Page 1

PowerFlex® DC Drive

Frame D AC Current Transducers

Installation Instructions

ATTENTION: Only qualified personnel familiar with DC drives

and associated machinery should plan or implement the installation,

start-up and subsequent maintenance of the system. Failure to comply

may result in personal injury and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, ensure that all

power to the drive has been removed before performing the following.

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other applicable ESD protection

handbook.

What This Kit Includes

Tools That You Need

What You Need to Do

• Two AC current transducers

• Four mounting screws

• Static strap

• Hexalobular screwdriver

• Flathead screwdriver

• Torque wrench

To install the AC current transducers:

❐ Step 1: Remove power from the drive

❐ Step 2: Remove the protective covers and open the control panel

❐ Step 3: Remove the existing AC current transducers

❐ Step 4: Install the new AC current transducers

❐ Step 5: Close the control panel, replace the covers and document the

change

Publication 20P-IN059A-EN-P

Page 2

2

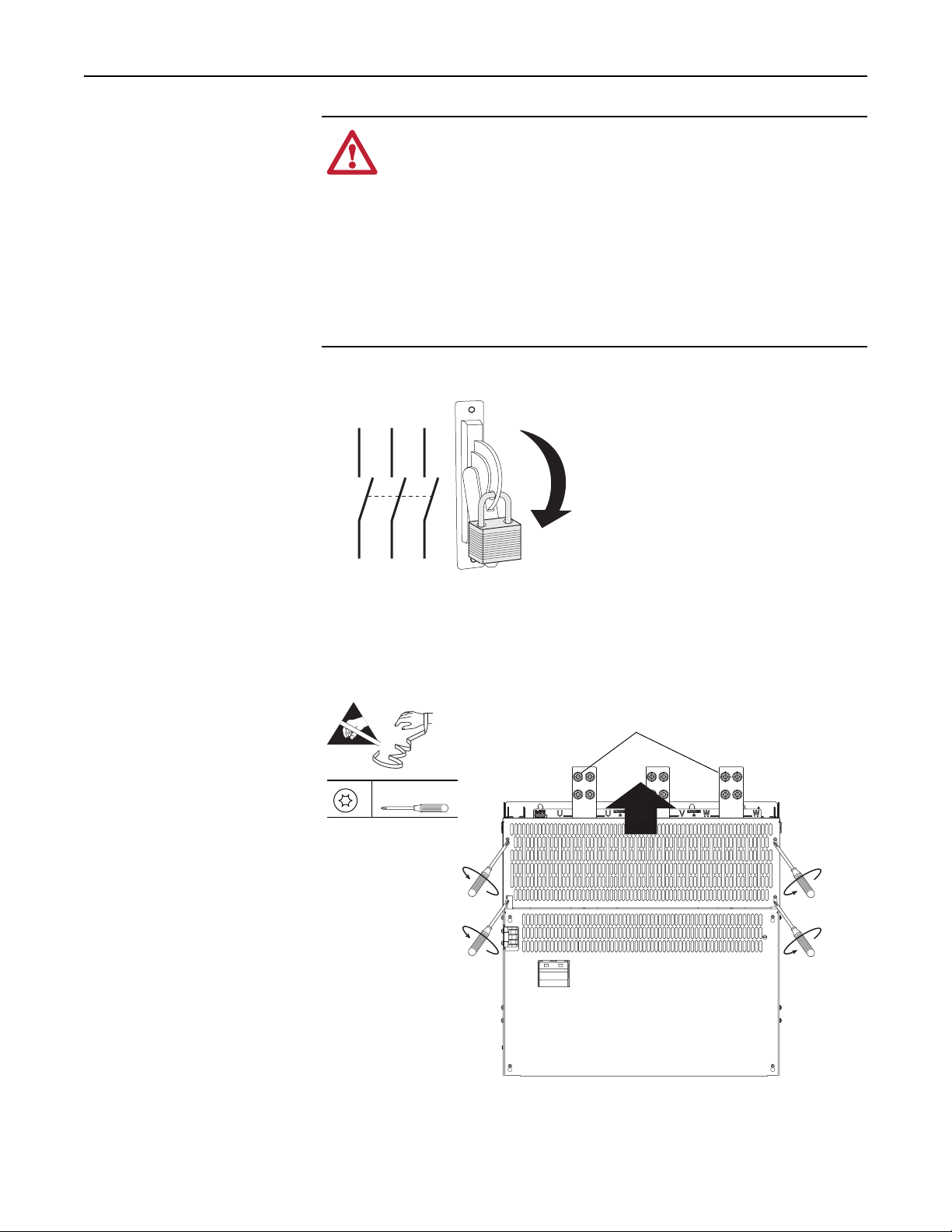

Step 1: Remove Power

from the Drive

ATTENTION: Remove power before making or breaking cable

connections. When you remove or insert a cable connector with

power applied, an electrical arc may occur. An electrical arc can

cause personal injury or property damage by:

• sending an erroneous signal to your system’s field devices,

causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create electrical

resistance.

• Remove and lock-out all incoming power to the drive.

L1 L2 L3

I

O

Step 2: Remove the

Protective Covers and Open

the Control Panel

1. Loosen, but do not remove, the four hexalobular screws that secure the top

protective cover to the drive, then slide the cover up and off the drive

chassis. Tightening torque is noted in the illustration for reassembly.

AC current transducers located on

=

T15

Tightening torque:

1.5 N•m (13 lb•in)

U and W terminals behind cover

Publication 20P-IN059A-EN-P

Page 3

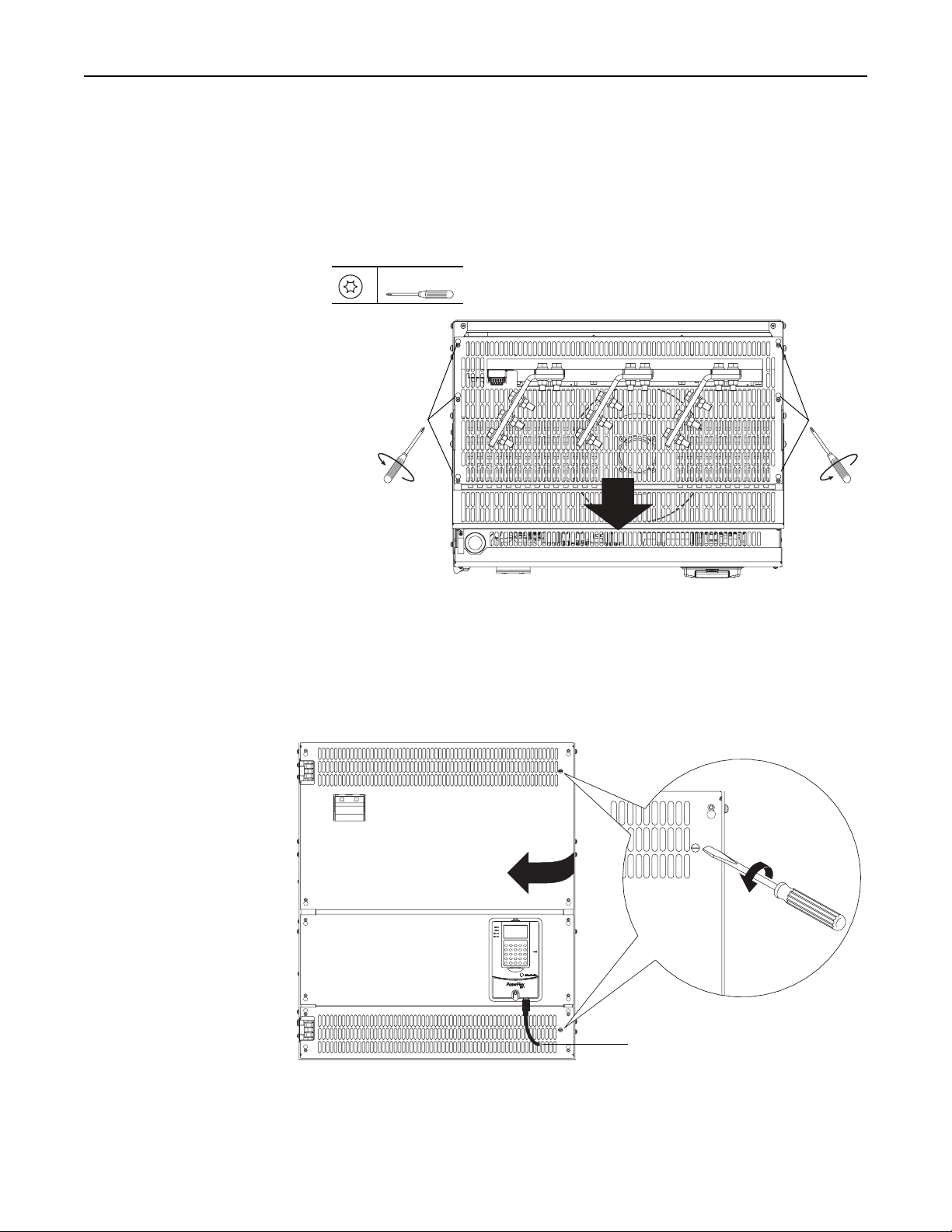

2. Loosen, but do not remove, the six hexalobular screws that secure the top air

flow plate to the drive, then slide the plate forward to lift it off the screws.

Tightening torque is noted in the illustration for reassembly.

Note: The air flow plate cannot be removed from the drive unless the AC

input wiring and bus bar extensions (if installed) are removed. However, the

plate must be removed to remove the AC input terminals below it.

3

T15

Tightening torque:

1.5 N•m (13 lb•in)

Loosen

screws

Top View of Drive

Loosen

screws

Pull plate forward to lift off screws

3. Disconnect the DPI cable from the HIM (if present).

4. Insert a flathead screwdriver into the holes in the right side of the protective

covers on the drive, turn the latch 90° counter-clockwise, and open the

control panel to the left.

Disconnect DPI cable

90°

Publication 20P-IN059A-EN-P

Page 4

4

Step 3: Remove the

Existing AC Current

Transducers

Important: Mark all connections and wires before removal to avoid

incorrect wiring during reassembly.

1. The U and W phase AC input terminal bus bars must be disconnected and

pulled up in order to remove the AC current transducers. Remove the wiring

from the U and W phase AC input terminal bus bars, if necessary.

2. Remove the four bolts and washers that secure the top insulator bar, over the

AC input terminal bus bars, to the drive frame and remove the insulator bar.

Disconnect wiring from

U and W phase AC

input terminal bus bars

Top insulator bar

XF XC

Remove bolts and

washers and

insulator bar

AC current

transducers

Publication 20P-IN059A-EN-P

Page 5

XF XC

5

3. Remove the bolt and washer that secures each of the U and W phase AC

input terminal bus bars to the rear insulator bar.

Remove bolt

and washer

4. Remove the two nuts and washers that secure the signal wires to the

terminals on each of the AC current transducers and remove the wires.

5. Loosen the two screws that secure each of the AC current transducers to the

U and W phase terminal bus bar. The current transducers will be loose on

the bus bars.

Remove nut, washer

and, signal wires

Loosen two

screws on CTs

Publication 20P-IN059A-EN-P

Page 6

6

6. Remove the four M12 bolts and washers that secure each of the U and W

phase AC input terminal bus bars to the input bus bars and carefully slide

the terminal bus bars up until the AC current transducers can be removed

from the bus bars.

Slide bus bars up until AC current

transducers can be removed

Step 4: Install the New AC

Current Transducers

W phase bus bar

Signal wireU phase bus bar

Remove bolts and

washers from U and

W phase bus bars

Install the new AC current transducers in reverse order of removal as detailed in

Step 3: Remove the Existing AC Current Transducers

above.

• Tightening torque for the M12 bolts is 45 N•m (398 lb•in).

• Verify that signal wire that was disconnected from the U and W phase bus

bars when removing the current transducers is re-installed.

Publication 20P-IN059A-EN-P

Page 7

7

Step 5: Close the Control

Panel, Replace the Covers

and Document the Change

1. Close the control panel and replace the top air flow plate and protective

cover in the order as described in Step 2: Remove the Protective Covers and

Open the Control Panel on page 2.

2. Record the installation of the new AC current transducers and date of

installation on the Field Installed Option label on the side of the drive (as

shown below).

Related Documentation

Allen-Bradley publications are available on the internet at

www.rockwellautomation.com/literature.

For . . . Read this document

In depth information regarding the

operation of PowerFlex Digital DC drives

User Manual - PowerFlex Digital DC Drives 20P-UM001…

Publication

Number

Publication 20P-IN059A-EN-P

Page 8

A

A

1S7A63

www.rockwellautomation.com

Power, Control and Information Solutions

mericas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000,

Europe/Middle East/Africa:

sia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Rockwell Automation SA/NV, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Publication 20P-IN059A-EN-P - January 2011

Copyright © 2011 Rockwell Automation. All rights reserved. Printed in USA.

Fax: (1) 414.382.4444

Loading...

Loading...