Page 1

Installation Instructions

900 Watt Passive Shunt Module

Ultra Series drives and controllers can require external power

dissipation when large inertial loads are present. To ensure that drive

faults due to excessive bus voltage do not occur, loads requiring

power dissipation that exceed a drive’s internal shunt capability

require the use of external shunt resistor(s).

The passive shunt (Catalog No. 1398-SR9PF or 2090-UCSR-P900) can

be used with the following products:

Drive Catalog No.

ULTRA 200 Drives 1398-DDM-075, -075X, -150, and -150X

ULTRA Plus Drives 1398-PDM-075 and 1398-PDM-150B

Ultra3000 Drives 2098-DSD-075, -075-SE, -075-DN, -075X, -075X-DN, -150,

-150-SE, -150-DN, -150X, and -150X-DN

Ultra5000 Drives 2098-IPD-075, -075-DN, -150, and -150-DN

ATTENTION

Using the passive shunt with modules not listed can

cause equipment damage or personal injury.

!

As a motor decelerates, power is returned from the motor to the drive

module, causing the bus voltage on the drive to increase. Ultra servo

amplifier products have circuitry that senses the voltage on the drive’s

DC bus and dissipates power when needed. When the bus voltage

reaches the shunt turn-on voltage of the drive, the internal shunt

circuitry allows the excessive regenerated power to be dissipated

through an external resistor. After the bus voltage is reduced to the

turn-off voltage level, the shunt transistor turns-off and no additional

power is dissipated by the shunt resistor.

1 Publication 2090-IN001A-EN-P — March 2001

Page 2

2 900 Watt Passive Shunt Module

Installing the Shunt

Do not mount shunt module

on its side

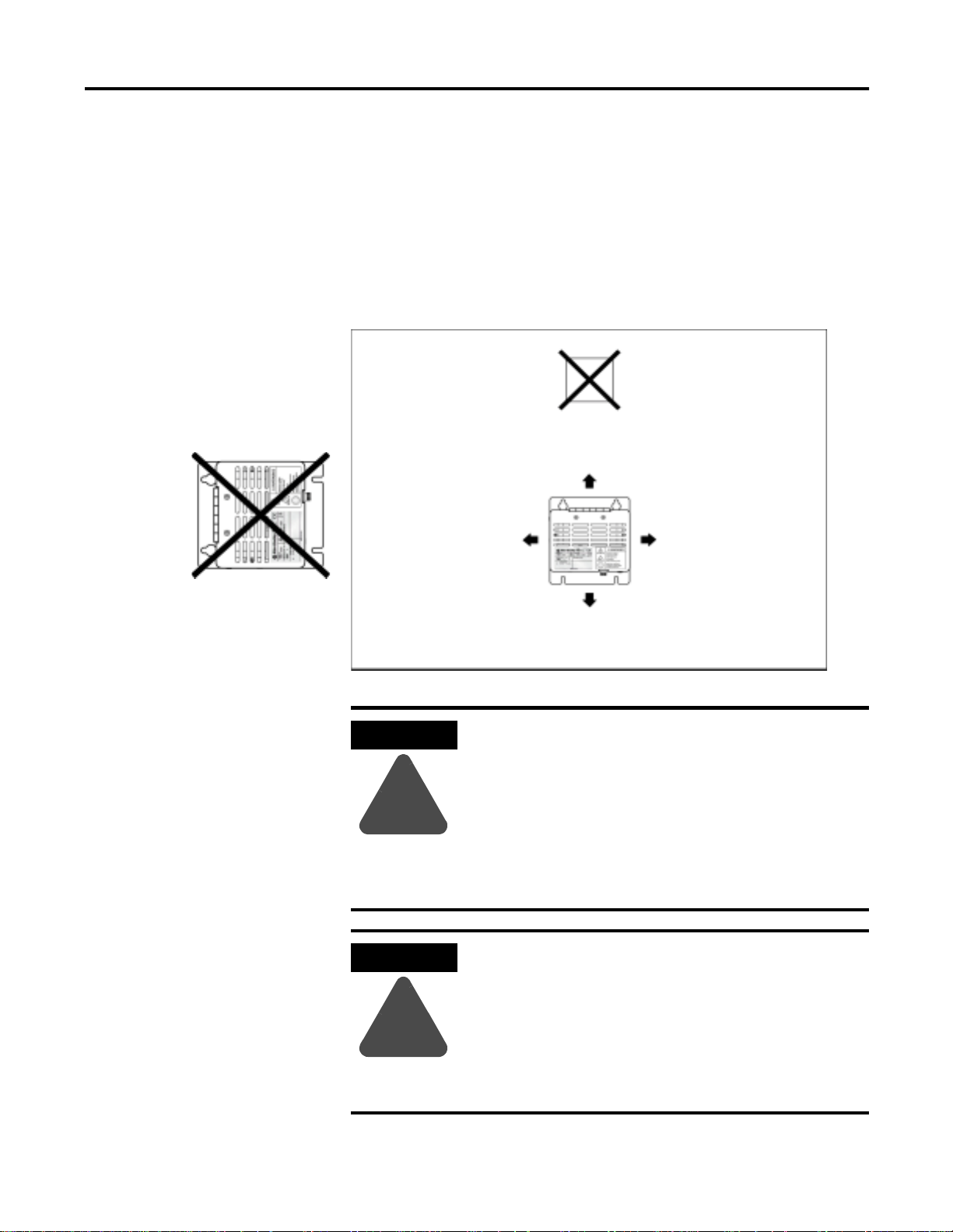

Orientation and Clearance

The following enclosure restrictions must be considered because the

shunt module dissipates excess regenerative power in the form of

heat. Refer to Figure 1 on page 2 and Figure 4 on page 9 for shunt

module spacing requirements.

Figure 1 Shunt Module Spacing Requirements Within an Enclosure

Do not mount temperature

sensitive components above

shunt module

155 mm (6.1 in.) min. of clearance

above the shunt module.

155 mm (6.1 in.) min. of

clearance on each side of the

shunt module.

155 mm (6.1 in.) min. of

clearance on each side of the

shunt module.

ATTENTION

!

ATTENTION

!

155 mm (6.1 in.) min. of clearance

below the shunt module

The shunt module can release a large amount of heat

over time.

Any materials above the shunt module or its

enclosure may need the protection of a metal plate

to keep from deteriorating.

Failure to observe this precaution could result in

damage to surrounding materials, possibly leading to

fire.

The shunt module can release a large amount of heat

inside an enclosure.

Ensure there is enough ventilation so as the

maximum ambient temperature of 50° C (122° F) is

not exceeded.

Failure to observe this precaution could result in

damage to the shunt module.

Publication 2090-IN001A-EN-P — March 2001

Page 3

900 Watt Passive Shunt Module 3

If the work environment dictates, mount the shunt module in an

enclosure providing protection against dust and splashing water

(IP54), or dust free and protected against water jets (IP65).

ATTENTION

!

Many NEMA (National Electrical Manufacturers Association) Type 4

cabinets provide this level of protection.

ATTENTION

Avoid contaminating electronic components.

Provide a quality air source to cabinets; free of

debris, oil, corrosives, or electrically conductive

contaminates. All cabinets should have scheduled

inspections and be cleaned as needed.

Failure to observe these safety procedures could

result in breakdown and damage to equipment.

If you mount the shunt module inside a cabinet, you

must make sure that the ambient temperature inside

the cabinet does not exceed 50° C (122° F).

!

Publication 2090-IN001A-EN-P — March 2001

Page 4

4 900 Watt Passive Shunt Module

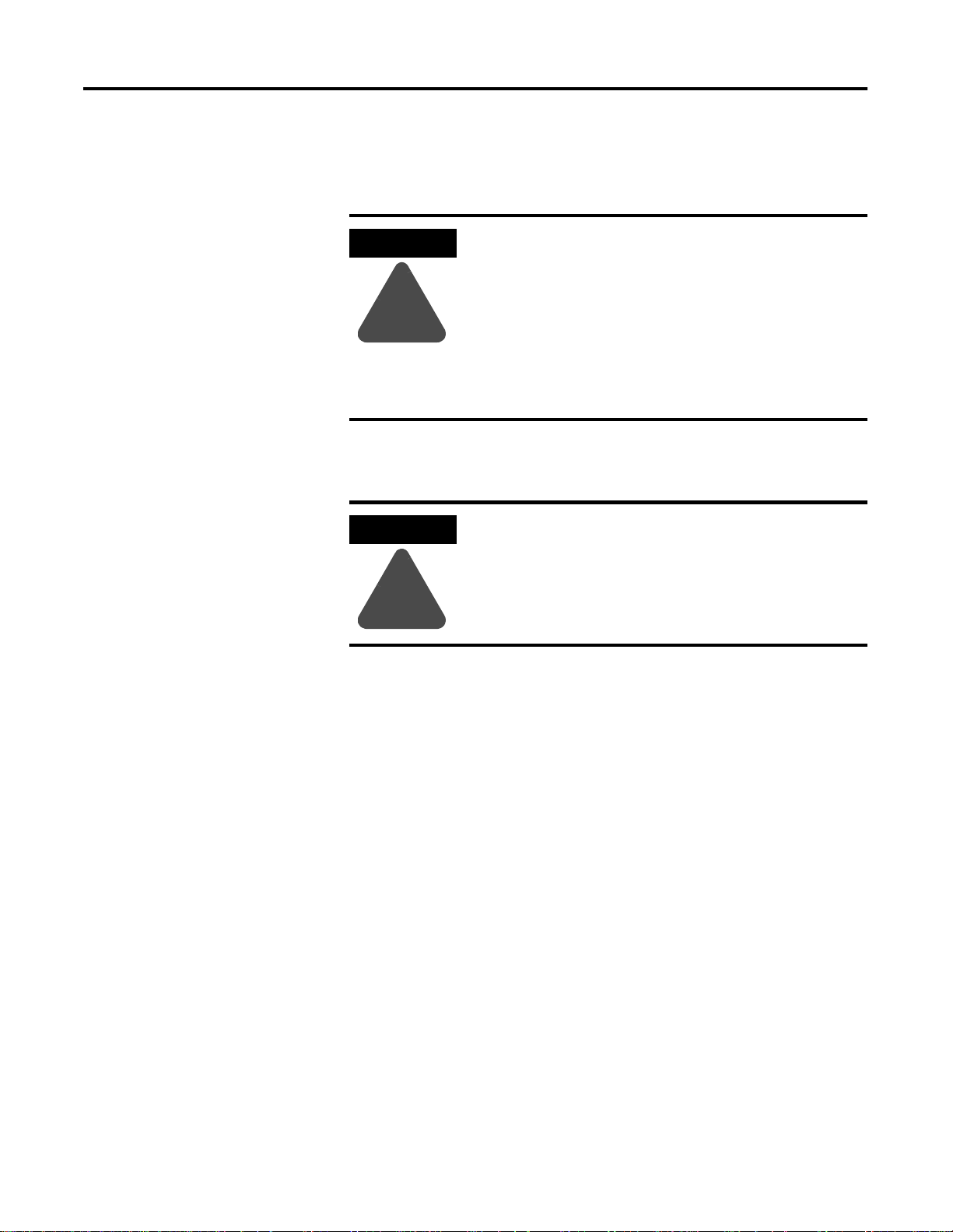

900 Watt Continuous Dissipation Cabinet Layout

Figure 2 details the proper position and cable separation for mounting

a single shunt module with a one drive inside a cabinet.

Motor power cable

IMPORTANT

Only one passive shunt module can be used per

DDM/PDM/DSD-075, IPD-075 or damage to the

drive will result.

Figure 2 Typical Shunt Module Position and Conductor Routing for 900W Continuous Dissipation

AC power cable

155 mm (6.1 in.) of minimum clearance on all

sides of the shunt module

Always separate low voltage signal

wiring from high voltage power wiring to

reduce affects of EMI

Twist conductors (2 twists per foot min.)

Publication 2090-IN001A-EN-P — March 2001

Shielded metal conduit, shielded cable,

and ferrite filters are also recommended

for reducing the effects of EMI

When shielding is used, the shield must

be grounded to the shunt and drive as is

the motor power cable

Low voltage communications, Control I/O, and

Motor feedback cables

Page 5

900 Watt Passive Shunt Module 5

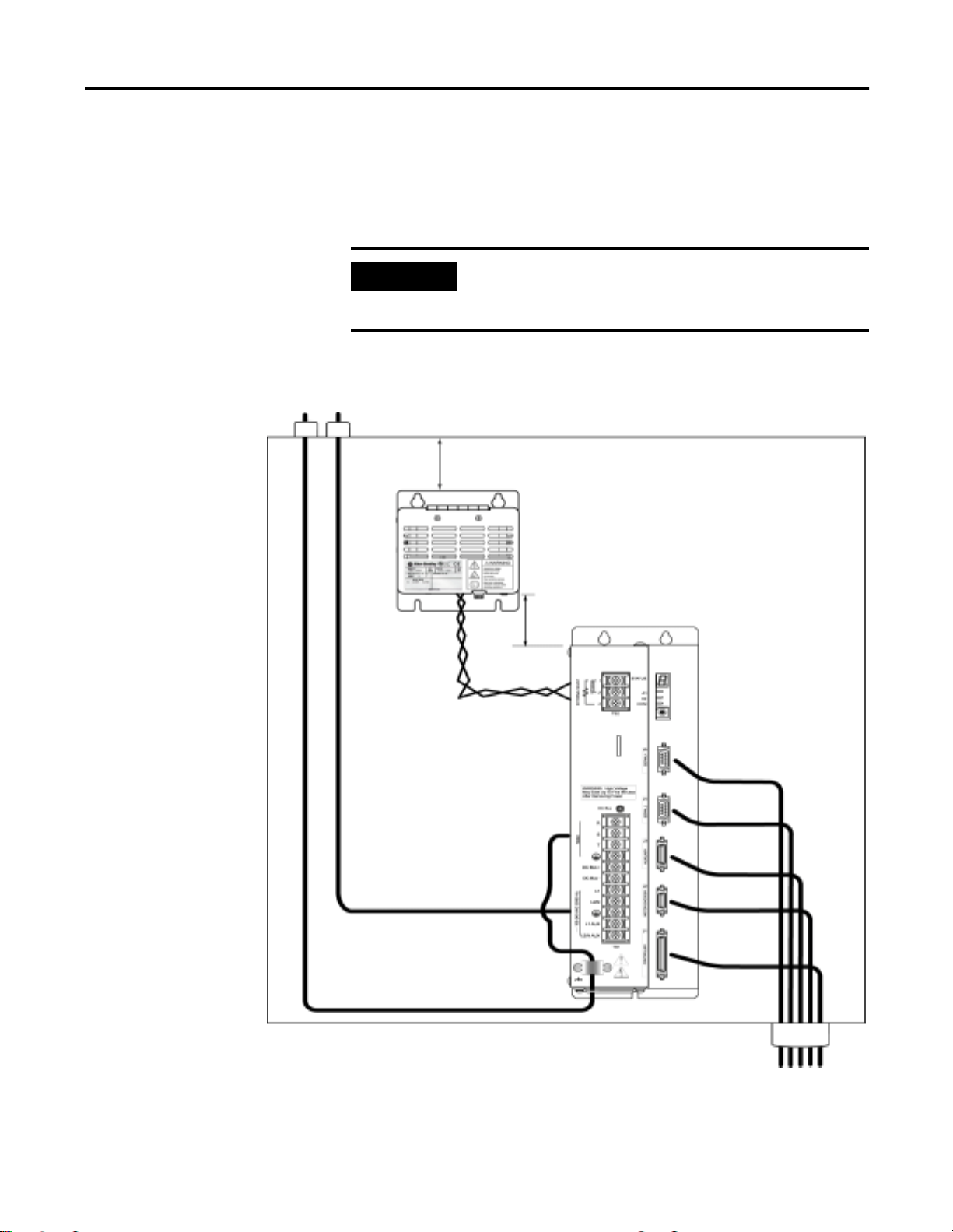

1,800 Watt Continuous Dissipation Cabinet Layout

Figure 3 details the proper position and cable separation for mounting

two shunt modules with one drive inside a cabinet. Two 900W shunt

modules are connected in a parallel, which doubles, to a total of

1,800W, the amount of continuous power dissipation on the DC bus.

Motor power cables

IMPORTANT

No more than two passive shunt modules can be

used per DDM/DSD/IPD-150, PDM-150B or damage

to the drive will result.

Figure 3 Typical Shunt Module Position and Conductor Routing for 1,800W Continuous Dissipation

AC power cables

155 mm (6.1 in.) of minimum clearance

on all sides of the shunt module

Twist conductors

Shielded metal

conduit, shielded

cable, and ferrite

filters are also

recommended for

reducing the effects

of EMI

(2 twists per foot min.)

Always separate low

voltage signal wiring

from high voltage

power wiring to reduce

affects of EMI

When shielding is used, the

shield must be grounded to the

shunt and drive as is the motor

power cable

Publication 2090-IN001A-EN-P — March 2001

Page 6

6 900 Watt Passive Shunt Module

Securing the Passive Shunt Module

The following procedure assumes you have prepared your mounting

panel. To mount your passive shunt module:

1. Install the top two mounting fasteners on the sub panel for the

shunt module. Refer to Product Specifications on page 8 for

specifications.

2. Mount the shunt module on the two fasteners.

3. Install the lower fasteners.

4. Tighten all mounting fasteners.

Wiring the Passive Shunt Module to a Drive

It is recommended to use shielded, high temperature (75° C, 600V),

8.4 mm

should be 3.05m (10 ft) with the shield grounded at both ends.

Unshielded wiring should be kept as short as possible.

Three recommended methods for wiring to reduce EMI noise can be

used to connect the passive shunt module with your drive.

You can use twisted conductors (2 twists per foot minimum) with

ferrite filters, shielded twisted cable, or shielded metal conduit.

When shielding is used, the shield must be grounded to the shunt and

drive chassis as is the motor power cable.

2

(8 AWG) copper wire. The maximum length of each wire

Publication 2090-IN001A-EN-P — March 2001

Page 7

900 Watt Passive Shunt Module 7

Connecting to the Shunt Terminal Block

1. Locate the external shunt terminal block (TB2) on your drive.

2.

Ensure there is no power applied to the drive.

3. Remove the jumper installed between terminals 1 and 2 of TB2.

4. Connect the lead wires to terminals 1 and 3 of TB2. Tighten screws

to 1.25 Nm (11 in-lbs).

5. Gently pull on each wire to make sure it does not release from its

terminal.

6. Re-insert and tighten any loose wires.

7. Open the front door of the passive shunt.

Insert wires

8. Connect the lead wires to terminal block inside front cover.

Polarity is not important. Tighten screws to 2.25 Nm (20 in-lb).

9. Close and secure cover of shunt module.

Publication 2090-IN001A-EN-P — March 2001

Page 8

8 900 Watt Passive Shunt Module

Product Specifications

Specifications for the passive shunt module are provided in the

following tables. Physical measurements are shown in Figure 4 on

page 9.

General Specifications Description

Weight net 3.31 kg (7 lbs)

Resistance

Power rating peak 10 kW

Fuse 10 Amp, 700 VDC, fast acting

Environmental Conditions Value

Vibration 2g at 10 to 2000 Hz

Shock 15g 11 msec half sine

Altitude 1500 m (5000 ft)

Humidity 5% to 95% non-condensing

Ambient operating temperature

shipping 4.08 kg (9 lbs)

18

Ω ± 10%

continuous 900 W

(Bussmann FWP10A14F)

1

0° to 50° C (32° to 122° F)

Air flow clearances 155 mm (6.1 in.) on all sides for air flow.

1

Power performance increases about 5.5 W for every 1°C (3.1 W/°F) drop in ambient temperature.

Mounting Hardware Size

Hex cap screws 1/4 in. - 20

Hex cap screws (metric) M6

Wiring Size

75°C copper wire

8.4mm

2

(8 AWG)

Terminal Block Screws Torque

Chrome plated brass 4.0 Nm (35 in.-lbs)

Publication 2090-IN001A-EN-P — March 2001

Page 9

Figure 4 900 Watt Passive Shunt Module Dimensions

900 Watt Passive Shunt Module 9

Measurements are in millimeters and (inches).

Publication 2090-IN001A-EN-P — March 2001

Page 10

10 900 Watt Passive Shunt Module

Notes

Publication 2090-IN001A-EN-P — March 2001

Page 11

900 Watt Passive Shunt Module 11

Publication 2090-IN001A-EN-P — March 2001

Page 12

Allen-Bradley is a registered trademark of Rockwell Automation.

Publication 2090-IN001A-EN-P — March 2001 PN 0013-1092-001-01

Supersedes Publication 1398-5.13 M ay 1999 © 2001 Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...