Page 1

Installation Instructions

External Shunt Modules

Catalog Numbers

1394-SR9A, 1394-SR9AF, 1394-SR36A, 1394-SR36AF,

2090-SR120-09, 2090-SR040-09, 2090-SR040-18

Topic Page

About the External Shunt Modules 1

Important User Information 2

Catalog Number Explanation 3

Before You Begin 3

Install the External Shunt Module 13

Replace the Shunt Module Fuse 20

External Shunt Module Specifications 21

Additional Resources 22

About the External Shunt Modules

These externally-mounted passive shunt modules provide a means for

servo drives to dissipate excess regenerative energy from the DC bus.

This is needed when system loads require power dissipation beyond

the capability of the shunt resistor internal to the servo drive. These

are passive shunt resistors and require transistor activation by the

servo drive.

A properly-sized shunt module regulates excessive bus voltage by

passing current through a resistor, which dissipates the current as heat

and minimizes drive faults caused by excess bus voltage.

Shunt Module Compatibility

Shunt Cat. No. Drive Cat. No.

2090-SR120-09 2098-xxx-HV030 and 2098-xxx-HV050

2090-SR040-09 2098-xxx-HV100

2090-SR040-18 2098-xxx-HV100

1394-SR9A

1394-SR9AF

1394-SR36A

1394-SR36AF

(1)

The 2094-BSP2 shunt module is mounted on the Bulletin 2094 power rail and

provides connections to an external shunt module.

2094-BSP2

1394x-SJT22-x

(1)

and

Page 2

2 External Shunt Modules

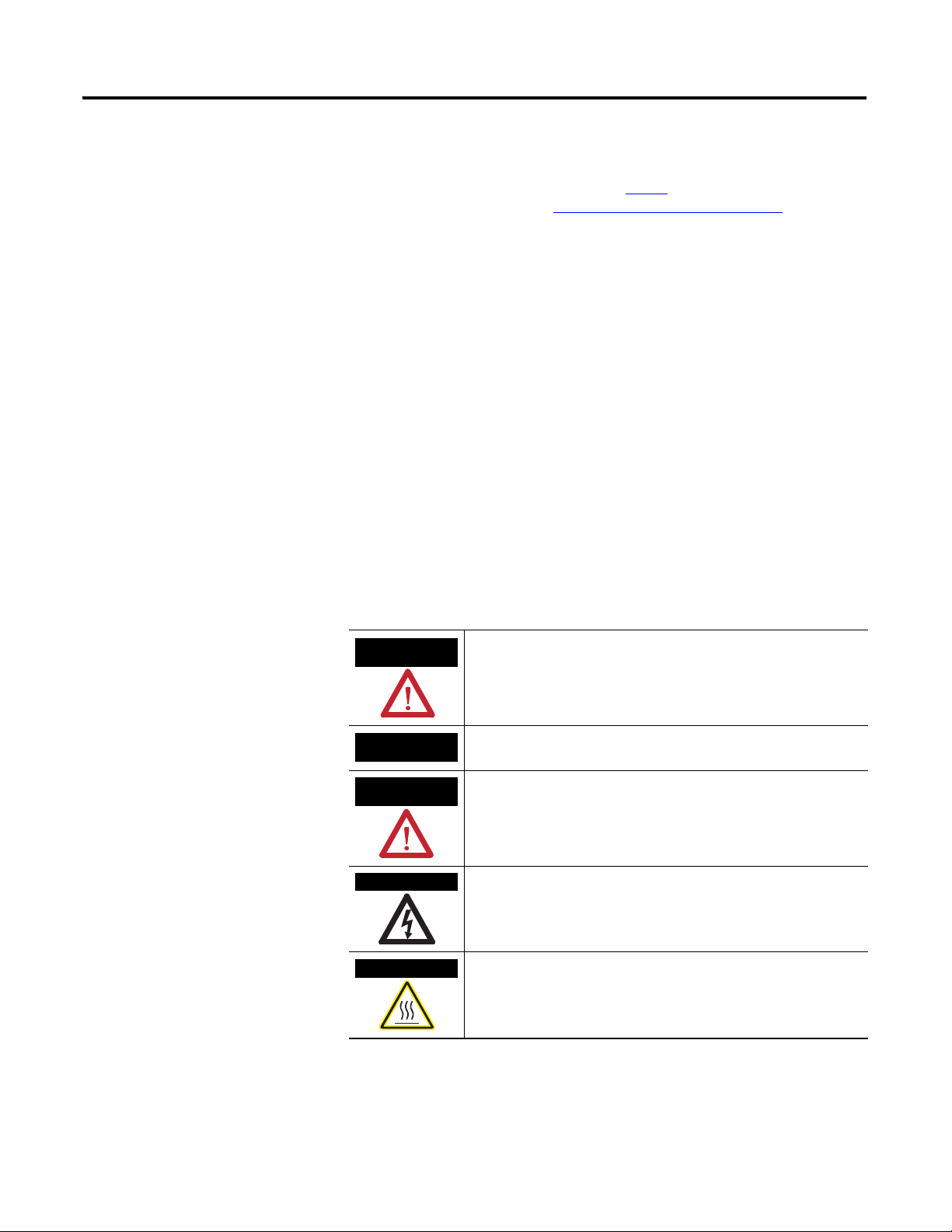

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://literature.rockwellautomation.com

some important differences between solid state equipment and hard-wired

electromechanical devices. Because of this difference, and also because of the wide variety

of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular installation,

Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on

the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission

of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety

considerations.

available from your local Rockwell

) describes

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you to identify a hazard, avoid a hazard, and recognize

the consequences.

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may reach dangerous

temperatures.

Publication 2090-IN004B-EN-P — June 2008

Page 3

External Shunt Modules 3

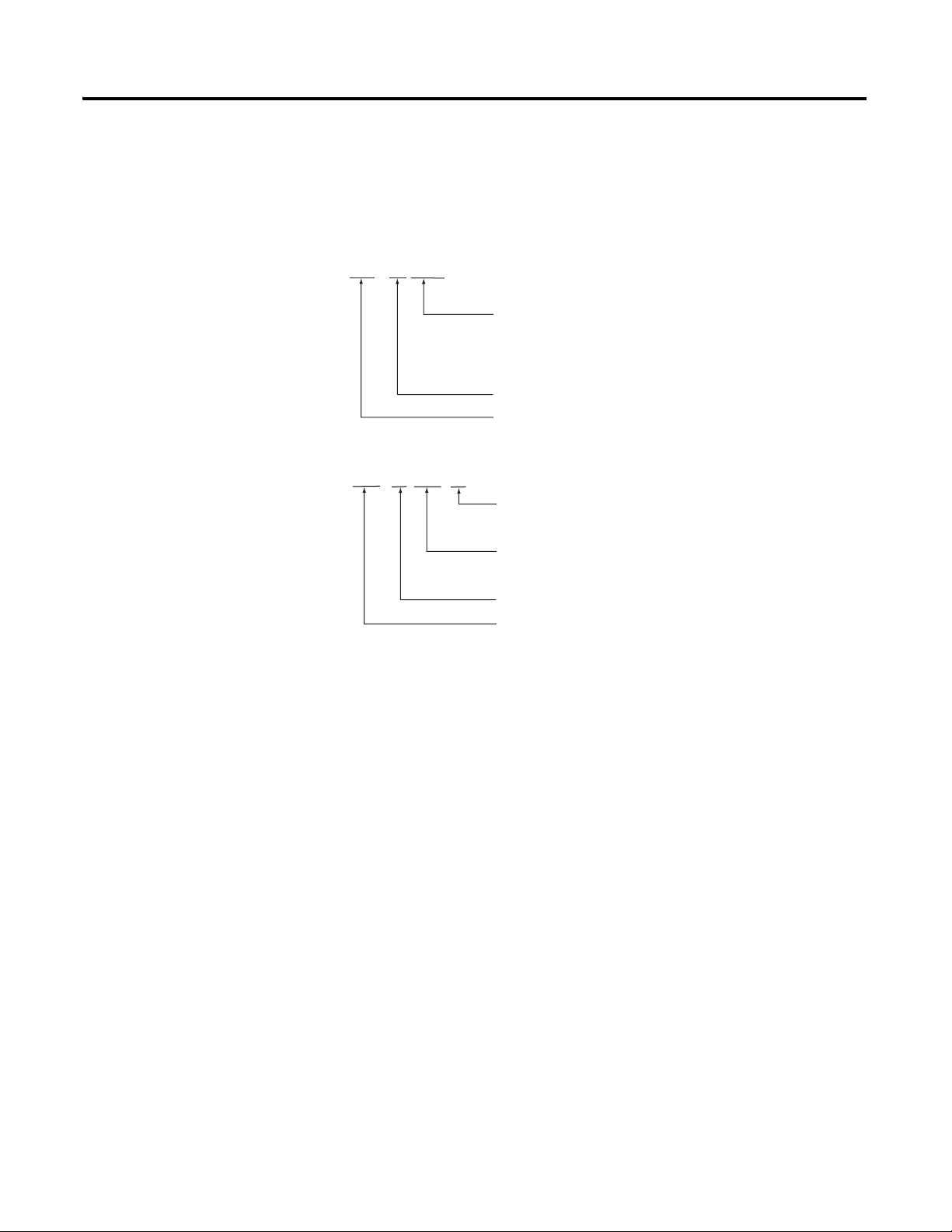

1394 - SR xxxx

Bulletin Number

SR = Shunt Resistor

kW Rating

9A = 300 W continuous, 4 Ω , no fan

9AF = 900 W continuous, 4 Ω , no fan

36A = 1800 W continuous, 4 Ω , no fan

36AF = 3600 W continuous, 4 Ω , fan-cooled, thermal switch

2090 - SR

xxx - xx

Bulletin Number

Resistance Rating

120 = 120 Ω

040 = 40 Ω

SR = Shunt Resistor

Continuous Power Rating

09 = 900 W continuous, no fan

18 = 1800 W continuous, no fan

Catalog Number Explanation

Catalog numbers consist of various characters, each of which

identifies a specific version or option for that component. Use the

catalog numbering charts below to understand the configuration of

your shunt module.

Bulletin 1394 External Shunt Modules

Bulletin 2090 External Shunt Modules

Before You Begin

Before you begin mounting your shunt module, make sure you:

• have the required tools and materials.

• understand the mounting requirements.

• understand high-frequency bonding.

• know how to establish noise zones.

Required Tools and Materials

These tools and materials are required to complete the installation of

an external shunt module:

• Screwdrivers

• User-supplied power wiring

• Mounting fasteners

Publication 2090-IN004B-EN-P — June 2008

Page 4

4 External Shunt Modules

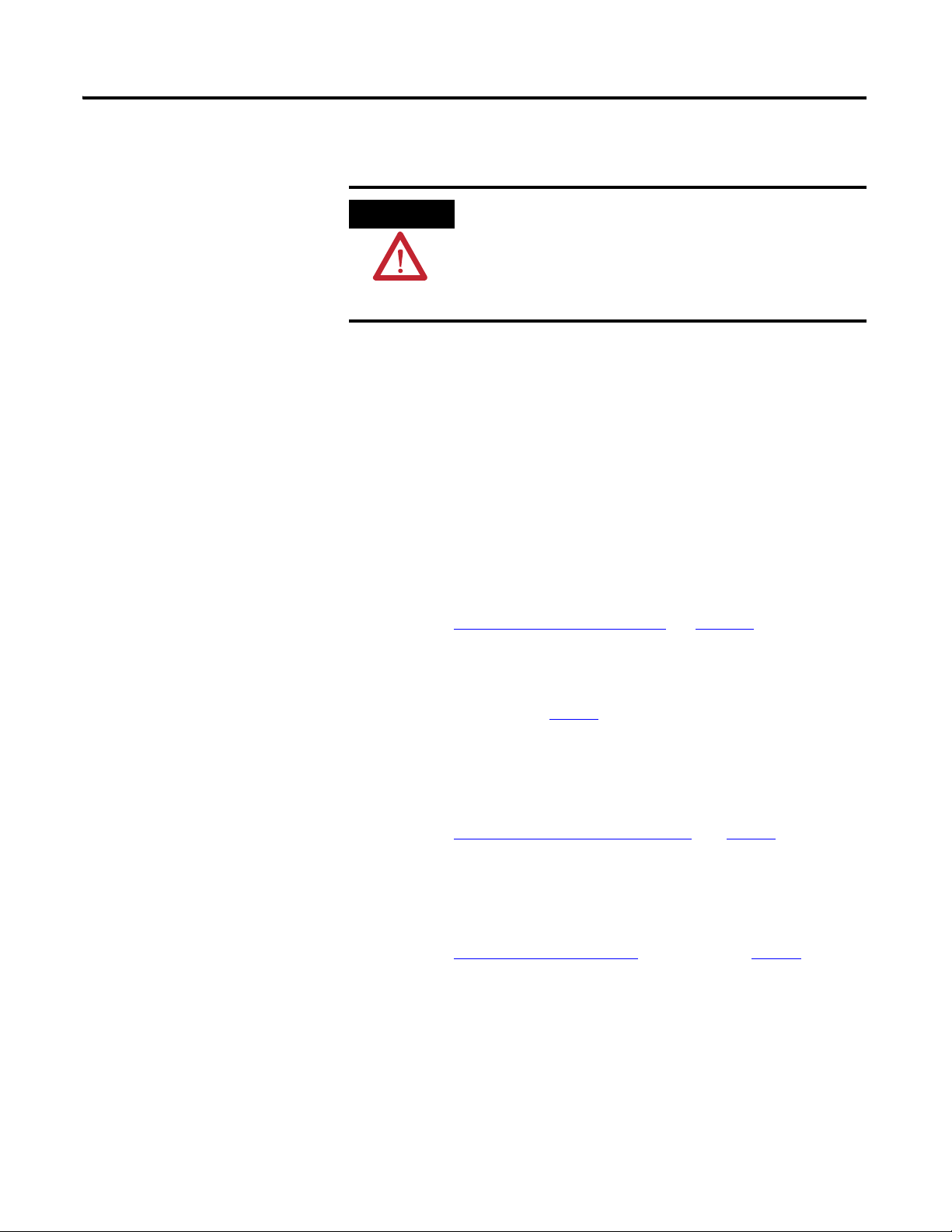

ATTENTION

Mounting Requirements

Plan the installation of your system so that you can perform all cutting,

drilling, tapping, and welding with the system removed from the

enclosure. Because the system is of the open type construction, be

careful to keep any metal debris from falling into it. Metal debris or

other foreign matter can become lodged in the circuitry, which can

result in damage to components.

These requirements apply when preparing to mount your shunt

module:

• Mo

unt the shunt in an enclosure providing protection against

dust and splashing water (IP54), or dust free and protected

against water jets (IP65).

Many NEMA (National Electrical Manufacturers Association)

ype 4 cabinets provide this level of protection.

T

• Install

the panel for mounting your system components inside

the enclosure on a flat, rigid, vertical surface that won’t be

subjected to shock, vibration, moisture, oil mist, dust, or

corrosive vapors.

Refer to

Environmental Specifications on page 21 for specific

recommendations.

• Maintain minimum clearances for proper airflow, easy module

access, and proper bend radius for the cables as shown in the

figures beginning on page 5

.

• Use high-frequency (HF) bonding techniques to connect the

module, enclosure, machine frame, and motor housing, and to

provide a low-impedance return path for high-frequency (HF)

energy and reduce electrical noise.

Refer to HF Bonding Your Shunt Module, on page 6, for more

information.

Publication 2090-IN004B-EN-P — June 2008

• Se

gregate DC-bus wiring from control wiring and motor

feedback cables. Do not run shunt wiring in wireways. Use

twisted pair cable from the drive to external shunt module.

Refer to

Establishing Noise Zones, beginning on page 6, for

specific recommendations.

Page 5

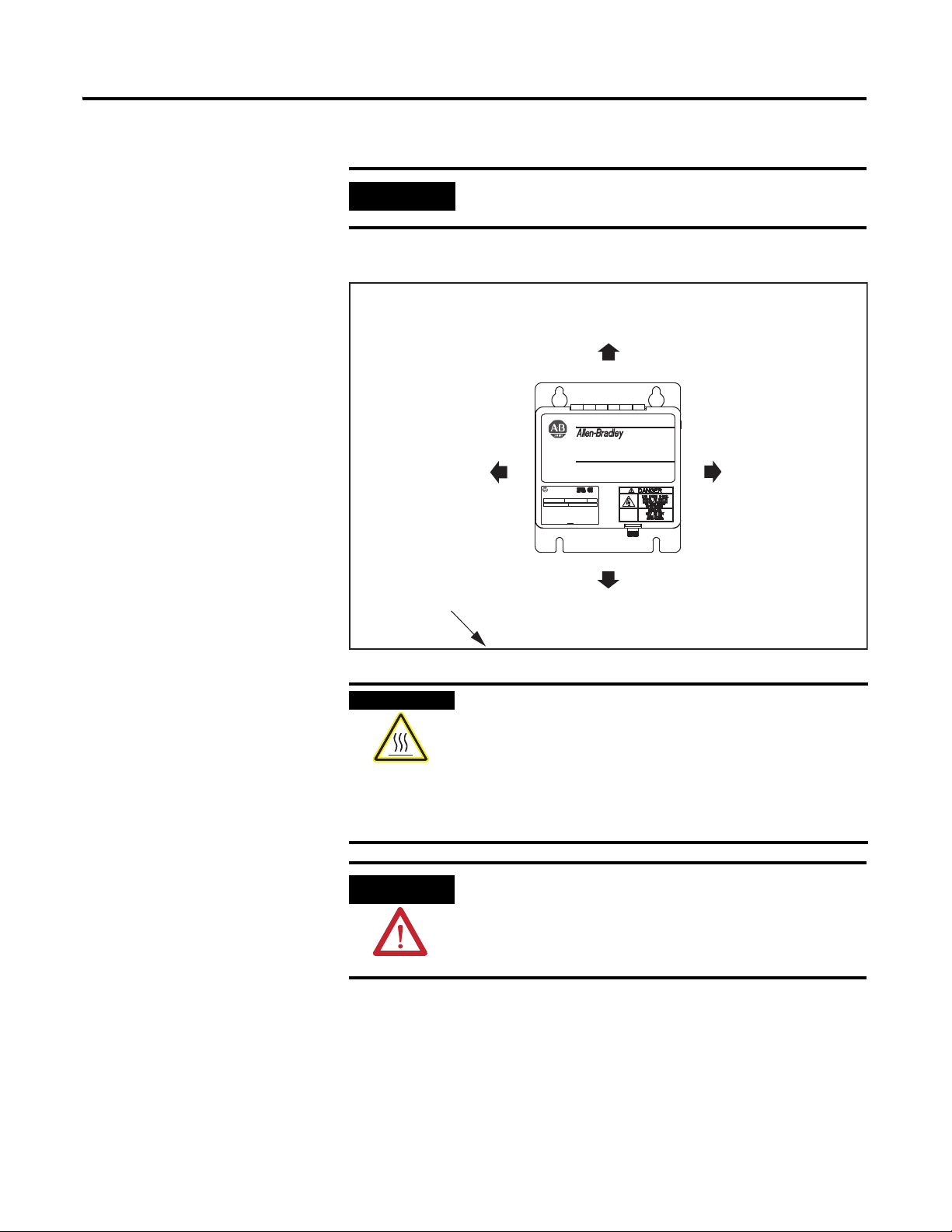

IMPORTANT

Mount the shunt module in an upright position. Do not mount the

150 mm (6.0 in.) clearance

for airflow and installation.

150 mm (6.0 in.) clearance

for airflow and installation.

150 mm (6.0 in.) clearance

for airflow and installation.

150 mm (6.0 in.) clearance

for airflow and installation.

Enclosure

Bulletin 1394 and 2090

External Shunt Modules

(1394-SR9Ax module is

shown in this example.)

BURN HAZARD

ATTENTION

shunt module on its side.

Minimum Clearance Requirements (within an enclosure)

Shunt Module

ALLEN-BRADLEY

R

BULLETIN 1394 300W SHUNT MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

External Shunt Modules 5

The shunt resistors can reach temperatures in excess of 350 °C

(662 °F). Do not handle a shunt module that has been operational until

it has cooled sufficiently.

Combustible materials above the shunt module or its enclosure may

need the protection of a metal plate to shield them from the heat.

Failure to observe these precautions could result in damage to

surrounding materials, possibly leading to a fire or personal injury.

The shunt resistors release large amounts of heat. When mounted

inside an enclosure, you must provide adequate ventilation so the

maximum ambient temperature of 50 °C (122 °F) is not exceeded.

Failure to observe this precaution could result in damage to the

module.

Publication 2090-IN004B-EN-P — June 2008

Page 6

6 External Shunt Modules

1394 Digital Servo Controller

3600W Shunt Module

BULLETIN 1394 3600W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

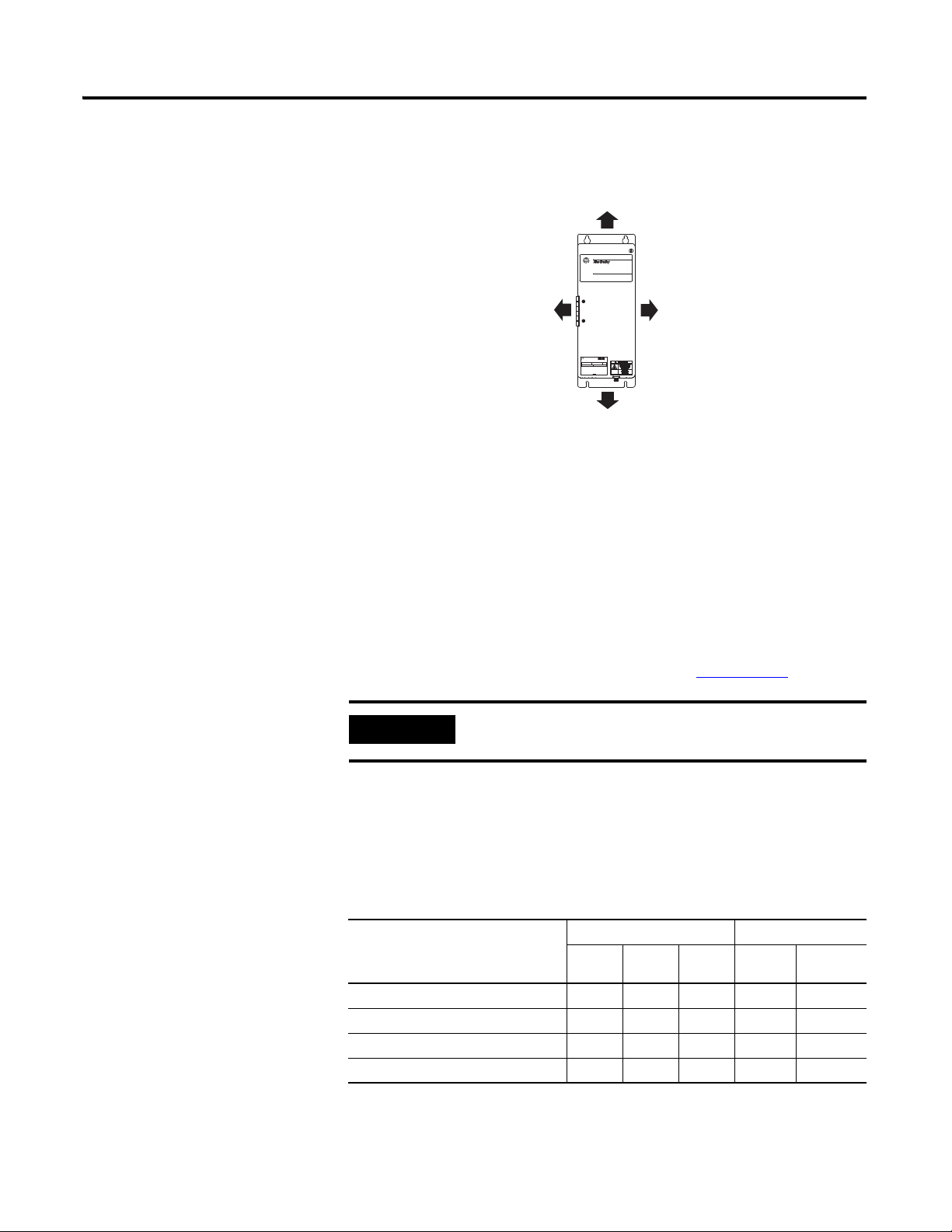

150 mm (6.0 in.) clearance

for airflow and installation.

150 mm (6.0 in.) clearance

for airflow and installation.

150 mm (6.0 in.) clearance

for airflow and installation.

254 mm (10.0 in.) clearance

for airflow and installation.

Bulletin 1394 and 2090

External Shunt Modules

(1394-SR36Ax module is

shown in this example.)

IMPORTANT

Minimum Clearance Requirements (outside the enclosure)

HF Bonding Your Shunt Module

Bonding is the practice of connecting metal chassis, assemblies,

frames, shields, and enclosures to reduce the effects of

electromagnetic interference (EMI). For more information on the

concept of high-frequency (HF) bonding, the ground plane principle,

and electrical noise reduction, refer to System Design for Control of

Electrical Noise Reference Manual, publication

To improve the bond between the drive system and subpanel,

construct your subpanel out of zinc plated (paint-free) steel.

GMC-RM001.

Establishing Noise Zones

This table provides the zoning requirements of cables connecting to

the external shunt module.

Zone Method

Wire/Cable

COL, DC+ (shielded option) X X

COL, DC+ (unshielded option) X

Thermal switch X X

Fan (if present) X

Very

Dirty

Dirty Clean

Ferrite

Sleeve

Shielded

Cable

Publication 2090-IN004B-EN-P — June 2008

Page 7

External Shunt Modules 7

C

D

D

D

D

D

VD

C

VD

D

1394 Digital Servo Controller

300W Shunt Module

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

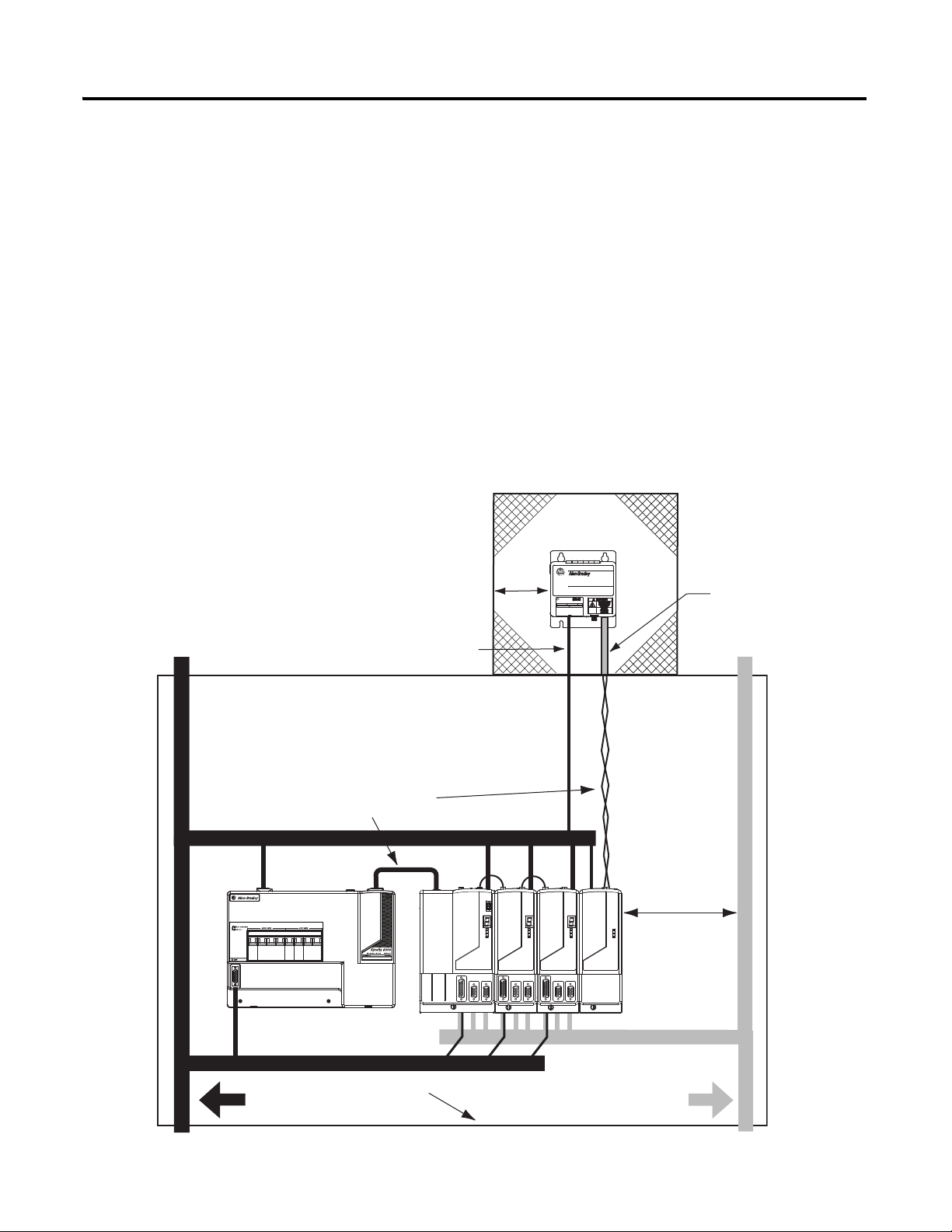

(1)

Line Interface Module

Kinetix 6000

Drive System

Dirty Wireway

Clean Wireway

Motor Power Cables

Very Dirty Connections Segregated

(not in wireway)

Customer-supplied

Metal Enclosure

150 mm (6.0 in.)

clearance, min on all four

sides of the shunt module.

Enclosure

2094-BSP2

Shunt Module

Shunt DC-bus Wiring Methods:

Twisted pair in conduit (1st choice).

Shielded twisted pair (2nd choice).

Twisted pair, two twists per foot, min (3rd choice).

Metal Conduit

(where required

by local code)

I/O and Feedback Cables

Shunt Thermal Switch and Fan Wires (when present)

No sensitive

equipment within

150 mm (6.0 in.).

Route 24V DC I/O

shielded cable.

Route encoder/analog/registration

shielded cables.

Noise Zones for Kinetix 6000 Drives

Observe these guidelines when mounting your external shunt module

outside the enclosure:

• Mount circuit components and wiring in the very dirty zone or

in an externally shielded enclosure. Run shunt DC-bus and fan

wiring inside metal conduit to minimize the effects of EMI and

RFI.

• Mount resistors (other than metal-clad) in a shielded and

ventilated enclosure outside the cabinet.

• Keep unshielded wiring as short as possible. Keep shunt DC-bus

wiring as flat to the cabinet as possible.

• Route thermal switch and fan wires separate from shunt DC-bus.

External Shunt Module Mounted Outside the Enclosure

Publication 2090-IN004B-EN-P — June 2008

Page 8

8 External Shunt Modules

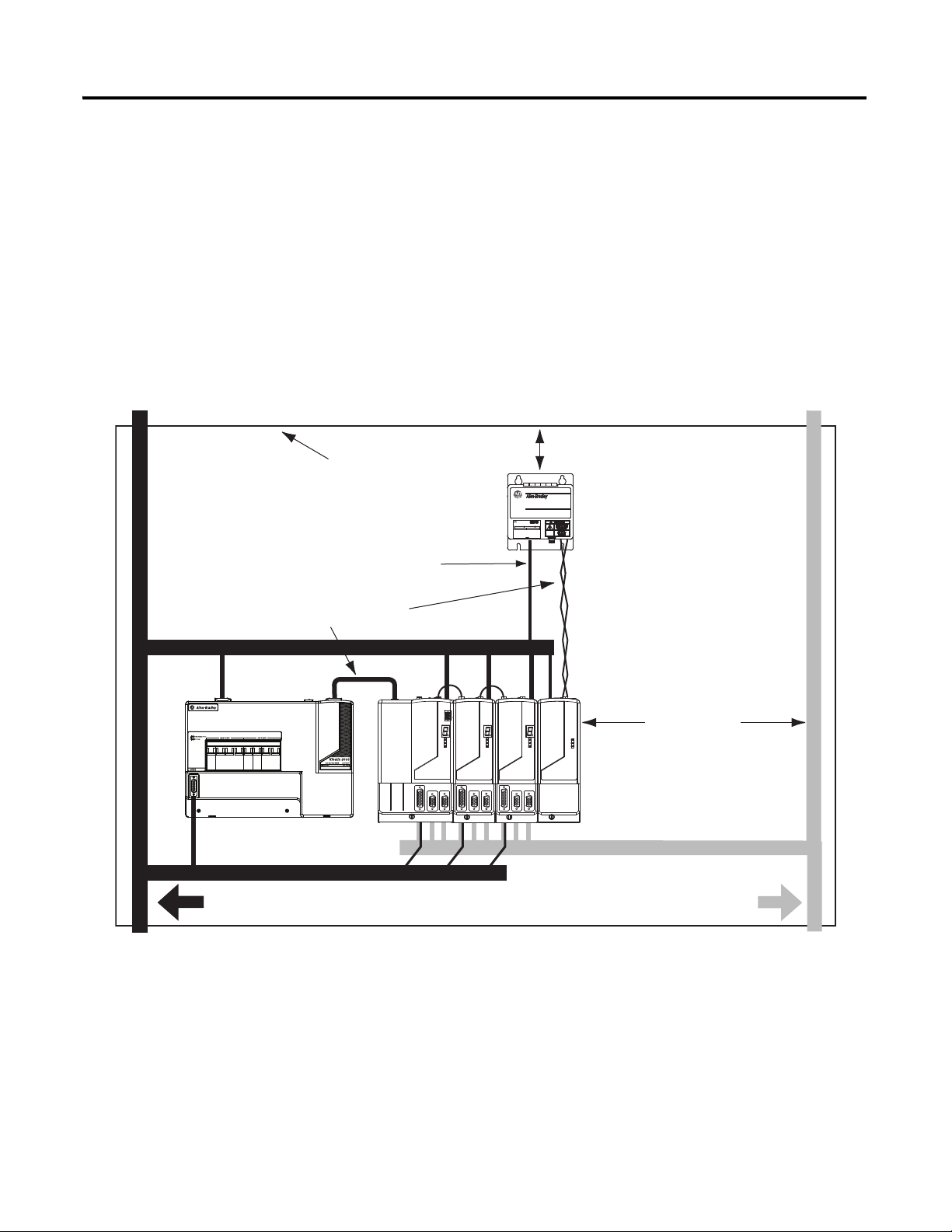

C

D

D

D

D

D

VD

C

VD

1394 Digital Servo Controller

300W Shunt Module

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

D

Line Interface Module

Kinetix 6000

Drive System

Dirty Wireway

Clean Wireway

Motor Power Cables

Enclosure

2094-BSP2

Shunt Module

I/O and Feedback Cables

150 mm (6.0 in.)

clearance, min on all four

sides of the shunt module.

Shunt Thermal Switch and Fan Wires (when present)

Very Dirty Connections Segregated

(not in wireway)

Shunt DC-bus Wiring Methods:

Twisted pair in conduit (1st choice).

Shielded twisted pair (2nd choice).

Twisted pair, two twists per foot, min (3rd choice).

No sensitive

equipment within

150 mm (6.0 in.).

Route 24V DC I/O

shielded cable.

Route encoder/analog/registration

shielded cables.

When mounting your shunt module inside the enclosure, follow these

additional guidelines:

• Metal-clad modules can be mounted anywhere in the dirty zone,

but as close to the Kinetix 6000 system as possible.

• Shunt DC-bus wires can be run with motor power cables.

• Keep unshielded wiring as short as possible. Keep shunt wiring

as flat to the cabinet as possible.

• Separate shunt DC-bus cables from other sensitive, low voltage

signal cables.

External Shunt Module Mounted Inside the Enclosure

Publication 2090-IN004B-EN-P — June 2008

Page 9

External Shunt Modules 9

C

C

VD

1394 Digital Servo Controller

300W Shunt Module

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

D

D

VD

D

D

D

Motor

DC Bus

100-240 VAC

50/60 Hz

L1

AUX

L2/N

AUX

L2/N

L1

-

+

W

V

TB1

External

Shunt

3

2

1

Internal

TB2

U

Dirty Wireway

Clean Wireway

Motor Power Cable

Very dirty shunt connections

segregated (not in wireway).

Maximum length is 3.05 m (10 ft).

Route Motor Power

Shielded Cable

Route Encoder/Analog/Registration

Shielded Cables

Customer-supplied

Metal Enclosure

Metal Conduit

(where required by local code)

Enclosure

Shunt DC-bus Wiring Methods:

Twisted pair in conduit (1st choice).

Shielded twisted pair (2nd choice).

Twisted pair, 2 twists per foot, min (3rd choice).

24V

Power Supply

Circuit

Breaker

XFMR

AC

Line Filter

DC

Filter

Contactors

Ultra3000

(460V) Drive

System

Very dirty power connections

segregated (not in wireway).

150 mm (6.0 in.)

clearance, min on all four

sides of the shunt module.

Noise Zones for Ultra3000/Ultra5000 Drives

Observe these guidelines when mounting your external shunt module

outside the enclosure:

• Mount circuit components and wiring in the very dirty zone or

in an externally shielded enclosure. Run shunt DC-bus and fan

wiring inside metal conduit to minimize the effects of EMI and

RFI.

• Mount resistors (other than metal-clad) in a shielded and

ventilated enclosure outside the cabinet.

• Keep unshielded wiring as short as possible. Keep shunt DC-bus

wiring as flat to the cabinet as possible.

External Shunt Resistor Mounted Outside the Enclosure

Publication 2090-IN004B-EN-P — June 2008

Page 10

10 External Shunt Modules

C

C

VD

D

D

VD

D

D

1394 Digital Servo Controller

300W Shunt Module

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Motor

DC Bus

100-240 VAC

50/60 Hz

L1

AUX

L2/N

AUX

L2/N

L1

-

+

W

V

TB1

External

Shunt

3

2

1

Internal

TB2

U

Dirty Wireway

Clean Wireway

Motor Power Cable

Route Motor Power

Shielded Cable

Route Encoder/Analog/Registration

Shielded Cables

Enclosure

24V

Power Supply

Circuit

Breaker

XFMR

AC

Line Filter

DC

Filter

Contactors

Ultra3000

(460V) Drive

System

Very dirty power connections

segregated (not in wireway).

Very dirty shunt connections

segregated (not in wireway).

Maximum length is 3.05 m (10 ft).

Shunt DC-bus Wiring Methods:

Twisted pair in conduit (1st choice).

Shielded twisted pair (2nd choice).

Twisted pair, 2 twists per foot, min (3rd choice).

150 mm (6.0 in.)

clearance, min on all four

sides of the shunt module.

When mounting your shunt module inside the enclosure, follow these

additional guidelines:

• Metal-clad modules can be mounted anywhere in the dirty zone,

but as close to the Ultra3000 drive as possible.

• Shunt DC-bus wires can be run with motor power cables.

• Keep unshielded wiring as short as possible. Keep shunt DC-bus

wiring as flat to the cabinet as possible.

• Separate shunt DC-bus cables from other sensitive, low voltage

signal cables.

External Shunt Resistor Mounted Inside the Enclosure

Publication 2090-IN004B-EN-P — June 2008

Page 11

External Shunt Modules 11

(1)

Dirty Wireway

Clean Wireway

Customer-supplied

Metal Enclosure

Enclosure

Metal Conduit

(where required

by local code)

Route 24V DC I/O

Shielded Cable

Route Encoder/Analog/Registration

Shielded Cable

Very dirty shunt connections

segregated (not in wireway).

24V Motor

Brake PS

Circuit

Breaker

XFMR

AC

Line Filter

DC

Filter

Contactors

1394x-SJT22-x Drive System

I/O and

Feedback Cables

Enclosure

Shunt thermal switch and

fan wires (when exist).

Shunt DC-bus Wiring Methods:

Twisted pair in conduit (1st choice).

Shielded twisted pair (2nd choice).

Twisted pair, 2 twists per foot, min (3rd choice).

150 mm (6.0 in.)

clearance, min on all four

sides of the shunt module.

Noise Zones for 1394 Drives

Observe these guidelines when mounting your external shunt module

outside the enclosure:

• Mount circuit components and wiring in the very dirty zone or

in an externally shielded enclosure. Run shunt DC-bus and fan

wiring inside metal conduit to minimize the effects of EMI and

RFI.

• Mount resistors (other than metal-clad) in a shielded and

ventilated enclosure outside the cabinet.

• Keep unshielded wiring as short as possible. Keep shunt DC-bus

wiring as flat to the cabinet as possible.

• Route thermal switch and fan wires separate from shunt DC-bus.

External Shunt Module Mounted Outside the Enclosure

C

SERCOS System Module

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

Status

DANGER

VD

C

1394 Digital Servo Controller

ALLEN-BRADLEY

R

BULLETIN 1394 300W SHUNT MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

300W Shunt Module

D

DD

C

Publication 2090-IN004B-EN-P — June 2008

Page 12

12 External Shunt Modules

C

C

D

D

VD

D

C

VD

Status

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

SERCOS System Module

1394 Digital Servo Controller

300W Shunt Module

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Enclosure

Enclosure

Dirty Wireway

Clean Wireway

Route 24V DC I/O

Shielded Cable

Route Encoder/Analog/Registration

Shielded Cable

24V Motor

Brake PS

Circuit

Breaker

XFMR

AC

Line Filter

DC

Filter

Contactors

1394x-SJT22-x Drive System

I/O and

Feedback Cables

Shunt thermal switch and

fan wires (when exist).

Very dirty shunt connections

segregated (not in wireway).

Shunt DC-bus Wiring Methods:

Twisted pair in conduit (1st choice).

Shielded twisted pair (2nd choice).

Twisted pair, 2 twists per foot, min (3rd choice).

150 mm (6.0 in.)

clearance, min on all four

sides of the shunt module.

When mounting your shunt module inside the enclosure, follow these

additional guidelines:

• Metal-clad modules can be mounted anywhere in the dirty zone,

but as close to the 1394 drive as possible.

• Shunt DC-bus wires can be run with motor power cables.

• Keep unshielded wiring as short as possible. Keep shunt DC-bus

wiring as flat to the cabinet as possible.

• Separate shunt DC-bus cables from other sensitive, low voltage

signal cables.

External Shunt Module Mounted Inside the Enclosure

Publication 2090-IN004B-EN-P — June 2008

Page 13

External Shunt Modules 13

IMPORTANT

Install the External Shunt Module

These procedures assume you have prepared your mounting panel

and understand how to bond your system components.

Mount the External Shunt Module

Follow these steps to mount your external shunt module.

1. Lay out the position for your shunt module.

Refer to Establishing Noise Zones, beginning on page 6, for

panel layout recommendations. Refer to Product Dimensions

beginning on page 14

2. Attach the shunt module to the cabinet by using M6 (0.25 in.)

bolts.

Make sure all fasteners are properly bonded to the subpanel.

, for locating the mounting holes.

To improve EMC performance, mount the module on the same

panel as the drive and as close to the drive as possible.

,

3. Tighten all mounting fasteners.

Publication 2090-IN004B-EN-P — June 2008

Page 14

14 External Shunt Modules

280

(11.0)

125

(4.9)

8.0

(0.31)

10.1

(0.40)

15.9

(0.63)

12.0

(0.47)

8.0

(0.31)

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Shunt Module

150

(5.9)

25.0

(0.98)

8.0

(0.32)

100

(3.9)

25

(0.97)

155

(6.1)

(1)

175

(6.9)

Front View

Dimensions are in mm (in.)

Side View

All slots accept M6 or

1/4-20 mounting screws.

Mounting Hole Detail

(1)

Dimension shown is for mounting

hardware location and does not reflect the

location of the lower slot radius.

350

(13.7)

8.0

(0.32)

150

(5.9)

100

(3.9)

25.0

(0.98)

24.8

(0.98)

BULLETIN 1394 3600W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Shunt Module

385.0

(15.2)

(1)

8.0

(0.31)

10.1

(0.40)

15.9

(0.63)

8.0

(0.31)

12.0

(0.47)

350

(13.7)

280

(11.0)

400

(15.7)

Front View

(1)

Dimension shown is for mounting

hardware location and does not reflect the

location of the lower slot radius.

All slots accept M6 or

1/4-20 mounting screws.

Side View

Dimensions are in mm (in.)

Mounting Hole Detail

Product Dimensions

Mounting Dimensions

(2090-SR120-09, 2090-SR040-09, 1394-SR9A, and 1394-SR9AF shunt modules)

Publication 2090-IN004B-EN-P — June 2008

Mounting Dimensions

(1394-SR36A, 1394-SR36AF, and 2090-SR040-18 shunt modules)

Page 15

External Shunt Modules 15

IMPORTANT

ATTENTION

ATTENTION

Wire the External Shunt Module

This section assumes you have mounted your external shunt module

and are ready to wire the shunt module power connections.

Refer to Additional Resources on page 22 for the servo drive user

manual with the drive-end installation instructions.

The National Electrical Code and local electrical codes take

precedence over the values and methods provided.

Wire should be copper with 105 ° C (221 ° F) 600V minimum rating.

DC-bus Wiring Requirements

External Shunt

Cat. No.

2090-SRxxx-xx

1394-SR9Ax,

1394-SR36Ax

Drive Module

Cat. No.

2098-xxx-HV030

2098-xxx-HV050

2098-xxx-HV100

2094-BSP2

1394x-SJT22-x

Shunt Module

Ter mi na l

Connections

COL

DC+

COL

DC+

Recommended

Wire Size

2

mm

(AWG)

6 (10) 1.25 (11)

8.4 (8) 2.5 (22.1)

Torque Value

N•m (lb•in)

Follow these steps to wire your external shunt module.

1. Remove power from your drive system that includes the Bulletin

1394 or 2090 shunt module.

This system may have multiple sources of power. More than

one disconnect switch may be required to de-energize the

system. To avoid shock hazard or personal injury, verify that all

power has been removed before proceeding.

This product contains stored energy devices. To avoid hazard

of electrical shock, verify that all voltage on the capacitors has

been discharged before attempting to service, repair, or

remove this unit. You should only attempt the procedures in

this document if you are qualified to do so and familiar with

solid-state control equipment and the safety procedures in

publication NFPA 70E.

Publication 2090-IN004B-EN-P — June 2008

Page 16

16 External Shunt Modules

IMPORTANT

Shunt Power

Connector

1394-SR36Ax and

2090-SR040-18

External Shunt Modules

(2)

1394-SR9Ax,

2090-SR120-09,

and 2090-SR040-09

External Shunt Modules

(1)

Shunt Power

Connector

Shunt Fan

(3)

Connector

Thermal Switch

(3)

Terminal Block

2. Prepare the shunt DC-bus wires for attachment to the shunt

power terminals by removing 10 mm (0.39 in.) of insulation.

Use caution not to nick, cut, or otherwise damage strands as

you remove the insulation.

3. Inse

4. Inser

5. T

rt one wire into the shunt power terminal labeled COL.

t the other wire into the shunt power terminal labeled DC+.

ighten both screw terminals.

Refer to torque values in the table on

6. Ge

ntly pull on each wire to make sure it does not come out of

its terminal; reinsert and tighten each loose wire.

Shunt Module Terminations

page 15.

Publication 2090-IN004B-EN-P — June 2008

(1)

Shunt module is shown with front cover open.

(2)

Shunt module is shown with front cover removed.

(3)

Only the 1394-SR36AF shunt module has the fan and thermal switch connections.

Page 17

External Shunt Modules 17

IMPORTANT

Wire the Shunt Module Fan

This procedure applies to only the 1394-SR36AF shunt module and

assumes that you have mounted the module and wired the shunt

DC-bus connections.

Refer to Additional Resources on page 22 for the servo drive user

manual with the drive-end installation instructions.

You can wire the shunt fan connections for 115V or 230V AC input

power. Wire should be copper with 75 °C (167 ° F) minimum rating.

Fan Power Specifications

Input Power Current

115V AC 0.2 A

230V AC 0.1 A

If you mount the shunt module outside the cabinet, the shunt fan

power wiring must be inside metal conduit to minimize the levels of

EMI and RFI.

Fan Power Wiring Requirements

External Shunt Module

Cat. No.

1394-SR36AF

Fan Terminal Connections

Pin

1115, 230

4115, 230

1…3 115

2…4 115

2…3 230

Voltage

(V AC)

Recommended

Wire Size

2

mm

(AWG)

1.3 (16) 0.6 (6)

Torque Value

N•m (lb•in)

Follow these steps to wire the shunt fan.

1. Verify that all power is removed from the system.

2. Open the front door of the shunt module.

3. Using a screwdriver, remove the plate that covers the fan wire

access hole on the bottom right side of the module.

Refer to the figure on page 16 for the location of the fan power

terminal block.

Publication 2090-IN004B-EN-P — June 2008

Page 18

18 External Shunt Modules

1

2

3

4

1

2

3

4

To Power Supply

To Power Supply

To Power Supply

To Power Supply

Wiring the Fan for 115V

Wiring the Fan for 115V

IMPORTANT

4. Insert the jumper wires that came with your shunt module to

support the input power used in your application.

5. Insert one wire from the AC power supply into terminal 1.

6. Insert the other wire from the AC power supply into terminal 4.

7. Tighten all screw terminals.

When tightening screws to secure the wires, refer to the table

page 17

for torque values.

8. Gently pull on each wire to make sure it does not come out of

its terminal; reinsert and tighten any loose wires.

Publication 2090-IN004B-EN-P — June 2008

Page 19

External Shunt Modules 19

TS1

TS2

Wire the Thermal Switch

This procedure applies to only the 1394-SR36AF shunt module and

assumes that you have mounted the module, wired the power

connections, and are ready to connect the thermal switch wires.

Refer to Additional Resources on page 22 for the servo drive user

manual with the drive-end installation instructions.

Wire should be copper with 75 ° C (167 ° F) minimum rating.

Thermal Switch Wiring Requirements

External Shunt Module

Cat. No.

1394-SR36AF

Thermal

Switch

Connections

TS1

TS2

Recommended

Wire Size

2

mm

(AWG)

0.75 (18) 0.6 (6)

Torque Value

N•m (lb•in)

Follow these steps to wire the thermal-switch terminal block.

1. Verify that all power is removed from the system.

2. Open the front door of the shunt module.

3. Insert one wire into the top terminal of the thermal-switch

terminal block.

4. Insert the other wire into the lower terminal of the

thermal-switch terminal block.

Refer to the figure on page 16 for the location of the

thermal-switch terminal block.

5. Tighten all screw terminals.

6. Gently pull on each wire to make sure it does not come out of

its terminal; reinsert and tighten any loose wires.

Publication 2090-IN004B-EN-P — June 2008

Page 20

20 External Shunt Modules

ATTENTION

ATTENTION

1394-SR36A,

1394-SR36AF, and

2090-SR040-18

Shunt Modules

1394-SR9A,

1394-SR9AF,

2090-SR120-09, and

2090-SR040-09

Shunt Modules

Fuse Holder

Replace the Shunt Module Fuse

Follow these steps to replace the fuse in your external shunt module.

1. Remove power from your drive system that includes the Bulletin

1394 or 2090 shunt module.

This system may have multiple sources of power. More than

one disconnect switch may be required to de-energize the

system. To avoid shock hazard or personal injury, verify that all

power has been removed before proceeding.

This product contains stored energy devices. To avoid hazard

of electrical shock, verify that all voltage on the capacitors has

been discharged before attempting to service, repair, or

remove this unit. You should only attempt the procedures in

this document if you are qualified to do so and familiar with

solid-state control equipment and the safety procedures in

publication NFPA 70E.

2. Open the front door panel and locate the fuse holder.

Publication 2090-IN004B-EN-P — June 2008

In each case, the fuse holder is located in the bottom center of

the shunt enclosure, in some cases, behind terminal blocks.

3. Remove the fuse from the fuse holder.

You may need a fuse puller or screwdriver to remove the fuse.

4. Replace the fuse.

Refer to External Shunt Module Specifications on page 21, for

the properly rated fuse.

5. Close and secure the door panel.

6. Apply power to your system and verify proper operation.

Page 21

External Shunt Modules 21

ATTENTION

External Shunt Module Specifications

External Shunt Module

Cat. No.

1394-SR9A

1394-SR9AF

1394-SR36A

1394-SR36AF

2090-SR120-09

2090-SR040-09

2090-SR040-18

(1)

Requires the use of an FNQ fuse with an adapter to allow the smaller body fuse to fit the larger FWP fuse holder.

Drive

Voltage

V AC

(1)

230

460 160.0 200 FWP50A14F

(1)

230

460 160.0 200 FWP50A14F

(1)

230

460 160.0 200 FWP50A14F

(1)

230

460 160.0 200 FWP50A14F

(1)

230

460 5.3 6.7 FWP-2.5A14F

(1)

230

460 16.0 20.0 FWP-5A14F

(1)

230

460 16.0 20.0 FWP-6.3A14F

This section provides specifications for the Bulletin 1394 and Bulletin

2090 external shunt modules.

External Shunt Module Specifications

Specifications

Resistance

Range

Ω

4

4

4

4

120-148

40-51

40-49

Peak

Power

kW

Peak

Current

Amps

41.0 101.25

41.0 101.25

41.0 101.25

41.0 101.25

1.33 3.35

4.0 10.0

4.0 10.0

Cont.

Power

Watts

Shipping

Weight

kg (lbs)

Bussmann

Replacement Fuse

FNQ-R-20-R1

300 3.63 (8)

900 3.63 (8)

1800 8.6 (19)

FNQ-R-20-R1

FNQ-R-20-R1

FNQ-R-25-R1

3600 9.0 (20)

900 3.63 (8.0)

900 3.63 (8.0)

FNQ-R-3/4-R1

FNQ-R-2-R1

FNQ-R-2-R1

1800 8.6 (19.0)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

The Bulletin 1394 and 2090 shunt modules ship with fuses

rated for 460V operation. For operation with drive systems

using 230V input power, you must replace the 460V shunt fuse

with a 230V fuse. Failure to observe this precaution could

result in equipment damage.

Environmental Specifications

Attribute Value

Ambient operating temperature

(1)

Vibration 2g at 10…2000 Hz

Shock

Altitude 1500 m (5000 ft)

Humidity 5…95% noncondensing

(1)

Power performance increases about 5.5 W for every 1°C (3.1 W/°F) drop in ambient temperature.

0…50 °C (32…122 °F)

15g 11 ms half sine

Publication 2090-IN004B-EN-P — June 2008

Page 22

22 External Shunt Modules

Additional Resources

These documents contain additional information concerning related

Rockwell Automation products.

Resource Description

900 Watt Passive Shunt Installation Instructions,

publication 2090-IN001

300 Watt Active Shunt Regulator Installation

Instructions, publication 2090-IN002

200 Watt Passive Shunt Regulator Installation

Instructions, publication 2090-IN003

1394 External Shunt Resistor Kit Installation

Instructions, publication 1394-5.6

Kinetix 6000 Multi-axis Servo Drive User Manual,

publication 2094-UM001

Ultra3000 Digital Servo Drives Installation Manual,

publication 2098-IN003

Ultra5000 Intelligent Positioning Drives Installation

Manual, publication 2098-IN001

1394 SERCOS interface Multi-axis Motion Control

System Installation Manual, publication 1394-IN002

1394 Digital AC Multi-axis Motion Control System

User Manual, publication 1394-5.0

System Design for Control of Electrical Noise

Reference Manual, publication GMC-RM001

EMC Noise Management DVD, GMC-SP004

Mounting and wiring instructions for use with

ULTRA 100, ULTRA 200, ULTRA Plus,

Ultra3000, and Ultra5000 230V drives.

Mounting and wiring instructions for use with

Bulletin 1394 (5 and 10 kW) 460V drives.

Mounting, wiring, setup with RSLogix 5000

software, power-up, troubleshooting, and

application diagrams.

Mounting, wiring, applying power,

troubleshooting, and application diagrams.

Mounting, wiring, setup with the HIM

module, power-up, troubleshooting, and

application diagrams.

Information, examples, and techniques

designed to minimize system failures caused

by electrical noise.

You can view or download publications at

http://literature.rockwellautomation.com. To order paper copies of

technical documentation, contact your local Rockwell Automation

distributor or sales representative.

Publication 2090-IN004B-EN-P — June 2008

Page 23

Notes:

External Shunt Modules 23

Publication 2090-IN004B-EN-P — June 2008

Page 24

Rockwell Automation

Support

Rockwell Automation provides technical information on the Web to assist

you in using its products. At http://support.rockwellautomation.com

, you can

find technical manuals, a knowledge base of FAQs, technical and application

notes, sample code and links to software service packs, and a MySupport

feature that you can customize to make the best use of these tools.

For an additional level of technical phone support for installation,

configuration, and troubleshooting, we offer TechConnect support programs.

For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, please

review the information that's contained in this manual. You can also contact a

special Customer Support number for initial help in getting your product up

and running.

United States

Outside United

States

1.440.646.3434

Monday – Friday, 8 a.m. – 5 p.m. EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully

operational when shipped from the manufacturing facility. However, if your

product is not functioning and needs to be returned, follow these

procedures.

Contact your distributor. You must provide a Customer Support case number

United States

Outside United

States

Allen-Bradley, Kinetix, Rockwell Automation, TechConnect, ULTRA 100, ULTRA 200, ULTRA Plus, Ultra3000,

and Ultra5000 are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(call the phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Publication 2090-IN004B-EN-P — June 2008 PN 196991-P02

Supersedes Publication 2090-IN004A-EN-P — March 2 002 Copyright © 2008 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...