Page 1

Installation Instructions

!

Resistive Brake Module

Unpacking Your Resistive Brake Module

(Catalog Numbers 2090-XB33-16, 2090-XB33-32,

2090-XB120-01, 2090-XB120-03, and 2090-XB120-06

This publication provides installation instructions for the

Allen-Bradley

instructions for mounting your RBM to the panel and wiring it to a drive

system. For installation and integration instructions specific to a drive

system, refer to Related Documentation on page 24.

Refer to the System Design for Control of Electrical Noise (publication

GMC-RM001x-EN-P) for greater detail on reducing electrical noise

when mounting your RBM.

There are no field replaceable components in an RBM.

Remove all packing material, wedges, and braces from within and

around the components. After unpacking, check the catalog number on

the item(s) nameplate against the purchase order.

Each RBM ships with:

• This installation sheet (publication 2090-IN009x-EN-P).

• One set of connectors for wiring the RBM to a drive:

• TB1 - Drive Connection

• TB2 - Motor Connection

• TB3 - I/O Connection

• TB4 - 230VAC Aux Power Connection (2090-XB120-xx only)

®

Bulletin 2090 Resistive Brake Module (RBM). Use these

Note: Power and I/O cables are not provided with the RBM. Refer to

Accessory Equipment on page 23 for catalog numbers of items

available from Rockwell Automation. I/O cables must be

supplied by the user.

ATTENTION

To avoid hazard of electrical shock, perform all

mounting and wiring prior to applying power to the

RBM or the drive system it connects to. Once power

is applied, connector terminals may have voltage

present even when not in use.

Publication 2090-IN009F-EN-P — November 2004

Page 2

2 Resistive Brake Module Installation Instructions

!

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley

intellectual property liability) for actual use based upon the examples shown in

this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley

office), describes some important differences between solid-state equipment

and electromechanical devices that should be taken into consideration when

applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations :

®

does not assume responsibility or liability (to include

ATTENTION

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Identifies information about practices or circumstances

that can lead to personal injury or death, property damage

or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Publication 2090-IN009F-EN-P — November 2004

Page 3

Resistive Brake Module Installation Instructions 3

!

Understanding Your Resistive Brake Module

The RBM provides an alternative way to brake a drive system. It provides the

control system engineer with the opportunity to design safety controls into a

machine’s drive system that have two key features:

• Physically and electrically separate the drive power output from its

corresponding motor.

• Reduce the stopping time for a motor and its load should a failure occur to

the machine in which it is installed.

Drive commands are the preferred and quickest way to bring a drive system to

a controlled stop. The RBM provides a non-mechanical method for braking a

drive system, by draining motor energy through a resistive load that dissipates

the energy as waste heat.

The RBM can resistively brake a motor once per minute with the following

inertia mismatch:

Resistive Brake Module Inertia Mismatch

2090-XB33-16, 2090-XB33-32

2090-XB120-01, 2090-XB120-03, 2090-XB120-06

Refer to the Motion Control Selection Guide (publication GMC-SG001x-EN-P)

for details on applicable RBM and motor combinations.

15:1 inertia mismatch

A contactor in the RBM physically and electrically separates the motor leads

from the drive output, and provides status outputs to a customer designed

safety circuit. To maximize the stopping speed, braking resistors are sized to

match the motor and load for a specific axis of the drive system. The resistors

are placed across the phases and brake the motor by quickly dissipating the

energy stored there.

ATTENTION

Implementation of safety circuits and risk assessment is the

responsibility of the machine builder. Reference

international standards EN1050 and EN954 estimation and

safety performance categories. For more information refer

to Understanding the Machinery Directive (publication

SHB-900).

Publication 2090-IN009F-EN-P — November 2004

Page 4

4 Resistive Brake Module Installation Instructions

!

System Mounting Requirements

There are several things that you need to take into account when preparing to

mount the Resistive Brake Module:

IMPORTANT

• The panel on which you install your components must be a flat, rigid,

vertical surface that is not subject to shock, vibration, moisture, oil mist,

dust, or corrosive vapors.

• The RBM must be enclosed in a grounded conductive enclosure offering

protection as defined in standard EN 60529 (IEC 529) to IP55 such that it

is not accessible to an operator or unskilled person, in order to comply

with UL

requirements providing protection to IP66.

ATTENTION

Plan the installation of your system so that you can

perform all cutting, drilling, tapping, and welding with the

system removed from the enclosure. Because the system is

of the open type construction, be careful to keep any metal

debris from falling into it. Metal debris or other foreign

matter can become lodged in the circuitry, which can result

in damage to components.

®

and CE requirements. A NEMA 4X enclosure exceeds these

We recommend that all equipment and components of

a machine or process system have a common earth

ground point connected to their chassis.

A grounded system provides a ground path for short

circuit protection. Grounding your modules and panels

minimizes the shock hazard to personnel and damage

to equipment caused by short circuits, transient

overvoltages, and accidental connection of energized

conductors to the equipment chassis.

Publication 2090-IN009F-EN-P — November 2004

For CE grounding requirements, refer to the

appropriate drive system installation manual listed in

Related Documentation.

• The ambient temperature of the enclosure in which you install the RBM

must not exceed 50° C (122° F).

• You need to maintain minimum clearances (refer to Figure 2 and 3) for

proper airflow, easy module access, and proper cable bend radius.

• The RBM can operate at elevations to 1500 m (5000 ft) without derating,

however, the continuous current rating must be de-rated by 3% for each

additional 300 m (1000 ft) up to 3000 m (10,000 ft). Consult your local

Allen-Bradley representative prior to operating at over 3000 m (10,000 ft).

Refer to Specifications on page 19 for mounting dimensions, power dissipation,

and environmental specifications for the RBM.

Page 5

Resistive Brake Module Installation Instructions 5

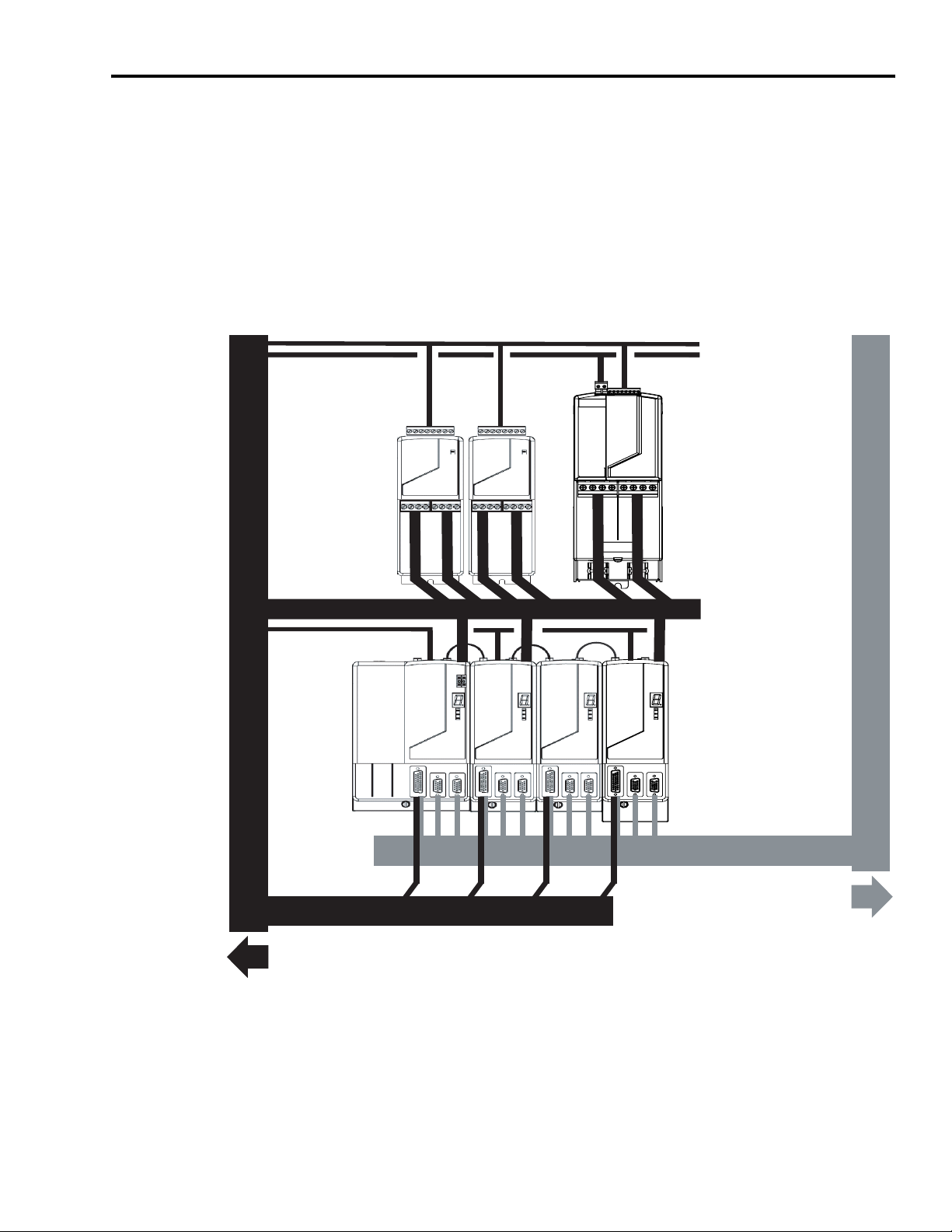

Establishing Noise Zones

The figure below depicts noise zones for routing wiring. All wiring for the

RBM should be routed in a dirty zone. Refer to the appropriate drive system

installation manual listed in Related Documentation.

Figure 1

Noise Zones for Electrical Wiring

Dirty Wireway

Clean Wireway

Brake I/O Cables

230 VAC Power Cables

Resistive Brake Modules

One (1) 2090-XB120-xx

and

Two (2) 2090-XB33-xx

Power Cable

Shield Clamp

Motor Power Cables

Brake I/O Cables

Drive/System Modules

I/O and Feedback Cables

Route Encoder/Analog/Registration

Route 24V dc I/O

Shielded Cable

1 If system I/O cables contain dirty (relay, etc.) wires, route these signals with a separate cable in the dirty wireway.

1

Shielded Cable

Publication 2090-IN009F-EN-P — November 2004

Page 6

6 Resistive Brake Module Installation Instructions

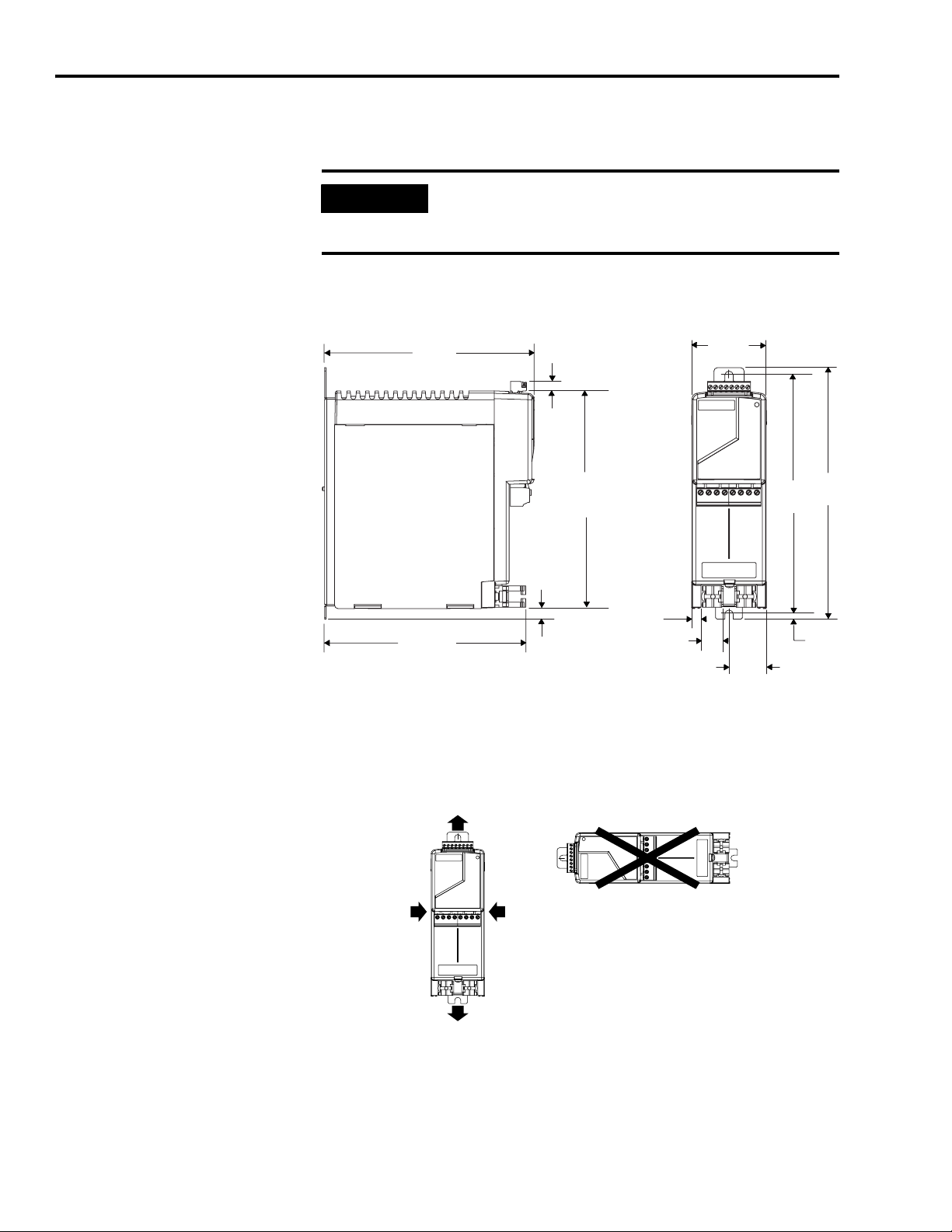

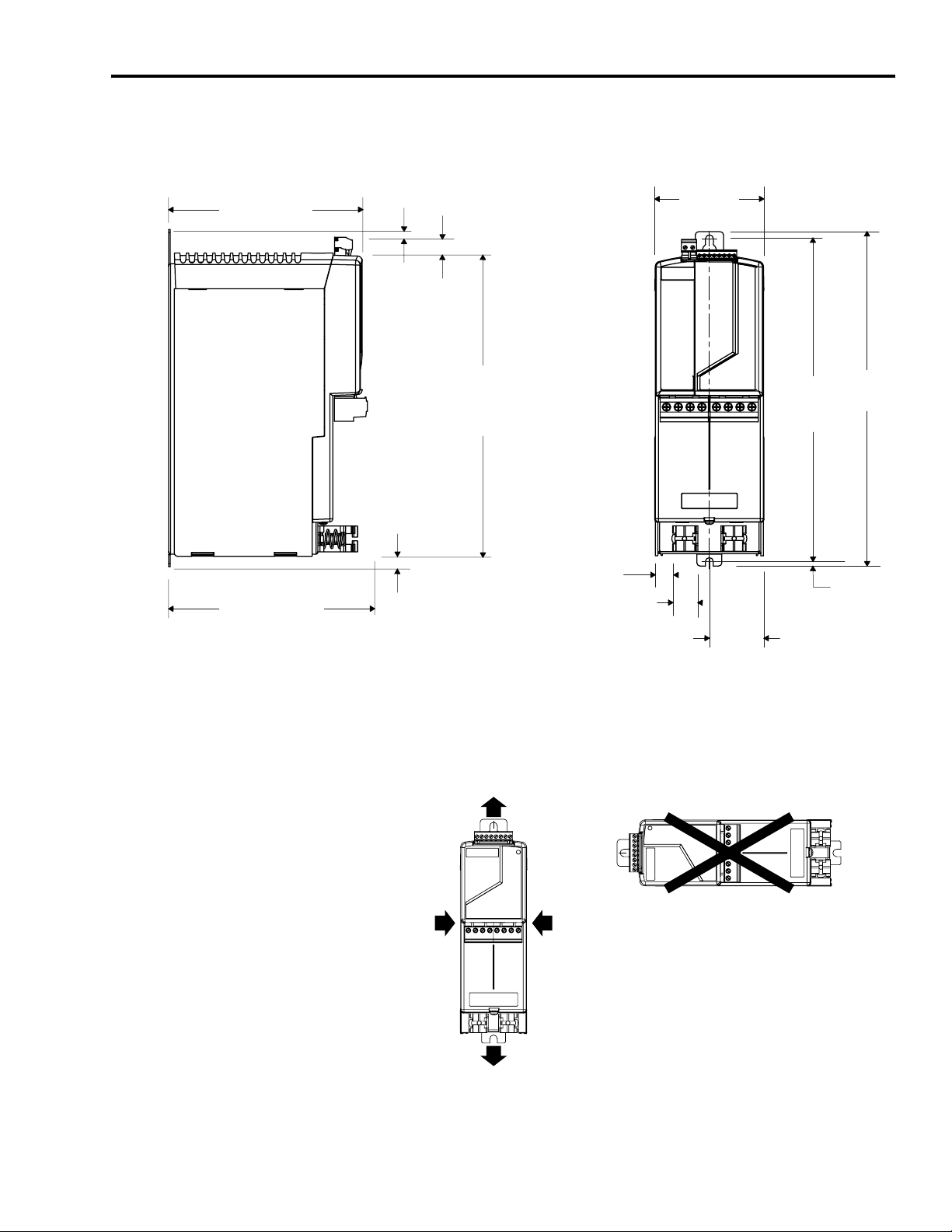

Dimensions and Clearance Requirements

Mounting dimensions and clearance requirements for the 2090-XB33-xx are

shown in Figures 2 and 3, and for the 2090-XB120-xx in Figures 4 and 6.

IMPORTANT

The RBM must be mounted vertically, as shown, to ensure

proper contactor operation. The vertical mounting

tolerance is ±2°.

Figure 2

2090-XB33-xx Mounting Dimensions

198.6

(7.82)

6.1

(0.24)

205.4

(8.09)

11.7

(0.46)

70.0

(2.76)

226.5

(8.92)

238.3

(9.38)

190.6

(7.50)

Dimensions are in millimeters (inches).

Figure 3

2090-XB33-xx Minimum Clearance Requirements

50 mm (1.97 in.)

clearance for airflow

Clearance left

of RBM is not

required

50 mm (1.97 in.)

clearance for airflow

Clearance right

of RBM is not

required

10.0

(0.40)

20.0

(0.79)

35.0

(1.38)

4.6

(0.18)

Publication 2090-IN009F-EN-P — November 2004

Page 7

195.0

(7.68)

Resistive Brake Module Installation Instructions 7

Figure 4

2090-XB120-xx Mounting Dimensions

7.8

16.0

(0.31)

(0.63)

110.9

(4.37)

190.3

(7.49)

305.6

(12.03)

10.4

(0.41)

18.05

(0.71)

25.66

(1.01)

55.6

(2.19)

Dimensions are in millimeters (inches).

Figure 5

2090-XB120-xx Minimum Clearance Requirements

50 mm (1.97 in.)

clearance for airflow

328.17

(12.92)

339.8

(13.38)

4.57

(0.18)

Clearance left

of RBM is not

required

Clearance right

of RBM is not

required

50 mm (1.97 in.)

clearance for airflow

Publication 2090-IN009F-EN-P — November 2004

Page 8

8 Resistive Brake Module Installation Instructions

!

Installing Your Resistive Brake Module

These procedures assume you have prepared your panel and understand how

to bond the groundplane of your system.

ATTENTION

Refer to the System Design for Control of Electrical Noise Reference Manual

(publication GMC-RM001x-EN-P) for HF bonding techniques.

The RBM contains ESD (Electrostatic Discharge) sensitive

parts and assemblies. You are required to follow static

control precautions when you install, test, service, or repair

this assembly. If you do not follow ESD control

procedures, components can be damaged. If you are not

familiar with static control procedures, refer to

Allen-Bradley publication 8000-4.5.2, Guarding Against

Electrostatic Damage or any other applicable ESD Protection

Handbook.

Attaching Your Resistive Brake Module to the Panel

To mount your RBM:

1. Layout the position for your RBM in the enclosure.

IMPORTANT

Refer to the mounting dimensions and clearance requirements for each

type of RBM as listed below.

Dimensions for:

Mounting Figure 2 on page 6 Figure 4 on page 7

Clearance Figure 3 on page 6 Figure 5 on page 7

2. Attach the RBM to the cabinet. The recommended mounting hardware is

two M6 (1/4 in. - 20) bolts. A key-hole tab is at the top of the unit, and a

slotted mounting tab is at the bottom of the unit.

To improve EMC performance, mount the RBM on

the same panel as the drive system, and as close to the

drive as possible.

Typically the RBM should be positioned immediately

above the module it supports. Refer to Related

Documentation on page 24 for mounting instructions

and restrictions specific to a drive system, and

information on use with safety relays.

2090-XB33-xx 2090-XB120-xx

Publication 2090-IN009F-EN-P — November 2004

Page 9

Resistive Brake Module Installation Instructions 9

Ensure all fasteners are properly bonded to the subpanel. Refer to the

System Design for Control of Electrical Noise Reference Manual (publication

GMC-RM001x-EN-P) for HF bonding techniques.

Understanding RBM Connectors

IMPORTANT

To improve the bond between the RBM and subpanel,

construct your subpanel out of zinc plated (paint-free)

steel.

3. Tighten all mounting fasteners. The minimum recommended torque for

M6 (1/4 in. - 20) bolts is 1 Nm (9 in-lb).

RBMs have connectors and status indicators as listed in the following table:

RBM Connectors or Indicators

TB1 - Drive Connection X X

TB2 - Motor Connection X X

TB3 - I/O Connection X X

TB4 - 230VAC Aux Power Connection – X

Status LED X –

24 VDC Status LED – X

230 VAC Status LED – X

2090-XB33-xx 2090-XB120-xx

• Connectors and indicators locations are shown in Figure 6 on page 10 for

the 2090-XB33-xx, and Figure 7 on page 10 for the 2090-XB120-xx.

• Block diagrams of electrical functions are provided as Figure 8 on page 11

for the 2090-XB33-xx, and Figure 9 on page 12 for the 2090-XB120-xx.

• Connector functions for the 2090-XB33-xx, and the 2090-XB120-xx are

described in RBM Wiring Requirements on page 13.

Publication 2090-IN009F-EN-P — November 2004

Page 10

10 Resistive Brake Module Installation Instructions

Figure 6

2090-XB33-xx Resistive Brake Module Connectors and LED Indicator

Front view of 2090-XB33-xx Resistive

Brake Module

TB3 - I/O Connection

Status LED

TB1 - Drive Connection

TB2 - Motor Connection

TS_21

TS_22

CONSTAT_41

CONSTAT_42

SHIELD

COIL_A1

COIL_A2

SHIELD

Drive V-Phase

Drive U-Phase

Drive W-Phase

Power Cable

Shield Clamps (2)

Figure 7

2090-XB120-xx Resistive Brake Module Connectors and LED Indicators

Ground

Ground

Motor V-Phase

Motor U-Phase

Motor W-Phase

Front view 2090-XB120-xx Resistive

Brake Module

TB4 - 230VAC Aux Power Connection

TB3 - I/O Connection

24 VDC Status LED

230 VAC Status LED

TB1 - Drive Connection

TB2 - Motor Connection

TS_21

TS_22

CONSTAT_41

CONSTAT_42

SHIELD

COIL_A1

COIL_A2

230 VAC L1

230 VAC L2

SHIELD

Drive U-Phase

Power Cable

Shield Clamps (2)

Ground

Drive V-Phase

Drive W-Phase

Ground

Motor V-Phase

Motor U-Phase

Motor W-Phase

Publication 2090-IN009F-EN-P — November 2004

Page 11

Resistive Brake Module Installation Instructions 11

!

Wiring the RBM to a Drive System

This section provides wiring instructions for the Resistive Brake Module

within a general drive system. Refer to Related Documentation on page 24 for

installation and integration instructions containing wiring information specific

to a drive system. In addition:

ATTENTION

To comply with UL 508C, a Resistive Brake Module

must be protected upstream by a 2.5 kV overvoltage

control device.

Kinetix and Ultra servo drives from Rockwell

Automation meet this requirement. For additional

drive applicability, please consult your Allen-Bradley

representative.

• Figure 1 on page 5 depicts suggested routing of RBM wiring within the

dirty noise zone.

• Figure 6 and Figure 7 on page 10 show connector locations and provides

pinouts for each RBM connector.

• Recommended wire sizes and torque values for I/O signal wires and

power wires are provided in RBM Wiring Requirements on page 13 and in

Specifications.

TB1 - Drive

Connection

Ground

W Drive

V Drive

U Drive

Figure 8

2090-XB33-xx Resistive Brake Module Block Diagram

100S-C23

4

3

2

1

CR1

12

34

56

11 12

21 22

31 32

41 42

A1 A2

D1

Printed

Circuit

Board

4

3

2

1

1

2

3

4

5

6

7

8

TB2 - Motor

Connection

Ground

W Motor

V Motor

U Motor

Status LED

TB3 - I/O

TS_21

TS_22

CONSTAT_41

CONSTAT_42

SHIELD

COIL_A1

COIL_A2

SHIELD

T2 (Warning)T1 (Fault)

Publication 2090-IN009F-EN-P — November 2004

Page 12

12 Resistive Brake Module Installation Instructions

Figure 9

2090-XB120-xx Resistive Brake Module Block Diagram

TB1 - Drive

Connection

Ground

W Drive

V Drive

U Drive

TB2 - Motor

100S-C85

4

3

2

1

N/C

DC Interface Module

100-JE

A1

E1

E2

CR1

12

34

56

11 12

21 22

31 32

41 42

53 54

A1 A2

N/C

Printed

Circuit

Board

T1 (Fault)

Connection

4

Ground

3

W Motor

2

V Motor

1

U Motor

24VDC Status LED

230VAC Status LED

TB3 - I/O

1

TS_21

TS_22

2

3

CONSTAT_41

CONSTAT_42

4

SHIELD

5

COIL_A1

6

COIL_A2

7

SHIELD

8

TB4 - 230V ac

L1

T2 (Warning)

1

L2

2

Publication 2090-IN009F-EN-P — November 2004

Page 13

Resistive Brake Module Installation Instructions 13

RBM Wiring Requirements

Connector

Drive

Connection

Motor

Connection

Connects to:

Te rm i na l

-Pin

Signal

TB1-1 U Drive –

TB1-2 V Drive –

TB1-3 W Drive –

1

2

TB1-4

TB2-1 U Motor –

TB2-2 V Motor –

TB2-3 W Motor –

1

2

TB2-4

TB3-1

TS_21 In

Input/

Output

–

–

Description and Usage

230/460V power input from drive

230/460V power output to motor

RBM output with integral thermal

warning

Recommended

Wire Size 4

mm2 (AWG)

Minimum gauge

for power cable

is dependent on

the motor/drive

combination,

2090-XB33-xx

6 (10) maximum

2090-XB120-xx:

25 (3) maximum

Insulation Strip

Length

mm (in.)

2090-XB33-xx

10.0

(0.375)

2090-XB120-xx:

16.0

(0.63)

2090-XB33-xx

10.0

(0.375)

2090-XB120-xx:

16.0

(0.63)

Torq u e Va l ue

Nm (lb-in.)

2090-XB33-xx:

0.5 - 0.6

(4.4 - 5.3)

2090-XB120-xx:

2.5 - 2.9

(22.1 - 25.7)

2090-XB33-xx:

0.5 - 0.6

(4.4 - 5.3)

2090-XB120-xx:

2.5 - 2.9

(22.1 - 25.7)

Customer use of this auxiliary

contact may include:

TB3-2 TS_22 Out

• PLC or control string input that

RBM is nearing its thermal

limit

TB3-3 CONSTAT_41 In RBM output of a normally closed

contact

(Closed = motor disconnected

from drive)

Customer use of this auxiliary

contact may include:

TB3-4 CONSTAT_42 Out

• PLC input connection,

indicating RBM contactor

status

I/O Signals

5,6

• Safety relay input for safety

string

• Part of RBM safety string for

1.5 - 0.08

(16 - 28)

6.0

(0.25)

0.22 - 0.25

(1.9 - 2.2)

mechanical redundancy

TB3-5 SHIELD

3

–

I/O Shield internally terminated at

chassis ground

TB3-6 COIL_A1 In RBM contactor coil with integral

thermal fault. Applying 24V Coil

Power picks-up the contactor,

which connects drive power to

motor leads (i.e., motor rotates).

TB3-7 COIL_A2 Out

Customer use may include:

• Control from a safety relay

output or signal relay output

indicating system is clear for

rotation

TB3-8 SHIELD

230V Power

(2090-XB120-x

x only)

1 Connectors are keyed to prevent misconnection of power interface cables to and from the RBM.

2 Ground connection for the motor cable passes through the drive and motor connectors.

Cable shielding must be grounded to the chassis via the spring-loaded cable clamps.

3 I/O Shield terminations are connected internally to chassis ground.

4 Wire supplied by user should be stranded copper with 75° C (167° F) minimum rating. An earth ground connection is required for safe and proper operation. Local agency

rules apply.

5 For additional contactor applications, refer to the Allen-Bradley Safety Product Catalog (Publication S114-CA001A-EN-P).

6 I/O is powered by an external 24V (22.4 - 26.4), 0.5A power supply.

7 Provided by an external 230V (207 - 253), 1A power supply.

7

TB4-1 L1 – Auxiliary power input from

TB4-2 L2 –

3

–

I/O Shield internally terminated at

chassis ground

external 230 VAC power source

(2090-XB120-xx only)

4.0 - 0.2

(10 - 24)

7.0

(0.28)

0.5 - 0.6

(4.4 - 5.3)

Publication 2090-IN009F-EN-P — November 2004

Page 14

14 Resistive Brake Module Installation Instructions

!

Wiring Instructions

1. Allow five minutes for the power supplies to completely discharge before

proceeding.

ATTENTION

2. Separate the I/O signal cable and the power cables as shown in Figure 1

on page 5 and described below:

• I/O signal connections are at the top of the RBM (TB3).

• Power cable connections enter (TB1) and exit (TB2) at the bottom of

the RBM.

• Auxiliary power connections (2090-XB120-xx only) are at the top of

the RBM (TB4)

IMPORTANT

To avoid hazard of electrical shock, verify that all

voltage on the capacitors has been discharged before

attempting to service, repair, or remove this unit. This

product connects to stored energy devices. You should

only attempt the procedures in this document if you are

qualified to do so and familiar with solid-state control

equipment and the safety procedures in publication

NFPA 70E.

To ensure correct wiring, verify connector orientation

on the RBM before wiring each connector. Figure 6

and Figure 7 on page 10 show connector locations and

pinouts.

Publication 2090-IN009F-EN-P — November 2004

3. Prepare your I/O signal wires by stripping the appropriate length of

insulation from the end of the wire. Use caution not to nick, cut, or

otherwise damage strands as you remove the insulation.

Insert the wires into the TB3 terminal and torque the screws to the

specified value. Gently pull on the wire to make sure it does not come out

of its terminal. Re-insert and test any loose wires.

Strip this length of

If RBM is:

2090-XB33-xx 6.0 mm (0.25 in.)

2090-XB120-xx 7.0 mm (0.28 in.)

insulation from the I/O

wire:

Torque TB3 terminal screw

within this range:

0.22 - 0.25 Nm (1.9 - 2.2 in-lbs)

Page 15

Resistive Brake Module Installation Instructions 15

4. Prepare your power cables as shown in Figure 10. by stripping the

appropriate length of insulation from the end of the wire. Use caution not

to nick, cut, or otherwise damage strands as you remove the insulation.

Insert the wires into the proper terminal (TB1 or TB2) and torque the

screws. Gently pull on the wire to make sure it does not come out of its

terminal. Re-insert and test any loose wires.

Outer Insulation

Power Cable

Exposed Braid

46 mm (1.8 in.)

If RBM is:

Strip this length of

insulation from the

Torque TB1 or TB2 terminal

screw within this range:

power wire:

2090-XB33-xx 10.0 mm (0.375 in.) 0.5 - 0.6 Nm (4.4 - 5.3 lbs-in.)

2090-XB120-xx 16.0 mm (0.63 in.) 2.5 - 2.9 Nm (22.1 - 25.7 lbs-in.)

Figure 10

Shielded Power Cable Preparation

2090-XB33-xx Strip Length 10 mm (0.375 in.)

2090-XB120-xx Strip Length 16 mm (0.63 in.)

3

1

2

3

2090-XB33-xx: 76 mm (3.0 in.)

2090-XB120-xx: 119 mm (4.7 in.)

2090-XB33-xx: 122 mm (4.8 in.)

2090-XB120-xx: 165 mm (6.5 in.)

Motor Power Wires

5. Prepare your 230VAC auxiliary power cables (2090-XB120-xx only) by

stripping the appropriate length of insulation from the end of the wire.

Use caution not to nick, cut, or otherwise damage strands as you remove

the insulation.

Insert the wires into the TB4 terminal and torque the screws to the

specified value. Pull on each wire to ensure it is secured to the terminal.

Re-insert and test any loose wires.

Strip this length of

If RBM is:

2090-XB33-xx This terminal is not present

2090-XB120-xx 7.0 mm (0.28 in.) 0.5 - 0.6 Nm (4.4 to 5.3 lbs-in.)

insulation from the I/O

signal wire:

Torque TB4 terminal screws

within this range:

Publication 2090-IN009F-EN-P — November 2004

Page 16

16 Resistive Brake Module Installation Instructions

Applying the Power Cable Shield Clamp

To apply your power cable shield clamp:

1. Use a small flat blade screwdriver to depress the spring loaded clamping

plate as shown in Figure 11.

Figure 11

Depressing the Spring Clamp

Flat Blade Screwdriver

3.5 mm (0.14 in.) tip

Cable Clamp

Screwdriver

tip in slot

2. Position the exposed portion of the cable braid directly in line with the

clamp.

3. Release the spring, making sure the cable and cable braid are held secure

by the clamp.

4. Attach tie wrap around cable and clamp, if additional strain relief is

required (refer to Figure 12).

Figure 12

Motor Cable and Clamp

Exposed Braid

(under clamp)

Cable Clamp

Tie Wrap

Publication 2090-IN009F-EN-P — November 2004

Outer Insulation

Motor

Cable

Page 17

Resistive Brake Module Installation Instructions 17

Troubleshooting

There are no field replaceable components in an RBM. If problems persist

after attempting to troubleshoot the system, contact your Allen-Bradley

representative for further assistance.

24 VDC Status LED

The Status LED is ON when 24V is applied between COIL_A1 and

COIL_A2 (e.g., a Brake Enable signal is received from a drive).

Use the table below for troubleshooting the RBM using the 24 VDC Status

LED.

If 24 VDC Status LED is: RBM Contactor Status is: Potential Cause is: Possible Resolution is:

Steady Green

Blinking Green

(audible clicking)

Off

(intended)

Off

(unintended)

Contactor engaged – direct connection

between drive and motor

Contactor disengaged – no connection

between drive and motor

Contactor rapidly engaging/disengaging

Contactor disengaged

(connection open between drive and

motor)

No faults or failures N/A

Contactor failure

Recommended grounding not

followed

Control circuit improperly wired Verify control wiring and programming

No faults or failures N/A

+24V not applied between COIL_A1

and COIL_A2

T1 (Fault) thermostat open

Verify by monitoring CONSTAT_41/42

status (output is NC)

Contact AB representative

• Verify grounding

• Route wires away from noise sources

• Refer to GMC-RM001x-EN-P

• +24V supply is off

•Verify wiring

• Drive not enabled

• Contact AB representative

Duty cycle: exceeded; allow RBM to

cool.

Publication 2090-IN009F-EN-P — November 2004

Page 18

18 Resistive Brake Module Installation Instructions

230 VAC Auxiliary Power Status LED (2090-XB120-xx RBM only)

The 230 VAC Status LED is ON when 230V AC is applied to L1 and L2

(TB4) and the contactor is engaged by applying 24V DC across COIL_A1 and

COIL_A2 (e.g., a Brake Enable signal is received from a drive).

Use the table below for troubleshooting the RBM using the 230 VAC Status

LED. ‘1

If 230 VAC Status LED is: RBM Contactor Status is: Potential Cause is: Possible Resolution is:

Engaged No faults or failures N/A

Steady Green

Blinking Green

(audible clicking)

Off

(intended)

Off

(unintended)

Disengaged Contactor failure

Grounding

Rapidly engaging/disengaging

Engaged

Disengaged No faults or failures N/A

Engaged

Disengaged

230VAC is varying

Control circuit improperly wired Verify control wiring and programming

Contactor failure

(contacts welded together)

Contactor failure

(contacts welded together)

LED failure

+24V signal not functioning properly See other Troubleshooting tables

Contactor failure (coil damaged) Contact A-B representative

No 230V signal

Verify by monitoring CONSTAT_41/42

Contact AB representative

• Verify grounding

• Re-route wires

• Refer to GMC-RM001x-EN-P

• Check VAC Loading

• Check VAC Source

•Verify wiring

Verify by monitoring CONSTAT_41/42

Contact AB representative

Verify by monitoring CONSTAT_41/42

Contact AB representative

Verify by monitoring CONSTAT_41/42

Contact AB representative

•Verify wiring

• Verify 230VAC source

Publication 2090-IN009F-EN-P — November 2004

Page 19

Resistive Brake Module Installation Instructions 19

General Troubleshooting

Use the table below for troubleshooting motor faults that may result from the

RBM on a specific axis.

Condition: Potential Cause is: Possible Resolution is:

Specifications

No Rotation

(drive faults)

No Rotation

(no fault action)

Specifications for the Resistive Brake Module are provided below.

Catalog No.

2090-XB33-16 230 or 460 16

2090-XB33-32 230 or 460 32

2090-XB120-01 230 or 460 1

2090-XB120-06 230 or 460 6

Improper timing Adjust delay times of brake output signals

Improper wiring Verify wiring

Improper wiring Verify wiring

RBM contactor disengaged

(connection open between dr ive

and motor)

RBM contactor engaged

(direct connection between

drive and motor)

Drive

Voltage

Volts Ohms Joules Amps

Power Specifications (per phase):

Resistance

1

• +24V supply is off

• Verify wiring

• Drive not enabled

• Duty cycle: exceeded; allow RBM to cool.

• Contact AB representative

• Verify wiring

• Contact AB representative

Peak Energy Peak Drive Current

2 Amps

0-pk

150 33 23 30

290 106 75 45 2090-XB120-03 230 or 460 3

Continuous

Power

Watts

rms

1 Tolerance = +10%, - 10%

2 0-pk refers to peak of sine wave

Publication 2090-IN009F-EN-P — November 2004

Page 20

20 Resistive Brake Module Installation Instructions

Environmental Specifications Value

Vibration

• operating

Shock

• operating 15g, 11 msec half sine

Altitude 1500 m (5000 ft)

Humidity 5% to 95% non-condensing

Storage temperature

Ambient operating temperature

• minimum

• maximum

Air flow clearance

• above and below

• left and right

Temperature limits

• T1 (Fault)

• T2 (Warning output)

Duty cycle:

• 2090-XB33-16

• 2090-XB33-32

• 2090-XB120-01

• 2090-XB120-03

• 2090-XB120-06

1Power performance increases about 5.5W for every 1°C (3.1W/°F) drop in ambient temperature.

2 Refer to the Motion Control Selection Guide (publication GMC-SG001x-EN-P) for proper sizing.

1

Complete stop with

15:1 inertia mismatch

0.35 mm (0.014 in.) max.

displacement at 5-53 Hz

2g max. acceleration at

53 to 500 Hz

-25° C

70° C

0° C

50° C

50 mm

0 mm

80°±5° C

65°± 5° C

2

60 per hour, or 2

once per minute

(-13° F)

(158° F)

(32° F)

(122° F)

(1.97 in.)

(0 in.)

(176±9° F)

(119°±9 ° F)

Connectors

Ty pe

2090-XB33-xx

Drive Connection (TB1) 4-position plugable

Phoenix-type

Motor Connection (TB2) 0.5 - 0.6 (4.4 - 5.3)

I/O Terminals (TB3)

1

(7.62mm spacing)

8-position plugable

Phoenix-type

(5.08mm spacing)

2090-XB120-xx

Drive Connection (TB1) 4-position plugable

42 Series Molex

Motor Connection (TB2) 2.5 - 2.9 (22.1 - 25.7)

(12mm spacing)

8-position plugable

I/O Terminals (TB3)

Phoenix-type

(5.08mm spacing)

2-position plugable

230V Power Terminals (TB4)

Phoenix-type

(7.62mm spacing)

To rqu e

Nm (lbs-in.)

0.5 - 0.6 (4.4 - 5.3)

0.22 - 0.25 (1.9 - 2.2)

2.5 - 2.9 (22.1 - 25.7)

0.22 - 0.25 (1.9 - 2.2)

0.5 - 0.6 (4.4 - 5.3)

Publication 2090-IN009F-EN-P — November 2004

Page 21

Resistive Brake Module Installation Instructions 21

Wiring Requirements

Material Stranded copper

2090-XB33-xx

TB1 - Drive Connection and

TB2 - Motor Connection

TB3 - I/O

maximum 1

minimum 1

maximum

minimum

6 mm2

–

1.5 mm2

0.08 mm2

(10 AWG)

–

(16 AWG)

(28 AWG)

2090-XB120-xx

TB1 - Drive Connection and

TB2 - Motor Connection

maximum

minimum 1

1

25.0 mm2

2.50 mm2

(3 AWG)

(14 AWG)

TB3 - I/O

TB4 - 230V Input

maximum

minimum

maximum

minimum

1.50 mm2

0.08 mm2

4.0 mm2

0.20 mm2

(16 AWG)

(28 AWG)

(10 AWG)

(24 AWG)

Voltage

Drive, Motor, and 230V Aux 600V

I/O 250V

Temperature (per UL)

• preferred

• manufacturer minimum

• field wiring minimum

2

105° C

90° C

75° C

(221° F)

(194° F)

(167° F)

Maximum Length

•TB1 - Drive

• TB2 - Motor

• TB3 - I/O

• TB4 - 230V Input

1 Specific gauge of motor power cable depends on motor/drive combination.

2 Separate UL standards exist for manufactured and field wiring. Installation must comply with

local regulations.

3 If this product is installed within the European Union or EEC regions and requires the CE mark or

is installed in Australia and New Zealand and requires C-tick marking, refer to Related

Documentation on page 24 for installation and integration instructions defining total length

restrictions on a system level.

See system level

requirements for power

cable length restrictions.

N/A for I/O.

3

Mechanical Specifications Value

Mounting

• Hex cap screws

• Torque

1

metric (english)

minimum

M6

1 Nm

(1/4 in. - 20)

(9 in-lb)

Mounting position Vertical, within ±2°

Product Outline

2090-XB33-xx

• Height

• Depth

•Width

238.3 mm

198.6 mm

70.0 mm

(9.38 in.)

(7.82 in.)

(2.76 in.)

2090-XB120-xx

• Height

• Depth

•Width

339 mm

195 mm

110 mm

(13.38 in.)

(7.68 in.)

(4.37 in.)

Publication 2090-IN009F-EN-P — November 2004

Page 22

22 Resistive Brake Module Installation Instructions

Mechanical Specifications Value

Clearances 2

• Top

•Side

•Bottom

Weight

• 2090-XB33-16

• 2090-XB33-32

• 2090-XB120-01

• 2090-XB120-03

• 2090-XB120-06

1 Additional dimensional information is provided in Figure 2 on page 6.

2 Combustible material adjacent to the brake module may require additional restrictions

Safety Contactor Specifications - Allen-Bradley 100S Series

The information in this section is adapted from the Allen-Bradley Safety Product

Catalog (Publication S114-CA001x-EN-P). That document should be referred

to for the most recent information on the 100S Series Contactors.

50 mm

0 mm

50 mm

1.91 Kg (4.22 lbs)

2.75 Kg (6.06 lbs)

(i.e., Clearance based on ambient temperature of the brake module within the application).

(1.97 in.)

(0 in.)

(1.97 in.)

24V Coil Power

Specifications

Pickup 19.2 to 26.4 9.2 40 to 70

Dropout 2.4 to 14.6 0 17 to 23

Hold-In 14.6 to 26.4 9.2 N/A

I

e

[A] kW (50 Hz) HP (60 Hz)

AC-3 AC-1 230V 380V, 415V, 400V 500V 690V

23 32 7.5 11 11 11 2 3 5 7.5 15 15

I

e

[A] kW (50 Hz) HP (60 Hz)

Ratings for Switching AC Motors - AC-2, AC-3, AC-4

230V Coil Power

Specifications

Pickup 195.5 to 253.0 200/110 20.0 to 40.0

Dropout 69.0 to 138.0 0 10.0 to 60.0

Hold-In 138.0 to 253.0 16/4.5 N/A

Ratings for Switching AC Motors - AC-2, AC-3, AC-4

Voltage Range

Vdc

Voltage Range

Vac

Coil Consumption

Watts

∅ 3∅

1

115V 230V 200V 230V 460V 575V

Coil Consumption

VA/W

Operating Time

milliseconds

Operating Time

milliseconds

AC-3 AC-1 230V 380V, 415V, 400V 500V 690V

85 100 25 45 45 45 7.5 15 25 30 60 60

Publication 2090-IN009F-EN-P — November 2004

1

∅ 3∅

115V 230V 200V 230V 460V 575V

Page 23

Resistive Brake Module Installation Instructions 23

Auxiliary Contact Specifications

Auxiliary Contacts in Contactor Catalog Number 100-S 1

Current Switching

AC-1Ith

AC-15 at Rated Operating Voltage

DC-13 at Rated Operating g Voltage

Short-Circuit Protection

gG Fuse

Type 2 Coordination

Rated Impulse Voltage U

Insulation Voltage

(between control and load circuit DIN,VDE 0106,Part 101

(NAMUR recommendation)

Positively Guided Contacts

kV n/a

imp

at 40° C

(104° F)

at 60° C

(10°0 F)

V n/a

A10

A 6

V 24 48 120 240 400 500 600 690

A666321.51.20,7

V 2448125220440

A 3 1.5 0.6 0.3 0.2

A n/a

Between auxiliary contacts: 250 V

V

Between load and direct-connected aux. circuits:

690 V

Yes,

NO and NC mutually unrestricted, including N.C. in

relation to N.O.

1 Information adapted from the Allen-Bradley Safety Product Catalog (Publication S114-CA001A-EN-P), page 53.

Accessory Equipment

The cables provide an interface between the Resistive Brake Module and drive

power terminals. Refer to RBM Wiring Requirements on page 13 for pin,

description, and signal information about the connector kit.

Description Catalog Number

®

6000 Drive Interface Cable, Resistive Brake - 14 AWG, 66cm 2090-XXNRB-14F0P7

Kinetix

Kinetix 6000 Drive Interface Cable, Resistive Brake - 4, 8, or 10 AWG 2090-XXNRB-aFxxPyy

Ultra™ Drive Interface Cable, Resistive Brake - 14 AWG, 132cm 2090-XXNRB-14F1P3

Ultra Drive Interface Cable, Resistive Brake - 6, 8 or 10 AWG 2090-XXNRB-aFxxPyy

Connector Kit, Resistive Brake, 33A (TB1, TB2, TB3 Connectors) 2090-XNRBM-1

Connector Kit, Resistive Brake, 106A (TB1, TB2, TB3, TB4 Connectors) 2090-XNRBM-2

1 Where a = wire gauge in AWG.

2Where xx = cable length in full meters, and yy = length in decimeters.

1, 2

1,2

Publication 2090-IN009F-EN-P — November 2004

Page 24

Related Documentation

These publications provide additional information concerning related

Allen-Bradley products. To order printed copies, contact your Allen-Bradley

Distributor. To view and download, go to Literature Library at

http://www.rockwellautomation.com/literature.

For Information About Read This Document Publication Number

Installing, wiring, and troubleshooting a Kinetix 6000 drive Kinetix 6000 Installation Manual 2094-IN001x-EN-P

Configuring a Kinetix 6000 drive and system Kinetix 6000 Integration Manual 2094-IN002x-EN-P

Programming a motion application using Logix Logix Controller Motion Instruction Set Reference Manual 1756-RM007x-EN-P

ControlLogix™ motion and application examples ControlLogix Motion Module Programming Manual 1756-RM086x-EN-P

Configuring and troubleshooting ControlLogix motion modules

Minimizing and controlling system-level noise System Design for Control of Electrical Noise GMC-RM001x-EN-P

Sizing and configuring an application

Servo drives, motor, and accessories, including general technical

specifications

Information about international standards EN1050 and EN954

estimation and safety performance categories.

ControlLogix Motion Module Setup and Configuration

Manual

Motion Book Servo Sizing CD

(v4.0 or above)

1756-UM006x-EN-P

Motion Book-mmmyy

Motion Control Selection Guide GMC-SG001x-EN-P

Understanding the Machinery Directive SHB-900

For more information refer to our web site: www.ab.com/motion

For Allen-Bradley Technical Support information refer to: www.ab.com/support or Tel: (1) 440.646.5800

Allen-Bradley, A-B, and Kinetix are registered trademarks of Rockwell Automation.

ControlLogix, Ultra3000, and Ultra5000 are trademarks of Rockwell Automation.

Windows is a registered trademark of Microsoft Corporation.

UL is a registered trademark of Underwriters Laboratories, Inc.

Publication 2090-IN009F-EN-P — November 2004 319232-P06

Supersedes Publication 2090-IN009E-EN-P Copyright © 2004 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...