Page 1

Allen-Bradley

AdaptaScan

Bar Code

Application

Readers

(Cat. Nos. 2755-SN3, -SN5, and

-SN8)

Guide

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

death, property damage or economic loss.

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

PLC, PLC-5, and PHOTOSWITCH are registered trademarks of Allen-Bradley, Inc.

PanelView, PanelView 900, PanelBuilder, AdaptaScan, Data Highway Plus, SLC, SLC 500, SLC 5/03, and SLC 5/04 are

trademarks of Allen-Bradley Company, Inc.

APS is a trademark of Rockwell Software, Inc.

DeviceNet is a trademark of the Open DeviceNet Vendor Association

Windows is a trademark of Microsoft

Page 3

Preface

Contents of this Guide P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support Services P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Auto-Load

Function

Chapter 1

Overview 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Power Source 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 1–2. . . . . . . . . . . . . . . . . . .

Configuring the Reader 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define a Bar Code Label 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 1–5. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Discrete Input Module 1–6. . . . . . . . . . . . . . . . . . . . .

Configure the Match Table 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure a Package 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Auto-Load Trigger Source 1–9. . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 1–10. . . . . . . . . . . . . . . . . . . .

Running the Application 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using ASCII Command Input

Chapter 2

Overview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a Computer to the Reader 2–2. . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 2–2. . . . . . . . . . . . . . . . . . .

Configuring the Reader 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 2–5. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 2–6. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the ASCII Commands 2–6. . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 4

Table of Contentstoc–ii

Create a Message 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 2–12. . . . . . . . . . . . . . . . . . . .

Running the Application 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Match Codes

from a Host Device

Chapter 3

Overview 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a Computer to the Reader 3–2. . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 3–2. . . . . . . . . . . . . . . . . . .

Configuring the Reader 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 3–5. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 3–6. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Match Entry and I/O Indicator LED 3–8. . . . . . . . . . . .

Sending the Configuration to the Reader 3–9. . . . . . . . . . . . . . . . . . . .

Finding Match Table Instances 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Computer to the RS-232 Port 3–10. . . . . . . . . . . . . . . . .

Downloading Match Codes 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Convert the Bar Code String to Hex 3–11. . . . . . . . . . . . . . . . . . . . . .

Place the String in the Data Packet 3–11. . . . . . . . . . . . . . . . . . . . . .

Send Data to the Reader 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Response Codes 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Other Host Commands 3–15. . . . . . . . . . . . . . . . . . . . . . .

Downloading Match Codes

via DH485 Protocol with an

SLC 5/03 or SLC 5/04

Controller

Publication 2755-6.8

Chapter 4

Overview 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 4–2. . . . . . . . . . . . . . . . . . .

Connecting to the DH-485 Network 4–2. . . . . . . . . . . . . . . . . . . . . . . .

Connecting Readers to SLC 5/03 Controller 4–3. . . . . . . . . . . . . . . .

Connecting Readers to SLC 5/04 Controller – 2 AIC Modules 4–4. . .

Connecting Readers to SLC 5/04 Controller – 1 AIC Module 4–5. . . .

Configuring Bar Code Reader 1 4–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 4–8. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents toc–iii

Configure the Decoder Trigger 4–9. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for Match Codes 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for a Package 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for an Output 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 4–16. . . . . . . . . . . . . . . . . . . .

Finding Match Table Instances 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Match Codes 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Convert the Bar Code String to Hex 4–17. . . . . . . . . . . . . . . . . . . . . .

Place the String in the Data Packet 4–17. . . . . . . . . . . . . . . . . . . . . .

Response Codes 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the SLC Controller 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC 5/04 Configuration 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Ladder Logic 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Match Codes in Slave Mode via the Reader’s LEDs 4–21. . . .

Viewing Match Code Downloads in Slave Mode via Ladder Logic 4–22

Viewing Match Code Downloads in Master Mode via Ladder Logic 4–25

Communicating with a

1746-BAS BASIC Module

Chapter 5

Overview 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a BASIC Module to the Reader 5–2. . . . . . . . . . . . . . . . . .

SLC Ladder Logic 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming the BASIC Module 5–4. . . . . . . . . . . . . . . . . . . . . . . . . .

SLC BASIC Module Code 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Reader 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 5–8. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 5–10. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 5–13. . . . . . . . . . . . . . . . . . . .

Running the Application 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with an SLC

over an RS-232 Link

Chapter 6

Overview 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 6

toc–iv

Table of Contents

Connecting an SLC Controller to the Reader 6–2. . . . . . . . . . . . . . . . .

Configuring the SLC Controller 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Ladder Logic Program 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Reader 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 6–6. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 6–7. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 6–1 1. . . . . . . . . . . . . . . . . . . .

Running the Application 6–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with an SLC

on a DH-485 Network

Chapter 7

Overview 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 7–3. . . . . . . . . . . . . . . . . . .

Connecting to the DH-485 Network 7–3. . . . . . . . . . . . . . . . . . . . . . . .

Connecting Readers to SLC 5/03 Controller 7–4. . . . . . . . . . . . . . . .

Connecting Readers to SLC 5/04 Controller – 2 AIC Modules 7–5. . .

Connecting Readers to SLC 5/04 Controller – 1 AIC Module 7–6. . . .

Configuring the SLC Controller 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC 5/04 Configuration 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Bar Code Reader 1 7–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 7–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 7–10. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 7–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 7–12. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 7–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 7–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to Reader 1 7–16. . . . . . . . . . . . . . . . . . . . .

Configuring Bar Code Reader 2 7–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Add a Second Bar Code Reader to the Project 7–16. . . . . . . . . . . . . .

Define the DeviceNet Address 7–16. . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 7–17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 7–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 7–18. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 7–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 7–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 7

Table of Contents toc–v

Define the Message Format 7–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to Reader 2 7–22. . . . . . . . . . . . . . . . . . . . .

Running the Application 7–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with a PLC-5

over an RS-232 or RS-422

Link

Chapter 8

Overview 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the PLC-5 Processor to the Reader 8–2. . . . . . . . . . . . . . .

Cabling 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the PLC Processor 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5 Ladder Logic Program 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Reader 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 8–7. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 8–8. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 8–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 8–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 8–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 8–12. . . . . . . . . . . . . . . . . . . .

Running the Application 8–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with an SLC

5/03 Processor on a

DeviceNet Network

Chapter 9

Overview 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the DeviceNet Network 9–2. . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 9–2. . . . . . . . . . . . . . . . . . .

SLC Ladder Logic 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Addressing 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Flow Control 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

N23 Data Table File Monitor 9–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

N22 Data Table File Monitor 9–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File 0 Monitor 9–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File M1 Monitor 9–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the DeviceNet Scanner 9–8. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Reader 9–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 9–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change the Baud Rate 9–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 9–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 9–16. . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 8

Table of Contentstoc–vi

Configure the Scanner 9–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 9–17. . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 9–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 9–19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 9–19. . . . . . . . . . . . . . . . . . . .

Running the Application 9–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the Module and Network 9–20. . . . . . . . . . . . . . . . . . .

Communicating with an SLC

5/03 Processor on a

DeviceNet Network using

Explicit Messaging

Chapter 10

Overview 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the DeviceNet Network 10–2. . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 10–2. . . . . . . . . . . . . . . . . . .

SLC Ladder Logic 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Addressing 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Flow Control 10–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

N23 Data Table File Monitor 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

N22 Data Table File Monitor 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File 0 Monitor 10–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File M1 Monitor 10–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the DeviceNet Scanner 10–8. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Reader 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change the Baud Rate 10–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 10–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 10–16. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 10–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 10–17. . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 10–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 10–19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for Match Codes 10–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for a Package 10–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for an Output 10–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 10–23. . . . . . . . . . . . . . . . . . . .

Running the Application 10–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explicit Message Program Control 10–24. . . . . . . . . . . . . . . . . . . . . . . .

Explicit Message Program Control Feature 10–25. . . . . . . . . . . . . . . .

Formatting the Explicit Message Transaction Block 10–26. . . . . . . . . . .

Processor and Scanner Module Manage Messages 10–28. . . . . . . . . .

Explicit Message Program Control Limitations 10–29. . . . . . . . . . . . . .

Explicit Messaging Ladder Logic Program 10–31. . . . . . . . . . . . . . . . .

Example Data Tables 10–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes on using Explicit Messaging 10–32. . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 9

Table of Contents toc–vii

Troubleshooting the Module and Network 10–33. . . . . . . . . . . . . . . . . . .

Downloading Other Host Commands 10–36. . . . . . . . . . . . . . . . . . . . . . .

Communicating with a PLC-5

Processor on a DeviceNet

Network

Chapter 11

Overview 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 1 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 1 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the DeviceNet Network 11–2. . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 1 1–2. . . . . . . . . . . . . . . . . . .

PLC Ladder Logic 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Addressing 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Flow Control 11–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File N23 Monitor 11–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File N22 Monitor 1 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the DeviceNet Scanner 1 1–7. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Reader 11–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 11–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change the Baud Rate 11–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 11–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 11–15. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 11–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 11–16. . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 11–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 11–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 11–18. . . . . . . . . . . . . . . . . . . .

Running the Application 11–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Your Module 11–19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with a PLC-5

Processor on a DeviceNet

Network using Explicit

Messaging

Chapter 12

Overview 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the DeviceNet Network 12–2. . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to the Reader 12–2. . . . . . . . . . . . . . . . . . .

PLC Ladder Logic 12–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Addressing 12–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Flow Control 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File N23 Monitor 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table File N22 Monitor 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the DeviceNet Scanner 12–7. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Reader 12–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 12–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change the Baud Rate 12–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 10

Table of Contentstoc–viii

Define the Bar Code Label 12–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 12–15. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 12–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 12–16. . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 12–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 12–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 12–18. . . . . . . . . . . . . . . . . . . .

Running the Application 12–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explicit Message Program Control 12–19. . . . . . . . . . . . . . . . . . . . . . . .

Explicit Message Program Control Feature 12–20. . . . . . . . . . . . . . . .

Formatting the Explicit Message Transaction Block 12–21. . . . . . . . . . .

How the Processor and Scanner Module Manage Messages 12–23. . . .

Explicit Message Program Control Limitations 12–24. . . . . . . . . . . . . .

Explicit Messaging Ladder Logic Program 12–26. . . . . . . . . . . . . . . . .

Example Data Tables 12–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes on using Explicit Messaging 12–27. . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Your Module 12–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Other Host Commands 12–31. . . . . . . . . . . . . . . . . . . . . . .

Communicating with a

2760-RB Module over an

RS-232 Link

Chapter 13

Overview 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 13–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5 Compatibility 13–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the RB Module to the Reader 13–2. . . . . . . . . . . . . . . . . . .

Classic PLC-5 Processor DIP Switches 13–3. . . . . . . . . . . . . . . . . . .

Enhanced PLC-5 Processor DIP Switches 13–3. . . . . . . . . . . . . . . . .

I/O Chassis Backplane DIP Switches 13–3. . . . . . . . . . . . . . . . . . . . .

2760-RB Module DIP Switches 13–3. . . . . . . . . . . . . . . . . . . . . . . . .

Cabling 13–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the PLC-5 Processor 13–6. . . . . . . . . . . . . . . . . . . . . . . . .

Using the 2760-RB Module, Revision H or Above, with the New

Generation PLC-5 Processor 13–7. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the 2760-RB Interface Module 13–7. . . . . . . . . . . . . . . . . . .

Configuring the Reader 13–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 13–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 13–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 13–12. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 13–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 13–13. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 13–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 13–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 13–16. . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 11

Table of Contents toc–ix

Communicating with a

2760-RB Module on a DH-485

Network

Chapter 14

Overview 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5 Compatibility 14–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the RB Module to the Reader 14–2. . . . . . . . . . . . . . . . . . .

Classic PLC-5 Processor DIP Switches 14–2. . . . . . . . . . . . . . . . . . .

Enhanced PLC-5 Processor DIP Switches 14–3. . . . . . . . . . . . . . . . .

I/O Chassis Backplane DIP Switches 14–3. . . . . . . . . . . . . . . . . . . . .

2760-RB Module DIP Switches 14–3. . . . . . . . . . . . . . . . . . . . . . . . .

Cabling 14–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the PLC-5 Processor 14–5. . . . . . . . . . . . . . . . . . . . . . . . .

Using the 2760-RB Module, Revision H or Above, with the New

Generation PLC-5 Processor 14–6. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the 2760-RB Interface Module 14–6. . . . . . . . . . . . . . . . . . .

Configuring the Bar Code Reader 14–8. . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 14–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 14–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 14–10. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 14–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 14–12. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 14–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 14–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 14–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 14–15. . . . . . . . . . . . . . . . . . . .

Downloading Match Codes

via DH485 using a PLC-5

Processor and a 2760-RB

Module

Chapter 15

Overview 15–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 15–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 15–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 15–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5 Compatibility 15–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the RB Module to the Reader 15–2. . . . . . . . . . . . . . . . . . .

Classic PLC-5 Processor DIP Switches 15–2. . . . . . . . . . . . . . . . . . .

Enhanced PLC-5 Processor DIP Switches 15–3. . . . . . . . . . . . . . . . .

I/O Chassis Backplane DIP Switches 15–3. . . . . . . . . . . . . . . . . . . . .

2760-RB Module DIP Switches 15–3. . . . . . . . . . . . . . . . . . . . . . . . .

Cabling 15–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the PLC-5 Processor 15–5. . . . . . . . . . . . . . . . . . . . . . . . .

Using the 2760-RB Module, Revision H or Above, with the New

Generation PLC-5 Processor 15–6. . . . . . . . . . . . . . . . . . . . . . . .

Configuring the 2760-RB Interface Module 15–6. . . . . . . . . . . . . . . . . . .

Configuring the Bar Code Reader 15–8. . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 15–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 12

Table of Contentstoc–x

Define the Bar Code Label 15–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 15–10. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 15–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 15–11. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 15–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for Match Codes 15–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for a Package 15–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for an Output 15–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configuration to the Reader 15–15. . . . . . . . . . . . . . . . . . . .

Downloading Match Codes 15–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Command Files 15–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Convert the Bar Code String to Hex 15–16. . . . . . . . . . . . . . . . . . . . . .

Place the String in the Data Packet 15–17. . . . . . . . . . . . . . . . . . . . . .

Match Code String in Block Transfer Write 15–17. . . . . . . . . . . . . . . . .

Response Codes 15–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with

AdaptaScan Bar Code

Readers via DeviceNet

Peer-to-Peer Protocol

Chapter 16

Overview 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirement 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the DeviceNet Network 16–2. . . . . . . . . . . . . . . . . . . . . .

Connecting a Power Supply to a Reader 16–2. . . . . . . . . . . . . . . . . . . .

Multiple Reader Connections using Other Power Supply 16–3. . . . . . .

Configuring Bar Code Reader 1 16–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Create a New Project 16–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 16–5. . . . . . . . . . . . . . . . . . . . . . . . .

Define the Bar Code Label 16–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 16–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 16–8. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Serial Port 16–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 16–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 16–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Bar Code Reader 2 16–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Select Bar Code Reader 2 in the Project 16–11. . . . . . . . . . . . . . . . . .

Define the DeviceNet Address 16–11. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 16–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 16–12. . . . . . . . . . . . . . . . . . . . . . . . .

Create a Message 16–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 16–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Bar Code Reader 3 16–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Bar Code Reader 3 in the Project 16–15. . . . . . . . . . . . . . . .

Define the DeviceNet Address 16–15. . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Scanner 16–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Decoder Trigger 16–16. . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 13

Table of Contents toc–xi

Create a Message 16–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Define the Message Format 16–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Configurations to the Readers 16–19. . . . . . . . . . . . . . . . . .

Running the Application 16–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with

PanelView 900 Terminals on

a DeviceNet Network

Chapter 17

Introduction 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Requirements 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 17–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DeviceNet PanelView Terminals 17–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Typical DeviceNet Network 17–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making DeviceNet Connections 17–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Making Serial Port Connections 17–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying DeviceNet Settings from the Terminal 17–6. . . . . . . . . . . . . . .

Setting up Communications using PanelBuilder 17–8. . . . . . . . . . . . . . .

Selecting a DeviceNet PanelView Terminal 17–8. . . . . . . . . . . . . . . .

Configuring DeviceNet Communications 17–9. . . . . . . . . . . . . . . . . .

PanelView Message Types 17–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Server Explicit and I/O Slave Messaging 17–11. . . . . . . . . . . . . . . . . .

Client Explicit Messaging 17–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Tag Editor 17–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Electronic Data Sheet 17–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Applications over a Serial Link 17–18. . . . . . . . . . . . . . . . .

Downloading Application using the Internal DF1 Driver 17–18. . . . . . . .

DeviceNet Application Report 17–19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages and Codes 17–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Tag Error Messages 17–19. . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Device Error Messages 17–20. . . . . . . . . . . . . . . . . . . . .

PanelBuilder Translation Error Messages 17–20. . . . . . . . . . . . . . . . . .

Electronic Data Sheet (EDS) File Error Messages 17–21. . . . . . . . . . .

Communication Status Error Messages 17–22. . . . . . . . . . . . . . . . . . .

Alert Messages 17–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Messages 17–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AdaptaScan Application 17–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections 17–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Screen 17–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Bar Code Data Tag Configuration 17–27. . . . . . . . . . . . . . . . . . .

Read Package Counter Tag Configuration 17–28. . . . . . . . . . . . . . . . .

Write Package Count Reset 17–29. . . . . . . . . . . . . . . . . . . . . . . . . . .

AdaptaScan Configuration 17–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making Bar Code Data Available 17–30. . . . . . . . . . . . . . . . . . . . . . . .

Making Package Counter Data Available 17–31. . . . . . . . . . . . . . . . . .

Publication 2755-6.8

Page 14

This guide describes a variety of applications in which the

AdaptaScan Bar Code Reader is used. Each chapter covers a

separate application and provides:

• overview of the application

• hardware requirements

• software requirements

Each application shows how to:

• connect the AdaptaScan Reader to a network or host device

• configure the AdaptaScan Bar Code Reader

• configure the controller, providing the necessary ladder logic (if

required)

Because of the variety of uses for the information, the user of and

those responsible for applying this information must satisfy

themselves as to the acceptability of each application and use of the

program. In no event will Allen-Bradley Company be responsible or

liable for indirect or consequential damages resulting from the use of

application of this information.

The examples shown in this document are intended solely to

illustrate the principles of the bar code reader and some of the

methods used to apply them. Particularly because of the many

requirements associated with any particular installation,

Allen-Bradley Company cannot assume responsibility or liability for

actual use based upon the illustrative uses and applications.

Publication 2755-6.8

Page 15

PrefaceP–2

Contents of this Guide

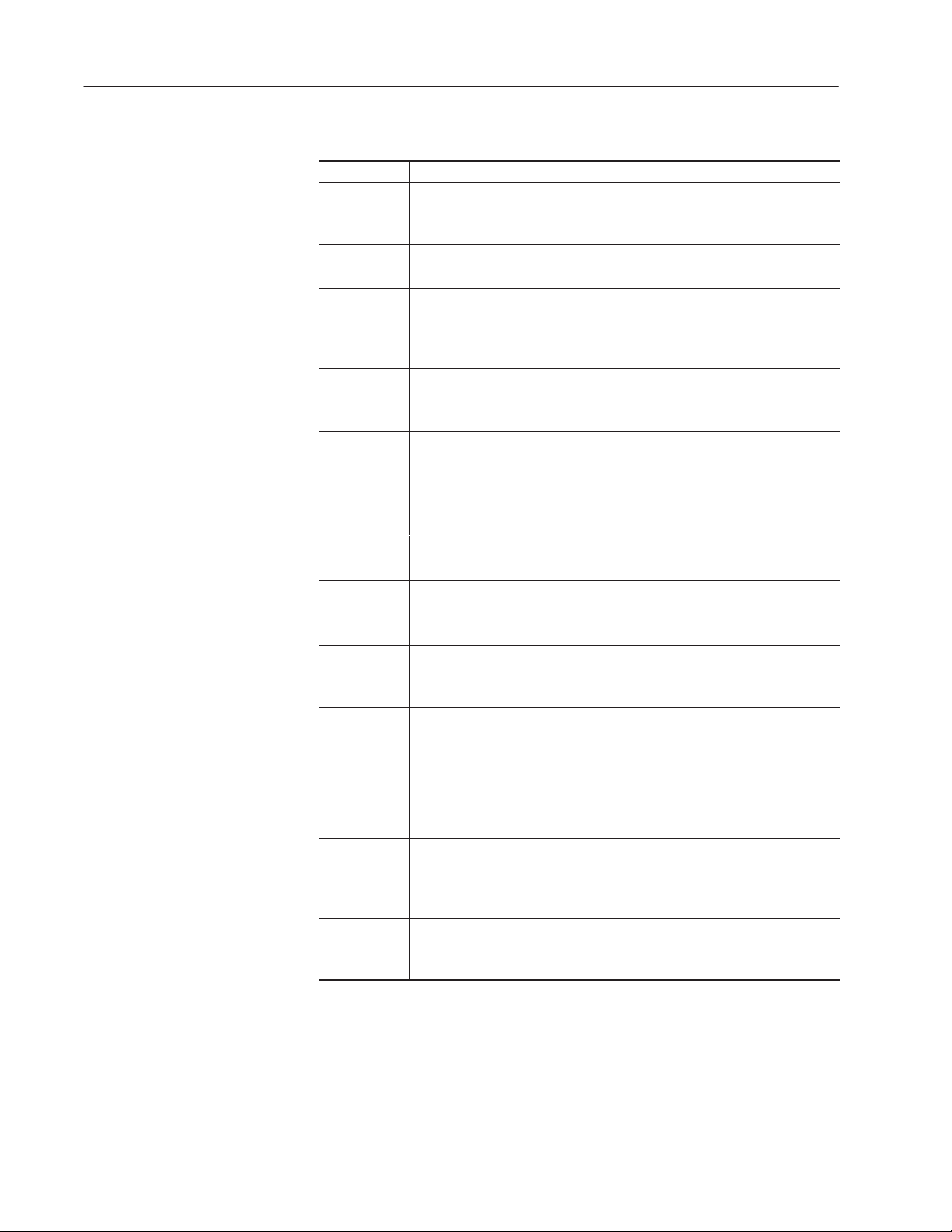

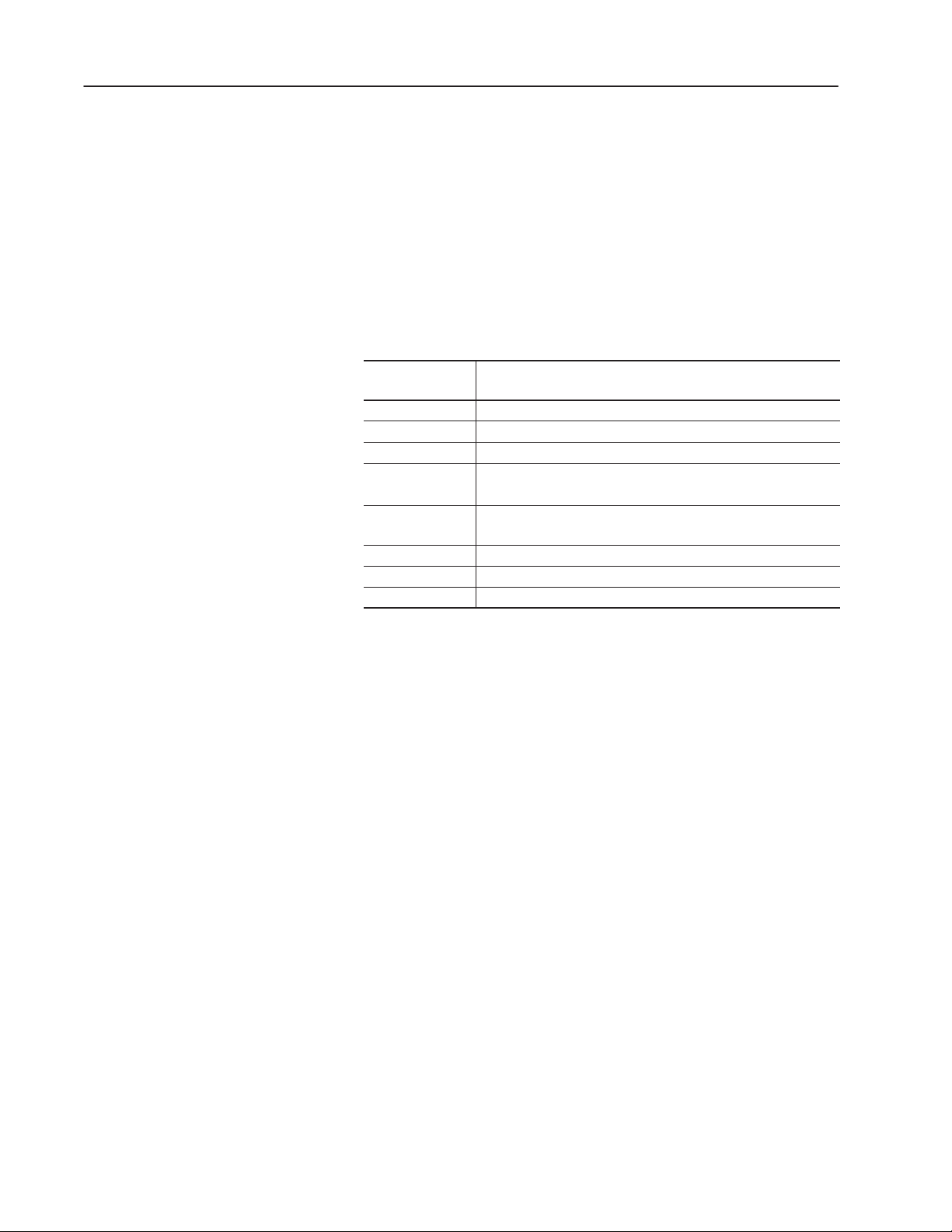

The following table describes the contents of this manual.

Chapter Title Contents

Describes the purpose, background, and scope of

Preface

1

2

3

4

5

Using the Auto-Load

Function

Using ASCII Command

Input

Downloading Match

Codes from a Host Device

Downloading Match

Codes via DH485

Protocol with an

SLC 5/03

SLC 5/04

Communicating with a

1746-BAS BASIC Module

t or

t Controller

this guide. Also specifies the audience for whom

this guide is intended.

Describes how to configure the reader to autoload

data into the match code table.

Shows how to configure the reader to start/stop

scanning when receiving ASCII commands from a

terminal emulator and then display the bar code

data on the emulator.

Shows how to download match codes (and other

host commands) from a terminal emulator to the

reader.

Shows how to download match codes from an

SLC 5/03 or SLC 5/04 controller to the reader.

Describes how to configure the reader to

communicate with a 1746-BAS BASIC module.

Communicating with an

6

7

8

9

10

11

SLC

t over an RS-232

Link

Communicating with an

SLC on a DH-485

Network

Communicating with an

R

PLC-5

or RS-422 Link

Communicating with an

SLC 5/03 Processor on a

DeviceNet

Communicating with an

SLC 5/03 Processor on a

DeviceNet Network using

Explicit Messaging

Communicating with a

PLC-5 Processor on a

DeviceNet Network

Table continued on the next page.

over an RS-232

t Network

Describes how to configure the reader to

communicate with an SLC controller over an

RS-232 serial connection.

Tells how to configure two readers to communicate

with an SLC controller over a DH-485 network

using master mode.

Describes how to configure the reader to

communicate with an PLC controller using either

RS-232 or RS-422 communication.

Shows how to configure a reader to communicate

with an SLC controller over a DeviceNet network in

master/slave mode.

Shows how to configure a reader to communicate

with an SLC controller over a DeviceNet network in

master/slave mode using explicit messaging.

Shows how to configure a reader to communicate

with a PLC-5 controller over a DeviceNet network in

master/slave mode.

Publication 2755-6.8

Page 16

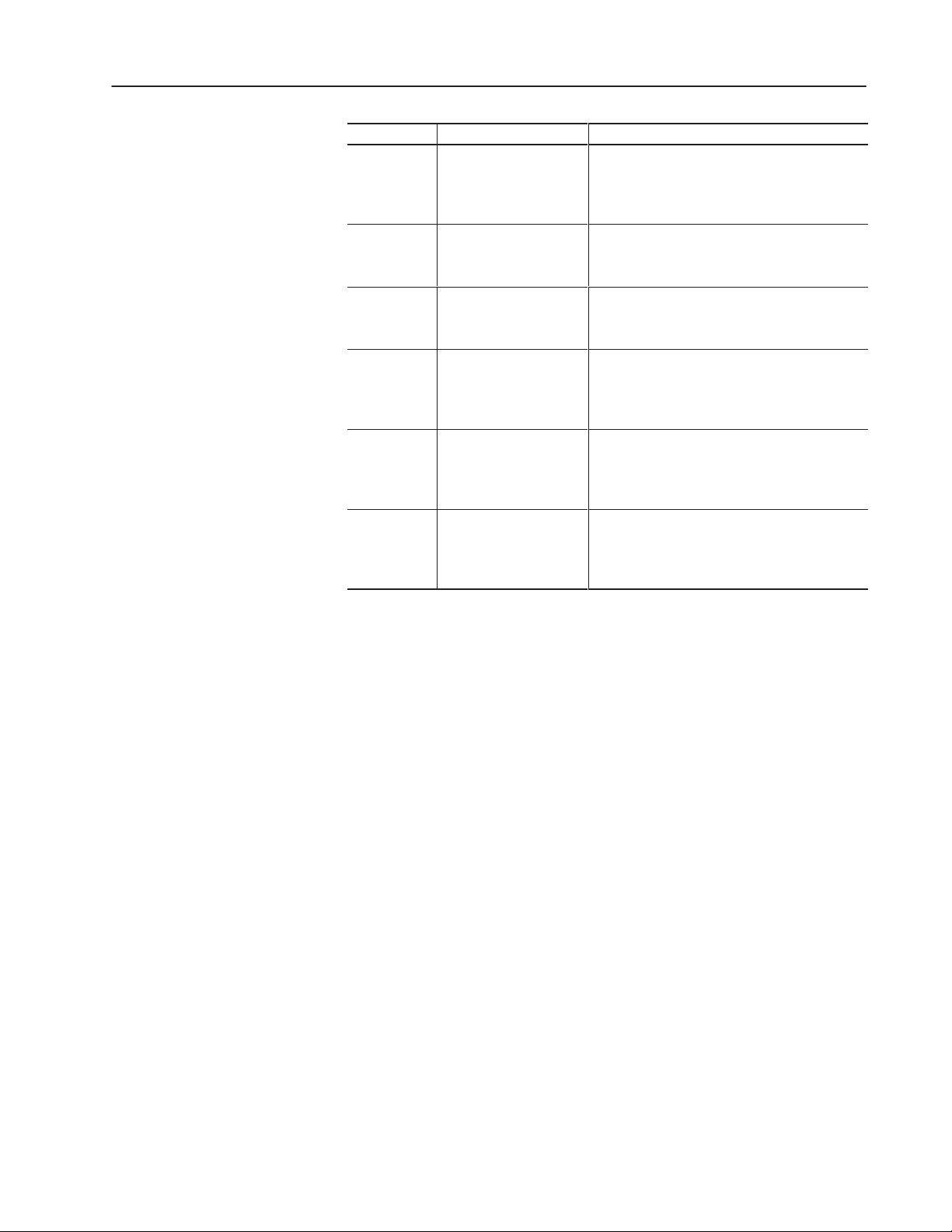

Preface P–3

Chapter Title Contents

12

Communicating with a

PLC-5 Processor on a

DeviceNet Network using

Explicit Messaging

Shows how to configure a reader to communicate

with a PLC-5 controller over a DeviceNet network in

master/slave mode using explicit messaging.

13

14

15

16

17

Communicating with a

2760-RB Module over an

RS-232 Link

Communicating with a

2760-RB Module on a

DH-485 Network

Downloading Match

Codes via DH485 using a

PLC-5 Processor and a

2760-RB Module

Communicating with

AdaptaScan Bar Code

Readers via DeviceNet

Peer-to-Peer Protocol

Communicating with

PanelView 900

Terminals on a DeviceNet

Network

Describes how to configure the reader to

communicate with a 2760-RB module using

RS-232 communication.

Describes how to configure the reader to

communicate with a 2760-RB module using

DH-485 communication.

Describes how to configure the reader to

communicate with a PLC-5 processor via DH485

protocol, using a 2760-RB module.

Describes how to configure three readers to

communicate with each other over a DeviceNet

network via peer-to-peer protocol.

Describes how to configure the reader to

communicate with the DeviceNet versions of the

PanelView 900 terminals.

Publication 2755-6.8

Page 17

PrefaceP–4

chnical

pport

Intended Audience

Related Publications

This application guide assumes that you understand how to:

• configure and operate the AdaptaScan Bar Code Reader using the

AdaptaScan Software.

• program and operate the logic controller that will communicate

with the reader

• configure the appropriate network communications

Publications that relate to the AdaptaScan Bar Code Readers and

other Allen-Bradley products used with the readers are:

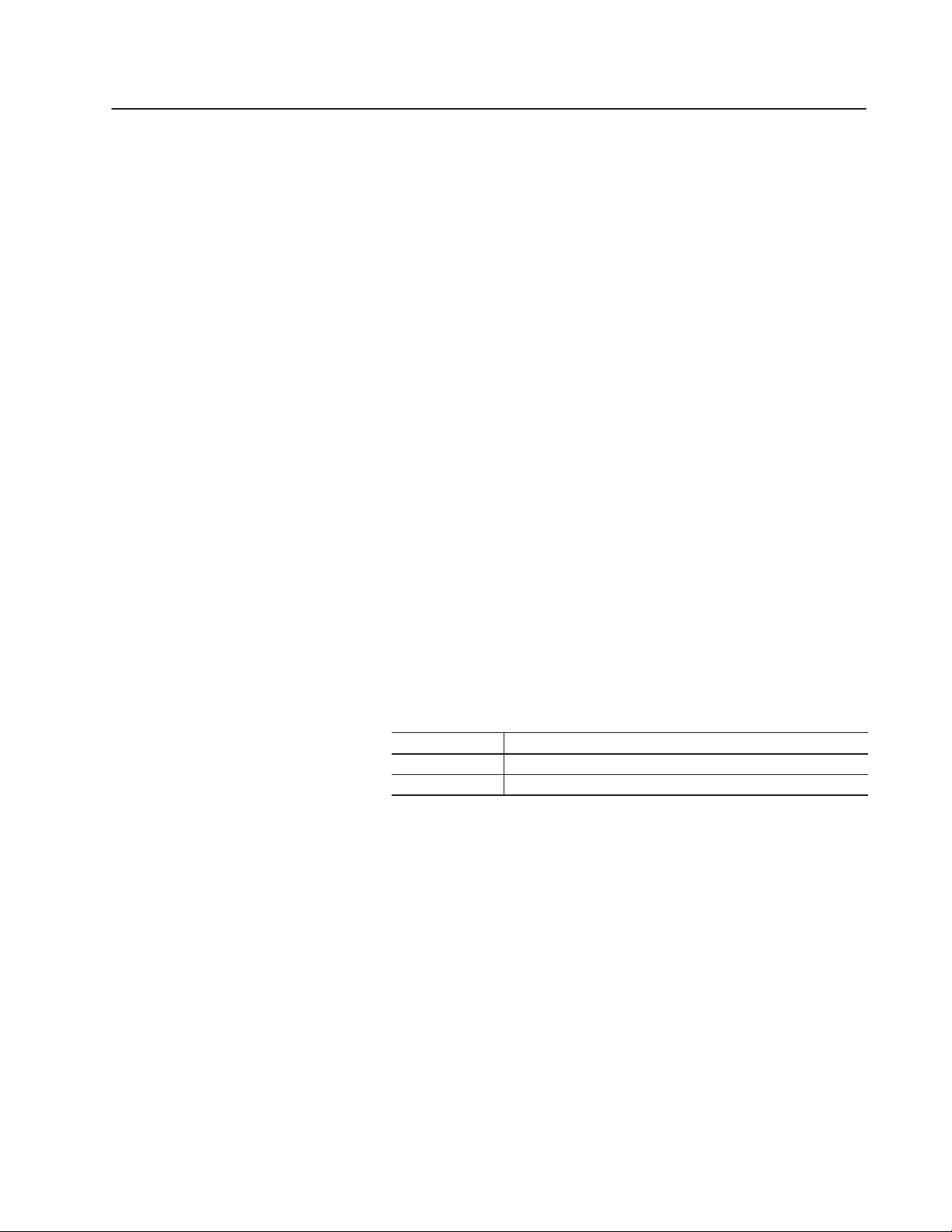

Publication

Number

2755-837 AdaptaScan Bar Code Reader User Manual

2755-838 AdaptaScan Software User Manual

1485-6.7.1 DeviceNet Cable System Planning and Installation Manual

1770-6.2.2

1787-6.5.3

1749-6.5.5 DeviceNet Adapter Module (Catalog No. 1749-ADN) User Manual

1747-6.5.2 DeviceNet Scanner (Catalog No. 1747-SDN) Configuration Manual

1771-6.5.118 DeviceNet Scanner (Catalog No. 1771-SDN) Configuration Manual

Data Highway / Data Highway Plus / Data Highway-485 Cable

Installation Manual

DeviceNet Manager Software (Catalog No. 1787-MGR) User

Manual

Description

Te

Su

Services

Each chapter refers to additional publications that relate to a specific

application.

If you have any questions about the AdaptaScan Bar Code Reader,

please consult this application guide first. If you can’t find the

answer, contact Rockwell Automation International Support:

Rockwell Automation

Technical Support

6680 Beta Drive

Mayfield Village, Ohio 36849

Inside USA and Canada, call 1–800–289–2279.

Outside USA and Canada, contact your Allen-Bradley office or call

USA (216) 646–6800.

Publication 2755-6.8

Page 18

Using the AutoĆLoad Function

Overview

Hardware Requirements

Software Requirements

This application describes how to set up the AdaptaScan Bar Code

Reader to use the Auto-Load function. The application uses a

PHOTOSWITCH

detector to trigger the decoder and a discrete input to activate the

Auto-Load.

The hardware items required for this application are:

R

(Catalog No. 42SRU-6203) as a package

• 2755-SN3, -SN5 or -SN8 AdaptaScan Bar Code Reader

• 2755-NB40 or -NB41 Wiring Base

• 2755-PW46 or -PW47 Power Supply

• 2755-NC43 or -NC48 Configuration Cable

• PHOTOSWITCH 42SRU-6203

• 2755-IB5S DC Input Module

• Computer running Windowst 3.1 (or later) or Windows 95

• 9-to-25 Pin Adapter (for computers with a 25-pin COM port)

The software requirements for this application is the 2755-ASN

AdaptaScan Offline Programming Software.

Related Publications

Publications you may want to refer to include:

Publication Description

2755-837 AdaptaScan Bar Code Readers User Manual

2755-838 AdaptaScan Software User Manual

Publication 2755-6.8

Page 19

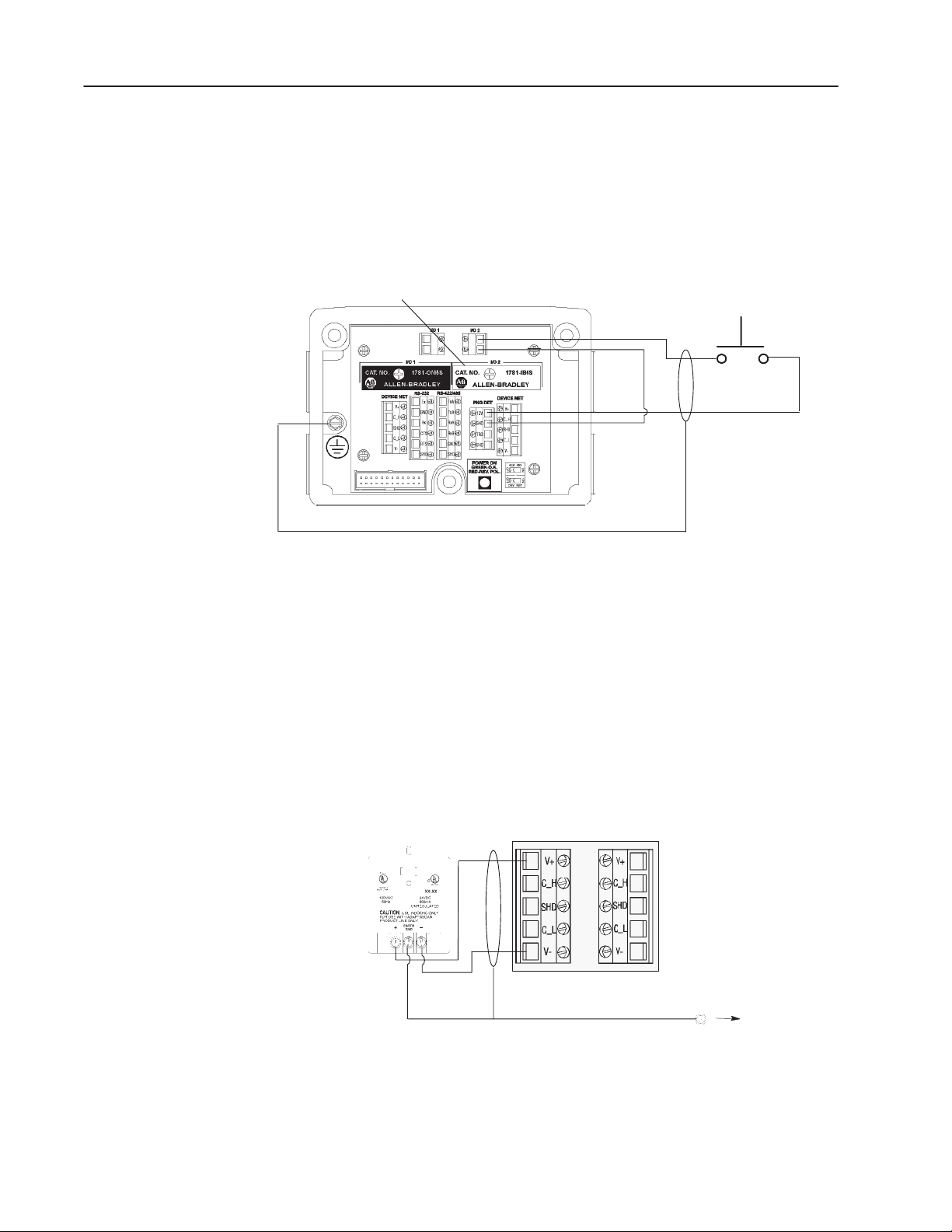

1–2 Using the Auto-Load Function

Internal Power Source

The following illustration shows the wiring base connections. The

2755-IB5S DC input module and the 42SRU-6203 PHOTOSWITCH

receive power from the Package Detect +12V internal power source

in this application. You could also use an external AC or DC power

source. Refer to the AdaptaScan Bar Code Readers User Manual

(Publication No. 2755-837) for more information regarding using an

external power source.

2755-IB5S

To +

To -

To +12V

To

GND

External

Input Contacts

Connecting a Power Supply to the Reader

The circuit must not draw more than 50mA from the Package Detect

terminal block.

The following illustration shows how to connect a 2755-PW46 or

-PW47 power supply to a single bar code reader.

Use a shielded cable (Belden 9316 recommended) to make the

connections. Connect the shield to the ground screw on the reader’s

wiring base.

2755-PW46

Power Supply

24V+

V-

Reader

Ground Screw

on Wiring Base

Publication 2755-6.8

Page 20

1–3Using the Auto-Load Function

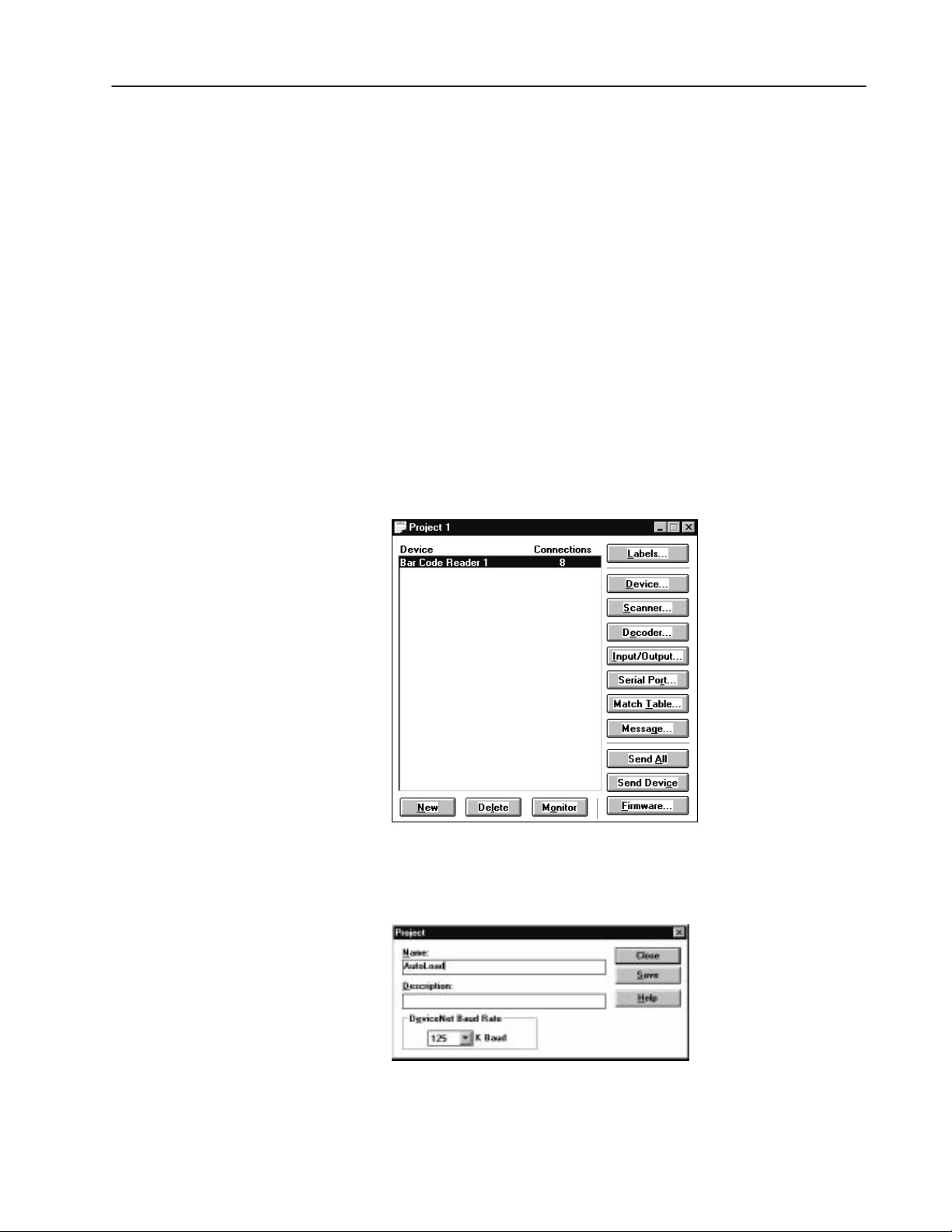

Configuring the Reader

This section shows how to configure the AdaptaScan Reader using

the AdaptaScan software (Catalog No. 2755-ASN).

The procedures in this section show how to:

• configure a bar code label and symbol

• define a DeviceNet address

• configure the scanner

• configure the decoder trigger

• configure the discrete input module

• configure the match table, package and autoload trigger source

Create a New Project

1. Select New from the Project menu to create a new project.

2. Click the New button to add a bar code reader (Bar Code Reader

1) to the project.

3. Choose Edit from the Project menu to rename the project

AutoLoad.

4. Click Save to save the project under the new name and then click

Close to return to the Project dialog.

Publication 2755-6.8

Page 21

1–4 Using the Auto-Load Function

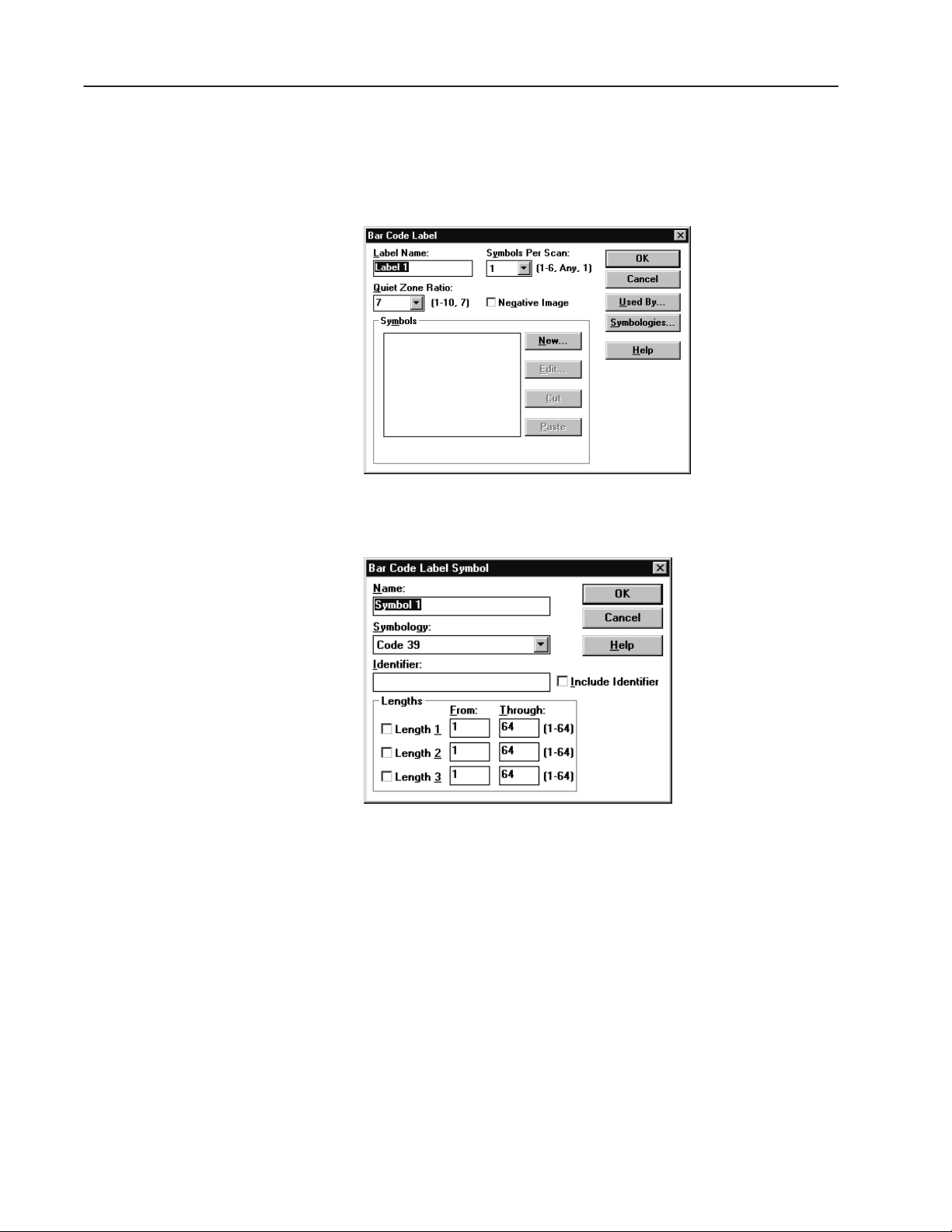

Define a Bar Code Label

1. Click the Labels button to open the Bar Code Labels dialog.

2. Click the New button to add a label.

3. Click the New button to add a symbol.

4. Select the symbology and define attributes such as Identifier and

Lengths.

5. Click OK until you return to the Bar Code Labels dialog.

6. Click Save to save the new label setup.

7. Click Close to return to the main Project dialog.

Publication 2755-6.8

Page 22

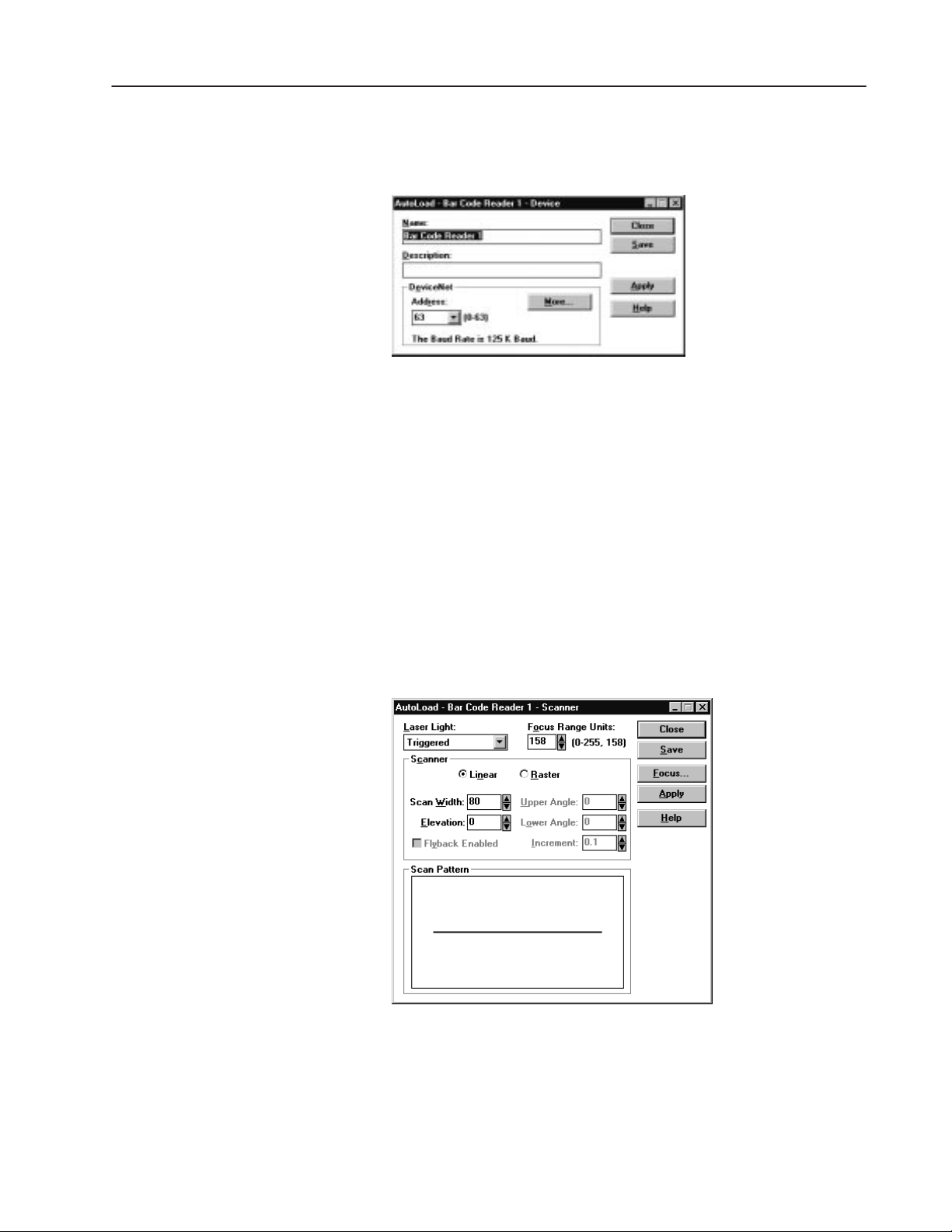

Define the DeviceNet Address

1. Click the Device button on the Project dialog.

2. Select a DeviceNet address.

3. Connect the 2755-NC43 or -NC48 Configuration Cable to the

reader.

4. Click the Apply button to send the DeviceNet address to the

reader.

1–5Using the Auto-Load Function

5. Click Save and Close to return to the main Project dialog.

Configure the Scanner

1. Click the Scanner button on the Project dialog to open the

Scanner dialog.

2. Configure the scan pattern and use the Focus procedure for

optimum scanner focus.

3. Click the Close button to return to the main Project dialog.

Publication 2755-6.8

Page 23

1–6 Using the Auto-Load Function

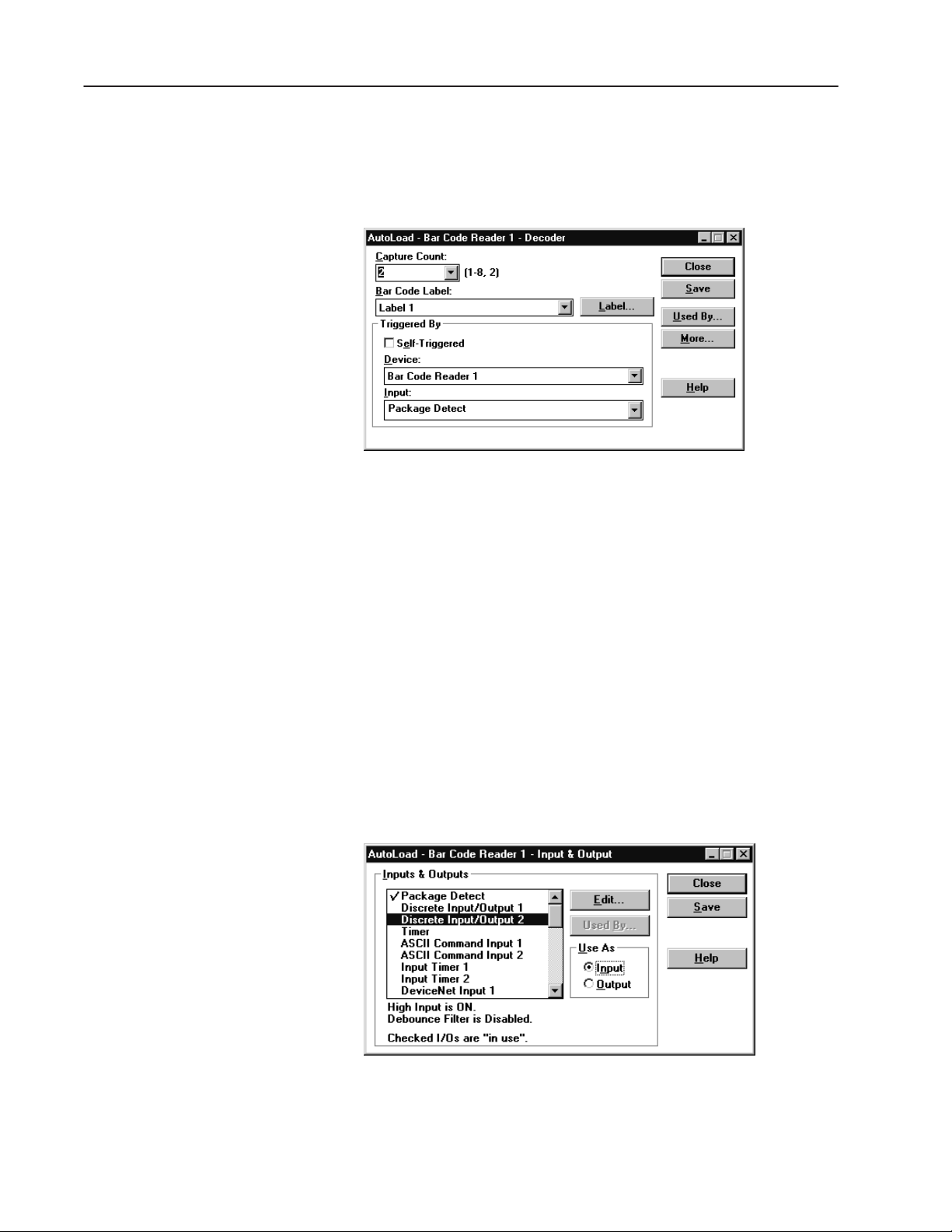

Configure the Decoder

1. Click the Decoder button from the main Project dialog.

2. Under Triggered By, select Package Detect from the Input list.

3. Click the Save button.

4. Click the Close button and return to the main Project dialog.

Configure the Discrete Input Module

The application uses a discrete input module to trigger the

Auto-Load function. The following procedure defines one of the

two input/output modules available in the AdaptaScan Bar Code

Reader as an input.

1. Click the Input/Output button on the main Project dialog.

2. Under Inputs & Outputs, select Discrete Input/Output 2. This is

the location of the 2755-IB5S DC Input Module in the reader’s

wiring base.

3. Under Use As, select Input.

Publication 2755-6.8

4. Click the Save button.

5. Click the Close button to return to the main Project dialog.

Page 24

1–7Using the Auto-Load Function

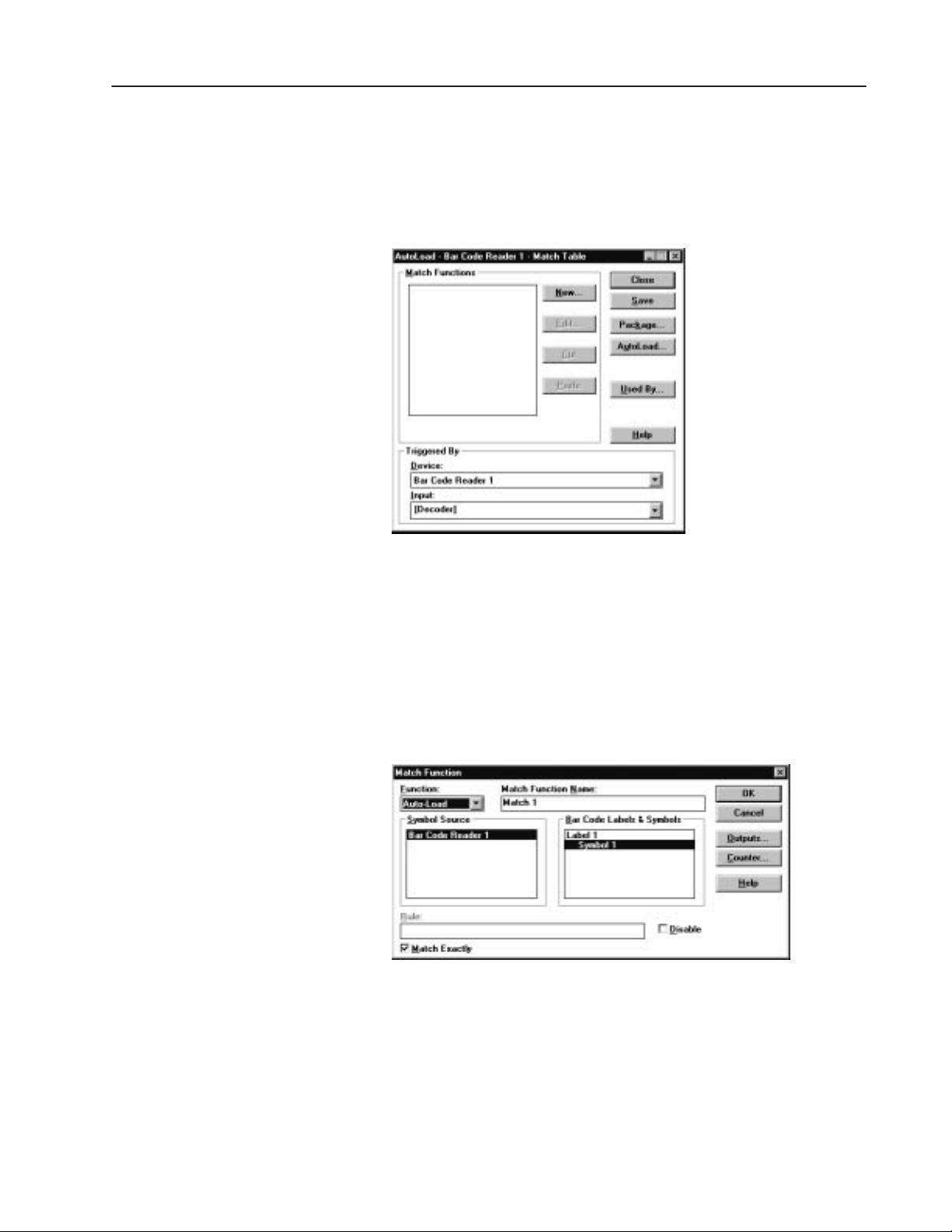

Configure the Match Table

The following procedure defines the contents of the match table and

the source of the symbol to be matched.

1. Click the Match Table button on the main Project dialog.

2. Click the New button to open the Match Function dialog.

3. Select the following parameters for the Match Function:

• Under Function, select Auto-Load

• Under Symbol Source, select Bar Code Reader 1

• Under Bar Code Labels & Symbols, select Symbol 1 under

Label 1

• Check (enable) the Match Exactly check box

4. Click the OK button to return to the Match Table dialog.

Publication 2755-6.8

Page 25

1–8 Using the Auto-Load Function

Configure a Package

When the application is running, the I/O 1 LED energizes (no output

module is actually installed in wiring base) when a No-Match or

No-Read occurs. The following procedure defines this package

function.

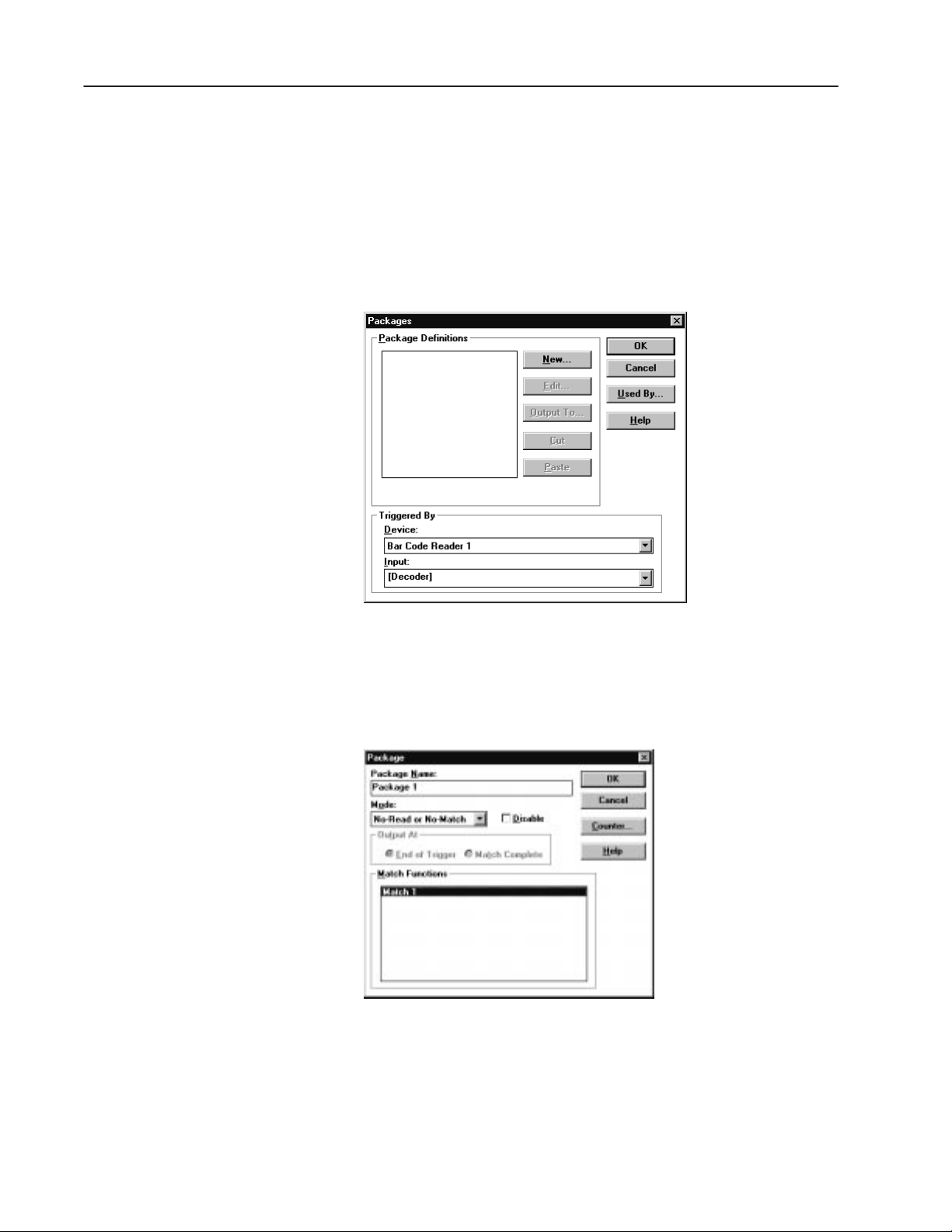

1. From the Match Table dialog, click the Package button to open

the Packages dialog.

2. Click the New button to create a package.

3. Under Mode, select No-Read or No-Match.

4. Select Match 1 under Match Functions.

5. Click OK to return to the Packages dialog.

Publication 2755-6.8

Page 26

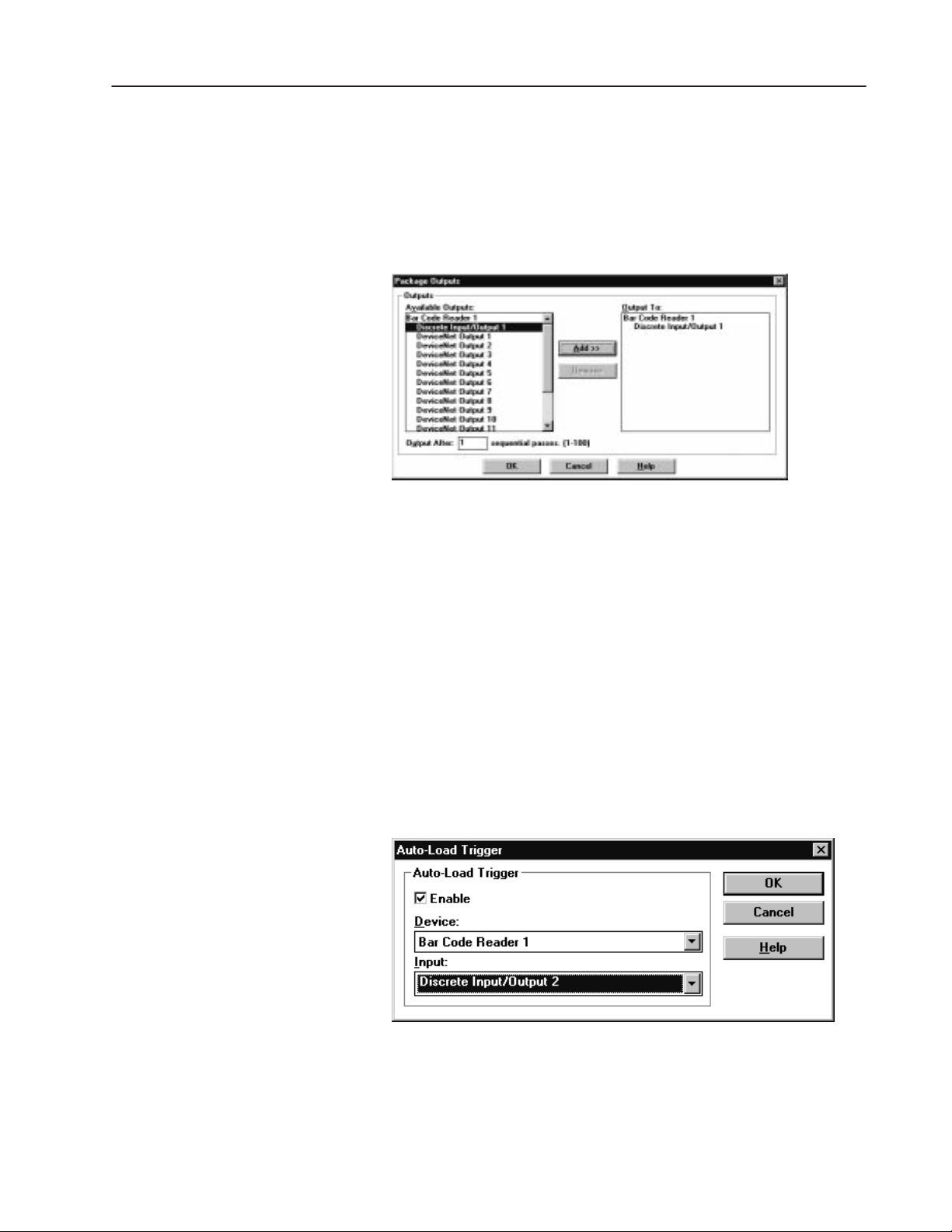

6. Click the Output To button to open the Package Outputs dialog.

7. Under Available Outputs, select Discrete Input/Output 1.

8. Click the Add>> button to add this selection under Output To:

Note: Discrete Input/Output 2 does not appear as an Available

Output because it was previously defined as an input.

1–9Using the Auto-Load Function

9. Click OK until you return to the Match Table dialog.

Configure the Auto-Load Trigger Source

The application uses a discrete input module (Discrete Input/Output

2) to activate the Auto-Load function. The following procedure

shows how to configure the input which will activate Auto-Load.

1. Click the AutoLoad button from the Match Table dialog.

2. Under Auto-Load Trigger:

• check the Enable check box.

• select Bar Code Reader 1 from the Device list.

• select Discrete Input/Output 2 from the Input list.

3. Click OK to return to the Match Table dialog.

4. Click Save and then Close to return to the Project dialog.

Publication 2755-6.8

Page 27

1–10 Using the Auto-Load Function

Sending the Configuration to the Reader

Running the Application

From the main Project dialog, click the Send Device button to

download the configuration to the bar code reader.

Use the Monitor dialog to verify bar code labels as they are decoded.

When the application is running, bar code data is autoloaded by

triggering the decoder (with Package Detect) when the desired

symbol is scanned and decoded. If the bar code data is unreadable or

does not match the autoloaded match string, I/O LED 1 turns on.

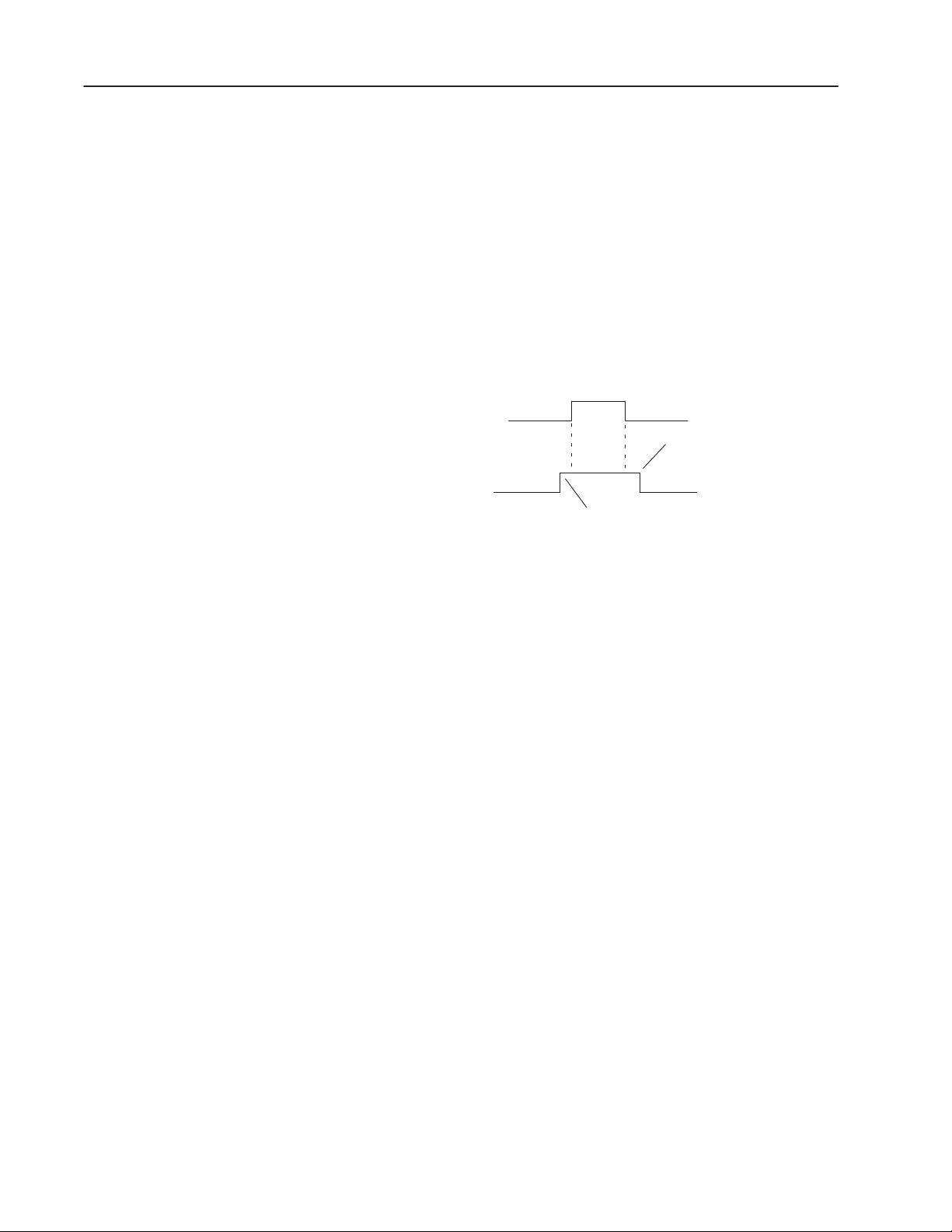

The following illustration shows the auto-load sequence using a

Package Detect as a decoder trigger.

Package Detect

Auto-Load Trigger remains on until

Package Detect is turned off

Auto-Load Trigger

Auto-Load trigger prior to

Package Detect

For more information on using Auto-Load, refer to chapter 10 in the

AdaptaScan Software User Manual (Publication No. 2755-838).

Publication 2755-6.8

Page 28

Using ASCII Command Input

Overview

Hardware Requirements

This application describes how to configure an AdaptaScan Bar

Code Reader to receive ASCII commands from a terminal emulator

over an RS-232 link:

• Terminal Emulator in Windows 3.1

• HyperTerminal in Windows 95

One character ASCII commands trigger the reader to start/stop

scanning. For each trigger command the reader receives, it echoes a

bar code string on the emulator.

The application includes the necessary cable diagrams and

configuration information for the AdaptaScan Bar Code Reader.

The hardware items required for this application are:

• 2755-SN3, -SN5 or -SN8 AdaptaScan Bar Code Reader

• 2755-NB40 or -NB41 Wiring Base

• 2755-NC43 or -NC48 Configuration Cable

• 2755-PW46 or -PW47 Power Supply

• Computer running Windows 3.1 (or later) or Windows 95

• 9-to-25 Pin Adapter (for computers with a 25-pin COM port)

Software Requirements

Related Publications

The software requirements for this application are:

• 2755-ASN AdaptaScan Offline Programming Software

• Terminal Emulator in Windows 3.1 or HyperTerminal in

Windows 95

Publications you may want to refer to include:

Publication Description

2755-837 AdaptaScan Bar Code Readers User Manual

2755-838 AdaptaScan Software User Manual

Publication 2755-6.8

Page 29

2–2 Using ASCII Command Input

Connecting a Computer to the Reader

with Your Computer RS-232 Port

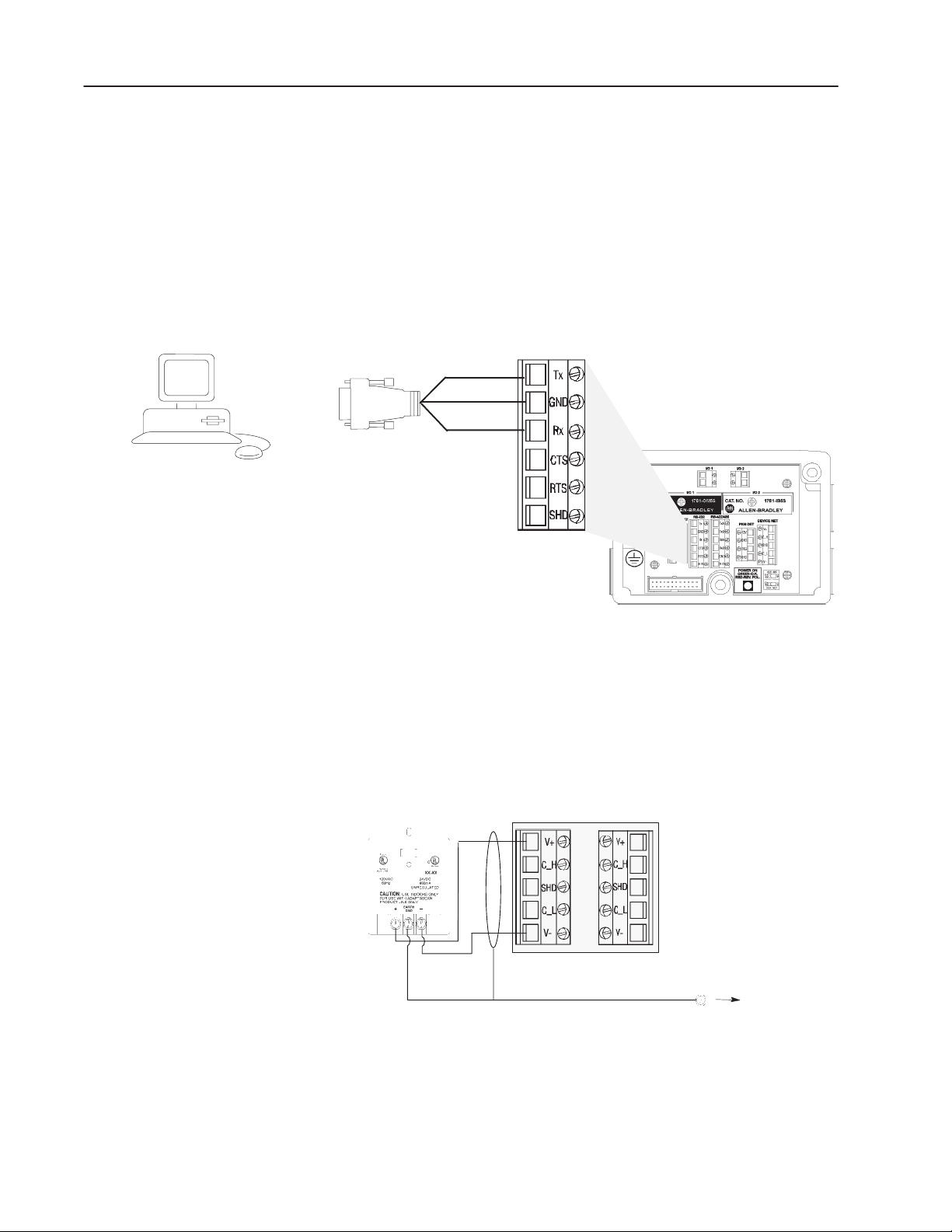

The following illustration shows the wiring base connections

between the AdaptaScan Bar Code Reader and the personal

computer. This RS-232 serial connection is used to download ASCII

commands to the reader and to display bar code messages on the

terminal emulator.

Create a cable using Belden 8303 (or equivalent) and a connector (to

match your computer’s RS-232 port). The other end of the cable is

wired to the RS-232 port in the reader wiring base.

Use Belden 8303 (or equivalent)

To Computer

To Connector Compatible

RX

GND

TX

Wiring Base of Reader

Connecting a Power Supply to the Reader

The following illustration shows how to connect a 2755-PW46 or

-PW47 power supply to a single bar code reader.

Use a shielded cable (Belden 9316 recommended) to make the

connections. Connect the shield to the ground screw on the reader’s

wiring base.

2755-PW46

Power Supply

24V+

V-

Reader

Ground Screw

on Wiring Base

Publication 2755-6.8

Page 30

2–3Using ASCII Command Input

Configuring the Reader

This section shows how to configure the AdaptaScan Reader using

the AdaptaScan Software (Catalog No. 2755-ASN).

The procedures in this section show how to:

• configure a bar code label and symbol

• define a DeviceNet address

• configure the scanner

• configure the decoder trigger for ASCII Command Input

• configure one character ASCII commands to start/stop scanning

• configure the serial port for terminal emulation

• define the format and content of messages

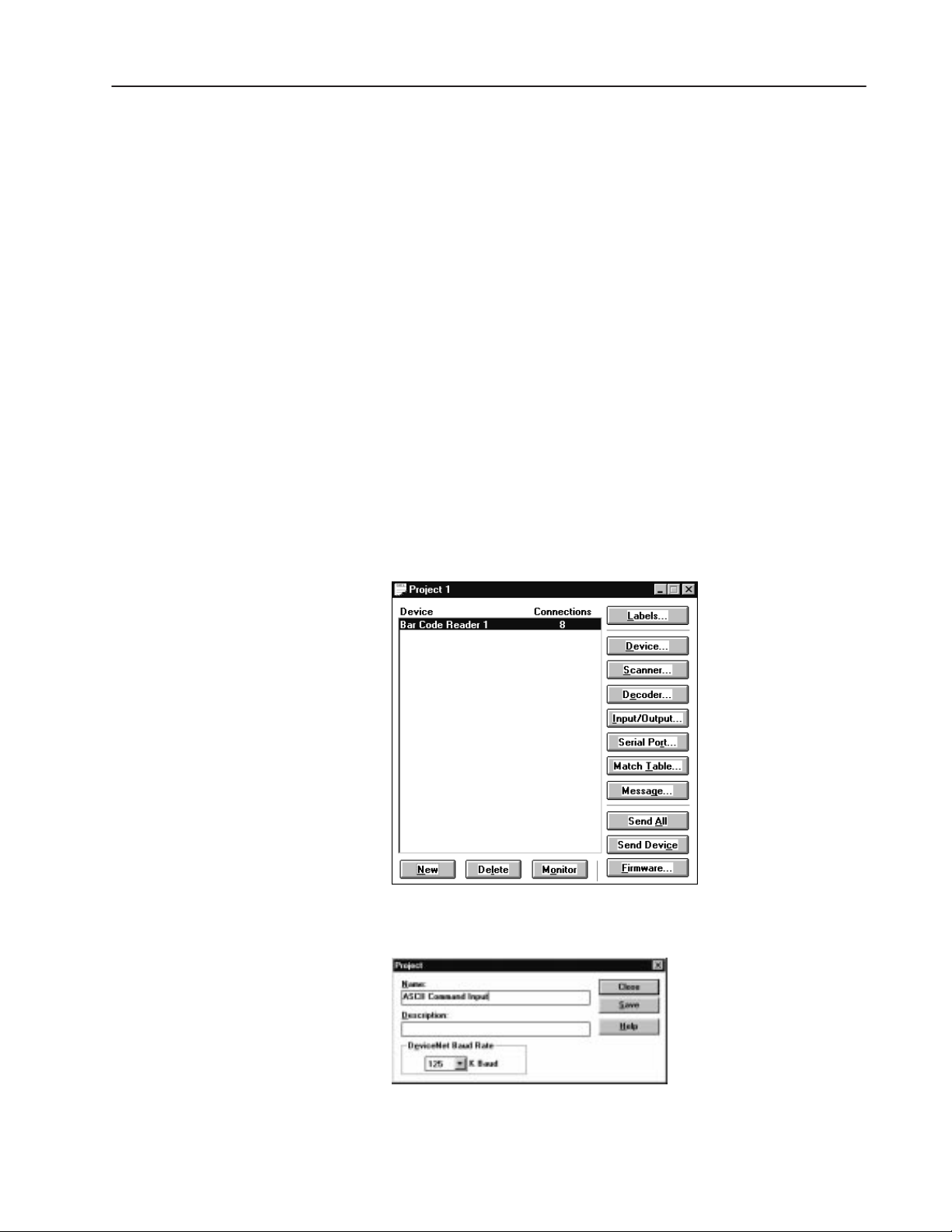

Create a New Project

Create a new project named ASCII Command Input for one

AdaptaScan Bar Code Reader (Bar Code Reader 1).

1. Choose New from the Project menu to create a new project.

2. Click the New button to add a bar code reader (Bar Code Reader

1) to the project.

3. Choose Edit from the Project menu to rename the project ASCII

Command Input.

4. Click Save to save the project under the new name and then Close

to return to the Project dialog.

Publication 2755-6.8

Page 31

2–4 Using ASCII Command Input

1. Click the Labels button to open the Bar Code Labels dialog.

2. Click the New button to define a label.

Define the Bar Code Label

3. Click the New button to define a symbol for the label.

4. Select the symbology and define attributes such as Identifier and

Lengths.

5. Click OK until you return to the Bar Code Labels dialog.

6. Click Save and then Close to return to the main Project dialog.

Publication 2755-6.8

Page 32

Define the DeviceNet Address

1. Click the Device button on the Project dialog.

2. Select a DeviceNet address.

3. Connect the 2755-NC43 or -NC48 Configuration Cable to the

reader.

4. Click the Apply button.

5. Click Save and Close to return to the Project dialog.

2–5Using ASCII Command Input

Configure the Scanner

1. Click the Scanner button on the Project dialog to open the

Scanner dialog.

2. Configure the scan pattern and use the Focus procedure for

optimum scanner focus.

3. Click the Close button and return to the Project dialog.

Publication 2755-6.8

Page 33

2–6 Using ASCII Command Input

1. Click the Decoder button from the main Project dialog.

2. Under Triggered By, select ASCII Command Input 1 from the

Configure the Decoder Trigger

This section defines ASCII Command Input 1 as the trigger for the

reader’s decoder.

Input list.

3. Click the Save button.

4. Click the Close button and return to the main Project dialog.

Configure the ASCII Commands

The following procedure defines the ASCII commands that will

trigger the decoder to start/stop scanning.

1. Click the Input/Output button on the main Project dialog.

2. Under Inputs & Outputs, select ASCII Command Input 1.

Publication 2755-6.8

Page 34

2–7Using ASCII Command Input

3. Click the Edit button to open the ASCII Command Input dialog.

The default ASCII commands for triggering the decoder are two

character commands:

• BS (Begin Scan)

• ES (End Scan)

This application uses one character ASCII commands to trigger

the decoder.

• B (Begin Scan)

• E (End Scan)

4. In the Turn On field, type the letter B. (The command is case

sensitive.)

5. In the Turn Off field, type the letter E. If you do not use an E in

the Turn Off field, the trigger will then turn off in 1000 ms. (The

command is case sensitive.)

6. Click the OK button.

7. Click the Save button to save the ASCII command definitions.

8. Click the Close button and return to the main Project dialog.

Publication 2755-6.8

Page 35

2–8 Using ASCII Command Input

1. Click the Serial Port button on the main Project dialog.

Configure the Serial Port

This section configures the RS-232 serial port so that it is compatible

with the Terminal Emulator in Windows 3.1 or HyperTerminal in

Windows 95.

2. Verify that Terminal is selected in the Protocol list box.

3. In the Maximum Length field, type 1.

With the Maximum Length set to 1, only one character is

downloaded to the reader through the terminal via RS-232 port.

If a message is configured, all bar code strings are read and

uploaded to the terminal via RS-232 port.

If the Maximum Length is set to 2, only two characters are

downloaded to the reader through the terminal via RS-232 port.

However, if a message is configured, only 2 bar code data

characters are uploaded to the terminal. The same is true for a

setting 3.

4. Select RS232 from the Connection list box.

Publication 2755-6.8

Page 36

5. Click the Edit button under Protocol.

6. Under Flow Control, select None.

7. Click OK to close the dialog.

8. Click the Save button to save the serial configuration.

2–9Using ASCII Command Input

9. Click Close to return to the main Project dialog.

Publication 2755-6.8

Page 37

2–10 Using ASCII Command Input

1. Click the Message button from the main Project dialog.

Create a Message

This section defines the content of the message sent from the reader

to the terminal emulator.

2. Under Triggered By, check the Enable check box.

3. Under Device, select Bar Code Reader 1.

4. Under Input, select [Decoder].

5. Click the New button to define a message field.

6. Under Symbol Source, select Bar Code Reader 1.

7. Under Bar Code Labels & Symbols, select Symbol 1.

8. Check (enable) the Match Exactly check box.

9. Click the Edit button to open the Message Field Edit dialog.

Publication 2755-6.8

Page 38

10. Under Replacement Strings, type nr in the Fail: field.

Bar code data is sent to the emulator on a valid read. The Fail

string sends the characters “nr” when a no read occurs.

11. Click OK to return to the Message Field dialog.

12. Click OK to return to the Message dialog.

2–11Using ASCII Command Input

Define the Message Format

This section defines the format of the message to display on the

terminal emulator.

1. Click the Format button from the Message dialog.

2. In the Trailer field, type \r\n (Carriage Return, Line Feed).

3. Under Message Destination, select Serial Port.

4. Click OK to return to the Message dialog.

5. Click the Save button and then the Close button to return to the

Project dialog.

Publication 2755-6.8

Page 39

2–12 Using ASCII Command Input

Sending the Configuration to the Reader

Running the Application

From the main Project dialog, click the Send Device button to

download the configuration to the bar code reader.

If your computer does not have two serial ports, switch the

2755-NC43 or -NC48 cable to the serial cable already wired to the

AdaptaScan Reader’s wiring base.

In the following illustration:

• ASCII command B is entered to trigger the decoder to start

scanning.

• ASCII command E is entered to stop scanning. A timeout occurs

if an E is not entered.

• Bar code data is displayed on the terminal emulator.

You must type B to trigger the decoder again and display the next bar

code string on the emulator.

Terminal Emulator Example

B

E

12345678

B

E

abcdefg

B

E

12345678

ASCII Turn On command

ASCII Turn Off command

Bar code data from AdaptaScan Reader

Publication 2755-6.8

Page 40

Downloading Match Codes

from a Host Device

Overview

Hardware Requirements

Software Requirements

This application describes how to download match codes to the bar

code reader from a terminal emulator using an RS-232 connection.

It also describes how to download other host commands using the

same procedures.

The hardware items required for this application are:

• 2755-SN3, -SN5, -SN8 AdaptaScan Bar Code Reader

• 2755-NB40 or -NB41 Wiring Base

• 2755-PW46 or -PW47 Power Supply

• 2755-NC43 or -NC48 Configuration Cable

• Communication Cable with Connector for PC

(Belden 8303 or equivalent)

• Computer running Windows 3.1 (or later) or Windows 95

• 9-to-25 Pin Adapter (for Computer with 25-pin COM port)

The software requirements for this application are:

• 2755-ASN AdaptaScan Offline Programming Software

• Terminal Emulator in Windows 3.1 or HyperTerminal in

Windows 95

Related Publications

Related publications include:

Publication Description

2755-837 AdaptaScan Bar Code Readers User Manual

2755-838 AdaptaScan Software User Manual

Publication 2755-6.8

Page 41

3–2 Downloading Match Codes from a Host Device

Connecting a Computer to the Reader

with Your Computer RS-232 Port

The following illustration shows the wiring base connections

between the AdaptaScan Bar Code Reader and the personal

computer. This RS-232 serial connection is used to download match

codes to the reader from a terminal emulator. Do not connect the

cable to the computer until after the application is downloaded to the

reader (see page 3–10).

Create a cable using Belden 8303 (or equivalent) and a connector (to

match your computer’s RS-232 port). The other end of the cable is

wired to the RS-232 port in the reader wiring base.

Use Belden 8303 (or equivalent)

To Computer

To Connector Compatible

RX

GND

Tx

Wiring Base of Reader

Connecting a Power Supply to the Reader

The following illustration shows how to connect a 2755-PW46 or

-PW47 power supply to a single bar code reader.

Use a shielded cable (Belden 9316 recommended) to make the

connections. Connect the shield to the ground screw on the reader’s

wiring base.

2755-PW46

Power Supply

24V+

V-

Reader

DeviceNet Connector

Ground Screw

on Wiring Base

Verify the connection by applying power to the wiring base and

observing the polarity LED. The LED should be green. If the LED

is red, the polarity needs to be reversed. Disconnect power from

wiring base until the reader is installed.

Publication 2755-6.8

Page 42

3–3Downloading Match Codes from a Host Device

Configuring the Reader

This section shows how to configure one the AdaptaScan Bar Code

Readers using the AdaptaScan Software (Catalog No. 2755-ASN).

The procedures in this section show how to:

• define the DeviceNet node address of the AdaptaScan Reader

• configure a bar code label and symbol

• configure the scanner

• configure the decoder trigger

• configure the serial port

• configure the format of messages and the message destination

The steps may vary for some procedures because of the different

requirements of applications. For example, the bar code labels may

vary from one application to the next.

Create a New Project

This section adds a bar code reader to a new project and then

renames the project Download Match Codes.

1. Choose New from the Project menu to create a new project.

2. Click the New button to add a bar code reader (Bar Code Reader

1) to the project.

3. Choose Edit from the Project menu to rename the project

Download Match Codes.

4. Click Save to save the project under the new name and then Close

to return to the Project dialog.

Publication 2755-6.8

Page 43

3–4 Downloading Match Codes from a Host Device

Define the Bar Code Label

This section configures the reader to scan/decode Interleaved 2 of 5

symbols.

1. Click the Labels button to open the Bar Code Labels dialog.

2. Click the New button to define a label.

3. Click the New button to define Symbol 1.

4. From the Symbology list box, select I 2 of 5.

To edit parameters of the selected symbology, click the

Symbologies button.

5. Click OK until you return to the Bar Code Labels dialog.

6. Click Save and then Close to return to the main Project dialog.

Publication 2755-6.8

Page 44

Define the DeviceNet Address

1. Click the Device button on the Project dialog.

2. Select a DeviceNet address.

3. Connect the 2755-NC43 or -NC48 Configuration Cable to the

Reader.

4. Click the Apply button.

5. Click the Close button and return to the Project dialog.

3–5Downloading Match Codes from a Host Device

Configure the Scanner

1. Click the Scanner button on the Project dialog to open the

Scanner dialog.

2. Configure the scan pattern and use the Focus procedure for

optimum scanner focus.

3. Click the Close button and return to the Project dialog.

Publication 2755-6.8

Page 45

3–6 Downloading Match Codes from a Host Device

Configure the Decoder Trigger

Bar Code Reader 1 is triggered by a Timer. The Timer is typically

used during initial setup to simulate a package detector.

The Timer is set for a specified On Time (1 second) and Off Time (1

second).

1. Click the Decoder button from the main Project dialog.