Page 1

Installation Instructions

300 W Active Shunt Regulator

The 300 W Active Shunt Regulator is used in systems that see significant dc

voltage regeneration from large inertial load applications. The Allen-Bradley

Ultra3000, Ultra5000, and ULTRA 100 drives (see table below) do not have

internal shunt circuitry to dissipate excess energy, resulting in overvoltage

faults. For the smooth braking of large inertial loads, the use of a shunt

regulator is recommen ded.

The active shunt (catalog number 2090-UCSR-A300

or 1398-SR3AF) can be

used with the following drive products.

Drive Family Cat. No.

Ultra3000 Drives

Ultra5000 Drives 2098-IPD-005, -005-DN, -010, -010-DN, -020, and -020-DN

ULTRA 100 Drives

2098-DSD-005, -005-SE, -005-DN, -010, -010-SE, -010-DN, -020, -020-SE,

-020-DN, -005X, -005X-DN, -010X, -010X-DN , -020X and -020X-DN

1398-DDM-005, -005-DN, -009, -009-DN, -019, -019-DN, -005X, -005X-DN,

-009X, -009X-DN, -01 9 X, and -019X-DN

The active shunt monitors the dc bus voltage of the drive. If the voltage

reaches activation level, the shunt drops the dc bus voltage and dissipates the

energy as heat. Figure 1 illustrates the drop in dc bus voltage.

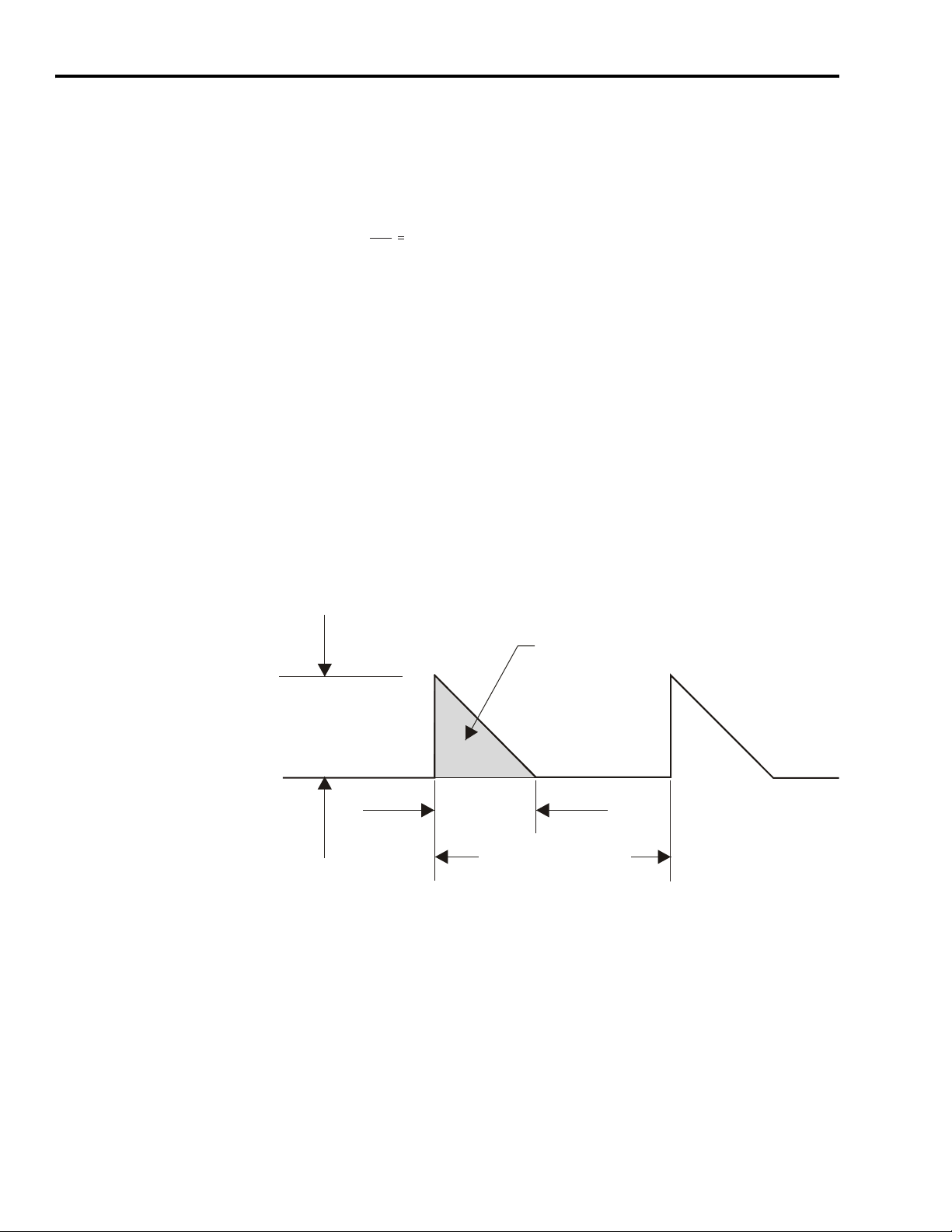

Figure 1

Shunt Activation on DC Bus Voltage

Voltage Drop for 1.0 ms, min

Activation Level

Bus Voltage

Actual Shunt Time

Time

1 Publication 2090-IN002C-EN-P — June 2007

Page 2

2 300 W Active Shunt Regulator

Performance

The peak shunting capability is a direct result of using a 36 Ω shunt resistor.

The peak shunt power can be calculated by dividing bus voltage squared, by

36. For example, if the bus voltage is 380V when the shunt is energized, the

shunt power is 4,011 W.

2

380V

4011 W

36 Ω

Continuous Shunt Capability

A shunt regeneration profile is defined by shunt time, cycle time, and peak

power level. Figure 2 illustrates a profile of regeneration during a machine

cycle.

• Shunt power is the peak shunt power during the shunt time.

• Shunt time is the time the power pulse is dissipated by the shunt.

• Cycle time is the time from the beginning of one shunt time to the

beginning of the next shunt time.

Figure 2

Shunt Regeneration Profile

Shunt Power

(watts)

Area = Shunt Energy (joule s)

Shunt Time

(seconds)

Cycle Time or

Machine Cycle

Publication 2090-IN002C-EN-P — June 2007

Page 3

300 W Active Shunt Regulator 3

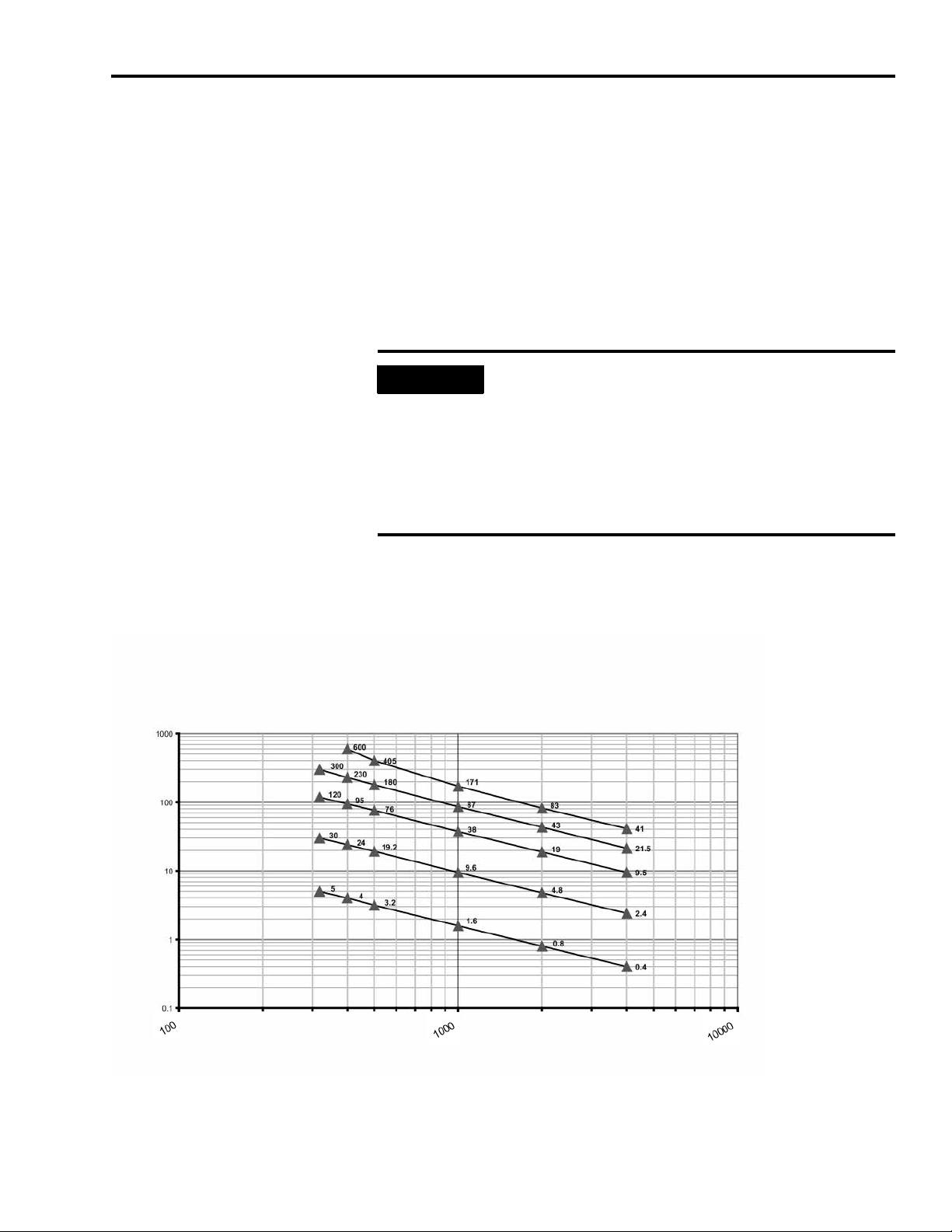

If the required average shunt power over the machine cycle is ≤ 300 W and t he

cycle time is ≤ 300 seconds, the active shunt can handle the application. Figure

3 illustrates the capability of an active shunt at

40 ºC (104 ºF) ambient temperature. The different lines represent different

cycle times (rates). The x-axis is the shunt power during the shunt time and the

y-axis is the maximum shunt time for that power and cycle time. For example,

the bottom line is a 5 second cycle time (meaning the shunt pulse comes every

5 seconds) and it intersects the 800 W pulse for 2 seconds every five seconds

in a 40 ºC (104 ºF) or less environment. This means that the shunt can handle

an 800 W pulse lasting for two seconds, every 5 seconds if the ambient

temperature is not above 40 ºC (104 ºF).

IMPORTANT

The limiting factor on how much average power can

be dissipated is temperature. The shunt power

capability increases approximately 5.5 W for every

1.0 ºC drop in ambient temperature (3.1 W/ ºF).

Increasing the air flow across the heat sink can

increase the continuous shunt capability significantly,

although obstructing air flow can decrease it

significantly.

Figure 3

Active Shunt Module Thermal Capacity

Pulse Time versus Pulse Power

Different Cycle Ti mes for the Active Shunt

Lower left of lines is safe, upper ri ght is unsafe.

Graph assumes 40 ºC (104 ºF) ambient.

Shunt Cycle Times

One-Shot

5 Minute Cycle

2 Minute Cycle

(showing seconds)

30 Second Cycle

Shunt Time (seconds)

5 Second Cycle

Shunt Power (watts)

Publication 2090-IN002C-EN-P — June 2007

Page 4

4 300 W Active Shunt Regulator

Install the Shunt

Do not mount shunt

module on its side.

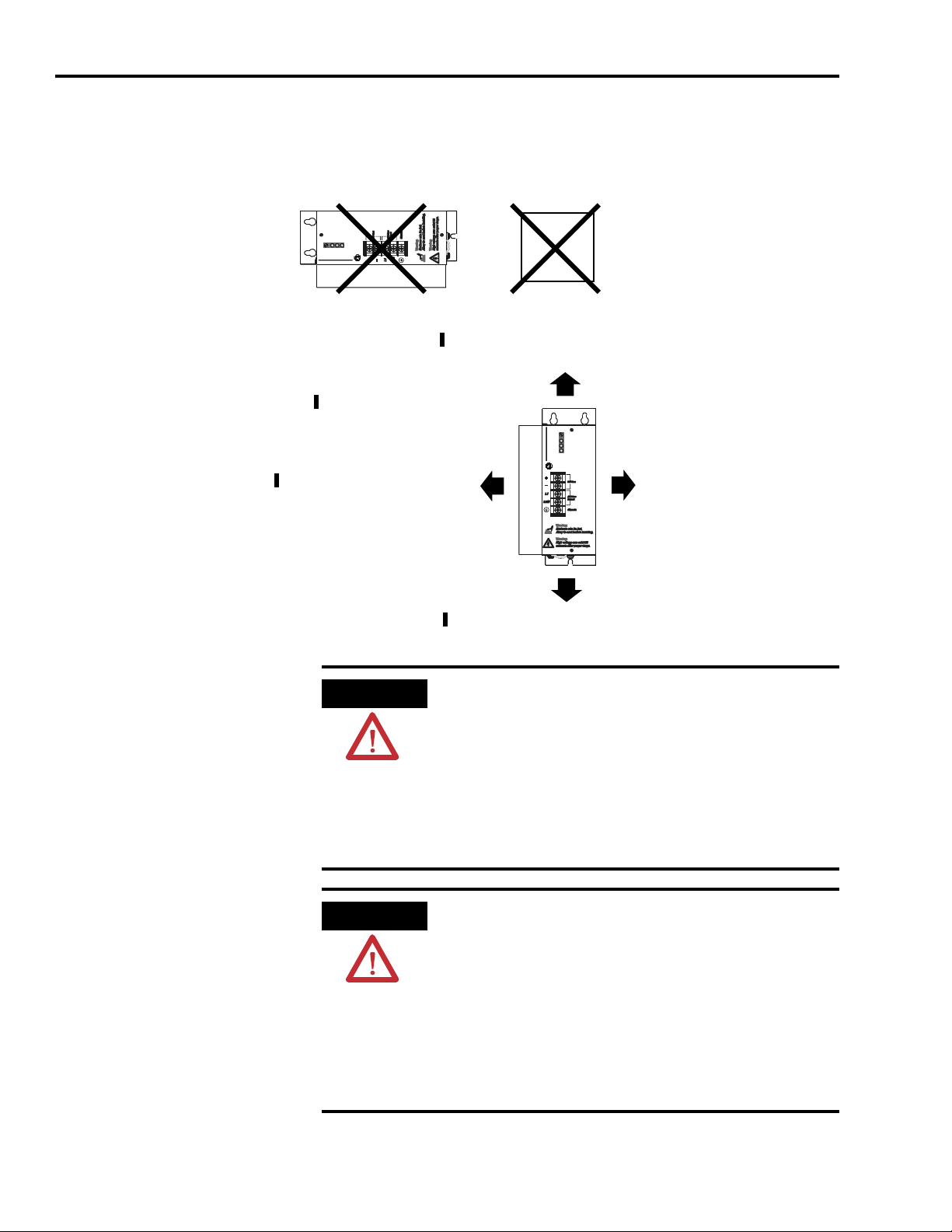

Refer to Figure 4 for shunt module spacing requirements.

Figure 4

Shunt Module Spacin g Requirements within an Enclosure

Active Shunt

Adjust

Overtemp

DC Bus

Active

t

l

r

U

r

e

a

S

e

i

s

A

le

B

ra

y

d

n

lle

25 mm (1.0 in.) min clearance in

front of the shunt module.

12.5 mm (0.5 in.) min clearance on

each side of the shunt module.

50 mm (2.0 in.) min clearance

above the shunt module.

Adjust

y

le

Overtemp

d

DC Bus

ra

s

B

e

i

Active

r

n

e

S

a

r

lle

t

l

U

A

Do not mount temperature

sensitive components above

the shunt module.

Active Shunt

12.5 mm (0.5 in.) min clearan c e on

each side of the shunt module.

ATTENTION

ATTENTION

50 mm (2.0 in.) min clearance

below the shunt module.

The shunt module can release a large amount of heat

over time.

Any materia ls above the shunt mo dule or its

enclosure may need the protection of a metal plate

to keep from deteriorating.

Failure to observe this precaution could result in

damage to surrounding materials, possibly leading to

fire.

The shunt module can release a large amount of heat

inside an enclosure.

Be sure there is enough ventilation so as the

maximum ambient temperature of 40 °C (104 °F) is

not exceeded. Power performance must be

decreased 5.5 W for every 1.0 °C (3.1 °F) of

increasing ambient temperature.

Publication 2090-IN002C-EN-P — June 2007

Failure to observe this precaution could result in

damage to the shunt module.

Page 5

300 W Active Shunt Regulator 5

If the work environment dictates, the shunt module should be in an enclosure

providing protection against dust and splashing water (IP54), or dust free and

protection against water jets (IP65).

ATTENTION

Avoid contaminating electronic components.

Provide a quality air source to cabinets: free of

debris, oil, corrosives, or electrically conductive

contaminates. All cabinets should have scheduled

inspections and be cleaned as needed.

Failure to observe these safety procedures could

result in breakdown and damage to equipment.

Many National Electrical Manufacturers Association (NEMA) Type 4 cabinets

provide this level of protection.

ATTENTION

If you mount the shunt module inside a cabinet, you

must make sure that the ambient temperature inside

the cabinet does not exceed 40 °C (104 °F). Power

performance must be dec reas ed 5.5 W for every

1.0 °C (3.1 °F) of increasing ambient temperature.

Mount the Active Shunt Module

To mount the shunt module on a flat, solid, grounded surface:

1. Install the top mounting fasteners on the subpanel for the shunt module.

Refer to Product Specifications on page 7 for fastener, wire, and terminal

torque specifications.

2. Mount the shunt module on the two fasteners.

3. Install the lower fasteners.

4. Tighten all mounting fasteners.

Publication 2090-IN002C-EN-P — June 2007

Page 6

6 300 W Active Shunt Regulator

Wire the Active Shunt Module to a Drive

It is recommended to use shielded, high temperature (75 °C, 600V), 4.0 to 2.5

2

mm

(12 to 14 AWG) copper wire, or run the wire through shielded conduit.

The maximum length of each wire should be 3.05 m (10 ft) with the shield

grounded at both ends. Unshielded wiring should be kept as short as possible.

1. Locate the terminal block on your active shunt.

2. Wire the +DC Bus connection to the positive (+) bus connection of the

drive, and the -DC Bus connection to the negative (-) bus connection of

the drive.

IMPORTANT

The dc bus connections should only be used to

connect a single drive to the active shunt module.

Contact your Allen-Bradley representative for further

assistance if your application requires additional dc

power connections.

3. Wire the AC Line Detect to the respective terminals (L1, L2/N) of the

drive or its ac power source.

The shunt module will actively sense when ac power is lost to the drive

and after 0.25/s, it will drop the dc bus.

4. Wire the Chassis ground to earth ground.

5. Tighten the terminal block screws to 1.2 Nm (11 lb-in).

6. Gently pull on each wire to make sure it does not release from its terminal.

Publication 2090-IN002C-EN-P — June 2007

7. Reinsert and tighten any loose wires.

Page 7

300 W Active Shunt Regulator 7

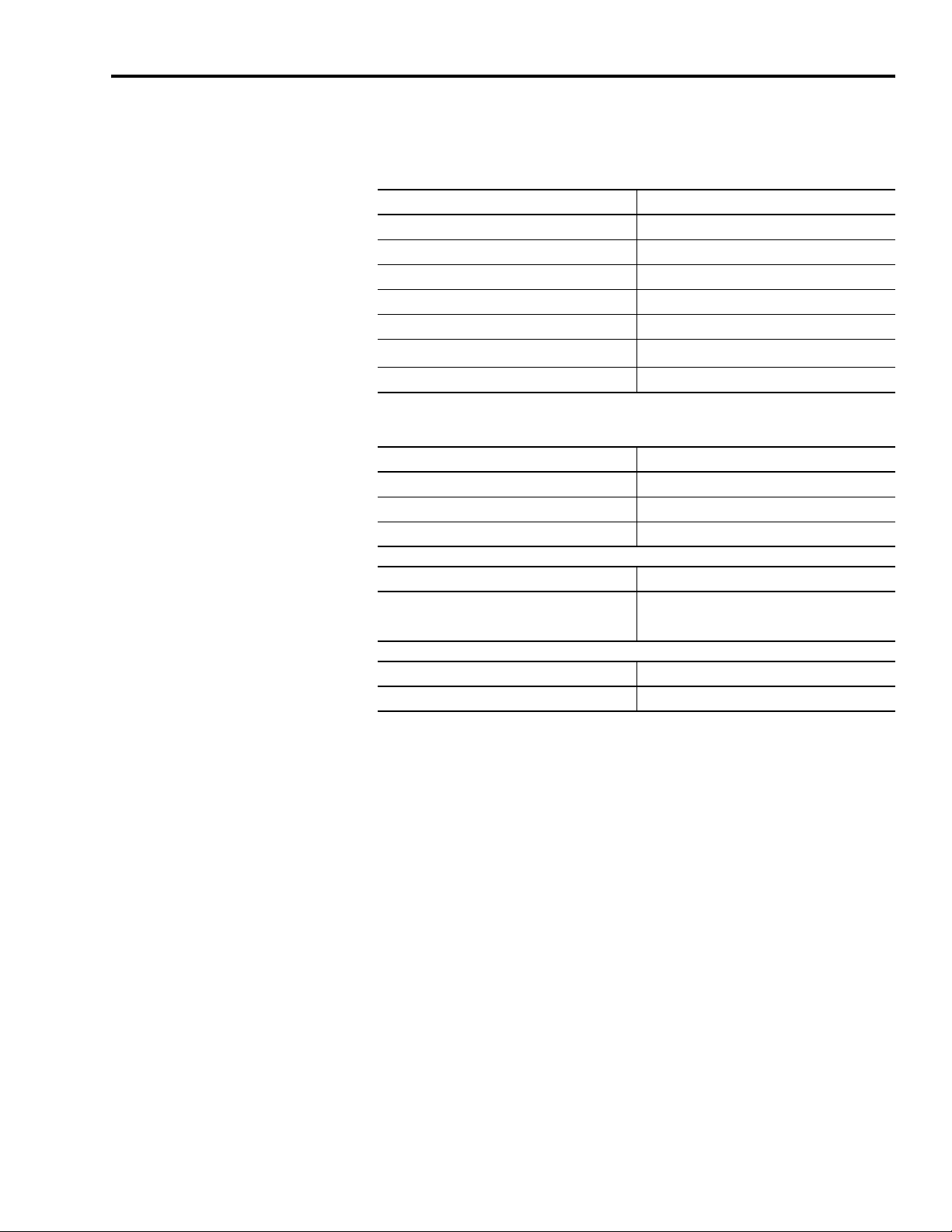

Product Specifications

Specifications for the activ e shunt module ar e provided in the follo wing tables.

Physical measurements are shown in 300 W Active Shunt Re gulat or Mountin g

Dimensions on page 8.

General Specifications Value

Weight 1.51 kg (3.34 lb)

Vibration 2 g at 10...2000 Hz

Shock 15 g 11 ms half sine

Altitude 1500 m (5000 ft)

Humidity 5...95% noncondensing

Ambient operating temperatu r e

Air flow clearances 50 mm (2.0 in.) above and below unit for air fl ow

(1)

Power performance increases/decreases approximately 5.5 W for every 1.0 °C (3.1 W/ °F) drop/rise in ambient

temperature.

Mounting Hardwar e Size

Metal screws #10

Hex cap screws 1/4 in.-20

Hex cap screws (metric) M5

(1)

0...40 °C (32...104 °F)

Wiring Size

2

(12 AWG) or

75 °C copper wire

Terminal Block Screws Torque

Chrome plated brass 1.2 Nm (11 lb-in)

4.0 mm

2.5 mm

2

(14 AWG)

Publication 2090-IN002C-EN-P — June 2007

Page 8

8 300 W Active Shunt Regulator

65.1

(2.5)

38.1

(1.5)

18.6

6.35

(0.25)

(0.7)

Active Shunt

Adjust

y

le

Overtemp

d

DC Bus

ra

s

B

e

i

Active

r

n

e

S

a

r

lle

t

l

U

A

Figure 5

300 W Active Shunt Regulator Mounting Dimensions

13.21

(0.5)

Clearance holes for #10 (M5) screws.

129

(5.0)

Dimensions are in m m (i n. )

186.7

(7.3)

5.6

(0.22)

198

(7.8)

97.3

(3.8)

143

(5.6)

Publication 2090-IN002C-EN-P — June 2007

Page 9

300 W Active Shunt Regulator 9

ULTRA 100 Radiated Emissions CE Compliance

In order for the ULTRA 100 drive to comply with the CE radiated emissions

standards, ferrites mu st be a d ded to th e ends o f the t wisted dc bus wires when

using an active shunt. Route both wires through the ferrites. Ferrites with an

impedance at 100 MHz between 100 to 200 Ω wer e fo un d to b e eff e ct i v e. The

following table lists some readily available ferrites with effective impedance

ratings.

Figure 6

DC Bus Wiring Layout Using Ferrites with Shielded Cable

Ferrites for CE Radiated Emissions Compliance

Mfg. Part/No. D E Impedance

SS28B2034 0.250 0.120

SS28B2037 0.350 0.200

SS28B2032 0.500 0.200

Box-shaped ferrite assembly in ful ly enclosed

nylon case. End ports are surrounded with

flexible spring flutes to grip a range of cable

diameters from 3.2...12.7 mm (0.125...0.500 in .).

FerriShield, Inc.

350 Fifth Avenue, Suite 7310

New York, NY 10118-7591

125

Ω

154 Ω

230 Ω

Active Shunt

Adjust

y

le

Overtemp

d

DC Bus

ra

s

B

e

i

Active

r

n

e

S

a

r

lle

t

l

U

A

2

2

• Place shunt in metal enclosure providing EMI noise

reduction.

• For ULTRA 100 drive only:

Install a 100 to 200 W ferrite RFI suppressor at both ends

of the dc bus wires to comply with CE radiated

emissions standard.

• Some drive terminals are marked R, S, and T instead of

U, V, and W.

Publication 2090-IN002C-EN-P — June 2007

Page 10

10 300 W Active Shunt Regulator

Maintain the Active Shunt

Figure 7 shows information relating to the adjust screw and the LEDs that

show shunt activity. Refer to Troubleshoot on page 11 for more information.

Figure 7

Shunt Module Adjustment Screw and LEDs

Adjust (screw)

Adjust

Overtemp

DC Bus

Active

Active Shunt

The Adjust screw sets the activati on level of the shunt. It is set at

the factory and ordinarily wil l not need adjustment.

Overtemp (LED)

The Overtemp (yellow) LED illuminates when the unit’s thermostat

has tripped. While the ther mostat is tripped, the unit will not shunt

excess voltage (but the dc bus drop fea tu re wil l st il l function) and

this will usually cause the host drive to fault on overvoltage. Once

this LED turns on, power must be removed bef ore it will shut off,

even if the active shunt unit has cooled and is functioning agai n.

DC Bus (LED)

The DC Bus (green) LED illuminates when there is sufficient bus

voltage. The higher the bus voltage, the brighter the LED wi ll glow.

Active (LED)

The Active (green) LED illuminates while the shunt is dissipat ing

power. This LED indicates not only that the shunt is functioning, but

shows how often the shunt is energized.

Publication 2090-IN002C-EN-P — June 2007

Page 11

Troubleshoot

Adjust

Overtemp

DC Bus

Active

Active Shunt

300 W Active Shunt Regulator 11

If this fault appears Then

The internal thermostat in the shunt unit is

getting too hot. To fix this problem:

• reduce the average shunt power,

• reduce the ambient temperature of the air

Overtemp light is on

Drive registers Bus Overvoltage faul t s , but the

active shunt is functioning and the Overtemp light

is off.

• increase the amount of air passing over the

Once this LED turns on, only removing power will

shut it off; even when the active shunt unit has

cooled and is functioning again.

There are two situations where this can happen.

• First, if the Bus Overvoltage trip level on the

• Second, if the regenerat ion power exceeds

around the shunt, or

heat-sink fins.

drive is too low. Since this is not adjustable

on the drive, the solution is to reduce the

turn-on threshold level of th e act ive shunt.

This is done by turning the Adjust po t

counter-clockwise.

the shunt power for too long. It is po ssible

for the drive to generate more power than

the active shunt can handle. There are tw o

possible solutions to this situation.

• Adjust the regeneration profile so that

the drive generates less power fo r a

longer time. The drive current l imit

parameters may be useful here.

• Reduce the turn-on threshold level of

the active shunt, which turns on the

shunt earlier in the regeneration

profile.

Publication 2090-IN002C-EN-P — June 2007

Page 12

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using

its products. At http://support.rockwellautomation.com, you can find technical

manuals, a kno w ledge ba se of FA Qs, technical and applicat io n no tes, sample code and

links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools.

For an additional level of technical phone suppor t for installation, configuration and

troubleshooting, we o ffer TechConnect Support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit http://

support.rockwellautomation.com.

Installation Assist an ce

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. Y ou can also

contact a special Customer Support number for initial help in getting your module up

and running:

United States

Outside United

States

1.440.646.3223

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when shipped

from the manufacturing facility. Howev er , if your product is not functioning and needs

to be return ed:

Contact your distributor. You must provide a Customer Support case number

United States

Outside United

States

Allen-Bradley, Ultra3000, Ultra5000, ULTRA 100, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(see phone number above to obtain one) t o your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Publication 2090-IN002C-EN-P — June 200712 PN 0013-1091-003

Supersedes Publication 2090-IN002B-EN-P — February 2007 Copyright © 2006 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...