Page 1

PowerFlex® DC Drive and Stand-Alone Regulator (SAR)

Control Circuit Board

Installation Instructions

ATTENTION: Only qualified personnel familiar with DC drives

and associated machinery should plan or implement the installation,

start-up and subsequent maintenance of the system. Failure to

comply may result in personal injury and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, ensure that all

power to the drive has been removed before performing the

following.

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other applicable ESD protection

handbook.

What This Kit Includes

What This Option Provides

Tools That You Need

• Control circuit board

• Five screws with captive lock washers

• Static strap

• Flathead screwdriver for terminal block connections

The Control circuit board is the main drive-mounted board that controls the

drive and provides these Input/Output (I/O) signals:

• Eight Digital Inputs

• Four Digital Outputs

• Three Analog Inputs

• Two Analog Outputs

• Digital Encoder Input

• DC Analog Tachometer Input

• Phillips® screwdriver

• Hexalobular screwdriver

• Flathead screwdriver

• Nut driver or wrench for hex stand-offs

®

Phillips

is a registered trademark of Phillips Screw Company.

Publication 20P-IN004B-EN-P

Page 2

2

What You Need to Do

Step 1: Save the Parameter Configuration

Step 2: Remove Power from the Drive

To install the Control board:

❐ Step 1: Save the Parameter Configuration

❐ Step 2: Remove Power from the Drive

❐ Step 3: Remove the Drive Covers

❐ Step 4: Remove the Communication Adapter and EMI Shield

❐ Step 5: Remove the Existing Connections and Option Board(s)

❐ Step 6: Remove the Existing Control Board

❐ Step 7: Install the New Control Board

❐ Step 8: Wire the Control Board

❐ Step 9: Document the Change

If possible, save the drive and adapter parameter configuration to a Human

Interface Module (HIM) Set or by up loading the drive and adapter parameters

to an offline database file using DriveExecutive™. Refer to the PowerF lex DC

Digital Drive User Manual, publication 20P-UM001

the HIM or the on-line Help provided with DriveExecutive.

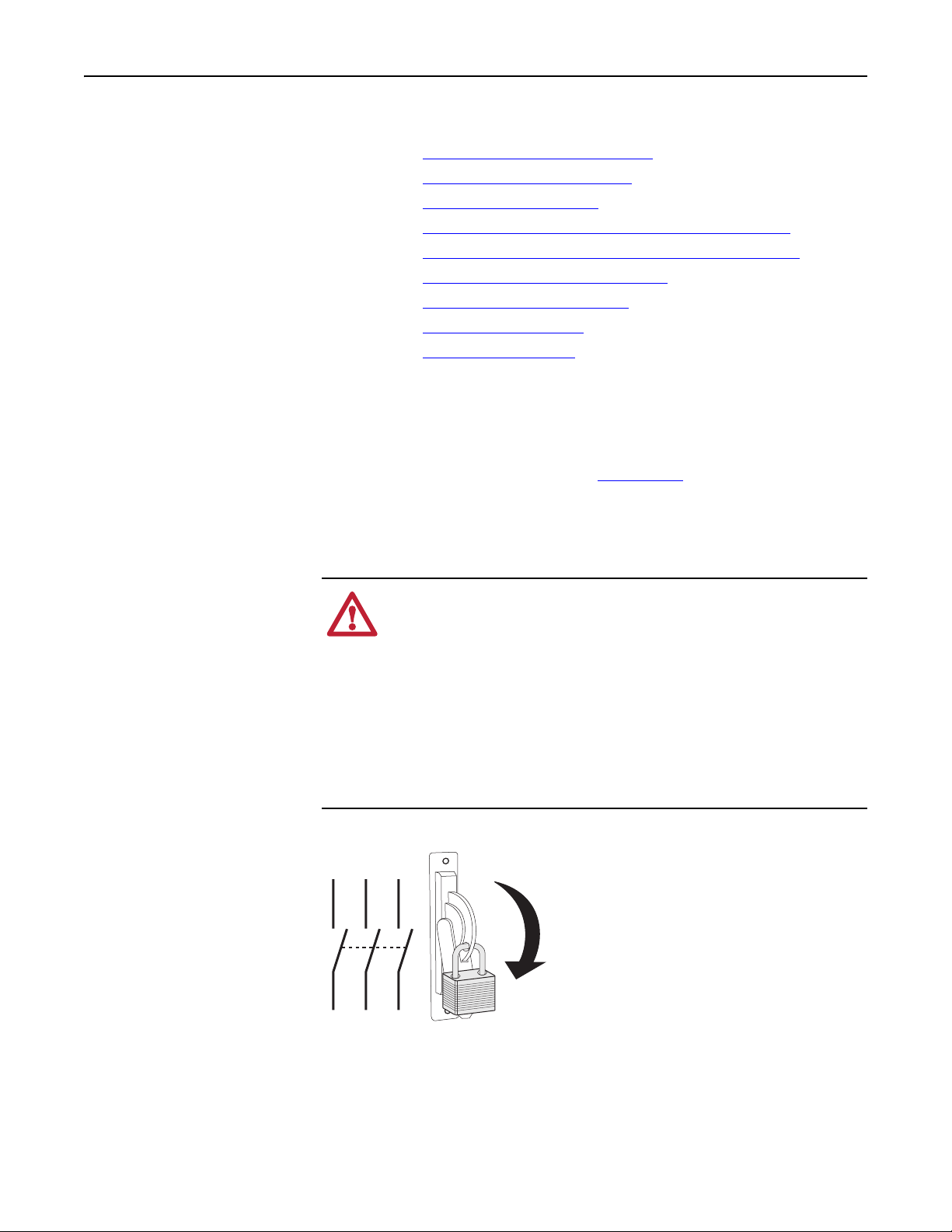

ATTENTION: Remove power before making or breaking cable

connections. When you remove or insert a cable connector with

power applied, an electrical arc may occur. An electrical arc can

cause personal injury or property damage by:

, for information on using

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create electrical

resistance.

Remove and lock-out all incoming power to the drive.

L1 L2 L3

I

O

Publication 20P-IN004B-EN-P

Page 3

3

Step 3: Remove the Drive Covers

• To open frame A drives and the stand-alone regulator, see Frame A Drives

and the Stand-Alone Regulator below.

• To open frame B and C drives see Frame B and C Drives

• To open frame D drives see Frame D Drives

on page 5.

on page 4.

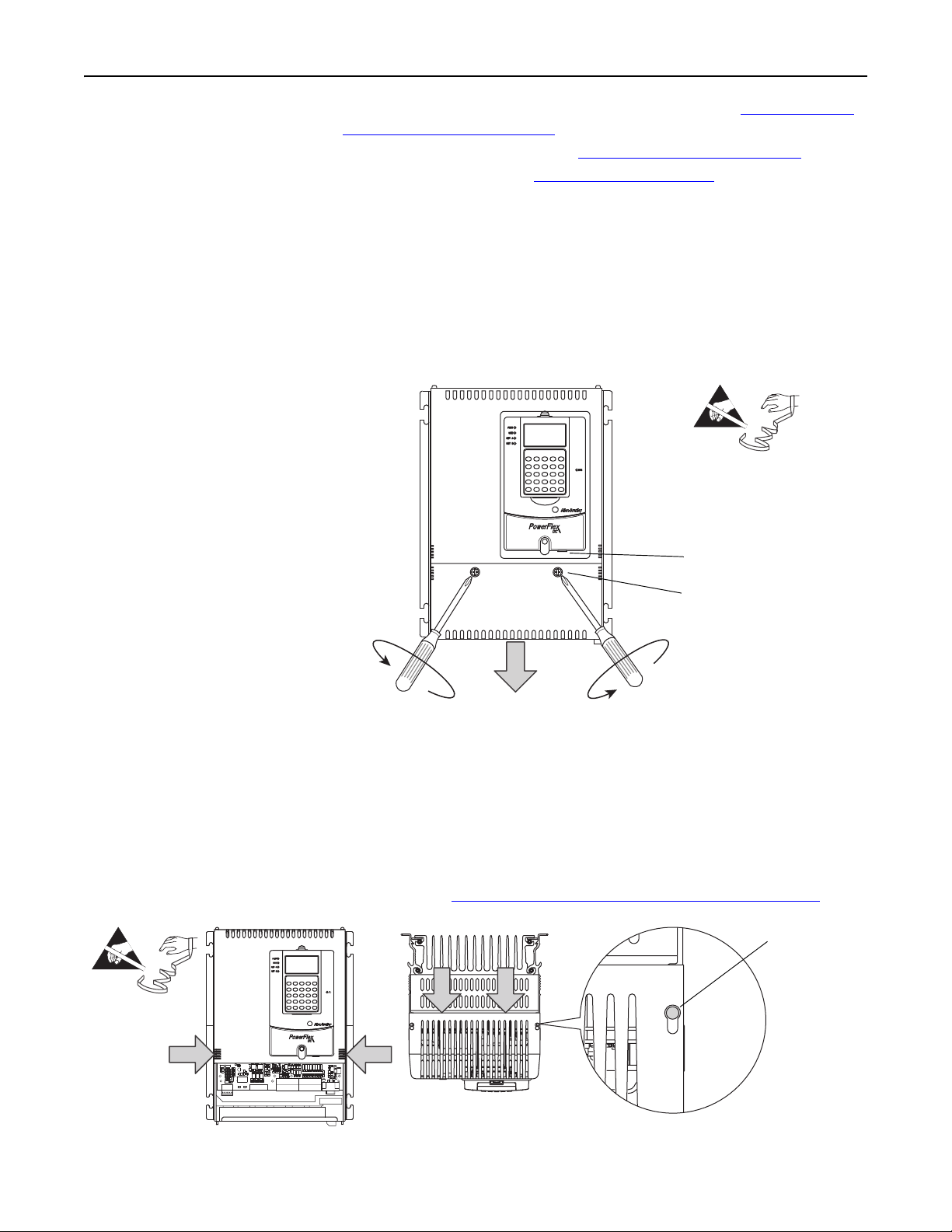

Frame A Drives and the Stand-Alone Regulator

1. Disconnect the Device Peripheral Interface (DPI) cable from the HIM

assembly (if present).

2. Loosen the captive screws that secure the bottom front cover to the drive,

then slide the cover down and off the drive chassis.

=

Disconnect DPI cable

Tightening torque:

1.5 N•m (13.3.lb•in)

3. Press in on the sides at the bottom edge of the top cover and pull the cover

toward you until the cover is partially off the drive chassis. Then pull the top

of the cover toward you until the mounting pins align with the keyholes in

the top of the cover. Then carefully lift the cover off of the drive chassis.

Important: The HIM assembly is connected to the control board via a

communication cable. Carefully set the top cover down next

to the chassis.

4. Continue with Disconnect the HIM Communication Cable

=

on page 6.

When mounting

pins fits in

keyhole, lift

cover off drive

chassis.

Publication 20P-IN004B-EN-P

Page 4

4

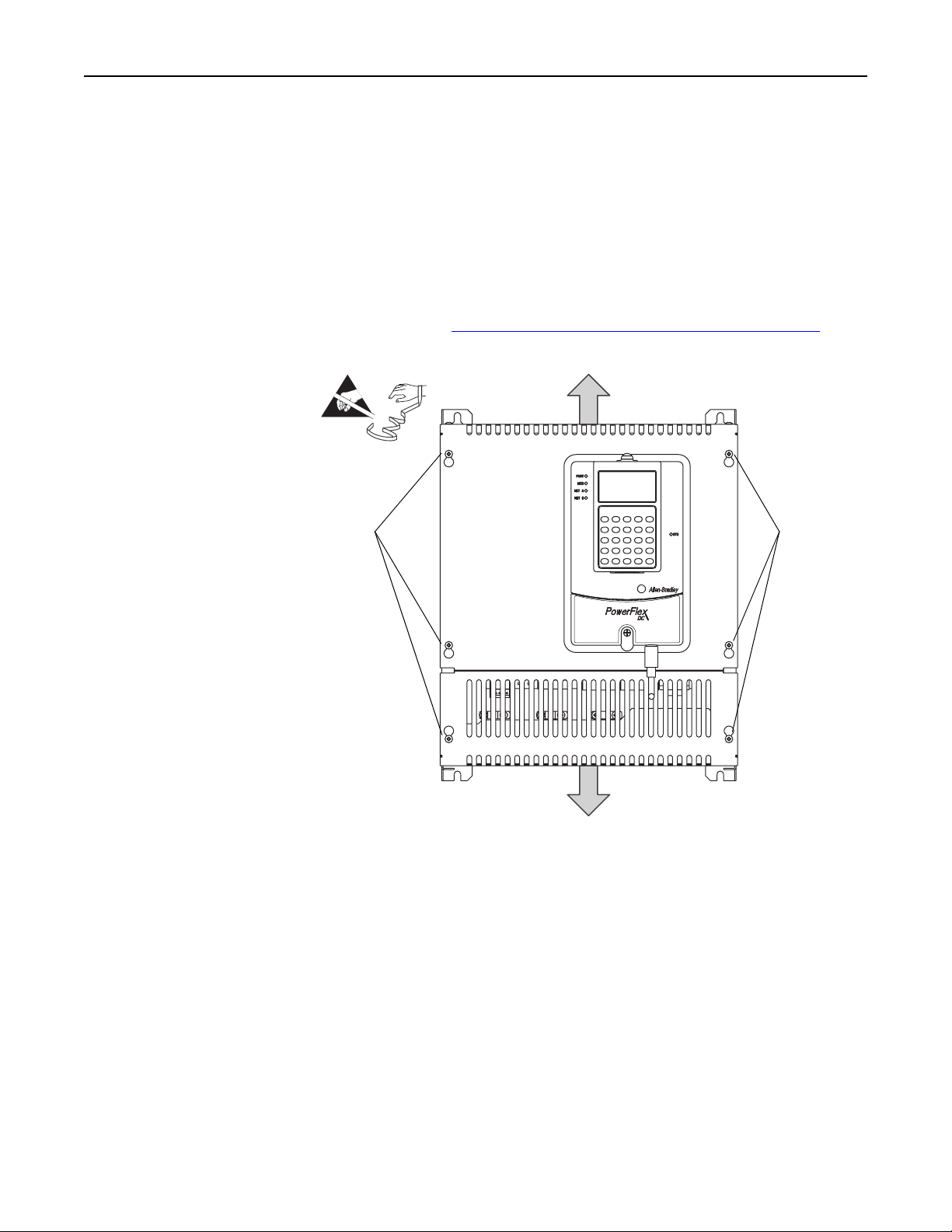

Frame B and C Drives

1. Disconnect the DPI cable from the HIM (if present).

2. Loosen, but do not remove, the screws that secure the top and bottom front

covers to the drive, then slide the covers off the drive chassis.

Important: The HIM assembly is connected to the control board via a

communication cable. Carefully set the top cover down next

to the chassis.

3. Continue with Disconnect the HIM Communication Cable

=

Frames B shown

Loosen

screws

Disconnect

DPI cable.

on page 6.

Tightening torque:

1.5 N•m (13.3.lb•in)

Loosen

screws

Publication 20P-IN004B-EN-P

Page 5

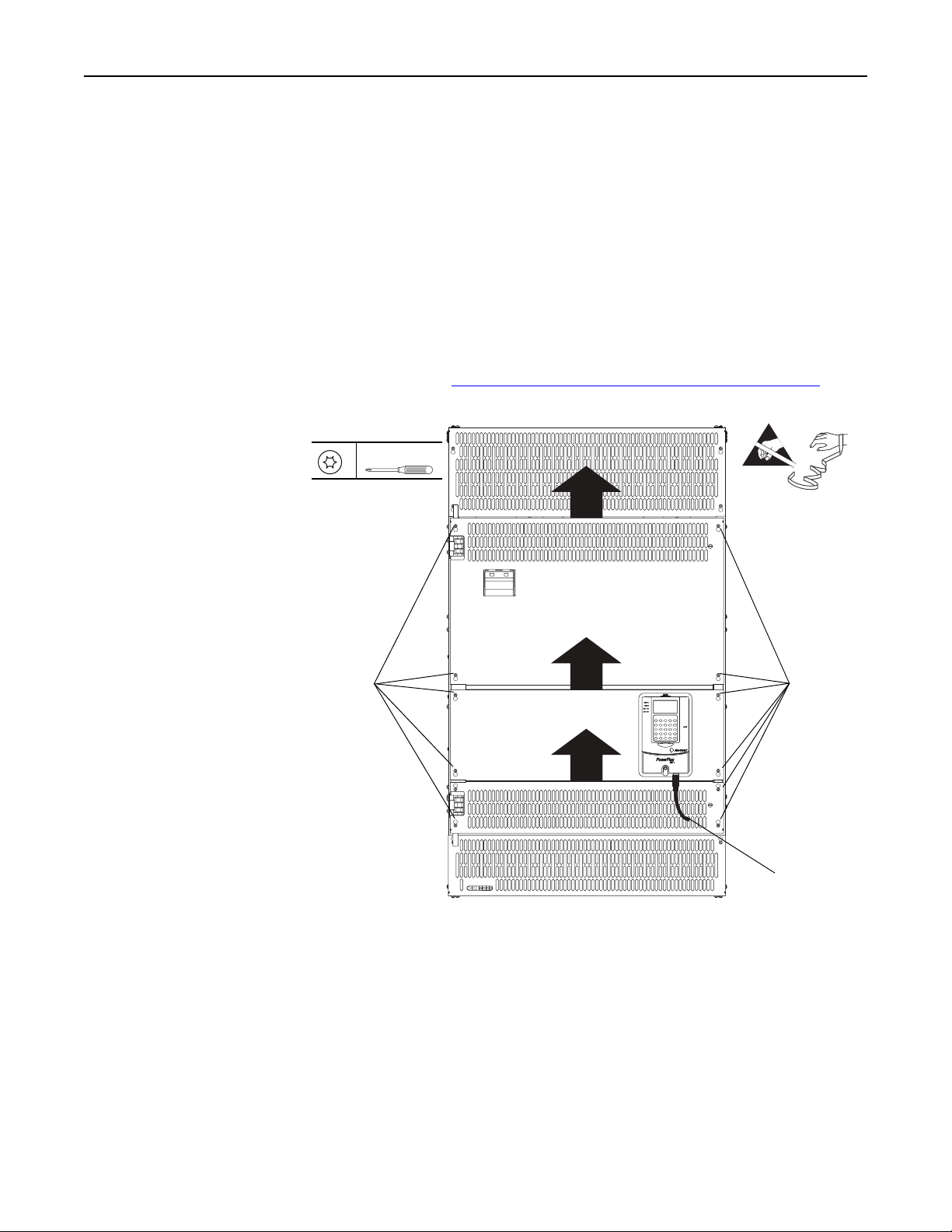

Frame D Drives

1. Disconnect the DPI cable from the HIM assembly (if present).

2. Loosen, but do not remove, the four hexalobular screws that secure each of

the three covers to the control pan on the drive, then slide the covers up and

off the drive chassis. Tightening torque is noted in the illustration for

reassembly.

Important: A communication cable connects the HIM assembly to the

control board mounted on the control pan. Therefore, the

middle control pan cover and HIM assembly cannot be fully

removed from the drive until the cable is disconnected.

5

3. Continue with Disconnect the HIM Communication Cable

T15

Tightening torque:

1.5 N•m (13 lb•in)

Loosen

screws

on page 6.

=

Loosen

screws

Disconnect

DPI cable

Publication 20P-IN004B-EN-P

Page 6

6

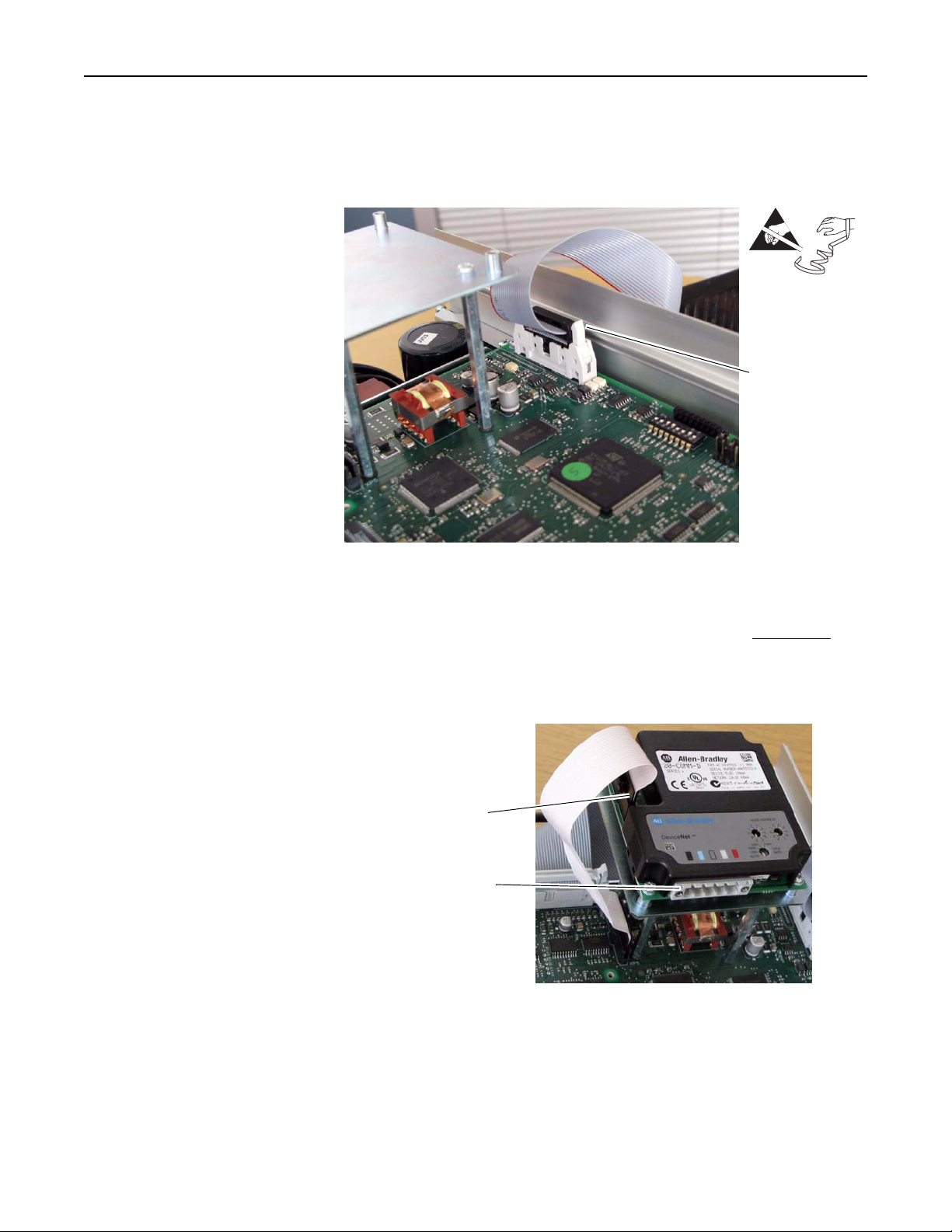

Disconnect the HIM Communication Cable

For all drives, disconnect the HIM communication cable from the connector on

the upper right corner of the control board and set the cover aside.

=

All Frames

(Frame A shown)

Pull tabs out

to disconnect

cable.

Step 4: Remove the Communication Adapter and EMI Shield

If a communication adapter is not installed, continue with step 4 on page 7.

1. Disconnect the interface cable from the adapter and set it aside.

2. Disconnect any network cables from the adapter and set them aside.

Disconnect interface cable

Disconnect network cables

Publication 20P-IN004B-EN-P

Page 7

3. Remove the four screws that secure the adapter to the EMI shield and

remove the adapter.

Remove four screws

Tightening torque:

0.9 N•m (8 lb•in)

4. Remove the three screws that secure the EMI shield to the stand-offs on the

control board and remove the EMI shield.

7

Remove three screws

Tightening torque:

1.0 N•m (8.9 lb•in)

5. Remove the three stand-offs from the control board.

Remove three standoffs

Tightening torque:

1.0 N•m (8.9 lb•in)

Publication 20P-IN004B-EN-P

Page 8

8

Step 5: Remove the Existing Connections and Option Board(s)

If the optional resolver feedback module, I/O expansion, and 115V AC to

24V DC converter boards are not installed on the control board, continue with

Step 6: Remove the Existing Control Board

on page 13.

Important:Mark all connections and wires before removing to avoid incorrect

wiring during reassembly.

Step 5A: Remove the Resolver Feedback Module

If the optional resolver feedback module is not installed, continue with Step 5B:

Remove the Optional I/O Expansion Board on page 10.

Important:The resolver feedback module can only be used with PowerFlex DC

drives with firmware version 5.002 or higher.

Important:The resolver feedback module consists of an interface board and a

feedback board. For this procedure, both boards of the resolver

feedback module are removed together, as an assembly.

1. Remove the three plug-in I/O terminal blocks from the resolver feedback

module assembly.

2. Remove the four mounting screws for the resolver interface board.

Resolver feedback board

Resolver interface board

=

Remove four screws

(resolver interface board)

Tightening torque is

0.7 N•m (6.2 lb•in)

Plug-in I/O terminal blocks

XR

XA

XP3

J1 J2

P4

S2

S4

P2 P3

XRE

P1

S21

TB1 TB2

P1

S15

XFCD

S1

Publication 20P-IN004B-EN-P

Page 9

3. Carefully lift the resolver interface module off of the control board, pulling

the stacker connector out of the XRE connectors on the control board.

Important: Lift the resolver interface board straight up so that the stacker

connector pins do not bend or break.

9

Resolver

interface board

XRE connector

Side view

Control board

Stacker

connector

XRE

connector

Resolver interface board

Capped pins

to right

Control board

Bottom view

4. Remove the four stand-offs and washers that support the resolver interface

board on the control board.

Publication 20P-IN004B-EN-P

Page 10

10

Step 5B: Remove the Optional I/O Expansion Board

If the optional I/O expansion board is not installed, continue with Step 5C:

Remove the 115V AC to 24V DC Converter Board on page 12.

1. Remove the plug-in I/O terminal blocks.

2. Remove the two screws that secure the board to the stand-offs on the control

board.

=

3. Carefully remove the I/O expansion board from the control board.

=

Pins connected to connector XBB

Lift board straight up

and off control board

Remove two screws

Tightening torque:

1.0 N•m (8.9 lb•in)

Important: Lift the board straight up so that the connector pins on the

I/O expansion board do not bend or break.

Publication 20P-IN004B-EN-P

Page 11

4. Remove the two stand-offs and washers that support the I/O expansion

board on the control board.

=

11

Remove two stand-offs

Tightening torque:

1.0 N•m (8.9 lb•in)

Publication 20P-IN004B-EN-P

Page 12

12

Step 5C: Remove the 115V AC to 24V DC Converter Board

If the optional 115V AC to 24V DC converter board is not installed, continue

with Step 6: Remove the Existing Control Board

1. Remove the plug-in I/O terminal blocks.

2. Remove the two screws that secure the I/O converter board to the stand-offs

on the control board and remove the converter board.

on page 13.

Remove two screws

Tightening torque:

1.0 N•m (8.9 lb•in)

3. Remove the two stand-offs and washers that support the converter board on

the control board.

Remove two stand-offs

Tightening torque:

1.0 N•m (8.9 lb•in)

Publication 20P-IN004B-EN-P

Page 13

13

Step 6: Remove the Existing Control Board

S14

S20

1 2 3 4 5 6 7 8

S4

S4

- A B C +

- A B C +

1. Record the DIP switch and jumper settings on the control board.

1 2 3 4 5 6 7 8

S14

ON

S20

ON

S10

21 22 23 24 25 26 27 28 29 30

21 22 23 24 25 26 27 28 29 30

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

31 32 33 34 35 36 37 38 39 40

31 32 33 34 35 36 37 38 39 40

11 12 13 14 15 16 17 18 19 20

11 12 13 14 15 16 17 18 19 20

DEBUG

S21

ENC_5 ENC_12

S11

S9

A+ A- B+ B- Z+ Z- COM +V

A+ A- B+ B- Z+ Z- COM +V

S15

1 2 3 4 5 6 7 8

RST

ACT

RUN

PWR

S15

S21

S9, S10, S11

Jumper/

Switch Function Setting

S4 Configures the input voltage of the DC analog tachometer.

S9 Configures the input signal of Analog Input 1 (terminals 1 and 2):

Note: The input signal type must also be programmed accordingly using parameter 71 [Anlg In1 Config].

S10 Configures the input signal of Analog Input 2 (terminal 3 and 4):

Note: The input signal type must also be programmed accordingly using parameter 76 [Anlg In2 Config].

S11 Configures the input signal of Analog Input 3 (terminals 5 and 6):

Note: The input signal type must also be programmed accordingly using parameter 81 [Anlg In3 Config].

S14 Field current resistors setting.

Important: In addition, the value selected with switch S14 must be entered in parameter 374 [Drv Fld Brdg Cur] in the

control software when the drive is commissioned.

S14-1 =

S14-2 =

S14-3 =

S14-4 =

S14-5 =

S14-6 =

S14-7 = (not used)

S14-8 = (not used)

S15 Configuration of the control circuit board to the appropriate drive size. This value is set to the appropriate size at the

factory.

S15-1 =

S15-2 =

S15-3 =

S15-4 =

S15-5 =

S15-6 =

S15-7 =

S15-8 =

S20 Monitoring of the Z channel of the digital encoder on connector XE2:

S21 Encoder power supply voltage and input adaptation selection:

Note: When control power is supplied to the drive, the appropriate LED lights to indicate the selection of the switch.

Publication 20P-IN004B-EN-P

Page 14

14

2. Carefully disconnect the cables from connectors XFCD, XA, and XR on the

control board.

3. Remove the plug-in I/O and control terminal blocks with the wiring kept in

place.

Disconnect

cables

=

Disconnect I/O

and control

wiring

Remove screws

Tightening torque:

1.0 N•m (8.9 lb•in)

4. Remove the five screws that secure the control board to the control EMI

shield and remove the board from the drive.

Publication 20P-IN004B-EN-P

Page 15

15

Step 7: Install the New Control Board

Step 8: Wire the Control Board

1. Install the new control board in the reverse order of removal as detailed in

Step 6: Remove the Existing Control Board

on page 13.

2. Verify that all DIP switch and jumper settings match those recorded in the

chart on page 13

publication 20P-UM001

. Refer to the PowerFlex DC Digital Drive User Manual,

, for detailed information on DIP switch and

jumper settings.

Install the I/O and control wiring in reverse order of removal.

Figure 1 I/O and Control Wire Routing

Route I/O and control

wiring between

bottom front cover

and power terminal

cover/shield.

(Frame A shown)

Publication 20P-IN004B-EN-P

Page 16

16

Step 9: Document the Change

1. Record the installation of the new control board and date of installation on

the field installed option label on the side of the drive (as shown below).

2. Replace the drive covers in the reverse order of removal as described in Step

3: Remove the Drive Covers

on page 3.

3. Install DPI cable (if present).

4. Down load the parameter configuration back into the drive.

Frame A Shown

Related Documentation

Publication 20P-IN004B-EN-P

Allen-Bradley publications are available on the internet at

www.rockwellautomation.com/literature

For . . . Read this document

In-depth information regarding the

operation of PowerFlex Digital DC drives

In-depth information regarding the

installation and wiring of the resolver

feedback option module

In-depth information regarding the

installation and wiring of the I/O

expansion circuit board

In-depth information regarding the

installation and wiring of the115V AC to

24V DC converter board

User Manual - PowerFlex Digital DC Drives 20P-UM001

Installation Instructions - PowerFlex DC

Drive Resolver Feedback Option Module

PowerFlex DC Drive Analog and Digital

I/O Expansion Circuit Board

PowerFlex DC Drive 115V AC to 24V DC

I/O Converter Circuit Board

.

Publication

Number

20P-IN071

20P-IN002

20P-IN003

Page 17

Notes:

17

Publication 20P-IN004B-EN-P

Page 18

1S7A42

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, E-mail: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

www.rockwel lautomation.com

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 20P-IN004B-EN-P - June 2011

Supersedes 20P-IN004A-EN-P - October 2007 Copyright © 2011 Rockwell Automation. All rights reserved. Printed in U.S.A.

Loading...

Loading...