

167 Accel Time 2

168 Decel Time 2

169 Internal Freq

170 Preset Freq 0

171 Preset Freq 1

172 Preset Freq 2

173 Preset Freq 3

174 Preset Freq 4

175 Preset Freq 5

176 Preset Freq 6

177 Preset Freq 7

178 Jog Frequency

179 Jog Accel/Decel

180 DC Brake Time

181 DC Brake Level

182 DB Resistor Sel

183 S Curve %

184 Boost Select

185 Start Boost

186 Brake Voltage

187 Brake Frequency

188 Maximum Voltage

189 Current Limit 1

190 Motor OL Select

191 PWM Frequency

192 Auto Rstrt Tries

193 Auto Rstrt Delay

194 Start At PowerUp

195 Reverse Disable

196 Flying Start En

197 Compensation

198 SW Current Trip

199 Process Factor

200 Fault Clear

201 Program Lock

202 Testpoint Sel

205 Comm Loss Action

206 Comm Loss Time

214 Slip Hertz @ FLA

215 Process Time Lo

216 Process Time Hi

217 Bus Reg Mode

218 Current Limit 2

219 Skip Frequency

220 Skip Freq Band

221 Stall Fault Time

224 Var PWM Disable

225 Torque Perf Mode

226 Motor NP FLA

227 Autotune

228 IR Voltage Drop

229 Flux Current Ref

230 PID Trim Hi

231 PID Trim Lo

232 PID Ref Sel

233 PID Feedback Sel

234 PID Prop Gain

235 PID Integ Time

236 PID Diff Rate

237 PID Setpoint

238 PID Deadband

239 PID Preload

240 StpLogic 0

241 StpLogic 1

242 StpLogic 2

243 StpLogic 3

244 StpLogic 4

245 StpLogic 5

246 StpLogic 6

247 StpLogic 7

250 StpLogic Time 0

251 StpLogic Time 1

252 StpLogic Time 2

253 StpLogic Time 3

254 StpLogic Time 4

255 StpLogic Time 5

256 StpLogic Time 6

257 StpLogic Time 7

260 EM Brk Off Delay

261 EM Brk On Delay

262 MOP Reset Sel

263 DB Threshold

264 Comm Write Mode

Publication 280E-QS001B-EN-P – February 2011

ControlLogix Command and Status Mapping

Table 17 - Default I/O Messaging Data

Default

Bulletin 280E/281E Bulletin 284E

Message type Cyclic Cyclic

Consumed Data Size (Rx) Command 3 Bytes (Instance 162) 6 Bytes (Instance 166)

Produced Data Size (Tx) Status 16 Bytes (Instance 150) 18 Byte (Instance 151)

Page 39

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 39

Figure 42 – Example of RSLogix

5000 Status Assembly Table

Default Input and Output (I/O) Assembly Formats

The tables below identify the default information produced and consumed by

Bulletin 280E, 281E and 284E. For additional formats and advance

configurations please reference the user manual.

Defaults for Standard Distributed Motor Controllers

Table 18 - Instance 150

Produce Assembly - Instance 150 "Starter Status" - 280E/281E Starters

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

1 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

2 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

3 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

4 Ready Running

5 140M On HOA Input 4 Input 3 Input 2 Input 1

6 Net Out 7 Net Out 6 Net Out 5 Net Out 4 Net Out 3 Net Out 2 Net Out 1 Net Out 0

7 Logic

Enable

8 Value of the parameter pointed to by "Parameter 13 Prod Assy Word 0" (low byte)

9 Value of the parameter pointed to by "Parameter 13 Prod Assy Word 0" (high byte)

10 Value of the parameter pointed to by "Parameter 14 Prod Assy Word 1" (low byte)

11 Value of the parameter pointed to by "Parameter 14 Prod Assy Word 1" (high byte)

12 Value of the parameter pointed to by "Parameter 15 Prod Assy Word 2" (low byte)

13 Value of the parameter pointed to by "Parameter 15 Prod Assy Word 2" (high byte)

14 Value of the parameter pointed to by "Parameter 16 Prod Assy Word 3" (low byte)

15 Value of the parameter pointed to by "Parameter 16 Prod Assy Word 3" (high byte)

Net Out

14

Net Out

13

Net Out

12

Rev

Net Out 11 Net Out 10 Net Out 9 Net Out 8

Running

Fwd

Warning Tripped

Publication 280E-QS001B-EN-P – February 2011

Page 40

40 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Figure 43 – Example of

RSLogix 5000 Command

Assembly Table

Table 19 - Instance 151

Produce Assembly - Instance 151 “Drive Status” - 284E Starters

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

1 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

2 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

3 Reserve Reserve Reserve Reserve Reserve Reserve Reserve Reserve

4At

Reference

5 Contact2 Contact1 140M On HOA Input 4 Input 3 Input 2 Input 1

6 Output Frequency (Low) (xxx.x Hz)

7 Output Frequency (High) (xxx.x Hz)

8 Net Out 8 Net Out 7 Net Out 6 Net Out 5 Net Out 4 Net Out 3 Net Out 2 Net Out 1

9 Logic

Enable

10 Value of the parameter pointed to by "Parameter 13 Prod Assy Word 0" (low byte)

11 Value of the parameter pointed to by "Parameter 13 Prod Assy Word 0" (high byte)

12 Value of the parameter pointed to by "Parameter 14 Prod Assy Word 1" (low byte)

13 Value of the parameter pointed to by "Parameter 14 Prod Assy Word 1" (high byte)

14 Value of the parameter pointed to by "Parameter 15 Prod Assy Word 2" (low byte)

15 Value of the parameter pointed to by "Parameter 15 Prod Assy Word 2" (high byte)

16 Value of the parameter pointed to by "Parameter 16 Prod Assy Word 3" (low byte)

17 Value of the parameter pointed to by "Parameter 16 Prod Assy Word 3" (high byte)

Net Ref

Status

Net Out

15

Net Ctl

Status

Net Out

14

Ready Running

Net Out

13

Rev

Net Out 12 Net Out 11 Net Out 10Net Out 9

Running

Fwd

Warning Tripped

Publication 280E-QS001B-EN-P – February 2011

Table 20 - Instance 162

Consume Assembly - Instance 162 “Starter Cmd” - 280E/281E Starters

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Output B Output A Fault Reset Run Rev Run Fwd

1 Net in 7 Net in 6 Net in 5 Net in 4 Net in3 Net in 2 Net in 1 Net in 0

2 Net in 15 Net in 14 Net in 13 Net in 12 Net in 11 Net in 10 Net in 9 Net in 8

Table 21 - Instance 166

Consume Assembly - Instance 166 “Drive Cmd” – 284E Starters

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 User Out B User Out A Jog Rev Jog Fwd Fault Reset Run Rev Run Fwd

1 Drive In 4 Drive In 3 Drive In 2 Drive In 1 Decel

Control 2

2 Comm Frequency Command (Low) (xxx.x Hz)

3 Comm Frequency Command (High) (xxx.x Hz)

4 Net in 8 Net in 7 Net in 6 Net in 5 Net in 4 Net in 3 Net in 2 Net in 1

5 Net in 16 Net in 15 Net in 14 Net in 13 Net in 12 Net in 11 Net in 10 Net in 9

Decel

Control 1

Accel

Control 2

Accel

Control 1

Page 41

Notes:

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 41

Publication 280E-QS001B-EN-P – February 2011

Page 42

42 ArmorStart EtherNet/IP Distributed Motor Controller Getting Started

Notes:

Publication 280E-QS001B-EN-P – February 2011

Page 43

Notes:

ArmorStart EtherNet/IP Distributed Motor Controller Getting Started 43

Publication 280E-QS001B-EN-P – February 2011

Page 44

Registered Trademark List

ArmorConnect, ArmorStart, RSLinx and ControlLogix are registered trademarks of Rockwell Automation, Inc.

Trademark List

RSLogix 5000, is a trademarks of Rockwell Automation, Inc. EtherNet/IP, DeviceNet and the DeviceNet logo are trademarks of the Open Device Vendors

Association (ODVA). Ethernet is a registered trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

Publication 280E-QS001B-EN-P — February 2011 PN-94027

Supercedes Publication 280E-QS001A-EN-P — November 2010 Copyright ©2011 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...